Technical Reference

MTS400 Series

MPEG Test Systems

Specifications and Performance Verification

071-1724-04

This document applies to firmware version 1.4

and above.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Table of Contents

General Safety Summary iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Manuals vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

Electrical Specifications 1−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Characteristics 1−19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Characteristics 1−20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certifications and Compliances 1−21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Preparation 2−1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification Procedures 2−3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MTS400 Series MPEG Test Systems Technical Reference

i

Table of Contents

List of Figures

Figure 2−1: Cable connections on the MTS400 Series system 2−3. . . . . . . . . . . . .

Figure 2−2: Clock settings dialog box 2−4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2−3: PCR Initial Value settings dialog box 2−5. . . . . . . . . . . . . . . . . . . . . . .

Figure 2−4: Others settings dialog box and Select Update Item settings dialog box ...2−6

Figure 2−5: Stream Interpretation display in the Open Transport Stream window ... 2−7

Figure 2−6: Real Time Analysis display in the Open Transport Stream window ... 2−8

Figure 2−7: ASI interface analysis results 2−9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2−8: Record Settings dialog box 2−10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2−9: Record Settings window with the recording function armed 2−11. . . . .

Figure 2−10: MPEG Player playing a SMPTE310M transport stream 2−13. . . . . . .

Figure 2−11: SMPTE310M interface analysis results 2−14. . . . . . . . . . . . . . . . . . . .

Figure 2−12: SPI interface analysis results 2−16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2−13: RF interface selection 2−17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2−14: RF interface settings 2−18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables

Table 1−1: Platform characteristics 1−2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−2: A11 and A12 Main MPEG I/O board electrical characteristics 1−4. . .

Table 1−3: A170 LVDS/ASI/SMPTE310M Interface board

electrical characteristics.. 1−6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−4: Baseband board electrical characterisics 1−8. . . . . . . . . . . . . . . . . . . .

Table 1−5: QPSK/8PSK interface board electrical characteristics

with a QPSK input 1−9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−6: QPSK/8PSK interface board electrical characteristics

with an 8PSK input 1−9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−7: 8PSK and QPSK measurements 1−10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−8: COFDM interface board electrical characteristics 1−11. . . . . . . . . . . . .

Table 1−9: COFDM measurements 1−12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−10: 8VSB board electrical characteristics 1−14. . . . . . . . . . . . . . . . . . . . . .

Table 1−11: 8VSB measurements 1−14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−12: QAM Annex B board characteristics 1−15. . . . . . . . . . . . . . . . . . . . . .

Table 1−13: QAM Annex B measurements 1−16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−14: Video over IP board - Ethernet Electrical Port 1−17. . . . . . . . . . . . . . .

Table 1−15: Video over IP board - Ethernet Optical port 1−17. . . . . . . . . . . . . . . . .

Table 1−16: AC power source electrical characteristics 1−18. . . . . . . . . . . . . . . . . .

Table 1−17: Mechanical characteristics 1−19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−18: Environmental characteristics 1−20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1−19: Certifications and compliances 1−21. . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

MTS400 Series MPEG Test Systems Technical Reference

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and Disconnect Properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Powering Off. The power cord provides Mains disconnect.

Replace Batteries Properly. Replace batteries only with the proper type and rating

specified.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

MTS400 Series MPEG Test Systems Technical Reference

iii

General Safety Summary

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

iv

CAUTION

Refer to Manual

WARNING

High Voltage

Protective Ground

(Earth) Terminal

Standby

MTS400 Series MPEG Test Systems Technical Reference

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

MTS400 Series MPEG Test Systems Technical Reference

v

Service Safety Summary

vi

MTS400 Series MPEG Test Systems Technical Reference

Preface

Related Manuals

This manual lists the electrical, mechanical, and environmental specifications,

and the certification and compliance statements for the Tektronix MTS400 Series

MPEG Test Systems instruments. Also provided are procedures for verifying the

performance of the instrument.

NOTE. Text in this manual about the MPEG Player refers to the MPEG player

application installed in the MTS400 Series systems (MTS400, and MTS430).

The MTX100B MPEG Player and Recorder is described in the MTX100B user

documentation.

The following manuals are also available to use with the MTS400 Series MPEG

Test Systems. These manuals are shipped with each system, and are also

available on the Tektronix Web site.

H MTS400 Series MPEG Test Systems Getting Started Manual (Tektronix part

numbers: 071-1505-xx, English; 071-1727-xx, Japanese). This manual

describes the functions and use of the instrument, and provides software

recovery and network troubleshooting information.

H MTS400 Series MPEG Test Systems User Manual (Tektronix part number

071-1507-xx). This manual provides in-depth operating information for the

software applications included in the MTS400 Series system.

H MTS400 Series MPEG Test Systems Programmers Manual (Tektronix part

number 071-1725-xx). This manual describes the remote control commands

available for the MPEG Player application.

H MTS400 Series MPEG Test Systems Release Notes (Tektronix part number

071-1726-xx). This manual provides information about software problems

and behaviors.

MTS400 Series MPEG Test Systems Technical Reference

vii

Preface

viii

MTS400 Series MPEG Test Systems Technical Reference

Specifications

This chapter contains specifications for the MTS400 Series MPEG Test Systems.

All specifications are guaranteed unless labeled “typical.” Typical specifications

are provided for your convenience but are not guaranteed.

Unless otherwise stated, all specifications apply to both the MTS400 and

MTS430 MPEG Test Systems.

To meet specifications, the following conditions must be met:

H The system must have been calibrated/adjusted in an ambient temperature

between 20 °C and 30 °C (68 °F and 86 °F).

H The system must be kept within the environmental limits specified in this

document.

H The system must be powered from a source maintaining voltage and

frequency within the limits described in this document.

H The system must have been operating continuously for at least 20 minutes

within the specified operating temperature range.

H The instrument must have had its signal-path-compensation routine last

executed after at least a 20 minute warm-up period at an ambient temperature

within 5 °C of the current ambient temperature.

Any conditions that are unique to a particular characteristic are expressly stated

as part of that characteristic.

NOTE. The product calibration classification for this system is List 2; no

calibration data reports are available. However, all measurement equipment

used to establish or verify conformance of the product with published specifications is traceable.

MTS400 Series MPEG Test Systems Technical Reference

1−1

Specifications

Electrical Specifications

The following tables list the published specifications for the MTS400 Series

MPEG Test Systems.

Platform Characteristics

Table 1−1 lists the general characteristics of the MTS400 Series platform.

Table 1−1: Platform characteristics

Characteristic Description

Operating system Microsoft Windows XP Professional with

Service Pack 2

Processor P4, 2.8 GHz

Disk space

Operating system and software applications 82 GB, Ultra ATA100 IDE hard drive

MPEG file storage 144 GB total (two, 72 GB SCSI hard drives,

one for Playout and one for Record)

MPEG storage disk I/O port SCSI-3 (Ultra 160), Micro D68 connector,

68 pin

RAM 1 GB (one SIM of DDRS memory)

CD-ROM drive CD−R/W, DVD−R/RW, DVD+R/RW

Floppy disk drive 3.5 inch, 1.44 MB high density, double-sided

(2HD)

Display LCD, 1024 X 768, 10.4 inch

Ethernet

10/100 One 10/100Base-T; RJ45 connector

1−2

Supported protocol: Ethernet/IP/UDP/

MPEG-TS and VLAN

When used in MPEG-TS protocol, the

minimum and maximum link bit rates are

250 kbps and 100 Mbps respectively

IP playout bit rate is typically up to 90 Mbps

10/100/1000 (GigE) One 10/100/1000Base-T; RJ45 connector

Supported protocol: Ethernet/IP/UDP/

MPEG-TS and VLAN

When used in MPEG-TS analysis and

record, the minimum and maximum link bit

rates are typically 250 kbps and 100 Mbps

respectively

IP playout bit rate is typically up to

190 Mbps

MTS400 Series MPEG Test Systems Technical Reference

Specifications

Table 1−1: Platform characteristics (Cont.)

Characteristic Description

Keyboard port Mini DIN, PS-2, one on the rear panel and

one on the left front side panel; not hot

pluggable

Mouse port Mini DIN, PS-2; one on the rear panel and

one on the left front side panel; not hot

pluggable

Printer port IEEE P1284. Bidirectional parallel commu-

nications port

External VGA Output 15-pin, high density, Sub-D; resolution

needs to be set to the same as the integral

LCD display, 1024 x 768

COM port RS-232

USB port USB device connector

MTS400 Series MPEG Test Systems Technical Reference

1−3

Specifications

A11 and A12 Main MPEG

I/O Board Characteristics

The electrical characteristics listed in Table 1−2 apply to both the A11 and A12

Main MPEG I/O boards.

Table 1−2: A11 and A12 Main MPEG I/O board electrical characteristics

Characteristic Description

Internal reference clock, typical 27 MHz "1 ppm

This clock is used for the following functions:

output clock, PCR/PTS/DTS timing, packet

operation timing, and TDT/STT timing

External reference / clock input

Input connector type BNC, 50 , AC coupled

Frequency

External reference input 8.12698 MHz, 10 MHz, 27 MHz

External clock input 160 kHz to 25 MHz (parallel clock)

1.28 MHz to 32 MHz (serial clock)

Amplitude

External reference input, typical 0 "6 dBm (peak-to-peak, sine wave)

0.5 V to 3.0 V (square wave)

External clock input, typical 0.5 V to 3.0 V (square wave)

External TTL trigger input

Input connector type BNC, 1 k

Threshold level

High level >3.5 V (maximum voltage limit is 7.0 V)

Low level <0.8 V

PPL

Frequency range 64 MHz to 128 MHz

Output clock

Maximum rate 64 MHz (serial clock)

25 MHz (parallel clock)

Internal and external 27 MHz Output clock = (X / (2 * Y * Z)) * 27 MHz

512 < X < 131071, 3400 < Y < 6000, 2 <= Z

<= 65536 (second power)

1−4

External parallel clock Output clock = 108 MHz * Y / X,

512 < X < 131071, 8 < Y < 16383

External serial clock Output clock = 864 MHz * Y / X,

512 < X < 131071, 8 < Y < 16383

Output data rate 250 kbps minimum,

214 Mbps maximum

P/N and jitter (serial clock) <−104 dBc/Hz, RBW = 300 Hz, @21.455707 MHz

+ 20 kHz

MTS400 Series MPEG Test Systems Technical Reference

Specifications

Table 1−2: A11 and A12 Main MPEG I/O board electrical characteristics (Cont.)

Characteristic Description

DVB−SPI Interface

Input/output configuration Output only

Connector type D-sub, 25-pin

Data rate 250 kbps to 108 Mbps (107 Mbps maximum in

duplex mode)

Pin assignment 1 DCLK

2 Ground

3 to 10 DATA 7 to DATA 0

11 DVALID

12 PSYNC

13 Shield

14 /DCLK

15 Ground

16 to 23 /DATA 7 to DATA 0

24 /DVALID

25 /PSYNC

Output amplitude, typical 240 mV to 550 mV (BUS LVDS with 100

termination)

Output offset 1.1 V to 1.5 V

Output impedance 100 , between differential outputs with output off

Data delay "5 ns from DCLK falling edge

Input level >200 mVpp, (RI+)−(RI−) with 100 termination

Data hold time T/2 "T/10, T=1/f, data latch on DCLK rising edge

MTS400 Series MPEG Test Systems Technical Reference

1−5

Specifications

A170

LVDS/ASI/SMPTE310M

Interface Board

Table 1−3 lists the electrical characteristics of the A170 LVDS/ASI/

SMPTE310M Interface board.

Table 1−3: A170 LVDS/ASI/SMPTE310M Interface board electrical

characteristics

Characteristic Description

Internal reference clock, typical 27 MHz "1 ppm

ASI interface

Connector type BNC (common connector with SMPTE310M

interface)

Bit rate 250 kbps to 213 Mbps (107 Mbps maximum in

duplex mode)

Output

Output impedance 75 transformer coupled

Voltage 800 mV "10% into 75 load

Jitter v0.2 UI

Maximum rise/fall time v1.2 ns, 20% to 80%

Return loss, typical >17 dB (5 MHz to 270 MHz) into 75 load

Transmission format Packet mode or Burst mode

Input

Input impedance 75 transformer coupled

Voltage 200 mV to 880 mV (maximum limit: 3 Vpp @AC,

15 mA @DC)

Data format Accepts both Packet mode and Burst mode ASI

signals

Return loss, typical >17 dB (5 MHz to 270 MHz) into 75 load

SMPTE310M interface

Connector type BNC (common connector with ASI interface)

Bit rate 19,392,658.5 bps

Output

Output impedance 75 transformer coupled

Voltage 800 mV "10% into 75 load

Jitter, typical <2 ns p-p logic 0 rising edge when triggered on

negative edge (EN50083-9.1998 Figure A.4)

1−6

<1.4 ns p-p logic 1 rising edge when triggered on

negative edge (EN50083-9.1998 Figure A.5)

Rise/fall time 0.4 ns v X v 5 ns, 20% to 80%

Return loss, typical >30 dB (5 MHz to 38.785316 MHz) into 75 load

MTS400 Series MPEG Test Systems Technical Reference

Table 1−3: A170 LVDS/ASI/SMPTE310M Interface board electrical

characteristics (Cont.)

Characteristic Description

SMPTE310M interface (cont.)

Input

Input impedance 75 transformer coupled

Voltage 200 mV to 880 mV (maximum limit: 3 Vpp @AC,

15 mA @DC)

Data format Bi-phase coded, compliant with SMPTE310M

Input bit rate 19,392,658.5 bps

Return loss, typical >17 dB (5 MHz to 38.785316 MHz) into 75 load

DVB−SPI interface

Input/output configuration Input only

Connector type D-sub, 25-pin

Data rate 250 kbps to 108 Mbps (107 Mbps maximum in

duplex mode)

Pin assignment 1 DCLK

2 Ground

3 to 10 DATA 7 to DATA 0

11 DVALID

12 PSYNC

13 Shield

14 /DCLK

15 Ground

16 to 23 /DATA 7 to DATA 0

24 /DVALID

25 /PSYNC

Specifications

Data delay "5 ns from DCLK falling edge

Input level >200 mVpp, (RI+)−(RI−) with 100 termination

Input impedance 100 , between differential inputs

Clock pulse width T/2 "T/10, T=1/f (f = byte clock frequency)

Data hold time T/2 "T/10, T=1/f, data latch on DCLK rising edge

MTS400 Series MPEG Test Systems Technical Reference

1−7

Specifications

Baseband Board

Characteristics

Table 1−4 lists the electrical characteristics of the MTM400 Baseband board.

Table 1−4: Baseband board electrical characterisics

Characteristic Description

ASI interface

Connector type BNC (common connector with SMPTE310M

interface)

Bit rate 250 kbps to 155 Mbps

ASI Input Accepts both Burst mode and Packet mode ASI

format

Signal amplitude 2.0 V peak-to-peak, maximum

Input impedance 75 transformer coupled

Return loss, typical 10 dB minimum, 5 MHz to 270 MHz

Link rate, typical 270 Mbaud "100 ppm

ASI Output

Signal amplitude 1.0 V peak-to-peak, maximum

600 mV peak-to-peak, minimum

into 75 load

Output impedance 75 transformer coupled

Return loss, typical 10 dB @ 270 MHz

SMPTE310M interface

Connector type BNC

Bit rate 19,392,658.5 bps "2.8 ppm

SMPTE Input

Input impedance 75 transformer coupled

Data format Bi−phase coded, compliant with SMPTE310M

Signal amplitude 2.0 V peak-to-peak, maximum

200 mV peak-to-peak minimum

Return loss, typical 10 dB minimum @ 20 MHz

SMPTE Output

Signal amplitude 600 mV minimum, 1.0 V maximum

into 75 load

Output impedance 75 transformer coupled

Return loss, typical 10 dB minimum @ 20 MHz

1−8

MTS400 Series MPEG Test Systems Technical Reference

Specifications

QPSK/8PSK Board

Characteristics

Tables 1−5 and 1−6 list electrical characteristics of the QPSK/8PSK board.

Table 1−5: QPSK/8PSK interface board electrical characteristics with a QPSK

input

Characteristic Description

Input frequency range 950 MHz to 2150 MHz with 1 MHz step size

Input signal amplitude range −60 dBm to −30 dBm for a CBER of <1e

Modulation format QPSK in accordance with ETSI EN 300 421

Modulated baud rate 1 MBaud min, 30 MBaud max

Viterbi values supported 1/2, 2/3, 3/4, 5/6, 6/7, 7/8

FEC In accordance with ETSI EN 300 421

Turbo viterbi values supported 1/2, 2/3, 3/4, 5/6, 7/8

Turbo FEC Turbo code

Connector style F-style

Input termination impedance 75 nominal

Input return loss 4 dB min, 950 MHz to 2050 MHz

LNB supply voltage Selectable; 13.0 V "1.5 V or 18.0 V "1.5 V, with

100 , 5 watt resistor load

LNB supply maximum current 200 mA maximum

LNB 22 kHz signaling frequency 17.6 kHz min, 26.4 kHz max (22 kHz "20%)

LNB 22 kHz signaling amplitude 600 mV p-p with a 100 load

Ultimate modulation error ratio (with

equalizer)

26 dB with an equalizer

−6

Table 1−6: QPSK/8PSK interface board electrical characteristics with an 8PSK

input

Characteristic Description

Input frequency range 950 MHz to 2150 MHz with 1 MHz step size

Input signal amplitude range −60 dBm to −30 dBm for a CBER of <1e

Modulation format Turbo 8PSK

Modulated baud rate 1 MBaud min, 30 MBaud max

Turbo viterbi values supported 2/3, 3/4 (2.05), 3/4 (2.1), 5/6, 8/9

Turbo FEC Turbo code

Connector style F-style

Input termination impedance 75 nominal

MTS400 Series MPEG Test Systems Technical Reference

−6

1−9

Specifications

Table 1−6: QPSK/8PSK interface board electrical characteristics with an 8PSK

input (Cont.)

Characteristic Description

Input return loss 4 dB min, 950 MHz to 2050 MHz

LNB supply voltage Selectable; 13.0 V "1.5 V or 18.0 V "1.5 V, with

100 , 5 watt resistor load

LNB supply maximum current 200 mA maximum

LNB 22 kHz signaling frequency 17.6 kHz min, 26.4 kHz max (22 kHz "20%)

LNB 22 kHz signaling amplitude 600 mV p-p with a 100 load

Ultimate modulation error ratio (with

equalizer)

26 dB with an equalizer

8PSK and QPSK

Measurements

Table 1−7 lists electrical characteristics for 8PSK and QPSK measurements.

Table 1−7: 8PSK and QPSK measurements

Characteristic Description

RF lock RF lock is indicated by LED and Status

Input level (signal strength) Range: −60 dBm to −30 dBm

Resolution: 1 dBm

Accuracy: "5 dBm

EVM (Error Vector Magnitude) Display Range: v 4.0% to w 30.0% rms

Resolution: 0.1%

Accuracy: "20% of reading

MER (Modulation Error Ratio) with an

equalizer

SNR (Signal-to-Noise Ratio) Display Range: 5 dB to 35 dB

Pre Reed Solomon (RS) BER (Bit Error

Rate)

Post RS BER and TEF (Transport Error

Flag)

Display Range: 10 dB to 26 dB with an equalizer

Resolution: 1 dB

Accuracy: "2 dB for range 10 dB to 20 dB

Resolution: 1 dB

Accuracy: "2 dB for range from 5 dB to 30 dB

Pre-RS BER is displayed

Post Reed Solomon BER (TEF ratio), TEF rate, and

number of Transport Error Flags (TEF count) are

displayed

1−10

Constellation RF constellation is displayed

MTS400 Series MPEG Test Systems Technical Reference

Specifications

COFDM Board

Characteristics

Table 1−8 lists electrical characteristics for the COFDM interface board.

Table 1−8: COFDM interface board electrical characteristics

Characteristic Description

Input frequency range 50 MHz to 858 MHz (to include low VHF)

Input signal amplitude range The receiver delivers QEF (Quasi Error Free)

operation over the following signal power ranges:

QPSK (4QAM): −85 dBm to −15 dBm (24 dBuV to

94 dBuV)

16QAM: −80 dBm to −15 dBm (29 dBuV to 94 dBuV)

64QAM: −72 dBm to −15 dBm (37 dBuV to 94 dBuV)

QEF operation is equivalent to a post Viterbi BER of

2x10−4 or better

w −50 dBm to ensure compliance to IEC 61000-4-3

immunity

Compliance COFDM (DVB-T) receptions and demodulation are

compliant with ETSI EN300-744, 2 K, and 8 K

transmission modes

Tuning resolution 166.7 kHz or smaller increments

Tuning accuracy Better than "50 ppm

Channel bandwidth 7 MHz and 8 MHz (software selectable)

Connector style F-style

Input termination impedance 75 nominal

Input return loss 7 dB minimum, 50 MHz to 858 MHz

Modulation schemes supported QPSK (4QAM), 16QAM, and 64QAM modulation

Transmission modes 2 K carriers, and 8 K carriers

Hierarchical modulation All hierarchies will be supported, to include no

hierarchy, and alpha = 1, 2 and 4.

Viterbi puncture rates 1/2, 2/3, 3/4, 5/6, 7/8

Guard intervals 1/32, 1/16, 1/8, 1/4

Spectrum polarity The receiver will operate with both inverted and

normal spectral polarity

Ultimate modulation error ratio, with

equalizer

w 37 dB with an equalizer

MTS400 Series MPEG Test Systems Technical Reference

1−11

Specifications

COFDM Board

Measurements

Table 1−9 lists the electrical characteristics for the COFDM measurements.

Table 1−9: COFDM measurements

Characteristic Description

Overall receiver lock status Overall receiver lock status is indicated by an LED on

the rear panel

Transmission coding parameters The receiver reports the current status of the

following transmission parameters:

− QPSK/16, QAM/64, QAM encoding

− 2K/8K Transmission mode

− Hierarchy status (hierarchy on/off, alpha value)

− Viterbi puncture rate

− Guard Interval Value

− Gross bit rate in the channel

− Spectrum polarity (inverted/non-inverted)

Input level (signal strength) Ranges, High Sensitivity mode:

QPSK (4QAM): −85 dBm to −10 dBm (24 dBuV to

99 dBuV)

16QAM: −80 dBm to −10 dBm (29 dBuV to

99 dBuV)

64QAM: −72 dBm to −13 dBm (37 dBuV to

96 dBuV)

Ranges, High Resolution mode:

QPSK (4QAM): −45 dBm to −10 dBm (64 dBuV to

99 dBuV)

16QAM: −45 dBm to −10 dBm (64 dBuV to

99 dBuV)

64QAM: −45 dBm to −13 dBm (64 dBuV to

96 dBuV)

Resolution: 1 dBm

Accuracy: "3 dBm

RF carrier offset Accuracy: "50 ppm of the tuned frequency

SNR (Signal to Noise Ratio) Display Range:

6 dB to 40 dB for QPSK (4QAM)

11 dB to 40 dB for 16QAM

16 dB to 40 dB for 64QAM

Resolution: 1 dB

Accuracy: "1 dB to 30 dB SNR (measured at

−30 dBm input in high resolution mode)

1−12

MTS400 Series MPEG Test Systems Technical Reference

Table 1−9: COFDM measurements (Cont.)

Characteristic Description

EVM (Error Vector Magnitude) Display Range:

v 1% to w 30% rms, for QPSK

v 1% to w 20% rms, 16QAM

v 1% to w 8.5% rms, 64QAM

Resolution: 0.1%

Accuracy: 1% (1 EVM unit), and an additional "20%

of the reading

Specifications

MER (Modulation Error Ratio) with an

equalizer

Carrier power distribution Carrier-by-carrier signal-to-noise power ratio is

Channel equalization status Channel estimate I and Q values for each carrier are

Constellation The RF constellation is displayed

BER Pre-Viterbi BER and Pre Reed-Solomon BER values

Post RS BER and TEF (Transport Error

Flag)

Both MER Peak and MER Average are displayed as

measured across all carriers

Display Range:

6 dB to 37 dB for QPSK (4QAM)

11 dB to 37 dB for 16QAM

16 dB to 37 dB for 64QAM

Resolution: 0.1 dB

Accuracy: "1 dB to 30 dB (Measured at −30 dBm

input in High Resolution mode). For best MER

accuracy, use High Resolution mode, and maintain

the input signal level between −45 dBm and

−15 dBm

displayed

Channel Flatness in dB can be viewed from the

spectrum display

Tilt in dB can be viewed from the spectrum display

displayed

are displayed

Post Reed Solomon BER (uncorrectable error count)

and number of Transport Error Flags are displayed

MTS400 Series MPEG Test Systems Technical Reference

1−13

Specifications

8VSB Board

Characteristics

8VSB Measurements

Table 1−10 lists the electrical characteristics for the 8VSB board.

Table 1−10: 8VSB board electrical characteristics

Characteristic Description

Input frequency range 54 MHz to 860 MHz, VHF/UHF channels 2 to 69 (to

include low VHF frequencies)

Input signal level −72 dBm to −6 dBm (−23 dBmV to )43 dBmV)

w −50 dBm to ensure compliance to IEC 61000-4-3

immunity

Modulation format 8VSB in accordance with ATSC A/53B

Receiver bandwidth 6 MHz

Input termination impedance 75 nominal

Connector type F-type

Input return loss 5 dB minimum

Ultimate equivalent MER, with an

equalizer

w 31 dB with an equalizer

Table 1−11 lists the electrical characteristics for the 8VSB measurements.

Table 1−11: 8VSB measurements

Characteristic Description

RF Lock RF lock is indicated by LED and Status

Input level (signal strength) Display Range:

−72 dBm to −2 dBm relative to 75 (−23 dBmV to

+47 dBmV)

Resolution: 1dB

Accuracy:"3dB

EVM (Error Vector Magnitude) Display Range: v3.0% to w12.5% rms

Resolution: 0.1%

Accuracy:"20% of reading

Equivalent MER (Modulation Error

Ratio) with Equalizer

SNR (Signal to Noise Ratio) Display Range: 15 dB to 35 dB

Display Range: 17 dB to 31 dB with Equalizer

Resolution: 0.1 dB

Accuracy: "1 dB for MER u25 dB;

"3 db for MER 25 dB to 31 dB

(Measured at −30 dBm input. For best MER

accuracy, maintain the input signal level between

−50 dBm and −15 dBm.)

Resolution: 1 dB

Accuracy: "1 dB for SNR < 25 dB;

"3 db for SNR 25 dB to 35 dB

1−14

MTS400 Series MPEG Test Systems Technical Reference

Specifications

Table 1−11: 8VSB measurements (Cont.)

Characteristic Description

BER Pre-RS BER, SER 1 second and 10 seconds

windows values are displayed

TEF (Transport Error Flag) Transport Error Flags (uncorrectable error count) in a

1 second window and 10 second window are

displayed

Constellation diagram The 8VSB constellation diagram is a display of I-data

history with histograms (the IQ constellation is not

available). This is displayed as Symbol Distribution in

the user interface

Echo profile Equalizer filter tap information is displayed.

Display Echo Level range: Normalized real tap

values over the range of −1 to 1

Display Delay range: −6.7 μs to 45.5 μs

QAM Annex B Board

Characteristics

Table 1−12 lists electrical characteristics for the QAM Annex B board.

Table 1−12: QAM Annex B board characteristics

Characteristic Description

Input frequency range 88 MHz to 858 MHz

Input signal level −64 dBm to −19 dBm (45 dBuV to 90 dBuV relative

to 75 )

With either a 64 or 256 QAM input, there are five or

fewer Transport Error Flags in 11 seconds, which

corresponds to a post FEC rate of 1e

w-40 dBm when operated in an electromagnetic

field of 3 V/m or more

Modulation format 64QAM, 256QAM (compliant with ITU J-83

Annex B)

Interleaving mode Level 1 and Level 2 interleaving support compliant

with all ITU J-83 Annex B, excluding I, J = (128,7)

and (128,8), and in 256 QAM excluding (8, 16) and

(16, 8)

Modulation baud rate 64 QAM: 5.056941 Mbaud/s

256 QAM: 5.360537 Mbaud/s

Spectrum polarity Demodulates both Normal and Inverted IF Spectrum

Receiver bandwidth, QAM B 6 MHz nominal

Connector type F type

Input termination impedance 75 nominal

−8

MTS400 Series MPEG Test Systems Technical Reference

1−15

Specifications

Table 1−12: QAM Annex B board characteristics (Cont.)

Characteristic Description

Input return loss 5 dB minimum

Ultimate Modulation Error Ratio with

equalizer

w37 dB with an equalizer

QAM Annex B Board

Characteristics

Table 1−13 lists electrical characteristics for the QAM Annex B measurements.

Table 1−13: QAM Annex B measurements

Characteristic Description

RF lock RF lock is indicated by LED and Status

Input level (signal strength) Range: −64 dBm to −19 dBm (45 dBuV to 90 dBuV

relative to 75 )

Resolution: 1 dB

Accuracy: "3 dB

EVM (Error Vector Magnitude) Display Range for 64 QAM: v1% to w5% rms

Display Range for 256 QAM: v1% to w2.5% rms

Resolution: 0.1%

Accuracy: "1%

MER (Modulation Error Ratio) with

Equalizer

SNR (Signal to Noise Ratio) Display Range:

BER (Bit Error Ratio) Pre-RS BER is displayed

TEF (Transport Error Flag) Transport Error Flags (uncorrectable error count) in a

Display Range:

64 QAM: 22 dB to 37 dB

256 QAM: 28 dB to 37 dB

Resolution: 0.1 dB

Accuracy: "1 dB for MER < 25 dB; "3 db for MER

25 dB to 34 dB (measured at −30 dBm input)

64QAM: 22 dB to 37 dB

256QAM: 28 dB to 37 dB

Resolution: 1 dB

Accuracy: "1 dB for SNR < 25 dB; "3 db for SNR

25 dB to 34 dB

1 second window and 10 second window are

displayed

1−16

Constellation The RF constellation is displayed

MTS400 Series MPEG Test Systems Technical Reference

Specifications

Video Over IP Electrical

Characteristics

Video Over IP Optical

Characteristics

Table 1−14 lists the general and electrical characteristics for the Video Over IP

board.

Table 1−14: Video Over IP board - Ethernet Electrical Port

Characteristic Description

Standard 10/100/1000BASE-T IEEE 802.3

Connector type RJ-45

Data Format 10/100 Base T NRZ

Data Format 1000 Base T Trellis encoded, PAM5 symbols, full-duplex on 4-pair Cat-5

UTP per IEEE 802.3ab

Table 1−15 lists the general and optical characteristics for the Video Over IP

board.

Table 1−15: Video Over IP board - Ethernet Optical port

Characteristic Description

Ethernet Optical Transmitter - General Characteristics

Optical operating mode

Connector type Duplex data link MSA compliant SFP connector

Standard 1000 BASE-X

Data format NRZ

Ethernet Optical Transmitter - Single mode 1550 nm using Tektronix supplied SFP

module

Output power −2 dBm to +4 dBm

Center wavelength - 1550 nm 1530 nm Min, 1550 nm typical, 1570 nm max

Total jitter (peak-to-peak) t170 ps

Extinction ratio w9.0 dBm

Ethernet Optical Receiver - Single mode 1550 nm using Tektronix supplied SFP module

Optical input power −26 dBm to −3 dBm, BER 1 X 10

Input wavelength 1270 nm = λ = 1610 nm

Single mode or Multimode

−12

MTS400 Series MPEG Test Systems Technical Reference

1−17

Specifications

Table 1−15: Video Over IP board - Ethernet Optical port (Cont.)

Characteristic Description

Ethernet Optical Transmitter - Single mode 1310 nm using Tektronix supplied SFP

module

Output power −11 dBm to −3 dBm

Center wavelength - 1310 nm 1270 nm Min, 1310 nm typical, 1355 nm max

Total jitter (peak-to-peak) t170 ps

Extinction ratio w9.0 dBm

Ethernet Optical Receiver - Single mode 1310 nm using Tektronix supplied SFP module

Optical input power −19 dBm to −3 dBm, BER 1 X 10

Input wavelength 1270 nm = λ = 1610 nm

Ethernet Optical Transmitter - Multimode 850 nm using Tektronix supplied SFP module

Output power −9.5 dBm to −2 dBm

Center wavelength - 850 nm 830 nm Min, 850 nm typical, 860 nm Ma

Total jitter (peak-to-peak) t170 ps

Extinction ratio w9.0 dBm

Ethernet Optical Receiver - Multimode 850 nm using Tektronix supplied SFP module

Optical input power −17 dBm to 0 dBm, BER 1 X 10

Input wavelength 770 nm = λ = 860 nm

−12

−12

1−18

AC Power Source

Characteristics

Table 1−16 lists the electrical characteristics of the AC power source.

Table 1−16: AC power source electrical characteristics

Characteristic Description

Source voltage 100 to 240 VAC "10% (90 to 264 VAC RMS)

Frequency range 50/60 Hz

Power consumption 4 A maximum (marked on rear panel)

Peak inrush current 13 A peak at 240 VAC, 50 Hz

Mains fuse value T6.3AH, 250 V, Fast; not operator replaceable.

Refer servicing to qualified service personnel

MTS400 Series MPEG Test Systems Technical Reference

Mechanical Characteristics

Table 1−17 lists the mechanical characteristics of the MTS400 Series platform.

Table 1−17: Mechanical characteristics

Characteristic Description

Classification Fixed location benchtop

Cooling airflow Intake is from the front and sides of the instrument.

Overall dimensions Height 226 mm (8.9 in), without bottom feet

Weight 17.7 kg (39 lb)

Shipping weight 27.3 kg (64.5 lb)

Specifications

Exhaust is to the bottom and rear of the instrument

For proper cooling, at least two inches (5.1 cm) of

clearance is needed on the rear and sides of the

instrument cabinet

Width: 432 mm (17 in)

Depth: 560 mm (22 in), with rear feet

MTS400 Series MPEG Test Systems Technical Reference

1−19

Specifications

Environmental Characteristics

Table 1−18 lists the environmental characteristics of the MTS400 Series

platform.

Table 1−18: Environmental characteristics

Characteristic Description

Atmospherics

Temperature

Operating +5 °C to +40 °C, 30 °C per hour maximum

Non-operating −20 °C to +60 °C, 30 °C per hour maximum

Humidity

Operating 20% to 80% relative humidity up to 29 °C.

Non-operating 10% to 80% relative humidity, non-condensing

Altitude

Operating 0 to 3000 m (9800 ft)

Non-operating 0 to 12,000 m (40,000 ft)

Dynamics

Random vibration

Operating 0.27 g

Non-operating 2.28 g

Sine vibration, operating 0.013 inch peak-to-peak displacement from 5 Hz to

Functional shock, non-operating 20 g, 11 ms half-sine

Transportation package material Transportation package material meets recycling

gradient; temperature of the intake air at the front

and sides of the instrument

gradient

Above 31 °C, derate linearly to 22% at 50 °C

total from 5 to 500 Hz

rms

total from 5 to 500 Hz

rms

55 Hz

criteria as described in Environmental Guidelines

for Package Design (Tektronix part number

063-1290-00) and Environmentally Responsible

Packaging Handbook (Tektronix part number

063-1302-00)

1−20

MTS400 Series MPEG Test Systems Technical Reference

Certifications and Compliances

Decl

g

Table 1−19 lists the certifications and compliances that apply to the MTS400

Series platform.

Table 1−19: Certifications and compliances

Category Standards or description

Specifications

EC Declaration of Conformity −

EMC

Australia / New Zealand

aration of Conformity −

EMC

FCC Emissions are within FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A limits

EC Declaration of Conformity −

Low Voltage

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 1010.1 : 1992 and No. 1010.1 : 1997

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 61326 EMC requirements for Class A electrical equipment for

measurement, control and laboratory use.

IEC 61000−4−2 Electrostatic discharge immunity (Performance criterion B)

IEC 61000−4−3 RF electromagnetic field immunity (Performance criterion A)

IEC 61000−4−4 Electrical fast transient / burst immunity (Performance criterion B)

IEC 61000−4−5 Power line surge immunity (Performance criterion B)

IEC 61000−4−6 Conducted RF immunity (Performance criterion A)

IEC 61000−4−11 Voltage dips and interruptions immunity (Performance criterion B)

EN 61000−3−2 AC power line harmonic emissions

EN 61000−3−3 Flicker

Complies with EMC provision of Radiocommunications Act per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Union:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1 : 2001 Safety requirements for electrical equipment for measurement

control and laboratory use.

UL61010B-1 : 2003 Equipment for measurement use.

Safety requirements for electrical equipment for measurement,

control, and laboratory use.

1

Additional Compliance ANSI/ISA S82.02.01:1999 Safety standard for electrical and electronic test, measuring,

controlling, and related equipment.

IEC61010-1:2001 Safety requirements for electrical equipment for measurement,

control, and laboratory use.

1

Refer to the RF interface card specification for the minimum RF input level required to ensure EMC immunity performance.

MTS400 Series MPEG Test Systems Technical Reference

1−21

Specifications

gy p

Table 1−19: Certifications and compliances (cont.)

Category Standards or description

Installation (Overvoltage)

Category Descriptions

Overvoltage Category Overvoltage Category II (as defined in IEC 61010-1)

Pollution Degree Descriptions A measure of the contaminates that could occur in the environment around and within a product.

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT III Distribution-level mains (usually permanently connected). Equipment at this level is

typically in a fixed industrial location.

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipment is usually cord-connected.

CAT I Secondary (signal level) or battery operated circuits of electronic equipment.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 1 No pollution or only dry, nonconductive pollution occurs. Products in

this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution Degree 2 Normally only dry, nonconductive pollution occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/home environment.

Temporary condensation occurs only when the product is out of

service.

Pollution Degree 3 Conductive pollution, or dry, nonconductive pollution that becomes

conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is

protected from direct sunshine, rain, or direct wind.

Pollution Degree Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 61010-1) − grounded product

1−22

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

The procedures in this section allow you to verify the performance of the

following MTS400 Series MPEG Test System components:

H ASI, SMPTE310M, and SPI signal interfaces

H RF interfaces

H IP interface

H MPEG Player (play and record functions)

H TS Compliance Analyzer

Preparation

Before you begin the Performance Verification procedures, review the following

information:

H Ensure that the procedures are performed only by qualified service personnel

who have read the General Safety Summary at the front of this manual.

Required Equipment

H Ensure that the service personnel are familiar with system operation (refer to

the MTS400 Series MPEG Test System Getting Started Manual).

The following equipment is required to perform the verification procedures:

H 75 BNC-to-BNC cable (quantity of one)

Tektronix part number 174-4954-00

H DB25-to-DB25 cable (quantity of one)

Tektronix part number 174-4955-00

H A copy of the “sym1.mpg” transport stream file on the E:\ drive of the

MTS400 Series system being tested

MTS400 Series MPEG Test Systems Technical Reference

2−1

Performance Verification

NOTE. The “sym1.mpg” transport stream file is supplied with every instrument

in the following directory: E:\Test Streams.

If this file has been deleted from the E:\ drive of the instrument, you will need to

copy the file from the MTS400 Series MPEG Test System Recovery CD-ROM

(Tektronix part number 063-3851-xx) to the E:\ drive of the instrument to be able

to perform these procedures. This CD-ROM is supplied as a standard accessory

with the MTS400 Series system.

Preparing the Instrument

Perform the following steps to prepare the instrument to be tested:

1. Make sure the dongle is securely installed on the parallel port.

2. Connect the keyboard and mouse to the appropriate side panel or rear panel

connectors.

3. Connect the power cord to the rear-panel power input connector.

4. Make the following cable connections on the instrument (see Figure 2−1):

H Connect the 75 BNC-to-BNC cable between the ASI/SMPTE In

connector and the ASI/SMPTE Out connector.

H Connect the DB25-to-DB25 cable between the DVB/SPI In connector

and the DVB/SPI Out connector.

5. Power on the MTS400 Series system by pushing the front panel ON/STBY

switch.

6. After the Windows XP desktop appears, launch the Windows Explorer from

the Start menu.

7. Use the Windows Explorer to locate the transport stream file named

“sym1.mpg” in the E:\Test Streams directory. All instruments are shipped

with this file.

2−2

8. Perform the following steps if the sym1.mpg transport stream file has been

deleted from the instrument:

a. Insert the MTS400 Series MPEG Test System Recovery CD-ROM into the

DVD drive of the MTS400 Series system.

b. Use the Windows Explorer to copy the transport stream file named

“sym1.mpg” from the CD-ROM to a location on the E:\ drive of the

MTS400 Series system.

9. Close the Windows Explorer.

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

75 BNC cable

12 3456 789101112

Reference C lock

ASI/SMPTE Out

ASI/SMPTE In

Input

External

Trigger

VGA

Parallel Port

Figure 2−1: Cable connections on the MTS400 Series system

Verification Procedures

Perform the following steps to verify that the MTS400 Series system is operating

properly. The steps are written with the assumption that you are performing all of

the steps in order. If you start the procedures in the middle, you will have to

review previous steps for instrument set up.

DVB/SPI In

DB25 cable

DVB/SPI Out

Ethernet

Keyboard

Mouse

Verifying the ASI Interface

1. Start the MPEG Player by double clicking the

desktop.

2. Make the following changes in the SPI/ASI/310M menu:

a. Click BNC Port, and then click ASI.

b. Click ASI Format, and then click Byte.

NOTE. In the SPI/ASI/310M menu, you do not need to make any setting changes

to the Through Out parameter.

MTS400 Series MPEG Test Systems Technical Reference

icon on the

2−3

Performance Verification

3. Use the File menu to select the transport stream file to play:

a. Click Open... to display the Open dialog box.

b. Use the Open dialog box to navigate to the E:\ drive directory where the

transport stream file named “sym1.mpg” is located.

c. Select the sym1.mpg file, and click Open. The transport stream file name

(sym1) will appear in the title of the MPEG Player window.

4. In the Play menu, verify that the Packet Size is set to 188.

NOTE. In the MPEG Player menus, a check mark appears next to the selected

setting for some menu parameters.

5. In the Play menu, click Clock... to open the Clock dialog box shown in

Figure 2−2.

a. Click Internal to set the Clock Source to internal.

b. Verify that the Data Rate is set to 41.470998 Mbps as shown in

Figure 2−2.

c. If necessary, click the Fixed ES Rate box so that a check mark appears in

the box.

d. Click OK to close the Clock dialog box.

2−4

Figure 2−2: Clock settings dialog box

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

6. In the Play menu, click Update and then click On.

7. In the Play menu, click Sync and then click TS Packet.

8. In the Play menu, click PCR Initial Value... to open the dialog box shown in

Figure 2−3.

a. Enter 0 in the Base Value entry box.

b. Enter 0 in the Extension Value entry box.

c. Click OK to close the PCR Initial Value dialog box.

Figure 2−3: PCR Initial Value settings dialog box

9. In the Play menu, click Source and then click Disk.

10. In the Play menu, click Loop and then click On.

11. In the Play menu, click Auto Play and then click Off.

NOTE. In the Play menu, you do not need to make any setting changes to the

Start/Stop parameters or to the Timer Play parameters.

MTS400 Series MPEG Test Systems Technical Reference

2−5

Performance Verification

12. In the Play menu, click Other... to open the Others dialog box shown in

Figure 2−4.

a. Use the Standard drop down list to select DVB.

b. Use the Numeric drop down list to select Hex.

c. Click on the SPI Output Enable box until a check mark appears. The Ext

Play Start setting does not matter.

d. Click Update to open the Select Update Item dialog box shown in

Figure 2−4.

H Click on Continuity Counter until a check mark appears.

H Click on PCR/PTS/DTS until a check mark appears.

H TDS/TOT/STT until a check mark appears.

H Click on NPT until no check mark appears.

H Click on Reed Solomon until no check mark appears.

H Use the Update Method drop down box to select Hardware.

H Click OK to close the Select Update Item dialog box.

e. Click OK to close the Others dialog box.

Figure 2−4: Others settings dialog box and Select Update Item settings dialog box

13. Start the TS Compliance Analyzer (TSCA) by double clicking the

icon on the desktop.

2−6

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

14. In the MPEG Player tool bar, click the green Play arrow to start playing the

transport stream file.

15. In the TSCA Open Transport Stream window, click Change... in the Stream

Interpretation section.

16. Make the following setting changes in the Stream Interpretation display (see

Figure 2−5).

a. Select DVB as the Base Standard.

b. Select No Extensions as the Region.

Figure 2−5: Stream Interpretation display in the Open Transport Stream window

MTS400 Series MPEG Test Systems Technical Reference

2−7

Performance Verification

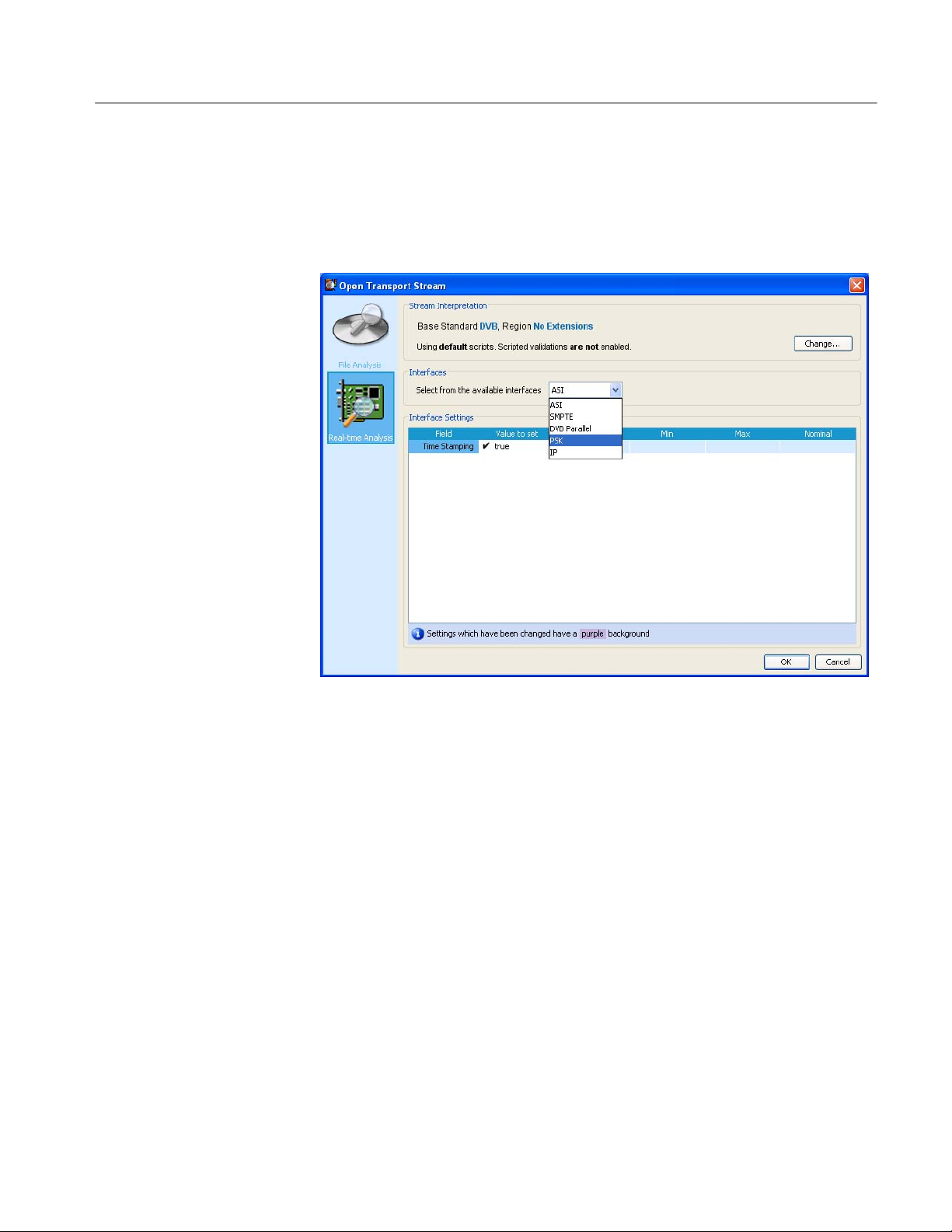

17. In the Open Transport Stream window, click Real-time Analysis.

18. Make the following setting changes in the Real-time Analysis display (see

Figure 2−6).

a. In the Interfaces drop-down box, select ASI and check that all of the

interface options for the unit are listed in the drop-down list.

b. In the Interfaces Settings section, click on the Time Stamping box until a

check mark appears.

2−8

Figure 2−6: Real Time Analysis display in the Open Transport Stream window

19. Click OK to close the Open Transport Stream window.

After a few seconds, the TS Compliance Analyzer window opens with the

analysis results of the ASI transport stream (see Figure 2−7).

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

20. Verify the following in the analyzer window:

H The TS Availability and Sync indicators at the bottom left of the

analyzer window are green.

H The bit rate readout at the bottom of the window reads 41.471 Mbps.

NOTE. It is normal if indicators other than the TS Availability and Sync turn red.

This merely indicates that the software is operating and has detected errors in

the transport stream.

Figure 2−7: ASI interface analysis results

MTS400 Series MPEG Test Systems Technical Reference

2−9

Performance Verification

Verifying the MPEG

Record Function

21. In the Record menu of the TS Compliance Analyzer, click Record Settings to

open the dialog box shown in Figure 2−8. Make the following setting

changes in the dialog box:

a. Enable Transport source (a green dot appears next to the selected

recording source).

b. Click on the ellipse box at the far right of the Path entry box to open the

Set Recording Name window.

c. In the Set Recording Name window (not shown), navigate to the

F:\ drive on the MTS400 Series system.

d. In the File Name box, enter the following file name:

record test.mpeg

e. Click Save to close the Set Recording Name window.

f. In the Record Settings window, enter 300 in the File Size entry box.

g. Select Manual as the Trigger type (a green dot appears next to the

selected trigger type).

h. Click on the “Activate this dialog when recording starts” box until a

check mark appears.

2−10

Figure 2−8: Record Settings dialog box

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

22. Click the Arm button. A red message appears in the Record Settings window

stating that the recording function is armed (see Figure 2−9).

Figure 2−9: Record Settings window with the recording function armed

23. Click the Start button. A red message appears in the Record Settings window

stating that the recording is currently in progress.

Observe the green bar showing the recording progress across the top of the

window. The recording should take about 30 seconds to complete. When the

recording is done, the progress bar says “Complete” as shown in Figure 2−8.

24. After the recording is finished, click Close to close the Record Settings

window.

MTS400 Series MPEG Test Systems Technical Reference

2−11

Performance Verification

25. Perform the following steps to verify that the transport stream file was

recorded to the F:\ drive of the instrument:

a. In the Record menu of the TS Compliance Analyzer, click Record

Settings to open the dialog box shown in Figure 2−8 on page 2−10.

b. Click on the ellipse box at the far right of the Path entry box to open the

Set Recording Name window.

c. In the Set Recording Name window, use the up arrow to navigate to the

F:\ drive on the MTS400 Series system.

d. Verify that the following file name appears:

record test.mpeg

e. Click Cancel to close the Set Recording Name window.

f. Click Close to close the Record Settings window.

26. Close the TS Compliance Analyzer by clicking Exit in the File menu.

2−12

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

Verifying the SMPTE310M

Interface

27. In the MPEG Player window, stop the player by clicking on the black Stop

button on the tool bar.

28. In the SPI/ASI/310M menu, click BNC Port, and then click 310M 8VSB.

29. Start the TS Compliance Analyzer by double clicking the

the desktop.

30. In the MPEG Player tool bar, click the green Play arrow to start playing the

transport stream file.

31. Verify that the TS rate displayed at the bottom of the MPEG Player window

displays the SMPTE310M rate of 19.392658 Mbps (see Figure 2−10).

icon on

Figure 2−10: MPEG Player playing a SMPTE310M transport stream

MTS400 Series MPEG Test Systems Technical Reference

2−13

Performance Verification

32. In the Open Transport Stream window, click Real Time Analysis.

33. In the Interfaces drop-down box, select SMPTE.

34. Click OK to close the Open Transport Stream window.

After a few seconds, the TS Compliance Analyzer window opens with the

analysis results of the SMPTE310M transport stream (see Figure 2−11 ).

35. Verify the following in the analyzer window:

H The TS Availability and Sync indicators at the bottom left of the

analyzer window are green.

H The bit rate readout at the bottom of the window reads 19.393 Mbps.

NOTE. It is normal if indicators other than the TS Availability and Sync turn red.

This merely indicates that the software is operating and has detected errors in

the transport stream.

36. Close the TS Compliance Analyzer by clicking Exit in the File menu.

2−14

Figure 2−11: SMPTE310M interface analysis results

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

Verifying the SPI Interface

37. In the MPEG Player window, stop the player by clicking on the black Stop

button on the tool bar.

38. Start the TS Compliance Analyzer by double clicking the

the desktop.

39. In the MPEG Player tool bar, click the green Play arrow to start playing the

transport stream file.

40. In the Open Transport Stream window, click Real Time Analysis.

41. In the Interfaces drop-down box, select DVB Parallel.

42. Click OK to close the Open Transport Stream window.

After a few seconds, the TS Compliance Analyzer window opens with the

analysis results of the SPI transport stream (see Figure 2−12).

43. Verify the following in the analyzer window:

H The TS Availability and Sync indicators at the bottom left of the

analyzer window are green.

H The bit rate readout at the bottom of the window reads 19.393 Mbps.

icon on

NOTE. It is normal if indicators other than the TS Availability and Sync turn red.

This merely indicates that the software is operating and has detected errors in

the transport stream.

44. Close the TS Compliance Analyzer by clicking Exit in the File menu.

MTS400 Series MPEG Test Systems Technical Reference

2−15

Performance Verification

RF Interfaces

Figure 2−12: SPI interface analysis results

The following steps ensure that any RF interfaces installed in the instrument is

available; only one interface can be installed at a time.

45. Start the TS Compliance Analyzer (TSCA) by double clicking the

icon on the desktop.

46. In the TSCA Open Transport Stream window, click Change... in the Stream

Interpretation section.

47. Make the following setting changes in the Stream Interpretation display

(see Figure 2−5).

a. Select DVB as the Base Standard.

b. Select No Extensions as the Region.

2−16

MTS400 Series MPEG Test Systems Technical Reference

Performance Verification

48. In the Open Transport Stream window, click Real-time Analysis.

49. In the Interfaces drop-down box, select the RF interface, for example, as

shown in Figure 2−13, PSK.

Figure 2−13: RF interface selection

50. Note that the Firmware version is current.

If the firmware version is not current, a message is displayed and the Update

Firmware button is activated. Click Update Firmware and allow the update

to complete.

51. Note that the Interface Settings are displayed. See Figure 2−14. If you want

to proceed with analysis, you may need to change the settings to suit your

local setup.

MTS400 Series MPEG Test Systems Technical Reference

2−17

Performance Verification

Shutting Down the

Instrument

Figure 2−14: RF interface settings

52. Click OK to close the Open Transport Stream window and proceed with

analysis.

After a few seconds, the TS Compliance Analyzer window opens with the

analysis results of the ASI transport stream (see Figure 2−7).

53. After you have checked the SPI interface, you have completed the Performance Verification procedures. Perform the following steps to power down

the instrument:

a. Select Shutdown from the Start menu. After the instrument shuts down,

you will see a message saying its safe to turn off the instrument.

b. Use the front-panel power switch to turn the instrument off.

c. Remove the two signal cables from the rear panel of the instrument.

d. Remove the power cord from the instrument.

2−18

MTS400 Series MPEG Test Systems Technical Reference

Loading...

Loading...