Page 1

Instruction Manual

OI2125 O/E Receiver

071-1053-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

T ektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of purchase from an authorized T ektronix distributor. If any such product proves

defective during this warranty period, T ektronix, at its option, either will repair the defective product without charge for

parts and labor, or will provide a replacement in exchange for the defective product. Batteries are excluded from this

warranty.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, shipping charges prepaid, and

with a copy of customer proof of purchase. T ektronix shall pay for the return of the product to Customer if the shipment is

to a location within the country in which the T ektronix service center is located. Customer shall be responsible for paying

all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE LISTED PRODUCTS IN LIEU OF

ANY OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix viii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Accessories 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting Signals 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Description 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Recovery Modules 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel Connections and Controls 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Rear-Panel Remote Interface 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O/E Receiver 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Recovery Modules 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Photodetector Optical Input 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Output 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Eye Pattern T est Matrix 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Recovery Module T ests 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OI2125 O/E Receiver T est Record 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Recovery Module T est Records 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Care 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exterior Cleaning 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Optical Connectors 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OI2125 O/E Receiver Instruction Manual

i

Page 6

Table of Contents

List of Figures

Figure 1: OI2125 Optical-to-Electrical Receiver 1. . . . . . . . . . . . . . . . .

Figure 2: Functional test setup 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3: Oscilloscope display of an eye pattern 7. . . . . . . . . . . . . . . . .

Figure 4: Connecting a fiber optic cable 11. . . . . . . . . . . . . . . . . . . . . . . .

Figure 5: OI2125 front panel 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6: Clock Recovery Modules for the receiver 14. . . . . . . . . . . . . . .

Figure 7: Installing a Clock Recovery Module 16. . . . . . . . . . . . . . . . . . .

Figure 8: Releasing the module with the latch 17. . . . . . . . . . . . . . . . . . .

Figure 9: OI1125 rear panel 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10: Rear Remote Interface connector pinout 19. . . . . . . . . . . . . .

Figure 11: OI2125 Output Voltage versus Input Optical Power 25. . . . .

Figure 12: O/E Receiver interconnect diagram 31. . . . . . . . . . . . . . . . . .

Figure 13: Setup for the LOS threshold test 38. . . . . . . . . . . . . . . . . . . . .

Figure 14: Setup for the bandwidth test 41. . . . . . . . . . . . . . . . . . . . . . . .

Figure 15: Proper positioning of the impulse

for optimum curve download 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 16: Setup for the eye pattern test matrix 46. . . . . . . . . . . . . . . . .

Figure 17: Measurements taken from the eye pattern 49. . . . . . . . . . . . .

Figure 18: OM1420 Clock Recovery Module test setup 51. . . . . . . . . . .

Figure 19: RMS Jitter measurement 53. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 20: Cleaning an optical connector 61. . . . . . . . . . . . . . . . . . . . . . .

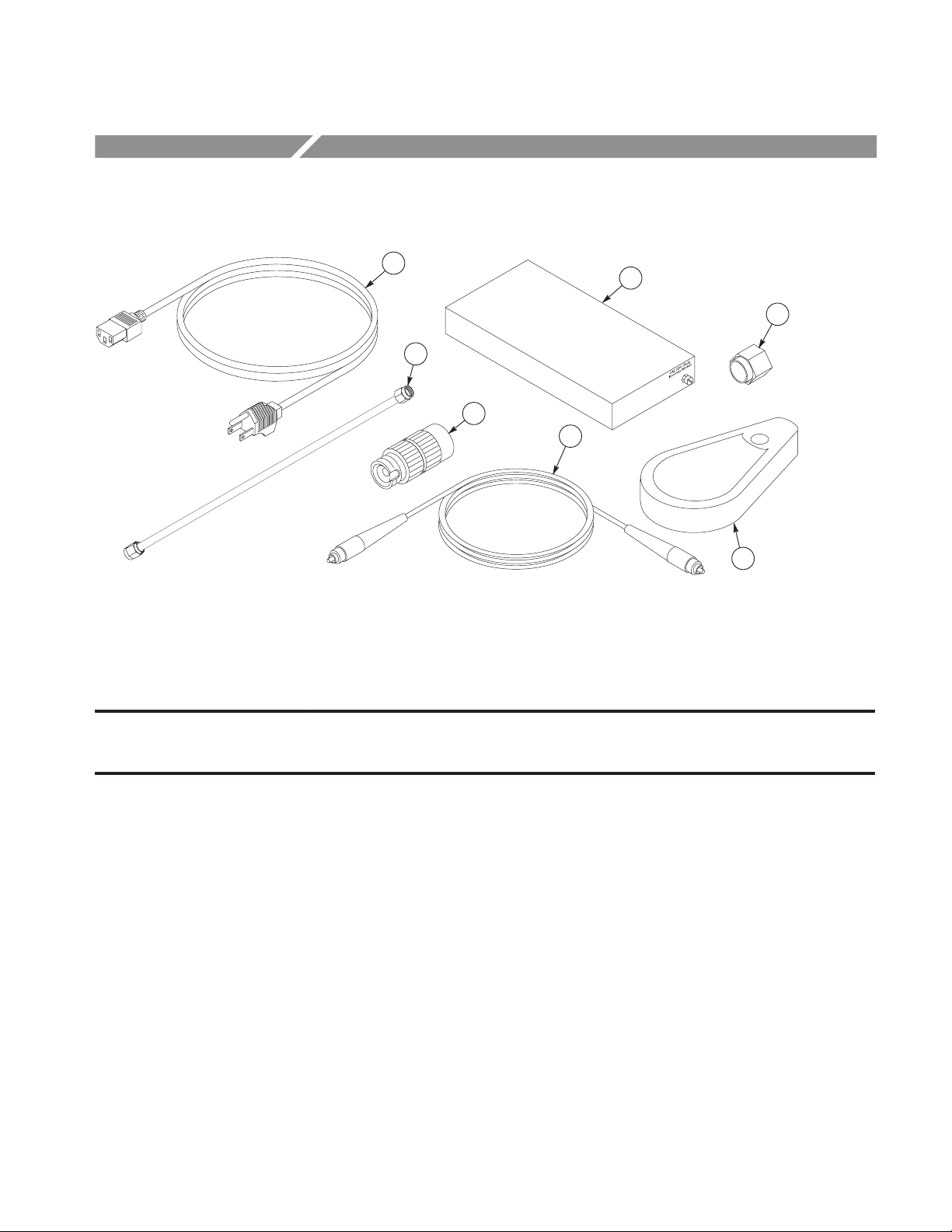

Figure 21: Standard accessories 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 22: Optional power cords 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

OI2125 O/E Receiver Instruction Manual

Page 7

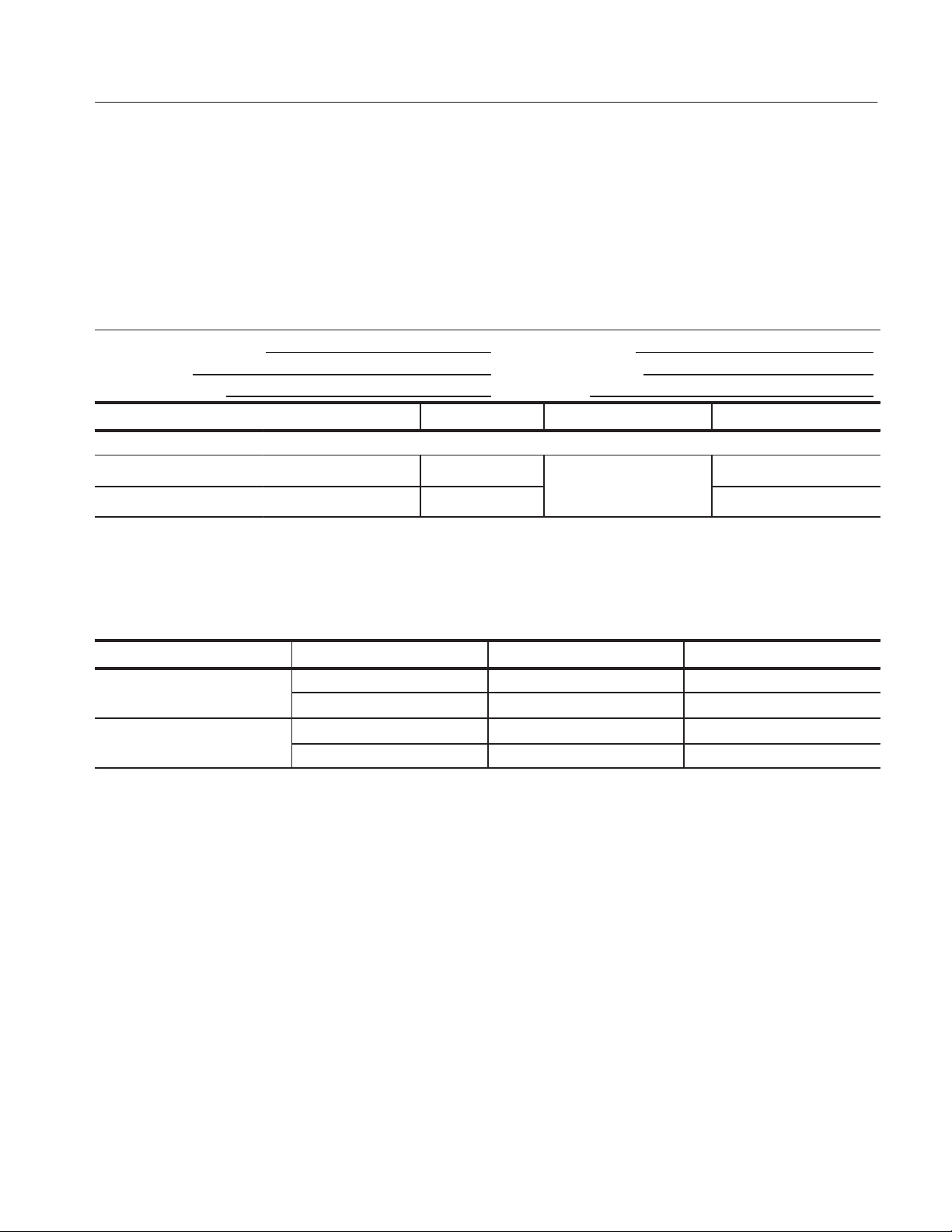

List of Tables

Table of Contents

Table 1: Power cord options 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2: Service options 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3: Receiver standard accessories 3. . . . . . . . . . . . . . . . . . . . . . . .

Table 4: Clock Recovery Module standard accessories 4. . . . . . . . . . .

Table 5: Optional accessories 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6: Remote Port signals 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7: OM1420 Module data rate select and status logic 20. . . . . . . .

Table 8: Clock recovery module type select logic 21. . . . . . . . . . . . . . . .

Table 9: OI2125 Receiver specifications 23. . . . . . . . . . . . . . . . . . . . . . . .

Table 10: OM1420 Clock Recovery Module specifications 24. . . . . . . .

Table 11: Environmental characteristics 26. . . . . . . . . . . . . . . . . . . . . . .

Table 12: Certifications and compliances 27. . . . . . . . . . . . . . . . . . . . . . .

Table 13: Safety characteristics 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 14: OI2125 Receiver PV checks 35. . . . . . . . . . . . . . . . . . . . . . . . .

Table 15: Clock Recovery Module PV checks 35. . . . . . . . . . . . . . . . . . .

Table 16: Test equipment 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 17: OI2125 Receiver test record 55. . . . . . . . . . . . . . . . . . . . . . . . .

Table 18: BERT input @2.48832 Gb/s bit rate 55. . . . . . . . . . . . . . . . . .

Table 19: BERT input @9.95328 Gb/s bit rate 55. . . . . . . . . . . . . . . . . .

Table 20: BERT input @12.50000 Gb/s bit rate 56. . . . . . . . . . . . . . . . .

Table 21: OM1420 test record 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 22: OM1420 clock output data 57. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 23: Inspection check list 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OI2125 O/E Receiver Instruction Manual

iii

Page 8

Table of Contents

iv

OI2125 O/E Receiver Instruction Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

OI2125 O/E Receiver Instruction Manual

v

Page 10

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Protective Ground

(Earth) Terminal

Avoid Exposure- Laser Radiation

is Emitted from this Aperture

vi

OI2125 O/E Receiver Instruction Manual

Page 11

Preface

This is the instruction manual for the OI2125 O/E Receiver. This manual

provides user information and performance verification procedures for the

instrument.

This manual also provides specifications and performance verification procedures for the optional Clock Recovery Modules.

OI2125 O/E Receiver Instruction Manual

vii

Page 12

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. – 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

viii

OI2125 O/E Receiver Instruction Manual

Page 13

Getting Started

The OI2125 (see Figure 1) is an optical-to-electrical receiver that converts a

modulated optical input signal to an electrical data output signal at data rates up

to 12.5 Gb/s. Using an amplified high-speed photodetector, the OI2125 O/E

Receiver operates over a wavelength range of 1100 nm to 1650 nm.

You can use the receiver in a test system to convert the optical signal from a

DUT (Device Under Test) to an electrical signal to be measured with an

oscilloscope or used as a part of a BER (Bit Error Rate) test. When you use the

receiver as part of a BER test, the BERT Pattern Generator supplies a data signal

that is converted to a modulated optical signal by an OI1125 E/O Transmitter.

The OI2125 O/E Receiver is used to convert the optical BER test pattern back to

an electrical signal for analysis by the BERT Error Analyzer.

Using the transmitter and receiver combined with a BERT, you can test the bit

error rate of optical signals in SONET/SDH and other optical transmission

systems.

Figure 1: OI2125 Optical-to-Electrical Receiver

The OI2125 O/E Receiver provides the following features:

H Supports standard SONET data rates from OC48 to OC192 and FEC data

rates up to 12.5 Gb/s.

H Optical wavelength range designed to operate in C band (1530 nm to

1565 nm), but is usable over an extended wavelength range of 1100 nm to

1650 nm.

H Optional clock recovery modules provide data rates for OC-192 and

OC-192 FEC.

OI2125 O/E Receiver Instruction Manual

1

Page 14

Getting Started

Options

The OI2125 O/E Receiver provides a slot for an optional clock recovery module.

Clock recovery modules currently available:

H The OM1420 clock recovery module provides clock recovery at one of two

selectable data rates: OC-192 (9.953280 Gb/s), and OC-192 Forward Error

Correction (10.66423 Gb/s).

The AC power input to the OI2125 O/E Receiver is supplied through a standard

IEC320 AC input connector. The internal power supply in the receiver operates

with AC power from 100 to 240 VAC at either 50 or 60 Hz. The standard power

cord supplied with the OI2125 O/E Receiver is a 120 VAC North American

power cord.

Table 1 lists the power cord options that are available for your OI2125 O/E

Receiver.

T able 1: Power cord options

Option Description

A1 European power cord (240 V, 50 Hz)

A2 UK power cord (240 V , 50 Hz)

A3 Australian power cord (240 V , 50 Hz)

A5 Swiss power cord (240 V , 50 Hz)

AC Chinese power cord

A99 No power cord

Table 2 lists the Tektronix service options. These options are modular, flexible,

and easy to order with your instrument. Designed to support tracking of

calibration to requirements of ISO9000 and to provide for extended repair

coverage, these options help fix your long-term maintenance costs and eliminate

unplanned expenditures.

T able 2: Service options

Option Description

D1 Provides the initial Test Data Report from the factory on delivery.

C3 Provides factory calibration certification on delivery, plus two more years of

calibration coverage. Throughout the coverage period, the instrument will be

calibrated according to its Recommended Calibration Interval.

D3 Provides test data on delivery plus a Test Data Report for every calibration

performed during three years of coverage (requires Option C3).

2

OI2125 O/E Receiver Instruction Manual

Page 15

Standard Accessories

Getting Started

T able 2: Service options (Cont.)

Option Description

R3 Extends product repair warranty to a total of three years.

C5 Provides factory calibration certification on delivery, plus four more years of

calibration coverage. Throughout the coverage period, the instrument will be

calibrated according to its Recommended Calibration Interval.

D5 Provides test data on delivery plus a Test Data Report for every calibration

performed during five years of coverage (requires Option C5).

R5 Extends product repair warranty to a total of five years.

Tektronix Service Options are available at the time you order your instrument.

Contact your local Tektronix Sales Office for more information.

Table 3 lists the standard accessories that come with the OI2125 O/E Receiver.

T able 3: Receiver standard accessories

Accessory Part number

US power cord 161-0066-00

Slot Cover Module (preinstalled) 119-6690-00

Low-loss SMA cable 015-0561-00

Optical cable, FC/PC-FC/PC, 2 M 174-3922-00

50 W terminator (2 ea, preinstalled) 015-1022-01

FC/PC adapter (preinstalled) 119-5115-00

Optical connector cleaning kit 006-8217-00

Instruction Manual 071-1053-XX

Certificate of Calibration –––

OI2125 O/E Receiver Instruction Manual

3

Page 16

Getting Started

The Clock Recovery Modules are orderable separately. Table 4 lists the standard

accessories that come with the modules.

T able 4: Clock Recovery Module standard accessories

Accessory Part number OM1420

Flexible SMA jumper cable 174-4699-00

n

Optional Accessories

Low-loss SMA cable 015-0561-00

50 W terminator (preinstalled) 015-1022-01

Certificate of Calibration ––––––––

Instructions 071-1055-XX

n

n (2 ea)

n

Table 5 lists the optional accessories that are recommended for the OI2125 O/E

Receiver.

T able 5: Optional accessories

Item Part number

SMA 2.5 UCI adapter 119-4517-00

DIAMOND 2.5 UCI adapter 119-4556-00

SMA UCI adapter 119-4557-00

DIAMOND 3.5 UCI adapter 119-4558-00

FC/PC adapter 119-5115-00

SC/APC adapter 119-5116-00

DIN/PC 47256 adapter 119-5887-00

ST/APC adapter 119-5888-00

FC/PC 5dB attenuator 131-7368-00

Side-By-Side Instrument Rack Adapter TVGF13

4

OI2125 O/E Receiver Instruction Manual

Page 17

Installation

Getting Started

To learn how to install, access the front panel, power on, and power off the

OI2125 O/E Receiver, do the following procedures:

Preparation

To properly install and power on the receiver, do the following steps:

1. Be sure the operating environment is within the specifications listed in

Table 11 starting on page 26.

CAUTION. To prevent damage to the receiver, provide proper ventilation. A small

fan is located on the bottom of the chassis. Do not block the cabinet ventilation

holes, or disable the fan. Do not remove the cabinet feet; the feet provide proper

clearance for ventilation.

2. Leave space for cooling. Do this by verifying that the ventilation holes on

the sides, top, and bottom of the cabinet are free of any airflow obstructions.

Leave at least 5.1 cm (2 inches) free on each side.

3. Check that you have the proper electrical connections. The OI2125 O/E

Receiver requires 100 to 240 VAC

4. Connect the proper power cord from the rear-panel power connector (see

Figure 9 on page 18) to the power system.

CAUTION. To prevent damage to your

while the receiver is powered on. Do not apply a voltage outside the Maximum

Nondestructive Input Voltage for the

handling the module and front panel electrical connectors.

"10%, 47 Hz to 63 Hz, and 40 W.

RMS

module, do not install or remove a module

module. Observe static precautions when

5. Verify that the power is off by ensuring the rear-panel rocker power switch is

in the off position.

6. Plug a clock recovery or slot cover module into the receiver: Slowly insert

the module into the slot in the front panel until it meets the connector at the

back of the module slot.

7. Firmly push the module in to seat it in the connector.

8. Once the module is seated, turn the hold-down screw clockwise to lock the

module into place.

If you are not going to use a clock recovery module, install the slot cover module

in the receiver to limit stray EMI emissions and to protect the receiver from

ambient RF noise.

Power on

Power off

OI2125 O/E Receiver Instruction Manual

To power on the receiver, push the rear-panel rocker power switch to toggle it on

(see Figure 9 on page 18).

To power off the receiver, push the rocker power switch to the off position.

5

Page 18

Getting Started

Functional Check

To perform a functional check of the OI2125 O/E Receiver, you must connect a

setup as shown in Figure 2. This setup creates an optical data source by

combining a pattern generator with an electrical-to-optical transmitter (with an

internal laser source). This optical data source is fed into the optical input of the

receiver, and the converted data output is displayed as an electrical eye pattern on

the oscilloscope. This is the method that is used in the Eye Pattern Test Matrix

on page 45 of the Performance Verification procedures.

The equipment required, besides the receiver and the optical and electrical cables

supplied as standard accessories, is listed below:

H A pattern generator capable of producing data rates from 2.48 Gb/s to

12.50 Gb/s, with output levels at about 1.0 V

p-p

.

H An electrical-to-optical transmitter capable of providing single-mode optical

signals in the 1550 nm band at data rates up to 12.50 Gb/s.

H A 50 W SMA cable to connect the pattern generator divided-clock output as

an oscilloscope trigger signal.

Pattern generator

Clock

/32

Data

OI1125

Laser out

Low-loss SMA cable

Figure 2: Functional test setup

H A 50 W low-loss SMA cable to connect the receiver output to the oscillo-

scope input.

H A 5 dB optical attenuator to limit the input power to the receiver to less than

0 dBm.

CSA8000/TDS8000 w/80E01

PMF fiber

Modulator

Data in

Modulator

out

Laser in

Single mode fiber

Optical in

(FC/PC)

OI2125

Data out

5 dB Optical

attenuator

Low loss SMA cable

Trigger

Direct In

SMA cable

Follow the Displaying an Eye Pattern procedure on the next page to do a

functional check of the OI2125 O/E Receiver. If you are unfamiliar with making

fiber optic connections, refer to Connecting Signals on page 9.

6

OI2125 O/E Receiver Instruction Manual

Page 19

Getting Started

Displaying an Eye Pattern

To display an eye pattern, do the following:

1. Connect the test setup as shown in Figure 2, and power on the equipment.

2. Set the BERT bit rate to 9.953280 Gb/s.

3. Set the pattern to PRBS-31.

4. Disable the adjustable duty cycle.

5. Set the mark ratio to 1/2.

6. Set the trigger to 1/32 clock.

7. Set the output mode to AC.

8. Turn the data output on and set the data amplitude to 1.0 V

p–p

.

9. Enable the transmitter laser by turning the keyswitch clockwise (to the

unlocked position). The Laser On LED and Laser Output Active LED light.

10. On the oscilloscope, press Autoset and then adjust the horizontal scale to

display an eye pattern (see Figure 3).

The oscilloscope displays an eye pattern as shown in Figure 3. This indicates

that the receiver is functioning correctly—it is converting the modulated input

optical signal to an electrical eye pattern that represents the data stream from the

BERT.

Figure 3: Oscilloscope display of an eye pattern

OI2125 O/E Receiver Instruction Manual

7

Page 20

Getting Started

8

OI2125 O/E Receiver Instruction Manual

Page 21

Operating Basics

Handling

This section describes the connectors and controls on the front and rear panels of

the OI2125 O/E Receiver. Figures 5 and 9 illustrate the front and rear panels of

the instrument.

Handle the OI2125 O/E Receiver carefully at all times. The instrument contains

sensitive optical and electrical components that can be damaged by physical

shocks.

WARNING. To prevent eye injury, do not look directly into any optical output

port. Laser light can be harmful to your eyes. Optical signals in the wavelength

range used by the OI2125 O/E Receiver are in the infrared band and are

invisible to the human eye.

CAUTION.To protect the module and instrument inputs, always use a wrist strap

when handling the module and when making electrical signal connections.

Always replace the terminators on the receiver and module when not in use.

Connecting Signals

Electrical Connectors

Optical Connector

The OI2125 O/E Receiver has two types of connectors for inputs and outputs.

The OI2125 O/E Receiver electrical outputs use high-performance SMA

connectors. Never attach a cable if the cable has a worn or damaged connector

because this may damage the OI2125 connector.

Use extra care when attaching or removing a cable from the connectors. Turn

only the nut, not the cable. Use light finger pressure to make this initial

connection. Then tighten the nut lightly with a wrench.

For best repeatability and to prolong the life of both cable and instrument

connectors, use a torque wrench and tighten the connection to the range of 79 to

112 N-cm (7 to 10 lb-in).

If the connectors will receive heavy use, such as in a production environment,

you should install connector-saver adapters on the OI2125 O/E Receiver to make

connections to the device under test.

The optical input connector of the OI2125 O/E Receiver is a Universal-Style

physical contact (PC) type that can couple to optical fibers with a core diameter

of up to 9 mm. An FC/PC adapter is supplied as a standard accessory for use with

the Universal-Style input connector. Alternative optical connector types can be

OI2125 O/E Receiver Instruction Manual

9

Page 22

Operating Basics

coupled by using the optional accessory adapters. (Refer to Optional Accessories

on page 4.)

If you connect fiber cores larger than 9 mm, the receiver may still couple light,

but the mismatch in core diameter will result in significant optical attenuation.

To attach a fiber optic cable with an FC/PC connector to the FC/PC input

receptacle, refer to Figure 4 on page 11 and do the following:

1. Remove the dust cover from the optical receptacle.

CAUTION. Use care when making optical connections. If you are not using an

optical connection, either on the receiver, cable or associated optical equipment,

always leave the protective dust cover on the connector. The glass surface of the

fiber optic core is easily contaminated by airborne dust particles.

Treat all optical connectors as you would a camera lens or other precision

optical equipment.

2. Clean the connector on the fiber optic cable using the procedure on page 60.

3. Carefully align the keyway on the receptacle with the key on the connector.

4. Tighten the nut lightly with finger pressure only. If you overtighten an

optical connector, you may get inconsistent optical signal performance.

10

OI2125 O/E Receiver Instruction Manual

Page 23

Keyway

Key

Operating Basics

Tighten

FC/PC

Receptacle

FC/PC

connector

Fiber optic cable with

FC/PC connector

Figure 4: Connecting a fiber optic cable

OI2125 O/E Receiver Instruction Manual

11

Page 24

Operating Basics

Front Panel Description

The front panel is functionally divided into two sections: the O/E receiver

section and the clock recovery module port. Use Figure 5 and the following

descriptions to help you connect and operate the receiver.

Input detected on

LED

Optical

input

Power

on

LED

Figure 5: OI2125 front panel

O/E Receiver

Data out (2)

Remote

enable

switch

Remote

enabled

LED

Clock Recovery

Module

The O/E receiver section is described here.

OPTICAL INPUT. The optical input port is designed to accept modulated optical

signals over a range of digital data rates and optical wavelengths. The port has a

single-mode fiber, universal optical input connector. To preserve the optical

integrity of the connector, keep the dust cover on the connector when not in use.

12

POWER ON. This green LED illuminates when the receiver is powered on.

INPUT DETECTED ON. This green LED illuminates when the optical input signal

on the input connector is above the optical power threshold of the internal

photodetector.

REMOTE ENABLE. This switch toggles the remote mode of the receiver (and the

LED indicator) on and off when the switch is pressed. All front-panel controls

and status indicators, including Clock Recovery Module functions are accessible

through the Remote Interface when in remote mode.

OI2125 O/E Receiver Instruction Manual

Page 25

Operating Basics

Remote Enabled. When power is first applied to the receiver, this green LED is

off, unless the remote interface Front Panel Unlock signal is low (active). If the

Front Panel Unlock signal is low, the LED is on, and will flash briefly when the

Remote Enable switch is pressed.

When the Front Panel Unlock signal is high at power-on, pressing the Remote

Enable switch toggles the LED on, indicating that the receiver is in remote

mode. Pressing the switch again returns the receiver to local (front panel) mode,

and the LED extinguishes.

DATA OUT (2). Two electrical data out connectors output the converted electrical

data signal. One of the outputs provides a signal to the Clock Recovery Module

Data input port, and the other output is available for measuring the quality of the

input optical signal with an oscilloscope or BERT. Generally, the Attenuated

Data Out signal from the receiver is connected to the Data In connector on the

Clock Recovery Module to keep from exceeding the maximum input voltage of

the module.

Clock Recovery

Module Port

The receiver has a front panel slot that accepts optional clock recovery modules.

A connector at the rear of the slot provides power and a control interface for the

modules. A slot cover module is a standard accessory for the receiver that should

remain installed in the receiver until a clock module is needed, to limit RF noise

and stray EMI emissions.

OI2125 O/E Receiver Instruction Manual

13

Page 26

Operating Basics

Clock Recovery Modules

Clock Recovery Modules are available for the OI2125 O/E Receiver:

H The OM1420 clock recovery module provides clock recovery at one of two

The slot cover module is a standard accessory that plugs into the receiver module

slot when a clock recovery module is not used. See Figure 6.

selectable rates–OC-192 data rate (9.95328 Gb/s), and an OC-192 Forward

Error Correction data rate (10.66423 Gb/s).

Clock Recovery

Module Features

Data in Clock out

Data rate

indicator LEDs

Select rate

pushbutton

Hold-down screw

Figure 6: Clock Recovery Modules for the receiver

The Clock Recovery Module features are described as follows:

DATA IN. This SMA connector accepts electrical input from either the OI2125

O/E Receiver Attenuated Data Out port or from an external signal source. Use

the short SMA cable included with the module to connect to the receiver

Attenuated Data Out connector.

14

CLOCK OUT. The recovered clock from the input signal is output on this SMA

connector.

SELECT RATE. A pushbutton switch selects between the data rates available in

the module. When you repeatedly push this momentary pushbutton switch, the

clock recovery module cycles through the data rates available in the module.

OI2125 O/E Receiver Instruction Manual

Page 27

Operating Basics

Data Rate Indicators. LEDs located to the left of the Data Rate Select switch

indicate which data rate is selected.

Hold-Down Screw. The hold-down screw locks the module into place once the

module is seated.

OI2125 O/E Receiver Instruction Manual

15

Page 28

Operating Basics

Installing a Clock

Recovery Module

The OI2125 O/E Receiver will operate without a clock recovery module.

However, if you do not need clock recovery in your application, you should

install the slot cover module in the receiver to limit stray EMI emissions and to

protect the receiver from ambient RF noise.

CAUTION. To prevent damage to your

module, do not install or remove the

module while the receiver is powered on. Do not apply a voltage outside the

Maximum Nondestructive Input Voltage for the

module. Observe static precau-

tions when handling the module and front panel electrical connectors.

To install a module, refer to Figure 7 and do the following:

1. Power off the receiver.

2. Slowly insert the module into the slot in the front panel until it meets the

connector at the back of the module slot.

When the module contacts the connector in the back of the module slot, the

front of the module is about an eighth-inch away from being flush with the

front panel of the receiver.

3. Firmly push the module into the receiver to seat it in the connector.

4. Once the module is seated, turn the hold-down screw clockwise to lock the

module into place.

5. Attach the short SMA cable from the attenuated data output of the receiver to

the input of the module. This step is not necessary when using the module as

a standalone instrument or when installing a slot cover module.

Insert the module

After module is seated,

tighten the hold-down

screw.

16

Figure 7: Installing a Clock Recovery Module

OI2125 O/E Receiver Instruction Manual

Page 29

Operating Basics

Removing a Clock

Recovery Module

Releasing the latch

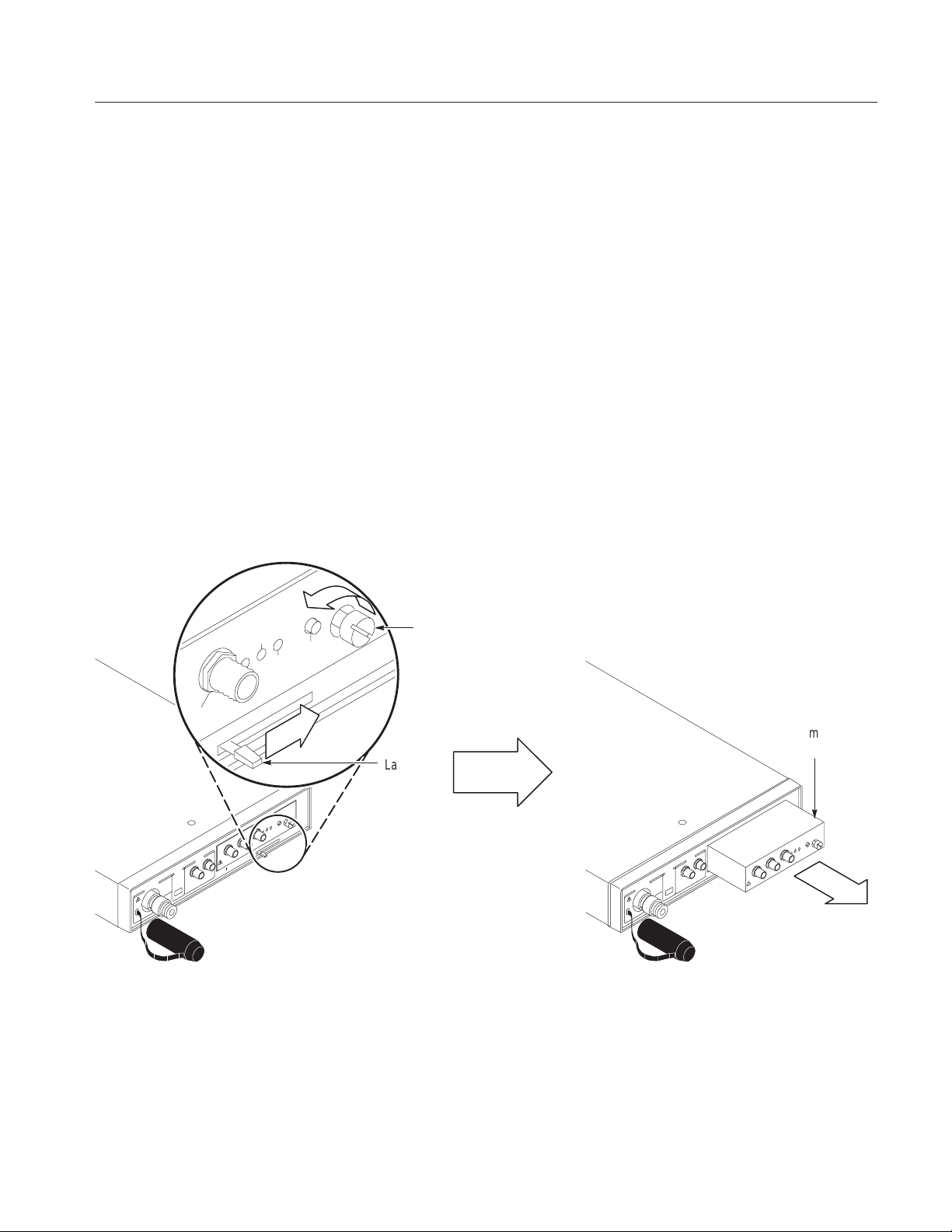

To remove a module, refer to Figure 8 and do the following:

1. Power off the receiver.

2. Remove any external cables from the the input of the module. This step is

not necessary when removing a slot cover module.

3. Remove the short SMA cable from the output of the receiver and the input of

the module, if necessary.

4. Turn the hold-down screw counterclockwise to unlock the module.

5. Move the latch to the right to release the module from the connector.

6. Pull the module out of the receiver, and store it in a safe location.

7. If you are not going to use another clock recovery module, install the slot

cover module in the receiver to limit stray EMI emissions and to protect the

receiver from ambient RF noise.

Figure 8: Releasing the module with the latch

Hold-down

screw

Removing the CR module

Remove

module

Latch

OI2125 O/E Receiver Instruction Manual

17

Page 30

Operating Basics

Rear Panel Connections and Controls

There are two connectors on the rear panel of the OI2125: Remote Interface and

AC Power In. Use Figure 9 and the following descriptions to connect the

transmitter to your system.

R

Figure 9: OI1125 rear panel

Remote Interface

Power In

On/Off Switch

The remote interface allows for remote control of the instrument. See Using the

Rear-Panel Remote Interface on page 19 for details.

Plug the power cord into this connector. The connector accepts 90–240 VAC,

50–60 Hz, using any of the power cords available for the receiver. The connector

contains an integral AC power line filter.

The on/off switch connects the line voltage from the power in connector to the

power supply in the instrument.

18

OI2125 O/E Receiver Instruction Manual

Page 31

Using the Rear-Panel Remote Interface

This section describes using the rear-panel remote interface to select the

transmitted signal.

Operating Basics

Controlling Operation

Remotely

Remote Interface

Input Optical Power

When the REMOTE pushbutton switch on the front panel is in the disabled

mode, the Enable LED is not illuminated, and you can select the optional clock

recovery module data rate from the front-panel controls.

When the REMOTE pushbutton switch on the front panel is in the enabled

mode, the Enable LED is illuminated, and you select the optional clock recovery

module data rate through the rear-panel remote interface. Refer to Figure 10 and

Table 6 on page 20 for the connector pinout and signal descriptions.

In remote mode when no TTL signal is applied at the rear-panel connector, the

default state of all remote control inputs is high due to internal pull-up resistors.

The remote interface is implemented with a 25-pin, male D connector on the rear

panel. Figure 10 illustrates the pinout. The remote interface provides access to all

of the front-panel control features using a TTL control interface. The remote

interface also allows access to some status indicators and control features not

available from the front panel.

Mod ID3

Opt In Detect

GND

GND

GND

Mod ID1

Clk_Rate1

GND

Rate_Sel1

Not used

Not used

GND

GND

Not used

GND

Mod-Sig

Mod ID4

Mod ID2

Figure 10: Rear Remote Interface connector pinout

Table 6 lists the signal descriptions for the Remote Interface connector. Unless

otherwise noted, the signals are active in both local and remote operating modes.

OI2125 O/E Receiver Instruction Manual

13

25

1

14

GND

Front Panel Unlock

Not used

Rate_Sel2

Not used

Clk_Rate2

19

Page 32

Operating Basics

T able 6: Remote Port signals

Pin

number

4 Rate_Sel1 Digital

17 Rate_Sel2 Digital

19 Clk_Rate2 Digital

6 Clk_Rate1 Digital

22 Mod_Sig Digital

15 Front Panel

9 Optical Input

11 Input Optical

7 Mod ID1 Digital

20 Mod ID2 Digital

8 Mod ID3 Digital

21 Mod ID4 Digital

Several Not used 2, 3, 16, 18, 24

Several Ground Analog,

Signal

name

Unlock

Detect

Power

Signal

type

input

input

output

output

output

Digital

input

Digital

output

Analog

output

output

output

output

output

digital

Description

These inputs work together to select up to four different clock recovery rates.

See Table 7 for the OM1420 clock rates.

These inputs are only active in remote mode.

These status signals work together to communicate up to four different clock recovery rates to

the remote port. See Table 7 for the OM1420 clock rates.

These inputs are active in either local or remote mode.

This output is not used by the OM1420 module.

When driven low, this input locks out access to the front-panel local mode control. Default mode

is unlocked when the instrument is powered on .

This output is driven high when the photodetector senses a valid threshold power level.

This pin outputs an analog voltage that corresponds to the optical power incident on the

photodetector.

Mod_ID1 to ID4 digital outputs form a four-bit binary code used to identify the clock recovery

modules. See Table 8 for the identification codes.

1, 5, 10, 12, 14, 23, 25

Table 7 shows the data rate select inputs and status outputs for the OM1420

module.

T able 7: OM1420 Module data rate select and status logic

Data Rate Rate_Sel2 Rate_Sel1 Clk_Rate2 Clk_Rate1

Data rate select (digital inputs) Data rate status (digital outputs)

OC-192 X 0 0 0

OC-192 FEC X 1 1 1

20

OI2125 O/E Receiver Instruction Manual

Page 33

Table 8 shows the four-bit identification codes on the Mod_ID outputs, used to

identify what type of clock recovery module is in the receiver.

T able 8: Clock recovery module type select logic

Data Rate Mod ID1 Mod ID2 Mod ID3 Mod ID4

Operating Basics

OC-192/OC-192 FEC

(OM 1420)

0 0 0 0

OI2125 O/E Receiver Instruction Manual

21

Page 34

Operating Basics

22

OI2125 O/E Receiver Instruction Manual

Page 35

Specifications

This section contains the specifications of the OI2125 O/E Receiver. All

specifications are guaranteed unless noted as “typical”. Typical specifications are

provided for your convenience but are not guaranteed. Specifications marked

with the n symbol have corresponding checks in the Performance Verification

section on page 35.

T able 9: OI2125 Receiver specifications

Specification Description

Photodetector Optical Input

Wavelength 1530 nm to 1565 nm (verified range), 1100nm to 1650nm (extended range)

n

Input Power – Operating –16dBm to 0dBm; 0dBm (1mW) maximum

n

Loss of Signal Threshold –25 dBm to "2 dBm

n

Input Return Loss u28 dB

Input Connector Single mode fiber (9/125 mm) Universal/PC with protective boot

Data Output

Data Rate 2.488Gb/s to 12.50 Gb/s (verified range), 622 Mb/s (extended range)

n

Jitter Transfer t1.5 ps

n

Eye Crossing % 50% "5%

n

Mask Testing No mask hits with 5% mask margin for OC-48, OC-192, and scaled 12.50 Gb/s SONET

n

masks, with 0 dBm to –8 dBm input power

BER Testing BER t10

BER t10

Data Output Voltage 0.5V

n

0.2 V

Attenuated Data Output Voltage 6 dB attenuation of the Data Output Voltage

Optical Power Bandwidth 50MHz to 7.5 GHz

Output Impedance 50 W AC coupled

Output Return Loss (Data Out) u12 dB, 50 MHz to 5 GHz; u5 dB, 5 GHz to 12 GHz

(Attenuated Data Out) u14 dB, 50 MHz to 2.5 GHz; u10 dB, 2.5 GHz to 20 GHz

, 2.488 Gb/s to 12.50 Gb/s

RMS

–12

for data rates up to OC-192

–10

for data rates above OC-192

p-p

p-p

- 1.5 V

- 1.5 V

, input power –8 dBm to 0 dBm

p-p

, input power –16 dBm to –8 dBm (See Figure 11 on page 25.)

p-p

Remote Port Interface Connector

TTL remote control logic control

voltage levels

Optical input power monitor

output voltage level (analog)

Input HIGH voltage (VIH): 2.0 V minimum

Input LOW voltage (V

Output HIGH voltage (VIH): 2.4 V minimum

Output LOW voltage (V

Voltages are relative to GND on the 25-pin remote connector

Optical conversion gain is 1 V/mW "20%

OI2125 O/E Receiver Instruction Manual

): 0.8 V maximum

IL

): 0.5 V maximum

IL

23

Page 36

Specifications

T able 9: OI2125 Receiver specifications (Cont.)

Specification Description

Remote Port ESD Protection Each pin on the DB25 connector is protected with a 100 W series resistor followed by

protection diodes tied to ground and +5 V

Power Supply

External AC levels 100 V to 240 V "10%, 50 to 60 Hz, t40 W ; CAT II

T able 10: OM1420 Clock Recovery Module specifications

Specification Description

Clock Recovery Rate 9.953280Gb/s in OC-192 mode

n

10.66423Gb/s in OC-192-FEC mode

Input Voltage – Operating 0.15V

n

Output Voltage 1.0 V to 2.5 V

n

Jitter Generation – Clock t2.0 ps

n

Input Voltage – Maximum 0.75V

Input Return Loss u10 dB, 100 MHz to 10 GHz

Output Return Loss u8 dB @ OC-192 and OC-192 FEC clock frequencies

Clock Recovery Data Rate Range Clock Out voltage u0.5 V

Clock Out voltage u0.5 V

Input Connector SMA connector, 50 W, AC coupled

Output Connector SMA connector, 50 W, AC coupled

to 0.75 V

p-p

RMS

p-p

p-p

, AC coupled

p-p

from 9.943 Gb/s to 9.963 Gb/s (OC-192)

p-p

from 10.654 Gb/s to 10.674 Gb/s (OC-192-FEC)

p-p

24

OI2125 O/E Receiver Instruction Manual

Page 37

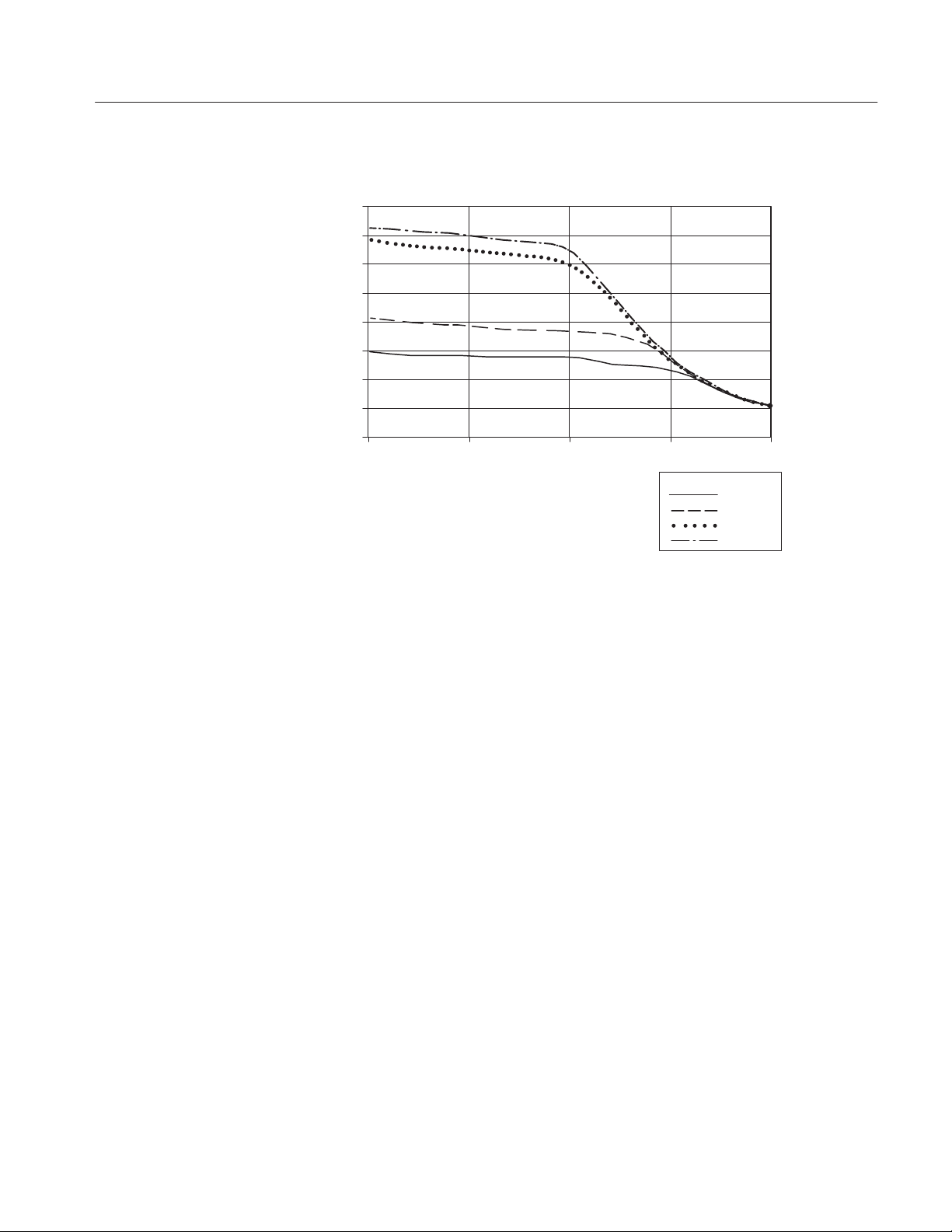

Voltage vs. Optical Power

1.6

1.4

1.2

1

0.8

0.6

Voltage (V)

0.4

0.2

0

0 –5 –10 –15 –20

Optical Power (dBm)

Key

Specifications

OC12

OC48

OC192

12.5Gb/s

Figure 11: OI2125 Output Voltage versus Input Optical Power

OI2125 O/E Receiver Instruction Manual

25

Page 38

Specifications

T able 11: Environmental characteristics

Specification Description

Temperature, nonoperating (–55 _C to +75 _C)

The environmental exposure is the procedure stated in Tektronix Design Standard

062-2847-00 for Class 6 equipment.

T emperature, operating 0 _C to +40 _C (32 to 104 _F)

This procedure conforms to the temperature portion of the test in MIL-T-28800E for

Type III, Class 6 equipment, using the limits above.

Humidity , nonoperating 0% to 75% relative humidity from +30_C to +60_C.

Humidity , operating 0% to 80% relative humidity to +31 _C, decreasing at a linear rate to 50% at +40 _C,

minimum.

Random vibration, nonoperating 2.46 g

Tektronix Standard 062-2858-00 rev . B modified, Random V ibration, Tektronix Class 3

with power spectral density break-points as follows:

, from 5 to 500 Hz, 10 minutes each axis.

RMS

Constant 0.020 g2/Hz from 5 Hz to 100 Hz, then falls at –3 dB/octave from 100 to

2

200 Hz, then constant 0.010 g

350 to 500 Hz to 0.007 g

Random vibration, operating 0.31 g

, from 5 to 500 Hz, 10 minutes each axis.

RMS

/Hz from 200 to 350 Hz, then falls at –3 dB/octave from

2

/Hz @ 500 Hz.

Tektronix Standard 062-2858-00 rev. B, Random Vibration, Tektronix Class 3

Packaged product vibration and shock The packaged product qualifies under the Distribution Cycle 1 Assurance Level II for

packaged products 0 to 20 lbs. Test 2 for Warehouse and Vehicle Stacking (compression)

is omitted.

Tektronix standard 062-2858-00, Rev. B.

Altitude, operating and nonoperating Operating: 3000 m (10,000 ft)

Nonoperating: 12200 m (40,000 ft)

MIL-T-2880E modified for more exposure time and more severe test levels than required

for any Type III equipment regardless of Class.

Weight instrument

1.72 kg (3.79 lb)

only

shipping

5.22 kg (11.5 lb), including standard accessories

Dimensions 45 mm x 204 mm x 331 mm (1.75 in x 8.0 in x 13 in) (H x W x D)

1

The humidity limits are derived from a psychrometric chart using a maximum wet bulb temperature of 29 _C. The highest

RH (20%) at the maximum temperature (+60 _C) diverges from the psychrometric chart (which would indicate 6%). The

20% number is a practical limit. Test chambers cannot be set below this number.

26

OI2125 O/E Receiver Instruction Manual

Page 39

T able 12: Certifications and compliances

Category Standards or description

Specifications

EC Declaration of

Conformity—EMC

Australia / New Zealand Complies with EMC provision of Radiocommunications Act per the following standard(s):

Declaration of Conformity—EMC

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits.

1

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test object.

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 61326 EMC requirements for Class A electrical equipment for

measurement, control and laboratory use.

IEC 61000–4–2 Electrostatic discharge immunity (Performance criterion B)

IEC 61000–4–3 RF electromagnetic field immunity (Performance criterion A)

IEC 61000–4–4 Electrical fast transient / burst immunity (Performance criterion B)

IEC 61000–4–5 Power line surge immunity (Performance criterion B)

IEC 61000–4–6 Conducted RF immunity (Performance criterion A)

IEC 61000–4–11 Voltage dips and interruptions immunity (Performance criterion B)

EN 61000–3–2 AC power line harmonic emissions

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

1

T able 13: Safety characteristics

Specification Description

Safety certifications UL31 11-1, CAN/CSA-C22.2 No. 1010.1

EC Declaration of Conformity –

Low Voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1/A2:1995 Safety requirements for electrical equipment for measurement control and

laboratory use.

OI2125 O/E Receiver Instruction Manual

27

Page 40

Specifications

28

OI2125 O/E Receiver Instruction Manual

Page 41

WARNING

The following servicing instructions are for use only by qualified personnel. To

avoid injury, do not perform any servicing other than that stated in the operating

instructions unless you are qualified to do so. Refer to all safety summaries before

performing any service.

Page 42

Page 43

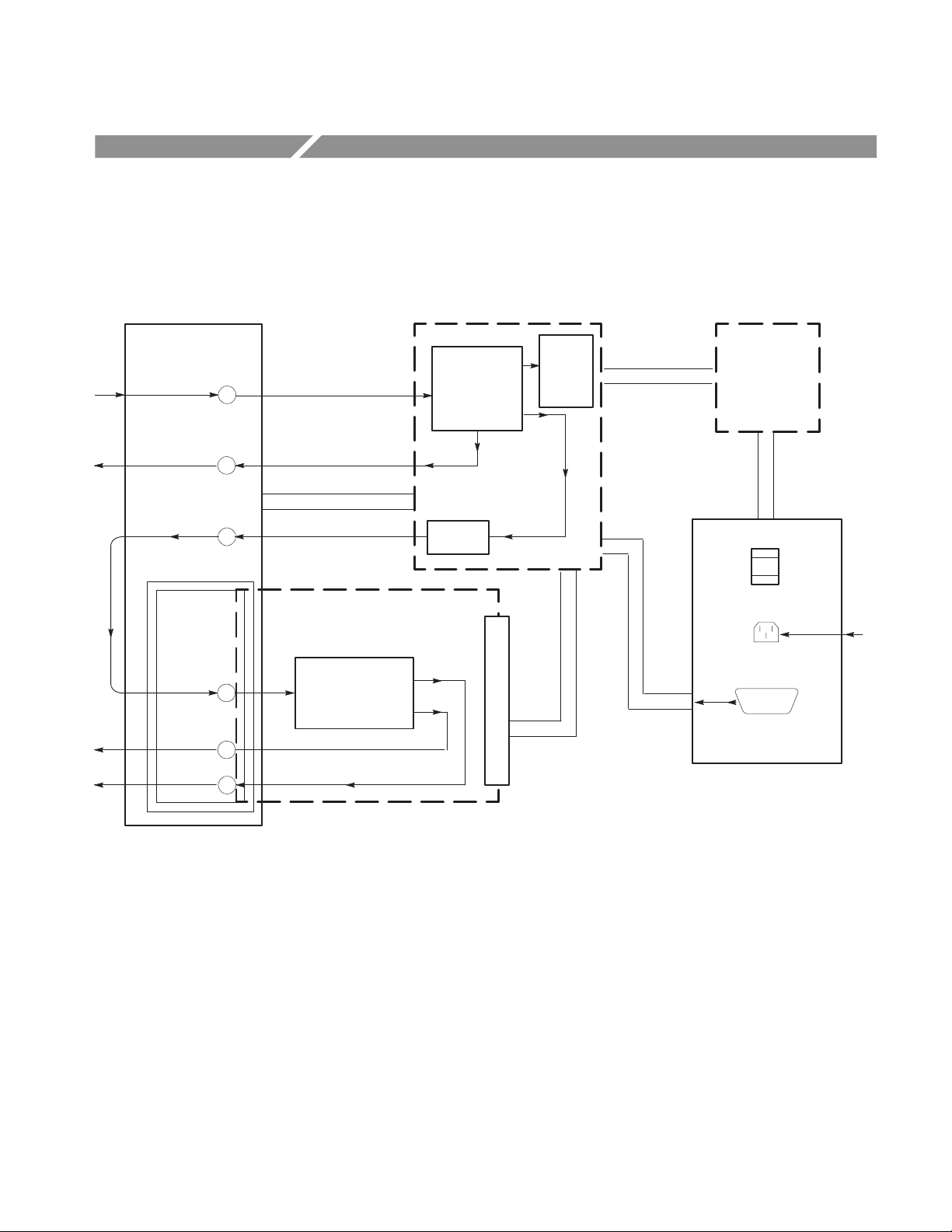

Theory of Operation

This section describes the electrical and optical circuit operation of the receiver

at the block diagram level. Refer to Figure 12 as you read the circuit description.

Front Panel

Optical Data in

Electrical

Data Out

Attenuated

Electrical

Data Out

Module

Front Panel

Electrical

Data In

Retimed

Data Out

Clock Out

F.P. Standard/Control Cable

Clock Recovery Module

Clock Recovery

O/E Rx Board

Photo

Detector

6 dB

attenuator

Optical

Input

Power

Monitor

Power Communication Cable

Module Interconnect

Power Cable

Control Cable

Power Supply

AC Line

On/Off Switch

AC Line In

Remote Interface

Rear Panel

Figure 12: O/E Receiver interconnect diagram

OI2125 O/E Receiver Instruction Manual

31

Page 44

Theory of Operation

O/E Receiver

The OI2125 O/E Receiver is made up of four interconnected assemblies: the

front and rear panels, the receiver board, and the DC power supply.

Front Panel

Rear Panel

The front panel of the receiver is divided into two sections: the receiver and the

clock recovery module slot.

Receiver. The receiver uses a single-mode fiber, universal FC/PC optical input

connector to couple external optical signals to the receiver board. An Input

Threshold Detected LED is driven by the internal optical power monitor. The

converted electrical data is output from the receiver board to the front panel via

two SMA connectors.

The SMA connector (Attenuated Data Out) closest to the clock recovery module

slot is intended for coupling the signal to one of the optional clock recovery

modules available for the OI2125 O/E Receiver. The output from the other SMA

connector (Data Out) can be used to monitor the quality of the converted

electrical data.

Clock Recovery Module Slot. The clock recovery module slot accepts optional

clock modules and provides DC power through a 32-pin connector at the rear of

the slot. A short SMA cable (standard module accessory) couples the converted

electrical data from the receiver to the module. SMA connectors on the clock

module provide a data input, a recovered clock output, and for some modules, a

retimed data output.

The rear panel of the receiver has three components—the AC line cord connector, the power on/off switch, and the remote interface connector. When any of the

international power cords available for the receiver are connected to the AC

connector, the power is passed through to the power on/off switch. When the

switch is turned on, the AC line is connected to the power supply input.

32

Receiver Board

The remote interface is a 25-pin D-connector that provides direct control of the

receiver board and the clock recovery module. Remote mode can be enabled

from either a front panel toggle switch or by pulling the front-panel unlock pin

(pin #15) low, which enables the other pins of the connector to pass through

TTL-level logic signals to control the receiver.

External optical signals that are applied to the front panel are directly coupled to

a high-speed, InGaAs photodiode module on the receiver board. The photodiode

converts the optical energy into electrical current, which is then converted into a

voltage by a fixed-gain transimpedance amplifier (TIA). The photodiode is

biased by a current source on the receiver circuit board. Monitoring the

photodetector bias current allows the average optical power to be detected and

output as an analog signal to the remote port connector.

OI2125 O/E Receiver Instruction Manual

Page 45

Theory of Operation

The output of the TIA is fed into an automatic gain control (AGC) amplifier,

which is part of the photodiode module. Gain control for the amplifier is

provided by feedback from a peak detector that monitors the optical signal in the

photodiode module. The AGC amplifier adjusts the gain of the photodetector

module to provide a uniform output swing over some range of input optical

power. See Figure 11 on page 25 for the typical AGC amplifier response to

varying data rate and input optical power.

The photodetector module output is AC-coupled to two 50 W connectors. One

output is brought directly out to the front-panel SMA connector (data output).

The other output (attenuated data output) passes through a 6 dB attenuator. This

is the data output that is used for the optional clock modules. The data output is

attenuated to ensure that the input limit on the modules is not exceeded.

DC Power Supply

The AC line voltage from the rear panel is fed to the power supply input,

through the rear-panel power switch. The DC power supply is a switching supply

that converts the line voltage (90 – 240 VAC) to +15 V, –15 V, and +5 V.

A six-conductor cable connects the power supply output to the receiver board.

Clock Recovery Modules

The clock recovery modules for the receiver are described below:

OM1420

The clock recovery of the dual-rate OM1420 module is done with a resonant

filter technique, which provides both low jitter and narrow bandwidth. The two

data rates selectable with the OM1420 are OC-192 (9.953280 Gb/s) and

OC-192 FEC (10.66423 Gb/s). The output amplifier of the clock recovery

module provides a large output voltage signal.

OI2125 O/E Receiver Instruction Manual

33

Page 46

Theory of Operation

34

OI2125 O/E Receiver Instruction Manual

Page 47

Performance Verification

Use the following procedures to verify the warranted specifications of the

OI2125 O/E Receiver. Before starting these procedures, photocopy the test

record beginning on page 55 to record the performance test results.

The recommended calibration interval is one year.

If you are doing a Performance Verification on a Clock Recovery Module,

photocopy the appropriate test record to record the performance test results.

Clock Recovery Module test records begin on page 57.

These procedures test the following specifications:

T able 14: OI2125 Receiver PV checks

Circuit Specification

Photodetector Optical Input Loss of Signal Threshold

Data Output Bandwidth

Eye Pattern Test Matrix

Photodetector Optical Input Input Wavelength

Data Output Data Output Voltage

Input Power

Data Rate

% Crossing

Mask Hits

T able 15: Clock Recovery Module PV checks

Circuit Specification

Input Clock Recovery Rates

Output Output Voltage

OI2125 O/E Receiver Instruction Manual

Input Voltage

Jitter Generation

35

Page 48

Performance Verification

Prerequisites

Equipment Required

The tests in this section comprise an extensive, valid confirmation of performance and functionality when the following requirements are met:

H The instrument must have been last calibrated/adjusted at an ambient

temperature between +20 _C and +30 _C, must have been operating for a

warm-up period of at least 30 minutes, and must be operating in an

environment with temperature, altitude, humidity, and vibration within the

operating limits described in Environmental Characteristics on page 26.

H All test equipment listed in Table 16 must be operating for a warm-up period

of at least 30 minutes.

Table 16 lists the equipment required to perform the performance verification

procedure. The types and quantities of connectors may vary depending on the

specific equipment you use.

CAUTION. To prevent damage to your equipment and cables, use the proper type

optical connectors. The optical connection styles shown in the test setups are

correct for the equipment called out in Table 16 below. If you use alternative

equipment, verify the connection style of the equipment, and use the appropriate

cable or adapter.

T able 16: Test equipment

Description Minimum requirements Example product

Controller PC/Macintosh/W orkstation w/FFT software and GPIB

interface

GPIB cable 2 m length Tektronix part number 012-0991-00

Sampling oscilloscope Bandwidth: 20 GHz

Jitter: t1 ps at minimum sampling delay

Optical sampling module Bandwidth: 20 GHz T ektronix 80C01

Electrical sampling head Bandwidth: 20 GHz T ektronix 80E01

Pattern Generator t2.4 Gb/s to u12.5 Gb/s Advantest D3186

Wavemeter 1530 nm to 1565 nm Burleigh WA-1100

Optical Power Meter

and Power Head

1550 nm, +15 dBm to –40 dBm, 0.01 dBm resolution,

±5% accuracy

PC w/Labview

T ektronix TDS8000

Advantest Q8221 with Q82227

power head

Optical Transmitter 1530 nm to 1565 nm Tektronix OI 1125

36

OI2125 O/E Receiver Instruction Manual

Page 49

Performance Verification

T able 16: Test equipment (cont.)

Description Example productMinimum requirements

Tunable Laser 10 dBm output power over 1530 nm to 1565 nm range,

PMF-style output connector

Optical pulse generator 1550 nm impulse w/trigger out Calmar FPL-01

Variable optical attenuator 1530 nm to 1565 nm range Tektronix OA5002

Optical attenuator 30mm, 10 dB, single-mode, FC to FC, female to male Tektronix part number 119-5118-00

Optical cable, PM FC-APC Single mode, 2 m Tektronix part number 174-4725-00

Optical cable FC-APC to FC/PC, Single mode, 2m Tektronix part number 174-4727-00

Optical cable, PM FC-APC Single mode, 18 cm Tektronix part number 174-4664-00

Optical cable (2) FC/PC to FC/PC, Single mode, 2 m Tektronix part number 174-3922-00

Cable, low-loss coax 50 W, SMA male each end, ~1m Tektronix part number 015-0561-00

Cable, coax 50 W, SMA male each end, 1m Tektronix part number 174-1341-00

Cable, coax

Attenuator, electrical

Attenuator, electrical

1

1

1

50 W, SMA male each end, 10cm Tektronix part number 174-4699-00

2 X, 50 W, SMA Tektronix part number 015-1001-00

5 X, 50 W, SMA Tektronix part number 015-1002-00

NetTest Tunics BT-1560 w/high

power option

Torque wrench 5/16-in, 7-10 in-lb. (8 mm, 79 to 112 N-cm) Pasternack Enterprises PE 5011-1

1

Only required for Clock Recovery Module tests

OI2125 O/E Receiver Instruction Manual

37

Page 50

Performance Verification

Photodetector Optical Input

This section includes one optical input check: the Loss of Signal Threshold test.

NOTE. To optimize performance, make sure that all optical connections are clean

and secure and that all components of the system are in good condition.

1/32

Clock

LOS Threshold

D3186

Data

Laser out

(FC/APC)

The loss of signal threshold test checks the minimum level of the incoming

optical signal that the receiver will recognize.

T est Overview.

1. Connect the test circuit.

2. Set the BERT parameters (store the bit rates for other tests).

3. Set the optical attenuator parameters.

4. Set the power meter parameters.

5. Take measurements.

T est Setup.

1. Connect the equipment as shown in Figure 13. Use a torque wrench to secure

the SMA connections to 7 to 10 lb-in (79 to 112 N-cm).

OI1125

Laser in

(FC/APC)

Modulator data in

Modulator out

(FC/APC)

Variable optical

attenuator

Optical in

(FC/PC)

Optical out

(FC/PC)

Optical power meter

Optical in

(FC/PC)

SMA cable

015-0561-00

Optical cable

174-4664-00

Figure 13: Setup for the LOS threshold test

38

Optical cable

Optical cable

174-4725-00

Optical in

(FC/PC)

174-3922-00

OI2125

OI2125 O/E Receiver Instruction Manual

Page 51

Performance Verification

BERT. Set the BERT settings as follows:

NOTE. Store the bit rate settings so that you can recall them when completing

other tables in the PV procedure.

1. Set the BERT bit rate to 2.488320 Gb/s (SONET OC-48 rate):

a. In the CLK ADJ section, select Memory # to assign a number to the bit

rate. This is the memory number you will use to recall this bit rate.

Suggestion: Use 1 for 2.488320, 2 for 9.953280, and 3 for

12.500000 Gb/s.

b. Press Edit, and use the dial or arrow keys to input the bit rate.

The left and right arrow keys select the digit to be changed. An

annunciation dot appears to the left of the digit to be changed.

c. The up and down arrow keys select the value of the digit selected.

d. When you have the correct bit rate entered (2.48832 GB/s), press Store

and Edit to assign this bit rate to the memory number you selected in

step a.

2. Repeat steps 1a through 1d for 9.953280 Gb/s and 12.500000 Gb/s bit rates.

3. Recall the 2.488320 Gb/s bit rate.

4. Set the trigger output to 1/32 clock.

5. Set the output mode to AC.

6. Turn the data output on and set the data amplitude to 1.5 V

p–p

.

Optical Attenuator. Set the optical attenuator settings:

1. Set the wavelength to 1550 nm.

2. Set the mode control to attenuation.

3. Set the attenuation to –20 dB.

Optical Power Meter. Set the optical power meter settings:

1. Set the wavelength to 1550 nm.

2. Set the units of measure to dBm.

3. Set the range to Auto.

4. If necessary, select the channel you will use.

OI2125 O/E Receiver Instruction Manual

39

Page 52

Performance Verification

T ake Measurements.

1. Enable the transmitter laser by turning the keyswitch clockwise (to the

unlocked position). The Laser On and Output Active LEDs both light.

2. Using the fine adjust on the optical attenuator, gradually decrease the output

power from the transmitter until the Input Detected LED on the front panel

of the receiver extinguishes. Note: The internal power monitor filter in the

receiver slows the optical power threshold detector response.

3. Disconnect the cable from the optical input of the receiver, and connect it to

the optical power meter.

4. Check the displayed power level on the optical power meter against the

limits in Table 17 of the test record. Record the results in Table 17.

5. Disable the transmitter laser by turning the keyswitch counterclockwise (to

the locked position). The Laser On and Output Active LEDs both extinguish.

40

OI2125 O/E Receiver Instruction Manual

Page 53

Data Output

Performance Verification

This section checks specifications of the data output signal.

Rear

trigger

Optical impulse

generator

Bandwidth

Variable optical

Check the bandwidth of the data output signal by doing the following:

T est Overview.

1. Connect the test circuit.

2. Set the optical attenuator parameters.

3. Set the oscilloscope scale factors.

4. Compensate the oscilloscope.

5. Preview the waveform.

6. Capture and process the impulse response waveform.

Connect the Test Circuit.

1. Connect the equipment as shown in Figure 14. Use a torque wrench to secure

the SMA connections to 7 to 10 lb-in (79 to 112 N-cm).

CSA8000/TDS8000 w/80E01

Optical in

attenuator

(FC/PC)

GPIB

cable

Output

direct

10dB Optical

attenuator

Optical cable

Optical

input

174-3922-00

Optical cable

174-3922-00

Figure 14: Setup for the bandwidth test

OI2125 O/E Receiver Instruction Manual

Optical

output

OI2125

Data out

SMA cable

015-0561-00

50 W coaxial cable

Trigger direct in

Controller

41

Page 54

Performance Verification

Optical Attenuator. Set the optical attenuator settings as follows:

1. Set the wavelength to 1550 nm.

2. Set the mode control to attenuation.

3. Set the attenuation to about 30 dB.

Oscilloscope. Set the TDS8000 settings as follows:

1. Press the SELECT ON/OFF button on the 80E01 so that the adjacent

indicator lights.

2. From the toolbar, select Setup→Acquire.

a. Select Average as the acquisition mode.

b. Set the number of samples to 64 Samples.

3. Select the Trig tab to set the trigger parameters.

a. Select External Direct for the trigger source.

b. Select Auto for Mode.

c. Select the rising edge for Slope.

d. Click the Set to 50% button to set the trigger point midway on the rising

signal.

4. Select the Horiz tab to set the horizontal parameters.

a. Set the Scale to 1.000 ns/div. (This setting will make it easier to initially

locate the optical pulse later in the procedure.)

b. Set the Position to 18.000 ns. (This setting will make it easier to locate

the first optical pulse later in the procedure.)

c. Set the Record Length to 2000.

5. Select the Disp tab to set the display parameters.

a. In the Style section, select Normal.

b. Check Show Vectors.

42

NOTE. If the Scale, Position, and Channel Offset control boxes are not displayed

in the following step, click the Basic>> button in the lower left part of the Vert

Setup dialog box.

6. Select the Vert tab to set the vertical parameters.

OI2125 O/E Receiver Instruction Manual

Page 55

Performance Verification

a. Set the Scale to 1 mV/div.

b. Set Position to 0.0 div.

c. Set Channel Offset to 0.0 V.

7. Close the Setup box.

Compensate the Oscilloscope.

1. Run a Signal Path Compensation from the Utilities menu.

Preview the Waveform. Refer to Figure 15 on page 44 as you do the following:

1. Adjust the attenuation of the variable optical attenuator until it produces an

impulse pulse amplitude of 2 mV

to 3 mV

p-p

p-p

.

2. Use the Horizontal Position control to position the impulse at the first

horizontal division. (This ensures that postimpulse aberrations are included

in the record.)

You may experience signal jitter if you try to display a signal that is not the

first impulse and is late in relation to time zero.

3. Adjust the Horizontal Scale control so that the width of the impulse at its

base is approximately 1/4 to 3/4 of a horizontal division on the display.

NOTE. If the width of the impulse is much greater than 3/4 of a horizontal

division, the resulting Fourier transform will not have enough frequency

resolution; if the width is much smaller than 1/4 of a horizontal division, the

amount of samples that fall on the impulse may be too coarse, resulting in

quantum errors in the resulting Fourier transform.

OI2125 O/E Receiver Instruction Manual

43

Page 56

Performance Verification

Figure 15: Proper positioning of the impulse for optimum curve download

Capture and Process the Impulse Response Waveform.

1. Using a controller (such as a PC, Macintosh, or workstation) attached to the

TDS8000 or CSA8000 instrument via GPIB, download the waveform.

NOTE. Alternatively, you can use the Save Waveform, Copy Waveform, or a

network connection to transfer a waveform curve to a spreadsheet, ASCII file, or

other application. Refer to the CSA8000 Communications Signal Analyzer &

TDS8000 Digital Sampling Oscilloscope User Manual for more information

about these methods of transferring waveform data.

2. Using the available controller software, such as Labview, perform a Fourier

Transform on the waveform; this transforms the time-domain impulse

response to a scalar frequency response.

3. Normalize the Fourier Transform result such that DC or low frequency is

0 dB.

4. Plot the frequency response.

44

5. Check that the OI2125 O/E Receiver meets the performance requirement

bandwidth. Record the result on the test record.

OI2125 O/E Receiver Instruction Manual

Page 57

Eye Pattern Test Matrix

Performance Verification

These procedures direct you to set up the equipment to display an eye pattern.

Use the eye pattern to measure the parameters listed in Tables 18 through 20 in

the test record.

Test Overview

To prepare the test matrix, do the following setups:

1. Connect the test circuit.

2. Set the BERT parameters.

3. Set the tunable laser parameters.

4. Set up the optical attenuator.

5. Set up the optical power meter.

6. Preview the eye pattern.

7. Set the oscilloscope measurement parameters.

8. Calibrate the oscilloscope.

9. Take measurements.

The following parameters are set up to measure the data for the first row in

Table 18 in the test record. As you progress through the tables, you must change

the bit rate of the BERT, the laser wavelength, the attenuator settings, and the

signal conditioning mode in the oscilloscope, according to the table and row you

are completing.

Test Circuit

OI2125 O/E Receiver Instruction Manual

Connect the equipment as shown in Figure 16 on page 46. A torque wrench is

recommended for securing the SMA connections to 7 to 10 lb-in (79 to

112 N-cm).

45

Page 58

Performance Verification

External

tunable laser

Trig

SMA cable

015-0561-00

1/32

Clock

D3186

Data

Opt

Out

Optical in

(FC/PC)

Modulator data in

Laser in

(FC/APC)

OI1125

Modulator out

(FC/APC)

Optical in

(FC/PC)

Optical cable

Optical cable

174-4727-00

(Connect to receiver input after setting optical level to 0 dBm)

Data out

174-4725-00

CSA8000/TDS8000 w/80E01/80C01

Optical attenuator

Optical out

(FC/PC)

Optical power meter

Optical in

(FC/PC)

Optical cable

174-3922-00

OI2125

Figure 16: Setup for the eye pattern test matrix

BERT

Set the BERT parameters as follows:

1. Recall the 2.48832 Gb/s bit rate.

2. Set the pattern to PRBS-31.

3. Disable the adjustable duty cycle.

4. Set the mark ratio to 1/2.

5. Set the trigger to 1/32 clock.

6. Set the output mode to AC.

7. Turn the data output on and set the data amplitude to 1.0 V

SMA cable

015-0561-00

2X attenuator

p–p

.

46

OI2125 O/E Receiver Instruction Manual

Page 59

Performance Verification

Tunable Laser

Optical Attenuator