Page 1

xx

OM1106, OM4006, OM4106

ZZZ

Coherent Lightwave Signal Analyzer

User Guide

*P071316000*

071-3160-00

Page 2

Page 3

xx

OM1106, OM4006, OM4106

ZZZ

Coherent Lightwave Signal Analyzer

User Guide

www.tektronix.com

071-3160-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, vis it www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, w ith shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

1 SAFETY INFORMATION ...................................................................................................................... 7

1.1 SAFETY NOTICES ............................................................................................................................. 7

1.2 LASER SAFETY ................................................................................................................................. 7

1.3 OM4000 SERIES LASER LABELS AND LOCATIONS .............................................................................. 8

2 INTRODUCTION ................................................................................................................................... 9

2.1 PURPOSE ......................................................................................................................................... 9

3 GETTING STARTED ........................................................................................................................... 10

3.1 CONFIGURING THE HARDWARE ....................................................................................................... 10

3.2 OVERVIEW AND CONFIGURATION OF THE SOFTWARE ....................................................................... 19

4 MAKING MEASUREMENTS ............................................................................................................... 43

4.1 SETTING UP YOUR MEASUREMENT ................................................................................................. 43

4.2 ENGINE FILE ................................................................................................................................... 43

4.3 PERFORMING MEASUREMENTS ........................................................................................................ 44

5 USING THE OUI .................................................................................................................................. 46

5.1 OUI OVERVIEW .............................................................................................................................. 46

5.2 ANALYSIS PARAMETERS ................................................................................................................. 48

5.3 CONSTELLATION DIAGRAMS ............................................................................................................ 54

5.4 EYE DIAGRAMS .............................................................................................................................. 57

5.5 SIGNAL VS. TIME ............................................................................................................................. 58

5.6 WAVEFORM AVERAGING ................................................................................................................. 59

5.7 MEASUREMENTS ............................................................................................................................ 61

5.8 POINCARÉ SPHERE ........................................................................................................................ 62

5.9 BIT-ERROR-RATE REPORTING ........................................................................................................ 63

5.10 PMD MEASUREMENT ...................................................................................................................... 63

5.11 RECORDING AND PLAYBACK ........................................................................................................... 64

5.12 ALERTS ......................................................................................................................................... 65

5.13 MANAGING DATA SETS WITH RECORD LENGTH > 1,000,000 ............................................................ 67

6 LASER / RECEIVER CONTROL PANEL ............................................................................................ 70

6.1 DEVICE SETUP AND AUTO CONFIGURE ............................................................................................ 70

6.2 CONFIGURATION ON A NETWORK USING DHCP ................................................................................ 71

6.3 CONFIGURATION ON A NETWORK WITH NO DHCP ............................................................................ 72

6.4 CONNECTING TO YOUR OM4000 SERIES DEVICE ............................................................................. 75

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 4 of 148

Page 8

6.5 SETTING LASER PARAMETERS ......................................................................................................... 77

7 ATE (AUTOMATED TEST EQUIPMENT) INTERFACE ..................................................................... 79

7.1 LRCP ATE INTERFACE .................................................................................................................. 79

7.2 OUI4006 ATE INTERFACE ............................................................................................................. 85

7.3 ATE FUNCTIONALITY IN MATLAB ................................................................................................... 91

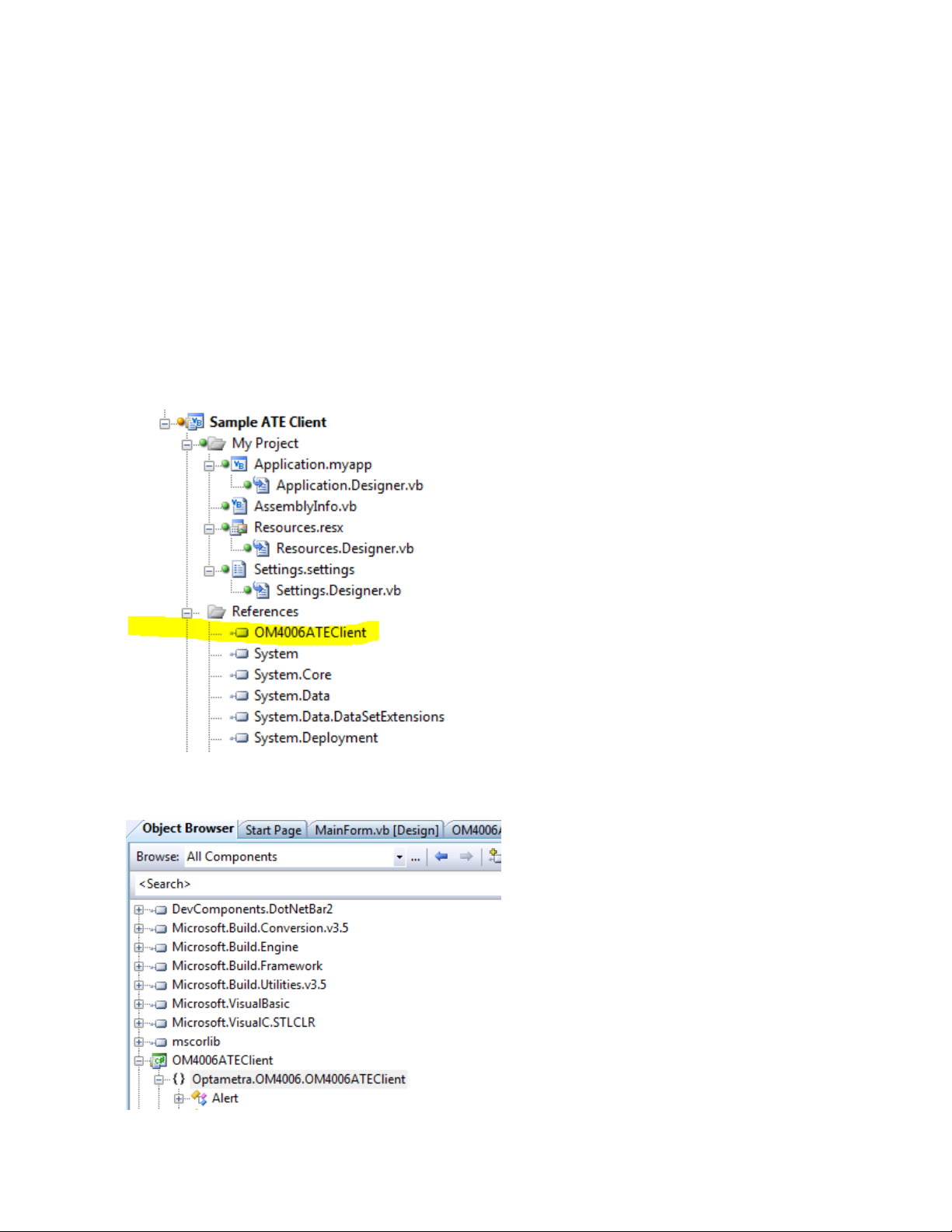

7.4 BUILDING AN OM4006 ATE CLIENT IN VB.NET .............................................................................. 93

8 MAINTENANCE AND CLEANING .................................................................................................... 102

9 DETAILED CONFIGURATION OF EXPERIMENTS ......................................................................... 103

10 CORE PROCESSING SOFTWARE GUIDE ................................................................................. 105

10.1 INTERACTION WITH OUI ................................................................................................................ 105

10.2 MATLAB VARIABLES ...................................................................................................................... 106

10.3 MATLAB FUNCTIONS ..................................................................................................................... 107

10.4 SIGNAL PROCESSING STEPS IN COREPROCESSING ........................................................................ 107

10.5 BLOCK PROCESSING ..................................................................................................................... 113

10.6 ALERTS MANAGEMENT .................................................................................................................. 114

11 CORE PROCESSING FUNCTION REFERENCE ........................................................................ 116

11.1 ALIGNTRIBS ................................................................................................................................. 116

11.2 APPLYPHASE ............................................................................................................................... 119

11.3 CLOCKRETIME ............................................................................................................................. 120

11.4 DIFFDETECTION ........................................................................................................................... 121

11.5 ESTIMATECLOCK .......................................................................................................................... 123

11.6 ESTIMATEPHASE .......................................................................................................................... 125

11.7 ESTIMATESOP ............................................................................................................................. 127

11.8 MASKCOUNT ................................................................................................................................ 128

11.9 GENPATTERN .............................................................................................................................. 129

11.10 JONES2STOKES ....................................................................................................................... 130

11.11 JONESORTH ............................................................................................................................. 131

11.12 LASERSPECTRUM ..................................................................................................................... 132

11.13 QDECTH .................................................................................................................................. 133

11.14 ZSPECTRUM ............................................................................................................................. 135

12 MATLAB VARIABLES USED BY CORE PROCESSING .............................................................. 136

13 APPENDIX A – ADVANCED USE CASES ................................................................................... 137

13.1 CONFIGURING TWO 70000 SERIES OSCILLOSCOPES ...................................................................... 138

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 5 of 148

Page 9

14 APPENDIX B: SOFTWARE LICENSE AGREEMENT .................................................................. 144

15 APPENDIX C – GLOSSARY OF TERMS ..................................................................................... 148

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 6 of 148

Page 10

1 Safety Information

CAUTION

CAUTION

!

WARNING

!

!

CAUTION

!

1.1 Safety Notices

Indicates a potentially hazardous condition or procedure that could result in damage to the

instrument.

Indicates a potentially hazardous condition or procedure that could result in minor or moderate

bodily injury.

Indicates a potentially hazardous condition or procedure that could result in serious injury or death.

This symbol on the unit indicates that the user should consult this document for further

information regarding the nature of the potential hazard and actions that should be

taken to avoid or mitigate the hazard.

1.2 Laser Safety

The laser sources included in this product are classified according to

IEC/EN 60825-1: 1994+A1:2001+A2:2001 and IEC/EN 60825-2:2004

This laser product complies with 21CFR1040.10 except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007.

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure. Under no circumstances should you

use any optical instruments to view the laser output directly.

Additional laser safety notifications appear in the OM4000 Series User Interface (OUI) control

software section.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 7 of 148

Page 11

1.3 OM4000 Series Laser Labels and Locations

INVISIBLE LASER RADIATION; DO NOT VIEW DIRECTLY WITH

OPTICAL INSTRUMENTS: CLASS 1M LASER PRODUCT

EMISSION DE RAYONS LASER INVISIBLES DE CLASSE 1M.

NE PAS OBSERVER A L’AIDE D’INSTRUMENTS OPTIQUES

Indicates the

location of a

laser aperture

Model

MAC Address

Under top Cover:

Serial Number

Manufactured

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 8 of 148

Page 12

2 Introduction

1

2

2.1 Purpose

The OM4000 Series Coherent Lightwave Signal Analyzer is a sophisticated, general-purpose

long-haul (C and L-band capable) fiber optics communications receiver that measures the

complete electric field (vs. time) in single-mode optical fiber. The system consists of the

Complex Modulation Receiver, Core Processing, and the OM4000 Series User Interface (OUI),

further incorporating a customer-supplied real-time 2- or 4-channel oscilloscope and external

computer, with the option for some oscilloscopes to run the OUI on the oscilloscope itself.

The Coherent Lightwave Signal Analyzer runs a Matlab1-based script, CoreProcessing, to

recover the phase of the complex-modulated lightwave signal and display the demodulated

result in several useful formats, such as eye diagrams of the tributaries, phase diagrams

(constellations) and the Poincaré sphere. This method offers access to the entire variable space

in Matlab, enabling you to change the order of processing, define new functions, and interact

with other programs, such as LabVIEW2.

MATLAB® is a registered trademark of The MathWorks, Inc. Other product and company names listed are

trademarks and trade names of their respective companies.

LabVIEW is a trademark of National Instruments, Inc.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 9 of 148

Page 13

3 Getting Started

3.1 Configuring the Hardware

3.1.1 OM4000 Series Receiver

Ensure that the required power sources for the OM4000 Series (100, 115 or 230 VAC, 50–60

Hz, 0.4 A), the associated oscilloscope, and the external computer (if used) are available.

The OM4000 Series Coherent Modulation Receiver, along with proprietary software comprises

the OM4000 Series Coherent Lightwave Signal Analyzer (CLSA). This system is used in

laboratory or industrial facilities to analyze next-generation complex-modulation fiber-optic data

signals. In operation, one of the receiver’s two laser outputs will be connected to one of the

optical input connectors (the reference, or local oscillator, input), and the second laser output

will be connected to the user’s device under test.

Note: The reference connection may optionally be configured internally at the factory.

The signal to be analyzed is connected to the “Signal” optical input. Four coaxial cables connect

the OM4000 Series to a high-speed sampling oscilloscope. An Ethernet connector will connect

the receiver, via a router, to a computer and to the oscilloscope. An IEC power cord is

connected to a rack or wall outlet. The OM4000 Series User Interface running on the computer

controls the OM4000 Series and the oscilloscope.

Note: A password is required to turn on the lasers through the Laser / Receiver Control Panel.

The default is ‘1234’

Associated cabling includes the power cord, an Ethernet cable, four coaxial cables (9 to 12

inches in length), and two fiber optic cables to connect the laser output and user’s signal to the

optical inputs.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 10 of 148

Page 14

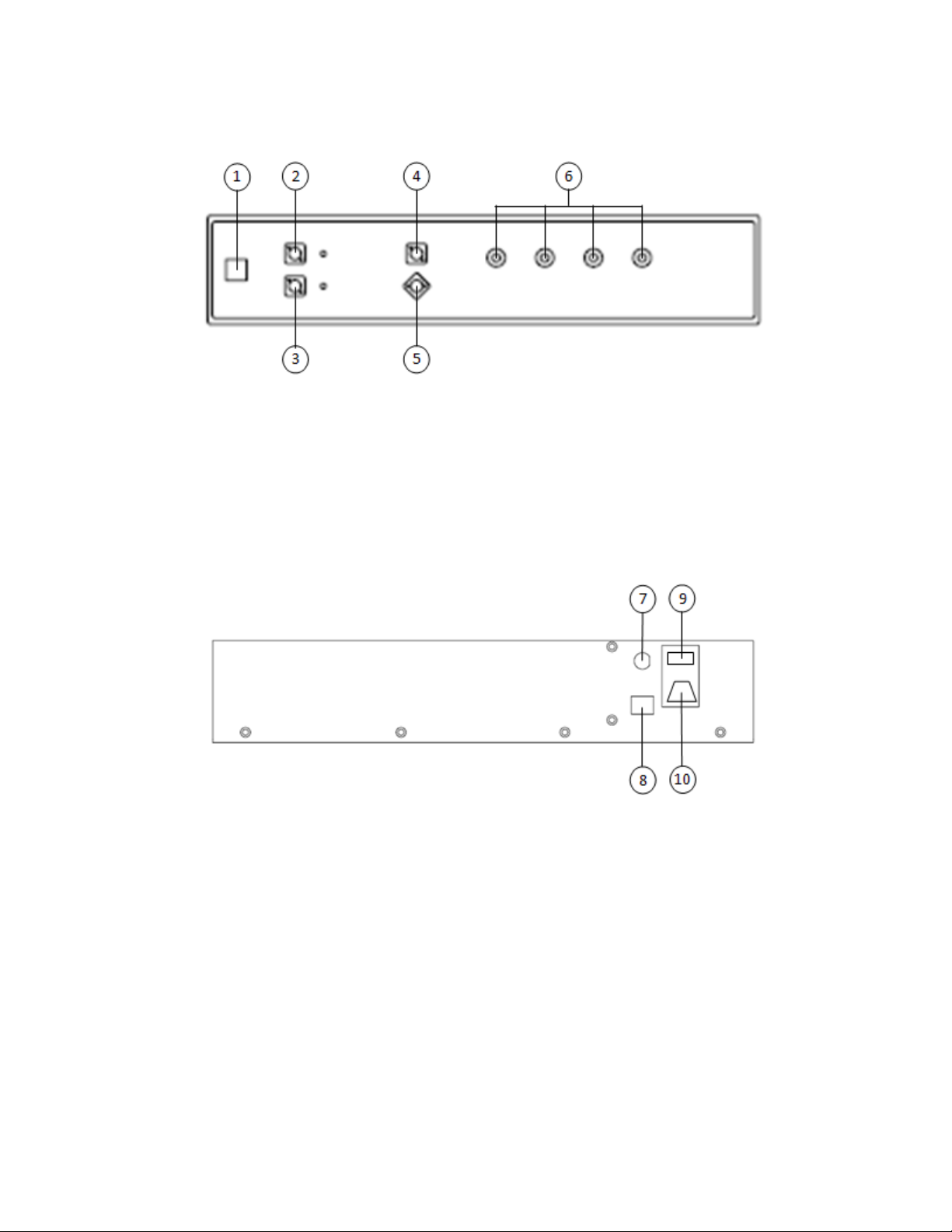

3.1.2 OM4000 Series Controls and I/O Connections

Front Panel Controls and I/O Connectors

1. On/Off switch

2. Laser 1 Output (with LED indicator)

3. Laser 2 Output (with LED indicator) (may be internally connected at the factory)

4. Input 1 (Signal input)

5. Input 2 (Reference input; may be internally connected at the factory)

6. RF connectors, to connect to the oscilloscope

Rear Panel Controls and I/O Connectors

7. BNC connector for optional laser remote interlock

8. Ethernet port

9. Fuse drawer

10. Input power receptacle

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 11 of 148

Page 15

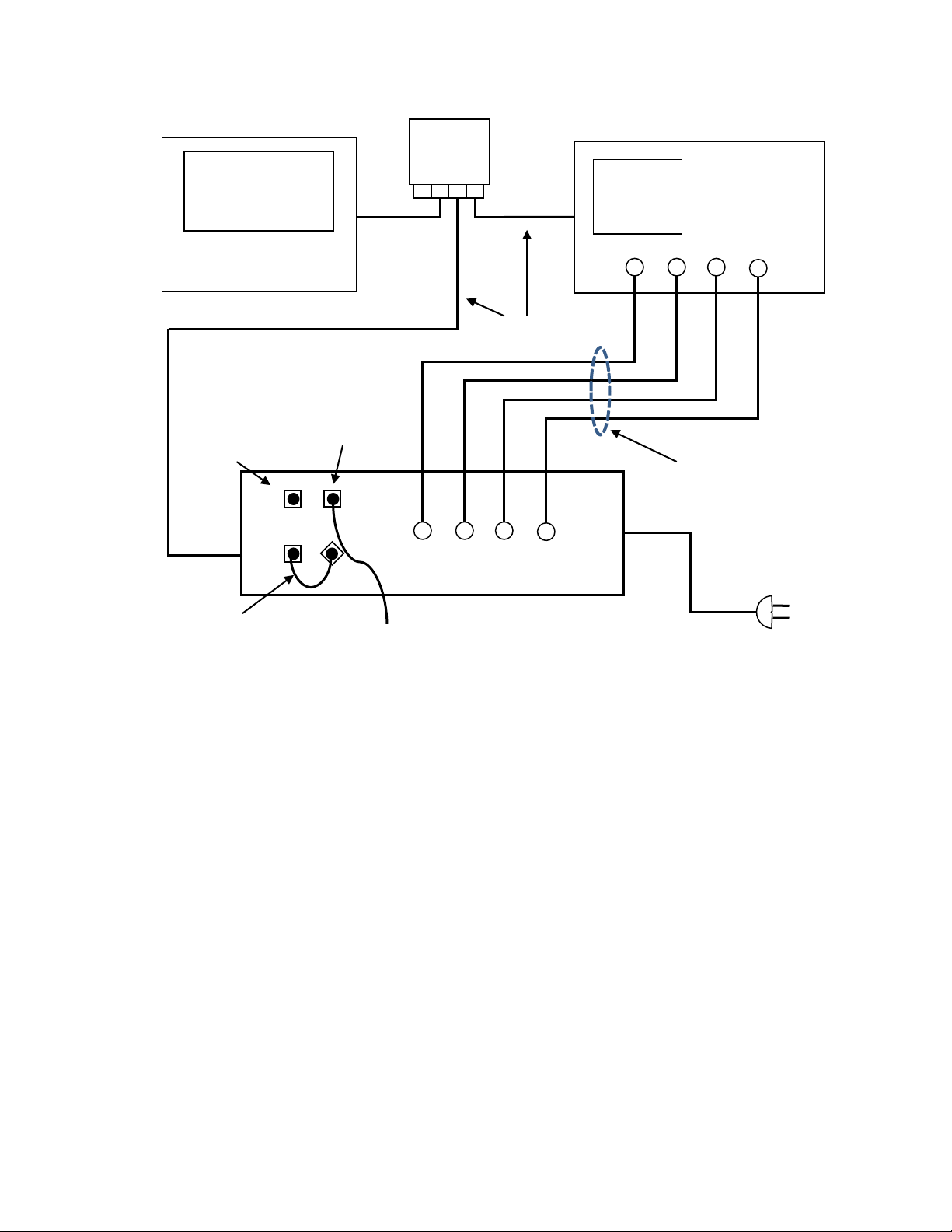

L1

L2

Computer –

PC or laptop

4-channel

Coaxial cables (4),

Fiber optic

Power cord

Ethernet

OM4000

Laser

outputs (2)

Optical

inputs (2)

IN1

IN2

To user’s

DUT

Gigabit

Switch

1 2 3 4

XI XQ YI YQ

patch cable

oscilloscope

6 -12 in. long typ.

Block diagram

3.1.3 List of Components

OM4000 Series Complex Modulation Receiver

IEC power cable

Ethernet cable

BNC shorting cap for interlock

(4) Dust covers for optical inputs not in use

(4) SMA caps to protect electrical outputs

Short PM patch cable to connect Laser 2 to Reference input

Short coaxial cables shaped to connect OM4000 Series outputs to oscilloscope inputs

Additional items needed, not part of Receiver:

Supported Oscilloscope (1 of the following)

o Real-time Tektronix Oscilloscope with at least 20 GS/s sampling rate on two or four

channels in the 70000 Series

o Equivalent-Time Tektronix Oscilloscope DSA8300 or DSA8200 with supported

sampling heads. See data sheet for supported samplers

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 12 of 148

Page 16

Power cable

WARNING

!

WARNING

!

CAUTION

!

Ethernet cable

Mouse and keyboard (unless touch-screen controlled)

System controller PC running Windows 7 or XP, Matlab, the OM4000 Series User

Interface (OUI) software, and the Laser Receiver Control Panel (LRCP) software.

o Monitor plus cable

o Mouse and keyboard

o Power cables

o Ethernet cable

An Ethernet switch or hub plus a router running DHCP, and associated cabling (not shown)

Equipment for calibration as needed (see Calibration section)

OMRACK, 19” rack, or other method of ensuring OM4000 Series and oscilloscope are

securely stacked

To avoid the possibility of electrical shock, do not connect your OM4000 to a power

source if there are any signs of damage to the instrument enclosure.

3.1.4 Electrical Power Requirements

The OM4000 Series can operate from any AC power source that provides 100, 115, or 230

VAC, at a frequency of 60 Hz or 50 Hz respectively with a 0.4A rating. (The US rack-mount

system has a power connector that requires the special 20 A outlet configuration.) The OM4000

Series must be connected directly to a grounded power outlet only.

The OM4000 Series must be connected to a 100, 115, or 230VAC at 60Hz or 50Hz

respectively grounded outlet only. Operating the OM4000 Series without connection to a

grounded power source could result in serious electrical shock. Always connect the unit

directly to a grounded power outlet.

Protective features of the OM4000 Series may be impaired if the unit is used in a manner

not specified by Tektronix.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 13 of 148

Page 17

3.1.5 Location and Positioning

CAUTION

If the OM4000 Series is to be used in an installation other than a standard 19” rack, be sure to

position the unit so that the power switch at the rear of the unit can be easily accessed.

Be sure not to obstruct the fan so that there is an adequate flow of cooling air to the

electronics compartment whenever the unit is operating.

3.1.6 Operating Environment

The OM4000 Series may be operated within the following conditions:

Temperature 10°C to +35°C (50°F to +95°F)

Humidity <85% R.H. non-condensing from 10°C to +35°C (50°F to +95°F)

Altitude < 2,000 m (6560ft)

3.1.7 Computer

Install software on target computer and Oscilloscope.

See Installation Instructions

Mathworks MATLAB is required but not included in the install package.

Windows 7 64-bit Operating System: Install Matlab 2011b

Windows XP 32-bit Operating System: Install Matlab 2009a 32-bit

Recommended and Minimum Computer Requirements:

Operating System: US Windows-7 64 bit OR US Windows XP Service Pack 3 32-bit (.NET 4.0

required),

Processor: recommended: Intel I7, i5 or equivalent; min clock speed 2 GHz; minimum:

Intel Pentium 4 or equivalent,

RAM: min: 4 GB, For 64-bit releases will benefit from as much memory as is

available

Hard Drive Space: At least 300 GB recommended for large data sets; minimum: 20 GB,

Video Card: nVidia dedicated graphics board w/ 512+ MB min. graphics memory

Note: Color grade display feature is not available on non-nVidia graphics

cards and so will not be available when running native on an oscilloscope

Networking: Gigabit Ethernet (1 Gb/s) or Fast Ethernet (100Mb/s)

Display: 20” min, Large flat screen recommended for displaying multiple graph types

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 14 of 148

Page 18

Other Hardware: DVD Optical drive, 2 USB 2.0 ports

Other Software: Computer must have Matlab installed according to instructions above.

Adobe PDF Reader is required for viewing the User Guide and Installation

instructions.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 15 of 148

Page 19

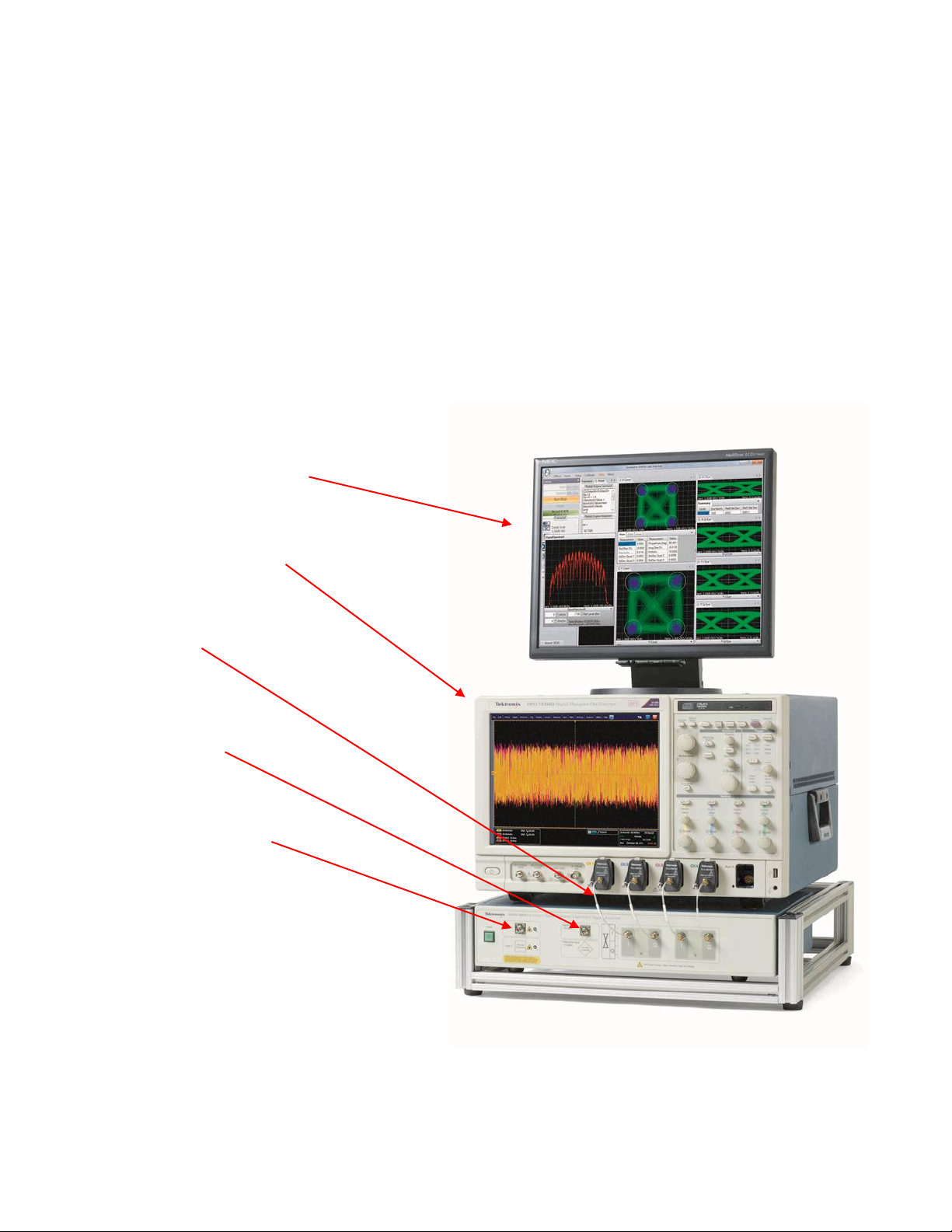

3.1.8 First Setup

Real time oscilloscope

RF interconnects

Signal-Laser Fiber Optic

System controller can be Win 7

Input signal SM APC

(from DUT)

System controller monitor or

Once everything is securely placed, make electrical connections in the following order:

1. Ethernet connections and other computer connections. See Section 3.1.2

2. Power connections from the OM4000 Series to the rack

3. Power from rack to mains (keeping main front panel switch off)

4. RF connections (the four coaxial cables from OM4000 Series to oscilloscope)

5. Fiber optic PM patch cable connection from Laser 2 to Reference (if needed)

6. Fiber optic Signal input connection (with no optical power present at setup)

7. Store all dust covers and coaxial connector caps for future use.

second monitor for Win 7

oscilloscope

PM APC output (if needed)

for DUT

oscilloscope or separate PC.

Separate PC required for certain

display options.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 16 of 148

Typical system configuration

Page 20

Once the equipment is positioned and connected, turn on the computer, the oscilloscope and

the main power switch on the back of the OM4000 Series. The OM4000 Series front-panel

power button will light briefly after main power is applied indicating it is searching for a DHCP

server. When an IP address has been assigned or when the search fails in the case of an

isolated network, the power light will go off. Press the power button one time to enable the unit.

The steady power button light indicates the OM4000 Series is ready for use and that lasers may

be activated at any time if a user connects via the Ethernet connection. The light will go out and

the unit will be disabled any time ac power is removed or the IP address is changed. Press the

power button to re-enable. This feature prevents a remote user from activating the lasers when

the local user may not be ready.

Note: Ethernet only allows devices on the same subnet to communicate.

You should now have three devices on an Ethernet network: computer, oscilloscope, and

OM4000 Series. This little network may be connected to your corporate network or router or you

may choose to leave it isolated. IP setup is normally done by at the time of installation. You

should only need the following instructions if you are reconfiguring your network.

3.1.8.1 IP setup on a network with DHCP (dynamic IP assignment)

DHCP allows “automatic” assignment of the IP address the connected devices need to

communicate with each other. However, automatic IP assignment must be selected on each

device before this will be allowed. The OM4000 Series is shipped with automatic IP assignment

enabled. Your computer and oscilloscope may need this turned on.

Once automatic IP assignment is selected, you may still need the cooperation of your corporate

IT department to get IP addresses assigned. If you are using a centralized server, ask your

network administrator to make an IP reservation for you so that you get the same number each

time the device is powered on. Once these are set up for the oscilloscope and the OM4000

Series you will have no trouble finding them in the future.

Once your equipment gets an IP address from DHCP you can find that address using the

operating system of the oscilloscope or computer. For example, in the XP operating system

there is a window that looks like the one below. Notice that when you select the active Ethernet

connection the IP address shows up in the Details box in the lower-left corner of the window.

To configure the IP connection of the OM4000 Series receiver, please see Chapter 6 on using

the Laser Receiver Control Panel (LRCP).

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 17 of 148

Page 21

3.1.8.2 IP setup on an isolated network or one not running a DHCP server

When there is no DHCP server, the Ethernet connected devices don’t know what address to

assign to themselves. In this case you must manually set the IP address. On a corporate

network this means getting the IP addresses from your network administrator first and then

setting each device. Your network administrator may need the MAC addresses of the computer,

oscilloscope, and OM4000 Series. The MAC address for your OM4000 Series box is located on

the rear panel label. On newer models the MAC address is printed on the real-panel label. See

Section 6.3 for instructions to set the OM4000 Series IP address. If you have a network isolated

from your corporate network you are free to use any IP numbering scheme. Tektronix

recommends 172.17.200.XXX where XXX is any unique number between 0 and 255 (each

device needs a unique number). There is nothing special about this scheme other than that it is

the default for new OM4000 Series units. Use the operating systems of the oscilloscope and

computer to set their IP addresses. The first three sets of numbers in the IP address need to be

the same on the computer and the connected devices for them to communicate in most cases.

Note: For setup purposes, to ease communication between the LRCP and the controller com-

puter, be sure the controller computer (e.g. laptop) has only one Ethernet medium (e.g.

wireless or wired) activated

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 18 of 148

Page 22

3.2 Overview and Configuration of the Software

OM4000 Series

User Interface

(OUI)

Matlab

IVI/Visa OR

Scope Service

Oscilloscope

Laser/Receiver

Control Panel

(LRCP)

OM4000 Series

Hardware

The OM4000 Series Software includes the OM4000 Series User Interface (OUI) and the Laser/

Receiver Control Panel (LRCP). The LRCP controls the hardware and communicates with the OUI

which is the primary user interface. The OUI collects data from the user, the LRCP, and the

oscilloscope and communicates with the Matlab Engine to input data and collect finished

calculations. The OUI can also communicate with customer applications via the Windows

Communication Foundation (WCF) interface described in Chapter 7.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 19 of 148

Page 23

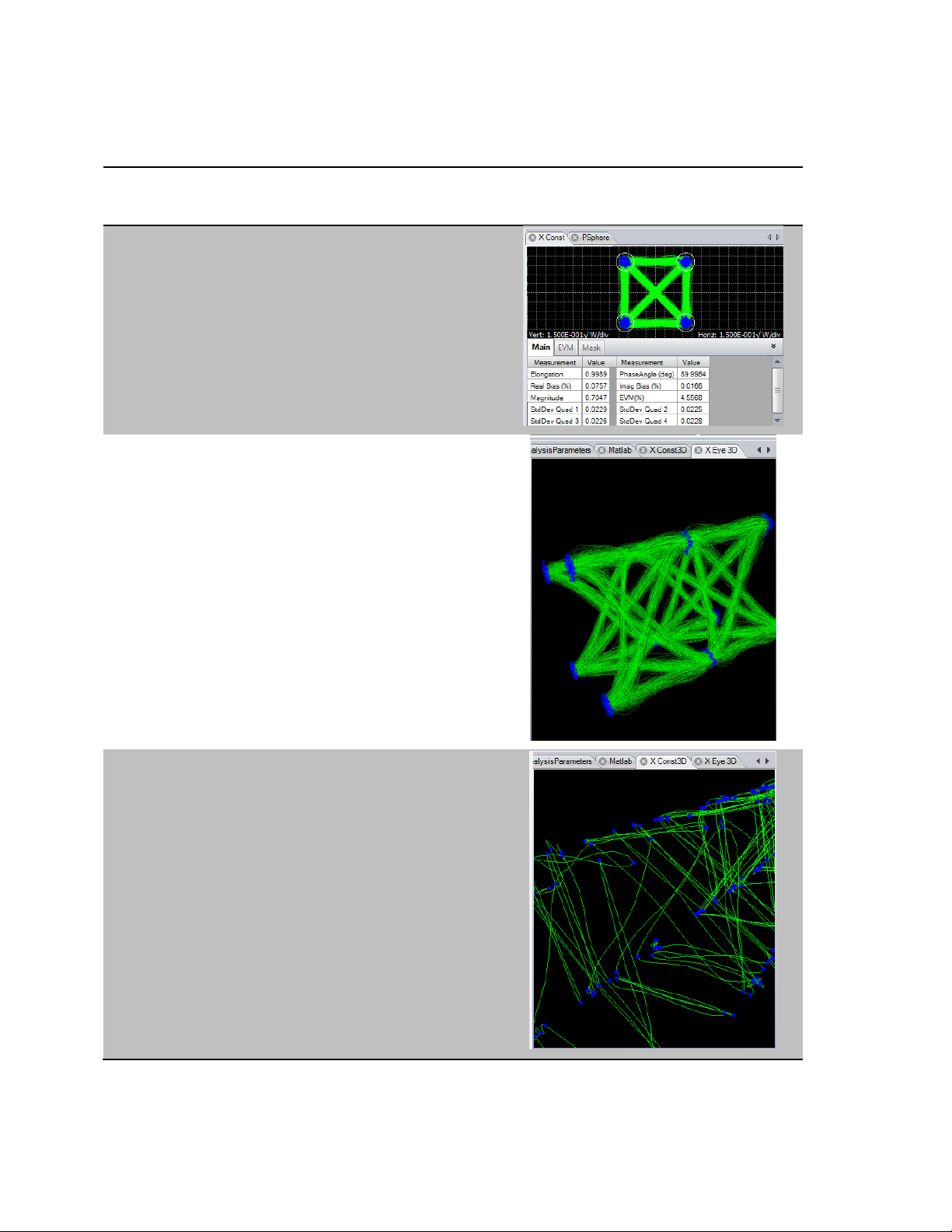

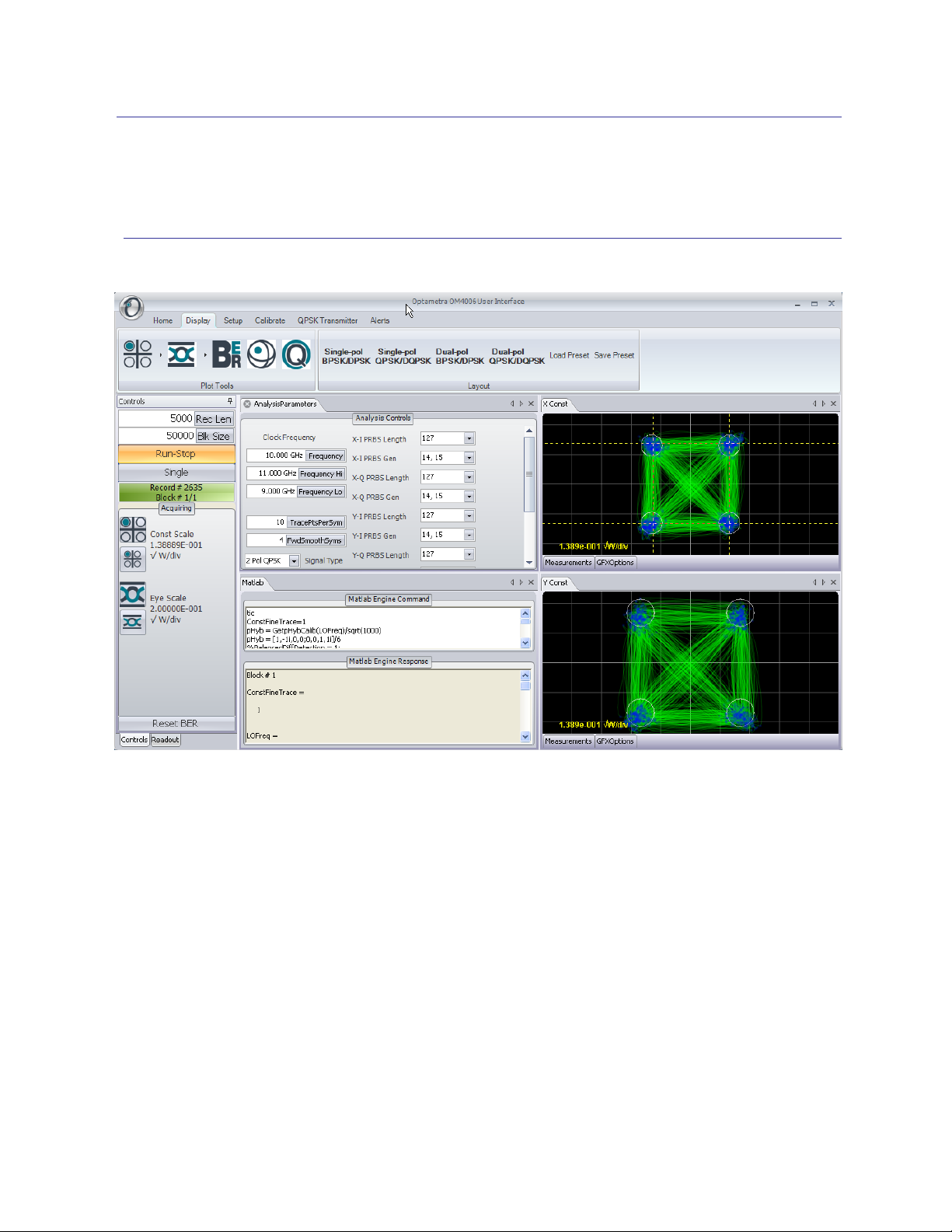

3.2.1 Summary of Plots and Measurements in the OUI

Description

Plot available with Real-time

Oscilloscope

Constellation Diagram for X or Y signal

polarization with numerical readout bottom tabs.

Right-click to see graphics options

Symbol-center values are shown in blue

Symbol errors are shown in red

Right-click for other color options

3d Eye for X or Y signal polarization.

This plot can be scaled and rotated to view on a

2d or 3d monitor. It shows the Constellation

Diagram with a time axis modulo two bit periods.

3d Constellation for X or Y signal polarization.

This plot can be scaled and rotated to view on a

2d or 3d monitor. It shows the Constellation

Diagram with a time axis.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 20 of 148

Page 24

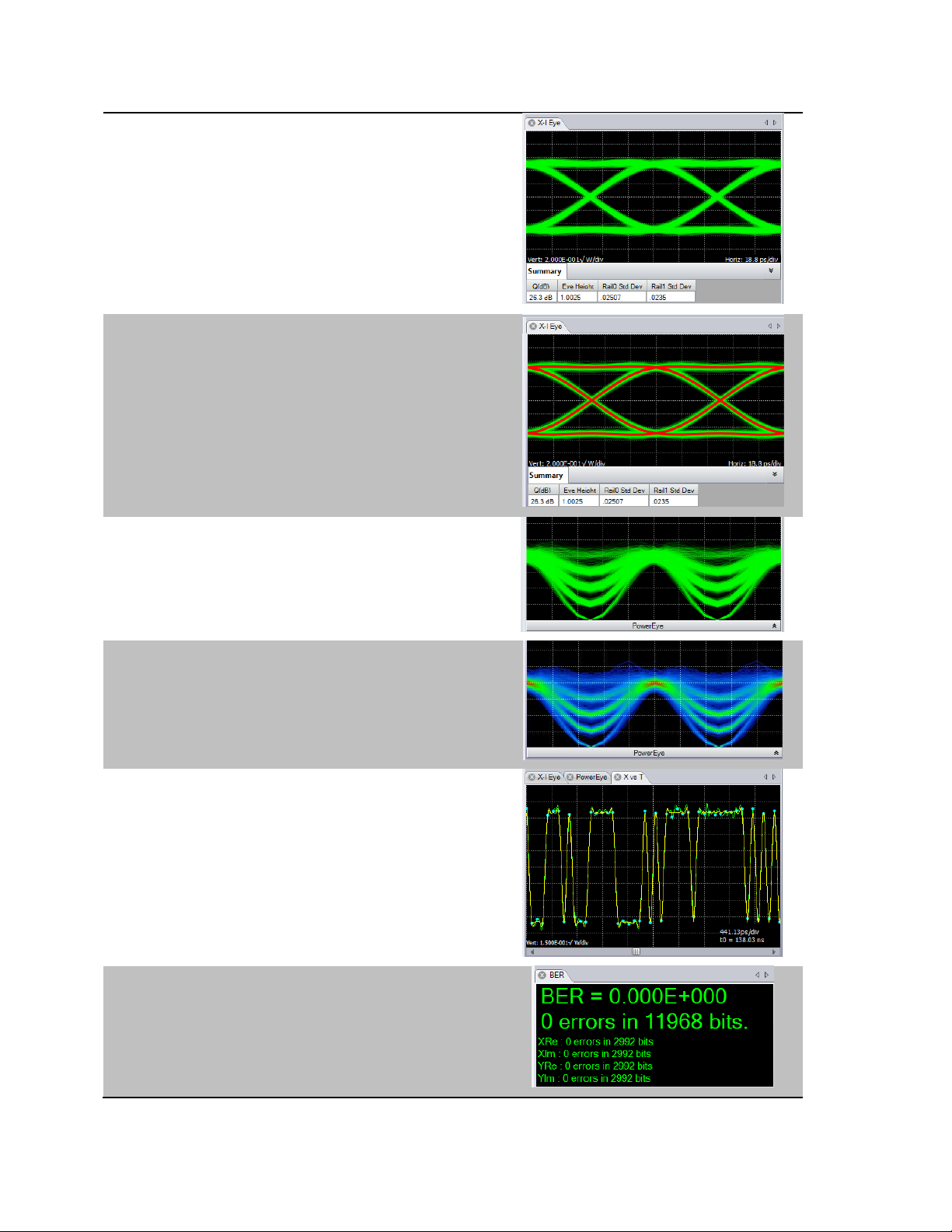

The coherent eye diagram for X or Y signal

polarization shows the In-Phase or Quadrature

components vs. time modulo two bit periods.

The Q-factor results are provided in a tab below

accessed by clicking on the arrows in the lower

left corner.

Right-click on the coherent eye diagram to get

options including transition and eye averaging.

The transition average shown in red is an

average of each logical transition. The

calculation is enabled in the Analysis Parameters

tab and is used for calculating transition

measurements.

The Power Eye shows the computed power per

polarization vs time modulo 2 bit periods. This is

a calculation of the eye diagram typically

obtained with a photodiode-input oscilloscope.

Most plots can be viewed in colorgrade by rightclicking on the plot.

Right-click on the X vs T plot to display field,

averaged-field, and symbol quantities. Zoom in

or out or scroll through the record. Error

symbols are shown in red.

BER is shown by physical tributary and in total.

Color changes on synch loss.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 21 of 148

Page 25

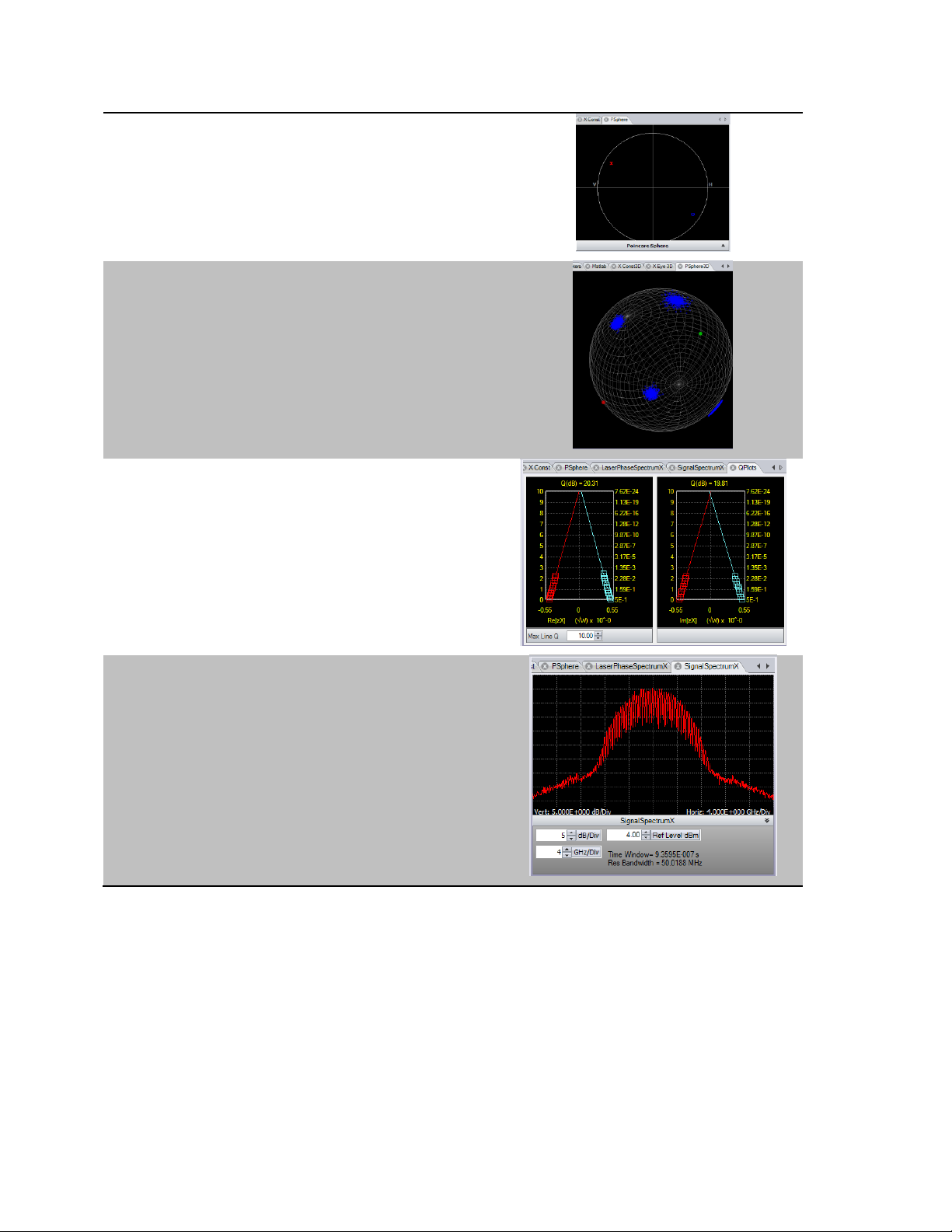

2d Poincare shows the position of the data

signal polarizations relative to the receiver’s H

(1, 2) and V (3, 4).

3d Poincare shows polarization of each symbolcenter value.

Click and drag to rotate the sphere.

The Decision-Threshold Q-Factor is an ideal

signal quality measurement based on measured

BER values. The horizontal axis corresponds to

the vertical axis on the corresponding coherent

eye plot. Linear Q is on the left and BER on the

right of the plot. Measured values are indicated

by squares: blue for 1’s red for 0’s.

The frequency spectrum of the signal field is

calculated using an FFT after polarization

separation to obtain the spectrum of each signal

polarization.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 22 of 148

Page 26

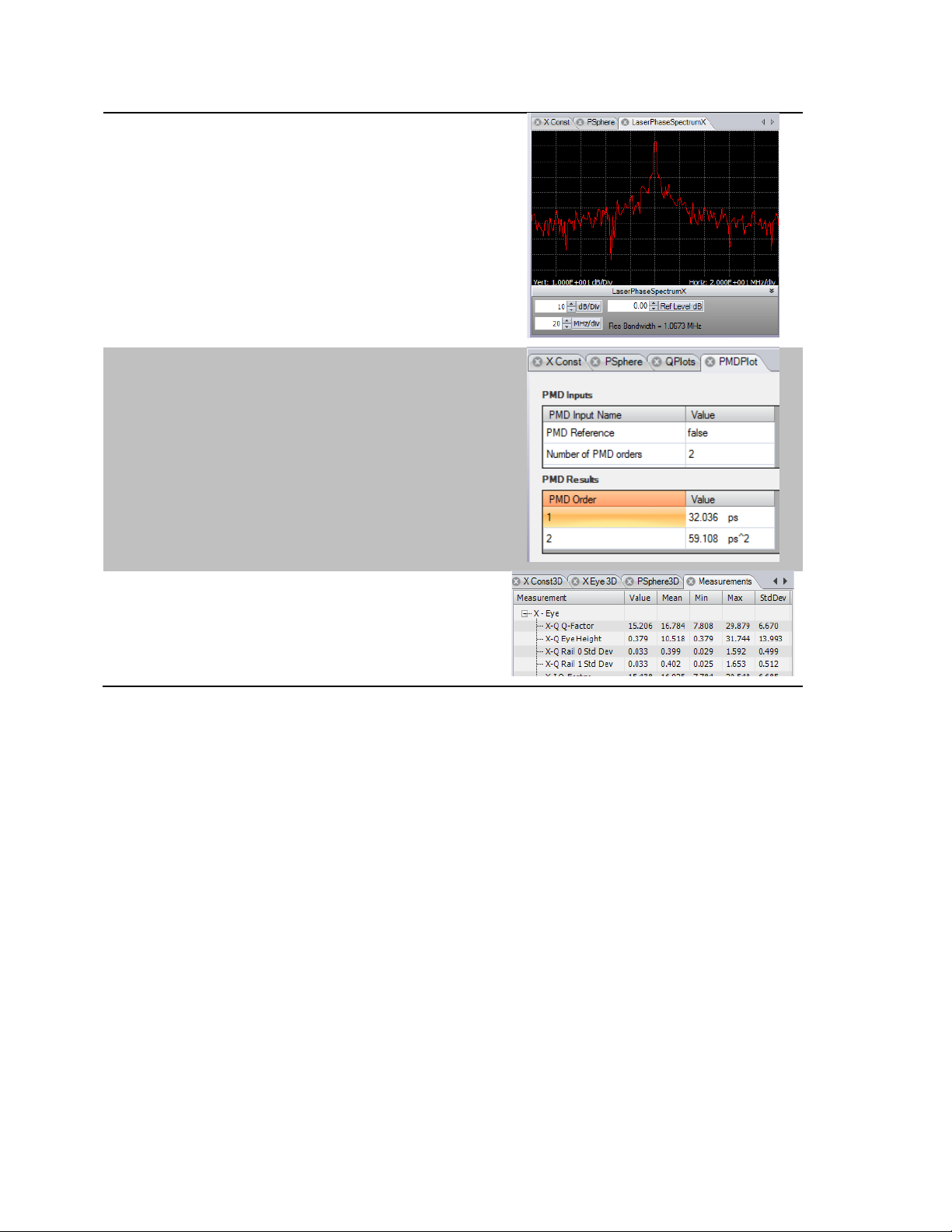

The laser phase noise spectrum is obtained by

taking an FFT of the where ϴ is the recovered

laser phase vs. time.

The PMDPlot provides the results of the PMD

Calculation

The Measurements Tab provides a convenient

place to find almost all of the numerical outputs

provided by the OUI with statistics on each

value.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 23 of 148

Page 27

3.2.3 Configuring the OM4000 Series User Interface (OUI)

VISA

Non-VISA Scope

Service Utility

Segmented readout for unlimited record size

YES

YES

Ability to collect data from two networked

oscilloscopes running the Scope Service

NO

YES

Software required on oscilloscope

LAN Server

Scope Service Utility or

ET Scope Service Utility

Real-time oscilloscope compatibility

Any real-time Tektronix

oscilloscope supported

by the IVI driver

C and D-model 70000

Series Oscilloscopes

with v6.4 firmware

Equivalent-time oscilloscope compatibility

NO

DSA8300 or 8200 with

ET Scope Service Utility

Start the OUI with the icon on your desktop or in the Programs menu.

Note: Be sure that Matlab is available and properly licensed, since the OUI will attempt to

launch a Matlab Command Window, and will appear to stall if Matlab is not available.

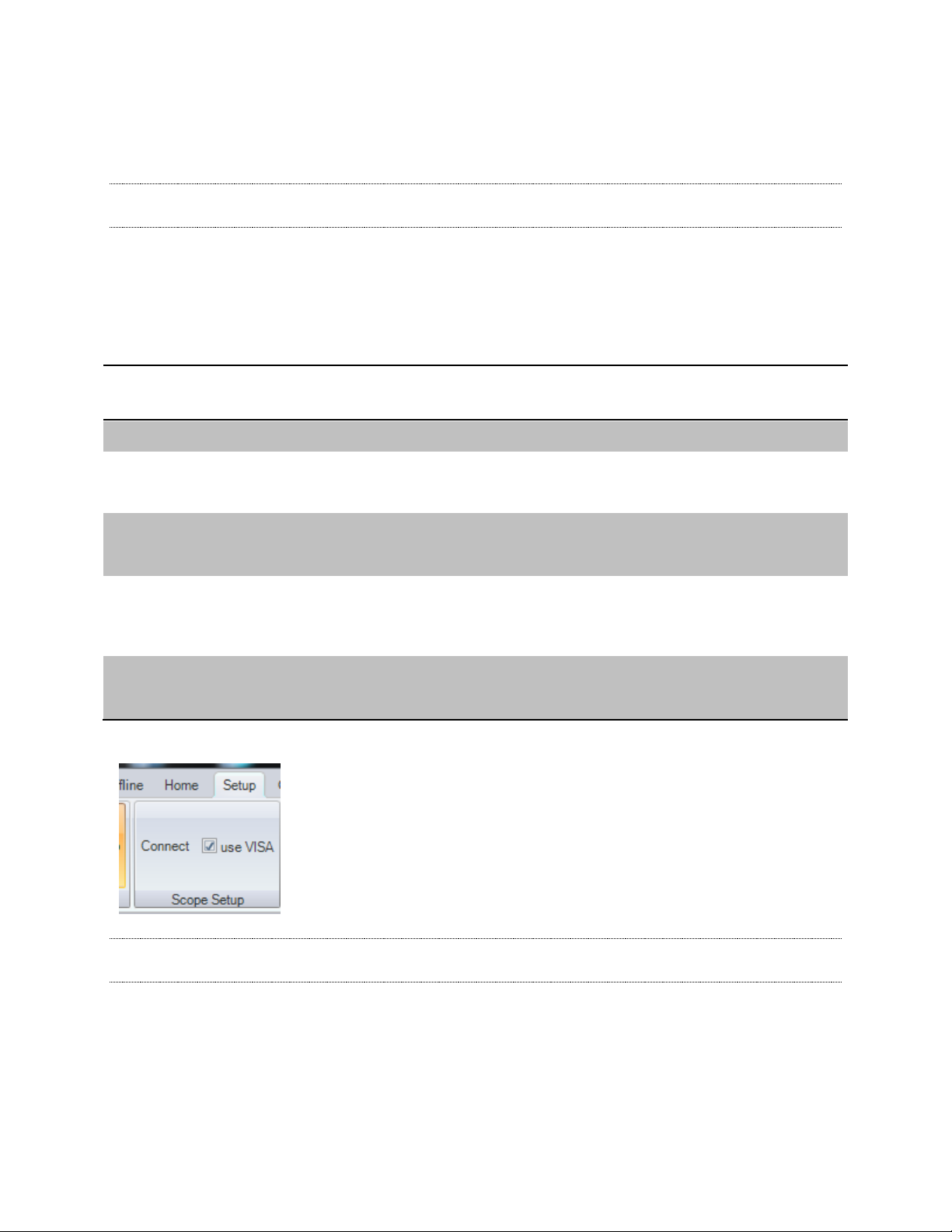

Connecting to the oscilloscope upon OUI startup is done with the Connect button in the Scope

Setup section of the Setup ribbon. Notice that there are two choices for making an oscilloscope

connection: VISA and non-VISA. VISA is only necessary when working with older real-time

oscilloscopes.

3.2.3.1 VISA Connections

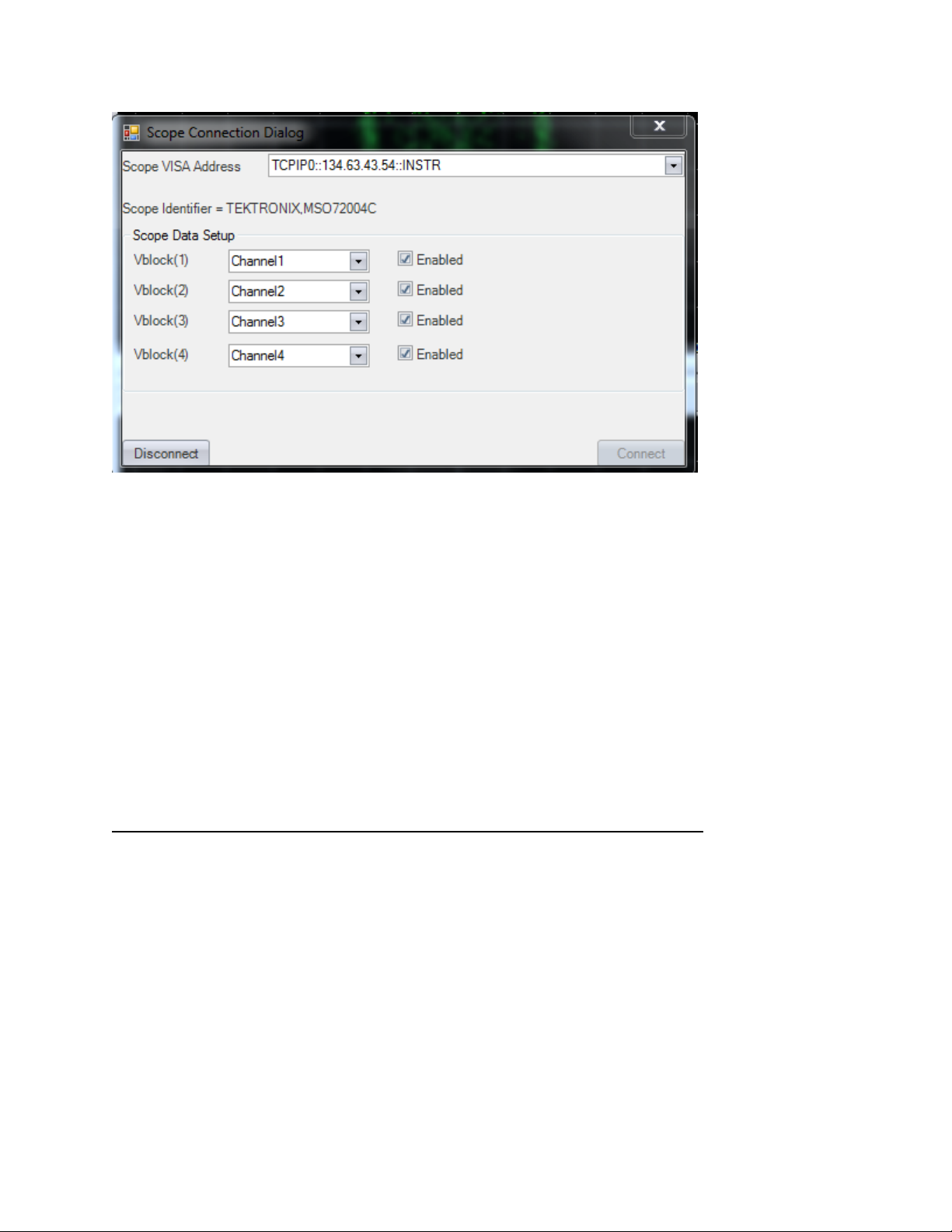

The VISA address of the oscilloscope contains its IP address, which is

retained from the previous session, so it should not normally need to be

changed, unless the network or the oscilloscope has changed. The

VISA address string should be TCPIP0::IPADDRESS::INSTR where

IPADDRESS is replaced by the scope IP address, e.g. 172.17.200.138

in the example below.

Note: To quickly determine the oscilloscope’s IP address, open a command window (“DOS

box”) on the oscilloscope, and use the IPCONFIG /ALL command.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 24 of 148

Page 28

After clicking Connect, the drop down boxes will be populated for channel configuration.

Choose the oscilloscope channel name which corresponds to each receiver output and Matlab

variable name. These are:

Vblock(1) – X-polarization, In-Phase

Vblock(2) – X-polarization, Quadrature

Vblock(3) – Y-polarization, In-Phase

Vblock(4) – Y-polarization, Quadrature

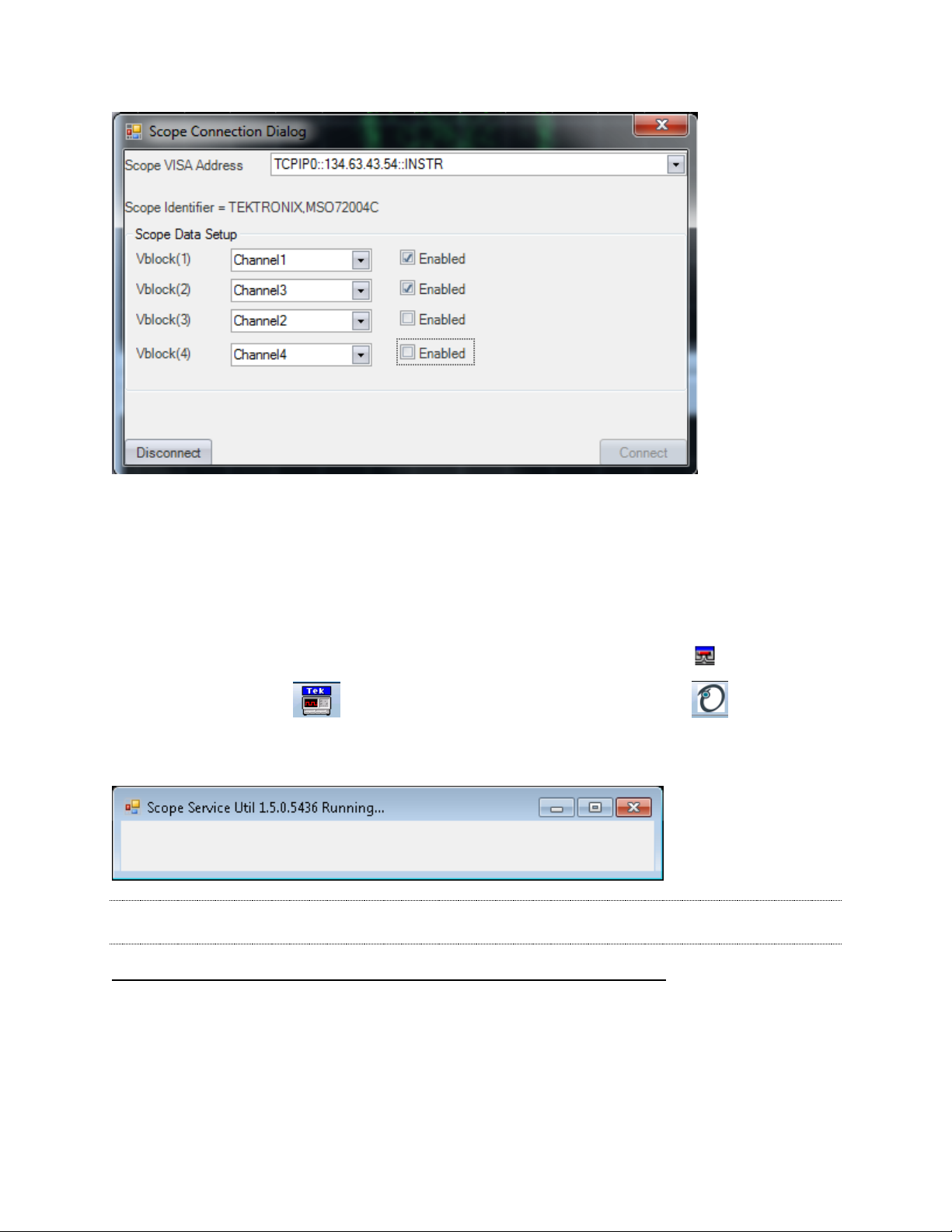

In the case below we disable two channels and set the other two to Channel 1 and Channel 3 since

these can be active channels in 100Gs/s mode. The disabled channels must still have some sort of

valid drop-down box choice. Do not leave the choice blank.

It is important to have the oscilloscope in single-acquisition mode (not Run mode). If you put the

oscilloscope into Run mode to make some adjustment, please remember to press Single on the

oscilloscope prior to connecting from the OUI.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 25 of 148

Page 29

3.2.3.2 Non-VISA Scope Service Connections

As mentioned above, the other choice for connecting to the oscilloscope and collecting data is the

Scope Service Utility. The Scope Service Utility is a program that runs on each oscilloscope to be

connected to the OUI.

Once the Utility is installed on the oscilloscope, please start the “Socket Server” and the

Oscilloscope Application before starting the Utility using the desktop icon .

The Scope Service has a small User Interface shown below.

Note: The Scope Service Utility runs on the target oscilloscope. Be sure to install the proper

version for either real-time or equivalent-time (ET) oscilloscopes. See installation guide.

It is best to have the oscilloscope in single-acquisition mode (not Run mode). The Scope Service

takes data directly from the oscilloscope memory and serves it up over a WCF interface to the OUI.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 26 of 148

Page 30

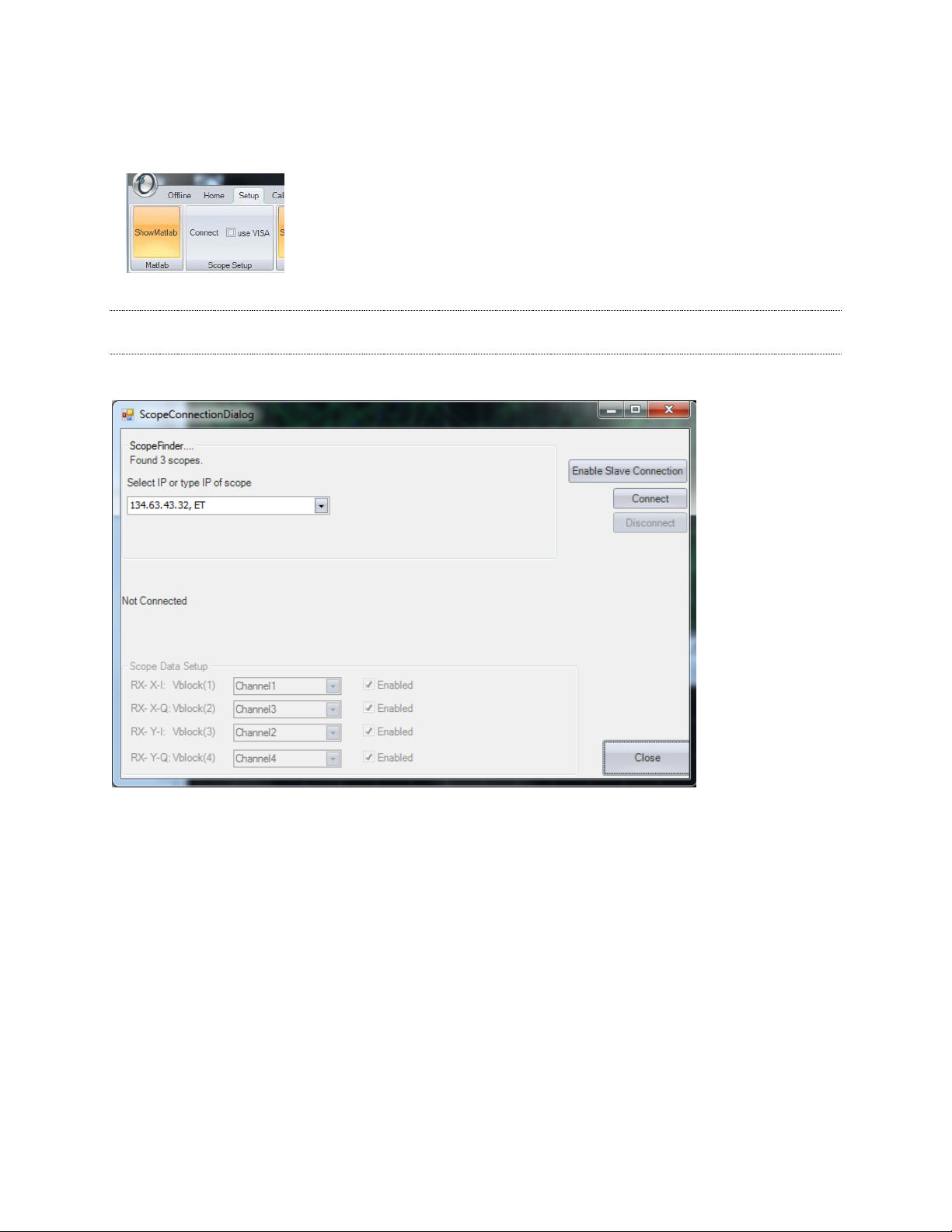

When connecting from the OUI, you will see a check box for VISA. Do not check the box unless you

require a VISA connection.

Note: Clicking Connect on the OUI Setup Tab brings up the Scope Connection Dialog box for

connecting to the Scope Service Utility

The green bar at the top indicates that the software is searching for oscilloscopes on the same

subnet that are running the Scope Service Utility. As they are found they are added to the dropdown menu. If the OUI Scope Connection Dialog box reports 0 Scopes Found, you will have to type

in the IP address manually. This happens when connecting over a VPN or when network policies

prevent the IP broadcast. When typing the address in manually, do not include “, ET” or “, RT” on the

end. Click connect.

After connection, map the channels to the physical receiver channels and corresponding Matlab

variables as shown. This means that data from the selected channel will be moved into the

indicated Vblock variable. Vblock(1) is X-Inphase, Vblock(2) is X-Quadrature, Vblock(3) is YInphase, Vblock(4) is Y-Quadrature. The mapping you choose will depend on the cable connections

made to the receiver.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 27 of 148

Page 31

Once connected and configured, close the connect dialog box. The OUI is ready to use.

3.2.3.3 Two-Oscilloscope Configuration – See Appendix A

OUI Version 1.5 supports a new configuration where two C- or D-model 70000-Series oscilloscopes

are both connected to an OM4000.

3.2.4 Calibration and Adjustment

The receiver requires four types of calibration:

1) DC calibration (to compensate for any offsets in the photodiode outputs)

2) Delay adjustment (channel to channel skew in the scope connections)

3) Hybrid calibration (correction for cross-talk and phase error in the hybrid)

4) Laser linewidth factor (choosing the correct filter for phase recovery)

5) Receiver equalization

3.2.4.1 DC calibration

Although the OM4000 Series units use balanced detection, there is usually some small offset

voltage present at the signal outputs. This offset voltage depends on the total optical power

input to the system and so can change. The offset is small enough that only large changes to

the reference or optical input power substantially affect the computation. “DC calibration”

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 28 of 148

Page 32

determines the DC levels in the receiver’s photodiodes, and subtracts this off within the

analysis. This can be done as often as needed or desired. If there is uncompensated dc offset in

the system, this will be evident by a smearing out of the constellation point groups. If the offset

is large enough, the point groups will begin to look like donuts. Perform a dc calibration

whenever there is any question.

3.2.4.2 Delay adjustment

Note: Initial delay adjustment should be done by trained personnel. This section is provided for

experienced users. Delay adjustment should be done during installation and should not

require attention unless the scope is removed and/or reconnected.

Delay adjustment among the four electrical channels of the oscilloscope is done through the

Channel Delay Calibration section of the Calibrate ribbon.

Access to the delay sliders is done via the checkbox shown below. Once this is accomplished

for a specific oscilloscope installation, it should not need further attention, and should be left

untouched. If the receiver/oscilloscope interface is altered (e.g. with the installation of new

cables or shifting of the instrument), delay calibration may need to be performed.

Use the Calibration ribbon to adjust the skews to get the best possible eye diagram and

constellation diagram. Improper skew will cause horizontal eye closure and filling in of the

constellation diagram. If the I and Q channels have unequal delay, there will be a phase offset

proportional to the difference frequency between the reference and signal laser oscillation

frequencies. This phase offset will turn a straight line on the phase diagram into a circle or a

portion of a circle. So, for verification, it is best to use a known Mach-Zehnder modulator to

generate a BPSK optical input. As the input signal polarization is adjusted, the phase diagram

should always be a straight line.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 29 of 148

Page 33

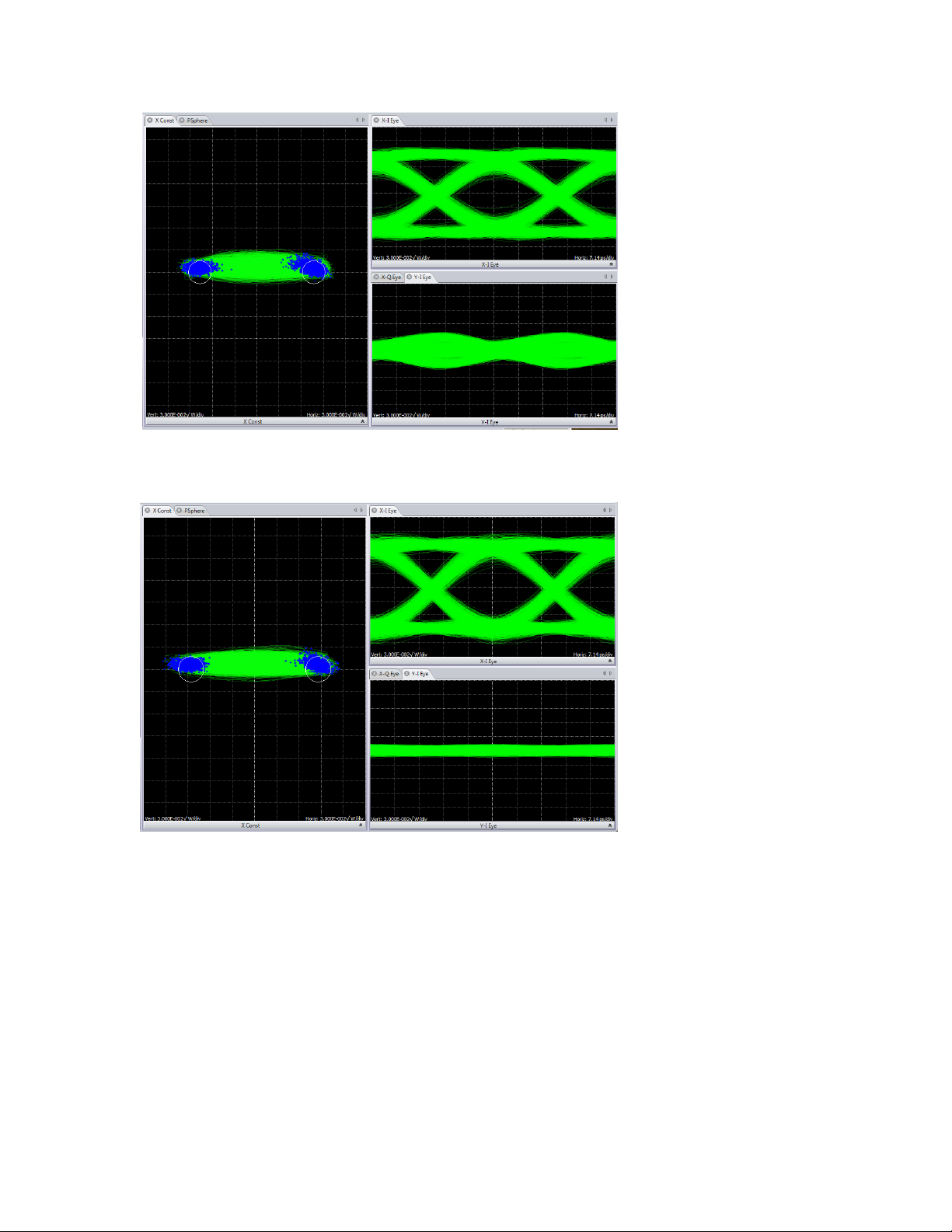

ChDelay(2) off by 4 ps causes curvature on constellation and

signal on Q-Eye for 28Gbps BPSK

The ChDelay variable is defined as follows:

ChDelay(1): delay between channels 1 and 1 which is zero.

ChDelay(2): delay between channels 1 and 2

ChDelay(3): delay between channels 1 and 3

ChDelay(4): delay between channels 1 and 4

Automatic ChDelay Calculation

When setting up for the first time or whenever the channel delays are completely unknown, it is

best to use the utility CalChDelay as shown in the figure below. To use this utility, take the

following steps:

1) Complete the initial setup outlined in Section 3.1

2) Launch the Laser Receiver Control Panel and Connect to the OM4000 Series receiver

as outlined in Section 6 and use the drop-down menu to choose the laser to be the

reference.

3) Connect a high-baud rate BPSK signal to the Input of the OM4000 Series receiver

4) Tune the reference laser to the same WDM channel as the BPSK signal. Use the

oscilloscope controls to verify that the BPSK source is on and at proper level. It does not

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 30 of 148

Page 34

have to be perfectly biased. Adjust the vertical gain on the oscilloscope so that the signal

is filling up at least 50% of the oscilloscope screen. Adjust the signal polarization as

needed to get good signal level on all four oscilloscope inputs.

5) Launch the OUI4006 software and connect to the oscilloscope using the Setup tab.

Ensure that the proper LO Frequency is displayed on the Setup tab as well. On the

display tab select Single-pol BPSK and also select 1 Pol BPSK on the Analysis

Parameters tab. Enter the Clock Frequency of the BPSK signal.

6) Enter the CalChDelay function in the Engine Window as shown below.

7) Click Single to take an acquisition; be sure no errors are reported in the Matlab Engine

Response.

8) Use the sliders in the Calibrate tab to set the displayed ChDelay for future use (only the

last 3 numbers are set since the first is always zero.

Manual ChDelay Determination:

Once you have used the sliders to set the delays at least close to their actual values, you can

use the shape of the phase-diagram curves to fine tune as described here. It is best to do this

one polarization at a time using the following steps:

1) Delete everything from the Matlab Engine Window except for CoreProcessing

2) Perform a DC calibration as outlined above in Section 3.2.3.2.1.

3) Adjust the input polarization so the signal is mostly on oscilloscope channels 1 and 2.

This can be done mathematically by putting the following statements before

CoreProcessing:

Vblock(3).Values = Vblock(3).Values*0.001;

Vblock(4).Values = Vblock(4).Values*0.001;

4) Now only the top slider will make any difference. Click Run to get a repeating

constellation and eye-diagram update. Click the + and – to make 0.1-ps adjustments to

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 31 of 148

Page 35

the top slider until the BPSK constellation as perfectly straight lines connecting the two

groups of constellation points.

5) Displaying the X-Q eye will show the signal going into the “wrong” quadrature. When the

delay is set properly the signal shown should only be noise.

6) Now shut down channels 1 and 2 by again moving the polarization state of the signal or

by zeroing it be deleting the lines from item 3 and replacing them with:

Vblock(1).Values = Vblock(1).Values*0.001;

Vblock(2).Values = Vblock(2).Values*0.001;

7) Now only the difference between the bottom slider will matter.

8) Move the last slider using the + and – buttons to get 0.1-ps changes until the

constellation looks as it did with channels 1 and 2. Once again use the X-Q eye as a

measure of residual error as well as constellation quality.

9) Once this is done get equal signal on both polarizations by deleting everything from the

Engine Command Window except for CoreProcessing and adjusting the input

polarization as needed.

10) The last step is to set the middle slide to achieve minimum signal in the Y-polarization.

Since the input is a single-pol signal at this point, nothing should be in the Y constellation

or eyes except for noise.

11) Display the Y-I or Y-Q eye diagrams and Y-Constellation to see the signal going into the

wrong polarization. This should just be noise when the middle slider is set properly.

12) The delay calibration is done if there is only noise in eye plots except the X-I and only

noise in the Y-constellation.

13) Click the check box to hide the sliders to avoid accidental change

14) Save the Matlab workspace as Delay.mat for later recovery of the delay data if needed.

The delays are now stored in the ChDelay variable.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 32 of 148

Page 36

When adjusting the middle slider, watch the Y-Eye to minimize the

signal in the Y-polarization

Final Channel Delay values provide only noise in Y polarization

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 33 of 148

Page 37

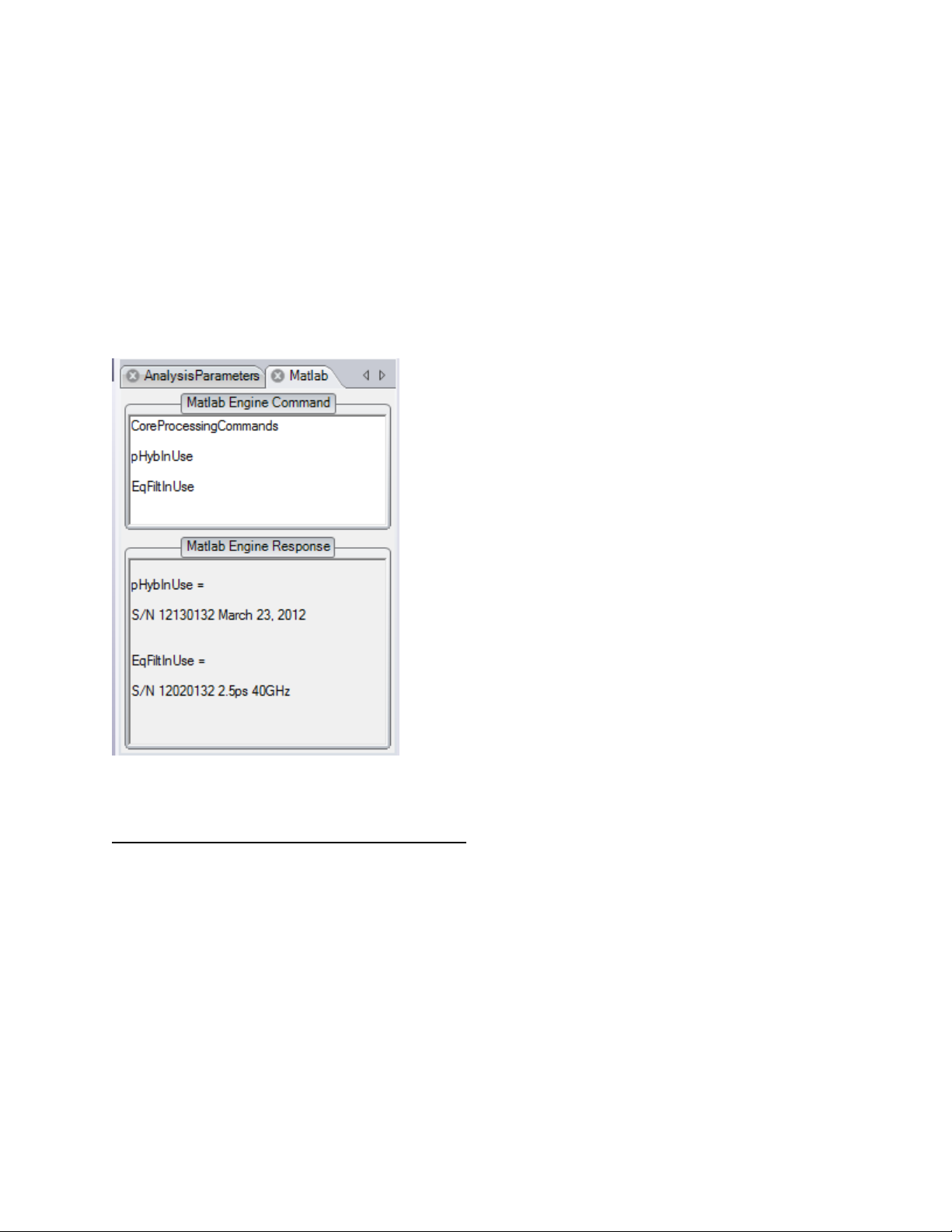

3.2.4.3 Hybrid calibration

This is a factory calibration. Imperfections in the OM4000 Series receiver are corrected using a

factory-supplied calibration table. Check the Setup tab for a green indicator to be sure the OUI is

successfully retrieving the Reference laser (Local Oscillator) frequency and power which are needed

to choose the correction factors from the calibration table. The table is the pHybCalib.mat file in the

ExecFiles directory. You can verify you have a valid pHybCalib file by connecting to an oscilloscope,

typing pHybInUse in the Matlab Engine Window, and clicking Single. Similarly, EqFiltInUse shows

the equalization filter in use (if any).

The info statement contains the serial number, date of calibration, and other notes about the

calibration. If the serial number is correct then you have the proper file.

Calibration Check and Quick-Cal Procedure

The following procedure can be used to verify and correct the calibration at a single wavelength

using a minimum of external hardware. This procedure assumes that “Laser 1” and Laser 2” can be

tuned to the same wavelength. It is easiest if you have a polarization controller before the signal

input, but the instructions are written assuming you are moving the fiber around to change the input

polarization.

1) Equipment set up for optical hybrid calibration verification:

a. System should be de-skewed following the procedure above.

b. Connect the Reference as usual from Laser 2 to the Reference input with short PM/APC

jumper.

c. Use a standard SM/APC (not PM) fiber to connect the Laser 1 to the Signal input. Use

the LRCP to set the Signal 1 power level to about 10dBm to start.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 34 of 148

Page 38

d. Use the LRCP to turn on both lasers and tune them to the same channel where you will

be working. Set the Laser 1 power to get about 100mV pp.

e. Use the LRCP to tune Laser 1 off grid by 100 to 500MHz

f. Click Run on the oscilloscope to get a rapidly updating display. You should see 100 to

500 MHz sine waves.

g. Move the SM fiber around until you get most signal on channels 1 and 2 (at least 3:1 ra-

tio between Channels 1 and 3. This is most easily done with a polarization controller).

h. Tape the fiber down so that you continue to get most signal on Channels 1 and 2.

i. Click Single on the oscilloscope.

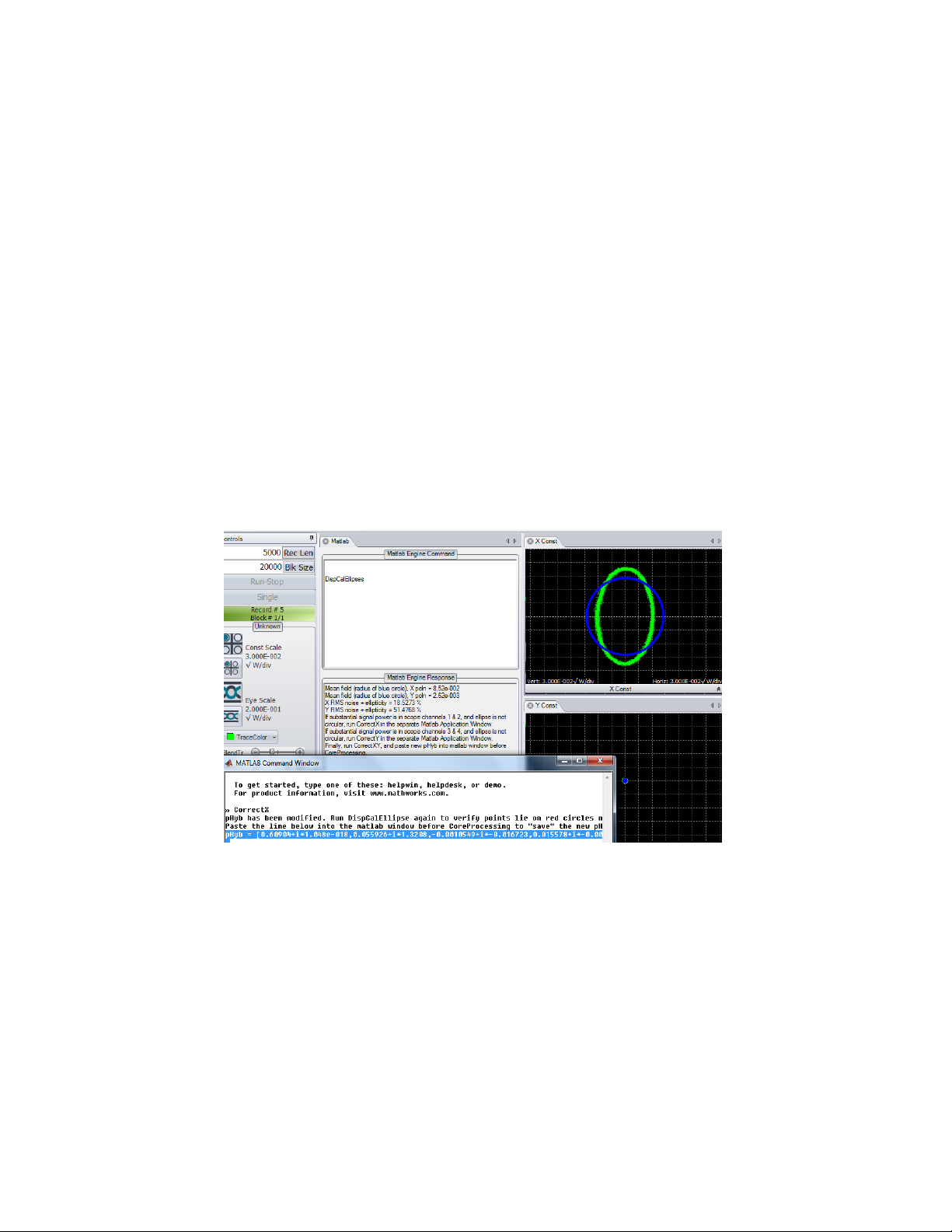

2) Procedure to Inspect and Correct the X-polarization Calibration:

a. Use the Optametra OUI to connect to the scope. Record length of ~20,000 points rec-

ommended in single block (BlockSize > 20,000).

b. Display the Matlab Engine Window, the X-Constellation Window and the Y-Constellation

Window. Close other windows.

c. Put DispCalEllipses in the Matlab Engine Window of the OUI. Delete everything else in

the Matlab Engine Window.

d. Click Run on the Optametra OUI

e. Observe that the ellipses are displayed on the Constellation plots. Right now only the X-

constellation has signal. The green trace should line up with the blue circle in the Xconstellation plot.

f. If the green trace in X-Constellation is elliptical:

i. Click Stop

ii. Type CorrectX in the separate Matlab Engine Window

iii. Copy and paste the resulting pHyb statement before DispCalEllipses in the

Matlab Engine Window in the OUI as shown below.

g. Click Run. The green trace should now be circular.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 35 of 148

Page 39

3) Procedure to Inspect and Correct the Y-polarization Calibration

a. Move the input fiber to get most of the signal on Channels 3 and 4. Tape it down.

b. Click Single on the Oscilloscope. Click Run on the OUI

c. Observe that the ellipses are displayed on the Constellation plots. Right now only the Y-

constellation has signal. The green trace should line up with the blue circle in the Yconstellation plot.

d. If the green trace in Y-Constellation is elliptical:

i. Click Stop

ii. Type CorrectY in the separate Matlab Engine Window

iii. Copy and paste the resulting pHyb statement before DispCalEllipses, replacing

any other pHyb statement.

e. Click Run. The green trace should now be circular.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 36 of 148

Page 40

4) Procedure to Correct the relative X-Y gain.

a. You must complete all of the above steps first including CorrectX and CorrectY.

b. Type CorrectXY in the separate Matlab Engine Window

c. Copy and paste the resulting pHyb statement before DispCalEllipses, replacing any other

pHyb statement.

d. Move the input fiber until there is signal on all four channels

e. Click Run. The green trace should now be circular in both Constellations.

5) The pHyb statement in step 5 is the final output that is corrected for Ch1-2 gain and phase, Ch3-

4 gain and phase, and Ch1-3 gain.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 37 of 148

Page 41

6) Replace the DispCalEllipses statement with CoreProcessing for normal operation. Keep the

Scope Sampling Rate

Reference Magnitude Response

Reference Phase

≤ 2x the bandwidth of the

OM4000 Series unit (BW)

Flat

Linear

> 2x the bandwidth of the

OM4000 Series unit (BW)

4th order digital (bilinear) Bessel

filter with 3dB cutoff at BW + 2GHz

Linear

pHyb statement as it is correcting the calibration.

3.2.4.4 Absolute Power Calibration

As of version 1.2.0, the OUI has the ability to provide signal data plotted on an absolute scale

independent of the LO signal strength. This requires absolute scaling of the pHybCalib.mat file which

was not available on all earlier versions. Check the absolute scale by connecting a CW signal of

known power (no modulation) with sufficient power to fill most of the oscilloscope display. Be sure

the OUI and LRCP are connected by checking for the green square on the SetUp Tab. Do a DC

calibration. The OUI should display one group of symbols in the X constellation. The distance from

the center of that group to the origin is the signal strength in root-Watts. Square this value and

compare to the known value in Watts. To use the built in Magnitude measurement, choose BPSK

signal type and a clock frequency equal to twice the offset between the signal and LO frequencies.

This will display two clusters of points and the Magnitude measurement will provide the average

signal strength. The power calibration should be accurate to 15%.

3.2.4.5 Laser linewidth factor

See discussion in Section 5.2 on modifying the default value of “Alpha.”

3.2.4.6 Receiver Equalization

Receiver Equalization is a factory calibration. Digital equalization is applied to the four channels

of the OM4000 Series receiver to account for the non-ideal frequency dependent response

introduced by the coherent optical receiver and the receiver radio frequency front end.

Depending on the sampling rate of the oscilloscope and the bandwidth of the OM4000 Series,

digital equalization is applied so that the combined effect of the receiver and the digital

equalization filter meet a specified reference response:

Equalization is specific to the sampling rate of the oscilloscope. As an example, if the bandwidth

of the OM4000 Series is 30 GHz and the sampling rate of the oscilloscope is 80 GSPS, the

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 38 of 148

Page 42

combined effect of the OM4000 Series receiver front end response and the digital equalization

0 0.5 1 1.5 2 2.5 3 3.5 4

x 10

10

-20

-15

-10

-5

0

Frequency

Magnitude response (dB)

Reference filter responose

filter will be that of a 4th order digital Bessel filter with 3dB cutoff at 32GHz (see below).

The digital filter is applied directly to the MATLAB workspace variables Vblock(1).Values through

Vblock(4).Values using a 100 tap FIR filter.

For more information, or for equalization support of a different scope sampling rate, contact

customer support.

3.2.5 Moving and Docking Windows

The OUI is designed to allow you maximum control of the graphical presentation. There are

three types of displays in the OUI: ribbons, fly-out panels, and windows. The main ribbon,

shown below, is normally displayed making the various tabs always available. To get more room

for graphics, you can hide the ribbon by double clicking in the tab area. Bring it back by double

clicking again on one of the tabs.

Flyout panels are used for information that is needed less often. Mousing over the Measurement

tab on an eye-diagram for example will bring up the panel below. Clicking on the push pin will

cause the panel to stay after you mouse away.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 39 of 148

Page 43

The graphics windows can be docked or free floating. To move a graphics window, click and

hold over the tab then drag. As you drag the window, different docking targets will appear as

shown below. Moving the pointer to the center of the target will cause the window being

dragged to be displayed on top of the existing window. Dragging it to one of the four squares

surrounding the center of the docking target will split the window so that both the new and old

windows are visible. You may also drag the window to another monitor or leave it free floating in

front of the OUI main window.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 40 of 148

Page 44

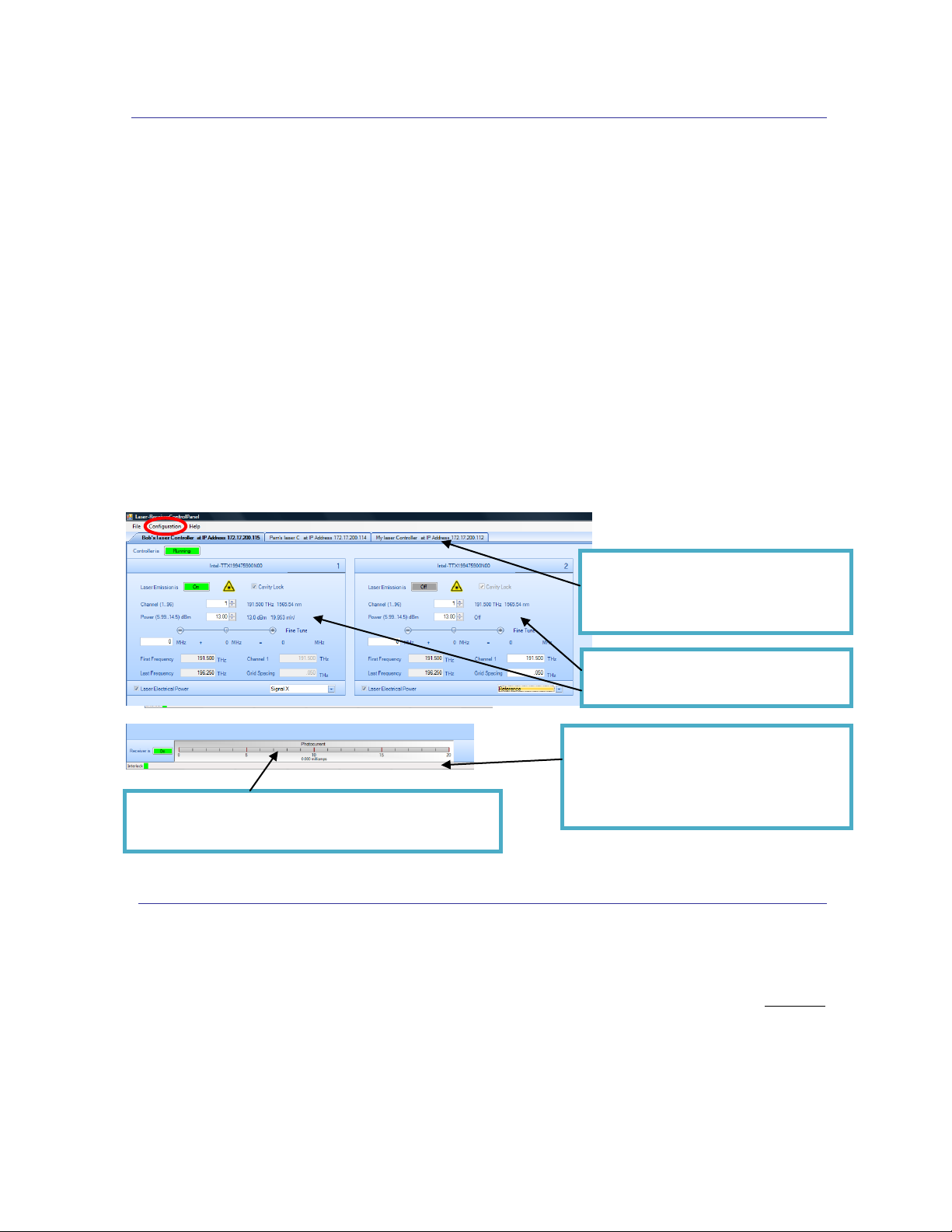

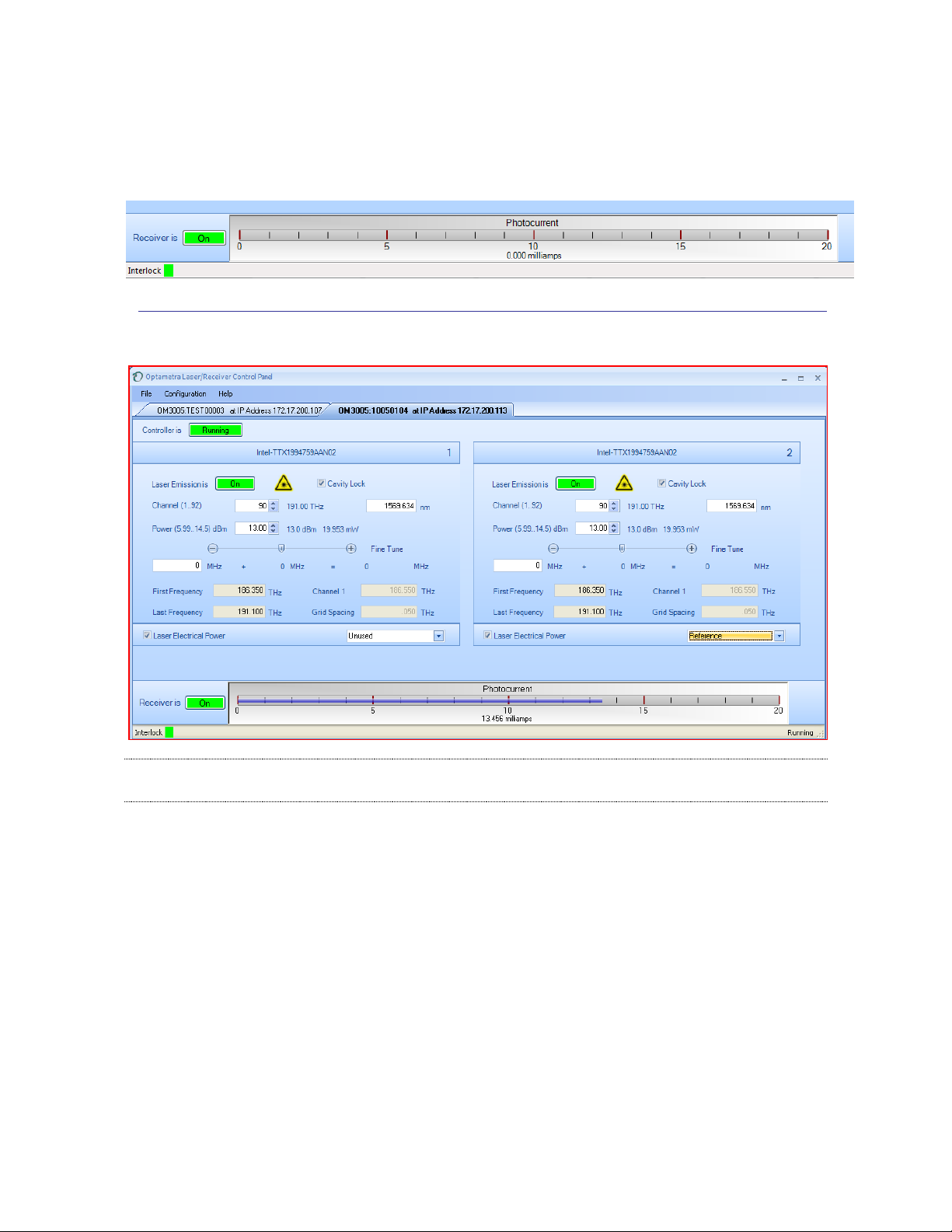

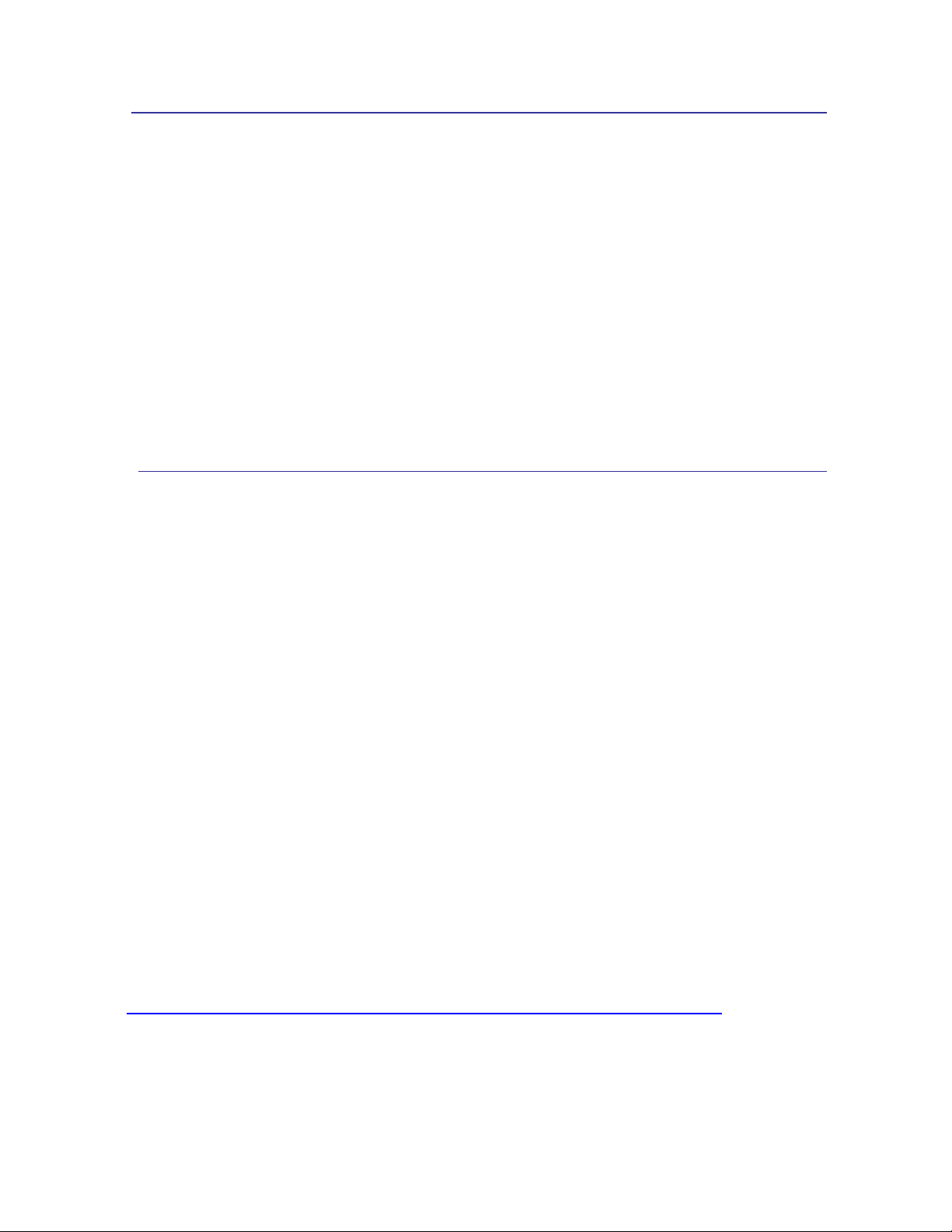

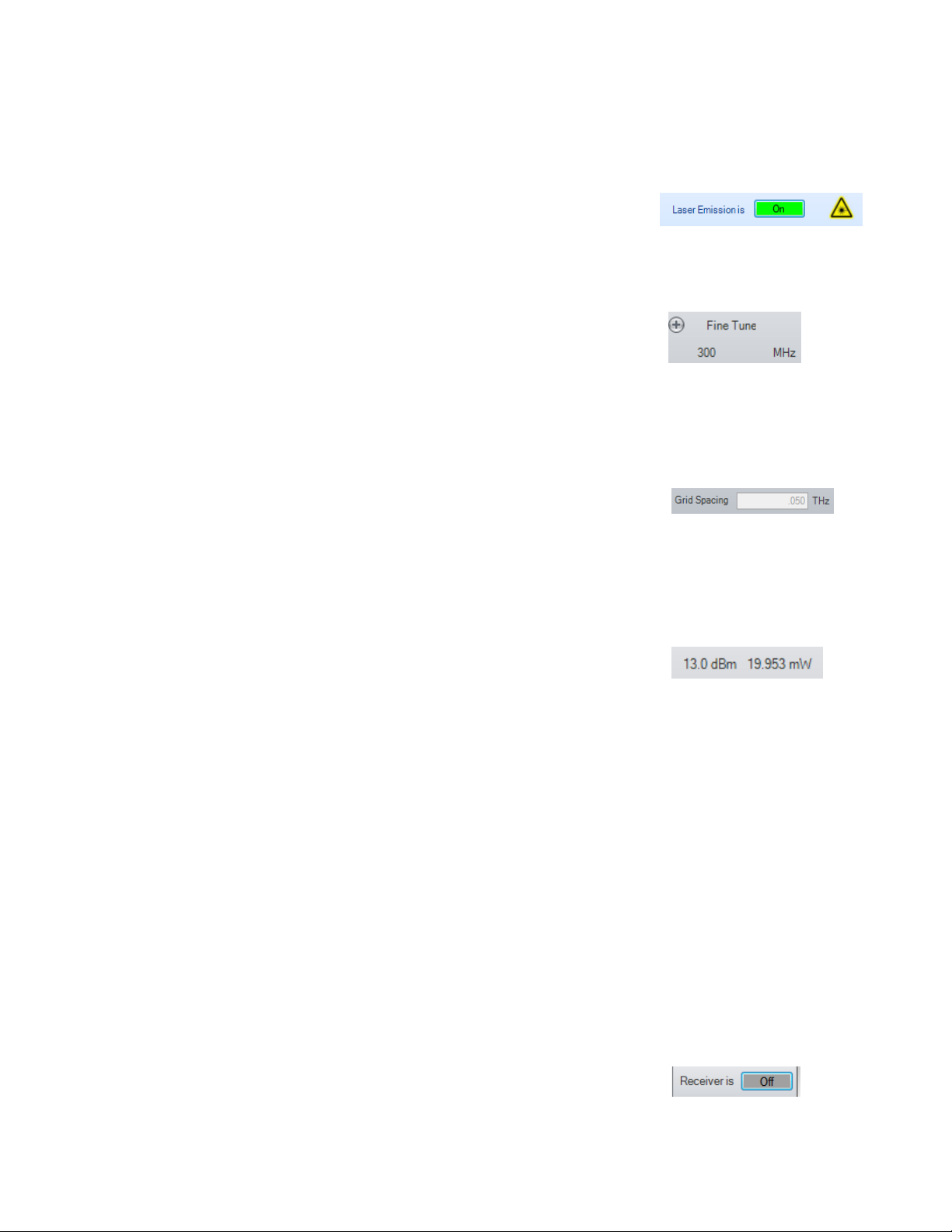

3.2.6 Laser / Receiver Control Panel (see Section 6 for first use)

3

Channel setting within the ITLA grid gives the corresponding frequency (in THz) and wavelength

(in nm). Power is set within the range allowed by the laser. It is best to set the Signal and

Reference lasers to within 1 GHz of each other. This is simple if using the internal OM4000

Series lasers: just type in the same channel number for each. If using an external transmitter

laser, you can type in its wavelength and the controller will choose the nearest channel. If this is

not close enough, try choosing a finer WDM grid or use the fine tuning feature. If available3, fine

tuning of the laser is done with the Fine Tune slider bar, and typically works over a range of +/10 GHz from the center frequency of the channel selected. Certain laser models have a cavity

lock feature that increases their frequency accuracy at the expense of dithering the frequency;

this feature can be toggled with the Cavity Lock button. Cavity Lock is necessary to tune the

laser, but can be unchecked to suppress the dither.

Once the Channel and Power for each laser is set, turn on laser emission for each laser by

clicking on its Laser Emission button; the emission status is indicated both by the orange

background of the button and by the corresponding green LED on the OM4000 Series front

panel.

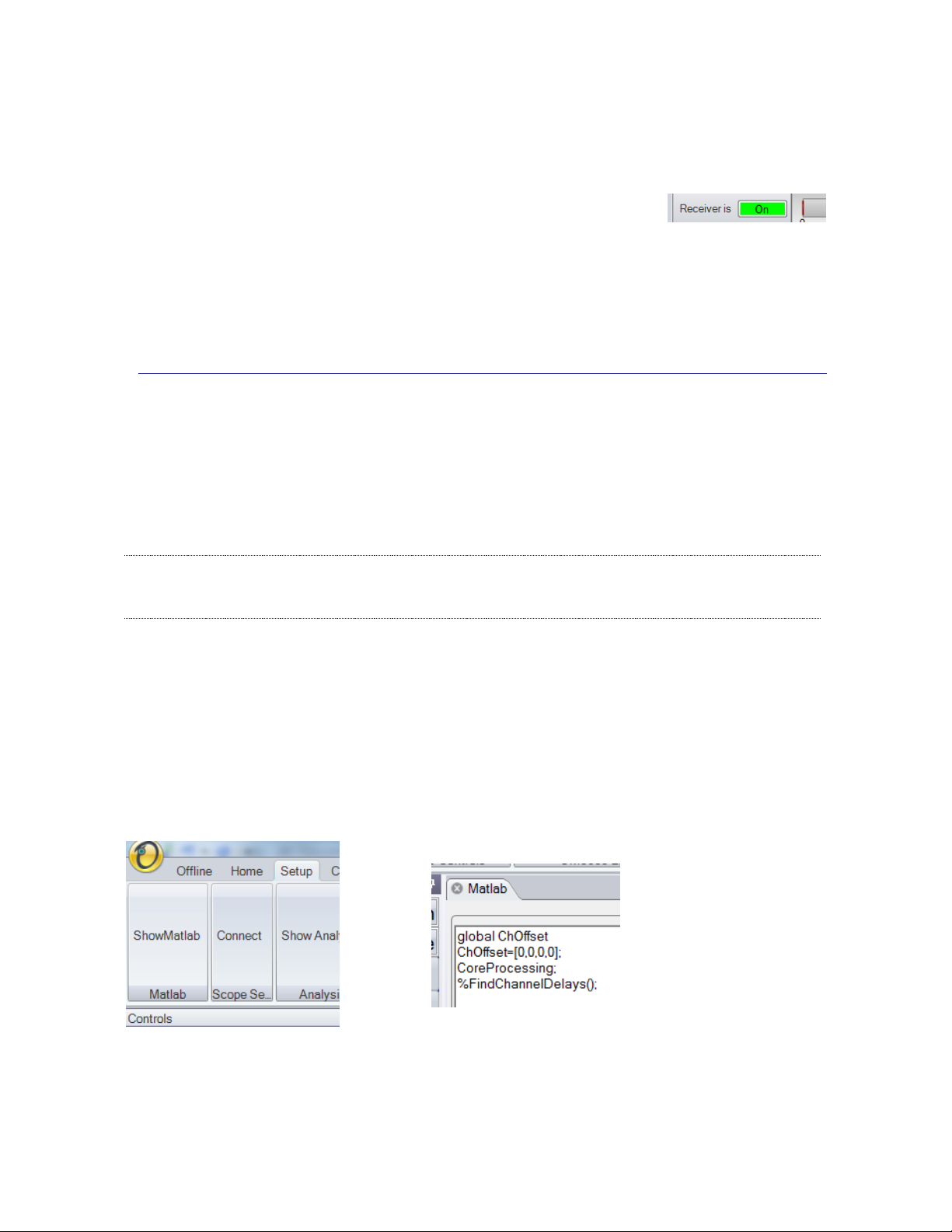

3.2.7 Matlab

When it is launched, the OUI in turn launches the default Matlab installation.

The default working directory is the installation directory. Use the cd command to change to

another directory if desired. Any files saved will go to the working directory. Once the OUI is

running, the Matlab workspace is populated with the variables and functions used in coherent

signal processing:

For example, the standard OM3x05 ships with Emcore lasers, which can be fine tuned.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 41 of 148

Page 45

3.2.8 Licensing

The software bundled with the OM4000 Series is licensed per the agreement in the Appendix.

Copy protection is enabled via HASP key, which must be present in permanent installations.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 42 of 148

Page 46

4 Making Measurements

4.1 Setting Up Your Measurement

Since the Coherent Lightwave Signal Analyzer is a reconfigurable (complex, dual-polarized)

reference receiver, it requires a modulated signal on the input fiber. Depending on the options

configured in the receiver, this modulation can be single- or dual-polarized, with several formats

available, including OOK (on-off keying), BPSK (binary phase-shift keying), and QPSK

(quadrature phase-shift keying), either coherent or differential.

The Coherent Lightwave Signal Analyzer includes two (C- or L-band) network-tunable sources;

you can use these or your own lasers for signal and reference inputs. Furthermore, each

polarization can be independently driven by a distinct source, though all sources must be tuned

to the same (ITLA) channel, or at least to the same wavelength. While no phase locking of the

sources is necessary, the beatnote between any signal laser and the reference should be at a

low enough frequency that the bandwidth of the real-time oscilloscope can accommodate the

modulation bandwidth plus the beatnote frequency.

Prior to testing a modulated source, ensure that there is no modulation of the lasers (i.e. that

your data source [pattern generator] is not enabled). With both lasers emitting and tuned to the

same channel, use the fine-tune feature of the Laser/Receiver Control Panel to obtain a 100500 MHz beat note on the oscilloscope. Then enable modulation, e.g. by activating your data

source or pattern generator.

4.2 Engine file

You can configure Matlab to perform a wide range of mathematical operations on the raw or

processed data using the Engine window. Normally the only call is to

CoreProcessingCommands, the set of routines performing phase and clock recovery.

Note: Accessing the Matlab Command Window and typing who will result in a full list of varia-

bles.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 43 of 148

Page 47

Note that CoreProcessingCommands will provide either ET or RT processing depending on what

mode the OUI is in. To ensure you only get ET processing you can use CoreProcessingET in the

window instead of CoreProcessingCommands. Similarly you can use CoreProcessing in the

Engine Window if you want to be sure you only get real-time processed data.

As with all other settings, the last engine file used is recalled; you can locate or create another

appropriate engine file and paste it into the OUI Matlab window. Subsequent chapters explain in

detail the operations of Core Processing.

In addition to any valid Matlab operations you may wish to use, there are some special variables that

can be set or read from this window to control processing for a few special cases:

EqFiltInUse – a string which contains the properties of the equalization filter in use

pHybInUse – a string which contains the properties of the optical calibration in use

DebugSave – logical variable that controls saving of detailed .mat files for analysis

DebugSave = 1 in the Matlab Engine Command window results in two files saved per block

plus one final save.

DebugSave = 0 or empty suppresses .mat file saves.

4.3 Performing measurements

Click on Single, and observe that the oscilloscope takes a burst of data; this

confirms the connection. Using a short record length (e.g. 2000 points) to speed up the display,

click on Run-Stop to show continuously-updated measurements.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 44 of 148

Page 48

Using the Home tab, set up the plots you want, either using the stored Layout button or by

clicking on the particular display format icon in the Plot Tools bar.

Display format icons (from left): Constellation, Eye, Bit Error Rate

(BER), Poincare Sphere. Presets are shown at right.

Displays can be rearranged within the UI window or dragged and positioned randomly on the

Windows Desktop. Clicking and dragging a window using its title tab brings up a positioning

guide. Hold down the left mouse button to position the window onto the positioning guide, then

release to organize the plots.

Constellation and Eye plots can be rescaled by clicking on the relevant scaling icons in the

Controls tab of the left panel of the UI. The scale in √W/div is indicated.

Options for each plot are accessed by Right-Clicking on the plot. Trace and symbol contrast can

be set globally using the sliders on the left bar of the OUI. Set trace and symbol properties for a

particular plot using the Right-Click on the plot.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 45 of 148

Page 49

5 Using the OUI

5.1 OUI Overview

The panel on the left side titled “Controls” is typically pinned so that it is always present to allow

control of the acquisition and plot scale. The first entry, Rec Len, determines the oscilloscope

record length for the next acquisition. The record length in turn determines the horizontal time

scale given a fixed sampling rate. Since different oscilloscopes allow different record lengths,

the OUI will replace your entry with the closest available larger record length after you click

Single or Run-Stop to start the acquisition.

The second entry in the Control panel is Blk Size. Block Size is the number of points that are

processed at one time. For record lengths up to 10,000 or even 50,000 points, it makes sense

to process everything at once. This will happen if Blk Size is greater than or equal to Rec Len.

However, for record sizes above 50,000, there can be a delay of many seconds waiting for

processing. In this case, breaking the processing up into blocks gives you more frequent screen

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 46 of 148

Page 50

updates and a progress bar so know what is happening while you wait. This is accomplished by

Rec Len

Blk Size

Behavior

< 1,000,000

≥ Rec Len

All data processed in one block. Aggregated variables

such as constellation and eye diagrams available for

plotting.

< 1,000,000

< Rec Len

Data broken up into blocks for processing. Aggregated

variables such as constellation and eye diagrams

available for plotting after each block has completed.

> 1,000,000

< 1,000,000

Data broken up into blocks for processing. Only BER and

other summary measurements are aggregated block to

block. Raw data and time series variables are erased

when next block is processed. Need to save workspace

of intermediate blocks of interest for later viewing.

Run/Stop mode is disabled.

Any

= 1,000,000

The maximum allowable entry in the Blk Size field is

1,000,000.

simply choosing Blk Size < Rec Len. Block Processing is further explained in Section 10.5.

Block Processing is most important when the size of the record is so large that it begins to tax

the memory limits of the computer. This can begin to happen at 200,000 points but is more likely

a problem at 1,000,000 points and above for XP machines with maximum RAM. For these

record sizes between 1,000,000 and the oscilloscope memory limit (usually many tens or

hundreds of megapoints), it is essential to break processing into blocks to avoid running out of

processor memory. In addition, since neither the entire waveform, nor the entire processed

variables will fit in computer memory at one time, it is necessary to make some decisions as to

what information will be retained as each block is processed. By default raw data, electric field

values, and other time series data are not aggregated over all blocks in a record greater than

1,000,000 samples. For more detail on how to manage large data sets, see Section 5.13.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 47 of 148

Page 51

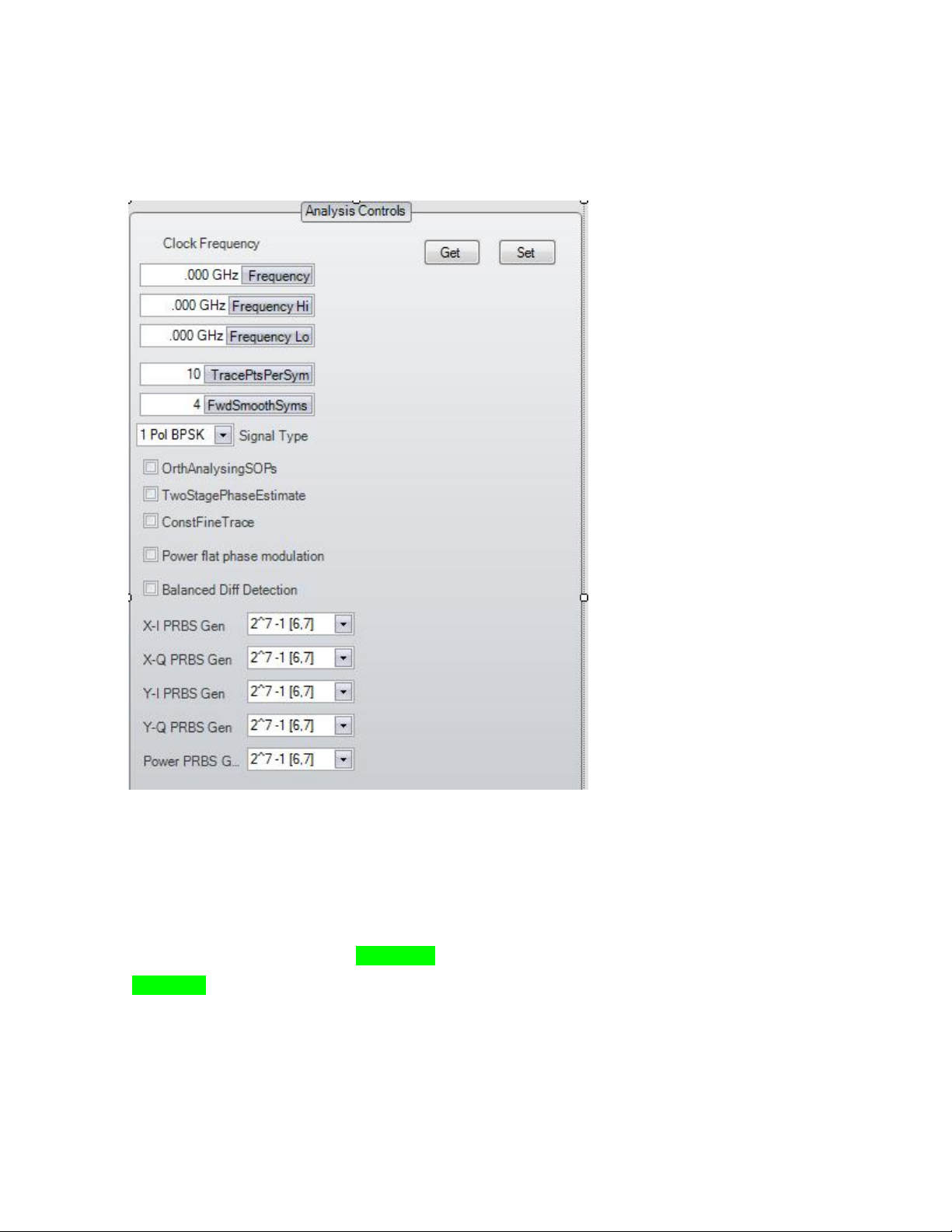

5.2 Analysis Parameters

The Analysis Parameters window allows you to set parameters relevant to the system and its

measurements. When any parameter is clicked on (left hand column) help on that item is

displayed in the window at the bottom of the parameter table.

Signal Type: Chooses the type of signal to be

analyzed and so also the algorithms to be applied

corresponding to that type.

Pure Phase Modulation: Sets the clock recovery

for when there is no amplitude modulation.

Clock Frequency: Is the nominal frequency of

the clock recovered by CoreProcessing bounded

by a low (Low) and a high frequency (High)

provided the clock signal power is sufficient;

Assume Orthogonal Polarizations: Checking

this box forces Core Processing to assume that

the polarization multiplexing is done in such a

way that the two data signals have perfectly

orthogonal polarization. Making this assumption

speeds processing since only one polarization

must be found while the other is assumed to

orthogonal. In this case, the resulting SOPs will

be a best effort fit if the signals are not in fact

perfectly orthogonal. Unchecking the box forces

the code to search for the SOP of both data

signals.

Reset SOP Each Block: Checking this causes

the SOP to be recalculated for each Block of the

computation. By adjusting the Block Size (see

Blk Size) you can track a changing polarization.

When false, the SOP is assumed constant for the

entire Record (see Rec Len).

2nd Phase Estimate: Checking this box forces Core Processing to do a second estimate of the

laser phase after the data is recovered. This second estimate can catch cycle slips, that is, an

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 48 of 148

Page 52

error in phase recovery that results in the entire constellation rotating by a multiple of 90

)ln(/T

degrees. Once the desired data pattern is synchronized with the incoming data stream, these

slips can be removed using the known data sequence.

Homodyne: The first step in phase estimation is to remove the residual IF frequency that is the

difference between the LO and Signal laser frequencies. The function EstimatePhase will fail if it

there is no difference frequency. This case occurs when the Signal laser is split to drive both the

modulator and the Reference Input of the receiver (ie. only one laser). Checking the Homodyne

box will prevent EstimatePhase from failing by adding an artificial frequency shift, which is

removed by EstimatePhase.

Phase estimation time constant parameter: (Alpha) After removing the optical modulation

from the measured optical field information, what remains is the instantaneous laser phase

fluctuations plus additive noise. Filtering the sample values improves the accuracy of the laser

phase estimation by averaging the additive noise. The optimum digital filter has been shown to

be of the form 1/(1+z-1) where is related to the time constant, of the filter by the relation

where T is the time between symbols. So, an when the baud rate is

10Gbaud gives a time constant, ps or a low-pass filter bandwidth of 350 MHz. The value

of also gives an indication of how many samples are needed to provide a good

implementation of the filter since the filter delay is approximately equal to the time constant.

Continuing with the above example, approximately 5 samples (~ T are needed for the filter

delay. This of course is not a problem, but an would require 1000 samples and put a

practical lower limit on the record length and block size chosen for the acquisition. As a simple

rule, the record or block size should be ≥ 10/(1-).

The selection of the optimum value of Alpha is discussed later in the CoreProcessing guide

Section 11.6 and reference [1]. This optimum value depends on the laser linewidth and level of

additive noise moving from a value near 1 when the additive noise is vastly greater than the

phase noise to a value near zero when phase noise is the only consideration (e.g. no filtering

needed). In practice, a value of 0.8 is fine for most lasers. If Alpha is too small for a given laser

there will be insufficient filtering which is evidenced by an elliptical constellation group with its

long axis pointed toward the origin (along the symbol vector). When Alpha is too large then

there is excessive filtering for the given laser linewidth. Excessive phase filtering is evidenced

by the constellation group stretching out perpendicular to the symbol vector and may also lead

to non-ideal rotation of the entire constellation.

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 49 of 148

Page 53

As is often the case, when laser frequency wander is greater than the linewidth, very long

2/

2

2

)(

i

eH

c

Dpsnm

2

10

10

*

2

0

9

12

2

record lengths will lead to larger variance in laser phase. This means that an Alpha that worked

well with 5000 sample points might not work well with 500,000 points. Longer record lengths will

not be a problem if you choose a block size small enough that peak-to-peak frequency wander

is on the order of the laser linewidth. For the lasers supplied with the OM4000 Series receiver, a

block size of 50,000 points is a good choice. See Section 5.1 on Block Processing for further

information.

Balanced Differential Detection: Checking this box causes the differential-detection emulator

to emulate balanced instead of single-ended detetection.

Continuous Traces: Checking this box ensures that the fine traces connecting the constellation

points will be drawn. If unchecked, the traces will be suppressed for calculation speed if the

calculations are not needed for other plots such as eye diagrams.

Mask Threshold: The ratio of radius to symbol spacing used for the circular constellation

masks.

Continuous trace points per symbol: is the number of samples per symbol for the clock

retiming that is done to create the fine traces in the phase and eye diagrams.

Tributaries contribution to average: the average waveforms are based on finding the symbol

impulse response and convolving with the data pattern. This setting switches which possible

crosstalk contributions are included in the calculation of impulse response.

Number of symbols in impulse response: the number of values calculated for the impulse

response. More values should provide a more accurate average but take longer to calculate.

Show linear average eye: controls computation of the average eye. Refresh rate is faster when

disabled, but must be enabled for the linear average to be displayed in an eye diagram.

Show linear average vs. time: controls computation of the average signal vs. time. Refresh

rate is faster when disabled, but must be enabled for the linear average to be displayed in the X

v. T diagram.

Show transition average: controls computation of the transition average. Refresh rate is faster

when disabled. However, this must be checked to enable calculations based on transition

average such as risetime.

Compensate CD: Checking this box will apply a mathematical model to remove chromatic

dispersion. The mathematical model used for the inverse filter is:

; where

Tektronix OM4006/OM4106 Coherent Lightwave Signal Analyzer User Guide V1.5.1 10/24 ©2012 Page 50 of 148

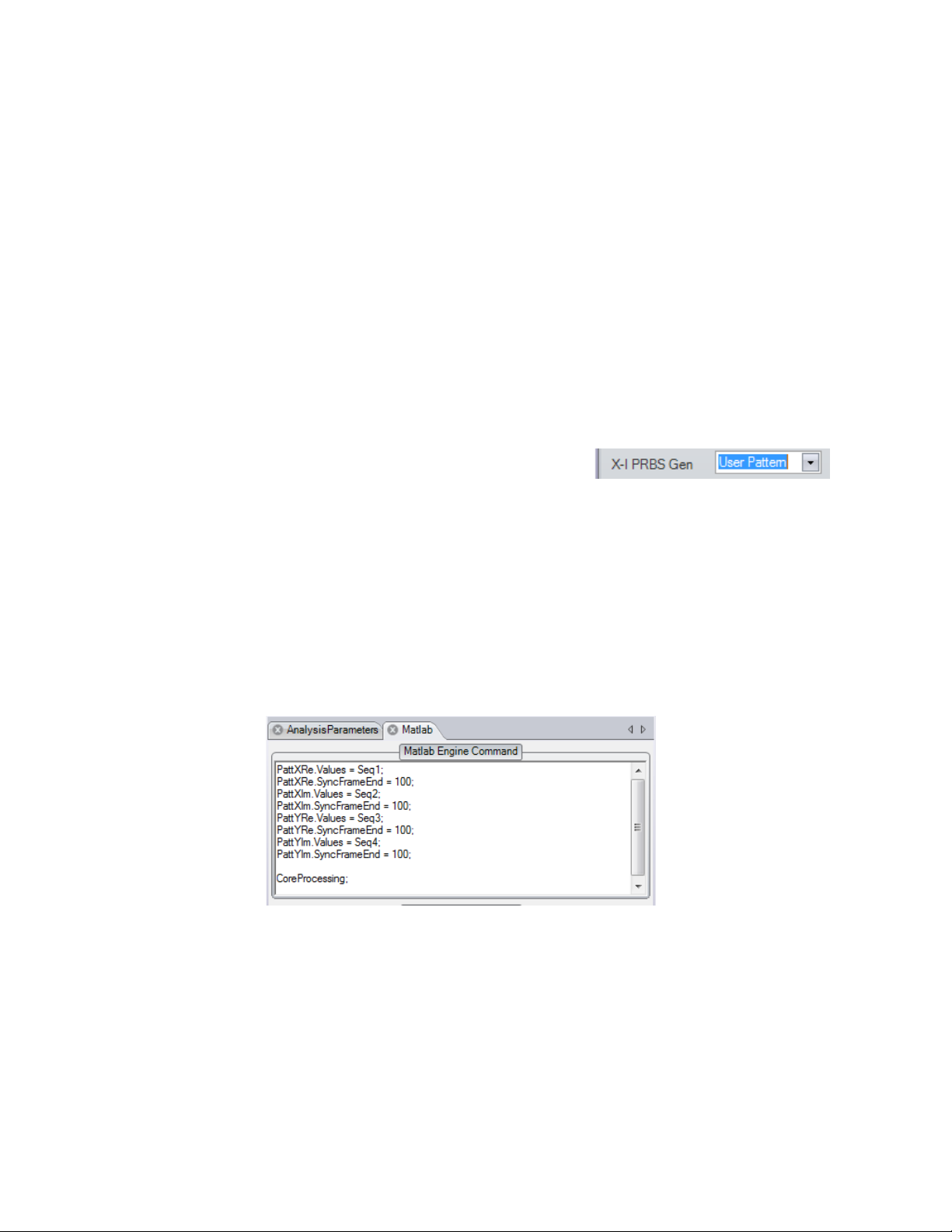

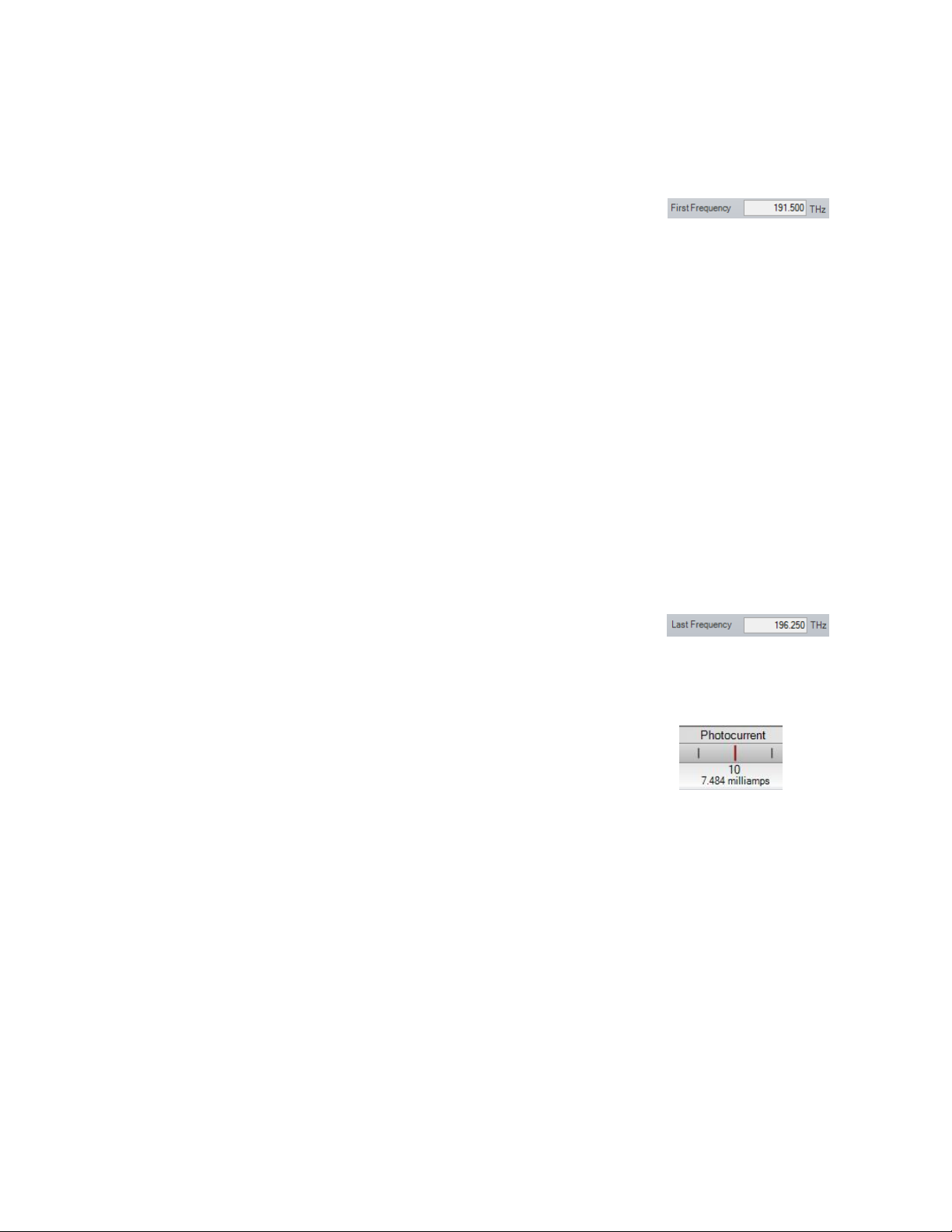

Page 54