xx

MSO3000 and DPO3000 Series

ZZZ

Digital Phosphor Oscilloscopes

Service Manual

*P071266700*

071-2667-00

xx

MSO3000 and DPO3000 Series

ZZZ

Digital Phosphor Oscilloscopes

Service Manual

This document applies to firmware version 2.00 and above.

Warning

The servicing instructions are for use by qualified personnel

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do so. Refer to all safety summaries

prior to performing service.

Revision B

www.tektronix.com

071-2667-00

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

TekLink is a trademark of Tektronix, Inc.

Tektronix is an authorized licensee of the CompactFlash® trademark.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . Bo x 50 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

World wide , visi t www.tektronix.com to find contacts in your area.

Table of Contents

General safety summary .. ................................ ................................ ........................ iv

Service safety summary........................................................................................... vi

Preface ............................................................................................................. vii

Manual Conv

Related Documentation ..................................................................................... vii

Operating Information ............................................................................................. 1

Theory of Operation... ................................ ................................ ............................. 3

Block Diagram ................................ ................................ ................................. 3

Power Supply................................................................................................... 4

I/O Boar

Attenuator Board.......... ................................ ................................ ..................... 4

Main Board..................................................................................................... 4

Front-Panel Board .. ................................ .................................. ......................... 5

Adjustment Procedures ............................................................................................ 7

Required Equipment.......................... ................................ ................................. 7

view of the Adjustment Process........................................................................ 8

Over

Factory Adjustment Procedure ............................................................................... 9

Completing the Procedure ......... .................................. ................................ ........ 12

Maintenance........................................................................................................ 17

Preventing ESD ............................................................................................... 17

Inspection and Cleaning.................... ................................ .................................. 17

erview of Removal Procedures .......................... ................................ ................ 21

Ov

Removal Procedures.......................................................................................... 22

Troubleshooting................................... ................................ ............................ 28

Troubleshooting Procedure .... ................................ ................................ .............. 29

Unpacking and Repacking Instructions ........................ ................................ ............ 31

Replaceable Parts List................... ................................ ................................ .......... 33

Parts Ordering Information .................................................................................. 33

Using the Replaceable Parts List............................................................................ 35

Index

entions...................... ................................ ................................ ... vii

d ....................................................................................................... 4

MSO3000 and DPO3000 S eries Digital Phosphor Oscilloscopes Service Manual i

Table of Contents

List of Figure

Figure 1: Oscilloscope module interconnections .. . .. .. . .. .. . .. .. . .. .. . . . .. . .. .. .. . .. .. . .. .. . .. .. . .. .. . .. .. . .. . 3

Figure 2: Re

Figure 3: Utility page menu . . .. .. . .. .. . .. .. . .. .. . .. .. . . . .. . .. .. . . . .. . .. .. .. . .. . .. .. .. . .. . .. .. .. . .. . .. .. .. . .. . . . .. 10

Figure 4: Calibration selection............................. .................................. .................... 10

Figure 5: Factory information dialog............................................................................ 11

Figure 6: Digital channel input (MSO only) ................................................................... 14

Figure 7: Locator for internal modules.............. ................................ ............................ 21

Figure 8:

Figure 9: Fan cable dress ........................... ................................ .............................. 24

Figure 10: Disconnecting the main board ...................................................................... 26

Figure 11: Display cable shield in place ........ ................................ ................................ 27

Figure 12: Exploded view: rear case and rear chassis......................................................... 37

Figure 13: Exploded view: I/O and main boards .............................................................. 39

e 14: Exploded view: Front panel and power supply ......... .................................. ........ 41

Figur

Figure 15: Exploded view: Front panel labels . ................................ ................................ 43

Figure 16: Exploded view: Main board shield and attenuator board .................... .................... 45

Figure 17: Exploded view: Front chassis and LCD assembly................................................ 47

Figure 18: Exploded view: front panel board and front case................................................. 49

ar panel......................... ................................ .................................. ..... 9

Reconnecting the fan cable ........................................................................... 24

s

ii MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

List of Tables

Table 1: External inspection check list.......................................................................... 19

Table 2: Int

Table 3: Replaceable parts list: Rear case and rear chassis ................................................... 36

Table 4: Replaceable parts list: I/O and main boards ..................... ................................ .... 38

Table 5: Replaceable parts list: Front panel and power supply .... ................................ .......... 40

Table 6: Replaceable parts list: Front panel labels ............................ ................................ 42

Table 7: Replaceable parts list: Attenuator ..................................................................... 44

Table 8: R

Table 9: Replaceable parts list: Front panel and front case ................................................... 48

Table 10: Replaceable parts list: Standard accessories ....................................................... 50

Table 11: Replaceable parts list: Optional accessories ........... ................................ ............ 50

ernal inspection check list............. ................................ .............................. 20

eplaceable parts list: Front chassis and LCD... ................................ .................... 46

Table of Contents

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual iii

General safety summary

General safet

To avoid fir

e or personal

injury

ysummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

Use proper

certified for the country of use.

Connect a

leads while they are connected to a voltage source.

Ground th

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe all terminal ratings. To a void fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product o nly as specified.

power cord. Use only the power cord specified for this product and

nd disconnect properly. Do not connect or disconnect probes o r test

eproduct.This product is grounded through the grounding conductor

Connect the probe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power disconnect. The power cord disconnects the product from the power source.

Donotblockthepowercord;itmustremain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation. Refer to the manual's installation instructions for details

on installing the product so it has proper ventilation.

iv MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

General safety summary

Terms in this manual

Symbols and terms on the

product

These terms may

WAR N ING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER in

the marking.

WAR N IN G

read the marking.

CAUTIO

The following symbol(s) may appear on the product:

appear in this manual:

dicates an injury hazard immediately accessible as you read

indicates an injury hazard not immediately accessible as you

N indicates a hazard to property including the product.

MSO3000 and DPO3000 S eries Digital Phosphor Oscilloscopes Service Manual v

Service safety summary

Service safet

ysummary

Only qualifie

safety summary and the General safety summary before performing any service

procedures.

Do not service alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect power. To avoid electric shock, switch o ff the instrument power, then

disconnect the power cord from the mains power.

Use care when servicing with power on. Dangerous voltages or currents may exist

in this p

test leads before removing protective panels, soldering, or replacing components.

To a voi

d personnel should perform service procedures. Read this Service

roduct. Disconnect power, remove battery (if applicable), and disconnect

d e lectric shock, do not touch exposed connections.

vi MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Preface

Manual Conventions

This service manual provides information that you need to troubleshoot,

disassemble, and replace parts on the Tektronix MSO3000 and DPO3000 Series

Digital Phos

phor Oscilloscopes.

Modules

Replaceable Parts

Safety

Related Documentation

This manua

before attempting service.

Throughout this manual, any replaceable component, assembly, or part is referred

to by the t

A module is composed of electrical and mechanical assemblies, circuit boards,

interco

This manual refers to any field-replaceable assembly or mechanical part

specifically by its name or generically as a replaceable part. In general, a

repla

mechanical part, such as the I/O port connectors, that is listed in the replaceable

parts list.

Symb

To read about Use these documents

Installation and Operation MSO3000 and DPO3000 Series Oscilloscopes User

ecifications and Performance

Sp

Programmer Commands MSO3000 and DPO3000 Series Programmer Manual

Analysis and Connectivity Tools Getting Started with OpenChoice ® Solutions Manual

Installing and testing applications

modules

Oscilloscope calibrator Fluke Oscilloscope Calibrator Manual at

l uses certain conventions that you should become familiar with

erm module.

nnecting cables, and user-accessible controls.

ceable part is any circuit board or assembly, such as the hard disk drive, or a

ols and terms related to safety appear in the General Safety Summary

nual (available in 11 languages)

Ma

O3000 and DPO3000 Series Technical Reference

MS

(PDF only)

(PDF only)

Tektronix 3000 Series Application Module Installation

Instructions Manual

http://us.fluke.com

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual vii

Preface

viii MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Operating Information

For information on installing and operating your MSO3000 or DPO3000 Series

Oscilloscope, refer to the MSO3000 and DPO3000 Series Oscilloscopes User

Manual.

This manual is available, in 11 languages, on the Web at www.tektronix.com.

MSO3000 and DPO3000 S eries Digital Phosphor Oscilloscopes Service Manual 1

Operating Information

2 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Theory of Operation

This chapter describes the electrical operation of the oscilloscope to the module

level. The following figure shows the oscilloscope module interconnections.

Block Diagram

Figure 1: Oscilloscope module interconnections

MSO3000 and DPO3000 S eries Digital Phosphor Oscilloscopes Service Manual 3

Theory of Operation

Power Supply

I/O Board

Attenuator Board

The Power Supply board converts AC line voltage to +12 V and +6 V to power all

internal circuits.

The I/O board contains two USB ports (one host port and one device port), an

Ethernet p

ort (LAN), a WVGA Video port, and a Trigger Out BNC connector.

Main Board

Acquisition System

Trigger System

The Atten

Acquisition s ystem begins with the analog signal path, on the Attenuator board,

and ends with a digitized signal in memory, on the Main board.

The signal enters a channel input, and then passes through an attenuator and

preamplifier. The signal is then passed to the Main board.

The Main board module contains the following functions:

The A

board and ends with a digitized signal in memory, on the Main board. The analog

signal from each preamplifier on the Attenuator board goes through a digitizer, a

time base controller, and then into acquisition memory. The analog signal from

each preamplifier is also distributed to a trigger circuit.

The Trigger system processes the analog signals from the preamplifiers on the

Attenuator board, and sends trigger information to the time-base controller.

Advanced trigger functions are enabled only when the appropriate application

modules and supporting software are installed.

uator board contains the analog portions of the acquisition system. The

cquisition system begins with the analog signal path, on the Attenuator

isplay System

D

Processor System

4 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

The Display system combines live waveform data from acquisition memory with

menus and text, and stores this information in display memory. It then uses this

data to refresh the XGA display module (LCD).

The Processor system contains a 440EP Power PC microprocessor that controls

the entire instrument. The processor system also contains FLASH ROM, system

RAM, and interfaces to the USB ports.

Theory of Operation

Power Converter

Digital Channels

Front-Panel Board

The Power Conve

and generates voltages for the analog and digital circuitry on the Main board.

The MSO3000 series main board also includes threshold DACs and comparators

for the digit

The Front Pa

and controls, and then sends this information to the processor system on the Main

board. The Front Panel board also generates the probe compensation output signal

and p rovides an interface to the application modules.

rter receives the +12 V and +6 V from the main power supply

al channels.

nel board contains a microprocessor that reads the front-panel buttons

MSO3000 and DPO3000 S eries Digital Phosphor Oscilloscopes Service Manual 5

Theory of Operation

6 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Adjustment Procedures

This chapter contains the factory adjustment procedure for the MSO3000

and DPO3000 Series oscilloscopes. Only qualified personnel should perform

adjustment procedures. Read the Service Safety Summary and the General Safety

Summary before performing any service procedures.

NOTE. The vo

ltage references inside the oscilloscope are very stable over time

and should not require routine adjustment. Before performing any procedure

in this chapter, do the Performance Verification procedures to check whether

the oscilloscope meets specifications. See the MSO3000 and DPO3000 Series

Specifications and Performance Verification Technical Reference.

Successful completion of this adjustment procedure automatically updates the

stored time and date of the latest successful adjustment. Completion of the

Performance Verification procedure does not update this date and time. If no

adjustm

ent is needed, there is also no need to update the time and date of the

adjustment.

Required Equipment

The following equipment, or a suitable equivalent, is required to complete these

procedures.

The following table specifies required equipment for adjusting the oscilloscope.

Description Minimum requirements Example

DC voltage source 50 mV to 70 V, ±0.1% amplitude accuracy Fluke or Wavetek 9500 Oscilloscope

Calibrator with 9530 active heads

Sine Generator 1 kHz 1 GHz Fluke or Wavetek 9500 Oscilloscope

Calibrator with one 9510 Output Module

Edge Generator

50 Ω BNC cable BNC male to BNC male, about 10 in (25 cm.)

Adjustment tool

1 kHz with < 50 ps ch-ch skew

long

Non-conducting shaft with diameter = 0.1 in.

(= 2.5 mm)

Fluke or Wavetek 9500 Oscilloscope

Calibrator with one 9510 Output Module

Tektronix part number 012-0208-00

Tektronix part number 003-1433-00

MSO3000 and DPO3000 S eries Digital Phosphor Oscilloscopes Service Manual 7

Adjustment Procedures

Overview of th

e Adjustment Process

Before performing adjustment procedures, you must warm up the oscilloscope

for at least 30 minutes in an ambient temperature between 20 °C and 30 °C.

Adjustments

result in poor performance or calibration failure.

The factory

through these steps, the oscilloscope display provides instructions that describe

the specific input signal requirements for each step. If the oscilloscope passes the

step, it moves on to the next step. If the oscilloscope fails, you can repeat the

step or choose to abort the procedure.

If you have difficulty completing the steps, refer to the Completing the Procedure

section for specific instructions and troubleshooting information. (See page 12.)

To complete the calibration procedure, you must know how to operate the

oscilloscope calibrator. Please refer to the user manual, which can be found at

http://us.fluke.com

NOTE.

Step or Previous Step buttons during the adjustment procedure. Doing so will

cause the oscilloscope to abort the adjustment procedure. The oscilloscope uses

the previous calibration constants if the adjustment p rocedure is aborted or fails.

performed before warm-up or outside this temperature range may

adjustment procedure consists of a series of steps; as you move

Do not turn any knobs or push any front-panel buttons other than the Next

.

The screen does not display the actual oscilloscope settings (such as channel input

impedance, or vertical and horizontal settings) during the adjustment procedure.

The oscilloscope automatically sets the instrument settings, but these settings may

not read out correctly on the display.

During some steps, the instrument may appear to be idle for several minutes while

it is processing information internally.

If the oscilloscope completes all steps in the procedure successfully, a "Pass"

message is displayed and the new calibration constants take effect. If the

oscilloscope does not pass a step, you can repeat the step. To cancel the calibration

procedure, press the Menu Off front panel button on the oscilloscope. This

reverts the oscilloscope to the old calibration constants.

8 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Factory Adjustment P rocedure

To perform the factory adjustment procedure, complete these steps:

1. Connect the oscilloscope to an AC power source.

NOTE. You must connect the oscilloscope and the test equipment to the same

AC power circuit. Connect the oscilloscope and test instruments to a common

power strip if you are unsure of the AC power circuit distribution. Connecting the

oscilloscope and test instruments to separate AC power circuits can result in offset

voltages b

2. Power on the oscilloscope and warm it up for 30 minutes.

3. Power on the oscilloscope calibrator and warm it up for 30 minutes.

4. Connect the active heads from the calibrator to the oscilloscope, ensuring

that Channel 1 on the calibrator connects to Channel 1 on the oscilloscope,

and so on.

Adjustment Procedures

etween the equipment, which can invalidate the adjustment procedure.

NOTE. F

the MSO3000, there will be either 2 or 4 channels to connect, plus an additional

channel connection for the digital probe. Plug the digital probe into the Channel

5 active head on the calibrator, but do not plug the probe into the oscilloscope

until you begin a Deskew test.

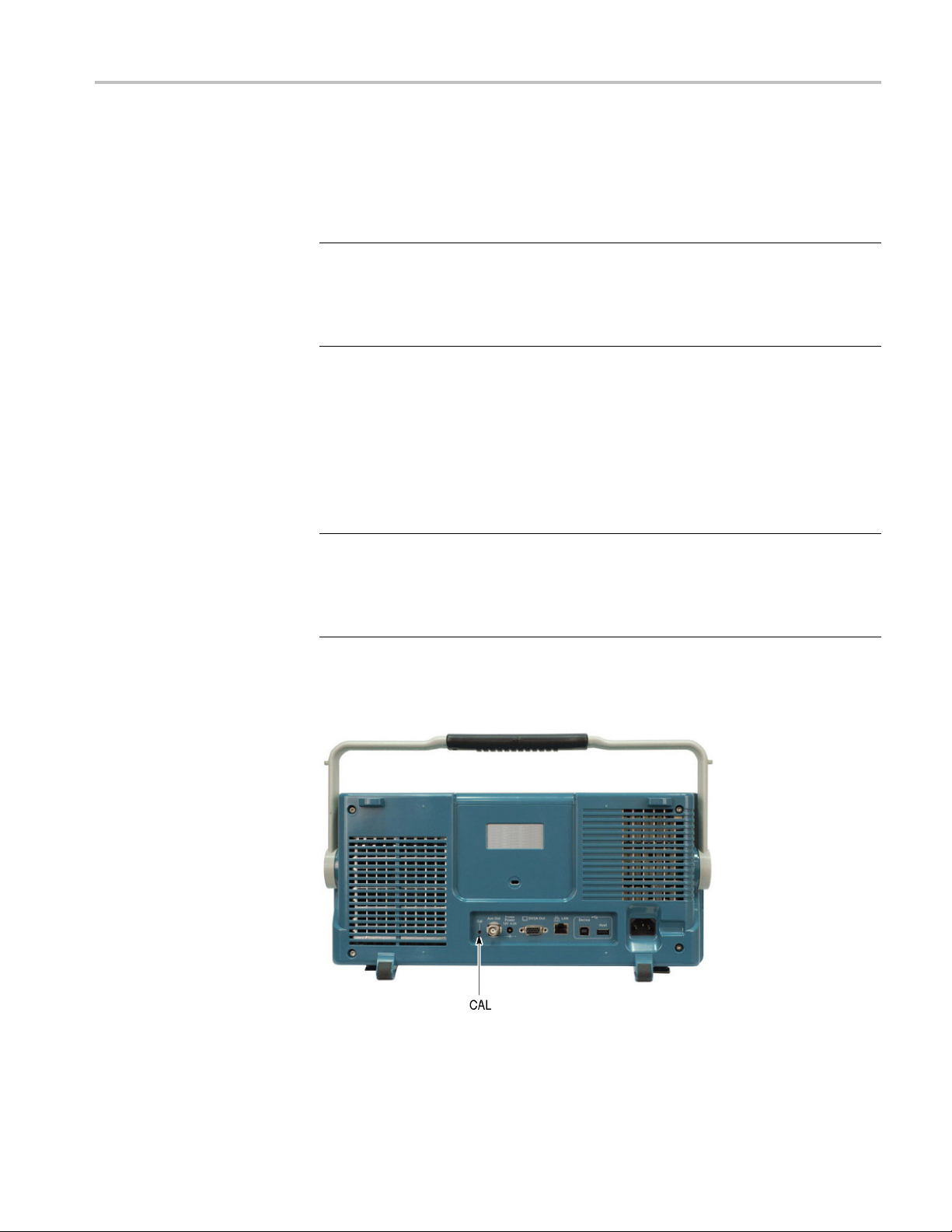

5. Power off the oscilloscope. Locate the hole in the rear panel that provides

or the DPO3000, there will be either 2 or 4 channels to connect. For

access to the CAL switch.

Figure 2: Rear panel

MSO3000 and DPO3000 S eries Digital Phosphor Oscilloscopes Service Manual 9

Adjustment Procedures

6. Insert the adju

hold the CAL switch in while you power on the oscilloscope. Keep holding

the switch until the oscilloscope shows the "Power-on self test passed"

message with the oscilloscope graticule in the background. This can take up

to a minute.

7. Push the Default Setup button on the front panel of the oscilloscope.

8. Push the Utility button on the front panel of the oscilloscope.

9. Push the Utility Page lower-bezel button. The utility page menu appears.

stment tool into the CAL switch hole. Use the tool to push and

Figure 3 : Utility page menu

10. Use the Multipurpose a knobtoselectCalibration.

gure 4: Calibration selection

Fi

ush the Factory lower-bezel button. The information dialog appears.

11.P

10 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Adjustment Procedures

Figure 5: Factory information dialog

12. Push the OK Do Factory Adjustment side-bezel button to start the

adjustme

nt process. Prompts appear on the oscilloscope screen to indicate the

signal type and the channels to which it should be connected.

NOTE. The oscilloscope adjusts itself automatically using the calibrator signal as

a reference. You do not need to make any adjustments.

If you m

ake an error, such as connecting the wrong input signal, you can repeat

the last step by pushing the Return to Previous Screen side bezel button.

13. For ea

ch step, refer to the next table to identify the signal type, and then

carefully follow the instructions for that signal type on the specified page.

Signal type Example prompt Procedure to follow Parameters to set

DC Voltage Apply 0 V DC 50 Ω

termination signal to 3.

Time Mark Apply 500 mV Pk-Pk 625 Hz

50 Ω termination time mark

signal to 3.

Deskew Apply 1.0 V P k-P k 1 kHz

50 Ω termination deskew

signal to 3.

Sine Signal

Apply 2.0 V Pk-Pk 164M

50 Ω termination sine signal

to 3.

(See page 12, DC Voltage.) Waveform type, voltage,

termination, channel

(See page 14, Time Mark.) Waveform type, voltage,

frequency, termination,

channel

(See page 14, Deskew

(MSO Only).)

(See page 15, Sine Signal.) Waveform type, voltage,

Waveform type, voltage,

frequency, termination,

channel

frequency, termination,

channel

NOTE. The oscilloscope screen will not provide you with all of the information

that you need to complete the steps successfully, so it is critical that you follow the

steps outlined in the Completing the Procedure section. Each time a new prompt

appears, refer to the table above to identify the signal type, and then ensure that

you are following every step that is outlined for that specific signal type.

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 11

Adjustment Procedures

14. Continue with t

15. Complete the performance verification tests to verify that the adjustment

Completing the Procedure

Instructions follow for completing the DC Voltage, Time Mark, Deskew, and Sine

Signal te

numbered instructions for the specific test type, and carefully complete each step.

If the os

this chapter, revert to the previous step and try again. If the step fails again, return

to the first step in the calibrationprocedureandtrytheentire procedure again.

If the procedure fails, there could be problem with the oscilloscope. Consider

seeking customer support.

he adjustment process until it is complete and you receive the

Pass notification. You can cancel the process at any time by pushing the

MENU OFF button.

procedure has correctly calibrated the oscilloscope. (See the MSO3000

and DPO3000 Series Specification and Performance Verification Technical

Reference.) Incorrect use of calibration equipment can cause the oscilloscope

to pass the Calibration Procedure but fail Performance Verification.

sts. For each step in the calibration procedure, start at the beginning of the

cilloscope fails a step, consult the Troubleshooting sectionattheendof

DC Voltage

The DC Voltage test is the first test to appear on the prompts, and it usually makes

up the majority of the calibration procedure tests. For each DC Voltage test,

complete all 8 steps listed below to best ensure that the test will pass.

1. Push the DC/Square

2. Push the WAV E F O R M lower-bezel button, and then push the DC Positive

right-bezel button.

sh the CHANNEL SELECT lower-bezel button.

3. Pu

4. Push the LOAD lower-bezel button to highlight either 1M Ω or 50 M Ω.

5. Select the specified channels, by using the side-bezel buttons, and then click

the EXIT lower-bezel button.

6. If the amplitude field is not selected, use the front panel scroll buttons. Type

the specified voltage, and then push the appropriate unit in the right-bezel

menu.

For 0 V: ground the signal by pushing the grounding lower-bezel

button. When this is active, you will not be able to make a channel

selection, so in some cases you might need to temporarily deselect the

grounding option while you make a channel selection. If the prompt

button.

12 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Adjustment Procedures

requires all ch

will default to Channel 1.

For any nonzer

ensure that the calibrator is in direct mode. Push the

button until 1.0 is selected.

For6Vor-6V:

a. Push the AUX front panel button.

b. Push the

side-bezel button for a -6 V signal. The polarity will be indicated only

by the ico

c. Set the amplitude to either 6 V or -6 V.

d. Set the Pulse/Energy setting to 7.2 Joules (the time should show 10s).

e. When a ll of t he parameters are set and you ensure that the output is

ON, push the Trig Pulse side-bezel and IMMEDIATELY push the

OK Do Next Step side-bezel button on the oscilloscope.

ON. Once you push the Trig Pulse button on the calibrator,

CAUTI

you have only 9 seconds to push the OK Do Next Step button on the

oscilloscope. If the instrument fails one of these tests, go all the way back

to the first 6 V test (6 V on channel 1) and start that sequence over again.

annels and the signal is grounded, The calibrator screen

ovoltage: Before you select the voltage, you must first

lower-bezel

side-bezel button for a 6 V signal or push the

n that appears in the upper-left corner of the calibrator screen.

7. Ensure that the red light is illuminated to indicate that the output is on. If not,

push the ON button, as shown below:

8. On the oscilloscope, push the OK Do Next Step side-bezel button.

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 13

Adjustment Procedures

Deskew

Time Mark

(MSO Only)

TheTimeMarkte

you receive a time mark prompt, complete the following steps:

1. Push the Markers

2. Push the WAV E F O R M lower-bezel button, and then push the

side-bezel button.

NOTE. If a 62

3. Select the Amplitude field using the front panel scroll b uttons, and then

change th

4. Ensure that the red light is illuminated to indicate that the output is on. If not,

push the

5. On the oscilloscope, push the OK Do Next Step right-bezel button.

If you are using the MSO3000 Series oscilloscope, and you receive a prompt for a

deskew test, complete the following steps:

1. Plug the probe, notch down, into the digital channel input, as shown in the

following figure. Ensure that it snaps into place. Keep the probe plugged in

for the remainder of the calibration procedure.

st is often the second test type to appear in the prompts. When

front-panel button.

5 Hz signal is required, set the time marker to 1.6 ms.

e voltage by using the large front panel knob on the calibrator.

ON button.

Figure 6: Digital channel input (MSO only)

14 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Adjustment Procedures

2. Push the Aux front-panel button, and then push the Zero skew

side-bezel button.

3. Set the specified voltage, frequency, and termination.

4. Push the CHANNEL SELECT button and ensure that all channels are

selected, including Channel 5.

5. Ensure that the red light is illuminated to indicate that the output is on. If not,

push the ON button.

6. On the oscilloscope, push the OK Do Next Step right-bezel b utton. In some

cases, this can take several minutes.

CAUTION. Keep the digital probe plugged in to the oscilloscope. Unplugging the

probe ma

y result in aborting the test.

Sine Signal

When a Sine Signal prompt appears, complete the following steps:

1. Push the Sine

2. To ensure that the voltage is in direct mode, push the

button and select 1.0.

3. Push the CHANNEL SELECT lower-bezel button, and then ensure that

Channel 5 is selected.

4. Ensure that the red light is illuminated to indicate that the output is on. If not,

push the ON button.

5. On the oscilloscope, push the OK Do Next Step right-bezel button.

front panel button.

lower-bezel

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 15

Adjustment Procedures

Troubleshooting

Refer to the fol

lowing table for common issues encountered during the calibration

procedure.

Problem Things to try

The instrument fails a test

I can't set the amplitude to 0 V, as

specified in the prompt

I can't find the parameters that I

need to set

I can't set the voltage to 625 Hz

I can't set the signal to all channels

I'm having trouble with tests that

require 6 V or -6 V

The Sine Signal test failed If the prompt specified Channel 4, try setting the signal to Channel 5, instead.

Are the channels hooked up properly, routed to the right channels, and turned on

Is the signal set to the correct waveform, frequency, and termination (if applicable to the test)

Is the output set to ON (the red light will be illuminated)

Ifyoumakeacorrectionorfind that everything appears to be correct, click the Go back a

step button to try the test again.

Ground the signal by pushing the

Is the waveform set correctly

Is the grounding button on? When this is active, you will not be able to make a channel

selection, so in some cases you might need to temporarily deselect the grounding option

while you make a channel selection.

If you can find the termination settings, click the CHANNEL SELECT lower-bezel button.

Set the time marker to 1.6 Ms. This will automatically set the voltage to 625 Hz.

If you are unable to set the signal to all channels, try setting the signal to Channel 1.

Follow the steps for 6 V and -6 V that appear in Step 6 of the DC Voltage test. (See page 12,

DC Voltage.)

Ensure that the polarity is correct, by referring to the icon that appears in the upper-left corner

of the calibrator screen.

If the instrument fails a test, go all the way back to the first 6 V test (6 V on Channel 1) and

start the sequence over again.

lower-bezel button.

16 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Maintenance

This section contains the information needed to do periodic and corrective

maintenance on the oscilloscope, as well as repackaging instructions if you need

to return the oscilloscope to Tektronix for service.

Preventing

ESD

Before servicing this product, read the Safety Summary and Introduction at the

front of the manual and the electrostatic discharge (ESD) information below.

CAUTION. S

oscilloscope

When performing any service that requires internal access to the oscilloscope,

adhere t

components due to electrostatic discharge.

1. Minimi

2. Transport and store s tatic-sensitive modules in their static protected containers

or on a

3. Discharge the static voltage from your body by wearing a grounded antistatic

wris

only at a static-free work station.

4. Do n

work station surface.

tatic discharge can damage any semiconductor component in this

o the following precautions to avoid damaging interna l modules and their

ze handling of static-sensitive circuit boards and components.

metal rail. Label any package that contains static-sensitive boards.

t strap while handling these modules. Service static-sensitive modules

ot place anything capable of generating or holding a static charge on the

5. Han

6. Do not slide the circuit boards over any surface.

7. Avoid handling circuit boards in areas that have a floor or work-surface

dle circuit boards by the edges when possible.

covering capable of generating a static charge.

Inspection and Cleaning

Inspection and cleaning are done as preventive maintenance. Preventive

maintenance, when done regularly, may prevent oscilloscope malfunction and

enhance its reliability.

Preventive maintenance consists of visually inspecting and cleaning the

oscilloscope and using general care when operating it.

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 17

Maintenance

General Care

Flat Panel Display Cleaning

How often you do

which the oscilloscope is used. A proper time to perform preventive maintenance

is just before oscilloscope adjustment.

The cabinet h

place when operating the oscilloscope.

The display is a soft plastic display and must be treated with care during cleaning.

CAUTION. Improper cleaning agents or methods can damage the flat panel

display.

Avoid using abrasive cleaners or commercial glass cleaners to clean the display

surface.

Avoid spraying liquids directly on the display surface.

Avoid scrubbing the display with exces sive force.

Clean the flat panel display surface by gently rubbing the display with a

clean-room wipe (such as Wypall Medium Duty Wipes, #05701, available from

Kimberly-Clark Corporation).

maintenance depends on the severity of the environment in

elps keep dust out of the oscilloscope and should normally be in

ior Cleaning

Inter

Exterior Cleaning

Use a dry, low-velocity stream of air to clean the interior of the chassis. Use a

soft-bristle, non-static-producing brush for cleaning around components. If you

must use a liquid for minor interior cleaning, use a 75% isopropyl alcohol solution

inse with deionized water.

and r

WARNING. To avoid injury, power down the instrument and disconnect it from

line v oltage before performing any procedure that follows.

Clean the exterior surfaces and knobs of the instrument with a dry lint-free cloth

or a soft-bristle brush. If any dirt remains, use a cloth or swab dipped in a 75%

isopropyl alcohol solution. Use a swab to clean narrow spaces around controls

and connectors. Do not use abrasive compounds on any part of the instrument

case that may damage the case.

18 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Maintenance

Exterior Inspection

Clean the On/St

andby switch using a dampened cleaning towel. Do not spray or

wet the switch directly.

CAUTION. Avoid the use of chemical cleaning agents, which might damage the

plastics used in this oscilloscope. Use only deionized water when cleaning the

menu buttons or front-panel buttons. Use a 75% isopropyl alcohol solution as a

cleaner and rinse with deionized water. Before using any other type of cleaner,

consult you

r Tektronix Service Center or representative.

Lubrication. There is no periodic lubrication required for this oscilloscope.

Inspect the outside of the oscilloscope for damage, wear, and missing parts,

using the following table a s a guide. Immediately repair defects that could cause

personal injury or lead to further damage to the oscilloscope.

Table 1: External inspection check list

Item Inspect for Repair action Repair action

Cabinet, front panel, and

cover

Front-panel knobs Missing, damaged, or loose

Connectors

Carrying handle, and

cabinet feet

Accessories

Cracks, scratches,

deformations, damaged

hardware.

knobs.

Broken shells, cracked

insulation, and deformed

contacts. Dirt in connectors.

Correct operation. Repair or replace defective

Missing items or parts of

items, bent pins, broken or

frayed cables, and damaged

connectors.

Repair or replace defective

module.

Repair or replace missing or

defective knobs.

Repair or replace defective

modules. Clear or wash out

dirt.

module.

Repair or replace damaged

or missing items, frayed

cables, and defective

modules.

If the display is very dirty, moisten the wipe with distilled water or a 75%

isopropyl alcohol solution and gently rub the display surface. Avoid using excess

force or you may damage the plastic display surface.

CAUTION. To prevent getting moisture inside the oscilloscope during external

cleaning, use only enough liquid to dampen the cloth or applicator.

Interior Inspection

To access the inside of the oscilloscope for inspection and cleaning, refer to the

Removal Procedures in this section.

Inspect the internal portions of the oscilloscope for damage and wear, using the

following table as a guide. Repair any defects immediately.

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 19

Maintenance

If any circuit b

oard is repaired or replaced, check the table to see if it is necessary

to adjust the oscilloscope.

CAUTION. To prevent damage from electrical arcing, ensure that circuit boards

and components are dry before applying power to the oscilloscope.

Table 2: Internal i nspection check list

Item Inspect for Repair action Repair action

Circuit boards

Resistors Burned, cracked, broken,

Solder connections Cold solder or rosin joints.

Capacitors

Wiring and cables Loose plugs or connectors.

Chassis Dents, deformations, and

Loose, broken, or corroded

solder connections.

Burned cir

Burned, broken, or cracked

circuit-run plating.

blistered condition.

Damaged or leaking cases.

Corroded solder on leads or

termina

Burned

wiring.

damag

cuit boards.

ls.

, broken, or frayed

ed hardware.

Remove and replace

damaged circuit board.

Remove and replace

damaged circuit board.

Resolder joint and clean

with isopropyl alcohol.

Remove and replace

damaged circuit board.

Firmly seat connectors.

or replace modules

Repair

with defective wires or

cables.

Straighten, repair, or replace

tive hardware.

defec

Cleaning Procedure — Interior. To clean the oscilloscope interior, do the following

steps:

1. Blow off dust with dry, low-pressure, deionized air (approximately 9 psi).

2. 2. Remove any remaining dust with a lint-free cloth dampened in isopropyl

alcohol (75% solution) and rinsed with warm deionized water. (A

cotton-tipped applicator is useful for cleaning in narrow spaces and on circuit

ards.)

bo

NOTE. If, after doing steps 1 and 2, a module is clean u pon inspection, skip the

following steps.

If there is still dust or dirt on the module, the oscilloscope may be spray washed

using a solution of 75% isopropyl alcohol by doing the following steps:

20 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Maintenance

1. Gain access to t

and panels (see Removal Procedures).

2. Spraywashdir

majority of the alcohol to evaporate.

3. Use hot (120

4. Dry all parts with low-pressure, deionized air.

5. Dry all components and assemblies in an oven or drying compartment using

low-temperature (125 °F to 150 °F) circulating air.

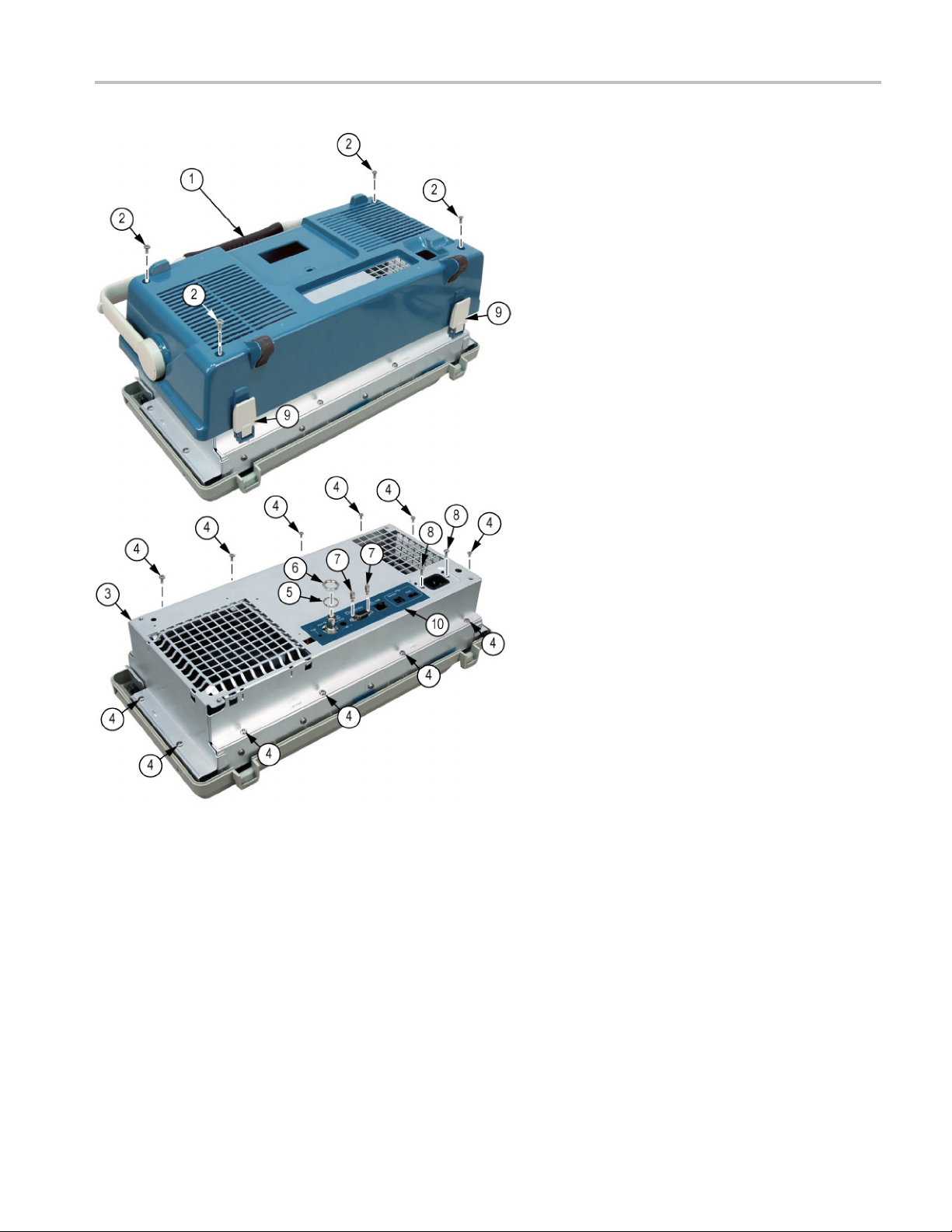

Overview of Removal Procedures

The following figure shows the location of modules that you are removing or

ing.

install

he parts to be cleaned by removing easily accessible shields

ty parts with the isopropyl alcohol and wait 60 seconds for the

°F to 140 °F) deionized water to thoroughly rinse them.

Figure 7: Locator for internal modules

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 21

Maintenance

List of Modules

Tools Required

The Replaceabl

ePartsListchapter provides a list of all replaceable modules. Any

replaceable component, assembly, or part is referred to as a module.

WARNING. Only qualified personnel should perform service procedures. Before

doing this or any other procedure in this manual, read the General Safety

Summary and Service Safety Summary located at the beginning of this manual.

Also, take precautions to prevent ESD damage to electrical components. (See

page 17, Preve

nting ESD.)

You will need the following tools to remove and replace all the modules in the

instrume

nt.

Torque-limiting screwdriver, 12 in-lb (1.3 N-m) range with TORX T15 tips.

If you ar

e using a magnetic screwdriver with interchangeable bits, the T15 bit

must be a long bit, at least 5 cm. (2 in) overall length.

Screwd

3

5

5

river with

/16inch nut driver

/16in. wrench

/8in. wrench

1

/8inch flat blade

Removal Procedures

Needle-nose pliers

X-ACTO knife or other razor k nife

Beginning with the rear case, remove modules as necessary to gain access to the

moduleyouneedtoremove.

WARNING. Before doing any procedure in this subsection, disconnect the power

cord from the line voltage source. Failure to do so could cause serious injury

or death.

CAUTION. When removing or installing the keypad, do not touch the switch

contacts with your fingers. The oils on your fingers will degrade or damage the

switch contacts. To help prevent damage to the keypad, use cotton gloves when

removing or installing the keyboard pad.

CAUTION. To avoid damage to the front panel standby/on switch assembly, do not

set the display module assembly on a work surface. Sliding the oscilloscope over

the edge of the work surface could break off the on/standby switch a ssembly.

22 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Maintenance

Rear Case

Rear Chassi

Follow these st

eps to remove the rear case assembly. Use a TORX T15 screwdriver

tip. (See Figure 12 on page 37.)

1. Place the osci

lloscope face down on the work surface.

2. Remove the four T15 screws from the back of the rear case assembly. When

reinstalli

ng the rear case torque these screws to 8.0 in/lb.

3. Grasp the case and pull outwards to remove it.

Follow these steps to remove the rear chassis assembly. You will need a5/8in.

s

wrench, a

3

/16in. nutdriver, a5/16in. wrench, and a TORX T15 screwdriver tip.

(See Figure 12 on page 37.)

5

1. Remove the

/8in. nut from the Aux Out BNC. When reinstalling torque

this nut to 25 in/lb.

3

2. Remove the two

/8in. jackscrews from the WVGA Video connector. When

reinstalling torque these to 4.0 in/lb.

3. Remove the two T15 screws attaching the power connector. When reinstalling

torque these screws to 8.0 in/lb.

4. Remove the 12 T15 screws attaching the rear chassis to the front chassis.

When reinstalling torque these screws to 8.0 in/lb.

5. Lift the rear chassis from the oscilloscope, and unplug the fan power cable

from the I/O board. When reinstalling the rear chassis there are several steps

ollow:

to f

a. Make sure the captured nuts are still in place, in the black plastic bracket

t holds the IEC power connector.

tha

b. Make sure the connectors from the I/O board line up with their respective

les in the rear chassis.

ho

c. Make sure the two guide pins on the power connector line up with their

ositioning holes.

p

d. Thread the fan power cable through the hole in the rear chassis closest to

the fan, so that it goes to the outside of the rear chassis.

e. After the rear chassis is reattached to the front chassis, u se a spudger or a

pair of needle-nose pliers to insert the fan power connector back through

the hole and onto J200 on the I/O board. (See Figure 8.)

f. Push the rest of the fan power cable into the hole, so that the entire cable

is inside the Rear Chassis. (See Figure 8.)

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 23

Maintenance

Figure 8: Reconnecting the fan cable

Fan

Follow these steps to remove the fan assembly. You need to have previously

removed the rear case assembly and rear chassis. Use a pair of pliers. (See

Figure 13 on page 39.)

1. Use a pair of pliers to bend the tabs that hold the fan in the chassis.

2. Slide the fan assembly out and away from the chassis.

3. When reinstalling, dress the fan power cable carefully. (See Figure 9.)

Figure 9 : Fan cable dress

I/O Board

24 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Follow these steps to remove the I/O board. You need to have previously removed

the rear case assembly and rear chassis. (See Figure 13 on page 39.)

1. Disconnect the power cable from J104 on the I/O board.

2. Rock the board slightly while pulling straight up to disconnect the board

from the edge connector.

3. Disconnect the cable from J103 on the I/O board and lift the board away.

4. Place the board on a static-free surface.

Maintenance

Power Supply Module

Main Board

Follow these st

previously removed the rear case assembly rear chassis, and I/O board. Use a

TORX T15 screwdriver tip. (See Figure 14 on page 41.)

1. Disconnect the power cable from J104 on the I/O board (if still attached)

and from J0403 on the Main board.

2. Disconnect the cable from the Power Supply module to J0401 on the Main

board.

3. Disconnect the power connector ground lead from the chassis.

4. Remove the

chassis. When reinstalling torque these screws to 8.0 in/lb.

5. Lift the P

chassis and place it on a static-free surface.

Follow these steps to remove the main board. You need to have previously

remove

TORX T15 screwdriver tip. (See Figure 13 on page 39.)

1. Disco

2. Disconnect the display backlight cable from the J6500 on the main board.

d the rear case assembly, rear chassis, power supply, and I/O board. Use a

eps to remove the power supply module. You need to have

five T15 screws that attach the Power Supply module to the

ower Supply module, including the power connector, off of the

nnect the Front Panel cable from J6000 on the main board.

3. Disconnect the front panel cable from J0400 on the main board.

4. Disconnect the power supply control cable from J0401 on the main board.

5. Disconnect the LCD display cable from the J6600 on the main board.

6. Disconnect the front panel USB cable from J0501 on the main board.

sconnect the power supply cable from J0403 on the main board.

7. Di

8. Remove the seven T15 screws that connect the main board to the chassis.

hen reinstalling torque these screws to 8.0 in/lb.

W

9. Use a screwdriver or other bar to pry the main board up, to disconnect the

onnection to the Attenuator board. Place the point of the screwdriver under

c

themiddleheatsinkspringandusethechassisedgeasthefulcrum. (See

Figure 10.)

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 25

Maintenance

Attenuator Board

Figure 10:

10. Lift the m

11. When reinstalling make sure to align the main board and attenuator board

For MSO3000 Series oscilloscopes, make sure that the Digital Probe Guide is

in place before reinstalling the main board.

Follo

removed the rear case assembly, rear chassis, power supply, I/O board, and main

board. Use a TORX T15 screwdriver tip. (See Figure 16 on page 45.)

1. Remove the six T15 screws that connect the main board shield to the chassis.

2. Remove the main board shield and set it aside.

3. Remove the nine T15 screws that connect the attenuator board to the chassis.

Disconnecting the main board

ain board out of the chassis and place it on a static-free surface.

connect

on page 39.) Then use a spudger or small screwdriver to make sure that J101

is firmly seated on the front panel board. (See Figure 17 on page 47.)

w these steps to remove the attenuator board. You need to have previously

Note that there are two lengths; the shorter ones go through the side rail.

When reinstalling torque these screws to 8.0 in/lb.

Note that there are two lengths; the shorter ones go through the side rail.

When reinstalling torque these screws to 8.0 in/lb.

ors and press down until the connector snaps together. (See Figure 13

4. Remove the attenuator board and place it on a static-free surface.

26 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Maintenance

Front Chassis

Display Module

Follow these st

eps to remove the front chassis. You need to have previously

removed the rear case assembly, rear chassis, power supply, I/O board, main

board, and attenuator board. Use a TORX T15 screwdriver tip. (See Figure 17

on page 47.)

1. Disconnect the cables connected to J101 and J103 on the front panel board.

2. Remove the eight T15 screws that connect the front chass

is to the front case.

When reinstalling torque these screws to 8.0 in/lb.

3. Lift the front chassis from the front case and p lace it on a static-free surface

with the LCD assembly facing up.

Follow these steps to remove the display module. You need to have previously

removed the rear case assembly, rear chassis, power supply, I/O board, main

board, attenuator board, and front chassis. Use a TORX T15 screwdriver tip.

(See Figure 17 on page 47.)

1. Place the front chassis on a soft, static-free surface with the LCD assembly

down.

2. Remove the four

5

/16in nuts that connect the display cable shield to the front

chassis, and remove the display cable shield. When reinstalling torque these

nuts to 8.0 in/lb. (See Figure 11.)

Figure 11: Display cable shield in place

3. Turn the front chassis over and remove the eight T15 screws that connect the

display to the front chassis. (See Figure 17 on page 47.) When reinstalling

torque these screws to 8.0 in/lb.

4. Gently lift the display up and off of t he chassis.

CAUTION. Be careful when removing and reinstalling the Display module cables.

If the connectors have bent pins or are installed incorrectly, the Display may

be destroyed.

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 27

Maintenance

Front-panel USB

Connector

Front Panel Module

Usethisproced

previously removed the rear case assembly, rear chassis, power supply, I/O board,

main board, attenuator board, and front chassis. Use a TORX T15 screwdriver tip,

needle-nose pliers, and a razor knife. (See Figure 17 on page 47.)

1. Place the front chassis on the work surface with the LCD facing up.

2. Remove the two T15 screws that connect the U SB lower bracket to the

chassis, and remove the bracket and its attached EMI clip.

3. Use a pair of needle nose pliers to remove the upper EMI clip from the front

chassis.

4. Turn the front chassis over and use the razor knife to trim off the plastic ears

on both sides of the USB c onnector. (See Figure 17.)

5. Slide the USB connector and cable out toward the front of the chassis. When

reinstalling slide the new USB cable and housing in from the front of the

chassis and push the connector in until it snaps into place.

Follow these steps to remove the Front Panel module. You need to have previously

removed the rear case assembly, rear chassis, power supply, I/O board, main

board, attenuator board, and front chassis. Use a TORX T15 screwdriver tip. (See

Figure14onpage41.) (SeeFigure18onpage49.)

ure to remove the front-panel USB connector. You must have

Troubleshooting

1. Remove all the front panel knobs.

2. Remove the 14 T15 screws (10 with ground spring contacts) holding the Front

Panel board to the chassis. When reinstalling torque these screws to 8.0 in/lb.

3. Lift the Front Panel board off of the chassis.

CAUTION. Do not touch the keypad switch contacts with your fingers. The oils

on your fi ngers will degrade or damage the switch contacts. To help prevent

damage to the keypad, use cotton gloves.

This section contains information and procedures to help you isolate a defective

module in the oscilloscopes.

WARNING. Before doing this or any other procedure in this manual, read the

General Safety Summary and Service Safety Summary found at the beginning

of this manual. Also, take precautions to prevent ESD damage to electrical

components. (See page 17, Preventing ESD.)

28 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Maintenance

Adjustment After Repair

Required Tools and

If you replace t

page 7, Adjustment Procedures.)

You need the following equipment to troubleshoot the instrument.

Equipment

Tools and Equipment Example

DMM 3.5 digits or greater

Troubleshooting Procedure

The following diagrams are troubleshooting procedure flowcharts. Beginning

with Flowchart 1, use them to troubleshoot an instrument failure.

WAR N ING. Before removing the cabinet, disconnect the power cord from the line

voltage s

he Main board, you must adjust the instrument after repair. (See

ource. Failure to do so could cause serious injury or death.

Flowchart 1 — Primary troubleshooting procedure

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 29

Maintenance

Flowchart 2 — AC power supply troubleshooting procedure

30 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Maintenance

Flowchart 3 — Module isolation troubleshooting procedure

Unpacking and Repacking Instructions

This section contains the information needed to u npack the oscilloscope and

ack it for shipment or storage.

rep

Unpacking

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 31

The oscilloscope and its standard accessories are carefully packed at the factory in

a shipping carton. If, upon receipt, damage to the shipping carton is evident, notify

e shipper. Tektronix, Inc. is not responsible for damage caused during shipping.

th

Maintenance

Repacking

If you have not a

accessories from the shipping carton and inspect them for damage. Save the

shipping carton for repacking or storage.

Useacorruga

275 pounds (125 kg) and with an inside dimension a t least six inches (15.25 cm)

greater than the instrument dimensions.

If the instrument is being shipped to a Tektronix Service Center, enclose the

following information:

The owner’s address

Name and p

Type and serial number of the instrument

Reason for returning

A complete description of the service required

Seal the shipping carton with an industrial stapler or strapping tape.

Mark the address of the Tektronix Service Center and also your own return address

on the shipping carton in two prominent locations. See www.tektronix.com/service

to find a service center near you.

lready done so, carefully remove the oscilloscope and its

ted cardboard shipping carton having a test strength of at least

hone number of a contact person

Storage

The oscilloscope should be stored in a clean, dry environment. The following

environmental characteristics apply for both shipping and storage:

Temperature range: -20 °C to +60 °C

titude: To 15,000 m

Al

See the MSO3000 and DPO3000 Series Specifications and Performance

rification Technical Reference for a complete listing of the environmental

Ve

characteristics.

32 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Replaceable Parts List

This chapter contains a list of the replaceable modules for the MSO3000 and

DPO3000 Series Oscilloscopes. Use this list to identify and order replacement

parts.

Parts Order

ing Information

Part Number Revision

Level

Replacement parts are available through your local Tektronix field office or

representative.

Changes to Tektronix products are sometimes made to accommodate improved

components as they become available and to give you the benefit of the latest

improvem

following information in your order.

If you order a part that has been replaced with a different or improved part, your

local Tektronix field office or representative will contact you concerning any

change in part number.

Change information, if any, is located at the rear of this manual.

Tektronix part numbers contain two digits that show the revision level of the

part. For some parts in this manual, you will find the letters XX in place of the

revision level number.

ents. Therefore, when ordering parts, it is important to include the

Part num

Instrument type or model number

Instrument serial number

Instrument modification number, if applicable

ber (see Part Number Revision Level below)

When you order parts, Tektronix will provide you with the most current part for

your product type, serial number, and modification (if applicable). At the time of

your order, Tektronix will determine the part number revision level needed for

your product, based on the information you provide.

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 33

Replaceable Parts List

Module Servicing

Modules can be s

local Tektronix service center or representative for repair assistance.

Module Exchange. In some cases you may exchange your module for a

remanufactured module. These modules cost significantly less than new modules

and meet the same factory specifications. For more information about the module

exchange pr

Module Repair and Return. You may ship your module to us for repair, after

which we will return it to you.

New Modules. You may purchase replacement modules in the same way as other

replacem

ent parts.

erviced by selecting one of the next three options. Contact your

ogram, call 1-800-833-9200, extension 2.

34 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Using the Replaceable Parts List

This section contains a list of the mechanical and/or electrical components that

are replaceable for the instrument. Use this list to identify and order replacement

parts. The following table describes each column in the parts list.

Column Column name Description

1

2 Tektronix Part

3 and 4

5

6

Figure & Index

Number

Number

Serial Nu

Qty This ind

Name &

Description

mber

Items in this section are referenced by figure and index

numbers to the exploded view ill ustrations that precede

the list.

Use this part number when ordering replacement parts

from Tektr

Column th

was first effective. Column four indicates the serial number

at which the part was discontinued. No entries indicates

the part i

An item

(:). Because of space limitations, an item name may

sometimes appear as incomplete. Use the U.S. Federal

Catalo

Replaceable Parts List

onix.

ree indicates the serial number at which the part

s good for all serial numbers.

icates the quantity of parts used.

name is separated from the description by a colon

g handbook H6-1 for further item name identification.

Abbreviations

Exploded Views

viations conform to American National Standard ANSI Y1.1-1972.

Abbre

The following figures show the module-level exploded views of the MSO3000

and DPO3000 Series oscilloscopes. Each exploded view is indexed by the

numbers in the figure.

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 35

Replaceable Parts List

Table 3: Replac

eable parts list: Rear case and rear chassis

Fig. &

index

number

12-1

-2 211-1275-00 4

-3 441-2509-00 1

-4 211-1272-00 12

-5

-6 220-0265-00 1

-7

-8 211-1276-00 2

-9 348-1910-00 2

-10 335-1875-00 1

Tektronix

part number

065089300

202-0462-00 1

367-0548-XX 1

348-1909-XX 2

210-1039-00 1

214-3903-00 2

Serial no.

effective

Serial no.

discont’d Qty Name & descrip tion

MODULE ASSY;SERVICE REPLACEMENT KIT,REAR CASE

ASSEMBLY

CASE, REAR ASSEMBLY

HANDLE; CARRYING; SAFETY CONTROLLED

FOOT REAR; SAFETY CONTROLLED

SCREW,MACHINE; W/HEAVY PATCH THREADLOCKING MATERIAL;

6-32 X 0.312 L,PNH,STL CAD PLT,T15

CHASSIS, REAR

SCREW,MACHINE; 6-32 X 0.250,PNH,STL,ZNPL,T-15 TORX

WASHER,LOCK; 0.521 ID,INT,0.025 THK,410 SS, PASSIVATED

NUT,PLAIN,HEX; 0.5-28 X 0.625 HEX,BRS,NKL PL

SCREW, JACK; 4-40 X 0.312 LONG, 0.188 H HEX HEAD STAND OFF,

4-40 INT THD, X 0.312 THD EXT 4-40, STEEL, SN PLATED

SCREW, MACHINE; 6-32 X 0.375, PNH, STL,ZNPL, T-15 TORX DR

FOOT FRONT CABINET HINGED FSN.PRT

LABEL, REAR, IO; SAFETY CONTROLLED

36 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Replaceable Parts List

Figure 12: Exploded view: rear case and rear chassis

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 37

Replaceable Parts List

Table 4: Replac

eable parts list: I/O and main boards

Fig. &

index

number

13-1 119-7365-00 1

-2 870-0015-01 1

-3

-4 211-1275-01 8

Tektronix

part number

870-0407-00 1

870-0406-00 1

870-0408-00 1

870-0263-00 1

870-0264-00 1

870-0237-00 1

870-0236-00 1

870-0235-00 1

870-0234-00 1

870-0019-00 1

870-0016-00 1

Serial no.

effective

Serial no.

discont’d Qty Name & descrip tion

FAN; 120MM, TUBEAXIAL, 12 VDC; SAFETY CONTROLLED

CIRCUIT BOARD ASSY;2 & 4 CH I/O

MAIN;389378600;TESTED;DPO3000

CIRCUIT BD ASSY;4 CH ACQUISITION BD

MAIN;3894164XX;TESTED MSO3054

CIRCUIT BD ASSY;4 CH ACQUISITION BD

MAIN;3894164XX;TESTED MSO3034

CIRCUIT BD ASSY;2 CH ACQUISITION BD MAIN; 3894164XX;

TESTED MSO3032

CIRCUIT BD ASSY;4 CH ACQUISITION BD

MAIN;3894164XX;TESTED MSO3014

CIRCUIT BD ASSY;2 CH ACQUISITION BD MAIN; 3894164XX;

TESTED MSO3012

CIRCUIT BOARD ASSY;4 CH ACQUISITION

BD;379377900;TESTED;DPO3054

CIRCUIT BOARD ASSY;2 CH ACQUISITION

BD;379377900;TESTED;DPO3052

CIRCUIT BOARD ASSY;4 CH ACQUISITION

BD;379377900;TESTED;DPO3034

CIRCUIT BOARD ASSY;2 CH ACQUISITION

BD;379377900;TESTED;DPO3032

CIRCUIT BOARD ASSY;4 CH ACQUISITION

BD;389377900;TESTED;DPO3014

CIRCUIT BOARD ASSY;2 CH ACQUISITION

BD;379377900;TESTED;DPO3012

SCREW, MACHINE; W/HEAVY PATCH THREADLOCKING

MATERIAL; 6-32 X 0.312 L, PNH,STL,ZNPL, T15

38 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Replaceable Parts List

Figure 13: Exploded view: I/O and main boards

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 39

Replaceable Parts List

Table 5: Replac

Fig. & index

number

14-1 119-7281-00 1

-2 211-1275-01

-3 211-1273-00 1

-4 366-0865-00 1

-5

-6 366-0867-01 1

-7

-8

-9

eable parts list: Front panel and power supply

Tektronix part

number

358-0883-0

366-0861-01 2

366-0859

366-0859-01 4

366-0860-01

366-0860

0

-01

-01

Serial no.

effective

Serial no.

discont’d Qty Name & descrip

tion

POWER SUPPLY; CUSTOM,MALIBU,AC-DC;85-275 VAC 45-440HZ

IN;+6VDC 6A,1

OUTPUT;SAFETY CONTROLLED

5

1

6

5

3

SCREW, MACHI

6-32 X 0.312 L, PNH,STL,ZNPL, T15

SCREW,PT; K

KNOB, JOG

BUSHING (JOG SHUTTLE KNOB)

KNOB, SHUT

KNOB, .925 DIA, SOFT TOUCH

KNOB, .470 DIA, SOFT TOUCH (4-CHANNEL MODELS)

KNOB, .47

KNOB, .685 DIA, SOFT TOUCH (4-CHANNEL MODELS)

KNOB, .685 DIA, SOFT TOUCH (2-CHANNEL MODELS)

2V 4A OUT;PLUS SOFT SWITCH & LINE TRIGGER

NE; W/HEAVY PATCH THREADLOCKING MATERIAL;

35-1.57,PAN HEAD,STL,ZNPL,T-15

TLE

0 DIA, SOFT TOUCH (2-CHANNEL MODELS)

40 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Replaceable Parts List

Figure 14: Exploded view: Front panel and power supply

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 41

Replaceable Parts List

Table 6: Replac

eable parts list: Front panel labels

Fig. &

index

number

15-1

-2 200-5049-00 1

Tektronix

part number

335-1926-00 1

335-1925-00 1

335-1924-00 1

335-1923-00 1

335-1922-00 1

335-1921-00 1

335-1920-00 1

335-1919-00 1

335-1918-00 1

335-1917-00 1

Serial no.

effective

Serial no.

discont’d Qty Name & descrip tion

LABEL. FRONT PANEL, OVERLAY, RUSSIAN

LABEL. FRONT PANEL, OVERLAY, KOREAN

LABEL. FRONT PANEL, OVERLAY, STD CHINESE

LABEL. FRONT PANEL, OVERLAY, SIM CHINESE

LABEL. FRONT PANEL, OVERLAY, PORTUGUESE

LABEL. FRONT PANEL, OVERLAY, JAPANESE

LABEL. FRONT PANEL, OVERLAY, SPANISH

LABEL. FRONT PANEL, OVERLAY, GERMAN

LABEL. FRONT PANEL, OVERLAY, ITALIAN

LABEL. FRONT PANEL, OVERLAY, FRENCH

COVER; DOOR, APP KEY

42 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Figure 15: Exploded view: Front panel labels

Replaceable Parts List

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 43

Replaceable Parts List

Table 7: Replac

Fig. & index

number

16-1

-2 211-1275-00

-3 211-1272-00 8

-4 351-1

-5

eable parts list: Attenuator

Tektronix part

number

050-3715-xx

337-4462-00

Order by

description

130-00

870-0030-00 1

870-0032-01 1

Serial no.

effective

C0 11121

C010309

C011323

C010538

C011229

C010713

Serial no.

discont’d Qty Name & descrip

C011120

C010308

C011322

C010537

C011228

C010712

tion

1

1

1

1

1

1

1

1

1

1

1

1

1

1

7

1

SHIELD, MAINBOARD, DPO3054 Only

SHIELD, MAINBOARD, DPO3052 Only

SHIELD, MAIN

SHIELD, MAINBOARD, DPO3032 Only

SHIELD, MAINBOARD, DPO3014 Only

SHIELD, MAI

SHIELD, MAINBOARD, DPO3054 Only

SHIELD, MAINBOARD, DPO3052 Only

SHIELD, MA

SHIELD, MAINBOARD, DPO3032 Only

SHIELD, MAINBOARD, DPO3014 Only

SHIELD, M

SHIELD, MAINBOARD, MSO3000 Series

**ATTACHED PART**

GASKET,

**END A

SCREW, MACHINE; W/HEAVY PATCH THREADLOCKING MATERIAL;

6-32 X 0

SCREW,MACHINE; 6-32 X 0.250,PNH,STL,ZNPL,T-15 TORX DR

DIGITAL PROBE GUIDE (MSO3000 SERIES ONLY)

ATTEN

WIRED (4-CHANNEL MODELS)

ATTE

WIRED (2-CHANNEL MODELS)

BOARD, DPO3034 Only

NBOARD, DPO3012 Only

INBOARD, DPO3034 Only

AINBOARD, DPO3012 Only

FOAM, CONDUCTIVE, W /ADHESIVE, 5.0 INCH of 348-1863-00

TTACHED PART**

.312 L, PNH,STL,ZNPL, T15

UATOR CIRCUIT BD ASSY;TESTED;8780030XX,3893928XX

NUATOR CIRCUIT BD ASSY;TESTED;8780030XX,3893928XX

44 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Replaceable Parts List

re 16: Exploded view: Main board shield and attenuator board

Figu

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 45

Replaceable Parts List

Table 8: Replac

eable parts list: Front chassis and LCD

Fig. &

index

number

17-1

-2 211-1273-00 8

-3 850-0043-00 1

-4 211-1272-00 8

-5

-6 131-7622-00 1

Tektronix

part number

050-3715-xx

441-2570-00

174-5411-00 1

Serial no.

effective

C011121 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3054 Only

C010309 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3052 Only

C011323 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3034 Only

C010538 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3032 Only

C011229 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3014 Only

C010713 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3012 Only

Serial no.

discont’d Qty Name & descrip tion

C011120

C010308 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3052 Only

C011322 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3034 Only

C010537 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3032 Only

C011228 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3014 Only

C010712 CHASSIS, FRONT; SAFETY CONTROLLED, DPO3012 Only

1

CHASSIS, FRONT; SAFETY CONTROLLED, DPO3054 Only

CHASSIS, FRONT; SAFETY CONTROLLED, MSO3000 Series

SCREW, PT; K35-1.57, PAN HEAD, STL, ZNPL, T-15

LCD DISPLAY ASSEMBLY

SCREW,MACHINE; 6-32 X 0.250,PNH,STL,ZNPL,T-15 TORX DR

CABLE EXTENSION, USB-HOST; SAFETY CONTROLLED

CONN,RCPT;GROUND JACK

46 MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual

Replaceable Parts List

gure 17: Exploded view: Front chassis and LCD assembly

Fi

MSO3000 and DPO3000 Series Digital Phosphor Oscilloscopes Service Manual 47

Replaceable Parts List

Table 9: Replac

eable parts list: Front panel and front case

Fig. &

index

number

18-1

-2 211-1273-00 18

-3 131-8139-00 10

-4 260-2853-00 1

-5

Tektronix

part number

878-0323-01 1

878-0322-01 1

878-0029-01 1

878-0028-01 1

050-3717-00 1

050-3716-00 1

050-3700-00 1

050-3701-00 1

Serial no.

effective

Serial no.

discont’d Qty Name & descrip tion

CIRCUIT BOARD SUBASSY;4 CH FRONT

PANEL;UNTESTED,389423000

(MSO 4-CHANNEL MODELS)

CIRCUIT BOARD SUBASSY;2 CH FRONT

PANEL;UNTESTED,389423000

(MSO 2-CHANNEL MODELS)

CIRCUIT BOARD ASSY;4 CH FRONT PANEL;TESTED,389378100

(DPO 4-CHANNEL MODELS)

CIRCUIT BOARD ASSY;2 CH FRONT PANEL;TESTED,389378000

(DPO 2-CHANNEL MODELS)

SCREW,PT; K35-1.57,PAN HEAD,STL,ZNPL,T-15

CONTACT, SPRING; FRONT PANEL ELEC

SWITCH, KEYPAD, ELASTOMERIC FRONT PANEL, 4 CHANNEL

PARTS REPL KIT; 4CH FRONT PANEL ASSY; MSO3014/3034/3054

PARTS REPL KIT; 2 CH FRONT PANEL ASSY; MSO3012/3032

PARTS REPL KIT; 2 CH FRONT PANEL ASSY; DPO3012/3032/3052