Tektronix MTM300, MTM301, MTM3F20, MTM3FAS, MTM3FMS User Manual

...

User Manual

MTM300 Series

MPEG Transport Monitor

071-0597-04

This document supports

firmware version 2.1.

www.tektronix.com

Copyright © Tektronix, Inc. All rights re served. Licensed software products are owned by Tektronix or its suppliers and

are protected by United States copyright laws and international treaty provisions.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of the

Rights in Technical Data and Computer Software clause at DFARS 252.227-7013, or subparagraphs (c)(1) and (2) of the

Commercial Computer Software -- Restricted Rights clause at FAR 52.227-19, as applicable.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

HARDWARE WARRANTY

Tektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defect ive during this warranty period, Tektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Custome r must not ify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

SOFTWARE WARRANTY

Tektronix warrants that the media on which this software product is furnished and the encoding of the programs on the

media will be free from defects in materials and workmanship for a period of three (3) months from the date of shipment.

If a medium or encoding proves defective during the warranty period, Tektronix will provide a replacement in exchange

for the defective medium. Except as to the media on which this software product is furnished, this software product is

provided “as is” without warranty of any kind, either express or implied. Tektronix does not warrant that the functions

contained in this software product will meet Customer’s requirements or that the operation of the programs will be

uninterrupted or error-free.

In order to obtain service under this warranty, Custome r must not ify Tektronix of the defect before the expiration of the

warranty period. If Tektronix is unable to provide a replacement that is free from defects in materials and workmanship

within a reasonable time thereafter, Customer may terminate the license for this software product and return this software

product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S PAYMENT IS THE SOLE AND EXCLUSIVE

REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF

THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

Getting Started

General Safety Summary xiii..........................................

Service Safety Summary xv..........................................

Preface xvii...................................................

Contacting Tektronix xx.............................................

Getting Started 1--1............................................

MTM300 Series MPEG Transport Monitor 1--1............................

Options and Accessories 1--8...........................................

Installation 1--11...............................................

Hardware Installation 1--11.............................................

Electrical Installation 1--17.............................................

Network Installation 1--22..............................................

Configuration 1-- 23.............................................

Logging On to the MTM300 Series MPEG Transport Monitor 1--23............

Starting and Exiting the Master Client Application 1--25......................

Shutting Down the MTM300 Series MPEG Transport Monitor 1--26............

Configuring the MTM300 Series MPEG Transport Monitor 1--28..............

Functional Check 1--35..........................................

Verifying the Performance of the MPEG-2 Components 1--35.................

Verifying the Performance of the TMCC Components 1--42...................

Verifying the Hardware Components 1--45.................................

Operating Basics

Operating Basics 2--1..........................................

Functional Overview 2--1.............................................

Tutorial 2--15..................................................

Preliminary Setup 2--15................................................

Starting the Master Client 2--16.........................................

Connecting to the Local Server Manager 2--17.............................

Configuring the Master Client Workspace 2--17.............................

Monitoring Transport Stream Inputs 2--19.................................

Configuring the Analysis Servers 2--25....................................

Configuring the Data Logging Function 2--28..............................

Analyzing a Stream Using the Expert Client 2--29...........................

MTM300 Series MPEG Transport Monitor User Manual

i

Table of Contents

Reference

Reference 3--1.................................................

MPEG Overviews 3--2................................................

Client-Server Overview 3--6...........................................

Master Client Refer ence 3--9....................................

Master Client Application Window 3--10..................................

Master Client Toolbars and Icons 3-- 17....................................

Master Client Menus 3--23.............................................

Workspace Dialog Box 3--26............................................

Workspace Tasks 3--30................................................

Error Reporting Tasks 3--38.............................................

Using the Master Client to Monitor PQM300 Program QoS Monitor Results 3--40.

Analyses Reference 3--43........................................

Analysis Servers 3--43.................................................

Default Analyses 3--44.................................................

User Controlled Analyses (Probes) 3--45..................................

ETR 290 Probe Descriptions 3--49.......................................

Multiplex Probe Descriptions 3--65.......................................

Syntax Probe Descriptions 3--71.........................................

Private Syntax Probe Descriptions 3--72...................................

Transport Syntax Probe Descriptions 3--73.................................

Section Syntax Probe Descriptions 3--77..................................

Mega Frame Syntax Probe Descriptions 3--79..............................

Timing Probe Descriptions 3--81.........................................

Transport Rate Probe Descriptions 3--84...................................

Section Rate Probe Descriptions 3--85....................................

Mega Frame Rate Probe Descriptions (DVB-T only) 3--87....................

TMCC Probe Descriptions 3--88.........................................

Expert Client Reference 3--93....................................

Expert Client Display Elements 3--94.....................................

Expert Client Menus 3--100..............................................

Manually Capturing a Transport Stream 3--103..............................

Configuring the Expert Client Views 3--105.................................

Using the Hierarchic View 3--110.........................................

Using the Report View 3--116............................................

Using the Client Area 3--132.............................................

Configuration Client Reference 3--159..............................

Changing Configurations 3--160..........................................

Saving and Restoring Configurations 3--161.................................

Managing Remote Transport Monitors 3--164...............................

Data Logging 3--166...................................................

Configuration Client Display Elements 3--168...............................

Configuration Settings 3--172............................................

ii

MTM300 Series MPEG Transport Monitor User Manual

Appendices

Table of Contents

TMCC Expert Client Reference 3--209..............................

Using the TMCC Expert Client Display Elements 3--210......................

Manually Capturing a TMCC Transport Stre am 3--216........................

TMCC Configuration Client Reference 3--219........................

Changing Configurations 3--220..........................................

Saving and Restoring Configurations 3--221.................................

TMCC Configuration Client Display Elements 3--222.........................

TMCC Configuration Settings 3--225......................................

Appendix A: Specifications A --1..................................

Performance Conditions A--1...........................................

Electrical, Hardware, and Signal Specifications A--1........................

System Components A--7..............................................

Power Characteristics A--8.............................................

Mechanical (Physical) Characteristics A--8................................

Environmental Characteristics A--9......................................

Certification and Compliances A--10......................................

Appendix B: Cleaning and Maintenance B--1......................

General Care B--1....................................................

Preventive Maintenance B--1...........................................

In Case of Problems B--3..............................................

Repackaging for Shipment B--10.........................................

Appendix C: Networking C--1...................................

Network Requirements C--1............................................

Network Installation C--2..............................................

Network Troubleshooting C--10..........................................

Appendix D: Software Repair and Installation D--1.................

Software Repair Strategy D--1..........................................

Restoring System Settings D--4.........................................

Restoring Device Drivers D--17..........................................

Restoring the MTM300 Series MPEG Transport Monitor Operating System D--24.

Installing the MTM300 Series Application Software D--26....................

Appendix E: Using the Private Syntax Interpreter E--1..............

Private Syntax Interpreter Interface E--2..................................

Editing Private Syntax Definitions E--12...................................

Compiling Private Syntax Definitions E--21................................

Analyzing Private Syntax with the Expert Client E--21.......................

Private Data Reference E--23............................................

Appendix F: ATSC Program Paradigm F--1.......................

Glossary

Index

MTM300 Series MPEG Transport Monitor User Manual

iii

Table of Contents

List of Figures

Figure 1--1: The MTM300 Series MPEG Transport Monitor 1--1......

Figure 1--2: Attaching the extension brackets to the

stationary tracks 1--13.......................................

Figure 1--3: Mounting hole selection on the front rails of the

equipment rack 1--13........................................

Figure 1--4: Attaching the extension bracket to the rear rail of the

equipment rack 1--14........................................

Figure 1--5: Mounting the stationary section to the front rail of the

equipment rack 1--15........................................

Figure 1--6: Stationary bracket, extension bracket, and attaching

screws 1--15................................................

Figure 1--7: Installing the instrument into the equipment rack 1--16....

Figure 1--8: MTM300 Series transport monitor rear p anel

connectors 1--18............................................

Figure 1--9: Keyboard and monitor connections 1--21................

Figure 1--10: On/Stby switch 1--23................................

Figure 1--11: Server Manager and Analysis Server icons in

system tray 1--24............................................

Figure 1--12: The Tektronix MPEG Transport Monitor

program group 1--25.........................................

Figure 1--13: Shutting down the transport monitor 1--26..............

Figure 1--14: Windows NT Shut Down Windows dialog box 1--27......

Figure 1--15: Router application showing two host machines 1--28......

Figure 1--16: SNMP Traps to Target dialog box 1--29.................

Figure 1--17: SNMP Traps to Target dialog box showing localhost

IP parameters 1--29.........................................

Figure 1--18: Router application 1--30..............................

Figure 1--19: IP parameters for network management station 1--31.....

Figure 1--20: Network management station added 1--32...............

Figure 1--21: Modified Hosts file 1--33.............................

Figure 1--22: Master client initial toolbar and Home button 1--36......

Figure 1--23: Workspace dialog box with one input selected 1--36.......

Figure 1--24: Monitoring a transport stream 1--37...................

Figure 1--25: Starting the Configuration client 1--38..................

Figure 1--26: Choosing the analysis type 1--38.......................

Figure 1--27: Adding all ETR290 probes 1--39.......................

Figure 1--28: Master client showing errors on Cinestar 1--40...........

iv

MTM300 Series MPEG Transport Monitor User Manual

Table of Contents

Figure 1--29: Expert client showing errors on Cinestar 1--41...........

Figure 1--30: Probes added in the TMCC Configuration Client 1--42....

Figure 1--31: TMCC Expert Client 1--43...........................

Figure 1--32: Hardware diagnostic tool 1--46........................

Figure 1--33: Default self test selections 1--46........................

Figure 1--34: Self test in progress 1--47.............................

Figure 1--35: Saving test results 1-- 48..............................

Figure 2--1: The Master client application window 2--2..............

Figure 2--2: The Expert client application window 2--4..............

Figure 2--3: The Configuration client application window 2--6........

Figure 2--4: The TMCC Expert client application window 2--7........

Figure 2--5: The TMCC Configuration client application window 2--10..

Figure 2--6: Front-panel elements 2--12.............................

Figure 2--7: Empty Master client application window 2--16............

Figure 2--8: Creating workspace bouquets 2--17.....................

Figure 2--9: Changing the analysis display options 2--18..............

Figure 2--10: Master client monitoring inputs 2--19..................

Figure 2--11: Master client showing errors on a service 2--22...........

Figure 2--12: Services panel details view 2--23.......................

Figure 2--13: Connected to the Configuration client 2--25.............

Figure 2--14: Setting ETR290 probes 2--26..........................

Figure 2--15: Changing the message level 2--27......................

Figure 2--16: Data Logging configuration panel 2--28.................

Figure 2--17: Selecting the Expert client 2--29.......................

Figure 2--18: Expert client showing errors 2--30.....................

Figure 2--19: ETR290 panel (for an MPEG-2 stream) 2--31............

Figure 3--1: Master client application window 3--10..................

Figure 3--2: Details view of the Services panel 3--14..................

Figure 3--3: Bouquet Selection panel 3--27..........................

Figure 3--4: Graphics panel 3--28.................................

Figure 3--5: Sound panel 3--29....................................

Figure 3--6: Selecting inputs in the Bouquet Selection panel 3--30......

Figure 3--7: Report Message Level panel in the

Configuration client 3--38....................................

Figure 3--8: Multiplex Analysis panel, Probe Type list box 3--46........

Figure 3--9: Expert client display elements 3--94.....................

Figure 3--10: View panel in the Settings window 3--105................

MTM300 Series MPEG Transport Monitor User Manual

v

Table of Contents

Figure 3--11: Report View configuration window 3-- 106................

Figure 3--12: Graphics View configuration window 3--108..............

Figure 3--13: PID Allocation View configuration window 3--109.........

Figure 3--14: Expert client hierarchic display 3--110...................

Figure 3--15: Specific information displayed for transport

strea m items 3--111...........................................

Figure 3--16: Report view display 3--116.............................

Figure 3--17: Report view display modes 3--120.......................

Figure 3--18: Analysis Results area of the Report view 3--121...........

Figure 3--19: Hierarchy levels in the Analysis Results area 3--123........

Figure 3--20: Error Graph panel for the Program report mode 3--124....

Figure 3--21: Message panel for the Program report mode 3--124........

Figure 3--22: Error Graph panel for the ETR 290 report mode 3--125....

Figure 3--23: Error Graph panel for the Advanced report mode 3--127...

Figure 3--24: Error Graph panel for the Error report mode 3--128.......

Figure 3--25: Program Allocation panel (Current Rate mode) 3--135.....

Figure 3--26: Reading the Program Allocation panel bar graphs 3--137...

Figure 3--27: PID Allocation panel (current rate mode) 3--138..........

Figure 3--28: Continuity Counter panel 3--141........................

Figure 3--29: Type Allocation panel 3--142...........................

Figure 3--30: TP (Transport Packet) Error Indicator panel 3--143.......

Figure 3--31: Unsynchronized Packets panel 3--144...................

Figure 3--32: ASI/M2S Distribution panel 3--145......................

Figure 3--33: ETR 290 view (DVB mode) 3--146......................

Figure 3--34: Section Analysis view 3--148...........................

Figure 3--35: Section Rate view 3--150...............................

Figure 3--36: PCR Analysis view 3--151.............................

Figure 3--37: PTS/DTS Analysis view 3--154.........................

Figure 3--38: MIP Packet Analysis view 3--155.......................

Figure 3--39: IP Monitoring view 3--158.............................

Figure 3--40: Data logging directory hierarchy 3--166..................

Figure 3--41: Data logging file structure 3--167.......................

Figure 3--42: Configuration client display elements 3--168..............

Figure 3--43: Hardware configuration panel 3--173....................

Figure 3--44: Analysis configuration panel 3--174.....................

Figure 3--45: ETR 290 configuration panel 3--176.....................

Figure 3--46: Multiplex Analysis configuration panel 3--177............

Figure 3--47: Syntactic Analysis configuration panel 3--179.............

Figure 3--48: Transport Syntactic Analysis configuration panel 3--181....

vi

MTM300 Series MPEG Transport Monitor User Manual

Table of Contents

Figure 3--49: Section Syntactic Analysis configuration panel 3--183......

Figure 3--50: Mega Frame Syntactic Analysis configuration panel 3--185.

Figure 3--51: PCR Timing Analysis configuration panel 3--187..........

Figure 3--52: PTS/DTS Timing Analysis configuration panel 3--189......

Figure 3--53: Mega Frame Timing Analysis configuration panel 3--191...

Figure 3--54: Transport Rate Analysis configuration panel 3--192.......

Figure 3--55: Section Rate Analysis configuration panel 3--193..........

Figure 3--56: Mega Frame Rate Analysis configuration panel 3--195.....

Figure 3--57: Report configuration panel 3--196......................

Figure 3--58: Report Message Level configuration panel 3--198.........

Figure 3--59: Event Configuration configuration panel 3--200...........

Figure 3--60: Event Settings dialog box 3--203........................

Figure 3--61: Filtering configuration panel 3--205.....................

Figure 3--62: Data Logging configuration panel 3--206.................

Figure 3--63: Security configuration panel 3--207.....................

Figure 3--64: TMCC Expert Client display elements 3--210.............

Figure 3--65: TMCC Configuration Client display elements 3--222.......

Figure 3--66: TMCC Input configuration panel 3--226.................

Figure 3--67: TMCC Analysis configuration panel 3--227..............

Figure 3--68: TMCC Data Storage configuration panel 3--229...........

Figure 3--69: Data Storage Event Configuration dialog box 3--232.......

Figure B--1: Connecting the loop throughs on the back of the

transport monitor B--5......................................

Figure B--2: Hardware diagnostic tool B--6.........................

Figure B--3: Default self test selections B--6........................

Figure B--4: Changing self test parameters B--7.....................

FigureB--5:Selftestinprogress B--8..............................

Figure B--6: Saving test results B--9...............................

Figure B--7: Repackaging the instrument (new packaging) B--11.......

Figure B--8: Repackaging the instrument (old packaging) B--13........

Figure B--9: Placement of bottom spacer pad in inner shipping box B--14

Figure C--1: Network dialog box showing TCP/IP Protocol item C--3...

Figure C--2: IP tab parameters C--4...............................

Figure C--3: DNS tab parameters C--5.............................

Figure C--4: Router application window C--8.......................

Figure C--5: IP parameters for network management station C--8......

Figure C--6: Management station added C--9.......................

MTM300 Series MPEG Transport Monitor User Manual

vii

Table of Contents

Figure C--7: Incorrect IP address C--11.............................

Figure C--8: Incorrect subnet mask C--12...........................

Figure C--9: Incorrect default gateway IP address C--13...............

Figure C--10: Ping.exe command window C--15......................

Figure C--11: Tracert.exe command window C--16....................

Figure C--12: Command prompt with nslookup results C--17..........

Figure C--13: Network name C--18.................................

Figure C--14: Network dialog box, Adapters tab C--21................

Figure C--15: Adapter card dialog box C--22........................

Figure C--16: Adapter card test complete C--22......................

Figure C--17: Connecting to a remote Server Manager with

the Router C--25.............................................

Figure C--18: List of machines receiving traps C--25..................

Figure D--1: Software Protection key D--26..........................

Figure D--2: Software protection key D--28..........................

Figure D--3: Check free disk space D--29............................

Figure D--4: Setup type dialog box D--30............................

Figure D--5: Interim reboot message D--31..........................

viii

MTM300 Series MPEG Transport Monitor User Manual

List of Tables

Table of Contents

Table 1--1: MTM300 Series transport monitor options 1--8..........

Table 1--2: Standard accessories for the transport mon itor 1--8.......

Table 1-- 3: Standard accessories for the network management

software 1--9..............................................

Table 1--4: Optional accessories 1--9..............................

T able 1--5: Electrical operating r equirements 1--17..................

Table 1--6: Rear-panel connectors 1--19............................

Table 1-- 7: Relay closure pin assignment for the relay board

in slot 8 1--20..............................................

Table 1-- 8: Relay closure pin assignment for the relay board

in slot 9 1--20..............................................

Table 2--1: Modulation mode color scheme 2--8....................

Table 2--2: Front panel-key controls 2--13..........................

Table 2-- 3: Touch screen techniques 2--14..........................

Table2--4:Erroriconstates 2--20.................................

Table 2--5: Error gauge icon states 2--20...........................

Table 2--6: Multiplex level Details panel icons 2--23..................

Table 2--7: Service (or Program) level Details panel icons 2--24........

Table 3-- 1: Master client toolbar buttons 3--17......................

Table 3--2: Master client multiplex and service icons 3--18............

Table 3--3: Multiplex icon variations 3--19.........................

Table3--4:Erroricons 3--19.....................................

Table 3--5: Error severity gauge icons 3--20.........................

Table 3-- 6: Detail panel error icons with an input selected 3--20........

T able 3--7: Detail panel err or icons with a service selected 3--21........

Table 3--8: Transport monitor server icons 3--22....................

T able 3--9: Master client Master menu 3--23........................

T able 3--10: Master client Workspace menu 3--23...................

Table 3-- 11: Master client View menu 3 -- 24.........................

Table 3--12: Master client Help menu 3 --24.........................

Table 3--13: Multiplex panel shortcut menu 3--24...................

T able 3--14: Services panel shortcut menu 3--25.....................

Table 3--15: ETR 290 tests 3--49..................................

MTM300 Series MPEG Transport Monitor User Manual

ix

Table of Contents

Table 3-- 16: Overview of service information defined in

ETS 300 468 3--61..........................................

T able 3--17: SI repetition rates according to DVB 3--62...............

Table 3--18: Multiplex analyses 3--65..............................

Table 3-- 19: Table ID analyses 3--67...............................

Table 3--20: Transport syntax analyses 3--73........................

Table 3--21: Section syntax analyses 3--77..........................

Table 3--22: Section syntax analyses 3--79..........................

Table 3--23: Section rate analyses 3--86............................

Table 3-- 24: Functions of the View Toolbar buttons 3--96.............

Table 3-- 25: Functions of the Report View Toolbar buttons 3--98.......

Table 3-- 26: Expert client Active View menu commands 3--100.........

Table 3-- 27: Expert client Session menu commands 3--101.............

Table 3-- 28: Expert client View menu commands 3--101...............

Table 3-- 29: Expert client Window menu commands 3--102............

Table 3-- 30: Expert client Help menu commands 3--102...............

Table 3-- 31: Mouse and keyboard actions in the Hierarchic view 3--112..

Table 3--32: Hierarchic view icon identification 3--113................

Table 3-- 33: Hierarchic view menu commands 3--115.................

Table 3-- 34: Functions of the Report View Toolbar buttons 3--117.......

Table 3--35: Report view shortcut menu 3--120.......................

Table 3--36: Error graph symbols 3--122............................

Table 3--37: Icons used in the Report view Analysis Results area 3--123..

T able 3--38: Message view column descriptions

(Program mode) 3--125.......................................

T able 3--39: Message view column descriptions

(ETR 290 mode) 3--126.......................................

T able 3--40: Message view column descriptions

(Advanced mode) 3--128......................................

T able 3--41: Message view column descriptions

(Error mode) 3--129..........................................

Table 3-- 42: Configuration client Session menu commands 3--169.......

Table 3-- 43: Configuration client Help menu commands 3--170.........

Table 3-- 44: Functions of the Configuration client

Toolbar buttons 3--170.......................................

Table 3--45: Multiplex analysis probes 3--178........................

Table 3--46: Transport syntax probes 3--182.........................

Table 3--47: Section syntax probes 3--184...........................

Table 3--48: Mega Frame syntax probes 3--186.......................

x

MTM300 Series MPEG Transport Monitor User Manual

Table of Contents

Table 3-- 49: Functions of the TMCC Expert Client

toolbar buttons 3--211........................................

T able 3--50: Color for each TMCC Expert Client

modulation mode 3--212......................................

Table 3--51: TMCC data syntax 3--213..............................

Table 3--52: Syntax view LED icons an d error conditions 3--214........

Table 3-- 53: Functions of the TMCC Configuration Client

Toolbar buttons 3--223.......................................

Table A--1: Processing Interface Adapter (PIA) board A--1...........

T able A--2: ASI mezzanine A--1..................................

T able A--3: SSI mezzanine A--2..................................

Table A--4: Alarm relay board A--3...............................

Table A-- 5: Rear panel interface characteristics A--4................

Table A--6: Relay closure for alarm relay boards A--5...............

Table A-- 7: Side and front panel interface characteristics A --6........

T able A--8: System components A--7..............................

T able A--9: AC power source characteristics A--8...................

T able A--10: Mechanical characteristics A--8.......................

Table A--11: Environmental characteristics A--9....................

Table A--12: Electromagnetic Compatibility A--10...................

T able A--13: Environmental Limits and Use Classification for

Safety Certification Compliance A--11..........................

Table B--1: Troubleshooting power-on failures B--3.................

T able D--1: MTM300 Series COM port settings D--8................

Table D-- 2: Touchscreen driver hardware settings D--22..............

Table E--1: Menu bar File menu E--4.............................

Table E--2: Menu bar Edit menu E--4.............................

T able E--3: Menu bar View menu E--5............................

Table E--4: Menu bar Window menu E--5.........................

Table E--5: Menu bar Help menu E--5............................

Table E--6: Private Syntax Interpreter toolbar buttons E--6..........

Table E--7: Hierarchic view icons and label descriptions E --7.........

Table E--8: Hierarchy position of added items E-- 14..................

Table E--9: Default parameters for added private syn tax fields E--15...

Table E--10: Private syntax data type definitions E--16...............

Table E--11: Private syntax expression operators and terminals E--16...

MTM300 Series MPEG Transport Monitor User Manual

xi

Table of Contents

Table E--12: Private syntax example interpretation expressions E--17...

Table E--13: Private section E--24.................................

Table E--14: Private descriptor E--26..............................

T able F--1: PID assignment for the elementary streams of a

program F--1..............................................

Table F--2: Program paradigm errors F--2.........................

xii

MTM300 Series MPEG Transport Monitor User Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

ToAvoidFireor

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is indirectly grounded through the grounding

conductor of the mainframe power cord. To avoid electric shock, the grounding

conductor must be connected to earth ground. Before making connections to the

input or output terminals of the product, ensure that the product is properly

grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

MTM300 Series MPEG Transport Monitor User Manual

xiii

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Protective Ground

(Earth) Terminal

xiv

MTM300 Series MPEG Transport Monitor User Manual

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

MTM300 Series MPEG Transport Monitor User Manual

xv

Service Safety Summary

xvi

MTM300 Series MPEG Transport Monitor User Manual

Preface

This manual describes the functions and use of the Tektronix MTM300 Series

MPEG Transport Monitor. The manual is organized into the following sections:

H Getting Started.

This section provides a functional description of the transport monitor

platform and the software modules that make up the MTM300 Series MPEG

Transport Monitor. It also provides a list of items shipped with the transport

monitor as well as optional accessories. Finally, Getting Started describes

how to install the transport monitor in your monitoring environment.

H Operating Basics.

This section provides a detailed description of the MTM300 Series MPEG

Transport Monitor and a brief tutorial that shows how the client modules are

used to monitor transport streams. Operating Basics also provides a

comprehensive list of the buttons, icons, and menu selections for each client

module.

H Reference.

This section provides detailed descriptions and procedures for using each of

the MTM300 Series client modules, including the TMCC real-time analysis

modules. It also provides a reference for all user-controlled analyses (called

probes) enabled by the MTM300 Series MPEG Transport Monitor.

H Appendices.

This section is comprised of the following appendices:

H Appendix A: Specifications. This appendix lists the electrical, physical,

and environmental specifications for your instrument.

H Appendix B: Cleaning and Maintenance. This appendix describes how to

perform periodic user maintenance. This section does not include repair

or replacement procedures.

H Appendix C: Networking. This appendix provides networking require-

ments and procedures for installing the MTM300 Series MPEG

Transport Monitor in a TCP/IP networking environment. Networking

also provides basic network troubleshooting procedures.

MTM300 Series MPEG Transport Monitor User Manual

xvii

Preface

Related Material

H Appendix D: Software Repair and Installation. This appendix provides

the procedure for replacing device drivers, restoring the transport

monitor operating system, and installing MTM300 Series applications

onto a network management station, a remote monitoring station, or the

transport monitor itself.

H Appendix E: Private Syntax Interpreter. This appendix describes how to

use the Private Syntax Interpreter. This application is a standard

accessory with each MTM300 Series MPEG Transport Monitor.

H Appendix F: ATSC Program Paradigm. This appendix describes the PID

value restrictions for program elements in ATSC transport streams.

H Glossary.

H Index.

In addition to the material in this manual, each MTM300 Series client module

has an online help system accessed through the Help menu. The Expert client

and Configuration client Help menus also provide access to an Analysis Server

online help, describing the analyses performed by Analysis Servers.

Included on the software application CD-ROM is the Read Me file for the

MTM300 Series software. This file lists the application files included with the

software installation types and other important information.

The Read This First document that ships with each MTM300 Series product lists

known problems with the software at the time the software was released and

workarounds for those issues.

The following URLs access the websites for the standards organizations listed

(the URLs listed were valid as of January, 2001):

H MPEG-2 standards (International Organization for Standards)

http://www.iso.ch/

H DVB standards (European Technical Standards Institute)

http://www.etsi.org/

H ATSC standards (Advanced Television Systems Committee)

xviii

http://www.atsc.org/

MTM300 Series MPEG Transport Monitor User Manual

Preface

The following ARIB (Association of Radio Industries and Business) and ITU-R

(International Telecommunications Union) standards were used to develop the

added ARIB and TMCC enhancements to the transport monitor:

H ARIB STD-B10 (1.2), 1999, Service Information for Digital Broadcasting

System

H ARIB STD-B16 (1.1), 1999, Digital Receiver Commonly Used for Digital

Satellite Broadcasting Services Using Communication Satellite

H ARIB STD--B20 (1.1), Digital Broadcasting System and Related Operation-

al Guidelines for Broadcasting Satellites

H ITU-R BO. 1408, Transmission System for Advanced Multimedia Services

Provided by Integrated Services Digital Broadcasting in A Broadcasting

Satellite Channel

Finally, a PDF file of the PQM300 Program QoS Monitor User Manual

(Tektronix part number, 071-0576-XX) is included on the software application

CD-ROM. Refer to this manual for operating instructions if you have installed

the PQM300 client module on your network management station and do not

have access to the printed version of the manual.

Manual Conventions

Naming conventions for the interface elements and Windows elements in this

manual follow the Microsoft Manual of Style, Third Edition. Naming conventions for MPEG-2, ATSC, and DVB structures follow the conventions derived

from the standards documents listed above. In addition, the following formatting

conventions apply to this manual:

H Bold text refers to specific interface elements that you are instructed to

select, click, or clear.

Example: Select Settings from the Configuration menu.

H Italic text refers to document names or sections. Italics are also used to refer

to a named item when it is first described.

Example: See Details Panel for more information.

Example: A transport stream (also called a multiplex) is an ordered series of

bytes representing valid MPEG-2, DVB, or ATSC elements.

MTM300 Series MPEG Transport Monitor User Manual

xix

Preface

Contacting Tektronix

Phone 1-800-833-9200*

Address Te ktronix, Inc.

Department or name (if known)

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

Web site www.tektronix.com

Sales support 1-800-833-9200, select option 1*

Service support 1-800-833-9200, select option 2*

Technical support Email: techsupport@tektronix.com

1-800-833-9200, select option 3*

6:00 a.m. -- 5:00 p.m. Pacific time

* This phone number is toll free in North America. After office hours, please leave a

voice mail message.

Outside North America, contact a Tektronix sales office or distributor; see the

Tektronix web site for a list of offices.

xx

MTM300 Series MPEG Transport Monitor User Manual

Getting Started

This section will help you install your MTM300 Series MPEG Transport

Monitor in your broadcast environment and configure it for monitoring transport

stream inputs. Getting Started includes the following information:

H MTM300 Series MPEG Transport Monitor and client applications overviews

H Transport monitor options and standard and optional accessories

H Hardware, electrical, and network installation procedures

H Procedures for configuring the MTM300 Series host machines

H Procedures for logging onto and turning off the transport monitor, as well as

procedures for starting and exiting the Master client

H Procedure for verifying that the MTM300 Series transport monitor is

working

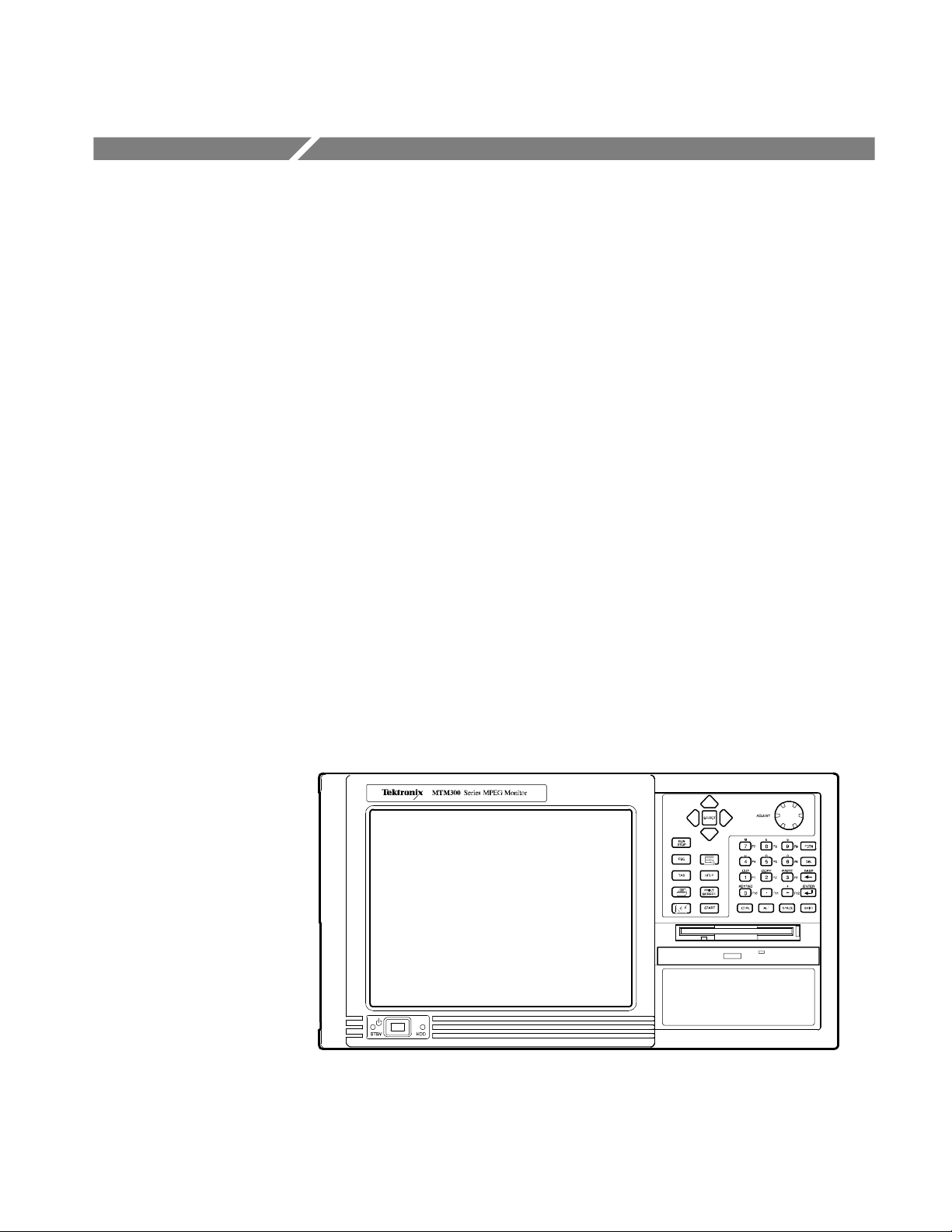

MTM300 Series MPEG Transport Monitor

The Tektronix MTM300 Series MPEG Transport Monitor is a rack-mounted,

MPEG-2 protocol monitor used to monitor single and multiple program transport

streams in MPEG-2, DVB, ATSC, and ISDB-S/ARIB environments. The

transport monitor depicted in Figure 1--1 includes the optional user interface

(keypad and touchscreen).

Figure 1- 1: The MTM300 Series MPEG Transport Monitor

MTM300 Series MPEG Transport Monitor User Manual

1- 1

Getting Started

NOTE. Refer to the MPEG-2, DVB, ATSC, and ISDB-S/ARIB standards for

detailed information about the syntax and semantics of each system.

Each monitor can analyze up to eight transport stream inputs simultaneously and

accepts inputs in the following electrical formats:

H ASI/M2S (the monitor automatically detects the format)

H SMPTE 310M

The transport monitor allows you to output alarm signals using a 25-pin serial

interface. Each critical or major error recorded by an Analysis Server closes a

contact tied to the specific input. The pin-out for the alarm relay is provided in

Appendix A: Specifications.

The transport monitor uses a client/server architecture consisting of of a Server

Manager, multiple Analysis Servers, and the following client applications:

H Master client, which you use to monitor up to eight transport stream inputs

in real time

Server Manager

H Expert client, which you use to analyze specific transport streams in real

time

H Configuration client, which you use to configure the types of analyses

performed on transport stream inputs

H TMCC Expert client, which you use to monitor a TMCC transport stream

input in real time

H TMCC Configuration client, which you use to configure the types of TMCC

analyses performed on TMCC basic and data streams

The Master client is tightly integrated with the other analysis and configuration

clients making the transport monitor easy to use for experts and non-experts.

The Server Manager is the process that makes the results of the Analysis Servers

available to Master clients and starts automatically when you start the transport

monitor. Only one Server Manager can run on a transport monitor or network

management station.

The Server Manager process interacts with the following entities:

H The Analysis Server sends analysis results (called traps)totheServer

Manager.

1- 2

H The Master client displays the data collected by the Server Manager.

H The PQM300 Program QoS Monitor client sends traps to the Server

Manager.

MTM300 Series MPEG Transport Monitor User Manual

Getting Started

Analysis Servers

Master Client

With this release of the software, there are two types of Analysis Server: one is

used to analyze any valid MPEG-2, DVB, or ATSC transport stream, and one is

used to analyze only TMCC transport streams. Analysis Servers are the

processes that actually analyze transport stream inputs. One Analysis Server for

each I/O port starts automatically when you start the transport monitor. Each

transport monitor can support up to eight Analysis Server processes

simultaneously.

The Analysis Server processes interact with the following entities:

H The Server Manager collects the Analysis Server results (called traps).

H The Expert client displays the results of the Analysis Server directly;

similarly, the TMCC Expert client displays the results of the TMCC

Analysis Server directly .

H The Configuration client sets the monitoring and analysis parameters for

each Analysis Server process operating on the inputs to the transport

monitor; similarly, the TMCC Configuration client sets the monitoring and

analysis parameters for each TMCC Analysis Server process.

The Master client provides an intuitive interface for monitoring the status of

transport stream inputs. You can also monitor a remote Tektronix PQM300

Program QoS Monitor from the Master client. Of the three MTM300 Series

applications, the Master client is the one you will use most often.

The Master client characteristics are shown in the following list:

H The Bouquet panel displays icons for the bouquets (groups of inputs) that

you have defined for the workspace.

H The Multiplex panel displays icons for the inputs that you have defined for a

bouquet (if enabled).

H The Services panel displays icons for the services (also called programs)

encoded in the transport stream.

H The Details panel displays icons indicating the type, status, and severity of

errors on a transport stream or service.

H The Expert and Configuration clients (MPEG-2 and TMCC), and PQM300

client can be started from the Master client. (See the PQM300 Program QoS

Monitor User Manual for operating information about this client.)

MTM300 Series MPEG Transport Monitor User Manual

1- 3

Getting Started

Expert Client

Configuration Client

The Expert client analyzes a single stream in greater detail. You will use the

Expert client to help troubleshoot errors in your digital transmission system.

The Expert client has the following characteristics:

H Graphical displays that show the structure (hierarchy) of the input transport

stream and display characteristics of each component of the input stream

(for example: PID and type allocation, section rate analyses, and timing

analyses).

H Report views that indicate the types of errors recorded by the Analysis

Server and the characteristics of the input stream.

H Error views that show specific errors recorded for the various components

of the transport stream; for instance, PMT section rate errors and ETR290

errors.

The Expert client displays the results of only one Analysis Server (input) at a

time.

The Configuration client allows you to specify which transport stream parameters you want monitored, and how you want errors in your system to be reported.

The Configuration client allows you to perform the following tasks:

H Specify the standard to which you are testing an input: MPEG-2, DVB, or

ATS C.

H Set, remove, or modify the probes that test transport streams for valid syntax

and semantics and rates.

H Specify the way in which errors are reported in both the Expert and Master

clients. You can configure each probe to report an error as Critical, Major,

Minor, Warning, or as information only.

H Specify the types of transport stream events that are recorded using the Data

Logging function. You can also set the maximum file size and time period of

each log file.

H Stop and restart an Analysis Servers running on a transport monitor.

H Set passwords on specific inputs that prevent others from changing the

Analysis Server configuration for that input.

H Set parameters for capturing part of an input transport stream.

1- 4

MTM300 Series MPEG Transport Monitor User Manual

Getting Started

TMCC Expert Client

TMCC Configuration

Client

The TMCC (Transmission Multiplexing Configuration Control) Expert Client is

a new application included with version 2.0 of the MTM300 Series MPEG

Transport Monitor. This client allows you to analyze the TMCC data of an

ARIB-compliant transport stream input in real time. You can also analyze an

ARIB-compliant transport stream file stored on your local disk.

The TMCC Expert client has the following characteristics:

H Indicates the presence of sync bytes (0x47 for TMCC basic streams and W1,

W2, or W3 sync bytes for TMCC data streams)

H Displays the syntax of TMCC data

H Displays Slot, TSID, TS Name, and Modulation mode information

H Displays information, warning, and error information

H Indicates the presence of TMCC alarm and update flags in the transport

stream

H Displays the overall stream rate

The TMCC (Transmission Multiplexing Configuration Control) Configuration

client is a new application included with version 2.0 of the MTM300 Series

MPEG Transport Monitor. This client allows you to set the monitoring, analysis,

and reporting parameters of the TMCC Analysis Servers.

The TMCC Configuration client has the following characteristics:

H Configures the TMCC Analysis Servers to operate in either TMCC basic or

TMCC data stream modes

H Enables you to specify a transport stream ID to analyze using the MPEG-2

Analysis Server (only in the TMCC data stream mode)

H Sets parameters for the following TMCC probes:

H Frame size

H Super frame size

H Modulation mode and slot consistency

H TMCC syntax

H TMCC update counter (only in TMCC data stream mode)

MTM300 Series MPEG Transport Monitor User Manual

1- 5

Getting Started

SNMP Capabilities

MTM300 Series MPEG

Transport Monitor

Installation Options

The MTM300 Series MPEG Transport Monitor includes two SNMP management information bases (MIB). The Tektronix RTA MIBs are textual descriptions

of the Analysis Server objects (functions and parameters) that can be monitored

and controlled by the network management station using SNMP controls. The

MIB text files are installed with each MTM300 Series MPEG Transport Monitor

installation (on both the transport monitor and a computer with the network

management software installed) at the following location:

C:\Mib\, where C is the letter designator of the local hard drive.

The two MIBs located in this directory, RTAv1.mib and RTAv2.mib, are used for

SNMP version 1 and SNMP version 2 systems respectively.

An HP OpenView plug-in is provided that allows you to integrate the transport

monitor into HP OpenView Network Node Manager network monitoring

systems.

The MTM300 Series MPEG Transport Monitor client and server modules

described in this manual can be installed as described in the following list. The

items in the list correspond to the options you select from when installing or

reinstalling the MTM300 Series software. See Appendix E: Software Installation

and Repair for installation procedures, minimum system requirements, and the

list of files and file locations for each installation option.

H MPEG Transport Monitor

All of the client and server modules (and required program files) are installed

on the transport monitors. Each transport monitor can monitor up to eight

transport streams simultaneously, with a combined maximum bit rate of

180 Mbps.

CAUTION. You must ensure that transport monitors sending traps, and the

network management stations receiving them, are using the same version of

MTM300 series software. The network management station software does not

work in mixed MTM300 series software version envirionments.

H Network Management Software (MTM3FMS)

NOTE. You must have the software key in place to install the MTM300 Series

Network Management Software. See Installing the MTM 300 Series Software on

page D--28 for more information.

1- 6

MTM300 Series MPEG Transport Monitor User Manual

Loading...

Loading...