Page 1

5 Series B MSO

MSO54B, MSO56B, MSO58B

Specifications and Performance Verification

Warning: The servicing instructions are for use by qualified personnel only. To avoid personal injury, do not perform any servicing unless you are qualified

to do so. Refer to all safety summaries prior to performing service.

Revision A. March 1, 2023. Supports product Firmware V1 and above.

Register now!

Click the following link to protect your product.

www.tek.com/register

*P 077172501 *

077-1725-01

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by national copyright laws and international treaty provisions. Tektronix products are covered by U.S. and foreign patents, issued

and pending. Information in this publication supersedes that in all previously published material. Specifications and price change privileges

reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

FlexChannel, e*Scope, and TekVPI are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

• In North America, call 1-800-833-9200.

• Worldwide, visit www.tek.com to find contacts in your area.

Page 3

Table of Contents

Table of Contents

List of Figures................................................................................................................................................................................5

List of Tables................................................................................................................................................................................. 6

General safety summary........................................................................................................................................................7

Terms in the manual...............................................................................................................................................................8

Terms on the product............................................................................................................................................................. 8

Symbols on the product......................................................................................................................................................... 9

Specifications.............................................................................................................................................................................. 10

Analog channel input and vertical specification................................................................................................................... 10

Timebase system.................................................................................................................................................................20

Trigger system..................................................................................................................................................................... 21

Serial Trigger specifications.................................................................................................................................................25

Digital acquisition system.....................................................................................................................................................27

Digital volt meter (DVM).......................................................................................................................................................27

Trigger frequency counter....................................................................................................................................................28

Arbitrary Function Generator system................................................................................................................................... 28

Display system.....................................................................................................................................................................30

Processor system................................................................................................................................................................ 31

Input/Output port specifications........................................................................................................................................... 31

Data storage specifications..................................................................................................................................................33

Power supply system........................................................................................................................................................... 33

Safety characteristics...........................................................................................................................................................34

Environmental specifications............................................................................................................................................... 34

Mechanical specifications.................................................................................................................................................... 35

Performance verification procedures.......................................................................................................................................... 36

Test records......................................................................................................................................................................... 36

Instrument information, self test record.........................................................................................................................36

Input Impedance test record......................................................................................................................................... 37

DC Balance test record.................................................................................................................................................38

DC Gain Accuracy test record...................................................................................................................................... 44

DC Offset Accuracy test record.................................................................................................................................... 55

Analog Bandwidth test record.......................................................................................................................................58

Random Noise, sample acquisition mode test record...................................................................................................93

Random Noise, High Res mode test record................................................................................................................116

Long term sample rate through AFG DC offset accuracy test records....................................................................... 139

Performance tests..............................................................................................................................................................163

Prerequisites...................................................................................................................................................................... 163

Self test.............................................................................................................................................................................. 163

Check input impedance..................................................................................................................................................... 164

Check DC balance............................................................................................................................................................. 165

Check DC gain accuracy................................................................................................................................................... 167

Check DC offset accuracy..................................................................................................................................................169

Check analog bandwidth....................................................................................................................................................171

Check random noise, sample acquisition mode ............................................................................................................... 173

Check random noise, High Res mode............................................................................................................................... 175

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 3

Page 4

Table of Contents

Check long term sample rate............................................................................................................................................. 177

Check delta time measurement accuracy..........................................................................................................................178

Check digital threshold accuracy....................................................................................................................................... 179

Check DVM voltage accuracy (DC)................................................................................................................................... 181

Check DVM voltage accuracy (AC)................................................................................................................................... 182

Check trigger frequency accuracy and maximum input frequency.................................................................................... 183

Arbitrary function generator............................................................................................................................................... 183

Check AFG sine and ramp frequency accuracy......................................................................................................... 183

Check AFG square and pulse frequency accuracy.....................................................................................................184

Check AFG signal amplitude accuracy.......................................................................................................................185

Check AFG DC offset accuracy..................................................................................................................................187

Index......................................................................................................................................................................................... 189

4

Page 5

List of Figures

List of Figures

Figure 1: Frequency/period test................................................................................................................................................ 184

Figure 2: Frequency/period test................................................................................................................................................ 185

Figure 3: 50 Ω terminator accuracy...........................................................................................................................................186

Figure 4: Amplitude test............................................................................................................................................................ 186

Figure 5: 50 Ω terminator accuracy...........................................................................................................................................187

Figure 6: DC offset tests............................................................................................................................................................188

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 5

Page 6

List of Tables

List of Tables

Table 1: 5 Series B MSO ............................................................................................................................................................22

Table 2: Expected gain worksheet............................................................................................................................................ 168

Table 3: Maximum bandwidth frequency worksheet................................................................................................................. 172

Table 4: CF (Calibration Factor) = 1.414 × ((50 / Measurement Ω) + 1)...................................................................................186

Table 5: CF (Calibration Factor) = 0.5 × (( 50 / Measurement Ω) + 1)......................................................................................187

6

Page 7

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product or any

products connected to it. Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition to the safety

precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

To avoid fire or personal injury

Use proper power cord Use only the power cord specified for this product and certified for the country of use. Do not use the

provided power cord for other products.

Ground the product This product is grounded through the grounding conductor of the power cord. To avoid electric shock, the

grounding conductor must be connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded. Do not disable the power cord

grounding connection.

Power disconnect The power cord disconnects the product from the power source. See instructions for the location. Do not

position the equipment so that it is difficult to operate the power cord; it must remain accessible to the user

at all times to allow for quick disconnection if needed.

Connect and disconnect

properly

Do not connect or disconnect probes or test leads while they are connected to a voltage source.

Use only insulated voltage probes, test leads, and adapters supplied with the product, or indicated by

Tektronix to be suitable for the product.

Observe all terminal ratings To avoid fire or shock hazard, observe all rating and markings on the product. Consult the product manual

for further ratings information before making connections to the product. Do not exceed the Measurement

Category (CAT) rating and voltage or current rating of the lowest rated individual component of a product,

probe, or accessory. Use caution when using 1:1 test leads because the probe tip voltage is directly

transmitted to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating

of that terminal.

Do not operate without covers Do not operate this product with covers or panels removed, or with the case open. Hazardous voltage

exposure is possible.

Avoid exposed circuitry Do not touch exposed connections and components when power is present.

Do not operate with suspected

failures

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 7

If you suspect that there is damage to this product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in

doubt about safety of the product, turn it off and disconnect the power cord. Clearly mark the product to

prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when

damaged. Do not use probes or test leads if they are damaged, if there is exposed metal, or if a wear

indicator shows.

Page 8

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Do not operate in wet/damp

conditions

Do not operate in an explosive

atmosphere

Keep product surfaces clean

and dry

Provide proper ventilation Refer to the installation instructions in the manual for details on installing the product so it has proper

Provide a safe working

environment

Be aware that condensation may occur if a unit is moved from a cold to a warm environment.

Remove the input signals before you clean the product.

ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise obstructed. Do

not push objects into any of the openings.

Always place the product in a location convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or prolonged keyboard

or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to

avoid stress injuries.

Use care when lifting and carrying the product. This product is provided with a handle or handles for lifting

and carrying.

WARNING: The product is heavy. To reduce the risk of personal injury or damage to the device

get help when lifting or carrying the product.

Use only the Tektronix rackmount hardware specified for this product.

Probes and test leads

Before connecting probes or test leads, connect the power cord from the power connector to a properly grounded power outlet.

Keep fingers behind the protective barrier, protective finger guard, or tactile indicator on the probes.

Remove all probes, test leads and accessories that are not in use.

Use only correct Measurement Category (CAT), voltage, temperature, altitude, and amperage rated probes, test leads, and adapters for

any measurement.

Terms in the manual

These terms may appear in this manual:

WARNING:

CAUTION: Caution statements identify conditions or practices that could result in damage to this product or other property.

Warning statements identify conditions or practices that could result in injury or loss of life.

Terms on the product

These terms may appear on the product:

• DANGER indicates an injury hazard immediately accessible as you read the marking.

• WARNING indicates an injury hazard not immediately accessible as you read the marking.

8

Page 9

• CAUTION indicates a hazard to property including the product.

Symbols on the product

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the potential hazards and

any actions which have to be taken to avoid them. (This symbol may also be used to refer the user to ratings in the manual.)

The following symbols may appear on the product:

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 9

Page 10

Specifications

Specifications

This chapter contains specifications for the instrument. All specifications are guaranteed unless noted as "typical." Typical specifications

are provided for your convenience but are not guaranteed. Specifications that are marked with the symbol are checked in this manual.

All specifications apply to all models unless noted otherwise.

To meet specifications, these conditions must first be met:

• The instrument must have been calibrated in an ambient temperature between 18 °C and 28 °C (64 °F and 82 °F).

• The instrument must be operating within the environmental limits. (See Environmental specifications on page 34.)

• The instrument must be powered from a source that meets the specifications. (See Power supply system on page 33.)

• The instrument must have been operating continuously for at least 20 minutes within the specified operating temperature range.

• You must perform the Signal Path Compensation procedure after the warmup period. See the online help for instructions on how to

perform signal path compensation. If the ambient temperature changes more than 5 °C (9 °F) , repeat the procedure.

Analog channel input and vertical specification

Number of input channels MSO54B: 4 BNC

MSO56B: 6 BNC

MSO58B: 8 BNC

Input coupling DC, AC

Input resistance selection 1 MΩ or 50 Ω

✓Input impedance 1 MΩ DC

coupled

Input capacitance 1 MΩ DC

coupled, typical

✓Input impedance 50 Ω, DC

coupled

Maximum input voltage, 1 MΩ 300 V

Maximum input voltage, 50

Ohm

DC balance ✓ 0.1 div with DC-50 Ω oscilloscope input impedance (50 Ω BNC terminated)

1 MΩ ±1%

14.5 pF ±1.5 pF, 2 GHz model

13 pF ±1.5 pF, 1 GHz, 500 MHz, 350 MHz models

50 Ω ±1% (VSWR ≤1.5:1, typical)

at the BNC. Installation Category II

RMS

Derate at 20 dB/decade between 4.5 MHz and 45 MHz; derate 14 dB/decade between 45 MHz and 450

MHz. Above 450 MHz, 5.5 V

Maximum peak input voltage at the BNC: ±425 V

5 V

, with peaks ≤ ±20 V (DF ≤6.25%)

RMS

✓ 0.2 div at 1 mV/div with DC-50 Ω oscilloscope input impedance (50 Ω BNC terminated)

0.4 div at 500 μV/div with DC-50 Ω oscilloscope input impedance (50 Ω BNC terminated)

✓ 0.2 div with DC-1 MΩ oscilloscope input impedance (50 Ω BNC terminated)

0.4 div at 500 µV/div with DC-1 MΩ oscilloscope input impedance (50 Ω BNC terminated)

RMS

Note: 500 µV/div is a 2X digital zoom of 1 mV/div. As such, it is guaranteed by testing the 1 mV/div setting.

Number of digitized bits 8 bits at 6.25 GS/s

10

Page 11

12 bits at 3.125 GS/s

13 bits at 1.25 GS/s

14 bits at 625 MS/s

15 bits at 312.5 MS/s

16 bits at 125 MS/s

Displayed vertically with 25 digitization levels (DL1) for 8-bit and 400 digitization levels for 12-bit per division,

10.24 divisions dynamic range.

Sensitivity range, coarse

1 MΩ 500 µV/div to 10 V/div in a 1-2-5 sequence

50 Ω 500 µV/div to 1 V/div in a 1-2-5 sequence

Note: 500 μV/div is a 2X digital zoom of 1 mV/div

Sensitivity range, fine

Allows continuous adjustment from 1 mV/div to 10 V/div, 1 MΩ and from 1 mV/div to 1 V/div, 50 Ω

1 MΩ 500 µV/div to 10 V/div

50 Ω 500 µV/div to 1 V/div

Sensitivity resolution, fine ≤1% of current setting

Specifications

DC gain accuracy

✓ DC gain accuracy

2 GHz model, Step Gain, 50

Ohm

2 GHz model, Step Gain, 1

Meg Ohm

1 GHz, 500 MHz, 350 MHz

models, Step Gain, 50 Ohm

Variable gain ±1.5%, de-rated at 0.100%/ °C above 30 °C.

Note: 500 µV/div is a 2X digital zoom of 1 mV/div. As such, it is guaranteed by testing the 1 mV/div setting.

Offset ranges, maximum

2 GHz models Input signal cannot exceed maximum input voltage for the 50 Ω input path.

±1.2%, (±2.5% at 1 mV/div and 500 µV/div settings), de-rated at 0.100%/ °C above 30 °C

±1.0%, (±2.0% at 1 mV/div and 500 µV/div settings), de-rated at 0.100%/ °C above 30 °C

±1.2%, (±2.5% at 1mV/Div and 500 µV/Div Settings), de-rated at 0.100%/ °C above 30 °C

Volts/div Setting Maximum offset range, 50 Ω Input

500 µV/div - 50 mV/div ±1 V

51 mV/div - 99 mV/div ± (-10 * (Volts/div Setting) + 1.5 V)

100 mV/div - 500 mV/div ±10 V

501 mV/div - 1 V/div ± (-10 * (Volts/div Setting) + 15 V)

1

DL is the abbreviation for digitization level. A DL is the smallest voltage level change that can be resolved by an 8-bit A-D Converter. This value is also known as an

LSB (least significant bit).

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 11

Page 12

Specifications

Volts/div Setting Maximum offset range, 1 MΩ Input

500 µV/div - 63 mV/div ±1 V

64 mV/div - 999 mV/div ±10 V

1 V/div - 10 V/div ±100 V

≤ 1 GHz models Input signal cannot exceed maximum input voltage for the 50 Ω input path.

Volts/div Setting Maximum offset range

50 Ω Input 1 MΩ Input

500 µV/div - 63 mV/div ±1 V ±1 V

64 mV/div - 999 mV/div ±10 V ±10 V

1 V/div - 10 V/div ±10 V ±100 V

Note: 500 µV/div is a 2X digital zoom of 1 mV/div. As such, it is guaranteed by testing the 1 mV/div setting.

Position range ±5 divisions

Offset accuracy ±(0.005 X | offset - position | + DC balance )

Number of waveforms for

2 to 10,240 Waveforms, default 16 waveforms

average acquisition mode

DC voltage measurement

accuracy, Average acquisition

mode

Measurement Type DC Accuracy (In Volts)

Average of ≥ 16 waveforms ±((DC Gain Accuracy) * |reading - (offset - position)|

+ Offset Accuracy + 0.1 * V/div setting)

Delta volts between any two averages of ≥ 16

±(DC Gain Accuracy * |reading| + 0.05 div)

waveforms acquired with the same oscilloscope

setup and ambient conditions

DC voltage measurement

accuracy, sample acquisition

mode, typical

Measurement Type DC Accuracy (In Volts)

Any Sample ±(DC Gain Accuracy * |reading - (offset - position)| +

Offset Accuracy + 0.15 div + 0.6 mV)

Delta Volts between any two samples acquired with

the same oscilloscope setup and ambient conditions

±(DC Gain Accuracy * |reading| + 0.15 div + 1.2

mV)

Bandwidth selections 50 Ω: 20 MHz, 250 MHz, and the full bandwidth value of your model

1 MΩ: 20 MHz, 250 MHz, 350 MHz2, 500 MHz

✓Analog bandwidth 50 Ω DC coupled

2

350 MHz models cannot be configured to 500 MHz in 1 MΩ mode.

12

Page 13

Specifications

2 GHz models

1 GHz models

500 MHz models

350 MHz models

Volts/Div Setting Bandwidth

10 mV/div - 1 V/div DC - 2.00 GHz

5 mV/div - 9.98 mV/div DC - 1.50 GHz

2 mV/div - 4.98 mV/div DC - 350 MHz

1 mV/div - 1.99 mV/div DC - 175 MHz

500 µV/div - 995 µV/div DC - 175 MHz

Volts/Div Setting Bandwidth

1 mV/div - 1 V/div DC - 1.00 GHz

500 µV/div - 995 µV/div DC - 250 MHz

Volts/Div Setting Bandwidth

1 mV/div - 1 V/div DC - 500 MHz

500 µV/div - 995 µV/div DC - 250 MHz

Volts/Div Setting Bandwidth

1 mV/div - 1 V/div DC - 350 MHz

500 µV/div - 995 µV/div DC - 250 MHz

Analog bandwidth, 1 MΩ, typical

All model bandwidths

except 350 MHz

350 MHz models

Analog bandwidth with

TPP0500, TPP1000 probes,

typical

The limits stated above are for ambient temperature of ≤30 °C and the bandwidth selection set to FULL.

Reduce the upper bandwidth frequency by 1% for each °C above 30 °C.

Volts/Div Setting Bandwidth

1 mV/div - 10 V/div DC - 500 MHz

500 µV/div - 995 µV/div DC - 250 MHz

Volts/Div Setting Bandwidth

1 mV/div - 10 V/div DC - 350 MHz

500 µV/div - 995 µV/div DC - 250 MHz

The limits are for ambient temperature of ≤30 °C and the bandwidth selection set to FULL. Reduce the

upper bandwidth frequency by 1% for each °C above 30 °C.

Instrument Volts/Div Setting Bandwidth

2 GHz, 1 GHz 5 mV/div - 100 V/div DC - 1 GHz (TPP1000 Probe)

500 MHz 5 mV/div - 100 V/div DC - 500 MHz (TPP0500 Probe)

Table continued…

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 13

Page 14

Specifications

Instrument Volts/Div Setting Bandwidth

350 MHz 5 mV/div - 100 V/div DC - 350 MHz (TPP0500 Probe)

Lower frequency limit, AC

coupled, typical

Upper frequency limit, 250 MHz

bandwidth limited, typical

Upper frequency limit, 20 MHz

bandwidth limited, typical

Calculated rise time

Calculated rise time, typical

Peak Detect or Envelope mode

pulse response, typical

<10 Hz when AC 1 MΩ coupled. The AC coupled lower frequency limits are reduced by a factor of 10 (<1

Hz) when 10X passive probes are used.

250 MHz, ± 25%

20 MHz, ± 20%

Model 50 Ω TPP0500 Probe TP1000 Probe

Vertical 500 µV-1 V 5 mV-10 V 5 mV-10 V

2 GHz 225 ps 800 ps 400 ps

1 GHz 400 ps 800 ps 400 ps

500 MHz 800 ps 800 ps 800 ps

350 MHz 1.15 ns 1.15 ns 1.15 ns

Minimum pulse width is >640 ps (6.25 GS/s)

Effective bits (ENOB), typical

Typical effective bits for a 9-division p-p sine-wave input, 50 mV/div, 50-ohm

2 GHz models, Sample

mode, 50 Ω

2 GHz models, High Res

mode, 50 Ω

Bandwidth Input frequency 6.25 GS/s

2 GHz 10 MHz 6.20

2 GHz 600 MHz 6.20

250 MHz 10 MHz 7.30

250 MHz 200 MHz 7.30

20 MHz 10 MHz 7.60

Bandwidth Input frequency 6.25 GS/s

1 GHz 10 MHz 7.00

1 GHz 300 MHz 7.00

250 MHz 10 MHz 7.80

250 MHz 100 MHz 7.80

20 MHz 10 MHz 8.70

14

Page 15

Specifications

1 GHz, 500 MHz, 350 MHz

models, Sample mode, 50

Ω

1 GHz, 500 MHz, 350 MHz

models, High Res mode, 50

Ω

Bandwidth Input Frequency 6.25 GS/s

1 GHz 10 MHz 7.10

1 GHz 300 MHz 7.10

500 MHz 10 MHz 7.40

500 MHz 150 MHz 7.40

350 MHz 10 MHz 7.60

350 MHz 100 MHz 7.60

250 MHz 10 MHz 7.50

250 MHz 100 MHz 7.50

20 MHz 10 MHz 7.70

Bandwidth Input frequency 6.25 GS/s

1 GHz 10 MHz 7.60

1 GHz 300 MHz 7.50

500 MHz 10 MHz 7.90

500 MHz 150 MHz 7.80

350 MHz 10 MHz 8.20

350 MHz 100 MHz 8.20

250 MHz 10 MHz 8.10

250 MHz 100 MHz 8.10

20 MHz 10 MHz 8.90

Random noise, sample acquisition mode

✓2 GHz models, Sample

mode (RMS)

2 GHz models 50 Ω 1 MΩ

V/div 2 GHz 250 MHz 20 MHz 500 MHz 250 MHz 20 MHz

1 mV/div

2 mV/div

5 mV/div

3

4

5

89.8 μV 89.8 μV 39.6 μV 270 μV 158 μV 85.5 μV

152 μV 114 μV 50.6 μV 291 μV 158 μV 90.1 μV

456 μV 155 μV 88.9 μV 315 μV 185 μV 121 μV

10 mV/div 643 μV 244 μV 174 μV 377 μV 271 μV 201 μV

20 mV/div 1.06 mV 436 μV 347 μV 572 μV 462 μV 373 μV

Table continued…

3

Bandwidth at 1 mV/div is limited to 175 MHz in 50 Ω.

4

Bandwidth at 2 mV/div is limited to 350 MHz in 50 Ω.

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 15

Page 16

Specifications

2 GHz models, Sample

mode (RMS), typical

2 GHz models 50 Ω 1 MΩ

V/div 2 GHz 250 MHz 20 MHz 500 MHz 250 MHz 20 MHz

50 mV/div 2.51 mV 1.06 mV 869 μV 1.32 mV 1.11 mV 922 μV

100 mV/div 6.15 mV 2.38 mV 1.74 mV 2.75 mV 2.24 mV 1.88 mV

1 V/div 39.6 mV 21.1 mV 17.4 mV 28.6 mV 23.5 mV 18.7 mV

2 GHz models 50 Ω 1 MΩ

V/div 2 GHz 250 MHz 20 MHz 500 MHz 250 MHz 20 MHz

1 mV/div

2 mV/div

5 mV/div

3

4

5

69.4 μV 69.4 μV 30.6 μV 208 μV 122 μV 66 μV

117 μV 88.0 μV 39.1 μV 225 μV 122 μV 69.7 μV

353 μV 120 μV 68.7 μV 243 μV 143 μV 93.8 μV

10 mV/div 497 μV 188 μV 125 μV 291 μV 209 μV 156 μV

20 mV/div 816 μV 337 μV 251 μV 442 μV 357 μV 288 μV

50 mV/div 1.94 mV 822 μV 627 μV 1.02 mV 857 μV 712 μV

100 mV/div 4.75 mV 1.84 mV 1.25 mV 2.13 mV 1.73 mV 1.45 mV

1 V/div 30.6 mV 16.3 mV 12.5 mV 22.1 mV 18.2 mV 14.5 mV

✓2 GHz models, High Res

mode (RMS)

2 GHz models, High Res

mode (RMS), typical

2 GHz models 50 Ω 1 MΩ

V/div 1 GHz 250 MHz 20 MHz 500 MHz 250 MHz 20 MHz

1 mV/div

2 mV/div

5 mV/div

3

4

5

86.5 μV 86.5 μV 35.2 μV 269 μV 152 μV 83.6 μV

125 μV 100 μV 36.9 μV 290 μV 152 μV 86.6 μV

261 μV 140 μV 48.4 μV 308 μV 172 μV 88.9 μV

10 mV/div 356 μV 191 μV 72.6 μV 359 μV 224 μV 108 μV

20 mV/div 607 μV 325 μV 137 μV 538 μV 360 μV 162 μV

50 mV/div 1.43 mV 763 μV 327 μV 1.19 mV 803 μV 351 μV

100 mV/div 3.56 mV 1.91 mV 779 μV 2.45 mV 1.76 mV 780 μV

1 V/div 23.8 mV 14 mV 6.05 mV 26.3 mV 18.9 mV 8.46 mV

2 GHz models 50 Ω 1 MΩ

V/div 1 GHz 250 MHz 20 MHz 500 MHz 250 MHz 20 MHz

1 mV/div

3

66.8 μV 66.8 μV 27.2 μV 208 μV 117 μV 64.6 μV

Table continued…

5

Bandwidth at 5 mV/div is limited to 1.5 GHz in 50 Ω.

16

Page 17

✓1 GHz, 500 MHz, 350

MHz models, Sample mode

(RMS)

Specifications

2 GHz models 50 Ω 1 MΩ

V/div 1 GHz 250 MHz 20 MHz 500 MHz 250 MHz 20 MHz

2 mV/div

5 mV/div

4

5

96.9 μV 77.5 μV 28.5 μV 224 μV 117 μV 66.7 μV

202 μV 108 μV 37.4 μV 238 μV 133 μV 68.7 μV

10 mV/div 275 μV 147 μV 56.1 μV 277 μV 173 μV 83.6 μV

20 mV/div 469 μV 251 μV 106 μV 416 μV 278 μV 125 μV

50 mV/div 1.10 mV 589 μV 253 μV 916 μV 620 μV 271 μV

100 mV/div 2.75 mV 1.47 mV 602 μV 1.90 mV 1.36 mV 603 μV

1 V/div 18.4 mV 10.8 mV 4.68 mV 20.3 mV 14.6 mV 6.54 mV

< 2 GHz models 50 Ω 1 MΩ

V/div 1 GHz 500

MHz

350

MHz

250 Mhz 20 MHz 500

MHz

350

MHz

250

MHz

20 MHz

1 mV/div 372 μV 253 μV 181 μV 153 μV 91.4 μV 258 μV 188 μV 158 μV 87.9 μV

2 mV/div 376 μV 262 μV 190 μV 164 μV 102 μV 254 μV 193 μV 158 μV 92.0 μV

5 mV/div 395 μV 292 μV 222 μV 201 μV 136 μV 272 μV 207 μV 185 μV 116 μV

10 mV/div 449 μV 359 μV 284 μV 272 μV 197 μV 319 μV 264 μV 251 μV 188 μV

20 mV/div 614 μV 529 μV 436 μV 435 μV 347 μV 455 μV 422 μV 422 μV 347 μV

50 mV/div 1.26 mV 1.14 mV 962 μV 982 μV 869 μV 1.03 mV 898 μV 1.00 mV 869 μV

100 mV/div 2.85 mV 2.50 mV 2.08 mV 2.09 mV 1.74 mV 2.18 mV 1.91 mV 2.06 mV 1.74 mV

1 V/div 24.6 mV 22.4 mV 18.9 mV 19.4 mV 17.4 mV 23.1 mV 21.1 mV 21.6 mV 17.4 mV

1 GHz, 500 MHz, 350

MHz models, Sample mode

(RMS), typical

< 2 GHz models 50 Ω 1 MΩ

V/div 1 GHz 500

MHz

350

MHz

250

MHz

20 MHz 500

MHz

350

MHz

250

MHz

1 mV/div 287 μV 196 μV 140 μV 118 μV 70.6 μV 199 μV 145 μV 122 μV 67.9 μV

2 mV/div 290 μV 202 μV 147 μV 127 μV 78.9 μV 196 μV 149 μV 122 μV 71.1 μV

5 mV/div 305 μV 226 μV 171 μV 156 μV 105 μV 210 μV 160 μV 143 μV 89.8 μV

10 mV/div 347 μV 277 μV 219 μV 210 μV 153 μV 246 μV 204 μV 194 μV 146 μV

20 mV/div 475 μV 409 μV 337 μV 336 μV 257 μV 352 μV 326 μV 326 μV 251 μV

50 mV/div 977 μV 883 μV 743 μV 758 μV 627 μV 796 μV 694 μV 775 μV 627 μV

100 mV/div 2.20 mV 1.93 mV 1.60 mV 1.61 mV 1.25 mV 1.68 mV 1.48 mV 1.59 mV 1.25 mV

1 V/div 19.0 mV 17.3 mV 14.6 mV 15.0 mV 12.5 mV 17.9 mV 16.3 mV 16.7 mV 12.5 mV

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 17

20 MHz

Page 18

Specifications

✓1 GHz, 500 MHz, 350

MHz models, High Res

mode (RMS)

1 GHz, 500 MHz, 350 MHz

models, High Res mode

(RMS), typical

< 2 GHz models 50 Ω 1 MΩ

V/div 1 GHz 500

MHz

1 mV/div 329 μV 256 μV 183 μV 152 μV 90.6 μV 245 μV 184 μV 153 μV 83.8 μV

2 mV/div 330 μV 256 μV 185 μV 157 μV 91.2 μV 251 μV 188 μV 156 μV 85.4 μV

5 mV/div 339 μV 262 μV 195 μV 172 μV 94.3 μV 254 μV 197 μV 169 μV 90.1 μV

10 mV/div 367 μV 282 μV 218 μV 205 μV 103 μV 274 μV 216 μV 200 μV 101 μV

20 mV/div 462 μV 354 μV 287 μV 288 μV 132 μV 348 μV 277 μV 289 μV 135 μV

50 mV/div 876 μV 667 μV 564 μV 595 μV 254 μV 634 μV 530 μV 621 μV 268 μV

100 mV/div 2.09 mV 1.60 mV 1.31 mV 1.34 mV 601 μV 1.51 mV 1.25 mV 1.36 mV 615 μV

1 V/div 16.8 mV 12.8 mV 10.9 mV 11.6 mV 4.88 mV 17.6 mV 13.7 mV 14.4 mV 7.08 mV

< 2 GHz models 50 Ω 1 MΩ

V/div 1 GHz 500

MHz

1 mV/div 254 μV 198 μV 141 μV 118 μV 70.0 μV 189 μV 143 μV 118 μV 64.8 μV

2 mV/div 255 μV 198 μV 143 μV 121 μV 70.4 μV 194 μV 145 μV 121 μV 66.0 μV

5 mV/div 262 μV 202 μV 150 μV 133 μV 72.8 μV 196 μV 152 μV 130 μV 69.6 μV

10 mV/div 283 μV 218 μV 169 μV 158 μV 79.8 μV 212 μV 167 μV 154 μV 78.2 μV

20 mV/div 357 μV 273 μV 222 μV 223 μV 102 μV 269 μV 214 μV 223 μV 104 μV

50 mV/div 677 μV 516 μV 436 μV 460 μV 196 μV 490 μV 410 μV 480 μV 207 μV

100 mV/div 1.61 mV 1.23 mV 1.02 mV 1.04 mV 464 μV 1.16 mV 964 μV 1.05 mV 475 μV

1 V/div 13.0 mV 9.88 mV 8.41 mV 8.94 mV 3.77 mV 13.6 mV 10.6 mV 11.1 mV 5.47 mV

350

MHz

350

MHz

250

MHz

250

MHz

20 MHz 500

MHz

20 MHz 500

MHz

350

MHz

350

MHz

250

MHz

250

MHz

20 MHz

20 MHz

Delay between analog

channels, full bandwidth,

typical

Deskew range -125 ns to +125 ns with a resolution of 40 ps

Crosstalk (channel isolation),

typical

Overdrive recovery time, typical

50 Ω, no probe, 1 GHz

bandwidth

18

≤ 100 ps for any two channels with input impedance set to 50 Ω, DC coupling with equal Volts/div or above

10 mV/div

≥ 200:1 up to the rated bandwidth for any two channels having equal Volts/div settings

Vertical

scale

1 mV/div <1 μs 2.0 ms 2.0 ms --- --- ---

10 mV/div <1 μs 3.0 ms 33 μs <1.2 μs <4.7 μs ---

Table continued…

500% overdrive 5000% overdrive

5% 1% 0.2% 5% 1% 0.2%

Page 19

Specifications

50 Ω, no probe, 2 GHz

bandwidth

TPP1000 Probe

Vertical

scale

100

mV/div

Vertical

scale

1 mV/div <1 μs 110 μs 2.0 ms --- --- ---

10 mV/div <1 μs <1 μs 2.0 ms <1 μs <1 μs ---

100

mV/div

Vertical

scale

10 mV/div 20 μs 2.0 ms 2.0 ms 30 μs 50 μs 2.2 ms

20 mV/div 14 μs 2.0 ms 2.0 ms 30 μs 50 μs 110 μs

50 mV/div 12 μs 60 μs 2.0 ms --- --- ---

100

mV/div

500% overdrive 5000% overdrive

5% 1% 0.2% 5% 1% 0.2%

<1 μs <1 μs 5.8 μs --- ---

500% overdrive 5000% overdrive

5% 1% 0.2% 5% 1% 0.2%

<1 μs <1 μs 2.3 ms --- ---

500% overdrive 5000% overdrive

5% 1% 0.2% 5% 1% 0.2%

12 μs 60 μs 2.0 ms --- --- ---

Total probe power TekVPI Compliant probe interfaces (8 per MSO58B, 6 per MSO56B, 4 per MSO54B)

MSO58B and MSO56B: 80 W maximum, (40 W maximum for channels 1 through 4, 40 W maximum for

channels 5 through 8)

MSO54B: 40 W maximum

Probe power per channel

TekVPI interconnect All analog channel inputs on the front panel conform to the TEKVPI specification.

Voltage Max Amperage Voltage Tolerance

5 V 60 mA ±10%

12 V 2 A (20 W maximum software

limit)

±10%

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 19

Page 20

Specifications

Timebase system

Timebase system

Sample rate

Interpolated waveform rate

range

Record length range

Standard 1 kpoints to 62.5 Mpoints in single sample increments

Optional 5-RL-125M 125 Mpoints

Optional 5-RL-250M 250 Mpoints

Optional 5-RL-500M 500 Mpoints

Max HW Capability Number of Channels

6.25 GS/s 1- 8

500 GS/sec, 250 GS/sec, 125 GS/sec, 62.5 GS/sec, 25 GS/sec, and 12.5 GS/sec

Seconds-Division range

Seconds/Division range

Model 1 K 10 K 100 K 1 M 10 M 62.5 M 125 M

MSO5X Standard

62.5 M

MSO5X Option 5RL-125M

200 ps - 64 s 200 ps - 640 s 200 ps - 1000 s

200 ps - 64 s 200 ps - 640 s 200 ps - 1000 s

Maximum triggered acquisition

rate, typical

Aperture uncertainty

✓Timebase accuracy

Analog or digital channels: single channel [Analog or Digital 8-bit channel] on screen, measurements and

math turned off. >40 wfm/sec

FastAcq Update Rate (analog only): >500 K/second with one channel active and >100 K/second with all

eight active.

FastAcq Update Rate (analog and analog/digital): >400 K/second with two channels active and >100

K/second with all eight analog channels active.

Digital channel: >40/second with one channel (8-bits) active. There is no FastAcq for digital channels, but

they do not slow down FastAcq for active analog channels.

≤ 0.450 fs + (1 * 10

±2.5 x 10-6 over any ≥1 ms time interval

Description Specification

Factory Tolerance

Temperature stability

Table continued…

-11

* Measurement Duration)

±5.0 x10

At calibration, 23 °C ambient, over any ≥1 ms interval

±5.0 x10

Tested at operating temperatures

-7

-7

, for measurements having duration ≤ 100 ms

RMS

20

Page 21

Description Specification

Crystal aging

±1.5 x 10

Frequency tolerance change at 25 °C over a period of 1 year

-6

Specifications

✓Delta-time measurement

accuracy

The formula to calculate delta-time measurement accuracy (DTA) for a given instrument setting and input

signal is as follows (assumes insignificant signal content above Nyquist frequency):

SR 1 = Slew Rate (1st Edge) around 1st point in measurement

SR 2 = Slew Rate (2nd Edge) around 2nd point in measurement

N = input-referred guaranteed noise limit (V

TBA = timebase accuracy or Reference Frequency Error

t p = delta-time measurement duration (sec)

(assume edge shape that results from Gaussian filter response)

The term under the square root sign is the stability and is due to TIE (Time Interval Error). The errors due

to this term occur throughout a single-shot measurement. The second term is due to both the absolute

center-frequency accuracy and the center-frequency stability of the timebase and varies between multiple

single-shot measurements over the observation interval (the amount of time from the first single-shot

measurement to the final single-shot measurement).

RMS

)

The formulas assume negligible errors due to measurement interpolation, and apply only

Note:

when the interpolated sample rate is 25 GS/s or higher.

Trigger system

Trigger bandwidth (edge,

pulse, and logic), typical

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 21

2 GHz models, Edge 2 GHz

2 GHz models, Pulse and Logic 1 GHz

1 GHz models 1 GHz

500 MHz models 500 MHz

350 MHz models 350 MHz

Page 22

Specifications

Edge-type trigger sensitivity,

DC coupled, typical

Table 1: 5 Series B MSO

Path Range Specification

1 MΩ path (all

models)

50 Ω path, 1

GHz, 500

MHz, 350 MHz

models

50 Ω path, 2

GHz models

Line Fixed

AUX Trigger in 200 mVPP, DC to 250 MHz

0.5 mV/div to 0.99

4.5 mV from DC to instrument bandwidth

mV/div

≥ 1 mV/div The greater of 5 mV or 0.7 div from DC to lesser of 500 MHz or

instrument BW, & 6 mV or 0.8 div from > 500 MHz to instrument

bandwidth

The greater of 5.6 mV or 0.7 div from DC to the lesser of 500

MHz or instrument BW, & 7 mV or 0.8 div from > 500 MHz to

instrument bandwidth

0.5 mV/div to 0.99

3.0 div from DC to instrument bandwidth

mV/div

1 mV/div to 9.98

1.5 divisions from DC to instrument bandwidth

mV/div

≥ 10 mV/div < 1.0 division from DC to instrument bandwidth

Trigger jitter, typical ≤ 5 ps

≤ 7 ps

≤ 40 ps

≤ 40 ps

AUX In trigger skew between

instruments, typical

±100 ps jitter on each instrument with 150 ps skew; ≤350 ps total between instruments. With manual

deskewing of individual channels, total instrument skew can reach 200 ps between different instrument

channels.

Skew improves for sinusoidal input voltages ≥500 mV

Edge-type trigger sensitivity,

not DC coupled, typical

Trigger Coupling Typical Sensitivity

NOISE REJ 2.5 times the DC Coupled limits

HF REJ 1.0 times the DC Coupled limits from DC to 50 kHz. Attenuates signals above

LF REJ 1.5 times the DC Coupled limits for frequencies above 50 kHz. Attenuates

Lowest frequency for

45 Hz

successful operation of Set

Level to 50% function, typical

for sample mode and edge-type trigger

RMS

for edge-type trigger and FastAcq mode

RMS

for non edge-type trigger modes

RMS

for AUX trigger in, Sample acquisition mode, edge trigger (MSO58LP only)

RMS

50 kHz.

signals below 50 kHz.

Logic-type, logic qualified

trigger, or events-delay

22

2.0 divisions, at vertical settings ≥5 mV/div.

Page 23

sensitivities, DC coupled,

typical

Specifications

Pulse-type runt trigger

sensitivities, typical

Pulse-type trigger width and

glitch sensitivities, typical

Logic-type triggering,

minimum logic or rearm time,

typical

Minimum clock pulse widths

for setup/hold time violation

trigger, typical

Setup/hold violation trigger,

setup and hold time ranges,

typical

2.0 division at vertical settings ≥5 mV/div.

2.0 divisions at vertical settings ≥5 mV/div.

Triggering type Pulse width Rearm time Time skew needed for 100%

6

8

Logic 160 ps + t

Time qualified logic 320 ps + t

t

is rise time of the instrument.

rise

Minimum pulsewidth, clock active

User's Hold Time 80 ps + t

t

is rise time of the instrument.

rise

rise

rise

rise

and no triggering

160 ps + t

320 ps + t

7

rise

rise

Minimum pulsewidth, clock inactive

320 ps +t

rise

>360 ps / <150 ps

>360 ps / <150 ps

Feature Min Max

Setup Time 0 ns 20 s

Hold Time 0 ns 20 s

Setup + Hold Time 80 ps 22 s

Input coupling on clock and data channels must be the same.

For Setup Time, positive numbers mean a data transition before the clock.

For Hold Time, positive numbers mean a data transition after the clock edge.

Setup + Hold Time is the algebraic sum of the Setup Time and the Hold Time programmed by the user.

Pulse type trigger, minimum

pulse, rearm time, transition

time

Pulse class Minimum pulse width Minimum rearm time

Runt 160 ps + t

Time-Qualified Runt 160 ps + t

Width 160 ps + t

Slew Rate (minimum transition

160 ps + t

rise

rise

rise

rise

160 ps + t

160 ps + t

160 ps + t

160 ps + t

rise

rise

rise

rise

time)

6

For Logic, time between channels refers to the length of time a logic state derived from more than one channel must exist to be recognized. For Events, the time is

the minimum time between a main and delayed event that will be recognized if more than one channel is used.

7

Active pulsewidth is the width of the clock pulse from its active edge (as defined in the Clock Edge menu item) to its inactive edge.

8

Inactive pulsewidth is the width of the pulse from its inactive edge to its active edge.

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 23

Page 24

Specifications

For trigger class width, pulse width refers to the width of the pulse being measured. Rearm time refers to the

time between pulses.

For trigger class runt, pulse width refers to the width of the pulse being measured. Rearm time refers to the

time between pulses.

For trigger class slew rate, pulse width refers to the delta time being measured. Rearm time refers to the

time it takes the signal to cross the two trigger thresholds again.

t

is rise time of the instrument.

rise

Active pulsewidth is the width of the clock pulse from its active edge (as defined in the Clock Edge menu

item) to its inactive edge

Inactive pulsewidth is the width of the pulse from its inactive edge to its active edge.

Transition time trigger, delta

time range

Time range for glitch, pulse

width, timeout, time-qualified

runt, or time-qualified window

triggering

Time accuracy for pulse,

glitch, timeout, or width

triggering

B trigger after events,

minimum pulse width and

maximum event frequency,

typical

B trigger, minimum time

between arm and trigger,

typical

160 ps to 20 s.

160 ps to 20 s.

Time Range Accuracy

320 ps to 500 ns ±(160 ps + (Time-Base-Accuracy * Setting))

520 ns to 10 s ±(160 ps + (Time-Base-Accuracy * Setting))

Minimum pulse width: 160 ps + t

rise

Maximum event frequency: Instrument bandwidth.

t

is rise time of the instrument.

rise

320 ps

For trigger after time, this is the time between the end of the time period and the B trigger event.

For trigger after events, this is the time between the last A trigger event and the first B trigger event.

B trigger after time, time range 160 ps to 20 seconds

B trigger after events, event

1 to 65,471

range

Trigger level ranges

Source Range

Any Channel ±5 divs from center of screen

Aux In Trigger ±5 V

Line Fixed at about 50% of line voltage

This specification applies to logic and pulse thresholds.

24

Page 25

Specifications

Trigger level accuracy, DC

coupled, typical

Trigger holdoff range 0 ns to 20 seconds

For signals having rise and fall times ≥10 ns:

Source Range

Any Input Channel ±0.20 div

AUX IN N/A

Line N/A

Serial Trigger specifications

Maximum serial trigger bits 128 bits

Optional serial bus interface triggering

I2C

SPI Data Trigger: 1 - 16 Bytes of user-specified data

Address Triggering: 7 & 10 bits of user-specified addresses supported

Data Trigger: 1 - 5 Bytes of user-specified data

Trigger on: Start, Repeated Start, Stop, Missing Ack, Data, Address, or Address & Data

Maximum Data Rate: 10 Mb/s

Trigger on: SS Active, Data

Maximum Data Rate: 20 Mb/s

CAN Data Trigger: 1 - 8 Bytes of user-specified data, including qualifiers of equal to (=), not equal to (≠), less than

(<), greater than (>), less than or equal to (<=), greater than or equal to (>=)

Trigger on: Start of Frame, Type of Frame, Identifier, Data, Identifier & Data, End of Frame, Missing Ack, or Bit

Stuffing Errors

Frame Type: Data, Remote, Error, Overload

Identifier: Standard (11 bit) and Extended (29 bit) identifiers

Maximum Data Rate: 1 Mb/s

LIN Identifier Trigger: 6 bits of user-specified data, equal to (=)

Data Trigger: 1 - 8 Bytes of user-specified data, including qualifiers of equal to (=), not equal to (≠), less than

(<), greater than (>), less than or equal to (<=), greater than or equal to (>=), inside range, outside range

Error Trigger: Sync, Identifier Parity, Checksum

Trigger on: Sync, Identifier, Data, Identifier & Data, Wakeup Frame, Sleep Frame, or Error

Maximum Data Rate: 100 kb/s

Flexray Indicator Bits: Normal (01XX), Payload (11XX), Null (00XX), Sync (XX10), Startup (XX11)

Frame ID Trigger: 11 bits of user-specified data, including qualifiers of equal to (=), not equal to (≠), less than

(<), greater than (>), less than or equal to (<=), greater than or equal to (>=)

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 25

Page 26

Specifications

Cycle Count Trigger: 6 bits of user-specified data , including qualifiers of equal to (=), not equal to (≠), less

than (<), greater than (>), less than or equal to (<=), greater than or equal to (>=)

Header Fields Trigger: 40 bits of user-specified data comprising Indicator Bits, Identifier, Payload Length,

Header CRC, and Cycle Count, equal to (=)

Data Trigger: 1 - 16 Bytes of user-specified data, with 0 to 253, or "don't care" bytes of data offset,including

qualifiers of equal to (=), not equal to (≠), less than (<), greater than (>), less than or equal to (<=), greater than

or equal to (>=), Inside Range, Outside Range

End Of Frame: User-chosen types Static, Dynamic (DTS), and All

Error Trigger: Header CRC, Trailer CRC, Null Frame-static, Null Frame-dynamic, Sync Frame, Startup frame

(No Sync)

Trigger on: Start of Frame, Frame ID, Indicator Bits, Cycle Count, Header Fields, Data, Identifier & Data, End

of Frame, or Error

Maximum Data Rate: 40 Mb/s

Audio (I2S)

Data Trigger: 32 bits of user-specified data in a left word, right word, or either, including qualifiers of equal to

(=), not equal to (≠), less than (<), greater than (>), less than or equal to (<=), greater than or equal to (>=),

inside range, outside range

Trigger on: Word Select, Data

Maximum Data Rate: 12.5 Mb/s

Left Justified (LJ)

Data Trigger: 32 bits of user-specified data in a left word, right word, or either, including qualifiers of equal to

(=), not equal to (≠), less than (<), greater than (>), less than or equal to (<=), greater than or equal to (>=),

inside range, outside range

Trigger on: Word Select, Data

Maximum Data Rate: 12.5 Mb/s

Right Justified (RJ)

Data Trigger: 32 bits of user-specified data in a left word, right word, or either, including qualifiers of equal to

(=), not equal to (≠), less than (<), greater than (>), less than or equal to (<=), greater than or equal to (>=),

inside range, outside range

Trigger on: Word Select, Data

Maximum Data Rate: 12.5 Mb/s

TDM

Data Trigger: 32 bits of user-specified data in a channel 1-64, including qualifiers of equal to (=), not equal

to (≠), less than (<), greater than (>), less than or equal to (<=), greater than or equal to (>=), inside range,

outside range

Trigger on: Frame Sync, Data

Maximum Data Rate: 25 Mb/s

RS232 Bit Rate: 50 bps - 10 Mbps

Data Bits: 7, 8, or 9

Parity: None, Odd, or Even

26

Page 27

Trigger on: Start, End of Packet, Data, Parity Error

MIL-STD-1553 Bit Rate: 1 Mb/s

Trigger on:

Sync

Word Type (Command, Status, Data)

Command Word (set RT Address (=, ≠, <, >, ≤, ≥, inside range, outside range), T/R, Sub-address/ Mode, Data

Word Count/Mode Code, and Parity individually)

Status Word (set RT Address ((=, ≠, <, >, ≤, ≥, inside range, outside range), Message Error, Instrumentation,

Service Request Bit, Broadcast Command Received, Busy, Subsystem Flag, Dynamic Bus Control Acceptance

(DBCA), Terminal Flag, and Parity individually)

Data Word (user-specified 16-bit data value)

Error (Sync, Parity, Manchester, Non-contiguous data)

Idle Time (minimum time selectable from 4 μs to 100 μs; maximum time selectable from 12 μs to 100 μs;

trigger on < minimum, > maximum, inside range, outside range)

For MIL-STD-1553, Trigger selection of Command Word will trigger on Command and ambiguous Command/

Status words. Trigger selection of Status Word will trigger on Status and ambiguous Command/Status words

Specifications

USB Data Rates Supported: High: 480 Mbs, Full: 12 Mbs, Low: 1.5Mbs

Trigger On: Sync, Reset, Suspend, Resume, End of Packet, Token Packet, Data Packet, Handshake Packet,

Special Packet, Error

Ethernet Bit Rate: 10 BASE-T, 10 Mbps; 100 BASE-TX, 100 Mbps

Trigger On: Start of Frame, MAC Address, MAC Length/Type, IP Header, TCP Header, Client Data, End of

Packet, Idle, FCS (CRC) Error, MAC Q-Tag control Information

Digital acquisition system

Digital channel maximum

sample rate

Transition detect (digital peak

detect)

Digital-To-Analog trigger skew 1 ns

Digital to digital skew 320 ps from bit 0 of any TekVPI channel to bit 0 of any TekVPI channel.

Digital skew within a

FlexChannel

6.25 GS/s

Displayed data at sample rates less than 6.25 GS/s (decimated data), that contains multiple transitions

between sample points will be displayed with a bright white colored edge.

160 ps within any TekVPI channel

Digital volt meter (DVM)

Measurement types DC, AC

Voltage resolution 4 digits

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 27

RMS

+DC, AC

RMS

Page 28

Specifications

Voltage accuracy

DC: ±((1.5% * |reading - offset - position|) + (0.5% * |(offset - position)|) + (0.1 * Volts/div))

De-rated at 0.100%/°C of |reading - offset - position| above 30 °C

Signal ± 5 divisions from screen center

AC: ± 2% (40 Hz to 1 kHz) with no harmonic content outside 40 Hz to 1 kHz range

AC, typical: ± 2% (20 Hz to 10 kHz)

For AC measurements, the input channel vertical settings must allow the VPP input signal to cover between 4

and 10 divisions and must be fully visible on the screen

Trigger frequency counter

Resolution 8-digits

✓Accuracy ±(1 count + time base accuracy * input frequency)

The signal must be at least 8 mVpp or 2 div, whichever is greater.

✓Maximum input frequency 10 Hz to maximum bandwidth of the analog channel

The signal must be at least 8 mVpp or 2 div, whichever is greater.

Arbitrary Function Generator system

Function types Arbitrary, sine, square, pulse, ramp, triangle, DC level, Gaussian, Lorentz, exponential rise/fall, sin(x)/x,

random noise, Haversine, Cardiac

Amplitude range Values are peak-to-peak voltages

Waveform 50 Ω 1 MΩ

Arbitrary 10 mV to 2.5 V 20 mV to 5 V

Sine 10 mV to 2.5 V 20 mV to 5 V

Square 10 mV to 2.5 V 20 mV to 5 V

Pulse 10 mV to 2.5 V 20 mV to 5 V

Ramp 10 mV to 2.5 V 20 mV to 5 V

Triangle 10 mV to 2.5 V 20 mV to 5 V

Gaussian 10 mV to 1.25 V 20 mV to 2.5 V

Lorentz 10 mV to 1.2 V 20 mV to 2.4 V

Exponential Rise 10 mV to 1.25 V 20 mV to 2.5 V

Exponential Fall 10 mV to 1.25 V 20 mV to 2.5 V

Sine(x)/x 10 mV to 1.5 V 20 mV to 3.0 V

Random Noise 10 mV to 2.5 V 20 mV to 5 V

Haversine 10 mV to 1.25 V 20 mV to 2.5 V

Cardiac 10 mV to 2.5 V 20 mV to 5 V

28

Page 29

Maximum sample rate 250 MS/s

Specifications

Arbitrary function record

128 K Samples

length

Sine waveform

Frequency range 0.1 Hz to 100 MHz

Frequency setting

0.1 Hz

resolution

Frequency accuracy 130 ppm (frequency ≤ 10 kHz), 50 ppm (frequency > 10 kHz)

This is for Sine, Ramp, Square and Pulse waveforms only.

Amplitude range 20 mVpp to 5 Vpp into Hi-Z; 10 mVpp to 2.5 Vpp into 50 Ω

Amplitude flatness, typical ±0.5 dB at 1 kHz

±1.5 dB at 1 kHz for < 20 mVpp amplitudes

Total harmonic distortion,

typical

1% for amplitude ≥ 200 mVpp into 50 Ω load

2.5% for amplitude > 50 mV AND < 200 mVpp into 50 Ω load

This is for Sine wave only.

Spurious free dynamic

40 dB (Vpp ≥ 0.1 V); 30 dB (Vpp ≥ 0.02 V), 50 Ω load

range, typical

Square and pulse waveform

Frequency range 0.1 Hz to 50 MHz

Frequency setting

0.1 Hz

resolution

Duty cycle range 10% - 90% or 10 ns minimum pulse, whichever is larger

Minimum pulse time applies to both on and off time, so maximum duty cycle will reduce at higher frequencies

to maintain 10 ns off time

Duty cycle resolution 0.1%

Minimum pulse width,

10 ns. This is the minimum time for either on or off duration.

typical

Rise/Fall time, typical 5 ns, 10% - 90%

Pulse width resolution 100 ps

Overshoot, typical < 6% for signal steps greater than 100 mV

pp

This applies to overshoot of the positive-going transition (+overshoot) and of the negative-going (-overshoot)

transition

Asymmetry, typical ±1% ±5 ns, at 50% duty cycle

Jitter, typical < 60 ps TIE

, ≥ 100 mVpp amplitude, 40%-60% duty cycle

RMS

Cardiac maximum frequency 1 MHz

Ramp and triangle waveform

Frequency range 0.1 Hz to 1 MHz

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 29

Page 30

Specifications

Frequency setting

resolution

Variable symmetry 0% - 100%

Symmetry resolution 0.1%

DC level range ±2.5 V into Hi-Z

Gaussian pulse, Haversine, and Lorentz pulse

Maximum frequency 10 MHz

Exponential rise fall maximum

frequency

Sin(x)/x

Maximum frequency 4 MHz

Random noise amplitude

range

0.1 Hz

±1.25 V into 50 Ω

10 MHz

20 mVpp to 5 Vpp into Hi-Z

10 mVpp to 2.5 Vpp into 50 Ω

For both isolated noise signal and additive noise signal.

✓Sine and ramp frequency

accuracy

✓Square and pulse frequency

accuracy

Signal amplitude resolution 1 mV (Hi-Z)

✓Signal amplitude accuracy ±[ (1.5% of peak-to-peak amplitude setting) + (1.5% of absolute DC offset setting) + 1 mV ] (frequency = 1

DC offset range ±2.5 V into Hi-Z

DC offset resolution 1 mV (Hi-Z)

✓DC offset accuracy ±[ (1.5% of absolute offset voltage setting) + 1 mV ]

1.3 x 10-4 (frequency ≤10 kHz)

5.0 x 10-5 (frequency >10 kHz)

1.3 x 10-4 (frequency ≤10 KHz);

5.0 x 10-5 (frequency >10 KHz)

500 μV (50 Ω)

kHz)

±1.25 V into 50 Ω

500 μV (50 Ω)

Add 3 mV of uncertainty per 10 °C change from 25 °C ambient. Refer DC Offset Accuracy test record

Display system

Display type Display size: 15.6 inches diagonal

30

Page 31

Display type: TFT liquid crystal display (LCD)

Display resolution 1,920 horizontal × 1,080 vertical pixels (High Definition)

Luminance, typical

Color Support 262 K colors (6-bit RGB)

Display Options

Persistence Off, Infinite, Variable (Persistence Time is variable) or Auto

Waveform styles Vectors, dots

Graticule Grid, Time, Full or None

Graticule Intensity Variable

Display Mode Overlay or Stacked

Interpolation Sin(x)/x or Linear

Waveform Intensity Variable

250 cd/m2, (Minimum: 200 cd/m2), Display luminance is specified for a new display set at full brightness.

Processor system

Host processor Intel Core i5-8400H @ Coffee Lake 2.5 GHz 64-bit Quad Core Processor

Operating system Default instrument: Closed Linux

Specifications

Instrument with option 5B-WIN installed: Microsoft Windows 10

Input/Output port specifications

Ethernet interface An 8-pin RJ-45 connector that supports 10/100/1000 Mb/s

DVI connector A 29-pin DVI-D connector; connect to show the oscilloscope display on an external monitor or projector

Maximum supported resolution, Windows: 1920 x 1200 @ 60 Hz

Maximum supported resolution, Linux: 1920 x 1080 @ 60 Hz

Only a single TMDS link is provided

Analog VGA signaling is not provided

DisplayPort connector A 20-pin DisplayPort connector; connect to show the oscilloscope display on an external monitor or

projector

Maximum supported resolution, Windows: 2560 x 1440 @ 60Hz

Maximum supported resolution, Linux: 1920 x 1080 @ 60 Hz

DP++ adapter: Maximum supported resolution: 2560 x1440 @ 60 Hz

Simultaneous displays Up to 3 displays (including the internal display) with a maximum of 1 display per port.

USB interface (Host, Device

ports)

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 31

5 Series MSO Front panel USB Host ports: Two USB 2.0 Hi-Speed ports, one USB 3.0 SuperSpeed port

All instruments, Rear panel USB Host ports: Two USB 2.0 Hi-Speed ports, two USB 3.0 SuperSpeed ports

All instruments, Rear panel USB Device port: One USB 3.0 SuperSpeed Device port providing USBTMC

support

Page 32

Specifications

Probe compensator signal

output voltage and frequency,

typical

Characteristic Value

Output Voltage Default: 0-2.5 V amplitude

Impedance 1 kΩ

Frequency 1 kHz

✓Auxiliary output, AUX OUT, Trigger Out, Event, or Reference Clock Out

Selectable output Acquisition Trigger Out

Reference Clock Out

AFG Trigger Out

Acquisition Trigger Out User selectable transition from HIGH to LOW, or LOW to HIGH, indicates the trigger occurred. The signal

returns to its previous state after approximately 100 ns

Acquisition trigger jitter 300 ps (peak-to-peak)

Reference Clock Out Reference clock output tracks the acquisition system and can be referenced from either the internal clock

reference or the external clock reference

AFG Trigger Out The output frequency is dependent on the frequency of the AFG signal as shown in the following table:

AFG signal frequency AFT trigger frequency

≤ 4.9 MHz Signal frequency

> 4.9 MHz to 14.7 MHz Signal frequency / 3

> 14.7 MHz to 24.5 MHz Signal frequency / 5

> 24.5 MHz to 34.3 MHz Signal frequency / 7

> 34.3 MHz to 44.1 MHz Signal frequency / 9

> 44.1 MHz to 50 MHz Signal frequency / 11

AUX OUT Output Voltage

Characteristic Limits

Vout (HI) ≥ 2.5 V open circuit; ≥ 1.0 V into a 50 Ω load to ground

Vout (LO) ≤ 0.7 V into a load of ≤ 4 mA; ≤0.25 V into a 50 Ω load to ground

External reference input

Nominal input frequency 10 MHz

Frequency Variation

9.99996 MHz to 10.00004 MHz (±4.0 x 10-6)

Tolerance

Sensitivity, typical Vin 1.5 V

Maximum input signal 7 V

using a 50 Ω termination

p-p

pp

Impedance 1.2 K Ohms ±20% in parallel with 18 pf ±5 pf at 10 MHz

32

Page 33

Data storage specifications

Specifications

Nonvolatile memory retention

time, typical

Real-time clock A programmable clock providing time in years, months, days, hours, minutes, and seconds.

Nonvolatile memory capacity

Instrument S/N A 2 kbit EEPROM on the main board that stores the instrument serial number, instrument start up count, total

Companion CvP A pair of 16 Mbit flash memory devices that stores a portion of the Companion FPGA image data. One device

AFG S/N A 2 kbit EEPROM on the AFG riser card that stores a copy of the instrument serial number which is used to

Front Panel ID A 64 kbit EEPROM on the LED board that stores the USB vendor ID and device ID for the internal front panel

BIOS A 128 Mbit flash memory device that stores the firmware image and device configuration for the host processor

CMOS Memory The host processor chipset includes an integrated memory device, powered by the real-time clock (RTC)

Memory SPD Each SODIMM (memory module) contains a serial presence detect (SPD) memory device implemented using

UCD9248 The instrument includes 3 UCD9248 power supply controllers. Each controller contains an unspecified quantity

PMU A power management unit (PMU) microcontroller is used to manage instrument power supplies and hardware

Analog Board Controller A microcontroller is used to manage analog board operation. The PMU includes 64 KB of nonvolatile memory

Carrier FPGA The carrier FPGA stores its own configuration in its own internal 0.33 Mbit nonvolatile memory. The carrier

No time limit for front panel settings, saved waveforms, setups, product licensing, and calibration constants.

uptime and administration passwords.

serves as a backup for the other device.

validate the AFG calibration.

controller.

and chipset sub-processors. This includes the Basic Input Output System (BIOS), Management Engine (ME),

Embedded Controller (EC) and Network Interface Controller (NIC). The Ethernet MAC address is stored in this

device.

battery, which stores BIOS configuration settings. A customer accessible switch disconnects the RTC battery

from the chipset which clears the contents of the integrated CMOS memory device.

an unspecified memory technology. Each SPD device contains the parameter data specific to its memory

module. All SPD devices are treated by the instrument as read only. The size of a given SPD is unspecified.

The 4 channel instrument includes 4 SPD devices. The 6 channel and 8 channel instruments include 6 SPD

devices.

of nonvolatile memory that stores various power supply configuration settings.

initialization. The PMU includes 32 KB of nonvolatile memory for storage of its own binary executable and

redundant storage of UCD9248 device settings.

for storage of its own binary executable.

FPGA implements simple "glue logic" for the instrument.

Mass storage device capacity

Linux ≥ 250 GB. Form factor is a 2.5 inch SSD with a SATA-3 interface. Waveforms and setups are stored on the

solid state drive. Provides storage for saved customer data and the Linux operating system.

Windows (optional) ≥ 500 GB. Form factor is a 2.5 inch SSD with a SATA-3 interface. This drive is customer installable and

provides storage for the Windows operating system option, and saved customer data.

Power supply system

Power

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 33

Page 34

Specifications

Power consumption 400 Watts maximum

Source voltage 100 - 240 V ±10% (50 Hz to 60 Hz)

Source frequency 50 Hz to 60 Hz ±10%, at 100 - 240 V ±10%

400 Hz ±10% at 115 V ±10%

Fuse Rating 12.5 A, 250 V

ac

Safety characteristics

Safety certification US NRTL Listed - UL61010-1 and UL61010-2-030

Canadian Certification - CAN/CSA-C22.2 No. 61010.1 and CAN/CSA-C22.2 No 61010.2.030

EU Compliance - Low Voltage Directive 2014-35-EU and EN61010-1.

International Compliance - IEC 61010-1 and IEC61010-2-030

Pollution degree Pollution degree 2, indoor, dry location use only

Environmental specifications

Temperature

Operating +0 °C to +50 °C (32 °F to 122 °F)

Non-operating -20 °C to +60 °C (-4 °F to 140 °F)

Humidity

Operating 5% to 90% relative humidity (% RH) at up to +40 °C

5% to 55% RH above +40 °C up to +50 °C, noncondensing, and as limited by a maximum wet-bulb

temperature of +39 °C

Non-operating 5% to 90% relative humidity (% RH) at up to +40 °C

5% to 39% RH above +40 °C up to +50 °C, noncondensing, and as limited by a maximum wet-bulb

temperature of +39 °C

Altitude

Operating Up to 3,000 meters (9,843 feet)

Non-operating Up to 12,000 meters (39,370 feet)

Temperature

Operating +0 °C to +50 °C (32 °F to 122 °F)

Non-operating -20 °C to +60 °C (-4 °F to 140 °F)

Humidity

Operating 5% to 90% relative humidity (% RH) at up to +40 °C

5% to 55% RH above +40 °C up to +50 °C, noncondensing, and as limited by a maximum wet-bulb

temperature of +39 °C

Non-operating 5% to 90% relative humidity (% RH) at up to +40 °C

34

Page 35

5% to 39% RH above +40 °C up to +50 °C, noncondensing, and as limited by a maximum wet-bulb

temperature of +39 °C

Altitude

Operating Up to 3,000 meters (9,843 feet)

Non-operating Up to 12,000 meters (39,370 feet)

Mechanical specifications

Weight Weight of instruments by model:MSO54B 1 GHz: 22.7 lbs (10.3 Kg)

MSO54B 2 GHz: 23.6 lbs (10.7 Kg)

MSO56B 1 GHz: 23.5 lbs (10.7 Kg)

MSO56B 2 GHz: 24.3 lbs (11.0 Kg)

MSO58B 1 GHz: 23.8 lbs (10.8 Kg)

MSO58B 2 GHz: 24.7 lbs (11.2 Kg)

Dimensions

Specifications

Height: 371 mm (14.6 in) feet folded in, handle folded up

309 mm (12.2 in) feet folded in, handle folded to the backside of the instrument

Width: 454 mm (17.9 in) from handle hub to handle hub

Depth: 205 mm (8.0 in) from back of feet to front of knobs

297 mm (11.7 in) feet folded in, handle folded to the backside of the instrument

Clearance requirements The clearance requirement for adequate cooling is 2.0 in (50.8 mm) on the right side (when looking at the

front of the instrument) and on the rear of the instrument

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 35

Page 36

Performance verification procedures

Performance verification procedures

This chapter contains performance verification procedures for the specifications marked with the symbol. The following equipment, or a

suitable equivalent, is required to complete these procedures.

The performance verification procedures verify the performance of your instrument. They do not adjust your instrument. If your instrument

fails any of the performance verification tests, repeat the failing test, verifying that the test equipment and settings are correct. If the

instrument continues to fail a test, contact Tektronix Customer Support for assistance.

These procedures cover all 5 Series B MSO instruments (MSO54B, MSO56B, MSO58B).

Print the test records on the following pages and use them to record the performance test results for your oscilloscope. Disregard checks

and test records that do not apply to the specific model you are testing.

Note: Completion of the performance verification procedure does not update the instrument time and date.

Required equipment:

Required equipment Minimum requirements Examples

DC voltage source 3 mV to 4 V, ±0.1% accuracy Fluke 9500B Oscilloscope Calibrator with a

9530 Output Module

Leveled sine wave generator 50 kHz to 2 GHz, ±4% amplitude accuracy

Time mark generator

Logic probe Low capacitance digital probe, 8 channels. TLP058 probe

BNC-to-0.1 inch pin adapter to connect the

logic probe to the signal source.

Digital multimeter (DMM) 0.1% accuracy or better Tektronix DMM4020

One 50 Ω terminator Impedance 50 Ω; connectors: female BNC

One 50 Ω BNC cable Male-to-male connectors Tektronix part number 012-0057-01

Optical mouse USB, PS2 Tektronix part number 119-7054-00

RF vector signal generator Maximum bandwidth of instrument Tektronix TSG4100A

80 ms period, ±1.0 x 10-6 accuracy, rise time

<50 ns

BNC-to-0.1 inch pin adapter; female BNC to

2x16 .01 inch pin headers.

input, male BNC output

Tektronix adapter part number 878-1429-00;

to connect the Fluke 9500B to the TLP058

probe.

Tektronix part number 011-0049-02

You might need additional cables and adapters, depending on the actual test equipment you use.

Test records

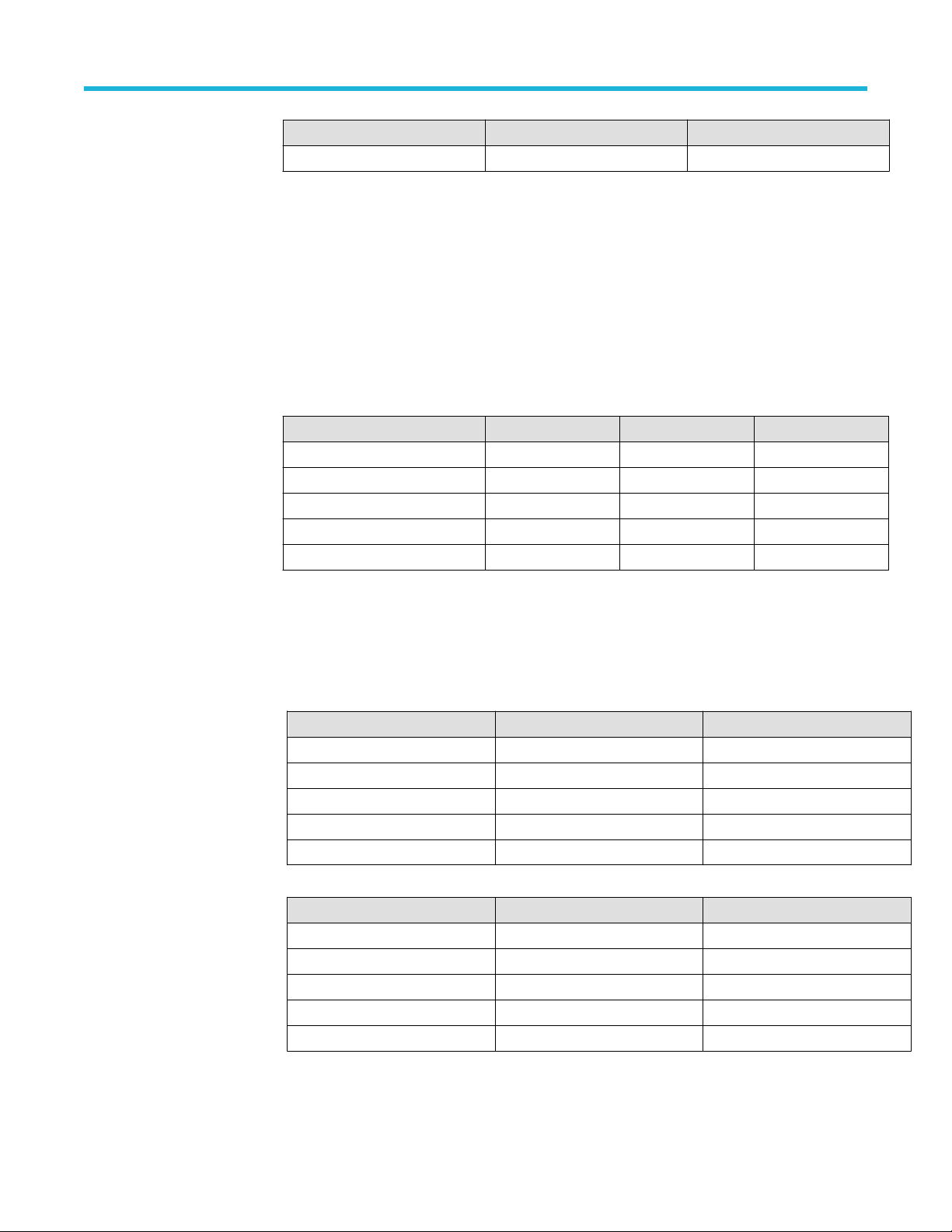

Instrument information, self test record

Model Serial # Procedure performed by Date

Test Passed Failed

Self Test

36

Page 37

Performance verification procedures

Input Impedance test record

Input Impedance

Performance checks Vertical scale Low limit Test result High limit

All models

Channel 1 Input

Impedance, 1 MΩ

Channel 1 Input

Impedance, 50 Ω

Channel 2 Input

Impedance, 1 MΩ

Channel 2 Input

Impedance, 50 Ω

Channel 3 Input

Impedance, 1 MΩ

Channel 3 Input

Impedance, 50 Ω

Channel 4 Input

Impedance, 1 MΩ

Channel 4, Input

Impedance, 50 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

MSO56B, MSO58B models

Channel 5 Input

Impedance, 1 MΩ

Channel 5 Input

Impedance, 50 Ω

Channel 6 Input

Impedance, 1 MΩ

Channel 6 Input

Impedance, 50 Ω

MSO58B model

Channel 7 Input

Impedance, 1 MΩ

Channel 7 Input

Impedance, 50 Ω

Channel 8 Input

Impedance, 1 MΩ

Channel 8, Input

Impedance, 50 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

100 mV/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 Ω

100 mV/div 49.5 Ω 50.5 Ω

5 Series B MSO MSO54B, MSO56B, MSO58B Specifications and Performance Verification 37

Page 38

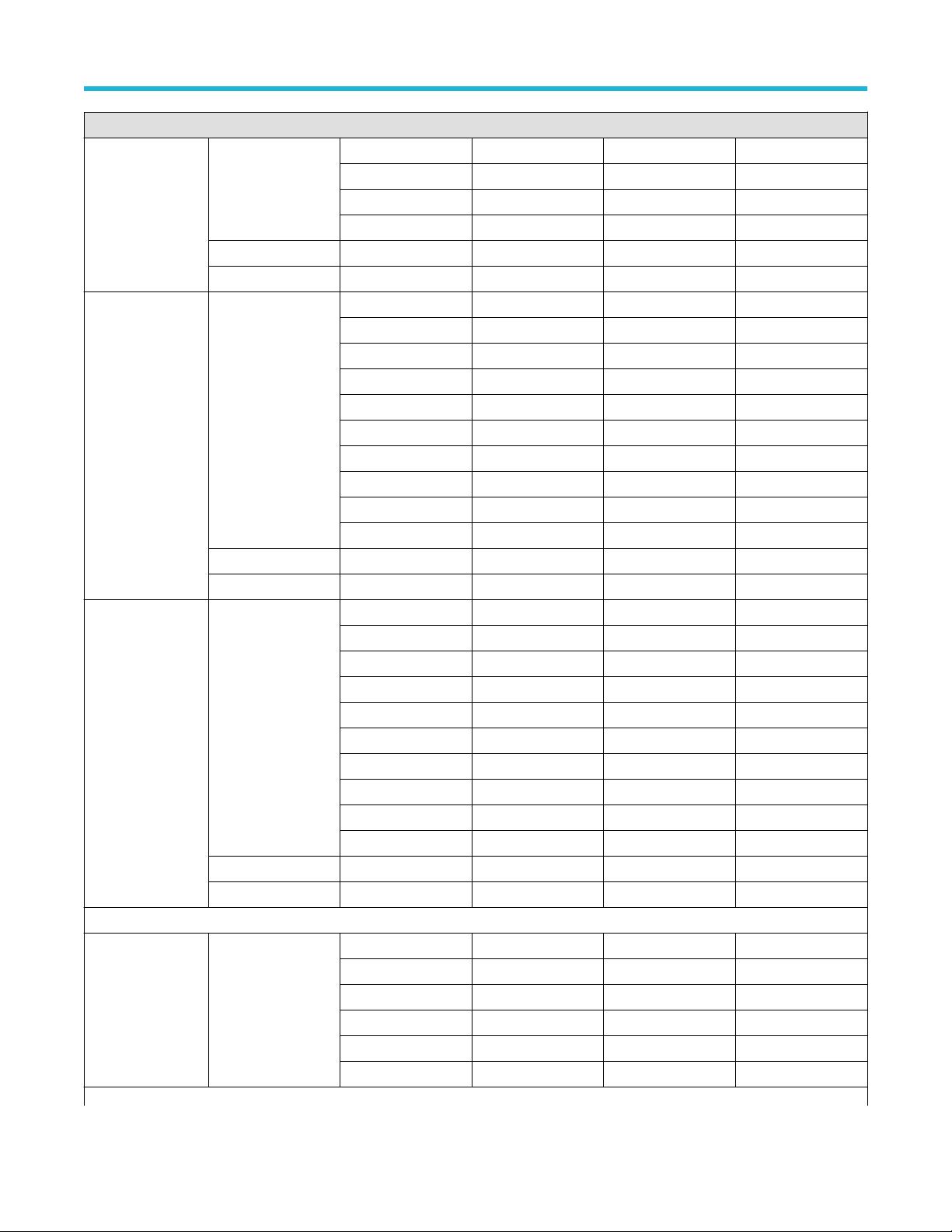

Performance verification procedures

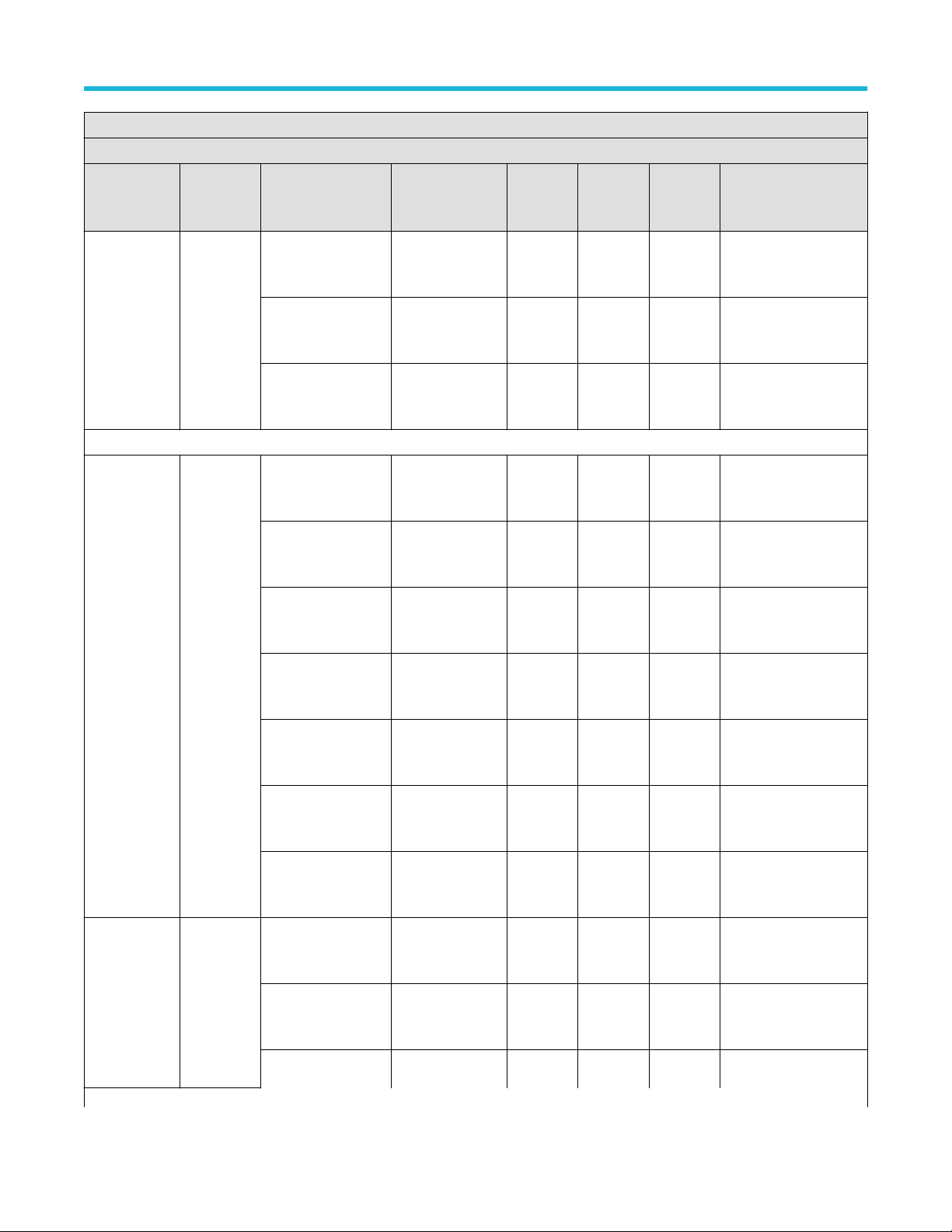

DC Balance test record