4 Series MSO

(MSO44, MSO46)

Service

Register now!

Click the following link to protect your product.

www.tek.com/register

*P 077154701*

077-1547-01

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by national copyright laws and international treaty provisions. T

and pending. Information in this publication supersedes that in all previously published material. Specifications and price change privileges

reserved.

ektronix products are covered by U.S. and foreign patents, issued

TEKTRONIX and TEK are registered trademarks of T

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

• In North America, call 1-800-833-9200.

• Worldwide, visit www.tek.com to find contacts in your area.

ektronix, Inc.

Table of Contents

Table of Contents

List of Figures................................................................................................................................................................................5

List of Tables................................................................................................................................................................................. 6

Important safety information..........................................................................................................................................................7

General safety summary........................................................................................................................................................7

Service safety summary.........................................................................................................................................................9

Terms in the manual.............................................................................................................................................................10

Terms on the product........................................................................................................................................................... 10

Symbols on the product....................................................................................................................................................... 10

Preface........................................................................................................................................................................................ 11

Supported products..............................................................................................................................................................11

Replaceable parts................................................................................................................................................................ 11

Where to find operating information..................................................................................................................................... 11

Theory of operation..................................................................................................................................................................... 12

Power supply....................................................................................................................................................................... 12

Processor board...................................................................................................................................................................12

Main board........................................................................................................................................................................... 12

Front panel and display........................................................................................................................................................13

Adjustment procedures............................................................................................................................................................... 14

Adjustment........................................................................................................................................................................... 14

Adjustment interval.............................................................................................................................................................. 14

Adjustment after repair.........................................................................................................................................................14

Maintenance................................................................................................................................................................................15

Preventing ESD................................................................................................................................................................... 15

Inspection and cleaning....................................................................................................................................................... 15

Exterior cleaning (other than dissplay)..........................................................................................................................15

Flat panel display cleaning........................................................................................................................................... 16

Interior cleaning............................................................................................................................................................ 16

Lubrication.................................................................................................................................................................... 17

Returning the instrument for service.............................................................................................................................17

Removal and replacement procedures................................................................................................................................ 17

Required equipment..................................................................................................................................................... 18

Removal/Replacement procedures...............................................................................................................................18

Troubleshooting................................................................................................................................................................... 30

Service level................................................................................................................................................................. 30

Check for common problems........................................................................................................................................30

Equipment required...................................................................................................................................................... 30

Troubleshooting flow chart............................................................................................................................................30

Instrument self tests......................................................................................................................................................31

Software updates..........................................................................................................................................................32

After repair.................................................................................................................................................................... 32

Replaceable parts....................................................................................................................................................................... 33

Parts ordering information....................................................................................................................................................33

Module servicing.................................................................................................................................................................. 33

Abbreviations....................................................................................................................................................................... 33

4 Series MSO (MSO44, MSO46) Service 3

Table of Contents

Using the replaceable parts list............................................................................................................................................33

Rear case assembly with handle and feet........................................................................................................................... 34

Front assembly

.................................................................................................................................................................... 36

Rear chassis assembly with power supply and fans............................................................................................................38

Front assembly (Backside).................................................................................................................................................. 40

Front chassis assembly with acqusition board and processor board...................................................................................42

4 Series MSO (MSO44, MSO46) Service 4

List of Figures

List of Figures

Figure 1: 4 Series MSO block diagram....................................................................................................................................... 12

Figure 2: Primary troubleshooting tree........................................................................................................................................31

Figure 3: Rear case assembly with handle and feet exploded view........................................................................................... 34

Figure 4: Front assembly exploded view.....................................................................................................................................36

Figure 5: Rear chassis assembly with power supply and fans - exploded view..........................................................................38

Figure 6: Front assembly (Backside) exploded view...................................................................................................................40

Figure 7: Front chassis assembly with acqusition board and processor board- exploded view..................................................42

4 Series MSO (MSO44, MSO46) Service 5

List of Tables

List of Tables

Table 1: External inspection checklist......................................................................................................................................... 16

Table 2: Internal inspection checklist...........................................................................................................................................17

Table 3: Required equipment for removal and replacement....................................................................................................... 18

Table 4: Failure symptoms and possible causes.........................................................................................................................30

Table 5: Parts list column descriptions........................................................................................................................................ 33

Table 6: Rear case...................................................................................................................................................................... 35

Table 7: Front assembly.............................................................................................................................................................. 37

Table 8: Rear chassis assembly with power supply and fans..................................................................................................... 39

Table 9: Front assembly (Backside)............................................................................................................................................ 41

Table 10: Front chassis assembly with acqusition board and processor board ......................................................................... 42

4 Series MSO (MSO44, MSO46) Service 6

Important safety information

Important safety information

This manual contains information and warnings that must be followed by the user for safe operation and to keep the product in a safe

condition.

To safely perform service on this product, see the Service safety summary that follows the General safety summary.

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product or any

products connected to it. Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition to the safety

precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other component manuals

for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Use proper power cord Use only the power cord specified for this product and certified for the country of use.

Use proper power cord Use only the power cord specified for this product and certified for the country of use. Do not

use the provided power cord for other products.

Use proper voltage setting Before applying power, ensure that the line selector is in the proper position for the source

being used.

Ground the product This product is grounded through the grounding conductor of the power cord. To avoid

electric shock, the grounding conductor must be connected to earth ground. Before making

connections to the input or output terminals of the product, ensure that the product is properly

grounded. Do not disable the power cord grounding connection.

Ground the product This product is indirectly grounded through the grounding conductor of the mainframe power

cord. T

o avoid electric shock, the grounding conductor must be connected to earth ground.

Before making connections to the input or output terminals of the product, ensure that the

product is properly grounded. Do not disable the power cord grounding connection.

Power disconnect The power switch disconnects the product from the power source. See instructions for the

location. Do not position the equipment so that it is difficult to disconnect the power switch; it

must remain accessible to the user at all times to allow for quick disconnection if needed.

Power disconnect The power cord disconnects the product from the power source. See instructions for the

location. Do not position the equipment so that it is difficult to operate the power cord; it must

remain accessible to the user at all times to allow for quick disconnection if needed.

Use proper AC adapter Use only the AC adapter specified for this product.

Connect and disconnect properly Do not connect or disconnect probes or test leads while they are connected to a voltage

source.

4 Series MSO (MSO44, MSO46) Service 7

Important safety information

Use only insulated voltage probes, test leads, and adapters supplied with the product, or

indicated by T

ektronix to be suitable for the product.

Observe all terminal ratings T

Observe all terminal ratings To avoid fire or shock hazard, observe all rating and markings on the product. Consult the

Do not operate without covers Do not operate this product with covers or panels removed, or with the case open. Hazardous

Avoid exposed circuitry Do not touch exposed connections and components when power is present.

Do not operate with suspected

failures

Replace batteries properly Replace batteries only with the specified type and rating.

Recharge batteries properly Recharge batteries for the recommended charge cycle only.

Use proper fuse Use only the fuse type and rating specified for this product.

Wear eye protection Wear eye protection if exposure to high-intensity rays or laser radiation exists.

Do not operate in wet/damp

conditions

Do not operate in an explosive

atmosphere

Keep product surfaces clean and dry Remove the input signals before you clean the product.

Provide proper ventilation Refer to the installation instructions in the manual for details on installing the product so it has

Provide a safe working environment Always place the product in a location convenient for viewing the display and indicators.

o avoid fire or shock hazard, observe all rating and markings on the product. Consult the

product manual for further ratings information before making connections to the product. Do

not exceed the Measurement Category (CAT) rating and voltage or current rating of the lowest

rated individual component of a product, probe, or accessory. Use caution when using 1:1 test

leads because the probe tip voltage is directly transmitted to the product.

product manual for further ratings information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the

maximum rating of that terminal.

Do not float the common terminal above the rated voltage for that terminal.

The measurement terminals on this product are not rated for connection to mains or Category

II, III, or IV circuits.

voltage exposure is possible.

If you suspect that there is damage to this product, have it inspected by qualified service

personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates

incorrectly. If in doubt about safety of the product, turn it off and disconnect the power cord.

Clearly mark the product to prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and

replace when damaged. Do not use probes or test leads if they are damaged, if there is

exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Be aware that condensation may occur if a unit is moved from a cold to a warm environment.

proper ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise

obstructed. Do not push objects into any of the openings.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or

prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics

professional to avoid stress injuries.

4 Series MSO (MSO44, MSO46) Service 8

Important safety information

Use care when lifting and carrying the product. This product is provided with a handle or

handles for lifting and carrying.

Warning: The product is heavy. T

device get help when lifting or carrying the product.

Warning: The product is heavy. Use a two-person lift or a mechanical aid.

Use only the T

ektronix rackmount hardware specified for this product.

o reduce the risk of personal injury or damage to the

Probes and test leads

Before connecting probes or test leads, connect the power cord from the power connector to a properly grounded power outlet.

Keep fingers behind the protective barrier, protective finger guard, or tactile indicator on the probes.

Remove all probes, test leads and accessories that are not in use.

Use only correct Measurement Category (CA

any measurement.

Beware of high voltages Understand the voltage ratings for the probe you are using and do not exceed those ratings.

T), voltage, temperature, altitude, and amperage rated probes, test leads, and adapters for

Two ratings are important to know and understand:

The maximum measurement voltage from the probe tip to the probe reference lead

•

• The maximum floating voltage from the probe reference lead to earth ground

These two voltage ratings depend on the probe and your application. Refer to the

Specifications section of the manual for more information.

Warning: To prevent electrical shock, do not exceed the maximum measurement

or maximum floating voltage for the oscilloscope input BNC connector, probe tip, or

probe reference lead.

Connect and disconnect properly Connect the probe output to the measurement product before connecting the probe to the

circuit under test. Connect the probe reference lead to the circuit under test before connecting

the probe input. Disconnect the probe input and the probe reference lead from the circuit under

test before disconnecting the probe from the measurement product.

Connect and disconnect properly De-energize the circuit under test before connecting or disconnecting the current probe.

Connect the probe reference lead to earth ground only

Do not connect a current probe to any wire that carries voltages or frequencies above the

current probe voltage rating.

Inspect the probe and accessories Before each use, inspect probe and accessories for damage (cuts, tears, or defects in the

probe body, accessories, or cable jacket). Do not use if damaged.

Ground-referenced oscilloscope use Do not float the reference lead of this probe when using with ground-referenced oscilloscopes.

The reference lead must be connected to earth potential (0 V).

Floating measurement use Do not float the reference lead of this probe above the rated float voltage.

.

Risk assessment warnings and information

Service safety summary

The Service safety summary section contains additional information required to safely perform service on the product. Only qualified

personnel should perform service procedures. Read this Service safety summary and the General safety summary before performing any

service procedures.

4 Series MSO (MSO44, MSO46) Service 9

Important safety information

To avoid electric shock Do not touch exposed connections.

Do not service alone Do not perform internal service or adjustments of this product unless another person capable of

rendering first aid and resuscitation is present.

Disconnect power To avoid electric shock, switch off the product power and disconnect the power cord from the

mains power before removing any covers or panels, or opening the case for servicing.

Use care when servicing with poweronDangerous voltages or currents may exist in this product. Disconnect power, remove battery

(if applicable), and disconnect test leads before removing protective panels, soldering, or

replacing components.

Verify safety after repair Always recheck ground continuity and mains dielectric strength after performing a repair.

Terms in the manual

These terms may appear in this manual:

Warning: Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION: Caution statements identify conditions or practices that could result in damage to this product or other property.

T

erms on the product

These terms may appear on the product:

• DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

•

• CAUTION indicates a hazard to property including the product.

Symbols on the product

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the potential hazards and

any actions which have to be taken to avoid them. (This symbol may also be used to refer the user to ratings in the manual.)

The following symbols may appear on the product:

4 Series MSO (MSO44, MSO46) Service 10

Preface

Preface

This manual contains service information for your instrument.

Read the General and Service safety summaries before servicing the product.

Be sure to read the introductions to all procedures. These introductions provide important information needed to perform the service

correctly, safely, and efficiently.

Supported products

This manual contains information that is necessary to service the following products:

• MSO44

• MSO46

Check for a specific product designation in the header at the top of the page, in a heading, table or figure title, or within text. Material that

does not have any specific product designation applies to all products in the manual.

Replaceable parts

This manual refers to any field-replaceable assembly or mechanical part specifically by its name or generically as a replaceable part. In

general, a replaceable part is any circuit board or assembly, (such as the hard disk drive), or a mechanical part, (such as the I/O port

connectors), that is listed in the replaceable parts list that can be replaced in the field. (See Replaceable parts.)

Where to find operating information

For information on installing, operating, and networking the instrument, refer to the online help or user manual that was provided with your

oscilloscope. You can also find the manual at www.tek.com/manuals, by searching for your product.

4 Series MSO (MSO44, MSO46) Service 1

1

Theory of operation

Theory of operation

This chapter describes the electrical operation of the oscilloscope to the module level. The block diagram shows the oscilloscope module

interconnections.

Figure 1: 4 Series MSO block diagram

Power supply

The Power Supply board converts AC line voltage to +12 V to power for all internal circuits.

Processor board

The processor board contains the following functions:

Processor system The processor system contains a microprocessor that controls the entire instrument. The

processor system also contains the flash memory for the operating system, system RAM, and

interfaces to I/O ports and the acquisition system.

Rear panel I/O ports The processor board contains USB ports, an Ethernet port (LAN), a HDMI Video port, the

USB-TMC port, an AUX OUT BNC connector, an EXT REF IN BNC connector

Out generator BNC connector.

Other functions The processor board also houses the AFG generator, USB-TMC controller and USB host hub.

, and the AFG

Main board

The Main board contain the following functions:

4 Series MSO (MSO44, MSO46) Service 12

Theory of operation

Acquisition system The Acquisition system begins with the analog signal path and ends with a digitized signal

in memory

preamplifier

acquisition memory. The analog signal from each preamplifier is also distributed to a trigger

circuit.

Analog Front-end All of the analog and digital inputs are routed to the analog Front-end circuitry. The analog

channels are amplified and attenuated through the front-end circuitry, and are output to the

acquisition ASICs. The digital channels simply pass through the front-end circuitry to the

acquisition ASICs.

Power converter The Carrier interface assembly converts the +12 V power to all voltages used for the analog

and digital circuitry throughout the system. Standby power is used to keep portions of the

system powered at all times that AC power is connected to the instrument.

Other functions The Main board interfaces to the Power supply and various cooling fans.

. The signal enters a channel input, and then passes through an attenuator and

. The analog signal from each preamplifier goes through a digitizer, and then into

Front panel and display

The Front Panel board contains digital logic that reads the front-panel buttons and controls and sends this information to the processor

system on the Processor board. The Front Panel board also generates the probe compensation output signal, provides USB ports on the

front panel and houses the main power switch. The front panel routes the digital front-end signals from the probe directly to the main

board.

4 Series MSO (MSO44, MSO46) Service 13

Adjustment procedures

Adjustment procedures

This chapter contains information about instrument adjustment.

Adjustment

Adjustment and calibration can be performed only by a Tektronix Service Center. See Contacting Tektronix, following the title page in this

manual, for information on contacting Tektronix Service Support.

Adjustment interval

The voltage and timing references inside the instrument are very stable over time and do not need routine adjustment.

If the instrument fails the performance tests in the Specifications and Performance Verification manual, adjustment may be required.

To download the 4 Series MSO Specification and Performance Verification manual (Tektronix part number 077-1546-XX), go to http://

www.tek.com/product-support, enter the manual part number (with no dashes) in the field, click GO, and then select the Specification and

Performance Verification document to download.

If your organization requires periodic calibration, a general rule is to verify performance and make adjustments (only if needed) every

2000 hours of operation or once a year if the instrument is used infrequently.

Adjustment after repair

After removal and replacement of any module, you must perform the Performance Verification procedures, found in the Specifications and

Performance Verification manual (Tektronix part number 077-1546-XX), available to download from the Tektronix web site (www.tek.com/

product-support).

If the instrument fails any Performance Verification tests, it must be returned to a Tektronix Service Center for adjustment and calibration.

4 Series MSO (MSO44, MSO46) Service 14

Maintenance

Maintenance

This section contains information needed to perform periodic and corrective maintenance on the instrument.

Preventing ESD

Before servicing this product, read the General Safety Summary and the Service Safety Summary at the front of the manual, as well as the

following ESD information.

CAUTION: Electrostatic discharge (ESD) can damage any semiconductor component in this instrument.

When performing any service that requires internal access to the instrument, adhere to the following precautions to avoid damaging

internal modules and their components due to electrostatic discharge:

1. Minimize handling of static-sensitive circuit boards and components.

2. Transport and store static-sensitive modules in their static protected containers or on a metal rail. Label any package that contains

static-sensitive boards.

3. Discharge the static voltage from your body by wearing a grounded antistatic wrist strap while handling these modules.

4. Service static-sensitive modules only at a static-free work station.

5. Do not allow any items capable of generating or holding a static charge on the work station surface.

6. Handle circuit boards by the edges when possible.

7. Do not slide the circuit boards over any surface.

8. A

void handling circuit boards in areas that have a floor or work-surface covering capable of generating a static charge.

Inspection and cleaning

Inspection and Cleaning describes how to inspect for dirt and damage. It also describes how to clean the exterior and interior of the

instrument. Inspection and cleaning are done as preventive maintenance. Preventive maintenance, when done regularly, may prevent

instrument malfunction and enhance its reliability.

Preventive maintenance consists of visually inspecting and cleaning the instrument and using general care when operating it.

How often to perform maintenance depends on the severity of the environment in which the instrument is used. A proper time to perform

preventive maintenance is just before instrument adjustment.

Exterior cleaning (other than dissplay)

Clean the exterior surfaces of the chassis with a dry lint-free cloth or a soft-bristle brush. If any dirt remains, use a cloth or swab dipped in

a 75% isopropyl alcohol solution. Use a swab to clean narrow spaces around controls and connectors. Do not use abrasive compounds on

any part of the chassis that may damage the chassis.

Clean the On/Standby switch using a cleaning towel dampened with deionized water. Do not spray or wet the switch itself.

CAUTION: Avoid the use of chemical cleaning agents which might damage the plastics used in this instrument. Use only

deionized water when cleaning the front-panel buttons. Use a 75% isopropyl alcohol solution as a cleaner for cabinet parts. Before

using any other type of cleaner

Inspection - Exterior. Inspect the outside of the instrument for damage, wear, and missing parts. Immediately repair defects that could

cause personal injury or lead to further damage to the instrument.

, consult your Tektronix Service Center or representative.

4 Series MSO (MSO44, MSO46) Service 15

Maintenance

Table 1: External inspection checklist

Item Inspect for Repair action

Cabinet, front panel, and cover Cracks, scratches, deformations, damaged

hardware

Front-panel knobs Missing, damaged, or loose knobs Repair or replace missing or defective knobs

Connectors Broken shells, cracked insulation, and

deformed contacts. Dirt in connectors

Carrying handle and cabinet feet Correct operation Repair or replace defective module

Accessories Missing items or parts of items, bent pins,

broken or frayed cables, and damaged

connectors

Repair or replace defective module

Repair or replace defective modules. Clear

or brush out dirt

Repair or replace damaged or missing items,

frayed cables, and defective modules

Flat panel display cleaning

Clean the flat panel display surface by gently rubbing the display with a clean-room wipe (such as Wypall Medium Duty Wipes, #05701,

available from Kimberly-Clark Corporation), or an abrasive-free cleaning cloth.

If the display is very dirty

gently rub the display surface. Use only enough liquid to dampen the cloth or wipe. Avoid using excess force or you may damage the

display surface.

CAUTION: Improper cleaning agents or methods can damage the flat panel display

•

Do not use abrasive cleaners or surface cleaners to clean the display.

• Do not spray liquids directly on the display surface.

• Do not scrub the display with excessive force.

CAUTION: To prevent getting moisture inside the instrument during external cleaning, do not spray any cleaning solutions directly

onto the screen or instrument.

, moisten the wipeor cloth with distilled water, a 75% isopropyl alcohol solution, or standard glass cleaner, and

.

Interior cleaning

Y

ou can only clean the interior of the rear chassis assembly

Procedures topics.

Do not disassemble or clean the front chassis assembly (other than cleaning the front panel display and removing panel knobs).

Disassembling the front chassis assembly requires that the instrument be returned to your nearest Tektronix Service Center for calibration.

Warning: To avoid electric shock or damage to the instrument, remove instrument power. Before performing any procedure that

follows, power down the instrument and disconnect it from line voltage.

•

Blow off dust with dry, low-pressure (approximately 9 psi), deionized air.

• Use a soft-bristle, non-static-producing brush for cleaning around components.

•

Remove any remaining dust with a lint-free cloth dampened in isopropyl alcohol (75% solution). (A cotton-tipped applicator is useful for

cleaning in narrow spaces and on circuit boards).

• If you must use a liquid for minor rear chassis interior cleaning, use a clean-room wipe (such as Wypall Medium Duty Wipes, #05701,

available from Kimberly-Clark Corporation) dampened with a 75% isopropyl alcohol solution.

• Inspect the internal portions of the instrument for damage and wear. See Table 2 on page 17. Defects should be repaired immediately.

• If any circuit board is repaired or replaced, you must perform the Performance Verification procedure in the specifications and

performance verification manual, which was provided with your instrument. This manual is also available at www.tektronix.com/

manuals, by searching for your product name. If the instrument fails the Performance Verification tests, it must be returned to a

Tektronix Service Center for repair and calibration.

. To access the rear chassis assembly, see the Removal and Installation

4 Series MSO (MSO44, MSO46) Service 16

CAUTION: To prevent damage from electrical arcing, ensure that circuit boards and components are dry before applying power to

the instrument.

able 2: Internal inspection checklist

T

Item Inspect for Repair action

Circuit boards Loose, broken, or corroded solder

connections. Burned circuit boards. Burned,

broken, or cracked circuit-run plating.

Resistors Burned, cracked, broken, blistered condition.

Capacitors Damaged or leaking cases. Corroded solder

on leads or terminals.

Wiring and cables Loose plugs or connectors. Burned, broken,

or frayed wiring.

Chassis Dents, deformations, and damaged

hardware.

Remove and replace damaged circuit board.

Firmly seat connectors. Replace defective

cables.

Straighten, repair, or replace defective

hardware.

Lubrication

There is no periodic lubrication required for this instrument.

Maintenance

Returning the instrument for service

When repacking the instrument for shipment, use the original packaging. If the packaging is unavailable or unfit for use, contact your local

Tektronix representative to obtain new packaging.

Seal the shipping carton with an industrial stapler or strapping tape.

Before returning the instrument for service, contact the Service Center to get an RMA (return material authorization) number, and any

return or shipping information you may need.

If the instrument is being shipped to a T

• The RMA number.

• The owner's address.

• Name and phone number of a contact person.

• Type and serial number of the instrument.

• Reason for returning.

• A complete description of the required service.

Mark the address of the Tektronix Service Center and the return address on the shipping carton in two prominent locations.

ektronix Service Center, enclose the following information:

Removal and replacement procedures

This section contains procedures for removal and installation of replaceable modules in the instrument. Refer to Replaceable parts for lists

and exploded views of replaceable modules.

Any module inside of the chassis that does not have a remove and replace procedure requires that the entire instrument be returned to

Tektronix Service Center for service.

Warning: Before performing this or any other procedure in this manual, read the safety summaries found at the beginning of

this manual. Also, to prevent possible injury to service personnel or damage to the instrument components, read Preventing

ESD on page 15.

4 Series MSO (MSO44, MSO46) Service 17

Before performing any procedure in this subsection, disconnect the power cord from the line voltage source. Failure to do so could

cause serious injury or death.

Note: Read the cleaning procedure before disassembling the instrument for cleaning.

Required equipment

Maintenance

Most assemblies in this instrument can be removed with a T-10 or T8 T

orx® screwdriver tip.

Table 3: Required equipment for removal and replacement

Item No. Name Description

1 Screwdriver handle Accepts Torx-driver bits

2 T-10 Torx tip Used for removing instrument screws. Torx-

driver bit for T-10 size screw heads

3 T

4 9/16 inch open-end wrench Used to remove nut posts

5 Proper antistatic work environment To prevent electrostatic damage to

-8 Torx tip Used for removing instrument screws. Torxdriver bit for T-8 size screw heads

components whenever you work on

the instrument, wear properly-grounded

electrostatic prevention wrist and foot straps,

and work in a tested antistatic environment

on an antistatic mat.

Removal/Replacement procedures

Removal of the front-panel knobs

The following procedure describes the removal and replacement of the front-panel knob assemblies, There are eight knob assemblies that

can be removed from the front case.

Prerequisite:

• T

o prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

Procedure:

1. To remove a knob assembly, pull the knob straight out of the front panel. Finger strength is adequate to pull knobs. Do not use pliers.

2. To reinstall a knob, align the knob with the shaft indent and push the knob onto the shaft. Turn the knob to make sure there is a smooth

rotation.

Removal of the feets

The following procedure describes the removal and replacement of the feets, There are two feets that can be removed from the bottom of

the instrument.

Prerequisite:

• To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

Procedure:

1. Remove all cables and the power cord from the rear panel.

4 Series MSO (MSO44, MSO46) Service 18

Maintenance

2. Set the instrument on its back side so the bottom is facing you.

3. Flip open both feet assemblies.

-10 T

4. Use a screwdriver with T

5. Remove the feet assembles.

6. To reinstall, reverse the above steps. Use a screwdriver with T-10 Torx tip to secure the eight screws. First insert and tighten the

screws that are near the front edge of the instrument, then insert and tighten the screws that are near the rear edge of the instrument.

ighten to 0.65 N·m.

T

orx tip to remove the four screws from each foot assembly.

Removal of the handle

The following procedure describes the removal and replacement of the handle.

Prerequisite:

• To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

Procedure:

1. Use a screwdriver with T-10 Torx tip to remove two screws from each side of the handle.

2. Disengage the handle from the pins on the couplers and remove the handle.

4 Series MSO (MSO44, MSO46) Service 19

3. Remove the two couplers.

4. To reinstall, reverse the above steps. Use a screwdriver with T-10 Torx tip to secure the screws. Tighten to 0.65 N·m.

Removal of the rear grill and case

The following procedure describes the removal and replacement of the rear grill and case.

Prerequisite:

Maintenance

• To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

Procedure:

1. Use a screwdriver with T-10 Torx tip to remove the 10 screws securing the grill to the rear case.

4 Series MSO (MSO44, MSO46) Service 20

Maintenance

2. Put fingers in handle hub holes on both side of the grill and pull the grill from the rear case.

3. Use a screwdriver with T-10 T

4. Slide away the rear case from the rear chassis.

5. To reinstall, reverse the above steps. Tighten the six T-10 Torx rear case screws to 0.65 N·m.

orx tip to remove the six screws securing the rear case to the rear chassis.

Removal of the rear chassis assembly

The following procedure describes the removal and replacement of the rear chassis assembly.

Prerequisite:

4 Series MSO (MSO44, MSO46) Service 21

Maintenance

• To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

Remove the rear grill and case.

•

Procedure:

1. Use a 9/16" socket to remove BNCs with three washers and three nuts. Black arrow is for nut and red arrow is for washer.

2. Use a screwdriver with a with T-10 T

orx tip to remove the 25 screws securing the rear chassis to the front chassis.

4 Series MSO (MSO44, MSO46) Service 22

Maintenance

3. Carefully lift the rear chassis off of the front chassis and disconnect the power cables, fan cables, and line filter cable.

4 Series MSO (MSO44, MSO46) Service 23

4. To reinstall, reverse the above steps.Tighten the 25 screws with T-10 bit to 0.65 N·m.

5. Secure BNCs with three washers and three nuts using 9/16" socket and 2.5 N.M hand driver

Remove the power supply bracket

The following procedure describes the removal and replacement of the power supply bracket.

Prerequisite:

Maintenance

.

• To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

• Remove the rear grill and case.

• Remove the rear chassis assembly.

Procedure:

1. Set the rear chassis with the rear side down.

2. Use a screwdriver with a with T-10 Torx tip to remove the 15 screws from the power supply bracket.

4 Series MSO (MSO44, MSO46) Service 24

Maintenance

3. To reinstall, reverse the above steps.Tighten the 15 screws with T-10 bit to 0.65 N·m. to attach the power supply bracket to chassis

with the order of the red arrow

.

Remove the power supply

The following procedure describes the removal and replacement of the power supply.

Prerequisite:

•

To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

• Remove the rear grill and case.

4 Series MSO (MSO44, MSO46) Service 25

• Remove the rear chassis assembly.

Procedure:

Maintenance

1. Disconnect the line input cable from the power supply

2. Use a T-10 Torx screwdriver to remove the seven screws from the power supply.

.

3. To reinstall, reverse the steps. Tighten the T-10 Torx screws to 0.65 N·m when reinstalling.

Remove the main fan assembly

The following procedure describes the removal and replacement of the power supply bracket.

Prerequisite:

To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

•

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

• Remove the rear grill and case.

• Remove the rear chassis assembly.

Procedure:

1. Use a T-10 Torx screwdriver to remove the seven screws from the main fan assembly bracket.

4 Series MSO (MSO44, MSO46) Service 26

2. Remove the cable ties and main fan assembly from the rear chassis.

Maintenance

o remove the fan from the bracket, carefully pull the fan from each corner of the bracket to disconnect the elastic fan attachments .

3. T

4. T

o reinstall, reverse the steps. Install the fan on the bracket in the correct orientation for the fan power cable (see photo). Use a needle

nose plier to reinstall the fan elastic attachments on each corner. Tighten the T-10 Torx screws to 0.65 N·m when reinstalling.

Remove the main board

The following procedure describes the removal and replacement of the main board.

Prerequisite:

• To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

• Remove the front chassis assembly.

4 Series MSO (MSO44, MSO46) Service 27

Procedure:

Maintenance

1. Disconnect the front panel cable from the main board as shown below

2. Use a T-10 Torx screwdriver to remove the 23 screws that have attached the main board to the front chassis assembly .

.

3. To reinstall, reverse the above steps. Tighten the T-10 Torx screws to 0.65 N·m when reinstalling.

Remove the processor board

The following procedure describes the removal and replacement of the processor board.

Prerequisite:

To prevent electrostatic damage to components whenever you work on the instrument, wear properly-grounded electrostatic prevention

•

wrist and foot straps, and work in a tested antistatic environment on an antistatic mat.

• Remove the front chassis assembly.

Procedure:

1. Use a T-10 Torx screwdriver to remove the seven screws that have attached the processor board to the front chassis assembly.

4 Series MSO (MSO44, MSO46) Service 28

2. Carefully disconnect the processor board from the main board.

Maintenance

3. Disconnect the display cable from the processor board as shown below.

4. To reinstall, reverse the above steps. Tighten the T-10 Torx screws to 0.65 N·m when reinstalling.

4 Series MSO (MSO44, MSO46) Service 29

Maintenance

Troubleshooting

CAUTION: Before performing this or any other procedure in this manual, read the General Safety Summary and Service Safety

Summary found at the beginning of this manual.

o prevent possible injury to service personnel or damage to electrical components, please read information on Preventing ESD.

T

(See

Preventing ESD on page 15.)

This section contains information and procedures designed to help you isolate faults to a module.

This section requires that service personnel have the appropriate skills to work on this instrument, including PC troubleshooting and

Microsoft Windows operating system skills. Details of PC and Windows operation and service are not in this manual.

For assistance, contact your local Tektronix Service Center.

Service level

This subsection contains information and procedures to help you determine if a faulty power supply is the problem with your instrument. If

replacing the power supply does not fix the fault, you will need to return the instrument to a Tektronix Service Center for repair, as no other

internal electronic assemblies or modules are user-replaceable.

Check for common problems

Use the following table to help isolate possible failures. The table lists problems and possible causes. The list is not exhaustive, but it may

help you eliminate a problem that is quick to fix, such as a loose power cord. For more detailed troubleshooting, see the Troubleshooting

flow chart on page 30.

Table 4: Failure symptoms and possible causes

Symptom Possible cause(s)

Instrument will not power on

Instrument powers on, but one or more fans will not operate

Flat-panel display blank or has streaks in display

• Power cord not plugged in

Faulty power supply

•

•

Defective micro-controller assembly

• Faulty fan power cable

• Fan power cable not connected to circuit board

• Defective fan

• Faulty power supply

• One or more defective point of load regulators

• Faulty LCD screen or video circuitry.

Equipment required

• Digital voltmeter to check power supply voltages.

0.1 inch spacing 2-pin jumper.

•

• An antistatic work environment.

Troubleshooting flow chart

Follow the troubleshooting flow chart to determine the action for a fault condition.

4 Series MSO (MSO44, MSO46) Service 30

Maintenance

Figure 2: Primary troubleshooting tree

Instrument self tests

The instrument runs self test diagnostics during every power on. The power on self tests ensure that the hardware and software are

functionally working. The tests provide limited diagnostic information, and provide no performance information.

If the instrument detects errors during power on, a pop-up message indicates that a failure has occurred. To display the Self test menu and

results, select Utility > Self Test. Select a test mode and run the self tests. If you continue to get errors on one or more tests, you will need

to return the instrument to your nearest Tektronix Service Center for repair.

4 Series MSO (MSO44, MSO46) Service 31

Software updates

To update the application software:

Maintenance

1. Go to

2. Enter a model number (MSO44 or MSO46) in the Enter Product or Product Series Name field and click Go. Any 4 Series model

3. Click the Software tab.

4. On the oscilloscope, tap Help > About.

5. Compare the version number of the installed software to the version on the web:

6. Select the highest-numbered version (4 Series MSO Embedded OS Firmware - VX.X).

7. Click Download File to start the download.

8. When done downloading, unzip the downloaded file.

9. Open the file install.txt and follow the instructions in the file.

www.tek.com/product-support.

number will do, as all models use the same software update.

a. If the version number on the oscilloscope is the same as the version on the web, you have the latest version. You do not need to

install new software. Exit this procedure.

b. If the version number on the oscilloscope is a lower number than the version on the web, you can download and install new

software. Continue with the rest of this procedure.

After repair

After removal and replacement of the power supply module, you must perform the Performance Verification procedures, found in the

Specifications and Performance Verification manual (Tektronix part number 077-1546-XX). Download this manual from the Tektronix Web

site (www.tek.com/manuals).

If the instrument fails the Performance Verification tests, it must be returned to a Tektronix Service Center for adjustment.

4 Series MSO (MSO44, MSO46) Service 32

Replaceable parts

Replaceable parts

This section contains separate subsections for different product groups. Use the lists in the appropriate section to identify and order

replacement parts for your product.

Standard accessories. Standard accessories for these products are listed in your user manual. The user manual is available at

www.tek.com/manuals.

Parts ordering information

Replacement parts are available through your local Tektronix field office or representative.

Changes to Tektronix products are sometimes made to accommodate improved components as they become available and to give you the

benefit of the latest improvements. Therefore, when ordering parts, it is important to include the following information in your order:

• Part number

• Instrument type or model number

• Instrument serial number

• Instrument modification number, if applicable

If you order a part that has been replaced with a different or improved part, your local Tektronix field office or representative will contact you

concerning any change in part number.

Module servicing

Modules can be serviced by selecting one of the following three options. Contact your local Tektronix Service Center or representative for

repair assistance.

Module exchange. In some cases, you may exchange your module for a remanufactured module. These modules cost significantly

less than new modules and meet the same factory specifications. For more information about the module exchange program, call

1-800-833-9200. Outside North America, contact a Tektronix sales office or distributor; see the Tektronix Web site (www.tek.com) for a list

of offices.

Module repair and return. You may ship your module to us for repair, after which we will return it to you.

New modules. You may purchase replacement modules in the same way as other replacement parts.

Abbreviations

Abbreviations conform to American National Standard ANSI Y1.1-1972.

Using the replaceable parts list

This section contains a list of the replaceable mechanical and/or electrical components. Use this list to identify and order replacement

parts. The following table describes each column in the parts list.

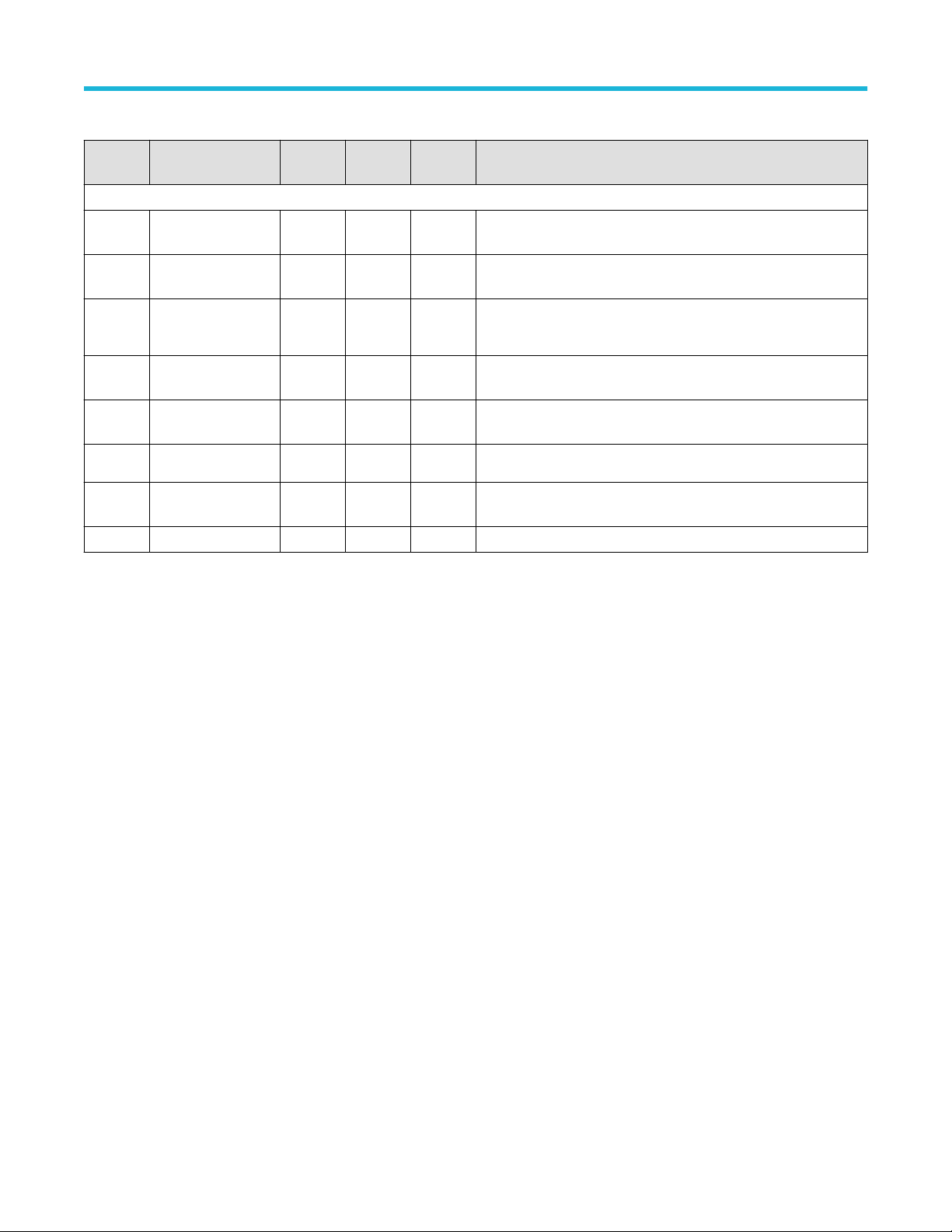

Table 5: Parts list column descriptions

Column Column name Description

1 Figure & index number Items in this section are referenced by figure and index numbers to the exploded view

illustrations that follow.

2

Table continued…

Tektronix part number Use this part number when ordering replacement parts from Tektronix.

4 Series MSO (MSO44, MSO46) Service 33

Replaceable parts

Column Column name Description

3 and 4 Serial number Column three indicates the serial number at which the part was first effective. Column four

indicates the serial number at which the part was discontinued. No entry indicates the part

is good for all serial numbers.

5 Qty This indicates the quantity of parts used.

6 Name & description An item name is separated from the description by a colon (:). Because of space

limitations, an item name may sometimes appear as incomplete. Use the U.S. Federal

Catalog handbook H6-1 for further item name identification.

Rear case assembly with handle and feet

Figure 3: Rear case assembly with handle and feet exploded view

4 Series MSO (MSO44, MSO46) Service 34

Table 6: Rear case

Replaceable parts

Index

number

Figure 3 on page

-1

-2 050-3905-XX 1 MODULE ASSY:SERVICE REPLACEMENT KIT, HANDLE METAL

-3 211-1636-XX 4

-4 065-1058-XX 1 MODULE ASSY:SERVICE REPLACEMENT KIT;HANDLE HUB

-5

-6

-7 065-1047-XX 2 MODULE ASSY:SERVICE REPLACEMENT KIT;REAR FLIP FEET,

-8 202-0567-XX 1 CASE, REAR, MSO4K SERIES, SAFETY CONTROLLED

Tektronix part

number

34

211-1688-XX 4 SCREW, MACHINE, M3X0.5X10, FLAT HEAD 90 DEG, SUS410

378-0961-XX 1 GRILL, COSMETIC, REAR, MSO4K SERIES, SAFETY

211-1686-XX 12 SCREW, MACHINE; M3X0.5X10, FLAT HEAD, STL, TORX 10

Serial no.

effective

Serial no.

discont'd

Qty Name & description

NYLOK, TORX T10

BASE W/PLASTIC GRIP AND HARDWARE, MSO4 SERIES

SCREW, MACHINE, M3x0.5x8MM PAN HEAD, TORX T10 WITH

NYLON PATCH

LEFT AND RIGHT (SET), MSO4 SERIES

CONTROLLED

MSO4 SERIES

4 Series MSO (MSO44, MSO46) Service 35

Front assembly

Replaceable parts

Figure 4: Front assembly exploded view

4 Series MSO (MSO44, MSO46) Service 36

Table 7: Front assembly

Replaceable parts

Fig. &

index

number

Figure 4 on page

-1

-2 065-1056-XX 1

-3 211-1584-XX 4 SCREW, MACHINE, M3X0.5X6 MM PAN HEAD, TORX T10

-4 366-0945-XX 1 ASSEMBLY, KNOB, LARGE WITH OVERMOLD

-5 366-0943-XX 1 ASSEMBLY, KNOB, SMALL WITH OVERMOLD

-6 366-0946-XX 1 ASSEMBLY, KNOB, PAN WITH OVERMOLD

Tektronix part

number

36

065-1052-XX 1

065-1055-XX 1 MODULE ASSY:SERVICE REPLACEMENT KIT;4CH FRONT

Serial no.

effective

Serial no.

discont'd

Qty Name & description

MODULE ASSY:SERVICE REPLACEMENT KIT;DISPLAY/TOUCH

SCREEN ASSY

Return the instrument to Tektronix for service.

MODULE ASSY:SERVICE REPLACEMENT KIT;6CH FRONT

CASE WITH LABELS

MSO46

CASE WITH LABELS

MSO44

-7 358-0890-XX 1 BUSHING, SPACER, RING JOG-SHUTTLE

-8 366-0947-XX 1 ASSEMBLY, KNOB, ZOOM WITH OVERMOLD

-9 366-0944-XX

1

ASSEMBLY, KNOB, MEDIUM WITH OVERMOLD

4 Series MSO (MSO44, MSO46) Service 37

Rear chassis assembly with power supply and fans

Replaceable parts

Figure 5: Rear chassis assembly with power supply and fans - exploded view

4 Series MSO (MSO44, MSO46) Service 38

Table 8: Rear chassis assembly with power supply and fans

Replaceable parts

Fig. &

index

number

Figure 5 on page

-1

-2 337-4731-XX 1

-3 119-8939-XX 1

-4 119-9093-XX 1 POWER SUPPLY: 400W(MAX),AC-DC,OPEN FRAME;

-5 337-4717-XX 1 SHIELD, MOUNT, POWER SUPPLY, SAFETY CONTROLLED

-6 119-8919-XX 1 FAN ASSEMBLY, SAN ACE 9GA0812P4J0011 W/ TERMINATION,

-7 407-6151-XX 1 BRACKET, 2 FANS

-8 348-2082-XX 12 GROMMET, FAN MOUNT, NOISE DAMPING

-9 441-2902-XX 1 CHASSIS, REAR

Tektronix part

number

38

407-6131-XX 1

Serial no.

effective

Serial no.

discont'd

Qty Name & description

BRACKET, POWER SUPPLY, 750W

SHIELD, INSULATOR, POWER SUPPLY, SAFETY CONTROLLED

FAN WITH 2X2 CONN, 60X25MM, 12V, SAFETY CONTROLLED

90-264VAC,47-63 HZ IN; +12V@33.33A, +5V@2A, +12V@0.6A

OUT; SAFETY CONTROLLED

SAFETY CONTROLLED

-10 335-4011-XX 1 LABEL, REAR, IO, TOP

-11 335-4012-XX 1 LABEL, REAR, IO, BOTTOM

-12 119-8742-XX 1 FILTER, EMI, AC LINE FILTER, CHASSIS MOUNT,

FN9244R10-06, SAFETY CONTROLLED

-13 211-1584-XX 7 SCREW, MACHINE, M3X0.5X6MM PAN HEAD, TORX T10

-14 407-6130-XX 1 BRACKET, POWER SUPPLY, FAN

-15 211-1686-XX 2 SCREW, MACHINE; M3X0.5X10, FLAT HEAD, STL, TORX 10

4 Series MSO (MSO44, MSO46) Service 39

Front assembly (Backside)

Replaceable parts

Figure 6: Front assembly (Backside) exploded view

Note: None of the components listed are user-replaceable. Return the instrument to your nearest Tektronix Service Center to

repair or replace any internal components or assemblies in this diagram.

4 Series MSO (MSO44, MSO46) Service 40

Table 9: Front assembly (Backside)

Replaceable parts

Fig. &

index

number

Figure 6 on page

-1

-2 366-0920-XX 1

-3 065-1053-XX 1

-4 335-4073-XX 1

Tektronix part

number

40

202-0564-XX 1

065-1054-XX

Serial no.

effective

Serial no.

discont'd

Qty Name & description

CASE, FRONT

Return the instrument to Tektronix for service.

BUTTON, POWER SWITCH, SAFETY CONTROLLED

Return the instrument to Tektronix for service.

MODULE ASSY, SERVICE REPLACEMENT KIT, 4CH PROBE

INTERFACE WITH VPI BUCKETS

Return the instrument to Tektronix for service.

MSO44

1 MODULE ASSY:SERVICE REPLACEMENT KIT;6CH PROBE

INTERFACE WITH VPI BUCKETS

Return the instrument to Tektronix for service.

MSO46

LABEL, BLACKOUT, EMAT OVERLAY

Return the instrument to Tektronix for service.

-5 260-3144-XX 1

-6 065-1045-XX 1

-7 361-1890-XX 1

-8 878-1584-XX 1

-9 380-1322-XX

-10

131-9410-XX 1 CONNECTOR, RECEPTACLE, GROUND JACK

SWITCH, KEYPAD, ELASTOMERIC

Return the instrument to Tektronix for service.

MODULE ASSY, SERVICE REPLACEMENT KIT, FRONT PANEL

LED 878-1899-XX WITH 259-0245-XX

Return the instrument to Tektronix for service.

SPACER, FRONT PANEL

Return the instrument to Tektronix for service.

CIRCUIT BOARD ASSY, FRONT PANEL ENCODER 4CH/6CH,

389-5341-XX

Return the instrument to Tektronix for service.

1 HOUSING, PROBE COMP

Return the instrument to Tektronix for service.

Return the instrument to Tektronix for service.

4 Series MSO (MSO44, MSO46) Service 41

Front chassis assembly with acqusition board and processor board

Replaceable parts

Figure 7: Front chassis assembly with acqusition board and processor board- exploded view

Note: None of the components listed are user-replaceable. Return the instrument to your nearest Tektronix Service Center to

repair or replace any internal components or assemblies in this diagram.

T

able 10: Front chassis assembly with acqusition board and processor board

Fig. &

index

number

Figure 7 on page

able continued…

T

4 Series MSO (MSO44, MSO46) Service 42

Tektronix part

number

42

Serial no.

effective

Serial no.

discont'd

Qty Name & description

Replaceable parts

Fig. &

index

number

-1 441-2901-XX 1

-2

-3 878-1376-XX 1

-4 211-1584-XX 10 SCREW, MACHINE, M3X0.5X6 MM PAN HEAD, TORX T10

Tektronix part

number

878-1383-XX 1

878-1593-XX 1 CIRCUIT BOARD ASSY, 4CH MAIN, 878-1593-XX TESTED WITH

Serial no.

effective

Serial no.

discont'd

Qty Name & description

CHASSIS, FRONT, ASSEMBLY

Return the instrument to T

CIRCUIT BOARD ASSY, PROCESSOR, 878-1383-XX TESTED

WITH PACKAGING

Return the instrument to Tektronix for service.

CIRCUIT BOARD ASSY, 6CH MAIN, 389-5345-XX, BOMBLD STD

Return the instrument to Tektronix for service.

MSO46

PACKAGING

Return the instrument to Tektronix for service.

MSO44

ektronix for service.

4 Series MSO (MSO44, MSO46) Service 43

Loading...

Loading...