Page 1

xx

OM1106

Optical Modulation Analysis Software

ZZZ

Version 2.2.x and Below

User Manual

*P077109302*

077-1093-02

Page 2

Page 3

xx

OM1106

Optical Modulation Analysis Software

ZZZ

Version 2.2.x and Below

User Manual

Register now!

Click the following link to protect your product.

► www.tek.com/register

www.tek.com

077-1093-02

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

MATLAB is a registered trademark of The MathWorks, Inc.

Other product and company names listed are trademarks and trade names of their respective companies.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Table of Contents

Preface ............................................................................................................. vii

Related documents.................. ................................ ................................ ......... vii

Install software........................... ................................ .................................. ......... 1

PC hardware and software requirements........... ................................ ......................... 1

®

MATLAB

Set Windows 7 user account setting before installing software . . ..... . ..... . . ... . . . ..... . ..... . ..... . . .. 2

Required software to install................................ .................................. ................. 2

To install MATLAB software............... ................................ ............................. 3

To install TekVISA software ............................................................................ 3

To install power meter software (for RXTest and OM2210) .................. ....................... 4

To install OMA software........ ................................ .................................. ....... 5

To install Scope Service Utility (SSU) software. . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... 7

Updating existing OMA (OUI) installations................................................................ 9

Verify software installation ........ ................................ ................................ .......... 10

Further information......... ................................ .................................. ................ 11

Verify or set OM series instrument IP address ................................................................. 13

Verify OM instrument connectivity on DHCP-enabled network ...... .................................. 13

Set OM instrument IP address for use on non-DHCP network ............ .............................. 14

OM1106 Optical Modulation Analysis (OMA) user interface ............................................... 19

OMA user interface elements ............................................................................... 21

The Menu ribbon.............................................................................................. 21

The Plots panel................................................................................................ 22

The global Controls panel ................................................................................... 28

The Setup tab controls ............................................................................................ 29

Scope Setup controls ............................ ................................ ................................ .. 29

Scope Connect button ........................................................................................ 29

Use VISA control (Scope Setup)...... .................................. ................................ .... 31

Auto Scale and DC Calib button............................................................................ 34

Scope & Receiver Deskew button .......................................................................... 34

Optical Connect.................................................................................................... 36

Optical Control Panel (LRCP) ................................................................................... 38

Connect to an OM instrument ....... ................................ ................................ ........ 39

The Laser controls ............................................................................................ 40

The Modulator controls .... .................................. ................................ ................ 42

The Driver Amp controls .............. ................................ .................................. .... 47

MATLAB Command/Response tab ............................................................................. 48

Analysis Parameters control and configuration tab .......... ................................ .................. 50

Front end filtering............................................................................................. 57

LMS filtering...... .................................. ................................ .......................... 59

software requirements........................................................................... 2

OM1106 Analysis Software User Manual i

Page 6

Table of Contents

Direct assignm

Direct assignment of pattern variables when not using a PRBS......................................... 62

Example capturing unknown pattern ....................................................................... 63

The Multicarrier Setup window . . .... . . .... . . .... . . .... . . .... . . .... . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ... 65

Multicarrier channel list... . ... . . . .... . ..... . ..... . .... . ..... . ..... . .... . . .... . ..... . ..... . .... . ..... . ..... . .. 66

Multicarrier display layout. . . .... . . .... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ..... . ... . . ..... . ..... . .... 67

The Receiver Test configuration tab............................................................................. 68

To perform a receiver test.................................................................................... 71

State controls ................................. ................................ ................................ ...... 80

The Home tab .................. ................................ ................................ .................... 81

Constellation plots............ .................................. ................................ .............. 81

Eye plots ....................................................................................................... 86

BER plots...................... ................................ .................................. .............. 91

Poincaré plots . ................................ ................................ ................................ 92

Q factor plots .............................. ................................ ................................ .... 94

Spectrum plots ................................................................................................ 95

Measurement plots.................. ................................ ................................ ........ 100

Signal vs. Time plot ........................................................................................ 103

Layout controls.......... .................................. ................................ .................. 106

The Calibrate tab ................................................................................................ 107

Enable Sliders (signal delay fine adjusts) (RT).................. ................................ ........ 107

DC Calibration (real-time oscilloscopes) . ..... . ..... . ..... . ...... . ...... . . ..... . . ..... . . ..... . . ..... . . .. 108

Get Calibration Files ............... ................................ ................................ ........ 108

The Offline tab ................................................................................................... 109

The Alerts tab .......... .................................. ................................ ........................ 111

The About tab .................................................................................................... 113

The global Controls panel ........ ................................ ................................ .............. 115

Appendix A: Hybrid calibration (RT)... ................................ ................................ ...... 117

Appendix B: OM5110 information ............................................................................ 121

Theory of operation......................................... .................................. .............. 121

Appendix C: OM2210 information............................................................................ 123

Product description . .................................. ................................ ...................... 123

Appendix D: Connection diagrams ............................................................................ 125

OM4000-series equipment setup........................ ................................ .................. 125

OM2210 equipment setup ................................................................................. 131

OM2012 equipment setup ................................................................................. 133

Appendix E: Receiver Test ..................................................................................... 135

Receiver Test overview .............. .................................. ................................ .... 135

Receiver test setup.................. ................................ ................................ ........ 137

Software operation.......................................................................................... 138

Test vs modulation frequency ............................................................................. 141

ent of pattern variables ....................... ................................ .............. 62

ii OM1106 Analysis Software User Manual

Page 7

Table of Contents

Test v s Wave len

Receiver Test ATE Commands............................................................................ 146

Appendix F: DSA8300 equivalent-time (ET) oscilloscope operation ..... . ..... . ..... . ..... . ..... . ..... . . 149

Configuring the software (ET) .... ................................ .................................. ...... 149

OMA and equivalent-time (ET) instruments ............................................................ 151

Calibration and adjustment (ET) ...... .................................. ................................ .. 153

Taking measurements (ET) .................... ................................ ............................ 163

OMA Controls panel (ET) ................................................................................. 163

Analysis Parameters window (ET)............................ .................................. .......... 164

Appendix G: Configuring two Tektronix 70000 series oscilloscopes.................................. .... 167

Oscilloscope settings ..... . ..... . ..... . ... . . ..... . ..... . ..... . .... . . .... . ..... . ..... . ..... . ..... . .... . ..... . 170

OMA settings for two-oscilloscope operation . ..... . ..... . ... . . . .... . ..... . ..... . ..... . ..... . ..... ..... . 172

Appendix H: Alert codes ....................................................................................... 175

Appendix I: MATLAB CoreProcessing software guide....................................... .............. 177

MATLAB interaction with OMA ....... ................................ .................................. 177

MATLAB variables......................................................................................... 178

MATLAB functions ...... ................................ .................................. ................ 179

Signal processing steps in MATLAB CoreProcessing.............................. .................... 180

MATLAB block processing ............................................................................... 185

Alerts management ......................................................................................... 186

Appendix J: The ATE (automated test equipment) interface ............................................... 189

The LRCP ATE interface .................. .................................. .............................. 189

The OMA ATE interface................................................................................... 203

Building an OMA ATE client in VB.NET ............................................................... 215

Appendix K: MATLAB CoreProcessing function reference............................................ .... 221

AlignTribs ................................................................................................... 221

ApplyPhase........................ ................................ .................................. ........ 224

ClockRetime................... ................................ ................................ .............. 225

DiffDetection................................................................................................ 226

EstimateClock............................................................................................... 227

EstimatePhase ............................................................................................... 229

EstimateSOP .. .................................. ................................ ............................ 230

MaskCount .................................................................................................. 231

GenPattern ................................................................................................... 232

Jones2Stokes ...... ................................ .................................. ........................ 233

JonesOrth .................................................................................................... 234

LaserSpectrum .............................................................................................. 234

QDecTh ...................................................................................................... 235

zSpectrum.................................................................................................... 236

Appendix L: MATLAB variables used by CoreProcessing ................................................. 237

MATLAB input variables ................................ ................................ .................. 237

gth ................. ................................ ................................ ........ 145

OM1106 Analysis Software User Manual iii

Page 8

Table of Contents

MATLAB calcula

Appendix M: Managing data sets with record length > 1,000,000......................................... 239

Saving intermediate data sets: examples................................................................. 239

Examples of save statements for unique file name.................................. .................... 239

Examples of if-statements and alerts to trigger a save ................................ .................. 240

Index

ted variables .................. ................................ .......................... 238

iv OM1106 Analysis Software User Manual

Page 9

List of Figures

Figure 1: The OMA screen with plots and measurements .......... ................................ .......... 19

Figure 2: Default OMA startup screen.................... ................................ ...................... 21

Figure 3: LRCP tab showing OM5110 controls................................................................ 38

Figure 4: LR

Figure 5: Multicarrier setup window . ..... . ..... ..... . ..... . .... . . .... . ..... . ... . . ..... . ..... . .... . ..... . ..... . . 65

Figure 6: Multicarrier constellation plots ..... . ..... . .... . ..... . ..... . .... . . .... . ..... . ..... . .... . ..... . ..... . .. 85

Figure 7: Multicarrier spectrum context menu . . .... . ... . . ..... ..... . .... . ..... ..... . .... . ... . . ... . . ..... ..... . 96

Figure 8: Multicarrier spectrum plot ..... . ... . . ..... . ..... . .... . ..... . ... . . ..... . ..... . .... . ..... . ... . . ..... . ... 98

Figure 9: Multicarrier spectrum plot details ..... . ..... . .... . ..... ..... . .... . ... . . ... . . ..... ..... . .... . ..... .... 99

Figure 1

Figure 11: Real-time (RT) oscilloscope setup diagram: Tektronix DSO/MSO70000C/D/DX series and

OM4245 Optical Modulation Analyzer .... ................................ .............................. 125

Figure 12: Real-time (RT) oscilloscope setup diagram: <80 GBaud single polarization testing using

DPO77002SX ATI oscilloscopes and OM4245 Optical Modulation Analyzer . . ..... . ..... . .... . ... 126

Figure 13: Real-time (RT) oscilloscope setup diagram: <60 GBaud dual polarization testing using

DPO77

Figure 14: Real-time (RT) oscilloscope setup diagram: 400G (<80 GBaud) dual-polarization signal testing

using DPO77002SX ATI oscilloscopes and OM4245 Optical Modulation Analyzer... . ..... . ..... 128

Figure 15: Equivalent-time (ET) oscilloscope setup diagram: DSA8300 and OM4245 ..... . .... . . .... 129

Figure 16: Heterodyne coherent receiver test system diagram ................... .......................... 136

Figure 17: Relay connections on the S46T when used with the SX70000................................ 136

gure 18: ChDelay(2) off by 2 ps causes curvature on constellation and signal on Q-Eye for 28 Gbps

Fi

BPSK......................................................................................................... 155

Figure 19: When adjusting the middle slider, watch the Y-Eye and Y-Const to minimize the signal in the

Y-polarization . ................................ .................................. ............................ 157

Figure 20: Final channel delay values provide only noise in Y polarization ..................... ........ 158

CP tab showing OM4200 controls.................................. .............................. 38

0: OM5110 block diagram................ ................................ ............................ 121

002SX ATI oscilloscopes and OM4245 Optical Modulation Analyzer . . .... . . .... . ..... . ... 127

OM1106 Analysis Software User Manual v

Page 10

Table of Contents

List of Tables

Table 1: Oscilloscope connectivity capabilities (TekVISA vs. Scope Service Utility) . ..... . ..... . ..... . . 33

Table 2: La s

Table 3: OM5110 Modulator controls (Auto-Set mode) (LRCP) ............................................ 43

Table 4: OM5110 Modulator controls (manual mode) (LRCP) .............................................. 44

Table 5: OM5110 Driver Amp controls (LRCP)........................... ................................ .... 47

Table 6: Analysis Parameters fields ............................................................................. 50

Table 7: RXTest parameters...................................................................................... 69

Table 8: R

Table 9: RxTest: Wavelength sweep plots ........................ .................................. ............ 76

Table 10: RxTest: Modulation Frequency sweep plots........................................................ 79

Table 11: Constellation plots..................................................................................... 81

Table 12: Eye plots................ ................................ ................................ ................ 86

Table 13: BER plots............................................................................................... 91

Table

Table 15: Q factor plots........................................................................................... 94

Table 16: Spectrum plots . .................................. ................................ ...................... 95

Table 17: Multicarrier spectrum menu choices (right-click). . ..... . ... . . . .... . . .... . ..... . ..... . ..... . ..... . . 96

Table 18: Multicarrier spectrum controls .... . ..... . ... . . ..... . ..... . ... . . ..... . ... . . . .... . ..... . ... . . ..... . .... 97

Table 19: Measurement plots................................................................................... 100

ble 20: Signal vs. Time plot ......... ................................ ................................ ........ 103

Ta

Table 21: Offline controls .. ................................ .................................. .................. 109

Table 22: Controls panel elements........................... ................................ .................. 115

Table 23: Record length and block interaction behavior .................................................... 116

Table 24: Receiver Test configurations and channel mappings ............................................ 140

Table 25: Test properties........................................................................................ 143

Table 26: Alert code descriptions........ ................................ ................................ ...... 175

er controls (LRCP).................................................................................. 41

eceiver test readout tabs .................. ................................ ............................ 74

14: Poincaré plots .......................................................................................... 92

vi OM1106 Analysis Software User Manual

Page 11

Preface

Preface

Related documents

This documen

t describes how to install, configure, and operate the OM1106

Optical Modulation Analyzer (OMA) software version 2.2.x and lower.

Tektronix part

Document

OM4245, OM4225 Optical Modulation Analyzer Installation and Safety

ons

Instructi

OM2210 Coherent Receiver Calibration Source Installation Safety Instructions

OM2012 nLaser Tunable Laser Source Installation and Safety Instructions

OM5110 4

Instructions

Tektro

Declassification and Security Instructions

Avert

OM4006D, O M2210, OM2012 et OM5110)

6 GBaud Multi-Format Optical Transmitter Installation and Safety

nix OM5000, OM4000, OM2000 Series Optical Modulation Instruments

issements - Mises en garde (manuels OM4245, OM4225, OM4106D,

number

071-3414-xx

071-3050-xx

071-3154

071-3203-xx

077-0992-xx

071-3184-xx

-xx

OM1106 Analysis Software User Manual vii

Page 12

Preface

viii OM1106 Analysis Software User Manual

Page 13

Install software

The OM1106 Optical Modulation Analyzer software (referred to as OMA in this

document) provides an ideal platform for research and testing of coherent optical

systems. It o

ffers a complete software package for acquiring, demodulating,

analyzing, and visualizing complex modulated systems with an easy-to-use user

interface. The software performs all calibration and processing functions to enable

real-time burst-mode constellation diagram display, eye diagram display, Poincaré

sphere display, and BER evaluation.

This section descr

ibes how to install and configure the OMA software and OM

series instruments to correctly communicate with each other.

PC hardware and software requirements

The following are the PC requirements needed to install and run the OMA

software to control the OM4000 and OM2000 series instruments. The term PC

applies to a supported oscilloscope, PC, or laptop on which the OMA and other

required software is installed, and t

a local network.

Item Description

Operating

system

Windows

.NET version

(32– or 64-bit

Windows)

Processor

RAM

Hard Drive

Space

Video Card

U.S.A. Microsoft Windows 7 (32- or 64-bit), with latest updates and service

packs installed

4.51 or later

NOTE. The OMA install process updates the .NET software if required.

Intel i7, i5 or equivalent; min clock speed 2 GHz

Minimum: Intel Pentium 4 or equivalent

Minimum: 4 GB

64-bit releases benefit from as much memory as is available

Minimum: 20 GB

>300 GB recommended for large data sets

nVidia dedicated graphics board with 512+ MB minimum graphics memory

hat is connected to OM instruments over

NOTE. OMA will run with video cards other than nVidia. However, color

gradient display (for plots that support that feature) and some advanced

plot features are only available when running OMA on an oscilloscope or

PC that has an nVidia graphics card installed.

Download and install the latest drivers available from the video card

manufacturer. There may be newer drivers available even if Windows says

the drivers are up to date.

Networking

Display

Gigabit Ethernet (1 Gb/s) or Fast Ethernet (100 Mb/s)

20” minimum flat screen recommended for displaying multiple graph types

OM1106 Analysis Software User Manual 1

Page 14

Install software

Item Description

Other

Hardware

Adobe Reader

2 USB 2.0 ports

Adobe reader used for viewing PDF format files

MATLAB®sof

Set W

indows 7 user account setting before installing software

tware requirements

The OMA software requires the appropriate version of the MathWorks, Inc.

MATLAB

product so

MATLAB version for your PC (www.mathworks.com).

OMA requi

NOTE. OMA uses the most recently installed MATLAB software. If you need to

revert to a previously installed Matlab, please see further instructions below.

Default Windows 7 user account settings interfere with OMA IVI/Visa operation.

To fix this, do the following before installing any software:

®

ftware media. Please contact The MathWorks, Inc. to obtain the correct

res the following versions of MATLAB:

For Microsoft Windows 7 (64-bit), U.S.A. version:

MATLAB v

For MicrosoftWindows 7 (32-bit) U.S.A. version:

MATLAB

Click Start > Control Panel > User Accounts.

software for performing analysis. MATLAB is not included on the

ersion 2011b (64-bit) or 2014a (64-bit)

version 2009a (32-bit)

Click Change User Account Control settings and set the notify control

to Never notify.

quired software to install

Re

Software required on the

Install the following software on the controller PC in the order listed.

controller PC

NOTE. Install all software as an Administrator.

CAUTION. Do not insert the product USB HASP key when installing the following

software. Only install the HASP key after all software is installed and you are

ready to run the OMA software.

2 OM1106 Analysis Software User Manual

Page 15

Install software

Software required on the

oscilloscope

To install MATLAB

software

1. MATLAB: Requir

installing OMA. (See page 3.)

2. TekVISA: Requ

series oscilloscopes.

NOTE. Do not load TekVISA for MSO/DSO70000C/D/DX/SX series real-time

(RT) oscilloscopes or the DSA8300 equivalent-time (ET) oscilloscope. These

oscilloscopes use the Scope Service Utility (SSU).

3. Power meter software: Required to run OMA Receiver Test functions

(RXTest) in conjunction with the OM2210.

4. OM1106 (OMA) software.

If you are using a Tektronix MSO/DSO70000C/D/DX/SX series real-time (RT)

oscilloscopes, and/or the DSA8300 equivalent time (ET) oscilloscope, then you

need to install the Scope Service Utility (SSU) on the oscilloscope. This software

is installed on the oscilloscope.

The OMA software requires the appropriate version of the MathWorks, Inc.

MATLAB

included on the product USB software media. Please contact The MathWorks,

Inc. to obtain the correct MATLAB version for your PC (www.mathworks.com).

®

software to perform analysis on the acquired data. MATLAB is not

ed for OMA, must be installed and activated before

ired when using Tektronix MSO/DSO70000 or 70000B

To install TekVISA software

OMA requires the following versions of MATLAB:

For Microsoft Windows 7 (64-bit), U.S.A. version:

MATLAB version 2011b (64-bit) or 2014a (64-bit)

For Microsoft Windows 7 (32-bit) U.S.A. version:

MATLAB version 2009a (32-bit)

Follow the instructions provided with MATLAB to install, activate, and verify

the software opens and runs.

NOTE. MATLAB must be installed and activated before installing OMA. Do not

install the rest of the software until you have confirmed that MATLAB runs and

is activated.

NOTE. Only install TekVISA when you are using Tektronix MSO/DSO70000B,

70000, or earlier series oscilloscopes.

OM1106 Analysis Software User Manual 3

Page 16

Install software

To install power meter

software (for RXTest and

OM2210)

TekVISA is requ

MSO/DSO70000B, 70000, or earlier serie s oscilloscopes. If used, make sure to

install TekVISA on the controller PC before installing the OMA software.

TekVISA is not included on the product USB flashdrive software media.

To download

1. Go to www.tek.com/downloads.

2. Enter tekvisa in the search field, select Software in the download type field,

and click GO.

3. Click TEKVISA CONNECTIVITY SOFTWARE, V4.0.4. Follow

on-screen instructions to download the software file.

4. Copy the downloaded file to the controller PC (where the OMA software

will be installed).

5. Double-click the TekVISA install fi le. Follow any on-screen instructions.

The power meter s oftware and drivers enable communication with the instrument

optical power meter. This software is only required to run the OMA Receiver Test

(RXTest) measurements with an OM2210 instrument.

ired when using the OMA software with Tektronix

and install the correct version of TekVISA:

NOTE. The power meter software only runs on Windows 7 64-bit installations.

ows 7 32-bit installations are not supported at this time.

Wind

To install the power meter software:

1. Ins

2. Na

3.D

NOTE. Windows 7 comes with a .zip-file-compatible compression-decompression

program. If you cannot access the contents of the .zip file, check that the .zip file

type is associated with the decompression program.

4. Double-click setup.exe to install the power meter software. Follow any

ert the product software media USB drive into a USB port on the controller

PC (where the OMA software will be installed).

vigate to the following file (from the USB root drive):

ThorLabsSoftware\PM100x_Instrument_Driver_64bit_V3.1.0.zip

ouble-click the file to display the compressed file contents.

on-screen instructions.

4 OM1106 Analysis Software User Manual

Page 17

Install software

To install OMA

software

NOTE. The OMA so

displayed by the installer.

NOTE. Do not plug the O

installing OMA. The required HASP and related drivers must be loaded as part of

the OMA install before you can use the USB HASP key.

To install the OMA software:

1. Insert the OMA soft

PC.

2. Navigate to the ap

root drive) for your Windows 7 OS:

For Windows 7 64-

NOTE. MATLAB 2011 b or 2014a (for Windows 7 64-bit) must be installed and

activated before installing the 64-bit version of the OMA software.

For Windows 7 32-bit: SetupOUI_x.x.x.x 32-bit OS.exe

ftware is labeled as OUI4006 in the screens and menu paths

MA USB HASP key into the controller PC before

ware media USB drive into a USB port on the controller

propriate OMA software installation file (from the USB

bit: SetupOUI_x.x.x.x.exe

NOTE. MATLAB 2009a (for Windows 7 32-bit) must be installed and activated

before installing the 32-bit version of the OMA software.

3. Double-click the appropriate program file to begin the install and open the

InstallShield Wizard.

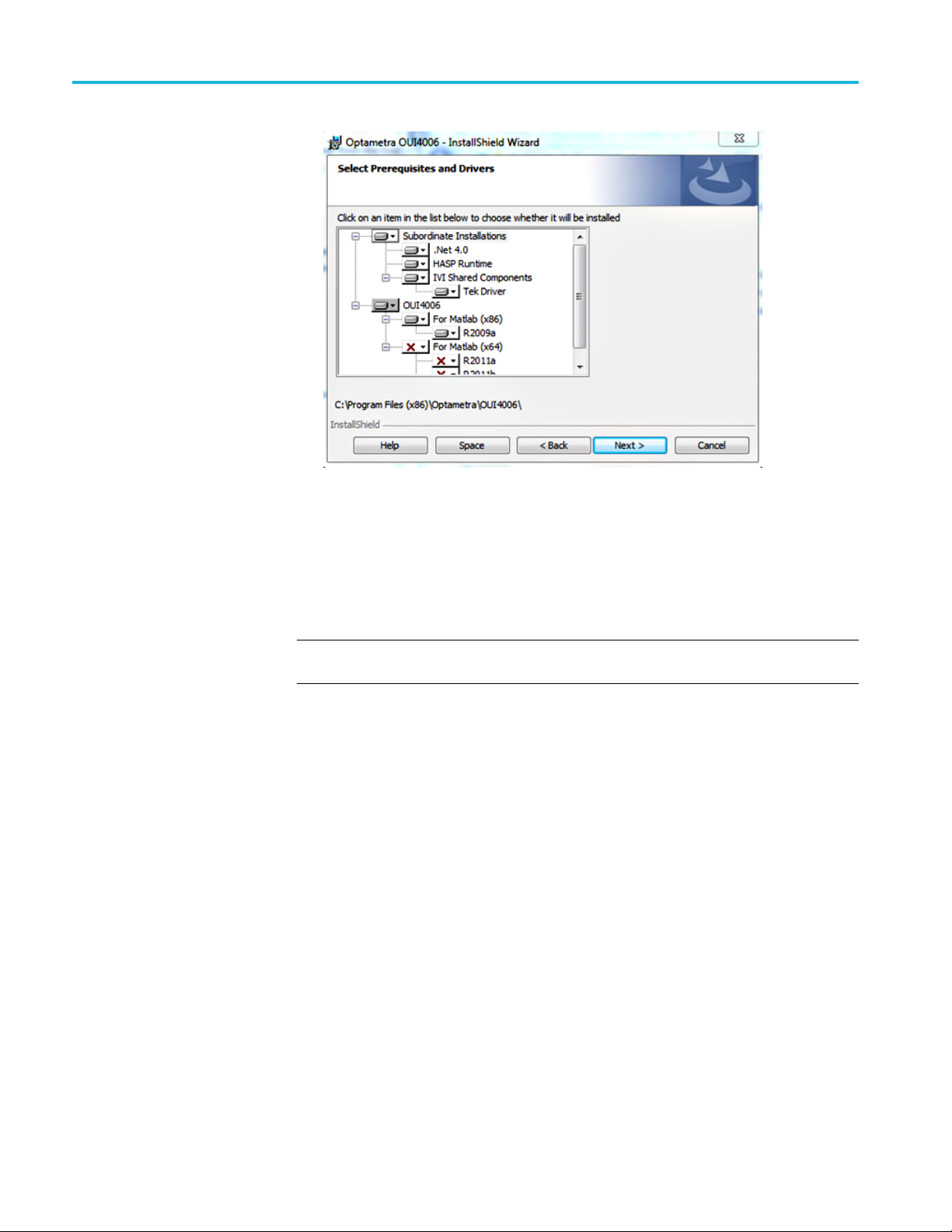

4. Accept the license agreement and select the default options until you get

to the choice for Complete or Custom. Select Custom to open the Select

Prerequisites and Drivers dialog box.

OM1106 Analysis Software User Manual 5

Page 18

Install software

5. Examine t

the installer has properly identified the correct MATLAB version to use with

the OMA. In the above example, the installer has identified that MATLAB

R2009a is installed and will be used with the OMA.

If there are multiple Matlab versions, use this list to disable all versions of

MATLAB except the one that is required for your Windows O S.

NOTE. For future partial updates or re-installs, turn off all of the Subordinate

Installation items except for the ones you are updating.

6. Click Next to begin installation. The Install Wizard launches individual

installers as required, such as for the HASP and IVI software.

7. Select Finish when the installer completes successfully.

OMA desktop icons. The install program adds two OMA application icons to

The

the desktop, which start different versions of OMA:

he Select Prerequisites and Drivers installation list to verify that

6 OM1106 Analysis Software User Manual

Page 19

Install software

Tektronix OUI (xx-bit) - Vertex Processing: This version

uses your Graphics Processing Unit (GPU) to add features and enhance

performance of the User Interface. The required minimum OpenGL version

is 2.1.0 which most recent PCs support. If the graphics driver is out of

date, a prom

recommended nVidia type, color-grade features will be enabled.

that lack support for Open GL 2.1.0 and for which no driver is available.

This version disables some features including 3-D plots, Signal-vs-Time, and

color grade options.

To determine if color shading and 3-d plots work on your controller PC, see the

verify installation procedure. (See page 10, Verify software installation.)

pt to install latest driver may appear. If the GPU present is the

Tektronix OUI (xx-bit): This version is for older computers

To install Sco pe Service

Utility (SSU) software

The Scope Service Utility (SSU) is required for OMA to communicate with

Tektronix MSO/DSO70000C/D/DX/SX series real-time (RT) oscilloscopes and

the DSA8300 equivalent-time (ET) oscilloscope. The SSU is installed and runs

on the target oscilloscope to collect and send data to the OMA.

There are separate SSU installation programs for RT oscilloscopes and ET

oscilloscopes.

To install the SSU:

1. If SSU is installed on the oscilloscope, uninstall the current version before

installing the new version.

2. Insert the OMA software media USB drive into a USB p ort on the

oscilloscope.

3. Navigate to the appropriate SSU software installation file (RT or ET) (from

the USB root directory):

For MSO/DSO70000C/D/DX/SX RT oscilloscopes:

OUI\Tektronix Scope Service Utilityx.x.x.x.exe

For the DSA8300 ET oscilloscope:

OUI\Tektronix Scope Service For ET Utilityx.x.x.x.exe

4. Double-click the appropriate program file to install. Follow any on-screen

instructions. The installer adds SSU icons on the oscilloscope desktop.

Using the SSU. Double-click the Tektronix Scope Service Utility icon to start

the SSU software on the oscilloscope before using the OMA to acquire data and

analyze results. You can also drag the SSU icon to the Startup folder on real-time

OM1106 Analysis Software User Manual 7

Page 20

Install software

oscilloscopes

the instrument (not available on the DSA8300). The Non-VISA oscilloscope

connections (Scope Service Utility) section has more information on SSU. (See

page 33, Non-VISA oscilloscope connections (Scope Service Utility).)

NOTE. For ET SSU: Make sure that the oscilloscope application AND the Socket

Server are running before running the ET Scope Service Utility. To start the socket

server, rig

ET SSU operation. The first time you run the SSU program on the ET oscilloscope,

it will as

E: DSA8300 equivalent-time (ET) oscilloscope operation. Once you do this and

click OK, the default state is saved to My Documents\TekScope\UI\default.st.

This default file loads each time you start the Scope Service Utility to recall the

deskew and other important settings. You can change the default state at any time

by saving over the de fault state file.

To verify equivalent-time function of the OMA, load a simulated ET file and

display the results:

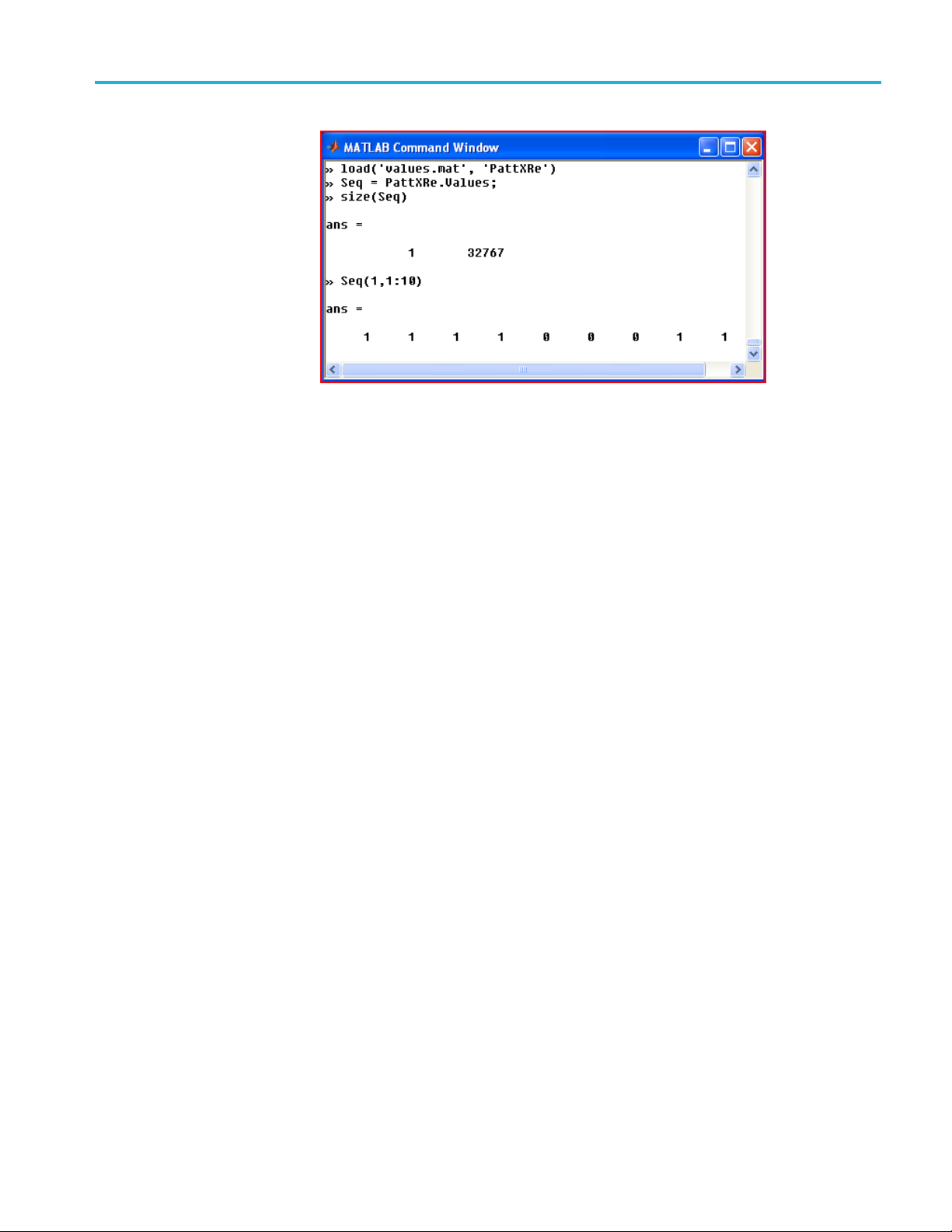

1. Check that the OMA Matlab Engine Command Window contains the line

CoreProcessingCommands (this is used instead of CoreProcessing to enable

either ET o

so that the SSU starts automatically when you power-on or reboot

ht click the network icon on the oscilloscope.

k you to set up the oscilloscope according to the instructions in Appendix

r RT processing of the data).

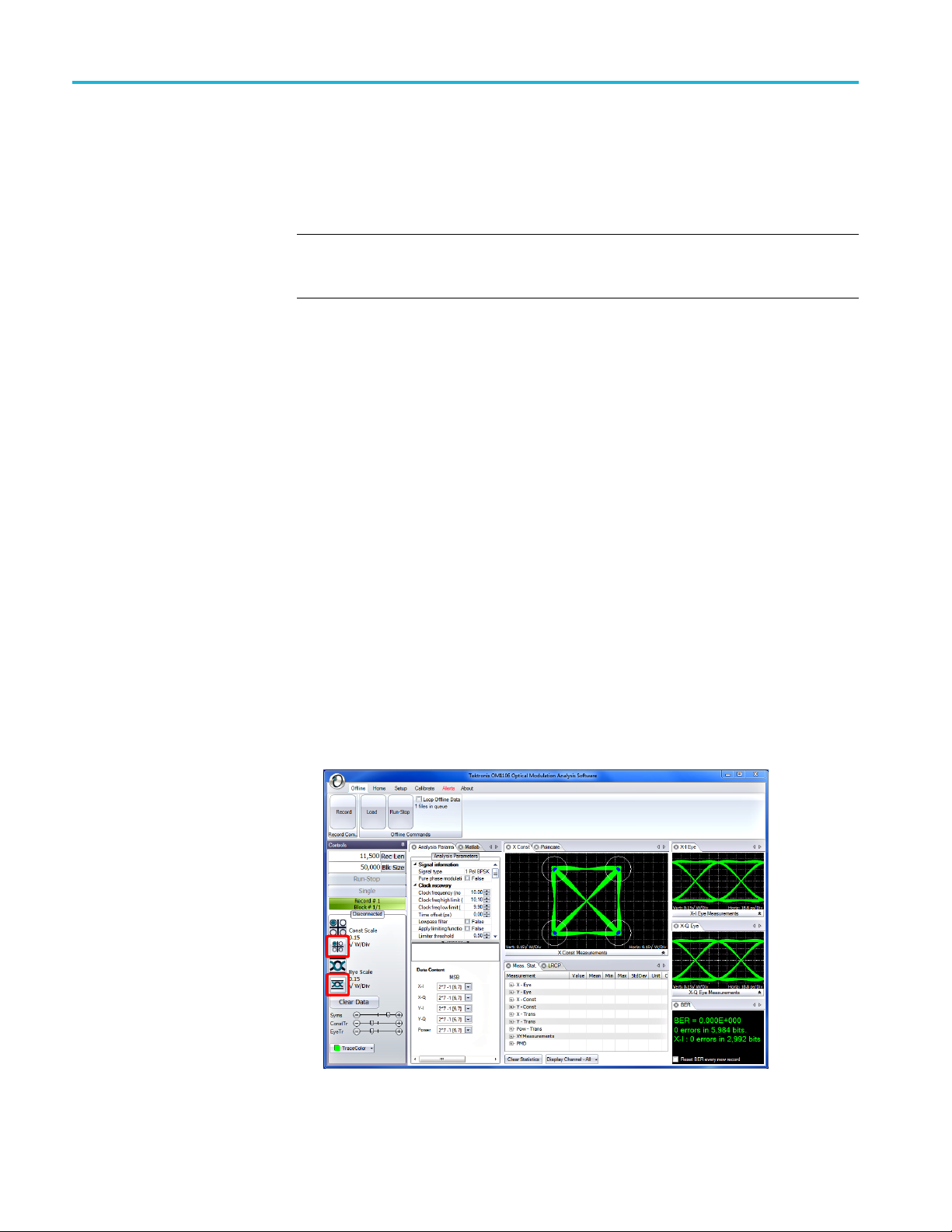

2. Click Home > 1-pol I&Q.

3. Click Offline > Load and navigate to and select the file My Documents\Tek

Applications\OUI\MAT Files\Simulated ET Data Files\QPSK2chAET.mat.

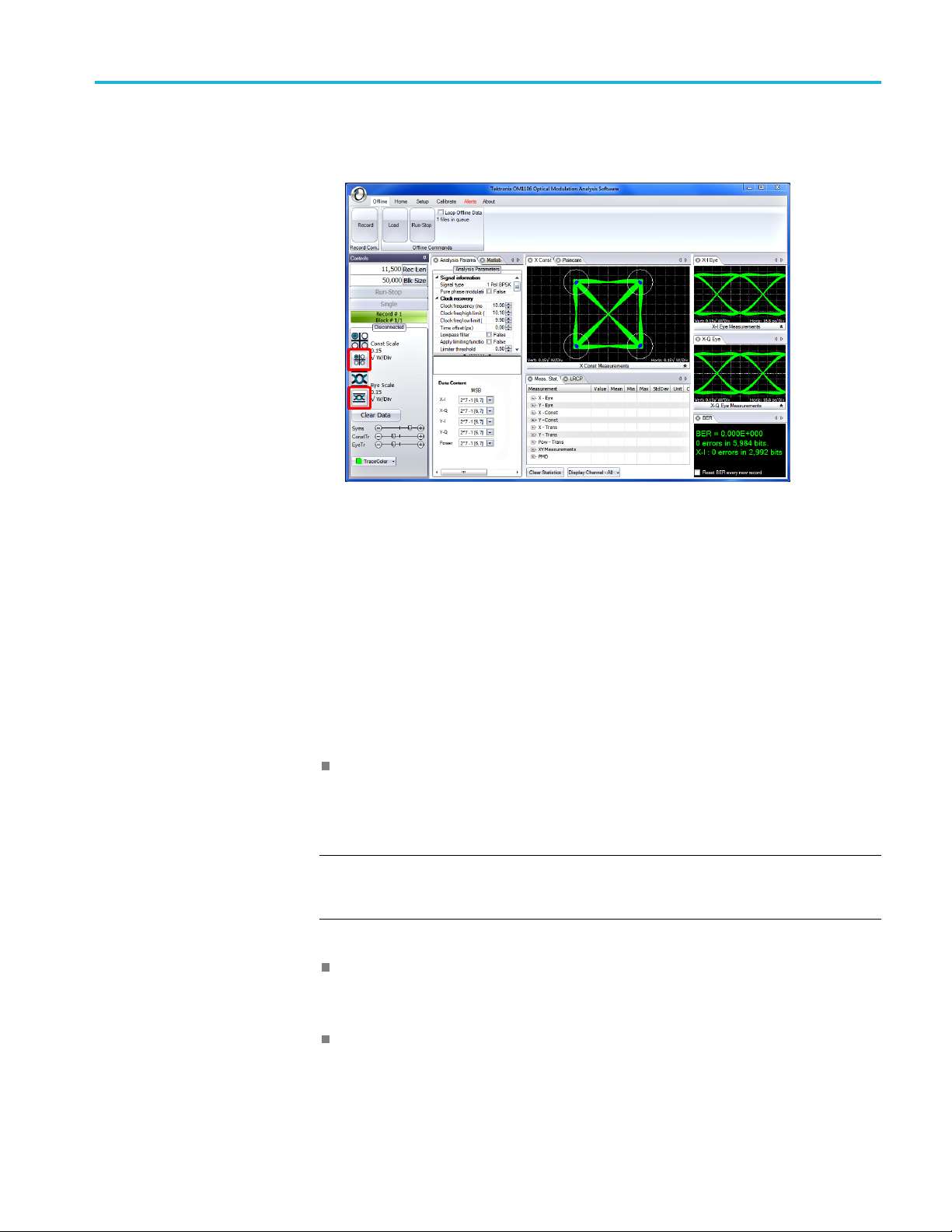

4. Click the Run-

shown in the following image (after using the plot scaling controls, marked in

red, to reduce the plot sizes):

Stop button in the Offline Commands area. A successful run is

8 OM1106 Analysis Software User Manual

Page 21

Install software

Updating exis

ting OMA (OUI) installations

Do the following before replacing an earlier version of OMA (referred to as OUI

in earlier releases):

Back up any critical data files; in particular, back up pHybCalib.mat and

EqFiltCoef.mat from the C:\Program Files\TekApplications\OUI\ folder, and

replace the

Back up any files you may have edited in the \Program Files\Optametra folder

or \Progra

Record your channel delay values on the Calibration tab. If upgrading from an

older OUI

Starting with OUI V1.6, the top slider is the Channel XI to XQ delay, the

middle slider is Channel XI to YI and the bottom is now Channel YI to YQ.

If you have the XI to YQ value but not the YI to YQ value, simply subtract the

XI to YI value from the XI to YQ value to get the YI to YQ value.

NOTE. Please call Tektronix for assistance if upgrading from OUI V1.4 or V1.5

that is installed on an oscilloscope.

Do the following to upgrade from OUI4006 Version 1.3 or earlier to the

current software, when installed on a PC (not an oscilloscope). Using the

Remove Program tool in the system Control Panel to:

m in the new ExecFiles folder after the upgrade is complete.

m Files\TekApplications sub folders.

version, the format of the Channel Delay sliders may be different.

Uninstall the Scope specific IVI driver (for example, TekScope IVI Driver

2.7).

Uninstall the IVI Shared Components (do NOT uninstall the VISA Shared

Components).

Uninstall OUI4006 (version 1.3 or earlier).

Uninstall LRCP (if present) by using the remove program feature in the

system Control Panel.

Install this version of OMA and required softwa re.

If the OUI installer asks to uninstall an old HASP driver and install a new one,

click YES. This p revents future problems with Windows Updates.

OM1106 Analysis Software User Manual 9

Page 22

Install software

Verify softwa

re installation

Do the following to verify that OMA and MATLAB are installed correctly:

1. Insert the product USB HASP key in a USB port on the controller PC.

2.

3. Click the Home menu tab, and then click the 1-pol I&Q button (in the Layout

4. Right-c

Double-click the desktop OMA icon Tektronix OUI (xx bit)

Vertex Processing. Wait for the OMA application to open. If the OMA

application opens but seems to be locked up, see the troubleshooting s ection.

(See page 11,

section o

readout, and control tabs for the 1-pol I&Q measurement.

If the Color Grade menu item is selectable, then the graphics card on your

contro

If the Color Grade menu item is grayed out, then the graphics card on your

contr

Close OMA and then restart OMA using the Tektronix OUI (xx bit)

desktop icon. Then repeat this procedure and continue to the next step.

Troubleshooting OMA/MATLAB installation.)

f the menu bar). The OMA screen populates to show the plot,

lickintheX-I Eye plot to open the X-I Eye Options context menu:

ller PC supports color grade and 3-d plots.

oller PC does not support the Vertex Processing version of OMA.

5. Click Offline in the menu bar, click Load, and navigate to My

Documents\TekApplications\OUI\Mat Files\Simulated Data Files.

6. Select file QPSK1chA.mat. and click Open.

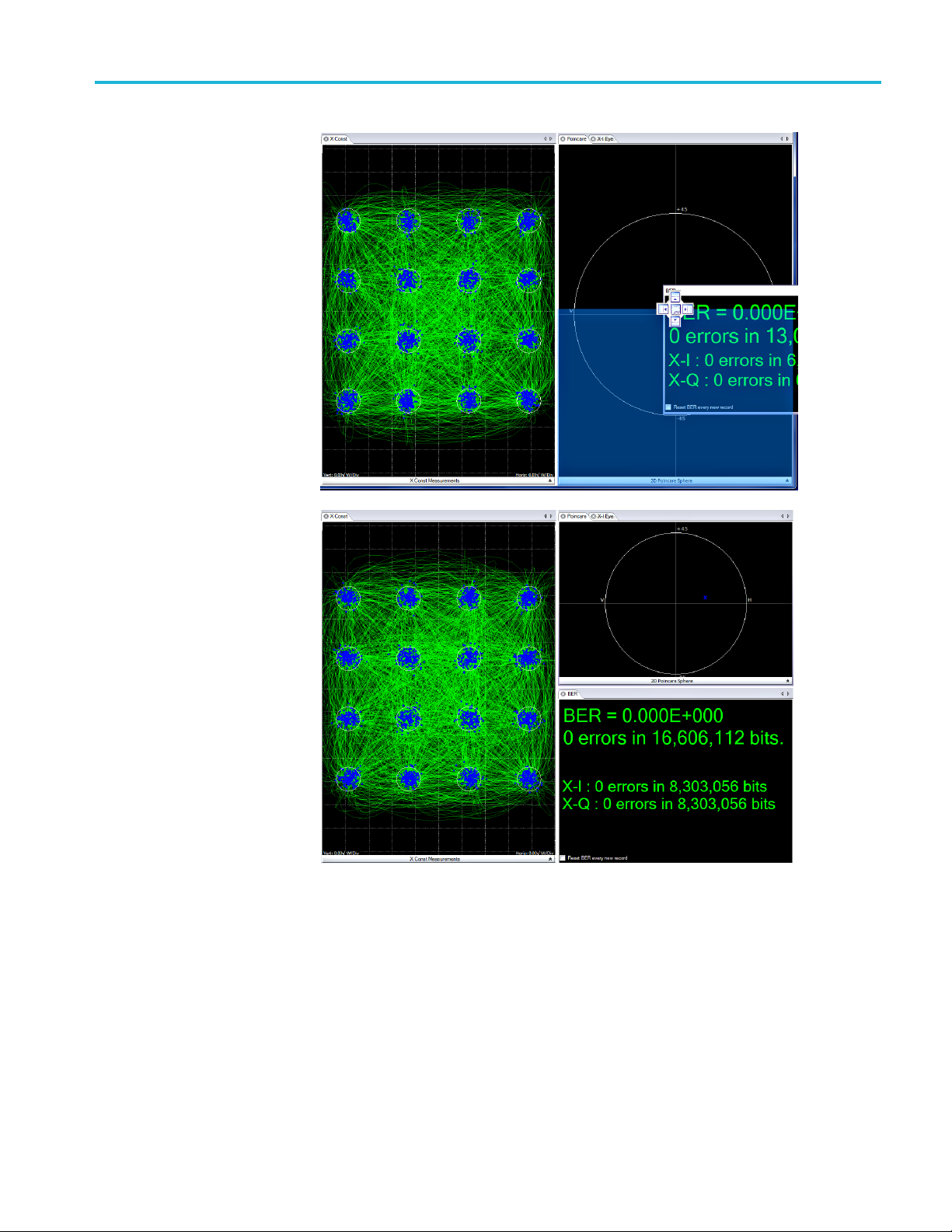

ick Run-Stop (in the Offline menu bar). The OMA screen should look

7. Cl

similar to the following image:

10 OM1106 Analysis Software User Manual

Page 23

Install software

8. Click the Cont S

image) to reduce the plot scales to show the entire plot.

9. If you see the above screen, then OMA and MATLAB installed correctly.

Go to the Verify or set OM series instrument IP address section to set OM

instrument connections. (See page 13.)

cale and Eye Scale buttons (marked in red on the following

Further information

Troubleshooting

OMA/M

ATLAB installation

Go to the Scope Connect section to learn how to connect to an oscilloscope.

(See page 29, Scope Connect button.)

If the OMA window opens, but is not functional (appears to lock up), the most

ly cause is a MATLAB version or activation problem.

like

Open the MATLAB software interface and check that the correct version was

talled. If the wrong version of MATLAB was installed, uninstall both

ins

MATLAB and OMA, and then reinstall the software following the installation

order and instructions in this manual.

TE. If more than one MATLAB version is installed on the controller PC, OMA

NO

may be ‘connected’ to the wrong version. (See page 12, Using other MATLAB

installations.)

f the version is correct, confirm that the MATLAB software was successfully

I

activated after the install (see the MATLAB install instructions for h ow to

activate the program).

If the above items do not fix the problem, please contact Tektronix Customer

Support for assistance.

OM1106 Analysis Software User Manual 11

Page 24

Install software

Using other MATLAB

installations

Unexpected results

Verify HASP protection

Reverting to ot

multiple MATLAB installation: To use a version of MATLAB that is not the most

recent one installed on your computer, you need to register the older version as the

COM server. This is done as follows:

Once MATLAB installation completes, find the shortcut for the MATLAB

version you want to use and double click it to start the MATLAB Desktop

for that version.

Run the following two lines in the MATLAB Command window to establish

the running Matlab.exe as the correct Com-Server:

cd(fullfile(matlabroot,'bin',computer('arch')))

!matlab /

If you get unexpected results, note a nything reported in the MATLAB

Engine Response Window, or in the Alerts tab. Also open the MATLAB

Comman

CoreProcessingCommands, and note any response. Provide this information

when contacting Tektronix Customer Service.

You c a

Control Center:

n verify the HASP protection b y opening the SafeNet Sentinel Admin

her MATLAB versions or post installation steps for a system with

regserver

d Window from the MATLAB desktop application, enter

1. Open

2. Cli

3. Verify that your key is listed as a local HASP HL Pro key.

a web browser on the controller PC and enter http://localhost:1947 in

the address bar to open the Sentinel Admin Control Center Web page.

ck the Sentinel Keys link in the left panel.

12 OM1106 Analysis Software User Manual

Page 25

Verify or set OM series instrument IP address

Verify or set O

Verify OM

instrument connectivity on DHCP-enabled network

M series instrument IP address

Before you ca

that IP addresses of the connected OM series instruments are set correctly for

your network, to enable communications between the instruments and the OMA

software. The following sections describe how to connect OM instruments to

DHCP and non-DHCP networks.

All OM instruments must be set to the same network subnet (DHCP-enabled

networks do this automatically) to communicate with each other.

OM series instruments are set by default to use DHCP to automatically assign IP

addresses. If you are connecting the OM instruments and PC controller over a

DHCP net

as the DHCP server automatically assigns an IP address during each instrument’s

power-on process.

The following procedure describes how to verify that the OMA software can

detect and connect to OM instruments that are set to use DHCP-generated IP

addresses on a DHCP-enabled network:

n use the OMA software to take measurements, you must make sure

work, you do not need to specifically set the OM instrument IP address,

Verify OMA can detect

M instruments on DHCP

O

network

Prerequisites:

Required software is installed on the controller PC (OMA, MATLAB, and so

on).

OM instrument(s) and the controller PC are connected to the same

DHCP-enabled local network.

OM instruments are set to use DHCP (default configuration).

To verify that the OMA software can detect and connect to OM instruments

ocated on a DHCP-enabled local network:

l

1. Connect the OM instrument(s) to the D HCP-enabled local network.

2. Power on each OM instrument. The instrument queries the DHCP server

to obtain an IP address. Wait until the front panel Enable/Standby button

light turns off, indicating it has obtained an address. Push the front panel

Enable/Standby button to enable the network connection (button light turns

On).

3. Double-click the Tektronix OUI software desktop icon to start the OMA

software.

4. Click Setup > Optical Connect to open the Device Setup dialog box.

OM1106 Analysis Software User Manual 13

Page 26

Verify or set OM series instrument IP address

5. Click Auto Con fi

instruments. If all connected instruments are listed, then correct IP addresses

were automatically assigned.

If the Device Setup dialog does not list all connected instruments:

Verify that

network.

Verify that

for network access (front panel power button light is on).

Work wit h y

6. Click OK to close the Device Setup dialog box and return to the OMA main

screen. T

he OMA software can now access and control the OM instruments.

gure to search the network and list all detected OM

instruments are connected to the correct DHCP-enabled

instruments are powered on and in the correct power-on state

our IT resource to resolve the connection problem.

Set OM instrument IP address for use on non-DHCP network

To conn

IP address and related settings on the OM instrument to match those of your

non-DHCP network. All devices on non-DHCP network (OM instruments,

PCs running OM software, and other remotely accessed instruments such as

oscilloscopes) need the same subnet values (first three number groups of the IP

address) to communicate, and a unique instrument identifier (the fourth number

grou

ect the OM series instrument to a non-DHCP network, you must set the

p of the IP address) to identify each instrument.

Work with your network administrator to obtain a unique IP address for each

ice. If your network administrator needs the MAC address of the OM

dev

instrument, the MAC address is located on the instrument rear panel label.

NOTE. Make sure to record the IP addresses used for each OM instrument, or

attach a label with the new IP address to the instrument.

If you are setting up a new isolated network just for controlling OM and associated

nstruments, Tektronix recommends using the OM instrument default IP subnet

i

address of 172.17.200.XXX, where XXX is any number between 0 and 255.

NOTE. Use the system configuration tools on the oscilloscope and computer to

set their IP addresses.

NOTE. If you need to change the default IP address of more than one OM

instrument, you must connect each instrument separately to change the IP address.

14 OM1106 Analysis Software User Manual

Page 27

Verify or set OM series instrument IP address

Change OM instrument

IP address using DHCP

network

There are two wa

Connect the OM instrument(s) to a DHCP-enabled network and use the LRCP

tab in OMA to change the IP address (easiest way).

Connect t

already set to the same IP address subnet as the OM instrument, and use the

LRCP tab controls in OMA to change the IP address.

To use a DHCP network to c hange the IP address of an OM instrument:

1. Connect the OM instrument(s) to the DHCP-enabled network.

2. Power on the OM instrument. The instrument qu

to obtain an IP address. Wait until the front panel Enable/Standby button

light turns off, indicating it has obtained an address. Push the front panel

Enable/Standby button to enable the network connection (button light turns

On).

3. Access the connection setup controls:

OM1106:

a. Double-click the OM1106 software desktop icon.

b. Click Setup > Optical Connect to open the Device Setup dialog box.

ys to change the IP address of an OM instrument:

he OM instrument directly to a PC (with OMA installed) that is

eries the DHCP server

LRCP:

Double-click the LRCP desktop icon. Enter password 1234 if

requested.

Click Device Setup to open the Device Setup dialog box.

4. Click Auto Configure to search the network and list all detected OM

instruments.

If the Device Setup dialog does not list all connected instruments:

Verify that instruments are connected to the correct DHCP-enabled

network

Verify that instruments are powered on

Work with your IT resource to resolve the connection problem

5. Double-click in the IP Address field of the instrument to change and enter the

new IP address for that OM instrument.

6. Click the corresponding Set IP button. A warning dialog box appears

indicating that the IP address will be changed and that you must record the

new IP address. Losing the IP address will require connecting the instrument

to a DHCP router.

7. Click Ye s to set the new IP address.

OM1106 Analysis Software User Manual 15

Page 28

Verify or set OM series instrument IP address

Change OM instrument IP

address using direct PC

connection

8. Edit the Gatewa

support).

9. Click OK.

10. Repeat steps 5 through 9 to change any other OM instrument IP addresses.

11. Exit the OM program.

12. Power off the OM instrument(s) and connect it to the non-DHCP network.

13. Run LRCP or OM1106 on the non-DHCP netwo

button in the Device Setup dialog box to verify that the instrument is listed

with the new IP address.

To use a direct PC connection to change the default IP address of an OM

instrument, you need to:

Install OM1106 or LRCP on the PC

UsetheWindowsNetworktoolstosettheIPaddressofthePCtomatchthat

of the current subnet setting of the OM series instrument whose IP address

youneedtochange

Connect the OM instrument directly to the PC, or through a hub or switch

(not over a network)

y and Net Mask (obtain this information from your network

rk and use the Auto Config

Use OM1106 or LRCP to change the OM instrument IP address

Do the following steps to use a direct PC connection to change the IP address

of an OM series instrument:

NOTE. The following instructions are for Windows 7.

NOTE. If you need to change the default IP address of more than one OM

instrument using this procedure, you must connect each instrument se

change the IP address.

Set PC IP address to match OM instrument.

1. On the PC with OM1106 or LRCP installed, click Start > Control Panel.

2. Open the Network a nd Sharing Center link.

3. Click the Manage Network Connections link to list c onnections for your PC

4. Right-click the Local Area Connection entry for the Ethernet connection and

select Properties to open the Properties dialog box.

5. Select Internet Protocol Version 4 and click Properties.

parately to

16 OM1106 Analysis Software User Manual

Page 29

Verify or set OM series instrument IP address

6. Enter a new IP ad

used by the OM instrument. For example, 172.17.200.200. This sets your

PC to the same subnet (first three number groups) as the default IP address

setting for the OM series instruments.

7. Click OK to set the new IP address.

8. Click OK to exit the Local Area Connection dialog box.

9. Exit the Control Panel window.

Run OMA on direct-connected PC to change OM instrument IP address.

1. Connect the OM instrument to the PC (directly, or through a hub or switch

connected to the PC). Do not connect over a network.

2. Power on the OM instrument. Wait until the front panel Enable/Standby

button light turns Off.

3. Push the Enable/Standby button again to enable the network connection

(button light turns On).

4. Double-click the OM1106 software desktop icon.

5. Click Setup > Optical Connect to open the Device Setup dialog box.

6. Click Auto Configure to search the network and list all detected OM

instruments.

dress for your PC, using the same first three numbers as

If the Device Setup dialog does not list all connected instruments:

Verify that instruments are connected to the correct DHCP-enabled

network

Verify that instruments are powered on

Work with your IT resource to resolve the connection pr

7. Double-click in the IP Address field of the instrument to change and enter the

new IP address for that OM instrument.

8. Click the corresponding Set IP button. A warning dialog box appears

indicating that the IP address will be changed and that you must record the

new IP address. Losing the IP address will require connecting the instrument

to a DHCP router.

9. Click Ye s to set the new IP address.

10. Edit the Gateway and Net Mask (obtain this information from your network

support).

11. Click OK.

12. Exit the OM program.

13. Power off the OM instrument.

oblem

OM1106 Analysis Software User Manual 17

Page 30

Verify or set OM series instrument IP address

14. Disconnect the

15. Connect the OM instrument to the target network.

16. Run the OM1106 or LRCP software on the PC connected to the same

network as the OM instrument to verify that the OM software detects the

OM instrume

OM instrument from the PC.

nt.

18 OM1106 Analysis Software User Manual

Page 31

OM1106 Optical Modulation Analysis (OMA) user interface

The OM1106 Optical Modulation Analysis Software user interface (referred to

as the OMA or OMA software throughout this document) is a powerful and

flexible pane

of OMA are:

l-based user interface for optical signal analysis. The main functions

Detect OM in

Set parameters on the OM instruments (laser, modulator, and so on)

Provide communication between all detected OM instruments, oscilloscopes,

and the OMA software

Acquire and process signals from OM instruments and the oscilloscope

Display plots and measurements

struments on the local network.

Figure 1: The OMA screen with plots and measurements

OM1106 Analysis Software User Manual 19

Page 32

OM1106 Optical Modulation Analysis (OMA) user interface

To sta rt the OMA

screen.

NOTE. Inser

the OMA.

t the application HASP key into a USB port on the PC before starting

software, double-click the desktop icon to open the default

The OM

be installed on the same PC as the OMA sofware. The OMA automatically

launches and interfaces with the MATLAB application using engine mode. No

direct user interaction with MATLAB is needed for most operations while using

the OMA.

NOTE. MATLAB must be installed and activated before running the OMA

sof

NOTE. Typin g desktop in the separate Matlab application window opens the

fu

A requires a third party program, MATLAB by MathWorks, which must

tware.

ll Matlab UI.

20 OM1106 Analysis Software User Manual

Page 33

OM1106 Optical Modulation Analysis (OMA) user interface

OMA user inter

face elements

The Menu ribbon

Figure 2: Default OMA startup screen

Item Description

1

2

3

The Menu ribbon provides fast access to key tasks. Click a main menu tab to

show the associated task buttons.

Clickanicontoshowthemenuofavailable functions and sub-functions, open a

dialog box, or run that task.

The Menu ribbon provides fast access to key tasks.

The Plots panel is a flexible panel-based area that displays the plots, measurement,

and parameter control panels. (See page 22.)

The global Controls panel sets record length and block size, runs and stops live

data acquisitions, sets plot display scales, and shows other controls as needed for

particular plots. (See page 28.)

OM1106 Analysis Software User Manual 21

Page 34

OM1106 Optical Modulation Analysis (OMA) user interface

The menu ribbon buttons can be hidden to provide more room for plots and

control tabs. To hide the menu bar, double click any main menu tab other than

About. Unhi

de by double clicking again on a tab.

The Plots panel

The Plots

and parameter control panels. The Plots panel is empty by default when you

start OMA. Select a predefined plot layout from the Home > Layout buttons to

quickly populate the plot panel with parameter, control, and plots for the selected

measurement. The following image shows the Plots panel populated by selecting

the 2-pol I&Q layout button.

panel is a flexible panel-based area that displays the plots, measurement,

Select individual plots and measurements from the Home menu items to add to

the Plots panel. New individually added plots open as full-screen plot on blank

screens, or are added to an existing a rea when inserted in an existing layout, with

each plot, readout, or control on its own tab. You can move plot, control, and

readout tabs (referred to a s plots throughout this manual) within the Plots panel

area or drag them to the PC desktop.

22 OM1106 Analysis Software User Manual

Page 35

OM1106 Optical Modulation Analysis (OMA) user interface

To change plot tab order. To change the plot tab order (within the same group of

plot tab

To move/arrange plots in the Plots panel. To move and arrange plots within the

Plots panel, click and drag a plot tab into any open plot. OMA shows a plot

position icon. Continue holding the mouse button and drag the cursor on to the

positioning guide.

s), click and hold on the tab and drag it horizontally in the same tab group.

s you drag the cursor on the different areas of the plot position icon, the screen

A

is shaded light blue to indicate where the plot will be positioned (above, below,

left, or right of the current plot).

OM1106 Analysis Software User Manual 23

Page 36

OM1106 Optical Modulation Analysis (OMA) user interface

Release the mouse button and the OMA places the plot into a new panel in the

selected area.

The following images show moving the BER plot to display below the Poincaré

plot, and the X-I Eye plot to display below the constellation plot.

24 OM1106 Analysis Software User Manual

Page 37

OM1106 Optical Modulation Analysis (OMA) user interface

OM1106 Analysis Software User Manual 25

Page 38

OM1106 Optical Modulation Analysis (OMA) user interface

Dragging a plot to the center of the positioning icon places the m oved plot as a tab

in the plot pane to which it was dragged.

To move a

desktop, click and hold on the plot tab and drag it to the desktop. To return the plot

to the OMA application, double click in the title bar of the desktop plot window.

NOTE. The plot may not move back to the same position in the Plots panel from

whereyourdraggedit.

plot to the desktop. To move a plot to a separate window on the

26 OM1106 Analysis Software User Manual

Page 39

OM1106 Optical Modulation Analysis (OMA) user interface

To save p

using the Load Preset and Save Preset functions in the Home ribbon menu. (See

page 106, Layout controls.)

To show additional plot controls, information. Plots may have dropdown panels

to show extra information or controls associated with that plot. Click the double

arrow on the bottom border of a tab

for that tab.

To re

area between plots; the cursor changes shape to a bar with arrows. Click and hold

the right mouse button and drag the panel divider to change the panel size.

To delete a plot. To delete a plot, click the X icon (circled in red in the following

image).

To show additional plot display settings. Plots may have additional display

settings (markers, save to, color grade, trace color, and so on). Right-click in a

plot to see available display or other options.

lot layouts. You can save and recall (load) custom plot layouts by

to display or hide the extra information

size plot panels. To resize a plot panel, position the cursor in the g ray d ivider

OM1106 Analysis Software User Manual 27

Page 40

OM1106 Optical Modulation Analysis (OMA) user interface

The global Con

trols panel

The global Controls panel sets record length and block size, runs and stops live

data acq

particular plots. This control panel is pinned to the left side of the application

by default for easy access. You can click the pushpin icon in the upper right to

minimize the controls to allow for maximum Plot panel area.

uisitions, sets plot display scales, and shows other controls as needed for

You can rescale Constellation and Eye plots by clicking on the relevant Plot icons

in the Controls panel (located by default on the left side of the application). The

scale units are √W/div.

There are also controls to adjust the intensity of symbol points and the intensity

and color of constellation and eye traces. You can also adjust trace color and

intensity levels may using the right-click menu on each individual plot. (See

e115,The global Controls panel.)

pag

28 OM1106 Analysis Software User Manual

Page 41

The Setup tab controls

Use the Setup tab controls to detect, connect, and configure connected

oscilloscopes (real-time and equivalent time) and OM series instruments to

perform meas

the controls in detail, grouped by the control categories (Scope Setup, Optical

Setup, Reference Laser, Show Controls, and State Control).

Scope Setup controls

Scope Connect button

The Scope Connect functions search for and connect to network-connected

oscilloscopes, and assign oscilloscope channels to the OM instrument inputs.

Click Scope Connect on the Setup tab to open the ScopeConnectionDialog box.

urements with the OMA software. The following sections describe

NOTE. The Scope Connect functions require that the Scope Service Utility (SSU)

stalled and running on connected oscilloscopes.

be in

OM1106 Analysis Software User Manual 29

Page 42

Scope Setup controls

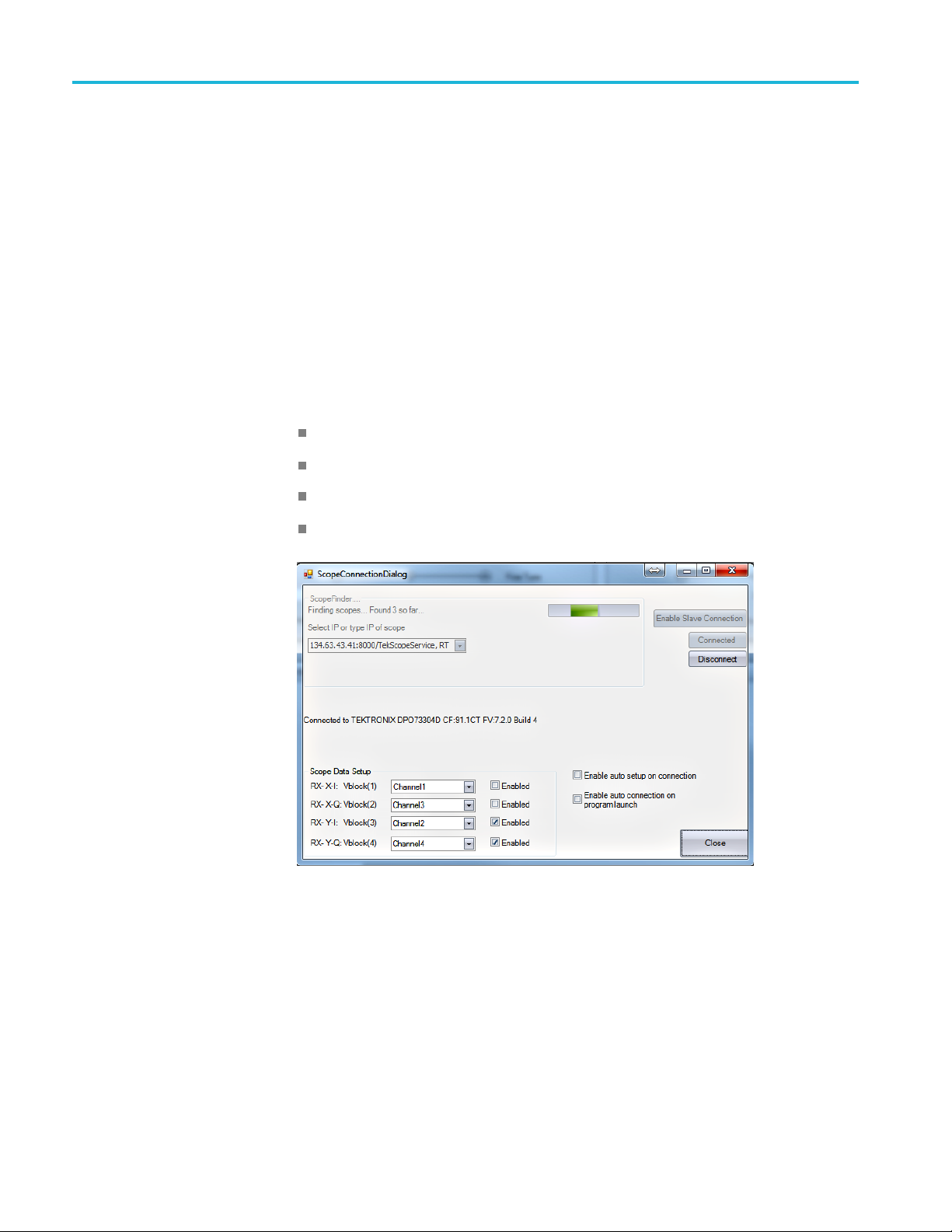

A green progres

oscilloscopes on the same subnet that are running the Scope Service Utility (SSU).

As they are found they are added to the drop-down menu. Click the IP address

field and select the IP of the oscilloscope to which to connect, then click Connect.

If the OMA Scope Connection Dialog box reports 0 Scopes Found, you will have

to manually enter the IP address. This happens when connecting over a VPN or

when network policies prevent the IP broadcast. When typing the address in

manually, do not include “, ET” or “, RT” on the end; just enter the IP address.

Click Conn

After connection, use the Scope Data Setup fields to map the oscilloscope channels

to the OM i

fields. The MATLAB variable storing the oscilloscope data is named Vblock.

Data from the selected channel is moved into the indicated Vblock variable.

Vblock(1) – X-polarization, In-Phase

Vblock

Vblock(3) – Y-polarization, In-Phase

Vblock(4) – Y-polarization, Quadrature

s bar at the top indicates that the software is searching for

ect.

nstrument receiver channels and corresponding MATLAB variable

(2) – X-polarization, Quadrature

There are two features which may be enabled on this di alog box . "Enable auto

setup on connection" means that any time you connect to an oscilloscope, the

oscilloscope will be requested to restore the state saved the last time the OUI

was closed.

"Enable auto connection on program launch" means the oscillosc ope connection

will be made automatically when the OUI software is launched. This assumes that

the oscilloscope is present at the last IP address where it was found and that the

Scope Service Utility is running on the oscilloscope. It is a good idea to use fixed

or reserved IP addresses when using any autoconnect features.

30 OM1106 Analysis Software User Manual

Page 43

Scope Setup controls

Once connected

Click Enable Slave Connection to enable selecting a second IP address. Find the

two oscillosc

the one receiving the external trigger. The Slave oscilloscope is the one triggering

on the sync board output only. (See page 167, Configuring two Tektronix 70000

series oscilloscopes.)

NOTE. The DPO/DPS70000SX series oscilloscopes behave as a single

oscilloscope when connected in the UltraSync configuration, and do not require

the second

Use VISA control (Scope Setup)

Click (select) the Use VISA box in the Scope Setup area of the Setup menu to

use TekV

series oscilloscope.

NOTE. Click Use VISA before clicking Scope Connect.

NOTE. Do not select the “Use VISA” box when connecting to Tektronix DSA8300

equivalent time (ET) sampling o scilloscope or MSO/DSO70000C/D/DX/SX series

real-time (RT) oscilloscopes.

ISA to communicate with a Tektronix MSO/DSO70000 or 70000B

and configured, close the connect dialog box.

opes and decide which one is the Master. The Master oscilloscope is

IP address.

Click the Connect button to open the VISA-specific Scope Connection Dialog box.

OM1106 Analysis Software User Manual 31

Page 44

Scope Setup controls

VISA connections

The VISA addres

from the previous session, so it should not normally need to be changed, unless

the network or the oscilloscope has changed. The VISA address string should

be TCPIP0::IPADDRESS::INSTR where IPADDRESS is replaced by the

oscilloscope IP address, for example 172.17.200.138 in the example below.

NOTE. To quickly determine the oscilloscope IP address, open a command

window (“DO

instrument IP address.

After clicking Connect, the drop down boxes are populated for channel

configuration. Choose the oscilloscope channel name which corresponds to each

receiver output and MATLAB variable name. These are:

Vblock(1) – X-polarization, In-Phase

Vblock(2) – X-polarization, Quadrature

Vblock(3) – Y-polarization, In-Phase

Vblock(4) – Y-polarization, Quadrature

llowing example disables two channels and sets the other two channels to

The fo

Channel 1 and Channel 3, since these can be active channels in 100Gs/s mode.

The disabled channels must still have some sort of valid drop-down box choice.

Do not leave the choice blank.

s of the oscilloscope contains its IP address, which is retained

S box”) on the oscilloscope and enter ipconfig/allto display the

NOTE. It is important to have the oscilloscope in single-acquisition mode (not Run

mode). If you put the oscilloscope into Run mode to make some adjustment, please

ember to click Single on the oscilloscope before connecting from the OMA.

rem

32 OM1106 Analysis Software User Manual

Page 45

Scope Setup controls

Table 1: Oscill

OMA Capabilit

Segmented re

Ability to c

oscilloscopes running the Scope Service

Scope config, Auto connect, Auto scale, and

Deskew

Software required on oscilloscope

DPO/DPS 7

Real-time oscilloscope compatibility Any real-time

lent-time oscillos cope compatibility

Equiva

oscope connectivity capabilities (TekVISA vs. Scope Service Utility)

y

adout for unlimited record size

ollect data from two networked

0000 SX series compatibility

TekVISA

Yes Yes

No Yes

No Yes

LAN server

No Yes

ix

Tektr on

oscilloscope

supported by the

er

IVI driv

No

Scope

Service U tility

(non-TekVISA

RT or ET Scope

Service U

MSO/DSO

D, DX, SX series

oscilloscopes with

firmware

later

DSA8300 with ET

Scope Service

y

Utilit

)

tility

70000C,

v6.4 or

Non-VISA oscilloscope

connections (Scope

Service Utility)

As men

tioned above, the other choice for connecting to the oscilloscope and

collecting data is through the Scope Service Utility (SSU). The SSU is a program

that runs on each oscilloscope c onnected to the OMA controller PC.

NOTE. The Scope Service Utility runs on the target oscilloscope. Be sure to

install the proper version of SSU for either real-time or equivalent-time (ET)

oscilloscopes. See installation guide.

ce the SSU is installed on the oscilloscope, start the “Socket Server” and the

On

TekScope oscilloscope application, then double-click the SSU desktop icon to

start the SSU application. Minimize the application before connecting to the

oscilloscope from OMA.

NOTE. It is best to set the oscilloscope to single-acquisition mode (not Run mode).

The Scope Service Utility takes data directly from the oscilloscope memory and

sends it over a WCF interface to the OMA.

OM1106 Analysis Software User Manual 33

Page 46

Scope Setup controls

Auto Scal

When connectin

check the box unless you require a VISA connection.

NOTE. Clicking Connect on the OMA Setup Tab opens the Scope Connection

dialog box for connecting to the SSU. (See page 29, Scope Connect button.)

Once the oscilloscope connection is configured, close the Connect dialog box.

Then use the Configure Scope, Auto Scale, and Scope & Receiver Deskew buttons

(in that order) to finish setting up oscilloscope.

e and DC Calib button

Click the Auto Scale and DC Calib button once you have connected to an

oscilloscope and have prepared your signal and Reference laser as required for

your tes

may have changed.

DC Cali

anytime the an Auto Scale is requested. To run DC Calibration without an Auto

Scale, use the button on the Calibration tab.

ting. Click Auto Scale any time the signal level from the oscilloscope

bration (measuring and removing static dc offsets) will be performed

g from the OMA, you will see a check box for VISA. Do not

Auto Scale senses the size of the signal on each oscilloscope input to determine

the proper scale and offset settings, and then sets the o scilloscope with the settings.

Scope & Receiver Deskew button

Click the Scope & Receiver Deskew button to open the tool dialog box.

34 OM1106 Analysis Software User Manual

Page 47

Scope Setup controls

The Scope & Rece

new OMA setup or one that has had any changes to the X, Y, I, or Q path lengths

or cabling. The dialog box includes instructions on how to set up for deskewing.

Select the Skew measurement range. The range should be between 25% and 50%

of the combined OMA/oscilloscope sys tem bandwidth. The default value of

10 GHz works in most cases.

The laser grid is changed for this measurement because it may be necessary to

tune continuously across grid points. If you are already using a 10 or 12.5 GHz

grid, choose that value for the grid to be used for the deskew. If you are using

a different grid, the grid is set back to its original value after the deskew is

complete

time or decreased to collect more data.

Select t

original wavelength after the deskew. Skew is a not a significant function of

wavelength, so the test wavelength can be chosen to be any convenient value

inside of the tuning range of the Signal and Reference lasers.

Set the minimum expected system bandwidth to be equal to the lesser of the OMA

and oscilloscope bandwidths. The deskew utility will report an error if no signal is

found at any frequency below this v alue. The default value works in most cases.

Once setup is complete and the readiness checks are passed, click Start Deskew

to perform the deskew process.

. A step size of 500 MHz is recommended but can be increased to save

he desired test wavelength for the deskew. The lasers are set back to their

iver Deskew dialog box facilitates the deskew process for a

The signal and reference lasers are fine tuned over the specified skew mea surement

range to measure the average phase slope and calculate the relative path delays

(skews).

When the deskew process is complete, the values in the Calibration tab "Sliders"

area are updated to those measured.

It is a good idea to save the OMA state after completing a deskew to save the

values. (see Setup: Save State)

OM1106 Analysis Software User Manual 35

Page 48

Optical Connect

Optical Conne

ct

The Optical C

dialog box, which detects and connects to all OM instruments that it detects on

the local network.

Run the Setup > Optical Connect task when you run the OMA software for the

first time, and any time that you add or remove instruments from the network.

To have OMA detect network-connected instruments:

1. Start OM

2. Click SETUP > Optical Connect to open the Device Setup dialog box.

3. Click Auto Con figure to search the network and list all detected OM

instruments. This search can take a few minutes.

If the Device Setup dialog does not list all connected instruments:

onnect button (Setup > Optical Connect) opens the Device Setup

A.

Verify that OM instruments are connectedtothecorrectnetwork