Page 1

x

DPO2000 and MSO2000 Series

Oscilloscopes

ZZZ

User Manual

*P071231902*

071-2319-02

Page 2

Page 3

xx

DPO2000 and MSO2000 Series

Oscilloscopes

ZZZ

User Manual

www.tektronix.com

071-2319-02

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

e*Scope, FilterVu, OpenChoice, TekSecure, and TekVPI and Wave Inspector are registered trademarks of Tektronix, Inc.

PictBridge is a registered trademark of the Standard of Camera & Imaging Products Association CIPA DC-001-2003 Digital Photo

Solutions for Imaging Devices.

Contacting

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

Tektronix

Page 5

MSO2000 and DPO 2000 Series Oscilloscopes

Warranty

Tektronix warrants that the product will be free from defects in materials and workmanship for a period of three (3) years from the date

of original pu

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Batteries are excluded from this warranty. Parts, modules and replacement products used by Tektronix for warranty

work may be ne

rchase from an authorized Tektronix distributor. If the product proves defective during this warranty period, Tektronix, at its

w or reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to ob

period and make suitable arrangements for the performance of s ervice. Customer shall be responsible for packaging and shipping

the defective product to the service center designated by Tektronix, shipping charges prepaid, and with a copy of customer proof of

purchase. T

the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other

charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tekt

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to serv

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS

IS THE SOLE AND E XCLU S IVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. T EKT RONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPE

DAMAGES.

[W16 – 15AUG04]

tain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty

ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which

ronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

ice a product that has been modified or integrated with other products when the effect of such modification or integration

FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

CTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE N OTICE OF THE PO SSIBILITY OF SUCH

Page 6

P2221 Probe

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from the date of

shipment. If a

product without charge for parts and labor, or will provide a replacement in exchange for the defective product. Parts, modules and

replacement products used by Tektronix for warranty work may be new or reconditioned to like new performance. All replaced

parts, modul

ny such product proves defective during this warranty period, Tektronix, at its option, either will repair the defective

es and products become the property of Tektronix.

In order to ob

and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the

defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay for the return of the

product to C

be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

other than

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to service a product that has been modified or integrated with other products when the effect of such modification or integration

increase

THIS WARR

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RE SPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

IS THE SO

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE PO SSIBILITY OF SUCH

DAMAGES

[W2 – 15

tain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty period

ustomer if the shipment is to a location within the country in which the Tektronix service center is located. Customer shall

Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

s the time or difficulty of s ervicing the product.

ANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

LE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FO R BREACH OF THIS WARRANTY. TEKTRONIX

.

AUG04]

Page 7

P6316 Probe

Warranty

Tektronix warrants that the product will be free from defects in materials and workmanship for a period of one (1) year from the date of

original purc

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Batteries are excluded from this warranty. Parts, modules and replacement products used by Tektronix for warranty

work may be ne

hase from an authorized Tektronix distributor. If the product proves defective during this warranty period, Tektronix, at its

w or reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to ob

period and make suitable arrangements for the performance of s ervice. Customer shall be responsible for packaging and shipping

the defective product to the service center designated by Tektronix, shipping charges prepaid, and with a copy of customer proof of

purchase. T

the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other

charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tekt

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to serv

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS

IS THE SOLE AND E XCLU S IVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. T EKT RONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPE

DAMAGES.

[W15 – 15AUG04]

tain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty

ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which

ronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

ice a product that has been modified or integrated with other products when the effect of such modification or integration

FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

CTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE N OTICE OF THE PO SSIBILITY OF SUCH

Page 8

Page 9

Table of Contents

General Safety Summary ... ... .. . .. .. . .. ... .. . .. ... .. . .. .. . .. ... .. . .. ... .. . .. .. . .. ... .. . .. ... .. . .. .. . .. ... .. . .. ... .. . .. .. . .. ... .. . ... iii

Compliance Information............................................................................................................... v

EMC Compliance................................................................................................................. v

Safety Compliance.............................................................................................................. vii

Environmental Considerations................................................................................................... ix

Preface................................................................................................................................. x

Key Features .....................................................................................................................x

Conventions Used in This Manual.. . .. .. . .. . .. ... .. . .. . . . .. . .. ... .. . .. ... .. . .. . . . .. . .. ... .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . . xi

Installation.............................................................................................................................. 1

Before Installation................................................................................................................ 1

Operating Considerations........................................................................................................ 5

Connecting Probes. .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . . 8

Securing the Oscilloscope ....................................................................................................... 9

Powering On the Oscilloscope ................................................................................................. 10

Powering Off the Oscilloscope.................................................................................................. 11

Functional Check. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. . .. .. . .. . . . .. . .. .. . .. . .. ... .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. 11

Compensating a Passive Voltage Probe . . .. .. . .. ... .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. 12

Application Module Free Trial... .. . .. . . . .. . .. .. . .. .. . .. . . . .. . .. .. . .. .. . .. . . . .. . .. .. . .. .. . .. . . . .. . .. .. . .. .. . .. . . . .. ... .. . .. .. . .. . 14

Installing an Application Module. . .. . .. .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. .. . .. . . . .. . .. .. . .. .. . .. . . . . 14

Changing the User Interface Language . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. 14

Changing the Date and Time .. . .. . .. .. . .. . .. .. . .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. ... .. . .. . .. .. . .. . .. .. . .. . .. ... .. . .. . .. .. . .. . .. .. 15

Signal Path Compensation . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . 17

Upgrading Firmware ............................................................................................................ 18

Connecting Your Oscilloscope to a Computer ... .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. ... .. 21

Connecting a USB Keyboard to Your Oscilloscope. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. ... .. . .. .. . .. . .. .. . .. . .. .. . 25

Getting Acquainted with the Oscilloscope . . .. . .. .. . .. .. . .. ... .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. ... .. . .. .. . .. .. . .. . .. .. . .. . 27

Front-Panel Menus and Controls. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. ... .. . .. .. . .. ... .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. 27

Front-Panel Connectors ... .. . .. ... .. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. ... .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. 39

Side-Panel Connector... .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. . .. .. . .. . .. .. . .. ... .. . .. . .. 39

Rear-Panel Connectors. .. . .. . .. .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. ... .. . .. .. . .. . . . .. . .. .. . .. 40

ire the Signal ... ... .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. ... .. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. ... .. . .. .. . .. .41

Acqu

Setting Up Analog Channels.. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. . .. .. . .. . . . .. . .. .. . .. . .. ... .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. 41

Using the Default Setup......................................................................................................... 44

Using Autoset ................................................................................................................... 45

Acquisition Concepts............................................................................................................ 46

How the Analog Acquisition Modes Work.. .. . .. . . . .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. ... .. . .. .. . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. 48

Changing the Acquisition Mode, Record Length, and Delay Time. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. . .. .. . 48

Using Roll Mode................................................................................................................. 50

Setting Up a Serial or Parallel Bus ............................................................................................. 51

Setting Up Digital Channels (MSO2000 Series Only) . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. ... .. . .. .. . . 60

Reducing Unwanted Noise With FilterVu ...................................................................................... 61

Using FilterVu ...................................................................................................................63

Table of Content

s

DPO2000 and MSO2000 Series Oscilloscopes User Manual i

Page 10

Table of Content

Trigger Setup . .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . ....... 65

Display Wave

Analyze Waveform Data. . .. . .. .. . .. .. . .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . ... 87

Save and Recall Information....................................................................................................... 109

g Application Modules .. .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. . 122

Usin

Appendix: Warranted Specifications, Safety Certifications, and Electromagnetic Compatibility . . . .. .. . .. .. . .. .. . .. .. . .. .. . .. .. 123

Index

s

Triggering Con

Choosing a Trigger Type . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. ... .. . .. .. . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . 68

Selecting Triggers. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. ... .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. ... .. . .. .. . .. .. . .. . ..68

Triggering on

Checking Trigger Settings .. .. . .. ... .. . .. .. . .. . . . .. . .. .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. .. . .. . .. .. . .. .. . .. ... .. . .. .. . .. . . . .. . . 74

Starting and Stopping an Acquisition. ... .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . 75

Adding and Removing a Waveform ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. .. . .. . .. .. . .. ... .. . .. 76

Setting the Display Style and Persistence ..................................................................................... 76

Setting Wav

Scaling and Positioning a Waveform ........................................................................................... 80

Setting Input Parameters . . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . . 81

Positioni

Positioning, Scaling, and Grouping Digital C hannels .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. ... .. . 83

Viewing Digital Channels . . .. .. . .. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. ... .. . .. .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. .. . .. . .. .. . .. 85

Annotati

Taking Automatic Measurements............................................................................................... 87

Selectin

Customizing an Automatic Measurement...................................................................................... 91

Taking Manual Measurements with Cursors ... . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. 94

Using Ma

Using FFT ....................................................................................................................... 98

Using Reference Waveforms ................................................................................................. 101

Using W

Saving a Screen Image ........................................................................................................ 111

g and Recalling Waveform Data........................................................................................ 112

Savin

Saving andRecalling Setups................................................................................................. 114

Saving with One Button Push ................................................................................................ 116

g Setup, Screen Image, and Waveform Files. . . .. . .. ... .. . .. . .. .. . .. . . . .. . .. ... .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . . 116

Savin

Printing a Hard Copy.......................................................................................................... 118

Erasing Oscilloscope Memory................................................................................................ 120

cepts............................................................................................................. 65

Buses............................................................................................................. 70

form Data .............................................................................................................. 76

eform Intensity ..................................................................................................... 79

ng and Labeling Bus Signals. . .. . .. ... .. . .. ... .. . .. .. . .. . .. .. . .. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . .. .. . .. . 83

ng the Screen .......................................................................................................... 86

g Automatic Measurements............................................................................................ 88

th Waveforms ......................................................................................................... 97

ave Inspector to Manage Long Record Length Waveforms. . .. .. . .. . . . .. . .. .. . .. . .. .. . .. . .. .. . .. ... .. . .. ... .. . .. . . 103

ii DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 11

General Safety S

ummary

General S afet

Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and certified for the country of use.

Connect and Disconnect Properly. Do not connect or d isconnect probes or test leads while they are c onnected

to a voltage source.

Connect and Disconnect Properly. De-energize the circuit under test before connecting or disconnecting the current

probe.

Ground th

shock, the grounding conductor must be connected to earth ground. Before making c onnections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings and markings on the product. Consult

the prod

Connect

e Product.

uct manual for further ratings information before making connections to the product.

the probe reference lead to earth ground only.

y Summary

This product is grounded through the grounding conductor of the power cord. To avoid electric

Do not ap

Power D

must remain accessible to the user at all times.

ply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

isconnect.

The power cord disconnects the product from the power source. Do not block the power cord; it

Do Not Operate Without Covers. Do not operate this product with covers or panels removed.

Do Not Operate With Suspected Failures. If you suspect that there is damage to this product, have it inspected by

qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components when power is present.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation.

per ventilation.

pro

Refer to the manual’s installation instructions for details on installing the product so it has

Terms in this Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

DPO2000 and MSO2000 Series Oscilloscopes User Manual iii

Page 12

General Safety S

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and Terms on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you read the marking.

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

ummary

iv DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 13

Compliance Info

rmation

Compliance In

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument

complies.

EMC Compliance

EC Declaration of Conformity – EMC

Meets intent of Directive 2004/108/EC for E lectromagnetic Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EN 61326-1:2006, EN 61326-2-1:2006. EMC requirements for electrical equipment for measurement, control, and

laboratory use.

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2002. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient/bur

IEC 61000-4-5:2001. Power line surge immunity

IEC 61000-4-6:2003. Conducted RF immunity

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

123

formation

4

st immunity

5

6

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European Contact.

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

1

This product is intended for use in nonresidential areas only. Use in residential areas may c ause electromagnetic interfe

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test object.

3

To ensure compliance with the EMC standards listed here, high quality shielded interface cables should be used.

4

Trace bloom not exceeding 4 divisions pk-to-pk may be induced under the conditions of the IEC 61000-4-3 test.

5

Trace bloom not exceeding 1 division pk-to-pk may be induced under t he conditions of the IEC 61000-4-6 test.

6

Performance Criterion C applied at the 70%/25 cycle Voltage-Dip and the 0%/250 cycle Voltage-Interruption test levels

(IEC 61000-4-11).

rence.

Australia / New Zealand Declaration of Conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per the following standard, in accordance with ACMA:

DPO2000 and MSO2000 Series Oscilloscopes User Manual v

Page 14

Compliance Info

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in accordance w ith EN 61326-1:2006 and

EN 61326-2-1:2

rmation

006.

vi DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 15

Safety Compliance

EC Declaration of Conformity – Low Voltage

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Communities:

Low Voltage Directive 2006/95/EC.

EN 61010-1: 2001. Safety requirements for electrical equipment for measurement control and laboratory use.

Compliance Info

rmation

U.S. Nation

UL 61010-1:2004, 2ndEdition. Standard for electrical measuring and test equipment.

ally Recognized Testing Laboratory Listing

Canadian Certification

CAN/CSAlaboratory use. Part 1.

C22.2 No. 61010-1:2004. Safety requirements for electrical equipment for measurement, control, and

Additional Compliances

IEC 61010-1: 2001. Safety requirements for electrical equipment for measurement, control, and laboratory use.

Equipment Type

Test and measuring equipment.

y Class

Safet

Class 1 – grounded product.

Pollution Degree Description

asure of the contaminants that could occur in the environ ment around and within a p roduct. Typically the internal

Ame

environment inside a product is considered to be the same as the external. Products should be used only in the environment

for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

capsulated, hermetically sealed, or located in clean rooms.

en

llution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a t emporary conductivity that is

Po

caused by condensation must be expected. This location is a typical office/home environment. Temporary condensation

occurs only when the product is out of service.

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation.

hese are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct

T

sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical

outdoor locations.

DPO2000 and MSO2000 Series Oscilloscopes User Manual vii

Page 16

Compliance Info

Pollution Degree

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Installation (Overvoltage) Category Descriptions

Terminals on this product may have different installation (overvoltage) category designations. The installation categories are:

Measurement Category IV. For measurements performed at the source of low-voltage installation.

Measurement Category III. For m easurements performed in the building installation.

Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

Measurement Category I. For measurements performed on circuits not directly connected to MAINS.

rmation

Overvolta

Overvoltage Category II (as defined in IEC 61010-1).

ge Category

viii DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 17

Environmental Considerations

This section provides information about the environmental impact of the product.

Product End-of-Life Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and use of natural resources. The

equipment may contain substances that could be harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the environment and to reduce the use of natural

resources, we encourage you to recycle this product in an appropriate system that will ensure that most of the materials are

reused or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according

to Directives 2002/96/EC and 2006/66/EC on waste electrical and electronic equipment (WEEE) and

batteries. For information about recycling options, check the Support/Service section of the Tektronix Web

site (www.tektronix.com).

Compliance Info

rmation

Mercury N

to environmental considerations. Please contact your local authorities or, within the United States, refer to the E-cycling

Central Web page (www.eiae.org) for disposal or recycling information.

Restric

This product has been classified as Monitoring and Control equipment, and is outside the scope of the 2002/95/EC RoHS

Directive.

otification.

tion of Hazardous Substances

This product uses an LCD backlight lamp that contains mercury. Disposal may be regulated due

DPO2000 and MSO2000 Series Oscilloscopes User Manual ix

Page 18

Preface

Preface

This manual describes the installation and operation of the following oscilloscopes:

DPO2024 DPO2014 DPO2012

MSO2024 MSO2014 MSO2012

Key Features

DPO2000 and MSO2000 series oscilloscopes can help you verify, debug, and characterize electronic designs. Key features

include:

200 MHz and 100 MHz bandwidths

2 channel and 4 channel models

Sample rates up to 1 GS/s on all analog channels

1 M points record length on all channels

5,000 waveforms/second waveform capture rate

I2C, SPI, CAN, LIN, RS-232, RS-422, RS-485, and UART bus triggering and analysis (with the appropriate application

module and model oscilloscope)

Wave Inspector controls for m anaging long record lengths, w ith zoom and pan, play and pause, search and mark

Large 178 mm (7 inch) WQVGA wide screen color display

Small and lightweight, at 140 mm (5.5 inch) deep and 3.6 kg (7 lbs, 14 oz)

FilterVu provides a variable low pass filter to block unwanted noise while still displaying high frequency events

USB flash drive port for quick and easy storage of measurement results

Direct printing to any PictBridge compatible printer

Ethernet port for remote programmability with the optional connectivity module

Video Out port to display the oscilloscope screen on an external monitor with the optional connectivity module

USB 2.0 Device port for direct PC control of the oscilloscope using USBTMC protocol

OpenChoice documentation software for simple transfer of screen shots and waveform data to a PC

National Instrument’s LabVIEW SignalExpress™ Tektronix Edition productivity and analysis software

Remote viewing and control with e*Scope

Remote control with VISA connectivity

TekVPI Versatile Probe Interface supports active, differential, and current probes for automatic scaling and units

MSO2000 series of mixed signal oscilloscopes also offer:

16 digital channels

Parallel bus triggering and analysis

Easy connection to your device-under-test through the convenient design of the P6316 digital probe

x DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 19

Conventions Used in This Manual

The following icons are used throughout this manual.

Preface

Sequence Step

Front panel power

Connect power

Network

USB

DPO2000 and MSO2000 Series Oscilloscopes User Manual xi

Page 20

Preface

xii DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 21

Installation

Before Installation

Unpack the oscilloscope and check that you received all items listed as standard accessories. The following pages list

recommended accessories and probes, instrument options, and upgrades. Check the Tektronix Web site (www.tektronix.com)

for the most current information.

Standard Accessories

Accessory Description

DPO2000 and MSO2000 Series

Oscilloscopes User Manual

DPO2000 and MSO2000 Series

Oscilloscopes Documentation Browser

CD

NI LabVIEW SignalExpress Tektronix Edition

andTektronix OpenChoice Desktop PC

Communications CDs

Calibration certificate documenting

traceability to national metrology institute(s),

and ISO9001 quality system registration.

Front panel overlay

English (Option L0)

French (Option L1)

Italian (Option L2)

German (Option L3)

Spanish (Option L4)

Japanese (Option L5)

Portuguese (Option L6)

Simple Chinese (Option L7)

Traditional Chinese (Option L8)

Korean (Option L9)

Russian (Option L10)

Electronic versions of documents, including

the Programmer M anual and the Technical

Reference.

Productivity, analysis, and documentation

software.

French (Option L1)

Italian (Option L2)

German (Option L3)

Spanish (Option L4)

Japanese (Option L5)

Portuguese (Option L6)

Simple Chinese (Option L7)

Traditional Chinese (Option L8)

Korean (Option L9)

Russian (Option L10)

Installation

Tektronix part

number

071-2319‑XX

071-2320‑XX

071-2321‑XX

071-2322‑XX

071-2323‑XX

071-2324‑XX

071-2325‑XX

071-2326‑XX

071-2327‑XX

071-2328‑XX

071-2329‑XX

063-4118‑XX

063-3967‑XX

——

335-2020-00

335-2021-00

335-2022-00

335-2023-00

335-2024-00

335-2025-00

335-2026-00

335-2027-00

335-2028-00

335-2029-00

DPO2000 and MSO2000 Series Oscilloscopes User Manual 1

Page 22

Installation

Standard Accessories (cont.)

Accessory Description

For DPO2000 and MSO2000 series: Probes One, 200 MHz, 1X/10X passive probe per

channel

For MSO2000 series: Digital probe One, 16-channel digital probe

For MSO2000 series: Accessories pouch Pouch that attaches to the handle for carrying

probes and other accessories.

Three year warranty

Power cord

For details, refer to the warranty in the front of

this manual

North America (Opti o n A0)

Universal Euro (Option A1)

United Kingdom (Option A2)

Australia (Option A3)

Switzerland (Option A5)

Japan (Option A6)

China (Option A10)

India (Option A11)

No power cord or AC adapter (Option A99)

Tektronix part

number

P2221

P6316

016-2008-00

——

161-0348-00

161-0343-00

161-0344-00

161-0346-00

161-0347-00

161-0342-00

161-0341-00

161-0349-00

——

2 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 23

Optional Accessories

Tektronix part

Accessory Description

DPO2EMBD

The embedded serial triggering and analysis

module enable

informationonI

s triggering on packet level

2

C and SPI serial buses, as

well as bus views, bus decoding, search tools,

and packet de

code tables with timestamp

information

DPO2AUTO

The automoti

ve serial triggering and analysis

module enables triggering on packet level

information on CAN and LIN serial buses, as

well as bus v

iews, bus decoding, search tools,

and packet decode tables with timestamp

information

DPO2COMP

The computer triggering and analysis module

enables triggering on RS-232, RS-422, RS-485

and UART se

rial buses, search tools, bus

views, bus decoding in hex, binary, and ASCII,

and decode tables with timestamp information

DPO2CONN

The connectivity module adds an Ethernet port

for remote programmability and a Video Out

port to di

splay the oscilloscope screen on an

external monitor

NEX-HD2

HEADER

Adapter that routes the channels from a Mictor

connector to 0.1 inch header pins

TPA-BNC TekV PI to TekProbe II BNC Adapter TPA-BNC

TekVPI external power adapter

Supplies external power to a TekVPI probe

Deskew pulse generator Deskew pulse generator and signal source

with TekVPI oscilloscope interface

Power measurement deskew and calibration

fixture

USB-488 Adapter

TEK-

Converts TEK-DPG pulse generator output

a series of test point connections

into

to USB Adapter

GPIB

Rackmount kit Adds rackmount brackets RMD2000

Soft transit case Case for carrying an oscilloscope ACD2000

Hard transit case

PO2000 and MSO2000 Series

D

Oscilloscopes Service manual

Traveling hard case, which requires use of the

ft transit case (ACD2000)

so

ervice information on DPO2000 and

S

MSO2000 series oscilloscopes

number

DPO2EMBD

DPO2AUTO

DPO2COMP

DPO2CONN

NEX-HD2

119‑7465‑XX

TEK-DPG

067-1686-00

USB-488

TEK-

HCTEK4321

071-2331‑XX

Installation

HEADER

DPO2000 and MSO2000 Series Oscilloscopes User Manual 3

Page 24

Installation

Optional Accessories (cont.)

Tektronix part

Accessory Description

DPO2000 and MSO2000 Series

Oscilloscopes Application Module Installation

The DPO2000 and MSO2000 series oscilloscopes work with multiple optional probes. (See page 8, Connecting Probes.)

Check the Tektronix Web site (www.tektronix.com) for the most current information.

Describes how to install application modules in

DPO2000 and MSO2000 series oscilloscopes

number

071-2330‑XX

Related Documentation

Accessory Description Tektronix part number

DPO2000 and MSO2000 Series

Oscilloscopes Programmer Manual

DPO2000 and MSO2000 Series

Oscilloscopes Technical Reference

Manual

Describes commands for remote control

of the oscilloscope; available electronically

on the D ocumentation Browser CD or for

download from www.tektronix.com/manuals

Describes the oscilloscope specifications

and performance verification procedure;

available electronically on the Documentation

Browser CD or for download from

www.tektronix.com/manuals

077-0097‑XX

077-0096‑XX

4 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 25

Operating Considerations

DPO2000 and MSO2000 Series Oscilloscopes

Power Supply Input Voltage: 100 V to 240 V ± 10%

Power Supply Input Power Frequency:

50/60 Hz at 100 V to 240 V

400 Hz at 115 V

Power Consumption: 80 W maximum

Weight: 3.6 kg (7 lbs 14 oz), stand-alone oscilloscope

Height, including the feet but not the handle:

175 mm (6.885 inch)

Installation

Width: 377 mm (14.85 inch)

Depth: from the feet to the front of the knobs: 134 mm (5.3 inch)

Depth: fr

Clearan

Input V

300 V

Installation Category II - for measurements performed

on circ

installation

Tempe

Operating: 0 °C to +50 °C

Nonoperating: -20 °C to +60 °C

Humidity:

Operating: High: 40 °C to 50 °C, 10% to 60% RH

Operating: Low: 0 °C to 40 °C, 10% to 90% RH

Non-operating: High: 40 °C to 60 °C, 5% to 60% RH

Non-operating: Low: 0 °C to 40 °C, 5% to 90% RH

om the feet to the front of the front cover: 139 mm (5.47 inch)

ce: 50 mm (2 inch)

oltage (between the signal and reference):

CAT II

RMS

uits directly connected to the low-voltage

rature:

DPO2000 series

MSO2000 series

Altitude:

Operating: 3,000 m (9,842 ft)

Nonoperating Altitude: 12,000 m (39,370 ft)

DPO2000 and MSO2000 Series Oscilloscopes User Manual 5

Page 26

Installation

Random Vibrati

Operating: 0.31 G

Non-operating: 2.46 G

on:

, 5 - 500 Hz, 10 minutes per axis, 3 axes (30 minutes total)

RMS

, 5 - 500 Hz, 10 minutes per axis, 3 axes (30 minutes total)

RMS

Pollution Degree: 2, Indoor use only

CAUTION. To ensure proper cooling, keep the sides and rear of the oscilloscope clear of obstructions.

P2221 Passive Probe

Input Voltage (bet

300 V

RMS

Installation Category II - for measurements performed on circuits directly connected to the low-voltage installation

Temperature:

Operating: 0 °C to +50 °C (+32 °F to +122 °F)

Nonoperating: -5

Pollution Degree: 2, Indoor use only

Humidity: 10% to 95% RH

ween the signal and reference):

CAT II

5 °C to +75 °C ( -67 °F to +167 °F)

MSO2000 Series Oscilloscope with a P6316 Digital Probe

Threshold Accuracy: ±(100 mV + 3% of threshold)

Threshold Range: ±20 V

Maximum nond

Minimum signal swing: 500 mV

Input resistance: 101 kΩ

Input capacitance: 8.0 pF

Temperat

Operating: 0 °C to +50 °C (+32 °F to +122 °F)

Nonoperating: -40 °C to +71 °C (-40 °F to +160 °F)

Altitude:

Operating: 3,000 m (9,843 ft) maximum

Nonoper

Pollution Degree: 2, Indoor use only

estructive input signal to probe: ±40 V

peak-to-peak

ure:

ating: 12,000 m (39,370 ft) maximum

6 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 27

Installation

Humidity:

5% to 95% relative humidity

Cleaning

Inspect the oscilloscope and probes as often as operating conditions require. To clean the exterior surface, perform the

following steps:

1. Remove loose dust on the outside of the oscilloscope and probes with a lint-free cloth. Use care to avoid scratching the

clear glass display filter.

2. Use a soft cloth dampened with water to clean the oscilloscope. Use an aqueous solution of 75% isopropyl alcohol

for more efficient cleaning.

CAUTION. To avoid damage to the surface of the oscilloscope or probes, do not use any abrasive or chemical cleaning

agents.

DPO2000 and MSO2000 Series Oscilloscopes User Manual 7

Page 28

Installation

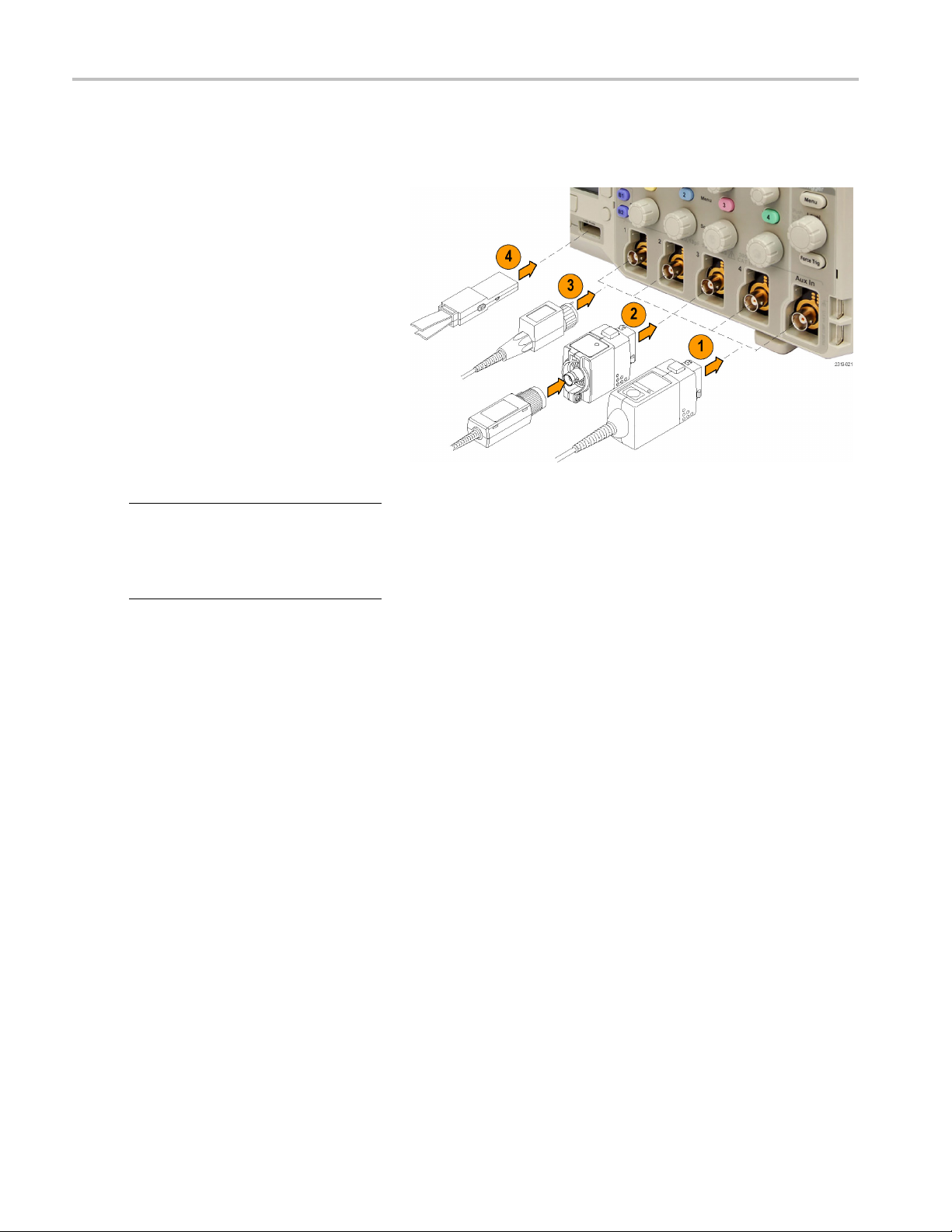

Connecting Probes

The oscilloscope supports probes with the following:

1. Tektronix Versatile Probe Interface

(TekVPI)

These probes support two-way

communication with the oscilloscope

through on-screen menus and remotely

through programmable support. The

remote control is useful in applications

like an ATE (automated test environment)

where you want the system to preset

probe parameters.

2. TPA-BNC Adapter

The TPA-BNC Adapter allows you to

use Tek Probe II probe capabilities,

such as providing probe power, and

passing scaling and unit information to

the oscilloscope.

NOTE. To use a TekVPI probe and a

TPA-BNC adapter, connect a TekVPI

external power adapter (Tektronix part

number 119

Probe Power connector.

‑

7465‑XX) to the side panel

8 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 29

3. Plain BNC Interfaces

Some probes use TekProbe capabilities

to pass the wav

to the oscilloscope. Other probes

only pass the signal and there is no

communicati

eform signal and scaling

on.

Installation

4. Digital Prob

only)

The P6316 probe provides 16 channels

of digital (

For more in

www.tektronix.com.

e Interface (MSO2000 series

on or off state) information.

formation on the many probes available for use with DPO2000 and MSO2000 series oscilloscopes, refer to

Securing the Oscilloscope

1. Use a standard laptop computer style

security

to your location.

This photo also shows the optional

DPO2CONN

module provides an Ethernet port and a

Video Out port for the oscilloscopes.

lock to secure your oscilloscope

module installed. The

DPO2000 and MSO2000 Series Oscilloscopes User Manual 9

Page 30

Installation

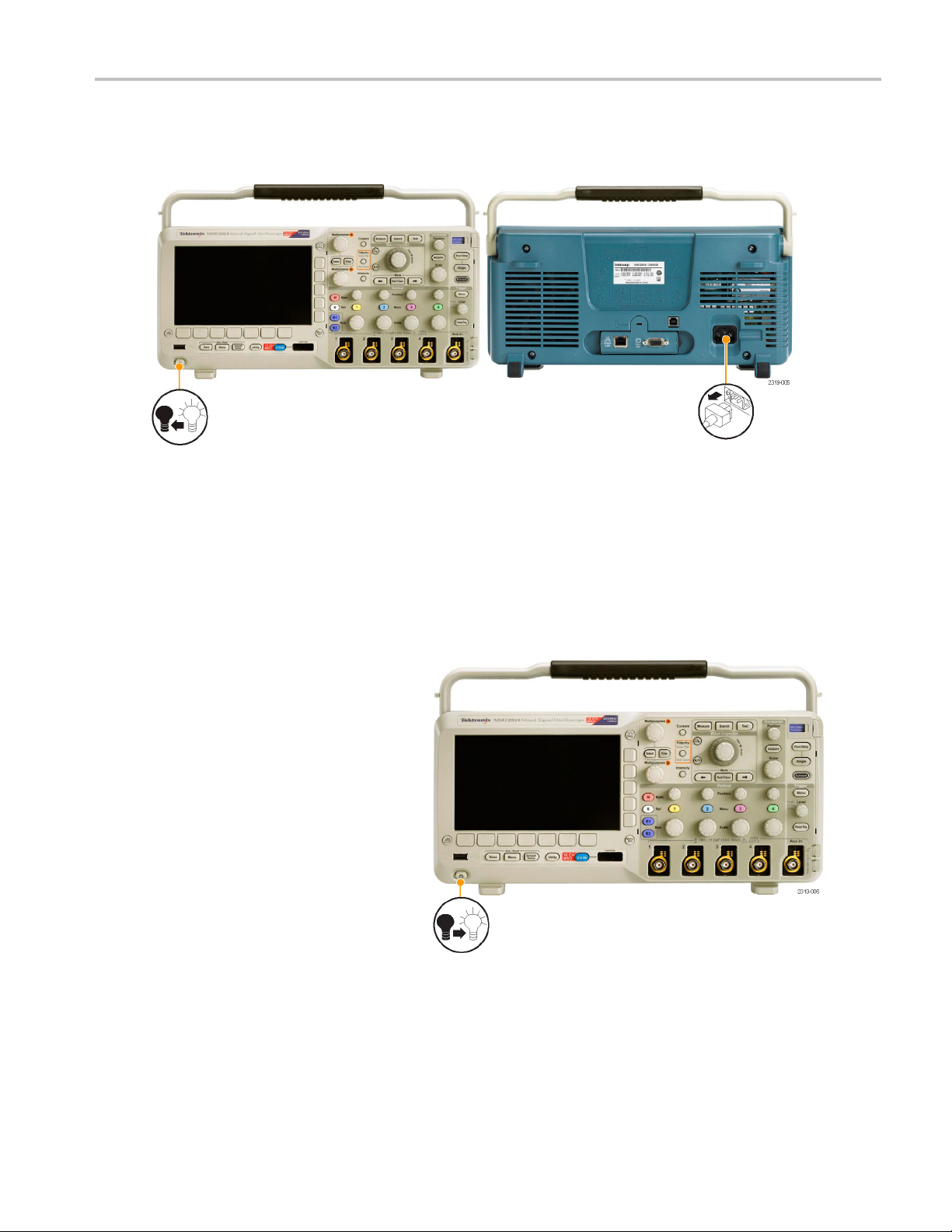

Powering On the Oscilloscope

Ground the Oscilloscope and Yourself

Before pushing the power switch, connect the oscilloscope to an electrically neutral reference point, such as earth ground.

Do this by plu

gging the three-pronged power cord into an outlet grounded to earth ground.

Grounding th

same ground as any circuits that you are testing.

To connect the power cord and power on the oscilloscope:

e oscilloscope is necessary for safety and to take accurate measurements. The oscilloscope needs to share the

Quick Tips

Ifyouareworkingwithstaticsensitive

components, ground yourself. Static

electricity that builds up on your body

can damage static-sensitive components.

Wearing a grounding strap safely sends

static charges on your body to earth ground.

10 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 31

Powering Off the Oscilloscope

To power off the oscilloscope and remove the power cord:

Installation

Functional Check

Perform this quick functional check to verify that your oscilloscope is operating correctly.

1. Connect the oscilloscope power cable

as described in Powering On the

Oscilloscope. (See page 10.)

2. Power on the oscilloscope.

DPO2000 and MSO2000 Series Oscilloscopes User Manual 11

Page 32

Installation

3. Connect the P2221 probe tip and

reference lead to the PROBE COMP

connectors on

4. Push Default Setup .

5. Push Autoset. The screen should now

display a square wave, approximately

5Vat1kHz.

the oscilloscope.

NOTE. For best performance, it is

recommended that you set the Vertical scale

to1V.

If the signal appears but is misshapen,

perform the procedures for compensating

the probe. (See page 12.)

If no signal appears, rerun the procedure.

If this does not remedy the situation,

have the oscilloscope serviced by

qualified service personnel.

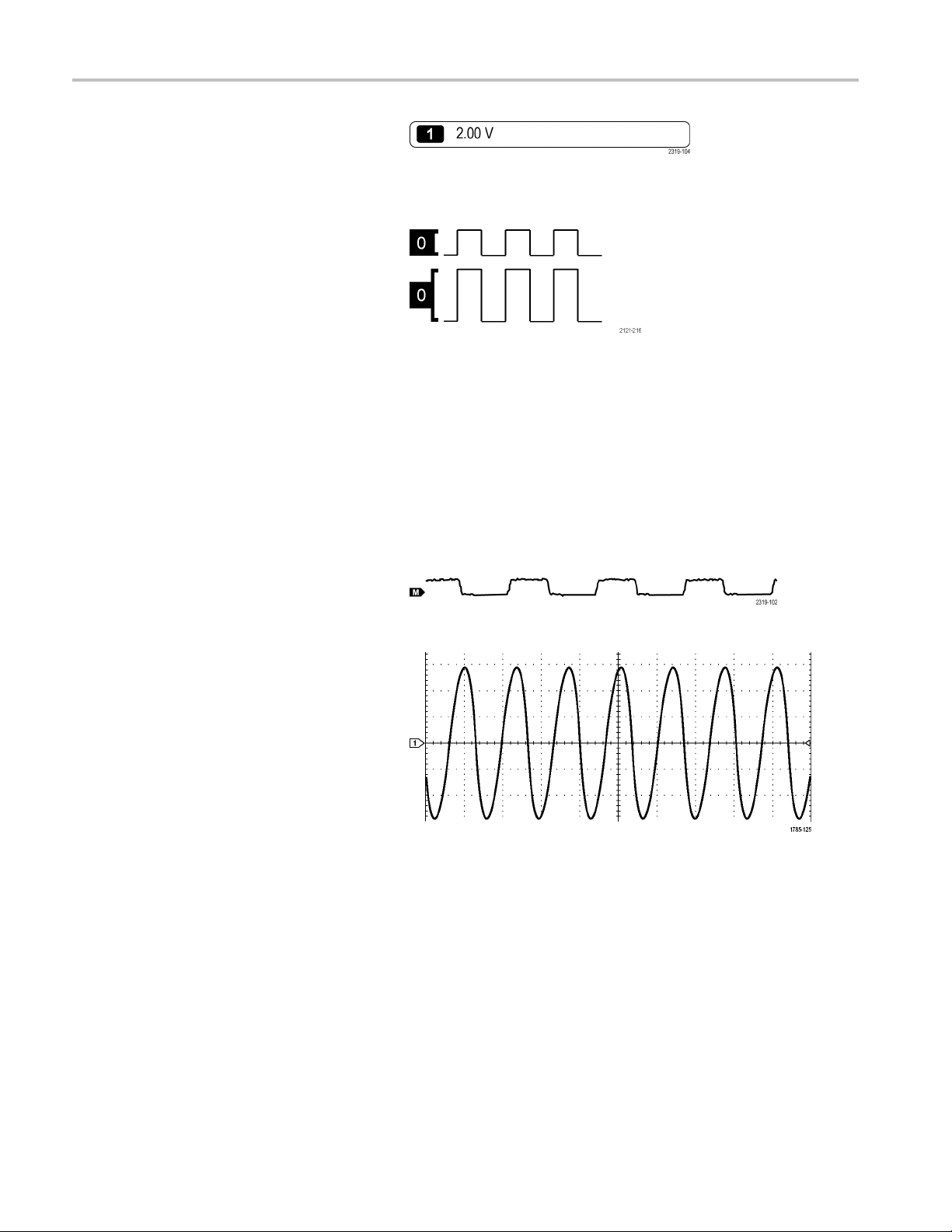

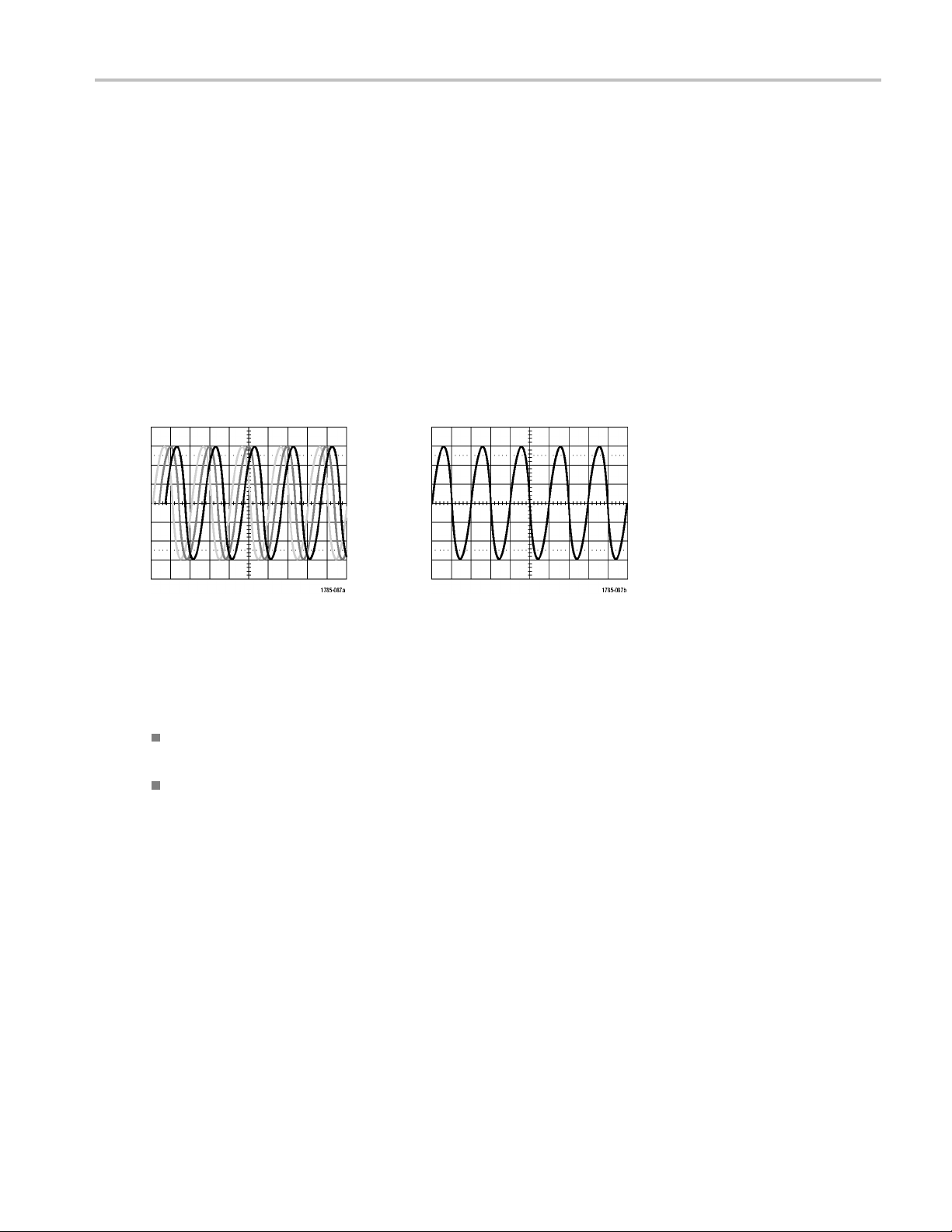

Compensating a Passive Voltage Probe

ever you attach a passive voltage probe for the first time to any input channel, compensate the probe to match it to

When

the corresponding oscilloscope input channel.

To properly compensate your passive probe:

1. Follow the steps for the functional

check. (See page 11.)

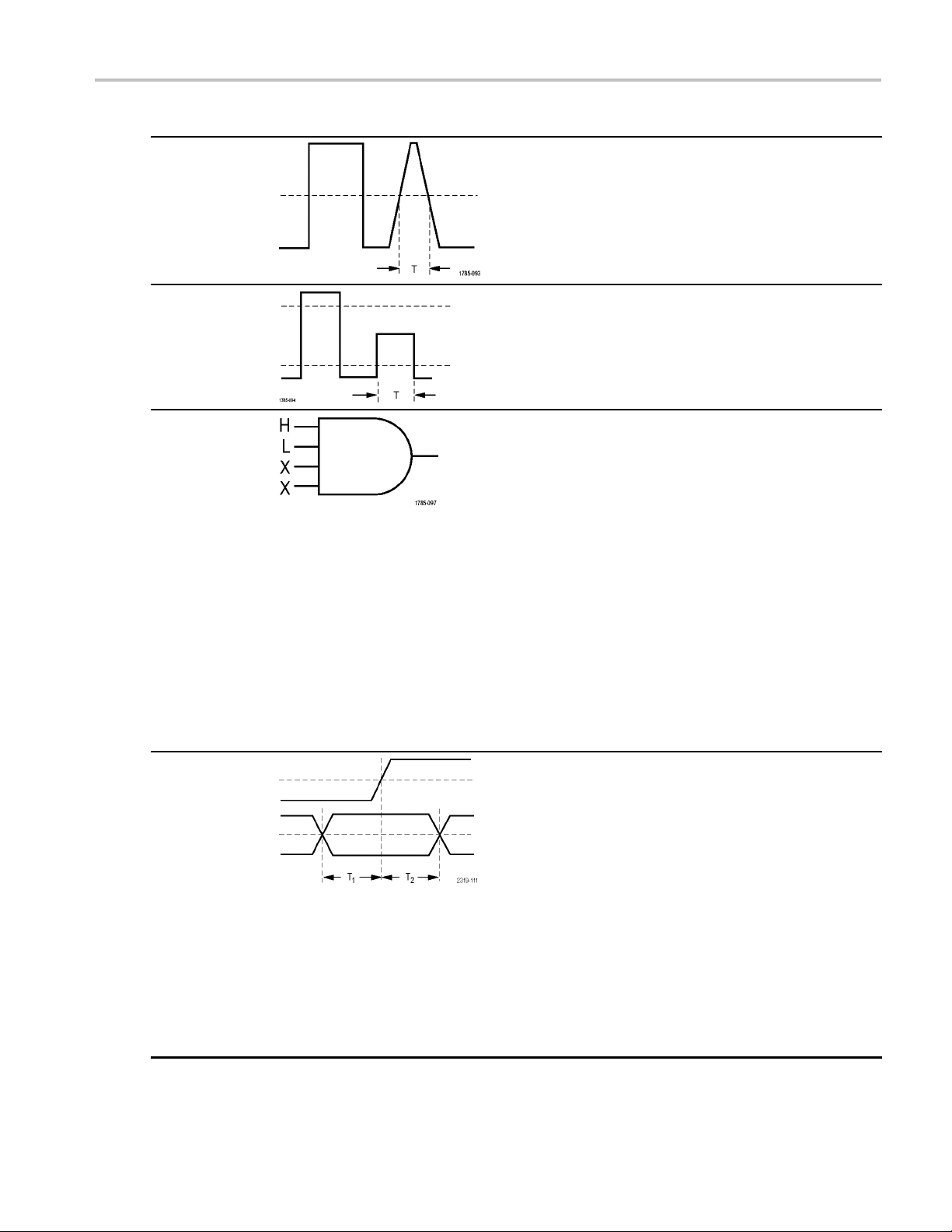

2. Check the shape of the displayed

waveform to determine if your

probe is properly compensated.

Properly compensated

Under compensated Over compensated

12 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 33

3. If necessary, adjust your probe.

Repeat as needed.

Quick Tips

Use the shortest possible ground lead

and signal path to minimize probe-induced

ringing and distortion on the measured

signal.

th a sh ort ground lead

Signal wi

Installation

Signal with a long ground lead

DPO2000 and MSO2000 Series Oscilloscopes User Manual 13

Page 34

Installation

Application Module Free Trial

A 30-day free trial is available for all application modules not installed in your oscilloscope. The trial period begins when you

power on the oscilloscope for the first time.

After 30 days, you must purchase the module if you want to continue using the application. To see the date when your free

trial period expires, push the front panel Utility button, push the lower-bezel Utility Pag e button, use multipurpose knob a to

select Config, and push the lower-bezel About button.

Installing an Application Module

CAUTION. To avoid damage to the oscilloscope or application module, observe ESD (electrostatic discharge) precautions.

(See page 10, Powering On the Oscilloscope.)

Turn off the oscilloscope power while removing or adding an application module.

(See page 11, Powering Off the Oscilloscope.)

Optional application module packages extend the capability of your oscilloscope. You can install one or two application

modules at one time. An application module goes into the slot with a window in the upper right corner of the front panel.

Another slot is directly behind the one that you can see. To use this slot, install the module with the label facing away from you.

For more information on how to install and test application modules, refer to the DPO2000 and MSO2000 Series

Oscilloscopes Application Module Installation manual.

NOTE. If you remove an application module, the features provided by the application module become unavailable. To

restore the features, turn off the oscilloscope power, reinstall the module and turn on the oscilloscope power.

Changing the User Interface Language

To change the language of the o scilloscope user interface, and to change the front-panel button labels through the use

verlay:

of an o

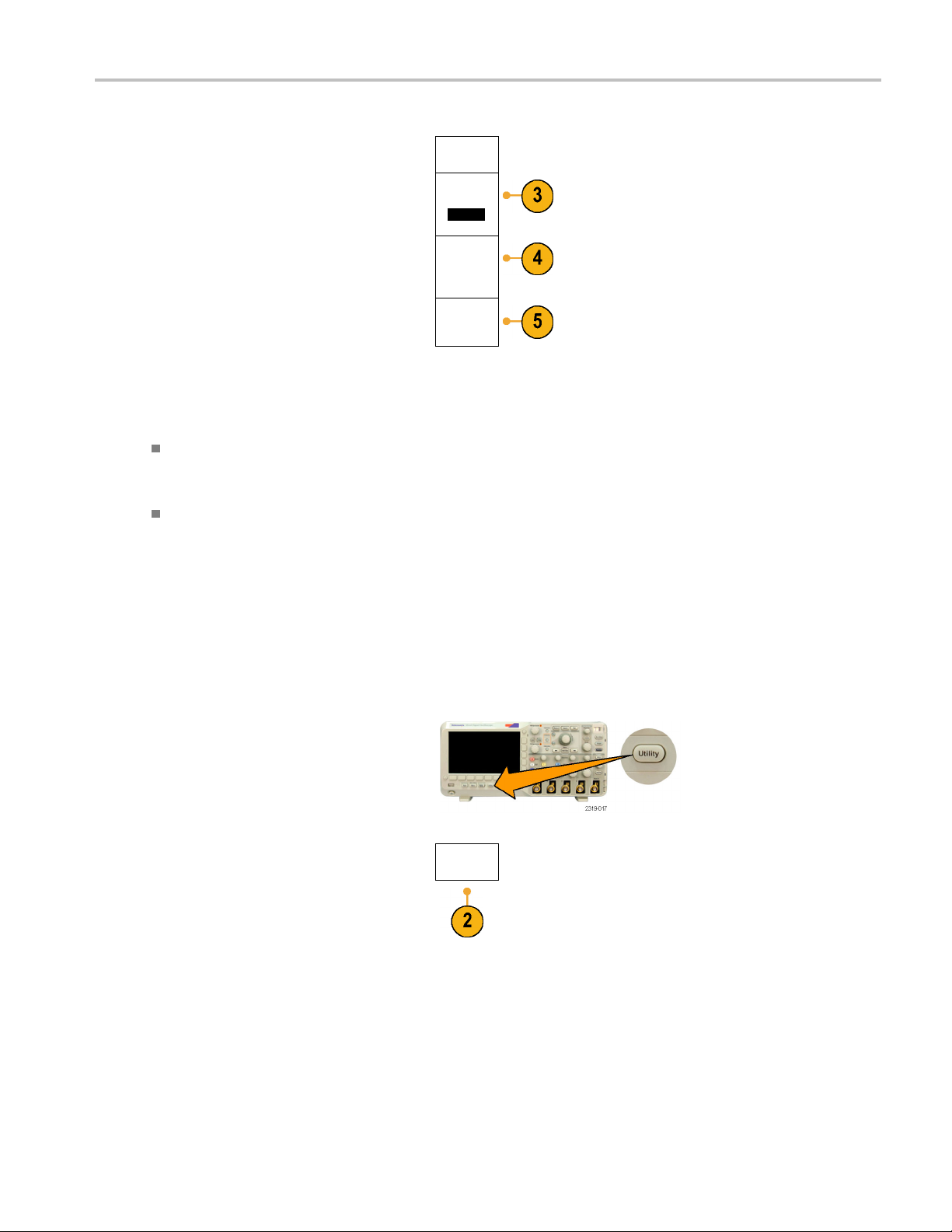

1. Push U

2. Push Utility Page.

tility.

Utility

Pag

e

14 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 35

Installation

3. Turn multipurpose knob a and select Config.

4. Push Language

from the resulting

lower-bezel menu.

5. Turn multipu

rpose knob a and select the

desired language. Choose among: English,

French, German, Italian, Spanish, Brazilian

Portuguese

, Russian, Japanese, Korean,

Simplified Chinese, and Traditional Chinese.

6. If you choose to use English, be sure that

the plastic front-panel overlay is removed.

If you choose a language other than English,

place the plastic overlay for the language

that you desire over the front panel to display

labels in that language.

Utility

Page

Config

Language

English

Set Date &

Time

TekSecure

Erase

Memory

About

Changing the Date and Time

the internal clock with the current date and time:

To se t

1. Push

DPO2000 and MSO2000 Series Oscilloscopes User Manual 15

Utility.

Page 36

Installation

2. Push Utility P

age.

3. Turn multipurpose knob a and select Config.

4. Push Set Dat

5. Push the si

e&Time.

de-bezel buttons and use

multipurpose knobs a and b to set the Day,

Month, Year, Hour, and Minute values.

6. Push Display and turn multipurpose knob a

to choose Date & Time, Date Only, Time

Only,or

None.

Utility

Page

System

Config

Set Date &

Time

Display

Time Only

Select

Day

Day

3

Language

English

Set Date &

Time

TekSecure

Erase

Memory

About

7. Push OK Enter Date & Time.

OK Ente

Date &

Time

r

16 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 37

Signal Path Compensation

Signal Path Compensation (SPC) corrects for DC inaccuracies caused by temperature variations and/or long-term drift.

You should run the SPC whenever the ambient temperature has changed by more than 10 °C or once a week if you

use vertical settings of 5 mV per division or less. Failure to do so may result in the oscilloscope not meeting warranted

performance levels at those volts per division settings.

To compensate the signal path:

1. Warm up the oscilloscope for at least

20 minutes. Remove all input signals

(probes and cables) from channel inputs.

Input signals with AC components adversely

affect SPC.

Installation

2. Push Utility.

3. Push Utility Page.

4. Turn multipurpose knob a and select

Calibration.

5. Push Signal Path from the lower-bezel

menu.

6. Push OK Com pensate Signal Paths from

the resulting side-bezel menu.

Utility

Page

Utility

Page

Calibration

OK Com-

pensate

Signal

Paths

Signal

Path

Pass

Factory

Pass

DPO2000 and MSO2000 Series Oscilloscopes User Manual 17

Page 38

Installation

The oscillosco

pe displays a message when

the calibration is complete. Push Menu Off

to remove the message.

7. After calibr

ation, v e rify that the status

indicator on the lower-bezel menu displays

Pass.

Utility

Page

Calibration

Signal

Path

Pass

Factory

Pass

If it does not, then recalibrate the

oscilloscope or have the oscilloscope

serviced b

y qualified service personnel.

Service personnel use the factory calibration

s to calibrate the internal voltage

function

references of the oscilloscope using

external sources. Refer to your Tektronix

field offic

e or representative for assistance

with factory calibration.

NOTE. Signal Path Compensation does not include calibration to the probe tip. (See page 12, Compensating a Passive

Voltage Probe.)

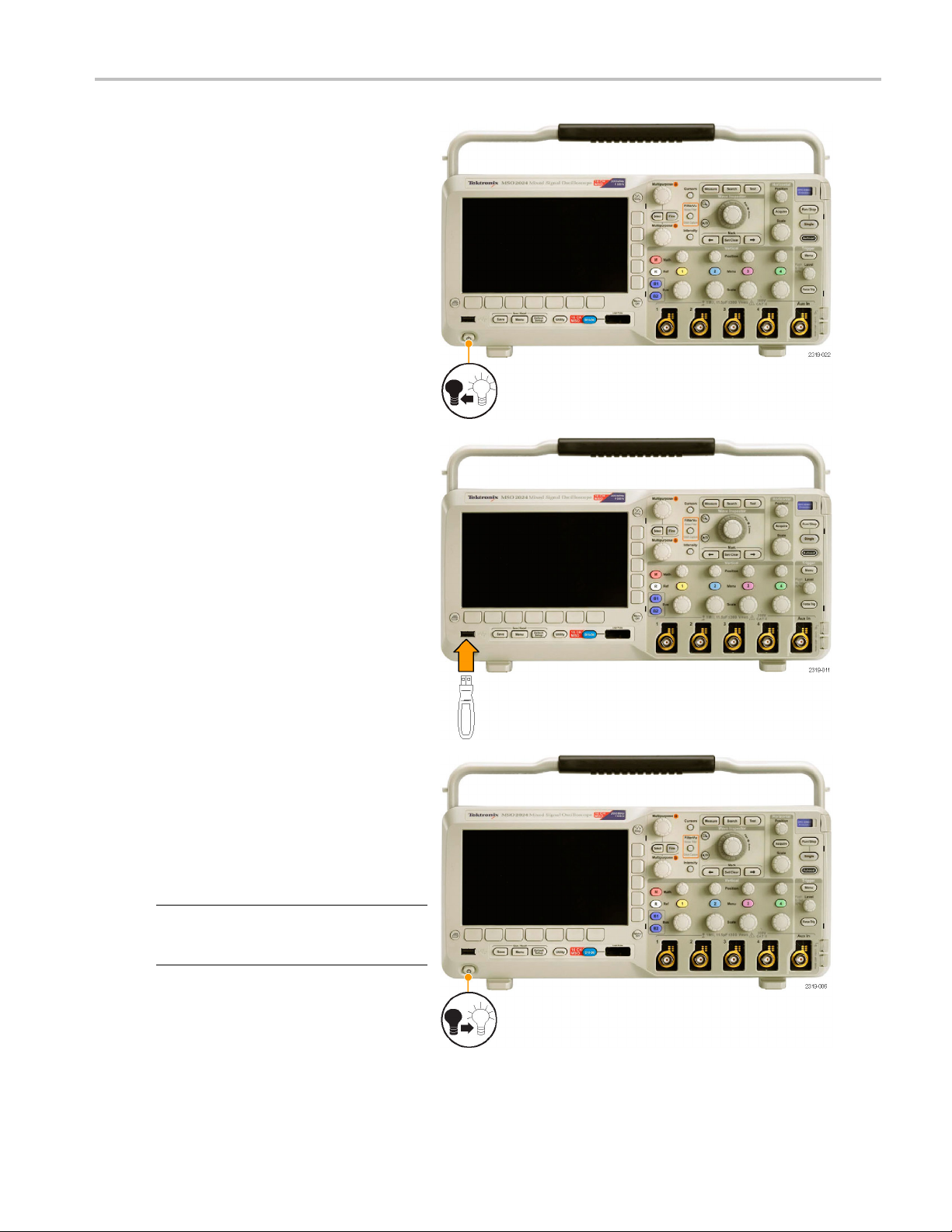

Upgrading Firmware

To upgrade the firmware of the oscilloscope:

1. Open up a Web browser and go to

www.tektronix.com/software. Proceed to

the software finder. Download the latest

firmware for your oscilloscope on your PC.

ip the files and copy the firmware.img

Unz

file into the root folder of a USB flash drive.

18 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 39

2. Power off your oscilloscope.

3. Insert the USB flash drive into the front-panel

USB port o

n your oscilloscope.

Installation

4. Power on the oscilloscope. The oscilloscope

automatically recognizes and installs the

replacement firmware.

If the oscilloscope does not install the

firmware, rerun the procedure. If the

problem continues, try a different model of

USB flash drive. Finally, if needed, contact

qualified service personnel.

NOTE. Do not power off the oscilloscope or

remove the USB flash drive until the oscilloscope

finishes installing the fi rmware.

DPO2000 and MSO2000 Series Oscilloscopes User Manual 19

Page 40

Installation

5. Power off the oscilloscope and remove the

USB flash drive.

6. Power on the oscilloscope.

7. Push Utility.

ity

8. Push

Utility Page.

Util

Page

20 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 41

Installation

9. Turn multipurpose knob a and select Config.

Utility

Page

Config

Language

English

10. Push About. The oscilloscope displays the

firmware versi

11. Confirm that t

on number.

he version number matches

that of the new firmware.

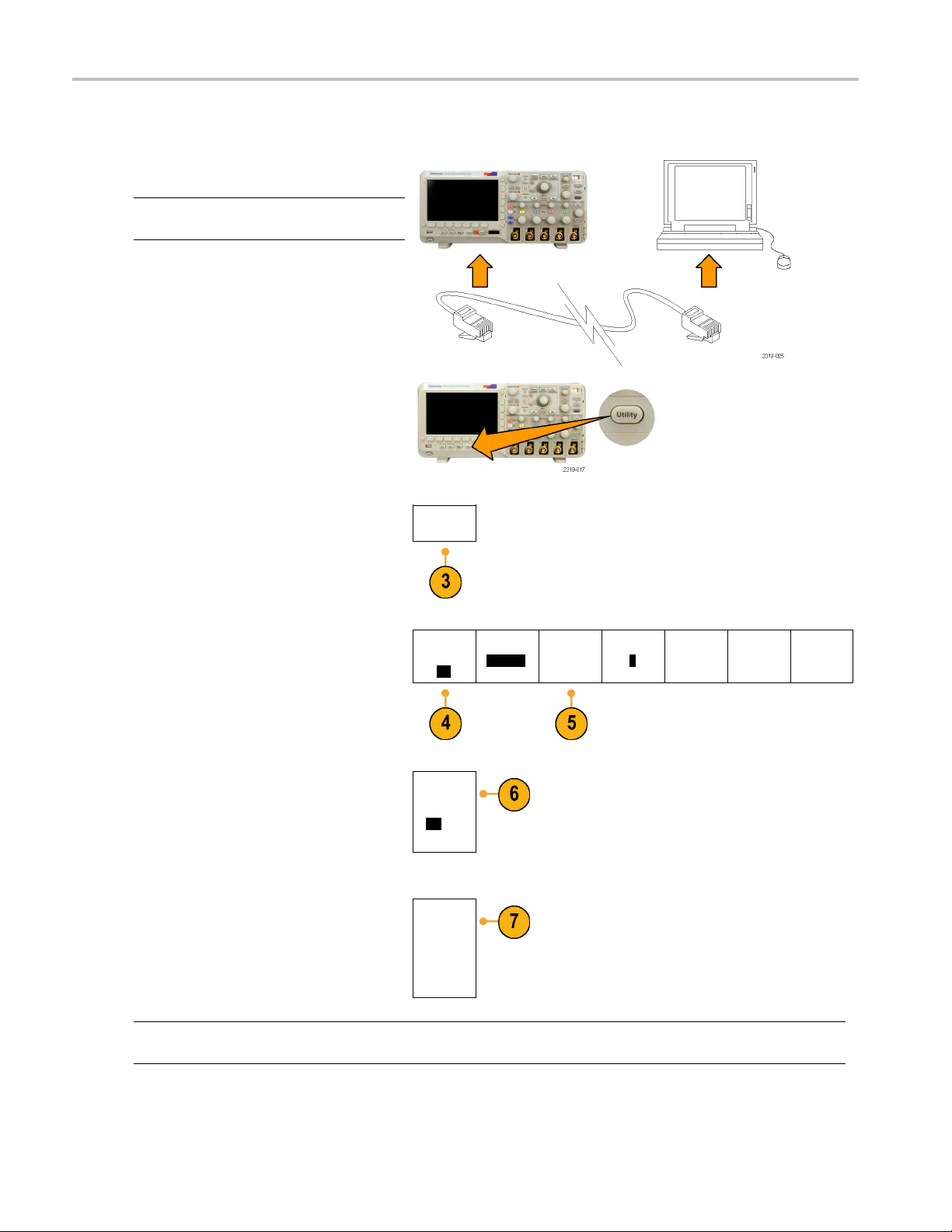

Connecting Your Oscilloscope to a Computer

You may want to document your work for future reference. Instead of saving screen images and waveform data to a USB

flash drive and generating a report later, you may want to get a copy of the image or waveform data directly from a remote

PC for analysis. You may also want to control an oscilloscope at a remote location from your computer. (See page 111,

Saving a Screen Image.) (See page 112, Saving and Recalling Waveform Data.)

Two ways to connect your oscilloscope to a computer are through the V ISA (Virtual Instrument Software Architecture) drivers

and the e*Scope Web-enabled tools. Use VISA to communicate with your oscilloscope from your computer through a

software application. Use e*Scope to communicate with your oscilloscope through a Web browser.

Using VISA

VISA let

runs on your PC, such as Microsoft Excel, National Instruments LabVIEW, or a program of your own creation. You can use a

common communications connection, such as USB or Ethernet, to connect the computer to the oscilloscope.

s you use your MS-Windows computer to acquire data from your oscilloscope for use in an analysis package that

Set Date &

Time

TekSecure

Erase

Memory

About

To set up VISA communications between your oscilloscope and a computer:

1. Load th

e VISA drivers on your computer.

You will find the drivers on the appropriate

CD that comes with your oscilloscope or

Tektronix software finder Web page

at the

(www.tektronix.com).

DPO2000 and MSO2000 Series Oscilloscopes User Manual 21

Page 42

Installation

2. Connect the oscilloscope to your computer

with the appropriate USB or Ethernet cable.

NOTE. You need

a DPO2CONN module to

make the Ethernet connection.

To communicate between the oscilloscope

and a GPIB system, connect the oscilloscope

to the TEK-USB-488 GPIB-to-USB Adapter

with a USB cable. Then connect the adapter

to your GPIB system with a GP IB cable.

Cycle the power on the oscilloscope.

3. Push Utility.

4. Push Utility Page.

5. Turn multipurpose knob a and select I/O.

6. If a USB cable is connected between

the oscilloscope and your computer, the

oscilloscope automatically sets itself up for

you.

Check the USB on the lower-bezel menu to

be sure it is enabled. If it is not enabled, push

USB and make an appropriate selection in

the side-bezel menu.

Utility

Page

Utility

Page

I/O

USB

Computer

Ethernet

Network

Settings

GPIB

1

22 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 43

Installation

7. To use Ethernet

, push Ethernet Network

Settings.

8. On the side-be

zel menu, if you are on a

DHCP Ethernet network and using a through

cable, set DHCP to On. If you are using a

cross-over c

able, set it to Off and set a hard

coded TCPIP address.

9. If you are using GPIB, push GPIB. Enter

the GPIB ad

dress on the side-bezel menu,

using multipurpose knob a.

This will

set the GPIB address on an

attached TEK-USB-488 Adapter.

10. Run your

application software on your

computer.

Quick Tips

Change

Instrument

Settings

DHCP/

BOOTP

On|Off

Talk/List

Address

(a) 1

en

The CDs that are shipped with your oscilloscope include a variety of Windows-based software tools designed to ensure

nt connectivity between your oscilloscope and your computer. There are toolbars that enhance connectivity with

efficie

Microsoft Excel and Word. There is also a stand-alone acquisition program called the OpenChoice Desktop.

USB Host port

e front-panel USB 2.0 Host port for USB flash drives and keyboards.

Use th

USB Device port

he rear-panel USB 2.0 Device port for PCs or PictBridge printers.

Use t

ng e*Scope

Usi

e*Scope lets you access any Internet-connected D PO2000 or MSO2000 series oscilloscope from a browser on your

workstation, PC, or laptop computer. No matter where you are, your oscilloscope is as close as the nearest browser.

DPO2000 and MSO2000 Series Oscilloscopes User Manual 23

Page 44

Installation

To set up e*Scope communications between your oscilloscope and a Web browser running on a remote computer:

1. Connect the oscilloscope to your computer

network with the appropriate Ethernet cable.

NOTE. You need a DPO2CONN module to

make the Ethernet connection.

If you are connecting directly to your

computer, y ou need a Crossover Ethernet

Cable. If you are connecting to a network or

a hub, you need a Straight Through Ethernet

Cable.

2. Push Utility.

3. Push Utility Page.

4. Turn multipurpose knob a and select I/O.

5. Push Ethernet Network Settings.

6. On the side-bezel menu, if you are on a

DHCP Ethernet network and using dynamic

addressing, set DHCP to On. If you are

using static addressing, set it to Off.

7. Push Change Instrument Settings.Ifyou

are using DHCP, note the Ethernet address

and instrument name. If you are using Static

addressing, enter the Ethernet address you

will be using.

Utility

Page

Utility

Page

I/O

DHCP/

BOOTP

On|Off

Change

Instrument

Settings

USB

Enabled

Ethernet

Network

Settings

GPIB

1

NOTE. Depending on the type and speed of network to which your oscilloscope is connected, you may not see the

DHCP/BOOTP field update instantaneously after pressing the DHCP/BOOTP button. It may take a few seconds to update.

24 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 45

8. Start your browser on your remote computer. In the browser address line, enter the IP address or, if DHCP is set to On

in the oscilloscope, simply enter the instrument name.

You should now

work, rerun the procedure. If it still does not work, contact qualified service personnel.

see the e*Scope screen showing the oscilloscope display on your Web browser. If e*Scope does not

Connecting a USB Keyboard to Your Oscilloscope

You can connect a USB keyboard to the USB Host port on the front panel of the oscilloscope. The oscilloscope will detect the

keyboard, even if it is plugged in while the oscilloscope is powered on. (See page 42, Labeling Channels and Buses.)

Installation

DPO2000 and MSO2000 Series Oscilloscopes User Manual 25

Page 46

Installation

26 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 47

Getting Acquain

ted with the Oscilloscope

Getting Acqua

inted with the Oscilloscope

Front-Panel Menus and Controls

The front panel has buttons and controls for the functions that you use most often. Use the menu buttons to access

more specialized functions.

Using the Menu System

To use the menu system:

1. Push a front-panel menu button to

display the menu that you want to use.

2. Push a lower-bezel button to select a

menu item. If a pop-out menu appears,

turn multipurpose knob a to select

the desired choice. If a pop-up menu

appears, press the button again to select

the desired choice.

DPO2000 and MSO2000 Series Oscilloscopes User Manual 27

Page 48

Getting Acquain

ted with the Oscilloscope

3. Push a side-bez

el button to choose a

side-bezel menu item.

If the menu item contains more than

one choice, pu

sh the side-bezel button

repeatedly to cycle through the choices.

If a pop-out menu appears, turn

multipurpos

e knob a to select the desired

choice.

4. Toremoveas

ide-bezel menu, push the

lower-bezel button again or push Menu

Off.

28 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 49

5. Certain menu choices require you to set

a numeric value to complete the setup.

Use the upper a

knobs a and b to adjust values.

6. Push Fine to turn off or on the ability to

make smaller adjustments.

nd lower multipurpose

Using the Menu Buttons

Getting Acquain

ted with the Oscilloscope

Use the me

1. Measure. Push to perform automated

2. Search.

3. Test. Push to activate advanced or

4. Acquire. Push to set the acquisition

5. Autoset. Push to perform an automatic

6. Tri

7. Uti

nu buttons to perform many functions in the oscilloscope.

measurements on waveforms or to

ecursors.

configur

Push to search through

an acquisition for user-defined

events/criteria.

application-specific testing features.

mode and adjust the record length.

p of oscilloscope settings.

setu

gger Menu. Push to specify trigger

settings.

lity. P ush to activate the system utility

functions, such as selecting a language

or setting the date/time.

8. Save / Recall Menu. Push to save and

call setups, waveforms, and screen

re

images to internal memory, or a USB

flash drive.

DPO2000 and MSO2000 Series Oscilloscopes User Manual 29

Page 50

Getting Acquain

9. Channel 1, 2, 3,or4Menu. Push

to set vertical parameters for input

waveforms and

the corresponding waveform from the

display.

ted with the Oscilloscope

to display or remove

30 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 51

10. B1 or B2. Pushtodefine and

display a serial bus if you have the

appropriate m

The DPO2AUTO module supports CAN

and LIN buses. The DPO2EMBD module

supports I

module supports RS-232, RS-422,

RS-485, and UART buses.

Parallel bus

MSO2000 products.

Also, push the B1 or B2 buttontodisplay

or remove th

the display.

11. R. Push to manage reference waveforms,

including the display or removal of each

referenc

odule application keys.

2

and SPI. The DPO2COMP

C

support is available on

e corresponding bus from

e waveform from the display.

Getting Acquain

ted with the Oscilloscope

12. M.Pushto

including the display or removal of the

math waveform from the display.

Using O

These buttons and knobs control waveforms, cursors, and other data input.

1. Turn the upper multipurpose knob a,

when activated, to move a cursor, to set

a numerical parameter value for a menu

item, or to select from a pop-out list of

choices. Push the Fine button to toggle

between coarse and fine adjustment.

Screen icons tell you when a or b are

active.

2. Cursors. Push once to activate the

two vertical cursors. Push again to turn

on the two vertical and two horizontal

cursors. Push again to turn off all

cursors.

When the cursors are on, you can turn

the multipurpose knobs to control their

position.

manage the math waveform,

ther Controls

DPO2000 and MSO2000 Series Oscilloscopes User Manual 31

Page 52

Getting Acquain

3. Select. Push to activate special

functions.

For example, w

cursors (and no horizontal ones are

visible), you can push this button to link

or unlink the

vertical and two horizontal cursors are

both visible, you can push this button to

make either t

horizontal cursors active.

4. FilterVu.Pushtofilter unwanted noise

from your signal and still capture glitches.

5. Fine. Push to toggle between making

coarse and fine adjustments with the

vertical

trigger level knob, and many operations

of multipurpose knobs a and b.

6. Intensity. Push to enable multipurpose

knob a to control waveform display

intensi

intensity.

ted with the Oscilloscope

hen using the two vertical

cursors. When the two

he vertical cursors or the

and horizontal position knobs, the

ty and knob b to control graticule

7. Turn th

8. Zoom b

9. Pan (outer knob). Turn to scroll the zoom

10. Zoom (inner knob). Turn to control the

11. Play-pause button. Push to start or stop

e lower multipurpose knob b,

when activated, to move a cursor or set

a numerical parameter value for a menu

ush Fine to make adjustments

item. P

more slowly.

utton. Push to activate zoom

mode.

window through the acquired waveform.

m factor. Turning it clockwise zooms

zoo

in further. Turning it counterclockwise

zooms out.

the automatic panning of a waveform.

ntrol the speed and direction with the

Co

pan knob.

32 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 53

Getting Acquain

ted with the Oscilloscope

12. ← Prev. Push to j

waveform mark.

13. Set/Clear Mark. Push to establish or

delete a waveform mark.

14. → Next. Push to jump to the next

waveform mark.

15. Horizontal Position. Turn to adjust

the trigger point location relative to the

acquired wa

smaller adjustments.

16. Horizontal Scale. Turn to adjust the

horizontal scale (time/division).

17. Run/Stop. Push to start or stop

acquisitions.

18. Single. Push to make a single

acquisition.

ump to the previous

veforms. Push Fine to make

19. Autoset. Push to automatically set the

vertical, horizontal, and trigger controls

for a usable, stable display.

20. Trigger Level. Turn to adjust the trigger

level.

Push Level to Set 50%. Push the

Trigger level knob to set the trigger level

to the midpoint of the waveform.

21. Force Trig. Push to force an immediate

trigger event.

22. Vertical Position. Turn to adjust the

vertical position of the corresponding

eform. Push Fine to make smaller

wav

adjustments.

2, 3, 4 Menu. Push to display or

23.1,

remove the corresponding waveform

from the display and access the vertical

nu.

me

DPO2000 and MSO2000 Series Oscilloscopes User Manual 33

Page 54

Getting Acquain

24. Vertical Scale. Turn to adjust the

vertical scale factor of the corresponding

waveform (vol

25. Print. Push to print to a PictBridge

printer.

ted with the Oscilloscope

ts/division).

26. P ower switc

the oscilloscope.

27. USB 2.0 Host port. Insert a USB

peripheral to the oscilloscope, such as a

keyboard o

28. S ave. Pus

save operation. The save operation uses

the current save parameters, as defined

in the Sav

29. Default Setup. Push to perform an

immediate restore of the oscilloscope to

the default settings.

30. D15 - D0. Push to display or remove the

digital channels from the display, and to

access the digital channel setup menu

(MSO2000 series only).

h. Push to power on or off

raflash drive.

h to perform an immediate

e / Recall menu.

31. Menu Off. Push to clear a displayed

menu from the screen.

34 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 55

32. Waveform Only. Push to remove menu

and readout information from the screen

so the oscillo

waveform or bus. Push a second time

to recall the previous menu and readout

information

scope only displays the

.

Identifying Items in the Display

The items shown to the right may appear in

the display. Not all of these items are visible

at any give

outside the graticule area when menus are

turned off.

n time. Some readouts move

Getting Acquain

ted with the Oscilloscope

1. The acquisition readout shows when an

acquisition is running, stopped, or when

acquisition preview is in effect. Icons are:

Run: Acquisitions enabled

Stop: Acquisitions not enabled

Roll: In Roll mode (40 ms per division

or slower)

PreVu: In this state, the oscilloscope

is stopped or between triggers.

You can change the horizontal

or vertical position or scale to

see approximately what the next

acquisition will look like.

DPO2000 and MSO2000 Series Oscilloscopes User Manual 35

Page 56

Getting Acquain

ted with the Oscilloscope

2. The trigger sta

status. Status conditions are:

Trig’d: Triggered

Auto: Acquiring untriggered data

PrTrig: Acquiring pretrigger data

Trig?: Waiting for trigger

3. The trigger

the trigger occurred in the acquisition.

4. The expansion point icon (an orange

e) shows the point that the

triangl

horizontal scale expands and

compresses around.

tus readout shows trigger

position icon shows where

5. The waveform record view shows the

r location relative to the waveform

trigge

record. The line color corresponds to the

selected waveform color.

6. The FilterVu indicator shows if the

ble low pass filter is active.

varia

7. The cursor readout shows time,

itude, and delta (Δ) values for each

ampl

cursor.

For FFT measurements, it shows

uency and magnitude.

freq

For serial buses, the readout shows the

decoded values.

36 DPO2000 and MSO2000 Series Oscilloscopes User Manual

Page 57

Getting Acquain

ted with the Oscilloscope

8. The trigger lev

level on the waveform. The icon color

corresponds to the trigger source color.

9. The trigger readout shows the trigger

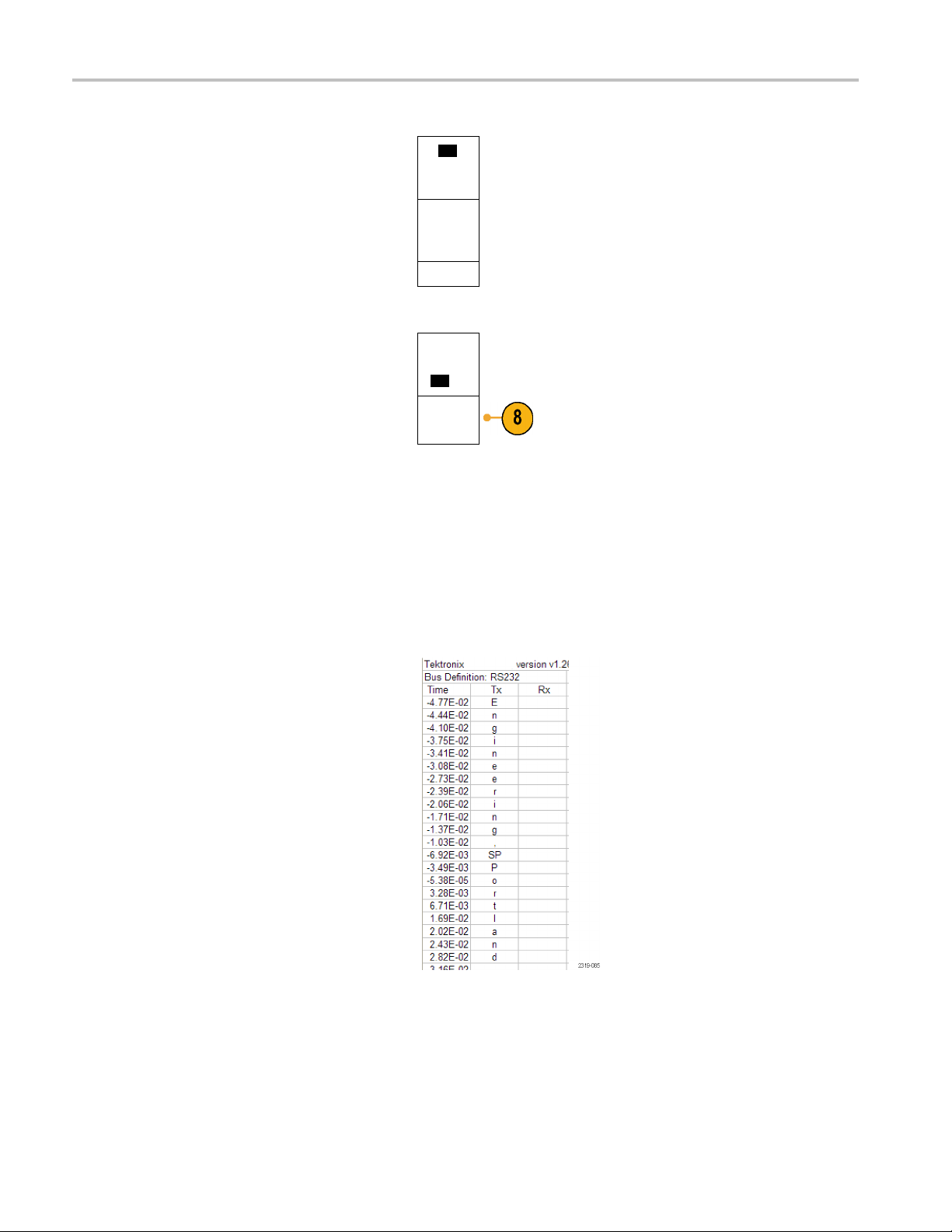

source, slope, level, and frequency for