Tektronix MTS300 Reference manual

Technical Reference

MTS300 MPEG Test System

Hardware and Software Installation

071-0667-04

This document applies to firmware version 6.1.

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Spec ifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defecti ve product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products ret urned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or i nadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repai r damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS W ARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

Hardware Installation

First Time Operation

General Safety Summary v...................................

Service Safety Summary vii....................................

Related Documents ix...............................................

Contacting Tektronix xi.............................................

Hardware Installation 1--1......................................

Unpacking the MTS300 System 1--2.....................................

Accessories 1--2.................................................

Options 1--3.....................................................

Upgrades 1--5...................................................

Hardware Installation 1--6.............................................

Connecting MTS300 System I/O Ports 1--11...............................

Repackaging for Shipment 1--16.........................................

First Time Operation 2--1.......................................

Starting the MTS300 System 2--1.......................................

Shutting Down the MTS300 System 2--4.................................

Functional Check 2--7..........................................

10 MHz Reference Clock 2--7..........................................

Re m o v i n g t h e C a b i n e t 2 --- 8...........................................

I/O System 2--16.....................................................

MPEG-2 Software Components 2--23.....................................

TMCC Software Components 2--35......................................

Specifications

Specifications 3--1.............................................

Monitoring Characteristics 3--1.........................................

Interface Platform Characteristics 3--2...................................

I/O Port Electrical Characteristics 3--2...................................

Power Characteristics 3--11.............................................

Environmental Characteristics 3--11......................................

Mechanical (Physical) Characteristics 3--12................................

Certifications and Compliances 3--12.....................................

Software Repair and Recovery

Software Repair and Recovery 4--1...............................

Software Repair Strategy 4--1..........................................

Restoring System Settings 4--3.........................................

Restoring Device Drivers 4--17..........................................

Restoring the Operating System and Application Software 4--23...............

Index

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

i

Table of Contents

List of Figures

Figure 1--1: Typical MTS300 test system rear panel connectors 1--7....

Figure 1--2: Keyboard and mouse alternative connections 1--8........

Figure 1--3: Software Key 1--9...................................

Figure 1--4: Rear-panel configuration with one ASI/M2S (Option AS)

interface installed 1--12......................................

Figure 1--5: Rear-panel configuration with two ASI/M2S (Option AS)

interfaces installed 1--12......................................

Figure 1--6: Rear-panel configuration with ASI/M2S (Option AS)

and SSI (Option SS) interfaces installed 1--13....................

Figure 1--7: Rear-panel configuration with ASI/M2S (Option AS)

and DHEI (Option DE) interfaces installed 1--13.................

Figure 1--8: Rear-panel configuration with ASI/M2S (Option AS)

and SPI (Option LV) interfaces installed 1--14...................

Figure 1--9: Rear-panel configuration with one SSI (Option SS)

interface installed 1--14......................................

Figure 1--10: Rear-panel configuration with two SSI (Option SS)

interfaces installed 1--15......................................

Figure 1--11: Rear-panel configuration with SSI (Option SS)

and ASI/M2S (MTS3FAS) interfaces installed 1--15...............

Figure 1--12: Repackaging the instrument (new packaging) 1--17.......

Figure 1--13: Repackaging the instrument (old packaging) 1--19.......

Figure 1--14: Placement of bottom spacer pad in inner shipping box 1--20

Figure 2--1: On/Stby switch 2--1.................................

Figure 2--2: Removing the cabinet handle 2--9......................

Figure 2--3: Removing the cabinet feet 2--9........................

Figure 2--4: Removing the circuit board retaining plate 2--10..........

Figure 2--5: Location of 10 MHz clock test point 2--11................

Figure 2--6: Removing the PIA+ module 2--13.......................

Figure 2--7: Adjusting the 10 MHz reference clock 2--14..............

Figure 2--8: Typical initial equipment setup 2--17....................

Figure 2--9: Tektronix MPEG Test System program window 2--18......

Figure 2--10: Connect to local Server Manager 2--18.................

Figure 2--11: Start the testing routine 2--19.........................

Figure 2--12: Begin the self test routine 2--19........................

Figure 2--13: Window showing sample test results summary 2--20......

Figure 2--14: Message box with connection requirements 2--21.........

ii

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Table of Contents

Figure 2--15: Connections for trigger test 2--22......................

Figure 2--16: Connections for clock test 2--22........................

Figure 2--17: ASI cabling 2--23....................................

Figure 2--18: Initial Master Client application window 2--24...........

Figure 2--19: Connecting to the local Server Manager 2--24............

Figure 2--20: Master Client window showing no assigned ports 2--25....

Figure 2--21: Port Manager panel showing Analysis Server selected 2--26

Figure 2--22: Selecting Launch Stream Player Client 2--26............

Figure 2--23: Stream Player Application window 2--27...............

Figure 2--24: C:\MTS300\Cfg-Trp directory 2--28....................

Figure 2--25: Starting transport stream analysis 2--29................

Figure 2--26: Master Client in Analysis mode 2--29...................

Figure 2--27: Expert Client application window 2--30................

Figure 2--28: Setup for testing second input 2--31....................

Figure 2--29: Exit Expert Client application 2--31....................

Figure 2--30: Expert Client application window 2--33................

Figure 2--31: Rear panel connections for I/O #3 test procedure 2--34....

Figure 2--32: Probes added in the TMCC Configuration Client 2--35....

Figure 2--33: TMCC Expert Client 2--36...........................

Figure 3--1: Parallel data timing, 188-byte packets 3--5..............

Figure 4--1: Deleting partitions using the Disk Administrator utility 4--7

Figure 4--2: Software Protection key 4--25..........................

Figure 4--3: Checking the free disk space 4--26......................

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

iii

Table of Contents

List of Tables

T able 1--1: Standard accessories for the MTS300 system 1--2.........

Table 1--2: Optional accessories 1--3..............................

Table 1--3: MTS300 test system options 1--3.......................

Table 1--4: Possible interface configurations 1--4...................

Table 1--5: MTS300 test system upgrades 1--5.....................

Table 1--6: Rear-panel connectors 1--6............................

T able 1--7: Electrical operating requirements 1--9..................

T able 2--1: Adjustment table for 10 MHz reference clock 2--15.........

Table 3--1: Platform characteristics 3--2...........................

T a b l e 3 -- 2 : A S I 3 -- 2...........................................

Table 3--3: SPI-LVDS parallel (Option MTS3FLV) 3-- 3.............

Table 3--4: LVDS parallel data pin connections 3-- 5.................

Table 3--5: SSI (Option SS) 3--6.................................

Table 3--6: DHEI-Digicipher II 3--7..............................

Table 3--7: DHEI Expansion In pin connections 3--9................

Table 3--8: DHEI Expansion Out pin connections 3-- 10..............

T able 3--9: AC power source characteristics 3--1 1....................

T able 3--10: Environmental characteristics 3--1 1....................

T able 3--11: Mechanical characteristics 3--12.......................

Table 3--12: Certifications and compliances 3--12....................

Table 3--13: Environmental limits and use classification for safety

certification compliance 3--13.................................

Table 4--1: MTS300 system COM port settings 4--8.................

Table 4--2: Touchscreen driver hardware settings 4--22...............

iv

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

v

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Protective Ground

(Earth) Terminal

vi

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

vii

Service Safety Summary

viii

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Preface

This manual provides installation and first-time operating instructions for the

MTS300 MPEG Test Systems software version 6.1.

The individual sections of this manual provide specific information on the

following topics:

H The Hardware Installation section contains basic instructions on how to

install and operate the test system.

H The First Time Operation section contains procedures to verify the test

system is functioning properly.

H The Specifications section lists the electrical characteristics of the platform,

I/O system, and the Synchronous Serial Interface. This section also includes

environmental and physical characteristics and repackaging information.

H The Software Repair and Recovery section contains procedures to trouble-

shoot and restore the operating system and device drivers and reinstall the

MTS300 applications software.

For the latest information about MTS300 system software features and bugs,

refer to the MPEG Test System Software Version 6.1 Read This First document,

Tektronix part number 071-0666-XX, that accompanied your test system,

software product, or upgrade.

Related Documents

For additional information about using MTS300 system software to monitor,

analyze, and generate MPEG-2, DVB, and ATSC data streams, refer to the

following manuals:

The MTS300 MPEG Test System Real-Time Analysis User Manual, Tektronix

part number 071-0658-XX, contains information about using the Real-Time

MPEG-2 Analyzer application.

The MTS300 MPEG Test System MPEG-2 DVB/ATSC/ISDB-S/ARIB System

Analyzer User Manual, Tektronix part number 071-0659-XX, contains information about using the Deferred-Time Analyzer and DVB Channel Coding and

Decoding applications.

The MTS300 MPEG Test System Program Stream Analyzer User Manual,

Tektronix part number 071-0662-XX, contains information about using the

deferred-time Program Stream Analyzer application.

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

ix

Preface

The MTS300 MPEG Test System Stream Creation Applications User Manual,

Tektronix part number 071-0778-XX, contains information about using the

Multiplexer, DVB Table Editor, ATSC Table Editor, DVB Channel Coding and

Decoding, Jitter Adder, Error Injector, and Open MUX Controller applications.

The MTS300 MPEG Test System Dolby Digital Audio Stream Analyzer User

Manual, Tektronix part number 071-0661-XX, contains information about using

the deferred-time AC-3 Audio Stream Analyzer application.

The MTS300 MPEG Test System Audio Stream Analyzer User Manual, Tektronix

part number 071-0663-XX, contains information about using the deferred-time

MPEG Audio Stream Analyzer application.

The MTS300 MPEG Test System Video Stream Analyzer User Manual, Tektronix

part number 071-0664-XX, contains information about using the deferred-time

MPEG Video Stream Analyzer application.

The MTS300 MPEG Test Options User Manual, Tektronix part number

1000-3031, contains information about using the Data Broadcast Carousel

Analyzer application, the Elementary Stream Analyzer application, and the

Multiplexer application.

For additional information about test system maintenance and repair, refer to the

optional MTS300 MPEG Test System Service Manual, Tektronix part number

071-0668-XX. Contact your nearest Tektronix representative or field office for

ordering information.

For additional information about the Windows NT operating system, refer to the

online help provided with the test system.

x

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Contacting Tektronix

Preface

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix Web site for a list of offices.

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

xi

Preface

xii

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Hardware Installation

Hardware Installation

This section contains the following information:

H Unpacking the MTS300 system

H Hardware installation

H Repackaging the MTS300 system for shipment

For information on generating and analyzing MPEG transport streams, refer to

the MTS300 system user manuals. See page ix for a list of the available manuals.

Refer to First Time Operation on page 2--1 for instructions on how to verify

basic instrument operation after the MTS300 system has been installed.

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

1- 1

Hardware Installation

Unpacking the MTS300 System

The tables in this section list the standard and optional accessories available for

the MTS300 system.

NOTE. You must use the original box and packaging when returning your test

system to Tektronix. In the event shipping is required for upgrade or repair, refer

to Packaging for Shipment on page 1--16.

Accessories

Table 1--1 lists the standard accessories that are shipped with your MTS300

system. Use this list to ensure that your order is complete.

Table 1- 1: Standard accessories for the MTS300 system

Quantity Description Part number

1ea Read This First 071-0666-XX

1ea MTS300 MPEG Test System Hardware and Software

Installation Technical Reference (this manual)

1ea MTS300 MPEG Test System Real-Time Analysis User

Manual (includes 063-3325-XX CD-ROM)

1ea MTS300 MPEG Test System Stream Creations User

Manual

1ea Applications software recovery disc (supplied with

071-0658-XX manual)

1ea Operating system recovery disc 063-3366-XX

1ea License Password document

Note: Keep this document in a safe place. You will need it

if you ever have to reinstall your software.

1ea Power cord (North American) 161-0066-00

071-0667-XX

071-0658-XX

071-0778-XX

063-3325-XX

(not orderable)

063-3158-XX

1- 2

1ea Stylus (for use with the touchscreen) 119-6107-XX

1ea SCSI terminator (installed on the t est syst em) 650-4062-XX

1ea Front panel cover 200-4408-XX

1ea Emergency backup disk (floppy disk)

1ea Mouse

1ea Keyboard

1ea Statement of ISO Compliance (in envelope)

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Hardware Installation

Table 1--2 lists the optional accessories you can order for your MTS300 system.

See your Tektronix representative for help ordering these optional accessories.

Table 1- 2: Optional accessories

Description Part number

MTS300 MPEG Test System Service Manual 071-0668-XX

Rackmount cabinet conversion kit w ith instructions 016-1921-XX

Power cord options:

Option A1 Universal Euro 161-0066-09

Option A2 United Kingdom 161-0066-10

Option A3 Australian 161-0066-11

Option A5 Swiss 161-0154-00

Options

Table 1--3 lists the options available when you purchase the test system.

Table 1--4 lists the possible interface configurations.

Table 1- 3: MTS300 test system options

Category Option Description

MTS300 Basic instru-

ment

Interface

1

Option AS ASI/M2S asynchronous serial interface

Option DE DHEI (GI-Digicypher) interface

Option LV SPI (LVDS) sychronous parallel interface

Option SS SSI (SMPTE310M) synchronous serial interface

Test System with at least one user-selected interface and the

following client applications:

Master Client

Expert Client

TMCC Expert Client

Configuration Client

TMCC Configuration Client

Stream Player Client

Stream Recorder Client

The MTS300 also comes with the Private Syntax Interpreter

and the Jitter Adder applications.

2

2

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

1- 3

Hardware Installation

Table 1- 3: MTS300 test system options (Cont.)

Category DescriptionOption

Software Option DA Deferred-Time Analysis System (user manual 071-0659-XX),

which includes the following applications:

MPEG-2 DVB/ATSC/ISDB-S/ARIB System Analyzer

TMCC Deferred-Time Analyzer

MPEG-2 DVB/ATSC/ISDB-S/ARIB Multiplexer

DVB Table Editor

ATSC Table Editor

ARIB Table Editor

DVB Channel Coding and Decoding

Error Injector

Option AC3 Dolby Digital (AC-3) Analyzer (user manual 071-0661-XX)

Option OC ViAccess Conditional Access (requires Option DT)

Option OM OpenMuxTMReal-Time Multiplexer (user manual 071-0778-XX)

Option ES MPEG Audio and MPEG Video Elementary Stream Analyzers

(user manuals 071-0663-XX and 071-0664-XX)

Option PS Program Stream Analyzer (user manual 071-0662-XX)

Option TM TMCC Combiner

1

Each hardware interface option adds two input/output pairs, clock, and trigger

connections. The test system maximum capacity is any two interface options except

as noted in Table 1 - 4.

2

The SPI (LVDS) and DHEI (GI-Digicypher) interfaces can only be ordered when you

order an ASI/M2S interface.

Table 1- 4: Possible interface configurations

First mezzanine Second mezzanine (one of the following)

ASI/M2S interface None

ASI/M2S interface

SMPTE310M (SSI) interface

DHEI (GI-Digicypher) interface

SPI (LVDS) interface

1

SSI (SMPTE310M) interface None

SSI (SMPTE310M) interface

ASI/M2S interface

1

The SPI (LVDS) and DHEI (GI-Digicypher) interfaces can only be ordered when you

2

order an ASI/M2S interface.

2

This configuration is only available when you install the MTS3FAS hardware upgrade

into an existing MTS300 with an SSI (SMPTE310M) interface.

1

1- 4

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Hardware Installation

Upgrades

Table 1--5 lists the upgrades available for an existing MTS300 MPEG Test

System. You can order some of these upgrades when you purchase your

instrument and they will be installed at the factory.

NOTE. All of the MTS300 upgrade kits require that you run the Sales Wizard file

MTS3WIZ.ZIP. The latest version is available from www.tektronix.com.

Table 1- 5: MTS300 test system upgrades

Category Part number Description

Interface

Software MTS3FDA Adds Deferred-Time Analysis System to existing MTS300

1

MTS3FAS Adds ASI/M2S interface to existing MTS300

MTS3FDE Adds DHEI (GI-Digicypher) interface to existing MTS300

MTS3FLV Adds SPI (LVDS) sychronous parallel interface to existing

MTS300

MTS3FSS Adds SSI (SMPTE310M) synchronous serial interface to

existing MTS300

MTS3FAC Adds Dolby Digital (AC--3) Analyzer to existing MTS300

MTS3FOC Adds ViAccess Conditional Access to existing MTS300

MTS3FOM Adds Real-Time Multiplexing (Open Mux) to existing

MTS300

MTS3FES Adds MPEG Audio/Video Elementary Stream Analyzers to

existing MTS300

MTS3FPS Adds Program Stream Analyzer to existing MTS300

MTS3FTM Adds TMCC Combiner to existing MTS300

MTS3FDB Adds Data Broadcast Carousel Analyzer to existing

MTS300

MTS3FIN Adds Elementary S tream Analyzer for all MPEG-1 and

MPEG-2 transport streams to existing MTS300

MTS3FMX Adds off-line Multiplexer to existing MTS300

1

Each interface option adds two input/output pairs, clock, and trigger connections.

The test system maximum capacity is any two interface options except as noted in

Table 1- 4.

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

1- 5

Hardware Installation

Hardware Installation

This section provides instructions for installing the MTS300 system and making

the necessary electrical connections. The MTS300 system can be operated from a

bench or installed in a rack using the optional rack-mount kit. The rack-mount

kit includes installation instructions.

CAUTION. For proper cooling, provide at least two inches (5.1 cm) of clearance

at the rear and to the sides of the test system, and ensure that the air temperature

at all air intake vents (inside of the equipment rack) does not exceed 40

°C.

Use the two collapsible front feet on the bottom of the MTS300 system to

change the height of the front panel.

Test System

Interconnections

The location of the connectors on a typical test system rear panel is shown

Figure 1--1. Table 1--6 describes the transport stream, network, and peripheral

device connectors. Refer to Connecting the MTS300 System I/O Ports on

page 1--11 for illustrations of the various rear-panel connector configurations.

Table 1- 6: Rear-panel connect ors

Connector Description

Transport stream input/out put

ASI/M2S Input/Output

SPI (LVDS) Input/Output

DHEI (GI Digicypher)

Input/Output

SSI Input/Output

Monitor 15-pin female high density-D-sub connector for SVGA

Keyboard Mini-DIN connectors for PS2 compatible keyboard (on rear

Mouse Mini-DIN connectors for PS2 compatible mouse (on rear and

Each format includes two input/output pairs

monitor

and side panels)

side panels)

1- 6

Printer 25-pin sub-D connector for parallel communi cation

LAN (Ethernet) 10 Base-T/100 Base-T, RJ45 connector for Ethernet

communications

RS-232/422 9-pin D-sub type connector for serial communication

SCSI Standard, PC compatible Ultra-Wide SCSI port, 68 Pins

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Power

ASI I/O

SPI (LVDS) I/O

(Option LV or MTS3FLV)

Hardware Installation

Ethernet

Parallel Port

RS-232

COM Port 1

Figure 1- 1: Typical MTS300 test system rear panel connectors

SCSI

MouseKeyboardSVGA

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

1- 7

Hardware Installation

The following procedure identifies the electrical connections.

1. Plug in the keyboard and mouse to the proper rear panel connectors. Refer to

Figure 1--1. Figure 1--2 shows alternative connectors for a mouse and

keyboard. The optional connections are located on the instrument side panel.

Earphones

USB

Keyboard

Mouse

Figure 1- 2: Keyboard and mouse alternative connections

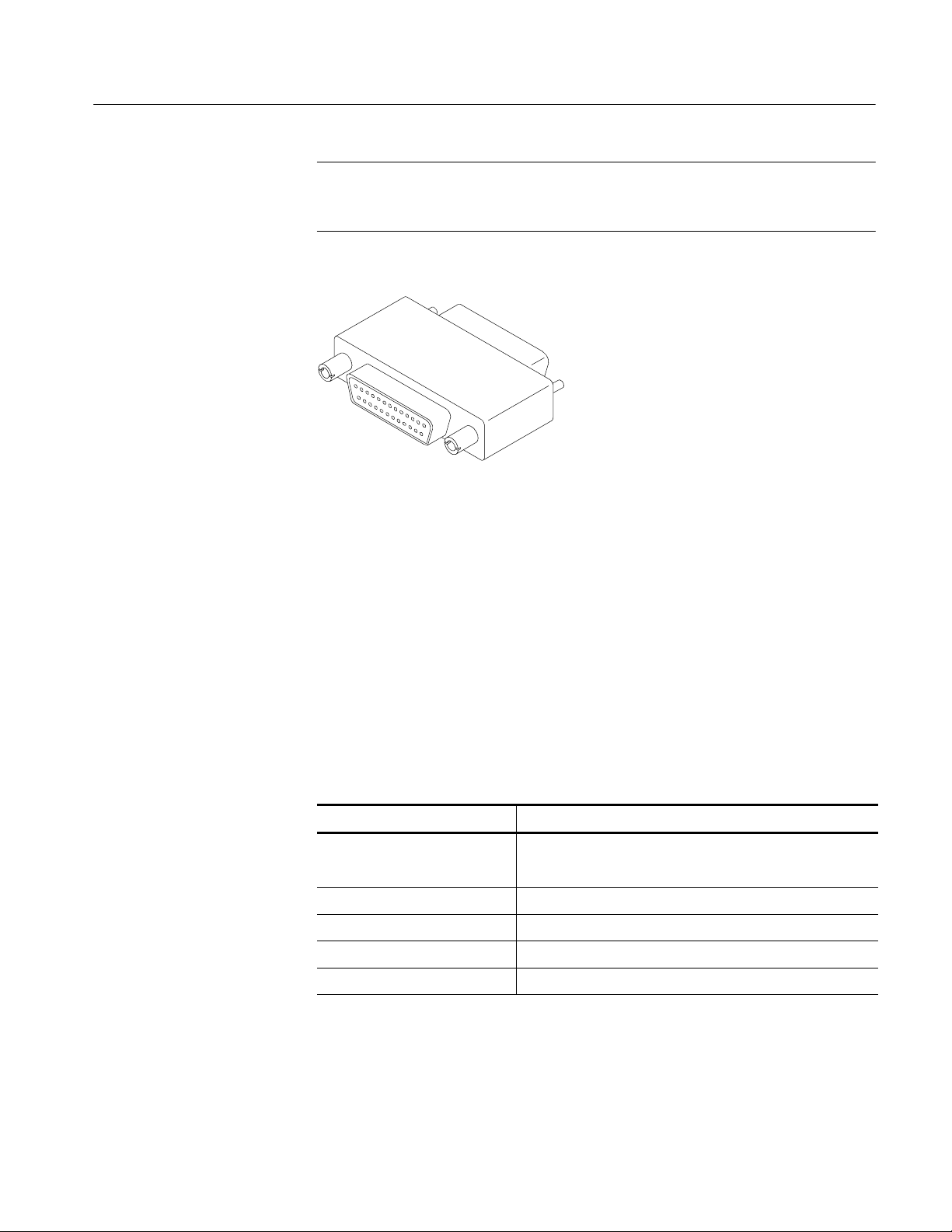

2. Install the Software Key on the rear panel Parallel port. MTS300 MPEG Test

System software applications will not run without the Software Key

installed; do not remove or misplace the Software Key.

To use the Parallel port with the Software Key installed, attach any parallel

port cables (such as a printer) directly to the Software Key. The Software

Key does not interfere with parallel communications.

1- 8

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Hardware Installation

NOTE. To run MTS300 MPEG Test System applications, the Software Key must

be on the computer Parallel port. If you return the test system to a Tektronix

Service Center for upgrade or repair, include the Software Key.

Figure 1- 3: Software Key

Supplying Power

The MTS300 MPEG Test System platform is designed to operate from a

single-phase power source having one of its current carrying conductors at or

near earth ground (the neutral conductor). Power sources that have both current

carrying conductors live with respect to ground, such as phase-to-phase or

multiphase systems, are not recommended. A protective ground connection, by

way of the grounding conductor in the power cord, is essential for safe operation.

The electrical operating requirements are listed in Table 1--7.

Table 1- 7: Electrical operating requirements

Requirement Specification

Source Voltage 100 VAC to 240 VAC

47 Hz to 63 Hz

Fuse Rating 10 A Fast / 250 V

Maximum Power Consumption 170 Watts typical

Inrush Surge Current 36 Amps maximum

Power Factor Correction Yes

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

1- 9

Hardware Installation

After you have installed the MTS300 system and completed making the signal,

network, and peripheral connections, plug the power cord into the mains. See

Figure 1--1 for location of power connector.

CAUTION. Do not supply power to the instrument until all connections have been

made.

WARNING. The test system is designed for connection to an earth-grounded AC

outlet. To avoid risk of electrical shock or equipment damage, do not disable the

grounding plug.

Mains Voltage Range. You can power the test system computer and monitor from

mains that supply between 100 VAC and 240 VAC without setting a voltage

selection switch.

Mains Frequency. The test system computer and monitor operate on either 50 Hz

or 60 Hz line frequencies.

CAUTION. To prevent damage, protect the system computer from power fluctuations and temporary interruptions with a regulating noninterruptible power

supply. This device protects the hardware from damage caused by power surges

and voltage spikes. In addition, it allows the system to operate temporarily

during a power failure.

Power Cord Options. Unless a specific power cord option is ordered, the system

computer and monitor come standard with a power cord for North American

60 Hz, 120 VAC supplies. Table 1--2 on page 1--3 lists the power cord options.

1- 10

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

Connecting MTS300 System I/O Ports

Figure 1--4 through Figure 1--11 show the available input and output (I/O)

connector configurations on the MTS300 rear panel. For I/O port specifications,

refer to the Specifications section beginning on page 3-1. Use the I/O ports that

best suit your operating environment and signal sources. A description of each

connector type follows.

Hardware Installation

Input

Trigger Input

Clock Input

Output to Other

Equipment

You must provide input to the MTS300 system to monitor an MPEG-2, DVB, or

ATSC bit stream. The MTS300 system I/O ports can be ASI serial, SPI (LVDS),

DHEI (GI-Digicypher), or SSI (SMPTE310M). To change the configuration,

refer to Configuration Client Reference in the MTS300 MPEG Test System

Real-Time Analysis User Manual.

The trigger input accepts a TTL level (0 to +5 V) signal you can use to control

capture of the MTS300 system input stream to the system disks. You can

configure the system to start/stop data capture on either the rising edge (low to

high transition) or the falling edge (high to low transition) of the trigger signal.

Refer to the MTS300 MPEG Test System Real-Time Analysis User Manual for

further information on capturing transport stream inputs.

Each output port has a corresponding clock input which can be used to clock the

transport stream output when using Stream Player. The clock rate is at the byte

rate of the transport stream for the ASI/M2S and SPI (LVDS) formats. The clock

rate is at the bit rate of the transport stream for the SMPTE310M (SSI) and

DHEI (GI Digicypher) formats.

Applications generating an output will do so on the I/O port to which the

application has been assigned. Applications requiring an input have an output

activation option that will loop-through the input signal to the output connector

on the assigned I/O port.

When an output port is used to generate signals using the Stream Player or

OpenMux applications, the corresponding input port cannot be used.

MTS300 MPEG Test System Hardware and Software Installation Technical Reference

1- 11

Hardware Installation

ASI/M2S I/O

Figure 1- 4: Rear-panel configuration with one ASI/M2S (Option AS) interface installed

ASI/M2S I/O ASI/M2S I/O

Figure 1- 5: Rear-panel configuration with two ASI/M2S (Option AS) interfaces installed

1- 12

MTS300 MPEG Test System Hardware and Software Installation Technical Reference