Page 1

Service Manual

MTS300

MPEG Test System

071-0668-00

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(i i) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software -- Restricted Rights clause at FAR 52.227-19, as applicable.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered tradem arks of Tektronix, Inc.

Page 3

Hardware Warranty

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and

workmanship for a period of one (1) year from the date of shipment. If a product proves defective during this

warranty period, Tektronix, at its option, either will repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR

THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Software Warranty

Tektronix warrants that the media on which thi s software product is furnished and the e ncoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If a medium or encoding proves defective during the warranty period, Tektronix will provide a

replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished, this software product is provided “as is” without warranty of any kind, either express or impl ied.

Tektronix does not warrant that the functions contained in this software product will meet Customer’s

requirements or that the operation of the programs will be uninte rrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If Tektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS W ARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS

OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’

RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’SPAYMENTIS

THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER

TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 5

Table of Contents

Specifications

General Safety Summary ix...................................

Service Safety Summary xi....................................

Preface xiii...................................................

Manual Structure xiii................................................

Manual Conventions xiv..............................................

Related Documents xvi...............................................

MPEG Test System Applications xvi....................................

Contacting Tektronix xxi.............................................

Product Description 1--1........................................

Characteristic Tables 1--11.......................................

Monitoring Characteristics 1--11.........................................

Interface Platform Characteristics 1--12...................................

I/O Port Electrical Characteristics 1--12...................................

Power Characteristics 1--21.............................................

Environmental Characteristics 1--21......................................

Mechanical (Physical) Characteristics 1--22................................

Certifications and Compliances 1--22.....................................

Operating Information

Theory of Operation

Installation

Hardware Installation 2--1.............................................

Connecting MTS300 System I/O Ports 2--7...............................

Networking 2--12.....................................................

Operating Information 2--19.....................................

Starting the MTS300 System 2--20.......................................

Shutting Down the MTS300 System 2--25.................................

Application Overviews 2--28............................................

Front Panel Controls 2--39..............................................

Tutorial 2--43..................................................

Preliminary Setup 2--43................................................

Starting and Configuring the Master Client 2--44............................

Assigning Servers and Generating a Transport Stream 2--47...................

Monitoring a Transport Stream Input 2--48.................................

Configuring the Analysis Server 2--51....................................

Configuring the Data Logging Function 2--54..............................

Analyzing a Transport Stream 2--55......................................

Recording a Transport Stream Input 2--58.................................

Mainframe Operation 3--1.............................................

MTS300 System Modules Operation 3--5.................................

MTS300 MPEG Test System Service Manual

i

Page 6

Table of Contents

Performance Verification

10 MHz Reference Clock 4--1..........................................

I/O System 4--10.....................................................

MPEG-2 Software Components 4--17.....................................

TMCC Software Components 4--29......................................

Adjustment Procedures

Maintenance

Maintenance 6--1..............................................

Servicing Preparation 6--1.............................................

Cleaning and Preventive Maintenance 6--3................................

Repackaging for Shipment 6--6.........................................

Power-on Diagnostics and Troubleshooting 6--10............................

Network Troubleshooting 6--14..........................................

Troubleshooting the SCSI Drives 6--22....................................

Software Repair and Recovery 6--23...............................

Software Repair Strategy 6--23..........................................

Restoring System Settings 6--25.........................................

Restoring Device Drivers 6--39..........................................

Restoring the Operating System and Application Software 6--45...............

Removal and Replacement Procedures 6--53........................

Replaceable Modules 6--53.............................................

Recommended Tools 6--54.............................................

Accessing Replaceable Modules 6--54....................................

Replacing MTS300 Test System Modules 6--58.............................

Replacing Mainframe Modules 6--70.....................................

Options

Replaceable Electrical Parts

Diagrams

Replaceable Mechanical Parts

Parts Ordering Information 10--1.........................................

Module Servicing 10--2................................................

Using the Replaceable Parts List 10--2....................................

ii

MTS300 MPEG Test System Service Manual

Page 7

List of Figures

Table of Contents

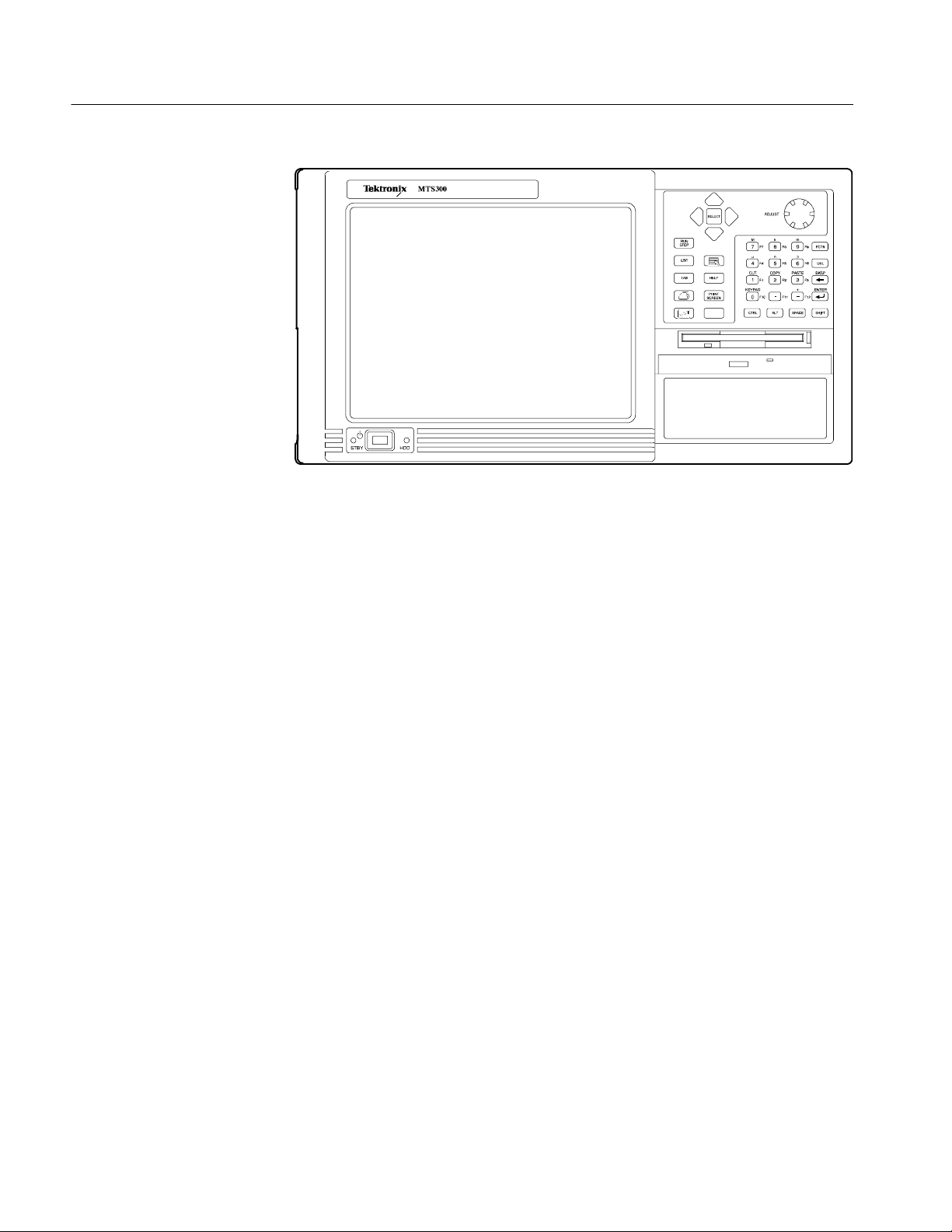

Figure 1--1: MTS300 MPEG Test System 1--2......................

Figure 1--2: Parallel data timing, 188-byte packets 1--15..............

Figure 2--1: Typical MTS300 test system rear panel connectors 2--2....

Figure 2--2: Keyboard and mouse alternative connections 2--3........

Figure 2--3: Software Key 2--4...................................

Figure 2--4: Rear-panel configuration with one ASI/M2S (Option AS)

interface installed 2--8......................................

Figure 2--5: Rear-panel configuration with two ASI/M2S (Option AS)

interfaces installed 2--8......................................

Figure 2--6: Rear-panel configuration with ASI/M2S (Option AS)

and SSI (Option SS) interfaces installed 2--9....................

Figure 2--7: Rear-panel configuration with ASI/M2S (Option AS)

and DHEI (Option DE) interfaces installed 2--9.................

Figure 2--8: Rear-panel configuration with ASI/M2S (Option AS)

and SPI (Option LV) interfaces installed 2--10...................

Figure 2--9: Rear-panel configuration with one SSI (Option SS)

interface installed 2--10......................................

Figure 2--10: Rear-panel configuration with two SSI (Option SS)

interfaces installed 2--11......................................

Figure 2--11: Rear-panel configuration with SSI (Option SS)

and ASI/M2S (MTS3FAS) interfaces installed 2--11...............

Figure 2--12: Network dialog box showing TCP/IP Protocol item 2--14..

Figure 2--13: IP tab parameters 2--15..............................

Figure 2--14: DNS tab parameters 2--16............................

Figure 2--15: On/Stby switch 2--20................................

Figure 2--16: The Master client application window 2--29.............

Figure 2--17: The Expert client application window 2--30.............

Figure 2--18: The Configuration client application window 2--32.......

Figure 2--19: The Stream Player client application window 2--33.......

Figure 2--20: Stream Recorder client application window 2--34.........

Figure 2--21: TMCC Expert Client display 2--37.....................

Figure 2--22: TMCC Configuration Client display 2--38..............

Figure 2--23: Front-panel elements 2--39............................

Figure 2--24: Initial setup for the tutorial 2--44......................

Figure 2--25: Initial Master Client application window 2--45...........

Figure 2--26: Master Client connected to the local Server Manager 2--45.

MTS300 MPEG Test System Service Manual

iii

Page 8

Table of Contents

Figure 2--27: Changing the analysis display options 2--46.............

Figure 2--28: Assigning servers to I/O ports 2--47....................

Figure 2--29: Stream Player client 2--48............................

Figure 2--30: Monitoring a transport stream 2--49...................

Figure 2--31: Services panel details view 2--50.......................

Figure 2--32: Configuration Client display 2--51.....................

Figure 2--33: Setting ETR290 probes 2--52..........................

Figure 2--34: Changing the message level 2--53......................

Figure 2--35: Data Logging configuration panel 2--54.................

Figure 2--36: Launching the Expert Client 2--55.....................

Figure 2--37: Expert Client display showing errors 2--56..............

Figure 2--38: ETR290 view panel in the Expert Client 2--57...........

Figure 2--39: Stream Recorder client application window 2--58.........

Figure 3--1: Mainframe simplified block diagram 3--2...............

Figure 4--1: Removing the right-side handle screws 4--3..............

Figure 4--2: Removing the rear-panel feet 4--3......................

Figure 4--3: Removing the circuit board retaining plate 4--4..........

Figure 4--4: Location of 10 MHz clock test point 4--5................

Figure 4--5: Removing the PIA+ module 4--7.......................

Figure 4--6: Adjusting the 10 MHz reference clock 4--8..............

Figure 4--7: Typical initial equipment setup 4--11....................

Figure 4--8: Tektronix MPEG Test System program window 4--12......

Figure 4--9: Connect to local Server Manager 4--12..................

Figure 4--10: Start the testing routine 4--13.........................

Figure 4--11: Begin the self test routine 4--13........................

Figure 4--12: Window showing sample test results summary 4--14......

Figure 4--13: Message box with connection requirements 4--15.........

Figure 4--14: Connections for trigger test 4--16......................

Figure 4--15: Connections for clock test 4--16........................

Figure 4--16: ASI cabling 4--17....................................

Figure 4--17: Initial Master Client application window 4--18...........

Figure 4--18: Connecting to the local Server Manager 4--18............

Figure 4--19: Master Client window showing no assigned ports 4--19....

Figure 4--20: Port Manager panel showing Analysis Server

selected 4--20...............................................

Figure 4--21: Selecting Launch Stream Player Client 4--20............

Figure 4--22: Stream Player Application window 4--21...............

iv

MTS300 MPEG Test System Service Manual

Page 9

Table of Contents

Figure 4--23: C:\MTS300\Cfg-Trp directory 4--22....................

Figure 4--24: Starting transport stream analysis 4--23................

Figure 4--25: Master Client in Analysis mode 4--23...................

Figure 4--26: Expert Client application window 4--24................

Figure 4--27: Setup for testing second input 4--25....................

Figure 4--28: Exit Expert Client application 4--25....................

Figure 4--29: Expert Client application window 4--27................

Figure 4--30: Rear panel connections for I/O #3 test procedure 4--28....

Figure 4--31: Probes added in the TMCC Configuration Client 4-- 29....

Figure 4--32: TMCC Expert Client 4--30...........................

Figure 6--1: Repackaging the program monitor 6--7.................

Figure 6--2: Placement of bottom spacer pad in inner shipping box 6--8

Figure 6--3: Incorrect IP address 6--15.............................

Figure 6--4: Incorrect subnet mask 6--16...........................

Figure 6--5: Incorrect default gateway IP address 6--17...............

Figure 6--6: Ping.exe command window 6--19.......................

Figure 6--7: Tracert.exe command window 6--20.....................

Figure 6--8: Command prompt with nslookup results 6--21............

Figure 6--9: Deleting partitions using the Disk Administrator

utility 6--28.................................................

Figure 6--10: Software Protection key 6--47.........................

Figure 6--11: Checking the free disk space 6--48.....................

Figure 6--12: Removing the cabinet handle 6--55.....................

Figure 6--13: Removing the cabinet feet 6--55.......................

Figure 6--14: Circuit board retaining plate 6--58.....................

Figure 6--15: Easily damaged capacitor on the PIA+ module 6--59......

Figure 6--16: Clock and trigger cable connections for the ASI or

SSI board on the PIA+ module 6--61...........................

Figure 6--17: Attaching the SSI or ASI trigger and clock cables to

the rear-panel bracket 6--61...................................

Figure 6--18: Installing an optional SSI or ASI board on the

PIA+ module 6-- 62..........................................

Figure 6--19: Clock and trigger cable connections on an additional

SSI or ASI board 6--63.......................................

Figure 6--20: Additional ASI or SSI interface installation 6--63.........

Figure 6--21: Installing the DHEI board on the PIA+ module 6--64.....

Figure 6--22: Installing the ribbon cable on the DHEI board 6--65......

Figure 6--23: Optional DHEI interface installation 6--65..............

Figure 6--24: Installing the SPI board on the PIA+ module 6--66.......

MTS300 MPEG Test System Service Manual

v

Page 10

Table of Contents

Figure 6--25: Assembling the SPI rear-panel brackets and cables 6--67..

Figure 6--26: Connecting the ribbon cables on the SPI board 6--68.....

Figure 6--27: Optional SPI interface installation 6--69................

Figure 6--28: LCD Display assembly removal 6--70...................

Figure 6--29: Keypad assembly removal 6--72.......................

Figure 6--30: Floppy disk drive and CD audio connector

installation 6--73............................................

Figure 6--31: Chassis screw locations for CD drive 6--74..............

Figure 6--32: Chassis screw locations for the floppy disk drive 6--75....

Figure 6--33: Speaker installation 6--77............................

Figure 6--34: Front panel interface circuit board connectors 6--79......

Figure 6--35: Screw locations for the Front Panel Interface board 6--80..

Figure 6--36: Routing of fan and speaker wires to Front Panel

Interface board 6--81........................................

Figure 6--37: Removing the IDE hard drive 6--83....................

Figure 6--38: Power supply long and short screw locations 6--85........

Figure 6--39: Controller board orientation and screw locations 6--87....

Figure 6--40: Installing the Processor I/O board into slot 10 6--89.......

Figure 6--41: Installing the Processor I/O board into the backplane 6--90

Figure 6--42: Processor I/O board to Controller board

interconnections -- top connectors 6--90.........................

Figure 6--43: Processor I/O board to Controller board

interconnections -- bottom connectors 6--91......................

Figure 6--44: Top connection to Controller board 6--92...............

Figure 6--45: Location of J220 connections and wiring orientation 6--92.

Figure 6--46: Backplane orientation and screw locations 6--94.........

Figure 6--47: SCSI hard drive removal 6--96........................

Figure 6--48: Configuring the SCSI drive jumpers 6--97..............

Figure 6--49: Installing the mounting brackets on the SCSI drive 6--98..

Figure 10--1: Modules 10--6......................................

Figure 10--2: Front panel and associated parts, Backplane board,

anddiskdrives 10--9.........................................

Figure 10--3: Cables and hard drives 10--12..........................

Figure 10--4: Cabinet parts and accessories 10--14....................

vi

MTS300 MPEG Test System Service Manual

Page 11

List of Tables

Table of Contents

Table i: Tektronix MPEG Test System version 6.1 applications xiii...

Table 1--1: Platform characteristics 1--12...........................

T a b l e 1 -- 2 : A S I 1 -- 1 2...........................................

Table 1--3: SPI-LVDS parallel (Option MTS3FLV) 1-- 13.............

Table 1--4: LVDS parallel data pin connections 1--15.................

Table 1--5: SSI (Option SS) 1--16.................................

Table 1--6: DHEI-Digicipher II 1--17..............................

Table 1--7: DHEI Expansion In pin connections 1--19................

Table 1--8: DHEI Expansion Out pin connections 1--20..............

T able 1--9: AC power source characteristics 1--21....................

T able 1--10: Environmental characteristics 1--21....................

T able 1--11: Mechanical characteristics 1--22.......................

Table 1--12: Certifications and compliances 1--22....................

Table 1--13: Environmental limits and use classification for safety

certification compliance 1--23.................................

Table 2--1: Rear-panel connectors 2--1............................

T able 2--2: Electrical operating requirements 2--5..................

Table 2--3: Power cord identification 2--6.........................

Table 2--4: Default user names and passwords 2--21.................

Table 2--5: Front panel-key controls 2--40..........................

Table 2--6: Touch screen techniques 2 --41..........................

T able 4--1: Adjustment table for 10 MHz reference clock 4--9.........

Table 6--1: Static susceptibility 6--2..............................

Table 6--2: Packaging material 6--7..............................

Table 6--3: Troubleshooting power-on failures 6--10..................

Table 6--4: Power-up error messages 6--11..........................

Table 6--5: MTS300 system COM port settings 6--30.................

Table 6--6: Touchscreen driver hardware settings 6--44...............

Table 7--1: MTS300 test system options 7--1.......................

Table 7--2: Possible interface configurations 7--2...................

Table 7--3: MTS300 test system upgrades 7--3.....................

MTS300 MPEG Test System Service Manual

vii

Page 12

Table of Contents

viii

MTS300 MPEG Test System Service Manual

Page 13

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

MTS300 MPEG Test System Service Manual

ix

Page 14

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Protective Ground

(Earth) Terminal

x

MTS300 MPEG Test System Service Manual

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

MTS300 MPEG Test System Service Manual

xi

Page 16

Service Safety Summary

xii

MTS300 MPEG Test System Service Manual

Page 17

Preface

Manual Structure

This document describes how to service the Tektronix MTS300 MPEG Test

System. Basic operating information is included to aid you in the servicing of

the instrument.

If you purchased a Tektronix MTS300 MPEG Test System and are looking for

detailed installation instructions or first-time operation procedures, refer to the

MTS300 MPEG Test System Hardware and Software Installation Technical

Reference, Tektronix part number, 071-0667-XX.

This service manual is organized into the following sections:

Specifications. This section contains a brief product description and lists the

specification tables describing the performance characteristics of the MTS300

MPEG Test System.

Operating Information. This section contains installation and operating information related to the servicing of the instrument.

Theory of Operation. This section contains a description of how the MTS300

MPEG Test System operates to the level needed to perform module-level

servicing of the instrument.

Performance Verification. This section contains procedures to verify that the

instrument is performing according to the specifications.

Adjustment Procedures. This section contains procedures to adjust the instrument

so that the instrument can perform according to the specifications.

Maintenance. This section contains procedures for inspecting and cleaning the

instrument, instructions for removing and replacing internal modules and

components, procedures for troubleshooting the instrument, and other information useful for maintaining or repairing the instrument.

Options. This section lists the options that may be installed in the instrument.

MTS300 MPEG Test System Service Manual

xiii

Page 18

Preface

Manual Conventions

Replaceable Electrical Parts. This section lists the replaceable electrical assemblies and components of the instrument.

Diagrams. This section contains interconnect diagrams for the instrument.

Replaceable Mechanical Parts. This section lists the replaceable mechanical

assemblies and components of the instrument.

Glossary. The Glossary contains definitions of new, uncommon, and/or unique

terms used in this manual.

Throughout this manual the following typographic, symbolic, and terminology

conventions apply:

Typographic Conventions

In this manual the following typographic conventions apply:

H Bold terms are found in procedures and denote interface items that you need

to select in order to cause an event to occur. For instance, to configure

default directories the procedure would read as follows:

Select Directories from the Options menu.

In this example, even though the Options menu is an interface element, the

Directories selection is the element that displays the needed dialog box

(causes an event to occur) and is the only bold term in the step. When

interface items are referred to outside of procedures, the terms are not

boldface.

H Manual names, manual section names, and words that are defined in the text

are italicized.

H Specific input that you need to make is indicated in the text using

mono-spaced font. Unless otherwise stated, do not enter punctuation at the

end of a mono-spaced font entry.

xiv

MTS300 MPEG Test System Service Manual

Page 19

Preface

Symbols and Terminology

Conventions

This manual uses symbols and terminology consistent with the following

publications:

H For PSI elements, ISO/IEC Standard 11172 and 13818 (parts 1, 2, and 3)

H For DVB elements, ETSI Publication prETS 300 468

H For DVB-T elements, ETSI Publication TS 101 191 V1.2.1

H For ATSC elements, ATSC Document A/65

H For Windows elements, The Microsoft Manual of Style for Technical

Publications, 2nd ed.

The following ARIB (Association of Radio Industries and Business) and ITU-R

(International Telecommunications Union) standards were used to develop the

added ARIB and TMCC enhancements to the stream creation applications:

H ARIB STD-B10 (1.2), 1999, Service Information for Digital Broadcasting

System

H ARIB STD-B16 (1.1), 1999, Digital Receiver Commonly Used for Digital

Satellite Broadcasting Services Using Communication Satellites

H ARIB STD--B20 (1.1), 1999, Digital Broadcasting System and Related

Operational Guidelines for Broadcasting Satellites

H ITU-R BO. 1408, Transmission System for Advanced Multimedia Services

Provided by Integrated Services Digital Broadcasting in A Broadcasting

Satellite Channel

In cases where terms, symbols, or references are or may be ambiguous, check the

Glossary located at the back of this manual for definitions. Also, refer to the

Glossary for definitions unique to the MTS300 test system and applications.

Refer to the your Windows documentation for definitions and explanations of

Windows specific terminology.

MTS300 MPEG Test System Service Manual

xv

Page 20

Preface

Related Documents

For additional information about using MTS300 software to monitor, analyze,

and generate MPEG-2, DVB, and ATSC data streams, refer to the following

manuals:

H The MTS300 MPEG Test System Real-Time Analysis User Manual,

Tektronix part number 071-0658-XX, contains information about using the

real-time MPEG-2 System Analyzer application.

H The MTS300 MPEG Test System MPEG-2 DVB/ATSC System Analyzer User

Manual, Tektronix part number 071-0659-XX, contains information about

using the deferred-time MPEG-2 System Analyzer.

H The MTS300 MPEG Test System Program Stream Analyzer User Manual,

Tektronix part number 071-0662-XX, contains information about using the

deferred-time Program Stream Analyzer application.

H The MTS300 MPEG Test System Dolby Digital Audio Stream Analyzer User

Manual, Tektronix part number 071-0661-XX, contains information about

using the deferred-time AC-3 Audio Stream Analyzer application.

H The MTS300 MPEG Test System MPEG Audio Stream Analyzer User

Manual, Tektronix part number 071-0663-XX, contains information about

using the deferred-time MPEG Audio Stream Analyzer application.

H The MTS300 MPEG Test System Video Stream Analyzer User Manual,

Tektronix part number 071-0664-XX, contains information about using the

deferred-time MPEG Video Stream Analyzer application.

MPEG Test System Applications

The applications that appear in your MTS300 MPEG test System depend on the

software version and the options installed in the instrument. Table i summarizes

all of the test system applications available in software version 6.1.

xvi

MTS300 MPEG Test System Service Manual

Page 21

Table i: Tektronix MPEG Test System version 6.1 applications

Icon Application title Function User document

Master Client Continuously monitor an input bitstream for

compliance with the MPEG-2, DVB-SI,

ATSC PSIP, and ISDB/ARIB digital television

standards. Use this client to start or assign to an

input/output the following real-time applications

and servers:

Analysis Server, used to perform real-time

analysis on a transport stream input

TMCC Analysis Server,usedtoperform

real-time analysis on a TMCC transport stream

input

Expert Client, used display the results of

real-time transport stream analysis performed by

an analysis server.

MTS300 MPEG Test System

Real-Time Analysis User Manual

071-0658-XX

Preface

TMCC Expert Client, used to display t he results

of real-time transport stream analysis performed

by a TMCC analysis server.

Configuration Client, used to configure

analysis servers for specific errors.

TMCC Configuration Client, used to configure

TMCC analysis servers for specific errors.

Stream Player, used to generate transport

streams from a local file.

Stream Recorder, used to capture transport

stream input.

OpenMux, used to configure and generate

transport streams from local transport stream

and elementary stream files

Hardware Diagnostic Perform onboard self-tests for the MPEG Test

System.

Private Syntax Interpreter Create table definitions used by the Real-Time

Analyzer to interpret private syntax sections.

MTS300 MPEG Test System

Hardware and Software Installation

Technical Reference 071-0667-XX

(Information repeated in both

manuals)

MTS300 MPEG Test System Service Manual

xvii

Page 22

Preface

Table i: Tektronix MPEG Test System version 6.1 applications (Cont.)

Icon User documentFunctionApplication title

MPEG-2 DVB/ATSC

System Analyzer

Analyze transport streams and packetized

elementary streams saved to the system disks.

MTS300 MPEG Test System

MPEG-2 DVB/ATSC System

Analyzer User Manual 071-0659-XX

DVB Channel Coding

and Decoding

Program Stream Analyzer Analyze MPEG program stream files. MTS300 MPEG Test System

MPEG Video Stream

Analyzer

MPEG Audio Stream

Analyzer

Dolby Digital Audio Stream

Analyzer

MPEG-2 Transport Stream

Multiplexer

DVB Table Editor Create and edit PSI and DVB SI table files for

Code and decode transport stream files to DVB

specifications.

Analyze MPEG-1 and MPEG-2 video elementary

streams files or streams extracted from the

MPEG-2 System Analyzer or Program Stream

Analyzer.

Analyze MPEG-1 and MPEG-2 audio elementary

streams files or streams extracted from the

MPEG-2 System Analyzer or Program Stream

Analyzer.

Analyze Dolby Digital (AC-3) audio elementary

stream files or streams extracted from the

MPEG-2 System Analyzer.

Create transport stream files from PSI/SI/PSIP

table files, elementary stream files, and data

files.

use with the transport stream multiplexer.

MTS300 MPEG Test System

Stream Creation Applications User

Manual 071-0778-XX

(Information repeated in both

manuals)

Program Stream Analyzer User

Manual 071-0662-XX

MTS300 MPEG Test System Video

Stream Analyzer User Manual

071-0664-XX

MTS300 MPEG Test System Audio

Stream Analyzer User Manual

071-0663-XX

MTS300 MPEG Test System Dolby

Digital Audio Stream Analyzer User

Manual 071-0661-XX

MTS300 MPEG Test System

Stream Creation Applications User

Manual 071-0778-XX

xviii

ATSC Table Editor Create and edit PSI and ATSC PSIP table files

for use with the transport stream multiplexer.

ARIB Table Editor Create and edit PSI and ISDB ARIB table files

for use with the transport stream multiplexer. You

also use this editor to create and modify the SIT

and DIT.

Jitter Adder Add jitter to PCR data in MPEG-2 transport

stream files.

Error Injector Insert or correct errors in transport stream

packets.

MTS300 MPEG Test System Service Manual

Page 23

Table i: Tektronix MPEG Test System version 6.1 applications (Cont.)

Icon User documentFunctionApplication title

TMCC Combiner Adds TMCC information to a multiplex to

generate a valid ISDB-S transport stream fi le.

Tektronix Software

Protection

Enter or reenter the general password to enable

licensed applications.

Preface

MTS300 MPEG Test System

Stream Creation Applications User

Manual 071-0778-XX

Read This First, MTS300 MPEG

Test System Software V6.1

071-0666-XX

MPEG2_Part1

(ISO/IEC 13818-1)

Uninstall MTS Remove MPEG Test System software from the

Other Information Sources

For information about the Windows NT operating system, refer to the Microsoft

documentation that accompanied your system.

For the latest information about MTS300 Series Real-Time Analyzer features

and bugs, refer to the MTS300 Series Software Version 6.1 Read This First

document that accompanied your Tektronix MPEG Test System product.

Two sources of online information are provided with the MTS300 MPEG Test

System Stream Creation Applications: the application online help files and an

online help file of the MPEG-2, Part 1 (Systems) document. You can access

these sources of information using the following techniques:

H Access help topics by selecting Contents from the Help menu.

The international MPEG-2 system standard in

Windows Help format.

system disk.

none

MTS300 MPEG Test System User

Manuals

H To display the help, double click the MPEG-2 icon in the Tektronix MPEG

Test System program group window.

Included on the software application CD-ROM is a Read Me file for the

software. This file lists the application files included with the software installation types and other important information.

MTS300 MPEG Test System Service Manual

xix

Page 24

Preface

The following URLs access the websites for the standards organizations listed

(the URLs listed were valid as of January, 2001):

H MPEG-2 standards (International Organization for Standards)

http://www.iso.ch/

H DVB standards (European Technical Standards Institute)

http://www.etsi.org/

H ATSC standards (Advanced Television Systems Committee)

http://www.atsc.org/

xx

MTS300 MPEG Test System Service Manual

Page 25

Contacting Tektronix

Preface

Phone 1-800-833-9200*

Address Tektronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

MTS300 MPEG Test System Service Manual

xxi

Page 26

Preface

xxii

MTS300 MPEG Test System Service Manual

Page 27

Product Description

This Specifications section contains a product description and lists the characteristic tables for the MTS300 MPEG Test system.

Refer to Options on page 7--1 for a list of the options you may find installed in

the instrument. Refer to Replaceable Mechanical Parts on page 10--1 for a list of

the standard and optional accessories available with the instrument.

Product Overview

The MTS300 MPEG Test System is a component of the Video Quality of

Service (VQoS) products offered by Tektronix. The MTS300 system (see

Figure 1--1) is a high-performance MPEG protocol diagnostic and analysis tool

that provides you with innovative solutions to meet the challenges of designing,

verifying, and characterizing products and systems using MPEG-2 technology.

The MTS300 system offers powerful acquisition and computational capabilities

for analyzing designs based on MPEG, DVB, ATSC, and ISDB standards. These

flexible and expandable capabilities include real-time monitoring, data rate

analysis, and Tektronix-exclusive timing analysis to help diagnose the most

challenging problems and characterize real-time performance.

NOTE. Refer to the MPEG-2, DVB, ATSC, and ISDB-S/ARIB standards for

detailed information about the syntax and semantics of each system.

The deferred-time (off-line) analysis provided by the MTS300 system helps you

fully verify compliance to standards and diagnose problems in complex transport

streams. Easy-to-use transport stream capture, playout, and on-line storage lets

you build extensive suites of test streams, and then use these streams to exercise

your designs. Additional stream editing capability, with error and jitter injection

and real--time multiplexing, gives you the ability to create and playout test

sequences that fully stress and characterize design parameters.

Each test system can monitor up to two transport stream inputs simultaneously

and accepts inputs in the following electrical formats:

H ASI/M2S (the test system automatically detects the format)

H SPI (LVDS parallel); available when you order the MTS3FLV upgrade

H DHEI (GI Digicipher II): available when you order the MTS3FDE upgrade

H SSI (SMPTE 310M); available when you order the MTS3FSS upgrade

MTS300 MPEG Test System Service Manual

1- 1

Page 28

Product Description

MPEG Test System

Figure 1- 1: MTS300 MPEG Test System

Primary Applications

Key Features

The MTS300 system was designed for the following applications:

H Evaluation and verification of MPEG, DVB, ATSC and ISDB designs

Design and verification of digital-video set-top boxes (STBs)

H

H Stress and characterization of electrical circuits and ICs developed for

products using MPEG-2 compressed digital-video technology

The MTS300 system provides the following key features:

H Real-time monitoring and compliance testing of MPEG, DVB, ATSC and

ISDB transport streams for complete application flexibility

H Dolby Digital AC--3 compliance testing and AAC stream monitoring for

testing advanced audio capabilities

H Tektronix-exclusive PCR overall jitter, drift and offset measurements allow

you to diagnose the most challenging real--time performance problems

H Real-time analysis of transport streams used in data broadcasting applica-

tions based on ISO/IEC 13818-6 (DSM-CC) and EN 301 192 standards

H Analysis of Mega-frame Initialization Packets (MIPs), specified in the DVB

TS 101 191 standard

1- 2

H Detailed off-line analysis of transport streams, program streams and

elementary streams available to fully verify design performance

H Logging of user-selected analysis events to tab-delimited text files for record

keeping and further analysis

MTS300 MPEG Test System Service Manual

Page 29

Product Description

H ASI/M2S, SPI (LVDS), SMPTE310M, and DHEI interfaces available to

support a variety of design configurations

H SNMP agent allows you to control the instrument from a remote location

H Private syntax table editor allows you to describe the syntax of a private

table

H Optional real-time multiplexing of elementary and transport streams

provides flexible real-time manipulation of stream content and parameters

H Optional TMCC data testing and transport stream creation for ISDB

environments

H Capture (manual and triggered), playback, and on-line storage of transport,

program and elementary streams

H Optional editing capability allows you to create custom transport streams and

inject errors or jitter to fully stress your design

H Modular architecture allows you to easily upgrade in the future

System Architecture

H Rackmount configuration kit included

H Microsoft NT operating system provides robust networking, performance

and functionality

The MTS300 system uses a client/server architecture consisting of a Server

Manager, two Analysis Server pairs (each pair consists of one MPEG analysis

server and one TMCC analysis server), and the following client applications:

Master Client, Expert Client, Configuration Client, Stream Recorder, Stream

Player, TMCC Expert Client, and TMCC Configuration Client

Combined, these client/server modules enable you to monitor multiple transport

stream inputs simultaneously, perform in-depth analyses on one transport stream

input, and to configure the monitoring and reporting parameters. The system is

tightly integrated, making it easy to use for experts and non-experts alike.

MTS300 MPEG Test System Service Manual

1- 3

Page 30

Product Description

Server Manager. The Server Manager is the process that makes the results of the

Analysis Servers and other real-time application servers available to Master

Clients. The Server Manager starts automatically when you start the transport

monitor. Only one Server Manager can run on a test system.

The Server Manager process interacts with the following entities:

H The Analysis Server sends analysis results (called traps)totheServer

Manager.

H The Stream Player, Stream Recorder, and optional OpenMux (MTS300,

Option OM) servers send state traps to the Server Manager. Unlike the

Analysis Server traps, the traps sent by these servers is limited to

H The Master Client displays the data collected by the Server Manager.

Analysis Servers. The Analysis Server is the process that actually analyzes

transport stream inputs. Each Analysis Server process consists of one MPEG

Analysis Server and one TMCC Analysis Server . Each MTS300 system can

support up to two Analysis Server processes of each type simultaneously.

The Analysis Server processes interact with the following entities:

H The Server Manager collects the Analysis Server results (called traps).

H The Expert Client displays the results of the MPEG Analysis Server directly.

Likewise, the TMCC Expert Client displays the results of the TMCC

Analysis Server .

H The Configuration Client sets the monitoring and analysis parameters for

each MPEG Analysis Server process operating on the inputs to the MTS300

system. Likewise, the TMCC Configuration Client sets the monitoring and

analysis parameters for each TMCC Analysis Server process.

1- 4

MTS300 MPEG Test System Service Manual

Page 31

Product Description

Master Client. The Master Client application provides an intuitive interface for

controlling and monitoring the status of the I/O ports on the MTS300 system.

You can run only one Master Client on each MTS300 system. In a network

environment, if a remote MTS300 system has a Master Client open, you must

shut down the remote Master Client before you can connect your local Master

Client to the Server Manager running on the system.

NOTE. Each MTS300 system is limited to operating two Analysis Server

processes of each type at a time, and can run only one Stream Player, one Stream

Recorder, and one OpenMux application at a time. In addition, the MTS300

system is limited to an aggregate data rate of 140 Mbs between all operating

applications.

From the Master Client, you can perform the following tasks:

H Monitor and analyze MPEG transport streams in real time using the Expert

Client and Configuration client applications.

H Monitor and analyze single- and multi-program TMCC transport streams in

real time using the TMCC Expert Client and TMCC Configuration Client

applications.

H Record and playback MPEG and TMCC transport streams using the Stream

Recorder and Stream Player applications.

H Generate multiplexed transport streams in real time using the OpenMux

application (MTS300, Option OM).

The Master Client uses three areas to display different type of information:

H The I/O Port Manager panel displays icons representing real-time application

servers and the input and output ports configured on your test system.

H The Services panel displays icons for the services (also called programs)

encoded in the transport stream you are monitoring.

H The Details panel displays icons indicating the type, status, and severity of

errors on a transport stream or service.

MTS300 MPEG Test System Service Manual

1- 5

Page 32

Product Description

Expert Client. The Expert Client application allows you to analyze a single

MPEG transport stream in greater detail. You will use the Expert Client as your

primary tool to help troubleshoot errors in your digital transmission system.

The Expert Client characteristics are shown in the following list:

H Graphical displays that show the structure (hierarchy) of the input transport

stream and display characteristics of each component of the input stream

(for example: PID and type allocation, section rate analyses, and timing

analyses).

H Report views that indicate the types of errors recorded by the Analysis

Server and the characteristics of the input stream.

H Error views that show specific errors recorded for the various components

of the transport stream; for instance, PMT section rate errors and ETR290

errors.

The Expert Client can display the results of only one MPEG Analysis Server

(input) at a time.

Configuration Client. The Configuration Client allows you to perform the

following tasks:

H Specify to which standard you are testing: MPEG-2, DVB, ATSC, or ISDB.

H Set, remove, or modify the probes that test transport streams for valid syntax

and semantics and rates.

H Specify the way in which errors are reported in both the Expert and Master

Clients. You can configure each probe to report an error as Critical, Major,

Minor, Warning, or as information only.

H Specify the types of transport stream events that are recorded using the Data

Logging function. You can also set the maximum file size and time period of

each log file.

H Stop and restart an MPEG Analysis Server running on a MTS300 system.

H Set passwords on specific inputs that prevent others from changing the

Analysis Server configuration for that input.

H Set parameters for capturing part of an input transport stream.

1- 6

MTS300 MPEG Test System Service Manual

Page 33

Product Description

Stream Recorder Client. The Stream Recorder application allows you to record a

transport stream onto the hard drive of the MTS300 system using a VTR-like

interface. You can specify the stream format, duration, file name, and location of

the recorded file.

The Stream Recorder is governed by the following MTS300 system limits:

H Only one Stream Recorder can be launched at a time on each MTS300

system.

H The Stream Recorder can only record transport stream files with data rates

between 1 Mbs and 140 Mbs onto the hard drive of the MTS300 system on

which the application was launched. You cannot record remote transport

stream files or use a remote Stream Recorder to record a local transport

stream file.

NOTE. It is recommended that you store transport stream files on the SCSI hard

drives (E: drive) of the MTS300 system. The response time of the C: drive on the

MTS300 system is limited and may affect the performance of the Stream

Recorder and Stream Player applications when you try to capture or play back

streams with bitrates greater than 30 Mbs.

H If the SCSI hard drives (E:) are 90% or more full, it is recommended that

you use a defrag utility to defragment the SCSI drives. You can use any

defrag utility that is compatible with the Microsoft Windows NT 4.0

operating system.

H The MTS300 system is limited to an aggregate data rate of 140 Mbs between

all operating applications. You may have to shut down other MTS300

applications if you need to record a transport stream with high data rates.

MTS300 MPEG Test System Service Manual

1- 7

Page 34

Product Description

Stream Player Client. The Stream Player application allows you to play back

transport streams saved on the hard disk of the MTS300 system using a

VTR-like interface. You can specify which portion of the transport stream to play

back, the rate of the transport stream (you can also apply an external clock to set

the rate), the format (ASI or M2S) of the transport stream, and the playback

mode (one time or loop).

The Stream Player is governed by the following MTS300 system limits:

H Only one Stream Player can be launched at a time on each MTS300 system.

H The Stream Player can only play back transport stream files with data rates

between 1 Mbs and 140 Mbs stored on the hard drive of the MTS300 system

on which the application was launched. You cannot play back remote

transport stream files or use a remote Stream Player to play back a local

transport stream file.

NOTE. It is recommended that you store transport stream files on the SCSI hard

drives (E: drive) of the MTS300 system. The response time of the C: drive on the

MTS300 system is limited and may affect the performance of the Stream

Recorder and Stream Player applications when you try to capture or play back

streams with bitrates greater than 30 Mbs.

H If the SCSI hard drives (E:) are 90% or more full, it is recommended that

you use a defrag utility to defragment the SCSI drives. You can use any

defrag utility that is compatible with the Microsoft Windows NT 4.0

operating system.

H The MTS300 system is limited to an aggregate data rate of 140 Mbs between

all operating applications. You may have to shut down other MTS300

applications if you need to play back a transport stream with high data rates.

1- 8

MTS300 MPEG Test System Service Manual

Page 35

Product Description

TMCC Expert Client. The TMCC (Transmission and Multiplexing Configuration

Control) Expert Client application allows you analyze the TMCC data of an

ISDB-S/ARIB-compliant transport stream input in real time. You can also

analyze an ISDB-S/ARIB-compliant transport stream file stored on your local

disk.

The TMCC Expert client has the following characteristics:

H Indicates the presence of sync bytes (0x47 for TMCC basic streams and W1,

W2, or W3 sync bytes for TMCC data streams)

H Displays the syntax of TMCC data

H Displays Slot, TSID, TS Name, and Modulation mode information

H Displays information, warning, and error messages

H Indicates the presence of TMCC alarm and update flags in the transport

stream

H Displays the overall stream rate

The TMCC Expert Client displays the results of only one TMCC Analysis

Server (input) at a time. You can connect more than one TMCC Expert Client to

the same TMCC Analysis Server input from your own instrument, or you can

connect to an Analysis Server from a remote MTS300 system.

MTS300 MPEG Test System Service Manual

1- 9

Page 36

Product Description

TMCC Configuration Client. The TMC C (Transmission and Multiplexing

Configuration Control) Configuration Client is used to configure the analyses

performed by the TMCC Analysis Server. The results of the analyses are

displayed in the TMCC Expert Client.

NOTE. Only one TMCC Configuration Client at a time can set parameters on a

TMCC Analysis Server. If a TMCC Configuration Client is already connected to

a TMCC Analysis Server, you can view the current settings, but you cannot

change them.

The settings in the TMCC Configuration Client only configure the measurements

made by the TMCC Analysis Server, which are displayed in the TMCC Expert

Client application. The TMCC Configuration Client settings do not affect the

configuration settings in the Configuration Client, which is used to configure the

measurements made by the MPEG Analysis Server.

The TMCC Configuration Client has the following characteristics:

SNMP Capabilities

H Uses multiple configuration panels to group related configuration functions.

H Uses a hierarchic navigation panel to select one of the multiple configuration

panels.

H Configures the TMCC Analysis Servers to operate in either TMCC basic or

TMCC data stream modes

H Enables you to specify a transport stream ID to analyze using the MPEG-2

Analysis Server (only in the TMCC data stream mode)

The MTS300 system includes SNMP management information bases (MIB)

installed at the following directory location: C:\Mib\. The Tektronix MIB is a

textual description of the Analysis Server objects (functions and parameters) that

can be monitored and controlled via SNMP. Refer to the user manual or the

online help for more information about the networking requirements of the

MTS300 system.

The MIB files are used by the real-time analysis applications and the Stream

Player, Stream Recorder, and OpenMux (MTS300, Option OM only)

applications.

The MIB file pairs for each application, for example, the RTAv1.mib and

RTAv2.mib files, are used for SNMPv1 and SNMPv2 systems respectively.

1- 10

The operations in SNMP are limited to retrieving the value of management

information, modifying the value of management information, and reporting an

event.

MTS300 MPEG Test System Service Manual

Page 37

Characteristic Tables

This section lists the electrical, environmental, and physical specifications of the

MTS300 system. All specifications are guaranteed unless labeled typical. Typical

specifications are provided for your convenience and are not guaranteed.

Electrical characteristics apply to test systems operating within the environmental conditions specified in Table 1--10.

To verify performance of the test system, use the procedures in the performance

verification section of the MTS300 MPEG Test System Service Manual,an

optional accessory. Contact your Tekronix representative for ordering information.

Monitoring Characteristics

MPEG Characteristics:

H Supports MPEG--2, DVB, and ATSC protocols.

Monitors transport and multiplex errors.

H Monitors PSI, SI, and PSIP table syntax and consistency errors.

Monitors transport signal for sync loss.

H Generates MPEG transport streams (including ATSC and DVB--SI).

Data Rate Characteristics:

H Up to 140 Mbps with one input or 240 Mbps total using 2 to 4 inputs.

For example, Port 1 can run at 100 Mbps while port 2 is running at

140 Mbps for a total of 240 Mbps.

Number of Inputs:

H Standard Inputs: Two ASI/M2S input/output pairs

H Optional inputs: Two SPI (LVDS parallel), two SMPTE310M (SSI), or two

DHEI (GI-Digicypher) input/output pairs.

MTS300 MPEG Test System Service Manual

1- 11

Page 38

Characteristic Tables

Interface Platform Characteristics

Table 1- 1: Platform characteristics

Characteristic Description Supplemental information

Operating system Windows NT 4.0 (Service pack 6)

Disk space System: 10 GB

MPEG Storage: 27 GB

COM Port RS-232

Ethernet 10/100-base T; RJ45

Mouse Mini DIN

Keyboard Mini DIN

SVGA 15-pin, High density, Sub-D

RAM 256MB

CD-ROM drive 8x

Display LCD, 800 x 600

Character input Touch screen and keyboard

Printer Port IEEE P1284

I/O Port Electrical Characteristics

Table 1- 2: ASI

Characteristic Description Supplemental information

Input Port (ASI/M2S)

Connector BNC

Bit Rate 270 Mbps ±100 ppm

Transport Stream Data rate Maximum: 140 Mbps

Minimum: 1 Mbps

Signal Amplitude Maximum: 800 mV

Minimum:: 200 mV

Termination 75 Ω nominal

p-p

p-p

Return Loss 17 dBm minimum from 27 MHz to 270 MHz

Output Port (ASI/M2S)

Connector BNC

Bit Rate 270 Mbps ±100 ppm

1- 12

MTS300 MPEG Test System Service Manual

Page 39

Table 1- 2: ASI (Cont.)

Transport Stream Data Rate Maximum: 140 Mbps

Minimum: 1 Mbps

Characteristic Tables

Supplemental informationDescriptionCharacteristic

Signal Amplitude Maximum: 880 mV

Minimum: 500 mV

Termination 75 Ω

Format Can be configured as ASI Burst, ASI Packet,

or M2S

Rise and Fall times 1.2 ns maximum, typical 20% to 80%

External Clock Input Port Clocks the stream player output byte rate

Voltage Levels TTL

Low: <0.8 V. typical

High: >2.0 V, typical

Termination 50 Ω resistive

nominal

Frequency Range 125 kHz to 17.5 MHz

External Trigger Input Port Initiates a capture of a transport stream input

Voltage Levels TTL

Low: <0.8 V

High: >2.0 V

Termination 50 Ω resistive

nominal

p-p,

p-p,

typical

typical

Table 1- 3: SPI-LVDS parallel (Option MTS3FLV)

Characteristic Description Supplemental information

Input Port See Table 1--4 on page 1--15 for pin descrip-

tions. See Figure 1--2 on page 1--15 for the

timing diagram.

Connector 25-pin sub D-type

Data Rate Maximum: 140 Mbps

Minimum: 1 Mbps

Signal Amplitude LVDS

Termination 100 Ω resistive

nominal, line-to-line

Timing reference Rising edge of clock

MTS300 MPEG Test System Service Manual

1- 13

Page 40

Characteristic Tables

Table 1- 3: SPI-LVDS parallel (Option MTS3FLV) (Cont.)

Supplemental informationDescriptionCharacteristic

Clock-to-Data Timing Data must be stable 5 ns of rising clock

edge

Output Port See Table 1--4 on page 1--15 for pin descrip-

tions. See Figure 1--2 on page 1--15 for the

timing diagram.

Connector 25-pin sub D-type

Data Rate Maximum: 140 Mbps

Minimum: 1 Mbps

Signal Amplitude (LVDS) Maximum: 454 mV

Minimum: 247 mV

,typical

p-p

p-p,

typical

Termination 100 Ω resistive

nominal, line-to-line

Signal Common-Mode Range

1.125 V to 1.375 V, typical

(LVDS)

External Clock Input Port Clocks the stream player output byte rate

Voltage Levels TTL

Low: <0.8 V

High: >2.0 V

Termination 50 Ω resistive

nominal

Frequency Range 125 KHz to 17.5 MHz

External Trigger Input Port Initiates a capture of a transport stream input

Voltage Levels TTL

Low: <0.8 V

High: >2.0 V

Termination 50 Ω resistive

nominal

1- 14

MTS300 MPEG Test System Service Manual

Page 41

Table 1- 4: LVDS parallel data pin connections

1

5

1

6

5

6

2

0

2

1

1

1

1

2

LVDS/ECL/RS422

parallel port

1

2

3

4

6

7

8

9

10

12

13

Asserted Low differential signal.

Pin Function Pin Function

1 DCLK 14 DCLK

2 Ground 15 Ground

14

3 DATA 7 16 DATA 7

4 DATA 6 17 DATA 6

16

17

5 DATA 5 18 DATA 5

18

6 DATA 4 19 DATA 4

19

7 DATA 3 20 DATA 3

8 DATA 2 21 DATA 2

21

9 DATA 1 22 DATA 1

22

23

10 DATA 0 23 DATA 0

24

11 DVALID 24 DVALID

25

12 PSYNC 25 PSYNC

13 Shield

Characteristic Tables

Active edge

DCLK

PSYNC

Data 0.....7

DVALID

Stuffing bytes

Figure 1- 2: Parallel data timing, 188-byte packets

Byte 1Byte 188Byte 187

MTS300 MPEG Test System Service Manual

1- 15

Page 42

Characteristic Tables

Table 1- 5: SSI (Option SS)

Characteristic Description Supplemental information

SSI input (SMPTE310M)

Connector BNC, Female

Input bit rate 19,392,658.5 bps 1000 bps

(typical)

38,785,316.9 bps 1000 bps

(typical)

Synchronization 0x47 Synchronization will occur when the

sync_byte is 0x47

Data format Compliant with SMPTE310M

Packet length 188 byte

Signal amplitude 880 mV

720 mV

Signal DC offset 0.5 VDC, maximum

Termination 75 Ω

Return loss –17 dB, 100 kHz to 77.6 MHz

SSI output (SMPTE310M)

Connector BNC, Female

Output bit rate 19,392,658.5 bps

(nominal) or

, maximum

p-p

, minimum

p-p

Same as the input when the output is a loop

through of the input

38,785,316.9 bps

(nominal)

Data format Compliant to SMPTE310M

Signal amplitude 880 mV

720 mV

maximum

p-p

minimum

p-p

Signal DC offset 0.5 VDC, maximum

Signal rise and fall times 0.4 ns minimum

5.0 ns maximum

Signal overshoot 10% of m aximum signal amplitude

Output impedance 75 Ω

Return loss –17 dB, 100 kHz to 77.6 MHz

Rise and fall times shall not diff er by more

than 1.6 ns, measured between 20% and

80%

1- 16

MTS300 MPEG Test System Service Manual

Page 43

Characteristic Tables

Table 1- 5: SSI (Option SS) (Cont.)

Characteristic Supplemental informationDescription

External Clock Input Port Clocks the stream player output bit rate

Voltage Levels TTL

Low: <0.8 V

High: >2.0 V

Termination 50 Ω resistive

nominal

Frequencies 19.393 MHz

38.785 MHz

External Trigger Input Port Initiates a capture of a transport stream input

Voltage Levels TTL

Low: <0.8 V

High: >2.0 V

Termination 50 Ω resistive

nominal

Table 1- 6: DHEI-Digicipher II

Characteristic Description Supplemental information

Expansion Input Port

Connector 26-pin D, HD-22 Series See Table 1--7 on page 1--19 for the pin

descriptions

Data Rate Maximum: 40 Mbps

Minimum: 1 Mbps

Signal Amplitude ECL

Termination 120 Ω resistive

nominal, line-to-line

Timing reference Falling Edge of clock

Clock-to-Data Timing Data must be stable 5 ns of falling clock

edge

Output Port See Table 1--8 on page 1--20 for the pin

descriptions

Connector 26-pin D, HD-22 Series

Data Rate Maximum: 40 Mbps

Minimum: 1 Mbps

Signal Amplitude ECL

MTS300 MPEG Test System Service Manual

1- 17

Page 44

Characteristic Tables

Table 1- 6: DHEI-Digicipher II (Cont.)

Supplemental informationDescriptionCharacteristic

Termination 120 Ω resistive

nominal, line-to-line

External Clock Input Port Clocks the stream player output bit rate

Voltage Levels TTL

Low: <0.8 V

High: >2.0 V

Termination 50 Ω resistive

nominal

Frequency range 1 MHz to 40 MHz

External Trigger Input Port Initiates a capture of a transport stream being

input to the real-time analyzer

Voltage Levels TTL

Low: <0.8 V

High: >2.0 V

Termination 50 Ω resistive

nominal

1- 18

MTS300 MPEG Test System Service Manual

Page 45

Table 1- 7: DHEI Expansion In pin connections

1

0

2

6

9

DHEI 26- pin connector Pin Function Description

1 PROTOGND Protective or shield ground

2 SENSEAIR Enable sense A input return

1

9

18

3 PSYNCAI-- Packet sync A input (--)

19

4 PDATAI-- Packet data A input (--)

5 PCLKAI+ Packet clock A input (+)

6 PCLKAI-- Packet clock A input (--)

7 REFCLKAI+ Ref_clock A input (+)

8 REFCLKAI-- Ref_clock A input (--)

9 SIGND Signal or circuit ground reference

10 RSVD DHEI reserved

11 SENSEAIL Enable sense A loop input

12 PSYNCAI+ Packet sync A input (+)

13 PDATAI+ Packet data A input (+)

14 RSVD DHEI reserved

15 PDATBO-- Packet data B output (--)

16 PSYNCBO-- Packet sync B output (--)

17 SENSEBOR Enable sense B output return

18 RSVD DHEI reserved

19 REFCLKBO+ Ref_clock B output (+)

20 REFCLKBO-- Ref_clock B output (--)

21 PCLKBO+ Packet clock B output (+)

22 PCLKBO-- Packet clock B output (--)

23 PDATBO+ Packet data B output (+)

24 PSYNCBO+ Packet sync B output (+)

25 SENSEBOL Enable sense B loop output

26 RSVD DHEI reserved

Characteristic Tables

MTS300 MPEG Test System Service Manual

1- 19

Page 46

Characteristic Tables

1

0

1

1

9

2

6

Table 1- 8: DHEI Expansion Out pin connections

DHEI 26- pin connector Pin Function Description

10

1 PROTOGND Protective or shield ground

2 SENSEAOR Enable sense A output return

3 PSYNCAO-- Packet sync A output (--)

4 PDATAO-- Packet data A output (--)

5 PCLKAO+ Packet clock A output (+)

6 PCLKAO-- Packet clock A output (--)

7 REFCLKAO+ Ref_clock A output (+)

8 REFCLKAO-- Ref_clock A output (--)

9 SIGND Signal or circuit ground reference

26

9

10 RSVD DHEI reserved

11 SENSEAOL Enable sense A loop output

18

12 PSYNCAO+ Packet sync A output (+)

13 PDATAO+ Packet data A output (+)

14 RSVD DHEI reserved

15 PDATBI-- Packet data B input (--)

16 PSYNCBI-- Packet sync B input (--)

17 SENSEBIR Enable sense B input return

18 RSVD DHEI reserved

19 REFCLKBI+ Ref_clock B input (+)

20 REFCLKBI-- Ref_clock B input (--)

21 PCLKBI+ Packet clock B input (+)

22 PCLKBI-- Packet clock B input (--)

23 PDATBI+ Packet data B input (+)

24 PSYNCBI+ Packet sync B input (+)

25 SENSEBIL Enable sense B loop input

26 RSVD DHEI reserved

1- 20

MTS300 MPEG Test System Service Manual

Page 47

Characteristic Tables

Power Characteristics

Table 1- 9: AC power source characteristics

Characteristic Description

Source Voltage 100 VAC to 240 VAC

47 Hz to 63 Hz, continuous range CAT II

Maximum Power Consumption 170 Watts, typical

Environmental Characteristics

Table 1- 10: Environmental characteristics

Characteristic Description

Cooling Airflow Intake is from the front and sides of the instrument. Exhaust is to t he bott om and rear of

the instrument.

Required Clearance 2 in (50 mm) air space adjacent to the bottom of the instrument is required.

Use Rating Rated for indoor use only.

Atmospherics

Temperature:

Operating +5° Cto+40° C, 30° C/hr max gradient, noncondensing (derated 1° C per 1,000 ft

above 5,000 ft altitude)

Nonoperating -- 2 0 ° Cto60° C, 30° C/hr max gradient (without disk m edia installed in disk drives)

Humidity

Operating 20% to 80% relative humidity, noncondensing. Max wet bulb temperature: 29° C

(derates relative humidity to ~22% at 50° C)

Nonoperating 8% to 80% relative humidity, noncondensing. Max wet bulb temperature: 40° C

(derates relative humidity to ~55% at 50° C)

Altitude

Operating Up to 10,000 ft (3,040 m), (derated 1°C per 1,000 ft above 5,000 ft altitude)

Nonoperating Up to 40,000 ft (12,190 m)

MTS300 MPEG Test System Service Manual

1- 21

Page 48

Characteristic Tables

Mechanical (Physical) Characteristics

Table 1- 11: Mechanical characteristics

Characteristic Description

Classification Transportable platform intended for either rackmount or bench applications

Overall Dimensions

Height 8.9 i n (w/o feet) (22.6 cm)

Width 17 in (43.2 cm)

Depth 22 in (56 cm)

Weight 38 lb (17.3 kg)

Rack Space 5 rack units, standard length

Certifications and Compliances

Table 1- 12: Certifications and compliances

Category Standard

EC Declaration of Conformity-EMC Meets the intent of Directive 89/336/EEC for El ectromagnetic Compatibility.

Compliances was demonstrated using EN 61326: 1997 EMC Product Family Standard for

Electrical Equipment for Measurement, Control, and Laboratory use.

Emissions

EN 61326 Class A Radiated and Conducted Emissions

IEC 61000-3-2 Conducted Power Line Harmonic Current

Immunity

IEC 61000-4-2 Electrostatic Discharge Immunity

IEC 61000-4-3 Radiated RF Electromagnetic Field Immunit y

IEC 61000-4-4 Electrical Fast Transient/Burst Immunity

IEC 61000-4-5 Power Line Surge Immunity

IEC 61000-4-6 Conducted RF Immunity

IEC 61000-4-11 Voltage Dips and Short Interruptions Immunity

Australia/New Zealand declaration of

conformity

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A

Complies with EMC Framework and demonstrated per Emission standard:

AS/NZS 2064 Industrial, Scientific, and Medical Equipment.

Limits

1

:

1

:

2

2

1

Compliance demonstrated using high quality, shielded interface cables.

2

Performance Criterion: Product continues to operate properly and display remains readable.

1- 22

MTS300 MPEG Test System Service Manual

Page 49

Characteristic Tables

Table 1- 13: Environmental limits and use classification for safety certification compliance

Category Standards or description

Safety Certification Compliance

Temperature, operating +5_ Cto+40_ C

Altitude (maximum operating) 2000 meters

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC 61010-1, Annex H) -- grounded product

Installation (Overvoltage)

Category

Pollution Degree Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Supply Voltage Range 100 VAC to 240 VAC, 50/60 Hz, single phase

Fuse Rating Mains fuse is 10A, 250V, Fast; Not operator replaceable. Refer servicing to qualified service

Current Rating 6.0 Amps maximum

Relative Humidity

(maximum operating)