Page 1

User Manual

MTS200 Series MPEG Test System

Data Store Administrator

071-0536-00

This document supports MPEG Test System version 3.00 software.

Page 2

Copyright © T ektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in T echnical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software – Restricted Rights clause at F AR 52.227-19, as applicable.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

HARDWARE WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

SOFTWARE WARRANTY

Tektronix warrants that the media on which this software product is furnished and the encoding of the programs on the

media will be free from defects in materials and workmanship for a period of three (3) months from the date of shipment.

If a medium or encoding proves defective during the warranty period, T ektronix will provide a replacement in exchange

for the defective medium. Except as to the media on which this software product is furnished, this software product is

provided “as is” without warranty of any kind, either express or implied. T ektronix does not warrant that the functions

contained in this software product will meet Customer’s requirements or that the operation of the programs will be

uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period. If T ektronix is unable to provide a replacement that is free from defects in materials and workmanship

within a reasonable time thereafter, Customer may terminate the license for this software product and return this software

product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS THE SOLE AND EXCLUSIVE

REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF

THE POSSIBILITY OF SUCH DAMAGES.

Page 5

Table of Contents

Getting Started

Operating Basics

Reference

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Version xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting T ektronix xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input and Output Connections 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Time Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Repair 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terms 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Features of the Data Store Disks 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting the Application 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring Data 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generating (Outputting) Data 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disk Management 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

The Application Window 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T oolbar Command Buttons 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Menu Commands 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acq/Gen Menu Commands 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Menu Commands 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Help Menu 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suppressing the Transfer is Finished Message 43. . . . . . . . . . . . . . . . . . . . . . . . . .

Data Store Transfers 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problems and Troubleshooting 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: I/O Specifications 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Functional Check 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Equipment 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MTS 200 Series MPEG Test System Data Store Administrator

i

Page 6

Table of Contents

List of Figures

Figure 1: Data Store inputs and outputs (Compaq Proliant) 2. . . . . . .

Figure 2: Data Store inputs and outputs (Compaq Prosignia) 3. . . . . .

Figure 3: Pulse specification for a G.703 8.448 MHz pulse 50. . . . . . . . .

Figure 4: Pulse specification for G.703 34.368 MHz 52. . . . . . . . . . . . . .

Figure 5: Parallel data timing, 188-byte packets 54. . . . . . . . . . . . . . . . .

Figure 6: Parallel data timing, 204-byte packets 55. . . . . . . . . . . . . . . . .

Figure 7: Timing diagram for the ECL serial port 56. . . . . . . . . . . . . . .

Figure 8: ECL Timing diagram with control port 57. . . . . . . . . . . . . . . .

Figure 9: Timing for the TTL port and the separate clock input 58. . . .

Figure 10: Timing diagram for the 10 Mbit Serial port 59. . . . . . . . . . .

Figure 11: Initial test system connections for the functional check 62. .

Figure 12: Starting the Data Store Administrator 63. . . . . . . . . . . . . . . .

Figure 13: Setup for measuring the G.703 34.368 Mbit/s output 64. . . .

Figure 14: Setup for measuring the TTL 50 ohm clock I/O port 65. . . .

Figure 15: Setup for measuring the TTL 50 ohm data I/O port 66. . . . .

ii

MTS 200 Series MPEG Test System Data Store Administrator

Page 7

List of Tables

Table of Contents

Table i: MPEG Test System version 3.0 applications ix. . . . . . . . . . . . . .

Table ii: MTS 200 MPEG Test System (V3.0) supported applications xi

Table 1: ECL Parallel data pinout 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2: ECL Serial data pinout 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3: ECL Control data pinout 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4: 10 Mbit Serial data pinout 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5: Estimated maximum cable lengths 7. . . . . . . . . . . . . . . . . . . .

Table 6: Data Store generation settings 17. . . . . . . . . . . . . . . . . . . . . . . .

Table 7: Toolbar command buttons 26. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8: File menu commands 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9: Acq/Gen menu commands 31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10: Frequencies available for each port 33. . . . . . . . . . . . . . . . . . .

Table 11: How synchronization works 34. . . . . . . . . . . . . . . . . . . . . . . . .

Table 12: Parameters available for each Port selection 37. . . . . . . . . . .

Table 13: Service menu commands 38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 14: Data Store resource parameters 39. . . . . . . . . . . . . . . . . . . . . .

Table 15: DefaultAlwaysdialogbox registry parameter values 43. . . . . .

Table 16: MTS to MTS transfer results 44. . . . . . . . . . . . . . . . . . . . . . . .

Table 17: G.703 — 8.448 MHz 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 18: G.703 — 34.368 MHz 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 19: ECL parallel, serial, and control ports 53. . . . . . . . . . . . . . . .

Table 20: ECL parallel data pinout 54. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 21: ECL serial data pinout 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 22: ECL control port pinout 57. . . . . . . . . . . . . . . . . . . . . . . . . . . .

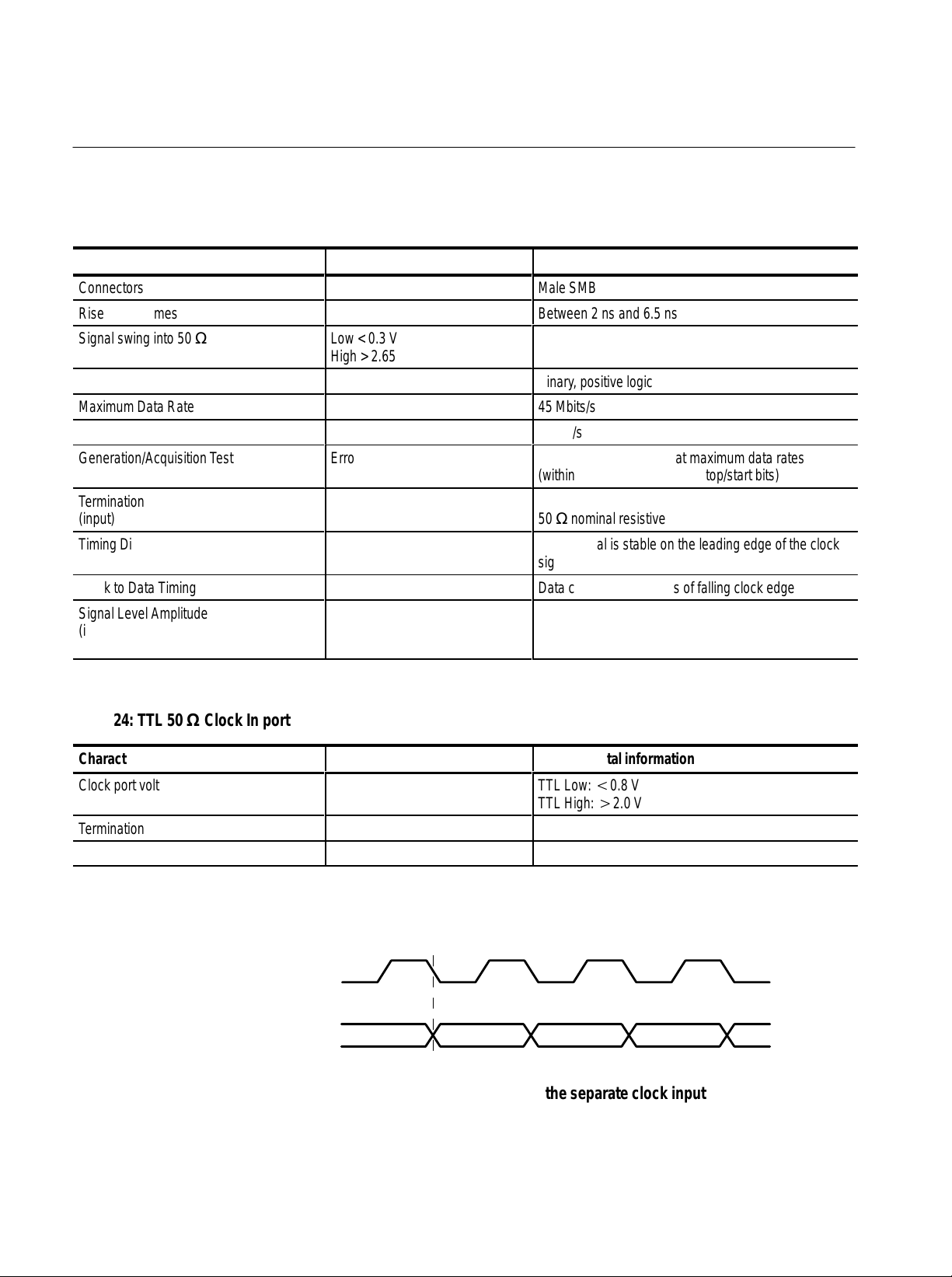

Table 23: 50 W TTL I/O 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 24: TTL 50 W Clock In port 58. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 25: 10 Mbit serial port (RS-422 levels I/O Port) 59. . . . . . . . . . . .

Table 26: 10 Mbit serial port pinout 59. . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 27: PLL 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MTS 200 Series MPEG Test System Data Store Administrator

iii

Page 8

Table of Contents

iv

MTS 200 Series MPEG Test System Data Store Administrator

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified

for this product.

Avoid Electric Overload. To avoid electric shock or fire hazard, do not apply a

voltage to a terminal that is outside the range specified for that terminal.

Avoid Overvoltage. To avoid electric shock or fire hazard, do not apply potential

to any terminal, including the common terminal, that varies from ground by

more than the maximum rating for that terminal.

Avoid Electric Shock. To avoid injury or loss of life, do not connect or disconnect

probes or test leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not

operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified

for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Product Damage

Precautions

MTS 200 Series MPEG Test System Data Store Administrator

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

Provide Proper Ventilation. To prevent product overheating, provide proper

ventilation.

v

Page 10

General Safety Summary

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

DANGER

High Voltage

Certifications and

Compliances

Refer to the specifications section for a listing of certifications and compliances

that apply to this product.

vi

Protective Ground

(Earth) T erminal

MTS 200 Series MPEG Test System Data Store Administrator

ATTENTION

Refer to Manual

Double

Insulated

Page 11

Preface

Manual Structure

This document applies to the Tektronix MPEG Test System Data Store

Administrator software and hardware. The Data Store system is an integral part

of the Tektronix MTS 210 and MTS 215 MPEG Test Systems.

For the latest information about MTS200 Series Software features and bugs,

refer to the MPEG Test System Software Version 3.0 Read This First document,

Tektronix part number 071-0537-XX, that accompanied your test system,

software product, or upgrade.

This manual is divided into the following sections:

Getting Started. The Getting Started section contains all the information you will

need to get your Real-Time Analyzer up and running.

Operating Basics. The Operating Basics section contains a tutorial that new users

should use to familiarize themselves with the Data Store Administrator.

Experienced users can also consult the tutorial for detailed instructions for

unfamiliar tasks.

Terms

Reference. The Reference section contains in-depth descriptions of the analyzer

capabilities, the software interface, and configuration options.

Appendix A: Specifications. Appendix A contains hardware specifications for the

Tektronix MTS 200 Series MPEG Test System Data Store system.

Appendix B: Functional Check. Appendix B outlines a procedure for confirming

proper function of the Data Store system.

Glossary. Consult the glossary when you encounter an unfamiliar term.

Index.

This manual uses two terms as defined below. Refer to the Glossary for

additional definitions.

CARB (Carte d’Acquisition / Restitution Binaire)

French for Binary Acquisition/Restitution Board: The Data Store system,

which can capture, store, and output MPEG-2 compliant transport streams.

MTS 200 Series MPEG Test System Data Store Administrator

vii

Page 12

Preface

Related Documents

The acronym CARB is used in this manual only where necessary to reflect

usage in the user interface.

DSA

Data Store Administrator: the software application that controls the Data

Store system.

The Tektronix MPEG Test System consists of several different hardware and

software configurations, options, and stand-alone software products. Please refer

to the following documents for additional information about other test system

components.

The MTS200 Series Real-Time Analyzer User Manual, Tektronix part number

071-0076-XX, contains information about using the Real-Time Analyzer and

Private Syntax Interpreter applications.

The MTS200 Series MPEG-2 DVB/ATSC System Analyzer User Manual,

Tektronix part number 071-0532-XX, contains information about using the

Deferred-Time Analyzer and DVB Channel Coding and Decoding applications.

The MTS200 Series Stream Creation Applications User Manual, Tektronix part

number 071-0534-XX, contains information about using the Multiplexer, DVB

Table Editor, ATSC Table Editor, DVB Channel Coding and Decoding, Jitter

Adder, Error Injector, and Open Mux Controller applications.

The MTS200 Series Program Stream Analyzer User Manual, Tektronix part

number 071-0384-XX, contains information about using the deferred-time

Program Stream Analyzer application.

The MPEG Test System Dolby Digital Audio Stream Analyzer User Manual,

Tektronix part number 071-0535-XX, contains information about using the

deferred-time AC-3 Audio Stream Analyzer application.

The MTS200 Series MPEG Audio Stream Analyzer User Manual, Tektronix part

number 071-0192-XX, contains information about using the deferred-time

MPEG Audio Stream Analyzer application.

The MTS200 Series Video Stream Analyzer User Manual, Tektronix part number

071-0249-XX, contains information about using the deferred-time MPEG Video

Stream Analyzer application.

For information about the Windows NT Workstation operating system, refer to

the Microsoft documentation that accompanied your test system.

For information about the Compaq server, refer to the Compaq documentation

that accompanied your test system.

viii

MTS 200 Series MPEG Test System Data Store Administrator

Page 13

Related Applications

ime Analyzer User

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

The applications that appear in your version 3.0 Tektronix MPEG Test System

program group and Start menu depend on the system configuration and its

installed options. Table i summarizes all test system applications available in

release 3.0.

For additional information about software options and licensing, see the version

3.0 Read This First document included with the test system.

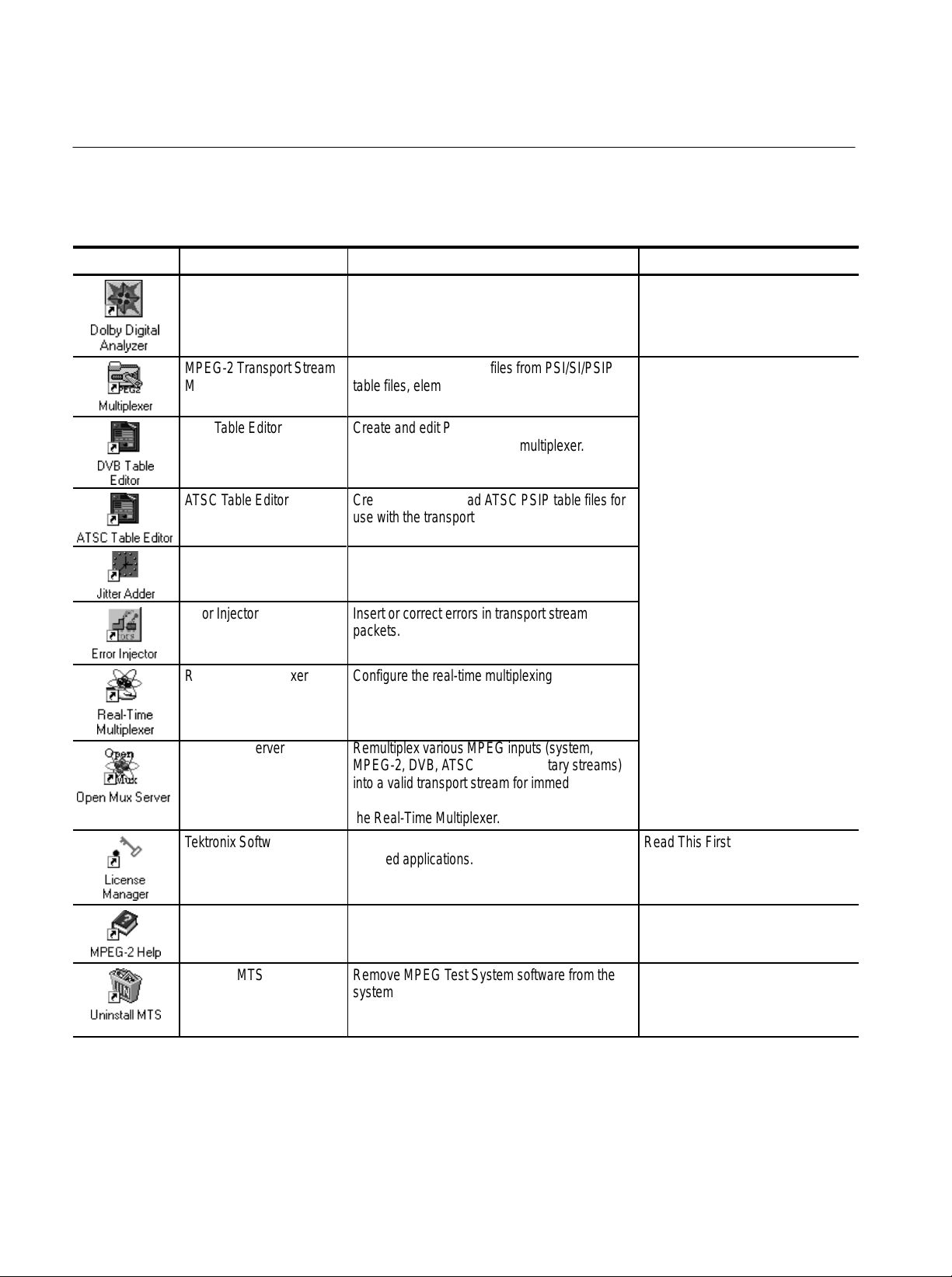

T able i: MPEG Test System version 3.0 applications

Icon Application title Function User Document

Real-Time Analyzer Continuously monitor an input bitstream for

compliance with the MPEG-2, DVB SI, and

ATSC PSIP digital television standards.

Private Syntax Interpreter Create table definitions used by the Real-Time

Analyzer to interpret private syntax sections.

MTS200 Real-T

Manual 071-0076-XX

Preface

Data Store Administrator

ББББББ

ББББББ

MPEG-2 DVB/A TSC

System Analyzer

ББББББ

ББББББ

DVB Channel Coding

and Decoding

ББББББ

ББББББ

ББББББ

Manage the data store (CARB) disks and control

acquisition/generation of MPEG-2 transport

БББББББББББ

streams.

БББББББББББ

Analyze transport streams and packetized

elementary streams saved to system disk or

БББББББББББ

data store (CARB) files.

БББББББББББ

Code and decode transport stream files to DVB

specifications.

БББББББББББ

БББББББББББ

БББББББББББ

MTS200 MPEG Test System Data

Store Administrator User Manual

ББББББББ

071-0536-XX

ББББББББ

MTS200 MPEG-2 DVB/A TSC

System Analyzer User Manual

ББББББББ

071-0532-XX

ББББББББ

MTS200 Stream Creation Applications User Manual 071-0534-XX

ББББББББ

ББББББББ

(Information repeated in both

manuals)

ББББББББ

Program Stream Analyzer Analyze MPEG program stream files. MTS200 Series Program Stream

Analyzer User Manual 071-0384-XX

MPEG Video Stream

Analyzer

Analyze MPEG-1 and MPEG-2 video elementary

streams files or streams extracted from the

MPEG Test System Video Stream

Analyzer User Manual 071-0249-XX

MPEG-2 System Analyzer or Program Stream

Analyzer.

MPEG Audio Stream

Analyzer

Analyze MPEG-1 and MPEG-2 audio elementary

streams files or streams extracted from the

MPEG Test System Audio Stream

Analyzer User Manual 071-0192-XX

MPEG-2 System Analyzer or Program Stream

Analyzer.

MTS 200 Series MPEG Test System Data Store Administrator

ix

Page 14

Preface

Á

Á

Á

tream Creation Applica-

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

T able i: MPEG Test System version 3.0 applications (Cont.)

Icon User DocumentFunctionApplication title

Dolby Digital Audio Stream

Analyzer

Analyze Dolby Digital (AC-3) audio elementary

stream files or streams extracted from the

MPEG-2 DVB/A TSC System Analyzer.

MTS200 Dolby Digital Audio

Stream Analyzer User Manual

071-0535-XX

MPEG-2 Transport Stream

Multiplexer

ББББББ

DVB Table Editor

ББББББ

ББББББ

ATSC Table Editor

ББББББ

Jitter Adder

ББББББ

ББББББ

Create transport stream files from PSI/SI/PSIP

table files, elementary stream files, and data

БББББББББББ

files.

Create and edit PSI and DVB SAI table files for

БББББББББББ

use with the transport stream multiplexer.

БББББББББББ

Create and edit PSI ad ATSC PSIP table files for

БББББББББББ

use with the transport stream multiplexer.

Add jitter to PCR data in MPEG-2 transport

БББББББББББ

stream files.

БББББББББББ

Error Injector Insert or correct errors in transport stream

packets.

Real-Time Multiplexer Configure the real-time multiplexing application

to remultiplex system and or elementary streams

for immediate output.

Open Mux Server Remultiplex various MPEG inputs (system,

MPEG-2, DVB, ATSC, and elementary streams)

into a valid transport stream for immediate

output. The user interface for this application is

the Real-Time Multiplexer .

T ektronix Software

Protection

Enter or reenter the general password to enable

licensed applications.

MTS200 S

tions User Manual 071-0534-XX

ББББББББ

ББББББББ

ББББББББ

ББББББББ

ББББББББ

ББББББББ

ББББББББ

ББББББББ

ББББББББ

ББББББББ

Read This First, MTS200 Software

V3.0 071-0537-XX

MPEG2_Part1

(ISO/IEC13818-1)

Uninstall MTS Remove MPEG T est System software from the

x

The international MPEG-2 system standard in

Windows Help format.

system disk.

MTS 200 Series MPEG Test System Data Store Administrator

none

MTS200 User Manuals

Page 15

Software Version

Á

ÁÁÁÁ

Á

Á

Á

Á

Table ii lists the MTS 200 MPEG Test System application version numbers

supported by this manual. To verify an application version number, select Help

in the application menu bar; then select About from the Help menu.

Table ii: MTS200 MPEG Test System (V3.0) supported applications

Preface

Supported

Application

Data Store Administrator

БББББББ

version

V2.0 and

above

Contacting Tektronix

ÁÁ

Applicable document(s)

MTS200 Series MPEG Test System Data Store Administrator User Manual

ББББББББББББББББББ

Product

Support

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tektronix.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Service

Support

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

Manual

part number

071-0536-XX

ÁÁ

www.tektronix.com

For other

information

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

To write us Tektronix, Inc.

P.O. Box 1000

Wilsonville, OR 97070-1000

MTS 200 Series MPEG Test System Data Store Administrator

xi

Page 16

Preface

xii

MTS 200 Series MPEG Test System Data Store Administrator

Page 17

Getting Started

All Tektronix MTS 210 and MTS 215 MPEG Test Systems contain the Data

Store system, which can acquire and output transport streams at rates from

1 Mbit/s to 60 Mbit/s (maximum) and store up to 18 Gbytes of data. At the

highest data rate, the Data Store system can store over 40 minutes of transport

stream data; you can also use end-to-start looping to continuously (and indefinitely) acquire or output transport stream data.

This section contains information to help you get started using the Data Store

Administrator, the application that controls and manages the Data Store system.

Refer to the following subsections as necessary:

H Input and Output Connections, page 2

H First Time Operation, page 9

H Software Repair, page 12

Refer to the Operating Basics section, beginning on page 13, for information

about using the Data Store Administrator.

MTS 200 Series MPEG Test System Data Store Administrator

1

Page 18

Getting Started

Input and Output Connections

Figure 1 shows the test system Data Store input and output (I/O) connectors on

the Compaq Proliant rear panel. Figure 2 shows the same connectors on the

Compaq Prosignia rear panel (MPEG Test Systems with serial numbers below

B040000). A detailed description of each connector follows the illustrations. Use

the I/O port(s) best suited to your signal sources and operating environment.

For I/O port specifications, refer to Specifications beginning on page 49.

ECL parallel/serial

I/O port

ECL control port

Figure 1: Data Store inputs and outputs (Compaq Proliant)

TTL 50 W serial

port (Clk I/O)

TTL 50 W serial

port (Data I/O)

External clock

input (Clk In)

10 Mbit serial I/O

port (RS-422

levels)

G.703 input

G.703 output

(34.368 Mbits/s)

G.703 output

(8.448 Mbits/s)

ECL Parallel/Serial I/O Port

2

The ECL Parallel/Serial I/O port receives and transmits MPEG-2 transport

streams at ECL levels. The port is differential, bidirectional, and operates

independently or in conjunction with the ECL Control port. The port transmits or

receives either parallel or serial data depending on the Data Store Administrator

application settings.

ECL Operating Modes. If the ECL Parallel/Serial I/O port is used independently

of the ECL Control port, there are three basic operating modes:

H Slave acquisition mode. Captures input signals using the ECL Parallel/Serial

I/O port clock signal as the timing source.

MTS 200 Series MPEG Test System Data Store Administrator

Page 19

Getting Started

H Master generation mode. Outputs signals using the test system internal clock

as the timing source.

H Master generation with external clock mode. Outputs signals using the

external clock input (Clk In) as the timing source.

Using the ECL Parallel/Serial I/O port in conjunction with the ECL Control port

provides the following additional operating modes:

H Master acquisition mode. Captures input signals using control signals from

the ECL Control port to drive the signal source.

H Master acquisition with external clock mode. Same as above but uses a

timing signal from the external clock input (Clk In) as the timing source.

H Slave generation mode. Outputs signals using the ECL Control port inputs as

the timing source.

NOTE. A Master generates the data transmission clock. A Slave returns an

external clock as the source.

ECL control port

G.703 input

G.703 output

(34.368 Mbits/s)

G.703 output

(8.448 Mbits/s)

Figure 2: Data Store inputs and outputs (Compaq Prosignia)

7

ECL parallel/serial

I/O port

6

10 Mbit serial I/O

port (RS-422

5

4

3

levels)

External clock

input (Clk In)

TTL 50 W serial

port (Data I/O)

TTL 50 W serial

port (Clk I/O)

2

1

MTS 200 Series MPEG Test System Data Store Administrator

3

Page 20

Getting Started

3

5

5

5

3

5

5

5

T able 1: ECL Parallel data pinout

ECL parallel pinout Pin Function Pin Function

1 DCLK 14 DCLK

1

2

4

6

7

8

9

10

11

12

13

Asserted Low differential signal.

2 Ground 15 Ground

14

3 DA TA 7 16 DATA 7

1

4 DA TA 6 17 DATA 6

16

17

5 DA TA 5 18 DATA 5

18

6 DA TA 4 19 DATA 4

19

7 DA TA 3 20 DATA 3

20

8 DA TA 2 21 DATA 2

21

21

9 DA TA 1 22 DATA 1

22

23

10 DA TA 0 23 DATA 0

24

11 DV ALID 24 DV ALID

2

12 PSYNC 25 PSYNC

13 Shield

T able 2: ECL Serial data pinout

ECL serial pinout Pin Function

1 DCLK

1

2

4

6

7

8

9

10

11

12

13

Asserted Low differential signal.

2 Ground

14

3 thru 9 Not managed

1

10 DA TA 0

16

17

11 DVALID

18

12 PSYNC

19

13 Shield

20

14 DCLK

21

21

15 Ground

22

23

16 thru 22 Not managed

24

23 DA TA 0

2

24 DVALID

25 PSYNC

4

MTS 200 Series MPEG Test System Data Store Administrator

Page 21

Getting Started

5

ECL Control Port

G.703 Output

(8.448 and 34.368 Mbit/s)

and G.703 Input

The ECL Control port is optional. This bidirectional differential control port

adds flexibility to the ECL Parallel and Serial Ports, providing three control

signals and two more operating modes.

T able 3: ECL Control data pinout

ECL control pinout Pin Function

1 CHCLK (channel clock)

2 Ground

1

2

2

3

4

Asserted Low differential signal.

3 CHSYNC (channel sync)

6

4 CHCLKEN (channel clock enable)

7

5 Shield

8

6 CHCLK (channel clock)

9

7 Ground

8 CHSYNC (channel sync)

9 CHCLKEN (channel clock enable)

The G.703 serial interface complies with the electrical characteristics of ITU-T

Recommendation G.703 (HDB3 code) for 8.448 Mbit/s and 34.368 Mbit/s.

The G.703 port operates in the following modes:

H Acquisition mode. Locks to the incoming signal and is self clocking.

H Generation (internal clock source) MODE. Uses an internal clock source.

The G.703 serial interface uses three Data Store circuit-board mounted SMB

connectors. One connector is a dedicated input for both bit rates. The other two

connectors are dedicated outputs, one for the 34.368 Mbit/s output and the other

for the 8.443 Mbit/s output. To reduce spurious emissions, connect only the

output in use.

NOTE. Do not leave SMB-to-BNC adapter cables on unused G.703 outputs.

Doing so will cause the test system to exceed EMC emission requirements.

MTS 200 Series MPEG Test System Data Store Administrator

5

Page 22

Getting Started

5

10 Mbit Serial Port

(RS-422 Levels I/O Port)

The 10 Mbit Serial port transmits and receives MPEG transport signals and

includes bidirectional clocks and data pairs. The maximum operating frequency

is 10 Mbit/s. The port uses RS-422 voltage levels with a line-to-line input

termination of 110 W.

T able 4: 10 Mbit Serial data pinout

10 Mbit serial pinout Pin Function

1 DA TA IN

2 CLK IN

1

2

2

3

4

Asserted Low differential signal.

3 DA TA OUT

6

4 CLK OUT

7

5 Ground

8

6 DA TA IN

9

7 CLK IN

8 DA TA OUT

9 CLK OUT

The 10 Mbit Serial port uses the following signals:

Clock Input

H Data In and Data Out (MPEG serial bit streams).

H Clock In and Clock Out (continuous data transmission).

The 10 Mbit Serial port operates in the following modes:

H Acquisition mode. Captures an input signal using an external timing

reference.

H Internal generation mode. Generates an output signal using the MPEG Test

System internal clock as the timing reference.

H External generation mode. Generates an output signal using the Clock input

as the timing reference.

The Clk In connector provides an optional timing input for the ECL Serial, ECL

Parallel, TTL, and 10 Mbit Serial outputs. The input operates at a maximum

frequency of 45 MHz.

For example, a 45 MHz clock input can generate a 45Mbit/s serial ECL signal. A

45 Mbit/s ECL output requires a 5.624 Mbit/s (byte-wide) clock input.

6

MTS 200 Series MPEG Test System Data Store Administrator

Page 23

Getting Started

TTL 50 W Serial Port

(Data & Clock I/O)

Data Store I/O Cables and

Mating Connectors

The TTL 50 W Serial Port consists of dedicated clock and data inputs that

transmit and receive at TTL levels. The Data signal is a serial bitstream that uses

a continuous data transmission clock. The maximum operating frequency is

45 Mbits/s.

The

TTL 50 W Serial Port operates in the following modes:

H Acquire mode. Captures an input signal.

H Internal Generation mode. Generates a signal locked to the internal clock.

H External Generation mode. Generates a signal locked to an external reference

supplied by the Clock Input.

The MPEG Test System includes adapters to connect the Data Store SMB

connectors to standard BNC connectors. You may also need to acquire or

assemble other signal-connecting cables and adapters to install the test system in

your facility.

Cable Lengths. Maximum cable length is a function of data rate, cable type, and

ambient environment as summarized in Table 5. In general, low data rates

tolerate longer cable lengths than do high data rates. Low-loss coaxial cable and

low capacitance properly pair-twisted cable support longer transmission paths

than do miniature coaxial cable or ribbon cable. Induced RF noise can further

limit usable cable length.

The only test system ports designed for data transmission are the G.703 I/O

ports. All other ports are intended for short-range interconnects. With most ports,

you must control cable delay matching to maintain clock-to-data timing margins

or data integrity will suffer.

T able 5: Estimated maximum cable lengths

Port Data Rate

(Mbits/s)

G.703 8.448 275 Belden 8281 4 dB atten at

G.703 34.368 125 Belden 8281 4 dB atten at

10 MBit

(RS422)

10 MBit

(RS422)

TTL 10 50 RG58 type Calculated Value

1 100 24 AWG

10 15 24 AWG

Maximum length

(meters)

Cable type Comments

4.224 MHz

17.18 MHz

Ref. ANSI/TIA/

unshielded

twisted pair

unshielded

twisted pair

EIA-422-B-1994

Ref. ANSI/TIA/

EIA-422-B-1994

MTS 200 Series MPEG Test System Data Store Administrator

7

Page 24

Getting Started

T able 5: Estimated maximum cable lengths (cont.)

Software Key

Port CommentsCable typeMaximum length

TTL 50 25 RG58 type Calculated Value

ECL Parallel 1 50 Belden 8112 Calculated Value

ECL Serial 45 5 Belden 8112 Calculated Value

Data Rate

(Mbits/s)

(meters)

Adapters. The MPEG Test System includes six SMB-to-BNC adapter cables.

Three of the adapter cables match the impedance of the G.703 75 W inputs and

outputs. The other three match the impedance of the TTL 50 W Serial Port

(CLK I/O, DATA I/O, and CLK IN).

The Rainbow Technologies software key, or Dongle, is not required to run the

Data Store Administrator; however, it must be installed on the computer parallel

port to start and run most other Tektronix MPEG Test System applications.

NOTE. The software key that matches your system must be installed on the

parallel port to start and run most MTS 200 Series software applications. Do not

remove or misplace the software key. Do not exchange the software key with the

key from another Tektronix MPEG Test System.

8

MTS 200 Series MPEG Test System Data Store Administrator

Page 25

First Time Operation

Getting Started

To power on the test system computer, slide the power switch cover plate to the

right and press the power switch.

Slide power switch

cover plate

Power switch

The Windows NT initialization process takes up to two minutes to complete.

Under normal circumstances, no action is required. (For further information on

the Windows NT initialization process, see the Windows NT documentation

included with the test system.) When the Begin Logon window appears,

simultaneously press the

CTRL + ALT + DELETE keys to open the Logon Informa-

tion dialog box.

Logging On

To log on to the test system, enter MTS100 in the User name box, leave the

Password box blank, and press

factory). Use this logon for most of your work.

There are two other logons and passwords available. The first is guest with no

password. This level has only limited access to files and applications. The

second level is administrator with MPEG2 as the password. This user has

MTS 200 Series MPEG Test System Data Store Administrator

ENTER (these are the default values set at the

9

Page 26

Getting Started

administrator privileges. You must use this logon when performing all software

upgrades.

CAUTION. The administrator user logon includes all privileges. If you are

connected to a network, you may have special privileges within the network. Do

not use this logon to perform normal operations.

Changing Passwords. You can change passwords at this time. See the Windows NT documentation for instructions. If you change any password, be sure to

create a new emergency repair disk. See page 12 for additional information.

Starting the

Data Store Administrator

When logon is complete, the Tektronix MPEG Test System program group

window appears as shown below. Double-click the Data Store Administrator

icon to start the program. Refer to the Operating Basics section, beginning on

page 13, for information about using the Data Store Administrator.

Refer to the appropriate User manual for information about other MPEG Test

System applications. Refer to Related Documents and Related Applications, both

in the Preface of this manual, for the correct manual title and part number.

NOTE. Although Windows NT permits several applications to run simultaneously,

hardware limitations prevent simultaneous use of the Deferred-Time Analyzer or

Multiplexer with the Data Store Administrator.

10

MTS 200 Series MPEG Test System Data Store Administrator

Page 27

Getting Started

Exiting the Data Store

Administrator

Shutting Down the

Computer

To exit Data Store Administrator, select Exit/Quit from the application File

menu or click the close button in the upper-right corner of the application

window.

Close

button

To avoid loss of data and possible problems during subsequent Windows NT

initialization, always shut down Windows NT before switching computer power

off. To shut down Windows NT, select Shut Down from the Start menu.

In the Shut Down Windows dialog box, select Shut down the computer? and

then click Yes. After a few seconds, the Shutdown Computer window appears

with the message “It is now safe to turn off your computer.” You can now power

off the computer.

CAUTION. Do not switch computer power off before the message “It is now safe

to turn off your computer” appears. Doing so may result in lost data and

difficulty in restarting Windows NT.

MTS 200 Series MPEG Test System Data Store Administrator

11

Page 28

Getting Started

Software Repair

If you experience operating problems and suspect that one or more MPEG Test

System files have been corrupted, refer to the Software Repair appendix in either

of the following manuals:

The MTS200 Series MPEG-2 DVB/ATSC System Analyzer User Manual,

Tektronix part number 071-0532-XX.

The MTS200 Series Stream Creation Applications User Manual, Tektronix part

number 071-0534-XX.

12

MTS 200 Series MPEG Test System Data Store Administrator

Page 29

Operating Basics

Terms

The Data Store Administrator application manages the Data Store disks and

MPEG-2 transport stream acquisition and generation to and from the disks.

Because Windows NT cannot manage the Data Store disks, the Data Store

Administrator performs all the low-level functions normally accomplished with

the Windows NT Explorer application.

The Data Store Administrator, the SCSI drivers, and the EISA card are optimized

to provide a continuous data acquisition or generation rate of up to 60 Mbits/s

(ECL) for a minimum of 40 minutes (18 Gbyte data store disk capacity) without

interruption or data loss. Looping acquisition and generation is also possible.

The terms Data Store disk and system disk are NOT interchangeable. CARB is a

French acronym that is synonymous with Data Store.

Data Store Disk. The Data Store disks are four hard drives totalling 18 Gbytes

that are physically connected to the Data Store circuit board. These disks are

used by the Data Store Administrator when generating and acquiring transport

streams. They can also be used by the following applications when dealing with

files that are too large for the system disk: Multiplexer, DVB/ATSC System

Analyzer, Audio stream Analyzer, Video stream Analyzer, Program Stream

Analyzer, and Dolby Digital Audio analyzer.

System Disk. The system disk is the fixed disk drive (hard disk) that contains the

Windows NT operating system files and the MTS200 Series application

software. You can access this disk using the Windows NT Explorer application.

The system disk is configured during manufacture as the C drive.

CARB. The term CARB, a French acronym referring to the Data Store disks or

the Data Store board, is used often in the Data Store Administrator user interface.

CARB appears in this manual when necessary to reflect on-screen nomenclature

and to avoid ambiguity.

MTS 200 Series MPEG Test System Data Store Administrator

13

Page 30

Operating Basics

Special Features of the Data Store Disks

In order to generate or acquire MPEG-2 transport streams, the Data Store disks

have these special features required to accommodate constant, high bit rate

input/output:

H The data store disks can be divided into single shot and looping partitions.

H The Single Shot partition can contain up to 255 files. File acquisition must

stop when the partition is full.

H The looping partition permits continuous capture of input, which is stored as

a single file. If you create a six Gbyte looping partition, you can fill the

partition and continue acquisition. The partition always contains the most

recently acquired data. After you stop acquisition you can analyze or replay

the last six Gbytes of input.

Each new acquisition to the looping partition overwrites any previously-acquired data. You can store only one file on the looping partition.

H You can output any file from either partition repeatedly in looping mode.

H You can partition the Data Store disks as entirely single shot, entirely

looping, or any combination between those two extremes (for example,

16 Gbytes single shot and 2 Gbytes looping).

H You can change the relative sizes of the partitions at any time; however,

repartitioning the Data Store disks erases all files on the disks. Refer to

Partitioning the Disks on page 19 for more information.

H In order to sustain extremely high rates of data transfer, the Single Shot

partition uses a rigid file structure. Unlike a normal computer disk, on which

file data can be fragmented and stored wherever there is free space, the Data

Store disks must store each file as a single data block immediately “below”

the last-acquired file. As a result, you cannot simply delete an arbitrary file

to free up disk space. This is explained further under Compress Disks on

page 40.

NOTE. Because of the rigid file structure, it is strongly advised that you use the

Data Store disks only for acquiring, storing, and generating transport stream

files. For best results, always transfer small files onto the MTS200 Series system

disk for long-term storage.

14

MTS 200 Series MPEG Test System Data Store Administrator

Page 31

Starting the Application

Acquiring Data

Operating Basics

There are two ways to start the application:

H Double-click the Data Store Administrator icon in the Tektronix MPEG

Test System program group window.

H Select Data Store Administrator from the Programs/Tektronix MPEG Test

System submenu of the Windows NT Start menu.

NOTE. You cannot start the Data Store Administrator application if either the

Deferred-Time Analyzer or the Multiplexer applications are running.

Follow this outline procedure to receive and save data on the Data Store disks.

1. Connect the data source to the appropriate Data Store system input. For

descriptions of the inputs, refer to Appendix A: Data Store I/O Specifications

or Getting Started in the MTS 200 Series Hardware Installation and

Specifications Compaq Proliant 1600 Platform Technical Reference,

Tektronix part number 071-0261-XX.

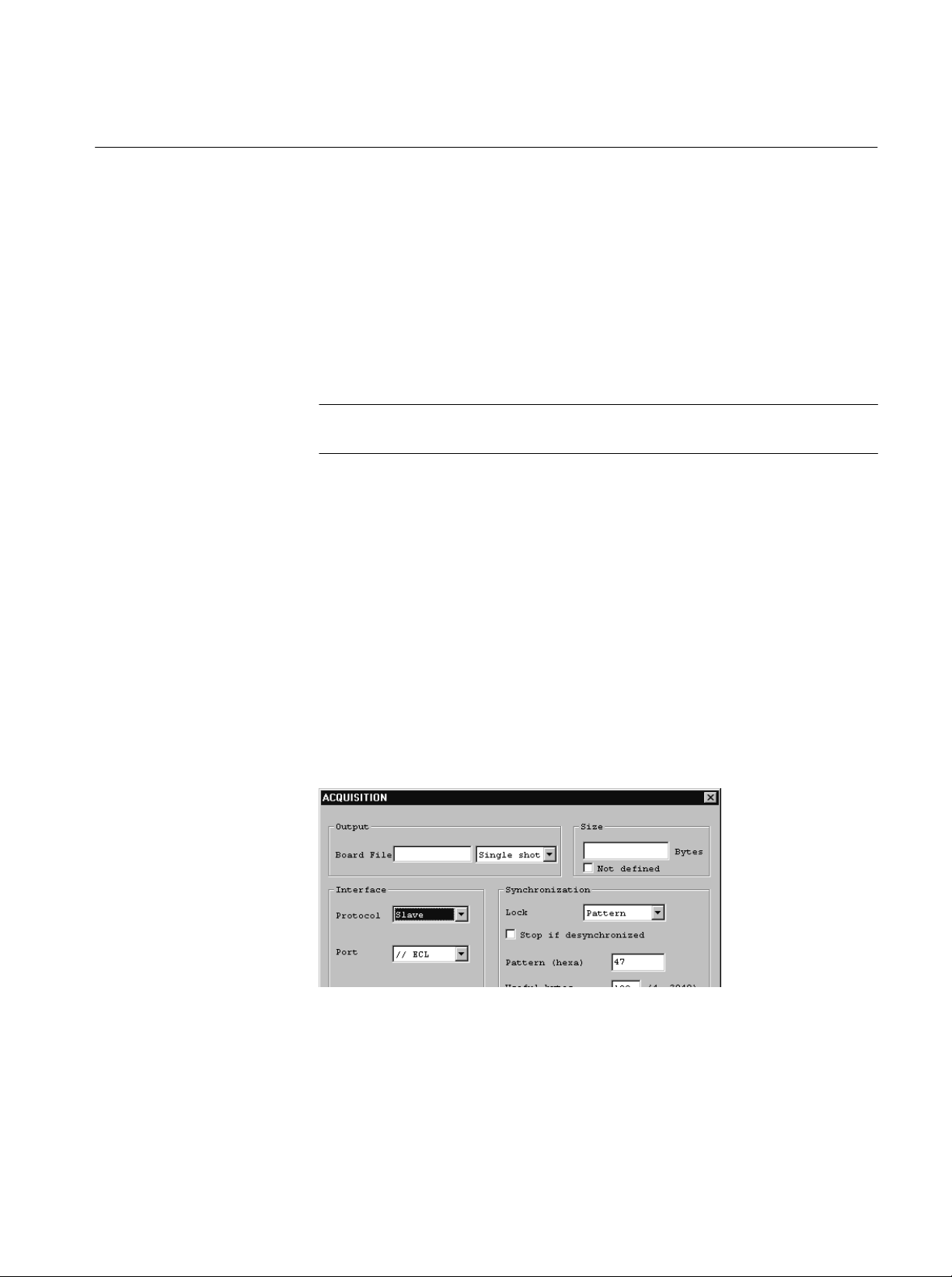

2. Click the A (acquisition) command button to open the ACQUISITION

settings window.

3. Enter a name for the file to be saved in the Board File text box. If you intend

to analyze the file with the Deferred-Time Analyzer, use an appropriate file

name extension (*.trp, for example).

4. If the Data Store disks have both a Single Shot and a Loop partition, select

the target partition.

MTS 200 Series MPEG Test System Data Store Administrator

15

Page 32

Operating Basics

5. Enter a size to specify how much of the input stream to capture; select Not

defined if you intend to stop acquisition manually (such as when capturing

indefinitely to the Loop partition).

6. Select Slave protocol to use the source clock; select Master protocol to use

the internal Data Store clock.

7. Select the input port. Choices depend on the following protocol selection:

H Inputs available with Slave protocol: //ECL, Serial ECL, G703, TTL,

and 10 Mbits.

H Inputs available with Master protocol: //ECL and Serial ECL.

8. Depending on the port selection, you may have additional Interface choices.

Refer to Acquisition on page 31 for further information.

9. Select the appropriate Synchronization settings. To acquire an MPEG-2

transport stream made up of 188 byte packets, use the settings (Pattern/47/188) shown in the example ACQUISITION window above. Refer to

Acquisition on page 31 for further information.

10. Click Start. If the settings are correct for the input, the Acquisition in

progress message appears in the application window.

11. If you defined a file size, acquisition ends when the specified amount of data

is received. Otherwise, select Interrupt Transfer from the Acq/Gen menu

or click the corresponding (red hand) command button to stop acquisition.

In the default configuration, the Data Store Administrator dialog box

containing the message “Transfer is finished” appears after each acquisition

of a specified size. Click OK to acknowledge the message. You can edit the

Windows NT registry to prevent appearance of this message; refer to

Suppressing the “Transfer is Finished” message on page 43 for instructions.

When acquisition ends, the new file is added to the File information list.

16

MTS 200 Series MPEG Test System Data Store Administrator

Page 33

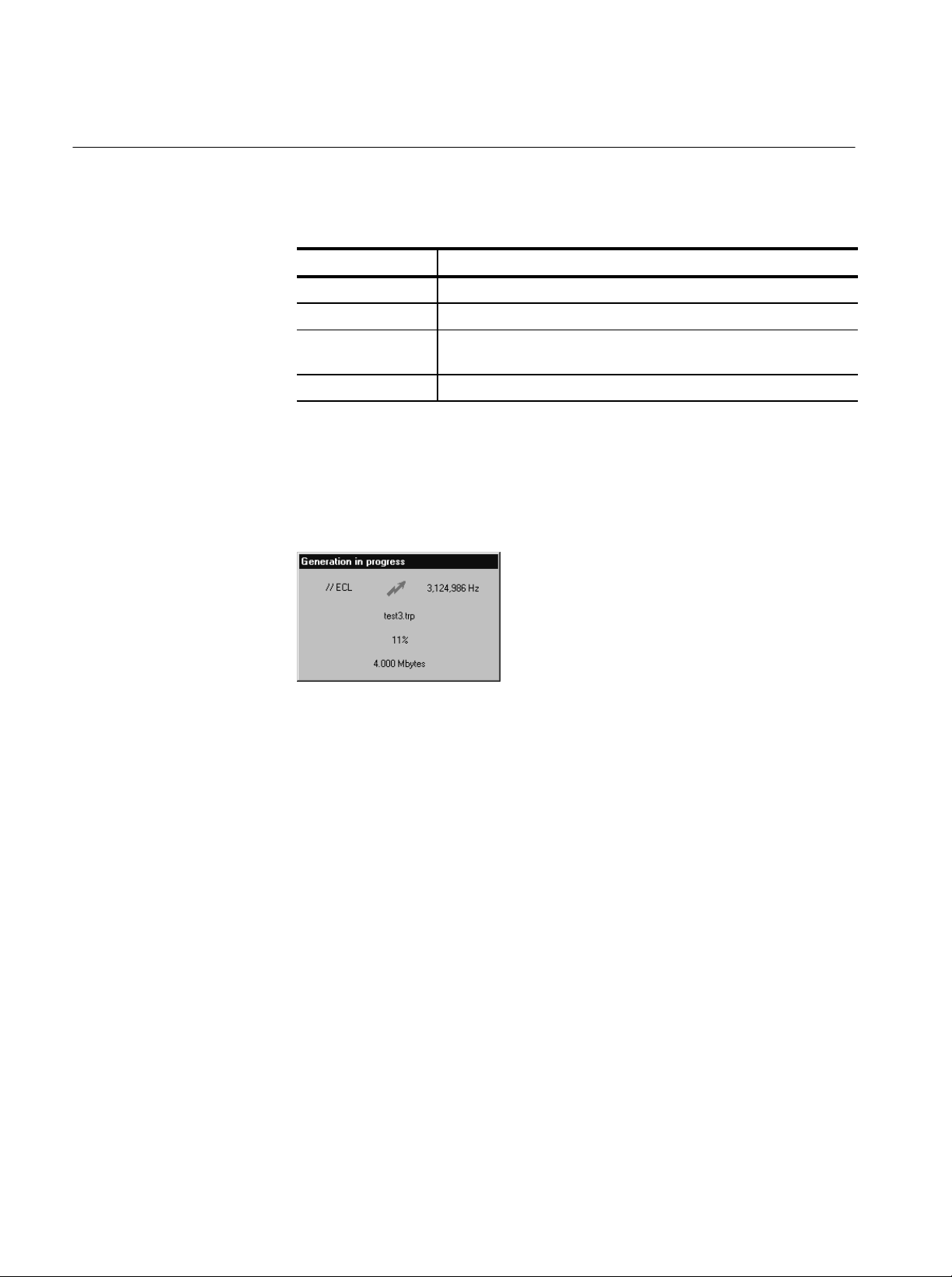

Generating (Outputting) Data

Follow this outline procedure to output data from the Data Store disks. You can

refer to Generation, beginning on page 35, for additional information.

1. Select a file from the File information list and right-click to open the

shortcut menu.

2. Click Generation to open the GENERATION settings window.

Operating Basics

3. Make the following selections:

T able 6: Data Store generation settings

Settings parameter Choices/explanation

Loop Select to repeatedly output entire file

Size Portion of the file to output once. Not available when loop is selected

Offset Bytes at the beginning of file to ignore. Not available when loop is

selected.

Protocol Master or Slave

Port //ECL, Serial ECL, G703, TTL, 10 Mbits

MTS 200 Series MPEG Test System Data Store Administrator

17

Page 34

Operating Basics

T able 6: Data Store generation settings (Cont.)

Settings parameter Choices/explanation

Output clock Depends on Port; see Table 12 on page 37.

Frequency Depends on Port and clock; see Table 12 on page 37.

Msb first Available with serial ports only and if Data Store system is configured;

refer to Msb first on page 37 for additional information.

Control signals Available with ECL ports only, forces burst mode output

4. Click Start. The Generation in progress message appears and remains on the

Data Store Administrator application window as long as generation

continues. You can minimize the application window during generation, but

you cannot exit the Data Store Administrator.

Disk Management

5. If you selected Loop generation, select Interrupt Transfer from the

Acq/Gen menu or click the corresponding (red hand) command button to end

generation. Otherwise, generation ends when the end of the source file is

reached.

In the default configuration, the Data Store Administrator dialog box

containing the message “Transfer is finished” appears after each one-time

(not looping) generation. Click OK to acknowledge the message. You can

edit the Windows NT registry to prevent appearance of this message; refer to

Suppressing the “Transfer is Finished” message on page 43 for instructions.

The Data Store system hardware and software is specially designed for unusually

high rates of data transfer. As a result, you cannot use standard Windows NT file

management practices to manage the Data Store disks. Although the Data Store

system is visible as folder C:\Carb0 through the My Computer icon and the

18

MTS 200 Series MPEG Test System Data Store Administrator

Page 35

Operating Basics

Windows NT Explorer application, you can copy, output, and erase Data Store

files only through the Data Store Administrator application.

Partitioning the Disks

The Data Store disks can have two types of partition:

H Single Shot, for acquisition and storage of up to 255 individual files.

Acquisition can continue only until the partition is full.

H Looping, for continuous acquisition of a single file. When the partition is

full, new input data overwrites the oldest data on the partition.

You can partition the Data Store disks as entirely Single Shot, entirely Looping,

or any combination between the two extremes (for example, 16 Gbytes single

shot and 2 Gbytes looping).You can change the relative sizes of the partitions

whenever the Data Store system is not generating or acquiring; however,

repartitioning the Data Store disks erases all files on the disks.

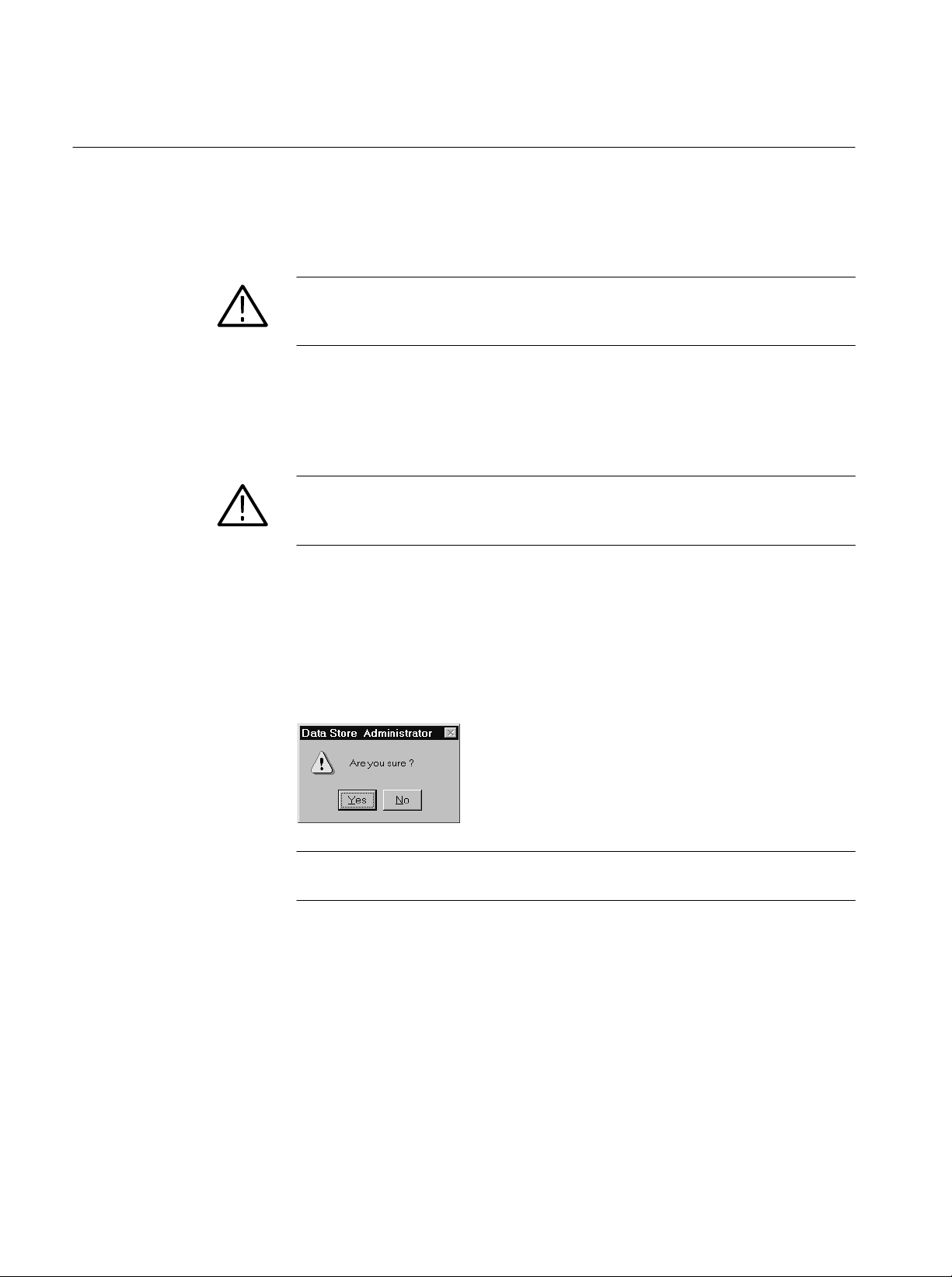

CAUTION. Partitioning the Data Store disks erases all file directory information

and makes it impossible to read, retrieve, or use previously-stored data. Be sure

to transfer irreplaceable and important files to the system disk or other storage

media before partitioning the Data Store disks.

Use the following procedure to partition the Data Store disks:

1. Transfer all important Data Store files to the System Disk or to another

MPEG Test System. Refer to Copying Files to the Computer on page 20 or

Data Store Transfers on page 44 for instructions and additional information.

2. Select Partition Disks from the Service menu. The Partitionning window

opens.

3. Select the appropriate Partition type from the list.

MTS 200 Series MPEG Test System Data Store Administrator

19

Page 36

Operating Basics

4. If you selected only Single shot or only Loop partition type, click OK to

create the partition.

5. If you selected Single shot & loop, enter the desired size of the loop partition

and click OK to create the partitions.

6. Click Yes in the resulting Are you sure? message window to confirm your

choice (click No to abort partitioning).

When partitioning is complete, the Disk information reflects your partitioning choices and the File information list is empty.

Copying Files

from the Computer

You can copy files to the Single Shot partition from any drive that the computer

has access to, such as the system disk, the CD ROM drive, and any network

drives. Use the following procedure to copy files from MPEG Test System disks

to the Data Store disks:

1. Check the Single Shot partition Disk information to verify that the Available

size is large enough for the file.

2. Select PC to Board (Write) from the File menu or click the W command

button. The File Write to CARB window opens.

3. Click Browse to open a standard Windows Open dialog box.

4. Locate and select the appropriate file (double-click on the file name or click

OK to dismiss the Open dialog box).

By default, the PC file name is used as the name of the Data Store file. You

can edit the name in the Name of the CARB File text box.

20

Copying Files

to the Computer

5. Click Start to begin writing the file onto the Single Shot partition. A

message box appears to show the progress of the operation. Another box

appears when the transfer is complete; click OK to acknowledge. The file

name appears at the bottom of the Single Shot partition files list.

You can copy files from either Data Store partition to any drive that the computer

has access to, such as the system disk and network drives. Use the following

procedure to copy files from the Data Store disks to MPEG Test System disks:

1. Verify that there is enough room on the target drive to accept the file. (To

check disk free space, open the My Computer window and click on the target

MTS 200 Series MPEG Test System Data Store Administrator

Page 37

Operating Basics

drive icon; the disk free space is reported on the status bar at the bottom of

the window.)

NOTE. Due limitations of the File Allocation Table (FAT) file system, you cannot

copy files larger than four Gbytes onto the system disk.

2. Highlight the name of the source file on the Data Store Administrator File

information list.

3. Right-click to open the shortcut menu; then click Read.

The File Read from CARB window opens.

4. To copy the entire file under its original name in the C:\Mts200\Cfg-trp

directory, click Start.

5. To copy the file to a different directory and file name, enter the path and

name in the Name of the PC file text box or click Browse to access the

appropriate drive and directory and enter the file name.

6. To copy only a portion of the file, enter the desired size in the Size box. If

you enter 20000000 (or 20,000,000 or 20 000 000), for example, only the

first 20 Mbytes of the file will be written to the PC disk. To copy only

packets 11 through 110 from a stream of 188-byte packets, enter 1880 in the

Offset box and enter 18800 in the size box.

MTS 200 Series MPEG Test System Data Store Administrator

21

Page 38

Operating Basics

Erasing All Files

Erasing Files to Increase

Available Disk Space

To quickly erase all files from both partitions of the Data Store disks, choose Fat

Delete from the service menu. The “Are you sure?” message appears. To delete

all files from the Data Store disks, click Yes.

CAUTION. The Fat Delete command is irreversible. You cannot recover deleted

files. Never use the Fat Delete command before confirming that important Data

Store files have been backed up on the system disk or on other media.

In some circumstances, you may want to delete some files from the Data Store

disks in order to make room for additional acquisitions while preserving other

important files that may be too large to transfer to the system disk. Because Data

Store files must occupy contiguous regions of the disks, you must first mark the

unwanted files for deletion and then compress the disks to create the largest

possible segment for new acquisitions.

1. Delete unwanted files as follows:

a. Select the unwanted files on the File information list.

To select several files in a row, hold the

SHIFT key down while making

your selections; to select several files that are not listed consecutively,

hold the

CTRL key down while making your selections.)

b. Right-click to open the shortcut menu. If you have selected more than

one file, Delete is the only command available.

c. Click Delete. Click Yes or Yes to All in the resulting confirmation

window. Until you compress the disks, you can undelete all but the last

file on the list.

22

MTS 200 Series MPEG Test System Data Store Administrator

Page 39

Operating Basics

d. If you decide not to erase a file that is marked deleted, highlight the file

name and right-click; then click Undelete in the shortcut menu.

2. Compress the Data Store disks as follows:

a. To erase files that are marked deleted and to consolidate the remaining

files in contiguous regions of the data store disks, select Compress

Disks from the Service menu.

NOTE. The last file and files marked delete cannot be recovered following disk

compression.

b. One again the “Are you sure?” message appears. Click Yes to proceed.

NOTE. The Compress function requires approximately one second per megabyte

of disk space to compress the Data Store disks.

For example, 1 Gbyte = 1024 Mb; 1024 seconds is approximately 17 minutes.

c. When disk compression is complete, the File information list contains

only the names of the remaining files.

MTS 200 Series MPEG Test System Data Store Administrator

23

Page 40

Operating Basics

24

MTS 200 Series MPEG Test System Data Store Administrator

Page 41

Reference

This section contains detailed information about the Data Store Administrator.

The following subsections begin on the indicated pages:

H The Application Window, page 26

H Toolbar Command Buttons, page 26

H File Menu Commands, page 27

H Acq/Gen Menu Commands, page 31

H Service Menu Commands, page 38

H The Help Menu, page 43

H Suppressing the “Transfer is Finished” Message, page 43

H Data Store Transfers, page 44

H Problems/Troubleshooting, page 45

MTS 200 Series MPEG Test System Data Store Administrator

25

Page 42

Reference

The Application Window

Menu bar

Toolbar

When you open the Data Store Administrator, the application window shown

below occupies the screen.

Toolbar Command Buttons

The toolbar contains command buttons for several frequently used menu

commands. Click a button to select the corresponding menu command.

T able 7: Toolbar command buttons

Button Corresponding menu command

FAT Read (page 27)

Board to PC (Read) (page 28)

PC to Board (Write) (page 28)

Acquisition (page 31)

Generation (page 35)

Interrupt transfer (page 38)

26

MTS 200 Series MPEG Test System Data Store Administrator

Page 43

File Menu Commands

Á

Á

Á

Á

Reference

The File menu contains file management commands.

T able 8: File menu commands

Use To

FAT Read

FAT Read

Board to PC (Read)

List the files available on the Data Store disks

Copy a file from the Data Store disks to the system hard drive (or oth-

er disk)

PC to board (Write)

БББББ

Copy a file from the system hard drive or other media to the Data

ББББББББББББББББ

Store disks

Delete

БББББ

Undelete

Mark a Data Store file to be deleted (unless the file is at the bottom of

ББББББББББББББББ

the list, it can be undeleted any time before disk compression)

Remove the delete mark from a Data Store file

Exit Quit the Data Store Administrator application

FAT stands for File Allocation Table. The FAT Read command lists the files

available on the Data Store disks and shows their status. A FAT Read occurs

automatically when the Data Store Administrator is started and after most file

read and write operations.

MTS 200 Series MPEG Test System Data Store Administrator

27

Page 44

Reference

The FAT Information display occupies the application window and provides the

following information:

H Number of Disks detected on the Data Store board. There should be four

disks; any fewer indicates that you may have a malfunctioning disk. (The

MTS 200 Series can operate with fewer than four disks if one or more fails

and immediate replacements are not available.)

H Size of each disk (in bytes).

H Partition information.

H File name(s).

H File size(s) in bytes.

H Files marked as deleted (DEL). These files are deleted when the Compress

Disks command is next selected from the Service menu.

Board to PC (Read)

PC to Board (Write)

Use the Board to PC (Read) command to copy a file from the Data Store system

to the system disk (or another regular disk).

The most common reasons to copy a file to the system disk are as follows:

H To save an important file before repartitioning the Data Store disks.

H To save a file from the Loop partition before acquiring another file in

looping mode.

After selecting the name of the file to copy from the File information list, you

can invoke the read command in the following ways:

H Right-click in the File information box and then select Read from the

resulting shortcut menu.

H Press

CTRL+R.

H Click the R command button.

H Select Board to PC (Read) from the File menu.

Refer to Copying Files to the Computer on page 20 for step-by-step instructions.

The PC to board (Write) command copies a file from the system to the Data

Store disks. Use this command to move transport stream files created with the

Multiplexer application (or modified with the Packet Jitter or Coder/Decoder

applications) to the Data Store disks. After you move the files, you can use them

to generate transport streams.

28

MTS 200 Series MPEG Test System Data Store Administrator

Page 45

Reference

NOTE. It is not always necessary to use the PC to board (Write) command to

write files to the Data Store disks. You can write files directly to the Data Store

disks from the Multiplexer application using the c:\carb0\mono directory.

1. Select the PC to board (Write) command from the File menu, press

CTRL+W, or click the corresponding (W) toolbar button. The File Write to

CARB dialog box opens.

Delete

2. Enter the full path and file name or click Browse to select the file that you

want to transfer to the Data Store disks.

3. Enter an appropriate file name in the Name of the CARB File text box.

4. Click Start to copy the file onto the Data Store disks.

Use the Delete command to free up space on the Data Store disks.

To delete a file do the following:

1. Select the file(s) in the File information list.

2. Select Delete from the File menu or right-click to open the shortcut menu

and click Delete.

MTS 200 Series MPEG Test System Data Store Administrator

29

Page 46

Reference

3. The Confirm delete file warning message opens.

In most cases, you can undelete a file that is marked as deleted as long as

you have not compressed the Data Store disks (see page 40). However, if

you delete the last file (or files) in the FAT table, it (or they) will be removed

immediately. In this case, you are given a special warning that the file is not

recoverable.

Undelete

Use the Delete command to free up space on the Data Store disks. However, if

you remove files listed anywhere except at the end of the FAT, you must also

select the Compress Disks command from the Service menu (refer to Compress

Disks on page 40 for more information).

The Undelete command removes the (DELETED) mark from a file on the Data

Store disks. If you decide not to erase a file, use this command to return it to

normal status.

To undelete a file, highlight its name in the File information box. Select the

Undelete command from the File menu or right-click to open the shortcut menu

and click Undelete.

30

MTS 200 Series MPEG Test System Data Store Administrator

Page 47

Acq/Gen Menu Commands

Á

Á

Á

Á

The Acq/Gen menu gives you access to commands to acquire or generate

MPEG-2 transport streams.

T able 9: Acq/Gen menu commands

Use To

Reference

Acquisition

Acquisition

БББББ

Generation

БББББ

Interrupt transfer

Acquire a transport stream from the selected input port and save it as

ББББББББББББББББ

a Data Store file

Generate a transport stream from a transport stream file stored on the

ББББББББББББББББ

Data Store disks and outputs it from the selected output port

Stop the current Acquire or Generation process

Select the Acquisition command to open the ACQUISITION window. Use this

window to configure the Data Store system to acquire a transport stream and to

begin saving the stream to a file on the Data Store disks.

Some ACQUISITION window settings can affect the availability of other

settings and the appearance of the window can also change in response to your

choices.

MTS 200 Series MPEG Test System Data Store Administrator

31

Page 48

Reference

This section explains the following acquisition settings groups: Output, Size,

Interface, Synchronization, and Control Port (Master ECL Interface only).

Output. The Output group contains the Board File text box and a partition type

selection box. Enter a name for the file in which you will save the incoming

transport stream. If the Data Store disks have both a single shot and a loop

partition, then select the target partition from the list box.

NOTE. Use a Data Store File name that is not already in use or marked as

deleted.

Size. The Size group allows you to define the size of the file to be acquired. If

you want to leave the file size undefined, select the Not Defined check box. This

option allows the file to continue acquiring data until you select the Interrupt

transfer command (see page 38). If you do not select this check box, you must

enter a value in the text box. This number cannot be larger than the selected

partition size. When the MTS 200 Series has collected a file the same size as

defined in the text box, the acquisition process stops.

NOTE. The File Size must be greater than 1024 bytes.

Interface. The Interface group contains the Protocol, Port, Internal Clock, and

Frequency parameters.

The acquisition Protocol can be Slave or Master. If it is Slave, the input signal

supplies the clock; therefore, neither Internal Clock nor Frequency parameters

are available. If the Port is set to G.703, the clock frequency must be specified

however. If Protocol is set to Master, the Data Store board generates the clock.

Only the Parallel ECL and Serial ECL ports can have Master Protocol.

32

MTS 200 Series MPEG Test System Data Store Administrator

Page 49

Reference

The Port option selects the signal input port. The individual ports have their own

specifications. The following ports are available: //ECL (Parallel ECL), Serial

ECL, G.703, TTL (50 Ohm TTL), and 10 Mbit Serial Port (RS–422).

The Msb first option is available only when the Serial ECL port is selected.

Select Msb first to output each byte of data “most-significant bit” first.

The Internal Clock option, available with Master protocol, selects which of the

internal references is used as the clock. The following options are available:

PLL, Osc. 34.368 MHz, Osc. 8.448 MHz, and External Clock. If you select PLL,

the Frequency setting is available.

The Frequency setting should match the incoming signal rate. The available

frequency range is port dependent as specified in Table 10.

NOTE. Data rates for G.703 ports must be exact. Since PLL is unavailable, the

optional rates are 8.448 MHz or 34.368 MHz.

T able 10: Frequencies available for each port

Port Minimum frequency Maximum frequency

Parallel ECL

Serial ECL

G.703

TTL

10 Mbit Serial (RS422)

125 kHz

1 MHz

8.448 MHz

1 MHz

1 MHz

7.5 MHz

60 MHz

34.368 MHz

45 MHz

10 MHz

NOTE. Frequency step size is 1 Hz.

Synchronization. The Synchronization group determines how the incoming signal

locks. The options include: none, PSYNC signal, and Pattern. None and Pattern

are available to all ports. PSYNC is only available to the ECL ports.

If you are using a serial port and select None, synchronization is not guaranteed

to start at the beginning of a byte or packet. In this case, it is better to select the

pattern synchronization option.With Pattern synchronization, the first three

packets are lost however.

MTS 200 Series MPEG Test System Data Store Administrator

33

Page 50

Reference

If Pattern is selected as the lock mode, you must enter three additional parameters: Stop if Desynchronized, Pattern (hex), and Useful Bytes. If the Stop if

Desynchronized check box is selected, the acquisition stops with an error

message box after 8 bad synchronization bytes.

The Pattern is the actual synchronization signal in hexadecimal. For standard

transport packets, the sync byte is 47.

The Useful Bytes parameter is the size of the transport packet. The standard size

is 188.

The simultaneous presence of PSYNC and the synchronization pattern is not

verified. The PSYNC signal is only used to trigger the start of acquisition

(detection of the first leading edge). Thus no desynchronization criterion exists

in this case. After the start of acquisition, the presence of the PSYNC signal is

not verified.

The mechanisms of synchronization and loss of synchronization vary according

to the synchronization method used. See Table 11.

T able 11: How synchronization works

Synchronization method Acquisition begins with Loss of synchronization

None 1st clock received Never

By PSYNC signal 1 recognition Never

By pattern 3 exact recognitions Absence of exact recognition

during 8 cycles

34

MTS 200 Series MPEG Test System Data Store Administrator

Page 51

Reference

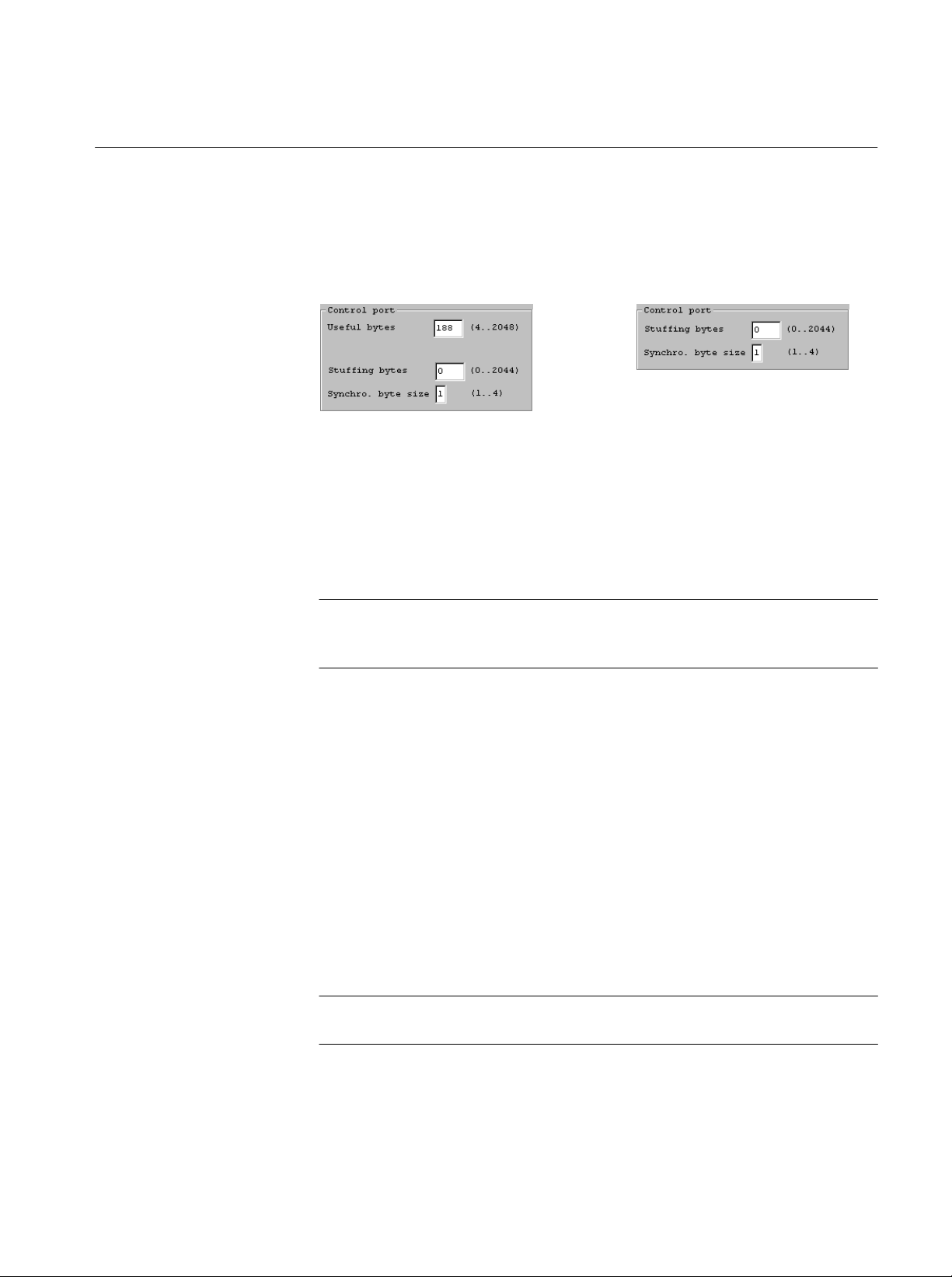

Control Port. If either of the ECL ports are in Master mode, an additional group,

Control Port, is presented. There are two or three parameters in this group,

depending on the Synchronization Lock type.

The Useful Bytes parameter is the number of useful bytes as validated by a

validation signal.

Stuffing Bytes is the number of bytes when the DEN (data enable) is off.

Synchro. Byte Size is the synchronization signal size, in bytes. It can range from

1 to 4 bytes.

Generation

NOTE. To prevent anomalous data, connect equipment only to those ports that

are in use. For example, for G.703 output, both G.703 ports are active at the

selected rate, but the voltage level is different on each port.

When a file name is selected in the File information list, the Generation

command opens the GENERATION settings window. You can configure the

Data Store system to generate a transport stream from the selected file and output

the stream through the specified port.

Use any of the following methods to open the GENERATION window:

H Right-click in the File information list; then click Generation on the

resulting shortcut menu.

H Click the G command button.

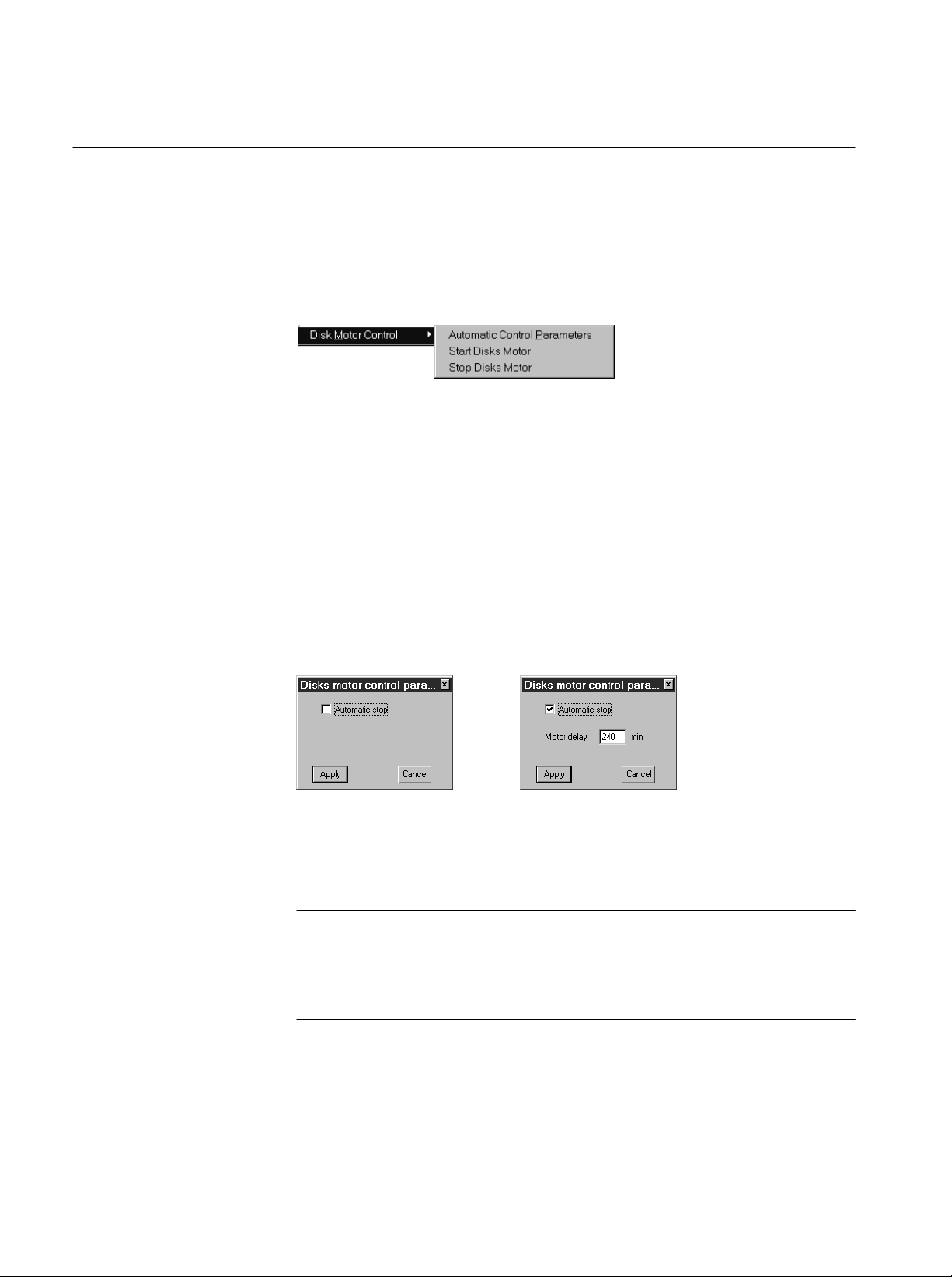

H Select Generation from the Data Store Administrator File menu.