Page 1

xx

MSO4000 and DPO4000 Series

Digital Phosphor Oscilloscopes

ZZZ

Specifications and Performance Verification

Technical Reference

*P077024701*

077-0247-01

Page 2

Page 3

xx

MSO4000 and DPO4000 Series

Digital Phosphor Oscilloscopes

ZZZ

Specifications and Performance Verification

Technical Reference

Revision D

This document supports firmware version 2.00 and above

for both MSO4000 Series instruments and DPO4000 Series

instruments.

Warning

The servicing instructions are for use by qualified personnel

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do so. Refer to all safety summaries

prior to performing service.

www.tek.com

077-0247-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Tektronix is an authorized licensee of the CompactFlash trademark.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . Bo x 5 0 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Table of Contents

General safety summary .......................................................................................... iii

Specifications ....................................................................................................... 1

Performance Verification ......................................................................................... 19

Upgrade the

Test Record .................................................................................................... 21

PerformanceVerification Procedures....................................................................... 37

Firmware ....................................................................................... 19

MSO4000 and DPO4000 Series Specifications and Performance Verification i

Page 6

Table of Contents

List of Tables

Table 1: Analog channel input and verticalspecifications..................................................... 1

Table 2: Dig

Table 3: Horizontal and acquisition system specifications... .. .. ... . .. ........................................ 8

Table4: Trigger specifications.................................................................................... 8

Table5: Display specifications................................................................................... 14

Table6: Input/Outputportspecifications....................................................................... 14

Table 7: Power source specifications............................................................................ 14

Table 8: D

Table 9: Environmental specifications .......................................................................... 15

Table10: Mechanical specifications............................................................................. 16

Table 11: P6516 DigitalProbe specifications .................................................................. 17

Table12: MaximumBandwidth Frequency worksheet ....................................................... 41

Table13: Gain Expected worksheet............................................................................. 44

ital channel input specifications, MSO4000 only ................................................ 8

atastorage specifications............................................................................. 15

ii MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 7

General safety summary

General safet

To avoid fire or personal

injury

y summary

Review the fo

this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Connect and disconnect properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

llowing safety precautions to avoid injury and prevent damage to

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Connect the probe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power disconnect. The power switch disconnects the product from the power

source. See instructions for the location. Do not block the power switch; itmust

remain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation. Refer to the manual's installation instructions for details

on installing the product so it has proper ventilation.

MSO4000 and DPO4000 Series Specifications and Performance Verification iii

Page 8

General safety summary

Termsinthismanual

Symbols and terms on the

product

These terms may

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER in

the marking.

WAR NI NG

read the marking.

CAUTIO

The following symbol(s) may appear on the product:

appear in this manual:

dicates an injury hazard immediately accessible as you read

indicates an injury hazard not immediately accessible as you

N indicates a hazard to property including the product.

iv MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 9

Specifications

This chapter contains specifications for the DPO4000 and the MSO4000 series

oscilloscopes. All specifications are guaranteed unless noted as "typical."

Typica l spec

Specifications that are marked with the

Ver ification.

All specifications apply to all DPO4000 and MSO4000 models unless noted

otherwise. To meet specifications, two conditions must first be met:

The oscilloscope must have been operating continuously for twenty minutes

within the operating temperature range specified.

You must perform the Signal Path Compensation (SPC) operation described

in the Tektronix 4000 Series Digital Phosphor Oscilloscopes User Manual

prior to evaluating specifications. If the operating temperature changes by

more than 10 °C (18 °F), you must perform the SPC operation again.

Table 1: Analog channel input and vertical specifications

Characteristic Description

Number of input

channels

Input coupling

Input resistance

selection

Input impedance,

DC coupled

Maximum input voltage

(50 Ω)

Maximum input voltage

(1 MΩ)

DC Balance

DPO4032, MSO4032 DPO4104, DPO4054, DPO4034, MSO4104,

2 analog, digitized simultaneously 4 analog, digitized simultaneously

DC, AC, or GND

GND coupling approximates ground reference by measuring the CVR output set to GND. The signal being

measured on the BNC is not disconnected from the channel input load.

1MΩ or 50 Ω

DPO4104, MSO4104: Bandwidth is limited to 500 MHz with 1 MΩ impedance selected.

1MΩ ±1% in parallel with 13 pF ±2 pF

50 Ω ±1%

DPO4104, MSO4104: VSWR ≤1.5:1 from DC to 1 GHz, typical

DPO4054, MSO4054: VSWR ≤1.5:1 from DC to 500 MHz, typical

DPO4034, DPO4032, MSO4034, MSO4032: VSWR ≤1.5:1 from DC to 350 MHz, typical

5V

with peaks ≤ ±20 V (DF ≤ 6.25%)

RMS

The m aximum input voltage at the BNC, between the center conductor and shield is 400 V

39.2%), 250 V

The m aximum transient withstand voltage is ±800 V

0.2 div with the input DC 50 Ω coupled and 50 Ω terminated

0.25 div at 2 mV/div with the input DC 50 Ω coupled and 50 Ω terminated

0.5 div at 1 mV/div with the input DC 50 Ω coupled and 50 Ω terminated

0.2 div with the input DC 1 MΩ coupled and 50 Ω terminated

0.3 div at 1 mV/div with the input DC 1 MΩ coupled and 50 Ω terminated

to 130 kHz derated to 2.6 V

RMS

ifications are provided for your convenience but are not guaranteed.

at 500 MHz.

RMS

symbol are checked in Performance

MSO4054, MSO4034

peak

peak

(DF ≤

MSO4000 and DPO4000 Series Specifications and Performance Verification 1

Page 10

Specifications

Table 1: Analog channel input and vertical specifications (cont.)

Characteristic Description

Delay between

channels, full

bandwidth, typical

Deskew range

Crosstalk (channel

isolation), typical

TekVPI Interface The probe interface allows installing, powering, compensating, and controlling a wide range of probes

Total probe power

Probe power per

channel

Number of digitized

bits

(coarse)

Sensitivity range (fine) 1 mV/div to 5 V/div: <-50% to >+50% of selected setting, 1 MΩ

Sensitivity resolution

(fine), typical

Position range ±5 divisions

Analog bandwidth,

50 Ω

≤100 ps between any two channels with input impedance set to 50 Ω, DC coupling

Note: all settings in the instrument can be manually time aligned using the Probe Deskew function from

-100 ns to +100 ns with a resolution of 20 ps.

-100 ns to +100 ns with a resolution of 20 ps

≥100:1 at ≤100 MHz and ≥30:1 at >100 MHz up to the rated bandwidth for any two channels having

equal Volts/Div settings

offering a variety of features.

The interface is available on all front panel inputs including Aux In. Aux In only provides 1 MΩ input

impedance and does not offer 50 Ω as do the other input channels.

DPO4032, DPO4034, DPO4054, MSO4032, MSO4034, MSO4054: 50 W

DPO4104, MSO4104: 50 W with a derating of 0.8 W/°C for ambient temperatures ≥25 °C

Voltage Max Amperage Voltage Tolerance

5V

12 V

8bits

Displayed vertically with 25 digitization levels (DL) per division, 10.24 divisions dynamic range.

"DL" is the abbreviation for "digitization level." A DL is the smallest voltage level change that can be

resolved by an 8-bit A-D Converter. This value is also known as the LSB (least significant bit).

1MΩ 50 ΩSensitivity range

1 mV/div to 10 V/div in a 1-2-5 sequence 1 mV/div to 1 V/div in a 1-2-5 sequence

10 V/div: <-50% to 0%, 1 M Ω

1 mV/div to 500 mV/div: <-50% to >+50% of selected setting, 50 Ω

1 V/div: <-50% to 0% , 50 Ω

Allows continuous adjustment from 1 mV/div to 10 V/div, 1 M Ω

Allows continuous adjustment from 1 mV/div to 1 V/div, 50 Ω

≤1% of current setting

The limits stated below are for ambient temperature of ≤30 °C and the bandwidth selection set to FULL.

Reduce the upper bandwidth frequency by 1% for each °C above 30 °C.

Instrument

DPO4104, MSO4104 DC to 1 GHz DC to 350 MHz DC to 200 MHz

DPO4054, MSO4054 DC to 500 MHz DC to 350 MHz DC to 200 MHz

Instrument

DPO4034, MSO4034 DC to 350 MHz DC to 200 MHz

DPO4032, MSO4032 DC to 350 MHz DC to 200 MHz

50 mA (250 mW) ±5%

2 A (24 W) ±10%

5 mV/div to 1 V/div 2 mV/div to

4.98 mV/div

2 mV/div to 1 V/div 1 mV/div to 1.99 V/div

1 mV/div to

1.99 mV/div

2 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 11

Table 1: A nalog channel input and vertical specifications (cont.)

Characteristic Description

Analog bandwidth,

1MΩ with P6139A 10X

Probe, typical

Calculated rise time,

typical

Analog bandwidth

selections

Lower frequency limit,

AC coupled, typical

Upper frequency limit,

250 MHz bandwidth

limited, typical

Upper frequency limit,

20 MHz bandwidth

limited, typical

DC gain accuracy

The limits stated below are for ambient temperature of ≤30 °C and the bandwidth selection set to FULL.

Reduce the upper bandwidth frequency by 1% for each °C above 30 °C.

Instrument

DPO4104, MSO4104 DC to 500 MHz DC to 300 MHz DC to 175 MHz

DPO4054, MSO4054 DC to 500 MHz DC to 300 MHz DC to 175 MHz

DPO4034, MSO4034 DC to 350 MHz DC to 300 MHz DC to 175 MHz

DPO4032, MSO4032 DC to 350 MHz DC to 300 MHz DC to 175 MHz

The formula is calculated by measuring -3 dB bandwidth of the oscilloscope. The formula accounts for the

rise time contribution of the oscilloscope independent of the rise time of the signal source.

Instrument

DPO4104, MSO4104

DPO4054, MSO4054

DPO4034, MSO4034

DPO4032, MSO4032

Instrument

DPO4104, MSO4104

DPO4054, MSO4054

DPO4034, MSO4034

DPO4032, MSO4032

20 MHz, 250 MHz and Full (all models)

< 10 Hz when AC to 1 MΩ coupled

The AC coupled lower frequency limits are reduced by a factor of 10 when 10X passive probes are used.

250 MHz, ±20% (all models)

20 MHz, ±20% (all models)

For 1 MΩ path: For 50 Ω path:

±1.5%, derated at 0.100% /°C above 30 °C

±3.0% Variable Gain, derated at 0.100%/°C above

30 °C

50 mV/div to 100 V/div 20 mV/div to

50 Ω : 1 mV/div to

1.99 mV/div

1.75 ns 778 ps 350 ps

1.75 ns 778 ps 700 ps

1.75 ns 1 ns 1 ns

1.75 ns 1 ns 1 ns

1MΩ (P6139A

probe): 10 mV/div

to 19.9 mV/div

1 ns 700 ps

1 ns 700 ps

1ns 1ns

1ns 1ns

Specifications

10 mV/div to

49.8 m V/div

50 Ω : 2 mV/div to

4.99 mV/div

1MΩ (P6139A probe): 20 mV/div to 100 V/div

±1.5%, derated at 0.050% /°C above 30 ° C

±3.0% Variable Gain, derated at 0.050%/°C above

30 °C

19.9 m V/div

50 Ω : 5 mV/div to

1V/div

MSO4000 and DPO4000 Series Specifications and Performance Verification 3

Page 12

Specifications

Table 1: Analog channel input and vertical specifications (cont.)

Characteristic Description

DC voltage

measurement

accuracy

Sample

acquisition mode,

typical

Average

acquisition mode

Offset ranges

Offset accuracy ±[0.005 × | offset - position | + DC Balance]

Measurement type

Any sample

Delta volts between any two samples acquired

with the same oscilloscope setup and ambient

conditions

Note: Offset, position, and the constant offset term must be converted to volts by multiplying by the

appropriate volts/div term.

Average of ≥ 16 waveforms ±[DC gain accuracy x | reading - (offset - position) |

Delta Volts between any two averages of ≥16

waveforms acquired with the same oscilloscope

setup and ambient conditions

Note: Offset, position, and the constant offset term must be converted to volts by multiplying by the

appropriate volts/div term.

The basic accuracy specification applies directly to any sample and to the following measurements: High,

Low, Max, Min, Mean, Cycle Mean, RMS, and Cycle RMS. The delta volt accuracy specification applies to

subtractive calculations involving two of these measurements.

The delta volts (difference voltage) accuracy specification applies directly to the following measurements:

Positive Overshoot, Negative Overshoot, Pk-Pk, and Amplitude.

1 mV/div to 50 mV/div

50.5 m V/div to 99.5 mV/div

100 mV/div to 500 mV/div

505 mV/div to 995 mV/div

1 V/div to 5 V/div

5.05 V /div to 10 V/div

1

1

Input Signal cannot exceed Max Input Voltage for the 50 Ω input path. Refer to the Max Input Voltage

specification for more information.

Note: Both the position and constant offset term must be converted to volts by multiplying by the

appropriate volts/div term.

DC Accuracy (in volts)

±[DC gain accuracy x | reading - (offset - position) |

+ Offset Accuracy + 0.15 div + 0.6 mV]

±[DC gain accuracy x | reading | + 0.15 div +

1.2 mV]

+ O ffset Accuracy + 0.1 div]

±[DC gain accuracy x | reading | + 0.05 div]

Offset rangeVolts/div setting

1MΩ input 50 Ω input

±1 V ±1 V

±0.5 V ±0.5 V

±10V ±10V

±5 V ±5 V

±100 V ±5 V

±50 V Not applicable

4 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 13

Table 1: A nalog channel input and vertical specifications (cont.)

Characteristic Description

Random Noise

Sample Acquisition

Mode

Aperture uncertainty

,

Model Bandwidth selection 1 MΩ 50 Ω

DPO4104

Full Bandwidth

250 MHz

20 MHz

DPO4054

Full Bandwidth

250 MHz

20 MHz

DPO4034

Full Bandwidth

250 MHz

20 MHz

DPO4032

Full Bandwidth

250 MHz

20 MHz

≤(3 ps + 0.1 ppm × Record Duration)

, for records having duration ≤1 minute

RMS

RMS Noise

≤(133 µV + 7.3% of

Volts/div Setting)

≤(99.5 µV + 5.0% of

Volts/div Setting)

≤(20.8 µV + 3.3% of

Volts/div Setting)

≤(130 µV + 7.6% of

Volts/div Setting)

≤(96.2 µV + 5.2% of

Volts/div Setting)

≤(22.7 µV + 3.8% of

Volts/div Setting)

≤(139 µV + 6.4% of

Volts/div Setting)

≤(94.0 µV + 4.8% of

Volts/div Setting)

≤(22.3 µV + 3.4% of

Volts/div Setting)

≤(141 µV + 7.2% of

Volts/div Setting)

≤(87.9 µV + 4.9% of

Volts/div Setting)

≤(18.5 µV + 3.1% of

Volts/div Setting)

Specifications

≤(72.3 μV + 6% of

Volts/div Setting)

≤(49.6 µV + 3.7% of

Volts/div Setting)

≤(12.8 µV + 3.3% of

Volts/div Setting)

≤(77.9 μV + 3.1% of

Volts/div Setting)

≤(56.7 µV + 3.3% of

Volts/div Setting)

≤(13.6 µV + 3.3% of

Volts/div Setting)

≤(77.7 µV + 3.3% of

Volts/div Setting)

≤(76.6 µV + 3.2% of

Volts/div Setting)

≤(16.0 µV + 3.1% of

Volts/div Setting)

≤(81.6 µV + 3.1% of

Volts/div Setting)

≤(73.8 µV + 3.9% of

Volts/div Setting)

≤(12.7 µV + 3.6% of

Volts/div Setting)

MSO4000 and DPO4000 Series Specifications and Performance Verification 5

Page 14

Specifications

Table 1: Analog channel input and vertical specifications (cont.)

Characteristic Description

6 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 15

Table 1: A nalog channel input and vertical specifications (cont.)

Characteristic Description

Delta Time

Measurement

Accuracy

The formula to calculate delta-time measurement accuracy (DTA) for a given instrument setting and input

signal is given below (assumes insignificant signal content above Nyquist)

=SlewRate(1stEdge) around 1stpoint in measurement

SR

1

=SlewRate(2ndEdge) around 2ndpoint in measurement

SR

2

N = input-referred noise (volts

, Refer to Random Noise, Sample Acquisition Mode)

rms

TBA = timebase accuracy (5 ppm, Refer to Long-term sample rate and delay time accuracy)

= delta-time measurement duration (sec)

t

reading

RecordDuration = (Record Length) / (Sample Rate)

= 1/(Sample Rate)

t

samplerate

Specifications

Assumes that error due to aliasing is insignificant

The term under the square-root sign is the stability, and is due to TIE (Time Interval Error). The

to this term occur throughout a single-shot measurement. The second term is due to both the absolute

center-frequency accuracy and the center-frequency stability of the time base and varies between multiple

single-shot measurements over the observation interval (the amount of time from the first sing

measurement to the final single-shot measurement).

1

For 50 Ω path, 1 V/div is the maximum vertical setting.

errors due

le-shot

MSO4000 and DPO4000 Series Specifications and Performance Verification 7

Page 16

Specifications

Table 2: Digita

l channel input specifications, MSO4000 only

Characteristic Description

Threshold vol

Digital threshold accuracy

Timing resolution

tage range

-2 V to +5 V

±[100 mV + 3% o

f the threshold setting after calibration]

2 ns for the main memory and 60.6 ps for MagniVu memory

Table 3: Horizontal and acquisition system specifications

Characteristic

Long-term sample rate and delay

time accuracy

Seconds/Division r ange

Record Length

1 K 400 ps – 40 s 1 ns – 40 s

10 K 400 ps – 400 s 1 ns – 400 s

100 K

1M

10 M

response, typical

Sample-rate range DPO4104, MSO4104: 5 GS/s-0.1 S/s

Record length range 10 M, 1 M, 100 k, 10 k, 1 k

Maximum update rate

Aperture Uncertainty, typical

Number of Waveforms for Average

Acquisition Mode

Description

±5 ppm over any ≥1mstimeinterval

DPO4104, MSO4104

400 ps – 1,000 s 1 ns – 1,000 s

1-2-4 sequence 1-2-4 sequence except one position in each

Minimum pulse widthPeak Detect or Envelope mode pulse

DPO4104, MSO4104: > 200 ps

DPO4054, DPO4034, DPO4032, MSO4054, MSO4034, MSO4032: > 400 ps

DPO4054, DPO4034, DPO4032, MSO4054, MSO4034, MSO4032: 2.5 GS/s – 0.1 S/s

Maximum triggered acquisition rate: 50,000 wfm/s

≤(3 ps + 0.1 ppm × record duration)

, for records having duration ≤1 m inute

RMS

2 to 512 waveforms

Default of 16 waveforms

DPO4054, DPO4034, DPO4032,

MSO4054, MSO4034, MSO4032

record length selection, which is 0.8-2-4.

Table 4: Trigger specifications

Characteristic Description

Aux In (External) trigger maximum

input voltage

Aux In (External) trigger input

The maximum input voltage at the BNC, between center conductor and shield, is 400 V

(DF ≤39.2%), 250 V

The maximum transient withstand voltage is ±800 V

to 2 MHz derated to 5 V

RMS

@ 500 MHz.

RMS

peak

.

1MΩ ±1%inparallelwith13pF±2pF

peak

impedance, typical

Aux In (External) trigger bandwidth,

250 MHz ±20%

typical

Trigger bandwidth, Edge, Pulse, and

Logic, typical

DPO4104, MSO4104: 1 GHz

DPO4054, MSO4054: 500 MHz

DPO4034, DPO4032, MSO4034, MSO4032: 350 MHz

Time accuracy for Pulse, Glitch,

Timeout, or Width triggering

Time range Accuracy

1 ns to 500 ns

520 ns to 1 s

±(20% of setting + 0.5 ns)

±(0.01% of setting + 100 ns)

8 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 17

Table 4: Trigger specifications (cont.)

Characteristic Description

Edge-type trigger sensitivity, DC

coupled, typical

Edge trigger sensitivity, not DC

coupled, typical

Trigger level ranges

Lowest frequency for successful

operation of "Set Level to 50%"

function, typical

Trigger level accuracy, DC coupled

typical

Trigger holdoff range

Video-type trigger sensitivity, typical

Video-type trigger formats and field

rates

Trigger Source Sensitivity

Any input channel

Aux in (External) 200 mV from DC to 50 MHz, increasing to

Line Fixed

Trigger Coupling Typical Sensitivity

NOISE REJ 2.5 times the DC-coupled limits

HF REJ

LF REJ

Source Sensitivity

Any input channel

Aux In (External)

Line Not applicable

The line trigger level is fixed at about 50% of the line voltage.

This specification applies to logic and pulse thresholds.

45 Hz

For signals having rise and fall times ≥10 ns, the limits are as follows:

Source

Any channel ±0.20 divisions

Aux In (external trigger) ±(10% of setting + 25 mV)

Line Not applicable

20 ns minimum to 8 s maximum

The limits for both delayed and main trigger are as follows:

Source Sensitivity

Any input channel

Aux In (External)

Triggers from negative sync composite video, field 1 or field 2 for interlaced systems, on any

field, specific line, or any line for interlaced or non-interlaced systems. Supported systems

include NTSC, PAL, and SECAM.

Specifications

0.40 div from DC to 50 MHz, increasing to

1 div at oscilloscope bandwidth

500 mV at 250 MHz

1.5 times the DC-coupled limit from DC to

50 kHz. Attenuates signals above 50 kHz

1.5 times the DC-coupled limits for

frequencies above 50 kHz. Attenuates

signals below 50 kHz

±8 divisions from center of screen,

±8 divisions from 0 V when vertical LF reject

trigger coupling is selected

±8 V

Range

0.6 to 2.5 divisions of video sync tip

Video not supported through Aux In

(External) input

MSO4000 and DPO4000 Series Specifications and Performance Verification 9

Page 18

Specifications

Table 4: Trigger specifications (cont.)

Characteristic Description

Logic-type or logic qualified trigger

or events-delay sensitivities, DC

coupled, typical

Pulse-type runt trigger sensitivities,

typical

Pulse-type trigger width and glitch

sensitivities, typical

Logic-type triggering, minimum logic

or rearm time, typical

Minimum clock pulse widths for

setup/hold time violation trigger,

typical

Setup/hold violation trigger, setup

and hold time ranges, DPO4000 only

MSO4000 only

1.0 division from DC to maximum bandwidth

1.0 division from DC to maximum bandwidth

1.0 division

For all vertical settings, the minimums are:

Trigger type Minimum pulse

Logic Not applicable 2 ns 1 ns

Time Qualified

Logic

For all vertical settings, the minimums are:

Minimum pulse width, clock active

User hold time + 2.5 ns

Feature Min Max

Setup time

Hold time 4 ns 8 s

Setup + Hold time

Feature Min Max

Setup time

Hold time 1 n s 1.0 ms

Setup + Hold time

Input coupling on clock and data channels must be the same.

For Setup time, positive numbers mean a data transition before the clock.

For Hold time, positive numbers mean a data transition after the clock edge.

Setup + Hold time is the algebraic sum of the Setup Time and the Hold Time programmed by

the user.

width

Minimum re-arm

time

Minimum time

between channels

4ns 2ns 1ns

2

3

Minimum pulse width, clock inactive

2ns

0ns 8s

4ns 16s

-0.5 ns 1.0 ms

0.5 ns 2.0 ms

1

2

10 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 19

Table 4: Trigger specifications (cont.)

Characteristic Description

Pulse type trigger, minimum pulse,

rearm time, minimum transition time

Transition time trigger, delta time

range

Time range for glitch, pulse width,

timeout, time-qualified runt, or

time-qualified window triggering

B trigger after events, minimum

pulse width and maximum event

frequency, typical

B trigger, minimum time between

arm and trigger, typical

B trigger after time, time range

B trigger after events, event range

Maximum serial trigger bits 128 bits

Standard Parallel bus interface

triggering (MSO4000 only)

Pulse class Minimum pulse

Glitch

Runt 4 ns 2 ns

Time-qualified runt

Width 4 ns

Slew rate

For the trigger class width and the trigger class runt, the pulse width refers to the width of the

pulse being measured. The rearm time refers to the time between pulses.

For the trigger class slew rate, the pulse width refers to the delta time being measured. The

rearm time refers to the time it takes the signal to cross the two trigger thresholds again.

4nsto8s

4nsto8s

4 ns, 500 MHz

4ns

For trigger after time, this is the time between the end of the time period and the B trigger

event.

For trigger after events, this is the time between the last A trigger event and the first B trigger

event.

4 ns to 8 seconds

1 to 9,999,999

DataTrigger:1to20bitsofuserspecified data on 4-channel models and 1 to 18 bits of

user specified data on 2-channel models.

width

4ns

4ns

4ns

Specifications

Minimum rearm time

2 ns + 5% of glitch width setting

8.5 ns + 5% of width setting

2 ns + 5% of width upper limit setting

8.5 ns + 5% of delta time setting

MSO4000 and DPO4000 Series Specifications and Performance Verification 11

Page 20

Specifications

Table 4: Trigger specifications (cont.)

Characteristic Description

Standard serial bus interface triggering

I2C Address Triggering: 7 and 10 bit user specified address, as well as General Call, START

byte, HS-mode, EEPROM, and CBUS

Data Trigger: 1 to 5 bytes of user specified data

Trigger On: Start, Repeated Start, Stop, Missing Ack, Data, or Address and Data

Maximum Data Rate: 10 Mbps

SPI Data Trigger: 1 to 16 bytes of user specified data

Trigger On: SS Active, Start of Frame, MOSI, MISO, or MOSI and MISO

Maximum Data Rate: 10 Mbps

CAN Data Trigger: 1 to 8 bytes of user specified data, including qualifiers of equal to (=), not equal

to (<>), less than (<), greater than (>), less than or equal to (<=), greater than or equal to (>=)

Trigger On: Start of Frame, Type of Frame, Identifier, Data, Identifier and Data, End of Frame,

Missing Ack, or Bit Stuffing E rror

Frame Type: Data, Remote, Error, Overload

Identifier: Standard (11 bit) and Extended (29 bit) identifiers

Maximum Data Rate: 1 Mbps

RS-232 Trigger On: Tx Start Bit, Rx Start Bit, Tx End of Packet, Rx End of Packet, Tx Data, Rx Data,

Tx Parity Error, or Rx Parity Error

Maximum Data Rate: 10 Mbps

4

LIN

Identifier Trigger: 6 bits of user-specified data, equal to (=)

Data Trigger: 1 to 8 bytes of user-specified data, including qualifiers of equal to (=), not equal

to (<>), less than (<), greater than (>), less than or equal to (<=), greater than or equal to

(>=), inside range, or outside range

Error: Sync, Identifier Parity, Checksum

Trigger On: Sync, Identifier, Data, ID & Data, Wakeup Frame, Sleep Frame, or Error

Maximum Data Rate: 100 kbps

12 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 21

Specifications

Table 4: Trigger specifications (cont.)

Characteristic Description

FlexRay

I2S

Left Justified

Right Justified

TDM

1

For logic, time between channels refers to the length of time a logic state derived from more than one channel must exist to be recognized. For events, thetime

is the minimum time between a main and delayed event that will be recognized if more than one channel is used.

2

nactivepulsewidthisthewidthoftheclockpulsefromitsactiveedge(asdefined through the Define Inputs lower-bezel button and the Clock Edge side-bezel

A

menu) to its inactive edge. An inactive pulse width is the width of the pulse from its inactive edge to its active edge.

3

The User hold time is the number selected by the user through the Times lower-bezel button and the Hold Time side-bezel menu.

4

DPO4000 Series: S/N CO20000/B020000 and above; MSO4000 Series: all units.

4

Indicator bits: Normal Frame, Payload Frame, Null Frame, Sync Frame, Startup Frame

Identifier Trigger: 11 bits of user-specified data, equal to (=), not equal to (<>), less than (<),

greater than (>), less than or equal to (<=), greater than or equal to (>=), Inside Range, or

Outside Range

Cycle Count Trigger: 6 bits of user-specified data, equal to (=)

Header Fields Trigger: 40 bits of user-specified data comprising Indicator Bits, Identifier,

Payload Length, Header CRC, Cycle Count, or equal to (=)

Data Trigger: 1 to 16 Bytes of user-specified data, with 0 to 253, or "don't care" bytes of data

offset, including qualifiers of equal to (=), not equal to <>, less than (<), greater than (>), less

than or equal to (<=), greater than or equal to (>=), Inside Range, Outside Range

End Of Frame: User-chosen types Static, Dynamic (DTS), and All

Error: Header CRC, Trailer CRC, Null Frame-static, Null Frame-dynamic, Sync Frame,

Startup Frame

Trigger On: Start of Frame, Indicator Bits, Identifier, Cycle Count, Header Fields, Data,

Identifier & D ata, End of Frame, or Error

Maximum Data Rate: 10 Mbps

4

Data Trigger: 32 bits of user-specified data in a left word, right word, or either, including

qualifiers of equal to (=), not equal to <>, less than (<), greater than (>), less than or equal to

(<=), greater than or equal to (>=), inside range, outside range

Trigger on: Word Select, Data

Maximum Data Rate: 12.5 Mbps

4

Data Trigger: 32 bits of user-specified data in a left word, right word, or either, including

qualifiers of equal to (=), not equal to <>, less than (<), greater than (>), less than or equal to

(<=), greater than or equal to (>=), inside range, outside range

Trigger on: Word Select, Data

Maximum Data Rate: 12.5 Mbps

4

Data Trigger: 32 bits of user-specified data in a left word, right word, or either, including

qualifiers of equal to (=), not equal to <>, less than (<), greater than (>), less than or equal to

(<=), greater than or equal to (>=), inside range, outside range

Trigger on: Word Select, Data

Maximum Data Rate: 12.5 Mbps

4

Data Trigger: 32 bits of user-specified data in a channel 0-7, including qualifiers of equal to

(=), not equal to <>, less than (<), greater than (>), less than or equal to (<=), greater than or

equal to (>=), inside range, outside range

Trigger on: Frame Sync, Data

Maximum Data Rate: 25 Mbps

MSO4000 and DPO4000 Series Specifications and Performance Verification 13

Page 22

Specifications

Table 5: Displa

Characteristic Description

Display type

Display resolution 1000 horizontal by 651 vertical displayed pixels

Luminance, typical

Waveform display color scale The TFT display can support up to 262,144 colors. A subset of these colors are used for the

yspecifications

Display area: 210.4 mm (8.28 inches) (H) x 157.8 mm (6.21 inches) (V), 264 mm

(10.4 inches) diagonal, 6-bit RGB full color, XGA (1024 x 768) TFT liquid crystal display

(LCD).

Minimum 240 cd/m

oscillosc

ope display, all of which are fixed colors and not changeable by the customer.

2

, typical 300 cd/m

2

Table 6: Input/Output port specifications

Characteristic Description

Ethernet interface Standard on all models: 10/100 Mbps

USB interface 1 D evice and 3 Host connectors (all models)

GPIB interface Available as an optional accessory that connects to USB Device and USB Host port. with

the T EK-US B-488 GPIB to USB Adapter

Control interface is incorporated in the instrument user interface.

Video signal output

Probe compensator output voltage

and frequency, typical

ger (Auxiliary) output (AUX

Trig

OUT)

A 15 pin, XGA RGB-type connector

Output voltage: 0 V to 2.5 V ±1% behind 1 kΩ ±2%

Frequency: 1 kHz ±5%

LOW TRUE; LOW to HIGH transition indicates that the trigger occurred. The logic levels are:

Characteristic

Vout (HI) ≥2.5 V open circuit; ≥1.0Vintoa50Ω load

Vout (LO) ≤0.7 V into a load of ≤4mA;≤0.25 V into a

Limits

to ground

50 Ω load to ground

able 7: Power source specifications

T

Characteristic Description

Source voltage 100 V to 240 V ±10%

Source frequency (90 V to 264 V) 47 Hz to 66 Hz

(100 V to 132 V) 360 Hz to 440 Hz

Fuse rating T6.3AH, 250 V

The fuse i s not customer replaceable.

14 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 23

Specifications

Table 8 : Data st

orage specifications

Characteristic Description

Nonvolatile m

emory retention time,

No time limit for front-panel settings, saved waveforms, setups, and calibration constants

typical

Real-time cl

Compact Fla

ock

sh card

A programmab

Used to stor

Supply Volt

Switched 3

le clock providing time in years, months, days, hours, minutes, and seconds

e reference waveforms and front-panel settings

age

.3 V only

Form fac tor

Type 1 only

Table 9: Environmental specifications

Characteristic Description

Temperature

Humidity

Altitude

Pollution Degree Pollution Degree 2, indoor use only

Random vibration

Operating: 0 °C to +50 °C (+32 °F to +122 °F)

Nonoperating: -20 °C to +60 °C (-4 °F to +140 °F)

Operating:

High: 10% to 60% relative humidity, 40 °C to 50 °C (104 °F to 122 °F)

Low: 10% to 90% relative humidity, 0 °C to 40 ° C (32 °F to 104 °F)

Nonoperating:

High: 5% to 60% relative humidity, 40 °C to 60 °C (104 °F to 140 °F)

Low: 5% to 90% relative humidity, 0 °C to 40 °C (32 °F to 104 °F)

Operating: 3,000 m (9,843 ft)

Nonoperating: 12,000 m (39,370 ft)

Operating: 0.31 g

Nonoperating: 2.46 g

from 5 Hz to 500 Hz, 10 minutes on each axis, 3 axes

RMS

from 5 Hz to 500 Hz, 10 minutes on each axis, 3 axes (30 minutes

RMS

total).

Data bits

16 bit data

transfer

MSO4000 and DPO4000 Series Specifications and Performance Verification 15

Page 24

Specifications

Table 10: Mecha

Characteristic Description

Dimensions Nominal, non-

Weight

Clearance Requirements The clearance requirement for adequate cooling is:

nical specifications

rackmount:

Height: 229 mm (9.0 in), including feet: 272 mm (10.7 in), including vertical handle and feet

Width: 439 mm (17.3 in) from handle hub to handle hub

Depth:

137 mm (5.4 in) from feet to front of knobs

145 mm (5.7 in) from feet to front of front cover

Nominal, ra

Height: 218 mm (8.6 in)

Width: 488 mm (19.2 in) from outside of handle to outside of handle

Depth: 559 m

5.1kg(11.

8.7 kg (19.1 lbs), instrument with rackmount, without front cover

9.5 kg (21.0 lbs), when packaged for domestic shipment and without rackmount

50.8 m m (2

rear of the unit

ckmount (5U rack sizes):

m (22.0 in) from outside of handle to back of slide

3 lbs), stand-alone instrument, without front cover

in) on the left side (when looking at the front of the instrument) and on the

16 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 25

Specifications

Table 11: P6516

Characteristic Description

Number of channels

Threshold ac

Maximum sig

Minimum signal swing 500 mV peak-to-peak

Input resistance

Input capacitance 3.0 pF typical

Temperatu

Altitude

Pollution Degree 2, indoor use only

Humidity

re

Digital Probe specifications

curacy

nal swing

16

±(100 mV + 3% of threshold)

6.0 V peak-t

20 kΩ

Operating: 0 °C to +50 °C (+32 °F to + 122 °F)

Nonoperating: -55 °C to +75 °C (-67 °F to +167 °F)

Operating: 4,500 m (15,000 ft)

Nonoper

10% to 95% relative humidity

o-peak centered around the threshold voltage

ating: 15,000 m (50,000 ft)

MSO4000 and DPO4000 Series Specifications and Performance Verification 17

Page 26

Specifications

18 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 27

Performance Verification

This chapter contains performance verification procedures for the specifications

marked with the

required to c

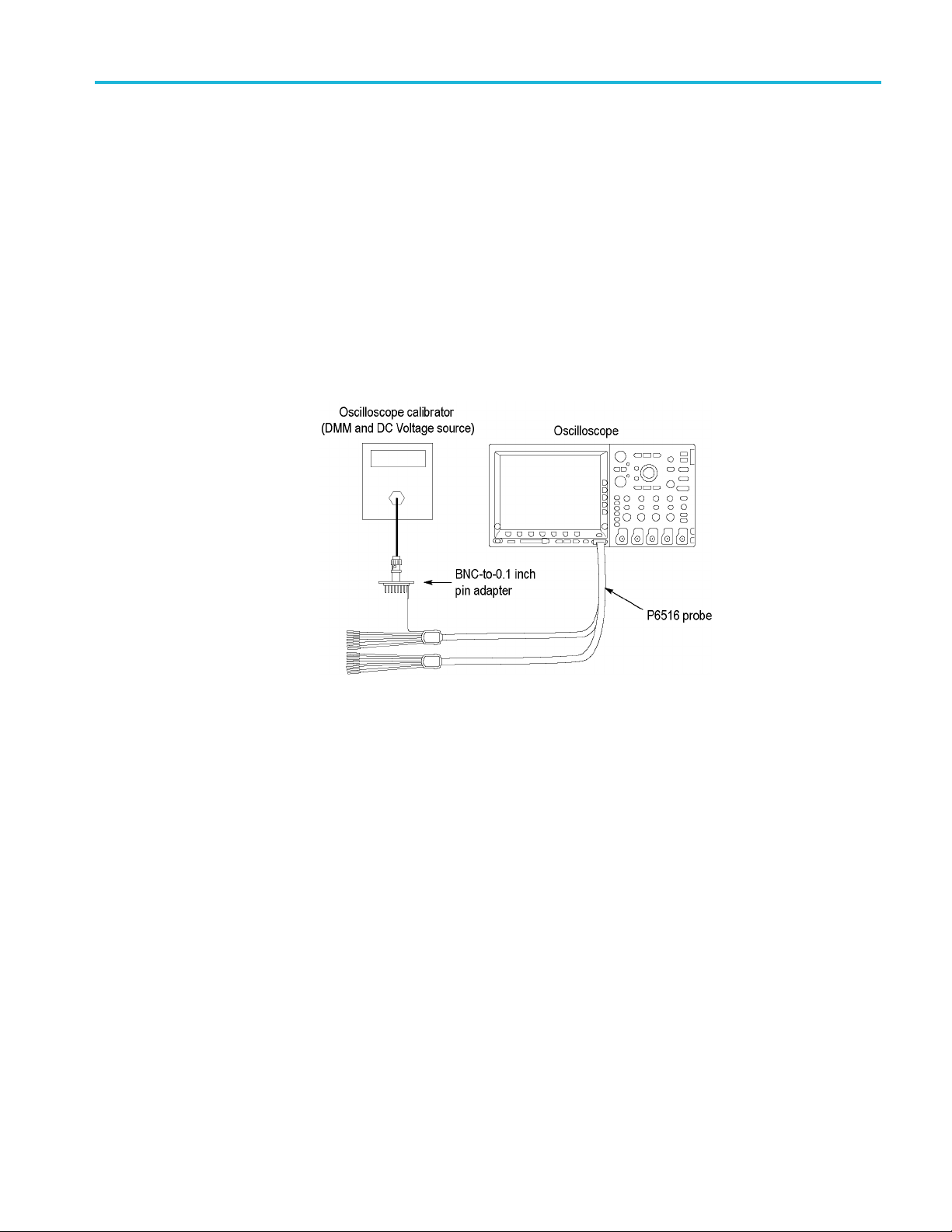

Description Minim um requirements Exam ples

DC voltage source 3 mV to 4 V, ±0.1% accuracy

Leveled sin

Time mark generator 80 ms period, ±1 ppm accuracy, rise time

Digital Multimeter (DMM) 0.1% accuracy or better

One 50 Ω BNC cable

One BNC to 0.1 inch pin adapter Female BNC to 2x16 0 .1 inch pin headers

e wave generator

50 kHz to 1000 MHz, ±4% amplitude

accuracy

<50ns

Male-to-male connectors Tektronix part number 012-0057-01

omplete these procedures.

You may need additional cables and adapters, depending on the actual test

equipm

ent you use.

These procedures cover all DPO4000 and MSO4000 models. Please disregard

s that do not apply to the specific model you are testing.

check

symbol. The following equipment, or a suitable equivalent, is

Fluke 9500 Oscilloscope Calibrator with a

9510 Output Module

An appropr

adapter between the Fluke 9500 and

P6516 probe

Tektronix part number 679-6240-00

iate BNC-to-0.1 inch pin

Upgrade the Firmware

Print the test record on the following pages and use it to record the performance

results for your oscilloscope.

test

NOTE. Completion of the performance verification procedure does not update

the stored time a nd date of the latest successful adjustment. The date and time

are updated only when the adjustment procedures in the service manual are

successfully completed.

The performance verification procedures verify the performance of your

instrument. They do not adjust your instrument. If your instrument fails any of

the performance verification tests, you should perform the factory adjustment

procedures as described in the Tektronix 4000 Series Service Manual.

For the best functionality, you can upgrade the oscilloscope firmware. To upgrade

the firmware, follow these steps:

1. Open up a Web browser and go to www.tektronix.com/software. Use the

Software and Firmware Finder to locate the most recent firmware upgrade.

2. Download the latest firmware for your oscilloscope onto your PC.

MSO4000 and DPO4000 Series Specifications and Performance Verification 19

Page 28

Performance Verification

3. Unzip the files a

USB flash drive.

4. Power off your

5. Insert the USB flash drive into a USB Host port on the front or back of the

oscillosco

6. Power on the oscilloscope. The oscilloscope automatically recognizes the

replacemen

If the instrument does not install the firmware, rerun the procedure. If the

problem co

NOTE. Do not power off the oscilloscope or remove the USB flash drive until the

oscilloscope finishes installing the firmware.

The oscilloscope displays a message when the installation is complete.

7. Power o

8. Power on the oscilloscope.

9. Push the Utility front-panel button.

ff the oscilloscope and remove the USB flash drive.

nd copy the "firmware.img" file into the root folder of a

oscilloscope.

pe.

t firmware and installs it.

ntinues, contact qualified service personnel.

10. Push the Utility Page lower-bezel button.

11. Turn multipurpose knob a and select Config.

12. Push the About lower-bezel button. The oscilloscope displays the firmware

version number.

13. Confirm that the version number matches that of the new firmware.

20 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 29

Performance Verification

Test Record

Model Serial Procedure performed by Date

Test Passed Failed

Self Test

Input Impedance

Performance checks Vertical scale Low limit Test result High limit

All models:

Channel 1 Input

Impedance, 1 MΩ

Impedance, 50 Ω

Channel 2 Input

Impedance, 1 MΩ

Impedance, 50 Ω

DPO4104, DPO4054, DPO4034, MSO4104, MSO4054, MSO4034:

Channel 3 Input

Impedance, 1 MΩ

Impedance, 50 Ω

Channel 4 Input

Impedance, 1 MΩ

Impedance, 50 Ω

10 mV/div 990 kΩ 1.01 MΩ

100 mV/div 990 kΩ 1.01 MΩ

1 V/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 ΩChannel 1 Input

100 mV/div 49.5 Ω 50.5 Ω

10 mV/div 990 kΩ 1.01 MΩ

100 mV/div 990 kΩ 1.01 MΩ

1 V/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 ΩChannel 2 Input

100 mV/div 49.5 Ω 50.5 Ω

10 mV/div 990 kΩ 1.01 MΩ

100 mV/div 990 kΩ 1.01 MΩ

1 V/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 ΩChannel 3 Input

100 mV/div 49.5 Ω 50.5 Ω

10 mV/div 990 kΩ 1.01 MΩ

100 mV/div 990 kΩ 1.01 MΩ

1 V/div 990 kΩ 1.01 MΩ

10 mV/div 49.5 Ω 50.5 ΩChannel 4, Input

100 mV/div 49.5 Ω 50.5 Ω

DC Balance

Performance checks Vertical scale Low limit Test result High limit

All models:

Channel 1 DC Balance,

50 Ω,20MHzBW

1 mV/div

2 mV/div

100 mV/div

1V/div

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

MSO4000 and DPO4000 Series Specifications and Performance Verification 21

Page 30

Performance Verification

DC Balance

Performance checks Vertical scale Low limit Test result High limit

Channel 1 DC Balance,

1MΩ,20MHzBW

Channel 1 DC Balance,

50 Ω, 250 MHz BW

Channel 1 DC Balance,

1MΩ, 250 MHz BW

Channel 1 DC Balance,

50 Ω,FullBW

Channel 1 DC Balance,

1MΩ,FullBW

Channel 2 DC Balance,

50 Ω,20MHzBW

Channel 2 DC Balance,

1MΩ,20MHzBW

Channel 2 DC Balance,

50 Ω, 250 MHz BW

Channel 2 DC Balance,

1MΩ, 250 MHz BW

Channel 2 DC Balance,

50 Ω,FullBW

1 mV/div

100 mV/div

1V/div

1 mV/div

2 mV/div

100 mV/div

1V/div

1 mV/div

100 mV/div

1V/div

1 mV/div

2 mV/div

100 mV/div

1V/div

1 mV/div

100 mV/div

1V/div

1 mV/div

2 mV/div

100 mV/div

1V/div

1 mV/div

100 mV/div

1V/div

1 mV/div

2 mV/div

100 mV/div

1V/div

1 mV/div

100 mV/div

1V/div

1 mV/div

2 mV/div

100 mV/div

1V/div

1

1

1

1

1

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

V

-0.5 m

-0.5 m

-20 m

-200

3mV

-0.

0mV

-2

00 mV

-2

0.5 mV

-

0.5 mV

-

V

V

mV

0.5 mV

0.5 mV

20 mV

200 m

mV

0.3

mV

20

0mV

20

.5 mV

0

.5 mV

0

-20mV 20mV

-200 mV 200 mV

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

V

22 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 31

Performance Verification

DC Balance

Performance checks Vertical scale Low limit Test result High limit

Channel 2 DC Balance,

1MΩ,FullBW

1mV/div

100 mV/div

1

1V/div

DPO4104, DPO4054, DPO4034, MSO4104, MSO 4054, MSO4034:

Channel 3 DC Balance,

50 Ω,20MHzBW

1 mV/div

2 mV/div

100 mV/div

1V/div

Channel 3 DC Balance,

1MΩ,20MHzBW

1mV/div

100 mV/div

1

1V/div

Channel 3 DC Balance,

50 Ω, 250 MHz BW

1 mV/div

2 mV/div

100 mV/div

1V/div

Channel 3 DC Balance,

1MΩ, 250 MHz BW

1mV/div

100 mV/div

1

1V/div

Channel 3 DC Balance,

50 Ω,FullBW

1 mV/div

2 mV/div

100 mV/div

1V/div

Channel 3 DC Balance,

1MΩ,FullBW

1mV/div

100 mV/div

1

1V/div

Channel 4 DC Balance,

50 Ω,20MHzBW

1 mV/div

2 mV/div

100 mV/div

1V/div

Channel 4 DC Balance,

1MΩ,20MHzBW

1mV/div

100 mV/div

1

1V/div

Channel 4 DC Balance,

50 Ω, 250 MHz BW

1 mV/div

2 mV/div

100 mV/div

1V/div

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

-0.3 mV 0.3 mV

-20mV 20mV

V

-200 m

-0.5 m

mV

-0.5

-20 m

0mV

-20

.3 mV

-0

0mV

-2

200 mV

-

0.5 mV

-

V

V

200 mV

0.5 mV

0.5 m

20 mV

mV

200

3mV

0.

mV

20

00 mV

2

.5 mV

0

V

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

MSO4000 and DPO4000 Series Specifications and Performance Verification 23

Page 32

Performance Verification

DC Balance

Performance checks Vertical scale Low limit Test result High limit

Channel 4 DC Balance,

1MΩ, 250 MHz BW

1 mV/div

100 mV/div

1

1V/div

Channel 4 DC Balance,

50 Ω,FullBW

1 mV/div

2 mV/div

100 mV/div

1V/div

Channel 4 DC Balance,

1MΩ,FullBW

1 mV/div

100 mV/div

1

1V/div

1

Immediately after calibration, the specification is -0.2 div to 0.20 div.

Performance checks: Bandwidth

Bandwidth at

Channel Impedance Vertical scale V

All models:

1

1

1

1

1

1

2

2

2

2

2

2

50 Ω 5 m V/div

50 Ω 2 m V/div

50 Ω 1 m V/div

1MΩ 5 mV/div

1MΩ 2 mV/div

1MΩ 1 mV/div

50 Ω 5 m V/div

50 Ω 2 m V/div

50 Ω 1 m V/div

1MΩ 5 mV/div

1MΩ 2 mV/div

1MΩ 1 mV/div

DPO4104, DPO4054, D PO4034, MSO4104, MSO4054, MSO4034:

3

3

3

3

3

3

4

50 Ω 5 m V/div

50 Ω 2 m V/div

50 Ω 1 m V/div

1MΩ 5 mV/div

1MΩ 2 mV/div

1MΩ 1 mV/div

50 Ω 5 m V/div

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

-0.5 mV 0.5 mV

-0.5 mV 0.5 mV

-20mV 20mV

-200 mV 200 mV

-0.3 mV 0.3 mV

-20mV 20mV

-200 mV 200 mV

For performance verification testing, the specification is -0.3 to 0.3 div.

in-pp

V

bw-pp

Limit

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

Test result

Gain =

V

bw-pp/Vin-pp

24 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 33

Performance Verification

Performance checks: Bandwidth

Test result

Bandwidth at

Channel Impedance Vertical scale V

4

4

4

4

4

50 Ω 2 m V/div

50 Ω 1 m V/div

1MΩ 5 mV/div

1MΩ 2 mV/div

1MΩ 1 mV/div

in-pp

V

bw-pp

Limit

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

≥ 0.707

DC Gain Accuracy

Performance checks Vertical scale Low limit Test result High limit

All models:

Channel 1 DC Gain

Accuracy, 0 V offset,

ical position,

0Vvert

20 MHz BW, 50 Ω

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

4.98 mV

-3.0% 3.0%

5 mV/div -1.5% 1.5%

10 m V/div -1.5% 1.5%

20 m V/div -1.5% 1.5%

8mV

49.

-3.0% 3.0%

50 m V/div -1.5% 1.5%

100 m V /div -1.5% 1.5%

200 m V /div -1.5% 1.5%

500 m V /div -1.5% 1.5%

1.0 V/div -1.5% 1.5%

Channel 1 DC Gain

Accuracy, 0 V offset,

0 V vertical position,

20 MHz BW, 1 MΩ

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

4.98 m V /div -3.0% 3.0%

5 mV/div -1.5% 1.5%

10 m V/div -1.5% 1.5%

20 m V/div -1.5% 1.5%

49.8 mV

-3.0% 3.0%

50 m V/div -1.5% 1.5%

100 m V /div -1.5% 1.5%

200 m V /div -1.5% 1.5%

500 m V /div -1.5% 1.5%

1 V/div -1.5% 1.5%

Gain =

V

bw-pp/Vin-pp

MSO4000 and DPO4000 Series Specifications and Performance Verification 25

Page 34

Performance Verification

DC Gain Accuracy

Performance checks Vertical scale Low lim it Test result High limit

Channel 2 DC Gain

Accuracy, 0 V offset,

0Vverticalp

20 MHz BW, 50 Ω

Channel 2 DC Gain

Accuracy, 0 V offset,

0Vv

20 MHz BW, 1 M Ω

DPO4104, DPO4054, D PO4034, MSO4104, MSO4054, MSO4034:

Channel 3 DC Gain

Accuracy, 0 V offset,

0 V vertical position,

20 MHz BW, 50 Ω

osition,

ertical position,

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

4.98 mV

5 mV/div -1.5% 1.5%

10 mV/div -1.5% 1.5%

20 mV/div -1.5% 1.5%

49.8 mV

50 mV/div -1.5% 1.5%

100 m V/div -1.5% 1.5%

200 m V/div -1.5% 1.5%

500 m V/div -1.5% 1.5%

1.0 V/div -1.5% 1.5%

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

4.98 m V/div -3.0% 3.0%

5 mV/div -1.5% 1.5%

10 mV/div -1.5% 1.5%

20 mV/div -1.5% 1.5%

9.8 mV

4

50 mV/div -1.5% 1.5%

100 m V/div -1.5% 1.5%

200 m V/div -1.5% 1.5%

500 m V/div -1.5% 1.5%

1 V/div -1.5% 1.5%

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

4.98 mV

5 mV/div -1.5% 1.5%

10 mV/div -1.5% 1.5%

20 mV/div -1.5% 1.5%

49.8 mV

50 mV/div -1.5% 1.5%

100 m V/div -1.5% 1.5%

200 m V/div -1.5% 1.5%

500 m V/div -1.5% 1.5%

1.0 V/div -1.5% 1.5%

-3.0% 3.0%

-3.0% 3.0%

-3.0% 3.0%

-3.0% 3.0%

-3.0% 3.0%

26 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 35

Performance Verification

DC Gain Accuracy

Performance checks Vertical scale Low limit Test result High limit

Channel 3 DC Gain

Accuracy, 0 V offset,

0Vverticalp

20 MHz BW, 1 MΩ

Channel 4 DC Gain

Accuracy, 0 V offset,

0Vv

20 MHz BW, 50 Ω

Channel 4 DC Gain

Accuracy, 0 V offset,

0 V vertical position,

20 MHz BW, 1 MΩ

osition,

ertical position,

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

4.98 m V /div -3.0% 3.0%

5 mV/div -1.5% 1.5%

10 m V/div -1.5% 1.5%

20 m V/div -1.5% 1.5%

49.8 mV

50 m V/div -1.5% 1.5%

100 m V /div -1.5% 1.5%

200 m V /div -1.5% 1.5%

500 m V /div -1.5% 1.5%

1 V/div -1.5% 1.5%

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

8mV

4.9

5 mV/div -1.5% 1.5%

10 m V/div -1.5% 1.5%

20 m V/div -1.5% 1.5%

9.8 mV

4

50 m V/div -1.5% 1.5%

100 m V /div -1.5% 1.5%

200 m V /div -1.5% 1.5%

500 m V /div -1.5% 1.5%

1.0 V/div -1.5% 1.5%

1 mV/div -1.5% 1.5%

2 mV/div -1.5% 1.5%

4.98 m V /div -3.0% 3.0%

5 mV/div -1.5% 1.5%

10 m V/div -1.5% 1.5%

20 m V/div -1.5% 1.5%

49.8 mV

50 m V/div -1.5% 1.5%

100 m V /div -1.5% 1.5%

200 m V /div -1.5% 1.5%

500 m V /div -1.5% 1.5%

1 V/div -1.5% 1.5%

-3.0% 3.0%

-3.0% 3.0%

-3.0% 3.0%

-3.0% 3.0%

MSO4000 and DPO4000 Series Specifications and Performance Verification 27

Page 36

Performance Verification

DC Offset Accuracy

Performance

checks Vertical scal

All models:

Channel 1 DC Offset

Accuracy,

20 MHz BW, 50 Ω

Channel 1 DC Offset

Accuracy,

20 MHz BW, 1 MΩ

Channel 2 DC Offset

y,

Accurac

20 MHz BW, 50 Ω

Channel 2 DC Offset

acy,

Accur

20 MHz BW, 1 MΩ

1mV/div

1mV/div

2mV/div

2mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

1mV/div

1mV/div

2mV/div

2mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

1.01 V/div

1.01 V/div

1mV/div

1mV/div

2mV/div

2mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

1mV/div

1mV/div

2mV/div

2mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

1.01 V/div

1.01 V/div

e

Vertical offs

1

et

Low limit Test result

High limit

900 mV 895.0 mV 905.0 mV

-900 mV -905.0 m V -895.0 m V

500 mV 497.0 mV 503.0 mV

-500 mV -503.0 m V -497.0 m V

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 m V -495 mV

5.0 V 4.955 V 5.045 V

-5.0 V -5.045 V -4.955 V

900 mV 895.2 mV 904.8 mV

-900 mV -904.8 m V -895.2 m V

500 mV 497.1 mV 502.9 mV

-500 mV -502.9 m V -497.1 m V

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 m V -495.5 m V

5.0 V 4.955 V 5.045 V

-5.0 V -5.045 V -4.955 V

99.5 V 98.80 V 100.2 V

-99.5 V -100.2 V -98.80 V

900 mV 895.0 mV 905.0 mV

-900 mV -905.0 m V -895.0 m V

500 mV 497.0 mV 503.0 mV

-500 mV -503.0 m V -497.0 m V

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 m V -495.5 m V

5.0 V 4.955 V 5.045 V

-5.0 V -5.045 V -4.955 V

900 mV 895.2 mV 904.8 mV

-900 mV -904.8 m V -895.2 m V

500 mV 497.1 mV 502.9 mV

-500 mV -502.9 m V -497.1 m V

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 m V -495.5 m V

5.0 V 4.955 V 5.045 V

-5.0 V -5.045 V -4.955 V

99.5 V 98.80 V 100.2 V

-99.5 V -100.2 V -98.80 V

28 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 37

DC Offset Accuracy

Performance

checks Vertical scal

e

Vertical offs

1

et

DPO4104, DPO4054, DPO4034, MSO4104, MSO 4054, MSO4034:

Channel 3 DC Offset

Accuracy,

20 MHz BW, 50 Ω

Channel 3 DC Offset

Accuracy,

20 MHz BW, 1 MΩ

Channel 4 DC Offset

y,

Accurac

20 MHz BW, 50 Ω

1 mV/div

1 mV/div

2 mV/div

2 mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

1 mV/div

1 mV/div

2 mV/div

2 mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

1.01 V/div

1.01 V/div

1 mV/div

1 mV/div

2 mV/div

2 mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

900 mV 895.0 mV 905.0 mV

-900 mV -905.0 mV -895.0 mV

500 mV 497.0 mV 503.0 mV

-500 mV -503.0 mV -497.0 mV

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 mV -495.5 mV

5.0 V 4.955 V 5.045 V

-5.0 V -5.04.5 V -4.955 V

900 mV 895.2 mV 904.8 mV

-900 mV -904.8 mV -895.2 mV

500 mV 497.1 mV 502.9 mV

-500 mV -502.9 mV -497.1 mV

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 mV -495.5 mV

5.0 V 4.955 V 5.045 V

-5.0 V -5.045 V -4.955 V

99.5 V 98.80 V 100.2 V

-99.5 V -100.2 V -98.80 V

900 mV 895.0 mV 905.0 mV

-900 mV -905.0 mV -895.0 mV

500 mV 497.0 mV 503.0 mV

-500 mV -503.0 mV -497.0 mV

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 mV -495.5 mV

5.0 V 4.955 V 5.045 V

-5.0 V -5.045 V -4.955 V

Low limit Test result

Performance Verification

High limit

MSO4000 and DPO4000 Series Specifications and Performance Verification 29

Page 38

Performance Verification

DC Offset Accuracy

Performance

checks Vertical scal

Channel 4 DC Offset

Accuracy,

20 MHz BW, 1 MΩ

1mV/div

1mV/div

2mV/div

2mV/div

10 mV/div

10 mV/div

100 mV/div

100 mV/div

1.01 V/div

1.01 V/div

1

Use this value for both the calibrator output and the oscilloscope offset setting.

e

Vertical offs

900 mV 895.2 mV 904.8 mV

-900 mV -904.8 m V -895.2 m V

500 mV 497.1 mV 502.9 mV

-500 mV -502.9 m V -497.5 m V

500 mV 495.5 mV 504.5 mV

-500 mV -504.5 m V -495.1 m V

5.0 V 4.955 V 5.045 V

-5.0 V -5.045 V -4.955 V

99.5 V 98.80 V 100.2 V

-99.5 V -100.2 V -98.80 V

Performance checks Low limit Test result High limit

Sample Rate and Delay Time Accuracy

Auxiliary (Trigger) Output

Trigger Output

High 1 MΩ

Low 1 MΩ

Trigger Output

High 50 Ω

Low 50 Ω

1

et

Low limit Test result

High limit

-1 divisions +1 divisions

≥ 2.5 V

–

≥ 1.0 V

–

–

≤ 0.7 V

–

≤ 0.25 V

Random Noise, Sample Acquisition Mode

Vertical sensitivity = 100 mV/div

Performance checks 1 MΩ 50 Ω

Bandwidth Test result (mV) High lim it (mV) Test result (mV) High limit (mV)

DPO4104/MSO4104

Channel 1

Full 7.43 6.07

250 M H z 5.10 3.75

20 MHz 3.32 3.31

Channel 2

Full 7.43 6.07

250 M H z 5.10 3.75

20 MHz 3.32 3.31

Channel 3

Full 7.43 6.07

250 M H z 5.10 3.75

20 MHz 3.32 3.31

Channel 4

Full 7.43 6.07

250 M H z 5.10 3.75

20 MHz 3.32 3.31

30 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 39

Performance Verification

Random Noise, Sample Acquisition Mode

Vertical sensitivity = 100 mV/div

Performance checks 1 MΩ 50 Ω

Bandwidth Test result (mV) High limit (m V) Test result (mV) High limit (mV)

DPO4054/MSO4054

Channel 1

Channel 2

Channel 3

Channel 4

DPO4034/MSO4034

Channel 1

Channel 2

Channel 3

Channel 4

DPO4032/MSO4032

Channel 1

Channel 2

Full 7.73 3.18

250 M Hz 5.30 3.36

20 M H z 3.82 3.31

Full 7.73 3.18

250 M Hz 5.30 3.36

20 M H z 3.82 3.31

Full 7.73 3.18

250 M Hz 5.30 3.36

20 M H z 3.82 3.31

Full 7.73 3.18

250 M Hz 5.30 3.36

20 M H z 3.82 3.31

Full 6.54 3.38

250 M Hz 4.89 3.28

20 M H z 3.42 3.12

Full 6.54 3.38

250 M Hz 4.89 3.28

20 M H z 3.42 3.12

l

Ful

250 M Hz 4.89 3.28

20 M H z 3.42 3.12

ll

Fu

250 M Hz 4.89 3.28

20 M H z 3.42 3.12

Full 7.34 3.18

250 M Hz 4.99 3.97

20 M H z 3.12 3.61

Full 7.34 3.18

250 M Hz 4.99 3.97

20 M H z 3.12 3.61

6.5

6.

4

54

3.3

3.

8

38

MSO4000 and DPO4000 Series Specifications and Performance Verification 31

Page 40

Performance Verification

Delta Time Measurem ent Accuracy

50 ohm, Full BW RMS

Channel 1–4 (M

SO/DPO4104)

MSO/DPO = 4 ns/Div, Source freq = 240 MHz

MSO/DPO V/D iv Source V

pp

Test result High limit

5 mV 40 mV 118 ps

100 mV 800 mV 117 ps

500 mV 4 V 117 ps

1 V 4 V 122 ps

MSO/DPO = 40 ns/Div, Source freq = 24 MH z

1 mV 8 mV 456 ps

5 mV 40 mV 275 ps

100 mV 800 mV 234 ps

500 mV 4 V 233 ps

1 V 4 V 417 ps

MSO/DPO = 400 ns /D iv, Source freq = 2.4 MHz

1 mV 8 mV 4.42 ns

5mV 40mV 2.50ns

100 mV 800 mV 2.05 ns

500 mV 4 V 2.03 ns

1 V 4 V 4.01 ns

MSO/DPO = 4 μs/Div, Source freq = 240 kHz

1mV 8mV 44.2ns

5mV 40mV 25.0ns

100 mV 800 mV 20.5 ns

500 mV 4 V 20.3 ns

1V 4V 40.1ns

MSO/DPO = 40 μs/Div, Source freq = 24 kHz

1 mV 8 mV 442 ns

5 mV 40 mV 250 ns

100 mV 800 mV 205 ns

500 mV 4 V 203 ns

1 V 4 V 401 ns

MSO/DPO = 400 μs/Div, Source freq = 2.4 kHz

1 mV 8 mV 4.42 μs

5mV 40mV 2.50μs

100 mV 800 mV 2.05 μs

500 mV 4 V 2.03 μs

1V 4V 4.01μs

32 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 41

Performance Verification

Delta Time Meas

Channel 1–4 (MS

urement Accuracy

O/DPO4054)

MSO/DPO = 4 ns/Div, Source freq = 240 MHz

MSO/DPO V/D iv Source V

pp

Test result High limit

5 mV 40 mV 232 ps

100 mV 800 mV 231 ps

500 mV 4 V 231 ps

1 V 4 V 232 ps

MSO/DPO = 40 ns/D iv, Source freq = 24 MHz

1 mV 8 mV 431 ps

5 mV 40 mV 280 ps

100 mV 800 mV 256 ps

500 mV 4 V 255 ps

1 V 4 V 312 ps

MSO/DPO = 400 ns/Div, Source freq = 2.4 MHz

1 mV 8 mV 3.66 ns

5mV 40mV 1.63ns

100 mV 800 mV 1.17 ns

500 mV 4 V 1.15 ns

1V 4V 2.13ns

MSO/DPO = 4 μs/Div, Source freq = 240 kHz

1mV 8mV 36.4ns

5mV 40mV 15.8ns

100 mV 800 mV 11.0 ns

500 mV 4 V 10.8 ns

1V 4V 20.9ns

MSO/DPO = 40 μs/Div, Source freq = 24 kHz

1 mV 8 mV 364 ns

5 mV 40 mV 158 ns

100 mV 800 mV 110 ns

500 mV 4 V 108 ns

1 V 4 V 209 ns

MSO/DPO = 400 μs/Div, Source freq = 2.4 kHz

1mV 8mV 3.64 μs

5mV 40mV 1.58 μs

100 mV 800 mV 1.10 μs

500 mV 4 V 1.08 μs

1V 4V 2.09 μs

MSO4000 and DPO4000 Series Specifications and Performance Verification 33

Page 42

Performance Verification

Delta Time M eas

Channel 1–4 (MS

urement Accuracy

O/DPO4034)

MSO/DPO = 4 ns/Div, Source freq = 240 MHz

MSO/DPO V/D iv Source V

pp

Test result High limit

5 mV 40 mV 232 ps

100 mV 800 mV 231 ps

500 mV 4 V 231 ps

1 V 4 V 232 ps

MSO/DPO = 40 ns/Div, Source freq = 24 MH z

1 mV 8 mV 436 ps

5 mV 40 mV 284 ps

100 mV 800 mV 259 ps

500 mV 4 V 258 ps

1V 4V 321ps

MSO/DPO = 400 ns /D iv, Source freq = 2.4 MHz

1 mV 8 mV 3.72 ns

5mV 40mV 1.70ns

100 mV 800 mV 1.23 ns

500 mV 4 V 1.21 ns

1 V 4 V 2.26 ns

MSO/DPO = 4 μs/Div, Source freq = 240 kHz

1mV 8mV 37.0ns

5mV 40mV 16.5ns

100 mV 800 mV 11.6 ns

500 mV 4 V 11.4 ns

1V 4V 22.3ns

MSO/DPO = 40 μs/Div, Source freq = 24 kHz

1 mV 8 mV 370 ns

5 mV 40 mV 165 ns

100 mV 800 mV 116 ns

500 mV 4 V 114 ns

1 V 4 V 223 ns

MSO/DPO = 400 μs/Div, Source freq = 2.4 kHz

1 mV 8 mV 3.70 μs

5mV 40mV 1.65 μs

100 mV 800 mV 1.16 μs

500 mV 4 V 1.14 μs

1V 4V 2.23 μs

34 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 43

Performance Verification

Delta Time Meas

Channel 1–2 (MS

urement Accuracy

O/DPO4032)

MSO/DPO = 4 ns/Div, Source freq = 240 MHz

MSO/DPO V/D iv Source V

pp

Test result High limit

5 mV 40 mV 232 ps

100 mV 800 mV 231 ps

500 mV 4 V 231 ps

1 V 4 V 232 ps

MSO/DPO = 40 ns/D iv, Source freq = 24 MHz

1 mV 8 mV 441 ps

5 mV 40 mV 281 ps

100 mV 800 mV 256 ps

500 mV 4 V 255 ps

1 V 4 V 312 ps

MSO/DPO = 400 ns/Div, Source freq = 2.4 MHz

1 mV 8 mV 3.78 ns

5mV 40mV 1.66ns

100 mV 800 mV 1.17 ns

500 mV 4 V 1.15 ns

1V 4V 2.13ns

MSO/DPO = 4 μs/Div, Source freq = 240 kHz

1mV 8mV 37.6ns

5mV 40mV 16.1ns

100 mV 800 mV 11.0 ns

500 mV 4 V 10.8 ns

1V 4V 21.0ns

MSO/DPO = 40 μs/Div, Source freq = 24 kHz

1 mV 8 mV 376 ns

5 mV 40 mV 161 ns

100 mV 800 mV 110 ns

500 mV 4 V 108 ns

1V 4V 210ns

MSO/DPO = 400 μs/Div, Source freq = 2.4 kHz

1mV 8mV 3.76μs

5mV 40mV 1.61 μs

100 mV 800 mV 1.10 μs

500 mV 4 V 1.08 μs

1V 4V 2.10 μs

MSO4000 and DPO4000 Series Specifications and Performance Verification 35

Page 44

Performance Verification

Performance checks: Digital Threshold Accuracy, MSO4000 series only

Digital

channel Threshold V V Low lim it Test result High limit

0 V -0.1 V 0.1 VD0

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD1

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD2

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD3

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD4

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD5

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD6

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD7

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD8

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD9

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD10

D12

15

D

78 V

0.1 V

-

V

1V

4 V 3.78

0 V -0.1 V 0.1 VD11

4 V 3.78 V 4.22 V

0V -0.

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD13

4V 3.

0 V -0.1 V 0.1 VD14

4 V 3.78 V 4.22 V

V

0

4 V 3.78 V 4.22 V

4.22

0.1

22 V

4.

.1 V

0

V

V

36 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 45

Performance Verification

Performance V

erification Procedures

The following three conditions must be met prior to performing these procedures:

1. The oscilloscope must have been operating continuously for twenty (20)

minutes in an environment that meets the operating range specifications for

temperature and humidity.

2. You must perform a signal path compensation (SPC). See Signal Path

Compensation in the Tektronix 4000 Series Digital Phosphor Oscilloscopes

User Manua

(18 °F), you must perform the signal path compensation again.

3. You mus t c

power circuit. Connect the oscilloscope and test instruments into a common

power strip if you are unsure of the AC power circuit distribution. Connecting

the oscilloscope and test instruments into separate AC power circuits can

result in offset voltages between the equipment, which can invalidate the

performance verification procedure.

The time required to complete the entire procedure is approximately one hour.

WAR N ING. Some procedures use hazardous voltages. To prevent electrical

k, always set voltage source outputs to 0 V before making or changing any

shoc

interconnections.

l. If the operating temperature changes by more than 10 °C

onnect the oscilloscope and the test equipment to the same AC

Sel

fTest

This procedure uses internal routines to verify that the oscilloscope functions and

passes its internal self tests. No test equipment or hookups are required. Start

the self test with these steps:

1. Disconnect all probes and cables from the oscilloscope inputs.

2. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

3. Push the Utility menu button.

4. Push the Utility Page lower-bezel button, and turn the Multipurpose a knob

to select Self Test.

5. Push the Self Test lower-bezel button. The Loop X Times side-bezel menu

will be set to Loop 1 Times.

6. Push the OK Run Self Test side-bezel button.

7. Wait while the self test runs. When the self test completes, a dialog box

displays the results of the self test.

8. Push the Menu Off button to clear the dialog box and Self Test menu.

MSO4000 and DPO4000 Series Specifications and Performance Verification 37

Page 46

Performance Verification

Check Input Impedance

(Resistance)

This test check

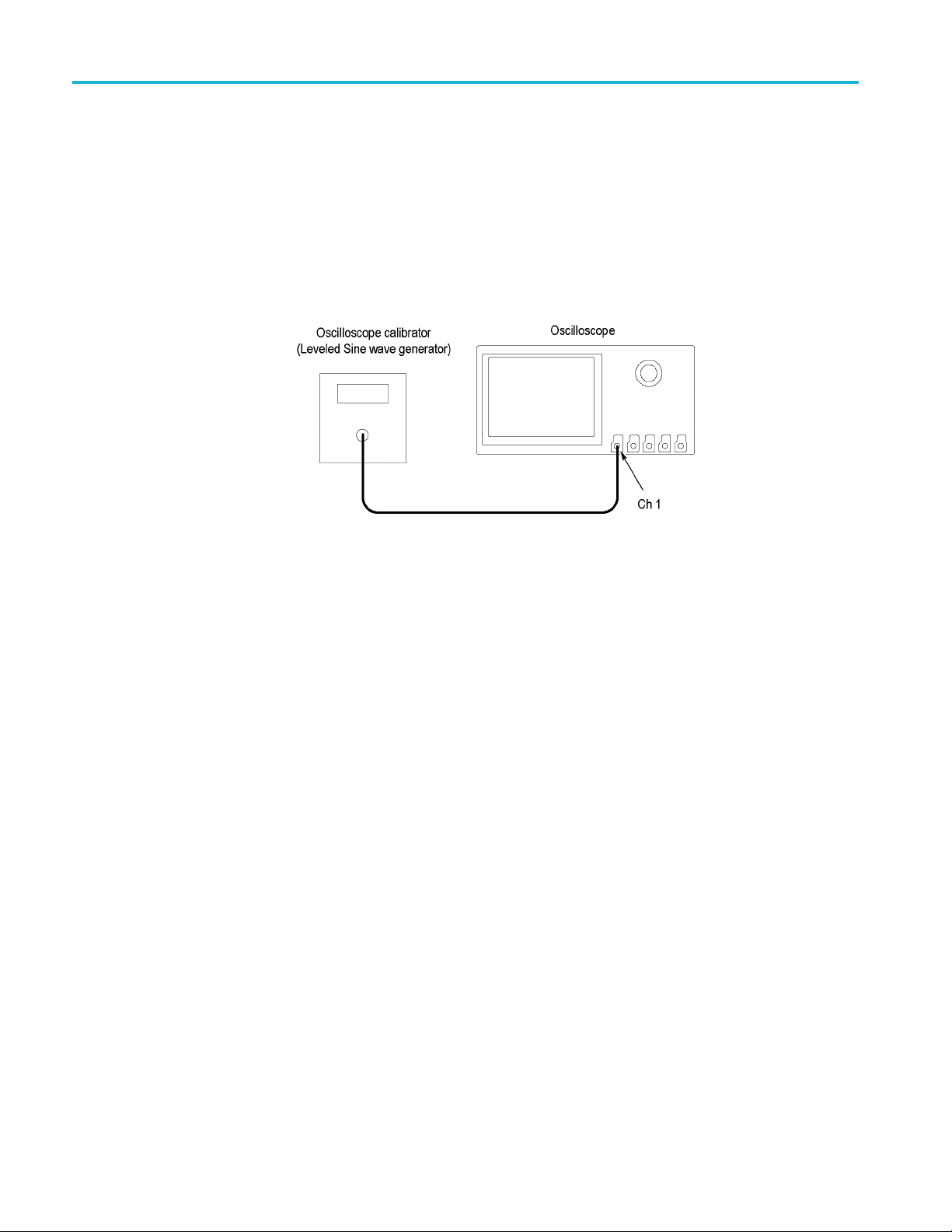

1. Connect the output of the oscilloscope calibrator (for example, Fluke 9500) to

the oscillosc

2. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

3. Push the front-panel channel button for the oscilloscope channel that you are

testing, as shown in the test record (for example, 1,2,3,4).

4. Confirm that the oscilloscope and calibrator impedances are both set to

1MΩ.ThedefaultImpedance setting is 1 MΩ.

s the Input Impedance.

ope channel 1 input, as shown below.

5. Turn the Vertical Scale knob to set the vertical scale, as shown in the test

record (for example, 10 mV/div, 100 mV/div, 1 V/div).

6. Measure the input resistance of the oscilloscope with the calibrator. Record

this value in the test record.

7. Repeat steps 5 and 6 for each volt/division setting in the test record.

8. Change the oscilloscope and calibrator impedance to 50 Ω and repeat steps 5

through 7.

9. Repeat steps 4 through 8 for each channel listed in the test record and relevant

to the model of oscilloscope that you are testing, as shown in the test record

(forexample,2,3,or4).

38 MSO4000 and DPO4000 Series Specifications and Performance Verification

Page 47

Performance Verification

Check DC Balance

This test check

You do not need to connect the oscilloscope to any equipment to run this test.

1. Attach a 50 Ω terminator to the channel input of the oscilloscope being tested.

2. Push the fr

default settings.

3. Push the f

testing, as shown in the test record (for example, 1,2,3,4).

4. Set the o

button to select 50 Ω.

5. Push th

side-bezel button for 20MHz, 250MHz,orFull, as given in the test record.

s the DC balance.

ont-panel Default Setup button to set the instrument to the factory

ront-panel channel button for the oscilloscope channel that you are

scilloscope impedance to 50 Ω. Push the Impedance lower-bezel

e lower-bezel Bandwidth button and push the appropriate bandwidth

6. Turn t

7. Turn the Vertical Scale knob to set the vertical scale, as shown in the test

8. Push the front-panel Acquire button.

9. Push the Mode lower-bezel button, and then, if needed, push the Average

10. If needed, adjust the number of averages to 16 with the Multipurpose a knob.

11. Push the Trigger Menu front-panel button.

12. Push the Source lower-bezel button.

13. Select the AC Line trigger source with the Multipurpose a knob. You do not

14. Push the front-panel Wave Inspector Measure button.

15. Push the Add Measurement lower bezel button.

16. Use the Multipurpose a knob to select the Mean measurement.

he Horizontal Scale knob to 1 ms/division.

rd (for example, 1 mV/div, 2 mV/div, 100 mV/div, 1 V/div).

reco

side bezel button.

need to connect an external signal to the oscilloscope for this DC Balance test.

MSO4000 and DPO4000 Series Specifications and Performance Verification 39

Page 48

Performance Verification

Check Bandwidth

17. Push the OK Add M

18. View the mean measurement value in the display and enter that mean value

as the test result in the test record.