3 Series MDO

Mixed Domain Oscilloscope

Printable Help

*P077149700*

077-1497-00

3 Series MDO

Mixed Domain Oscilloscope

Printable Help

Warning

The servicing instructions are for use by qualified personnel only. To avoid

personal injury, do not perform any servicing unless you are qualified to do

so. Refer to all safety summaries prior to performing service.

Supports Product Firmware V1.0 and above

www.tek.com

077-1497-00

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions. Tektronix products

are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all

previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

This product contains open source software. License information is available at (your instrument IP address)/

opensource. To find your instrument IP address tap Utility > I/O. For programs licensed under the "GNU General

Public License (GPL) or Lesser GNU General Public License (LGPL)" the complete corresponding sources are

available. You can order a CD containing the sources from us for a period of three years after download of the

software, by sending a written request to:

Chief Intellectual Property Counsel, Tektronix, Inc.

MS 50/LAW

14150 SW Karl Braun Dr.

Beaverton OR, 97077

This offer is valid to anyone in receipt of this information.

Your request should include: (i) the name of the product, (ii) your (company) name, and (iii) your return mailing

and email address (if available).

Please note that we may charge you a fee to cover the cost of performing this distribution.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

■

In North America, call 1-800-833-9200.

■

Worldwide, visit www.tek.com to find contacts in your area.

Table of Contents

TEKTRONIX SOFTWARE LICENSE AGREEMENT ................................................................... 11

Open Source GPL License Notice ..................................................................................................... 15

GPU disclosure .................................................................................................................................. 17

Welcome to the 3 Series MDO instrument help .............................................................................. xix

Product documents and support

Related documents .......................................................................................................................... 1

Product support and feedback ......................................................................................................... 2

Accessories

Standard accessories ....................................................................................................................... 3

Recommended accessories ............................................................................................................. 3

Recommended probes ..................................................................................................................... 4

Options

Bandwidth options .......................................................................................................................... 7

Spectrum analyzer frequency range options ................................................................................... 9

Arbitrary Function Generator (AFG) (optional) ............................................................................. 9

Enhanced instrument security (factory option) ............................................................................ 10

Serial bus decode and trigger options ........................................................................................... 10

Power Analysis option .................................................................................................................. 11

DVM option .................................................................................................................................. 12

Power cord options ....................................................................................................................... 12

Service options ............................................................................................................................. 13

How to install an option license ................................................................................................... 14

Install your instrument

Check shipped accessories ............................................................................................................ 15

Safely rotate the handle ................................................................................................................ 16

Operating requirements ................................................................................................................ 17

Input signal requirements ............................................................................................................. 17

Powering the oscilloscope ............................................................................................................ 18

Check that the oscilloscope passes power-on self tests ................................................................ 19

Secure (lock) the oscilloscope ...................................................................................................... 20

Connecting probes ........................................................................................................................ 21

MDO32, MDO34 Help i

Table of Contents

Rackmount information ................................................................................................................ 22

Getting acquainted with your instrument

Front panel controls and connectors ............................................................................................. 23

Rear panel connections ................................................................................................................. 33

The user interface screen .............................................................................................................. 34

Identifying items in the time domain display ............................................................................... 35

Identifying items in the frequency domain display ...................................................................... 39

Identifying items in the arbitrary function generator display ....................................................... 41

Identifying items in the digital voltmeter display ......................................................................... 41

Badges .......................................................................................................................................... 42

Configuration menus .................................................................................................................... 48

Zoom user interface elements ....................................................................................................... 49

Using the touchscreen interface for common tasks ...................................................................... 50

Accessing application help ........................................................................................................... 52

Configure the instrument

Set the date and time ..................................................................................................................... 53

Functional check ........................................................................................................................... 54

Download and install the latest firmware ..................................................................................... 54

Run Signal Path Compensation (SPC) ......................................................................................... 55

Compensate TPP0250, TPP0500B, or TPP1000 probes .............................................................. 56

Compensate passive probes .......................................................................................................... 58

Connect to a network (LAN) ........................................................................................................ 59

Mount a network drive ................................................................................................................. 59

Unmount a network drive ............................................................................................................. 60

Deskew analog input channels - quick visual method .................................................................. 61

Deskew analog input channels - measurement method ................................................................ 62

Connect a keyboard or mouse ...................................................................................................... 63

Connect an external monitor or projector ..................................................................................... 63

ESD prevention guidelines ........................................................................................................... 63

Analog channel operating basics

Acquiring a signal ......................................................................................................................... 65

Quickly display a waveform (autoset) .......................................................................................... 66

Set horizontal parameters ............................................................................................................. 67

How to trigger on a signal ............................................................................................................ 67

Set the acquisition mode ............................................................................................................... 69

ii MDO32, MDO34 Help

Start and stop an acquisition ......................................................................................................... 70

Add a channel waveform to the display ....................................................................................... 71

Configure channel or waveform settings ...................................................................................... 72

Add a math, reference, or bus waveform ...................................................................................... 73

Add a measurement ...................................................................................................................... 75

Configure a measurement ............................................................................................................. 77

Delete a measurement or search badge ......................................................................................... 78

Display an XY waveform ............................................................................................................. 79

Display an FFT math waveform ................................................................................................... 79

Add a search ................................................................................................................................. 80

Change waveform view settings ................................................................................................... 81

Display and configure cursors ...................................................................................................... 82

Using Default Setup ...................................................................................................................... 83

Using Fast Acq ............................................................................................................................. 83

Remote access from a Web browser ............................................................................................. 85

Connect the oscilloscope to a PC using a USB cable ................................................................... 85

Table of Contents

Acquiring digital signals

Acquiring digital signals ............................................................................................................... 87

Connect and set up digital signals ................................................................................................ 87

Add a serial bus to the Waveform view ....................................................................................... 90

Add a parallel bus to the Waveform view .................................................................................... 92

Advanced triggering

Advanced triggering ..................................................................................................................... 95

Triggering concepts ...................................................................................................................... 95

Trigger on a pulse width event ..................................................................................................... 96

Set Trigger Holdoff ...................................................................................................................... 97

Trigger on sequential events (A and B triggers) ........................................................................... 98

Set up trigger on a parallel bus ..................................................................................................... 99

Set up trigger on a serial bus ........................................................................................................ 99

Trigger using the AUX input ........................................................................................................ 99

Setting waveform display parameters

Setting waveform display parameters ......................................................................................... 101

Set the waveform persistence style and intensity ....................................................................... 101

Set the graticule style and intensity ............................................................................................ 102

MDO32, MDO34 Help iii

Table of Contents

Zooming on waveforms

Zooming on waveforms .............................................................................................................. 103

Turn on Zoom mode ................................................................................................................... 103

Zoom mode and Searches ........................................................................................................... 104

Customizing measurements

Customizing measurements ........................................................................................................ 105

Set measurement reference levels ............................................................................................... 105

Set measurement gates ................................................................................................................ 106

Saving and recalling information

Save a screen image .................................................................................................................... 108

Save a waveform to a file ........................................................................................................... 109

Save instrument settings to a file ................................................................................................ 110

Recall a Reference waveform ..................................................................................................... 110

Recall a Setup file ....................................................................................................................... 111

Menus and dialog boxes

The Acquisition configuration menu .......................................................................................... 113

Add Measurements configuration menu overview ..................................................................... 115

Amplitude Measurements panel ............................................................................................ 116

Time Measurements panel ..................................................................................................... 118

Other Measurements panel .................................................................................................... 120

The Power Measurements panel (optional) ........................................................................... 121

Measurement configuration menu .............................................................................................. 127

Measurement Name panel (Measurement configuration menu) ........................................... 128

Global Measurement Settings panel (Measurement configuration menu) ............................ 129

Power measurement configuration menu overview (optional) ................................................... 131

Power Measurement Name panel (Measurement configuration menu) ................................ 131

SOA Mask definition controls and fields .............................................................................. 132

Reference Levels panel (Power measurement configuration Menu) .................................... 132

Bus configuration menu .............................................................................................................. 133

ARINC429 serial bus menu .................................................................................................. 134

Audio serial bus configuration menu .................................................................................... 135

CAN serial bus configuration menu ...................................................................................... 137

FlexRay serial bus configuration menu ................................................................................. 139

iv MDO32, MDO34 Help

I2C serial bus configuration menu ........................................................................................ 140

LIN serial bus configuration menu ........................................................................................ 141

MIL-STD-1553 serial bus menu ........................................................................................... 143

Parallel Bus configuration menu ........................................................................................... 144

Parallel Bus - Define Inputs menu ........................................................................................ 145

RS-232 serial bus menu ......................................................................................................... 145

SPI serial bus configuration menu ......................................................................................... 147

USB serial bus configuration menu ....................................................................................... 148

Add Results Table ...................................................................................................................... 150

Search configuration menu overview ......................................................................................... 151

Bus Search configuration menus ........................................................................................... 151

ARINC429 serial bus search configuration menu ................................................................. 152

Audio serial bus search configuration menu ......................................................................... 154

CAN serial bus search configuration menu ........................................................................... 155

FlexRay serial bus search configuration menu ...................................................................... 156

I2C serial bus search configuration menu ............................................................................. 158

LIN serial bus search configuration menu ............................................................................ 159

MIL-STD-1553 Search configuration menu ......................................................................... 160

Parallel bus search configuration menu ................................................................................. 161

RS-232 serial bus search configuration menu ....................................................................... 162

SPI serial bus search configuration menu ............................................................................. 163

USB serial bus search configuration menu ........................................................................... 163

Edge Search configuration menu .......................................................................................... 165

Logic Search configuration menu ......................................................................................... 166

Logic Search - Define Inputs configuration menu ................................................................ 168

Pulse Width Search configuration menu ............................................................................... 169

Rise/Fall Time Search configuration menu ........................................................................... 170

Runt Search configuration menu ........................................................................................... 172

Setup and Hold Search configuration menu .......................................................................... 173

Setup and Hold Search - Define Inputs configuration menu ................................................. 175

Timeout Search configuration menu ..................................................................................... 175

Analog Channel configuration menu .......................................................................................... 177

Probe Setup panel (Channel configuration menu) ................................................................ 178

Probe Compensation configuration menu (analog channels Probe Setup panel) .................. 179

Other panel (Channel configuration menu) ........................................................................... 179

Deskew configuration menu (Other panel Channel configuration menu) ............................ 180

AFG configuration menu ............................................................................................................ 182

Save As configuration menu (AFG menu) ................................................................................. 184

Table of Contents

MDO32, MDO34 Help v

Table of Contents

RF configuration menu ............................................................................................................... 185

Traces panel (RF configuration menu) .................................................................................. 185

Horizontal badge configuration menu ........................................................................................ 187

Spectral math configuration menu .............................................................................................. 188

Spectral Ref configuration menu ................................................................................................ 188

Cursor configuration menu ......................................................................................................... 189

Date and Time configuration menu ............................................................................................ 190

Digital channel configuration menu ........................................................................................... 191

DVM configuration menu .......................................................................................................... 192

Menu bar overview ..................................................................................................................... 192

Recall configuration menu (File menu) ................................................................................. 193

Save As configuration menu (File menu) .............................................................................. 194

Print configuration menu ....................................................................................................... 197

Add Printer configuration menu ............................................................................................ 197

File Utilities configuration (File menu) ................................................................................. 198

Mount Network Drive configuration menu ........................................................................... 199

User Preferences (Utility menu) ............................................................................................ 200

I/O (Utility menu) .................................................................................................................. 201

LAN Reset configuration menu (Utility > I O menu) ........................................................... 205

Self Test configuration menu (Utility menu) ........................................................................ 206

Calibration configuration menu (Utility menu) ..................................................................... 207

Security configuration menu (Utility menu) ......................................................................... 208

Enter Password configuration menu (optional) ..................................................................... 209

Set Password configuration menu (optional) ........................................................................ 210

Demo (Utility menu) ............................................................................................................. 210

Help (Help menu) .................................................................................................................. 211

About (Help menu) ................................................................................................................ 211

Horizontal configuration menu ................................................................................................... 212

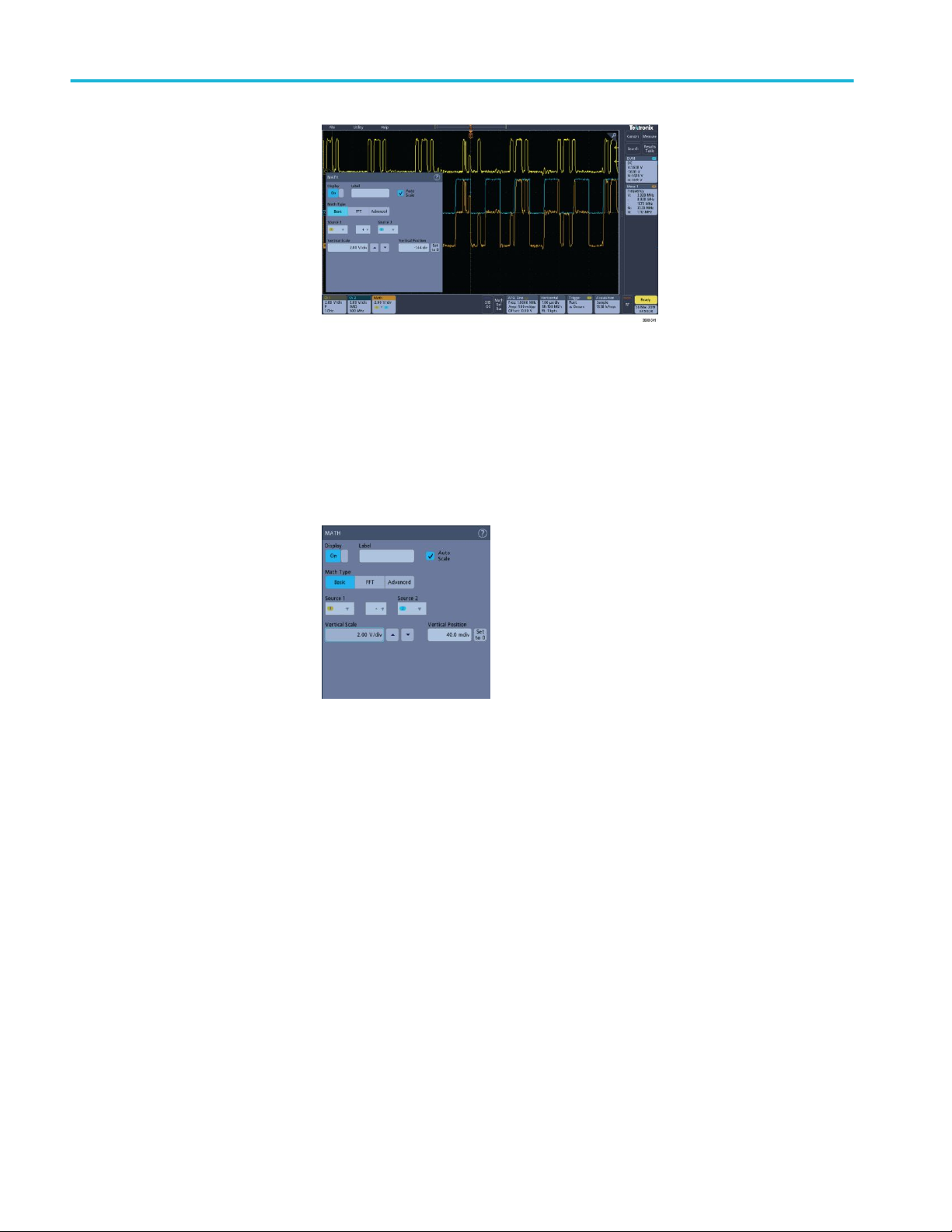

Math configuration menu overview ........................................................................................... 213

Math configuration menu ...................................................................................................... 213

Equation Editor (Math configuration menu) ......................................................................... 215

Add Functions (math Equation Editor) ................................................................................. 216

Pick Measurement ................................................................................................................. 217

Reference waveform configuration menu .................................................................................. 218

Recall configuration menu (Ref waveform configuration menu) .............................................. 219

Search configuration menu ......................................................................................................... 220

Trigger configuration menu overview ........................................................................................ 220

Bus Trigger configuration ..................................................................................................... 221

ARINC429 serial bus trigger settings panel .......................................................................... 221

vi MDO32, MDO34 Help

Audio serial bus trigger settings panel .................................................................................. 223

CAN serial bus trigger settings panel .................................................................................... 224

FlexRay serial bus trigger settings panel ............................................................................... 225

I2C serial bus trigger settings panel ...................................................................................... 227

LIN serial bus trigger settings panel ...................................................................................... 228

MIL-STD-1553 serial bus trigger settings panel ................................................................... 229

Parallel serial bus trigger settings panel ................................................................................ 232

RS-232 serial bus trigger settings panel ................................................................................ 232

SPI serial bus trigger settings panel ...................................................................................... 233

USB serial bus trigger settings panel .................................................................................... 233

Edge Trigger configuration menu ......................................................................................... 235

Logic Trigger configuration menu ........................................................................................ 237

Logic Trigger - Define Inputs configuration menu ............................................................... 239

Pulse Width Trigger configuration menu .............................................................................. 240

Rise Fall Time Trigger configuration menu .......................................................................... 241

Runt Trigger configuration menu .......................................................................................... 243

Sequence Trigger configuration menu .................................................................................. 244

Setup & Hold Trigger configuration menu ........................................................................... 246

Setup & Hold Trigger - Define Inputs configuration menu .................................................. 247

Timeout Trigger configuration menu .................................................................................... 247

Video trigger configuration menu ......................................................................................... 249

Mode and Holdoff panel ........................................................................................................ 250

Viewing the trigger frequency ............................................................................................... 251

Virtual Keyboard ........................................................................................................................ 251

Binary, decimal, hex, and octal virtual keypads ......................................................................... 252

Numeric input keypad ................................................................................................................ 252

IP address keypad ....................................................................................................................... 253

Waveform View configuration menu ......................................................................................... 253

Cursors menu (RF view) ............................................................................................................ 255

RF badge menu ........................................................................................................................... 256

Table of Contents

Waveform acquisition concepts

Acquisition concepts ................................................................................................................... 259

Acquisition hardware ............................................................................................................ 259

Sampling process ................................................................................................................... 259

Waveform record ................................................................................................................... 260

Acquisition modes ...................................................................................................................... 261

How the acquisition modes work .......................................................................................... 261

Coupling ..................................................................................................................................... 262

MDO32, MDO34 Help vii

Table of Contents

Scaling and positioning .............................................................................................................. 263

Vertical acquisition considerations ............................................................................................. 263

Horizontal acquisition considerations ........................................................................................ 264

Using reference waveforms and traces ....................................................................................... 265

Frequency-Domain concepts ...................................................................................................... 266

Displaying the Frequency Domain menu .............................................................................. 266

RF waveform view and badges ............................................................................................. 267

Spectrum trace handle ........................................................................................................... 267

Spectrum trace markers ......................................................................................................... 268

The RF waveform view user interface .................................................................................. 268

Using spectral analysis controls ............................................................................................ 269

Setting up the RF input .......................................................................................................... 270

Resolution bandwidth ............................................................................................................ 271

Spectrogram display .............................................................................................................. 272

Automatic peak markers ........................................................................................................ 273

Frequency domain cursors ..................................................................................................... 274

Use the Arbitrary Function Generator ........................................................................................ 275

Trigger concepts

Trigger sources ........................................................................................................................... 279

Trigger types ............................................................................................................................... 279

Trigger modes ............................................................................................................................. 280

Trigger holdoff ........................................................................................................................... 281

Trigger coupling ......................................................................................................................... 282

Trigger slope and level ............................................................................................................... 282

Trigger position in waveform record .......................................................................................... 283

Trigger delay ............................................................................................................................... 283

Bus triggering concepts .............................................................................................................. 284

Pulse width trigger concepts ....................................................................................................... 285

Timeout trigger ........................................................................................................................... 285

Runt trigger ................................................................................................................................. 285

Logic trigger concepts ................................................................................................................ 285

Setup and Hold trigger concepts ................................................................................................. 286

Rise/Fall time trigger concepts ................................................................................................... 287

Sequential (A B) trigger concepts .............................................................................................. 287

Waveform display concepts

Waveform display overview ....................................................................................................... 289

viii MDO32, MDO34 Help

Waveform preview mode ........................................................................................................... 290

Horizontal position and the horizontal reference point .............................................................. 290

Annotating the screen ................................................................................................................. 290

Measurement concepts

Taking automatic measurements in the time domain ................................................................. 291

Taking automatic measurements in the frequency domain ........................................................ 292

Taking digital voltmeter measurements ..................................................................................... 292

Taking manual measurements with cursors ................................................................................ 293

Making automated power measurements ................................................................................... 295

Using cursor readouts ................................................................................................................. 295

Using XY Cursors ...................................................................................................................... 296

Measurement variables ............................................................................................................... 297

Missing or out-of-range samples ................................................................................................ 299

Math waveforms ......................................................................................................................... 300

Math waveform elements ........................................................................................................... 300

Guidelines for working with math waveforms ........................................................................... 301

Math waveform editor syntax ..................................................................................................... 301

Math waveform differentiation ................................................................................................... 302

Math waveform offset position and scale ................................................................................... 303

Waveform integration ................................................................................................................. 303

Using math waveforms ............................................................................................................... 304

Using advanced math .................................................................................................................. 305

Using FFT ................................................................................................................................... 306

FFT process ................................................................................................................................ 307

FFT and aliasing ......................................................................................................................... 308

Blackman-Harris FFT window concepts .................................................................................... 309

Hanning FFT window ................................................................................................................. 309

Hamming window ...................................................................................................................... 310

Rectangular window ................................................................................................................... 310

Using spectrum math .................................................................................................................. 311

Table of Contents

References

Upgrading firmware ................................................................................................................... 313

Cleaning ...................................................................................................................................... 313

MDO32, MDO34 Help ix

Table of Contents

x MDO32, MDO34 Help

TEKTRONIX SOFTWARE LICENSE AGREEMENT

THE SOFTWARE, ENCODED OR INCORPORATED WITHIN EQUIPMENT

OR ACCOMPANYING THIS AGREEMENT, IS FURNISHED SUBJECT TO

THE TERMS AND CONDITIONS OF THIS AGREEMENT. UNLESS

PROVIDED TO THE UNITED STATES GOVERNMENT, BY RETAINING

THE SOFTWARE FOR MORE THAN THIRTY DAYS OR USING THE

SOFTWARE IN ANY MANNER YOU (A) ACCEPT THIS AGREEMENT

AND AGREE THAT LICENSEE IS LEGALLY BOUND BY ITS TERMS;

AND (B) REPRESENT AND WARRANT THAT: (I) YOU ARE OF LEGAL

AGE TO ENTER INTO A BINDING AGREEMENT; AND (II) IF LICENSEE

IS A CORPORATION OR OTHER LEGAL ENTITY, YOU HAVE THE

RIGHT, POWER, AND AUTHORITY TO ENTER INTO THIS AGREEMENT

ON BEHALF OF LICENSEE AND BIND LICENSEE TO ITS TERMS. IF

LICENSEE DOES NOT AGREE TO THE TERMS OF THIS AGREEMENT,

LICENSOR WILL NOT AND DOES NOT LICENSE THE SOFTWARE TO

LICENSEE AND YOU MUST NOT DOWNLOAD OR INSTALL THE

SOFTWARE OR DOCUMENTATION.

NOTWITHSTANDING ANYTHING TO THE CONTRARY IN THIS

AGREEMENT OR YOUR OR LICENSEE'S ACCEPTANCE OF THE TERMS

AND CONDITIONS OF THIS AGREEMENT, NO LICENSE IS GRANTED

(WHETHER EXPRESSLY, BY IMPLICATION, OR OTHERWISE) UNDER

THIS AGREEMENT, AND THIS AGREEMENT EXPRESSLY EXCLUDES

ANY RIGHT, CONCERNING ANY SOFTWARE THAT LICENSEE DID

NOT ACQUIRE LAWFULLY OR THAT IS NOT A LEGITIMATE,

AUTHORIZED COPY OF LICENSOR'S SOFTWARE.

IF THESE TERMS ARE NOT ACCEPTABLE, THE UNUSED SOFTWARE

AND ANY ACCOMPANYING DOCUMENTATION SHOULD BE

RETURNED PROMPTLY TO TEKTRONIX FOR A FULL REFUND OF THE

LICENSE FEE PAID. (FOR INFORMATION REGARDING THE RETURN

OF SOFTWARE ENCODED OR INCORPORATED WITHIN EQUIPMENT,

CONTACT THE NEAREST TEKTRONIX SALES OFFICE.)

DEFINITIONS.

"Tektronix" means Tektronix, Inc., an Oregon corporation, or local Tektronix'

legal entity that is supplying the equipment.

"Customer," "Licensee," or "You" means the person or organization in whose

name the Software was ordered.

LICENSE.

Subject to the terms and conditions of this Agreement, Tektronix grants You a

non-exclusive, non-transferable license to the Software, as follows

You may:

1. Use the Software with the Tektronix equipment it is encoded or incorporated

within, or if the Software is not encoded or incorporated in any Tektronix

equipment, on no more than one machine at a time; and

2. Copy the Software for archival or backup purposes, provided that no more

than one (1) such copy is permitted to exist at any one time, and provided

that each copy includes a reproduction of any copyright notice or restrictive

rights legend that was included with the Software, as received from

Tektronix;

3. Distribute or transfer the Software but only (i) in conjunction with the

equipment within which it is encoded or incorporated, and (ii) accompanied

by this license agreement; and

4. Integrate Tektronix products that contain the Software into a system and sell

or distribute that system to third parties, provided that those third parties are

bound by the terms of this Agreement, and provided that You (i) do not

separate the Software from the Tektronix products, (ii) do not retain any

copies of the Software, and (iii) do not modify the Software.

You may not:

1. Use the Software in any manner other than as provided above, except as part

of a system that contains one or more Tektronix products, as described

above;

2. Distribute or transfer the Software to any person or organization outside of

Your organization without Tektronix's prior written consent, except in

connection with the transfer of the equipment within which the programs are

encoded or incorporated;

3. Decompile, decrypt, disassemble, or otherwise attempt to derive the source

code, techniques, processes, algorithms, know-how, or other information

(collectively "Reverse Engineer") from the Software or permit or induce any

third party to do so, except to the limited extent allowed by directly

applicable law or third party license (if any), and only to obtain information

necessary to achieve interoperability of independently created software with

the Software;

4. Modify, translate, adapt, or create derivative works of the Software, or merge

the Software with any other software;

5. Copy the documentation accompanying the Software;

6. Remove any copyright, trademark, or other proprietary notices from the

Software or any media relating thereto; or

7. Export or re-export, directly or indirectly, the Software, any associated

documentation, or the direct product thereof, to any country to which such

export or re-export is restricted by law or regulation of the United States or

any foreign government having jurisdiction without the prior authorization, if

required, of the Office of Export Administration, Department of Commerce,

Washington, D.C. and the corresponding agency of such foreign government;

THE SOFTWARE MAY NOT BE USED, COPIED, MODIFIED, MERGED,

OR TRANSFERRED TO ANOTHER EXCEPT AS EXPRESSLY PERMITTED

BY THESE TERMS AND CONDITIONS.

OWNERSHIP

Title to the Software and all copies thereof, but not the media on which the

Software or copies may reside, shall be and remain with Tektronix or others from

whom Tektronix has obtained a respective licensing right.

GOVERNMENT NOTICE

If the Software or any related documentation is acquired by or for an agency of

the U.S. Government, the Software and documentation shall be considered

"commercial computer software" or "commercial computer software

documentation" respectively, as those terms are used in 48 CFR §12.212, 48 CFR

§227.7202, or 48 CFR §252.227-7014, and are licensed with only those rights as

are granted to all other licensees as set forth in this Agreement.

TERM

The license granted herein is effective until terminated. The license may be

terminated by You at any time upon written notice to Tektronix. The license may

be terminated by Tektronix if You fail to comply with any term or condition and

such failure is not remedied within fifteen (15) days after notice hereof from

Tektronix or such third party. Upon termination by either party, You shall return

to Tektronix or destroy, the Software and all associated documentation, together

with all copies in any form.

IF YOU TRANSFER ANY COPY, MODIFICATION, OR MERGED PORTION

OF THE SOFTWARE WITHOUT THE AS EXPRESS PERMISSION OF

THESE TERMS AND CONDITIONS OR PRIOR WRITTEN CONSENT OF

TEKTRONIX, YOUR LICENSE WILL BE AUTOMATICALLY

TERMINATED.

LIMITED WARRANTY.

Tektronix does not warrant that the functions contained in the Software will meet

Your requirements or that the operation of the Software will be uninterrupted or

error-free.

THE SOFTWARE IS PROVIDED "AS IS" WITHOUT ANY WARRANTY OF

ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO,

THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

THE SOFTWARE IS NOT DESIGNED OR INTENDED FOR USE IN

HAZARDOUS ENVIRONMENTS REQUIRING FAIL-SAFE

PERFORMANCE INCLUDING WITHOUT LIMITATION, IN THE

OPERATION OF NUCLEAR FACILITIES, AIRCRAFT NAVIGATION OR

COMMUNICATION SYSTEMS, AIR TRAFFIC CONTROL, WEAPONS

SYSTEMS, DIRECT LIFE-SUPPORT MACHINES, OR ANY OTHER

APPLICATION IN WHICH THE FAILURE OF THE SOFTWARE COULD

LEAD TO DEATH, PERSONAL INJURY OR SEVERE PHYSICAL OR

PROPERTY DAMAGE (COLLECTIVELY "HAZARDOUS ACTIVITIES").

TEKTRONIX AND ITS AFFILIATES, LICENSORS, AND RESELLERS

EXPRESSLY DISCLAIM ANY EXPRESS OR IMPLIED WARRANTY OF

FITNESS FOR HAZARDOUS ACTIVITIES.

LIMITATION OF LIABILITY

IN NO EVENT SHALL TEKTRONIX, ITS AFFILIATES, LICENSORS, OR

RESELLERS BE LIABLE FOR: (1) ECONOMICAL, INCIDENTAL,

CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR EXEMPLARY

DAMAGES, WHETHER CLAIMED UNDER CONTRACT, TORT OR ANY

OTHER LEGAL THEORY, (2) LOSS OF OR DAMAGE TO YOUR DATA OR

PROGRAMMING, (3) PENALTIES OR PENALTY CLAUSES OF ANY

DESCRIPTION, OR (4) INDEMNIFICATION OF YOU OR OTHERS FOR

COSTS, DAMAGES, OR EXPENSES RELATED TO THE GOODS OR

SERVICES PROVIDED UNDER THIS LIMITED WARRANTY, EVEN IF

TEKTRONIX OR ITS AFFILIATES, LICENSORS, OR RESELLERS HAVE

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

THIRD-PARTY DISCLAIMER

The Software may contain copyrighted software owned by third parties and

obtained under a license from those parties ("Third Party Software"). Your use of

such Third Party Software is subject to the terms and conditions of this

Agreement and the applicable Third Party Software licenses. Except as expressly

agreed otherwise, third parties do not warrant the Third Party Software, do not

assume any liability with respect to its use, and do not undertake to furnish any

support or information relating thereto.

GENERAL

Unless the Customer is the United States Government, this License Agreement

contains the entire agreement between the parties with respect to the use,

reproduction, and transfer of the Software, and shall be governed by the laws of

the state of Oregon.

If the Customer is the United States Government, all contract disputes arising out

of or relating to this License Agreement shall be governed by and construed in

accordance with the Contract Disputes Act (CDA), 41 U.S.C. §§ 7101-7109. Any

legal suit, action, or proceeding arising out of or relating to this License

Agreement or the transaction contemplated hereby shall be instituted in the court

or board of jurisdiction under the CDA. If the matter is tortious in nature, the

action shall be brought under the Federal Tort Claims Act (FTCA), 28 U.S.C. §

1346(b).

You shall be responsible for any taxes that may now or hereafter be imposed,

levied or assessed with respect to the possession or use of the Software or this

license, including any sales, use, property, and excise taxes, and similar taxes,

duties, or charges.

Any waiver by either party of any provision of this License shall not constitute or

be deemed a subsequent waiver of that or any other portion.

All questions regarding this License should be directed to the nearest Tektronix

Sales Office.

Open Source GPL License Notice

For programs licensed under the "GNU General Public License (GPL) or Lesser

GNU General Public License (LGPL)" the complete corresponding sources are

available. You can order a CD containing the sources from us for a period of

three years after download of the software, by sending a written request to:

Chief Intellectual Property Counsel, Tektronix, Inc.

MS 50/LAW

14150 SW Karl Braun Dr.

Beaverton OR, 97077

This offer is valid to anyone in receipt of this information.

Your request should include: (i) the name of the product, (ii) your (company)

name, and (iii) your return mailing and email address (if available).

Please note that we may charge you a fee to cover the cost of performing this

distribution.

GPU disclosure

This product utilizes a 3rd party device driver to enable the Graphics Processor

Unit. The driver was obtained from NXP and requires the end user to accept an

end-user licensing agreement.

This product uses Linux kernel version 3.0.35. If you wish to modify any of the

GPL or LGPL components of the Linux kernel, and re-compile them, you will

need to request a copy of the binary driver imx-gpu-viv-5.0.11.p4.5.bin from

NXP. Instructions for compiling the kernel with the binary driver are below.

The GPU binary files rely on the gpu-viv driver package to be compiled into the

kernel. This package can be found in the " drivers/mxc/gpu-viv" directory of this

kernel distribution. To compile the package the user need only enable the

following flags in the configuration file in the build configuration file named

"Config-tek_lk-3.0.35":

CONFIG_IMX_HAVE_PLATFORM_VIV_GPU=y

CONFIG_DRM_VIVANTE=y

CONFIG_HAS_DMA=y

CONFIG_MXC_GPU_VIV=m

An end user who wishes to utilize this binary package will need to ensure that the

binary files are placed into a suitable directory in their uImage linux boot file.

The command line used for installing the galcore.ko module which starts up the

GPU driver on an i.mx6 solo processor to perform 2D scaling is as follows:

" insmod /lib/modules/3.0.35/kernel/drivers/mxc/gpu-viv/galcore.ko" \

" registerMemBase=0x00000000 registerMemSize=0x00004000 irqLine=-1" \

" irqLine2D=42 registerMemBase3D=0x02200000

registerMemSize3D=0x00004000" \

" irqLineVG=43 registerMemBase2D=0x02204000

registerMemSize2D=0x00004000" \

" signal=48 baseAddress=0x80000000 fastClear=-1 " \

" contiguousSize=0x006f50000 contiguousBase=0x9E000000 "

Finally, in the board support configuration file, memory needs to be reserved for

the GPU. An example of how to configure the board can be found in the

following file: "/arch/arm/mach-mx6/ board-mx6q_sabresd.c". The salient lines

are:

#include <mach/viv_gpu.h>

…

static struct viv_gpu_platform_data imx6q_gpu_pdata __initdata = {

.reserved_mem_size = SZ_128M,

};

….

imx_add_viv_gpu(&imx6_gpu_data, &imx6q_gpu_pdata);

…

#if defined(CONFIG_MXC_GPU_VIV) ||

defined(CONFIG_MXC_GPU_VIV_MODULE)

if (imx6q_gpu_pdata.reserved_mem_size) {

phys = memblock_alloc_base(imx6q_gpu_pdata.reserved_mem_size,

SZ_4K, SZ_1G);

memblock_remove(phys, imx6q_gpu_pdata.reserved_mem_size);

imx6q_gpu_pdata.reserved_mem_base = phys;

}

#endif

Welcome to the 3 Series MDO instrument help

This help supports 3 Series MDO (MDO34, MDO32) instruments. See the

following list for information on the key features.

MDO34, MDO32 Key features and benefits

MDO3 Series Mixed Domain Oscilloscopes are 6-in-1 integrated oscilloscopes,

offering a built-in spectrum analyzer, arbitrary function generator, logic analyzer,

protocol analyzer, digital voltmeter and frequency counter. Key features include:

■

A dedicated RF input channel for frequency domain measurements

■

Bandwidths from 100 MHz to 1 GHz

■

2- and 4-channels for time domain measurements

■

Sixteen-channel digital input option

■

Large 11.6” HD (1920 x 1080 pixel) capacitive touchscreen display

■

User interface optimized for touchscreen use

■

Sample rates of 2.5 GS/s on all analog channels (5 GS/s on 1 or 2 channels

for the MDO34 or MDO32 with the 1 GHz option)

■

10 M points record length on all channels

■

Maximum waveform capture rate: 280,000 waveforms/second, with FastAcq:

>50,000 waveforms/second with normal operation

■

Advanced triggering and analysis: I2C, SPI, USB 2.0, CAN, CAN FD, LIN,

FlexRay, RS-232, RS-422, RS-485, UART, I2S, Left Justified (LJ), Right

Justified (RJ), TDM, MIL-STD-1553, ARINC429 (with the appropriate

option), and Parallel

■

Power analysis (optional)

■

Arbitrary function generator and 16 digital channels (optional)

■

Digital voltmeter and trigger frequency counter free with product registration

3 Series MDO Help, version 20190330-16:00 for Firmware v1.0.0

MDO32, MDO34 Help xix

Welcome to the 3 Series MDO instrument help

xx MDO32, MDO34 Help

Product documents and support

Related documents

Use the related documents for more information on instrument functions, how to

remotely program or operate the instrument, understand theory of operation,

replace suspected modules, and do other tasks.

3 Series MDO documents

To learn about Use this document

How to use instrument

functions

How to remotely control

the instrument

Instrument

specifications and

procedures to verify the

instrument meets

specifications

Instrument theory of

operation,

troubleshooting,

disassembly, and

replaceable parts

Installing the instrument

in a rack

3 Series MDO Help (Tektronix part number 076-0425-xx; Printable

version of the instrument Help; available at www.tek.com/downloads)

3 Series MDO Installation and Safety Manual (this document, Tektronix

part number 071-3608-xx); standard accessory with the instrument.

Single document with English, Japanese, and Simplified Chinese

languages. Other language versions are available to download from the

Tektronix web site.

3 Series MDO Programmer Manual (Tektronix part number 077-1498-xx;

available at www.tek.com/downloads)

3 Series MDO Specifications and Performance Verification Technical

Reference (Tektronix part number 077-1499-xx; available at

www.tek.com/downloads)

3 Series MDO Service Manual (Tektronix part number 077-1500-xx;

available at www.tek.com/downloads)

RM3 Rack Mount Kit Instructions (Tektronix part number 071-3609-xx;

available at www.tek.com/downloads)

MDO32, MDO34 Help 1

Product documents and support

Product support and feedback

Tektronix values your feedback on our products. To help us serve you better,

please send us your suggestions, ideas, or comments on your instrument,

application, or product documentation.

Contact through mail, telephone, or the Web site. See Contacting Tektronix for

more information or assistance with your product.

When you contact Tektronix Technical Support, please include the following

information (be as specific as possible):

■

General information

All instrument model numbers

■

Hardware options, if any

■

Probes used

■

Your name, company, mailing address, phone number

■

Please indicate if you would like to be contacted by Tektronix about your

suggestion or comments

Application specific

information

■

Software version number

■

Description of the problem such that technical support can duplicate the

problem

■

If possible, save and send the setup files for all the instruments used and the

application

■

If possible, save and send status messages text files

■

If possible, save and send the waveform on which you are performing the

measurement as a .wfm file

2 MDO32, MDO34 Help

Accessories

Standard accessories

Item Quantity Tektronix part

number

3 Series MDO (MDO34, MDO32) Installation and Safety

Manual

Passive Voltage Probe, depends on instrument bandwidth

(350 MHz, 500 MHz, and 1 GHz bandwidth)

(100 MHz and 200 MHz bandwidth)

Accessory bag 1 016-2144-xx

Power cord 1 Depends on

Calibration certificate 1 N/A

OpenChoice® Desktop Software (available for download

from www.tek.com/software/downloads.)

1 071-3608-xx

One per analog

channel

TPP0500B

TPP0250B

region

Recommended accessories

See the Tektronix Web site (www.tek.com) for the latest information on

recommended accessories for this product.

Recommended

accessories

Accessory Tektronix part

Preamplifier, 12 dB nominal Gain, 9 kHz - 6 GHz TPA-N-PRE

N-to-TekVPI adapter TPA-N-VPI

Near field probe set, 100 kHz - 1 GHz 119-4146-00

Flexible monopole antenna 119-6609-00

Service manual (English only) 077-0981-xx

TekVPI® to TekProbe™ BNC adapter TPA-BNC

TekVPI Deskew pulse generator signal source TEK-DPG

Power measurement deskew and calibration fixture 067-1686-xx

Vector Signal Analysis Software SignalVu-PC-SVE

GPIB-to-USB adapter TEK-USB-488

Soft transit case (includes front protective cover) SC3

number

MDO32, MDO34 Help 3

Accessories

Accessory Tektronix part

number

Hard Transit Case for 4 series MSO and 3 series MDO (requires front

protective cover 200-5476-00 for 3 series MDO and 200-5480-00 for

4 series MSO)

Rackmount kit RM3

HC43

Recommended probes

See the Tektronix Web site (www.tek.com) for the latest information on

supported probes for this product.

Probes

Tektronix offers over 100 different probes to meet your application needs. For a

comprehensive listing of available probes, please visit www.tek.com/probes.

Accessory Tektronix part

number

250 MHz, 10X TekVPI® passive voltage probe with 3.9 pF input

capacitance

500 MHz, 10X TekVPI® passive voltage probe with 3.9 pF input

capacitance

500 MHz, 2X TekVPI® passive voltage probe with 12.7 pF input

capacitance

2.5 kV, 800 MHz, 50X TekVPI® passive high-voltage probe TPP0850

1 GHz, 10X TekVPI® passive voltage probe with 3.9 pF input

capacitance

1.5 GHz TekVPI® active single-ended voltage probe TAP1500

2.5 GHz TekVPI® active single-ended voltage probe TAP2500

3.5 GHz TekVPI® active single-ended voltage probe TAP3500

50 MHz TekVPI® 20 Ampere AC/DC current probe TCP0020

120 MHz TekVPI® 30 Ampere AC/DC current probe TCP0030A

20 MHz TekVPI® 150 Ampere AC/DC current probe TCP0150

500 MHz TekVPI® differential voltage probe with ±42 V differential input

voltage

1 GHz TekVPI® differential voltage probe with ±42 V differential input

voltage

1.5 GHz TekVPI® differential voltage probe with ±8.5 V differential input

voltage

3.5 GHz TekVPI® differential voltage probe with ±2 V differential input

voltage

±1.5 kV, 200 MHz TekVPI® high-voltage differential probe THDP0200

TPP0250

TPP0500B

TPP0502

TPP1000

TDP0500

TDP1000

TDP1500

TDP3500

4 MDO32, MDO34 Help

Accessories

Accessory Tektronix part

number

±6 kV, 100 MHz TekVPI® high-voltage differential probe THDP0100

±750 V, 200 MHz TekVPI® high-voltage differential probe TMDP0200

RF probes

Contact Beehive Electronics to order: http://beehive-electronics.com/probes.html

Accessory Part number

EMC probe set 101A

EMC probe amplifier 150A

Probe cable 110A

SMA probe adapter 0309-0001

BNC probe adapter 0309-0006

MDO32, MDO34 Help 5

Accessories

6 MDO32, MDO34 Help

Options

Bandwidth options

These options let you upgrade a purchased oscilloscope to a higher bandwidth.

Bandwidth upgrade

options

These options can be ordered for already-purchased oscilloscopes. Some

upgrades require sending the oscilloscope to a service center to replace hardware

and recalibrate the instrument.

Table 1: 3 Series bandwidth upgrades

Option name Description Notes

SUP3 BW1T22 Bandwidth upgrade; from 100 MHz to

200 MHz on (2) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW1T24 Bandwidth upgrade; from 100 MHz to

200 MHz on (4) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW1T32 Bandwidth upgrade; from 100 MHz to

350 MHz on (2) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW1T34 Bandwidth upgrade; from 100 MHz to

350 MHz on (4) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW1T52 Bandwidth upgrade; from 100 MHz to

500 MHz on (2) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW1T54 Bandwidth upgrade; from 100 MHz to

500 MHz on (4) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW1T102 Bandwidth upgrade; from 100 MHz to

1GHz on (2) Analog Channel models

of 3 Series oscilloscopes

SUP3 BW1T104 Bandwidth upgrade; from 100 MHz to

1GHz on (4) Analog Channel models

of 3 Series oscilloscopes

A license file to upgrade your

oscilloscope will be placed in your

Tektronix AMS account. An email

notification will be sent to your

registered mail account. Install the

license file to enable the option

features.

Includes shipment of calibration data

and new front panel bandwidth label.

A license file to upgrade your

oscilloscope will be placed in your

Tektronix AMS account. An email

notification will be sent to your

registered mail account. Install the

license file to enable the option

features.

Includes shipment of calibration data

and new front panel bandwidth label.

Hardware upgrade; send instrument to

Tektronix Service Center.

Includes shipment of calibration data

and new front panel bandwidth label.

MDO32, MDO34 Help 7

Options

Option name Description Notes

SUP3 BW2T32 Bandwidth upgrade; from 200 MHz to

350 MHz on (2) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW2T34 Bandwidth upgrade; from 200 MHz to

350 MHz on (4) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW2T52 Bandwidth upgrade; from 200 MHz to

500 MHz on (2) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW2T54 Bandwidth upgrade; from 200 MHz to

500 MHz on (4) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW2T102 Bandwidth upgrade; from 200 MHz to

1 GHz on (2) Analog Channel models

of 3 Series oscilloscopes

SUP3 BW2T104 Bandwidth upgrade; from 200 MHz to

1 GHz on (4) Analog Channel models

of 3 Series oscilloscopes

SUP3 BW3T52 Bandwidth upgrade; from 350 MHz to

500 MHz on (2) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW3T54 Bandwidth upgrade; from 350 MHz to

500 MHz on (4) Analog Channel

models of 3 Series oscilloscopes

SUP3 BW3T102 Bandwidth upgrade; from 350 MHz to

1 GHz on (2) Analog Channel models

of 3 Series oscilloscopes

SUP3 BW3T104 Bandwidth upgrade; from 350 MHz to

1 GHz on (4) Analog Channel models

of 3 Series oscilloscopes

SUP3 BW5T102 Bandwidth upgrade; from 500 MHz to

1 GHz on (2) Analog Channel models

of 3 Series oscilloscopes

SUP3 BW5T104 Bandwidth upgrade; from 500 MHz to

1 GHz on (4) Analog Channel models

of 3 Series oscilloscopes

A license file to upgrade your

oscilloscope will be placed in your

Tektronix AMS account. An email

notification will be sent to your

registered mail account. Install the

license file to enable the option

features.

Includes shipment of calibration data

and new front panel bandwidth label.

Hardware upgrade; send instrument to

Tektronix Service Center.

Includes shipment of calibration data

and new front panel bandwidth label.

A license file to upgrade your

oscilloscope will be placed in your

Tektronix AMS account. An email

notification will be sent to your

registered mail account. Install the

license file to enable the option

features.

Includes shipment of calibration data

and new front panel bandwidth label.

Hardware upgrade; send instrument to

Tektronix Service Center.

Includes shipment of calibration data

and new front panel bandwidth label.

8 MDO32, MDO34 Help

Options

Spectrum analyzer frequency range options

These options let you upgrade a purchased oscilloscope to increase the input

frequency range and capture bandwidth of the integrated spectrum analyzer. With

increased spectrum analyzer bandwidth you can capture higher-frequency signals

and view a broader spectrum.

Table 2: 3 Series options

Option name Description

SUP3 SA1 Increase spectrum analyzer input frequency range to 9 kHz to 1 GHz and

capture bandwidth to 1 GHz

A license file to upgrade your oscilloscope will be placed in your Tektronix

AMS account. An email notification will be sent to your registered mail

account. Install the license file to enable the option features.

SUP3 SA3 Increase spectrum analyzer input frequency range to 9 kHz to 3 GHz and

capture bandwidth to 3 GHz

A license file to upgrade your oscilloscope will be placed in your Tektronix

AMS account. An email notification will be sent to your registered mail

account. Install the license file to enable the option features.

Arbitrary Function Generator (AFG) (optional)

This option adds a 50 MHz AFG function to your oscilloscope.

■

AFG features

Function types: Arbitrary, Sine, Square, Pulse, Ramp, Triangle, DC Level,

Gaussian, Lorentz, Exponential Rise/Fall, Sin(x)/x, Random Noise,

Haversine, Cardiac

■

Maximum frequency: 50 MHz (Sine)

■

Maximum output amplitude: 5 Vp-p

■

Maximum sample rate: 250 MS/s

■

Arbitrary function record length: 128K samples

MDO32, MDO34 Help 9

Options

Enhanced instrument security (factory option)

Advanced instrument security option provides the highest level of instrument

security. This option enables password protecting and disabling of all

communication ports and firmware upgrades. This option configures the

oscilloscope hardware to easily declassify the oscilloscope. This option must be

ordered at the same time you order an instrument.

Enhanced instrument

security preinstalled

This option preinstalls this feature when ordering the oscilloscope. This option

must be ordered at the same time you order an instrument.

option

Install option name Description

3 SEC No user access to the internal storage to store or save any user data to

Advanced instrument

security upgrade option

You cannot order this option as a field-installable upgrade, as the option requires

hardware reconfiguration.

Serial bus decode and trigger options

Serial bus and trigger options provide bus decode display and triggering for

testing and analysis of industry standard serial buses. You can upgrade a

purchased oscilloscope to add these options.

the oscilloscope memory.

Data can only be saved to or read from a USB storage device connected

to the instrument, Ethernet, or through the programmable interface.

Password protection to enable/disable external USB Host, USB Device,

and Ethernet communication ports.

Password protection to enable/disable firmware upgrades or

downgrades.

Serial bus upgrade

These options can be ordered and installed on already purchased oscilloscopes.

options

10 MDO32, MDO34 Help

Options

Option name Description Notes

SUP3 BND Application Bundle on 3 Series

oscilloscopes (includes all serial

options)

SUP3 SRAERO Aerospace serial triggering and

analysis (ARINC429, MIL-STD-1553)

SUP3 SRAUDIO Audio serial triggering and analysis

(I2S, LJ, RJ, TDM)

SUP3 SRAUTO Automotive serial triggering and

analysis (CAN, CAN FD, LIN,

FlexRay)

SUP3 SRCOMP Computer serial triggering and

analysis (RS-232/422/485/UART)

SUP3 SREMBD Embedded serial triggering and

analysis (I2C, SPI)

SUP3 SRUSB2 USB serial triggering and analysis

(USB 2.0 LS, FS, HS)

A license file to upgrade your

oscilloscope will be placed in your

Tektronix AMS account. An email

notification will be sent to your

registered mail account. Install the

license file to enable the option

features.

Power Analysis option

Power upgrade option

This option adds power measurements. You can upgrade an oscilloscope to add

this option.

Order this option to upgrade your oscilloscope with power measurements.

Upgrade option name Description

SUP3 PWR Adds power measurement and analysis.

A license file to upgrade your oscilloscope will be placed in your Tektronix

AMS account. An email notification will be sent to your registered mail

account. Install the license file to enable the option features.

MDO32, MDO34 Help 11

Options

DVM option

This option adds the digital voltmeter (DVM) option. You can upgrade an

oscilloscope to add this option.

Order this option to upgrade your oscilloscope with the DVM. This option is free

when you register your product. To register go to: www.tektronix.com/

register3mdo.

Upgrade option name Description

SUP3 DVM Adds a digital voltmeter and frequency counter.

A license file to upgrade your oscilloscope will be placed in your Tektronix

AMS account. An email notification will be sent to your registered mail

account. Install the license file to enable the option features.

Power cord options

These options let you order the oscilloscope with a country- or region-specific

power cord.

Power cord options

These options are ordered when ordering the oscilloscope.

Option name Description

A0 North America Power Cord

A1 Universal EURO Power Cord

A2 United Kingdom Power Cord

A3 Australia Power Cord

A4 240 V North America Power Cord

A5 Switzerland Power Cord

A6 Japan Power Cord

A8 None provided, product set to operate at 120 V

A9 None provided, product set to operate at 230 V

A10 China Power Cord

A11 India Power Cord

A12 Brazil Power Cord

A99 No Power Cord or AC Adapter

12 MDO32, MDO34 Help

Options

Service options

Service options improve the level of service response. You can order service

options when you purchase an oscilloscope, or purchase a service option at a later

date.

Service options

Option name Description

G3 Three Year Gold Care Plan. Includes expedited repair of all product failures

including ESD and EOS, access to a loaner product during repair or advanced

exchange to reduce downtime, priority access to Customer Support among

others.

G5 Five Year Gold Care Plan. Includes expedited repair of all product failures

including ESD and EOS, access to a loaner product during repair or advanced

exchange to reduce downtime, priority access to Customer Support among

others.

R3 Standard Warranty Extended to 3 Years. Covers parts, labor and 2-day

shipping within country. Guarantees faster repair time than without coverage.

All repairs include calibration and updates. Hassle free-a single call starts the

process.

R5 Standard Warranty Extended to 5 Years. Covers parts, labor and 2-day

shipping within country. Guarantees faster repair time than without coverage.