Page 1

Limit and Mask Test Application Software

Option LT, MTH, MTM Data Sheet

Option MTM – Mask Test Application Software

Perform Pass/Fail Testing against Telecommunication and Computer

Standards

Customized Mask Tests allow for M ultiple Actions upon Test Failures

Detailed Test Statistics provide Insight into True Signal Behavior

Designed for use on MSO/DPO5000 Series and DPO7000 Series

Oscilloscopes

Applications

Pass/Fail Testing

ITU-T

ANSI T1.102

SONET/SDH

Features & Benefits

Option LT – Limit Test Application Software

Conduct Limit Test Pass/Fail Testing against a “Golden” Waveform with

Tolerances

Customized Limit Tests allow for Multiple Actions upon Test Failures

Designed for use on MSO/DPO5000, DPO7000, and

A/MSO70000 Series Oscilloscopes

DPO/DS

100BASE-TX, 1000BASE-CX/SX Ethernet

CPRI

USB 1.1/2.0

Fibre Channel

OBSAI

InfiniBand

MTH – Mask Test Application Software

Option

Perform Pass/Fail Testing against Telecommunication and Computer

Standards

Customized Mask Tests allow for Multiple Actions upon Test Failures

Detailed Test Statistics pro vide Insight into True Signal Behavior

Designed for use on DPO/DSA/MSO70000 Series Oscilloscopes (comes

standard on D SA70 000 Series)

Serial ATA

SAS

IEEE1394b

Rapid IO

OIF

Video Standards

Page 2

Data Sheet

Automated Pass/Fail Testing

Validating signal quality is an important part of any embedded system

design. One way to determine how well your signals conform to expected

signal quality is to use mask testing. A mask de fines a portion, or portions,

of the oscillo

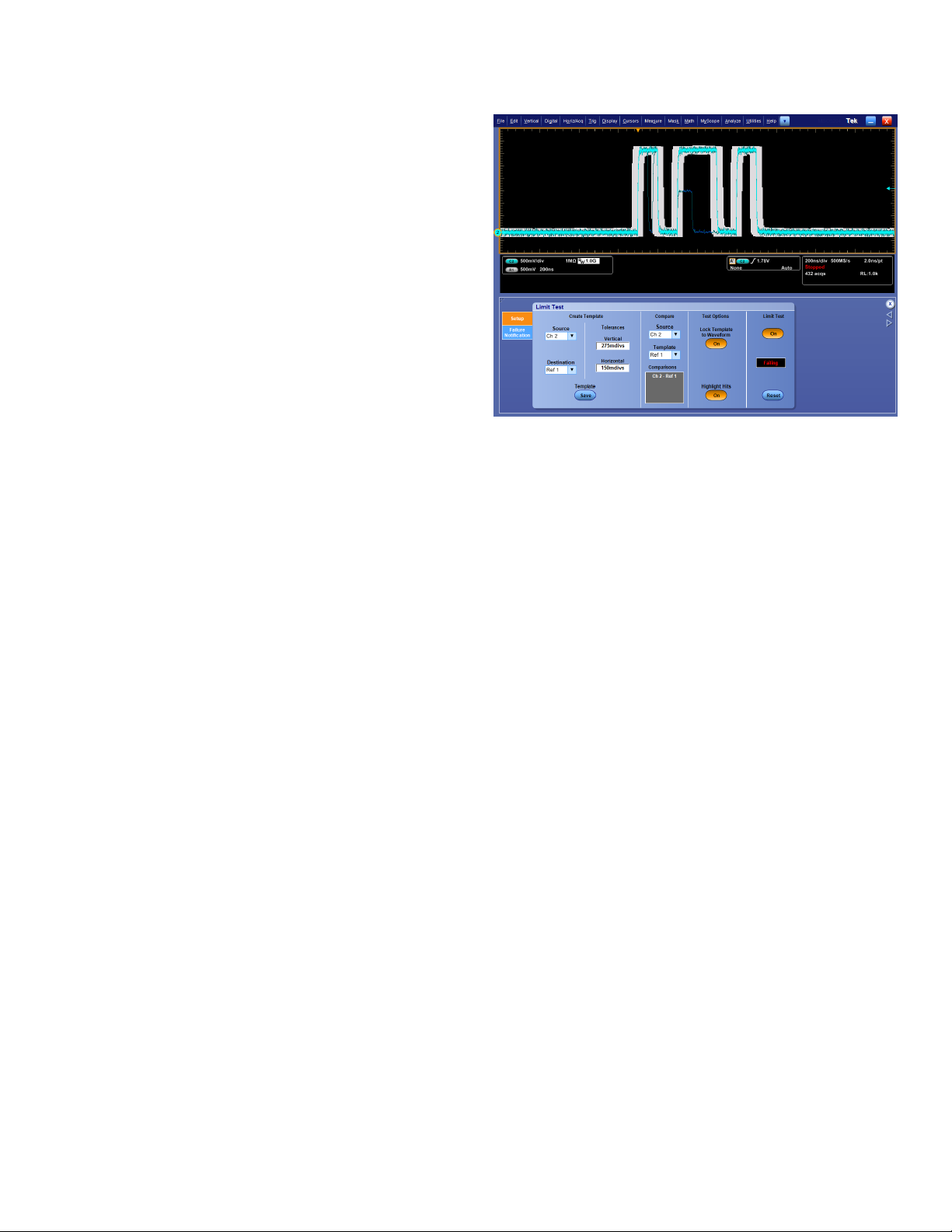

The Limit Test Application Software (Option LT) makes it easier to validate

how your sign

The Mask Test Application Software (Options MTH and MTM) en ables

testing aga

providing automated statistical analysis of signal quality.

Option LT – Limit Test Application Soft ware

A common method for understanding your signal quality is to compare

against a known good or “golden” waveform. You can apply horizontal and

vertical t

used for quick, accurate Pass/Fail testing. This method is also a great way

to perform go/no-go testing on a manufacturing line by enabling repeatable,

fast decisions on the quality of a component or system. The Limit Test

Application Software allows you to save your limit test template for use later

across multiple oscilloscopes in a lab or on a production line.

The Limit Test Application Software will highlight any waveform samples

that fall outside of the limit test template, providing you with quick visual

evidenc

scope display that a signal must not enter.

als are performing compared to a known good condition.

inst a well-defi ned telecommunication or computer standard

olerances to the golden waveform to create a template that can be

e of a failure.

finds infrequent glitches and runt signals using a mask created by adding vertical

Limit test

and horizo

waveform a

ntal tolerances around a golden waveform. Test your signals against a golden

nd quickly gain insight into anomalous behavior.

When a test failure is detected, the o scilloscope can perform a number of

actions in parallel. These actions include stopping the a cquisition, e-mailing

a message indicating the test has failed, saving a waveform to a file, logging

the date and time to a file, printing the waveform, and sending a GPIB SRQ

command.

2 www.tektronix.com

Page 3

Limit and Mask Test Application Software — Option LT, MTH, MTM

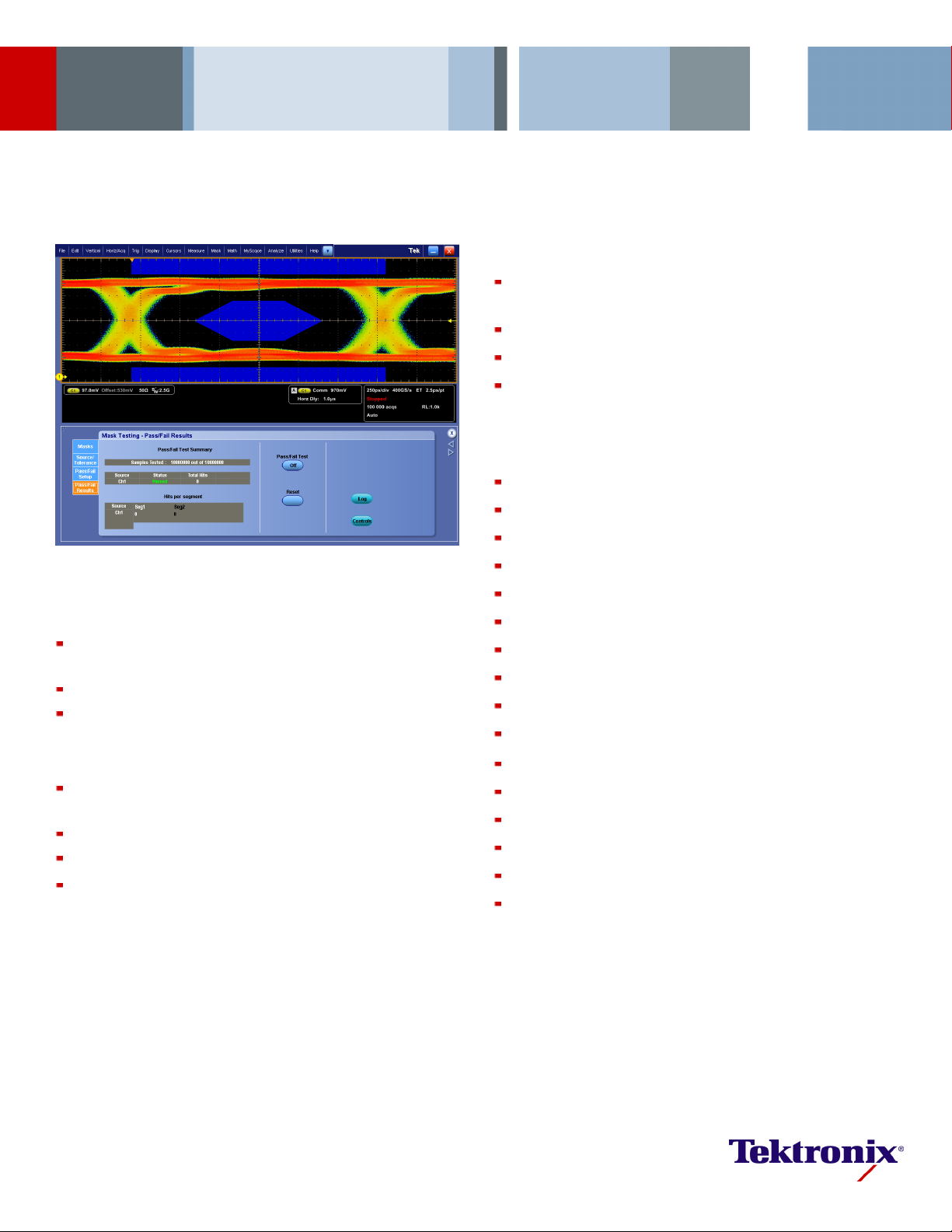

OC12 (622.

telecommu

quick and a

5 Mb/s) standard mask showing results from a mask test. A robust set of

nications and computer industry standard masks make testing to standards

ccurate.

Option MTH, MTM – Mask Test Application Software

When it is necessary to measure performance of your signals against

telecommunications or computer standard s to verify compliance and

interoperability, the Mask Test Application Software, with more than 100

standard masks, makes it easy. Each standard mask is easily loaded

from the oscilloscope internal memory and can be immediately used to

conduct P

ass/Fail testing. Adherence to a standard mask is determined

pixel-by-pixel throughout the display.

When a sta

ndard mask is loaded, the oscilloscope makes use of the

integrated Communication Trigger. Each standard mask is associated

with a communication standard and the m ask you select automatically

determines which communication trigger is used. Some models include

integrated clock recovery circuitry up to 6 Gb/s for NRZ eye patterns. Clock

recovery allows you to perform more reliable and accurate ma sk testing.

The oscilloscope can reduce setup time for making a mask test

measurement by performing an Autoset for vertical, horizontal, and trigger

ers on the source signal. Additionally, to reduce the chance of

paramet

failures, the oscilloscope can Autofit the waveform to the mask to minimize

hits within the m ask. It can do this a single time following an Autoset or it

can perform an Autofit after every triggered acquisition.

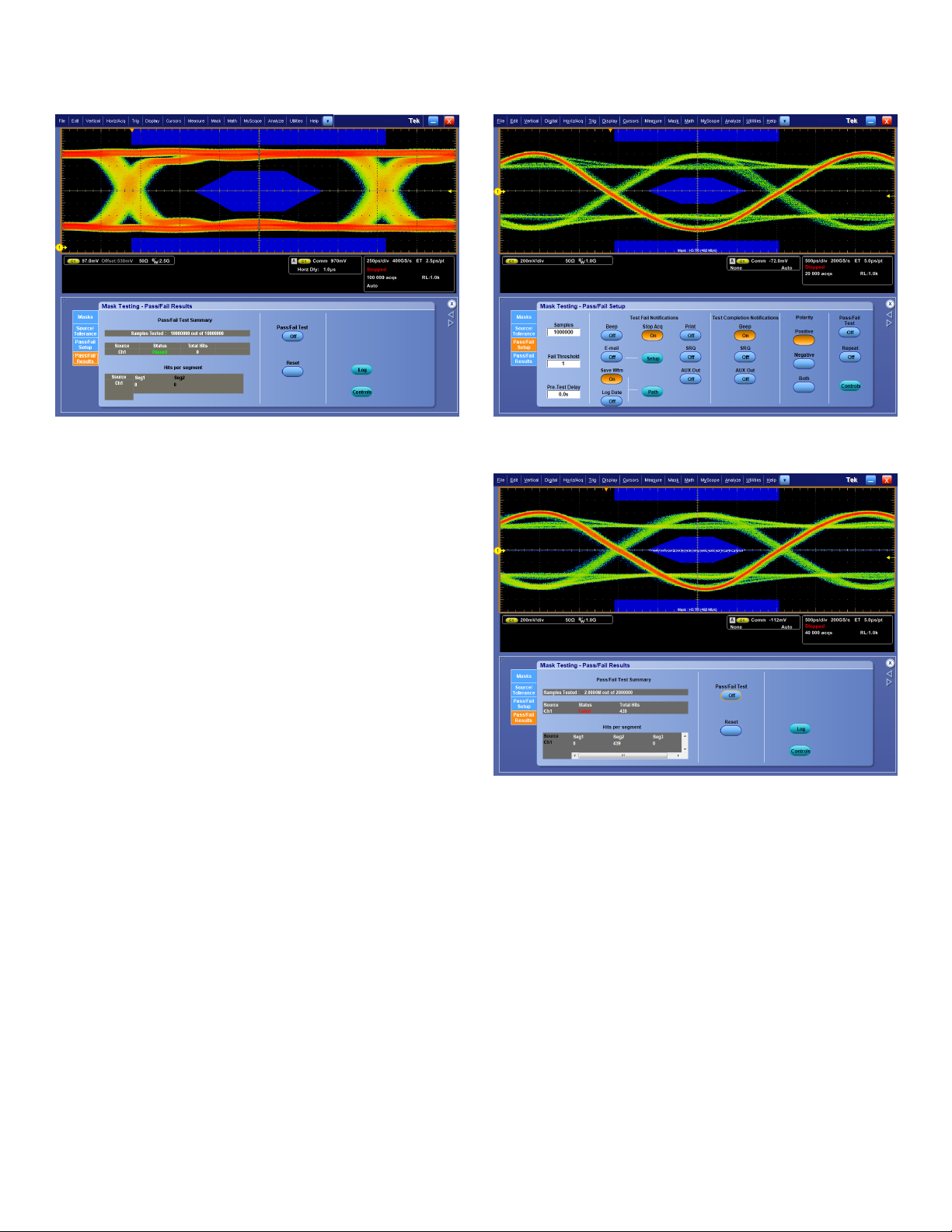

The Mask Test Application Software provides flexible test definitions

enabling you to tailor the test to your needs. You can run a test for a

user-defined number of waveforms (up to 2.14×10

9

). The Repeat Test

and Pretest Delay capability enables swapping of test locations before

ding with a test over multiple cycles of the test. You can set the

procee

number of violations that can occur before a test status is considered failed.

The oscilloscope can also perform a number of actions when a test fails or

completes. Actions the oscilloscope can perform when a test fails include

stopping the acquisition, e-mailing a message indicating the test has failed,

The Mask Test Application Software enables multiple actions upon a test failure or the

completion of a test, tailoring the test to your specific needs.

d mask test results show statistical information for the test. The results include

Detaile

tion on test sample size, failures, total number of hits, and the number of hits in

informa

k segment.

each mas

saving a waveform to file, logg ing the date and time of the fa ilure, printing a

waveform, sending a GPIB SRQ, and sending a trigger out pulse. Actions

the oscilloscope can perform when a test completes include sending a GPIB

SRQ and sending a trigger out pulse.

The Mask Test Application Software provides statistical results from each

ducted. The results include Pass/Fail status of the test, number

test con

of waveforms/samples tested, number of violations found, and the total

number of hits within the mask. A secondary display shows the total number

of hits in each segment of the mask providing further insight into any mask

violations.

www.tektronix.com 3

Page 4

Data Sheet

Characteristics

Option LT – Lim

Characteristic

Test Source Any Ch1 – Ch4, Math1 – Math4, R1 – R4

Template Storage

Template Creation

Margins

Lock Template to

Waveform

Highlight Hits

Limit Test Status Passed: No samples from the test source have fallen

Limit Test Control ON: Limit test is active and hits are being tracked

Reset

Actions on Limit Test

Failure

1

Not available on MSO/DPO5000 Series.

*

it Test Characteristics

Description

Limit test template can be saved into any R1 – R4

location or to a file

Vertical tolerance from 0 to 5 divisions in 0.1m

(1/10,000th) division increments

Horizontal tolerance from 0 to 5 divisions in 0.1m

(1/10,000th) division increments

Note: Use Average acquisition mode to help create a

smoother limit test template

Lock ON: Template automatically re-scales with source

channel settings changes

Lock OFF: Template does not re-scale with source

channel settings changes

Highlight Hits ON: Visually highlight any samples that fall

outside of the limit test template

Highlight Hits OFF: Samples that fall outside of the limit

test template are not visually highlighted

outside of the limit test template

Failed: At least one sample from the test source has

fallen outside of the limit test template

OFF: Limit test is not active and hits are not being

tracked

Clears all violations in preparation for another test

Stop Acq: When Stop Acq is ON, the instrument stops

acquiring if a limit test fails

1

Beep*

: When Beep is ON, the instrument beeps if a limit

test fails

E-mail: When E-mail is ON, the instrument sends an

e-mail if the limit test fails

Save Waveform: When Save Wfm is ON, failed

waveform data is saved to a file

Log Date: When Log Date is ON, the date and time for

each failed limit test is recorded to a file

Print: When Print is ON, the instrument sends the

waveform to a printer if a limit test fails

SRQ: When SRQ is ON, the instrument sends a GPIB

SRQ command if a limit test fails

Option MTH, MTM – Mask Test Characteristics

Characteristic

Description

TestSource AnyCh1–Ch4,M1–M4,R1–R4

Mask Creation Select standard mask from internal memory

Load custom mask from text file with up to 16 mask

segments

Copy a standard m ask to user mask and edit

Included Standard M ask

Types

ITU-T

The standards available vary by model depending on the

bandwidth and configuration of the instrument

DS0 Single (64 kb/s)

DS0 Double (64 kb/s)

DS0DataContra(64kb/s)

DS0 Timing (64 kb/s)

DS1 Rate (1.544 Mb/s)

E1 Sym Pair (2.048 Mb/s)

E1 Coax Pair (2.048 Mb/s)

Clk Intf. Sym (2.048 Mb/s)

Clk Intf. Coax (2.048 Mb/s)

DS2RateSym(6.312Mb/s)

DS2 Rate Coax (6.312 Mb/s)

E2 (8.448 Mb/s)

32Mb (32.064 Mb/s)

E3 (34.368 Mb/s)

DS3 Rate (44.736 Mb/s)

97Mb (97.728 Mb/s)

E4 Binary 0 (139.26 Mb/s)

E4 Binary 1 (139.26 Mb/s)

STM1E Binary 0 (155.52 Mb/s)

STM1E Binary 1 (155.52 Mb/s)

STM-0 HDBx (51.84 Mb/s)

STM-0CMI0(51.84Mb/s)

STM-0CMI1(51.84Mb/s)

ANSI T1.102 DS1 (1.544 Mb/s)

DS1A (2.048 Mb/s)

DS1C (3.152 Mb/s)

DS2 (6.312 Mb/s)

DS3 (44.736 Mb/s)

DS4NA (139.26 Mb/s)

DS4NA Max Output (139.26 Mb/s)

STS-1 Pulse (51.84 Mb/s)

STS-1 Eye (51.84 Mb/s)

STS-3 (155.52 Mb/s)

STS-3 Max Output (155.52 Mb/s)

SONET/SDH OC1/STM0 (51.84 Mb/s)

OC3/STM1 (155.52 Mb/s)

OC12/STM4 (622.08 Mb/s)

OC48/STM16 (2.4883 Gb/s)

OC48/STM16 FEC (2.666 Gb/s)

Ethernet

100BASE-TX STP (125 Mb/s)

100BASE-TX UTP (125 Mb/s)

1000B-SX/LX/PX (1.25 Gb/s)

1000B-CX Norm, TP2 (1.25 Gb/s)

1000B-CX Abs, TP2 (1.25 Gb/s)

1000B-CX Abs, TP3 (1.25 Gb/s)

XAUI, Near (3.125 Gb/s)

XAUI, Far (3.125 Gb/s)

CPRI (Common

Public Radio

Interface)

CPRI1228 (1.228 Gb/s)

CPRI2457 (2.457 Gb/s)

CPRI3072 (3.072 Gb/s)

USB 1.1/2.0 FS (12 Mb/s)

HS:T1(480Mb/s)

HS:T2(480Mb/s)

HS:T3(480Mb/s)

HS:T4(480Mb/s)

HS:T5(480Mb/s)

HS:T6(480Mb/s)

4 www.tektronix.com

Page 5

Limit and Mask Test Application Software — Option LT, MTH, MTM

Characteristic

Fibre Channel FC133 Optical (132.8 Mb/s)

Fibre Channel

Electrical

OBSAI (Open Base

Station Architecture

Initiative)

iBand

Infin

Serial ATA G1 Tx 5-Cycle (1.5 Gb/s)

AS

S

Description

FC266 Optical (265.62 Mb/s)

FC531 Optical (531.25 Mb/s)

FC1063 Optical (1.0625 Gb/s)

FC1063 Optical Draft Rev 11

FC2125 Optical (2.125 Gb/s)

FC133E Elec. (132.8 Mb/s)

FC266E Elec. (265.62 Mb/s)

FC531E Elec. (531.25 Mb/s)

FC1063E Elec. (1.0625 Gb/s)

FC1063E Norm, Beta, Transm

FC1063E Norm, Delta, Transm

FC1063E Norm, Gamma, Transm

FC1063E Abs, Beta, Transm

FC1063E Abs, Delta, Transm

FC1063E Abs, Gamma, Transm

FC1063E Abs, Beta, Recv

FC1063E Abs, Delta, Recv

FC1063E Abs, Gamma, Recv

FC2125E Norm, Beta, Transm

FC2125E Norm, Delta, Transm

FC2125E Norm, Gamma, Transm

FC2125E Abs, Beta, Transm

FC2125E Abs, Delta, Transm

FC2125E Abs, Gamma, Transm

FC2125E Abs, Beta, Recv

FC2125E Abs, Delta, Recv

FC2125E Abs, Gamma, Transm

FC4250E Norm, Beta, Transm

FC4250E Norm, Delta, Transm

FC4250E Norm, Gamma, Transm

FC4250E Abs, Beta, Transm

FC4250E Abs, Delta, Transm

FC4250E Abs, Gamma, Transm

FC4250E Abs, Beta, Recv

FC4250E Abs, Delta, Recv

FC4250E Abs, Gamma, Recv

OBSAI3072_Tx (3.072 Gb/s)

OBSAI3072_Rx (3.072 Gb/s)

OBSAI6144_Tx (6.144 Gb/s)

OBSAI6144_Rx (6.144 Gb/s)

ptical (2.5 Gb/s)

2.5 O

Electrical (2.5 Gb/s)

2.5

G1 Rx 5-Cycle (1.5 Gb/s)

G2 Tx 5-Cycle (3.0 Gb/s)

G2 Rx 5-Cycle (3.0 Gb/s)

G3 Tx 5-Cycle (6.0 Gb/s)

G3 Rx 5-Cycle (6.0 Gb/s)

AS IR (1.5 Gb/s)

S

AS CR (1.5 Gb/s)

S

AS XR (1.5 Gb/s)

S

SAS IR, AASJ (1.5 Gb/s)

SAS CR, AASJ (1.5 Gb/s)

SAS XR, AASJ (1.5 Gb/s)

SAS, SATA (1.5 Gb/s)

SAS IR (3.0 Gb/s)

SAS CR (3.0 Gb/s)

SAS XR (3.0 Gb/s)

SAS IR, AASJ (3.0 Gb/s)

SAS CR, AASJ (3.0 Gb/s)

SAS XR, AASJ (3.0 Gb/s)

SAS, SATA (3.0 Gb/s)

Characteristic

IEEE 1394b

Rapid IO LP-LVDS Drv (500 Mb/s)

Rapid IO Serial RIO Serial (1.25 Gb/s)

OIF Standards SFI/SPI-5 TA Data (2.488 Gb/s)

PCI Express PCI-Express Transm (2.5 Gb/s)

Video

Mask Polarity

Mask Display

Lock Mask to Waveform Lock to Waveform ON: Mask automatically re-scales with

Hit Counts ON: Any hit in any mask segment will be counted and

Highlight Hits

Description

S400b T1 (491.5 Mb/s)

S400b T2 (491.5 Mb/s)

S400ß Optical (491.5 Mb/s)

S800b T1 (983.0 Mb/s)

S800b T2 (983.0 Mb/s)

S800 ß Optical (983.0 Mb/s)

S1600b T1 (1.966 Gb/s)

S1600b T2 (1.966 Gb/s)

S1600ß Optical (1.966 Gb/s)

Drv (750 Mb/s)

Drv (1.0 Gb/s)

Drv (1.5 Gb/s)

Drv (2.0 Gb/s)

Ext Drv (500 Mb/s)

Ext Drv (750 Mb/s)

Ext Drv (1.0 Gb/s)

Ext Drv (1.5 Gb/s)

Ext Drv (2.0 Gb/s)

Rcv (500 Mb/s)

Rcv (750 Mb/s)

Rcv (1.0 Gb/s)

Rcv (1.5 Gb/s)

Rcv (2.0 Gb/s)

RIO Serial (2.5 Gb/s)

RIO Serial (3.125 Gb/s)

SFI/SPI-5TCData(2.488Gb/s)

SFI/SPI-5 TA Clk (2.488 Gb/s)

SFI/SPI-5 TC Clk (2.488 Gb/s)

SFI/SPI-5 RB Data (2.488 Gb/s)

SFI/SPI-5 RD Data (2.488 Gb/s)

SFI/SPI-5 RB Clk (2.488 Gb/s)

SFI/SPI-5 RD Clk (2.488 Gb/s)

SFI/SPI-5 TA Data (3.125 Gb/s)

SFI/SPI-5TCData(3.125Gb/s)

SFI/SPI-5 TA Clk (3.125 Gb/s)

SFI/SPI-5 TC Clk (3.125 Gb/s)

SFI/SPI-5 RB Data (3.125 Gb/s)

SFI/SPI-5 RD Data (3.125 Gb/s)

SFI/SPI-5 RB Clk (3.125 Gb/s)

SFI/SPI-5 RD Clk (3.125 Gb/s)

VSR OC192/STM64 (1.24416 Gb/s)

TFI-5 (2.488 Gb/s)

TFI-5 (3.1104 Gb/s)

PCI-Express Recv (2.5 Gb/s)

4FSC NTSC "D2" (143.18 Mb/s)

4:4:2 "D1" (270Mb/s)

DVB ASI (270 Mb/s)

4:2:2 SMPTE 259M-D (360 Mb/s)

SMPTE 292M (1.485 Gb/s)

This control is only displayed for certain mask types. Use

this control to select Positive or Negative polarity for the

mask

ON: Mask display is on

OFF: Mask will not be displayed

source channel settings changes

Lock to Waveform OFF: Mask does no t re-scale with

source channel settings changes

displayed in the Pass/Fail Test Summary

OFF: Hits in mask segments will not be counted

Highlight Hits ON: Visually highlight any samples that fall

within a mask segment

Highlight Hits OFF: Samples that fall inside of a mask

segment are not visually highlighted

www.tektronix.com 5

Page 6

Data Sheet

Characteristic

Mask Alignment:

Autoset

Description

Use Mask Autoset to automatically align the source

signal within the mask

Parameters that can be used in the Mask Autoset

procedure include: Vertical (Scale, Position, DC

Compensation), Horizontal (Scale, Position), and Trigger

Autoset Mode: Select Auto to have Autoset performed

after a standard mask has been selected. Select Manual

to make adjustments manually

Autofit Once: The waveform is autofit once following an

autoset

Mask Alignment: Autofit ON: The waveform is autofittothemaskandwill

minimize hits within the mask on each acquisition

OFF: The waveform will not be autofit to the mask on

each acquisition

Controls for setting the vertical and horizontal maximum

levels of adjustment are available

Mask Margin Tolerance

ON: The percentage of margin used in the mask test is

user-controllable

OFF: The percentage of margin used in the mask test is

not user-controllable

Range: –50% to +50% in 1% increments; A margin of

<0% moves mask segments further apart, making a

mask test easier to pass. A margin of >0% moves mask

segments closer together, demonstrating that the signal

passes the test with margin for further error

Test Criteria Run Until Minimum number of samples (from 5,000 to 2.14×109)

when in WfmDB acquisition mode. Minimum number of

waveforms (from 1 to 2.14×10

9

) in all other acquisition

modes

User Mask Edit

Modify a User Mask through an intuitive graphical user

interface

Select a mask segment and vertex to edit, and then set

the horizontal and vertical values

Addordeletesegmentsinanexistingmaskorverticesin

an existing mask segment

Saveamasktoafile, or recall a mask from a file

Pretest Delay From 0 s to 60 s

Fail Threshold From 1 to 2.14×10

9

Pass/Fail Test Control ON: Test is started and runs until completed or manually

stopped

OFF: Test is not running

Repeat on Completion ON: Test will repeat when the minimum number of

waveforms or minimum amount of time is reached

OFF: Test will run a single time and will not repeat

Mask Polarity Positive, Negative, or Both. Test will complete with the

selected mask polarity. When Both is selected the test

will run with Positive polarity and with Negative polarity

Actions on Mask Test

Failure

Stop Acq: When Stop Acq is ON, the instrument stops

acquiring if a mask test fails

1

Beep*

: When Beep is ON, the instrument beeps if a limit

test fails

E-mail: When E-mail is ON, the instrument sends an

e-mail if the limit test fails

Save Waveform: When Save Wfm is ON, failed

waveform data is saved to a file

Log Date: When Log Date is ON, the date and time for

each failed limit test is recorded to a file

Print: When Print is ON, the instrument sends the

waveform to a printer if a limit test fails

SRQ: When SRQ is ON, the instrument sends a GPIB

SRQ command if a limit test fails

AUX Out: When AUX Out is ON, the instrument sends a

trigger to the Auxiliary Out connector when a mask test

fails

Characteristic

Actions on Mask Test

Complete

Description

1

Beep*

: W hen Beep is ON, the instrument beeps when

the mask test is complete

SRQ: When SRQ is ON, the instrument sends a GPIB

SRQ command when the mask test is complete

AUX Out: When AUX Out is ON, the instrument sends a

trigger to the Auxiliary Out connector when a mask test

is complete

Pass/Fail Results

Display

Pass/Fail Test Summary: Includes information on the

outcome of a test

Samples Tested: Shows the current number of

samples tested out of the total number to be tested

Source: Indicates what signal source was used for the

test

Status: Indicates whether the test has Passed, Failed,

or is Passing

Total Hits: The total number of data points that

violated the mask

Failed Wfms: The total number of waveforms that

failed during the test

Hits per Segment: The number of hits that have violated

each segment in the mask

*1Not available on MSO/DPO5000 Series.

Ordering Information

Limit Test Application Software

Model New Instrument

MSO/DPO5000

Orders

Opt. LT DPO-UP Opt. LT DPOFL-LT

Series

DPO7000 Series Opt. LT DPO-UP Opt. LT DPOFL-LT

DPO/DSA/MSO70000

Opt. LT DPO-UP Opt. LT DPOFL-LT

Series

Mask Test Application Software

Model New Instrument

MSO/DPO5000

Orders

Opt. MTM DPO-UP Opt. MTM DPOFL-MTM

Series

DPO7000 Series Opt. MTM DPO-UP Opt. MTM DPOFL-MTM

DPO/MSO70000

Opt. MTH DPO-UP Opt. MTH DPOFL-MTH

Series

DSA70000 Series Standard Standard Standard

Recommended Probes

Please refer to www.tek.com/probes for further information on the

recommended models of probes and any necessary probe adapters.

t(s) are manufactured in ISO registered facilities.

Produc

Product

Upgrades

Product

Upgrades

Floating

Licenses

Floating

Licenses

6 www.tektronix.com

Page 7

Limit and Mask Test Application Software — Option LT, MTH, MTM

www.tektronix.com 7

Page 8

Data Sheet

Contact Tektronix:

ASEAN / Australa

Balkans, Israel, South Africa and other ISE Countries +41 52 675 3777

Central East Eu

Mexico, Central/South America & Caribbean (52) 56 04 50 90

* European toll-free number. If not accessible, call: +41 52 675 3777

rope, Ukraine, and the Baltics +41 52 675 3777

Central Europe & Greece +41 52 675 3777

Middle E ast,

Asia, and North Africa +41 52 675 3777

The Netherlands 00800 2255 4835*

People’s Rep

Republic of

United K ingdom & Ireland 00800 2255 4835*

sia (65) 6356 3900

Austria 00800 2255 4835*

Belgium 00800 22

Brazil +55(11)37597600

Canada 1 800 833 9200

Denmark +4580881401

Finland +41526

France 00800 2255 4835*

Germany 00800 2255 4835*

Hong Kong 400 8

India 000 800 650 1835

Italy 00800 2255 4835*

Japan 81 (3) 67

Luxembourg +41526753777

ublic of China 400 820 5835

Poland +41 52 675 3777

Korea 001 800 8255 2835

Russia & CIS +7 (495) 7484900

South Africa +41526753777

Spain 00800

Sweden 00800 2255 4835*

Switzerland 00800 2255 4835*

Tai wa n 886 (

55 4835*

75 3777

20 5835

14 3010

Norway 800 16098

Portugal 80 08 12370

2255 4835*

2) 2722 9622

USA 1 800 833 9200

Updated 25 May 2010

www.tektronix.com

For Further Information. Tektronix maintains a comprehensive, constantly expanding

collection of application notes, technical briefs and other resources to help engineers working

on the cutting edge of technology. Please visit www.tektronix.com

t © Tektronix, Inc. All rights reserved. Tektronix products are covered by U.S. and foreign patents,

Copyrigh

d pending. Information in this publication supersedes that in all previously published material.

issued an

tion and price change privileges reserved. TEKTRONIX and TEK are registered trademarks of

Specifica

x, Inc. All other trade names referenced are the service marks, trademarks, or registered trademarks

Tek t ro n i

espective companies.

of their r

11 Nov 2010 61W-26237-0

Loading...

Loading...