Page 1

Tektronix MDO4034-3 Manual

Get Pricing & Availability at

ApexWaves.com

Call Today: 1-800-915-6216

Email: sales@apexwaves.com

https://www.apexwaves.com/oscilloscopes/tektronix-inc/mdo4000/MDO4034-3

Page 2

x

MDO4000 Series

Mixed Domain Oscilloscopes

ZZZ

User Manual

*P071291300*

071-2913-00

Page 3

Page 4

xx

MDO4000 Series

Mixed Domain Oscilloscopes

ZZZ

User Manual

www.tektronix.com

071-2913-00

Page 5

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by na

tional copyright laws and international treaty provisions.

Tektronix pro

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

e*Scope, iView, OpenChoice, TekSecure, and TekVPI are registered trademarks of Tektronix, Inc.

MagniVu and Wave Inspector are trademarks of Tektronix, Inc.

PictBridge is a registered trademark of the Standard of Camera & Imaging Products Association CIPA DC-001-2003 Digital Photo

Solutions for Imaging Devices.

Contactin

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

ducts are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

g Tektronix

Page 6

MDO4000 Series Oscilloscopes

Warranty

Tektronix warrants that the product will be free from defects in materials and workmanship for a period of three (3) years from the date

of original pu

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Batteries are excluded from this warranty. Parts, modules and replacement products used by Tektronix for warranty

work may be ne

rchase from an authorized Tektronix distributor. If the product proves defective during this warranty period, Tektronix, at its

w or reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to ob

period and make suitable arrangements for the performance of s ervice. Customer shall be responsible for packaging and shipping

the defective product to the service center designated by Tektronix, shipping charges prepaid, and with a copy of customer proof of

purchase. T

the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other

charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate m aintenance and

care. Tekt

other than Tektronix representatives to install, repair o r service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Te ktronix supplies; or

d) to serv

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS

IS THE SOLE AND E XCLU S IVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPE

DAMAGES.

[W16 – 15AUG04]

tain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty

ektronix shall pay for the return of the product to C ustomer if the shipment is to a location within the country in which

ronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

ice a product that has been modified or integrated with other products when the effect of such modification or integration

FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

CTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

Page 7

P6616, TPP0500, and TPP1000 Probes

Warranty

Te ktronix w arrants that the product will be free from defects in materials and workmanship for a period of one (1) year from the date of

original purc

option, either will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Batteries are excluded from this warranty. Parts, modules and replacement products used by Tektronix for warranty

work may be ne

hase from an authorized Tektronix distributor. If the product proves defective during this warranty period, Tektronix, at its

w or reconditioned to like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to ob

period and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping

the defective product to the service center designated by Tektronix, shipping charges prepaid, and with a copy of customer proof of

purchase. T

the Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other

charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance and

care. Tekt

other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from improper use or

connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-Tektronix supplies; or

d) to serv

increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY OTHER WARRANTIES,

EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS

IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

IRRESPE

DAMAGES.

[W15 – 15AUG04]

tain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty

ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which

ronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts by personnel

ice a product that has been modifi ed or integrated with other products when the effect of such modification or integration

FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS

CTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

Page 8

Table of Contents

General Safety Summary ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . ... . .. . .. . ... ... . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... v

Compliance Information.............................................................................................................. vii

EMC Compliance................................................................................................................ vii

Safety Compliance ............................................................................................................. viii

Environmental Considerations................................................................................................... ix

Preface................................................................................................................................. xi

Key Features.....................................................................................................................xi

Conventions Used in This Manual.. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. xi

Installation.............................................................................................................................. 1

Before Installation................................................................................................................ 1

Operating Considerations........................................................................................................ 5

Operating Positions ..............................................................................................................7

Connecting Probes. .. . .. . ... . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... . .. . .. . ... . .. 8

Securing the Oscilloscope ....................................................................................................... 9

Powering onthe Oscilloscope .................................................................................................. 10

Powering off the Oscilloscope .................................................................................................. 11

Functional Check. ... . .. . ... ... . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . ... 11

Compensating a TPP0500 or TPP1000 Passive Voltage Probe.. . .. . .. . ... . .. . .. . ... . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... . .. . .. 12

Compensating a non-TPP0500 or non-TPP1000 Passive Voltage Probe. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . 14

Application Module Free Trial... . .. . ... ... . .. . .. . .. . ... . .. . .. . .. . ... ... . .. . .. . ... ... . .. . .. . .. . ... . .. . .. . .. . ... ... . .. . .. . ... ... . . 15

Installing an Application Module.. . .. . .. . ... ... . .. . .. . .. . ... . .. . .. . .. . ... . .. . .. . ... ... . .. . .. . ... ... . .. . .. . ... . .. . .. . .. . ... . .. . .. 15

Changing the Language of the User Interface or Keyboard.. . .. . . .. . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . 16

Changing the Date and Time ... . .. . ... . .. . .. . . .. . .. . ... . .. . ... . .. . .. . . .. . .. . ... . .. . ... ... . .. . . .. . .. . ... . .. . ... ... . .. . ... . .. . ... 17

Signal Path Compensation . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . ... . .. . 19

Upgrading Firmware ............................................................................................................ 21

Connecting Your Oscilloscope to a C omputer . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . . 24

Connecting a USB Keyboard to Your Oscilloscope. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . 32

Get Acquainted with the Instrument ................................................................................................. 33

Front-Panel Menus and Controls. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . . 33

Front-Panel Connectors .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. 47

-Panel Connector... . .. . ... . .. . ... ... . .. . ... . .. . ... . .. . ... ... . .. . ... . .. . ... . .. . ... ... . .. . ... . .. . ... . .. . ... ... . .. . ... . .. . ... . 47

Side

Rear-Panel Connectors. . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . . 48

Acquire the Signal ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . .. . . ...... 50

Setting Up Analog Channels.. . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... 50

Using the Default Setup......................................................................................................... 53

Using Autoset ................................................................................................................... 54

Acquisition Concepts............................................................................................................ 55

How the Analog Acquisition Modes Work.. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . 57

Changing the Acquisition Mode, Record Length, and Delay Time. . .. . . .. . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . . 57

Using Roll Mode................................................................................................................. 59

Setting Up a Serial or Parallel Bus ............................................................................................. 60

Setting Up Digital C hannels . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . 73

Table of Content

s

MDO4000 Series Oscilloscopes User Manual i

Page 9

Table of Content

Trigger Setup . ... ... . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... ... . .. . ... . .. . .. . ... ... . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... . .. . ....... 80

Display Waveform or Trace Data .................................................................................................... 96

Analyze Waveform or Trace Data.. . ... . .. . .. . ... . .. . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . ... . . 117

Save and Recall Information ....................................................................................................... 161

s

When and Why to Turn On MagniVu. . ... ... . .. . ... . .. . ... . .. . ... . .. . ... . .. . ... . .. . .. . ... . .. . ... . .. . ... . .. . ... . .. . .. . . .. . ... ... 75

Using MagniVu . . ... . .. . .. . .. . ... . .. . .. . .. . ... . .. . .. . .. . ... . .. . .. . ... ... . .. . .. . ... ... . .. . .. . ... . .. . .. . .. . ... . .. . .. . .. . ... ... . .. . . 75

Setting Up the RF Inputs.. . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... . .. . .. . ... ... . .. . . 76

Triggering Concepts............................................................................................................. 80

Choosing a Trigger Type. .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . ... . .. . ... ... 83

Selecting Triggers. . ... . .. . .. . ... ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. .84

Triggering on Buses............................................................................................................. 86

Checking Trigger Settings .. . .. . .. . ... ... . .. . .. . ... ... . .. . .. . ... . .. . .. . .. . ... . .. . .. . .. . ... ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... .. 90

Using Sequence Trigger (A (Main) and B (Delayed)). . ... ... . .. . ... ... . .. . .. . . .. . .. . ... . .. . .. . ... ... . .. . ... . .. . ... ... . .. . .. . .. 91

Starting and Stopping an Acquisition. . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . 93

Triggering on the RF Input .. . .. . ... . .. . .. . ... ... . .. . ... . .. . .. . ... ... . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... 93

Adding and Removing a Waveform ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. 96

Setting the Display Style and Persistence ..................................................................................... 96

Setting Waveform Intensity ................................................................................................... 100

Scaling and Positioning a Waveform......................................................................................... 101

Setting Input Parameters . . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. 102

Positioning and Labeling Bus S ignals . . ... . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... 106

Positioning, Scaling, and Grouping Digital Channels . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . .. 106

Viewing D igital Channels . . .. . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . .. . ... ... . .. . .. . . .. . .. . ... ... . 108

Annotating the Screen .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... . 108

Viewing the Trigger Frequency . ... . .. . .. . ... . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . ... . .. . .. . ... . .. . .. . . .. . .. . ... . .. . ... ... . .. 109

Displaying the Frequency Domain Menu... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . . 110

Using Markers in the Frequency Domain .. . ... ... . .. . .. . ... . .. . .. . .. . ... ... . .. . .. . ... ... . .. . .. . .. . . .. . .. . .. . ... ... . .. . .. . ... 117

Taking Automatic Measurements in the Frequency Domain ... ... . .. . ... ... . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . 120

Taking Automatic Measurements inthe Time Domain ...................................................................... 121

Selecting Automatic Measurements inthe Time Domain ................................................................... 122

Customizing an Automatic Measurement in the Time Domain.............................................................. 12

Taking Manual Measurements with Cursors ... . ... . .. . .. . ... . .. . ... ... . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . ... ... . .. . ... ... 129

Setting Up a Histogram ....................................................................................................... 133

Using Math Waveforms ....................................................................................................... 136

Using FFT ..................................................................................................................... 137

Using Advanced Math......................................................................................................... 140

Using Spectrum Math . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... . 141

Using Reference Waveforms and Traces.................................................................................... 142

Using Wave Inspector to Manage Long Record Length Waveforms.. . . .. . .. . ... . .. . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. 144

Auto-magnify .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . . 149

Time-Correlated Multi-Domain Display....................................................................................... 150

Limit and Mask Testing........................................................................................................ 154

Analyzing Power . . .. . .. . ... . .. . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . . .. . .. . . 160

Saving a Screen Image....................................................................................................... 163

Saving and Recalling Waveform and Trace Data............................................................................ 164

6

ii MDO4000 Series Oscilloscopes User Manual

Page 10

Table of Content

Saving and Recalling Setups................................................................................................. 167

Saving with One

Managing Drives, Directories, and Files . . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . ... ... . 170

Mounting a Network Drive .................................................................................................... 170

Printing a Har

Erasing Oscilloscope Memory ................................................................................................ 177

Using Application Modules .. ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . 179

Appendix A: M

Appendix B: TPP0500 and TPP1000 500 MHz and 1 GHz 10X Passive Probes Information ... . .. . .. . ... . .. . ... . .. . ... ... . .. . 184

Operating Information......................................................................................................... 184

Connecting

Compensating the Probe with MDO4000 Series Oscilloscopes . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . ... ... . .. . ... ... . .. 184

Standard Accessories. . .. . .. . ... ... . .. . ... ... . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... . .. . .. . 184

Optional A

Replacing the Probe Tip ...................................................................................................... 186

Specifications.................................................................................................................. 187

Performa

Safety Summary .............................................................................................................. 189

Appendix C: P6616 General-Purpose Logic P robe Information . .. . .. . ... . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... . .. . .. . ... ... . .. . .. 191

Product D

Connecting the Probe to the Oscilloscope ... . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . ... . .. . .. . ... ... . .. . .. . ... . .. . .. . ... . .. . .. . 191

Connecting the Probe to Your Circuit .. . .. . ... . .. . .. . ... ... . .. . ... . .. . .. . ... ... . .. . ... ... . .. . .. . ... . .. . ... ... . .. . .. . ... . .. . .. 192

nal Check.............................................................................................................. 192

Functio

Typical Application . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . ... ... . .. . .. . . .. . .. . ... ... . .. . 193

Accessories ................................................................................................................... 193

cations.................................................................................................................. 194

Specifi

Safety Summary .............................................................................................................. 195

Safety Terms and Symbols in This Manual................................................................................... 195

Index

Button Push ................................................................................................ 169

d Copy.......................................................................................................... 171

DO4000 Specifications............................................................................................. 180

the Probe to the Oscilloscope ................................................................................... 184

ccessories ......................................................................................................... 186

nce Graphs.. . ... . .. . ... ... . .. . ... . .. . ... . .. . .. . ... . .. . ... . .. . ... ... . .. . ... . .. . .. . . .. . .. . ... . .. . ... ... . .. . ... . .. . ... . 187

escription ........................................................................................................... 191

s

MDO4000 Series Oscilloscopes User Manual iii

Page 11

Table of Content

s

iv MDO4000 Series Oscilloscopes User Manual

Page 12

General Safety S

ummary

General Safet

Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or Personal Injury

Use proper power cord. Use only the power cord specified for this product and certified for the country of use.

Connect and disconnect properly. Do not connect or disconnect probes or test leads while they are connected

to a voltage source.

Connect and disconnect properly. De-energize the circuit under test before connecting or disconnecting the current

probe.

Ground th

shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings and markings on the product. Consult the

product

Connect

e product.

manual for further ratings information before making connections to the product.

the probe reference lead to earth ground only.

y Summary

This product is grounded through the grounding conductor of the power cord. To avoid electric

Do not ap

Power d

must remain accessible to the user at all times.

ply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

isconnect.

The power cord disconnects the product from the power source. Do not block the power cord; it

Do not operate without covers. Do not operate this product with covers or panels removed.

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by

qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

Do not operate in wet/damp conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide proper ventilation.

per ventilation.

pro

Refer to the manual’s installation instructions for details on installing the product so it has

MDO4000 Series Oscilloscopes User Manual v

Page 13

General Safety S

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning s tatements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Symbols and Terms on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the marking.

WARNING indicates an injury hazard not immediately accessible as you r ead the marking.

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

ummary

vi MDO4000 Series Oscilloscopes User Manual

Page 14

Compliance Info

rmation

Compliance In

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument

complies.

EMC Compliance

EC Declarati

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EN 61326-1:2006, EN 61326-2-1:2006. EMC requirements for electrical equipment for measurement, control, and

laborator

CISPR 11:2

IEC 61000

IEC 61000

IEC 61000

IEC 6100

IEC 6100

IEC 6100

on of Conformity – EMC

1234

yuse.

003. Radiated and conducted emissions, Group 1, Class A

-4-2:2001. Electrostatic discharge immunity

-4-3:2002. RF electromagnetic field immunity

-4-4:2004. Electrical fast transient/burst immunity

0-4-5:2001. Power line surge immunity

0-4-6:2003. Conducted RF immunity

0-4-11:2004. Voltage dips and interruptions immunity

formation

5

6

7

EN 61000-3-2:2006. AC power line harmonic emissions

EN 6100

0-3-3:1995.

Voltage changes, fluctuations, and flicker

European contact.

Te ktronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

1

2

3

4

5

6

7

product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic interference.

This

Emissions which exceed the levels required by this s tandard may occur when this equipment is connected to a test object.

To ensure compliance with the EMC standards listed here, high quality shielded interface cables should be used.

Instrument rebooting may be experienced where the EUT takes longer than 10 seconds to recover from a transient immunity test.

The instrument will exhibit ≤ 4.0 division waveform displacement and ≤ 8.0 division increase in peak-to-peak noise when subjected

to radiated interference per IEC 61000-4-3.

The instrument will exhibit ≤ 1.0 division waveform displacement and ≤ 2.0 division increase in peak-to-peak noise when subjected

to conducted interference per IEC 61000-4-6.

Performance Criterion C applied at the 70%/25 cycle Voltage-Dip and the 0%/250 cycle Voltage-Interruption test levels

(IEC 61000-4-11).

MDO4000 Series Oscilloscopes User Manual vii

Page 15

Compliance Info

Australia / New Zealand Dec laration of Conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per the following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in accordance with EN 61326-1:2006 and

EN 61326-2-1:2006.

Australia / New Zealand contact.

Baker & McKenzie

Level 27, AMP

50 Bridge Street

Sydney NSW 2000, Australia

rmation

Centre

Safety Com

EC Declaration of Conformity – Low Voltage

Complianc

Low Volta

EN 61010-

U.S. Nationally Recognized Testing Laboratory Listing

UL 61010-1:2004, 2ndEdition. Standard for electrical measuring and test equipment.

Canadian Certification

CAN/CSA-C22.2 No. 61010-1:2004. Safety requirements for electrical equipment for measurement, control, and

laboratory use. Part 1.

tional Compliances

Addi

IEC 61010-1: 2001. Safety requirements for electrical equipment for measurement, control, and laboratory use.

Equipment Type

pliance

e was demonstrated to the following specification as listed in the Official Journal of the European Communities:

ge Directive 2006/95/EC.

1: 2001. Safety requirements for elec trical equipment for measurement control and laboratory use.

t and measuring equipment.

Tes

Safety Class

Class 1 – grounded product.

viii MDO4000 Series Oscilloscopes User Manual

Page 16

Compliance Info

rmation

Pollution Degree Description

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal

environment inside a product is considered to be the same as the external. Products should be used only in the environment

for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

encapsulated, hermetically sealed, or located in c lean rooms.

Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is

caused by condensation must be expected. This location is a typical office/home environment. Temporary condensation

occurs only when the product is out of service.

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation.

These are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct

sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through c onductive dust, rain, or snow. Typical

outdoor locations.

Pollution Degree

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Installation (Overvoltage) Category Descriptions

Te rminals on this product may have different installation (overvoltage) category designations. T he installation categories are:

Measurement Category IV. For measurements performed at the source of low-voltage installation.

Measurement Category III. For measurements performed in the building installation.

Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

Measurement Category I. For measurements performed on circuits not directly connected to MAINS.

Overvoltage Category

Overvoltage Category II (as defined in IEC 61010-1).

ironmental Considerations

Env

This section provides information about the environmental impact of the product.

Product End-of-Life Handling

serve the following guidelines when recycling an instrument or component:

Ob

Equipment recycling. Production of this equipment required the extraction and use of natural resources. The equipment may

ontain substances that could be harmful to the environment or human health if im properly handled at the product’s end of life. In

c

MDO4000 Series Oscilloscopes User Manual ix

Page 17

Compliance Info

order to avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to

recycle this pr

rmation

oduct in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

This symbol ind

to Directives 2002/96/EC and 2006/66/EC on waste electrical and electronic equipment (WEEE) and

batteries. For information about recycling options, check the Support/Service section of the Tektronix Web

site (www.tek

icates that this product complies with the applicable European Union requirements according

tronix.com).

Restriction of Hazardous Substances

This product has been classified as Monitoring and Control equipment, and is outside the scope of the 2002/95/EC RoHS

Directive.

x MDO4000 Series Oscilloscopes User Manual

Page 18

Preface

This manual describes the installation and operation of the following oscilloscopes:

MDO4104-6 MDO4104-3 MDO4054-6 MDO4054-3

Key Features

MDO4000 Mixed Domain Oscilloscopes provide time-correlated acquisition of analog, digital, and RF signals in a single

instrument

in both the time and frequency domains simultaneously. Key features include:

. They can help you verify, debug, and characterize electronic designs by providing views and measurements

A dedicated RF input channel for frequency domain measurements

16 digital channels and four analog channels for time domain measurements

Time-correlated acquisition of analog, digital, and RF signals in a single instrument

The ability to independently set acquisition parameters on the time and frequency domain channels

1 GHz and 500 MHz bandwidths

Preface

Conven

The following icons are used throughout this manual.

Sample rates up to 2.5 GS/s on all analog channels

20 M points record length on all channels

>50,000 waveforms/second display rate

Advanced triggering and analysis: I2C, SPI, USB 2.0, CAN, LIN, FlexRay, RS-232, RS-422, RS-485, UART, I2S, Left

Justified (LJ), Right Justified (RJ), TDM, Ethernet, MIL-STD-1553 (with the appropriate application module), and Parallel

Power analysis application module (optional)

tionsUsedinThisManual

Sequence Step

Front panel power

Connect power

Network

USB

MDO4000 Series Oscilloscopes User Manual xi

Page 19

Preface

xii MDO4000 Series Oscilloscopes User Manual

Page 20

Installation

Before Installation

Unpack the oscilloscope and check that you received all items listed as standard accessories. T he following pages list

recommended accessories and probes, instrument options, and upgrades. Check the Tektronix Web site (www.tektronix.com)

for the most current information.

Standard accessories

Accessory Description

MDO4000 Series Oscilloscopes User Manual

MDO4000 Series Oscilloscopes

Documentation Browser CD

NI LabVIEW SignalExpress™, Tektronix

Edition and Tektronix OpenChoice Desktop

CD

Calibration certificate documenting

traceability to national metrology institute(s),

and ISO9001 quality system registration.

Front Panel Overlay

English (Option L0)

French (Option L1)

Italian (Option L2)

German (Option L3)

Spanish (Option L4)

Japanese (Option L5)

Portuguese (Option L6)

Simplified Chinese (Option L7)

Traditional Chinese (Option L8)

Korean (Option L9)

Russian (Option L10)

Electronic versions of documents, including

the Programmer M anual and the Technical

Reference.

Productivity, analysis, and documentation

software

French (Option L1)

Italian (Option L2)

German (Option L3)

Spanish (Option L4)

Japanese (Option L5)

Portuguese (Option L6)

Simplified Chinese (Option L7)

Traditional Chinese (Option L8)

Korean (Option L9)

Russian (Option L10)

Installation

Tektronix part

number

071-2913-XX

071-2914-XX

071-2915-XX

071-2916-XX

071-2917-XX

071-2918-XX

071-2919-XX

071-2920-XX

071-2921-XX

071-2922-XX

071-2923-XX

063-4367-XX

063-3967-XX

——

335-2376-XX

335-2377-XX

335-2378-XX

335-2379-XX

335-2380-XX

335-2381-XX

335-2382-XX

335-2383-XX

335-2384-XX

335-2385-XX

MDO4000 Series Oscilloscopes User Manual 1

Page 21

Installation

Standard accessories (cont.)

Tektronix part

Accessory Description

For 500-MHz models, one 500-MHz, 10X

passive probe per channel

For 1-GHz models, one 1-GHz, 10X passive

probe per channel

Front Cover

Hard plastic cover to help protect the instrument 200-5130-00

Power Cord North America (Option A0)

Universal Euro (Option A1)

United Kingdom (Option A2)

Australia (Option A3)

Switzerland (Option A5)

Japan (Option A6)

China (Option A10)

India (Option A11)

Brazil (Option A12)

No power cord or AC adapter (Option A99)

Logic probe

One, 16-channel logic probe, with accessories

Probe and accessory pouch Bag to hold probes and related accessories 016-2030-XX

number

TPP0500Probes

TPP1000

161-0104-00

161-0104-06

161-0104-07

161-0104-05

161-0167-00

161-A005-00

161-0306-00

161-0400-00

161-0357-00

——

P6616

Optional accessories

Accessory Description

Aerospace serial triggering and analysis

application module

Audio serial triggering and analysis

application module

Automotive serial triggering and analysis

application module

This module enables triggering on

MIL-STD-1553 serial buses. Also, it provides

digital views of the signal, bus views, bus

decoding, search tools, and decode tables with

time stamp information.

This module enables triggering on I

Justified (LJ), Right Justified (RJ), and TDM

audio buses. Also, it provides digital views of

the signal, bus views, packet decoding, search

tools, and packet decode tables with time

stamp information

This module enables triggering on packet level

information on CAN and LIN serial buses. Also,

it provides a digital view of the signal, bus view,

packet decoding, search tools, and a packet

decode table with time stamp information.

2

S, Left

Tektronix part

number

DPO4AERO

DPO4AUDIO

DPO4AUTO

2 MDO4000 Series Oscilloscopes User Manual

Page 22

Optional accessories (cont.)

Tektronix part

Accessory Description

FlexRay, CAN, and LIN serial triggering and

analysis application module

This module enables triggering on packet level

information in FlexRay, CAN, and LIN buses.

Also, it provides digital views of the signal, bus

views, packet decoding, search tools, packet

decode tables with time stamp information and

eye diagram analysis software.

Computer triggering and analysis application

module

This module enables triggering on RS-232,

RS-422, RS-485 and UART serial buses.

Also, it provides digital v iews of the signal,

bus views, packet decoding, search tools,

and packet decode tables with time stamp

information.

Embedded serial triggering and analysis

application module

This module enables triggering on packet

level information on I

2

C and SPI serial buses.

Also, it provides digital v iews of the signal,

bus views, packet decoding, search tools,

and packet decode tables with time stamp

information.

Ethernet serial triggering and analysis

application module

This module enables triggering on 10BASE-T

and 100BASE-TX buses. Also, it provides

search tools, bus views, and decode tables

with time stamp information.

Limit and mask test application module This module supports limit testing and testing

on telecom standard masks or custom masks.

Power analysis application module

This module supports measurements of power

quality, switching loss, harmonics, ripple,

modulation, safe operating area, and slew rate

(dV/dt and dI/dt).

Universal Serial Bus triggering and analysis

application module

This module enables triggering on packet level

information on USB 2.0 s erial buses. Also, it

provides digital views of the signal, bus views,

bus decoding data in hex, binary, and ASCII,

search tools, and packet decode tables with

time stamp information.

Extended video application module

This module enables triggering on a variety of

standard HDTV signals, as well as on custom

(non-standard) bilevel and trilevel video signals

with 3 to 4,000 lines.

Advanced RF triggering application module This module enables triggering with RF power

as the source for Pulse Width, Timeout, Runt,

Logic, and Sequence triggers

NEX-HD2HEADER

Adapter that routes the channels from a Mictor

connector to 0.1 inch header pins

TPA-BNC TekVPI to TekProbe II BNC Adapter TPA-BNC

TEK-USB-488 Adapter GPIB to USB Adapter TEK-USB-488

number

DPO4AUTOMAX

DPO4COMP

DPO4EMBD

DPO4ENET

DPO4LMT

DPO4PWR

DPO4USB

DPO4VID

MDO4TRIG

NEX-HD2HEADER

Installation

MDO4000 Series Oscilloscopes User Manual 3

Page 23

Installation

Optional accessories (cont.)

Tektronix part

Accessory Description

Rackmount kit Adds rackmount brackets RMD5000

Soft transit case Case for carrying instrument ACD4000B

Hard transit case

MSO4000B, DPO4000B, and MDO4000

Series Oscilloscopes Programmer Manual

MDO4000 Series Oscilloscopes Technical

Reference Manual

MDO4000 Series Oscilloscopes Service

Manual

MSO4000B, DPO4000B, and MDO4000

Series A pplication Module Installation

Instructions

DPO3PWR and DPO4PWR Power

Measurement Module User Manual

MDO4000 Series Oscilloscopes

Declassification and Security Instructions

TPA-N-VPI Adapter

Traveling case, which requires use of the soft

transit case (ACD4000B)

Describes commands for remote control of the

oscilloscope. Available electronically on the

Documentation Browser CD or for download

from www.tektronix.com/manuals.

Describes the oscilloscope specifications

and performance verification procedure.

Available electronically on the Documentation

Browser CD or for download from

www.tektronix.com/manuals.

Service information on MDO4000 Series

oscilloscopes

Describes how to install application modules

on your oscilloscope

English (Option L0)

French (Option L1)

Italian (Option L2)

German (Option L3)

Spanish (Option L4)

Japanese (Option L5)

Portuguese (Option L6)

Simplified Chinese (Option L7)

Traditional Chinese (Option L8)

Korean (Option L9)

Russian (Option L10)

Describes how to sanitize or remove memory

devices from the Tektronix MD4000Series

oscilloscopes.

Adapter from N connection (RF input) to

TekVPI probe.

number

HCTEK54

077-0510-XX

077-0583-XX

077-0585-XX

071-2136-XX

071-2631-XX

077-0235-XX

077-0236-XX

077-0237-XX

077-0238-XX

077-0239-XX

077-0240-XX

077-0241-XX

077-0242-XX

077-0243-XX

077-0244-XX

077-0584-00

TPA-N-VPI

The MDO4000 Series oscilloscopes work with multiple optional probes. (See page 8, Connecting Probes.) Check the

Tektronix Web site (www.tektronix.com) for the most current information.

4 MDO4000 Series Oscilloscopes User Manual

Page 24

Operating Considerations

Installation

MDO4000 Serie

Operating Li

Volts

100-240

115

Mains input

Maximum Power Consumption: 225 W

Weight:

5.0 kg (11.

cover

Height, feet folded in, handle folded down:

229 mm (9.

Width, from handle hub to handle hub: 439 mm

(17.3 in)

Depth, f

(5.8 in)

Depth, from back of feet to front of front cover: 155

mm (6.1 i

Temperature:

Operat

Non-operating: -20 °C to +60 °C (-4 °F to 140 °F)

0 lbs), standalone instrument, without front

rom back of feet to front of knobs: 147 mm

n)

ing:+0°Cto+50°C(+32°Fto122°F)

s Osc illoscopes

ne Frequency and Voltage Range

Hz

50-60

400

voltage range: 100 V - 240 V

0in)

MDO4000 Se

ries

ity:

Humid

Operating: High: 40 °C to 50 °C (104 °F to 122 °F),

10% to 60% RH

ting: Low: 0 °C to 40 °C (32 °F to 104 °F), 10

Opera

to 90% RH

Non-operating: High: 40 °C to 60 °C (104 °F to

F), 5 to 60% RH

140 °

Non-operating: Low: 0 °C to 40 °C (32 °F to 104 °F),

5to90%RH

Altitude:

Operating: 3,000 m (about 9,843 ft)

-operating Altitude: 12,000 m (39,370 ft)

Non

Pollution Degree: 2, Indoor use only

MDO4000 Series Oscilloscopes User Manual 5

Page 25

Installation

Acquisition System: 1 MΩ

The maximum input voltage at the BNC, 300 V

Derate at 20 dB

/decade between 4.5 MHz and 45 MHz.

. Installation Category II.

RMS

Derate at 14 dB/decade between 45 MHz and 450 MHz.

Above 450 MHz, 5 V

RMS

.

Acquisition System: 50 Ω

The maximum

input voltage at the BNC: 5 V

, with peaks ≤ ±20 V (DF ≤ 6.25%)

RMS

P6616: Digital Probe Inputs

The absolut

e maximum input voltage: ±42 V

Peak

.

Dedicated RF Input:

The maximu

m operating voltage: ±40 V

.

DC

6 MDO4000 Series Oscilloscopes User Manual

Page 26

Installation

CAUTION. To ensure proper cooling, keep the sides and rear of the instrument clear of obstructions. Ventilation clearance

should be at least 51 mm (2 in) on the left side, when looking at the front of the instrument, and on the rear of the instrument

Find more information on MDO4000 Series oscilloscope specifications in Appendix A. (See page 180, Appendix A:

MDO4000 Specification

s.).

Find information on T

500 MHz and 1 GHz 10X Passive Probes Information.)

Find information on P6616 probes in Appendix C. (See page 191, Appendix C: P6616 General-Purpose Logic Probe

Information.)

PP0500/TPP1000 probes in Appendix B. (See page 184, Appendix B: TPP0500 and TPP1000

Cleaning

Inspect the oscilloscope and probes as often as operating conditions require. To clean the exterior surface, perform the

following steps:

1. Remove loose dust on the outside of the oscilloscope and probes with a lint-free cloth. Use care to avoid scratching

the display.

2. Use a soft cloth dampened with water to clean the oscilloscope. Use an aqueous solution of 75% isopropyl alcohol

for more efficient cleaning.

CAUTION. Avoid getting moisture inside the unit during external cleaning. Use only enough cleaning solution to dampen

the cloth or swab.

CAUTION. To avoid damage to the surface of the oscilloscope or probes, do not use any abrasive or chemical cleaning

agents.

Operating Positions

Use the handle and front flip f

always have the handle in a down position.

eet to place the oscilloscope in a convenient operating position. When the feet are extended,

MDO4000 Series Oscilloscopes User Manual 7

Page 27

Installation

Connecting Probes

The oscilloscope supports probes with the following:

1. Tektronix Versatile Probe Interface

(TekVPI)

These probes support two-way

communication with the oscilloscope

through on-screen menus and remotely

through programmable support. The

remote control is useful in applications

like ATE where you want the system to

preset probe parameters.

2. Tektronix Versatile Probe Interface

(TekVPI) for Passive Probes

These probes build upon the functionality

of the TekVPI interface. Each probe

is matched with its c orresponding

oscilloscope channel, allowing the

oscilloscope to optimize the signal input

path. This provides AC compensation

across the frequency band.

3. TPA-BNC Adapter

The TPA-BNC Adapter allows you to

use TEKPROBE II probe capabilities,

such as providing probe power, and

passing scaling and unit information to

the oscilloscope.

4. BNC Interfaces

Some of these use TEKPROBE

capabilities to pass the waveform signal

and scaling to the oscilloscope. Some

only pass the signal and there is no other

communication.

5. Logic Probe Interface

The P6616 probe provides 16 channels

of digital (on or off state) information.

6. The TPA-N-VPI Adapter allows you to

use TekVPI probes in the RF input.

For more information on the many probes available for use with MDO4000 Series oscilloscopes, refer to www.tektronix.com.

8 MDO4000 Series Oscilloscopes User Manual

Page 28

Securing the Oscilloscope

1. Use a standard laptop computer style

security lock

to your location.

to secure your oscilloscope

Installation

MDO4000 Series Oscilloscopes User Manual 9

Page 29

Installation

Powering on the Oscilloscope

Ground the Oscilloscope and Yourself

To power on the instrument, connect the power cord that was provided with the instrument to the power connector on the

rear panel. C

power cord from the instrument.

onnect the power cord to a properly grounded electrical outlet. To power off the instrument, remove the

Grounding th

same ground as any circuits that you are testing.

If you are wo

components, ground yourself. Static

electricity that builds up on your body

can damage

Wearing a grounding strap safely sends

static charges on your body to earth ground.

To connect the power cord and power on the oscilloscope:

e oscilloscope is necessary for safety and to take accurate measurements. The oscilloscope needs to share the

rking with static sensitive

static-sensitive components.

10 MDO4000 Series Oscilloscopes User Manual

Page 30

Powering off the Oscilloscope

To power off the oscilloscope and remove the power cord:

Installation

Functional Check

Perform this quick functional check to verify that your oscilloscope is operating correctly.

1. Connect the oscilloscope power cable

as described in Powering On the

Oscilloscope. (See page 10.)

2. Power on the oscilloscope.

MDO4000 Series Oscilloscopes User Manual 11

Page 31

Installation

3. Connect the probe connector to

oscilloscope channel 1 and the probe tip

and reference

terminals on the oscilloscope front panel.

4. Push Default Setup.

5. Push Autoset. The screen should now

display a

2.5 V at 1 kHz.

If the signal appears but is misshapen,

perform

the probe. (See page 14, Compensating

a non-TPP0500 or non-TPP1000

Passive

If no signal appears, rerun the procedure.

If this does not remedy the situation,

have th

service personnel.

lead to the PROBE COMP

square wave, approximately

the procedures for compensating

Voltage Probe.)

e instrument serviced by qualified

Compensating a TPP0500 or TPP1000 Passive Voltage Probe

The MDO4000 Series oscilloscopes can automatically compensate TPP0500 and TPP1000 probes. This eliminates the need

for manual probe compensation, as is typically performed with other probes.

Each compensation generates values for a specific probe and channel combination. If you want to use the probe on another

channel and desire to compensate the new probe-channel pair, you must run a new set of compensation steps for that new

combination.

1. Connect the oscilloscope power cable. (See

page 10, Powering on the Oscilloscope.)

2. Power on the oscilloscope.

12 MDO4000 Series Oscilloscopes User Manual

Page 32

3. Connect the probe connector to the

oscilloscope channel and the probe tip

and reference

lead to the PROBE COMP

terminals on the oscilloscope front panel.

NOTE. Connect only one probe at a time to the

probe comp te

rminals.

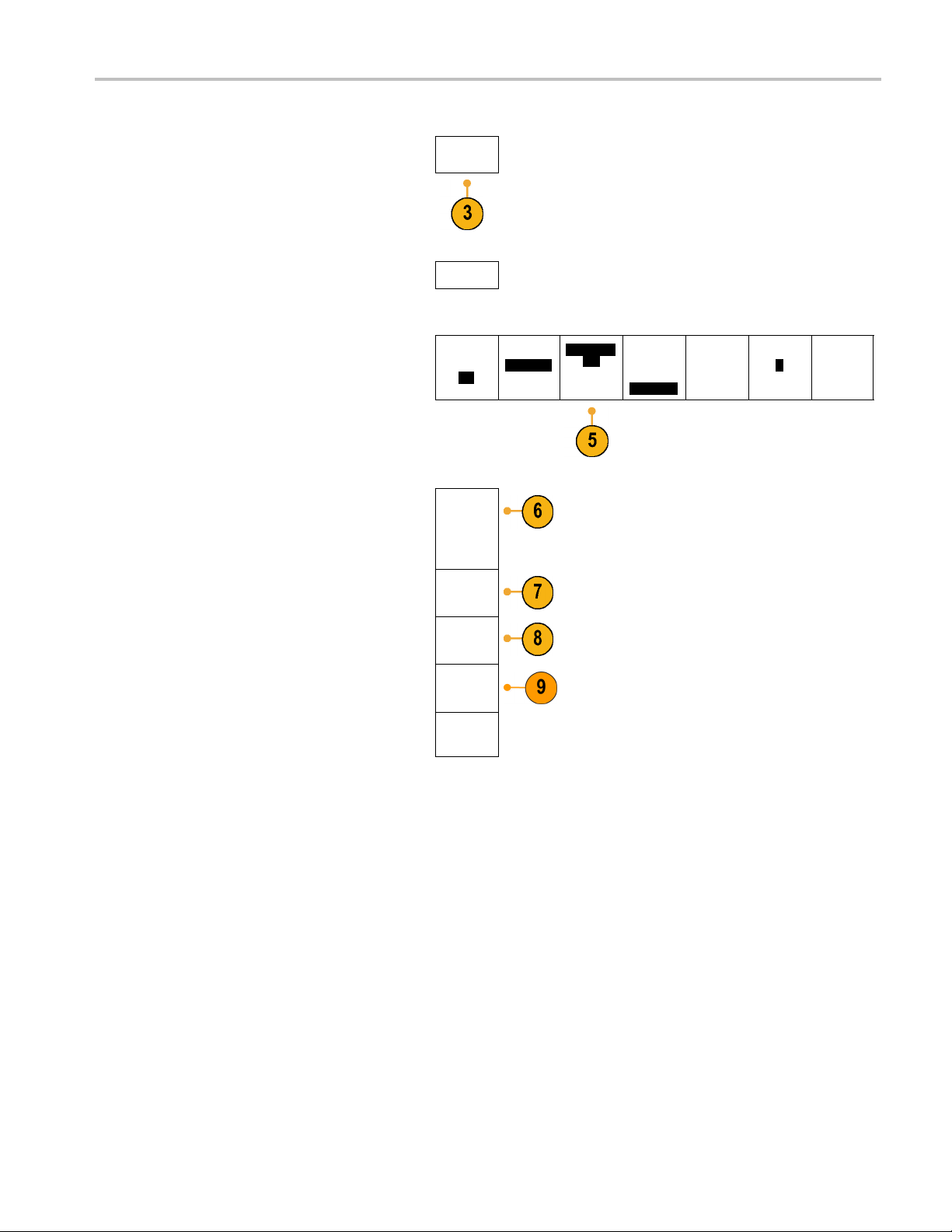

4. Push a front-panel button for an input

channel connected to the probe you wish to

compensate. (1, 2, 3,or4)

Installation

5. Notice on the lower menu that the

oscilloscope has automatically set the probe

termination value

6. Push More repeatedly to select Probe

Setup from the resulting pop-up menu.

Coupling

DC|AC

Term i n a -

tion set by

TPP1000

Invert

On|

Off

Bandwidth

Full

Label

More

MDO4000 Series Oscilloscopes User Manual 13

Page 33

Installation

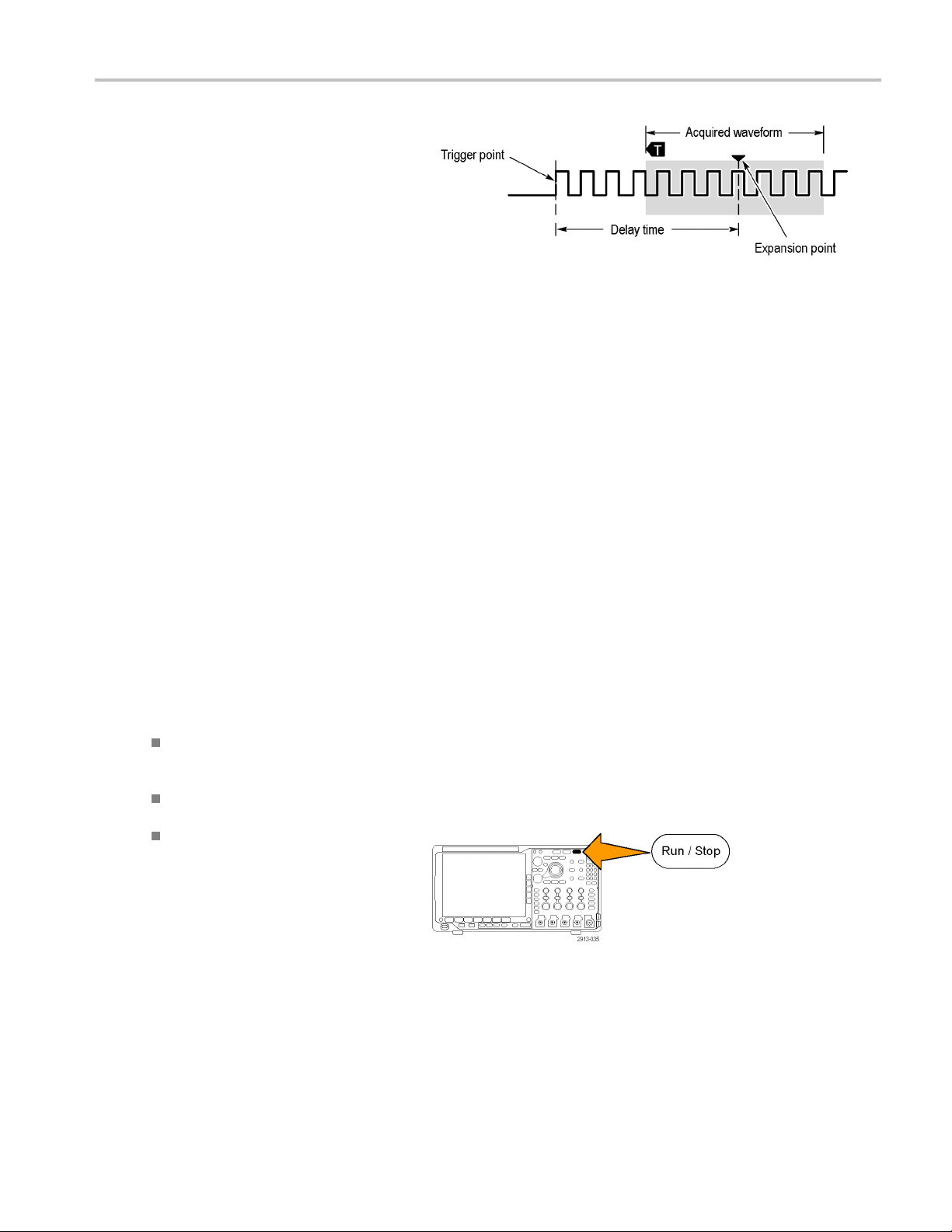

TPP1000

Probe

Setup

SN:

000001

Atten: 10X

7. Notice that the compensation status starts

as Default.

8. Push Compens

ate probe and follow the

instructions that appear on the display.

Compen-

sation

Status

Default

Compen-

sate probe

for 1

Measure

Current

Yes |

No

When compensating TPP0500/TPP1000 probes on the MDO4000 Series oscilloscopes:

Each compensation generates values for a specific probe and channel combination. If you want to use the probe on

another ch

annel and desire to compensate the new probe-channel pair, you must run a new set of compensation steps.

Compe

Each chann

el can store compensation values for 10 individual probes. If you try to compensate an 11th probe on a

channel, the oscilloscope will delete the values for the least recently used probe and add the values for the new probe.

The oscilloscope will assign default compensation values to a TPP0500 or TPP1000 probe connected to the Aux

In channel.

NOTE. Af

actory calibration will delete all stored compensation values

NOTE. A probe compensation failure is most likely due to intermittent connection of the probe tip or ground connection

during the probe compensation operation. If a failure occurs, the oscilloscope will re-use the old probe compensation values,

existed prior to the failed probe compensation operation.

if they

nsating a non-TPP0500 or non-TPP1000 Passive Voltage Probe

Whenever you attach a passive voltage probe for the first time to any input channel, compensate the probe to match it to

the corresponding oscilloscope input channel.

If you are interested in using the automatic probe compensation procedure described above for the TPP0500 and TPP1000 probes

(See page 12, Compensating a TPP0500 or TPP1000 Passive Voltage Probe.) on a non-TPP0500/TPP1000 Tektronix passive

probe, check the instruction manual for your probe to see if it qualifies. Otherwise, to properly compensate your passive probe:

1. Follow the steps for the functional

check. (See page 11, Functional

Check.)

14 MDO4000 Series Oscilloscopes User Manual

Page 34

2. Check the shape of the displayed

waveform to determine if your

probe is prope

rly compensated.

Properly compensated

Under compensa

ted

Over compensat

Installation

ed

3. If necessary,

Repeat as needed.

adjust your probe.

Quick Tips

Use the shortest possible ground lead

and signal path to minimize probe-induced

ringing a

signal.

nd distortion on the measured

Signal with a short ground lead

ith a long ground lead

Signal w

Application Module Free Trial

A 30-day free trial is available for all application module licenses not installed in your oscilloscope. The trial period begins

when you power on the oscilloscope for the first time.

After 30 days, you must purchase the module if you want to continue using the application. To see the date when your free

trial period expires, push the front panel Utility button, push the lower-bezel Utility Page button, use multipurpose knob a to

select Config, and push the lower-bezel About button.

Installing an Application Module

CAUTION. To avoid damage to the oscilloscope or application module, observe ESD (electrostatic discharge) precautions.

(See page 10, Powering on the Oscilloscope.)

Turn off the oscilloscope power while removing or adding an application module.

(See page 11, Powering off the Oscilloscope.)

MDO4000 Series Oscilloscopes User Manual 15

Page 35

Installation

Optional application module packages extend the capability of your oscilloscope.

You can physically install up to four application m odules at one time. Application modules go into the two slots with windows

in the upper ri

slots, install the module with the label facing away from you.

Each module has a license, which you can optionally transfer between your application modules and oscilloscope. You can

keep each license in the module, which will allow you to move the module from one instrument to another.

Alternatively, you can move the l icense from the module to the oscilloscope. This approach will allow you to store the module

separately f

your oscilloscope simultaneously.

To transfer a license from a module to your oscill oscope or from your oscilloscope to a module:

1. Turn off the power to the oscilloscope. Insert the application modules in the oscilloscope. Turn on the power.

2. Push the front-panel Utility button. If needed, push the lower-menu Utility Page button and turn multipurpose knob

a to select Config. Push the lower menu Application Module Licenses button and the appropriate side-menu

buttons to

up to four licenses at one time.

3. After you turn off the power to the oscilloscope, you can remove the physical application module from the oscilloscope.

Refer to the MSO4000B, DPO4000B, and MDO4000 Series Oscilloscopes Application Module Installation Instructions that

came with your application module for instructions on installing and testing an application module.

ght corner of the front panel. Two additional slots are directly behind the two that you can see. To use these

rom the oscilloscope for safe keeping. This approach will also allow you to use more than four applications on

transfer the license from the module to the oscilloscope or from the oscilloscope to the module. Transfer

NOTE. If

you transfer the license back from the oscilloscope to the m odule. Consider putting the physical module in an envelope

or other storage with a label with the date, the module name, and the model and serial number of the oscilloscope, which

holds it

and wonders why it does not work.

you transfer a license from a module to an oscilloscope, the module w ill not work on another oscilloscope until

s license. This will help prevent trouble later if someone finds the module, installs it in some other oscilloscope,

Changing the Language of the User Interface or Keyboard

To change the language of the oscilloscope user interface or keyboard, and to change the front-panel button labels through

the use of an overlay:

1. Push Utility.

2. Push Utility Page.

Utility

Page

3. Turn multipurpose knob a and select Config.

16 MDO4000 Series Oscilloscopes User Manual

Config

Page 36

Installation

4. Push Language from the resulting

lower-bezel menu.

5. Push Menus from the resulting side menu

and turn mul

tipurpose knob a to s e lect the

desired language for the user interface.

6. Push USB Ke

yboard from the resulting side

menu and turn multipurpose knob a to select

the desired language version of keyboard

to use.

7. If you choose to use an English user

ce, be sure that the plastic front-panel

interfa

overlay is removed.

If you choose a language other than English,

e plastic overlay for the language

place th

that you desire over the front panel to display

labels in that language.

Utility

Page

Config

Language

Menus

(a) English

USB

Keyboard

English

Language

Set Date &

Time

TekSecure

Erase

Memory

About

Chan

ging the Date and Time

To set the internal clock with the current date and time:

1. Push Utility.

MDO4000 Series Oscilloscopes User Manual 17

Page 37

Installation

2. Push Utility P

age.

3. Turn multipurpose knob a and select Config.

4. Push Set Dat

e&Time.

5. Push the side-bezel buttons and turn both

pose knobs (a and b)tosetthetime

multipur

and date values.

6. Push OK Set Date & Time.

Utility

Page

Config

Utility

Page

Config

Display

Date &

Time

On|Off

Hour

4

Minute

44

Month

May

Day

3

Year

2011

OK Set

Date &

Time

Language

Set Date &

Time

TekSecure

Erase

Memory

About

18 MDO4000 Series Oscilloscopes User Manual

Page 38

Signal Path Compensation

Signal Path Compensation (SPC) corrects for DC inaccuracies caused by temperature variations and/or long-term drift.

Run the compensation whenever the ambient temperature has changed by more than 10 °C (18 °F) or once a week

if you use vertical settings of 5 mV/division or less. Failure to do so may result in the instrument not meeting warranted

performance levels at those volts/div settings.

Signal Path Compensation for Time and Frequency Domain s

To compensate the signal path:

1. Warm up the oscilloscope for at least

20 minutes. Remove all input signals

(probes and cables) from channel inputs.

Input signals with AC components adversely

affect SPC.

Installation

2. Push Utility.

3. Push Utility Page.

4. Turn multipurpose knob a and select

Calibration.

Utility

Page

Calibration

MDO4000 Series Oscilloscopes User Manual 19

Page 39

Installation

5. Push Signal Path from the lower-bezel

menu.

6. Push OK Compensate Signal Paths from

the resulting side-bezel menu.

The calibra

tion will take approximately

10 minutes to complete.

7. After cali

bration, verify that the status

indicator on the lower-bezel menu displays

Pass.

If it does not, then recalibrate the instrument

or have the instrument serviced by qualified

service p

ersonnel.

Service personnel use the factory calibration

ns to calibrate the internal voltage

functio

references of the oscilloscope using

external sources. Contact your Tektronix

fice or representative for assistance

field of

with factory calibration.

Utility

Page

Calibration

OK Com-

pensate

Signal

Paths

Utility

Page

Calibration

Signal

Path

Pass

Signal

Path

Pass

Factory

Pass

Factory

Pass

NOTE. Signal Path Compensation does not include calibration to the probe tip. (See page 14, Compensating a

non-TPP0500 or non-TPP1000 Passive Voltage Probe.)

Signal Path Compensation for Frequency Domain Only

The signal path compensation (SPC) described above runs on both the time and the frequency domain inputs. If you only

want to compensate the RF input, you can save time by running SPC only on the RF input and skipping the time domain

part. You can do this as follows:

1. As with the time and frequency calibration,

warm up the oscilloscope for at least

20 minutes. Remove all input signals

(probes and cables) from the RF input.

2. Push RF to bring up the Frequency Domain

menu.

20 MDO4000 Series Oscilloscopes User Manual

Page 40

Installation

3. Push More to select Compensate SIgnal

Path.

4. On the resulti

ng side menu, push OK.

Compensate RF Signal Path.

Upgrading Firmware

To upgrade the firmware of the oscilloscope:

1. Open up a Web browser and go to

www.tektronix.com/software. P roceed to

the software finder. Download the latest

firmware for your oscilloscope on your PC.

e files and copy the firmware.img

Unzip th

file into the root folder of a USB flash drive

or USB hard drive.

Spectrum

Traces

RF Versus

Time

Traces

Spectro-

gram

On

Spectrum

Triggered

Detection

Method

Auto

Edit Labels

More

2. Power off your oscilloscope.

MDO4000 Series Oscilloscopes User Manual 21

Page 41

Installation

3. Insert the USB flash or hard drive into the

front-panel USB port on your oscilloscope.

4. Power on the oscilloscope. The instrument

automatic

firmware and installs it.

If the instrument does not install the

firmware,

problem continues, try a d ifferent model of

USB flash or hard drive. Finally, if needed,

contact

ally recognizes the replacement

rerun the procedure. If the

qualified service personnel.

NOTE. Do not power off the oscilloscope or

remove the USB drive until the oscilloscope

finishes

5. Power off the oscilloscope and remove the

installing the firmware.

USB flash or hard drive.

22 MDO4000 Series Oscilloscopes User Manual

Page 42

Installation

6. Power on the osc

7. Push Utility.

8. Push Utility Page.

illoscope.

Utility

Page

9. Turn mu

ltipurpose knob a and select Config.

10. Push About. The oscilloscope displays the

firmware version number.

11. Confirm that the version number matches

that of the new firmware.

Config

Utility

Page

Config

Language

English

Set Da

Time

te &

TekSe

Erase

Memory

cure

About

MDO4000 Series Oscilloscopes User Manual 23

Page 43

Installation

Connecting Your Oscilloscope to a Computer

Connect your oscilloscope directly to a computer to let the PC analyze your data, collect screen images, or to control your

oscilloscope. (See page 163, Saving a Screen Image.) (See page 164, Saving and Recalling Waveform and Trace D ata.)

Three ways to connect your oscilloscope to a computer are through the VISA drivers, the e*Scope Web-enabled tools, and

a socket server. Use VISA to communicate with your oscilloscope from your computer through a software application,

such as Tektronix OpenChoice Desktop®. Use e*Scope to communicate with your oscilloscope through a Web browser,

such as Microsoft Internet Explorer.

Using VISA

VISA lets yo

runs on your PC, such as Microsoft Excel, National Instruments LabVIEW, Tektronix OpenChoice Desktop software, or a

program of your own creation. You can use a common communications connection, such as USB, Ethernet, or GPIB,

to connect

To set up VISA communications between your oscilloscope and a computer:

1. Load the VISA drivers on your computer.

2. Connect the oscilloscope to your computer

u use your MS-Windows computer to acquire data from your oscilloscope for use in an analysis package that

the computer to the oscilloscope.

Also, load your application, such as

OpenChoice Desktop.

You will find the drivers and OpenChoice

Desktop software on the appropriate CD

that comes with your oscilloscope or at

the Tektronix software finder Web page

(www.tektronix.com).

with the appropriate USB or Ethernet cable.

To communicate between the oscilloscope

and a GPIB system, connect the oscilloscope

to the TEK-USB-488 GPIB-to-USB Adapter

with a USB cable. Then connect the adapter

to your GPIB system with a GPIB cable.

Cycle the power on the oscilloscope.

24 MDO4000 Series Oscilloscopes User Manual

Page 44

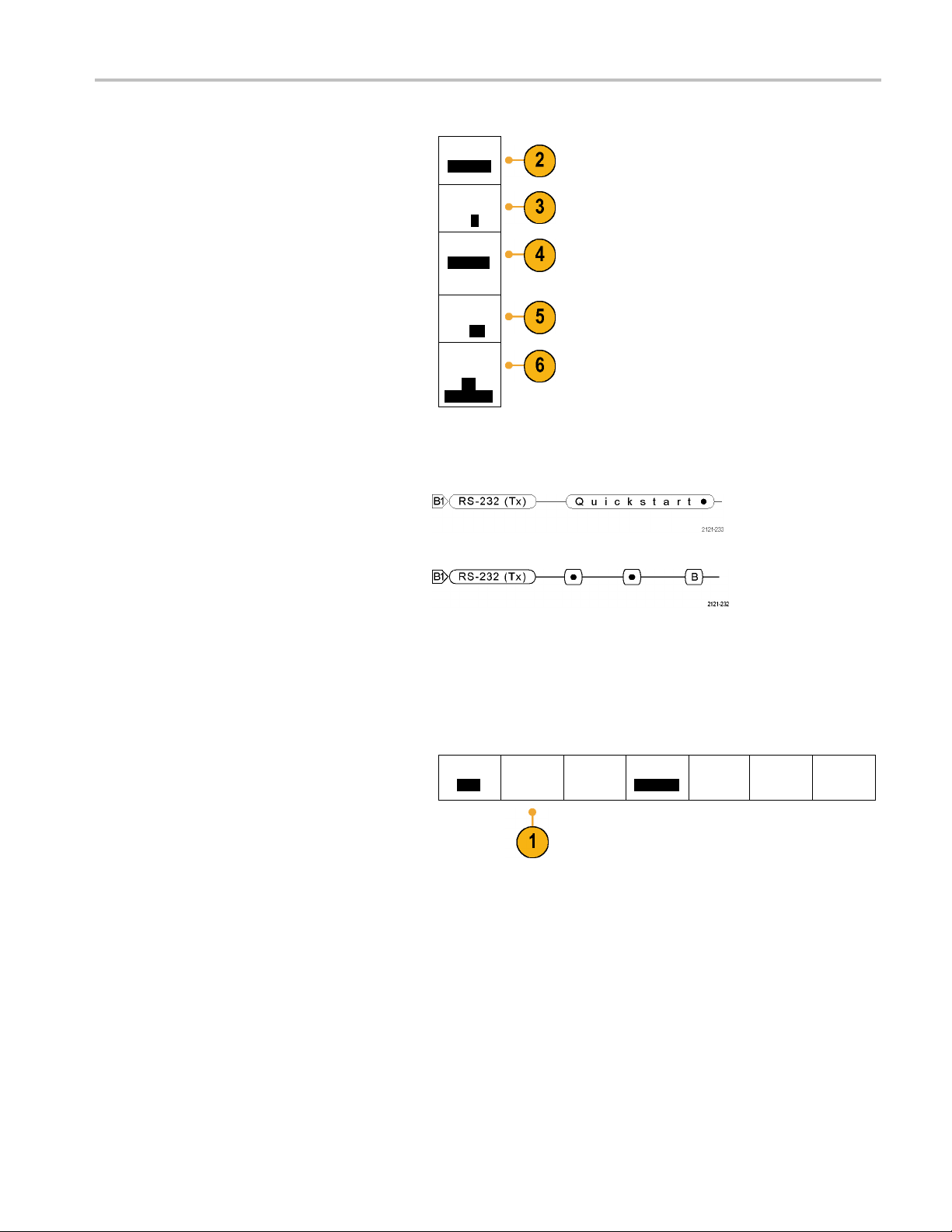

3. Push Utility.

Installation

4. Push Utility Page.

5. Turn multipurpose knob a and select I/O.

6. If you are using USB, the system sets itself

up automatically for you, if USB is enabled.

Check USB on the lower-bezel menu to

be sure t

hat USB is enabled. If it is not

enabled, push USB. Then push Connect to

Computer on the side-bezel menu.

7. To use Ethernet, push the Ethernet & LXI

lower-bezel button.

e side-bezel buttons to adjust

Use th

your network settings, as needed. For

more information, see the e*Scope setup

mation below.

infor

Utility

Page

I/O

Utility

Page

I/O

USB

Computer

Ethernet &

LXI

Network

Configura-

tion

Automatic

Socket

Server

GPIB

1

8. If you want to change socket server

meters, push Socket Server and enter

para

new values through the resulting side-bezel

menu.

9. If you are using GPIB, push GPIB. Enter

the GPIB address on the side-bezel menu,

ing multipurpose knob a.

us

Talk/Listen

ress

Add

(a) 1

This will set the GPIB address on an

tached TEK-USB-488 Adapter.

at

MDO4000 Series Oscilloscopes User Manual 25

Page 45

Installation

10. Run your application software on your

computer.

Quick Tips

Your oscilloscope shipped with a CD that contains a variety of Windows-based software tools for efficient connectivity

between your oscilloscope and your computer. These include toolbars that speed connectivity with Microsoft Excel and

Word. There are also two standalone acquisition programs called NI LabVIEW SignalExpress™, Tektronix Edition and

Tektronix OpenChoice Desktop.

The rear-panel USB 2.0 device port is the correct USB port for computer connectivity. Use the rear- and front-panel USB

2.0 host ports to connect your oscilloscope to USB flash drives. Use the USB Device port to connect your oscilloscope

to a PC or a PictBridge printer.

USB Host port

USB Device port

Using the LXI Web Page and e*Scope

With e*Scope, you can access any Internet-connected MDO4000 Series oscilloscope from a web browser on your computer.

To set up e*Scope communications between your oscilloscope and a Web browser running on a remote computer:

1. Connec

2. Push Utility.

t the oscilloscope to your computer

network with an appropriate Ethernet cable.

26 MDO4000 Series Oscilloscopes User Manual

Page 46

Installation

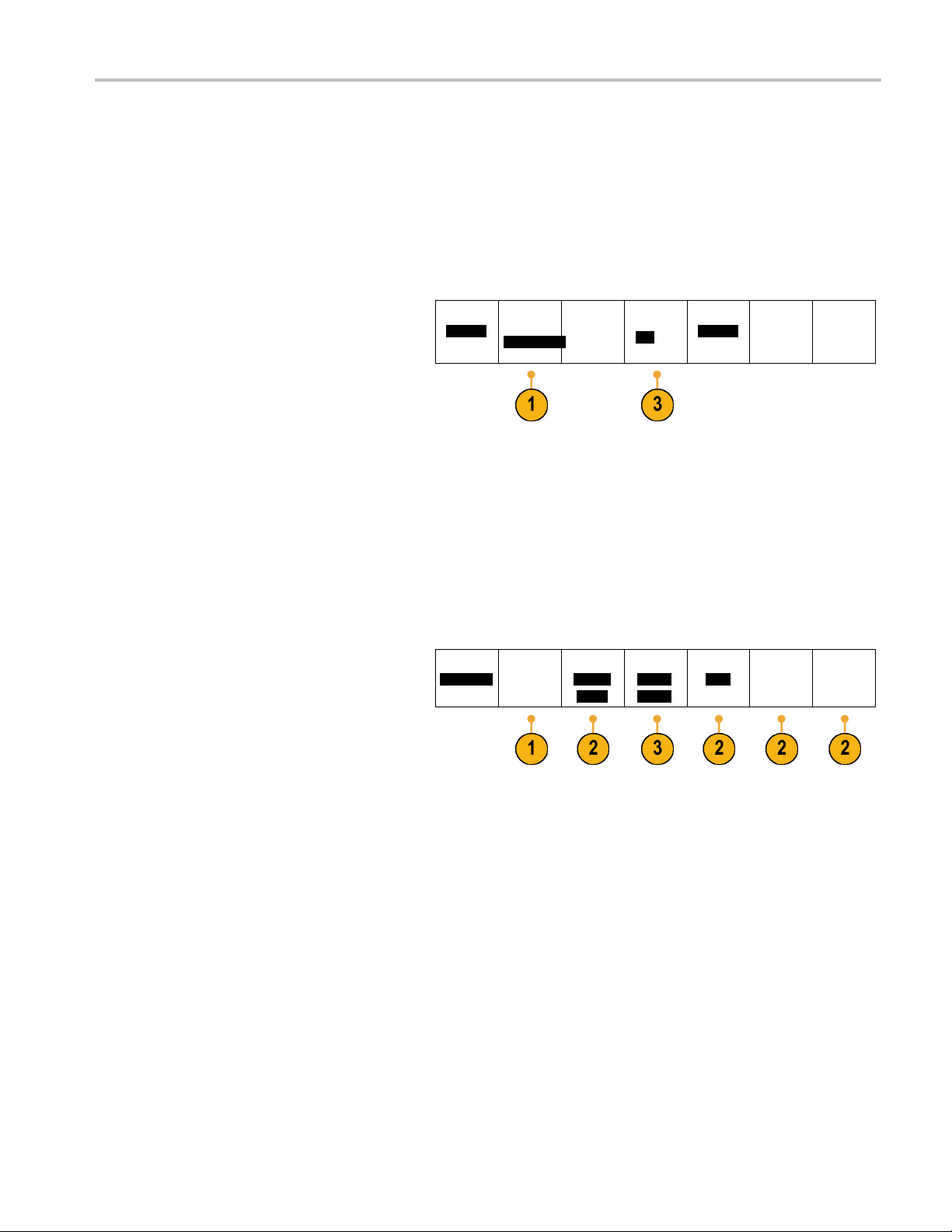

3. Push Utility P

age.

4. Turn multipurpose knob a and select I/O.

5. Push Ether

net & LXI.

6. View the top side-menu item to determine

the condition of the LAN. An indicator turns

r good status and red if the device

green fo

detects a fault.

7. Push LAN

Settings to display the network

parameters con figured on your oscilloscope.

Utility

Page

I/O

Utility

Page

I/O

Ethernet

LXI LAN

Status

LAN

Setting

&

s

USB

Computer

Ethernet &

LXI

Network

Configura-

tion

Automatic

Socket

Server

GPIB

1

8. Push LA

N Reset to restore the LAN defaults

to your oscilloscope.

9. Push Te

st Connection to check if your

oscilloscope can find an attached network.

10. Push m

ore to see another page of

side-menu items.

LAN Reset

Test Con-

nection

more 1 of 2

MDO4000 Series Oscilloscopes User Manual 27

Page 47

Installation

11. Push Change Names to change the name

of the oscillo

scope, the network domain, or

the service name.

12. Push Change E

thernet & LXI Password to

change the name of the password.

13. Push Ch ange

e*Scope Password to use

the LXI password to also protect your

oscilloscope from changes made to LAN

settings fr

om a Web browser.

14. S tart your browser on your remote computer.

In the bro

wser address line, enter the host

name, a dot, and the domain name together.

Alternatively, just enter the IP address of

rument. Either way, you should then

the inst

see the LXI Welcome page on your Web

browser on your computer screen.

Ethernet &

LXI

Change

Names

Change

Ethernet

&LXI

Password