Page 1

Page 2

Page 3

Instruction Manual

MCF Series

Video Transmission System

071-0229-02

*P071022902*

071022902

Page 4

Page 5

Installation and Service

MCF Series

Video Transmission System

071-0229-02

First Printing: November, 1995

Revised Printing: June, 1999

Page 6

Contacting Tektronix

Voice Fax Addresses Web Site

Customer

Support

Product,

Service, Sales

Information

North America (800) 547-8949 (530) 478-3181 Tektronix, Inc.

Elsewhere Distributor or sales office from which

equipment was purchased.

North America (800) 547-8949 (503) 627-7275 Tektronix, Inc.

Europe 44 (10) 1628 40 3300 44 (0)1628 40 3301

Asia (852) 2585-6688 (852) 2802-2996

Japan 81 (3) 5992 0621 81 (3) 5992 9377

Latin America (305) 477-5488 (305) 477-5385

Copyright © Tektronix, Inc. All rights reserved.

This document may not be copied, in whole or in part, or otherwise reproduced, except as specifically

permitted under U.S. copyright law, without the prior written consent of Tektronix, Inc., P.O. Box 1000,

Wilsonville, Oregon 97070-1000. TEKTRONIX is a registered trademark and Grass Valley is a trademark of Tektronix, Inc. All registered trademarks and trademarks are property of their respective holders. Tektronix products are covered by U.S. and foreign patents, issued and pending. Product options

and specifications subject to change without notice. The information in this manual is furnished for informational use only, is subject to change without notice, and should not be construed as a commitment

by Tektronix, Inc. Tektronix assumes no responsibility or liability for any errors or inaccuracies that

may appear in this publication.

Tektronix Grass Valley Products

http://www.tektronix.com

P.O. Box 1114

Grass Valley, CA 95945, USA

http://www.tektronix.com

Video and Networking Division

P.O. Box 500

M.S. 58-965

Beaverton, OR 97077-0001, USA

Page 7

Contents

Safety Terms and Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Terms in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Terms on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Symbols on the Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Section 1 — System Description and Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

MCF Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Six Rack Unit Frame (10.5 in. or 267 mm high) . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Two Rack Unit Frame (3.5 in. or 89 mm high). . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Fiber Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Combined Video/Audio Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Video Modules Input and Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Audio Modules Input and Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Serial Digital Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Video/Audio Diplexer Modules Input and Output . . . . . . . . . . . . . . . . . . . . 1-11

Backplanes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Backplane for the 6 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Backplane for the 2 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Fan Assembly (6 RU only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Deflector Assembly (6 RU only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Power Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Regulatory Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Environmental Criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Alarm Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Terms Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

Contents

Section 2 — Installation

Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Pre-Installation Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Calculating Optical Fiber Path Loss Budget . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Space Planning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Heat Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Unpacking the Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Equipment Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Test Equipment and Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

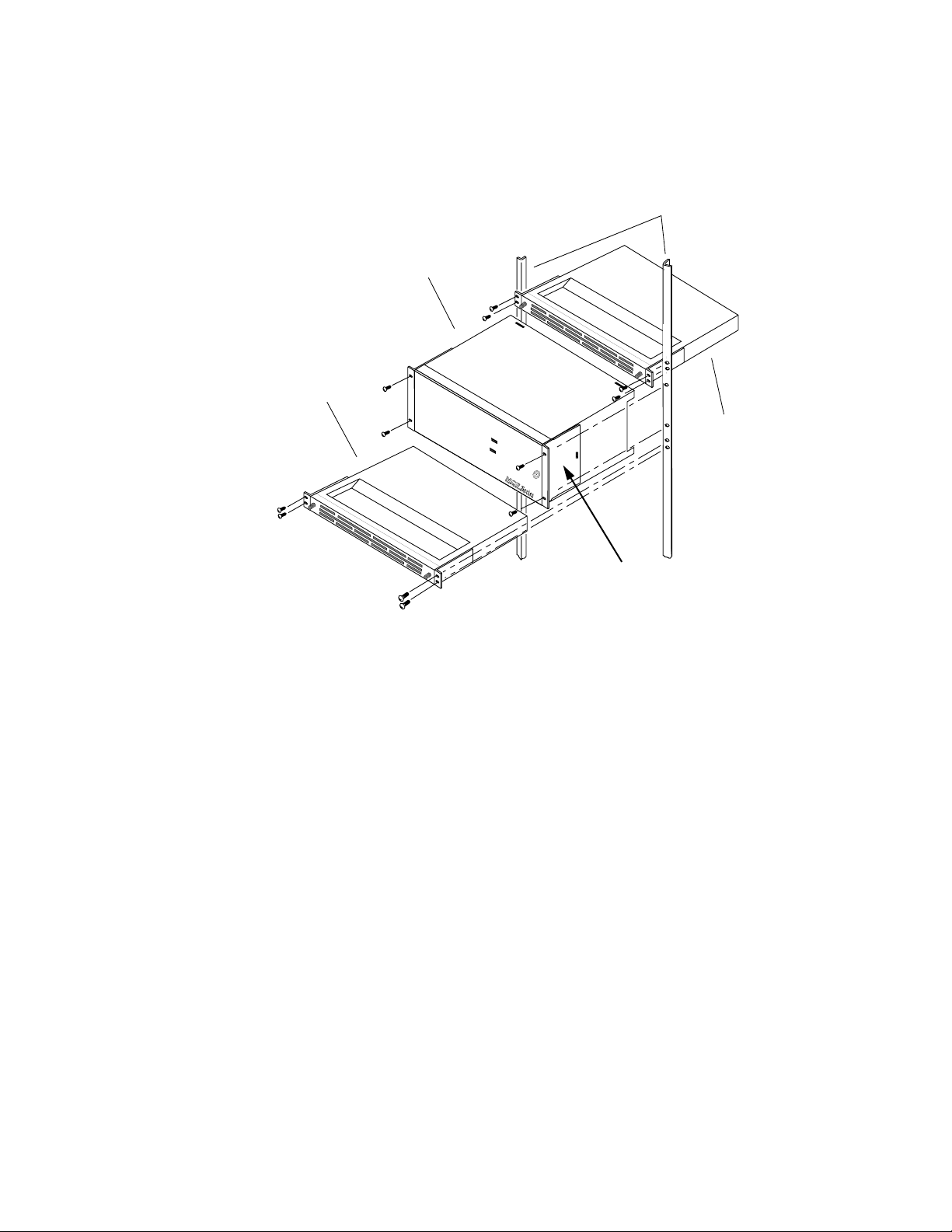

Installation of a 6 RU Frame in the Equipment Rack. . . . . . . . . . . . . . . . . . . . . . . 2-5

MCF Installation and Service iii

Page 8

Contents

Installing a 6 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Installing Multiple 6 RU Frames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Maximum 6RU Frame Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Installation of a 2 RU Frame in the Equipment Rack . . . . . . . . . . . . . . . . . . . . . . . 2-9

Installing a 2 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Installing Multiple 2 RU Frames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Making Frame Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Backplane for the 2 RU Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Grounding the Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Making Alarm Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Making Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Six RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Two Rack Unit Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

DC Power for the 6 RU Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

DC Power for the 2 RU Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Fan Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Fan for the 6 RU Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Making Signal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Administration Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

RS-485 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

RS-232 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Craft Port Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Video Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Serial Digital Video Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Other Video Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

NRZ and NRZI Modes and Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Incompatible Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Compatible Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

Modification of 066039-00 and -01 Transmitters. . . . . . . . . . . . . . . . . . . . . . . 2-32

Modification of 066039-10, -11, and -30 Transmitters . . . . . . . . . . . . . . . . . . 2-33

Modification of 066040-00, -01, -10, -20, and -21 Receivers . . . . . . . . . . . . . . 2-34

160293-00 Transmitter NRZ Jumper Setting . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Video Connections at Receiver Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

Audio Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

Audio Connector Orientation for the 6 RU Frame . . . . . . . . . . . . . . . . . . . . 2-38

Audio Connector Orientation for the 2 RU Frame . . . . . . . . . . . . . . . . . . . . 2-38

Audio Clip Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-39

Fiber-Optic Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Fiber Module Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Craft Port Parity and Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Transmitter or Receiver Frame Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

Slave Function (Transmitter Module only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

Boot Function (Transmitter/Receiver Module) . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

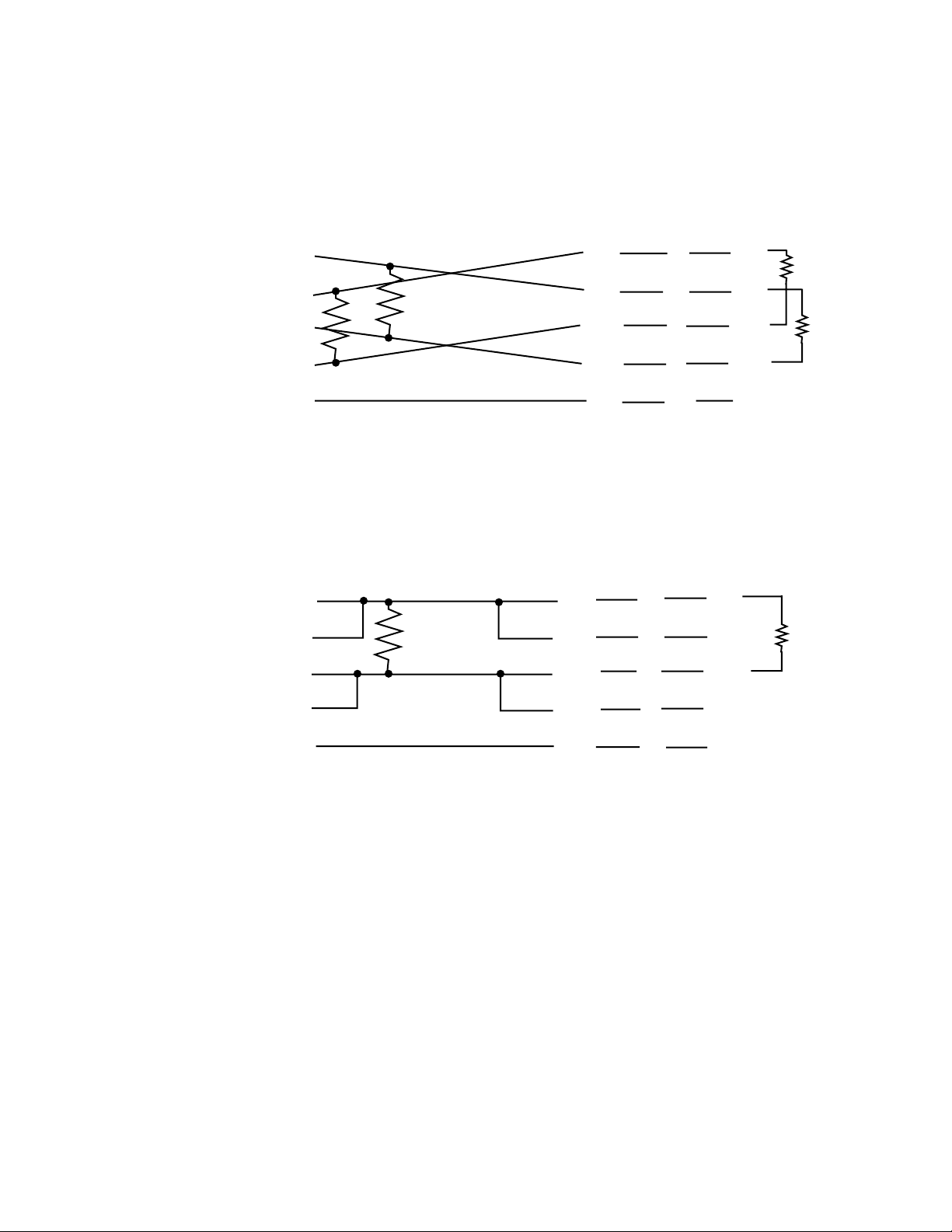

Video Input and Output Module Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Cable Equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Video Input Module Cable Equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Video Output Module Cable Equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

Installation of Hybrid Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-49

Video Signal Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

Video Squelch Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

DC Restore Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-51

iv MCF Installation and Service

Page 9

Video Input DC Restore Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Video Output DC Restore Jumper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-52

Audio Input Module Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

Input Audio Attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-53

Combined Video/Audio Module Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Input Cable Equalization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-54

Output Cable Equalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-56

Video Signal Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-57

DC Restore Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Video/Audio Input DC Restore Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-58

Video/Audio Output DC Restore Jumper. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Video Clamp Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-60

Video/Audio Input Video Clamp Jumper. . . . . . . . . . . . . . . . . . . . . . . . . . . 2-61

Video/Audio Output Video Clamp Jumper . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

Audio Input Impedance Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-62

Audio Attenuation Clip Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-63

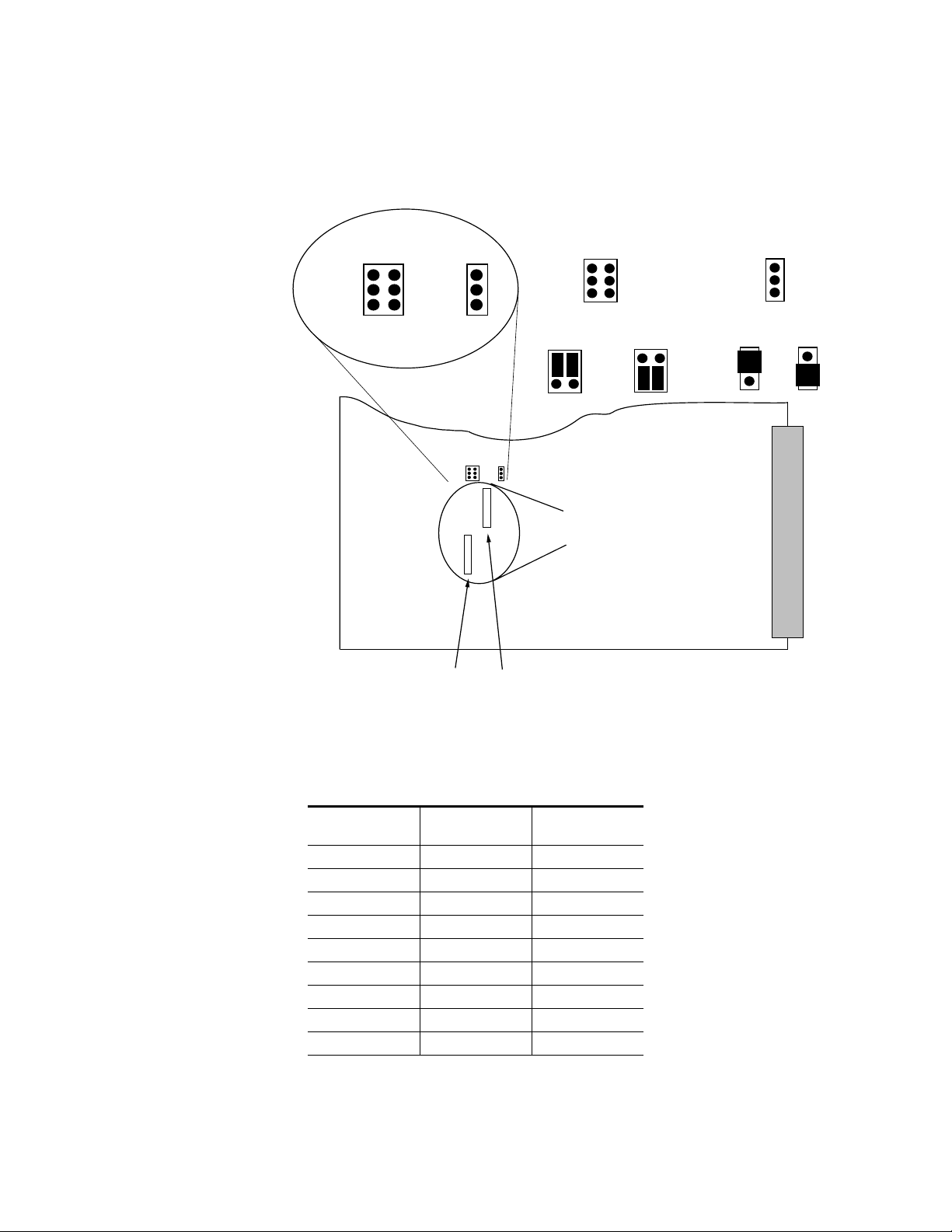

Serial Digital Module Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

Cable Equalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

270/143 Mode Selection on the Input Module . . . . . . . . . . . . . . . . . . . . . . . . . 2-66

MCF Six Slot Mode Selection for Both Input and Output . . . . . . . . . . . . . . . . 2-67

System/Backplane Mode Selection on the Output Module . . . . . . . . . . . . . . 2-69

Video/Audio Diplexer Module Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Video Cable Equalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-70

Output Cable Equalization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-71

Video Signal Termination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-72

DC Restore Jumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-73

Diplexer Input DC Restore Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

Diplexer Output DC Restore Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-74

Impedance Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-75

Audio Gain Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-76

Ramp Enable/Disable on DIP Switch 3 for Input Module . . . . . . . . . . . . . . . 2-78

Subcarrier Enable/Disable on DIP Switch 3 for Input Module . . . . . . . . . . . 2-79

OC-3/MCF Selection for Both Input and Output Modules . . . . . . . . . . . . . . 2-79

MCF Six Slot Mode Selection for Both Input and Output Modules. . . . . . . . 2-80

Mute Video Disable/Enable Selection on the Output Module. . . . . . . . . . . . 2-82

Mute Audio Disable/Enable Selection on the Output Module . . . . . . . . . . . 2-83

Filtered/Diplexed Mode Selection on the Output Module. . . . . . . . . . . . . . . 2-83

System/Backplane Mode Selection on the Output Module . . . . . . . . . . . . . . 2-84

Installing Modules in the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-84

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-86

Operational Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-87

Contents

Section 3 — Controls and Indicators

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Fiber Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Fiber Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Combined Video/Audio Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Combined Video/Audio Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Video Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Video Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Audio Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Audio Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

MCF Installation and Service v

Page 10

Contents

Serial Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Serial Digital Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Video/Audio Diplexer Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Video/Audio Diplexer Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Section 4 — Functional Description

Functional Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

System Protocol Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Fiber Transmitter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Timing Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Bus Interface Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Multiplexer and Serializer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Laser Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Repeater Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Laser Temperature Control Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Communication Port Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Monitor A to D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Video Sample Oscillator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Fiber Receiver Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Optical Preamplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Gain Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Data Low Pass Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Deserializer and Demultiplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Timing Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Bus Interface Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Communication Port Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Combined Video/Audio Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Video Input Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Video Test Ramp Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Video Analog-to-Digital Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Video Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Video FIFO Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Video FIFO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Video Bus Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Audio Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Audio A/D Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Audio FIFO Loader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Audio FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Audio Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Combined Video/Audio Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Video Output Bus Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Video FIFO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Video FIFO Unloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Video Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Video Digital-to-Analog Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Video Output Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Audio Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

vi MCF Installation and Service

Page 11

Audio FIFO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Audio FIFO Unloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Audio Digital-to-Analog Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Audio Output Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Audio Conversion Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Video Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Test Ramp Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Analog-to-Digital Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

FIFO Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Processor Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Video Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Video Output Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

FIFO Unloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Digital-to-Analog Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Output Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Processor Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Audio Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

A/D Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

FIFO Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Processor Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Audio Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Bus Interface Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

FIFO Unloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Processor Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

C-Bit Receiver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

D/A Converter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Output Drivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Audio Conversion Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Maintenance Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Serial Digital Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Digital Video Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

FIFO Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

FIFO (D1/D2 Channel). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

MCF Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Audio Input Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

AES/EBU Decoder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Audio Deserializer and Buffer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Audio Data Rate and MCF Bus Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Buffering and MCF Bus Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Maintenance Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

Contents

MCF Installation and Service vii

Page 12

Contents

Serial Digital Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Video FIFO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

FIFO Unloader (Video). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Serial Digital Video Output Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Audio FIFO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

FIFO Unloaders (audio channel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Video PLL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Serial Digital Audio Output Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Audio PLLs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Video/Audio Diplexer Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Video Input Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Audio Input Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Analog-to-Digital Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-39

FIFO Loader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

FIFO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Processor Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Video/Audio Diplexer Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Bus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

FIFO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

FIFO Unloader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Digital-to-Analog Converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Video Output Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Audio Output Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Processor Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Microcontroller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-43

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Power Supply for the 6 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Power Supply for the 2 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

Section 5 — Maintenance & Service

Section Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Air Intake Filter Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Module Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Fiber Transmitter/Receiver Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Status Packet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Power Supply Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Power Supply Service for the 6 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

F1 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

F2 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Power Supply Service for the 2 RU Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Obtaining Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

24-Hour Turnaround Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Return Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

viii MCF Installation and Service

Page 13

Shipping Charges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Replacement Parts Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Ordering Parts From Tektronix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Parts Substitution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Contents

MCF Installation and Service ix

Page 14

Contents

x MCF Installation and Service

Page 15

Safety Summary

Read and follow the important safety information below, noting especially

those instructions related to risk of fire, electric shock or injury. Additional

specific warnings not listed here may be found throughout the manual.

WARNING Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only. To reduce the risk

of electric shock, do not perform any servicing other than that contained in

the operating instructions unless you are qualified to do so.

Safety Terms and Symbols

Terms in This Manual

Safety-related statements may appear in this manual in the following form:

WARNING Warning statements identify conditions or practices that may result in per-

sonal injury or loss of life.

CAUTION Caution statements identify conditions or practices that may result in damage

to equipment or other property.

Terms on the Product

The following terms may appear on the product:

DANGER

the marking.

WARNING

sible as you read the marking.

— A personal injury hazard is immediately accessible as you read

— A personal injury hazard exists but is not immediately acces-

CAUTION

MCF Installation and Service xi

— A hazard to property, product, and other equipment is present.

Page 16

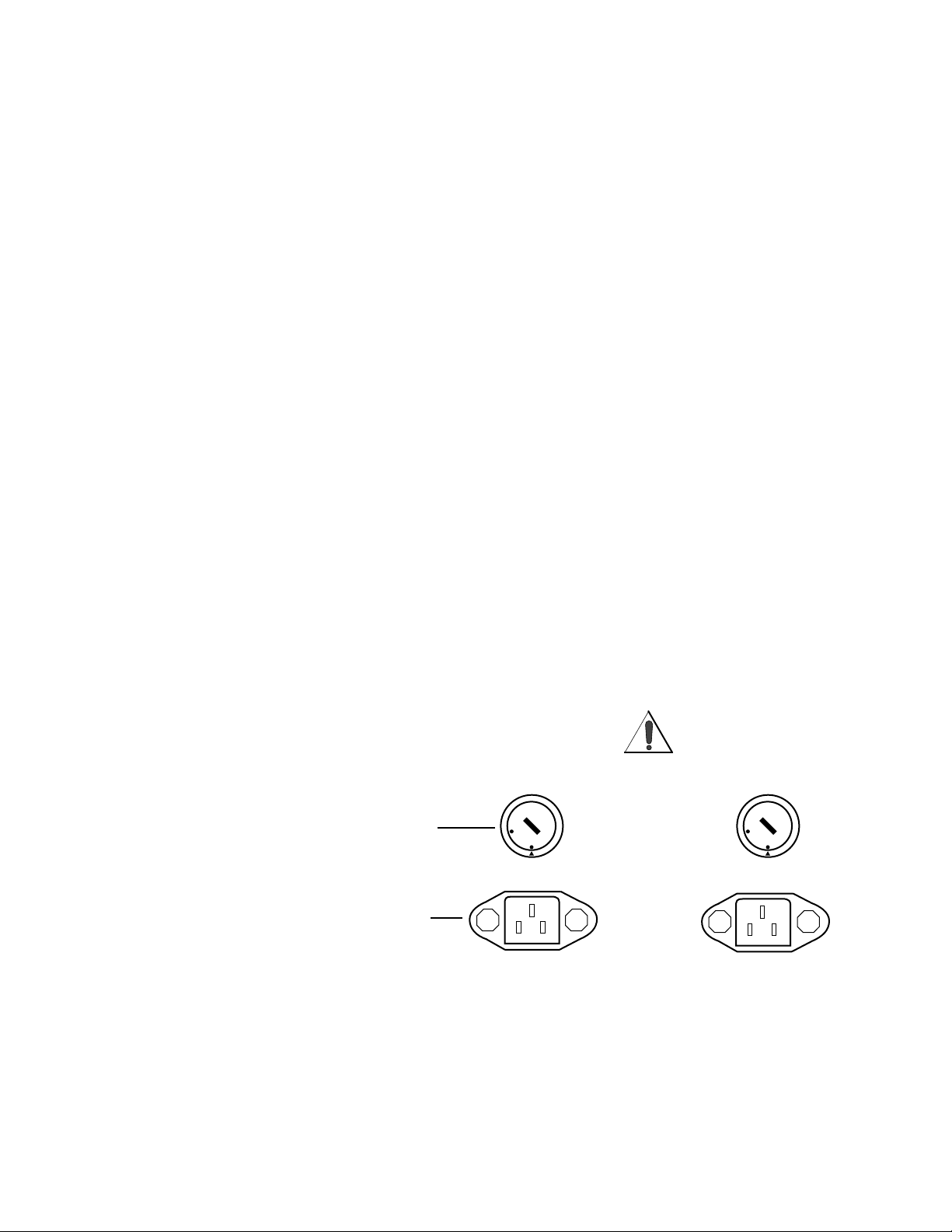

Symbols on the Product

The following symbols may appear on the product:

Indicates that dangerous high voltage is present within the

equipment enclosure that may be of sufficient magnitude to

constitute a risk of electric shock.

Indicates that user, operator or service technician should

refer to product manual(s) for important operating, maintenance, or service instructions.

This is a prompt to note fuse rating when replacing fuse(s).

The fuse referenced in the text must be replaced with one

having the ratings indicated.

Warnings

Identifies a protective grounding terminal which must be

connected to earth ground prior to making any other equipment connections.

Identifies an external protective grounding terminal which

may be connected to earth ground as a supplement to an

internal grounding terminal.

Indicates that static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static

procedures, equipment and surfaces during servicing.

The following warning statements identify conditions or practices that can

result in personal injury or loss of life.

Dangerous voltage or current may be present

battery (if applicable) before removing protective panels, soldering, or

replacing components.

— Disconnect power and remove

Do not service alone

person capable of rendering first aid and resuscitation is present.

Remove jewelry

and other metallic objects.

Avoid exposed circuitry

circuitry when power is present.

xii MCF Installation and Service

— Do not internally service this product unless another

— Prior to servicing, remove jewelry such as rings, watches,

— Do not touch exposed connections, components or

Page 17

Use proper power cord

— Use only the power cord supplied or specified for

this product.

Ground product — Connect the grounding conductor of the power cord to

earth ground.

Operate only with covers and enclosure panels in place

— Do not operate this

product when covers or enclosure panels are removed.

Use correct fuse

— Use only the fuse type and rating specified for this

product.

Use only in dry environment

Use only in non-explosive environment

— Do not operate in wet or damp conditions.

— Do not operate this product in an

explosive atmosphere.

High leakage current may be present

— Earth connection of product is essential

before connecting power.

Dual power supplies may be present

— Be certain to plug each power supply

cord into a separate branch circuit employing a separate service ground.

Disconnect both power supply cords prior to servicing.

Double pole neutral fusing

— Disconnect mains power prior to servicing.

Cautions

Use proper lift points — Do not use door latches to lift or move equipment.

Avoid mechanical hazards

— Allow all rotating devices to come to a stop before

servicing.

The following caution statements identify conditions or practices that can

result in damage to equipment or other property

Use correct power source

— Do not operate this product from a power source

that applies more than the voltage specified for the product.

Use correct voltage setting

— If this product lacks auto-ranging power supplies, before applying power ensure that the each power supply is set to

match the power source.

Provide proper ventilation

— To prevent product overheating, provide equip-

ment ventilation in accordance with installation instructions.

Use anti-static procedures

— Static sensitive components are present which

may be damaged by electrostatic discharge. Use anti-static procedures,

equipment and surfaces during servicing.

MCF Installation and Service xiii

Page 18

Do not operate with suspected equipment failure

— If you suspect product

damage or equipment failure, have the equipment inspected by qualified

service personnel.

Ensure mains disconnect

— If mains switch is not provided, the power cord(s)

of this equipment provide the means of disconnection. The socket outlet

must be installed near the equipment and must be easily accessible. Verify

that all mains power is disconnected before installing or removing power

supplies and/or options.

Route cable properly — Route power cords and other cables so that they ar not

likely to be damaged. Properly support heavy cable bundles to avoid connector damage.

Use correct power supply cords

— Power cords for this equipment, if provided,

meet all North American electrical codes. Operation of this equipment at

voltages exceeding 130 VAC requires power supply cords which comply

with NEMA configurations. International power cords, if provided, have

the approval of the country of use.

Use correct replacement battery

— This product may contain batteries. To

reduce the risk of explosion, check polarity and replace only with the same

or equivalent type recommended by manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

Troubleshoot only to board level

— Circuit boards in this product are densely

populated with surface mount technology (SMT) components and application specific integrated circuits (ASICS). As a result, circuit board repair at

the component level is very difficult in the field, if not impossible. For warranty compliance, do not troubleshoot systems beyond the board level.

xiv MCF Installation and Service

Page 19

System Description and

Specifications

Introduction

This is the Installation and Service manual for the Tektronix Multi-Channel

Fiber (MCF) Series Video Transmission System. The manual is divided into

sections identified and briefly described as follows.

Section 1 — System Description and Specifications: A general intro-

■

duction about MCF. It includes a system description with physical

specifications including weight, power requirements, and environmental and regulatory criteria.

Section

1

■ Section 2 — Installation: Installation procedures, including a func-

tional check after the physical installation.

■

Section 3 — Controls and Indicators: Descriptions and illustrations of

the various controls and indicators found on the frame rear panel and

on the front panels of the MCF modules.

■ Section 4 — Functional Description: A description of the major com-

ponents of the modules. It includes block diagrams.

■

Section 5 — Maintenance and Service: A description of the maintenance procedures, a troubleshooting table, and removal/replacement

procedures for the MCF system modules.

System Description

The MCF Video Transmission System provides digital transport of full

bandwidth video, and multiple channel audio over fiber. System architecture is modular, which allows channel growth by module addition. The

MCF is a point-to-point unidirectional communications link with a

transmit and a receive terminus.

MCF Installation and Service 1-1

Page 20

Section 1 — System Description and Specifications

Two frame sizes are available—a 6 rack unit (RU) and a 2 RU. Each 6 RU

frame requires a fan and deflector assembly. On the 2 RU frame the fan is

installed in the frame and no deflector assembly is required. (See Section 2,

“Installation,” for more information.)

The Audio and Video signals are formatted as follows:

■

Each Audio module (and the audio part of the Combined Video/Audio

module) provides two stereo audio pairs (four channels) per video

signal.

■ Each Video module (and the video part of any Combined Video/Audio

and Diplexer modules) provides one analog composite video channel.

■

Each Serial Digital module provides two AES/EBU serial audio interfaces and formats the video in either a 270 Mbs Component (D1) or 143

Mbs NTSC Composite (D2) serial video channel.

MCF Frames

Each Video/Audio Diplexer module provides monaural analog audio

■

(two channels), which is transmitted on FM subcarriers in the frequency band above the video.

On this and the following pages, you will find information regarding the

MCF frames (6 RU frame and 2 RU frame), the fan assembly, and the fan

deflector assembly.

The MCF frame houses the control and signal processing electronics, power

supplies, and the backplane. At the transmit end of the system, the frame is

configured with a Fiber Transmitter module, Video Input modules, and

Audio Input modules or any type of combined video and audio Input modules. At the receive end, the frame is configured with a Fiber Receiver

module, Video Output modules, and Audio Output modules or any type of

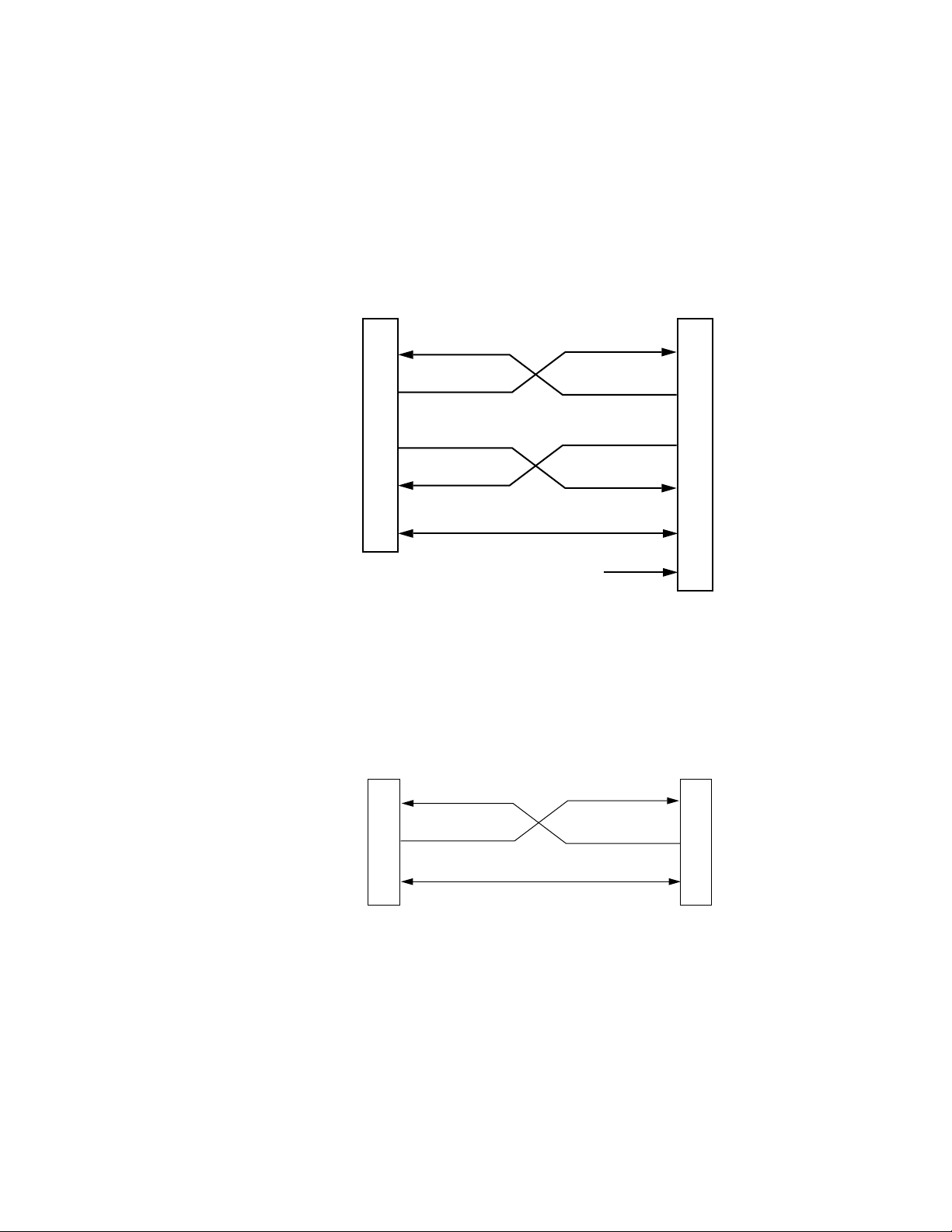

combined video and audio Output modules. Figure 1-1 shows how this

works.

TRANSMITTER FRAME

T

x

RECEIVER FRAME

R

x

Transmitter

Module Location

Figure 1-1. Normal MCF Transmission

Receiver

Module Location

1-2 MCF Installation and Service

Page 21

System Description

You can use either the 6 RU or 2 RU MCF frame as a repeater when transmitting over longer distances. The Repeater frame is located somewhere in

the middle of the transmission link and uses a Fiber Receiver module to

receive the signal and another Fiber Transmitter module to retransmit the

signal. Adding an Output module here allows you to monitor (for troubleshooting purposes) the incoming signal with a Drop Monitor function.

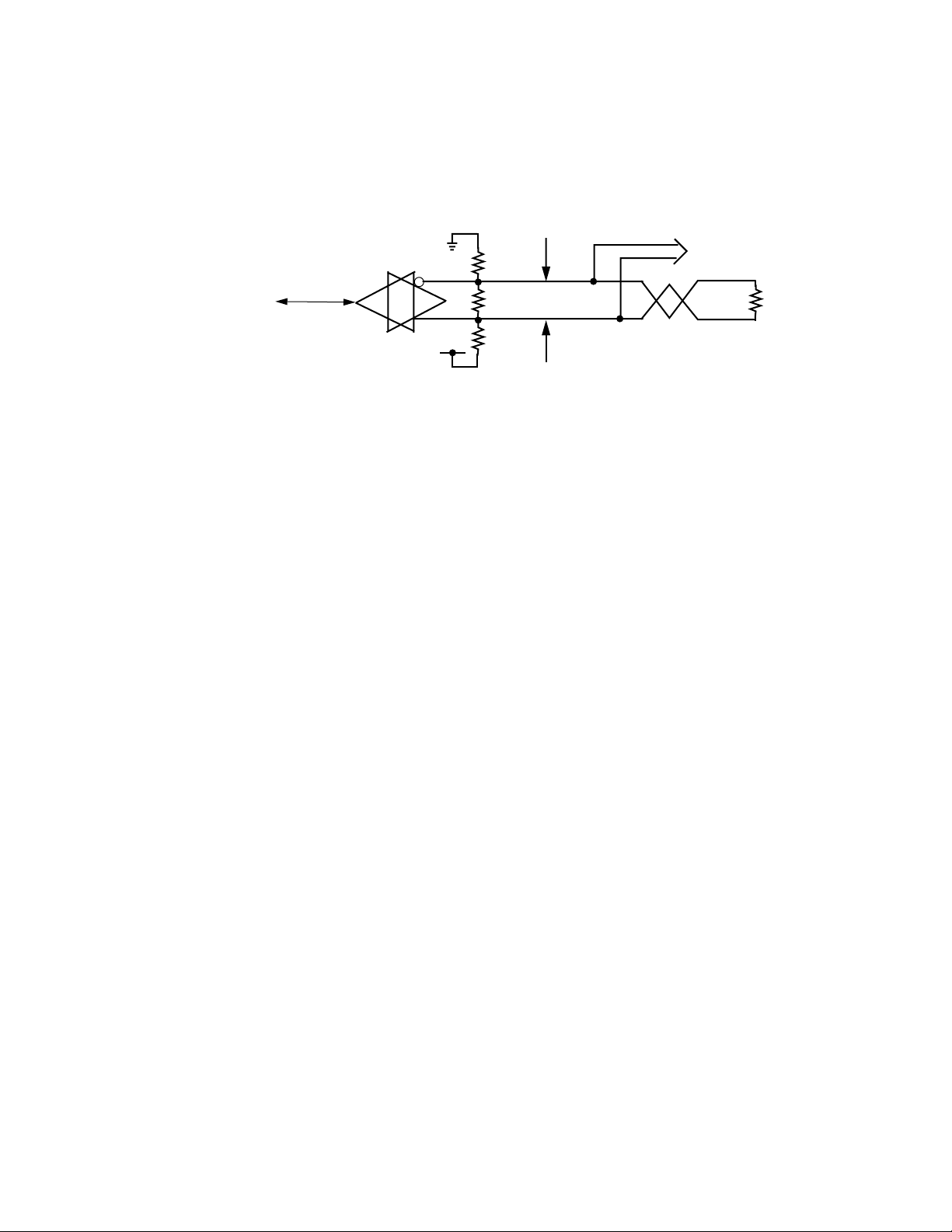

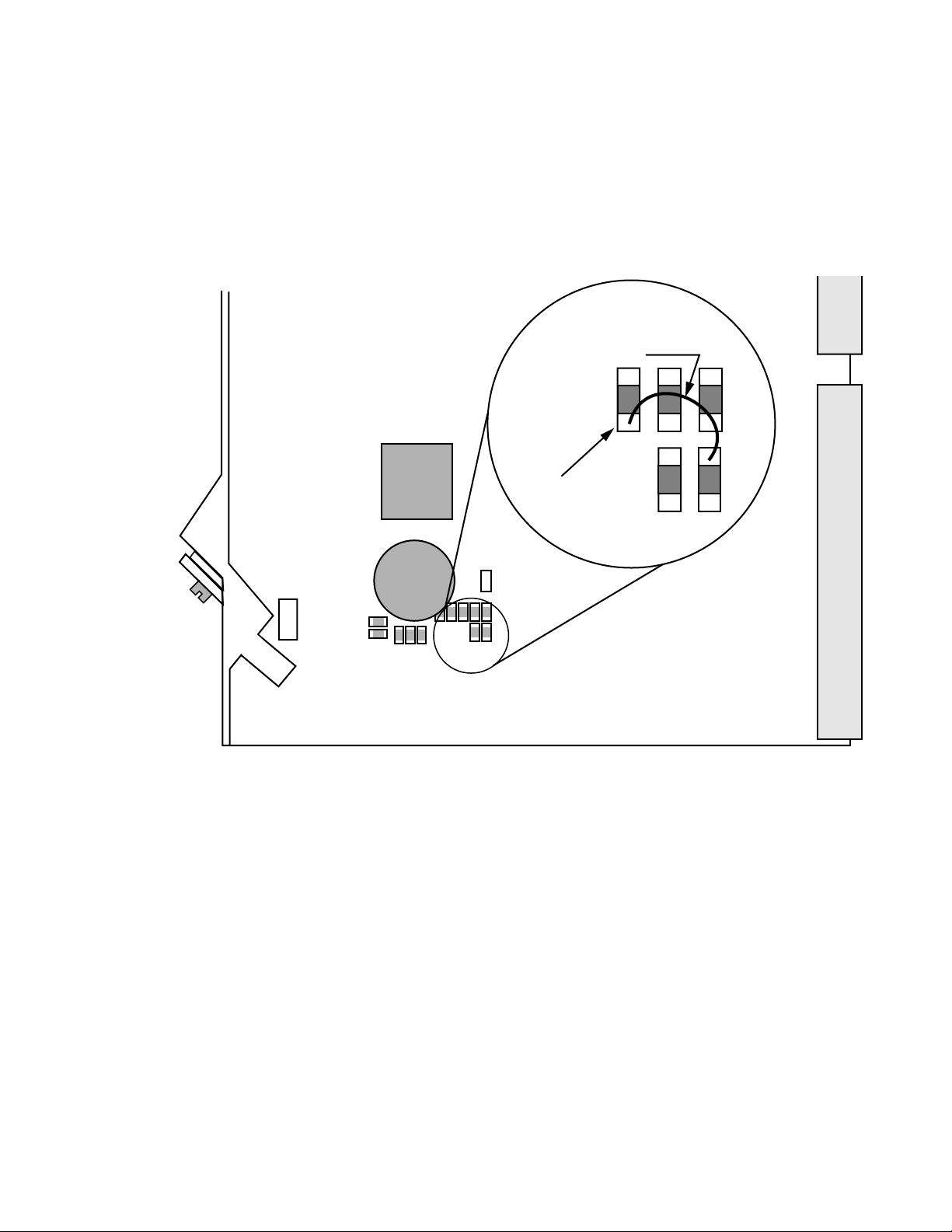

Figure 1-2 illustrates how this might look functionally.

TRANSMITTER FRAME

Transmitter

Module Location

T

x

Transmitter

Module Location

Receiver module placed in any module

location (10 thru 18) in a 6 RU frame

Figure 1-2. MCF Transmission with Repeater and Monitor Function

REPEATER FRAME

T

x

Transmitter Module

in module location 19 only

RECEIVER FRAME

Receiver

Module Location

R

x

6 RACK UNIT

MCF Installation and Service 1-3

Page 22

Section 1 — System Description and Specifications

A Repeater Frame housing Receiver modules running software version

1.06 or later allows add and drop/delete capabilities from any Transmitter

frame. Refer to Figure 1-3 for an example of Add/Delete functionality.

NEAR-END

TRANSMITTER FRAME

Transmitter

Module Location

T

x

FAR-END

RECEIVER FRAME

Figure 1-3. MCF Repeater Transmission with Add/Delete Function

Using the Mute and Take commands in software version 1.06 or later, (discussed in the Operation manual), you can enhance the Add/Delete functionality to create an Add/Drop function. Refer to Figure 1-4 for an

example of the Add/Drop operation.

REPEATER 2 RU FRAME

Video/Audio Deleted

on Receiver

at Time Slot

Time Slots

01

X

1

I

2

345

R

NPU

T

Receiver Module

x

New Video/Audio Added

T

x

at Time Slot

1

Transmitter Module

R

x

Receiver

Module Location

1-4 MCF Installation and Service

Page 23

System Description

Note The Add/Drop functionality operates only on later MCF Fiber Receiver modules

(Part Number 160294 or later) using version 1.06 or later software.

NEAR-END

TRANSMITTER FRAME

Transmitter

Module Location

FAR-END

RECEIVER FRAME

Module Location

Figure 1-4. MCF Repeater Transmission with Add/Drop Function

Receiver

MID-LOCATION

ADD/DROP FRAMES

Receiver Module

1

dropped

Dropped

Video/Audio

Signal

Drop Frame

T

x

x

R

T

T

P

U

O

T

Time Slot

U

x

Transmitter Module

Receiver Module

R

x

Add Frame

I

R

NPU

x

T

New Video/Audio

T

Added at Time Slot

Transmitter Module

Time Slots

x

01 345

2

1

Six Rack Unit Frame (10.5 in. or 267 mm high)

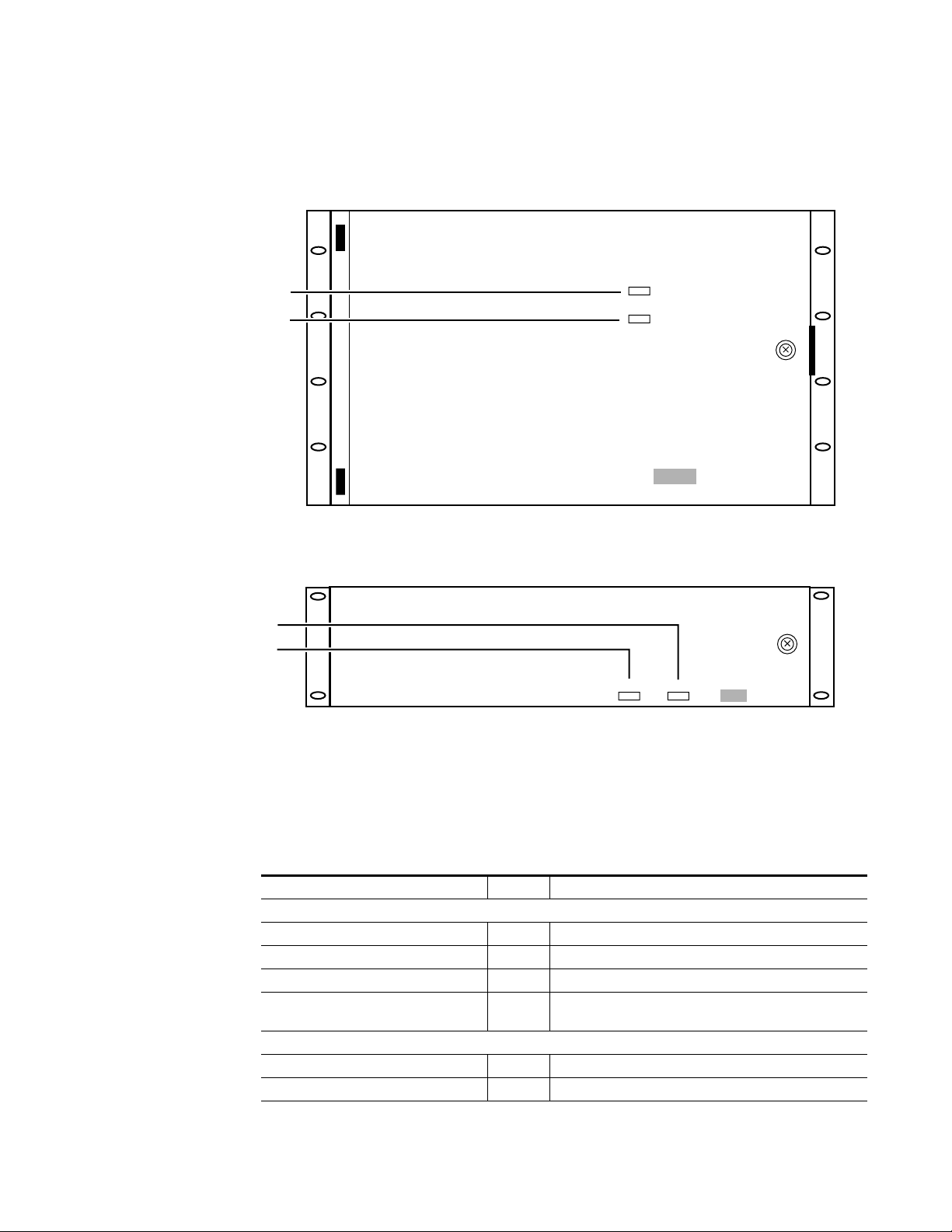

Figure 1-5 illustrates a 6 RU MCF frame with the door closed. Figure 1-6

illustrates a fully optioned 6 RU frame with the front door removed. You

may remove the front door to simplify any module placement and to

connect the fiber cable. The door is hinged and opens from right to left. It

is secured closed by turning the crosshead lock screw clockwise until fully

secure. To remove the door, turn the screw counterclockwise, open the door

fully, and then lift it up and away from the frame.

MCF Installation and Service 1-5

Page 24

Section 1 — System Description and Specifications

CAUTION The frame door must be kept closed during operation to ensure proper air flow

and system cooling.

TP5144-06

Hinge

Figure 1-5. MCF 6 RU Frame

Door

R

JO

A

M

M

R

A

L

A

R

O

IN

M

M

R

A

L

A

Lock

Screw

Fiber-Optic

Cable

TP5139-02

Figure 1-6. Fully Optioned MCF 6 RU Frame (with door removed)

1-6 MCF Installation and Service

Page 25

System Description

A maximum configuration (ten module slots) consists of one Fiber module

and nine of the other modules. You can substitute one module of any of the

video/audio combination modules (such as Serial/Digital) for the two

Video and Audio modules. However, because there are only six time slots

available, you can use only six combination modules. Serial digital and

baseband analog video and audio signals can be mixed in the system as

long as the six time slots are not exceeded. Serial digital requires one or two

timeslots depending upon configuration.

Note Slot 19 in the 6 RU frame

be used for a Fiber module.

must

Table 1-1 shows what types of modules you can have in a maximum 6 RU

configuration. Except for a Repeater frame (which receives and transmits),

MCF frames are used for either transmitting or receiving. You cannot mix

input and output modules in the same frame.

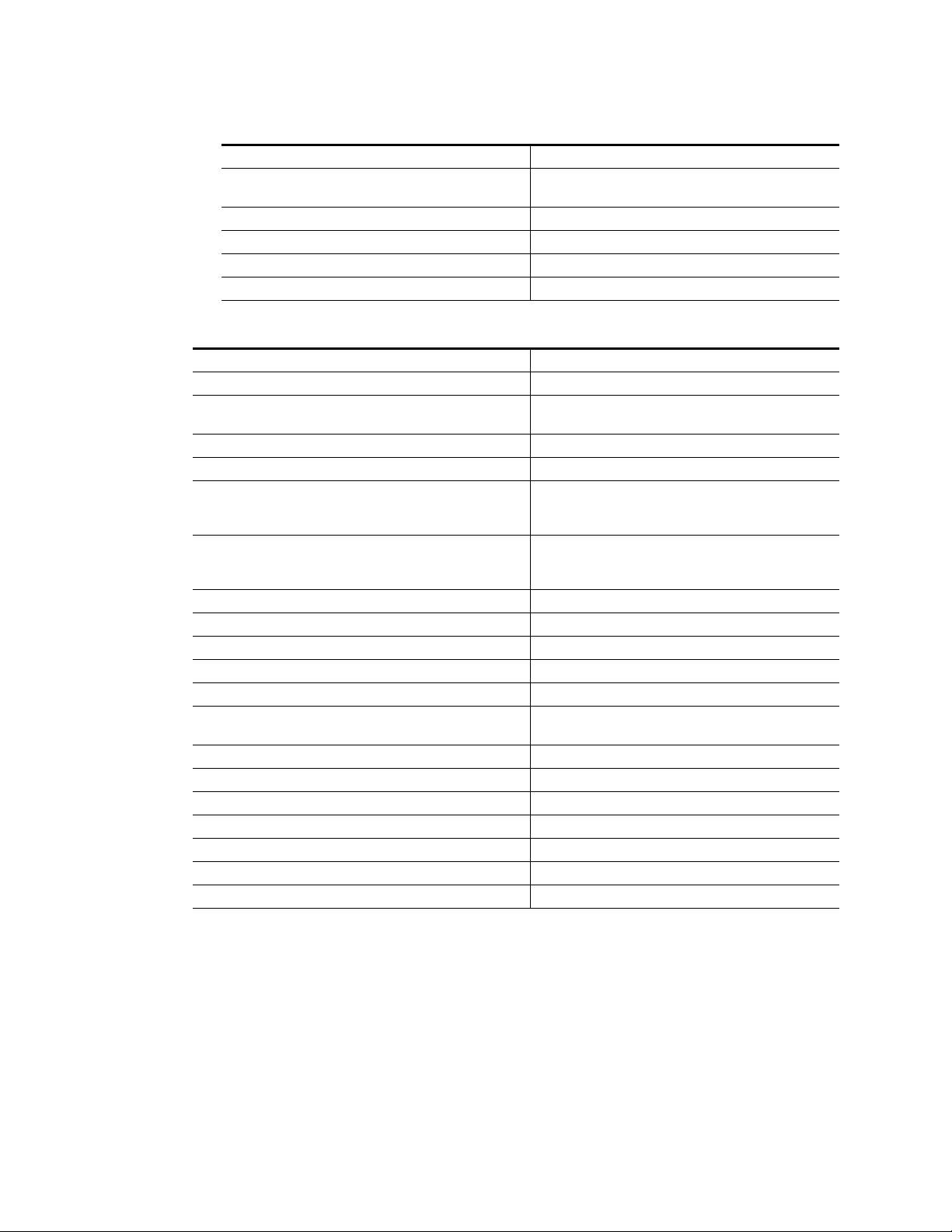

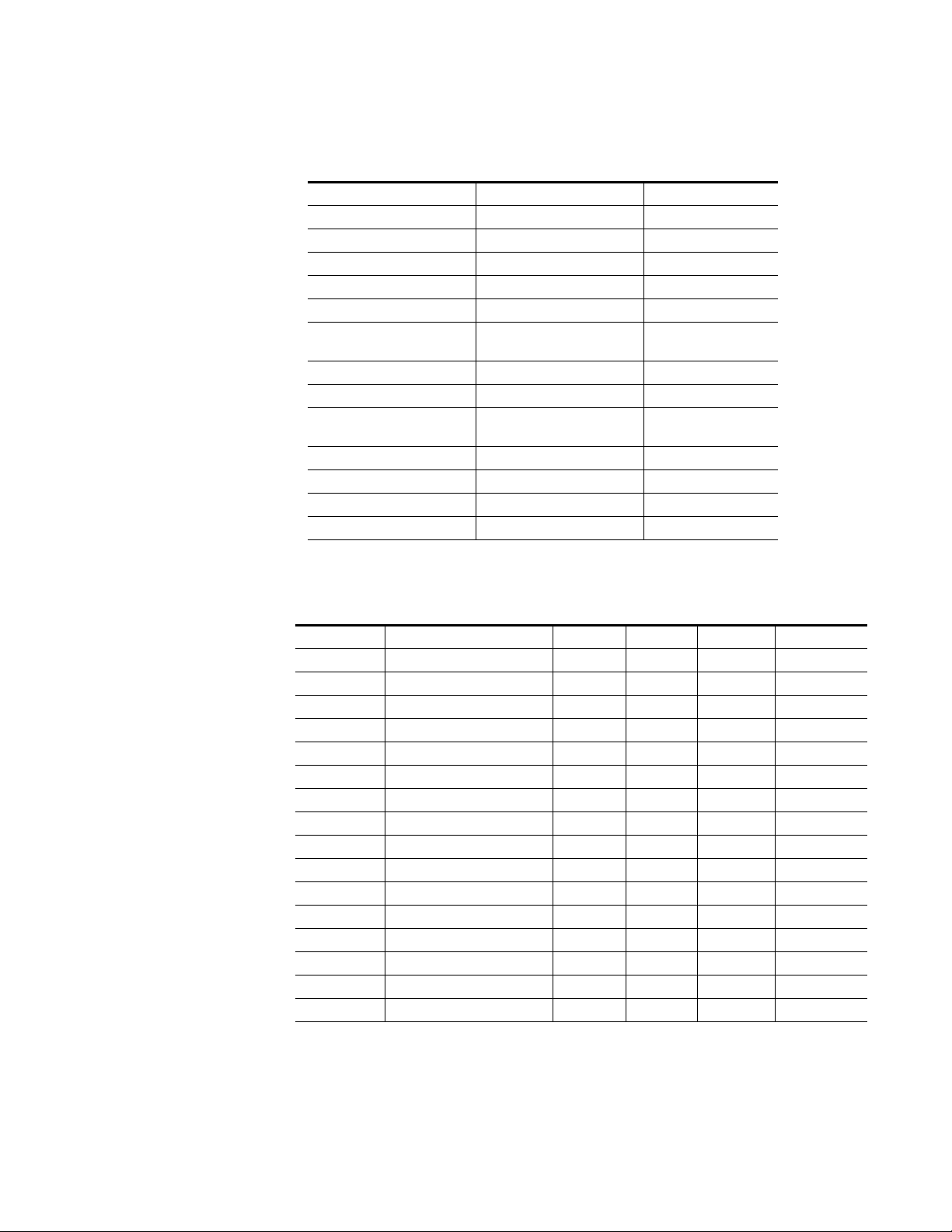

Table 1-1. MCF 6 RU Frame Configuration

Requirements Transmitter Frame Repeater Frame Receiver Frame

One Required Fiber Transmitter Fiber Receiver Fiber Receiver

One Required Does Not Apply Fiber Transmitter Does Not Apply

From one up to nine

modules. Logical

types can be mixed

within frame.

Exceptions:

Repeater frame maximum is eight modules

because two slots are

being used by Fiber

modules. Combination modules maximum is six

a

Optional. Used only for monitoring purposes in this type of frame.

Video Input Module(s) Video Output Module

Audio Input Module(s) Audio Output Module

Serial Digital Input Module(s) Serial Digital Output Module

Combined Video/Audio Input

Module(s)

Video/Audio Input Module(s) Video/Audio Output Module(s)

Combined Video/Audio Output Module

a

a

a

Video Output Module(s)

Audio Output Module(s)

Serial Digital Output Module(s)

Combined Video/Audio Output

a

Module(s)

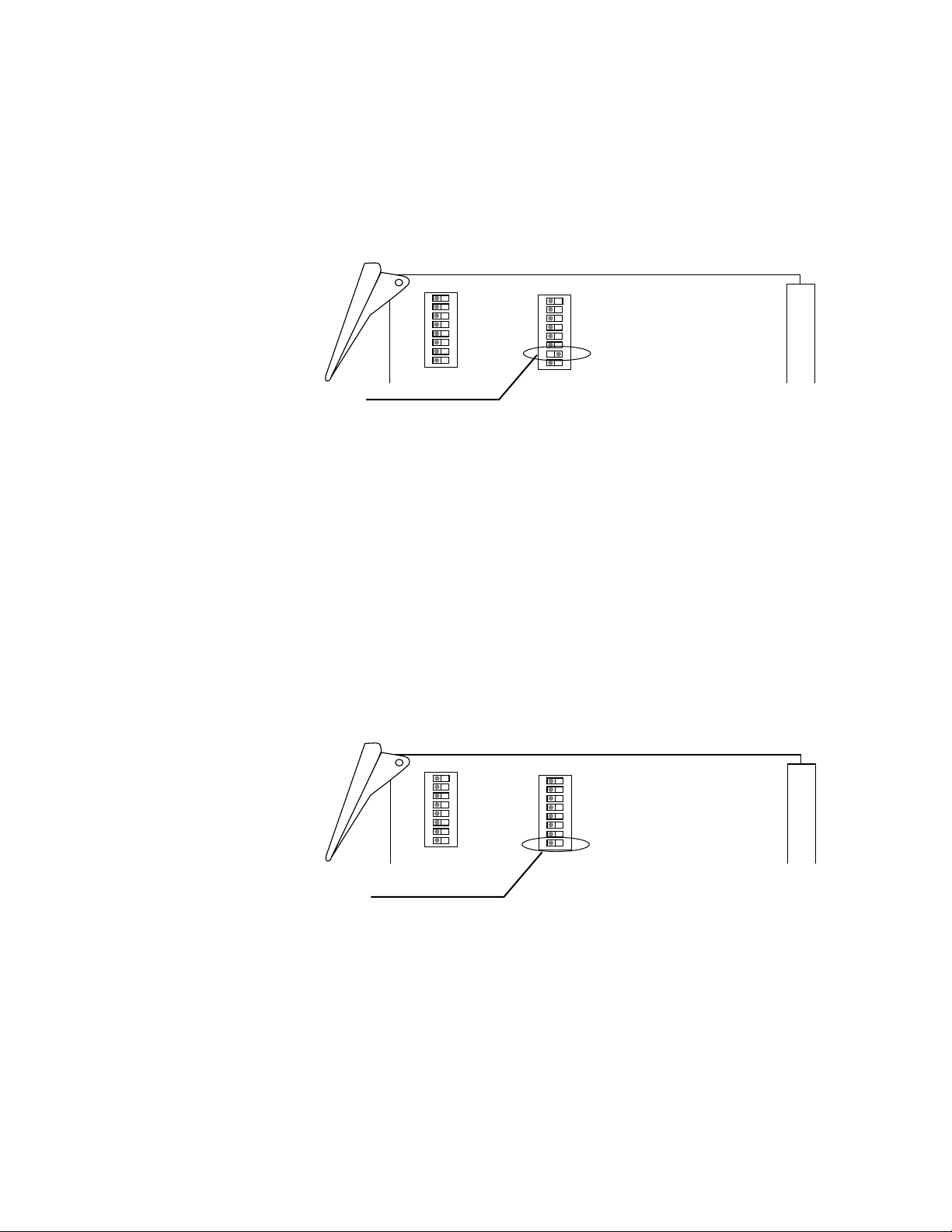

Two Rack Unit Frame (3.5 in. or 89 mm high)

Figure 1-7 illustrates a 2 RU MCF frame with the door closed. Figure 1-8

illustrates a 2 RU frame with the front door removed. You may remove the

front door to simplify any module placement and to connect the fiber cable.

The door panel is secured closed by turning the two crosshead lock screws

at the sides of the frame until fully locked. To remove the door panel, turn

both screws in the direction of the arrows, and then pull the door away

from the frame.

MCF Installation and Service 1-7

Page 26

Section 1 — System Description and Specifications

CAUTION The frame door must be kept closed during operation to ensure proper air flow

and system cooling.

G

ra

s

s

V

a

lle

y

L

O

C

K

Screw

5143-208

M

A

J

O

R

A

L

A

R

M

M

INO

R A

L

A

R

Door Panel

M

L

O

C

K

MCF

Series

Screw

Figure 1-7. MCF 2 RU Frame

AC POWER SUPPLY

POWER OK

DC POWER SUPPLY

POWER OK

VIDEO/

VIDEO/

MCF

AUDIO

AUDIO

FIBER

INPUT

INPUT

XMIT

CLIP QUIET

CLIP QUIET

MAJOR

ALARM

LASER

POWER

MODULE

TEMP

MINOR

ALARM

ONLINE

ONLINE

EQ

GAIN

EQ

GAIN

MONITOR

MONITOR

Figure 1-8. Fully Optioned MCF 2 RU Frame (with door removed)

A maximum configuration (three slots) is one Fiber module and up to two

of the other modules. You can substitute one module of any of the video/

audio combination modules (such as Combined Video/Audio) for the two

Video and Audio modules. Slot 12 in the 2 RU frame must be used for a

Fiber module.

5143-103

1-8 MCF Installation and Service

Page 27

System Description

Table 1-2 shows what types of modules you can have in a maximum 2 RU

configuration. Except for a Repeater frame (which receives and transmits),

MCF frames are used for either transmitting or receiving. You cannot mix

input and output modules in the same frame.

Table 1-2. MCF 2 RU Frame Configuration

Requirements Transmitter Frame Repeater Frame Receiver Frame

One Required Fiber Transmitter Fiber Receiver Fiber Receiver

One Required Does Not Apply Fiber Transmitter Does Not Apply

One or two modules. Logical

types can be mixed within frame

Exception:

Repeater frame maximum is one

module because two slots are

being used by Fiber modules.

a

Optional. Used only for monitoring purposes in this type of frame.

Video Input Module(s) Video Output Module

Audio Input Module(s) Audio Output Module

Serial Digital Input Module(s) Serial Digital Output Module

Combined Video/Audio Input

Module(s)

Video/Audio Input Module(s) Video/Audio Output Module(s)

Combined Video/Audio Output Module

a

a

a

Video Output Module(s)

Audio Output Module(s)

Serial Digital Output Module(s)

Combined Video/Audio Output

a

Module(s)

Fiber Modules

On the following pages, we discuss each of the frame components: Fiber

modules, Video modules, Audio modules, Serial Digital modules, Video/

Audio Diplexer modules, power supplies, and the backplane.

Fiber modules can be used as transmitters, receivers, or repeaters. As a

transmitter, the Fiber module transmits the MCF signal at the near end. As

a receiver, the Fiber module receives the MCF signal at the far end. A

repeater receives the MCF signal at one or more locations in the transmission link and then retransmits it again so it can be sent over longer distances. Refer to Section 1 of the MCF Operation Reference for more

information about the different operations.

The maximum optical loss budget of a current MCF system is 23 or 29 dB

when 0 dBm is launched. Fiber Transmitter modules operate in 1300 or

1550 nm wavelengths. Each Fiber module comes with FC/PC, SC, or ST

connectors. Except for the fiber-optic connector on the front of the board,

communication with the system passes through the backplane. The time

slot interchange function found on these modules allows time slot manipulation for greater flexibility.

It is also possible to drop signals for monitoring and distribution from

either the Repeater or Receiver MCF frame.

See Table 1-7 on page 19 for a list of functional specifications.

MCF Installation and Service 1-9

Page 28

Section 1 — System Description and Specifications

Combined Video/Audio Modules

The Video/Audio Input and Output modules consolidate the functions of

two MCF modules—they are the functional equivalent of the separate

Video and Audio Input and Output modules. Using these modules, up to

six video and 24 audio channels can be accommodated in the MCF system’s

6 RU frame. In the 2 RU frame, up to two video and eight audio channels

can be accommodated. MCF bus data for each module occupies one video

and one audio time slot.

The following descriptions for the separate Video and Audio Input and

Output modules are functionally the same and have more details. Refer to

them if you need more information. Also see Table 1-7 on page 1-19 for a list

of functional specifications.

Video Modules Input and Output

The MCF System bandwidth allows up to six video channels (one per

module) to be transported over a single fiber. Video is digitized and halfband filtered with a signal-to-noise ratio of >67 dB. Video is sampled at

31.054 MHz, which yields a flat video passband maximum of approximately 6.89 MHz.

MCF is format independent—NTSC, PAL, and other video formats can be

passed through these modules. Other video parameters are per EIA/TIA250-C Short Haul. Video and audio travel in separate time slots and are

switched separately.

Audio Modules Input and Output

The MCF System bandwidth allows up to twenty-four analog baseband

audio channels to be transported over a single fiber. Each audio module

provides two stereo audio pairs, or four channels.

Audio channels are digitized at 18-bits. Current interfaces are discrete

analog. Signal-to-noise ratio is approximately 90 dB. Other audio parameters are per EIA/TIA-250-C Short Haul, and ANSI T1.505.

Serial Digital Modules

The Serial Digital Input and Serial Digital Output modules are designed to

provide component serial video at 270 MHz (D1) or NTSC composite serial

video at 143 MHz (D2) and two AES/EBU serial audio interfaces to the

MCF transmission system. The AES/EBU audio may be embedded in the

serial digital video signal, or carried separately.

1-10 MCF Installation and Service

Page 29

Audio uses two asynchronous stereo pairs. The audio input data clock is 48

kHz (± 400 ppm) for both audio inputs. Each channel can be independently

enabled or disabled by software commands through the Fiber module.

Component (270 MHz, D1) serial video has a higher data rate that requires

more bandwidth, so two time slots are required. The audio that goes along

with the component video is not split between two time slots but is

assigned to the primary time slot. NTSC composite (143 MHz, D2) serial

video requires only one time slot.

See Table 1-8 on page 21 for a list of the video and audio performance specifications.

Video/Audio Diplexer Modules Input and Output

The Video/Audio Diplexer module occupies one MCF video time slot. The

video carried in this module is baseband analog (see the previously

described Video modules description for details). However, the audio is

different. The Diplexer uses an audio-follow-video scheme to add subcarriers with video in a common time slot. This analog audio is not meant to

replace digital audio—but to provide more channels. The audio input stage

accommodates 600 Ohm balanced +18 dBm peak level signals.

System Description

Backplanes

Backplane for the 6 RU Frame

Audio subcarriers of 5.8 and 6.4 MHz are diplexed onto traditional TV1

video signals. The center frequencies of the FM subcarriers are fixed at 5.8

and 6.4 MHz using slow feedback phase locked loops (PLLs). The peak-topeak deviation is 370 kHz at maximum modulation. The subcarriers are

summed with the filtered video at a relative level of –20 dBV (100 mV peakto-peak) per carrier.

See Table 1-7 on page 1-19 for a list of functional specifications and see

Table 1-9 on page 22 for a list of the audio performance specifications.

The following text describes the attributes of the system in the 6 RU frame

and 2 RU frame configurations.

Except for the fiber-optic cable connector and monitor connectors on the

Video Input/Output modules, connections to the MCF 6 RU frame are

made through the backplane. In addition to the communication connections, the backplane connector groupings for the 12 slots. Two are dedicated for power supplies and one for the Fiber module (either the Receiver

or Transmitter). The remaining nine slots are used for combinations of

video and audio type modules. Remember, you cannot mix input and

output modules in the same frame.

MCF Installation and Service 1-11

Page 30

Section 1 — System Description and Specifications

Each module connects to the backplane through two connectors. One connector is dedicated to analog interfaces. The second connector supports the

internal communications bus. All video and audio type modules connect to

this bus. On the rear of the backplane, each non-Fiber module has three

BNC connections (two video inputs for loop-through, and one video I/O)

and a screw strip connector for the two stereo audio pairs. Serial/Digital

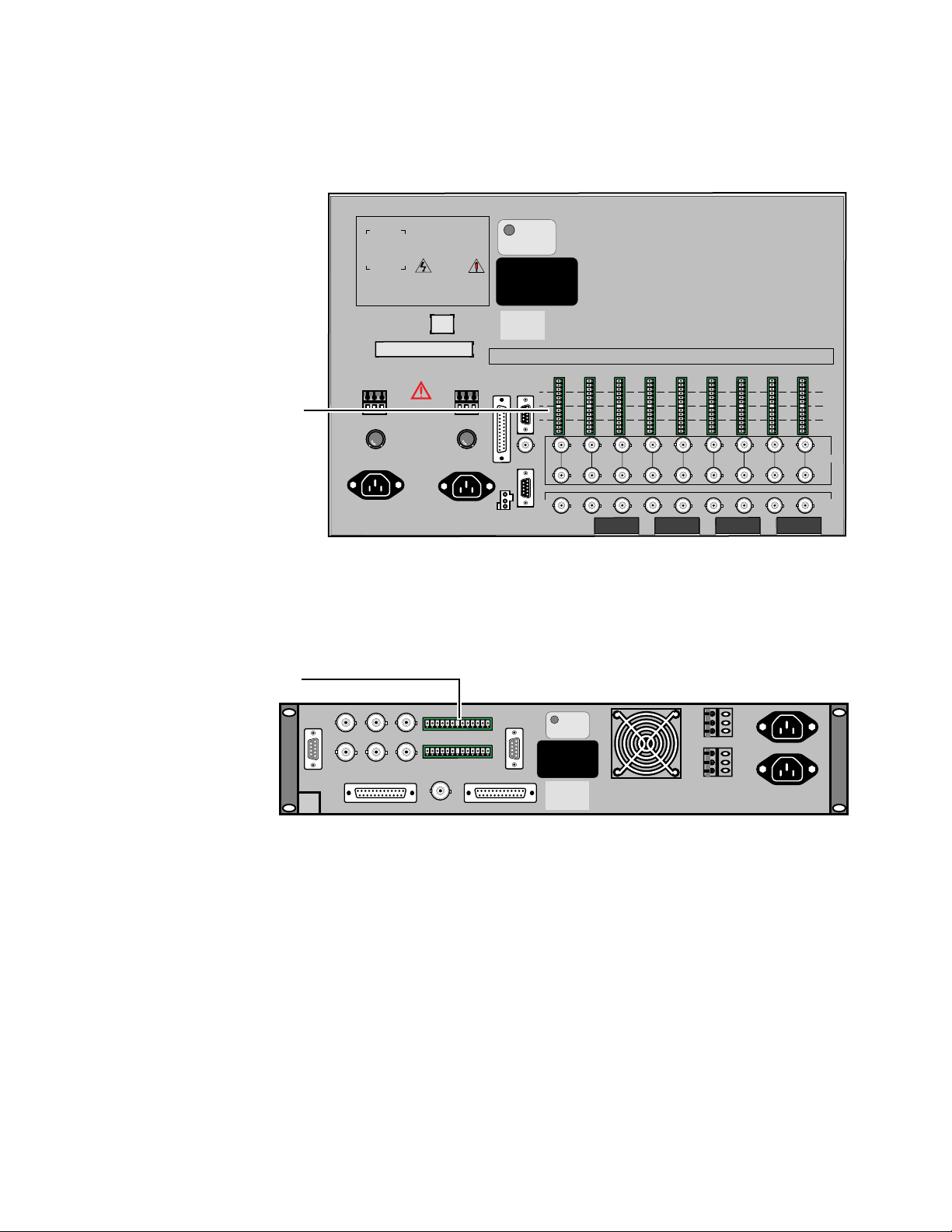

modules use the loop-through connectors separately (loop-through disabled) for I/O monitoring. Figure 1-9 illustrates the 6 RU backplane.

Video/Audio

Connectors

GRASS VALLEY GROUP, INC.

MODEL: MCF SERIES

DATE OF

MFG

MADE IN U.S.A.

Communication

Connectors

Power

Supply

RATED VOLTAGE: 100-120VAC~/200-240VAC~/ 48VDC

RATED CURRENT: 6 A MAX / 3 A MAX / 12 A MAX

FREQUENCY: 50-60Hz 50-60Hz

Connectors

48VDC

GND

J1

S1

110 220

J3

120/240 VAC

—+

WARNING

IF EQUIPPED WITH REDUNDANT POWER

THIS UNIT HAS TWO POWER CORDS.

TO REDUCE THE RISK OF ELECTRIC

SHOCK, DISCONNECT BOTH POWER

CORDS BEFORE SERVICING.

Zur Trennung vom Netz

§

beide Netzanschlu

Leitungen entfernen.

Fan Power

Connector

Figure 1-9. Backplane for the 6 RU Frame

Backplane for the 2 RU Frame

Except for the fiber-optic cable connector and monitor connectors on the

Combined Video/Audio and standard video modules, connections to the

MCF 2 RU frame are made through the backplane. Two slots are dedicated

for power supplies and one slot is dedicated for the Fiber module (either

Receiver or Transmitter). The remaining two slots are used for combinations of video and audio type modules. Remember, you cannot mix input

and output modules in the same frame.

WARNING

VERIFY VOLTAGE SETTING

BEFORE APPLYING POWER

Vor Anschlu§ on das Netz

Aufstellanitung beachten!

-

120/240 VAC

48VDC

GND

J2

S2

110 220

J4

—+

ETL LISTED

E

L

TELEPHONE

T

EQUIPMENT

Conforms to ULSTD 1459

ETL TESTING LABORATORIES, INC.

CORTLAND, NEW YORK, 13045

THIS DEVICE COMPLIES WITH PART

15 OF THE FCC RULES OPERATION

SUBJECT TO THE FOLLOWING TWO

CONDITIONS: (1) THIS DEVICE MAY

NOT CAUSE HARMFUL INTERFERENCE

(2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED INCLUDING

INTERFERENCE THAT MAY CAUSE

UNDESIRED OPERATIONS.

CAUTION:

This unit has more than one power source.

Disconnecting power cords

may not de-energize unit.

ATTENTION:

Ca produit a plus qu’une Source de pouvior

electrique. Debranchement n’ assure pas

de-energisation de I’ equipement.

0

SLOT

USE

FIBER1AUD/VID

RS485/

RS232

ADMIN.

PORT

J01

POWER

FAN

J5

AUDIO/

DATA

ALARM

J02

B

CC

D

J03

EXP

VIDEO

I/O

IN

VIDEO

I/O

RS232

CRAFT

PORT

J04

AUD/VID AUD/VID

-

+

-

+

-

+

-

+

IN 4

J32

J33

54

AUD/VID

AUDIO/

DATA

GND

-

AA

+

GND

-

B

+

GND

-

+

GND

-

D

+

J41

J51

IN 5

IN 6

J42

J52

J53

J43

AUD/VIDAUD/VID

AUD/VID DATA

AUDIO/AUDIO/AUDIO/AUDIO/

AUDIO/

DATA

B

CC

D

J61

IN 7

J62

J63

AUDIO/

DATA DATA DATA DATA

DATA

GND

-

AA

+

GND

-

B

+

GND

-

C

+

GND

-

D

+

J71

J81

IN 8

J72

J82

J83 J93

J73

3

2

AUD/VID

AUD/VID

AUDIO/

DATA

GND

-

+

GND

-

+

GND

-

+

GND

-

+

J11

IN 1

J12

I/O 1 I/O 2 I/O 3 I/O 4 I/O 5 I/O 6 I/O 7 I/O 8 I/O 9

J13

GND

A

GND

B

GND

GND

D

J21

J31

IN 2

IN 3

J22

J23

7

6

5158-99

98

SLOT

USE

GND

-

+

GND

-

+

GND

-

+

GND

-

+

J91

VIDEO

IN 9

IN

J92

VIDEO

I/O

Each module connects to the backplane through two connectors. One connector is dedicated to analog interfaces. The second backplane connector

supports the internal communications bus. All video and audio type

modules connect to this bus. On the rear of the backplane, each non-Fiber

type module has three video BNC connections (two for loop-through [J2-J3

or J5-J6] and one for I/O [J1 or J4]) and a screw strip connector for the two

1-12 MCF Installation and Service

Page 31

System Description

stereo audio pairs. Serial/Digital module use the loop-through connections

(J2-J3 or J5-J6) separately (loop-through disabled) for I/O monitoring.

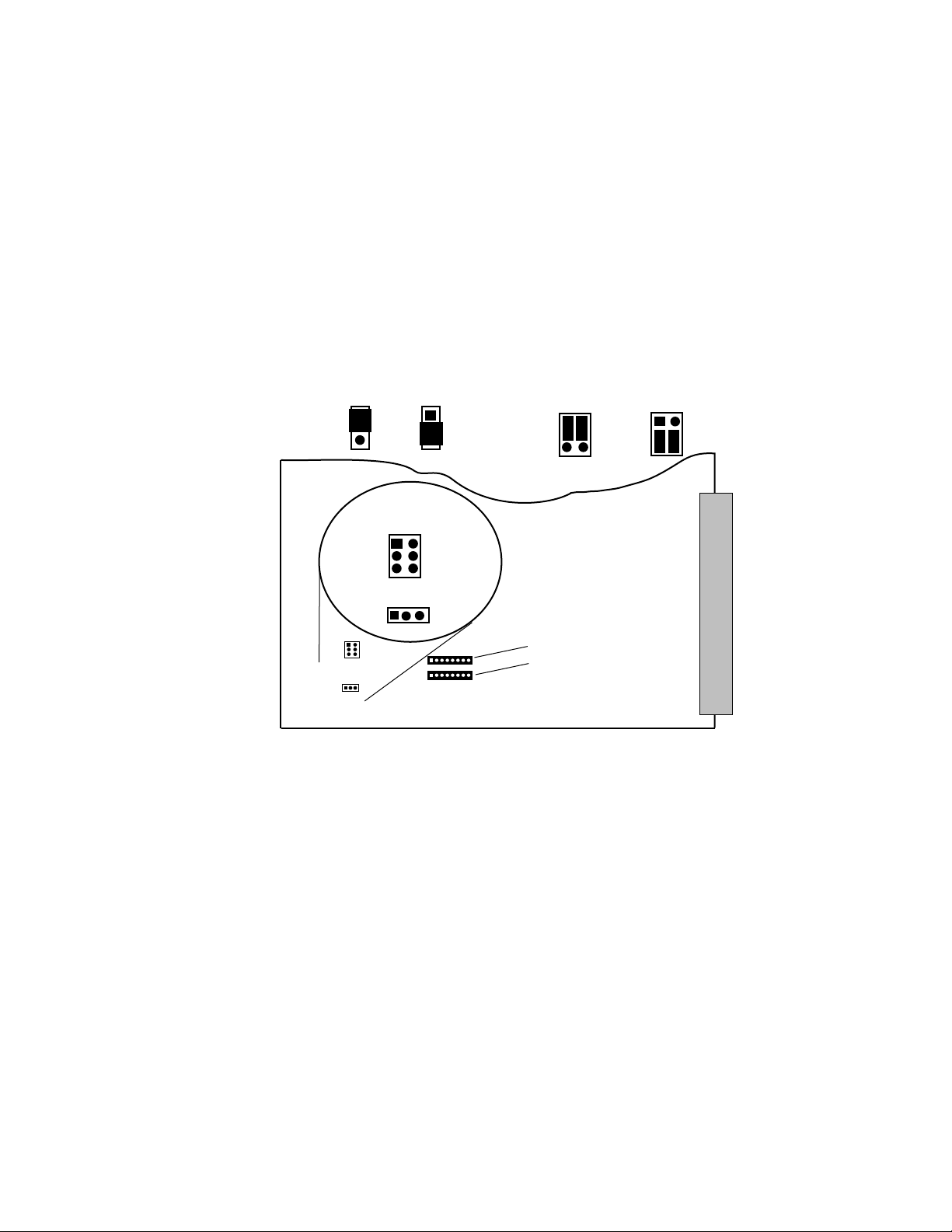

Figure 1-10 illustrates the 2 RU backplane.

Video/Audio

Connectors

J2 J3

J1

J10

J4

J5

J6

J11

J8

J9

J7

J13

J12

Communication

Connectors

Figure 1-10. Backplane for the 2 RU Frame

Fan Assembly (6 RU only)

The fan assembly consists of three (3) muffin fans in a housing which is

mounted immediately above the frame in the equipment rack. A removable

air filter is in the front panel. Warm air is drawn up through the frame and

Alarm

Connector

E

T

ETL TESTING LABORATORIES, INC.

CORTLAND, NEW YORK, 13045

THIS DEVICE COMPLIES WITH PART

15 OF THE FCC RULES OPERATION

SUBJECT TO THE FOLLOWING TWO

CONDITIONS: (1) THIS DEVICE MAY

NOT CAUSE HARMFUL INTERFERENCE

(2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED INCLUDING

INTERFERENCE THAT MAY CAUSE

UNDESIRED OPERATIONS.

CAUTION:

This unit has more than one power source.

Disconnecting power cords

may not de-energize unit.

ATTENTION:

Ca produit a plus qu'une Source de pouvior

electrique. Debranchement n' assure pas

de-energisation de I' equipement.

L

TELEPHONE

EQUIPMENT

Conforms to ULSTD 1459

ETL LISTED

Exhaust

Fan

Power Supply

Connectors

+

GND

–

+

GND

–

5158-98

MCF Installation and Service 1-13

Page 32

Section 1 — System Description and Specifications

exhausted out the back of the equipment rack. Power to the fan assembly

is supplied from a connector on the backplane of the frame. Figure 1-11

illustrates the fan assembly.

5144-02

Figure 1-11. MCF Fan Assembly

Deflector Assembly (6 RU only)

The deflector assembly consists of the same housing and air filter as the fan

assembly, except without fans. It is mounted immediately below the frame.

Ambient air is drawn in through a filter and deflected up through the

frame.

1-14 MCF Installation and Service

Page 33

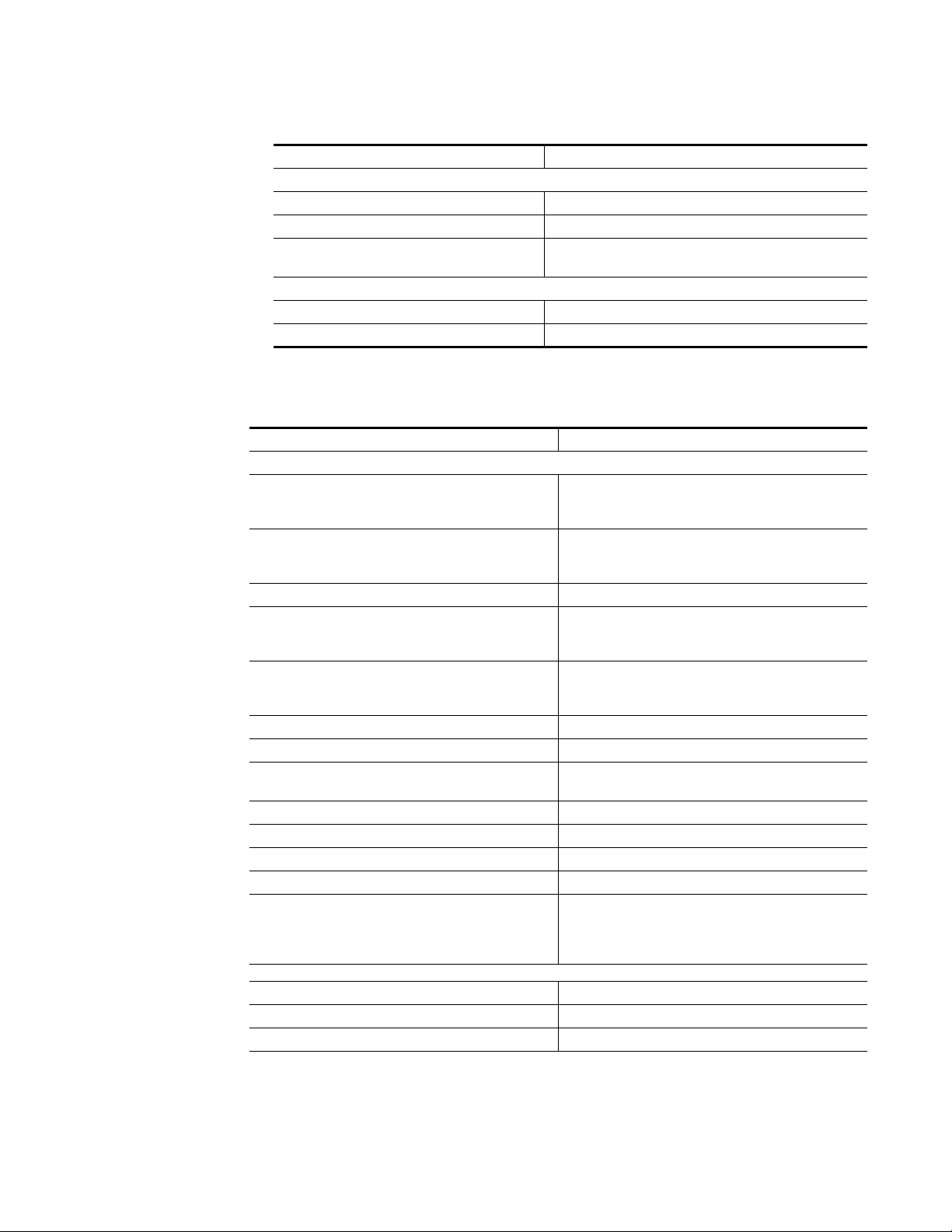

Physical Specifications

The physical specifications of each component of the MCF are listed in

Table 1-3.

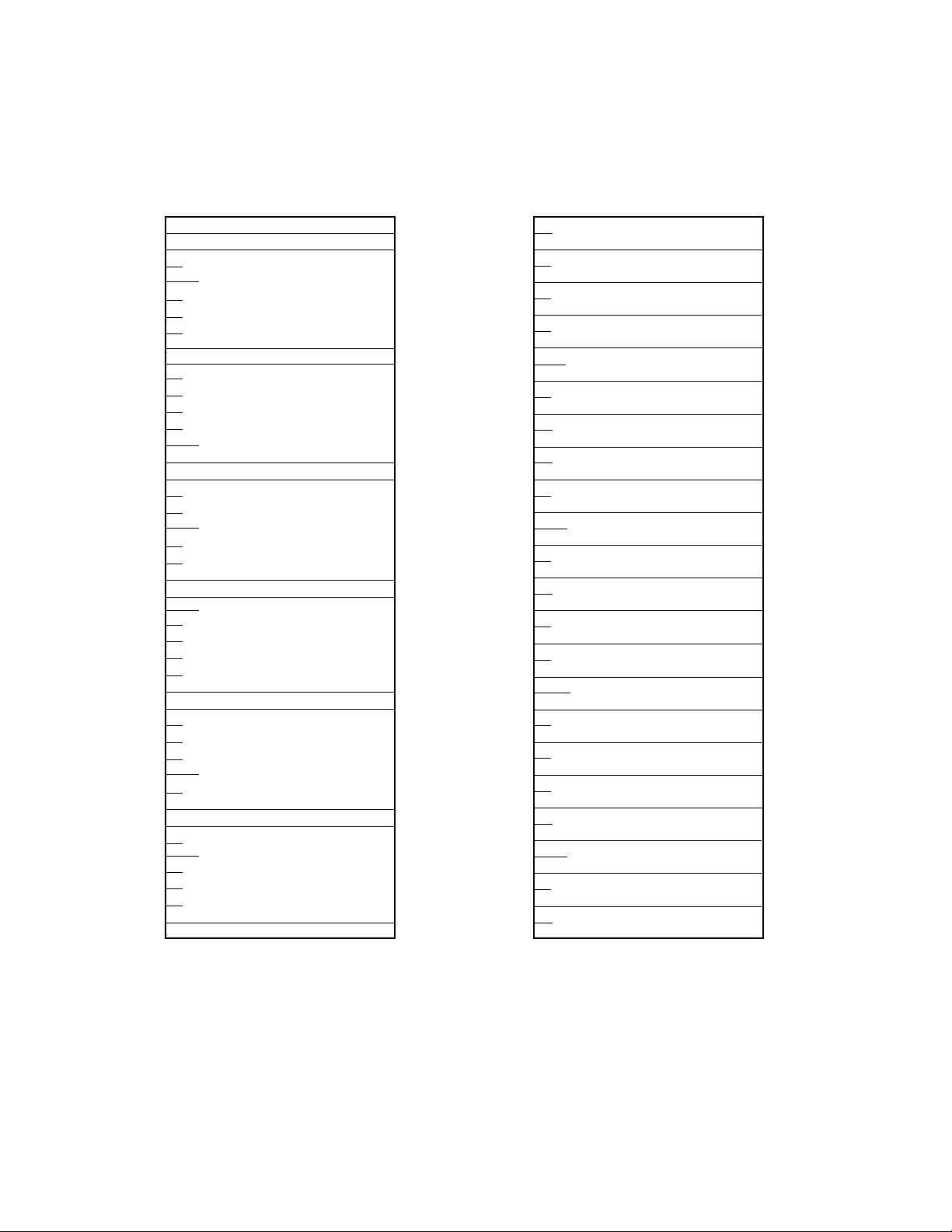

Table 1-3. MCF System Physical Specification

Component Height Width Depth Weight

2 RU Frame

6 RU Frame

Fan Assembly

Deflector Assembly

a

Fully optioned

3.5 in.

(88.9 mm)

10.5 in.

(267 mm)

1.75 in.

(44.4 mm)

1.75 in.

(44.4 mm)

17.25 in

(438 mm)

17.25 in

(438 mm)

17.25 in.

(438 mm)

17.25 in.

(438 mm)

10.5 in.

(267 mm)

10.5 in.

(267 mm)

10.5 in.

(267 mm)

10.5 in.

(267 mm)

Physical Specifications

a

20.0 lbs

(9.1 kg)

35.0 lbs

(15.9 kg)

8.5 lbs

(3.9 kg)

7.5 lbs

(3.4 kg)

Rack

Units

2

6

1

1

Power Specifications

Source power to the frame enters through connectors on the rear of the

backplane. Power for frame components is from one or two AC power supplies, one or two DC power supplies, or one of each, depending on your

facility requirements. Table 1-4 lists the power supply specifications.

Table 1-4. MCF Power Specifications

Parameter Value

Primary Power (AC, DC, or mixed AC/DC)

AC

DC

Power Capability

6 RU frame

2 RU frame

Redundancy (hot pluggable) Each AC or DC supply will support entire load

90–132 or 180–264 VAC, 47–63 Hz

–42 to –56.7 VDC

15W per module (nominal), 250W total

15W per module (nominal), 45W total

MCF Installation and Service 1-15

Page 34

Section 1 — System Description and Specifications

Regulatory Compliance

The MCF System meets the following regulatory requirements:

■ UL 1459

■ UL 1950

■ CSA 22.2 #950

■ EN 60950

■ NEBS TR-NWT-000063

■ FCC 15A

■ EN 55022 (CISPR–22A)

■ EN 50082-1 (IEC 801-2, -3, -4)

■ GR-1089 (sec. 2,3,4,7,9)

■ GR-63-CORE (sec. 2,3,4)

Environmental Criteria

The MCF System meets the environmental criteria listed in

Table 1-5.

Table 1-5. MCF System Environmental Criteria

Operating 0° to 50° C (per NEBS) 0–95% non-condensing

Non-Operating (Storage) –10° to 70° C 0–95% non-condensing

Cooling (6 RU) Forced air, 1 RU Active Vent, 1 RU Passive Filter

Alarm Indicators

The MCF system is equipped with both visual alarms and system (monitor)

indications. These alarms and messages are designated as Minor (possible

deterioration of system performance) and Major (loss of system operation).

Temperature Humidity

1-16 MCF Installation and Service

Page 35

Major Alarm

Minor Alarm

Alarm Indicators

Note that you can see the Minor and Major alarm indicators through the

MCF frame door. For the 6 RU frame, refer to Figure 1-12. For the 2 RU

frame, refer to Figure 1-13.

Grass Valley

MAJOR

ALARM

MINOR

ALARM

MCF Series

Minor Alarm

Major Alarm

Figure 1-12. Alarm Indicators for the 6 RU Frame

Grass Valley

Major Alarm

Minor Alarm

MCF Series

Figure 1-13. Alarm Indicators for the 2 RU Frame

Table 1-6 lists the source of an alarm, the visual alarm indicator, and the

system Minor and Major Alarm designations.

Table 1-6. MCF System Alarm Indications

Indicator Status System Indication (Minor/Major)

Fiber Transmitter

Major Alarm (red) On RF drive not present or invalid

Laser Power (red) On Laser Power out of limits (minor)

Module Temp (red) On Module temp out of limits (minor)

Minor Alarm (amber) On

Fiber Receiver

Major Alarm (red) On Optical input not present

Module Temp (red) On Module temp out of limits (minor)

Power supply failed or not present and out of current or temperature limits

MCF Installation and Service 1-17

Page 36

Section 1 — System Description and Specifications

Table 1-6. MCF System Alarm Indications - (continued)

Indicator Status System Indication (Minor/Major)

Input Pwr (green) Flash Optical input power too high (minor)

Input Pwr (red) On Optical input power too low (major)

Input Pwr (amber) On Bit error rate has degraded (minor)

Minor Alarm (amber) On

Combined Video/Audio Modules Input/Output

Clip (amber) On Module overdriven

Quiet (green) On No Input/Output

LOS (amber) (Video/Audio Output module

only)

Online (green) Off Module muted (offline) or inoperative

Video Modules Input/Output

Clip (amber) On Module overdriven

Quiet (green) On No Input/Output