Tektronix DSA70000D, DPO70000SX, DPO70000DX, DPO70000D, DSA70000C Best Practices Manual

...Page 1

xx

DSA70000D, DPO70000D/DX/SX,

MSO70000C/DX, DSA70000C,

DPO70000C, and DPO7000C

ZZZ

High Performance Oscilloscopes

Best Practices Manual

*P071298904*

071-2989-04

Page 2

Page 3

xx

DSA70000D, DPO70000D/DX/SX,

MSO70000C/DX, DSA70000C,

DPO70000C, and DPO7000C

ZZZ

High Performance Oscilloscopes

Best Practices Manual

www.tektronix.com

071-2989-04

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifica tions and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . Bo x 50 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 5

Best practices for using high performance oscilloscopes

Optimizing and maintaining the performance of your Tektronix product is critical

to your success. This document summarizes the Best Practices for using Tektronix

DSA70000C/D

Series products. Additional technical, application, and ser vice information is

available at the www.tektronix.com Web site.

, DPO70000C/D/DX/SX, MSO70000C/DX, and DPO7000C

Preventing electrostatic

discharge

Electrost

equipment. Most Tektronix instruments and probes are designed with robust ESD

protection. However, large discharges of static electricity applied to the signal

inputs may damage the equipment.

CAUTION. A direct static discharge can damage the input circuitry of the

instrument. To avoid damage, follow these techniques to prevent electrostatic

discha

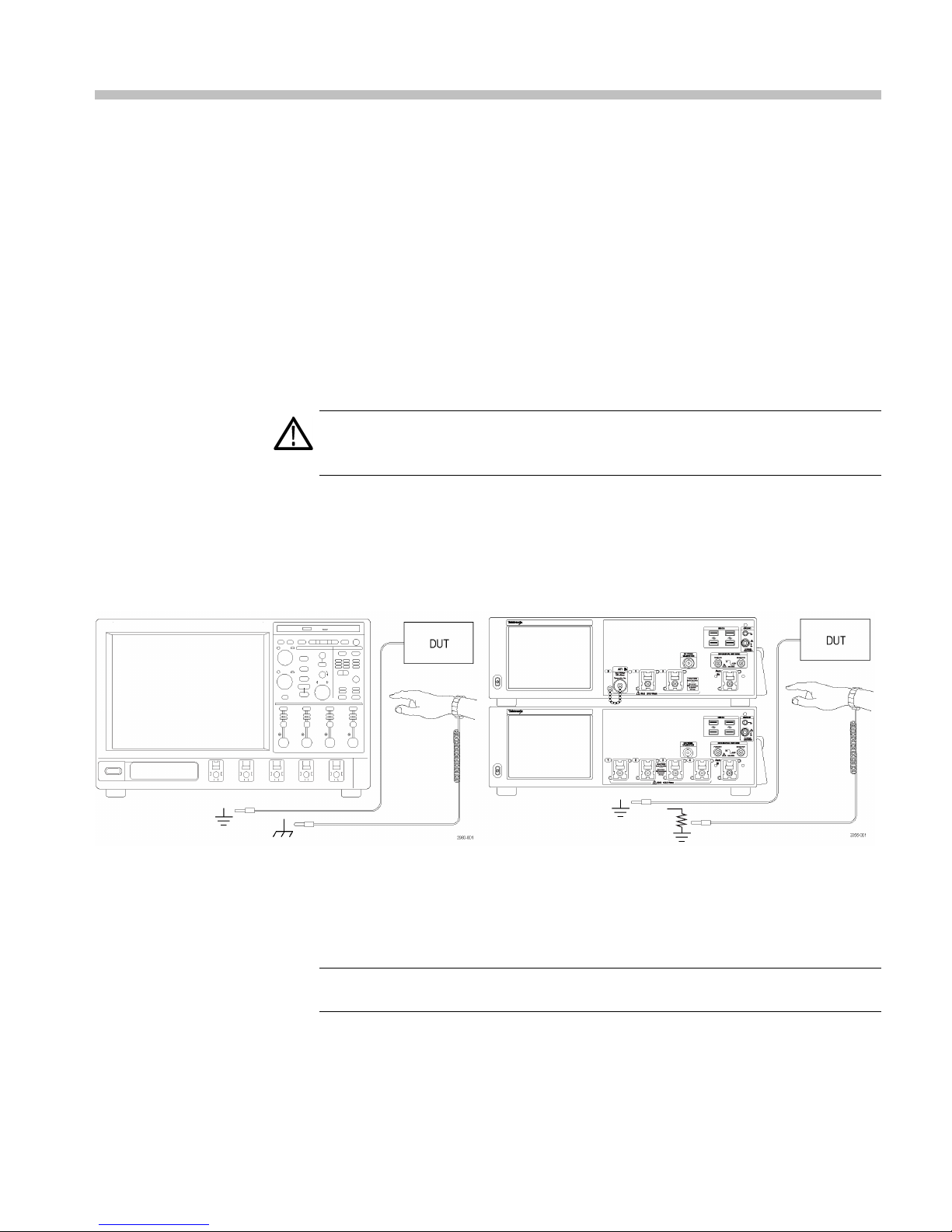

1. Discharge the static voltage from your body. To do so, wear a grounded

atic discharge (ESD) is a concern when handling any electronic

rge to the instrument:

tatic wrist strap when you connect and disconnect cables and adapters.

antis

Your instrument provides a convenient ground connection on the front panel

for this purpose.

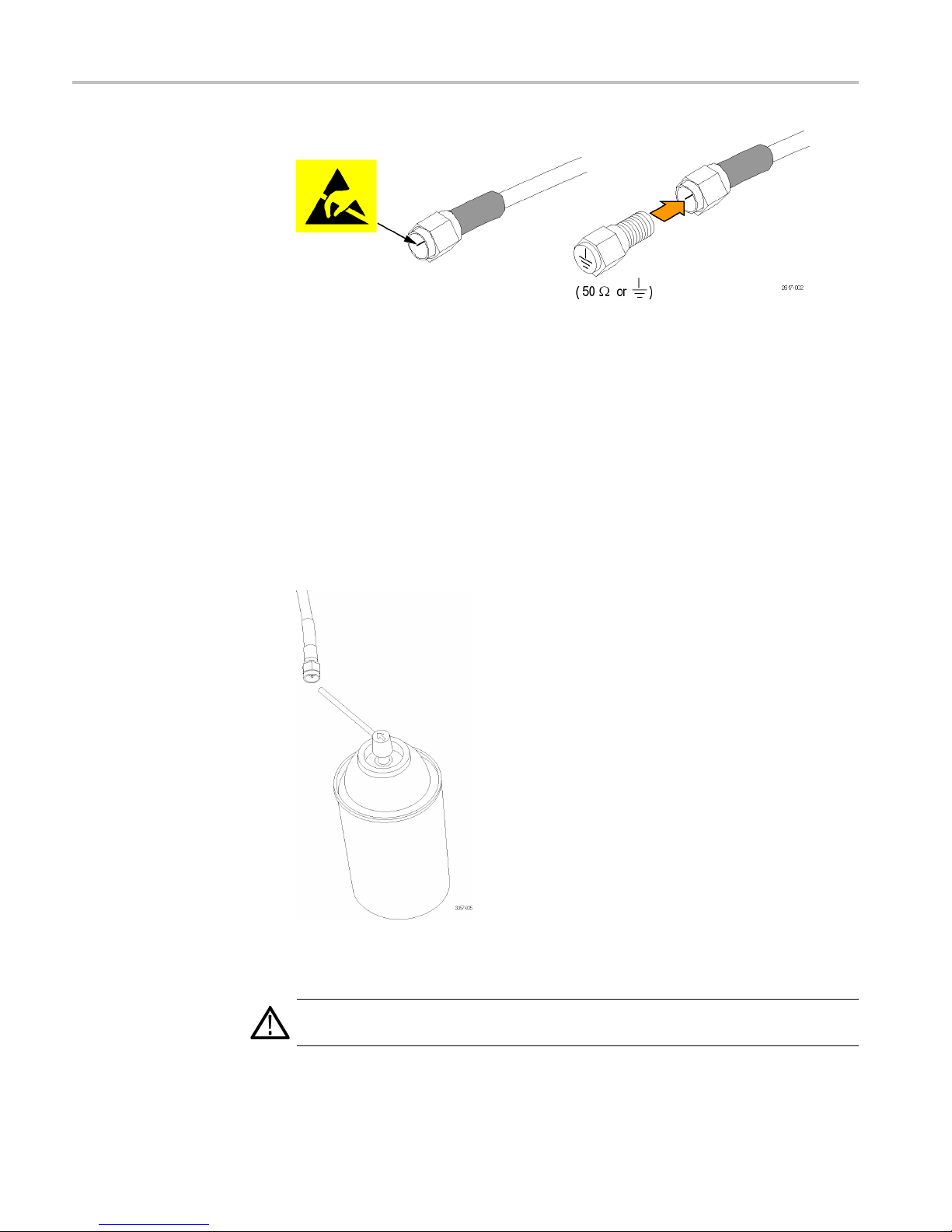

2. Discharge the static voltage from all cables before connecting them to the

NOTE. A cable that is left unconnected on a bench can develop a very large static

charge that can damage the instrument.

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 1

nstrument or to the device under test (DUT). Before you attach the cable to the

i

instrument, momentarily ground the center conductor of the cable, or connect

a50Ω termination to one end before attaching the cable to the instrument.

Page 6

Best practices for using high performance oscilloscopes

Connector cleaning

All connectors must be kept clean. Dirt in connectors can damage the connector

and any connectors the dirty connector is use with.

Before each use do the following:

1. Verify that the connectors are free of dirt, metal particles, scratches and

deformations.

2. Verify that the connectors are free of dirt, metal particles, scratches and

deformations.

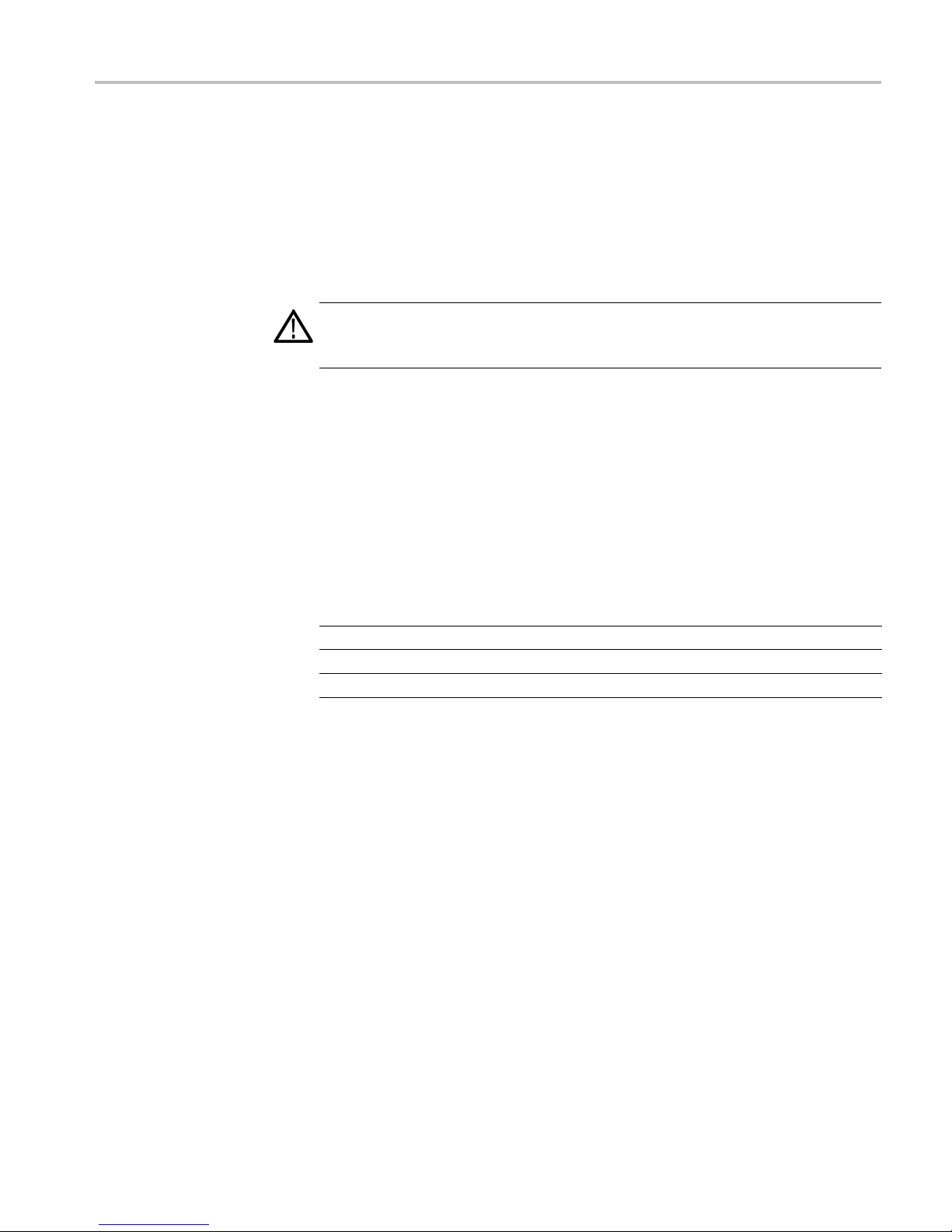

3. With the connector pointed down, use low pressure compressed air, at an

angle to the connector, to clean the connectors.

4. If the connector still needs cleaning, use an appropriately sized swab

CAUTION. Never put pressure on the center pin of the connectors. Applying

pressure to the center pin could damage the connector.

2 MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices

istened with isopropyl alcohol to clean the connector threads.

mo

Page 7

Best practices for using high performance oscilloscopes

Input connector protection

Use 8 inch-poun

ds of torque when making connections to a 1.85 mm connector

or to SMA connectors. Using the improper torque may degrade your signals

and damage the connectors.

Use the following procedure to make connections:

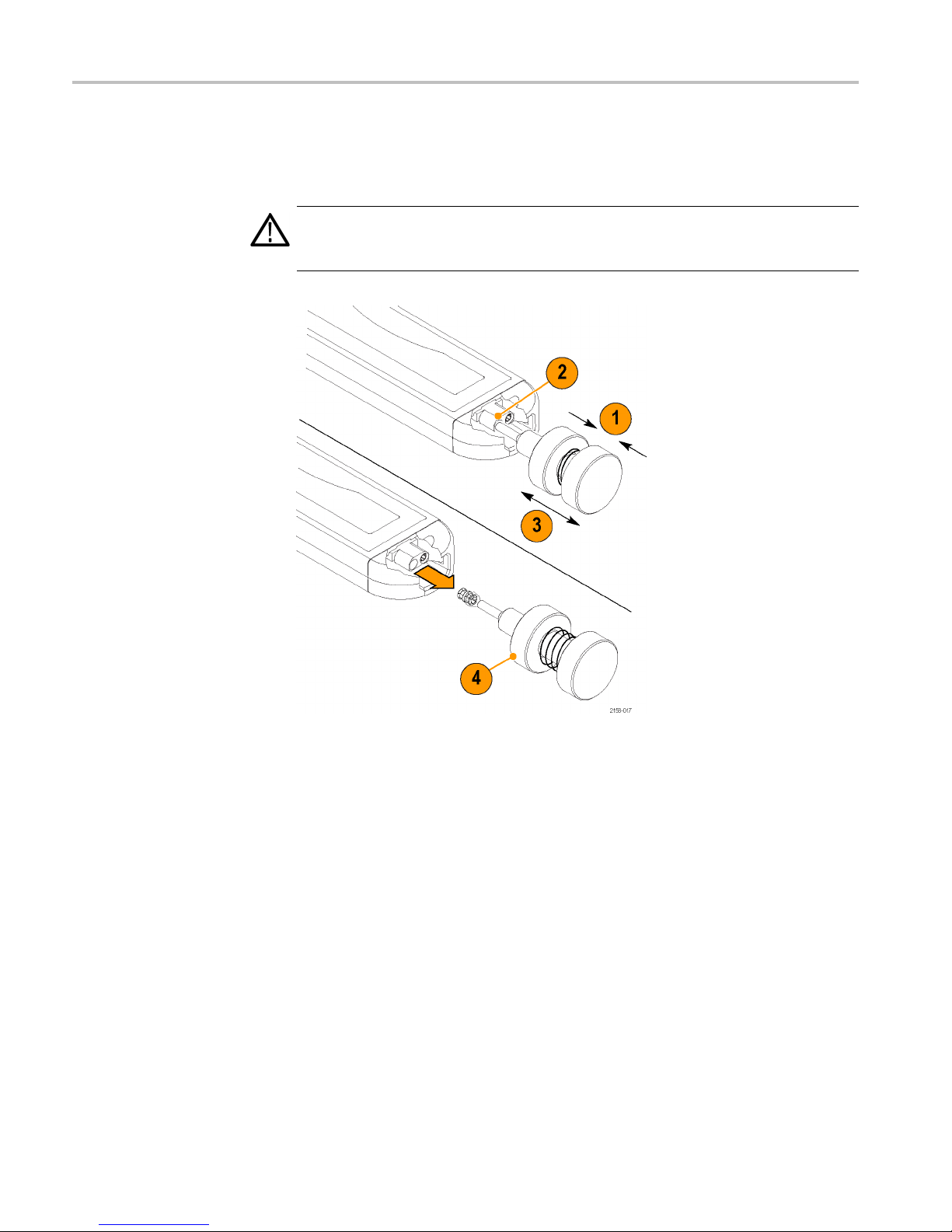

Discharge t

he static voltage from your body by wearing a grounded antistatic

wrist strap while connecting and disconnecting cables and adapters. The

instrument provides a front panel connection for this purpose.

Figure

1: Wear an antistatic wrist strap

e supplied connector saver to protect the instrument connector. When

Use th

not in use, protect against dirt and ESD damage by installing the end cap.

Alternate locations to store the ATI protective cover include the upper right

corner of the front panel and to the right of the audio connectors on the rear

panel. When installing the connector saver tighten to 8 inch-pounds.

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 3

Page 8

Best practices for using high performance oscilloscopes

Figure 2: Installing a connector saver

Use the backing wrench on the connector saver to prevent damage caused by

rotation of the connectors when installing a connector.

Use the supplied torque wrench to tighten (8 inch-pounds) your cable

connector to the connector saver.

UTION. Failure to use a backing wrench and torque wrench when making

CA

connections may dam age your instrument.

4 MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices

Page 9

Best practices for using high performance oscilloscopes

DPO70000SX

multi-instrument trigger

connections

Signal path compensation

and inst

rument calibration

Usecarewhenma

following procedure when making trigger connections:

1. Thoroughly in

damage.

CAUTION. Do not use a damaged connector. Using a damaged connector with

a good connector will damage the good connector.

2. Carefully align the cable connector with the connector on the instrument.

3. Insert the cable connector straight into the instrument connector.

4. Tighten t

of the connectors.

Signal Path Compensation (SPC) corrects for DC inaccuracies caused by

temper

connections and run the SPC routine occasionally or whenever the ambient

temperature of the instrument has changed by more than 5 °C (9 °F) to assure that

acquisitions are made with a high degree of accuracy.

ature variations or by long-term drift. Remove all channel input

king connections to the rear panel trigger connectors. Use the

spect each connector. Do not use connectors that display any

he connector screws to help maintain the connection and alignment

NOTE. For best accuracy, wait at least 3 hours after power on before running

SPC.

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 5

Page 10

Best practices for using high performance oscilloscopes

Instrument

temperature

and clearance

DPO70000

SX

environmental conditions

Deskew

channels

Adhere to a regu

Calibration Service plan is the most efficient way to ensure specified perform ance

over the lifetime of your Tektronix instrument. The service plan also guarantees

continuous compliance with international quality and traceability standards.

Contact your Tektronix Representative or refer to the www.tektronix.com Web

site for instrument calibration services.

The instrument must ha ve 3 inches of clearance on both the left and right sides for

proper ventilation. The air temperature around the instrument must be between

+5 °C and +45 °C (+41 °F and +113 °F).

For measurements impacted by sub-picosecond skew, leave the instrument

powered on for at least 6 hours to allow the instrument to stabilize to environmental

conditions before running SPC, deskew, or taking precision measurements.

Use the Deskew/Attenuation control window to compensate for propagation

delays of different length probes and to set the input/output ratio of any external

attenuation or gain between the signal and input channels. Deskew relates directly

vertical settings, so it is important to deskew at the vertical settings at which

to the

measurements will be taken or within the same amplifier range. Refer to the

Deskew/Attenuation Control Window topic in the Online Help of the instrument

for information on the deskew and attenuation procedures.

lar schedule of calibration of the instrument. A Tektronix

erating system restore

Op

pdates to firmware and

U

applications

6 MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices

The instrument contains an operating system restore file on a separate partition of

the hard drive. The preferred method to restore the operating system is to use the

hard disk restore fi le. For more information, see the instrument user manual.

You should regularly check for updates to the instrument firmware and

applications of your Tektronix products. Access the www.tektronix.com/software

Web page and search for the model number of your i nstrument (or application) to

check for updates.

Page 11

Best practices for using high performance oscilloscopes

Windows applications and

hard drive maintenance

Windows shut down

procedure

g acquisitions and

Takin

measurements

The Windows ins

application that is its primary function. It also provides the capability to run other

Windows compatible applications in the Windows Desktop. Some 3rd Party

applications (not from Tektronix) are included with the Windows instrument for

your convenience. Caution should be taken when adding new 3rd Party programs

to the Windows instrument so that the 3rd Party program will not interfere with

the operati

architecture.

The Windows instrument has specialized shut down procedures that assure the

integrit

s

Use the Shutdown command in the File menu of the oscilloscope, or the Shut

DowncommandintheStartmenuwhenpoweringdowntheinstrument. Avoid

abrupt shutdowns caused by pushing the On/Standby button for 5 seconds or

by removing the power cable.

Allow the instrument to complete its Start-up routine before shutting down the

oscilloscope. Do not power off the instrument before the Windows system is fully

loaded and running, as this action will harm the Windows System files.

Here are suggestions from Tektronix Application Engineers on the best practices

to follow when you take measurements:

on of the primary oscilloscope application and its supporting software

y of the system structure and data when powering down the instrument.

trument is highly specialized to execute the oscilloscope

Make sure that the cables are capable of the bandwidth that is being measured.

Torque the 1.85 mm and SMA connectors to 8 in-lbs for proper power

measurements.

Tighten the screw on high bandwidth probes and on the TCA-292 to avoid

connector float that can disturb the signal.

Push the Default Setup button to begin from a known state when configuring

the instrument for the acquisition.

Verify that the signal is properly characterized by using the highest Horizontal

Resolution possible.

Verify that the signal is m aximized from the bottom of the screen to the top

of the screen.

Use the Fine adjustment with the Vertical controls to get the best resolution.

Use a constant sample rate if the acquisition must be at the full sample rate

as the time base is adjusted.

Check the surrounding environment of the instrument for interfering signal

sources.

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 7

Page 12

Best practices for using high performance oscilloscopes

Maximum instrument input

voltage

Keep the lead le

ngths between the DUT and the instrument input connector

as short as possible.

Save relevant

waveform data files and screen shots to allow you to go back

and verify measurements.

WARNING. Observe all terminal ratings. To avoid damaging the instrument,

observe all rating and markings on the product. Consult the product manual for

further ratings information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

The maximum instrument input voltages are as follows:

DPO700

ATI (As

TekC o

scale settings and ±8 V on >1.2 V full scale settings

MSO70000DX and DPO70000DX Series

≤1.2 V Full S cale: ±5 V absolute maximum input

>1.2 V Full Scale: ±8.0 V. Limited by maximum V

at maximum temperature

DSA70000D and DPO70000D Series

±600 mV centered on the offset voltage (±4.6 V maximum)

±1.5 V relative to the termination bias (30 mA maximum)

MSO70000C, DPO70000C, and DSA70000C Series

<1.0 V/Full Scale settings: <1 V

≥ 1.0 V/Full Scale settings: <5.0 V

DPO7000 Series

1MΩ: ±150 V CAT I, derate at 20 dB/decade to 9 V

50 Ω:5V

00SX Series

ynchronous Time-Interleaved) input: 500 mV RMS and ±0.75 V pk

nnect inputs: ±1.5 V relative to the termination bias ( 30 mA maximum) on ≤ 1.2 V full

current and the attenuator power rating

term

RMS

RMS

above 200 kHz

RMS

with peaks less than ±24 V

RMS

NOTE. When using probes on the measurement inputs, do not exceed the

instrument or probe ratings. Refer to the user manual for additional information

available on the www.tektronix.com/manuals Web page.

8 MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices

Page 13

Best pra ctic es for using probes

Best practice

ESD and probes

TriMode probes

s for using probes

For P7500 Ser

(DC + peak AC).

For P7600 Se

+ peak AC), with tip adapter.

CAUTION. To avoid damage to the probe inputs, do not apply more than maximum

nondestructive input voltage (DC + peak AC) b etween each input, or between

either probe input and ground.

Refer to the probe user or instruction manual for additional information available

on the www.tektronix.com/manuals Web page.

To avoid ESD damage to the probe, always use an antistatic wrist strap and

work at a static-approved workstation when you handle the probe. (See page 1,

Preventing electrostatic discharge.)

Dynamic range. The differential signal ranges (with DC coupled) are as follows:

ies probes, the maximum nondestructive input voltage is: ±15 V

ries probes, the maximum nondestructive input voltage is ±8 V (DC

P7513 and P7516 P7520A P7630

±0.750 V at 5X attenuation ±0.625 V at 5X attenuation

±1.75 V at 12.5X attenuation ±1.60 V at 12.5X attenuation TA: 10 Vpp

xample operating voltage window (shown next) defines the maximum

An e

voltage that you can apply to each input, with respect to earth ground, without

saturating the probe input circuitry. A common-mode voltage that exceeds the

operating voltage window may produce an erroneous output waveform, even

when the differential-mode specification is met.

CA: 1.2 V

pp

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 9

Page 14

Best practices for using probes

Offset voltage range. Offset voltage ranges are as follows:

P7600

±4 V

P7513, P7

-1.5Vto

P7513, P7516

-2.0 V to +4.0 V for Single-Ended and Common mode (ground referenced)

P7520A

-1.8 V to +3.4 V for Single-Ended and Common mode (ground referenced)

516, and P7520A

+2.5 V for Differential mode

Soldering

The Offset Voltage Control, accessible from the attached instrument, allows the

probe dynamic range to be effectively moved up and down within the limits of the

offset voltage range and the operating voltage window. When the offset voltage is

o zero volts and the input signal is zero volts (analog channel inputs shorted to

set t

ground, not open), the displayed signal should be zero volts. If a noticeable zero

volt offset is present under the above conditions, a Probe Cal operation should be

performed. (See your probe user manual.)

To prevent damage to the c ircuit board or circuit board connec tions due to

accidental movement of the probe and soldered leads, we recommend that you

secure the tip to the circuit board using the adhesive tip tape provided in your

accessory kit. You can also use other materials s uc h as Kapton ta pe or hot glue.

To avoid damage to the tip or to the circuit under test, avoid applying excessive

heat from the soldering iron. Use a low wattage, temperature-controlled soldering

iron and appropriately sized soldering iron tip.

10 MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices

Page 15

Best pra ctic es for using probes

Precautions when handling

probe cables

Youneedtofoll

ow these precautions when you solder the tips:

For best soldering results, use a microscope to examine the quality of the

solder joints

.

Use a low-wattage, temperature-controlled soldering iron and a small-mass

soldering i

ron tip. The soldering iron temperature should be set as low as

possible, while still providing a reliable solder joint.

Use SAC305 s

older (included with the P7500 wire replacement kit) to attach

the tip wires to the DUT.

When repla

cing tip wires or axial-lead resistors, use solder wick to remove

the excess solder from the probe tip circuit board via holes. Be careful not to

overheat the via and damage the board.

The attachment wires should be bent symmetrically to vary the interconnect

spacing. Use care when you solder a tip to a DUT to avoid inadvertently

desoldering either the attachment wires or the damping resistor.

For best perform ance and signal integrity, keep the lead length between the

DUT and the tip as short as possible, and the lead lengths the same length.

Tektronix P7600, P6700, P7300, and P7500 Series probes are quality measurement

tools and should be treated with care to avoid damage or performance degradation

due to mishandling.

Be sure to follow these precautions when handling any probe cables:

Do not excessively pull or twist the probe cables when positioning the probe

for measurements.

Never crush the cable, as might occur when you run over the probe with a

chair wheel or drop something heavy on the cable .

To maximize probe life, limit the am o unt of cable twist relative to the probe

control box to ±180 degrees. Always uncoil a probe cable gently before

applying the twisting forces needed to orient the probe head for connection

to the probe tip.

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 11

Page 16

Best practices for using probes

Be sure to follo

w these additional precautions when handling P7500 Series p robe

cables:

Never over-be

nd the probe main or tip cables, which can put a permanent

kink into the cable. When storing the probe, do not coil it too tightly. It is best

to use the protective foam carrying case which is designed to not exceed the

minimum bend radius of 2.5 inches.

Be sure to follow these additional precautions when handling P6700 Series probe

cables:

Never over-bend the probe main or tip cables, which can put a permanent

kink into the cable. When storing the probe, do not coil it too tightly. Do not

d the minimum bend radius of 1 inch for either cable.

excee

Do not exceed the minimum bend radius of 2.5 inches side-to-side with a

e main cable laying flat.

prob

12 MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices

Page 17

Best pra ctic es for using probes

Maintenance of P7500

probes

The input to the probe body, the part of the probe that connects to the various tips,

was designed with replaceable G3PO RF bullets. These RF bullets are similar

ction to SMA barrel connectors. Since the P7500 Series probes can be

in fun

used with multiple interchangeable tips, there is the possibility of wearing out or

damaging the input connector. To address this issue, replace the RF bullets.

The bullet contacts in the probe body should be replaced every 200 insertion

cycles. For medium use situations, this should be a bout once a year.

Remove bullets. To remove the bullets, use the removal tool (Tektronix part

number: 003-1896-00) and follow these steps:

1. Squeeze the tool plunger to extend the holder tangs.

2. Insert the removal tool into the probe body so that the holder tangs surround

one of the bullets.

3. Release the plunger to secure the holder tangs on the bullet.

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 13

Page 18

Best practices for using probes

4. Gently pull the

tool outward to remove the bullet.

5. Repeat for the other bullet.

CAUTION. If you cannot extract the bullets with the bullet removal tool, use fine

needle-nosed pliers and a magnifying glass or microscope. Be careful not to

damage the probe body with the pliers.

Install bullets. When both bullets have been removed, install new bullets. To do

so, follow these steps:

1. Squeeze the tool plunger to extend the holder tangs.

2. Insert a new bullet into the tool so that the holder tangs surround the bullet.

3. Release the plunger to secure the h older tangs on the bullet.

4. Insert the tool into the probe body and seat the bullet in the recess.

5. Squeeze the tool plunger to release the bullet.

6. Gently pull the tool out of the probe body.

7. Repeat for the other bullet.

8. Test that the bullets are installed correctly by connecting and then removing

an accessory solder tip to the p robe head. Inspect the probe head and verify

that the bullets remain seated in the probe head.

14 MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices

Page 19

Best pra ctic es for using probes

MSO70000C/DX, DPO70000C/D/DX/SX, DSA70000C/D, DPO7000C Best Practices 15

Loading...

Loading...