Page 1

OM2210

xx

ZZZ

Coherent Receiver Calibration Source

User Guide

*P071305001*

071-3050-01

Page 2

Page 3

xx

OM2210

ZZZ

Coherent Receiver Calibration Source

User Guide

www.tektronix.com

071-3050-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, v isit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

1 SAFETY INFORMATION ...................................................................................................................... 5

1.1 SAFETY NOTICES ............................................................................................................................. 5

1.2 LASER SAFETY ................................................................................................................................. 5

1.3 OM2210 LASER LABELS AND LOCATIONS .......................................................................................... 6

2 INTRODUCTION ................................................................................................................................... 7

2.1 PURPOSE ......................................................................................................................................... 7

2.2 THE OPTAMETRA CALIBRATION APPROACH ....................................................................................... 7

3 GETTING STARTED ........................................................................................................................... 10

3.1 CONFIGURING THE HARDWARE ....................................................................................................... 10

4 OPTAMETRA CALIBRATION SOFTWARE ........................................................................................ 18

4.1 INSTALLATION ................................................................................................................................ 18

4.2 OPERATION .................................................................................................................................... 18

4.3 RESULTS ....................................................................................................................................... 25

5 MAINTENANCE AND CLEANING ...................................................................................................... 26

5.1 MAINTENANCE................................................................................................................................ 26

5.2 CLEANING ...................................................................................................................................... 26

6 APPENDIX A – REFERENCE DOCUMENTS .................................................................................... 27

6.1 SOFTWARE LICENSE AGREEMENT .................................................................................................... 27

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 4 of 29

Page 8

CAUTION

CAUTION

!

WARNING

!

CAUTION

!

!

1 Safety Information

1.1 Safety Notices

Indicates a potentially hazardous condition or procedure that could result in damage to the

instrument.

Indicates a potentially hazardous condition or procedure that could result in minor or moderate bodily

injury.

Indicates a potentially hazardous condition or procedure that could result in serious injury or death.

This symbol on the unit indicates that the user should consult this document for further

information regarding the nature of the potential hazard and actions that should be taken to

avoid or mitigate the hazard.

1.2 Laser Safety

The laser sources included in this product are classified according to IEC/EN 60825-1:

1994+A1:2001+A2:2001 and IEC/EN 60825-2:2004

This laser product complies with 21CFR1040.10 except for deviations pursuant to Laser Notice No.

50, dated June 24, 2007.

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Under no circumstances should you use any optical instruments to view the laser output

directly.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 5 of 29

Page 9

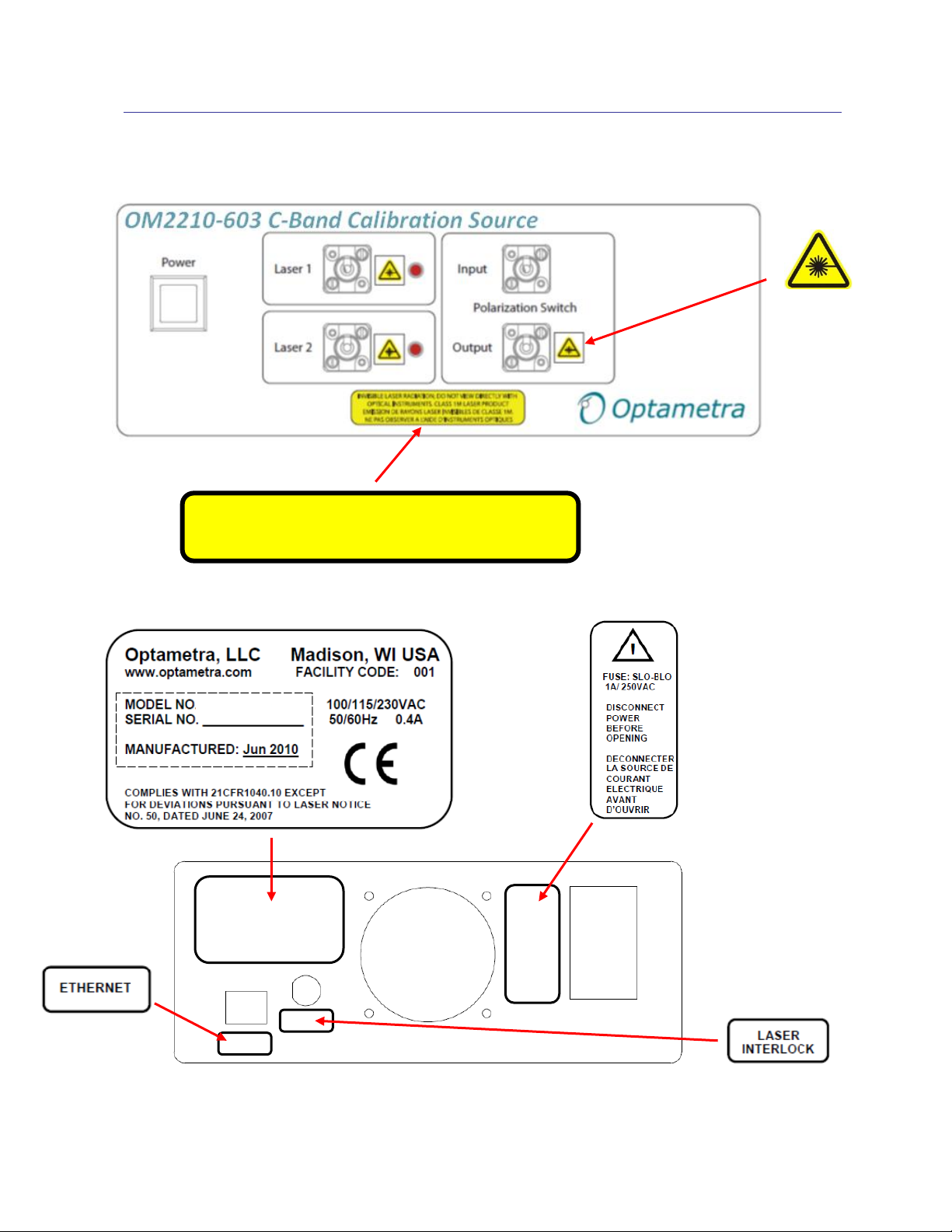

Indicates the

INVISIBLE LASER RADIATION; DO NOT VIEW DIRECTLY WITH

EMISSION DE RAYONS LASER INVISIBLES DE CLASSE 1M.

OM2210

1.3 OM2210 Laser Labels and Locations

location of a

laser aperture

OPTICAL INSTRUMENTS. CLASS 1M LASER PRODUCT

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 6 of 29

Page 10

EV H

2 Introduction

2.1 Purpose

The Optametra calibration products, featuring the OM2210 Calibration Source and Optametra‟s

proprietary software, are used in laboratory or industrial facilities to calibrate coherent fiber optic

receivers. These products are primarily targeted for calibrating polarization-diverse, phase-diverse

receivers that are linear or can be set in a linear mode. The end result is a transfer matrix,

measured at a particular heterodyne frequency over a specified wavelength range, which describes

the optical-to-electrical transfer function of the analog portion of the receiver. The transfer matrix is

then used to compute critical receiver specifications such as quadrature phase angle, polarization

cross-talk, and path gains. This information can be used for quantitative evaluation of the receiver,

or to provide calibrated optical field measurements when used with the Optametra signal analysis

software.

2.2 The Optametra Calibration Approach

Optical communications signals can be described as the combination of a continuous (cw) laser field

and a modulation field which carries the data. In the case of polarization multiplexed signals, there

can be as many as two independent lasers and modulators that are polarization multiplexed

together. Optametra signal processing software is designed to extract the cw and modulation for

each polarization from which data and signal quality metrics may be extracted. Since the software

extracts fields, not just data, it is necessary to have independent measurements of the receiver

properties so that the effect of the receiver may be removed. This process consists of a lowfrequency measurement of the linear OE transfer matrix relating the input field vector, E, to the

output voltages, V, and a separate frequency response measurement. The Optametra calibration kit

is provided to measure the linear OE transfer matrix, H, at frequencies well within the oscilloscope

bandwidth.

This process can be applied both to linear receivers like the Optametra OM3105 as well as

receivers with automatic gain control (AGC ) such as commercial coherent receivers. The AGC

must be turned off during the calibration so that the software can measure the linear portion of the

transfer function. The matrix can then be normalized to simulate the AGC operation.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 7 of 29

Page 11

The Optametra calibration kit contains the OM2210 Calibration Source that is available in the various

configurations shown below.

-603 C-band Calibration Source and Software. Includes 2

lasers. Use this option when C-band receiver has no Optametra

sources. (L-band version is -604)

-601 C-band Calibration Source and Software. Includes 1

laser. Use this option when C-band receiver has an Optametra

Reference Laser. (L-band version is -602)

A C+L version is also available (-605)

-600 Calibration Source and Software. Includes no lasers. Use

this option when receiver has 2 Optametra sources for

Reference and Signal.

Figure 1: C or L-band

Calibration Source options

The calibration kit extracts the hybrid matrix, H, by applying a heterodyne signal with different

polarizations and then measuring the resulting sine wave outputs on the oscilloscope and separately

monitoring the power. Proprietary calculations are performed to extract the hybrid matrix in the

presence of receiver impairments, heterodyne phase fluctuations, and channel skews. This process

is directed by the Optametra Hybrid Receiver Calibration (HRC) Software. The HRC software

controls the heterodyne source via the Optametra Laser Receiver Control Panel (LRCP) and collects

data from the oscilloscope via the Optametra User Interface (OUI).

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 8 of 29

Page 12

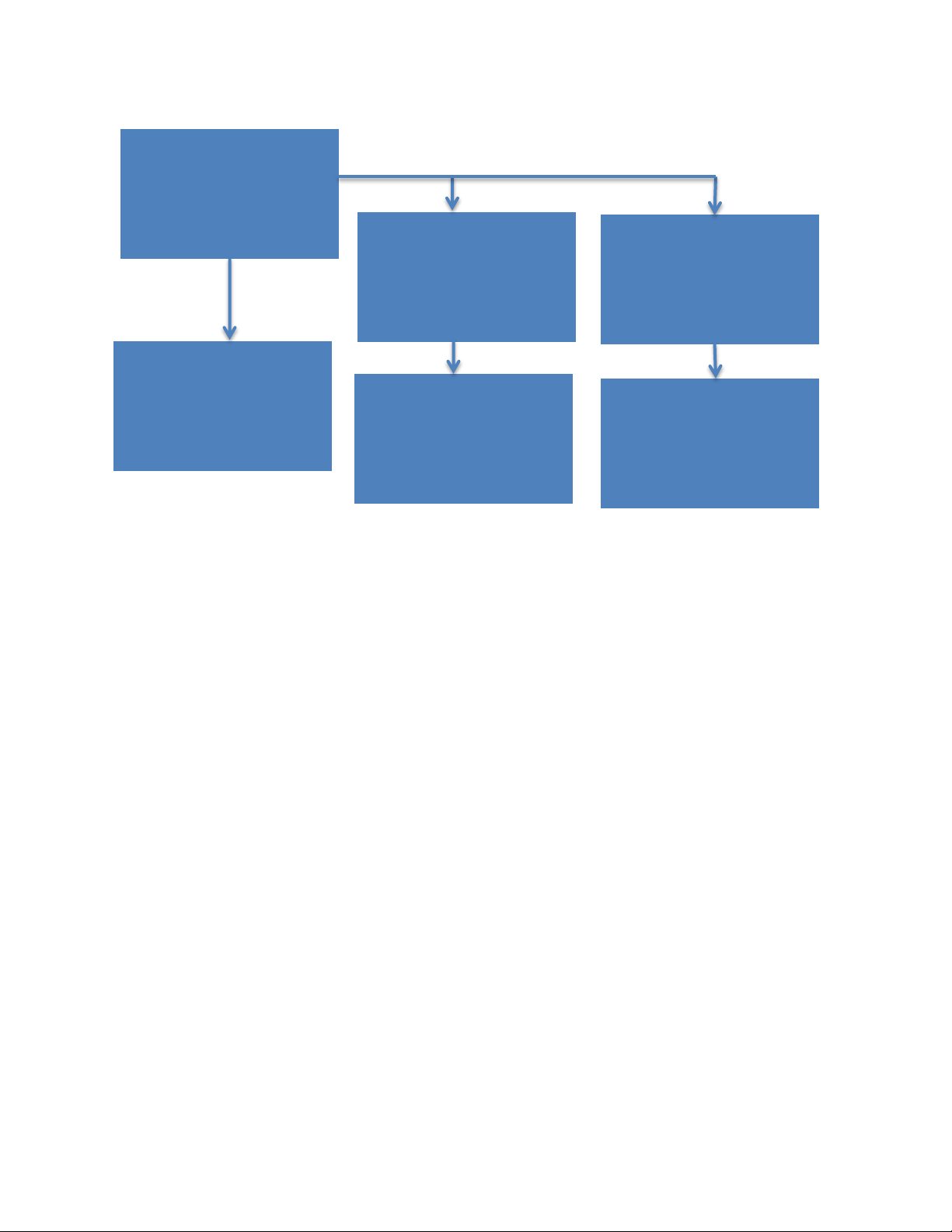

HRC Software

LRCP Software

OUI Software

Power Meter

Oscilloscope

Heterodyne source

and polarization

switch

Figure 2: Hierarchy of the software and hardware used to perform

the calibration

The final results are provided in .mat, .csv, and .xls formats. The .mat format is used by the

Optametra OUI software hybrid calibration function. The other formats are provided for viewing the

results. The results and configurations are also stored in an SQL database.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 9 of 29

Page 13

3 Getting Started

3.1 Configuring the Hardware

3.1.1 OM2210 Calibration Source

Ensure that the required power sources for the OM2210 (100, 115 or 230 VAC, 50–60 Hz, 0.4A), the

equipment to be calibrated, associated oscilloscope, and the external computer (if used) are

available. Use the IEC power cord provided to connect to a rack or wall outlet.

Associated cabling includes the IEC power cord, an Ethernet cable, and fiber optic cables to connect

the OM2210 and the Device Under Test (DUT).

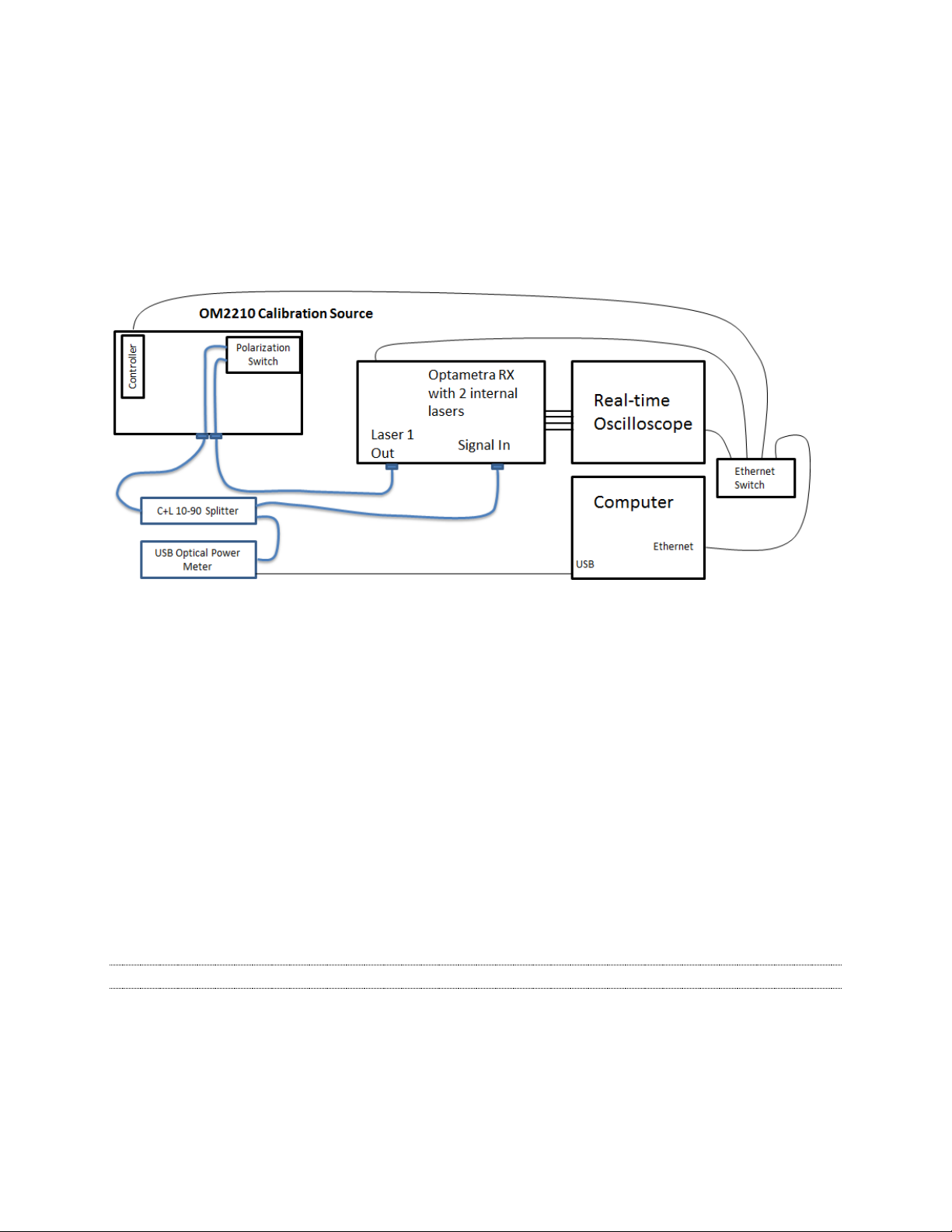

Several options for use of the OM2210 are available. For use with the Optametra OM3105 Coherent

Modulation Receiver, a polarization-maintaining (PM) fiber optic patchcord is used to connect the

OM3105‟s Laser 1 to the OM2210‟s Polarization Switcher Input, and the Polarization Switcher

Output is connected via single-mode (SM) fiber optic patchcord to an optical splitter. From the

splitter, 90% of the optical power is directed to the OM3105 Signal Input, and 10% is routed to an

optical power meter connected to the computer being used to run the calibration. Four coaxial cables

connect the receiver to a high-speed sampling oscilloscope. Ethernet cables connect the OM2210,

via a router, to a computer, receiver and oscilloscope. The Optametra User Interface running on the

computer controls the oscilloscope, while the Laser-Receiver Control Panel (LRCP) controls the

OM3005/3105 and the OM2210.

The OM2210 can also be purchased with internal lasers for use in calibrating receivers that do not

already contain two Optametra tunable lasers that can reach the same wavelength.

Note: A password is required to turn on the lasers through the Laser / Receiver Control Panel.

The default is „1234‟

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 10 of 29

Page 14

1 4 2

5

3

10

7

6

8

9

3.1.2 OM2210 Controls and I/O Connections

Front Panel Controls and I/O Connectors

1. On/Off switch

2. Laser 1 Output (with LED indicator)

3. Laser 2 Output (with LED indicator)

4. Input

5. Output

Rear Panel Controls and I/O Connectors

6. Power switch

7. BNC connector for optional laser remote interlock

8. Ethernet port

9. Fuse drawer

10. Input power receptacle

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 11 of 29

Page 15

WARNING

!

3.1.3 List of Components

OM2210 Calibration Source

IEC power cable

Ethernet cable

BNC shorting cap for interlock

Dust covers for optical inputs not in use (2 or 4)

Additional items supplied by Optametra or another source:

Digitizer or real time oscilloscope with at least 20 GS/s sampling rate on four channels. Agilent, Tek-

tronix, and LeCroy real time oscilloscopes with at least 10GHz bandwidth are supported. The Tektronix 8GHz oscilloscope is also supported.

Power cable

Ethernet cable

Mouse and keyboard (unless touch-screen controlled)

System controller PC running Windows XP, Matlab (if using the OM4x06) and the Optametra User

Interface (OUI) software

o Monitor plus cable

o Mouse and keyboard

o Power cables

o Ethernet cable

An Ethernet switch or hub plus a router running DHCP, and associated cabling (not shown)

SM patch cable ( 1 or 2, depending on the application) to connect the Polarization Switcher Output

to the DUT

PM patch cable to connect the DUT to the Polarization Switcher Input

Optical power meter

Optical amplifier

Optical splitter

To avoid the possibility of electrical shock, do not connect your OM2210 to a power source if

there are any signs of damage to the instrument enclosure.

3.1.4 Electrical Power Requirements

The OM2210 can operate from any AC power source that provides 100, 115, or 230 VAC, at a

frequency of 50 Hz or 60 Hz. The OM2210 must be connected directly to a grounded power outlet

only.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 12 of 29

Page 16

WARNING

!

CAUTION

CAUTION

!

The OM2210 must be connected to a 100, 115,or 230VAC/50 or 60Hz grounded outlet only.

Operating the OM2210 without connection to a grounded power source could result in

serious electrical shock. Always connect the unit directly to a grounded power outlet.

Protective features of the OM2210 may be impaired if the unit is used in a manner not

specified by Optametra.

3.1.5 Location and Positioning

Be sure to position the OM2210 so that the power switch at the rear of the unit can be easily

accessed.

Be sure not to obstruct the fan so that there is an adequate flow of cooling air to the

electronics compartment whenever the unit is operating.

3.1.6 Operating Environment

The OM2210 may be operated within the following conditions:

Temperature 10°C to +35°C (50°F to +95°F)

Humidity <85%R.H. non-condensing from 10°C to +35°C (50°F to +95°F)

Altitude < 2,000m (6560ft)

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 13 of 29

Page 17

3.1.7 Computer

Operating System: XP Service Pack 3 (.NET 4.0 required), or Windows-7

Processor: min: Intel Pentium 4 or equivalent, recommended: Intel Core2Duo,

Core2Quad, I7, or equivalent; min clock speed 2GHz.

RAM: 3 GB. Future 64-bit releases will benefit from as much memory as is

available.

Hard Drive Space: min 20 GB, 300GB recommended for large data sets

Video Card: NVIDIA dedicated graphics board w/ 512+ MB min. graphics memory;

Consult factory for compatibility if using a different card.

Networking: Gigabit Ethernet (1Gb/s)

Display: Large flat screen recommended for displaying multiple graph types eg. 20”

min

Other Requirements: DVD Optical drive, 2 USB 2.0 ports

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 14 of 29

Page 18

3.1.8 First Setup

Once everything is securely placed, make electrical connections in the following order:

1. Ethernet connections and other computer connections. See 3.1.2

2. Power connections for the OM2210 and other equipment.

3. RF connections from the DUT to oscilloscope

4. Fiber optic patch cable connections from the OM2210 to the DUT.

5. Store all dust covers and coaxial connector caps for future use.

Figure 3: Typical system configuration for calibration of Optametra Receiver. For 3rd

party receiver calibration, use an OM2210 with internal sources to provide the Laser 1

and LO laser functions.

Once the equipment is positioned and connected, turn on the computer, the oscilloscope, the DUT,

and the main power switch on the back of the OM2210. The OM2210 front-panel power button will

light briefly after main power is applied indicating it is searching for a DHCP server. When an IP

address has been assigned or when the search fails in the case of an isolated network, the power

light will go off. Press the power button one time to enable the unit. The steady power button light

indicates the OM2210 is ready for use and that lasers may be activated at any time if a user

connects via the Ethernet connection. The light will go out and the unit will be disabled any time

main power is removed or the IP address is changed. Press the power button to re-enable. This

feature prevents a remote user from activating the lasers when the local user may not be ready.

Note: Ethernet only allows devices on the same subnet to communicate.

You should now have four devices on an Ethernet network: computer, oscilloscope, DUT, and

OM2210. This little network may be connected to your corporate network or router or you may

choose to leave it isolated. IP setup is normally done by Optametra personnel at the time of

installation. You should only need the following instructions if you are reconfiguring your network.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 15 of 29

Page 19

3.1.8.1 IP setup on a network with DHCP (dynamic IP assignment)

DHCP allows “automatic” assignment of the IP address the connected devices need to communicate

with each other. However, automatic IP assignment must be selected on each device before this will

be allowed. The OM2210 is shipped with automatic IP assignment enabled. Your computer and

oscilloscope may need this turned on.

Once automatic IP assignment is selected, you may still need the cooperation of your corporate IT

department to get IP addresses assigned. If you are using a centralized server, ask your network

administrator to make an IP reservation for you so that you get the same number each time the

device is powered on. Once these are set up for the oscilloscope and the OM2210 you will have no

trouble finding them in the future.

Once your equipment gets an IP address from DHCP you can find that address using the operating

system of the oscilloscope or computer. For example, in the XP operating system there is a window

that looks like the one below. Notice that when you select the active Ethernet connection the IP

address shows up in the Details box in the lower-left corner of the window.

To configure the IP connection of the OM2210, please see the OM4006/OM4106 User Guide

Chapter on using the Laser Receiver Control Panel (LRCP).

3.1.8.2 IP setup on an isolated network or one not running a DHCP server

When there is no DHCP server, the Ethernet connected devices don‟t know what address to assign

to themselves. In this case you must manually set the IP address. On a corporate network this

means getting the IP addresses from your network administrator first and then setting each device.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 16 of 29

Page 20

Your network administrator may need the MAC addresses of the computer, oscilloscope, and

OM2210. Contact Optametra if you need the MAC address for your OM2210. On newer models the

MAC address is printed on the real-panel label. Please see the OM4006/OM4106 User Guide

Chapter on using the Laser Receiver Control Panel (LRCP) to set the IP address. If you have a

network isolated from your corporate network you are free to use any IP numbering scheme.

Optametra recommends 172.17.200.XXX where XXX is any unique number between 0 and 255

(each device needs a unique number). There is nothing special about this scheme other than that it

is the default for new OM2210 units. Use the operating systems of the oscilloscope and computer to

set their IP addresses. The first three sets of numbers in the IP address need to be the same on the

computer and the connected devices for them to communicate in most cases.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 17 of 29

Page 21

Feature

Number

Description

3

Optametra User Interface (OUI)

4

Optametra Signal Analysis Software

14

QAM and advanced formats

15

Hybrid Calibration

4 Optametra Calibration Software

4.1 Installation

The Optametra software is primarily distributed through the website http://portal.optametra.com . Call

Optametra if you need login credentials. Each customer location has a web page where the

customer can download the latest release as well as installation instructions and User‟s Guides.

Follow the installation instructions provided with the release you are installing. In general, Optametra

software consists of two portions: the Optametra software and the drivers needed for the software to

work with hardware components.

An important part of the Optametra software is the copy protection provided by the USB HASP key.

The HASP key is used in two ways: 1) It prevents the software from being run in more places than

there are HASP keys, and 2) it enables or disables features such as QAM and hybrid calibration. To

see which features are available on your key, you can direct a web browser to http://localhost:1947

and click on HASP Keys and Features. The following features are presently available:

4.2 Operation

As shown in Figure 2, the Optametra Hybrid Receiver Calibration (HRC) program controls the

Optametra User Interface (OUI) and the Laser Receiver Control Panel (LRCP). The OUI in turn

controls the oscilloscope, while the LRCP controls the Optametra hardware. To launch the complete

application, use the following procedure.

1) First follow the instructions in the Measurement Setup section to get the hardware configured

properly and powered up.

2) Launch the OUI. Click the “Show Matlab” button on the Setup tab. Delete the contents of the

Matlab Engine Window or place a % before each line since it will not be used for computations.

a. Click on Connect and use the dialog box to select four channels.

b. Be sure to enable four channels

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 18 of 29

Page 22

c. Disconnect

For further information on the OUI, see the OM4006/OM4106 Users Guide.

3) Launch the LRCP. Connect to the Optametra hardware that will be used for the calibration.

Turn on the lasers that will be used for the calibration and tune them to the same wavelength.

For further information on the LRCP, see the OM4006/OM4106 Users Guide.

4) Launch the HRC

5) Connect the USB Power Meter to the computer that is running the HRC. Be sure both lights on

the Power Meter are on.

6) Configure the system using the HRC. Click on System Configuration

7) Click on the Configure Equipment button and choose Configure Laser Source

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 19 of 29

Page 23

a. Be sure the that LRCP window shows a connection to the Calibration Source and all of

the laser sources to be used in the calibration

b. Click on Refresh to pull the information from the LRCP into the HRC, then click Close

8) Now choose Configure Oscilloscope

9) The Configure Oscilloscope screen helps you define the oscilloscope connection. Typical values

are shown above. The trailing command, ::INSTR is required for most instruments. Each oscilloscope setup has a Friendly Name that can be used for recalling the settings.

10) Follow the setup instructions shown to get a good heterodyne signal on the oscilloscope.

11) After making adjustments on the oscilloscope front panel, always press the “Single” button on

the oscilloscope front panel to get it ready for external control

12) Close the window when complete. Now choose File Locations.

a. The default location for the CoreProcessing Directory is

C:\Program Files (x86)\Optametra\OUI4006\. Don’t change this unless the OUI installed

to a different directory. For example, on 32 bit machines the directory is

C:\Program Files\Optametra\OUI4006\.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 20 of 29

Page 24

b. Browse to where you would like to save the results files by clicking on the Folder Icon on

the Results Folder row. It is best to choose … My Documents\Optametra\HybridReceiver Calibration\ to easily find the files again.

13) Next choose Configure Power Meter. Enter the correct serial number to replace the default val-

ue. The connect string, USB0::0x1313::0x8072::P2000608::INSTR has the serial number as the

last digits. The Power Meter serial number is printed on the body of the Power Meter. Choose a

Power Multiplier of 10 if the 10% coupler is being used to monitor the power.

14) Now it is time to setup the calibration. Click on the Calibration Setup tab and set the following

in the main body of the HRC on the left side:

a. Click New in the upper left of the Calibration Setup tab to create a new setup unless you

want to modify an existing setup.

b. Name: this is the base name that will be used with the time and date to form the file-

name for the results. It will also be used to recall this setup in the future. Use the serial

number of the device under test for easiest recall of data.

c. Choose the Reference Laser (LO), Signal Laser (the one connected through the polariza-

tion switch), and Polarization Switch using the drop-down menus.

d. Laser Line Width in Hz. This sets the time constant for the phase recovery algorithm.

Only an estimate is required. 100,000 is the best choice for Optametra ECDLs.

e. Start Channel, End Channel, Channel Step define the wavelength channels over which

the calibration will be performed. The channel definition is set by the LRCP. The calibration will be taken a number of times set by the Repeat Count and then averaged for

each wavelength.

f. The Record Length should be set so that the time window width on the oscilloscope is at

least 0.2 / (Line Width) or more. For a 100,000 Hz Line Width, a good choice is a 4us

window which is 200,000 samples at 20ps/sample.

g. Choose the oscilloscope configuration from the drop-down menu

h. Set the frequency limit for the heterodyne frequency during the calibration. Typical val-

ues of 400 to 900 MHz work well with ~40-50Gs/s oscilloscopes. The frequency can be

lower for lower sampling rates. The upper frequency should be <1/3 the system bandwidth to minimize phase error.

Click Save to store your settings for future use.

15) Click on Channel Delays. Enter the relative skew between channels 1 to 2, 1 to 3, and 1 to 4 in

the boxes provided if known. To determine the relative channel delays, this utility can measure

phase vs. frequency over a given range and find the average slope. Enter the min and max frequencies for the utility to use. These should auto-populate to equal to the range shown on the

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 21 of 29

Page 25

Calibration Setup window, but you can measure delays over any frequency range less than

10GHz. The range chosen should also be less than ~1/3 the oscilloscope bandwidth setting.

Once the range is set, click Recalculate Delays.

Once the utility completes a sweep over the desired range at a wavelength in the center of the

band to be tested, it will fill in the Channel Delays. Inspect the Matlab plot to verify that the data was taken over the desired range and is well behaved. You may also type Status in the separate Matlab program window to see the rms and peak phase error in the measurement. Close

the Recalculate Channel Delays utility to use these values.

16) (for advanced users) As mentioned above, entering a Frequency Range and Clicking on Recalcu-

late Delays will sweep the heterodyne frequency while measuring the resulting channel to

channel phase relationship. The slope of the phase vs. frequency gives the average channel delays. Alternatively, the FindChannelDelays function can be run from the OUI Matlab Engine

Window. Running the function manually in this way gives you more control over which frequencies are used for the delay calculation. When complete, you can type Status in the Matlab

Command Window to see the results and error magnitude.

17) Now that the system is configured, click on Calibration, then Start Calibration to get the calibra-

tion started.

18) The following screen gives you an opportunity to review the calibration setup before getting the

measurements underway. Once the measurement is started, it may take approximately 1 hour

to finish depending on the number of repeats and wavelengths chosen.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 22 of 29

Page 26

As the HRC executes, it shows the results of each step on a dashboard called “Calibration

Results” on the right side of the window. The area shows the channel and step status as well as

the following:

Calibration Matrix: The actual values being output to the calibration data file

Polarization Extinction: A list of calculated crosstalk levels based on the measured calibration

matrix.

Gain: the Relative gain between channels

Power A, B: Power measured for each polarization setting

Freq A, B: Measured heterodyne frequency at each polarization setting

Phase Data: Quadrature phase angles and calculated I-Q crosstalk

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 23 of 29

Page 27

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 24 of 29

Page 28

187 188 189 190 191 192 193 194 195 196

-5

0

5

Laser Frequency (THz)

Measured Quadrature Phase Error

Phase12-90

Phase34-90

187 188 189 190 191 192 193 194 195 196

-5

0

5

Laser Frequency (THz)

Measured Relative Gain (dB)

Gain 1-2

Gain 3-4

Gain 1-3

Gain 1-4

4.3 Results

The output of the calibration is both a hybrid-matrix data set and a set of calculated performance

metrics. These plots are updated at each wavelength step. Channels 1,2,3,4 are X-I, X-Q, Y-I, Y-Q

respectively. Example data is shown below:

These plots are calculated from the pHybTable variable which is the primary output of the program.

The pHybTable has one row for each laser channel tested: a column for each of the 8 entries in the

complex pHyb matrix and a first column for the laser channel frequency. This information is stored in

the following ways:

1) The pHybCalib.mat file. This file is designed for use with the OUI4006. To do so, move the file

from the place designated in the File Locations path to Program Files

(x86)\Optametra\ExecFiles. Rename the old version in case you need to go back. If the file

name is changed in any way, the OUI will not use the file. When using the OUI, you may type

load pHybCalib in the separate Matlab program window and then type SerialInformation to see

which file is in use.

2) The data is also stored in .mat, .csv, and .xls files in the directory indicated in the File Locations

box.

3) The configuration information is stored in an SQL database called OPTAMETRA in the

OPTAMETRACONFIG SQL server. SQL Server Management Studio Express (SSMSE) from Microsoft is a free program that can be used to examine the database.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 25 of 29

Page 29

WARNING

!

CAUTION

!

5 Maintenance and Cleaning

5.1 Maintenance

There are no user-serviceable components or subsystems within the OM2210. Attempting any

internal repairs will void your warranty. Never remove the external lid on the unit.

Removing the dust covers from the laser output connectors while the lasers are operating

may result in exposure to invisible laser radiation. Never view directly with optical

instruments.

If it becomes necessary to replace the fuse in the power input module in the rear of the unit, use

a 5X20mm “slo-blo” fuse rated at 1A, 250VAC. Use a small screwdriver to gently pry open the

fuse drawer.

Disconnect the unit from the power source when changing the fuse to ensure that line

voltage is not present during the replacement.

5.2 Cleaning

To clean the outside of the OM2210 enclosure, use a dry, soft cotton cloth. Do not use any liquid

cleaning agents or chemicals that could possibly infiltrate the enclosure, or that could damage

markings or labels.

If the dust filter on the underside of the unit becomes clogged, use a small vacuum or brush to

clean the filter.

From time to time it will be necessary to clean the optical input and output connectors on the

front of the unit. Use square-ended swabs made for this purpose to clean each connector.

Do not attempt to clean the inside of the instrument; cleaning of internal parts is not necessary.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 26 of 29

Page 30

6 Appendix A – Reference Documents

6.1 Software license agreement

This Software License Agreement ("AGREEMENT") is entered into between OPTAMETRA, LLC

("OPTAMETRA") and the licensee purchasing Core Processing software ("LICENSEE"). In

consideration of the mutual obligations described in this AGREEMENT and other good and valuable

consideration, the sufficiency and receipt of which are hereby severally acknowledged, the parties

agree as follows: 1. Term. This AGREEMENT shall become effective upon acceptance by

OPTAMETRA and shall continue in effect until terminated in accord with Section 10.

2. License.OPTAMETRA grants to LICENSEE a nonexclusive, perpetual, nontransferable

license to use its proprietary software known as Core Processing ("SOFTWARE").

3. Scope of Use. LICENSEE may use SOFTWARE only to process its own data. Any parent,

subsidiary, or affiliate of LICENSEE shall require a separate license to use SOFTWARE. LICENSEE

may copy SOFTWARE for itself so long as LICENSEE reproduces all copyright notices and other

proprietary legends on such copy. LICENSEE may run multiple copies of software on several

computers at the same time. LICENSEE shall not reverse assemble, reverse compile, or unlock

SOFTWARE in whole or in part for any reason. LICENSEE will not remove, obscure or alter any

proprietary rights notice or trademark and/or service mark rights notice which OPTAMETRA places

on or in SOFTWARE. LICENSEE shall not rent SOFTWARE or give SOFTWARE to third parties or

provide third parties with access to SOFTWARE through a commercial timesharing arrangement or

based on any other method for any reason.

4. Title. Title to SOFTWARE, including but not limited to, originals, translations, compilations

and partial copies, if any, shall not pass to LICENSEE.

5. Nondisclosure. LICENSEE understands and agrees that SOFTWARE contains confidential

and proprietary information and data ("CONFIDENTIAL INFORMATION"). During and subsequent to

the term of this AGREEMENT, LICENSEE shall protect such CONFIDENTIAL INFORMATION to the

same degree that it protects CONFIDENTIAL INFORMATION pertaining to its own business and

shall not disclose CONFIDENTIAL INFORMATION to any third party. LICENSEE shall not, either

directly or through any third party, use any confidential information of OPTAMETRA to create, modify

or enhance any computer software, program or user documentation that is substantially similar to

SOFTWARE and transmit such computer software, program or user documentation to a third party.

Notwithstanding the foregoing, CONFIDENTIAL INFORMATION shall not include information which:

(1) is at the time of disclosure, or thereafter becomes, a part of the public domain through no act or

omission of LICENSEE nor of any employee or agent of LICENSEE; or (2) was in LICENSEE‟s

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 27 of 29

Page 31

possession as shown by written records prior to the disclosure and had not been obtained by

LICENSEE either directly or indirectly from OPTAMETRA; or (3) is hereafter lawfully disclosed to

LICENSEE by a third party who did not acquire the information directly or indirectly from

OPTAMETRA.

The foregoing rights and obligations shall apply reciprocally with regard to information transmitted by

LICENSEE in order to obtain SUPPORT for SOFTWARE and which is designated as confidential by

LICENSEE.

6. Warranty.OPTAMETRA warrants that it is the owner or licensor of SOFTWARE and

OPTAMETRA warrants that it has the authority to license SOFTWARE as set forth in this

AGREEMENT. OPTAMETRA further warrants that SOFTWARE shall at the time of delivery of

SOFTWARE and for a period of ninety (90) days thereafter operate substantially in accordance with

OPTAMETRA' then-current published specifications. In the event that SOFTWARE does not so

operate, OPTAMETRA shall use its best efforts to cure such problem within a reasonable period of

time or to replace LICENSEE's copy of SOFTWARE with another copy of SOFTWARE in

OPTAMETRA' sole discretion. This shall be LICENSEE's sole and exclusive remedy. This warranty

shall not apply if: (1) SOFTWARE was not used in accordance with OPTAMETRA' then-current

published specifications; (2) SOFTWARE was altered, modified or converted by LICENSEE; (3)

LICENSEE's computer(s) malfunctioned and the malfunction caused the defect; (4) LICENSEE has

not paid all invoiced amounts due to OPTAMETRA pursuant to this AGREEMENT; and (5) any other

cause within the control of LICENSEE caused the defect. SOFTWARE shall be deemed working

according to specifications if it works on exemplary data files supplied by OPTAMETRA.

7. Limitation of Liability. THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED INCLUDING, BUT NOT LIMITED TO, ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

OPTAMETRA' LIABILITY FOR ANY AND ALL CLAIMS, SHALL NOT EXCEED IN THE

AGGREGATE, THE AMOUNT PAID BY CLIENT TO OPTAMETRA FOR THIS LICENSE. IN NO

EVENT SHALL OPTAMETRA BE LIABLE FOR INDIRECT, SPECIAL OR CONSEQUENTIAL

DAMAGES EVEN IF ADVISED THAT SUCH DAMAGES ARE POSSIBLE.

8. Support and Enhancements. Commencing upon execution of this AGREEMENT, and

thereafter for ninety (90) day terms ("RENEWAL TERMS") LICENSEE shall automatically be entitled

to SUPPORT and ENHANCEMENTS (all described below) for SOFTWARE.

A. Support. "SUPPORT" shall mean that OPTAMETRA shall provide to LICENSEE reasonable

technical email consultation relating to the operation of SOFTWARE.

B. Enhancements. "ENHANCEMENTS" shall mean that OPTAMETRA shall inform LICENSEE

when each new release of SOFTWARE containing system enhancements is made commercially

available, and upon written request from LICENSEE shall provide to LICENSEE one (1) copy of

each such release of SOFTWARE and corresponding technical documentation.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 28 of 29

Page 32

ENHANCEMENTS shall not mean that OPTAMETRA must provide any improvements to

SOFTWARE announced by OPTAMETRA as separately priced, optional or extra cost

improvements. ENHANCEMENTS shall be covered by the terms of this SOFTWARE LICENSE

AGREEMENT.

9. General.

A. Governing Law. This AGREEMENT will be governed by and interpreted in accordance with

the laws of the State of Wisconsin, excluding its conflict of law principles. In case of a dispute

arising from the interpretation or enforcement of OPTAMETRA‟ or its licensors‟ patents,

trademarks, copyrights, confidential information or other proprietary rights, U.S. federal copyright

law shall apply.

B. Assignment. Any assignment of this AGREEMENT by either party (except to an entity

controlling, controlled by or under common control with said party) without the written consent of

the other shall be void.

C. Severability. Any provision of this AGREEMENT that is held to be invalid by a court of

competent jurisdiction shall be severed from this AGREEMENT, and the remaining provisions

shall remain in full force and effect.

D. Waiver. Failure or delay by either party to enforce compliance with any term or condition of

this AGREEMENT shall not constitute a waiver of such term or condition.

E. Entire Agreement. This AGREEMENT constitutes the entire agreement between the parties

with regard to the subject matter of this AGREEMENT and supersedes all previous

communications, whether oral or written, between the Parties with respect to such subject

matter.

F. Foreign Trade Restrictions. LICENSEE shall not either directly or indirectly export or re-

export SOFTWARE in violation of the Export Administration Regulations promulgated by the

U.S. Department of Commerce.

10. Termination. LICENSEE may terminate this AGREEMENT at any time prior to the shipment

of SOFTWARE from OPTAMETRA. OPTAMETRA may terminate this AGREEMENT upon thirty (30)

days' prior written notice if LICENSEE fails to comply with any of the terms and conditions of this

AGREEMENT or the terms and conditions of the Purchase Order, and such noncompliance is not

cured during said thirty (30) day period. Promptly upon termination of this Agreement, LICENSEE

must immediately return to OPTAMETRA all SOFTWARE and CONFIDENTIAL INFORMATION

delivered by OPTAMETRA to LICENSEE including all copies, if any. LICENSEE's insolvency,

receivership, bankruptcy, or assignment for the benefit of creditors (or the institution of proceedings

therefor) shall immediately terminate this AGREEMENT without notice. Rights and obligations

accruing prior to termination of AGREEMENT shall survive termination of AGREEMENT.

Optametra OM2210 Calibration Source User Guide V1.0.1 1/7 ©2011 Page 29 of 29

Loading...

Loading...