Page 1

Tektronix DPO5204 Manual

Get Pricing & Availability at

ApexWaves.com

Call Today: 1-800-915-6216

Email: sales@apexwaves.com

https://www.apexwaves.com/oscilloscopes/tektronix-inc/dpo5000/DPO5204

Page 2

x

MSO70000/C Series Mixed Signal Oscilloscopes

DSA70000B/C Series Digital Signal Analyzers

DPO70000B/C Series Digital Phosphor Oscilloscopes

DPO7000 Series Digital Phosphor Oscilloscopes

MSO5000 and DPO5000 Series Oscilloscopes

ZZZ

User Manual

*P071279000*

071-2790-00

Page 3

Page 4

xx

MSO70000/C Series Mixed Signal Oscilloscopes

DSA70000B/C Series Digital Signal Analyzers

DPO70000B/C Series Digital Phosphor Oscilloscopes

DPO7000 Series Digital Phosphor Oscilloscopes

MSO5000 and DPO5000 Series Oscilloscopes

ZZZ

User Manual

This document supports firmware version 6.0

www.tektronix.com

071-2790-00

Page 5

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronixoritssubsidiariesor suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix,Inc.

FastFrame, OpenChoice, iCapture, Pinpoint, RT-Eye, MyScope, TekLink, TekVPI, TekSecure, Wave Inspector, MagniVu, and

MultiView Zoom are trademarks of Tektronix, Inc.

Contacting

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, O R 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

ducts are covered by U.S. and foreign patents, issued and pending. Informationinthispublication supersedes that in all

Tektronix

Page 6

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of

shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective

product without charge for parts and labor,orwill provide a replacement in exchange for the defective product. Parts, modules and

replacement products used by Tektronixfor warranty work may be new or reconditioned to like new performance. All replaced

parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty,CustomermustnotifyTektronixofthedefectbeforetheexpirationofthewarranty period

and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix,withshippingchargesprepaid. Tektronixshallpayforthereturnofthe

product to Customer if the shipment is to a location within the country in which the Tektronixservicecenterislocated. Customer shall

be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronixsupplies; or

d) to service a product that has been modified or integrated with other products when the effect of such modification or integration

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITYOR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIROR REPLACE DEFECTIVE PRODUCTS

IS THE SOLE A N D EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHE THER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

[W2 – 15AUG04]

Page 7

Page 8

Table of Contents

General Safety Summary ............................................................................................................. v

Compliance Information.............................................................................................................. vii

EMC Compliance................................................................................................................ vii

Safety Compliance ............................................................................................................... ix

Environmental Considerations................................................................................................... xi

Preface................................................................................................................................ xii

Key Features .................................................................................................................... xii

Documentation ................................................................................................................. xiv

Conventions Used in This Manual............................................................................................. xiv

Install YourInstrument................................................................................................................. 1

Standard Accessories............................................................................................................ 1

Operating Requirements.................................................................................................... ..... 2

PreventingESD .................................................................................................................. 5

Powering On the Instrument..................................................................................................... 5

Powering Off the Instrument..................................................................................................... 7

Removing the Power............................................................................................................. 7

Securing the Oscilloscope....................................................................................................... 8

Connecting to a Network......................................................................................................... 9

Adding a SecondMonitor....................................................................................................... 10

Operating System Restore...................................................................................................... 15

Installing the MSO5000 and DPO5000 Hard Drive............................................................................ 15

Getting Acquainted with YourInstrument............................................................................................ 16

Front Panel ......................................................................................................................16

Side and Rear Panels........................................... ................................................................ 17

Interface and Display ........................................................................................................... 21

Control Panel....................................................................................................................23

Accessing OnlineHelp.......................................................................................................... 25

Accessing Menus and Control Windows....................................................................................... 26

InspectYour Instrument .............................................................................................................. 28

VerifyInternal Diagnostics Pass................................................................................................ 28

isition............................................................................................................................ 29

Acqu

Signal Path Compensation ..................................................................................................... 29

Setting Up Analog Signal Input................................................................................................. 31

UsingDefaultSetup............................................................................................................. 33

UsingAutoset ................................................................................................................... 34

Probe Compensation, Calibration, and Deskew............................................................................... 35

AcquisitionConcepts............................................................................................................ 35

How the Acquisition Modes Work .............................................................................................. 38

Changing the Acquisition Mode ................................................................................................ 39

Starting and Stopping an Acquisition........................................................................................... 40

Selecting the HorizontalMode.................................................................................................. 40

UsingFastAcq................................................................................................................... 43

Table of Content

s

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual i

Page 9

Table of Content

Pinpoint Triggers...................................................................................................................... 67

Display a Waveform .................................................................................................................. 89

Analyzing Waveforms ..............................................................................................................113

s

Using DSP Enhanced Bandwidth ............................................................... ............................... 45

UsingRoll Mode................................................................................................................. 47

Setting Up Digital Signal Input.................................................................................................. 48

Setting Up Digital Channels .................................................................................................... 48

Setting Up a Bus ................................................................................................................ 50

When and Why to TurnOn MagniVu.............................. ................................. ............................ 56

Using MagniVu.................................................................................................................. 56

Viewing Analog Characteristics of Digital Wave

UsingFastFrame Mode......................................................................................................... 59

Using FastFrame Frame Finder................................................................................................ 61

Using TekLink and MultiScope Trigger......................................................................................... 63

TriggeringConcepts............................................................................................................. 67

Choosing a TriggerType........................................................................................................ 69

TriggerSelections...............................................................................................................71

Checking TriggerStatus ........................................................................................................ 73

Using A (Main) and B (Delayed) Triggers...................................................................................... 74

Triggeringwith B-EventScan................................................................................................... 77

Triggeringon a Parallel Bus .................................................................................................... 80

Triggeringon a Serial Bus ...................................................................................................... 83

Sending E-Mail on Trigger...................................................................................................... 85

Setting Up E-Mail on Event..................................................................................................... 86

UsingHorizontalDelay.......................................................................................................... 87

Setting the Display Style........................................................................................................ 89

Setting the Display Persistence ................................................................................................ 90

Setting the Display Format...................................................................................................... 91

Selecting the Waveform Interpolation.......................................................................................... 92

Adding Screen Text ............................................................................................................. 93

Setting the GraticuleStyle ...................................................................................................... 94

Setting the TriggerLevel Marker ............................................................................................... 95

Displayingthe DateandTime .................................................................................................. 95

UsingtheColor Palettes ........................................................................................................ 96

Setting Reference Waveform Colors ........................................................................................... 97

Setting MathWaveformColors................................................................................................. 97

UsingMultiViewZoom.......................................................................................................... 97

Zooming in Multiple Areas...................................................................................................... 99

Lock andScrollZoomedWaveforms......................................................................................... 101

Hide Waveformsin the Zoomed Window ................ .................................................................... 102

Using WaveInspector to Manage Long Record Length Waveforms........................................................ 103

Searching and Marking Waveforms.......................................................................................... 105

Taking Automatic Measurements............................................................................................. 113

AutomatedMeasurement Selections......................................................................................... 115

Customizing an AutomaticMeasurement.................................................................................... 118

forms......................................................................... 57

ii MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual

Page 10

Table of Content

Taking Cursor Measurements ................................................................................................ 121

Setting Up a Histogram ....................................................................................................... 123

UsingMath Waveforms ....................................................................................................... 125

Using Spectral Analysis.......................... ................................................... .......................... 128

UsingMask Testing ........................................................................................................... 131

UsingLimit Testing............................................................................................................ 135

MyScope

Saving and Recalling Information.................................................................................................. 143

Run ApplicationSoftware .......................................................................................................... 157

Application Examples............................................................................................................... 159

Appendix............................................................................................................................ 169

Appendix............................................................................................................................ 170

Appendix............................................................................................................................ 171

............................................................................................................................ 137

Creating a New MyScope Control Window .................................................................................. 137

Using MyScope Control Windows............................................................................................ 141

Saving Screen Captures...................................................................................................... 143

Saving Waveforms ............................................................................................................ 144

Recalling Waveforms ......................................................................................................... 146

Saving Digital Waveforms .................................................................................................... 147

Saving Instrument Setups.................................................................................................... 148

Recalling Instrument Setups.................................................................................................. 149

Saving Measurements ........................................................................................................ 150

Saving User Masks........................................................................................................... 151

Saving Histogram Data ....................................................................................................... 152

Saving Timestamps ........................................................................................................... 153

Copying Your Results to the Clipboard....................................................................................... 154

Printinga Hard Copy.......................................................................................................... 155

Capturing Intermittent Anomalies............................................................................................. 159

Using the Extended Desktop and OpenChoice Architecture for EfficientDocumentation ................................. 163

Triggeringon Buses........................................................................................................... 165

Triggeringon a Video Signal.................................................................................................. 166

Correlating Data Between a Tektronix Oscilloscope and Logic Analyzer................................................... 168

Cleaning....................................................................................................................... 169

Obtaining the Latest Oscilloscope Application andVersionReleases...................................................... 170

TPP0500 and TPP1000 500 MHz and 1 GHz 10X Passive Probes Instructions........................................... 171

Operating Information......................................................................................................... 171

Connecting the Probe to the Oscilloscope................................................................................... 171

Compensating the Probe ..................................................................................................... 172

Standard Accessories......................................................................................................... 172

Optional Accessories ......................................................................................................... 174

Replacing the Probe Tip...................................................................................................... 174

Specifications.................................................................................................................. 174

Performance Graphs.......................................................................................................... 175

Safety Summary .............................................................................................................. 176

s

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual iii

Page 11

Table of Content

Appendix............................................................................................................................ 178

Index

s

P6616 General-

Product Description ........................................................................................................... 178

Connecting the Probe to the Oscilloscope................................................................................... 179

Connecting th

Functional Check.............................................................................................................. 180

TypicalApplication ............................................................................................................ 181

Accessories

Specifications.................................................................................................................. 182

Safety Summary .............................................................................................................. 183

Safety Term

ContactingTektronix .......................................................................................................... 184

Warranty Information.......................................................................................................... 184

Purpose Logic Probe Instructions .......................................................................... 178

e Probe to Your Circuit ........................................................................................ 180

................................................................................................................... 181

s andSymbols in ThisManual................................................................................... 183

iv MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual

Page 12

General Safety S

ummary

General Safet

Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other

component manuals for warnings and cautions related to operating the system.

To Avoid Fire or Personal Injury

Use proper power cord. Use only the power cord specified for this product and certified for the country of use.

Connect and disconnect properly. Do not connect or disconnect probes or test leads while they are connected

to a voltag

Ground th

shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe all terminal ratings. Toavoid fire or shock hazard, observe all ratings and markings on the product. Consult the

product

Connect

e source.

e product.

manual for further ratings information before making connections to the product.

the probe reference lead to earth ground only.

y Summary

This product is grounded through the grounding conductor of the power cord. To avoid electric

Power di

must remain accessible to the user at all times.

sconnect.

The power cord disconnects the product from the power source. Donot block the power cord; it

Do not operate without covers. Do not operate this product with covers or panels removed.

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by

qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation.

per ventilation.

pro

Refer to the manual’s installation instructions for details on installing the product so it has

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual v

Page 13

General Safety S

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and Terms on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

ummary

vi MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual

Page 14

Compliance Info

rmation

Compliance In

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument

complies.

EMC Compliance

EC Declaration of Conformity – EMC

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility. Com

specifications as listed in the Official Journal of the European Communities:

EN 61326-1:2006, EN 61326-2-1:2006. EMC requirements for electrical equipment for measurement, control, and

laboratory use.

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient/burst immunity

IEC 61000-4-5:2001. Power line surge immunity

IEC 61000-4-6:2003. Conducted RF immunity

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

123

formation

pliance was demonstrated to the following

4

4

5

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European contact.

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic interference.

2

Emissions which exceed the levels required by t his standard may occur when this equipment is connected to a test object.

3

If interconnect cables are used, they must be low–EMI shielded cables such as t he following Tektronix part numbers or their

equivalents: 012-0991-01, 012-0991-02 or 0 12-0991-03 GPIB Cable; 012-1213-00 (or CA part number 0294-9) RS-232 Cable;

012-1214–00 Centronics Cable; or LCOM part number CTL3VGAMM-5 VGA Cable. Use an 012-0482-00 cable for the Ref O ut connector.

4

The performance criterion for when the oscilloscope is subjected to the continuously present electromagnetic phenomenon:

MSO70000/C, DSA70000/C, DPO70000/C, and DPO7000: 1 0 mV/division to 1 V/division: ≤0.4 division waveform displacement

or ≤0.8 division increase in peak–to–peak noise. Performa

electromagnetic phenomenon: Temporary, self–recoverable degradation or loss of performance is allowed, but no change of actual

operating state or loss of stored data is allowed.

MSO5000 and DPO5000: ≤4.0 division waveform displacement or ≤8.0 division increase in peak–to–peak noise. Performance

criterion for when the oscilloscope is subjected t o transient electromagnetic phenomenon: Temporary, self–recoverable degradation

or loss of perform ance is allowed, but no change of actual operating state or loss of stored data is allowed.

5

Performance Criterion C applied at the 70%/25 cycle Voltage-Dip and the 0%/250 cycle Voltage-Interruption test levels (IEC

61000-4-11). If the instrument powers down upon a voltage dip or interruption it will take longer than ten seconds to reboot.

nce criterion for when the oscilloscope is subjected to transient

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual vii

Page 15

Compliance Info

Australia / New Zealand Declaration of Conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per the following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in accordance with EN 61326-1:2006 and

EN 61326-2-1:2006.

Australia / New Zealand contact.

Baker & McKenzie

Level 27, AMP Centre

50 Bridge St

Sydney NSW 2000, Australia

rmation

reet

viii MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual

Page 16

Safety Compliance

EC Declaration of Conformity – Low Voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Communities:

Low Voltage Directive 2006/95/EC.

EN 61010-1: 2001. Safety requirements for electrical equipment for measurement control and laboratory use.

Compliance Info

rmation

U.S. Nation

UL 61010-1:2004, 2ndEdition. Standard for electrical measuring and test equipment.

ally Recognized Testing Laboratory Listing

Canadian Certification

CAN/CSAlaboratory use. Part 1.

C22.2 No. 61010-1:2004. Safety requirements for electrical equipment for measurement, control, and

Additional Compliances

IEC 61010-1: 2001. Safety requirements for electrical equipment for m easurem ent, control, and laboratory use.

Equipment Type

Test and measuring equipment.

y Class

Safet

Class 1 – grounded product.

Pollution Degree Description

asure of the contaminants that could occur in the environment around and within a product. Typically the internal

Ame

environment inside a product is considered to be the same as the external. Products should be used only in the environment

for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Productsin this category are generally

capsulated, hermetically sealed, or located in clean rooms.

en

llution Degree 2. Normally only dry,nonconductive pollution occurs. Occasionally a temporary conductivity that is

Po

caused by condensation must be expected. This location is a typical office/home environment. Temporarycondensation

occurs only w hen the product is out of service.

Pollution Degree 3. Conductive pollution, or dry,nonconductive pollution that becomes conductive due to condensation.

hese are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct

T

sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical

outdoor locations.

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual ix

Page 17

Compliance Info

Pollution Degree

Pollution Degree 2 (as defined in IEC 61010-1). Note: Ratedfor indoor use only.

Installation (Overvoltage) Category Descriptions

Terminals on this product may have differentinstallation (overvoltage) category designations. The installation categories are:

Measurement Category IV. For measurements performed at the source of low-voltage installation.

Measurement Category III. For measurements performed in the building installation.

Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

Measurement Category I. For measurements performed on circuits not directly connected to MAINS.

rmation

Overvolta

Mains: Overvoltage Category II

Measurement inputs:

MSO5000, DPO5000, and DPO7000 instruments in 50 Ohm mode and MSO70000/C, DSA70000B/C, and DPO70000B /C

instruments are CAT 1 with no impulse allowed.

DPO7000 instruments are CAT 1 in 1 Meg-Ohm mode.

MSO5000 and DPO5000 instruments are CAT II in 1 Meg-Ohm mode.

(As defined in IEC 61010-1)

ge Category

x MSO70000/C,DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User M anual

Page 18

Environmental Considerations

This section provides information about the environmental impact of the product.

Product End-of-Life Handling

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Productionof this equipment required the extraction and use of natural resources. The equipment

may contain substances that could be harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to reduce the use of natural resources, we

encourage you to recycle this product in an appropriate system that will ensure that most of the materials are reused

or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according

to Directives 2002/96/EC and 2006/66/EC on waste electrical and electronic equipment (WEEE) and

batteries. For information about recycling options, check the Support/Service section of the Tektronix Web

site (www.tektronix.com).

Compliance Info

rmation

Mercury n

to environmental considerations. Please contact your local authorities or, within the United States, refer to the E-cycling

Central Web page (www.eiae.org) for disposal or recycling information.

1

otification1.

This notification does not apply to MSO5000 and DPO5000 instruments. MSO5000 and DPO5000 instruments use an LED backlight

that does not contain mercury.

This product uses an LCD backlight lamp that contains mercury. Disposal may be regulated due

Perchlorate materials. This product contains one or more type CR lithium batteries. According to the state

of California, CR lithium batteries are classified as perchlorate materials and require special handling. See

www.dtsc.ca.gov/hazardouswaste/perchloratefor additional information.

Restriction of Hazardous Substances

roduct is classified as Monitoring and C ontrol equipment, and is outside the s cope of the 2002/95/EC RoHS Directive.

This p

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual xi

Page 19

Preface

Preface

This manual describes the installation and operation of MSO70000B/C Series, DSA70000B/C Series, DPO70000B/C Series,

DPO7000 Series, MSO5000 Series, and DPO5000 Series instruments. Basic operations and concepts are presented in this

manual. For more detailed information see the online help on your instrument. The following instruments are supported by

this manual:

DPO72004C, DSA72004C and MSO72004C

DPO71604C, DSA71604C and MSO71604C

DPO71254C, DSA71254C and MSO71254C

DPO70804B, DSA70804B and MSO70804

DPO70604B, DSA70604B and MSO70604

DPO70404B, DSA70404B and MSO70404

DPO7354

DPO7254

DPO7104

DPO7054

MSO5204 and DPO5204

MSO5104 and DPO5104

MSO5054 and DPO5054

MSO5034 and DPO5034

Key Features

MSO70000/C, DSA70000B/C, DPO70000B/C, DPO7000, MSO5000, and DPO5000 Series instruments can help you verify,

debug, and characterize electronic designs. Key features include:

20 GHz bandwidth and 100 GS/s real time sampling rate on 2 analog channels, MSO72004C, DSA72004C, and

DPO72004C

16 GHz bandwidth and 100 GS/s real time sampling rate on 2 analog channels, MSO71604C, DSA71604C, and

DPO71604C

12.5 GHz bandwidth and 100 GS/s real time sampling r ate on 2 analog channels, MSO71254C, DSA71254C, and

DPO71254C

8 GHz bandwidth and 25 GS/s real time sampling rate on analog channels, DPO70804B, DSA70804B, and MSO70804

6 GHz bandwidth and 25 GS/s real time sampling rate on analog channels, DPO70604B, DSA70604B, and MSO70604

4 GHz bandwidth and 25 GS/s real time sampling rate on analog channels, DPO70404B, DSA70404B, and MSO70404

3.5 GHz bandwidth and 10 GS/s real time sampling rate on all channels, 40 GS/s on 1 channel, DPO7354

2.5 GHz bandwidth and 10 GS/s real time sampling rate on all channels, 40 GS/s on 1 channel, DPO7254

xii MSO70000/C,DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User M anual

Page 20

Preface

1 GHz bandwidth and 5 GS/s (10 GS/s optional) real time sampling rate on all channels, 20 GS/s (40 GS/s optional)

on 1 channel, DP

500 MHz bandwidth and 5 GS/s real time sampling r ate on all channels, 20 GS/s on 1 channel, DP O7054

2 GHz bandwidth and 10 GS/s real time sampling rate on 2 analog channels, MSO5204 and DPO5204

1 GHz bandwidth and 10 GS/s real time sampling rate on 2 analog channels, MSO5104 and DPO5104

500 MHz bandwidth and 5 GS/s real time sampling rate on all analog channels, MSO5054 and DPO5054

350 MHz bandwidth and 5 GS/s real time sampling rate on all analog channels, MSO5034 and DPO5034

Enhanced Bandwidth capability that, when enabled, applies Digital Signal Processing (DSP) filters that can extend the

bandwidth and flatten the passband. Enhanced Bandwidth provides a matched response across enabled channels when

they are at maximum sample rate. Youcan limit the bandwidth down to 500 MHz to optimize the signal to noise ratio.

Enhanced bandwidth is extended to the probe tip for some high performance probes and tips.

Record lengths up to 500,000,000 samples, depending on model and option

Up to 1.0% DC vertical gain accuracy, depending on model

Four analog input channels (each with 8-bit resolution when not in Hi-Res mode), auxiliary trigger input and output

Sixteen digital channels available on MSO70000/C and MSO5000 Series instruments with an additional clock channel

available on the MSO70000/C

O7104

iCapture allows analyzing the analog characteristics of the digital channels on MS O70000/C Series instruments

Sample, envelope, peak-detect, high-resolution, waveform database, average, and FastAcq acquisition modes

Full programmability,with an extensive GPIB-command set and a message-based interface

PinPoint triggering with flexible A and B tr

DSA70000B/C, DPO70000B/C, and DPO7000/C

Complete set of triggers available on MSO5000 and DPO5000 Series instruments

Selectable trigger position correction to more accurately place the trigger and reduce jitter.

Serial triggering on industry standards, serial pattern triggering, and pattern lock triggering are available on some

models or options.

Parallel trigger available on MSO70000/C and MSO5000 Series instruments.

Powerful built-in measurement capability, including histograms, automatic measurements, eye pattern measurements

and measurement statistics

Mathematically combine waveforms to create waveforms that support your data-analysis task. Use arbitrary filters in

math equations. Use spectral analysis to analyze waveforms in the frequency domain.

A large 12.1 inch (307.3 mm) [10.4 inch (264 mm) MSO5000 and DPO5000] high resolution XGA color display that

supports color grading of waveform data to show sampl

Wave Inspector controls for managing long record length, with zoom and pan, play and pause, and search and mark

available on MSO5000 and DPO5000

igger events and logic qualified triggers available on MSO70000/C,

e density. Display 10 divisions both horizontally and vertically.

MagniVu 60.6 ps resolution, high-speed digital sampling rate on M SO5000

MultiView Zoom to view and compare up to four zoom areas at a time. Lock and manually or automatically scroll up to

four zoom areas. You can control the visibility of waveforms inside the zoom window

Automatically search and mark events of interest on your waveform

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual xiii

Page 21

Preface

Automatic DDR analysis using the DDR Memory Technology Analysis option

Customizable MyScope control windows

Ability to control sample rate and record length separately from horizontal scale

An intuitive, graphical user interface (UI), with online help that is built in and available on screen

Internal, removable disk storage

Wide array of probing solutions

Documentat

Review the following for the location of different types of information available for this product.

To read about Use these documents

Installation and Operation (overviews) User Manual. Provides general operating information.

In-Depth Operation and User Interface Help Online Help. Provides detailed instructions for using instrument functions.

Programmer Commands Programmer guide (on the documentation browser or available on-line at

Service Information Service manual (on the documentation browser or available on-line at

ion

Conventions Used in This Manual

The following icons are used throughout this manual.

panel

Sequence

Step

Front

power

Connect

power

Access online help from the Help button or Help menu for information on

controls and elements on screen. (See page 25, Accessing Online Help.)

www.tektronix.com/manuals). Includes the syntax of the GPIB commands.

www.tektronix.com/manuals).

rk

Netwo

PS-2 SVGA USB

xiv MSO70000/C,DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual

Page 22

Install Your Instrument

Unpack the instrument and check that you received all items listed as Standard Accessories. Recommendedaccessories,

probes, instrument options, and upgrades are listed in the online help. Checkthe TektronixWeb site (www.tektronix.com)

for the most current information.

Standard Accessories

Accessory Tektronix part number

MSO70000/C, DSA70000B/C, DPO70000B/C, DPO7000, MSO5000, and

DPO5000 Series Digital Phosphor Oscilloscopes User Manual

Product Software DVD, MSO70000/C, DSA70000B/C, DPO70000B/C, and

DPO7000 series

Operating System Restore D VD, MSO70000/C, DSA70000B/C,

DPO70000B/C, and DPO7000 Series

Online Help (part of the product software)

Performance Verification (on the documentation browser)

Programmer Online Guide (on the documentation browser)

NIST, Z540-1, and ISO9000 Calibration Certificate

One TekConnectadapter, ≥4 GHz models only TCA-BNC

Four TekConnect adapters, ≥4 GHz models only TCA-292MM

One 16-channel digital probe with accessory kit, MSO5000 models only

One passive probe per channel, MSO5204, MSO5104, DPO5204, and

DPO5104

One passive probe per channel, MSO5054, MSO5034, DPO5054, and

DPO5034

Touchscreen stylus, MSO5000 and DPO5000

NI SignalExpress software, MSO5000 and DPO5000

Keyboard, ≥4 GHz models only

Mouse, optical 119-7054-xx

Front Cover, MSO5000 and DPO5000

All other models

Wrist Strap, ≥4 GHz models only

Accessory Pouch

≥4GHzmodels

DPO7000 models

MSO5000 and DPO 5000 models

Nero OEM Software CD, ≥4 GHz and DPO7000 models

071-2790-xx

020-3026-xx

020-3019-xx

—

077-0063-xx

077-0010-xx

—

P6616

TPP1000

TPP0500

119-6107-xx

063-3967-xx

119-7083-xx

200-5052-xx

200-4963-xx

006-3415-05

016-1441-xx

016-1966-xx

016-2029-xx

063-3781-xx

Install Your Ins

trument

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 1

Page 23

Install Your Ins

Accessory Tektronix part number

Power Cord

trument

One of the following: MSO5000

and DPO5000

models

North America (Option A0)

Universal Euro (Option A1)

United Kingdom (Option A2)

Australia (Option A3)

North America 240 V (Option A4)

Switzerland (Option A5)

Japan (Option A6)

Option A10)

China (

(Option A11)

India

l (Option A12)

Brazi

wer cord or AC adapter (Option A99)

No po

161-0348-00 161-0104-00 161-0213-00

161-0343-00 161-0104-06 161-0209-00

161-0344-0

161-0346-0

—

161-0347-

161-0342

161-0341-00 161-0306-00 161-0352-00

161-0349-00 161-0324-00 161-0325-00

161-xxxx-00 161-0356-00 161-0358-00

———

00

-00

0

0

DPO7000

models

161-0104-0

161-0104-1

161-0104161-0167161-A005

08

00

-00

7

4

≥4GHz

models

161-0210-0

161-0211-0

—

161-0212161-0213

Notice: Do

not use the

provide

power cord

for other

product

-00

d

s.

0

1

00

Operating Requirements

MSO70000/C, DSA70000B/C, DPO70000B/C, and DPO7000

1. Place the instrument on a cart or bench.

The instrument should rest on its bottom

or rear feet. An optional rack mounting

kit is available. Observe the following

clearance requirements and dimensions:

Top:

Left and right side: 0 in (0 mm) on right side

Bottom:

Rear:

<4 GHz Models ≥4 GHz Models

0in(0mm) 0in(0mm)

3in(76mm)

3 in (76 mm) on left side

0 in (0 mm) standing on feet, flip

stands down

0 in (0 mm) on rear feet 0 in (0 mm) on rear feet

0 in (0 mm) standing on feet, flip

stands down

2 MSO70000/C, DPO/DSA70000B /C, D PO7000, and MSO /DP O5000 Series User Manual

Page 24

Install Your Ins

trument

2. Width:

3. Height:

4. Before opera

ting the instrument, verify

17.96 inches (

10.9 inches (2

5°Cto+45°C(

456 mm)

77 mm)

+41°Fto+113°F)

the ambient temperature:

5. Verify the operating humidity: 8% to 80% relative humidity with

a maximum wet-bulb temperature

of +29 °C (+8

4 °F) at or below

+45 °C (+113°F), noncondensing

Upper limit derated to 30% relative

t +45 °C (+113°F)

els: 3,000 m

6. Verify th

e operating altitude:

humidity a

<4 GHz mod

(9,843 feet)

7. Maximum input voltage, <4 GHz models:

5V

50 Ω

1MΩ

, with peaks ≤±24 V.

RMS

150 V,derate at 2 0 dB/decade to 9 V

oltage at the BNC, between center conductor and ground is

input v

400V peak. The RMS voltage is limited to <150 V for arbitrary waveshapes

including DC. The maximum pulse width for impulses with peaks over

s50μs. Example: At 0 V to 400 V peak, rectangular wave, the duty

150Vi

factor is 14%. The maximum transient withstand voltage is ±800 V peak.

17.75 inches (

11.48inches (

5°Cto+45°C(

451 mm)

292 mm)

+41°Fto+113°F)

8% to 80% relative humidity at up

to+32°C(+90°F)

5% to 45% rel

ative humidity above

+32 °C (+90 °F) up to +45 °C

(+113 °F), noncondensing, and

is limited

by a maximum wet-bulb

temperature of +29.4 °C (+85 °F)

(derates relative humidity to 32%

at +45 °C (

≥4GHzmod

+113°F))

els: 3,000 m

(9,843 feet), derate maximum

operating temperature by 1 °C

per 300 m

eters (984.25 feet)

above 1500 meters (4921.25 feet)

altitude.

above 200 kHz. Themaximum

RMS

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 3

Page 25

Install Your Ins

trument

Maximum input

50 Ω <1 V

Maximum nondestructive input voltage to

logic probes

voltage, ≥4 GHz models:

, MSO70000 Series:

±15 V

RMS

/FS settings and < 5.5 V

for <1 V

for ≥1 V/FS settings.

RMS

CAUTION. For proper cooling, keep the bottom and sides of the instrument clear of obstructions.

MSO5000 and DPO5000

1. Place the instrument on a cart or bench.

The instrument should rest on its bottom

or rear feet. An optional rack mounting

kit is available. Observe the following

clearance requirements and dimensions:

Rear:

Left side: 2 in (50.8 mm)

2. Width:

3. Height:

4. Before operating the instrument, verify

the ambient temperature:

5. Verify the operating humidity: High: 40 °C to 50 °C (104 °F to 122 °F), 10% to 60% relative humidity

6. Verify the

operating altitude:

7. Maximum input voltage:

50 Ω input impedance

1MΩ input

Maximum

impedance

nondestructive input voltage to

logic probes:

2in(50.8mm)

17.3 inches (4

9.2 inches (2

39 mm)

33 mm) including feet

10.7 inches (272 mm) including vertical handle and feet

5°Cto+50°C(+41°Fto+131°F)

Low: 0 °C to 4

3,000 m (9,

5V

RMS

300 V

RMS

0 °C (32 °F to 104 °F), 10% to 90% relative humidity

843 feet)

, with peaks ≤±20 V (DF ≤6.25%).

ith peaks ≤±425 V at the BNC.

w

For <100 mV/div derate at 20 dB/decade above 100 kHz to 30 V

1 MHz, 10 dB/decade above 1 MHz.

For ≥100

mV/div derate at 20 dB/decade above 3 MHz to 30 V

30 MHz, 10 dB/decade above 30 MHz.

±42 V

RMS

RMS

at

at

CAUTIO

N. For proper cooling, keep the back and left side of the instrument clear of obstructions.

4 MSO70000/C, DPO/DSA70000B /C, D PO7000, and MSO /DP O5000 Series User Manual

Page 26

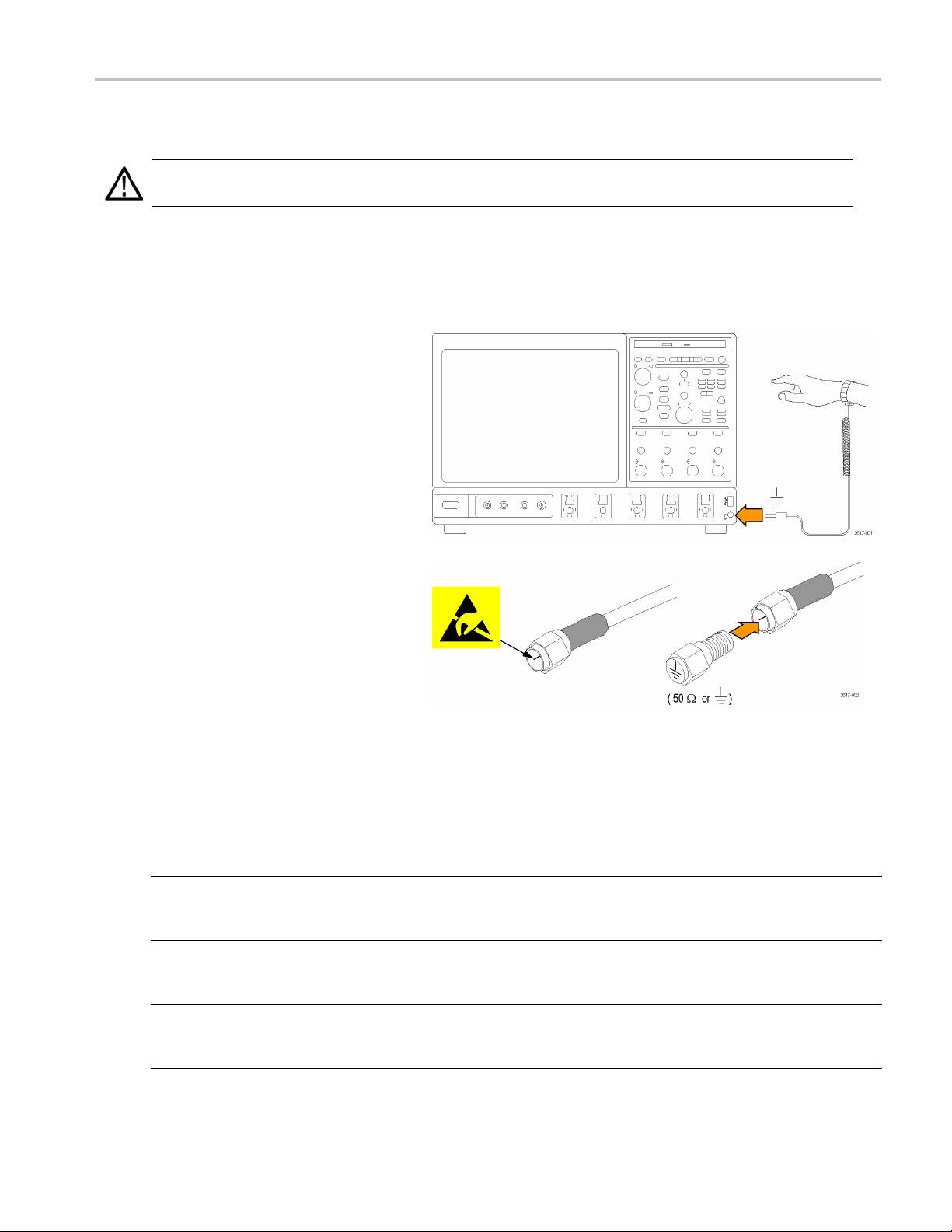

Preventing ESD

Install Your Ins

trument

CAUTION. Adir

ect electrostatic discharge can damage the instrument input. To learn how to avoid this damage, read

the following information.

Electrostatic discharge (ESD) is a concern when handling any electronic equipment. The instrument is designed with

robust ESD protectio

n, however it is still possible that large discharges of static electricity directly into the signal input

may damage the instrument. To avoid damage to the instrument, use the following techniques to prevent electrostatic

discharge to the instrument.

1. Discharge the static voltage from your

body by wearing a grounded antistatic

wrist strap while connecting and

disconnecting cables and TekConnect

adapters. The instrument provides a

front panel connection for this purpose.

2. A cable that is left unconnected on

a bench can develop a large static

charge. Discharge the static voltage

from all cables before connecting them

to the instrument or device under test

by momentarily grounding the center

conductor of the cable, or by connecting

a50Ω termination to one end, before

attaching the cable to the instrument.

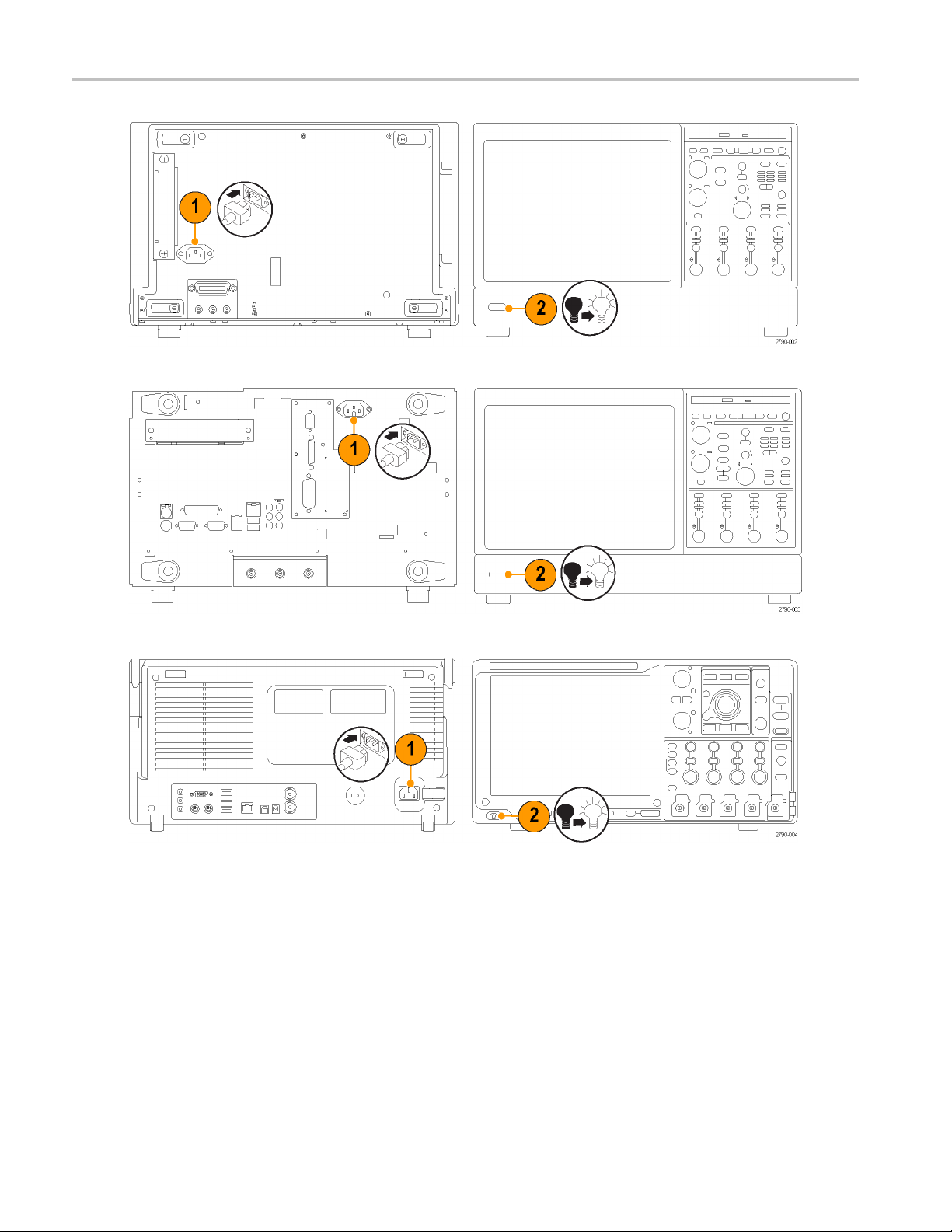

Powering On the Instrument

Power supply requirements

Source voltage and frequency Power consumption

MSO70000/C, DSA70000B/C, and DPO70000B/C Series:

100–240 V

or 115 V

±10%, 50–60 Hz

RMS

±10%, 400 Hz. CAT II

RMS

DPO7000 Series:

100–240 V

or 115 V

±10%, 47–63 Hz

RMS

±10%, 400 Hz

RMS

MSO5000 and DPO5000 Series:

100–240 V

±10% 50–60 Hz

RMS

115V440Hz

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 5

≤1100 VA

550 Watts maximum

275 Watts maximum

Page 27

Install Your Ins

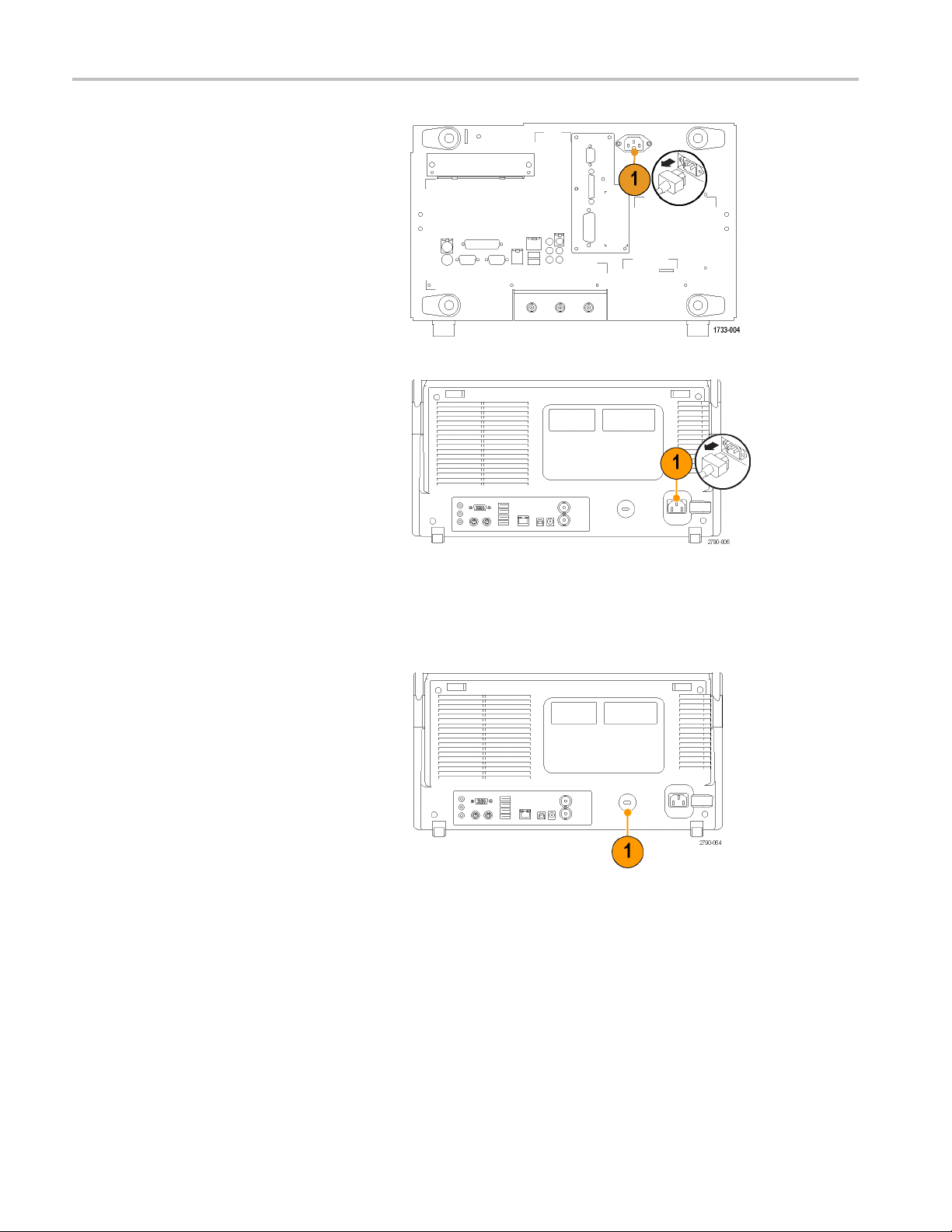

DPO7000 Series

trument

MSO70000/C, DSA70000B/C, and D PO70000B/C Series

MSO5000 and DPO5000 Series

6 MSO70000/C, DPO/DSA70000B /C, D PO7000, and MSO /DP O5000 Series User Manual

Page 28

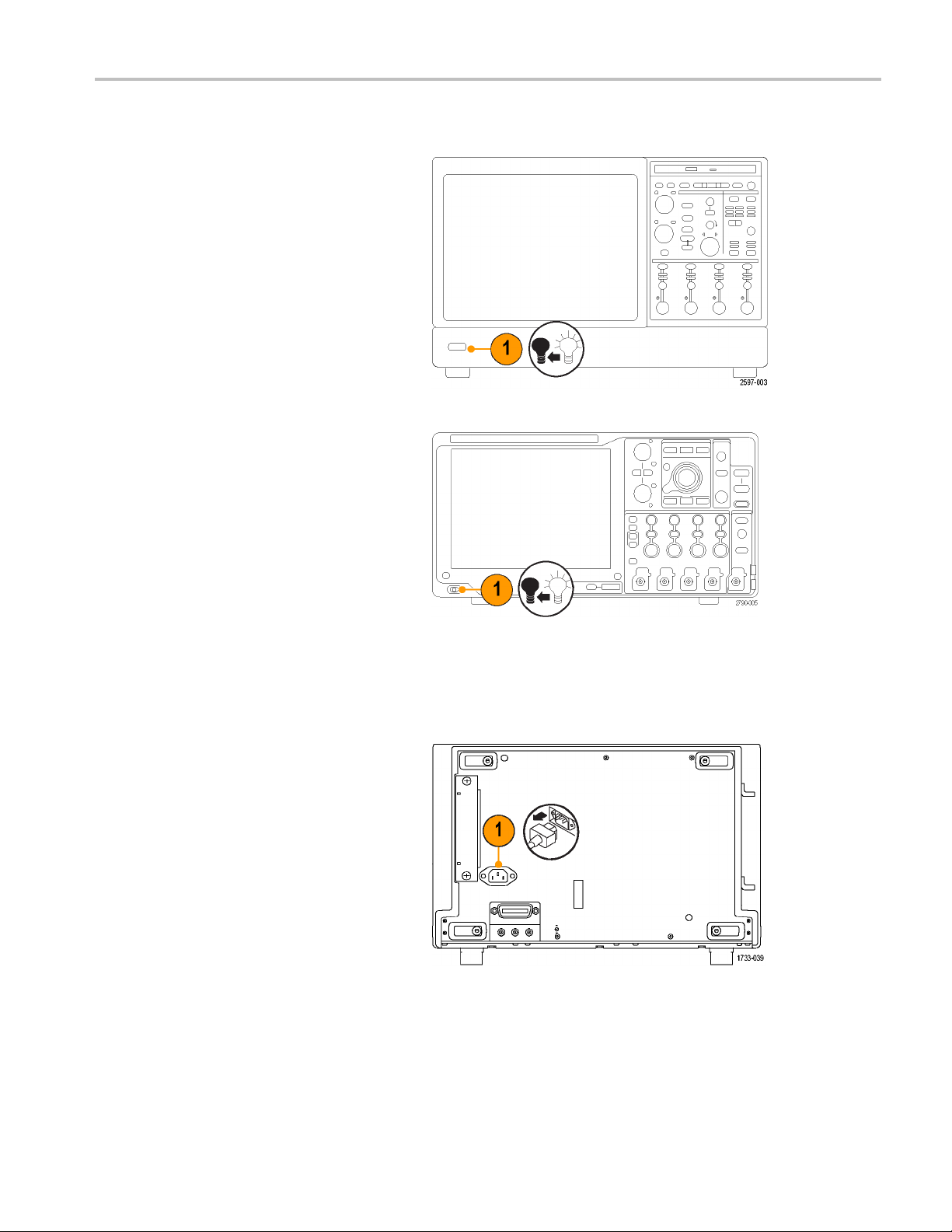

Powering Off the Instrument

Install Your Ins

MSO70000/C, DSA70000B/C, DPO70000B/C, and DPO7000 Series

trument

Removing the Power

MSO5000 and DPO5000 Series

DPO7000 Series

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 7

Page 29

Install Your Ins

trument

Securing the Oscilloscope

1. Use a standard laptop computer-style

security lock to secure your oscilloscope

to your location.

MSO70000C,

MSO5000 and DPO5000 Series

DSA70000B/C, and DPO70000B/C Series

MSO5000 and DPO5000 Series

8 MSO70000/C, DPO/DSA70000B /C, D PO7000, and MSO /DP O5000 Series User Manual

Page 30

Connecting to a Network

Install Your Ins

trument

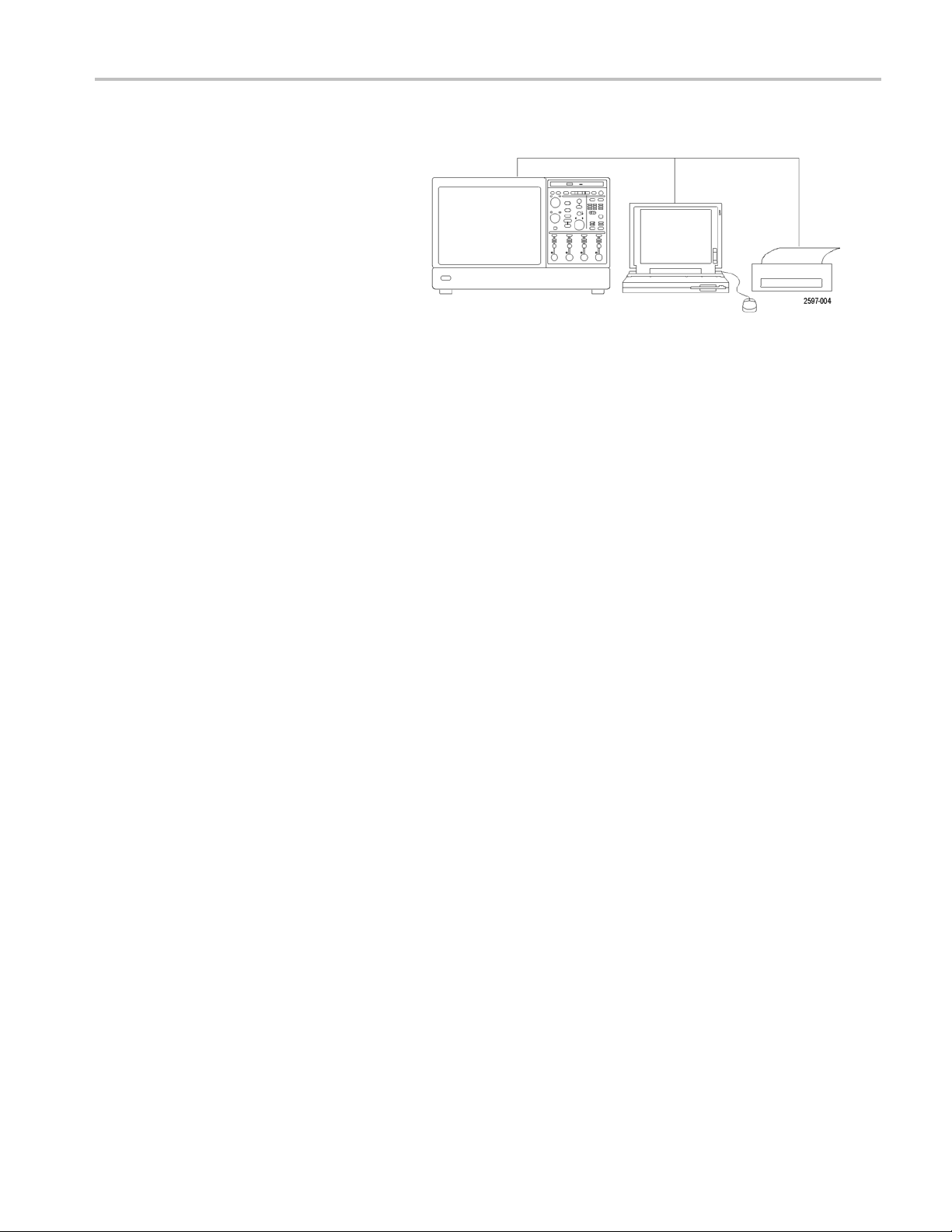

Connect your i

printing, file sharing, internet access, and

other functions. Consult with your network

administrato

utilities to configure the instrument for your

network.

Use the Remot

Windows to control and view the instrument

remotely.

nstrument to a network for

r and use the standard W indows

e Desktop Connection of

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 9

Page 31

Install Your Ins

trument

Adding a Second Monitor

You can operate the instrument while using Windows and installed applications on an external monitor. Follow the procedure

below to set up a dual monitor configuration.

MSO70000/C, DSA70000C, and DPO70000C Series

1. Turn power off.

2. Connect second monitor. If using a VGA

monitor,use a DVI to VGA adapter.

3. Connect keyboard.

4. Connect mouse.

5. Turn instrument power on.

6. Turn monitor power on.

MSO70000/C, DSA70000C, and DPO70000C Series

10 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 32

DSA70000B and DPO70000B Models

1. Turn power off.

2. Connect second monitor.

3. Connect keyboard.

4. Connect m ouse.

5. Turn instrument power on.

6. Turn monitor power on.

Install Your Ins

trument

DSA70000B and DPO70000B Series

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 11

Page 33

Install Your Ins

DPO7000 Models

trument

1. Turn off power

2. Connect secon

3. Connect key

4. Connect mou

5. Turn on in

6. Turn on mo

board.

strument power.

nitor power.

.

d monitor.

se.

DPO7000 Series

12 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 34

MSO5000 and DPO5000 Models

1. Turn off power.

2. Connect second monitor.

3. Connect keyboard.

4. Connect m ouse.

5. Turn on instrument power.

6. Turn on monitor power.

Install Your Ins

trument

MSO5000 and DPO5000 models

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 13

Page 35

Install Your Ins

If your instrument uses Windows XP,

continue with the following steps:

7. Right-click on the Windows desktop, and

trument

then select Pr

operties.

8. Select Sett

ings. Click the grayed out

external monitor ( 2 ), and drag it to the

left of monitor 1.

9. Select Yes when you are prompted to

enable the

10. Click Appl

new monitor.

y.

11. Click Yes to restart your instrument.

14 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 36

Operating System Restore

If your instrument shipped with an operating system restore DVD and you need to restore the operating system, you can

use the procedure that came with the DVD.

The instrument contains an operating system restore file on a separate partition of the hard drive.

The preferred method to restore the instrument operating system is to use the hard d isk restore file.

CAUTION. Using the restore process reformats the hard drive and reinstalls the operating system. All saved data is lost. If

possible, save important files to external media before performing a system restore.

1. Restart the instrument. During the boot-up process you will see the following message at the top of the s creen: Starting

Acronis Loader... press F5 for Acronis S tartup Recovery Manager

2. Repeatedly press the F5 k ey until the Acronis True Image Toolopens. There is a 15-second time period from when the

message appears until the instrument proceeds with the nor mal instrument startup. Ifthe instrument does not open the

Acronis application, power off the instrument, then power on the instrument and try again.

3. Click R estore.

4. In the Confirmation dialog box, click Yes to restore the instrument operating system, or No to exit the restore process.

The restore process takes approximately 30 minutes; the actual time depends on the instrument configuration.

Install Your Ins

trument

Installing the MSO5000 and DPO5000 Hard Drive

CAUTION. Inserting the hard drive

assembly upside down could damage the

instrument.

1. Verify that the instrument is off.

2. Insert the hard drive into the i nstrument

with the drive assembly chassis facing

up.

3. Secure the drive assembly using the

thumb screw.

4. Install the cover.

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 15

Page 37

Getting Acquain

ted with Your Instrument

Getting Acqua

Front Panel

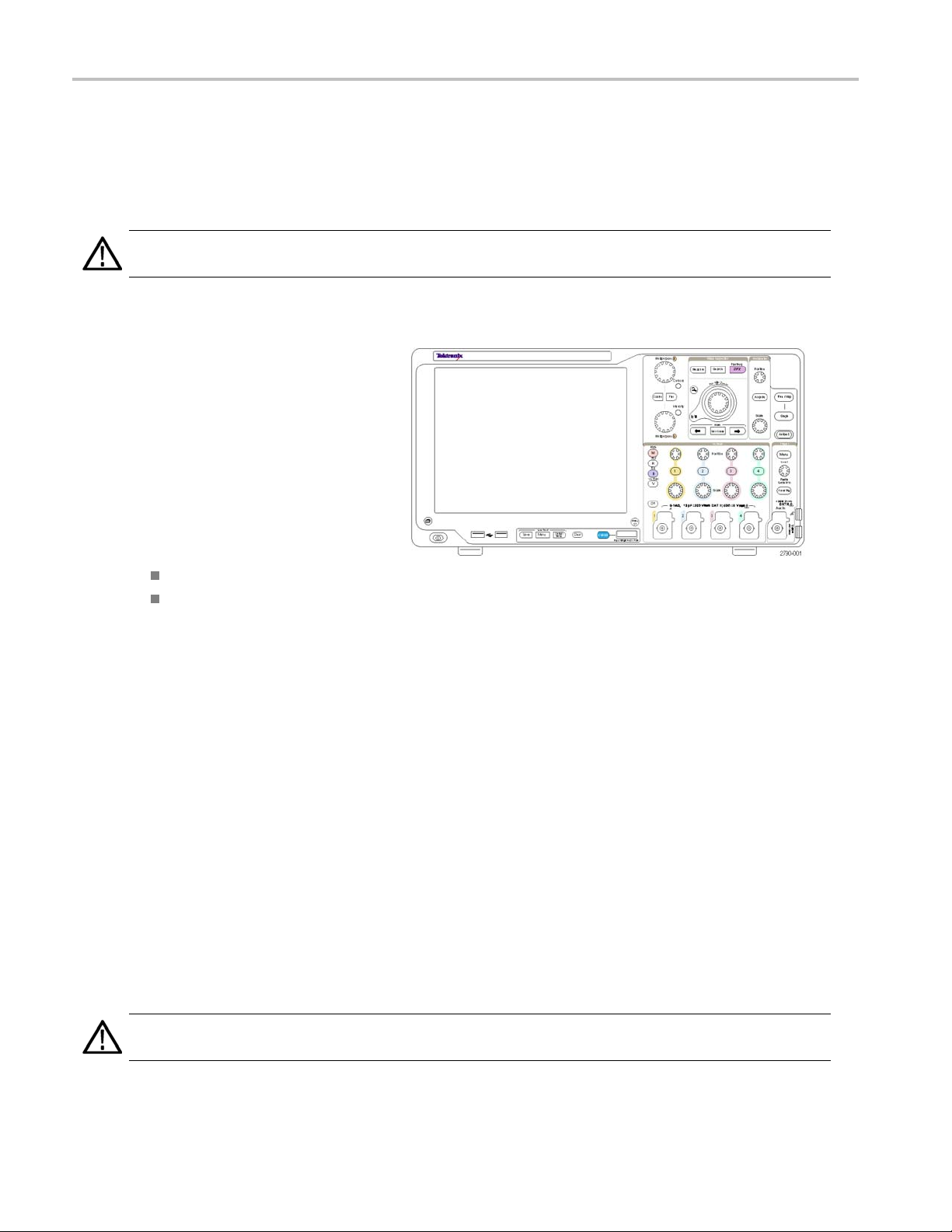

MSO70000/C, DSA7000B/C, DPO70000B/C, and DPO7000

1. DVD/CD-RW drive

2. Front panel controls

3. USB port

4. Ground terminal

5. Recovered data output (not available on

DPO7104 and DPO7054)

6. Recovered clock output (not available on

DPO7104 and DPO7054)

7. Probe compensation output

8. Probe calibration output

9. Channel 1–4 input

10. Auxiliary Trigger input

inted with Your Instrument

11. Fast Edge output

12. DC Probe Cal output

13. Logic probe input

DPO7000 Series

DSA70000B/C and DPO70000B/C Series

MSO70000/C Series

16 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 38

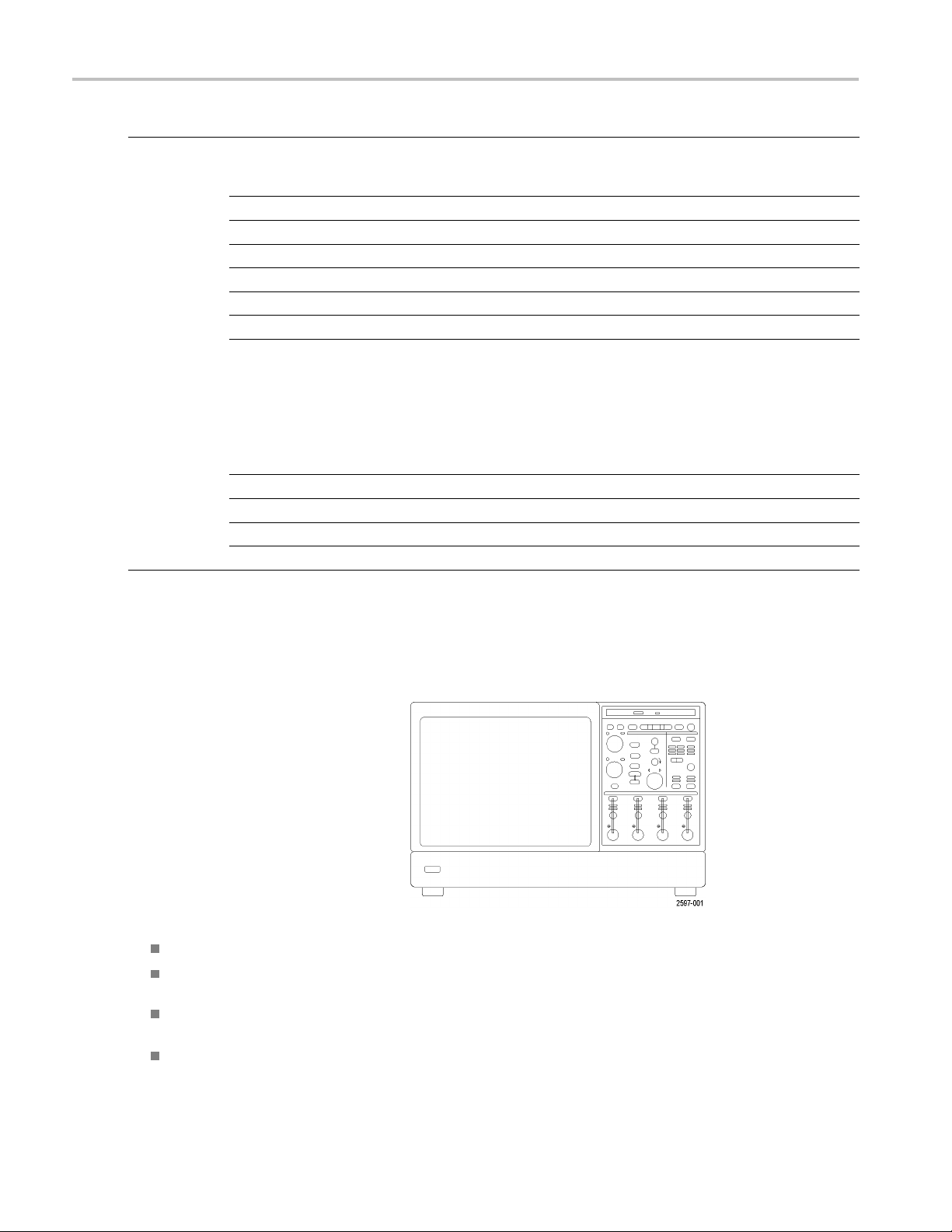

MSO5000 and DPO5000 Series

1. Front panel controls

2. Ground terminal

3. Probe compensation output

4. Auxiliary Triggerinput

5. Channel 1–4 inputs

6. Logic probe input

7. USB ports

Side and Rear Panels

MSO70000/C, DSA70000B/C, and DPO70000B/C

MSO5000 and DPO5000 Series

Getting Acquain

tedwithYourInstrument

1. Removable hard disk drive

2. PS-2 connector for mouse

3. USB host ports

4. Passive eSATAPort

5. RJ-45 LAN connector to connect to

network

6. TekLinkconnector

7. GPIB port to connect to controller

8. Line Out connector for speaker

NOTE. S o me instruments may have

additional audio connectors.

9. Mic connector for microphone

10. DVI-I Video port

11. COM 1 and COM 2 serial ports

12. PS-2 connector for keyboard

13. Auxiliary output

MSO70000/C, DSA70000B/C, and DPO70000B/C Series

14. Reference output

15. External reference input

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 17

Page 39

Getting Acquain

DSA70000B and, DPO70000B

1. Removable hard disk drive

2. PS-2 connector for mouse

3. USB host ports

4. Centronics Parallel Port

5. RJ-45 LAN connector to connect to

network

ted with Your Instrument

6. Video port to

7. TekLink con

8. GPIB port to

NOTE. Some instruments may have

additional audio connectors.

9. Line In connector

10. Line Out connector for speaker

11. Mic connector for microphone

12. Video port to connect a monitor

13. COM 1 serial port

14. PS-2 connector for keyboard

15. CTR Bass speaker

16. Side speaker out

17. Rear speaker out

18. Auxiliary output

19. Reference output

connect a monitor

nector

connect to controller

DSA70000B a

nd DPO70000B Series

20. External reference input

18 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 40

DPO7000

1. USB host ports

Getting Acquain

tedwithYourInstrument

2. Video port to c

NOTE. S o me instruments may have

additional audio connectors.

3. Mic connector for microphone

4. Line Out connector for speaker

5. Oscilloscope Only XGA Out video port to

connect a monitor

6. Printer c onnection

7. Line In connector

8. RJ-45 LAN connector to connect to

network

9. Centroni

10. COM 1 seri

11. PS-2 con

12. PS-2 con

13. Rear spe

onnect a monitor

cs Parallel Port

al port

nector for mouse

nector for keyboard

aker out

14. Side sp

15. CTR Bas

16. Remova

17. GPIB p

18. Auxil

19. Chann

20. Exter

iary output

el 3 output

nal reference input

eaker out

s speaker

ble hard disk drive

ort to connect to controller

DPO

7000 Series

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 19

Page 41

Getting Acquain

MSO5000 and DPO5000

1. Line In connector

2. Line Out connector for speaker

3. Mic connector for microphone

4. Video port to connect a monitor

5. PS-2 connector for keyboard

6. PS-2 connector for mouse

7. USB host ports

8. RJ-45 LAN connector to connect to

network

9. USBDeviceport

10. Probe Power input, use 119-7465-xx

power supply

11. External reference input

ted with Your Instrument

12. Auxiliary output

13. Security lock input

14. AC Power input

15. Removable hard disk drive cover

16. Ground connection

MSO5000 and DPO5000 Series

20 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 42

Getting Acquain

To use PS-2 devices, they must be plugged in before you power on the instrument. PS-2 devices must not be hot swapped.

tedwithYourInstrument

Interface and

The menu bar mode provides access to commands that control all of the instrument features and functions. The toolbar mode

provides acc

1. Menu Bar: Access to data I/O, printing,

online help,

2. Buttons/Me

toolbar and menu bar modes and to

customize your toolbar

3. Multipurpose Knob Readouts: Adjust

and displa

multipurpose knobs

4. Display: Live, reference, math, digital,

and bus waveforms display here, with

cursors

5. Waveform

change vertical position of a waveform

or bus. Click the handle and change the

nandscale usingthe multipurpose

positio

knobs.

6. Controls Status: Quick reference to

vertical selections, scale, offset, and

parame

Display

ess to the most common features.

and instrument functions

nu: Click to toggle between

y parameters c ontrolled by the

Handle: Click and drag to

ters

7. Readou

WARNING. If there is vertical clipping, there may be a dangerous voltage on the probe tip, but the readout will indicate a low

age. A

volt

measurements where the signal is vertically clipped produce inaccurate results. Clipping also causes inaccurate amplitude

values in waveforms that are stored or exported for use in other programs. If a math waveform is clipped, it will not affect

ampl

8. Sta

ts: Display cursor and

measurement readouts in this area.

Measurements are selectable from the

menu ba

is displayed, some combinations of

readouts move to the graticule area.

to record length and horizontal parameters

r or toolbar. If a control window

symbol appears in the measurement readout if a vertical clipping condition exists. Automatic amplitude-related

itude measurements on that math waveform.

tus: Display of acquisition status, mode, and number of acquisitions; trigger status; date; time; and quick reference

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 21

Page 43

Getting Acquain

1. Buttons/Menu: Click to toggle between

toolbar and menu bar modes and to

customize the

ted with Your Instrument

toolbar

2. Drag cursors t

screen

3. Drag the position icons to reposition a

waveform

4. Click the icon to assign the multipurpose

knobs to wave

scale

5. Drag across the waveform area to create

a box for zooming, enabling/disabling

histograms

6. Drag icon t

o measure waveforms on

form vertical position and

, and gating measurements

o change the trigger level

22 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 44

Control Panel

MSO70000/C, DSA70000B/C, DPO70000B/C, an d DPO7000

1. Push to automatically set up the vertical,

horizontal, and trigger controls based on

selected channels.

2. Push to return settings to default values.

3. Push to make a hard copy or save a

screen capture.

4. Push to turn on MultiView Zoom and add

a magnified graticule to the display.

5. Horizontally scale, position, delay, and

set record length (resolution) of all

waveforms.

6. Use to start and stop acquisition, start a

single acquisition sequence, clear data,

or start fast acquisitions.

7. Use to set the trigger parameters. Push

Advanced to display additional trigger

functions. T he Arm, Ready, and Trig’D

lights show the acquisition status.

Getting Acquain

tedwithYourInstrument

8. Turn to adjust waveform intensity.

9. Turn to adjust parameters selected from

the screen interface. Push to toggle

between normal and fine adjustment.

10. Push to turn cursors on or off.

11. Use to search and mark waveforms.

12. Push to turn the touch screen on and off.

13. Turn channel displays on and off.

Vertically scale, position, or offset the

waveform. Toggle between position and

offset.

On MSO70000 Series instruments, turn

on digital channels using the Digital

> Digital Setup menu. (See page 48,

Setting Up Digital Signal Input.)

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 23

Page 45

Getting Acquain

MSO5000 and DPO5000

ted with Your Instrument

1. Turn to adjust

the screen interface. Push Fine to select

fine adjustment, push Course to select

course adjust

2. Push to turn c

3. Push to adjus

a Multipurpose knob.

4. Push to turn on MultiView Zoom and add

a magnified graticule to the display.

5. Push to perform automated

measureme

an acquisition for user-defined

events/criteria, or start or stop fast

acquisiti

6. Horizonta

horizontal and acquisition parameters of

all waveforms.

7. Turn the inner zoom knob to control the

zoom fact

to scroll the zoom window through the

acquiredwaveform. Pushthe play-pause

button t

panning of a waveform. Control the

speed and direction with the pan knob.

parameters selected from

ment.

ursors on or off.

t waveform intensity using

nts, search through

ons.

lly scale, position, and set the

or. Turn the outer pan knob

o start or stop the automatic

8. Use to start and stop acquisition or start

e acquisition sequence.

a singl

9. Use to s

establish or delete a waveform m ark, or

to jump to the previous or next waveform

mark.

10. Pusht

horizontal, and trigger controls based on

selected channels.

earch and mark waveforms, to

o automatically set up the vertical,

24 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 46

Getting Acquain

tedwithYourInstrument

11. Usetosetthetr

Push Menu to display additional trigger

functions.

12. Turn channel displays on and off.

Verticallysc

OnMSO5000Series instruments,turn on

digital channels by pushing the D15–D0

button or usi

menu. (See page 48, Setting Up Digital

Signal Input.)

13. Push to turn the touch screen on and off.

14. Pushto display the math, reference, bus,

or vertica

15. Push to tur

16. Push to ac

(MSO5000 Series only).

17. Push to clear data.

18. Push to return settings to default values.

19. Push to save and recall setups,

waveforms, and screen images.

igger parameters.

ale or position the waveform.

ng the Digital > Digital Setup

l setup menus.

n off a displayed menu.

cess the digital setup menu

20. Push to make a hard copy or save a

capture.

screen

Accessing Online Help

In-depth information is available in the online help on all the features of your instrument.

To access context-sensitive help on the

active window, select Help > Help on

Window... or press F1.

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 25

Page 47

Getting Acquain

ted with Your Instrument

1. Toaccess any to

select Help > Contents and Index....

2. Use the Contents, Index, Search, or

Favorites tab to select the topic, and

then click Dis

To navigate within the help system:

Click a button in a help window to

navigate between the Overview and

specificto

Click the M

window to move help out of the way so

you can operate the instrument.

Click Alt and Tab to see the last help

topic aga

pic in the help system,

play.

pics.

inimize button in the help

in.

Accessing Menus and Control Windows

Access menus and control windows using the following techniques:

Click a menu, and then select a

command.

26 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 48

Getting Acquain

tedwithYourInstrument

Forashortcut m

enu,right-clickanywhere

in the graticule or on an object. The

shortcut menu is context sensitive and

varies with th

e area or object where you

right-clicked. Some examples a re shown

in the figure at right.

In the toolbar mode, click a button to

quickly access a setup control window.

(See page 21.)

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 27

Page 49

Inspect Your Ins

trument

Inspect Your Instrument

Use the following procedures to verify the functionality of your instrument.

Verify Internal Diagnostics Pass

1. Power o n the instrument.

2. Select Instrument Diagnostics....

3. Click Ru

diagnostics control window.

4. Verify that all tests pass. If diagnostic

failures occur, contact your local

Tektro

n. The test results appear in the

nix service personnel.

28 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 50

Acquisition

This section contains concepts of and procedures for using the acquisition system.

Signal Path Compensation

Use this procedure if the temperature has changed more than 5 °C (9 °F) since the last signal path compensation (SPC).

Perform the s

Tektronix considers it a best practice to run SPC when using the instrument to measure signals with higher sensitivity

(10 mV/div and lower) settings regardless of temperature shift or time since it was last run. Failureto do so may result in

the instrum

1. Prerequisites: instrument powered on for 20 minutes,

and all input signals removed.

2. Select Instrument Calibration.

ignal path compensation regularly to ensure that your measurements have the highest level of accuracy.

ent not meeting warranted performance levels.

Acquisition

3. When the Temperature Status changes

dy, click Run SPC to start the

to Rea

calibration. Calibrationmay take 10 to

15 minutes.

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 29

Page 51

Acquisition

2. Select Instrument Calibration.

4. If the instrument does not pass,

recalibrate the instrument, or have the

instrume

nt serviced by qualified service

personnel.

NOTE. To always show the SPC status icon

or displa

y a warning when SPC has not

been run in more than a month, click the

corresponding check box.

5. If the SPC needed icon is red, perform a

signal path compensation.

30 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 52

Setting Up Analog Signal Input

Use front-panel buttons to set up y our instrument to acquire the signal.

1. Connect the probe to the input signal source.

CAUTION. To prevent damage to the instrument, always wear an antistatic wrist strap when making connections to the

instrument and observe the maximum input voltage ratings for input connectors.

MSO70000/C, DSA70000B/C, and DPO70000B/C Series DPO7000 Series

Acquisition

MSO5000 and DPO5000 Series

2. Select the input channel by pushing the front-panel buttons to toggle the channels on and off.

MSO5000 and DPO5000 Series

MSO70000/C, DSA70000B/C, DPO 70000B/C, and DPO7000

Series

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 31

Page 53

Acquisition

3. Push Autoset.

4. Adjust the ver

MSO5000 a

tical position, scale, and offset using the front-panel knobs.

nd DPO5000 Series

MSO70000/C, DSA70000B/C, DPO70000B/C, and DPO7000

Series

5. Adjust the horizontal position and scale using the front-panel knobs.

The horiz

ontal position determines the number of pretrigger and posttrigger samples.

00 and DPO5000 Series

MSO50

MSO70000/C, DSA70000B/C, DPO70000B/C, and DPO7000

Series

32 MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO /DP O5000 Series U ser Manual

Page 54

Using Default Setup

Acquisition

1. Toquickly ret

DEFAULT SETUP.

urn to the factory default settings, push

MSO70000/C,

Series

MSO5000 and DPO5000 Series

DSA70000B/C, DPO70000B/C, and DPO7000

MSO70000/C, DPO/DSA70000B/C, DPO7000, and MSO/DPO5000 Series User Manual 33

Page 55

Acquisition

Using Autoset

Use Autoset to quickly and automatically set up the instrument (acquisition, horizontal, trigger, and vertical) based on the