Page 1

xx

DPO2000 and MSO2000 Series

Oscilloscopes

ZZZ

Specifications and Performance Verification

Technical Reference

*P077009600*

077-0096-00

Page 2

Page 3

xx

DPO2000 and MSO2000 Series

Oscilloscopes

ZZZ

Specifications and Performance Verification

Technical Reference

Revision B

This document supports firmware version 1.03 and above

for both MSO2000 Series instruments and DPO2000 Series

instruments.

Warning

The servicing instructions are for use by qualified personnel

only. To avoid personal injury, do not perform any servicing

unless you are qualified to do so. Refer to all safety summaries

prior to performing service.

www.tektronix.com

077-0096-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Tektronix is an authorized licensee of the CompactFlash trademark.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O . Bo x 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

World wi d e, visi t www.tektronix.com to find contacts in your area.

Page 5

Table of Contents

General safety summary .................. .................................. ................................ ...... iii

Specifications .................... ................................ .................................. ................. 1

Performance Verification ................... ................................ .................................. .... 11

Upgrade the

Test Record .............................. ................................ .................................. .... 13

Performance Verification Procedures............. ................................ .......................... 16

Firmware ....................................................................................... 12

DPO2000 and MSO2000 Series Specifications and Performance Verification i

Page 6

Table of Contents

List of Tables

Table 1: Analog channel input and vertical specifications ........................ ............................. 1

Table 2: Dig

Table 3: Horizontal and acquisition system specifications.................. ................................ ... 4

Table 4: Trigger specifications .................................................................................... 5

Table 5: Display specifications.................................................................................... 7

Table 6: Input/Output port specifications ........................................................................ 7

Table 7: Power source specifications.. ................................ .................................. ......... 8

Table 8: D

Table 9: Environmental specifications ............ ................................ ............................... 8

Table 10: Mechanical specifications.............................................................................. 9

Table 11: DC Gain Accuracy Worksheet ....... ................................ ................................ 21

ital channel input specifications, MSO2000 only ....................... ......................... 3

ata storage specifications.............................................................................. 8

ii DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 7

General safety summary

General safet

To avoid fir

e or personal

injury

y summary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

Use proper

certified for the country of use.

Connect a

leads while they are connected to a voltage source.

Ground th

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the p roduct is properly grounded.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

power cord. Use only the power cord specified for this product and

nd disconnect properly. Do not connect or disconnect probes or test

e product. This product is grounded through the grounding conductor

Connect the p robe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Use proper AC adapter. Use only the AC adapter specified for this product.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation. Refer to the manual's installation instructions for details

on installing the product so it has proper ventilation.

DPO2000 and MSO2000 Series Specifications and Performance Verification iii

Page 8

General safety summary

Termsinthismanual

Symbols and terms on the

product

These terms may

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER in

the marking.

WAR NI NG

read the marking.

CAUTIO

The following symbol(s) may appear on the product:

appear in this manual:

dicates an injury hazard immediately accessible as you read

indicates an injury hazard not immediately a ccessible as you

N indicates a hazard to property including the product.

iv DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 9

Specifications

This chapter contains specifications for the DPO2000 and the MSO2000 series

oscilloscopes. All specifications are guaranteed unless noted as "typical."

Typica l spec

Specifications that are marked with the

Ver ification.

All specifications apply to all DPO2000 and MSO2000 models unless noted

otherwise. To meet specifications, two conditions must first be met:

The oscilloscope must have been operating continuously for twenty minutes

within the operating temperature range specified.

You must perform the Signal Path Compensation (SPC) operation prior to

evaluating specifications. (See page 18, Signal Path Compensation (SPC).)

If the operating temperature changes by more than 10 °C (18 °F), you must

perform the SPC operation again.

Table 1: Analog channel input and vertical specifications

Characteristic Description

DPO2012, MSO2012 DPO20x4, MSO20x4Number of input

channels

Input coupling

Input resistance, DC

coupled

Input capacitance, DC

coupled

Maximum input

voltage

C Balance

D

Deskew range ±100 ns, analog channels only

isolation), typical

TekVPI Interface The probe interface allows installing, powering, compensating, and controlling a wide range of probes

Total probe power

2 analog, digitized simultaneously 4 analog, digitized simultaneously

DC, AC, or GND

AC coupling connects a capacitor in series with the input circuitry.

GND coupling provides a reference waveform derived from the values identified during SPC. This reference

waveform shows visually where ground is expected to be.

1MΩ ±2%

11.5 pF ±2 pF

The maximum input voltage at the BNC, between the center conductor and shield is 450 V

duration), 300 V

±(1mV+0.1div)

DPO2024, MSO2024 ≥100:1 with 200 MHz sinewave and equal V/div settings on each channel.Crosstalk (channel

DPO201x, MSO201x ≥100:1 with 100 MHz sinewave and equal V/div settings on each channel.

offering a variety of features

If a probe requires 12 V bulk power, it must be supplied by the Optional External Power Adapter

The interface is available on all front panel inputs including Aux In

50 W from optional 12 V VPI External Power Adapter

Zero 12 V bulk power without optional External Power Adapter

RMS

ifications are provided for your convenience but are not guaranteed.

symbol are checked in Performance

peak

to 4 MHz, derated to 6 V

at 200 MHz.

RMS

(<100 ms

DPO2000 and MSO2000 Series Specifications and Performance Verification 1

Page 10

Specifications

Table 1: Analog channel input and vertical specifications (cont.)

Characteristic Description

Number of digitized

bits

Sensitivity range 2 mV/div to 5 V/div in a 1-2-5 sequence with probe attenuation set to 1X

Position r

Analog bandwidth,

DC coupled

Calculated rise time

Com

rejection ratio (CMRR),

typical

Lower frequency limit,

coupled, typical

AC

pper frequency limit,

U

20 MHz bandwidth

limited, typical

DC gain accuracy

ange

mon mode

8bits

Displayed vertically with 25 digitization levels (DL) per division, 10 divisions dynamic range. Only 8 vertical

divisions are displayed

"DL" is the abbreviation for "digitization level." A DL is the smallest voltage level change that can be

resolved by the 8-bit A-D Converter. This value is also known as the LSB (least signifi cant bit).

±4 divisions

5 mV/div t

with an ambient

temperature of

0°Cto40

Instrument

DPO2024, MSO2024 DC to ≥200 MHz DC to ≥160 MHz

DPO2014, MSO2014,

DPO2012, MSO2012

The rise time i s calculated from the bandwidth of the oscilloscope. The formula accounts for the rise time

ibution of the oscilloscope independent of the rise time of the signal source.

contr

Instrument Risetime

DPO2024, MSO2024

DPO2014, MSO2014,

2012, MSO2012

DPO

:1 at 60 Hz, reducing to 10:1 with 50 MHz sinewave with equal Volts/div and Coupling settings

100

on each channel.

≤10 Hz

0 MHz, +50%, –0%

2

±3%, 5 V/div through 10 mV/div

±4%, 5 mV/div and 2 mV/div

More than shown above when using variable gain

(0 °F to 104 °F)

DC to ≥100 MHz

2.1 ns

3.5 ns

o 5 V/div

°C

5 mV/div t

with an ambient

temperature of

0°Cto50

(0 °F to 122 °F) <5 mV/div

o5V/div

°C

20 MHz

20 MHz

2 DPO2000 and MSO2000 Series Specifications and P erformance Verification

Page 11

Table 1: A nalog channel input and vertical specifications (cont.)

Characteristic Description

DC voltage

measurement

accuracy, Average

acquisition mode,

typical

al offset

Vertic

ranges

Vertical offset

accuracy

Measurement type

Average of ≥ 16 waveforms ±[DC gain accuracy) × |reading - (offset - position)|

Delta Volts between any two averages of ≥16

waveforms acquired with the same oscilloscope

setup and ambient conditions

Note: Offset, position, and the constant offset term must be converted to volts by multiplying by the

appropriate volts/div term.

The basic accuracy specification applies directly to any sample and to the following measurements: High,

Low, Max, and Min. The delta volt accuracy specification applies to subtractive calculations involving

two of these measurements.

The delta volts (difference voltage) accuracy specification applies directly to the following measurements:

Positive Overshoot, Negative Overshoot, Pk-Pk, and Amplitude.

Volts/div setting Offset range

2 m V/div to 200 mV/div

>200 mV/div to 5 V/div

±[0.01 × |offset - position| + DC Balance]

Note: Both the position and constant offset term must be converted to volts by multiplying by the

appropriate volts/div term.

Specifications

DC Accuracy (in volts)

+ Offset A ccuracy]

±[DC gain accuracy × |reading|]

±1 V

±25 V

le 2: Digital channel input specifications, MSO2000 only

Tab

Characteristic Description

reshold voltage range

Th

Digital threshold accuracy

Digital channel timing resolution,

sample rate

Min Detectable Pulse, typical

Number of Input Channels

Input Resistance, typical

Input Capacitance, typical

Min Input Signal Swing, typical

Max Input Signal Swing, typical

Peak Input Voltage Range (DC +

Peak AC)

Digital Channel to Digital Channel

Skew

-20 V to +20 V, selectable in two groups of 8

±[100 mV + 3% of the threshold setting after calibration]

1 ns when the lower ordered group of 8 inputs on the digital probe cable are used exclusively

2 ns whenever inputs from the upper ordered group of 8 inputs on the digital probe cable are

used. That is, all 16 digital channels would be sampled at 2 ns intervals

5ns

16 Digital Inputs

101 kΩ to ground

8pF

500 mV

p-p

±20 V, centered on the threshold voltage

±40 V

2 ns, typical

3ns,maximum

DPO2000 and MSO2000 Series Specifications and Performance Verification 3

Page 12

Specifications

Table 2: Digital channel input specifications, MSO2000 only (cont.)

Characteristic Description

Digital Record Length

1 Million Samples at all time base s ettings when a s ingle set of 8 inputs are used, all from

the same physical half of the digital probe cable

1 Million Samples at time base settings from 100 sec/div to 200 μs/div when inputs from

both halves of the digital probe cable are used

500,000 Samples at time base settings from 100 μs/div to 2 ns/div when inputs from both

halves of the digital probe cable are used

Table 3: H

Characteristic Description

horizontal position time accuracy

Delta time measurement accuracy

Seconds/Division range

FilterVu Peak Detect data record

pulse response

Sample-rate 1 GS/s

Waveform Interpolation Only (sin x)/x interpolation is provided

Record length 1 Million or 100,000 samples per record, user selectable

Waveform update rate Minimum triggered acquisition rate is 5,000 wfm/sec

orizontal and acquisition system specifications

Long-term sample rate and

±25 ppm o

The limits below are for signals having amplitude >5 divisions, slew rate at the measurement

points of >2.0 divisions/ns, and acquired at >10 mV/div:

Condition

Single shot, full bandwidth selected ±[1 Sample Interval + 25 ppm × |reading|

>16 averages, full bandwidth selected ±[1 Sample Interval + 25 ppm × |reading|

Note: The Sample Interval is the time between the samples in the waveform record

Instrument Range

DPO2024,

MSO2024

DPO2014,

MSO2014,

DPO2012,

MSO2012

The minimum single pulse widths for guaranteed 50% or greater amplitude capture:

Instrument Minimum pulse width

DPO2024,

MSO2024

DPO2014,

MSO2014,

DPO2012,

MSO2012

ver any ≥1mstimeinterval

Time Measurement Accuracy

+0.6ns]

+0.4ns]

2 ns/div to 100 sec/div in a 1-2-4 sequence

4 ns/div to 100 sec/div

3.5 ns

7ns

4 DPO2000 and MSO2000 Series Specifications and P erformance Verification

Page 13

Specifications

Table 4: Trigge

rspecifications

Characteristic Description

Aux In (External) trigger maximum

input voltage

At the BNC, between center conductor and shield, is 300 V

above 4 MHz to 6 V

For non-sinu

should be less than 100 ms duration. Signal level must be limited to 300 V

are exceeded, damage to the instrument may result

Aux In (External) trigger input

1MΩ ±2%

resistance

Aux In (Ext

ernal) trigger input

11.5 pF ±2 pF

capacitance

Line Trigg

er

Line Trigger mode provides a source to synchronize the trigger with the AC line input

Matches the AC power Source Voltage and S ource Frequency listed in the Power Supply

System se

pe trigger sensitivity, DC

Edge-ty

coupled

Source

Trigger

Analog inputs

Aux in (External Trigger) 200 mV from DC to 100 MHz, X1 attenuation

Edge trigger sensitivity, not DC

coupled, typical

Trigger Coupling Typical Sensitivity

J

HF RE

LF REJ

NOISE REJ 2.5 times the DC Coupled limits

igger level ranges

Tr

Source Sensitivity

y input channel

An

Aux In (External)

0Hz

Lowest frequency for successful

5

operation of "Set Level to 50%"

function, typical

Trigger level accuracy, DC coupled,

typical

Trigger holdoff range

Video-type trigger sensitivity, typical

±0.2 div for signals within ±4 div from center screen, with rise/fall times ≥20 ns

Aux In: ±200 mV for signals less than ±800 mV, X1 attenuation

20 ns minimum to 8 s maximum

Any analog channel, 0.6 divisions of video sync tip

Aux In does not support Video trigger

Video-type trigger formats and field

rates

Triggers from negative sync composite video, field 1 or field 2 for interlaced systems, on any

field, specific line, or any line for interlaced or non-interlaced systems. Supported systems

include NTSC, PAL, and SECAM.

Logic-type or logic qualified trigger

sensitivity, DC coupled, typical

0.75 division from DC to maximum bandwidth

Aux In does not support Logic trigger

, installation category II; derate

RMS

at 200 MHz

RMS

soidal waveforms, peak value must be less than 450 V. Excursion above 300 V

. If these values

RMS

ction

vity

Sensiti

DC to 50 M

Hz: 0.4 div

>50 MHz to 100 MHz: 0.6 div

>100 MHz to 200 MHz: 0.8 div

Same as DC Coupled limits from DC to

85 kHz. Attenuates signals above 85 kHz

1.2 times the DC Coupled limits for

quencies above 65 kHz. Attenuates

fre

signals below 65 kHz

±4.92 divisions from center of screen

6.25 V, X1 probe attenuation

±

±12.50 V, X10 probe attenuation

DPO2000 and MSO2000 Series Specifications and Performance Verification 5

Page 14

Specifications

Table 4: Trigger specifications (cont.)

Characteristic Description

Pulse-type runt trigger sensitivity,

typical

Pulse-type trigger width sensitivity,

typical

Logic-type triggering, minimum logic

or rearm time, typical

Minimum clock period for setup/hold

time violation trigger, typical

Setup/hold violation trigger, setup

and hold time ranges

Pulse type trigger, minimum pulse,

rearm time, minimum transition time

Rise.fall time trigger, delta time

range

0.75 division from DC to maximum bandwidth

Aux In does not support Pulse trigger

3.5 ns when only using digital channels D0-D7

4.5 ns when using any of the digital channels D8-D15

Aux In does not support Pulse trigger

For all vertical settings, the minimums are:

Trigger type Pulse width Re-arm time Time between

Logic Not applicable 2 ns 1 ns

Time Qualified

Logic

Aux in does not support Logic trigger

1

For Logic, time between channels refers to the length of time a logic state derived from

more than one channel must exist to be recognized. For Events, the time is the minimum time

between a main and delayed event that will be recognized if more than one channel is used.

User Setup Time + User Hold Time + 2 ns, with positive User Times

Feature Min Max

Setup time

Hold time –1 ns 2 s

Setup + Hold time 2 ns (Setup and

Input coupling on clock and data channels must be the same.

For Setup time, positive numbers mean a data transition before the clock.

For Hold time, positive numbers mean a data transition after the clock edge.

Setup + Hold time is the algebraic sum of the Setup Time and the Hold Time programmed by

the user.

Aux in does not support this trigger type

Pulse class Minimum pulse

Runt 2 ns 2 ns

Width 2 ns 2 ns

Rise/Fall time

For the trigger class width and the trigger class runt, the pulse width refers to the width of the

pulse being measured. The rearm time refers to the time between pulses.

For the trigger class Rise/Fall time, the pulse width refers to the delta time being measured.

The rearm time refers to the time it takes the signal to cross the two trigger thresholds again.

4nsto8s

Aux in does not support this trigger type

channels

4ns 2ns 1ns

–100 ns 2 s

4s

hold times cannot

both be negative)

Minimum rearm time

width

2ns 2ns

1

6 DPO2000 and MSO2000 Series Specifications and P erformance Verification

Page 15

Specifications

Table 4: Trigger specifications (cont.)

Characteristic Description

Time range for pulse width or runt

triggering

Time accuracy for Pulse Width

triggering

Time Resolution, Logic Type

Triggers

Trigger Frequency C ounter Provides the user a higher accuracy means of identifying the frequency of trigger signals.

Trigger Frequency Counter

Resolution

Trigger Frequency Counter Accuracy ±25 ppm including all reference errors and ±1 count errors

Trigger Frequency Counter

Frequency Range

Trigger Frequency Counter Signal

Source

1

For Logic, time between channels refers to the length of time a logic state derived from more than one channel must exist to be recognized. For Events, thetime

is the minimum time between a main and delayed event that will be recognized if more than one channel is used.

4nsto8s

The digital inputs do not support the runt trigger type

±2 ns

1ns

Averaging takes place over a longer time span, so the number of stable digits is improved

over the Automatic Measurement of the same type

6digits

AC coupled, 10 Hz minimum to rated bandwidth

Edge selected trigger source only

Table 5: Display specifications

racteristic

Cha

Display type

splay resolution

Di

Luminance, typical

ription

Desc

play area: 154.8 mm (6.09 inches) (H) x 87.05 mm (3.43 inches) (V), 180 mm (7.0 inches)

Dis

diagonal, 6-bit RGB full color, WQVGA (480 x 234) TFT liquid crystal display (LCD).

0 horizontal by 234 vertical displayed pixels

48

ximum 400 cd/m

Ma

2

Table 6: Input/Output port specifications

Characteristic Description

Ethernet interface Available as an optional accessory: DPO2CONN module

USB interface 1 High Speed 2.0 Host and 1 High Speed Device connector (all models)

GPIB interface Available as an optional accessory that connects to USB Device and USB Host ports:

TEK-USB-488 GPIB to USB Adapter.

Control interface is incorporated in the instrument user interface.

Video signal output

Probe compensator output voltage

and frequency, typical

Available as an optional accessory: DPO2CONN module

A 15 pin, VGA RGB-type connector

Output voltage: 0 V to 5 V ±10%

Frequency: 1 kHz ±25%

DPO2000 and MSO2000 Series Specifications and Performance Verification 7

Page 16

Specifications

Table 7: Power s

ource specifications

Characteristic Description

Source voltage 100 V

RMS

to 240 V

±10%, installation category II

RMS

Source frequency (90 V to 264 V ) 44 Hz to 65 Hz

(100 V to 132 V) 360 Hz to 440 Hz

Power Consumption

<80 W at 85 to 275 V

AC

input

Table8:Datastoragespecifications

Characteristic Description

Nonvolatile memory retention time,

No time limit for front-panel settings, saved waveforms, setups, and calibration constants

typical

Real-time clock A programmable clock providing time in years, months, days, hours, minutes, and seconds

Table 9: Environmental specifications

eristic

Charact

Temperature

Descrip

Operat

Nonoperating:

dity

Humi

Operating:

Nonoperating:

Altitude

Ope

Nonoperating: 12,000 m (39,370 ft)

Altitude is limited by possible damage to LCD at higher altitudes, independent of operation

Pollution Degree Pollution Degree 2, indoor use only

tion

ing:

0°Cto+50°C(+32°Fto+122°F),with 5 °C/minute maximum gradient,

non-condensing, up to 3000 m altitude. Instrument will be in specification after a 10

settling time and performance of SPC

minute

-40 °C to +71 °C (-40 °F to +160 °F), with 5 °C/minute maximum gradient. Instrument

einspecification after 5 minutes powered for each 5 °C change settling time

will b

and performance of SPC

High: 5% to 60% relative humidity, 30 °C to 50 °C (86 °F to 122 °F)

5% to 95% relative humidity, 0 °C to 30 °C (32 °F to 86 °F)

Low:

High: 5% to 60% relative humidity, 30 °C to 55 °C (86 °F to 131 °F)

: 5% to 95% relative humidity, 0 °C to 30 °C (32 °F to 86 °F)

Low

rating: 3,000 m (9,843 ft)

8 DPO2000 and MSO2000 Series Specifications and P erformance Verification

Page 17

Specifications

Table 10: Mecha

Characteristic Description

Dimensions Nominal, non-

Weight Nominal, n

Cooling method Forced air cooled, one fan

Clearance Requirements The clearance requirement for adequate cooling is:

nical specifications

rack mount:

Height:

Handle down: 175 mm (6.89 in)

Handle up: 18

Depth:

Handle down: 146 mm (5.74 in)

Handle up: 1

Width: 377 mm (14.85 in) from handle hub to handle hub

on-rack mount:

Stand-alone instrument: 3.6 kg (7.9 lbs)

Packaged for domestic shipment: 6.2 kg (13.7 lbs)

50 mm (2 in

0 mm (7.09 in)

34 mm (5.29 in)

) on the left side (when looking at the front of the instrument)

DPO2000 and MSO2000 Series Specifications and Performance Verification 9

Page 18

Specifications

10 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 19

Performance Verification

This chapter contains performance verification procedures for the specifications

marked with the

required to c

Description Minimum requirements Examples

DC voltage source 3 mV to 4 V, ±0.1% accuracy

Leveled sin

Time mark generator 1 ms period, ±1 ppm accuracy, rise time

One 50 Ω BNC cable

One 50 Ω feedthrough termination BNC male and BNC female connectors

For MSO2000 Series only:

One P6316 digital probe

One BNC-to-0.1 inch pin adapter BNC to 0.1 inch spaced pins An appropriate BNC-to-0.1 inch pin

e wave generator

omplete these procedures.

50 kHz to 1000 MHz, ±4% amplitude

accuracy

<25ns

Male-to-male connectors Tektronix part number 012-0057-01

16 channel digital probe Tektronix P6316

You may need additional cables and adapters, depending on the actual test

equipment you use.

symbol. The following equipment, or a suitable equivalent, is

Fluke 9500 Oscilloscope Calibrator with a

9510 Output Module

Tektronix part number 011-0049-02

er for use between the Fluke 9500

adapt

and the P6316 probe

These procedures cover all DPO2000 and MSO2000 models. Please disregard

checks that do not apply to the specific model you are testing.

Print the test record, on the following pages, and use it to record the performance

test results for your oscilloscope.

NOTE. Completion of the performance verification procedure does not update

he stored time and date of the latest successful adjustment. The date and time

t

are updated only when the adjustment procedures in the service manual are

successfully completed.

The performance verification procedures verify the performance of your

instrument. They do not adjust your instrument. If your instrument fails any of

the performance verification tests, you should perform the factory adjustment

procedures as described in the DPO2000 and MSO2000 Series Service Manual.

NOTE. If your oscilloscope firmware version is v1.02, it should be updated

before performing the Performance Verification procedures. Download the latest

firmware from www.tektronix.com/software.

DPO2000 and MSO2000 Series Specifications and Performance Verification 11

Page 20

Performance Verification

Upgrade the Firmware

For the best functionality, you can upgrade the oscilloscope firmware. To upgrade

the firmware, follow these steps:

1. Open up a Web browser and go to www.tektronix.com/software. Use the

Software and Firmware Finder to locate the most recent firmware upgrade.

2. Download the latest firmware for your oscilloscope onto your PC.

3. Unzip the files and copy the "firmware.img" file into the root folder of a

USB flash drive.

4. Power off your oscilloscope.

5. Insert th

oscilloscope.

6. Power on

replacement firmware and installs it.

If the i

numbers. This update procedure will fail if the version you are trying to load

is the same as the version that is in the instrument. If the version numbers are

different, rerun the procedure. If the problem continues, contact qualified

service personnel.

NOTE. Do not power off the oscilloscope or remove the USB flash d rive until the

lloscope finishes installing the firmware.

osci

The oscilloscope displays a message when the installation is complete.

7. Power off the oscilloscope and remove the USB flash drive.

8. Power on the oscilloscope.

9. Push the Utility front-panel button.

10. Push the Utility Page lower-bezel button.

eUSBflash drive into a USB Host port on the front of the

the oscilloscope. The oscilloscope automatically recognizes the

nstrument does not install the firmware, first check the firmware version

11. Turn Multipurpose knob a to select Config.

12. Push the About lower-bezel button. The oscilloscope displays the firmware

version number.

13. Confirm that the version number matches that of the new firmware.

12 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 21

Performance Verification

Test Record

Model Serial Procedure performed by Date

Test Passed Failed

Self Test

Signal Path Compensation ( SPC)

Performance Checks

DC Balance

Channel Coupling Low limit Test result High limit

Channel 1

DC

GND

Channel 2

DC

GND

Channel 3

1

DC

GND

Channel 4

1

DC

GND

1

Channels 3 and 4 are only on four channel oscilloscopes

-21 mV 21 mV

-21 mV 21 mV

-21 mV 21 mV

-21 mV 21 mV

-21 mV 21 mV

-21 mV 21 mV

-21 mV 21 mV

-21 mV 21 mV

DC Gain Accuracy

Channel Vertical scale Low limit Test result High limit

Channel 1

5 mV/div

200 mV/div

2V/div

Channel 2

5 mV/div

200 mV/div

2V/div

Channel 3

1

5 mV/div

200 mV/div

2V/div

Channel 4

1

5 mV/div

200 mV/div

2V/div

1

Channels 3 and 4 are only on four channel oscilloscopes

33.6 mV 36.4 mV

1.358 V 1.442 V

13.58 V 14.42 V

33.6 mV 36.4 mV

1.358 V 1.442 V

13.58 V 14.42 V

33.6 mV 36.4 mV

1.358 V 1.442 V

13.58 V 14.42 V

33.6 mV 36.4 mV

1.358 V 1.442 V

13.58 V 14.42 V

DPO2000 and MSO2000 Series Specifications and Performance Verification 13

Page 22

Performance Verification

Bandwidth

Channel Low limit Test result High limit

Channel 1

Channel 2

Channel 3

Channel 4

1

1

1

Channels 3 and 4 are only on four channel oscilloscopes

2.12 V

2.12 V

2.12 V

2.12 V

Vertical Position Range

Channel V/div setting

Channel 1

200 mV/div

5V/div

Channel 2

200 mV/div

5V/div

Channel 3

1

200 mV/div

5V/div

Channel 4

1

200 mV/div

5V/div

1

nnels 3 and 4 are only on four channel oscilloscopes.

Cha

Trace

position Offset DC Voltage source Pass/Fail

Top –1 V –1.800 V

Bottom +1 V +1.800 V

Top –25 V –45.0 V

Bottom +25 V +45.0 V

Top –1 V -1.800 V

Bottom +1 V +1.800 V

Top –25 V –45.0 V

Bottom +25 V +45.0 V

Top –1 V –1.800 V

Bottom +1 V +1.800 V

Top –25 V –45.0 V

Bottom +25 V +45.0 V

Top –1 V –1.800 V

Bottom +1 V +1.800 V

Top –25 V –45.0 V

Bottom +25 V +45.0 V

——

——

——

——

Sample Rate and Delay Time Accuracy Low limit Test result High limit

Sample Rate and Delay Time Accuracy

-2.5 divisions +2.5 divisions

14 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 23

Digital Threshold Accuracy, MSO2000 series only

Digital

channel Threshold V

s-

0 V -0.1 V 0.1 VD0

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD1

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD2

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD3

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD4

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD5

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD6

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD7

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD8

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD9

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD10

4 V 3.78

0 V -0.1 V 0.1 VD11

4 V 3.78 V 4.22 V

D12

0V -0.

4 V 3.78 V 4.22 V

0 V -0.1 V 0.1 VD13

4V 3.

0 V -0.1 V 0.1 VD14

4 V 3.78 V 4.22 V

15

D

V

0

4 V 3.78 V 4.22 V

Performance Verification

Test result

V

s+

Low limit

V

1V

78 V

0.1 V

-

V

sAvg

High limit

V

4.22

V

0.1

22 V

4.

.1 V

0

DPO2000 and MSO2000 Series Specifications and Performance Verification 15

Page 24

Performance Verification

Performance V

erification Procedures

NOTE. If your oscilloscope firmware version is v1.02, it should be updated

before performing the Performance Verification procedures. Download the latest

firmware from www.tektronix.com/software.

The following three conditions must be met prior to performing these procedures:

1. The oscilloscope must have been operating continuously for twenty (20)

minutes in an environment that meets the operating range specifications for

temperature and humidity.

2. You must perform a signal path compensation (SPC) before beginning these

procedures. (See page 18, Signal Path Compensation (SPC).) If the operating

temperature changes by more than 10 °C (18 °F), you must perform the signal

path compensation again.

3. You must connect the oscilloscope and the test equipment to the same AC

power circuit. Connect the oscilloscope and test instruments into a common

power

the oscilloscope and test instruments into separate AC power circuits can

result in offset voltages between the equipment, which can invalidate the

performance verification procedure.

strip if you are unsure of the AC power circuit distribution. Connecting

Self Test

The time required to complete the entire procedure is approximately one hour.

NOTE. The buttons on the oscilloscope toggle the various menu visibilities. If a

menu is not visible, push the respective menu button again.

WARNING. Some procedures use hazardous voltages. To prevent electrical

shock, always set voltage source outputs to 0 V before making or changing any

interconnections.

This procedure uses internal routines to verify that the oscilloscope functions and

passes its internal self tests. No test equipment or hookups are required. Start

the self test with these steps:

1. Disconnect all probes and cables from the oscilloscope inputs.

2. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

3. Push the Utility menu button.

4. Push the Utility Page lower-bezel button, and turn Multipurpose knob a to

select Self Test.

16 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 25

Performance Verification

5. Push the Self Te

will be set to Loop 1 Times.

st lower-bezel button. The Loop X Times side-bezel menu

DPO2000 and MSO2000 Series Specifications and Performance Verification 17

Page 26

Performance Verification

Signal Path

Compensation

(SPC)

6. Push the OK Run S

7. Wait while the self test runs. When the self test completes, a dialog box

displays the r

8. Push the Menu Off button to clear the dialog box and Self Test menu.

This process corrects for DC inaccuracies caused by temperature variations

and/or long term drift.

1. Remove all input signals (probes and cables) from channel inputs. Input

signals with AC components adversely affect SPC.

2. Push the front-panel Utility button, and then push the bottom-bezel Utility

Page button.

3. Use Multipurpose knob a to select Calibration.

4. Push the bottom-bezel Signal Path button, and then push the side-bezel OK

Compensate Signal Paths button.

5. Wait while the Signal Path Compensation runs. On completion a dialog box

informs you whether the Compensation completed successfully or not.

6. Push the Menu Off button to clear the dialog box and Self Test menu.

esults of the self test.

elf Test side-bezel button.

Check DC Balance

test checks the DC balance of each channel.

This

You do not need to connect the oscilloscope to any equipment to run this test.

1. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

2. Turn the Horizontal Scale knobto1ms/div.

3. Push the Trigger Menu front-panel button.

18 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 27

Performance Verification

4. Push the Source

5. Select the AC Line trigger source with Multipurpose knob a. You do not need

to connect an e

6. Push the front-panel Acquire button.

7. Push the Average lower-bezel button, and then push the Average side bezel

button to turn averaging ON.

NOTE. When

before taking the measurement.

8. If needed

9. Push the front-panel channel button for the oscilloscope channel to test, as

shown in

10. Set the channel being tested to 200 mV/div using the Vertical Scale knob.

11. Attach a 50 Ω terminator to the oscilloscope input channel being tested.

12. Push the lower-bezel Coupling button to select DC or GND coupling, as

given in the test record.

using averaging, allow the oscilloscope to acquire all the samples

, adjust the number of averages to 16 with Multipurpose knob a.

thetestrecord(forexample,1,2,3,or4).

lower-bezel button.

xternal signal to the oscilloscope for this DC Balance test.

13. Push the front-panel Wave Inspector Measure button.

14. Push the Add Measurement lower bezel button.

15. Use Multipurpose knob a to select the Mean measurement.

16. Pus

17.Vi

18.R

NOTE. When using averaging, make sure to allow the oscilloscope to acquire all

the samples before taking the measurement.

19. Repeat steps 9 through 18 for each remaining channel.

htheOK Add Measurement side-bezel button, and then push the Menu

Off button.

ew the mean measurement value in the display and enter that mean value

as the test result in the test record.

epeat step 9, then steps 12 through 17.

DPO2000 and MSO2000 Series Specifications and Performance Verification 19

Page 28

Performance Verification

Check DC Gain Accuracy

This test check

s the DC Gain Accuracy of each channel.

1. Push the front-panel Default Setup button to set the instrument to the factory

default setti

ngs.

2. Push the front-panel Horizontal Acquire button, then push the bottom-bezel

Average but

ton, and then push the side-bezel Average button, to turn

averaging on.

NOTE. When using averaging, allow the oscilloscope to acquire all the samples

before taking the measurement.

3. If necessary, use Multipurpose knob a to set the number of averages to 16.

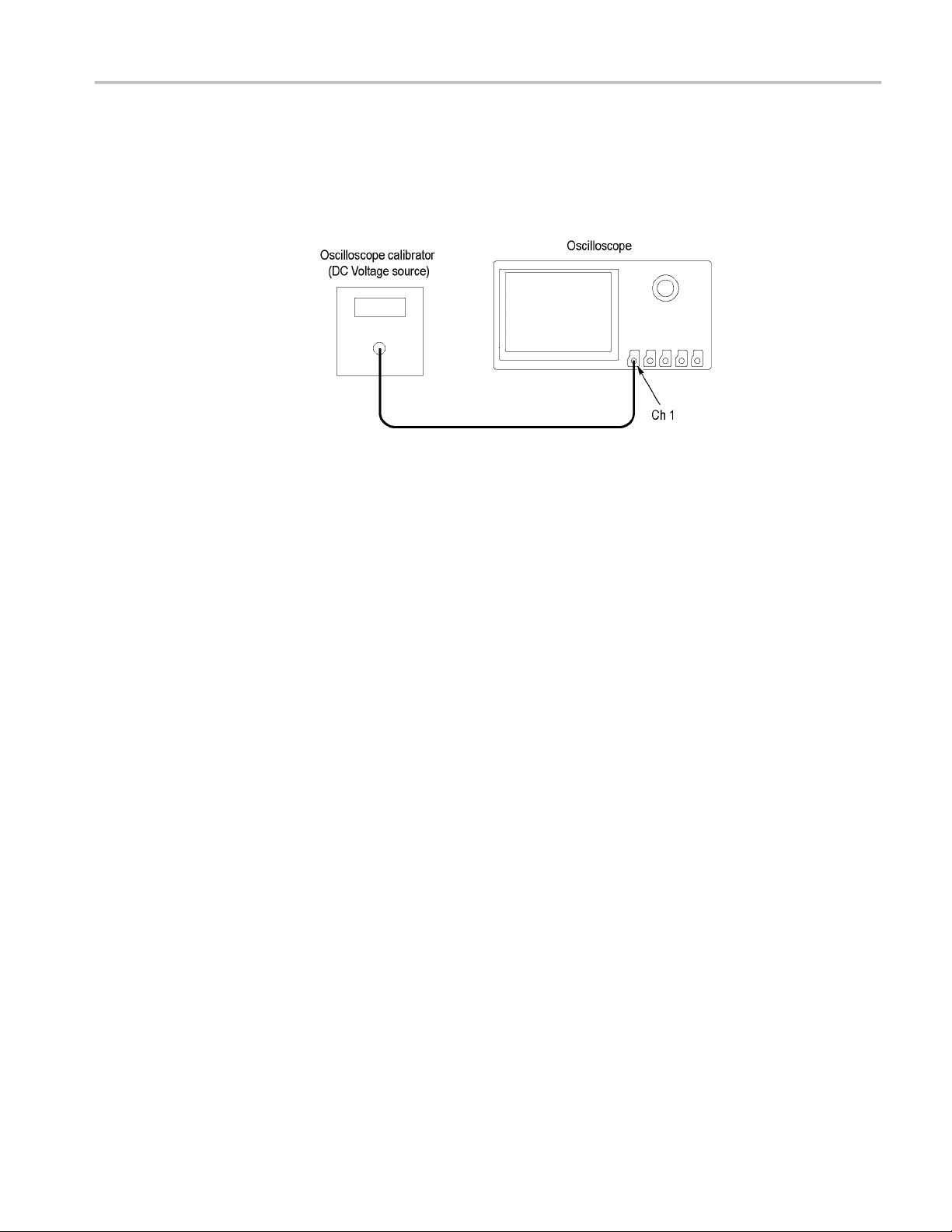

4. Set the DC voltage source to 0 V, and then connect it to channel 1, as shown.

If using a Fluke 9500 as the voltage source, connect the calibrator head to

channel 1.

5. Push the front panel button to select the channel to be tested (1, 2, 3, or 4)

6. Push the bottom-bezel Probe Setup button, and then push the Set to 1X

side-bezel button.

7. PushtheWaveInspectorMeasure button, and then push the bottom-bezel

Add Measurement button.

8. Use Multipurpose knob a to select the Mean measurement, then push the

side-bezel OK Add Measurement button, and then push the Menu Off

button.

9. For each Volts/div line in the following worksheet, perform these steps:

a. Set the channel’s volts/div to the value listed in the worksheet.

b. Set the DC voltage source output level to the positive voltage listed a nd

record the Mean measurement as V

pos

.

c. Set the DC voltage source to the negative level listed, and record the

Mean measurement as V

neg

.

20 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 29

Performance Verification

d. Calculate V

e. Enter V

Table 11: DC Gain Accuracy Worksheet

Vol ts/di v

setting Positive Negative V

Channel 1

5 mV/div

200 mV/div

2V/div

Channel 2

5 mV/div

200 mV/div

2V/div

1

Channel 3

5 mV/div

200 mV/div

2V/div

1

Channel 4

5 mV/div

200 mV/div

2V/div

1

Channels 3 and 4 are only on four channel oscilloscopes.

DC voltage source setting

+17.5 mV –17.5 mV 33.6 mV to 36.4 mV

+700 mV –700 mV 1.358 V to 1.442 V

+7.00 V –7.00 V 13.58 V to 14.42 V

+17.5 mV –17.5 mV 33.6 mV to 36.4 mV

+700 mV –700 mV 1.358 V to 1.442 V

+7.00 V –7.00 V 13.58 V to 14.42 V

+17.5 mV –17.5 mV 33.6 mV to 36.4 mV

+700 mV –700 mV 1.358 V to 1.442 V

+7.00 V –7.00 V 13.58 V to 14.42 V

+17.5 mV –17.5 mV 33.6 mV to 36.4 mV

+700 mV –700 mV 1.358 V to 1.442 V

+7.00 V –7.00 V 13.58 V to 14.42 V

diff=Vpos–Vneg

, and then enter V

example, on the 5 mV/div setting, if V

mV, then V

is 34.6 mV.

diff

in the worksheet, and in the t est record.

diff

pos

V

neg

in the test record. As an

diff

is 17.4 mV and V

pos

V

diff

is -17.2

neg

Accuracy limits

for V

diff

Check Bandwidth

10. Set the DC voltage source to 0 V, and move the BNC cable to the next

channel to be tested.

11. Repeat steps 5 through 10 for each remaining channel.

This test checks the bandwidth of all input channels.

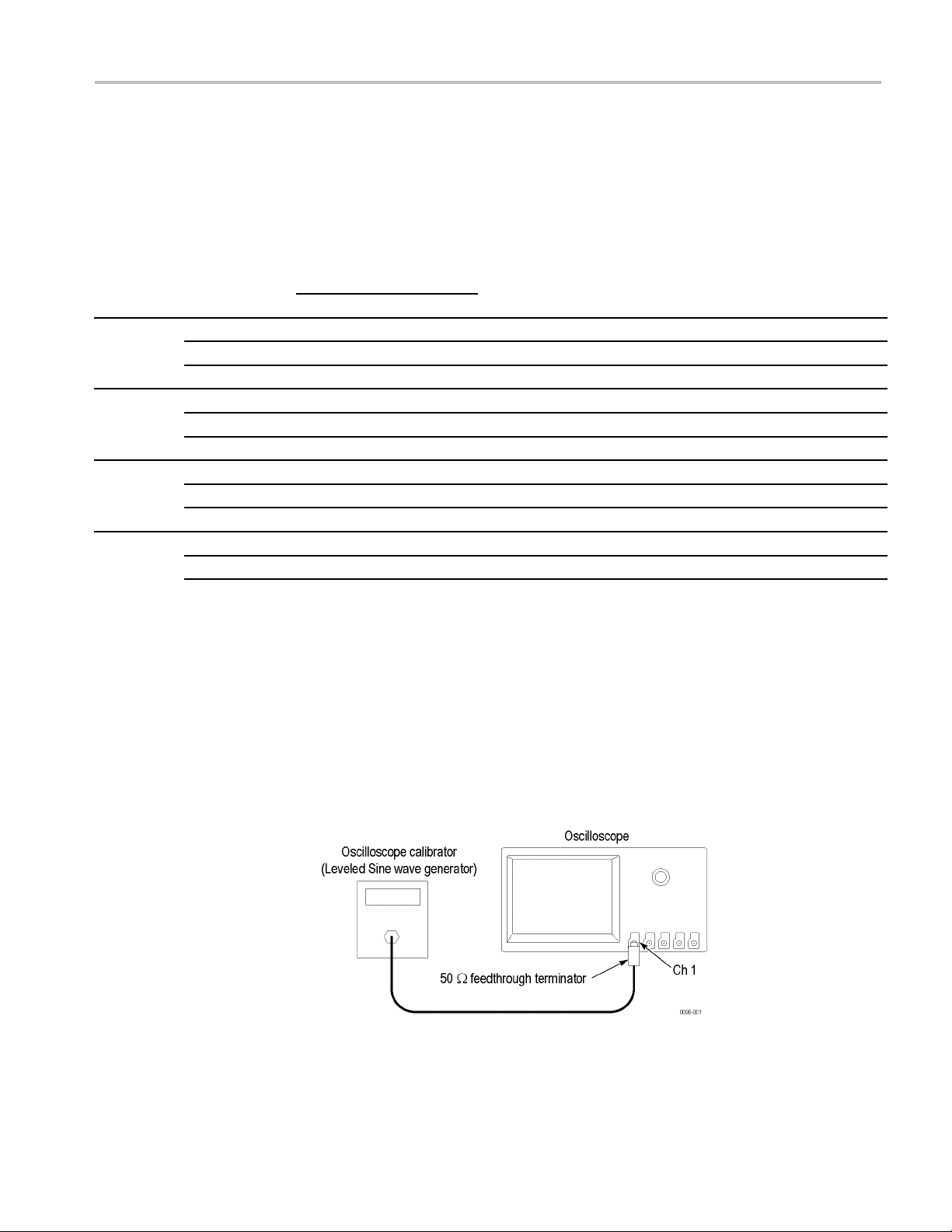

1. Connect the output of the leveled sine wave generator (for example, Fluke

9500) to the oscilloscope channel 1 input as shown below.

2. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

DPO2000 and MSO2000 Series Specifications and Performance Verification 21

Page 30

Performance Verification

3. Push the front-

panel Trigger Menu button.

4. Push the lower-bezel Coupling button, and then push the Noise Reject (DC

Low Sensitivi

ty) side-bezel button.

5. Push the Menu Off button 2 times, so you can see the screen.

6. Push the front-panel Trigger Menu button.

7. Push the lower-bezel Source button and use Multipurpose knob a to select the

channel being tested as the trigger source.

8. Push the channel button (1, 2, 3, or 4) for the channel that you want to check.

9. Push the lower-bezel Probe Setup button, and then push the Setto1X

side-bezel button.

10. Push the front-panel Measure button, and then push the bottom-bezel Add

Measurement button.

11. Use Multipurpose knob a to select the Peak-to-peak measurement, and then

push the OK Add Measurement side-bezel button.

12. Push the Menu Off button 2 times, so you can see the screen.

13. Turn the Vertical Scale knob to set the vertical scale to 500 mV/div.

14. Turn t

he Horizontal Scale knob to 400 μs/div.

15. Set the leveled sine wave generator frequency to 1kHz.

16. Set the leveled sine wave generator output level so the peak-to-peak

measurement is between 2.98 V and 3.02 V.

17. Set the leveled sine wave generator to the frequency shown for the

oscilloscope model:

Model Frequency

DPO2024, MSO2024

DPO2012, DPO2014, MSO2012, MSO2014

200 MHz

100 MHz

18. Use the Horizontal Scale knob to set the oscilloscope to 10 ns/div.

19. Check that the peak-to-peak measurement is ≥2.12 V. Enter this measurement

in the test record.

20. Move the input cable to the next channel to be tested.

21. Repeat steps 6 through 20 for each remaining channel.

22 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 31

Performance Verification

Check Vertical Position

Range

This test check

1. Connect the oscilloscope to a DC voltage source to run this test. If using the

Fluke calibrator as the DC voltage source, connect the calibrator head to the

oscilloscope channel to test.

2. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

3. Push the channel button (1, 2, 3, or 4) for the channel th

4. Push the bottom-bezel Probe Setup button, and then push the Set to 1 X

side-bezel button.

5. Use the Vertical Scale knob to set the oscilloscope to 200 mV/div.

s the offset range for each channel.

atyouwanttocheck.

6. Use the Vertical Position knob to place the trace at the bottom of the display

(-4 divisions).

7. Set the Offset to +1 V:

a. Push the bottom-bezel More button to select Offset.

b. Use Multipurpose knob a to set the offset to 1.000 V.

8. Set the DC Voltage source to +1.800 V.

9. Check that the vertical trace is now with in 0.2 divisions of the Zero volt line.

Record Pass or Fail in the test record.

10. Set the DC Voltage source to 0 V.

11. Push the Set to 0V side-bezel button.

12. Use the Vertical Position knob to place the trace at the top of the display

(+4 divisions).

13. Use Multipurpose knob a to set the offset to –1.000 V.

14. Set the DC Voltage source to –1.800 V.

15. Check that the vertical trace is now within 0.2 div

Record Pass or Fail in the test record.

16. Set the DC Voltage source to 0 V.

isions of the Zero volt line.

DPO2000 and MSO2000 Series Specifications and Performance Verification 23

Page 32

Performance Verification

17. Push the Set to 0

18. Use the Vertical Scale knob to set the oscilloscope to 5 V/div.

19. Use the Vertical Position knob to place the trace at the bottom of the display

(-4 divisions).

20. Use Multipurpose knob a to set the offset to +25.00 V.

21. Set the DC Voltage source to +45 V.

22. Check that the vertical trace is now within 0.2 divisions of the Zero volt line.

Record Pass or Fail in the test record.

23. Set the DC Voltage source to 0 V.

24. Push the Set to 0V side-bezel button.

25. Use the V

(+4 divisions).

26. Use Mul

27. Set the DC Voltage source to –45 V.

28. Check that the vertical trace is now within 0.2 divisions of the Zero volt line.

Record Pass or Fail in the test record.

ertical Position knob to place the trace at the top of the display

tipurpose knob a to set the offset to –25.00 V.

V side-bezel button.

29. Set the DC Voltage source to 0 V.

30. Push the Set to 0V side-bezel button.

31. Move the DC Voltage source cable to the next channel to b e tested.

32. Push the channel button (1, 2, 3, or 4) for the next channel to check.

33.Re

peat steps 4 through 32 for each of the remaining channels.

24 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 33

Performance Verification

Check Sample Rate and

Horizontal Pos itio n Time

Accuracy

This test check

s the sample rate and horizontal position time accuracy (time base).

1. Connect the output of the time mark generator to the oscilloscope

channel 1 inpu

tusinga50Ω cable and 50 Ω feedthrough terminator.

2. Set the time mark generator period to 1ms. Use a time mark waveform with a

fast rising edge.

3. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

4. Push the channel 1 button.

5. Push th

e lower-bezel Probe Setup button, and then push the Setto1X

side-bezel button.

6. Set th

e Vertical SCALE to 500 mV/div.

7. Set the Horizontal SCALE to 1ms/div.

8. If adjustable, set the time mark generator amplitude to approximately 1V

p-p

9. Push the Trigger Level knob, to set the trigger level to 50%.

10. Adjust the Vertical POSITION knob to center the time mark signal vertically

on the screen.

11. If necessary, adjust the Horizontal POSITION knob to move the trigger

location to the center of the screen (50%).

12. Turn the Horizontal POSITION knob counterclockwise to set the delay to

close to 1ms.

13. Set the Horizontal Scale to 10 ns/div.

.

DPO2000 and MSO2000 Series Specifications and Performance Verification 25

Page 34

Performance Verification

Check Digital Threshold

Accuracy (MSO2000 Series

only)

14. If necessary, t

1.0000 ms.

15. Compare the ri

line. The rising edge should cross the 0 V center within ±2.5 divisions

(±25 ns) of the center graticule line. Enter the deviation in the test record.

NOTE. One division of displacement from graticule center corresponds to a

10 ppm time base error.

For the MSO2000 series only, this test checks the threshold accuracy of the digital

channels. This procedure applies to digital channels D0 through D15, and to

channel threshold values of 0 V and +4 V.

1. Connect the P6316 digital probe to the MSO2000 series instrument.

urn the Horizontal Position knob to set the delay to exactly

sing edge of the marker with the center horizontal graticule

2. Connect one of the digital channels, such as D0, to the DC voltage source to

run this test.

If using the Fluke calibrator as the DC voltage source, connect the calibrator

head to the digital channel to test. You will need a BNC-to-0.1 inch pin

adapter to complete the connection. Be sure to connect the digital channel to

the corresponding signal pin and to a ground pin on the adapter.

3. Push the front-panel Default Setup button to set the instrument to the factory

default settings.

4. Push the front-panel D15-D0 button.

5. Push the D15-D0 On/Off lower-bezel button.

6. Push the Tu rn On D7 - D 0 and the Turn On D15 - D8 side-bezel buttons.

The instrument will display the 16 digital channels.

7. Push the Thresholds lower-bezel button.

26 DPO2000 and MSO2000 Series Specifications and Performance Verification

Page 35

Performance Verification

8. Push the side-b

ezel D7 - D0 button.

Before you change the threshold value, push the Fine front-panel button to

turn off the fin

e adjustment and make adjusting the value quicker.

9. Use Multipurpose knob a to set the D7-D0 threshold level to 0V.

10. Use Multipurpose knob b to set the D15-D8 threshold level to 0V.

The thresholds are now set for the 0 V threshold check, shown in steps 11

through 18.

11. Push the front-panel Trigger Menu button.

12. Push the Source lower-bezel button, and turn Multipurpose knob a to select

the appropriate channel, such as D0.

By default, the Type is set to Edge, Coupling is set to DC, Slope is set to

Rising, Mode is set to Auto, and Level is set to match the threshold of the

channel being tested.

13. Set the DC voltage source (Vs) to -400 mV. Wait 1 second. Check the logic

level of the corresponding digital channel in the display.

If the channel is a static logic level high, change the DC voltage source Vs

to -500 mV.

14. Increment Vs by +10 mV. Wait 1 second and check the logic level of the

corresponding digital channel in the display. If the channel is at a static logic

level high, record the Vs value as V

in the 0 V row of the test record.

s-

If the channel is a logic level low or is alternating between high and low,

repeat this step (increment Vs by 10 mV, wait 1 second, and check for a static

gic high) until a value for V

lo

is found.

s-

15. Push the Slope lower-bezel button to change the slope to Falling.

16. Set the DC voltage source (Vs) to +400 mV. Wait 1 second. Check the logic

level of the corresponding digital channel in the display.

If the channel is a static logic level low, change the DC voltage source Vs

to +500 mV.

17. Decrement Vs by -10 mV. Wait 1 second and check the logic level of the

corresponding digital channel in the display. If the channel is at a static logic

level low, record the Vs value as V

in the 0 V row of the test record.

s+

If the channel is a logic level high or is alternating between high and low,

repeat this step (decrement Vs by 10 mV, wait 1 second, and check for a static

logic low) until a value for V

18. Find the average, V

=(Vs-+Vs+)/2. Record the average as the test result

sAvg

is found.

s+

in the test record.

DPO2000 and MSO2000 Series Specifications and Performance Verification 27

Page 36

Performance Verification

Compare the tes

t result to the limits. If the result is between the limits,

continue with the procedure to test the channel at the +4 V threshold value.

19. The remaining part of this procedure is for the +4 V threshold test. Push the

front-panel D15-D0 button. The Thresholds menu should display.

20. With the Fine front-panel button turned off, turn Multipurpose knob a to set

the D7–D0 threshold value to 4.00 V (+4.0 V/div).

21. Turn Multipurpose knob b to set the D15–D8 threshold value to 4.00 V

(+4.0 V/div). To remove the menu from the display, push the front-panel

Menu Off button.

22. Set the DC voltage source (Vs) to +4.4 V. Wait 1 second. Check the logic

level of the corresponding digital channel in the display.

If the channel is a static logic level low, change the DC voltage source Vs to

+4.5 V.

23. Decrement Vs by -10 mV. Wait 1 second and check the logic level of the

corresponding digital channel in the display. If the channel is at a static logic

level low, record the Vs value as V

in the 4 V row of the test record.

s+

If the channel is a logic level high or is alternating between high and low,

repeat this step (decrement Vs by 10 mV, wait 1 second, and check for a static

logic low) until a value for V

is found.

s+

24. Push the front-panel Trigger Menu button.

25. Push the Slope lower-bezel button to change the slope to Rising.

26. Set the DC voltage source (Vs) to +3.6 V. Wait 1 second. Check the logic

level of the corresponding digital channel in the display.

If the channel is a static logic level high, change the DC voltage source V

sto

+3.5 V.

27. Increment Vs by +10 mV. Wait 1 second and check the logic level of the

corresponding digital channel in the display. If the channel is at a static logic

level high, record the Vs value as V

in the 4 V row of the test record.

s-

If the channel is a logic level low or is alternating between high and low,

repeat this step (increment Vs by 10 mV, wait 1 second, and check for a static

logic high) until a value for V

28. Find the average, V

sAvg

=(Vs-+Vs+)/2. Record the average as the test result

is found.

s-

in the test record.

Compare the test result to the limits. If the result is between the limits, the

channel passes the test.

29. Repeat the procedure starting with step 12 for each remaining digital channel,

D1 through D15.

This completes the performance verification procedure.

28 DPO2000 and MSO2000 Series Specifications and Performance Verification

Loading...

Loading...