Page 1

3 Series MDO

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Mixed Domain Oscilloscope

Installation and Safety Manual

Warning

The servicing instructions are for use by qualified personnel only. To avoid

personal injury, do not perform any servicing unless you are qualified to do

so. Refer to all safety summaries prior to performing service.

Supports 3 Series MDO Product Firmware V1.1 and above

www.tek.com

071-3608-00

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

protected by national copyright laws and international treaty provisions. Tektronix products are covered by U.S. and foreign patents, issued

and pending. Information in this publication supersedes that in all previously published material. Specifications and price change privileges

reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

■

In North America, call 1-800-833-9200.

■

Worldwide, visit www.tek.com to find contacts in your area.

Page 3

Table of Contents

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Important safety information ................................................................................................................................ iii

General safety summary ................................................................................................................................ iii

Service safety summary ................................................................................................................................. v

Terms in the manual ...................................................................................................................................... vi

Terms on the product .................................................................................................................................... vi

Symbols on the product ................................................................................................................................. vi

Preface ............................................................................................................................................................... vii

Key features .................................................................................................................................................. vii

Related documents ...................................................................................................................................... viii

Installing your instrument

Check shipped accessories ........................................................................................................................... 1

Safely rotate the handle ................................................................................................................................. 1

Operating requirements ................................................................................................................................. 2

Input signal requirements ............................................................................................................................... 2

Secure (lock) the oscilloscope ....................................................................................................................... 3

Powering the oscilloscope .............................................................................................................................. 4

Check that the oscilloscope passes power-on self tests ................................................................................ 5

Connecting probes ......................................................................................................................................... 5

Rackmount information .................................................................................................................................. 6

Remote access from a Web browser ............................................................................................................. 7

Connect the oscilloscope to a PC using a USB cable .................................................................................... 7

Cleaning ......................................................................................................................................................... 7

Getting acquainted with your instrument

Front panel controls and connectors .............................................................................................................. 9

Rear panel connections ............................................................................................................................... 15

The user interface screen ............................................................................................................................ 16

Identifying items in the time domain display ................................................................................................. 17

Identifying items in the frequency domain display ........................................................................................ 20

Badges ......................................................................................................................................................... 22

Configuration menus .................................................................................................................................... 27

Zoom user interface elements ...................................................................................................................... 28

Using the touchscreen interface for common tasks ..................................................................................... 29

MDO32, MDO34 Installation and Safety Manual i

Page 4

Table of Contents

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Configure the instrument

Set the date and time ................................................................................................................................... 31

Download and install the latest firmware ...................................................................................................... 32

Run Signal Path Compensation (SPC) ........................................................................................................ 32

Compensate TPP0250, TPP0500B, or TPP1000 probes ............................................................................ 33

Connect to a network (LAN) ......................................................................................................................... 34

EMC safety and environmental compliance

Compliance information ............................................................................................................................... 37

EMC compliance .................................................................................................................................... 37

Safety compliance .................................................................................................................................. 38

Environmental compliance ..................................................................................................................... 39

ii MDO32, MDO34 Installation and Safety Manual

Page 5

Important safety information

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

This manual contains information and warnings that must be followed by the user for safe operation and to keep the product in a

safe condition.

To safely perform service on this product, see the Service safety summary that follows the General safety summary.

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product or

any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition to

the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other

component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Use proper power cord. Use only the power cord specified for this product and certified for the country of use. Do not use the

provided power cord for other products.

Ground the product. This product is grounded through the grounding conductor of the power cord. To avoid electric shock, the

grounding conductor must be connected to earth ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded. Do not disable the power cord grounding connection.

Power disconnect. The power cord disconnects the product from the power source. See instructions for the location. Do not

position the equipment so that it is difficult to operate the power cord; it must remain accessible to the user at all times to allow for

quick disconnection if needed.

Connect and disconnect properly. Do not connect or disconnect probes or test leads while they are connected to a voltage

source. Use only insulated voltage probes, test leads, and adapters supplied with the product, or indicated by Tektronix to be

suitable for the product.

Observe all terminal ratings. To avoid fire or shock hazard, observe all rating and markings on the product. Consult the product

manual for further ratings information before making connections to the product. Do not exceed the Measurement Category

(CAT) rating and voltage or current rating of the lowest rated individual component of a product, probe, or accessory. Use caution

when using 1:1 test leads because the probe tip voltage is directly transmitted to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

Do not float the common terminal above the rated voltage for that terminal.

Do not operate without covers. Do not operate this product with covers or panels removed, or with the case open. Hazardous

voltage exposure is possible.

MDO32, MDO34 Installation and Safety Manual iii

Page 6

Important safety information

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by qualified

service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in doubt about safety of the

product, turn it off and disconnect the power cord. Clearly mark the product to prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. Do not use

probes or test leads if they are damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Use proper fuse. Use only the fuse type and rating specified for this product.

Do not operate in wet/damp conditions. Be aware that condensation may occur if a unit is moved from a cold to a warm

environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean the product.

Provide proper ventilation. Refer to the installation instructions in the manual for details on installing the product so it has

proper ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise obstructed. Do not push objects into

any of the openings.

Provide a safe working environment. Always place the product in a location convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or prolonged keyboard or pointer use may

result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress injuries.

Use only the Tektronix rackmount hardware specified for this product.

Probes and test leads

Before connecting probes or test leads, connect the power cord from the power connector to a properly grounded power outlet.

Keep fingers behind the protective barrier, protective finger guard, or tactile indicator on the probes.

Remove all probes, test leads and accessories that are not in use.

Use only correct Measurement Category (CAT), voltage, temperature, altitude, and amperage rated probes, test leads, and

adapters for any measurement.

iv MDO32, MDO34 Installation and Safety Manual

Page 7

Important safety information

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Beware of high voltages. Understand the voltage ratings for the probe you are using and do not exceed those ratings. Two

ratings are important to know and understand:

■

The maximum measurement voltage from the probe tip to the probe reference lead

■

The maximum floating voltage from the probe reference lead to earth ground

These two voltage ratings depend on the probe and your application. Refer to the Specifications section of the manual for more

information.

WARNING. To prevent electrical shock, do not exceed the maximum measurement or maximum floating voltage for the

oscilloscope input BNC connector, probe tip, or probe reference lead.

Connect and disconnect properly. Connect the probe output to the measurement product before connecting the probe to the

circuit under test. Connect the probe reference lead to the circuit under test before connecting the probe input. Disconnect the

probe input and the probe reference lead from the circuit under test before disconnecting the probe from the measurement

product.

Connect and disconnect properly. De-energize the circuit under test before connecting or disconnecting the current probe.

Connect the probe reference lead to earth ground only.

Do not connect a current probe to any wire that carries voltages or frequencies above the current probe voltage rating.

Inspect the probe and accessories. Before each use, inspect probe and accessories for damage (cuts, tears, or defects in the

probe body, accessories, or cable jacket). Do not use if damaged.

Ground-referenced oscilloscope use. Do not float the reference lead of this probe when using with ground-referenced

oscilloscopes. The reference lead must be connected to earth potential (0 V).

Service safety summary

The Service safety summary section contains additional information required to safely perform service on the product. Only

qualified personnel should perform service procedures. Read this Service safety summary and the General safety summary

before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this product unless another person capable of rendering

first aid and resuscitation is present.

Disconnect power. To avoid electric shock, switch off the product power and disconnect the power cord from the mains power

before removing any covers or panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist in this product. Disconnect power, remove

battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric strength after performing a repair.

MDO32, MDO34 Installation and Safety Manual v

Page 8

Important safety information

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Terms in the manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Terms on the product

These terms may appear on the product:

■

DANGER indicates an injury hazard immediately accessible as you read the marking.

■

WARNING indicates an injury hazard not immediately accessible as you read the marking.

■

CAUTION indicates a hazard to property including the product.

Symbols on the product

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the potential

hazards and any actions which have to be taken to avoid them. (This symbol may also be used to refer the user to

ratings in the manual.)

The following symbols may appear on the product:

vi MDO32, MDO34 Installation and Safety Manual

Page 9

Preface

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

This manual provides product safety and compliance information, describes how to connect and power on the oscilloscope, and

introduces the basic instrument features, controls, and operations. See the product Help file for more detailed information.

Key features

Welcome to the 3 Series MDO. The 3 Series MDO Oscilloscopes (MDO32 and MDO34) are 2- and 4-channel oscilloscopes,

enabling you to efficiently and cost-effectively perform mixed domain debugging.

■

A dedicated RF input channel for frequency domain measurements

■

Bandwidths from 100 MHz to 1 GHz

■

2- and 4-channels for time domain measurements

■

Sixteen-channel digital input option

■

Large 11.6” HD (1920 x 1080 pixel) capacitive touchscreen display

■

User interface optimized for touchscreen use

■

Sample rates of 2.5 GS/s on all analog channels (5 GS/s on 1 or 2 channels for the MDO34 or MDO32 with the 1 GHz

option)

■

10 M points record length on all channels

■

Maximum waveform capture rate: 280,000 waveforms/second, with FastAcq: >50,000 waveforms/second with normal

operation

■

Advanced triggering and analysis: I2C, SPI, USB 2.0, CAN, CAN FD, LIN, FlexRay, RS-232, RS-422, RS-485, UART, I2S,

Left Justified (LJ), Right Justified (RJ), TDM, MIL-STD-1553, ARINC429 (with the appropriate option), and Parallel

■

Power analysis (optional)

■

Arbitrary function generator and 16 digital channels (optional)

■

Digital voltmeter and trigger frequency counter free with product registration

MDO32, MDO34 Installation and Safety Manual vii

Page 10

Preface

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

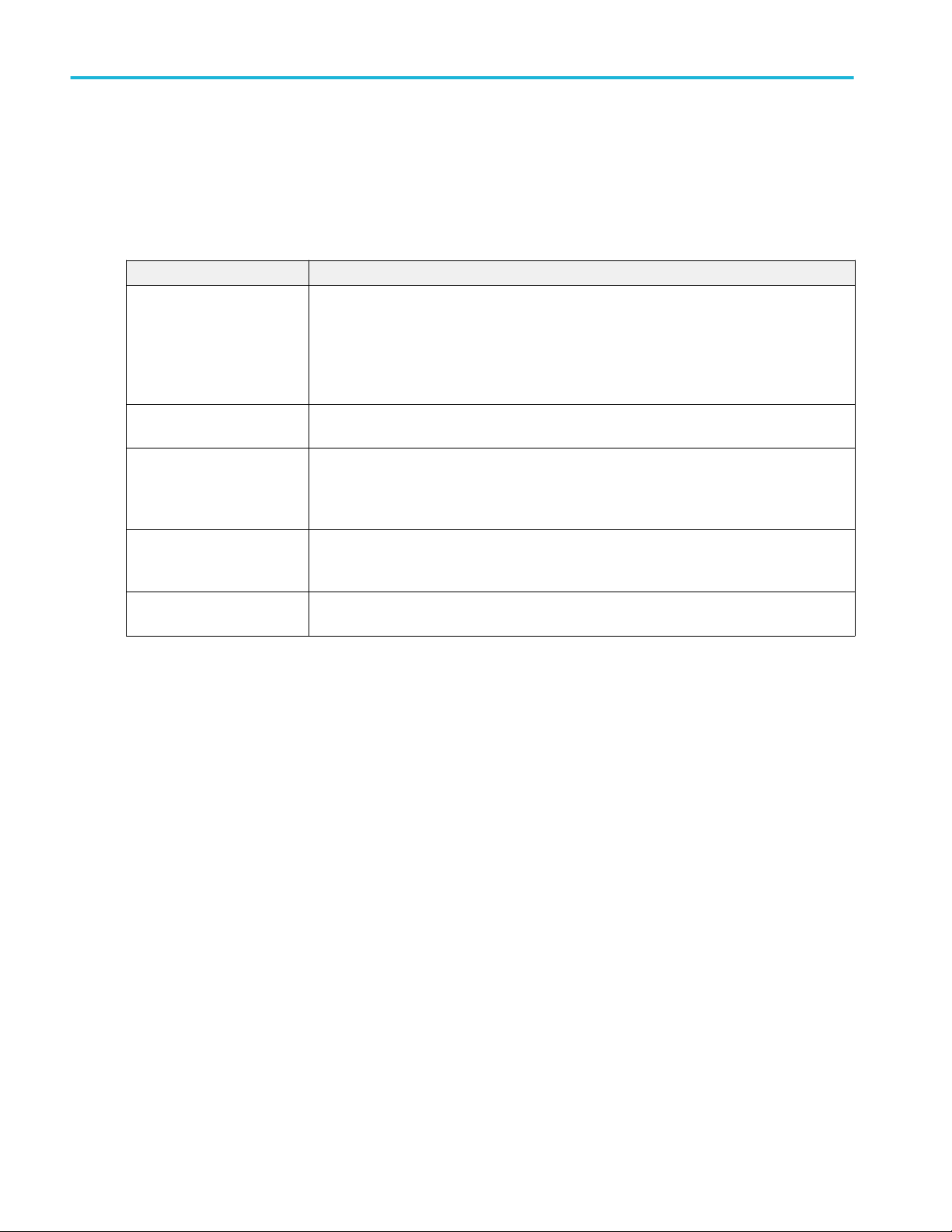

Related documents

Use the related documents for more information on instrument functions, how to remotely program or operate the instrument,

understand theory of operation, replace suspected modules, and other tasks.

MDO34, MDO32 documents

To learn about Use this document

How to use instrument

functions

How to remotely control the

instrument

Instrument specifications and

procedures to verify the

instrument meets

specifications

Instrument theory of operation,

troubleshooting, disassembly,

and replaceable parts

Installing the instrument in a

rack

3 Series MDO (MDO34, MDO32) Installation and Safety Manual (This document, Tektronix part

number 071-3608-xx); standard accessory with the instrument. Single document with English,

Japanese, and Simplified Chinese languages.

3 Series MDO Help (Printable version of the instrument Help that contains context-sensitive

descriptions of all instrument functions; available at www.tek.com/downloads)

3 Series MDO Programmer Manual (Tektronix part number 077-1498-xx; available at

www.tek.com/downloads)

3 Series MDO (MDO34, MDO32) Specifications and Performance Verification Technical

Reference (Tektronix part number 077-1499-xx; available at www.tek.com/downloads)

3 Series MDO (MDO34, MDO32) Service Manual (Tektronix part number 077-1500-xx;

available at www.tek.com/downloads)

RM3 Rack Mount Kit Instructions (Tektronix part number 071-3609-xx; available at

www.tek.com/downloads)

viii MDO32, MDO34 Installation and Safety Manual

Page 11

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Check shipped accessories

Make sure that you received everything you ordered. If anything is missing, contact Tektronix Customer Support. In North

America, call 1-800-833-9200. Worldwide, visit www.tek.com to find contacts in your area.

Check the packing list that came with your instrument to verify that you have received all standard accessories and ordered

items. If you purchased factory options, tap Help > About to confirm that the option(s) are listed in the Installed Options table.

Standard accessories

Item Quantity Tektronix part number

3 Series MDO (MDO34, MDO32) Installation and Safety Manual 1 071-3608-xx

Passive Voltage Probe, depends on instrument bandwidth

(350 MHz, 500 MHz, and 1 GHz bandwidth)

(100 MHz and 200 MHz bandwidth)

Accessory bag 1 016-2144-xx

Power cord 1 Depends on region

Calibration certificate 1 N/A

OpenChoice® Desktop Software (available for download from www.tek.com/

software/downloads.)

One per analog channel

TPP0500B

TPP0250B

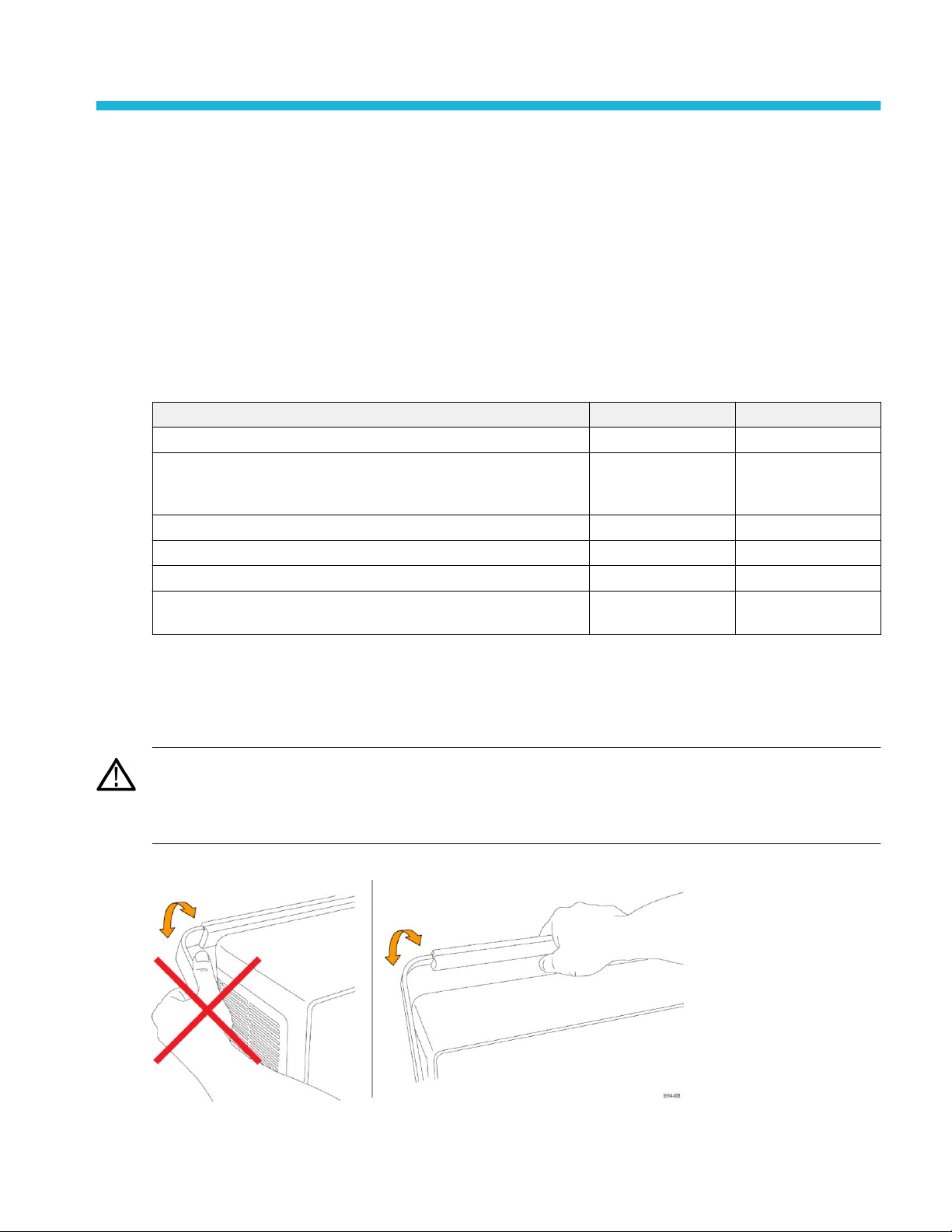

Safely rotate the handle

Use the correct process to eliminate the chance of pinching your thumb or rear-panel-connected cables while rotating the handle.

CAUTION. Hold the top of the handle to rotate the handle on the instrument. Do not hold the handle from the sides and rotate, as

this can pinch the base of your thumb between the handle and the case.

If you have routed any cables between the handle and the case, be careful when rotating the handle so that you do not pinch the

cables.

MDO32, MDO34 Installation and Safety Manual 1

Page 12

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Operating requirements

Use the oscilloscope within the required operating temperature, power, altitude, and signal input voltage ranges to provide the

most accurate measurements and safe instrument operation.

Environment requirements

Characteristic Description

Operating temperature -10 °C to +55 °C (+14 °F to +131 °F)

For proper cooling, keep the sides and rear of the instrument clear of obstructions for

2 inches (51 mm).

Operating humidity 5% to 90% relative humidity (% RH) up to +40 °C (+104 °F), Noncondensing.

5% to 60% RH above +40 °C up to +55 °C (+104 °F to +131 °F), Noncondensing.

Operating altitude Up to 3000 meters (9842 feet)

Power requirements

Characteristic Description

Power source voltage 100 V - 240 V

Power source frequency 50/60 Hz, 100-240 V

Input signal requirements

Keep the input signals within allowed limits to ensure the most accurate measurements and prevent damage to the analog and

digital probes or instrument.

Make sure that input signals are within the following requirements.

Table 1: Maximum analog input

Input Description

Analog input channels, 1 M Ω setting, maximum

input voltage at BNC

Analog input channels, 50 Ω setting, maximum

input voltage at BNC

RF input maximum input voltage Average Continuous Power: +20 dBm (0.1 W)

, ±10%, single phase

AC RMS

400 Hz ±10% at 100 to 132 V

300 V

RMS

Measurement Category II

De-rate at 20 dB/decade between 4.5 MHz and 45 MHz, De-rate 14 db

between 45 MHz and 450 MHz. Above 450 MHz, 5 V

5 V

with a peak at ±20 V. (DF ≤ 6.25%).

RMS

DC maximum before damage: ±40 VDC

Max no damage +33 dBm (2 W) CW

Peak Pulse Power: +45 dBm (32 W)

Peak Pulse Power defined as <10 μs pulse width, <1% duty cycle, and

reference level of ≥ +10 dBm

RMS

.

2 MDO32, MDO34 Installation and Safety Manual

Page 13

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Table 2: Maximum input with a P6316 Digital Probe

Input Description

Threshold Accuracy ±(100 mV + 3% of threshold setting after calibration)

Threshold Range +25 V to –15 V

Maximum nondestructive input signal to probe +30 V to -20 V

Minimum signal swing 500 mV

peak-to-peak

Input resistance 101 kΩ

Input capacitance 8.0 pF typical

Pollution Degree 2, indoor use only

Humidity 5% to 95% relative humidity

Secure (lock) the oscilloscope

Lock an oscilloscope to a test bench or equipment rack to prevent property loss.

Attach a standard laptop security lock to the rear panel of the oscilloscope, to secure the oscilloscope to a workbench, rack, or

other location.

MDO32, MDO34 Installation and Safety Manual 3

Page 14

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Powering the oscilloscope

Use this procedure to connect the oscilloscope to line power and power on and off the oscilloscope. Always connect the

oscilloscope to AC power using the power cord that shipped with the instrument.

Prerequisite: Use the AC power cord that shipped with your oscilloscope.

1. Connect the supplied power cord to the oscilloscope power connector.

Figure 1: Power cord connector and power standby switch

2. Connect the power cord to an appropriate AC mains source.

Power is supplied to the power supply and some other boards whenever the AC power cord is connected to a live mains

circuit, putting the instrument in standby mode.

3. Push the front panel power button to power the instrument on and off.

The power button color indicates instrument power states:

Unlit – no AC power applied

Yellow – standby mode

Blue – powered on

4. To completely remove power from the instrument, disconnect the power cord.

4 MDO32, MDO34 Installation and Safety Manual

Page 15

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Check that the oscilloscope passes power-on self tests

Power-on self tests verify that all oscilloscope modules are working correctly after power up.

1. Power on the oscilloscope and wait until the oscilloscope screen appears.

2. Select Utility > Self Test from the top-edge Menu bar to open the Self Test configuration menu.

3. Check that the status of all power-on self tests are Passed.

If one or more power-on self tests shows Failed:

a. Power cycle the oscilloscope.

b. Tap Utility > Self Test. If one or more power-on self tests still shows Failed, contact Tektronix Customer Support.

Connecting probes

Probes and cables connect the oscilloscope to your device under test (DUT). Use a probe that best matches your signal

measurement needs.

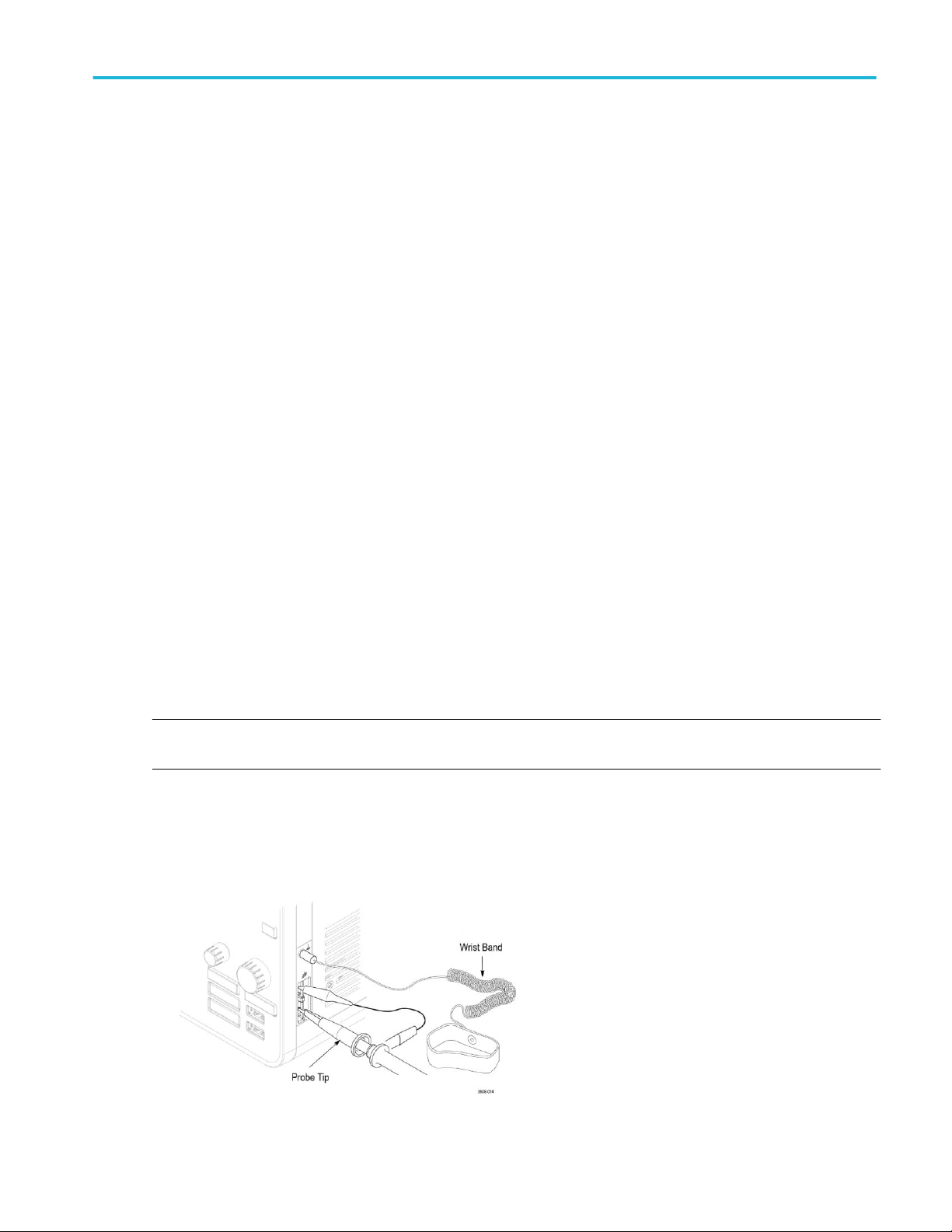

Figure 2: Connecting probes to the instrument

1. Tektronix Versatile Probe Interface (TekVPI)

These probes support two-way communication with the oscilloscope through on-screen menus and remotely through

programmable support. The remote control is useful in applications like ATE where you want the system to set probe

parameters.

2. Tektronix Versatile Probe Interface (TekVPI) for Passive Probes

These probes build upon the functionality of the TekVPI interface. Each probe is matched with its corresponding

oscilloscope channel, allowing the oscilloscope to optimize the signal input path. This provides AC compensation across the

frequency band.

MDO32, MDO34 Installation and Safety Manual 5

Page 16

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

3. TPA-BNC Adapter

The TPA-BNC Adapter allows you to use TEKPROBE II probe capabilities, such as providing probe power and passing

scaling and unit information to the oscilloscope.

4. BNC Interfaces

Some of these use TEKPROBE capabilities to pass the waveform signal and scaling to the oscilloscope. Some only pass

the signal and there is no other communication.

5. Logic Probe Interface

The P6316 probe provides 16 channels of digital (logical one or zero) information.

6. The TPA-N-VPI Adapter allows you to use TekVPI probes with the RF input.

Connect TPP0250, TPP0500B, TPP1000, TekVPI+, TekVPI, or other supported Tektronix analog probes by pushing them into

an input connector. The probe base latch locks with a 'click' when the probe is fully seated.

TekVPI probes automatically set the channel input parameters for that probe (bandwidth, attenuation, termination, and so on). If

a probe has a Menu button, push that button to open an on-screen configuration menu. Follow instructions provided with active

probes to set their parameters (auto zero, degauss, and so on).

Connect a BNC probe or cable by pushing it onto a channel BNC bayonet connector and turn the lock mechanism clockwise until

it locks.

For more information on the many probes available for use with 3 Series MDO oscilloscopes, visit the Oscilloscope Probe and

Accessory Selector Tool on the Tektronix website at www.tektronix.com.

NOTE. Connecting a probe does not automatically enable that channel (make it active). Use the instrument controls or

programmatic interface to turn on a channel and open its configuration menu to verify or change probe or cable settings

(bandwidth, attenuation, termination and so on).

Rackmount information

The optional RM3 Rackmount Kit lets you install the oscilloscope in standard equipment racks. The rack mount requires six rack

units (6U) of space to install.

Contact Tektronix Customer Support to purchase the rackmount kit option RM3. Follow the instructions that come with the

rackmount kit (RM3 Rackmount Kit Instructions, Tektronix part number 071-3609-xx).

Make sure to allow at least two inches of clearance on the sides for air ventilation and on the back for any cables you attach to

the rear panel.

6 MDO32, MDO34 Installation and Safety Manual

Page 17

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Remote access from a Web browser

You can remotely access your network-connected instrument from a Web browser to display the instrument user interface on a

PC.

This procedure describes how to remotely access the UI controls and screen for the instrument.

Prerequisites:

■

The oscilloscope must be connected to, and accessible from, the network to which the PC is connected. See Connect to a

network (LAN) on page 34

■

Determine the IP address of the oscilloscope that you want to access. To determine the oscilloscope's IP address, select

Utility > IO in the oscilloscope menu bar and view the network settings in the LAN panel.

1. Open a Web browser on a PC connected to the same network as the oscilloscope.

2. Enter just the oscilloscope IP address on the URL line of the browser and press Enter. For example: 135.62.88.157. The

browser searches for and opens the Web page for the oscilloscope.

Connect the oscilloscope to a PC using a USB cable

Use a USB cable to connect the oscilloscope directly to a PC for remote instrument control.

1. On the oscilloscope, select Utility > I/O from the menu bar.

2. Tap USB Device Port.

3. Confirm that the USB Device Port control is On (default setting).

4. Connect a USB cable from the PC to the USB Device port on the rear of the instrument.

5. If using the USB connection to remotely control the oscilloscope using GPIB commands, set the GPIB Talk/Listen Address

Cleaning

Use a dry, soft cotton cloth to clean the outside of the unit. If any dirt remains, use a cloth or swab dipped in a 75% isopropyl

alcohol solution. Use a swab to clean narrow spaces around controls and connectors. Do not use any liquid cleaning agents or

chemicals that could damage the touchscreen, case, controls, markings or labels, or possibly infiltrate the case.

for your configuration (0 - 30).

MDO32, MDO34 Installation and Safety Manual 7

Page 18

Installing your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

8 MDO32, MDO34 Installation and Safety Manual

Page 19

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

The following content provides a high-level description of the instrument controls and user interface.

Refer to the instrument help for detailed information on using the controls and user interface to display waveforms and take

measurements.

Front panel controls and connectors

The front panel controls provide direct access to key instrument settings such as vertical, horizontal, trigger, and cursors. The

connectors are where you input signals with probes or cables or insert USB devices.

Figure 3: 3 Series MDO controls

MDO32, MDO34 Installation and Safety Manual 9

Page 20

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

1. Acquisition and Cursors controls:

■

Run/Stop starts and stops waveform acquisition. The button color indicates the acquisition status (green = running and

acquiring; red = stopped). When stopped, the oscilloscope shows waveforms from the last completed acquisition. The

Run/Stop button on the screen also shows the acquisition status.

■

Cursors button turns cursors on or off. Use the Multipurpose knobs to move the cursors. Double-tap the cursor

readouts or on a cursor bar (line) to open the configuration menu to set cursor types and functionality.

■

Fast Acq™ enables or disables the fast acquisition mode. FastAcq provides high-speed waveform capture that

reduces the dead time between waveform acquisitions, enabling the capture and display of transient events such as

glitches and runt pulses. It is helpful in finding elusive signal anomalies. Fast acquisition mode can also display

waveform phenomena at an intensity that reflects their rate of occurrence.

■

Single/Seq enables making a single waveform acquisition, or a specified number of acquisitions (as set in the

Acquisition configuration menu). Pushing Single/Seq turns off Run/Stop mode and takes a single acquisition. The

button color indicates the acquisition status (quick green flash = single acquisition acquired; solid green = waiting for

trigger event). Pushing Single/Seq again takes another single acquisition.

■

High Res mode calculates the average of all the samples for each acquisition interval. High Res provides a higherresolution, lower-bandwidth waveform.

■

Clear deletes the current acquisitions and measurement values from memory.

2. Multipurpose knobs:

■

Multipurpose knobs (A, B) Multipurpose knobs A and B move cursors and set parameter values in configuration

menu input fields. Selecting a menu field that can use a Multipurpose knob assigns the indicated knob to change the

value in that input field. The ring around each knob lights when you can use that knob to do an action.

Push a Multipurpose knob to enable the Fine mode for making smaller increment changes. Push the knob again to exit

Fine mode.

NOTE. If you have a mouse attached, pressing the mouse wheel toggles between Coarse and Fine adjustments.

10 MDO32, MDO34 Installation and Safety Manual

Page 21

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

3. Trigger controls:

■

Force forces a trigger event at a random point in the waveform and captures the acquisition.

■

Level sets the amplitude level that the signal must pass through to be considered a valid transition. The color of the

Level knob indicates the trigger source except for dual-level triggers. The Level knob is disabled when the trigger type

requires two level settings or other trigger qualifiers (set from the Trigger configuration menu). Push the knob to set the

threshold level to 50% of the peak-to-peak amplitude range of the signal.

■

Slope sets the signal transition direction to detect for a trigger (low to high, high to low, or either direction). Push the

button to cycle through the selections. The Slope button is disabled when the trigger type requires other slope

qualifiers (set from the Trigger configuration menu).

■

Mode sets how the instrument behaves in the absence or presence of a trigger event:

■

Auto trigger mode enables the instrument to acquire and display a waveform whether or not a trigger event

occurs. If a trigger event occurs, the instrument displays a stable waveform. If a trigger event does not occur, the

instrument forces a trigger event and acquisition and displays an unstable waveform.

■

Normal trigger mode sets the instrument to acquire and display a waveform only when there is a valid trigger

event. If no trigger occurs, the last waveform record acquired remains on the display. If no last waveform exists,

no waveform is displayed.

MDO32, MDO34 Installation and Safety Manual 11

Page 22

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

4. Vertical controls:

■

Position moves the selected waveform up or down on the screen. The color of the Position knob indicates which

waveform the knob is controlling. Push the knob to center the waveform handle on the display.

■

Scale sets the amplitude units per vertical graticule division of the selected waveform. The scale values are shown on

the waveform badge. The color of the Scale knob indicates which waveform the knob is controlling.

■

Channel buttons turn on (display), select, or turn off a channel, as follows:

■

If the channel is not displayed, pushing a Channel button turns on that channel in the Waveform view.

■

If the channel is on the screen and is not selected, pushing that channel's button selects that channel.

■

If the channel is on the screen and is also selected, pushing that channel's button turns that channel off (removes

it from Waveform view).

■

The Math button adds or selects a Math waveform on the Waveform view, as follows:

■

If no Math waveform exists, pushing the Math button adds a Math waveform to the Waveform view and opens the

Math configuration menu.

■

If a Math waveform is displayed but not selected, pushing the button selects the Math waveform.

■

If a Math waveform is displayed and selected, pushing the button turns off the Math waveform (removes it from

Waveform view). Push the button again to display the waveform.

■

The Ref button adds or selects a Reference (saved) waveform on the Waveform view, as follows:

■

If no Reference waveform exists, pushing the Ref button opens the Browse Waveform Files configuration menu.

Navigate to and select a waveform file (*.isf) and tap Recall to load and display the reference waveform.

■

If only one Reference waveform is displayed, pushing the button turns off the Reference waveform (removes it

from the Waveform View). Push the button again to display the waveform.

■

If two or more Reference waveforms are displayed, pushing the button cycles through selecting each Reference

waveform.

■

The Bus button adds or selects a bus waveform on the Waveform view, as follows:

■

If no Bus waveform exists, pushing the Bus button adds a Bus waveform to the Waveform view and opens the

Bus configuration menu.

■

If only one Bus waveform is displayed, pushing the button turns off the Bus waveform (removes it from Waveform

view).

■

If two Bus waveforms are displayed, pushing the button cycles through selecting each Bus waveform.

12 MDO32, MDO34 Installation and Safety Manual

Page 23

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

■

The RF button adds the RF waveform on the Waveform view and switches from the time domain to the frequency

domain. All time domain waveforms are turned off and the spectrum analyzer is turned on. When you switch back to

the time domain, the time domain waveforms are restored.

■

The Digital button adds or selects a digital waveform on the Waveform view

■

If the digital channels are not displayed, pushing a Digital button turns on the channels in the Waveform view.

■

If the digital channels are on the screen, but not selected, pushing the Digital button selects the digital channels.

■

If the digital channels are on the screen and are also selected, pushing the Digital button turns the digital

channels off (removes them from Waveform view).

5. Horizontal controls:

■

Position moves the waveform from side to side on the screen (changing the trigger point position in the waveform

record). Push the knob to center the trigger event to the center of the graticule.

■

Scale sets the time per major horizontal graticule division and samples/second parameters for the oscilloscope. Scale

applies to all waveforms.

6. Miscellaneous controls:

■

Touch Off turns touchscreen capability off. The Touch Off button is lighted when the touchscreen is turned off.

■

Save is a one-push save operation that uses the current File > Save As settings to save screen shots (including open

menus and dialog boxes), waveform files, instrument settings, and so on, as follows:

■

If a File > Save or File > Save As operation has occurred since the last instrument startup, pushing Save saves

the file types to the location last set in the Save As configuration menu.

■

If no file save operation has occurred since the last instrument startup, pushing Save opens the Save As

configuration menu. Select a tab to select the type of file to save (Screen Capture, Waveform, and so on), set any

associated parameters, and where to save it, and select OK. The specified file or files are saved. The next time

you push Save, the same type of files are saved.

■

Screen Captures capture the entire screen, including displayed configuration menus and dialog boxes.

■

Default Setup restores the oscilloscope settings (horizontal, vertical, scale, position, and so on) to the default settings.

Default Setup does not change items found in the User Preferences menu.

■

Autoset automatically displays a stable waveform.

MDO32, MDO34 Installation and Safety Manual 13

Page 24

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

7. Ground and Probe Compensation connectors:

■

The Ground and Probe Compensation connectors are located at the lower right side of the instrument, near the front

panel. The Ground connector (the small hole in the case) provides an electrically grounded (through a resistor)

connection point to attach an anti-static wrist strap to reduce electrostatic damage (ESD) while you handle or probe the

DUT.

■

The Probe Compensation connections provide a ground connector (upper tab) and 1 kHz square wave source (lower

tab) for adjusting the high-frequency response of a passive probe (probe compensation). The oscilloscope uses this

signal to automatically compensate supported probes, including the ones that ship with the product. See Compensate

TPP0250, TPP0500B, or TPP1000 probes on page 33.

8. USB Host ports (USB 2.0):

■

USB ports are located at the lower right corner of the front panel and on the rear panel. Connect USB flash drives to

which you can save or recall data (such as instrument software updates, waveforms, settings, and screen captures) or

connect peripheral devices such as a mouse or keyboard.

14 MDO32, MDO34 Installation and Safety Manual

Page 25

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

9. Probe connectors:

■

Analog input connectors support all TekVPI+ and TekVPI measurement probes, BNC passive probes, the P6316 Logic

Probe, and BNC cables. See Connecting probes on page 5.

Rear panel connections

The rear panel connections supply power to the oscilloscope and provide connectors for network, USB devices, video, reference

signals, and the AFG output.

1. Power cord connector. Use only the power cord specified for this product and certified for the country of use.

2. AFG Out is the signal output for the optional Arbitrary Function Generator (AFG) feature.

MDO32, MDO34 Installation and Safety Manual 15

Page 26

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

3. AUX Out generates a signal transition on a trigger event or outputs a synchronization signal from the AFG.

4. LAN connector (RJ-45) connects the oscilloscope to a 10/100 Base-T local area network.

5. USB Device port lets you connect to a PC to remotely control the oscilloscope using the USBTMC protocol.

6. USB Host port lets you connect a USB memory device, keyboard, or mouse.

7. HDMI output lets you connect an external monitor or projector to show the oscilloscope screen.

8. Security lock connector lets you use a standard PC/laptop lock cable to secure the oscilloscope to a work bench or other

location.

The user interface screen

The touchscreen user interface contains waveforms, measurement readouts, and touch-based controls to access all oscilloscope

functions.

1. The Menu bar provides menus for typical operations including:

■

Saving, loading, and accessing files

■

Setting oscilloscope display and measurement preferences

■

Configuring network access

■

Running self tests

■

Erasing measurement and settings memory (TekSecure™)

■

Loading option licenses

■

Opening a Help viewer

2. The Waveform View area displays analog, digital, math, reference, and bus waveforms. The waveforms include waveform

handles (identifiers), trigger position, and level(s) indicators. See Identifying items in the time domain display on page 17.

16 MDO32, MDO34 Installation and Safety Manual

Page 27

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

3. The Results Bar contains controls for displaying cursors, adding result tables to the screen, and adding measurements to

the Results bar. The controls are:

■

The Cursors button displays on-screen cursors. Touch and drag or use the Multipurpose knobs to move the cursors.

Double-tap on a cursor or on the cursor readouts to open a configuration menu to set cursor types and related

functions.

■

The Measure button opens a configuration menu from which to select and add up to four measurements to the Results

bar. Each measurement you add has a separate badge. Double-tap a measurement badge to open its configuration

menu.

■

The Results Table button adds a Measurement, Bus, Search, and Harmonics results table to the screen. The Measure

tab displays all measurements present in the Results bar. The Bus tab displays bus decode information for displayed

bus waveforms. The Search tab displays search event information. The Harmonics tab displays harmonic

measurement results.

■

The Search button lets you detect and mark a waveform where specified events occur. Tap Search to open a Search

configuration menu and set the search conditions for analog and digital channels. Search badges are added to the

Results Bar.

■

The Measurement and Search badges show measurement and search results and are displayed in the Results Bar.

See Badges on page 22.

4. The Settings Bar contains System badges for setting Horizontal, Trigger, Acquisition, and Date/Time parameters; Inactive

Channel buttons to turn on channels; Math/Ref/Bus button to add math, reference, and bus waveforms to the display; and

Channel and Waveform badges that let you configure the individual waveform parameters. Tap a channel or waveform

button to add it to the screen and display a badge. Double-tap a badge to open its configuration menu. See Badges on

page 22.

5. Configuration Menus let you quickly change the parameters of the selected user interface item. You can open

configuration menus by double-tapping on badges, screen objects, or screen areas. See Configuration menus on page 27.

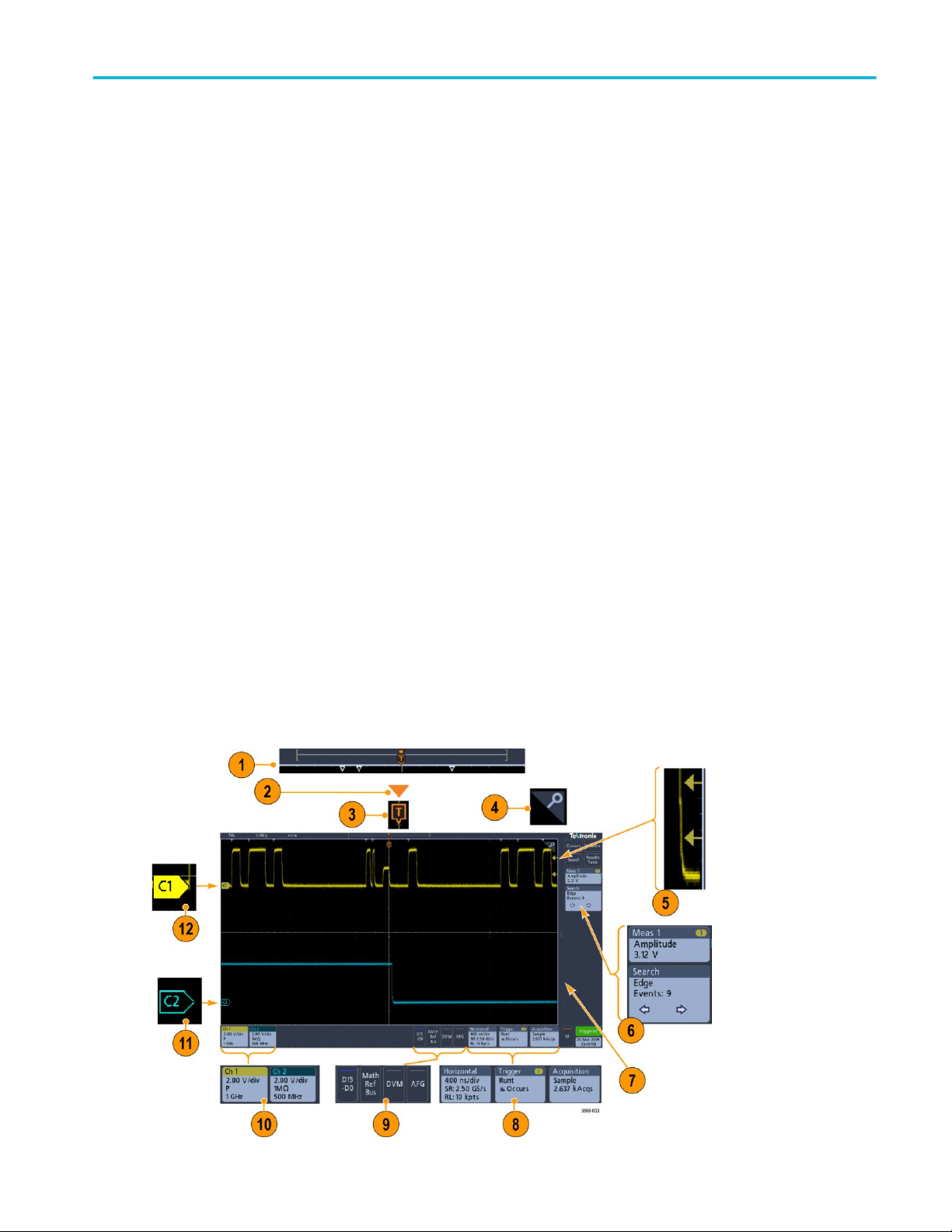

Identifying items in the time domain display

Each area of the user interface has a specific function that helps manage information or controls. This topic shows and describes

the key user interface elements.

MDO32, MDO34 Installation and Safety Manual 17

Page 28

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

1. The Waveform Record View is a graphical high-level view of the overall acquisition, how much of the acquisition is on the

screen (shown in brackets), the location of key time events including the trigger event, and the current position of waveforms

cursors.

If you are changing the horizontal time scale while the oscilloscope acquisition is stopped, the brackets change position to

show the part of the waveform record that is being viewed relative to the current acquisition total record length.

If cursors are active on a waveform, the Waveform Record View shows the relative cursor positions as small vertical dashed

lines.

When in Zoom mode, the Waveform Record View is replaced with the Zoom Overview. See Zoom user interface elements

on page 28.

2. The Expansion Point icon on the waveform view shows the center point around which the waveform expands and

compresses when changing horizontal settings.

3. The Trigger Position Indicator shows where the trigger event occurred in the waveform record.

4. The Zoom icon (in upper right corner of Waveform and Plot views) toggles zoom on and off.

5. The Trigger Level Indicator icon(s) shows the trigger level(s) on the trigger source waveform. Some trigger types require two

trigger levels.

6. Measurement and Search badges show measurement and search results. See Badges on page 22.

7. The Results Bar Handle opens or closes the Results bar to maximize waveform screen viewing when needed. To reopen

the Results bar, either tap the handle icon or swipe left from the right side of the display.

18 MDO32, MDO34 Installation and Safety Manual

Page 29

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

8. The System badges show global instrument settings (Horizontal, Trigger, Acquisition, Run/Stop status, and Date/Time).

See Badges on page 22.

9. The Inactive Channel buttons add channel waveforms to the Waveform view and add an associated Channel badge to the

Settings bar.

The Add Math Ref Bus button expands allowing you to add a math, reference, or bus waveform to the Waveform view and

add an associated Waveform badge to the Settings bar.

The RF button activates the frequency domain display and adds an RF badge. Double-tap the badge to open the RF

configuration menu to configure the RF input. This button is only active if one of the RF options is enabled.

The AFG button opens the AFG configuration menu to set and enable the AFG output. This button is only present if the

AFG option is installed.

The DVM button lets you use an analog probe to take DC, AC RMS, or DC+AC RMS voltage measurements on your DUT.

Tap the button to add a DVM badge to the Results Bar and open a configuration menu. The DVM option also enables a

trigger frequency counter, accessible from the Mode & Holdoff panel in the Trigger badge menu. This button is only

present if the DVM option is installed.

10. Double-tap a badge to open its associated configuration menu. See Badges on page 22. See Configuration menus on

page 27.

If you add more Channel or Waveform badges than can fit in the waveform badge display area, tap the scroll buttons at

each end of the waveform badge area to scroll and display hidden badges.

11. The Waveform Handles on each waveform identify the source of that waveform (Cx for channels, M for Math, Rx for

Reference waveforms, Bx for bus waveforms). The waveform handles are at the zero-volt level of the waveform by default.

The currently selected waveform handle is a solid color; unselected waveform handles are outlined.

Double-tapping a waveform handle opens the configuration menu for that waveform.

For digital channels, the waveform handle shows the channel number, with each individual digital signal labeled D0–D15

and displayed with a different color.

Double-tapping a digital waveform handle opens the digital channel configuration menu.

Dragging a digital signal handle over another handle swaps location of the signals in the waveform view. Dragging a digital

signal handle out of the group, creates a new group. A selected digital group or signal handle can be moved using the

Vertical Position control.

MDO32, MDO34 Installation and Safety Manual 19

Page 30

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Identifying items in the frequency domain display

This topic shows and describes each element of the frequency domain display.

To activate the frequency domain display, press the front panel RF button or tap the RF button in the display .

Each area of the user interface has a specific function that helps manage information or controls.

1. Vertical graticule labels

2. Start frequency

3. Reference level

4. Vertical scale

5. Center frequency

6. Span and resolution bandwidth

7. Stop frequency

8. Reference marker

20 MDO32, MDO34 Installation and Safety Manual

Page 31

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

9. Displayed trace indicators

a. An RF trace indicator is placed at the Reference Level.

b. A capital M appears if the maximum trace is turned on.

c. A capital A appears if the average trace is turned on.

d. A capital N appears if the normal trace is turned on.

e. The small m appears if the minimum trace is turned on.

Orange highlighting indicates the currently selected trace. In the figures the small m, which stands for the minimum

trace, is highlighted. This indicates that the minimum trace is currently selected.

10. Normal trace: Each acquisition is discarded as new data is acquired.

11. Max hold trace: The maximum data values are accumulated over multiple acquisitions of the Normal trace.

12. Min hold trace: The minimum data values are accumulated over multiple acquisitions of the Normal trace.

13. Average trace: Data from the Normal trace is averaged over multiple acquisitions. This is true power averaging, which

occurs before the log conversion. Each power of 2 averaging reduces the displayed noise by 3 dB.

MDO32, MDO34 Installation and Safety Manual 21

Page 32

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

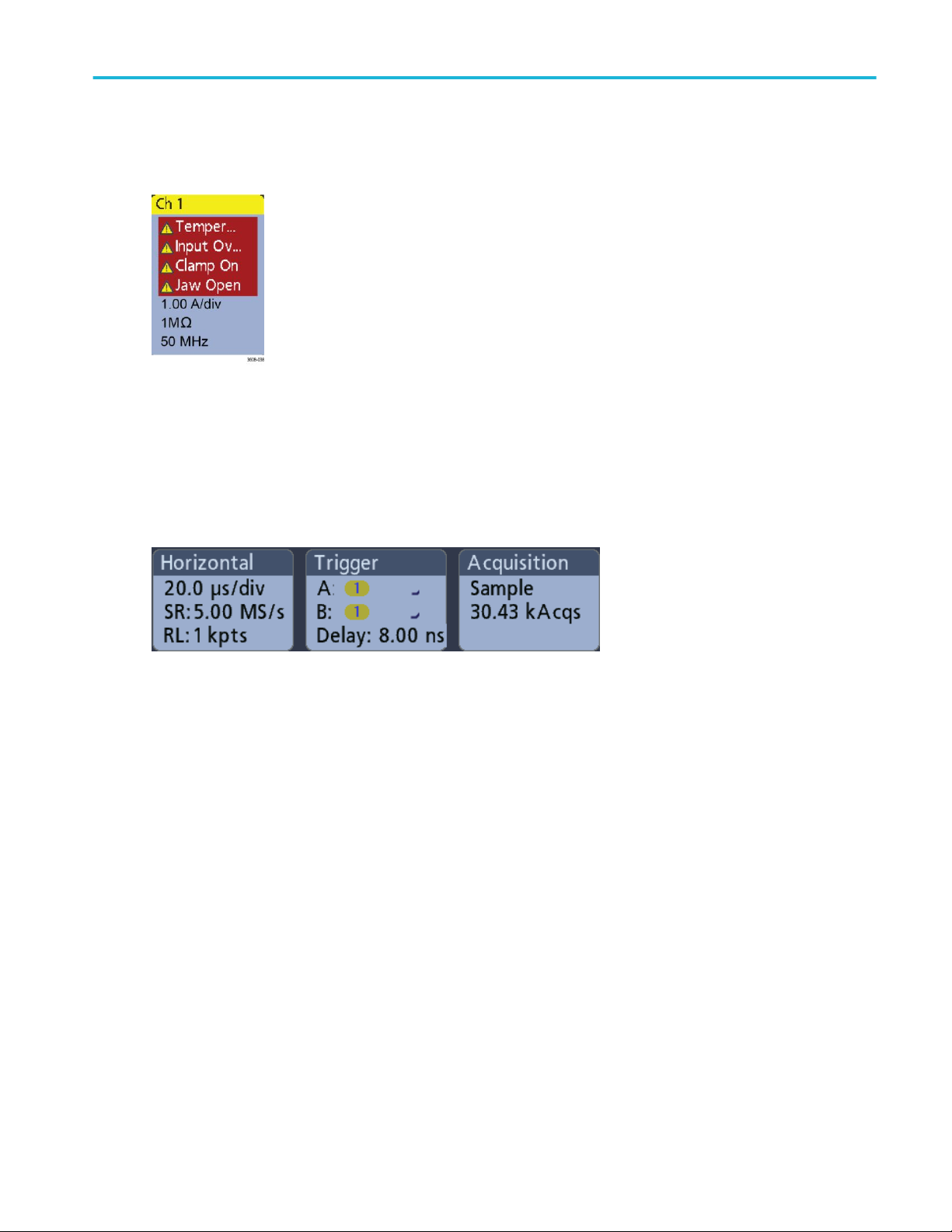

Badges

Badges are rectangular icons that show waveform, measurement, and instrument settings or readouts. Badges also provide fast

access to configuration menus. The badge types are Channel, Waveform, Measurement, Search, and System.

Channel and Waveform badges

Channel and Waveform (Math, Ref, Bus) badges are shown in the Settings Bar, located along the bottom left of the screen.

Each waveform has its own badge. The badges show high-level settings for each displayed channel or waveform. Double-tap a

badge to open its configuration menu.

Most Channel and Waveform badges also have Vertical Scale buttons, shown by single-tapping the badge. Use these buttons to

increase or decrease the vertical scale setting for that waveform.

You can drag or flick Channel and Waveform badges down off the display to turn them off. Swiping back up from the bottom of

the display restores them if they were accidentally deleted.

Channel badges are listed in the channel order. For more information, double-tap the badge to open its configuration menu or

search the instrument Help.

Measurement badges

Result badges are located in the Results Bar. They show measurement or search results. The badge title also shows the

measurement source or sources. To add a Measurement badge, tap the Measure button, select a measurement, and tap Add.

Double-tap a Measurement badge to open its configuration menu to change or refine settings.

22 MDO32, MDO34 Installation and Safety Manual

Page 33

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Some measurements and their badges are only available as options. For example, Power measurements are only listed in the

Add Measurement menu if the PWR option is installed.

To add statistical readouts to individual measurement badges, double-tap a measurement badge to open its configuration menu

and select Show Statistics in Badge.

You can drag or flick Measurement badges off to the right of the display to delete them. You can bring the badge back by swiping

in from the right.

Search badges

Search badges are also shown in the Results Bar, below the Measurement badges. A search badge lists the search source,

search type, and the number of search event occurrences in the current acquisition. The instrument marks the waveform where

those events occur with small down-pointing triangles along the top of the waveform graticule. Double-tap a search badge to

open its configuration menu to change or refine search settings.

MDO32, MDO34 Installation and Safety Manual 23

Page 34

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Search badges are created by tapping the Search button. Use the displayed configuration menu to set the search criteria.

Search badges have < (Previous) and > (Next) Navigation buttons that open the Zoom mode and center the waveform in the

display at the position of the previous or next search mark in the waveform record. Search badge Navigation buttons are only

usable when acquisitions are stopped.

You can drag or flick a Search badge to the right, off the display, to delete it. You can bring the badge back by swiping in from the

right.

Signal clipping and badges

Clipping causes inaccurate amplitude-related measurement results. Clipping also causes inaccurate amplitude values in saved

waveform files. If a math waveform is clipped, it will not affect amplitude measurements on that math waveform.

WARNING. Clipping is caused by excessive or dangerous voltages at the probe tip and/or a vertical scale setting that is not

adequate to display the entire vertical range of the waveform. Excessive voltage at the probe tip can injure the operator and

cause damage to the probe and/or instrument.

This instrument shows a warning triangle symbol and the word Clipping in a Channel badge when a vertical clipping condition

exists. Any measurement badges associated with that channel also indicate a clipping condition.

To close the clipping message, change the vertical scale to show the entire waveform, disconnect the probe tip from the

excessive voltage source, and check that you are probing the correct signal using the correct probe.

24 MDO32, MDO34 Installation and Safety Manual

Page 35

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Error messages and badges

This instrument shows a warning triangle symbol and an error message abbreviation in a Channel badge when an error occurs.

To remove the message from the badge, clear the error.

System badges

System badges (in the Settings bar) display the main Horizontal, Trigger, and Acquisition settings. You cannot delete System

badges.

Double-tap a System badge to open its configuration menu.

The Horizontal badge also has Scale buttons, shown by single-tapping the badge. Use the Horizontal Scale buttons to increase

or decrease the horizontal time/div setting.

MDO32, MDO34 Installation and Safety Manual 25

Page 36

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Common badge actions

Action Result Example

Single tap Immediate access controls (Scale,

Navigation).

Double tap Configuration menu with access to

all settings for the badge.

Touch and hold Right-click menu with single tap

access to common actions. Typical

actions include turning off a

channel and deleting a

measurement or search badge.

26 MDO32, MDO34 Installation and Safety Manual

Page 37

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Configuration menus

Configuration menus let you quickly set the parameters for channels, system settings (Horizontal, Trigger, Acquisition),

measurements, cursor readouts, Waveform view, and so on.

Double-tap an item (badge, Waveform View, cursor readouts, and so on) to open its configuration menu. For example, doubletap a Channel badge in the Settings Bar to open its configuration menu.

Selections or values that you enter take effect immediately. Menu contents are dynamic and can change depending on your

selections, instrument options, or attached probes.

Related settings are grouped into 'panels.' Tap the panel name to show those settings. Changes to panel settings can change

the values and/or fields shown in that panel and other panels.

Tap anywhere outside a configuration menu to close it.

MDO32, MDO34 Installation and Safety Manual 27

Page 38

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

To open Help content for a configuration menu, tap the question mark icon in the upper right corner of the menu.

Zoom user interface elements

Use the zoom tools to magnify waveforms to view signal details.

1. The Zoom Overview shows the entire waveform record.

NOTE. Using pinch and expand gestures on the Zoom Overview waveforms changes the horizontal time base settings.

2. The Zoom Box shows the area of the Zoom Overview to display in the Zoom View (see 4). You can touch and drag the box

to move the area to view.

NOTE. Moving the Zoom Box or changing its position does not change the horizontal time base settings.

3. The Zoom icon (in the upper right corner of the Waveform View) switches zoom mode on and off.

4. The Zoom View shows the zoomed waveforms as marked by the Zoom Box. Use pinch and/or drag options in the zoom

view to change the zoomed area of interest.

NOTE. Pinch, expand, and drag gestures in the Zoom View only change zoom magnification settings and Zoom Box

position.

5. Use the Zoom Title Bar controls to adjust the horizontal size of the zoom area. Click or tap the + or - buttons.

28 MDO32, MDO34 Installation and Safety Manual

Page 39

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Using the touchscreen interface for common tasks

Use standard touchscreen actions, similar to those found on smart phones and tablets, to interact with most screen objects. You

can also use a mouse to interact with the UI. The equivalent mouse operation is shown for each touch operation.

See the table to quickly learn the fundamental touch operations.

Table 3: Common touchscreen UI tasks (with mouse equivalents)

Task Touchscreen UI action Mouse action

Add a channel, math, reference, or bus

waveform to the screen.

Select a channel, math, reference, or bus

waveform to make it active.

Display scale or navigation buttons on a

badge (waveform, measurement

1

,

search, horizontal).

Open a configuration menu on any item

(all badges, views, cursor readouts,

labels, and so on).

Open a right-click menu (badges, views). Touch and hold on the badge, Waveform

Close a configuration menu

2

. Tap anywhere outside the menu or

Move a menu. Touch and hold the menu title bar or a

Change horizontal or vertical settings

directly on a waveform.

Vertical changes only apply to the

selected channel or waveform; horizontal

changes apply to all channels and

waveforms.

Increase or decrease the zoom area

(while in Zoom mode).

Quickly scroll or pan a waveform. Touch and drag in the waveform. Click and drag in the waveform or list.

Close or open the Results Bar to

increase the Waveform View area.

Tap an inactive channel button or the

Add Math Ref Bus button and select a

math, reference, or bus.

Tap the Channel or Waveform badge or

waveform handle.

Click an inactive channel button or the

Add Math Ref Bus button and select a

math, reference, or bus.

Click the Channel or Waveform badge or

waveform handle.

Tap the badge. Click the badge.

Double-tap the badge, view, or other

object.

Double-click the badge, view, or other

object.

Right-click the object.

View, or other screen item until a menu

opens.

Click anywhere outside the menu or

dialog.

dialog.

Click and hold the left mouse button on

blank area in the menu, then drag the

menu to new position.

Tap a badge and use the Scale buttons.

Or, use pinch/expand gestures.

Touch and hold two fingertips on the

waveform view, move them together or

title or blank area and then drag to new

position.

Click a channel, waveform, or Horizontal

badge and click on the Scale buttons.

Click the + or - buttons on the Zoom Title

bar.

apart vertically or horizontally, lift from

screen, and repeat.

Tap on the Results Bar Handle or

anywhere in the border between the

Waveform View and the Results Bar.

Click the Results Bar Handle or

anywhere in the border between the

Waveform View and the Results Bar.

Click and drag the Results Bar divider.

1

Not all measurement or search badges display navigation buttons.

2

Some dialog boxes will not close until you click an OK, Close, or other button in the dialog.

MDO32, MDO34 Installation and Safety Manual 29

Page 40

Getting acquainted with your instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

30 MDO32, MDO34 Installation and Safety Manual

Page 41

Configure the instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Set the date and time

Set the date and time so that saved files are marked with the correct date and time information.

1. Double-tap the Date/Time badge (bottom-right of screen) to open the configuration menu.

2. To turn off showing the date and time on the screen, tap the Display button to Off.

To turn on date/time display again, double-tap in the blank area where the date/time badge was displayed to open the

configuration menu and set the Display button to On.

3. You may also tap the Year, Day, Hour, Minute, or UTC Offset fields and use the multipurpose knobs to set the fields to the

correct time.

You may also double-tap the fields and use the numeric keypad to set the time.

4. Tap Month and select the month from the list.

5. Tap anywhere outside of the menu to close it.

MDO32, MDO34 Installation and Safety Manual 31

Page 42

Configure the instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Download and install the latest firmware

Installing the latest firmware helps ensure that your instrument is equipped with all of the best available measurement and

analysis improvements.

Prerequisite: Save any important on-instrument files (waveforms, screen captures, oscilloscope setups, and so on) to a USB

drive or network. The installation process does not remove user-created files, but it is a good idea to back up important files

before an update.

Update oscilloscope firmware from a USB drive

Prerequisite: Determine the current version of firmware installed on the oscilloscope (Help > About)

1. Open up a Web browser on a PC and go to www.tek.com/product-support.

2. Enter the oscilloscope model number in the search field and click Go.

3. Scroll down the screen and click the Software tab.

4. If the listed available firmware version is newer than what is on your oscilloscope, select and download that file to your PC.

5. Copy the firmware install file to a USB drive.

6. Insert the USB drive into any oscilloscope USB Host port:

7. Power off the oscilloscope and then power on the oscilloscope.

NOTE. Do not power off the oscilloscope or remove the USB flash drive until the oscilloscope finishes installing the

firmware. The oscilloscope displays a message when it is OK to turn off the oscilloscope.

The oscilloscopes detects the USB drive with the firmware file and starts the installation process. Follow on-screen

instructions to install the firmware.

8. When the firmware install is finished, remove the USB drive and restart the oscilloscope.

To confirm the firmware installation:

a. Tap Help > About in the Menu bar.

b. Verify that the firmware version number listed on the screen is the same version that you downloaded.

Run Signal Path Compensation (SPC)

Run SPC at regular intervals for best measurement accuracy. You should run SPC whenever the ambient (room) temperature

has changed by more than 5 °C (9 °F) or once a week if you use vertical scale settings of 5 mV/div or less.

Signal Path Compensation (SPC) corrects for DC level inaccuracies in the internal signal path caused by temperature variations

and/or long-term signal path drift. Failure to run SPC on a regular basis may result in the oscilloscope not meeting warranted

performance levels at low volts per division settings.

Prerequisite: Disconnect all probes and cables from the front-panel channel inputs and rear-panel signal connectors.

1. Power on and warm up the oscilloscope for at least 20 minutes.

2. Tap Utility > Calibration.

3. Tap Run SPC. The SPC Status readout shows Running while SPC is running. SPC can take several minutes per channel

to run, so wait until the SPC Status message changes to Pass before reconnecting probes and using the oscilloscope.

32 MDO32, MDO34 Installation and Safety Manual

Page 43

Configure the instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

4. Close the Calibration configuration dialog when SPC has completed.

5. If SPC fails, write down any error message text. Make sure that all probes and cables are disconnected and run SPC again.

If SPC still fails, contact Tektronix Customer Support.

Compensate TPP0250, TPP0500B, or TPP1000 probes

Probe compensation adjusts the high frequency response of a probe for best waveform capture and measurement accuracy. The

oscilloscope can automatically test and store compensation values for TPP0250, TPP0500B and TPP1000 probes.

The oscilloscope stores the compensation values for each probe/channel combination and automatically recalls the

compensation values when you plug in the probe again. Probe compensation status is shown in the Probe Setup panel of the

Channel configuration menu.

■

If the Probe Compensation Status field displays Pass, the probe is compensated and ready for use.

■

If the Probe Compensation Status field displays Default, the attached probe has not been compensated and needs to have

this probe compensation procedure run.

■

If the Probe Compensation Status field displays Fail, the attached probe has failed the probe compensation procedure.

Reconnect the probe and run probe compensation again.

■

If there is no probe compensation status field shown in the panel, the oscilloscope cannot store compensation values for

that probe. See the oscilloscope Help for how to manually compensate passive probes not supported by the probe

compensation function.

■

Each compensation generates values for a specific probe and channel combination. If you want to use the probe on another

channel and desire to compensate the new probe-channel pair, you must run a new set of compensation steps.

■

Each channel can store compensation values for 10 individual probes. If you try to compensate an 11th probe on a channel,

the oscilloscope will delete the values for the least recently used probe and add the values for the new probe.

Use this procedure to compensate a TPP0250, TPP0500B, TPP1000, or other supported TPP-family probe that shows a Default

status when connected to the oscilloscope.

NOTE. A Default Setup does not delete probe compensation values. A factory calibration deletes all stored probe compensation

values.

Prerequisite: The oscilloscope must be powered on for at least 20 minutes before compensating a probe.

1. Connect a supported probe to an input channel.

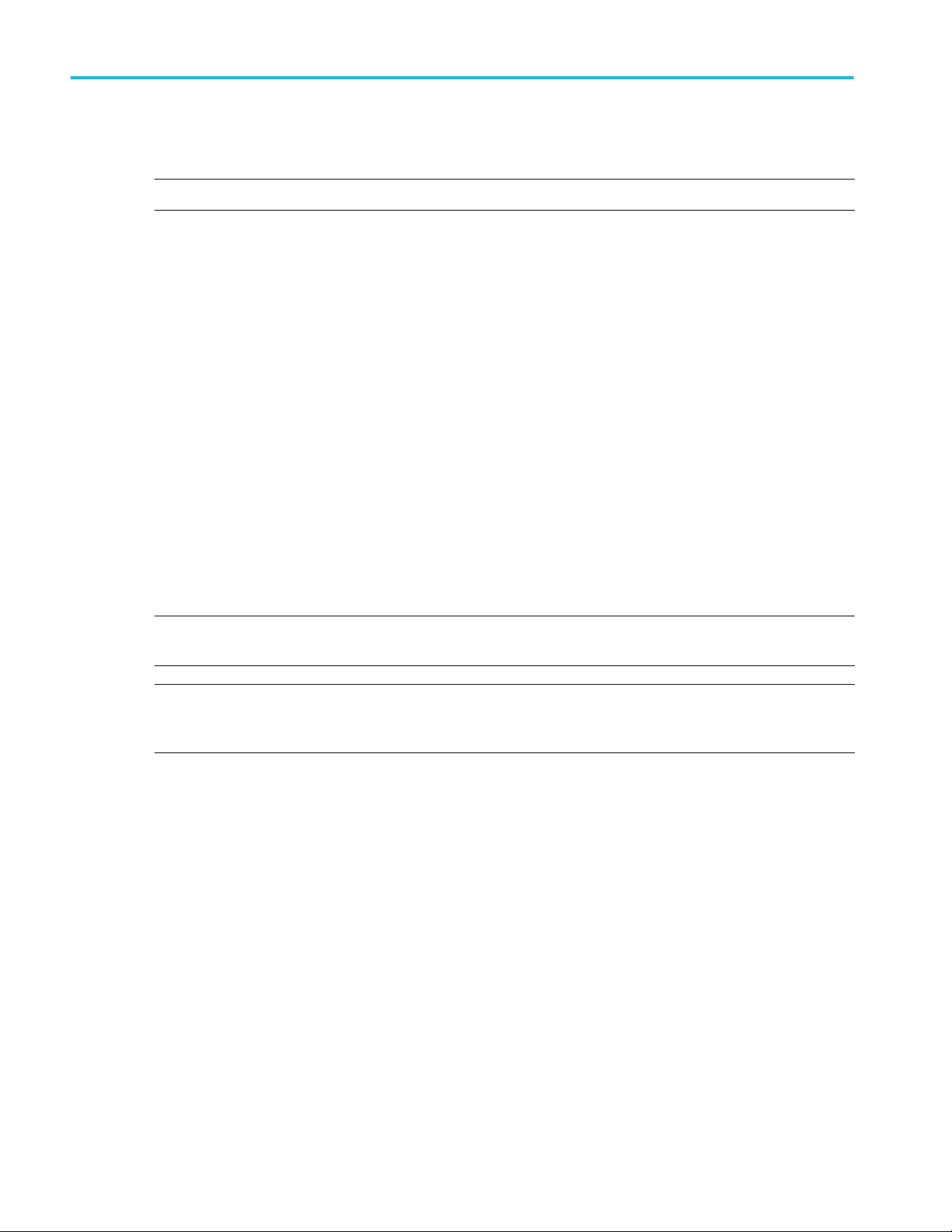

2. Connect the probe tip and ground lead of the probe to the PROBE COMP terminals on the lower right of the oscilloscope

(see following image).

Figure 4: Probe Comp connections.

MDO32, MDO34 Installation and Safety Manual 33

Page 44

Configure the instrument

ООО "Техэнком" Контрольно-измерительные приборы и оборудование www.tehencom.com

Connect the probe tip to the 1 kHz source and the ground clip to the ground. For best results, remove any probe tip

accessories and hold the probe tip directly onto the 1 kHz connector.

NOTE. Connect only one probe at a time to the PROBE COMP terminals.

3. Turn off all channels.

4. Turn on the channel to which the probe is connected.

5. Push the front-panel Autoset button. The screen displays a square wave.