Page 1

LPD64

6 Series Low Profile Digitizer

Installation and Safety Manual

*P071365900*

071365900

Page 2

Page 3

LPD64

6 Series Low Profile Digitizer

Installation and Safety Manual

Supports Product Firmware V1.20.x and above.

www.tek.com

071365900

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or suppliers, and are

protected by national copyright laws and international treaty provisions. Tektronix products are covered by U.S. and foreign patents, issued

and pending. Information in this publication supersedes that in all previously published material. Specifications and price change privileges

reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

■

In North America, call 1-800-833-9200.

■

Worldwide, visit www.tek.com to find contacts in your area.

Page 5

Table of Contents

Important safety information ................................................................................................................................ iii

General safety summary ................................................................................................................................ iii

Service safety summary ................................................................................................................................. v

Terms in the manual ...................................................................................................................................... vi

Terms on the product .................................................................................................................................... vi

Symbols on the product ................................................................................................................................. vi

Preface ............................................................................................................................................................... vii

Key features .................................................................................................................................................. vii

Related documents ...................................................................................................................................... viii

Installing your instrument

Check shipped accessories ........................................................................................................................... 1

Operating requirements ................................................................................................................................. 1

Input signal requirements ............................................................................................................................... 2

Installing the instrument in a rack ................................................................................................................... 2

Secure (lock) the instrument .......................................................................................................................... 4

Powering the instrument ................................................................................................................................ 4

Check that the instrument passes power-on self tests ................................................................................... 5

Connecting signals to the instrument ............................................................................................................. 5

Getting acquainted with your instrument

Front panel controls and connections, LPD64 ............................................................................................... 7

Rear panel connections ................................................................................................................................. 8

M.2 drive access ............................................................................................................................................ 9

The graphical user interface ......................................................................................................................... 10

Configure the instrument

Set the time zone and clock readout format ................................................................................................. 11

Download and install the latest instrument firmware .................................................................................... 12

Run Signal Path Compensation (SPC) ........................................................................................................ 13

Connect to a network (LAN) ......................................................................................................................... 13

Remote access from a Web browser (standard instrument) ........................................................................ 14

Operating basics

Operating basics ......................................................................................................................................... 17

LPD64 Installation and Safety Manual

i

Page 6

Table of Contents

Maintenance

Maintenance ................................................................................................................................................. 19

Cleaning ....................................................................................................................................................... 19

Performance verification interval and adjustment ........................................................................................ 19

Replaceable parts list ................................................................................................................................... 19

EMC Safety and environmental compliance

Compliance Information ............................................................................................................................... 23

EMC compliance .................................................................................................................................... 23

Safety compliance .................................................................................................................................. 24

Environmental compliance ..................................................................................................................... 25

ii LPD64 Installation and Safety Manual

Page 7

Important safety information

This manual contains information and warnings that must be followed by the user for safe operation and to keep the product in a

safe condition.

To safely perform service on this product, see the Service safety summary that follows the General safety summary.

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product or

any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition to

the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other

component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Use proper power cord. Use only the power cord specified for this product and certified for the country of use. Do not use the

provided power cord for other products.

Ground the product. This product is grounded through the grounding conductor of the power cord. To avoid electric shock, the

grounding conductor must be connected to earth ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded. Do not disable the power cord grounding connection.

Power disconnect. The power cord disconnects the product from the power source. See instructions for the location. Do not

position the equipment so that it is difficult to operate the power cord; it must remain accessible to the user at all times to allow for

quick disconnection if needed.

Connect and disconnect properly. Do not connect or disconnect probes or test leads while they are connected to a voltage

source. Use only insulated voltage probes, test leads, and adapters supplied with the product, or indicated by Tektronix to be

suitable for the product.

Observe all terminal ratings. To avoid fire or shock hazard, observe all rating and markings on the product. Consult the product

manual for further ratings information before making connections to the product. Do not exceed the Measurement Category

(CAT) rating and voltage or current rating of the lowest rated individual component of a product, probe, or accessory. Use caution

when using 1:1 test leads because the probe tip voltage is directly transmitted to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

Do not float the common terminal above the rated voltage for that terminal.

The measurement terminals on this product are not rated for connection to mains or Category II, III, or IV circuits.

LPD64 Installation and Safety Manual

iii

Page 8

Important safety information

Do not operate without covers. Do not operate this product with covers or panels removed, or with the case open. Hazardous

voltage exposure is possible.

Avoid exposed circuitry. Do not touch exposed connections and components when power is present.

Do not operate with suspected failures. If you suspect that there is damage to this product, have it inspected by qualified

service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in doubt about safety of the

product, turn it off and disconnect the power cord. Clearly mark the product to prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. Do not use

probes or test leads if they are damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Do not operate in wet/damp conditions. Be aware that condensation may occur if a unit is moved from a cold to a warm

environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean the product.

Provide proper ventilation. Refer to the installation instructions in the manual for details on installing the product so it has

proper ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise obstructed. Do not push objects into

any of the openings.

Provide a safe working environment. Always place the product in a location convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or prolonged keyboard or pointer use may

result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress injuries.

Use care when lifting and carrying the product. This product is provided with a handle or handles for lifting and carrying.

WARNING. The product is heavy. To reduce the risk of personal injury or damage to the device get help when lifting or carrying

the product.

Use only the Tektronix rackmount hardware specified for this product.

iv LPD64 Installation and Safety Manual

Page 9

Important safety information

Probes and test leads

Before connecting probes or test leads, connect the power cord from the power connector to a properly grounded power outlet.

Keep fingers behind the protective barrier, protective finger guard, or tactile indicator on the probes.

Remove all probes, test leads and accessories that are not in use.

Use only correct Measurement Category (CAT), voltage, temperature, altitude, and amperage rated probes, test leads, and

adapters for any measurement.

Beware of high voltages. Understand the voltage ratings for the probe you are using and do not exceed those ratings. Two

ratings are important to know and understand:

■

The maximum measurement voltage from the probe tip to the probe reference lead

■

The maximum floating voltage from the probe reference lead to earth ground

These two voltage ratings depend on the probe and your application. Refer to the Specifications section of the manual for more

information.

WARNING. To prevent electrical shock, do not exceed the maximum measurement or maximum floating voltage for the

oscilloscope input BNC connector, probe tip, or probe reference lead.

Connect and disconnect properly. Connect the probe output to the measurement product before connecting the probe to the

circuit under test. Connect the probe reference lead to the circuit under test before connecting the probe input. Disconnect the

probe input and the probe reference lead from the circuit under test before disconnecting the probe from the measurement

product.

Connect the probe reference lead to earth ground only.

Inspect the probe and accessories. Before each use, inspect probe and accessories for damage (cuts, tears, or defects in the

probe body, accessories, or cable jacket). Do not use if damaged.

Ground-referenced oscilloscope use. Do not float the reference lead of this probe when using with ground-referenced

oscilloscopes. The reference lead must be connected to earth potential (0 V).

Floating measurement use. Do not float the reference lead of this probe above the rated float voltage.

Risk assessment warnings and information

Service safety summary

The Service safety summary section contains additional information required to safely perform service on the product. Only

qualified personnel should perform service procedures. Read this Service safety summary and the General safety summary

before performing any service procedures.

To avoid electric shock. Do not touch exposed connections.

Do not service alone. Do not perform internal service or adjustments of this product unless another person capable of rendering

first aid and resuscitation is present.

Disconnect power. To avoid electric shock, switch off the product power and disconnect the power cord from the mains power

before removing any covers or panels, or opening the case for servicing.

Use care when servicing with power on. Dangerous voltages or currents may exist in this product. Disconnect power, remove

battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric strength after performing a repair.

LPD64 Installation and Safety Manual v

Page 10

Important safety information

Terms in the manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in damage to this product or other property.

Terms on the product

These terms may appear on the product:

■

DANGER indicates an injury hazard immediately accessible as you read the marking.

■

WARNING indicates an injury hazard not immediately accessible as you read the marking.

■

CAUTION indicates a hazard to property including the product.

Symbols on the product

When this symbol is marked on the product, be sure to consult the manual to find out the nature of the potential

hazards and any actions which have to be taken to avoid them. (This symbol may also be used to refer the user to

ratings in the manual.)

The following symbols may appear on the product:

vi LPD64 Installation and Safety Manual

Page 11

Preface

This manual provides product safety and compliance, how to connect and power on the instrument, and an introduction to the

instrument features, controls and basic operations. See the product Help file for more detailed information.

Key features

Welcome to the 6 Series Low Profile Digitizer LPD64.

■

Low profile instrument with no display, comes ready to install in a 2U rack mount space

■

4 channels with 50 Ω SMA inputs

■

1, 2.5, 4, 6, and 8 GHz bandwidths on all channels

■

Maximum 25 GS/s sample rate on all channels

■

125 M points record length on all channels (optional 250 M points available)

■

12 bits A/D resolution

■

Lowest-in-class noise

■

Highest-in-class ENOB (8.2 bits at 1 GHz)

■

500,000 waveforms/second maximum waveform capture rate

■

No set limit on the number of math, reference, and bus waveforms you can create (the number of waveforms depends on

available system memory)

■

Spectrum View enables simple, intuitive frequency domain analysis, independent of time domain controls, to show a

spectral trace for each channel

■

Real-Time 2 GHz DDC for RF bandwidth

■

FastFrame™ segmented memory acquisition uses multiple trigger events to capture widely spaced events of interest at high

sample rates while conserving acquisition memory

■

Integrated options include a 50 MHz arbitrary/function generator (AFG), and a Digital Voltmeter (DVM) and trigger frequency

counter

■

Advanced serial bus triggering and analysis options let you decode and trigger on industry standard buses. See the Serial

bus and trigger options Help topic

■

Power, DPM, and Jitter options provide additional measurement and analysis functions. See the Advanced Power Analysis,

DPM Analysis, and Advanced Jitter Analysis Help topics

LPD64 Installation and Safety Manual vii

Page 12

Preface

Related documents

Use the related documents for more information on instrument functions, how to remotely program or operate the instrument,

understand theory of operation, replace suspected modules, and do other tasks.

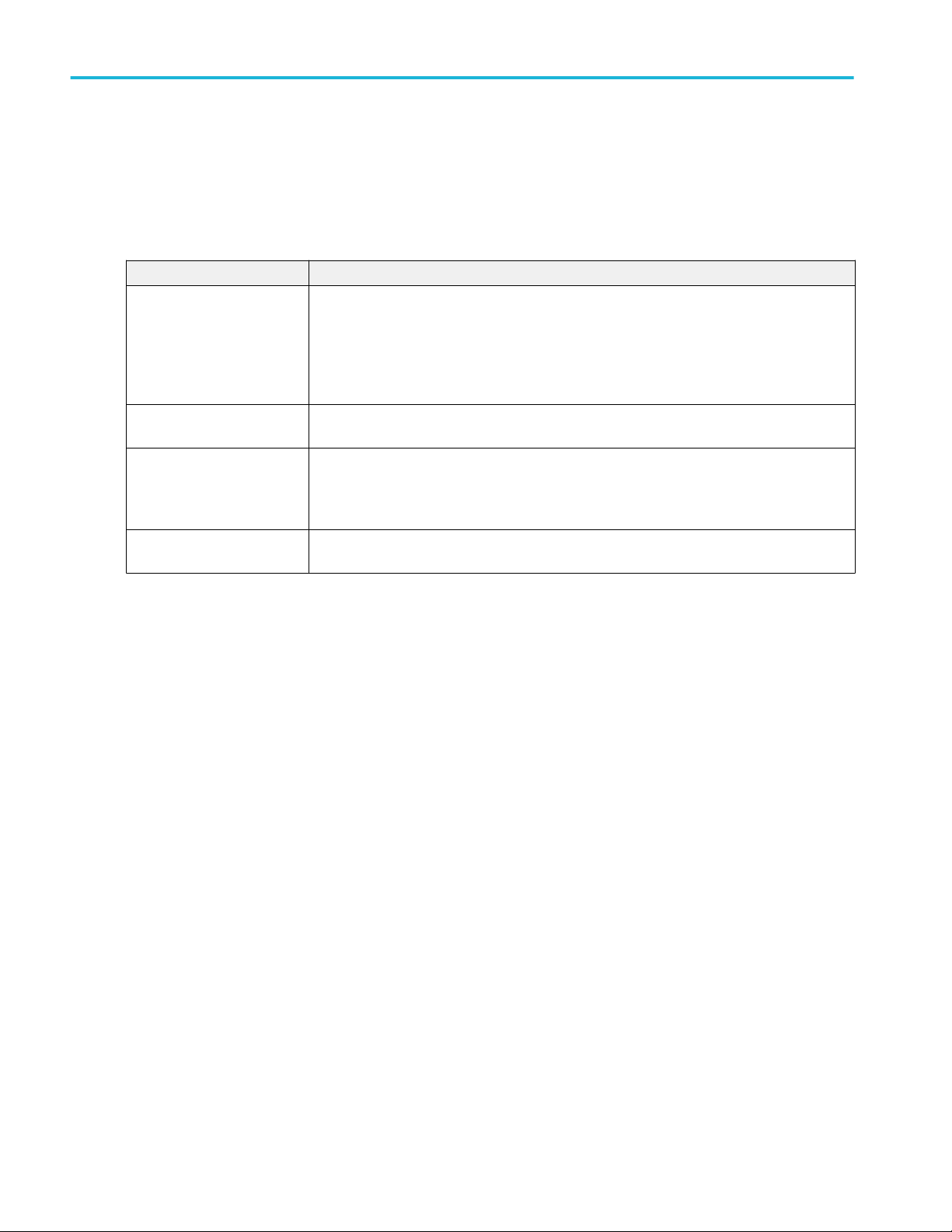

LPD64 documents

To learn about Use this document

How to use instrument

functions

How to remotely control the

instrument

Instrument specifications and

procedures to verify the

instrument meets

specifications

Converting the instrument for

benchtop use

6 Series Low Profile Digitizer LPD64 Installation and Safety Manual (this document, Tektronix

part number 071-3569-xx); standard accessory with the instrument. Single document with

English, French, and German languages.

4/5/6 Series MSO Help (Tektronix part number 077-1303-xx; Printable version of the instrument

Help; available at www.tektronix.com/downloads)

4/5/6 Series MSO Programmer Manual (Tektronix part number 077-1305-xx; available at

www.tek.com/downloads)

6 Series Low Profile Digitizer LPD64 Specifications and Performance Verification Technical

Reference (Tektronix part number 077-1568-xx; available at www.tek.com/downloads)

MSO58LP/LPD64 Bench Conversion Kit Instructions (Tektronix part number 075-1102-xx;

available at www.tek.com/downloads)

viii LPD64 Installation and Safety Manual

Page 13

Installing your instrument

Check shipped accessories

Make sure that you received everything you ordered. If anything is missing, contact Tektronix Customer Support. In North

America, call 1-800-833-9200. Worldwide, visit www.tek.com to find contacts in your area.

Check the packing list that came with your instrument to verify that you have received all standard accessories and ordered

items. If you purchased factory installed options such as a Serial Bus and Triggering option, or the Power measurements option,

tap Help > About to confirm that the option(s) are listed in the Installed Options table.

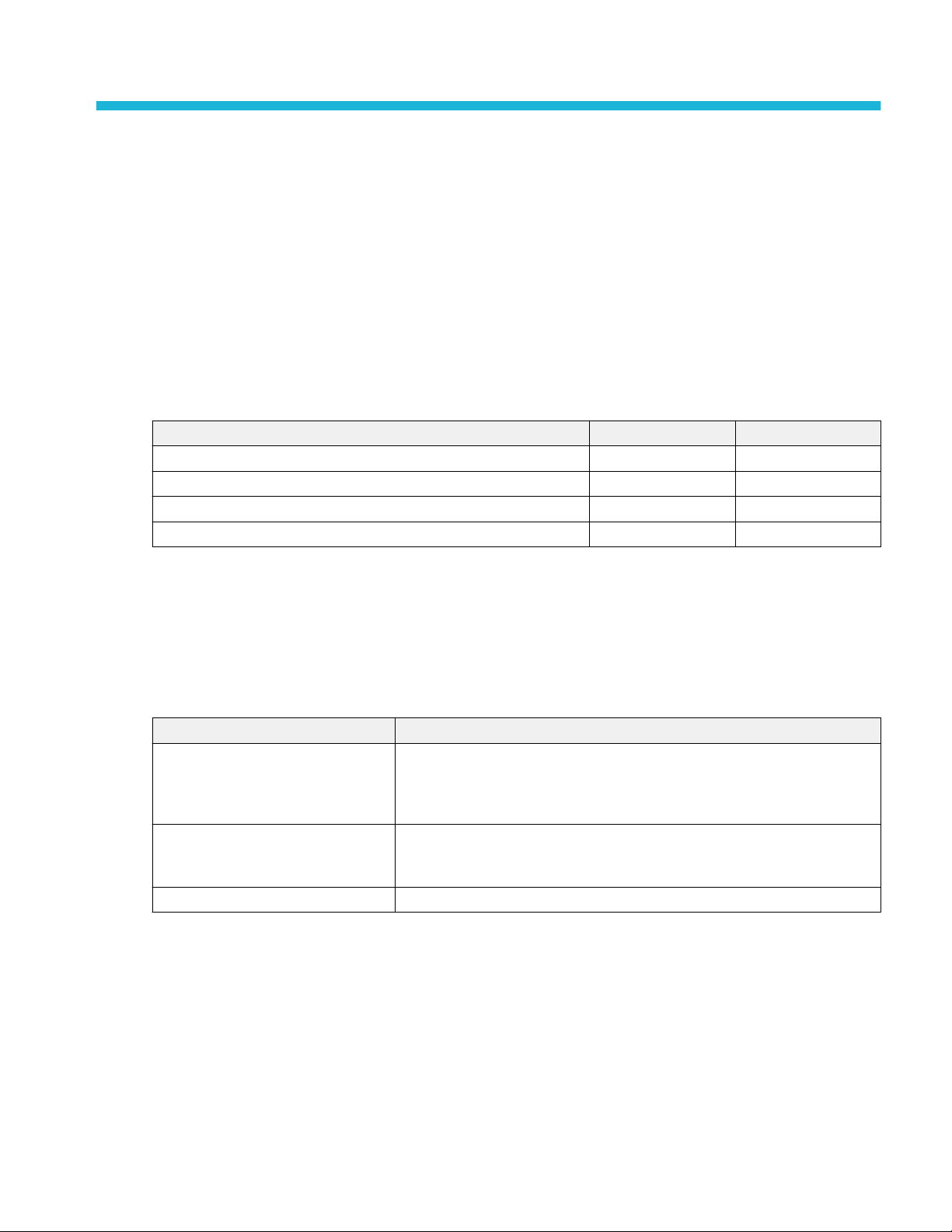

LPD64 standard accessories

Item Quantity Tektronix part number

6 Series Low Profile Digitizer LPD64 Installation and Safety Manual 1 071-3569-xx

Power cord 1 Depends on region

Calibration certificate 1 N/A

Report of factory installed licenses 1 N/A

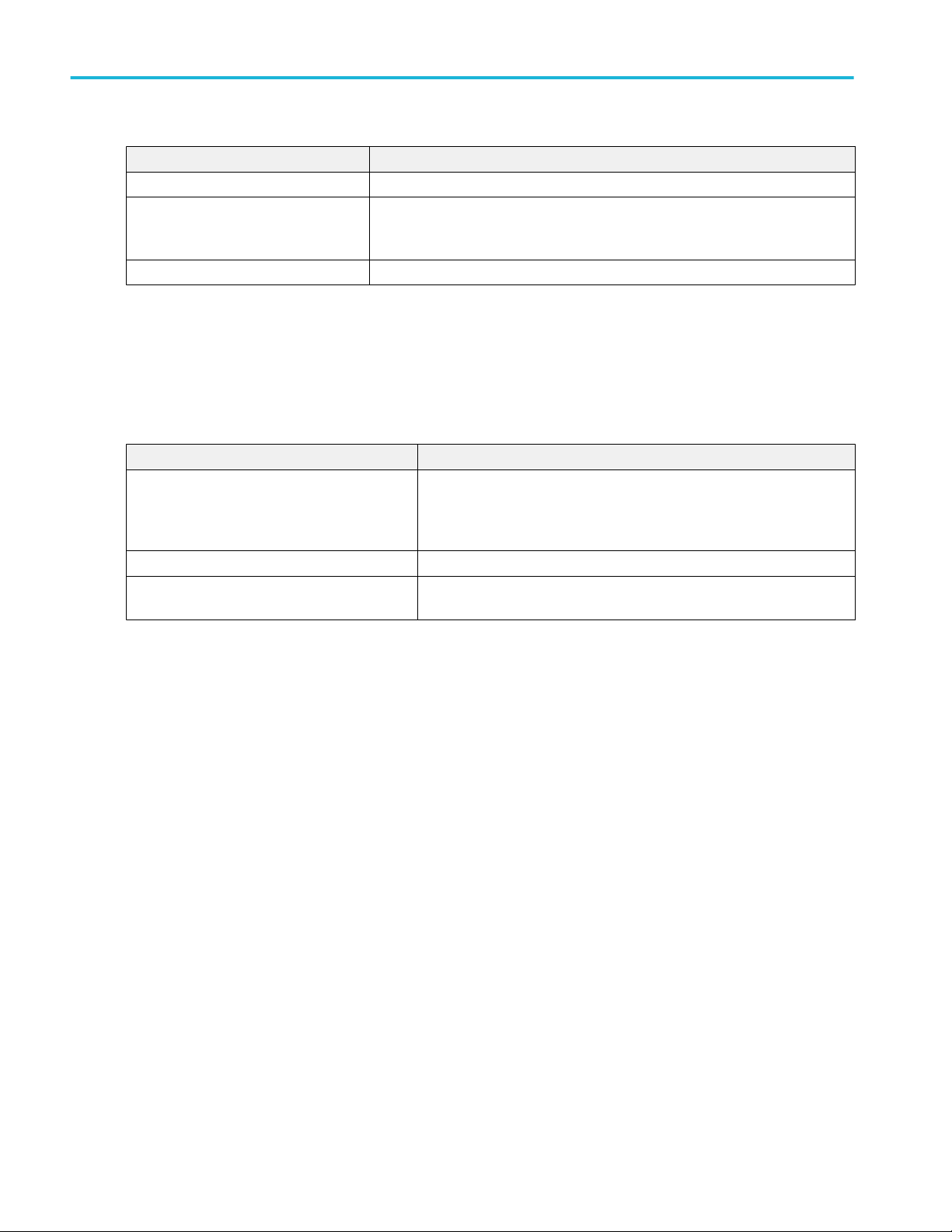

Operating requirements

Use the instrument within the required operating temperature, power, altitude, and signal input voltage ranges to provide the

most accurate measurements and safe instrument operation.

Environment requirements

Characteristic Description

Operating temperature 0 °C to +50 °C (+32 °F to +122 °F)

For proper cooling, keep the sides of the instrument clear of obstructions for 2 inches

(51 mm).

Operating humidity 5% to 90% relative humidity (% RH) up to +40 °C (+104 °F), Noncondensing.

5% to 50% RH above +40 °C up to +50 °C (+104 °F to +122 °F), Noncondensing.

Operating altitude Up to 3000 meters (9842 feet)

LPD64 Installation and Safety Manual 1

Page 14

Installing your instrument

Power requirements

Characteristic Description

Power source voltage 100 V - 240 V

Power source frequency 50/60 Hz, 100-240 V

400 Hz, 115 V

Power consumption All models: 360 W maximum

, ±10%, single phase

AC RMS

Input signal requirements

Keep the input signals within allowed limits to ensure the most accurate measurements and prevent damage to the analog and

digital probes or instrument.

Make sure that input signals connected to the LPD64 instrument are within the following requirements.

Input Description

Analog input channels, 50 Ω, maximum input

voltage at SMA connector

Ref In maximum input voltage at BNC (rear panel) 7 V

Aux In trigger input, 50 Ω, maximum input voltage

at SMA connector

5 V

RMS

Transient Overvoltage is 0 V. The measuring terminals on this product are

not rated for connection to mains or Category II, III, or IV circuits.

PP

±5 V

RMS

Installing the instrument in a rack

Use these instructions to install the Low Profile instrument into a standard 19" wide by 24" to 32" deep equipment rack.

The instrument comes equipped with the rack bracket hardware installed on the chassis. Use the bolts and washers from the bag

that ships with the instrument to install the rear rack brackets in the rack.

To use an Low Profile instrument on a bench, purchase and install the MSO58LP/LPD64 Benchtop Conversion kit (Tektronix part

number 020-3180-xx). The kit includes chassis feet and a handle, and lets you stack instruments on a bench.

Follow these steps to install the instrument in a rack:

2 LPD64 Installation and Safety Manual

Page 15

Installing your instrument

WARNING. To prevent injury, two people are required to install the instrument.

1. Use two bolts and washers from the supplied hardware to attach one of the rear rack brackets to the rear of the rack.

Tighten by hand.

2. Using two people to support the instrument, insert the instrument from the front of the rack so that the chassis rack bracket

inserts into the rear rack bracket.

3. Continue pushing from the front until the instrument is flush with the front of the rack.

4. Use four bolts and washers from the supplied hardware to attach the front of the instrument to the rack. Tighten by hand to

support the instrument.

5. From the rear of the rack, slide the second rear rack bracket onto the instrument chassis rack bracket until the rear rack

bracket is flush with the rear rack.

6. Use two bolts and washers from the supplied hardware to attach the second rear rack bracket to the rear of the rack.

Tighten by hand.

7. Tighten all bolts to 1.1 N·m.

8. Using a 5/16 inch wrench, attach two supplied hexhead bolts to the rack bracket assembly on each side, to lock the

brackets in place and prevent the instrument from unintentional removal when the front rack screws are removed (see the

following image). There are four bolt positions available on each side (see image). Tighten the bracket lock bolts to 0.7 N·m.

9. Attach power cord and cables to rear chassis as needed.

End of rack mount instructions.

LPD64 Installation and Safety Manual 3

Page 16

Installing your instrument

Secure (lock) the instrument

Lock an instrument to a test bench or equipment rack to prevent property loss.

Attach a standard laptop security lock to the rear panel of the instrument, to secure the instrument to a workbench, rack, or other

location.

Powering the instrument

Use this procedure to connect the instrument to line power and power on and off the instrument. Always connect the instrument

to AC power using the power cord that shipped with the instrument.

Prerequisite: Use the AC power cord that shipped with your instrument.

1. Connect the supplied power cord to the instrument power connector on the back of the instrument.

Figure 1: LPD64 power cord connector and power standby switch

2. Connect the power cord to an appropriate AC mains source.

Power is supplied to the power supply and some other boards whenever the AC power cord is connected to a live mains

circuit, putting the instrument in standby mode.

3. Push the front panel power button to power the instrument on and off.

The power button color indicates instrument power states:

Unlit – no AC power applied

Yellow – standby mode

Blue – powered on

4. To completely remove power from the instrument, disconnect the power cord.

4 LPD64 Installation and Safety Manual

Page 17

Installing your instrument

Check that the instrument passes power-on self tests

Power-on self tests verify that all instrument modules are working correctly after power up.

Prerequisite: For the Low Profile instruments, connect a monitor to a video output on the rear panel and connect a mouse to a

USB port.

1. Power on the instrument and wait until the instrument screen appears on the monitor.

2. Select Utility > Self Test from the top-edge Menu bar to open the Self Test configuration menu.

3. Check that the status of all power-on self tests are Passed.

If one or more power-on self tests shows Failed:

a. Power cycle the instrument.

b. Tap Utility > Self Test. If one or more power-on self tests still shows Failed, contact Tektronix Customer Support.

Connecting signals to the instrument

Cables connect the instrument to your device under test (DUT). Use a cable that best matches your signal measurement needs.

Figure 2: Connecting SMA cables to the LPD64

Connecting SMA cables (LPD64)

Connect SMA cables to the instrument. Hand tighten, then torque the cable connectors to 56 N-cm (5 in-lb).

LPD64 Installation and Safety Manual 5

Page 18

Installing your instrument

6 LPD64 Installation and Safety Manual

Page 19

Getting acquainted with your instrument

Front panel controls and connections, LPD64

The front panel is where you power on or off the instrument, connect signals with cables, connect an auxiliary trigger input signal,

and insert USB devices.

The LPD64 front panel

1. Acq status LED:

Shows the instrument trigger/acquisition status:

■

Green - Triggered

■

Yellow - Armed but not yet triggered

■

Red - Acquisition stopped

2. LAN Status LED:

Shows the network connection and activity status:

■

Off - No power to instrument

■

Green - Network connection is good

■

Red - Network connection has fault or is not connected

3. LAN Reset button (to the right of the LAN status LEDs):

Lets you manually reset the LAN settings.

4. USB Host ports (One USB 3.0; two USB 2.0):

Lets you save or recall data (such as instrument firmware updates, waveforms, settings, and screen captures) to a USB

memory device, or connect peripheral devices such as a mouse or keyboard.

5. Aux Trig trigger input connector:

An SMA connector to which you can connect an external trigger input signal. Use the AUX In trigger signal with the Edge

trigger mode.

6. SMA connectors:

LPD64 Installation and Safety Manual

7

Page 20

Getting acquainted with your instrument

SMA connectors support high bandwidth and frequency cables.

7. Power On/Standby button:

Powers the instrument on and off. The power button color indicates instrument power states:

■

No light - No AC power applied

■

Yellow - Standby mode

■

Blue - Powered on

Rear panel connections

The rear panel connections supply power to the instrument and provide connectors for network, USB devices, video, reference

signals, and the AFG output.

5 Series MSO, 6 Series MSO

Figure 3: 5 Series MSO (including MSO58LP) and 6 Series MSO (including LPD64)

1. Power cord connector. Use only the power cord specified for this product and certified for the country of use.

2. Ref In lets you connect a high-precision 10 MHz reference signal to the oscilloscope for more accurate measurements.

3. AUX Out generates a signal transition on a trigger event, outputs a 10 MHz reference signal, or outputs a synchronization

signal from the AFG.

4. AFG Out is the signal output for the optional Arbitrary Function Generator (AFG) feature.

5. Video outputs (Display Port, VGA, and DVI-D) let you connect an external monitor or projector to show the instrument's

graphical user interface.

6. USB 3.0 Device port lets you connect to a PC to remotely control the instrument using USBTMC protocol.

7. USB Host ports let you connect a USB memory device, keyboard, or mouse.

8. LAN connector (RJ-45) connects the instrument to a 10/100/1000 Base-T local area network. The LAN is LXI 1.5 compliant.

9. Security lock connector lets you use a standard PC/laptop lock cable to secure the instrument to a work bench or other

location.

8 LPD64 Installation and Safety Manual

Page 21

Getting acquainted with your instrument

M.2 drive access

The m.2 solid state drive is easily removable when you need to transport the instrument from a secured facility.

The m.2 drive:

■

Contains the system OS

■

Contains all user-related data that was saved to the C: (m.2) drive (waveforms, measurements, settings, and so on)

■

Is easily accessed from the bottom of the instrument with just a Torx screwdriver

NOTE. Licensed functions (installed options) and calibration constants are stored in the instrument, not on the m.2 drive.

NOTE. With the LPD64 6-SEC security option (installed at initial purchase), there is no C: drive on the instrument. User data

such as waveform acquisitions and vertical, horizontal, and trigger settings, are not retained on the m.2 drive after the instrument

is powered off. All acquisition data and setup information must be stored on external memory (USB or network).

To remove an m.2 drive:

CAUTION. Work on the instrument in an anti-static work area and use a wrist strap when removing or installing an m.2 drive.

Failing to do so could damage the m.2 board and the circuit board to which it connects.

1. Disconnect the power cord or unplug the instrument from the power source.

2. Turn the instrument bottom-up.

3. Locate the m.2 drive cover near the corner of the instrument.

4. Use a T-10 Torx screw driver to remove the three screws on the Sold State Drive cover, and remove the cover.

5. Use a T-10 Torx screwdriver to remove the screw from the end of the m.2 drive. The end of the m.2 board lifts upward as

you loosen the screw.

LPD64 Installation and Safety Manual 9

Page 22

Getting acquainted with your instrument

6. Grasp the edges of the raised end and pull to remove the board.

7. Store or destroy the memory card in accordance with your organization’s guidelines.

8. To install an m.2 board, follow these steps in reverse order.

9. Reattach the board cover.

The graphical user interface

Although designed for programmatic control, the LPD64 also has a graphical user interface that incorporates product Help topics.

You can access the graphical interface by connecting a monitor and mouse to the instrument, or by using a browser to access a

network-connected instrument.

Connect a monitor (standard or touchscreen) with a maximum resolution of 1,920 horizontal × 1,080 vertical pixels (High

Definition) to a video out connector on the rear panel.

To access from a browser, type the IP address of the instrument in the browser address field to open the instrument's browser

welcome page. Click the Instrument Control (e*Scope®) link on the left of the screen to open the graphical interface.

Connect a mouse (USB cable) or mouse dongle (for USB wireless mouse) to any USB port.

Refer to the 6 Series MSO Installation and Safety Manual (Tektronix part number 071-3579-xx), available to download from

www.tek.com/product-support, for details on understanding and using the graphical user interface.

You can also get information by opening the instrument Help system. Select Help > Help in the Menu bar and open the Getting

acquainted with your instrument topic.

10 LPD64 Installation and Safety Manual

Page 23

Configure the instrument

To access the user interface on a Low Profile instrument, connect a monitor to a video port on the rear of the instrument, and

connect a mouse to any USB Host port. You do not need to connect a mouse if your remote monitor is touch-capable. You can

also remotely access the user interface of a network-connected instrument by entering the instrument's IP address in a web

browser.

To remotely set controls or run this task on a Low Profile instrument, see the instrument Programmer Manual (Tektronix part

number 077-1305-xx) for the correct command or commands to use.

Set the time zone and clock readout format

Set the time zone to your region so that saved files are marked with the correct date and time information. You can also set the

time format (12 or 24 hour clock).

To access the user interface on a Low Profile instrument, connect a monitor to a video port on the rear of the instrument, and

connect a mouse to any USB Host port. You do not need to connect a mouse if your remote monitor is touch-capable. You can

also remotely access the user interface of a network-connected instrument by entering the instrument's IP address in a web

browser.

To remotely set a control or run this task on a Low Profile instrument, see the instrument Programmer Manual (Tektronix part

number 077-1305-xx) for the correct command or commands to use.

1. Double-tap the Date/Time badge (bottom-right of screen) to open the configuration menu.

2. To turn off showing the date and time on the screen, tap the Display button to Off.

To turn on date/time display again, double-tap in the blank area where the date/time badge was displayed to open the

configuration menu, and set the Display button to On.

3. Select a time format (12 Hour or 24 Hour).

4. Tap the Time Zone field and select the time zone that applies to your location.

5. Tap anywhere outside of the menu to close it.

LPD64 Installation and Safety Manual 11

Page 24

Configure the instrument

Download and install the latest instrument firmware

Installing the latest firmware helps ensure that your instrument has the lastest features and is taking the most accurate

measurements.

To access the user interface on a Low Profile instrument, connect a monitor to a video port on the rear of the instrument, and

connect a mouse to any USB Host port. You do not need to connect a mouse if your remote monitor is touch-capable. You can

also remotely access the user interface of a network-connected instrument by entering the instrument's IP address in a web

browser.

Prerequisite: Save any important on-instrument files (waveforms, screen captures, setups, and so on) to a USB drive or network.

The installation process does not remove user-created files, but it is a good idea to back up important files before an update.

Prerequisite: Determine the current version of firmware installed on the instrument (see Help > About).

Update instrument firmware from a USB drive

1. To download the instrument firmware and install onto a USB drive:

a. Open up a Web browser on a PC and go to www.tek.com/product-support.

b. Enter the instrument model number in the search field and click Go.

c. Scroll down the screen and click the Software tab.

d. If the listed available firmware version (Windows or non-Windows) is newer than what is on your instrument, select and

download that file to your PC.

e. Follow the installation instructions that are on the web site or that came with the downloaded firmware to create the

firmware install file.

f. Copy the firmware install file to a USB flash drive.

2. To install firmware on standard instruments:

a. Power on the instrument and wait for the instrument to fully boot up.

b. Insert the USB flash drive into any instrument USB Host port.

c. The instrument detects the update firmware and opens a dialog box. Follow the on-screen instructions to install the

firmware.

NOTE. Do not power off the instrument or remove the USB flash drive until the instrument finishes installing the firmware.

The instrument displays a message when it is OK to power off. Remove the USB drive before powering on the instrument.

3. To install firmware on instruments with the Windows option:

a. Close the TekScope program before updating the firmware.

b. Insert the USB drive into any instrument USB Host port.

c. Open the Windows desktop File Explorer and navigate to and select the install file.

d. Run the firmware update file from the USB drive, or copy the firmware update file to the desktop and run the file from

there.

e. Follow any on-screen instructions to install the firmware.

12 LPD64 Installation and Safety Manual

Page 25

Configure the instrument

f. When the firmware install is finished, remove the USB drive and restart the instrument.

NOTE. Do not power off the instrument, or remove the USB flash drive if installing from the drive, until the instrument

finishes installing the firmware. The instrument displays a message when it is OK to power off.

4. To confirm that the firmware was updated:

a. Tap Help > About in the Menu bar.

b. Check that the firmware version number listed on the screen is the same version that you downloaded.

Run Signal Path Compensation (SPC)

Run SPC when you first receive an instrument, and at regular intervals, for best measurement accuracy. You should run SPC

whenever the ambient (room) temperature has changed by more than 5 °C (9 °F), or once a week if you use vertical scale

settings of 5 mV per division or less.

To access the user interface on a Low Profile instrument, connect a monitor to a video port on the rear of the instrument, and

connect a mouse to any USB Host port. You do not need to connect a mouse if your remote monitor is touch-capable. You can

also remotely access the user interface of a network-connected instrument by entering the instrument's IP address in a web

browser.

Signal Path Compensation (SPC) corrects for DC level inaccuracies in the internal signal path, caused by temperature variations

and/or long-term signal path drift. Failure to run SPC on a regular basis may result in the instrument not meeting warranted

performance levels at low volts per division settings.

1. Power on and warm up the instrument for at least 20 minutes.

2. Tap Utility > Calibration.

3. Tap Run SPC. The SPC Status readout shows Running while SPC is running. SPC can take several minutes per channel

to run, so wait until the SPC Status message changes to Pass before using the instrument.

CAUTION. You can abort the SPC calibration by tapping Abort SPC. This may leave some channels uncompensated,

resulting in possible inaccurate measurements. If you do abort the SPC, make sure to run the SPC procedure completely

before using the instrument to take measurements.

4. Close the Calibration configuration dialog when SPC has completed.

5. If the SPC fails, write down any error message text. Make sure that all probes and cables are disconnected (except for the

LPD64) and run the SPC again. If the SPC still fails, contact Tektronix Customer Support.

Connect to a network (LAN)

Connecting to a network allows you to remotely access the instrument.

To access the user interface on a Low Profile instrument, connect a monitor to a video port on the rear of the instrument, and

connect a mouse to any USB Host port. You do not need to connect a mouse if your remote monitor is touch-capable. You can

also remotely access the user interface of a network-connected instrument by entering the instrument's IP address in a web

browser.

Work with your network administrator to obtain the required information to connect to your network (IP address, Gateway IP

address, Subnet Mask, DNS IP address, and so on).

1. Connect a CAT5 cable from the instrument LAN connector to your network.

2. Select Utility > I/O on the menu bar to open the I/O configuration menu.

LPD64 Installation and Safety Manual 13

Page 26

Configure the instrument

3. Obtain or enter the network address information:

■

If your network is DHCP-enabled, and the IP address field does not already show and address, tap Auto to obtain the

IP address information from the network. DHCP mode is the default mode.

■

If your network is not DHCP-enabled, or you need a permanent (non-changing) IP address for this instrument, tap

Manual and enter the IP address and other values provided by your IT or system administrator resource.

4. Tap Test Connection to verify that the network connection is working. The LAN Status icon turns green when the

instrument successfully connects to your network. If you have problems connecting to your network, contact your system

administration resource for help.

The front panel LAN status LED colors display the network connection status:

■

Off - No power to the instrument

■

Green - Network connection is good

■

Red - Network connection has a fault or is not connected

Remote access from a Web browser (standard instrument)

You can remotely access your network-connected standard instrument (not running Windows) from a Web browser to display the

instrument user interface on a PC.

This procedure describes how to remotely access the UI controls and screen for standard (non Windows 10) instruments. To

remotely access the UI controls and screen for Windows 10 instruments, see the Remote access to a Windows 10 instrument

topic in the Help.

Prerequisites:

■

The instrument must be connected to, and accessible from, the network to which the PC is connected. See Connect to a

network (LAN) on page 13

■

The IP address of the instrument that you want to access. To determine the instrument's IP address, select Utility > IO in

the instrument menu bar and view the network settings in the LAN panel.

■

You are accessing a standard (instrument that does not have the Windows OS option installed).

1. Open a Web browser on a PC connected to the same network as the instrument.

2. Enter just the instrument IP address on the URL line of the browser and press Enter. For example: 135.62.88.157. The

browser searches for and opens the Web page for the instrument.

14 LPD64 Installation and Safety Manual

Page 27

Configure the instrument

3. Select Instrument Control (e*Scope®). The browser displays the instrument screen.

4. Use a mouse to select and interact with the instrument controls shown in the Web browser. If your remote PC or laptop has

a touch screen monitor, you can use the remote touchscreen monitor to access the instrument controls.

NOTE. When you access the instrument from an e*Scope browser, you cannot directly paste text (such as path, IP address

information, and so on) from the PC to an instrument menu field. You must use an intermediate clipboard function that is

available in the e*Scope application.

Use the following steps to copy text from an e*Scope-connected PC to the instrument:

a.

Open a connection to the instrument using e*Scope.

b.

Select and copy the text on your PC.

c.

In e*Scope, press Ctrl-Alt-Shift to open the Clipboard menu.

d.

Paste the text into the Clipboard field.

e.

Press Ctrl-Alt-Shift to close the browser Clipboard menu.

f.

Use e*Scope to open the instrument menu to which to paste content, and position the cursor in the field where you

want to paste the text.

g.

Press Ctrl-V (on real keyboard or from virtual keyboard) to paste the text from the e*Scope browser clipboard to the

menu field.

h.

Repeat steps 4.b through 4.g to copy and paste other text from the PC to the instrument.

LPD64 Installation and Safety Manual 15

Page 28

Configure the instrument

16 LPD64 Installation and Safety Manual

Page 29

Operating basics

Operating basics

Refer to the 6 Series MSO (MSO64) Installation and Safety Manual (Tektronix part number 071-3579-xx) for details on

understanding and using the graphical user interface to trigger on and acquire waveforms and take measurements.

Refer to the 4/5/6 Series MSO (MSO44, MSO46, MSO54, MSO56, MSO58, MSO58LP, MSO64, LPD64 ) Programmer Manual

(Tektronix part number 077-1305-xx) for the correct command or commands to use to remotely operate the instrument.

Both manuals are available to download from www.tek.com/product-support.

LPD64 Installation and Safety Manual 17

Page 30

Operating basics

18 LPD64 Installation and Safety Manual

Page 31

Maintenance

Maintenance

This section contains information needed to perform periodic maintenance on the instrument.

CAUTION. Do not remove the top cover from the instrument except to replace a damaged cover. There are no user replaceable

parts inside the instrument. Return the instrument to Tektronix if it requires service.

Cleaning

Use a dry, soft cotton cloth to clean the outside of the unit. If any dirt remains, use a cloth or swab dipped in a 75% isopropyl

alcohol solution. Use a swab to clean narrow spaces around controls and connectors. Do not use any liquid cleaning agents or

chemicals that could damage the case, controls, markings or labels, or possibly infiltrate the case.

Performance verification interval and adjustment

The voltage and timing references inside the instrument are very stable over time and do not need routine adjustment.

If periodic calibration is one of your organization's requirements, a general rule is to verify performance every 2000 hours of

operation or once a year if the instrument is used infrequently. Use the procedures in the instrument Specifications and

Performance Verification manual, available online at www.www.tek.com/product-support.

If the instrument fails the performance tests in the Specifications and Performance Verification manual, adjustment may be

required. Adjustment can only be performed by a Tektronix Service Center. See Contacting Tektronix, following the title page in

this manual, for information on contacting Tektronix Service Support.

Replaceable parts list

This section contains replaceable parts information for your instrument. Use the lists in the appropriate section to identify and

order replacement parts for your product.

Standard accessories

Standard accessories for these products are listed near the beginning of this manual.

LPD64 Installation and Safety Manual 19

Page 32

Maintenance

Replaceable parts

The following figure shows the user-replaceable parts for the instrument. There are no user-replaceable parts inside the

instrument.

Figure 4: LPD64 replaceable parts diagram

20 LPD64 Installation and Safety Manual

Page 33

Maintenance

Table 1: Replaceable parts list

Index

number

1 407-6088-xx 2 BRACKET, FRONT, RACK MOUNT, 2U EAR

2 211-1682-xx 14 SCREW, 10-32 X 5/16 BUTTON HEAD, CAP, BLACK

3 407-6089-xx 2 BRACKET, REAR, RACK MOUNT, CHASSIS-SIDE

4 407-6090-xx 2 BRACKET, REAR, RACK MOUNT, RACK-SIDE

5 020-3180-xx 1 BENCH CONVERSION KIT (optional accessory)

Not shown:

Tektronix part number Qty Name & description

A0 1 North America power plug (115 V, 60 Hz)

A1 1 Universal Euro power plug (220 V, 50 Hz)

A2 1 United Kingdom power plug (240 V, 50 Hz)

A3 1 Australia power plug (240 V, 50 Hz)

A5 1 Switzerland power plug (220 V, 50 Hz)

A6 1 Japan power plug (100 V, 50/60 Hz)

A10 1 China power plug (50 Hz)

A11 1 India power plug (50 Hz)

A12 1 Brazil power plug (60 Hz)

LPD64 Installation and Safety Manual 21

Page 34

Maintenance

22 LPD64 Installation and Safety Manual

Page 35

EMC Safety and environmental compliance

Compliance Information

This section lists the EMC (electromagnetic compliance), safety, and environmental standards with which the instrument

complies. This product is intended for use by professionals and trained personnel only; it is not designed for use in households or

by children.

Questions about the following compliance information may be directed to the following address:

Tektronix, Inc.

PO Box 500, MS 19-045

Beaverton, OR 97077, USA

www.tek.com

EMC compliance

EU EMC Directive

Meets intent of Directive 2014/30/EU for Electromagnetic Compatibility. Compliance was demonstrated to the following

specifications as listed in the Official Journal of the European Communities:

EN 61326-1, EN 61326-2-1. EMC requirements for electrical equipment for measurement, control, and laboratory use.

1 2 3

4

■

CISPR 11. Radiated and conducted emissions, Group 1, Class A

■

IEC 61000-4-2. Electrostatic discharge immunity

■

IEC 61000-4-3. RF electromagnetic field immunity

■

IEC 61000-4-4. Electrical fast transient / burst immunity

■

IEC 61000-4-5. Power line surge immunity

■

IEC 61000-4-6. Conducted RF immunity

■

IEC 61000-4-11. Voltage dips and interruptions immunity

EN 61000-3-2. AC power line harmonic emissions

EN 61000-3-3. Voltage changes, fluctuations, and flicker

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test object.

3

Equipment may not meet the immunity requirements of applicable listed standards when test leads and/or test probes are connected due to coupling of electromagnetic

interference onto those leads/probes. To minimize the influence of electromagnetic interference, minimize the loop area between the unshielded portions of signal and

associated return leads, and keep leads as far away as possible from electromagnetic disturbance sources. Twisting unshielded test leads together is an effective way to

reduce loop area. For probes, keep the ground return lead as short as possible and close to the probe body. Some probes have accessory probe tip adapters to

accomplish this most effectively. In all cases, observe all safety instructions for the probes or leads used.

4

For compliance with the EMC standards listed here, high quality shielded interface cables that incorporate low impedance connection between the cable shield and the

connector shell should be used.

LPD64 Installation and Safety Manual 23

Page 36

EMC Safety and environmental compliance

EMC Compliance

Meets the intent of Directive 2014/30/EU for Electromagnetic Compatibility when it is used with the product(s) stated in the

specifications table. Refer to the EMC specification published for the stated products. May not meet the intent of the directive if

used with other products.

Australia / New Zealand Declaration of Conformity – EMC

Complies with the EMC provision of the Radiocommunications Act per the following standard, in accordance with ACMA:

■

EN 61326-1 and EN 61326-2-1. Radiated and conducted emissions, Group 1, Class A.

Safety compliance

This section lists the safety standards with which the product complies and other safety compliance information.

EU low voltage directive

Compliance was demonstrated to the following specification as listed in the Official Journal of the European Union:

Low Voltage Directive 2014/35/EU.

■

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

■

EN 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

2-030: Particular requirements for testing and measuring circuits.

U.S. nationally recognized testing laboratory listing

■

UL 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

■

UL 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

2-030: Particular requirements for testing and measuring circuits.

Canadian certification

■

CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use

– Part 1: General Requirements.

■

CAN/CSA-C22.2 No. 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory

Use – Part 2-030: Particular requirements for testing and measuring circuits.

Additional compliances

■

IEC 61010-1. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part 1:

General Requirements.

■

IEC 61010-2-030. Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use – Part

2-030: Particular requirements for testing and measuring circuits.

Equipment type

Test and measuring equipment.

24 LPD64 Installation and Safety Manual

Page 37

EMC Safety and environmental compliance

Safety class

Class I -- grounded product.

Pollution degree description

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal

environment inside a product is considered to be the same as the external. Products should be used only in the environment for

which they are rated.

■

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally

encapsulated, hermetically sealed, or located in clean rooms.

■

Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is caused

by condensation must be expected. This location is a typical office/home environment. Temporary condensation occurs only

when the product is out of service.

■

Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation.

These are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct

sunshine, rain, or direct wind.

■

Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical outdoor

locations.

Pollution degree rating

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor, dry location use only.

IP rating

IP20 (as defined in IEC 60529).

Measurement and overvoltage category descriptions

Measurement terminals on this product may be rated for measuring mains voltages from one or more of the following categories

(see specific ratings marked on the product and in the manual).

■

Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

■

Measurement Category III. For measurements performed in the building installation.

■

Measurement Category IV. For measurements performed at the source of low-voltage installation.

NOTE. Only mains power supply circuits have an overvoltage category rating. Only measurement circuits have a measurement

category rating. Other circuits within the product do not have either rating.

Mains overvoltage category rating

Overvoltage Category II (as defined in IEC 61010-1)

Environmental compliance

This section provides information about the environmental impact of the product.

LPD64 Installation and Safety Manual 25

Page 38

EMC Safety and environmental compliance

Restriction of hazardous substances

Complies with RoHS2 Directive 2011/65/EU.

Product end-of-life handling

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Production of this equipment required the extraction and use of natural resources. The equipment may

contain substances that could be harmful to the environment or human health if improperly handled at the product’s end of life.

To avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

This symbol indicates that this product complies with the applicable European Union requirements according to

Directives 2012/19/EU and 2006/66/EC on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, check the Tektronix Web site (www.tek.com/productrecycling).

Battery recycling

This product contains a small installed lithium metal button cell. Please properly dispose of or recycle the cell at its end of life

according to local government regulations.

Perchlorate materials. This product contains one or more type CR lithium batteries. According to the state of California, CR

lithium batteries are classified as perchlorate materials and require special handling. See

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

Transporting batteries

The small lithium primary button cell contained in this equipment does not exceed 1 gram of lithium metal content per cell, and

the cell type has been shown by the manufacturer to comply with the applicable requirements of the UN Manual of Tests and

Criteria Part III, Sub-section 38.3. Consult your carrier to determine which lithium battery transportation requirements are

applicable to your configuration, including to its re-packaging and re-labeling, prior to reshipment of the product by any mode of

transport

26 LPD64 Installation and Safety Manual

Page 39

Index

A

ACQ acquisition status LED, 7

AFG Out (rear panel), 8

AUX Out (rear panel), 8

Aux Trig trigger input, 7

C

cable lock, 8

clock format (12/24 hr), how to set, 11

connect lock cable, 4

connect to a network, 13

connecting probes, 5

L

LAN port (rear panel), 8

LAN status LEDs, 7

LAN, connect to, 13

lock to bench or rack, 4

M

Maintenance

replaceable parts, 19

N

E

e*Scope, 14

Environment requirements, 1, 2

Ethernet port (rear panel), 8

Ethernet, connect to, 13

F

firmware, how to update, 12

FlexChannel inputs, 7

front panel controls, 7

H

how to

check power-on self tests results, 5

connect probes, 5

connect to network, 13

download, install firmware, 12

remote access the instrument (from Web), 14

run signal path compensation (SPC), 13

set clock format (12/24 hr), 11

set time zone, 11

update firmware, 12

I

input signal level requirements, 2

network, connect to, 13

O

operating

altitude range, 1, 2

humidity range, 1, 2

temperature range, 1, 2

operating power requirements, 1, 2

P

power cord connector (rear panel), 8

power cords, 19

power requirements, 1, 2

power standby mode, 4

power-on test results, 5

powering on or off, 4

probes, connecting, 5

R

rear panel

AFG Out, 8

AUX Out, 8

cable lock, 8

Ethernet port (RJ-45), 8

LAN port (RJ-45), 8

LPD64 Installation and Safety Manual 27

Page 40

Index

power cord, 8

security cable lock, 8

USB Device port, 8

USB Host ports, 8

video output, 8

rear panel connections, 8

Ref In, 8

Ref In (rear panel), 8

remote access (e*Scope), 14

remote access (Web-based), 14

remove AC power from instrument, 4

Replaceable parts, 19

requirements

altitude, 1, 2

environment, 1, 2

humidity, 1, 2

power, 1, 2

signal inputs, 2

temperature, 1, 2

run signal path compensation, 13

set

clock format (12/24 hr), 11

time zone, 11

signal input levels, 2

SPC (signal path compensation), 13

standard accessories, 1

T

time zone, how to set, 11

turn instrument on or off, 4

U

USB Device port (rear panel), 8

USB Host ports (rear panel), 8

V

video output (rear panel), 8

S

security cable lock, 8

28 LPD64 Installation and Safety Manual

Page 41

LPD64

Numériseur profil bas Série 6

Manuel d’installation et de sécurité

*P071365900*

071365900

Page 42

Page 43

LPD64

Numériseur profil bas Série 6

Manuel d’installation et de sécurité

Prise en charge du firmware produit V1.20.x et ultérieures

www.tek.com

071365900

Page 44

Copyright © Tektronix. Tous droits réservés. Les produits logiciels sous licence sont la propriété de Tektronix, de ses filiales ou de ses

fournisseurs et sont protégés par les lois nationales sur le copyright, ainsi que par des traités internationaux. Les produits Tektronix sont

protégés par des brevets américains et étrangers déjà déposés ou en cours d'obtention. Les informations contenues dans le présent

document remplacent celles publiées précédemment. Les spécifications et les prix peuvent être soumis à modification.

TEKTRONIX et TEK sont des marques déposées de Tektronix, Inc.

Prendre contact avec Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

États-Unis

Pour obtenir des informations sur le produit, la vente, le service après-vente et l’assistance technique :

•

En Amérique du Nord, appelez le 1-800-833-9200.

•

Pour les autres pays, visitez le site www.tek.com pour connaître les coordonnées locales.

Page 45

Sommaire

Informations importantes relatives à la sécurité .................................................................................................. iii

Consignes générales de sécurité .................................................................................................................. iii

Consignes générales de maintenance .......................................................................................................... vi

Termes utilisés dans le manuel ..................................................................................................................... vi

Mentions figurant sur le produit ..................................................................................................................... vi

Symboles figurant sur le produit ................................................................................................................... vii

Préface ................................................................................................................................................................ ix

Principales fonctionnalités ............................................................................................................................. ix

Documentation connexe

Chapitre 1: Installation de l’instrument

Vérification des accessoires reçus ................................................................................................................. 1

Conditions de fonctionnement requises ......................................................................................................... 1

Conditions requises pour le signal d’entrée ................................................................................................... 2

Installation de l’instrument dans une baie ...................................................................................................... 2

Verrouillage de l’instrument ............................................................................................................................ 4

Mise sous tension de l’instrument .................................................................................................................. 4

Vérifiez que l’instrument réussit les auto-tests à la mise sous tension. ......................................................... 5

Connexion de signaux sur l’instrument .......................................................................................................... 5

................................................................................................................................. x

Chapitre 2: Présentation de l’instrument

Commandes et connecteurs de la face avant, LPD64 ................................................................................... 7

Connecteurs du panneau arrière ................................................................................................................... 8

Accès au disque m.2 ...................................................................................................................................... 9

Interface utilisateur graphique ...................................................................................................................... 10

Chapitre 3: Configuration de l’instrument

Réglage du fuseau horaire et du format d’horloge ....................................................................................... 11

Téléchargement et installation de la version la plus récente du firmware de l’instrument ........................... 12

Compensation du chemin du signal (SPC) .................................................................................................. 13

Connexion à un réseau local (LAN) ............................................................................................................. 14

Accès à distance depuis un navigateur Web (instrument standard) ............................................................ 14

Chapitre 4: Principes de fonctionnement

Principes de fonctionnement ....................................................................................................................... 17

Manuel d’installation et de sécurité du numériseur LPD64 i

Page 46

Sommaire

Chapitre 5: Maintenance

Maintenance

Nettoyage ..................................................................................................................................................... 19

Réglage et fréquence de vérification des performances .............................................................................. 19

Liste des pièces de rechange ...................................................................................................................... 20

................................................................................................................................................. 19

Chapitre 6: Conformité environnementale et sécurité CEM

Informations relatives à la conformité .......................................................................................................... 23

Conformité CEM ..................................................................................................................................... 23

Conformité en matière de sécurité ......................................................................................................... 24

Conformité environnementale ................................................................................................................ 26

ii Manuel d’installation et de sécurité du numériseur LPD64

Page 47

Informations importantes relatives à la sécurité

Ce manuel contient des informations et des avertissements que l'utilisateur doit impérativement respecter pour sa sécurité et

maintenir le produit en bon état.

Pour entretenir ce produit en toute sécurité, consultez les Consignes générales de maintenance qui suivent les Consignes

générales de sécurité.

Consignes générales de sécurité

Utilisez le produit uniquement dans les conditions spécifiées. Veuillez lire attentivement les précautions et consignes de sécurité

suivantes afin d'éviter toute blessure et toute détérioration matérielle de l'appareil et des produits qui lui sont connectés. Lisez

attentivement toutes les instructions. Conservez-les pour vous y reporter ultérieurement.

Ce produit doit être utilisé conformément aux codes locaux et nationaux.

Pour utiliser correctement et en toute sécurité ce produit, il est essentiel de respecter les procédures générales de sécurité en

vigueur en plus des consignes indiquées dans ce manuel.

Seul du personnel qualifié peut utiliser ce produit.

Seul du personnel qualifié connaissant les risques encourus peut enlever le capot pour effectuer des réparations, des opérations

de maintenance ou des réglages.

Avant d'utiliser l'appareil, contrôlez-le toujours avec une alimentation connue pour vérifier qu'il fonctionne correctement.

Ce produit n'est pas conçu pour détecter des tensions dangereuses.

Utilisez un équipement de protection personnel afin de vous protéger contre les risques d'électrocution et d'arc électrique

associés à l'exposition à des conducteurs sous tension.

En utilisant ce produit, vous pouvez avoir besoin d’accéder à d’autres composants d'un système plus important. Lisez les

consignes de sécurité des autres composants du système pour connaître les avertissements et les précautions d'utilisation du

système.

Si cet appareil est intégré dans un système, l'assembleur est responsable de la sécurité de ce système.

Pour éviter un incendie ou des blessures

Utilisez un cordon d'alimentation adapté. Utilisez uniquement le cordon d'alimentation prévu pour cet appareil et conforme

aux normes du pays d'utilisation. N'utilisez pas le cordon d'alimentation d'un autre appareil.

Raccordez l'appareil à la terre. Ce produit est raccordé à la terre par le fil de masse du cordon d'alimentation. Pour éviter tout

risque d'électrocution, ce fil de masse doit être connecté à une prise de terre. Avant de procéder aux branchements des bornes

d'entrée et de sortie du produit, veillez à ce que celui-ci soit correctement mis à la terre. Ne débranchez pas le raccordement à la

terre.

Déconnexion de l'alimentation. Le cordon d'alimentation permet de déconnecter le produit de l'alimentation électrique.

Consultez les instructions pour connaître son emplacement. Ne placez pas l'appareil d’une façon qui rend l'accès au cordon

d'alimentation difficile ; il doit rester accessible à l'utilisateur à tout moment afin de pouvoir le débrancher rapidement si besoin.

Branchez et débranchez correctement l'appareil.. Ne connectez ou ne déconnectez pas les sondes ou les conducteurs de

test lorsqu'ils sont connectés à une source de tension.Utilisez uniquement les sondes de tension isolées, les fils de test et les

adaptateurs fournis avec le produit ou recommandés par Tektronix et adaptés au produit.

Manuel d’installation et de sécurité du numériseur LPD64 iii

Page 48

Informations importantes relatives à la sécurité

Respectez toutes les caractéristiques nominales des bornes.. Pour éviter tout risque d'incendie ou d'électrocution, respectez

toutes les caractéristiques nominales et les marquages du produit. Avant de brancher le produit, consultez le manuel fourni pour

obtenir les caractéristiques nominales. Respectez la catégorie de mesure (CAT) ou la tension et le courant maximales autorisées

pour le composant affichant les caractéristiques les plus faibles d'un produit, d'une sonde ou d'un accessoire. Soyez prudent

lorsque vous utilisez des fils de test 1:1 : en effet, la tension à la pointe de la sonde est transmise directement au produit.

N'appliquez à une borne (y compris la borne commune) aucun potentiel supérieur à la caractéristique maximale de cette borne.

Ne laissez pas la borne commune flottante à une tension supérieure à la tension nominale de cette borne.

Les bornes de mesure de ce produit ne sont pas conçues pour être branchées sur l'alimentation secteur ou sur les circuits de

catégorie II, III et IV.

Ne mettez pas l'appareil en service sans ses capots.. Ne mettez pas l'appareil en service si ses capots sont retirés ou si le

boîtier est ouvert. Vous pouvez être exposé à une tension dangereuse.

Évitez tout circuit exposé.. Ne touchez à aucun branchement ou composant exposé lorsque l’appareil est sous tension.

N'utilisez pas l'appareil si vous suspectez une panne.. En cas de doute sur le bon état de cet appareil, faites-le contrôler par

un technicien qualifié.

Mettez l'appareil hors service s'il est endommagé. N'utilisez pas le produit s'il est endommagé ou s'il ne fonctionne pas

correctement. En cas de doute à propos de la sécurité du produit, éteignez-le et débranchez le cordon d'alimentation. Indiquez

clairement qu'il ne doit pas être utilisé.

Avant toute utilisation, vérifiez que les sondes de tension, les cordons de test et les accessoires ne sont pas mécaniquement

endommagés. Remplacez-les le cas échéant. N'utilisez pas de sondes ou de cordons de test endommagés, si du métal nu est

exposé ou s'il présente des signes d'usure.

Examinez l'extérieur du produit avant de l'utiliser. Recherchez des fissures ou des pièces manquantes.

Utilisez uniquement les pièces de rechange spécifiées.

N'utilisez pas l'appareil dans un environnement humide.. De la condensation peut se former si un appareil est déplacé d'un

environnement froid vers un environnement chaud.

N'utilisez pas l'appareil dans un environnement explosif..

Maintenez les surfaces de l'appareil propres et sèches.. Retirez les signaux d'entrée avant de nettoyer le produit.

Assurez une ventilation adéquate.. reportez-vous aux instructions d'installation du manuel pour installer le produit en

garantissant la ventilation correcte.

Pour la ventilation, l'appareil comporte des ouïes et des ouvertures qui ne doivent jamais être bouchées ou obstruées.

N'enfoncez pas d'objets dans les ouvertures.