Page 1

Instructions

040-1665-00

MTG100 & MTG300

Rackmount (Option 1R) Upgrade Kit

061-A020-50

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

*P061A02050*

061A02050

Page 2

Copyright © Tektronix Japan, Ltd. All rights reserved.

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Tektronix Japan, Ltd., 5 --9--31 Kitashinagawa, Shinagawa--ku, Tokyo 141--0001 Japan

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary in the product service manual

or the instruction manual.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

MTG100 and MTG300 Rackmount Upgrade Instructions

1

Page 4

Service Safety Summary

2

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 5

Kit Description

NOTE. The following conventions apply throughout this document:

H The MTG100 and MTG300 MPEG Generator is simply referred to as the

“MPEG generator.”

H The MPEG generator is referred to as being either a “standard” or

“Option 1R” version. The “standard” MPEG generator does not include

rackmounting hardware. The “Option 1R” MPEG generators have

rackmounting hardware on the sides of the instrument’s cabinet.

The MTG100 and MTG300 Rackmount (Option 1R) Upgrade Kit provides parts

and instructions for you to perform the following tasks:

H Replace the standard cabinet on your MPEG generator with an Option 1R

(rackmount ready) cabinet

H Install the MPEG generator into a standard 19-inch equipment rack

If your MPEG generator was ordered with Option 1R, Tektronix shipped the

MPEG generator with the rackmount cabinet already installed. If this is your

case, you will need to perform only the instructions for mounting your MPEG

generator into an equipment rack.

Products

NOTE. A standard equipment rack has rails with universal hole spacing. If your

equipment rack uses hole spacing that is different than universal hole spacing,

you may have to drill additional mounting holes in the rack to accommodate the

mounting hardware included in this kit.

CAUTION. Mounting the MPEG generator into an equipment rack requires

certain minimum clearances around the instrument. Be sure to read the

information in Environmental Requirements before you install the MPEG

generator into an equipment rack.

If you rackmount the MPEG generator using methods that are different than

those described in these instructions, the MPEG generator may not meet its

warranted specifications.

MTG100 and MTG 300 MPEG Generators All Instruments

MTG100 and MTG300 Rackmount Upgrade Instructions

3

Page 6

Kit Description

Environmental Requirements

Mounting the MPEG generator into an equipment rack requires certain minimum

clearances around the instrument. When the MPEG generator is installed in an

equipment rack according to the instructions in this document, the rackmounted

MPEG generator m eets all warranted specifications.

The rack into which the rack-adapted MPEG generator is mounted must provide

the following clearance requirements:

CAUTION. If you adhere to these clearance requirements when you rackmount the

MPEG generator, the instrument will have sufficient air circulation and room to

accommodate the power cord and mounting hardware. Failure to provide t hese

clearances can result in overheating and can cause the MPEG generator to not

operate properly and/or fail.

H A minimum of 50 mm (2 inches) of vertical space above the instrument.

H A minimum of 75 mm (3 inches) of rear space.

H A minimum width of 455 mm (17.9 inches) between the left- and right-front

rails in the rack.

H A minimum inside height depth of at least 635 mm (25 inches).

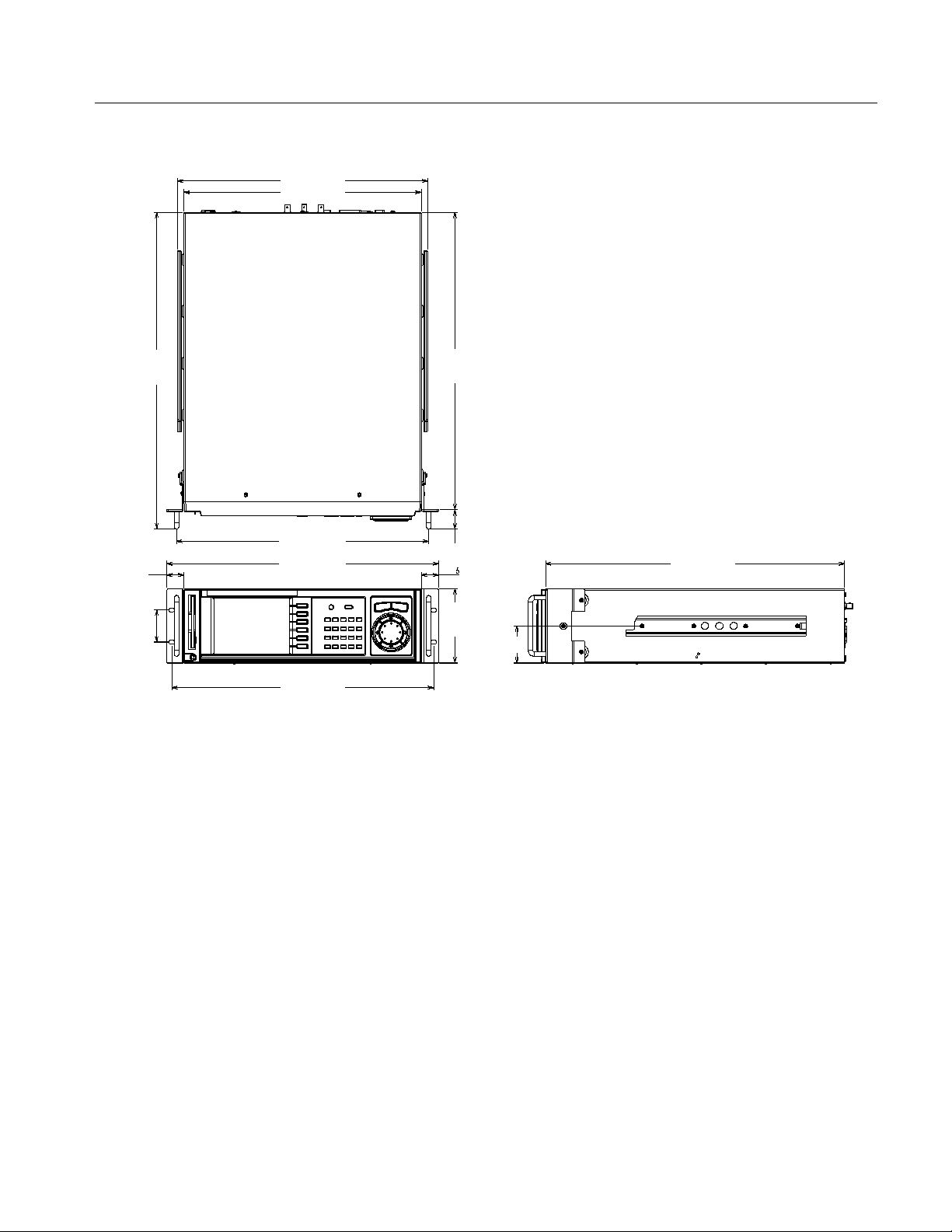

Figure 1 shows the dimensions of the MPEG generator after the rackmount

cabinet is installed.

4

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 7

444.6 (17.5)

421.6 (16.6)

Kit Description

528.4

(20.8)

34.0 (1.3)

30.5 (1.2)

132.0

(5.2)

30.5 (1.2)

57.2 (2.3)

562.4

(22.1)

448.4 (17.7)

482.6 (19.0)

465.2 (18.3)

Figure 1: The MPEG Generator with Rack Adapter Installed

531.4 (20.9)

66.0 (2.6)

MTG100 and MTG300 Rackmount Upgrade Instructions

5

Page 8

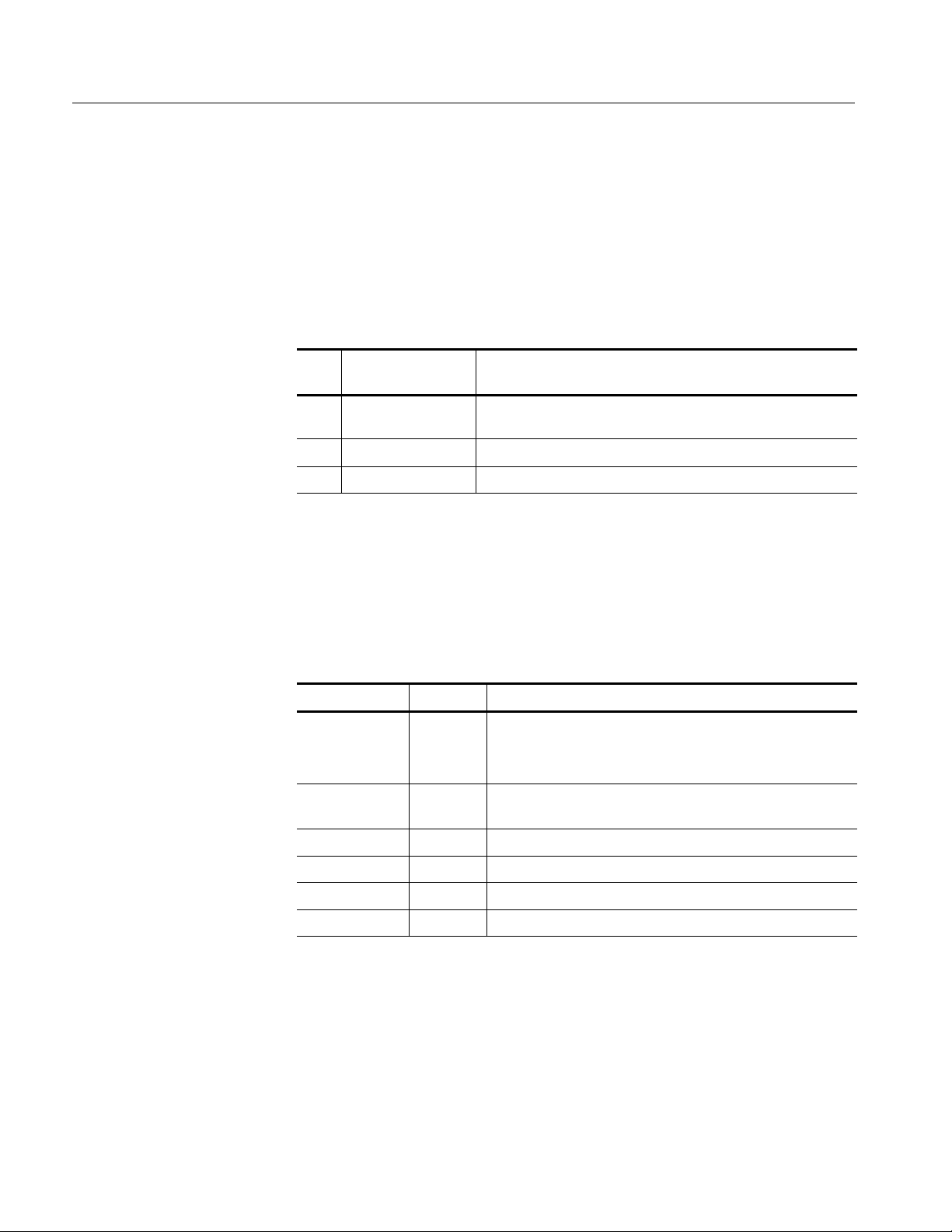

Kit Description

Required Tool and Equipment List

Table 1 lists the tools required to install the rack-adapter hardware,and to mount

the rack-adapted MPEG generator into a standard 19-inch equipment rack. All

tools are standard tools that are readily available. Depending on the type of

installation you are doing, you may not need every item in this list.

Table 1: Tools required for rackmount installation

Item

no.

Name Description

1 Screwdriver handle

(magnetic)

2 #2 Phillips tip PhillipsR-driver tip for M3 size screw heads

3 No. 2 Pozidrive tip PozidriveR-driver tip for number 2 size screw heads

Accepts

1

@

inch hex-head driver tips

4

Kit Parts List

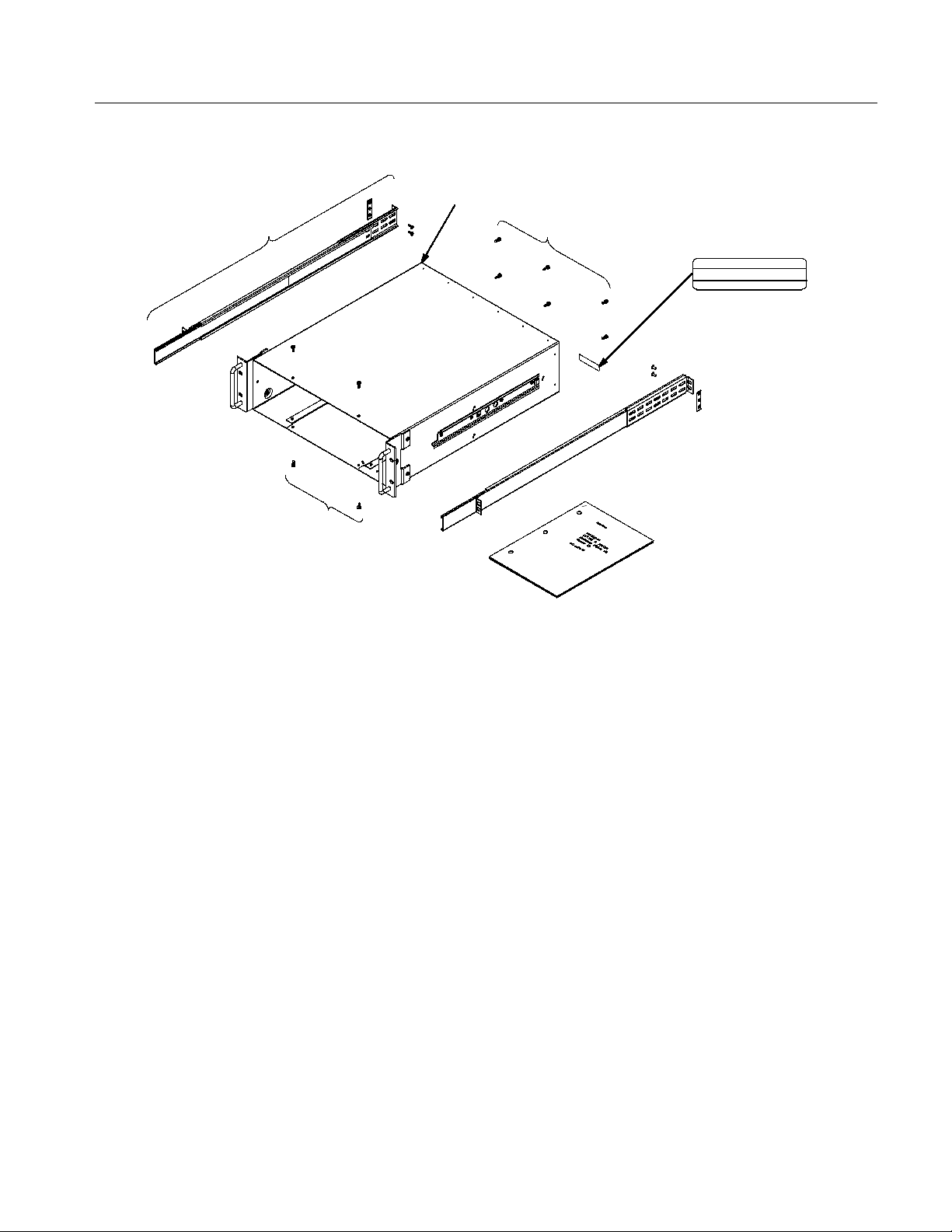

Table 2 lists the parts included in the MTG100 and MTG300 Rackmount

(Option 1R) Upgrade Kit. See Figure 2.

Table 2: Rackmount kit parts list

Part number Quantity Description

NS 1 MTG100 and MTG300 rackmount cabinet, assembled

Replaceable Mechanical Parts on page 21 lists the part

numbers for the replaceable parts of the rackmount cabinet.

351-0623-00 1 Slide--out Tracks kit

(both side tracks and mounting hardware are included)

211-0785-00 4 Screws, M3 X 6 mm

211-0945-00 6 Screws, M3 X 8 mm

NS 1 Marker, Ident, 040-1665-XX

061-A020-50 1 Rackmount kit instructions

NS -- Not Saleable

6

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 9

Slide--out

tracks kit

Screws,

M3 X 6 mm

MTG100 and MTG300 rackmount

cabinet, assembled

Screws, M3 X 8 mm

Marker, Ident

Tektronix Japan, Ltd. Made in JAPAN

Rackmount kit

instructions

IDENT NO.

040---1665 --- 00

Kit Description

Figure 2: Included parts of the MTG100 & MTG300 Rackmount (Option 1R) Upgrade Kit

MTG100 and MTG300 Rackmount Upgrade Instructions

7

Page 10

Kit Description

8

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 11

Installation Instructions

These instructions are written for personnel who are familiar with servicing the

MPEG generator. If you need further details for disassembling or reassembling

the instrument, refer to the MTG100 and MTG300 MPEG Generator Service

Manual (Tektronix, Inc. part number 071-0616-50). Contact your nearest

Tektronix, Inc., Service Center or Tektronix Factory Service if you need

installation assistance.

The installation instructions include the following procedures:

H Installing the Rackmount Cabinet on the MPEG Generator page 9

H Rackmounting the MPEG Generator page 13

Before You Begin

CAUTION. To prevent static discharge damage, service the product only in a

static-free environment. Observe standard handling precautions for static-sensitive devices while installing this kit. Always wear a grounded wrist strap,

grounded foot strap, and static resistant apparel while installing this kit.

Read the Service Safety Summary starting on page 1 before you perform these

installation instructions.

The procedures in these installation instructions refer t o the “front,” “back,”

“top,” etc. of the MPEG generator as shown in Figure 3.

Installing the Rackmount Cabinet on the MPEG Generator

Perform this procedure if you are replacing the standard cabinet on your MPEG

generator with a rackmount cabinet.

NOTE. Keep all of the parts that you remove from the MPEG generator during

this procedure. Some of the removed parts will be needed to complete the

rackmount installation. The remaining parts will be needed if you want to

reconfigure your MPEG generator to a standard cabinet at a later time.

MTG100 and MTG300 Rackmount Upgrade Instructions

9

Page 12

Installation Instructions

Figure 3: MPEG generator orientation

Removing the Standard

Cabinet

Perform the following procedure to remove the standard cabinet from the MPEG

generator:

1. Remove the power cord and disconnect any cables from the rear of the

MPEG generator.

2. Using the screwdriver with a #2 Phillips tip, remove the four screws securing

the front of the cabinet to the MPEG generator. See Figure 4.

3. Using the screwdriver with a #2 Phillips tip, remove the six screws securing

the rear of the cabinet to the MPEG generator. See Figure 4.

4. Position the MPEG generator so its bottom is on the work surface and its

front is facing you.

CAUTION. To prevent damage to internal instrument cabling, be careful not to

bind or snag the cabinet on internal cabling as you remove the cabinet.

5. Grasp the right and left edges of the cabinet near the back of the MPEG

generator, and then carefully slide the cabinet towards the back of the MPEG

generator to remove the cabinet. See Figure 4. Some force may be necessary

to get the cabinet to start sliding.

10

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 13

Slide the cabinet

backward to

remove.

Installation Instructions

Remove the

line cord.

Figure 4: Removing the standard cabinet

MTG100 and MTG300 Rackmount Upgrade Instructions

11

Page 14

Installation Instructions

Installing the Rackmount

Cabinet

Perform the following procedure to install the rackmount cabinet onto your

MPEG generator:

1. Position the MPEG generator so its bottom is on the work surface and its

front is facing you.

CAUTION. To prevent damage to internal instrument cabling, be careful not to

bind or snag the cabinet on internal cabling as you install the cabinet.

2. To install the cabinet, grasp the right and left edges of the cabinet, and then

carefully slide the cabinet towards the front of the MPEG generator. See

Figure 5.

3. Using the screwdriver with a #2 Phillips tip, install the six screws securing

the rear of the cabinet to the MPEG generator. See Figure 5.

4. Using the screwdriver with a #2 Phillips tip, install the four screws securing

the front of the cabinet to the MPEG generator. See Figure 5.

Slide the cabinet

forward to

install.

12

Figure 5: Installing the rackmount cabinet

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 15

Rackmounting the MPEG Generator

Use the procedures in this section to install your rackmount-ready MPEG

generator into an equipment rack.

NOTE. This kit contains extra hardware that allows you to mount the MPEG

generator into several different rack configurations. Depending on your specific

application, you will not need all of the hardware in this kit to rackmount your

MPEG generator.

The cabinet of the MPEG generator must be equipped with rackmount hardware

(Option 1R or from the hardware in this kit) before you can install the instrument

into an equipment rack.

This section contains the following procedures:

H Assembling t he slide-out tracks

H Installing the slide-out track assemblies

Installation Instructions

Assembling the

Slide-out Tracks

H Rackmounting the MPEG generator

The slide-out tracks permit the rackmounted MPEG generator to be extended out

of the equipment rack for rear-panel and connector maintenance without

removing the MPEG generator from the rack.

WARNING. To prevent personal injury and equipment damage, if you disassemble

the slide-out track assemblies for maintenance, do not interchange the inner left

and right tracks when you reinstall them into the outer left and right tracks.

If you interchange the inner left and right tracks, you will defeat the extension

stop (safety latch) feature of the tracks. The MPEG generator could, when

extended, come out of the slides and fall from the equipment rack, possibly

causing personal injury and equipment damage.

NOTE. The slide-out track assemblies included in the rackmount kit come

partially assembled with the inner tracks attached inside of the outer tracks.

Leave the track assemblies partially assembled to simplify their installation and

to avoid accidentally swapping their inner tracks. (See WARNING above.)

When the left and right slide -out tracks are correctly assembled and oriented as

shown in Figure 6 on page 15, the round cutout is below the square cutout at the

end of the both inner tracks.

MTG100 and MTG300 Rackmount Upgrade Instructions

13

Page 16

Installation Instructions

Perform the following procedure to assemble the slide-out tracks:

1. Identify the right and left slide-out track assemblies:

a. Find the date code label on each track assembly.

b. The track assembly to be mounted on the left side of the equipment rack

(the side of the rack nearest the left side of the MPEG generator (see

Figure 3 on page 10)) has a date code that ends with “LH,” for left hand.

c. The track assembly to be mounted on the right side of the equipment

rack has a date code ending with “RH,” for right hand.

2. Measure the distance between the front and rear rails of the equipment rack.

3. Align one of the rear brackets to the right slide-out track assembly as shown

in Figure 6.

NOTE. The rear brackets have multiple pairs of mounting holes. When you align

the rear bracket and the slide-out track, be sure to select a pair of holes that

mount the rear bracket so that the flange-to-flange distance (see Figure 6)

matches the front to rear rail measurement from step 2.

4. Use a screwdriver with a #2 Pozidrive tip to secure the rear bracket to the

right slide-out track using two screws (10-32) and a bar nut as shown in

Figure 6. Leave the screws loose so that the overall length of the slide-out

track assembly can be adjusted when you install it in the rack (refer to step 4

on page 17).

5. Repeat steps 3 and 4 to assemble the left slide-out track assembly.

14

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 17

Rear flange

(mounts to the

rear rail of the

equipment rack )

Installation Instructions

Right Slide-Out Track Assembly

10--32 screw

Button latch is

closest to the top

of the track

Outer track

Left Slide-Out Track Assembly

Front flange

(mounts to the

front rail of the

equipment rack )

Bar nut

Inner track

Flange-to flange: 20.25 in.

(514.4 mm) min to 26.50 in.

(673.1 mm) max

Rear bracket

Round cutout

must be below

square cutout

Figure 6: Assembling the slide-out tracks

MTG100 and MTG300 Rackmount Upgrade Instructions

15

Page 18

Installation Instructions

Installing the Slide-out

Track Assemblies

Perform the following procedure to i nstall the slide-out track assemblies into the

equipment rack:

NOTE. The slide-out tracks must be properly assembled before you install the

tracks into your equipment rack. Refer to Assembling the Slide-out Tracks on

page 13 for more information.

1. Select the mounting position in the equipment rack.

a. Select two ½ inch spaced holes in the front rail of the equipment rack.

b. Verify that the 5 inch and 10.5 inch clearances exist relative to those

mounting holes. See Figure 7.

Front rail of the

equipment rack

(left-front rail shown)

Securing holes for the

MPEG generator (must be

tapped for 10--32 screws)

7.5 in.

(190.5 mm)

10.5 in.

(266 mm)

5in.

(127 mm)

5in.

(127 mm)

0.50 in. (12.7 mm)

(required for the

correct position of the

MPEG generator’s

securing holes)

Figure 7: Required vertical clearances for rack installation

16

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 19

Installation Instructions

2. Select the method for mounting the slide-out track assemblies according to

the type of equipment rack.

a. To mount the slide-out tracks with their front and rear flanges outside of

the front and rear rails of the equipment rack, use mounting method A

(as shown in Figure 8) when you perform step 3. Add a bar nut to the

installation only if the rails have untapped mounting holes.

b. To mount the slide-out tracks with their front and rear flanges inside of

rails, use the mounting method B outlined in Figure 8. (This mounting

method assumes untapped mounting holes in the rail of the rack.)

3. Install the slide-out track a ssemblies into the equipment rack.

a. Using the method and hardware determined from step 2, secure the right

slide-out track assembly to the front and rear rails of the equipment rack.

b. The screws should be fully, but lightly, seated so that the mounting can

be adjusted later (refer to step 2 on page 19).

c. Repeat substeps a and b for the left slide-out track assembly.

4. Fix the front-to-rear length of the slide-out track assemblies.

a. Locate the screws securing the rear mounting bracket to the right

slide-out track assembly that were intentionally left loose in step 4 on

page 14.

b. Tighten the screws to fix the front-to-rear flange spacing of the right

slide-out track assembly.

c. Repeat substeps a and b for the left slide-out track assembly.

MTG100 and MTG300 Rackmount Upgrade Instructions

17

Page 20

Installation Instructions

Mounting Method A Mounting Method B

Use a bar nut if the front

rails are not tapped

Left-front rail of

equipment rack

Left s lide-out

track assembly

10-32 pan head

screws (4)

Secure the track assemblies using flat-head

screws if the rack rails have countersunk

mounting holes; otherwise use pan-head screws.

Bar nut

10-32 flat head

screws (4)

Figure 8: Installing the slide-out track assemblies into the equipment rack (top view)

Rackmounting the

MPEG Generator

Perform the following procedure to mount the MPEG generator into the

equipment rack:

10-32 pan head

screws (4)

18

WARNING. To prevent personal injury and equipment damage, the slide-out

tracks must be properly assembled and installed before you mount the MPEG

generator into the equipment rack. Refer to Assembling the Slide-out Tracks on

page 13 and Installing the Slide-out Track Assemblies on page 16 for more

information.

1. Install the MPEG generator into the equipment rack.

a. Working from the front of the equipment rack, slide out the inner track

of each slide-out track assembly until it extends from the front of the

rack. Continue to slide the inner tracks out from the rack until they lock

into place.

b. With the front of the MPEG generator facing away from the equipment

rack, insert the left and right rackmount tracks that extend from the

cabinet of the MPEG generator into the ends of the slide-out tracks you

just extended from the equipment rack. Make sure the rackmount tracks

on the MPEG generator slip inside the extended slide-out tracks.

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 21

Installation Instructions

c. Slide the MPEG generator back into the extended slide-out tracks until

the instrument stops.

d. Press in on the button latch located on both slide-out tracks (see Figure 6

on page 15), and then continue to slide the MPEG generator all the way

into the equipment rack.

2. Level the rackmounted MPEG generator.

a. With the MPEG generator all of the way back in the the rack, tighten the

two rear mounting screws on each slide-out track assembly that you

intentionally left loose when you performed step 3b on page 17. Tighten

the four 10-32 screws using 28 inch-lbs of torque.

b. Pull the MPEG generator part of the way out of the rack.

c. Be sure the front mounting screws on each slide-out track assembly are

loose enough to allow the slide-out track assemblies to seek their normal

positions when the MPEG generator ’s weight is resting on them. (These

screws were intentionally left loose when you performed step 3b on

page 17.)

d. Tighten the four front mounting screws on the slide-out tracks

(10-32 screws), and then push the MPEG generator all the way back into

the rack. If the instrument does not slide smoothly on the tracks, readjust

the level of the slide-out tracks using the method just detailed.

e. When you complete the leveling of the slide-out tracks (the instrument

slides smoothly in the tracks), tighten the four front mounting screws on

the slide-out tracks using 28 inch-lbs of torque.

3. Secure the MPEG generator in the rack.

a. Locate four 10-32 screws and four recessed washers. Insert each screw

through its recessed washer.

b. Use a #2 Pozidrive screwdriver to install two of the screw/washer

assemblies in the two mounting holes in the right front bracket of the

MPEG generator. Repeat for the left front bracket.

c. Tighten all four screws using 28 inch-lbs of torque.

d. Reinstall the power cord on the rear of the MPEG generator.

MTG100 and MTG300 Rackmount Upgrade Instructions

19

Page 22

Installation Instructions

20

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 23

Replaceable Mechanical Parts

This section contains a list of the replaceable components and accessories that

are used to adapt the MPEG generator for mounting in a standard 19-inch

(48.3 mm) rack. Use the parts list, as described below, to identify and order

replacement rackmounting hardware. Refer to the MTG100 and MTG300 MPEG

Generator Service Manual (Tektronix, Inc. part number 071-0616-50) for a

comoplete list of all replaceable mechanical parts for the MPEG generator.

Parts Ordering Information

Replacement parts are available from or through your local Tektronix, Inc.

service center or representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

circuit improvements. Therefore, when ordering parts, it is important to include

the following information in your order:

H Part number

H Instrument type or model number

H Instrument serial number

H Instrument modification number, if applicable

If a part you order has been replaced with a different or improved part, your local

Tektronix service center or representative will contact you concerning any

change in the part number.

MTG100 and MTG300 Rackmount Upgrade Instructions

21

Page 24

Replaceable Mechanical Parts

Using the Replaceable Parts List

The tabular information in the Replaceable Parts List is arranged for quick

retrieval. Understanding the structure and features of the list will help you find

the all the information you need for ordering replacement parts.

Item Names

Indentation System

In the Replaceable Parts List, an Item Name is separated from the description by

a colon (:). Because of space limitations, an Item Name may sometimes appear

as incomplete. For further Item Name identification, U.S. Federal Cataloging

Handbook H6-1 can be used where possible.

This parts list is indented to show the relationship between items. The following

example is of the indentation system used in the Description column:

12345 Name&Description

Assembly and/or Component

Attaching parts for Assembly and/or Component

(END ATTACHING PARTS)

Detail Part of Assembly and/or Component

Attaching parts for Detail Part

(END ATTACHING PARTS)

Parts of Detail Part

Attaching parts for Parts of Detail Part

(END ATTACHING PARTS)

Attaching parts always appear at the same indentation as the item it mounts,

while the detail parts are indented to the right. Indented items are part of, and

included with, the next higher indentation. Attaching parts must be purchased

separately, unless otherwise specified.

22

Abbreviations

Abbreviations conform to American National Standards Institute (ANSI)

standard Y1.1

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 25

Replaceable Mechanical Parts

Cross index -- mfr. code number to manufacturer

Mfr. code Manufacturer Address City, state, zip code

TK0435 LEWIS SCREW CO 4300 S RACINE AVE CHICAGO IL 60609 --3320

TK1163 POLYCAST INC 9898 SW TIGARD ST TIGARD OR 97223

TK1321 BERGFORD & ASSOCIATES 2705 WESTWIND DR NW OLYMPIA WA 98502

TK1465 BEAVERTON PARTS MFG CO 1800 NW 216TH AVE HILLSBORO OR 97124--6629

TK1719 NEDELCO BV (THOMAS & BETTS) POSTBUS 6431 3002 AK ROTTERDAM THE NETHERLANDS

0J9P9 GEROME MFG CO INC PO BOX 737

0KB01 STAUFFER SUPPLY 810 SE SHERMAN PORTLAND OR 97214

06383 PANDUIT CORP 17301 RIDGELAND TINLEY PARK IL 07094--2917

06666 GENERAL DEVICES CO INC 1410 S POST RD

28520 HEYCO MOLDED PRODUCTS 750 BOULEVARD

74868 AMPHENOL CORP

R F CONNECTORS (OPNS)

76814 NORTHERN ENGRAVING CORP 803 S BLACK RIVER ST SPARTA WI 54656 --2221

80009 TEKTRONIX INC 14150 SW KARL BRAUN DR

403 NORTH MAIN

PO BOX 39100

P O BOX 160

1 KENNEDY AVE DANBURY CT 06810--5803

PO BOX 500

NEWBERG OR 97132

INDIANAPOLIS IN 46239--9632

KENILWORTH NJ 07033--1721

BEAVERTON OR 97077--0001

MTG100 and MTG300 Rackmount Upgrade Instructions

23

Page 26

Replaceable Mechanical Parts

Replaceable parts list

Fig. &

index

number

9--1 351--0623--00 1 SLIDE,DWR,EXT:22.0X1.54,STEELSAFETY CONTROLLED 80009

--2 211--0945 --00 6 SCREW,MACHINE:M4X8MM L,STL,MFZN--C,CROSS REC 80009

--3 367--0520--00 2 HANDLE,BOW:100MM L,BLACK,BRASS 80009

--4 407--4760--01 2 BRACKET,ANGLE:SIDE,RACKMOUNT ,AL 80009

--5 212--A009--00 4 SCREW,MACHINE:M5X10MM L,FLH,STL,NI PL,CROSS REC 80009

--6 211--0945 --00 8 SCREW,MACHINE:M4X8MM L,STL,MFZN--C,CROSS REC 80009

--7 351--0104--03 1 SL SECT,DWR EXT:12.625 L,W/OHARDWARESAFETY

--8 390--1203--01 1 CABINET,ASSY:RACKMOUNT,AL 80009

--9 211--0785 --00 4 SCREW,MACHINE:M3X6MM L,FLH,STL,BLK ZN PL,CROSS

--10 211--0945--00 6 SCREW,MACHINE:M4X8MM L,STL,MFZN--C,CROSS REC 80009

--11 334 --1377 --50 1

Tektronix part

number

Serial no.

effective

Serial no.

discont’d

Qty Name & description

CONTROLLED

REC

MARKER,IDENT:MKD

Tektronix Japan, Ltd. Made in JA PAN

Mfr.

code

80009

80009

80009

Mfr. part number

ACCESSORY

061--A020--50 1 MANUAL,TECH: RACKMOUNTING INSTRUCTIONS 80009 061A02000

24

MTG100 and MTG300 Rackmount Upgrade Instructions

Page 27

Replaceable Mechanical Parts

1

6

8

7

2

5

4

3

9

3

10

11

7

6

5

1

2

4

Figure 9: Rackmount hardware exploded view

g End of document g

MTG100 and MTG300 Rackmount Upgrade Instructions

25

Page 28

Loading...

Loading...