Page 1

Instruction Manual

LPB 1300 & LPB 1550

Tunable Laser Sources

071-0587-00

Page 2

Copyright © T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that the products that it manufactures and sells will be free from defects in materials and workmanship

for a period of one (1) year from the date of shipment. If a product proves defective during this warranty period, T ektronix,

at its option, either will repair the defective product without charge for parts and labor, or will provide a replacement in

exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REP AIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

User Information

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Programs vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Accessories 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First Time Operation 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Numerical Values 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Power Control 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Functions 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Inputs and Outputs 1–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Control 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS-232-C Remote Control 1–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IEEE-488.1 Remote Control 1–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Errors 1–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Information

Performance Verification 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Absolute W avelength Accuracy 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wavelength Range and Output Power 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Caring for Optical Connectors and Fibers 2–17. . . . . . . . . . . . . . . . . . .

Calibration 2–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Line Fuse 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning the Exterior 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packaging for Shipment 2–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPB 1300 and LPB 1550 Tunable Laser Sources

i

Page 6

Table of Contents

Appendices

Index

Appendix A: Parameters A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Error Messages B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: RS-232-C Control Commands C–1. . . . . . . . . . . . . . . . . . . . .

Space Characters C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message T ermination C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D: IEEE-488.1 Control Command Summary D–1. . . . . . . . . . .

ii

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 7

List of Figures

Table of Contents

Figure 1–1: Front panel 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Rear panel 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: Auxiliary connectors 1–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Remote interlock connector 1–19. . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Accessing the line fuse 2–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Replaceable parts 2–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–3: Standard accessories 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Optional power cords 2–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LPB 1300 and LPB 1550 Tunable Laser Sources

iii

Page 8

Table of Contents

List of Tables

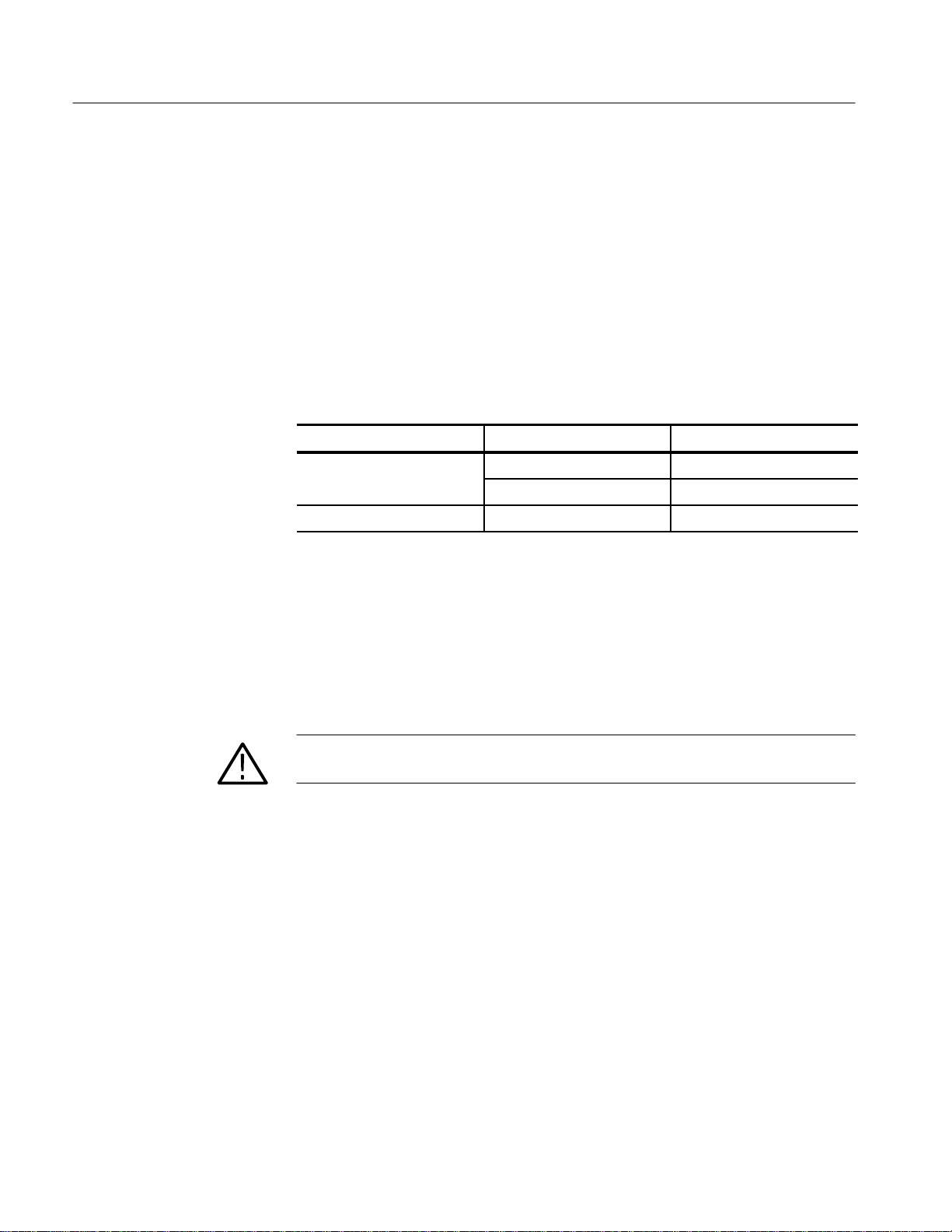

Table 1–1: Description of Display, Mode, and Setup keys 1–8. . . . . . . . .

Table 1–2: Voltage scaling of monitor outputs 1–18. . . . . . . . . . . . . . . . . . .

Table 1–3: Range of frequencies for modulating the optical power 1–20.

Table 1–4: Example of dialog between the controller and the

tunable laser (RS-232-C) 1–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Examples of message formats with numerics (RS-232-C) 1–24

Table 1–6: Command parameters (RS-232-C) 1–24. . . . . . . . . . . . . . . . . .

Table 1–7: Command responses (RS-232-C) 1–25. . . . . . . . . . . . . . . . . . . .

Table 1–8: Operating mode commands (RS-232-C) 1–25. . . . . . . . . . . . . .

Table 1–9: System parameters (RS-232-C) 1–26. . . . . . . . . . . . . . . . . . . . .

Table 1–10: Other system commands (RS-232-C) 1–27. . . . . . . . . . . . . . . .

Table 1–11: Definition of operating commands (GPIB) 1–28. . . . . . . . . . .

Table 1–12: Command parameters (GPIB) 1–29. . . . . . . . . . . . . . . . . . . . .

Table 1–13: Queries (GPIB) 1–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–14: Operating mode commands (GPIB) 1–30. . . . . . . . . . . . . . . .

Table 1–15: Bits in status word (GPIB) 1–32. . . . . . . . . . . . . . . . . . . . . . . .

Table 1–16: Specifications 1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–17: Laser class specifications 1–38. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–18: Certifications and compliances 1–39. . . . . . . . . . . . . . . . . . . . .

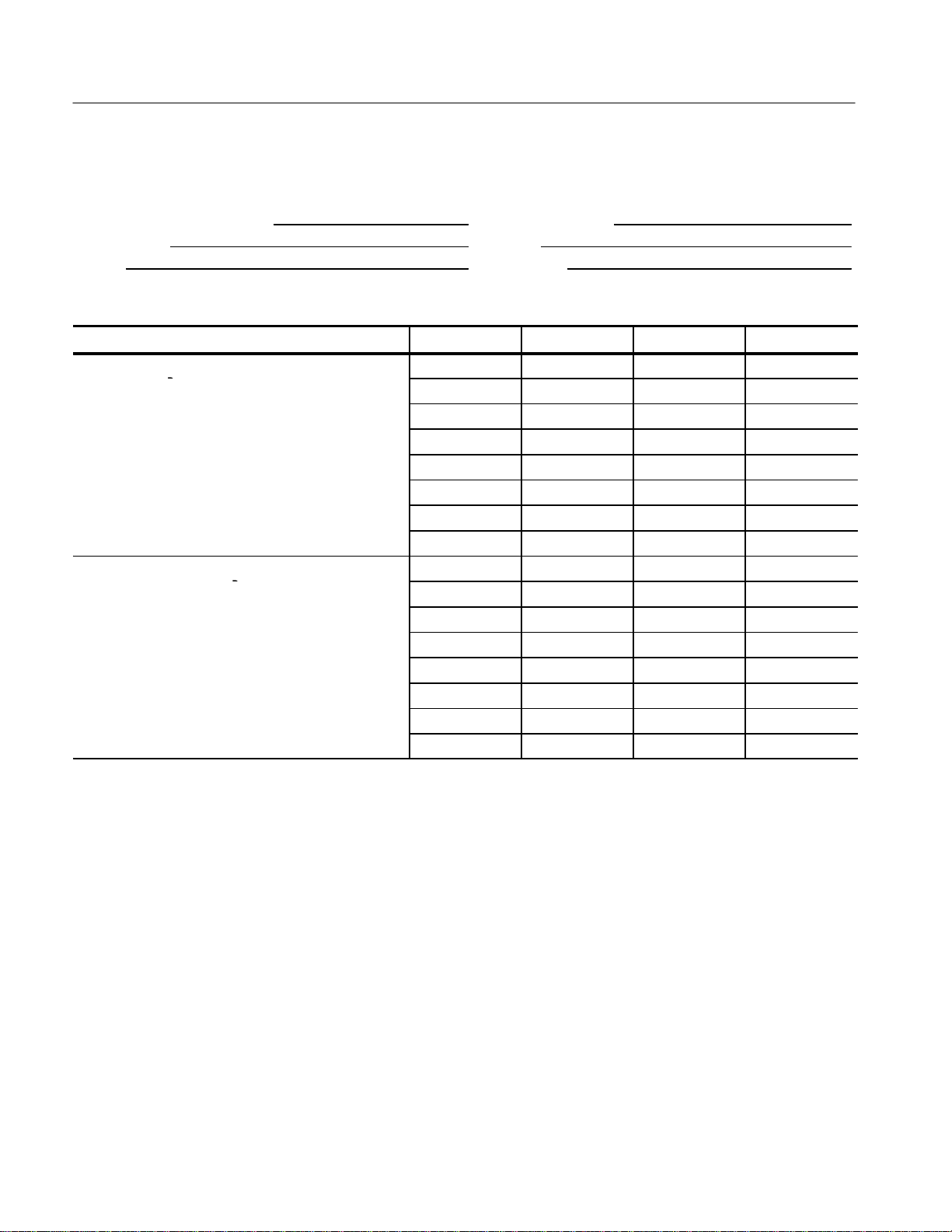

Table 2–1: Test equipment 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Wavelength range 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A–1: Valid range of parameter settings A–1. . . . . . . . . . . . . . . . . . .

Table B–1: Error Messages B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C–1: Summary of RS-232-C control commands C–1. . . . . . . . . . . .

Table D–1: Summary of IEEE-488.1 control commands D–1. . . . . . . . . .

Table D–2: Status word D–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Use Proper Fuse. Use only the fuse type and rating specified for this product.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Wear Eye Protection. Wear eye protection if exposure to high-intensity rays or

laser radiation exists.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry .

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

LPB 1300 and LPB 1550 Tunable Laser Sources

v

Page 10

General Safety Summary

Symbols and Terms

T erms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

T erms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

Laser Class 3A and Class IIIb

WARNING

WARNING

High Voltage

Protective Ground

(Earth) Terminal

Laser Source

WARNING

Laser Class 3A and Class IIIb

vi

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 11

Preface

Contacting Tektronix

This manual provides the user information necessary to operate, program, and

verify the performance of the LPB 1300 and LPB 1550 Tunable Laser Sources.

The manual also contains maintenance procedures that the user can perform from

outside the instrument and information about user serviceable parts.

Components inside the instrument are not user serviceable. Refer all servicing of

internal components to service personnel authorized by Tektronix.

Service Programs

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or contact us by e-mail:

tm_app_supp@tektronix.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or visit

our web site for a listing of worldwide service locations.

www.tektronix.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

Tektronix offers extended warranty and calibration coverage programs that you

can purchase as options with the product. These programs are cost-effective ways

to maintain genuine Tektronix service for your instrument. Ask your Tektronix

distributor or sales office for details.

LPB 1300 and LPB 1550 Tunable Laser Sources

vii

Page 12

Preface

viii

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 13

User Information

Page 14

Page 15

Getting Started

The LPB 1300 and LPB 1550 Tunable Laser Sources are compact, bench-top

instruments for the development and test of fiber-optic systems and components.

The flexible, general-purpose design is suitable for a wide range of applications.

The optical layout uses a modified Littman-Metcalf configuration. The doublepass reflection on the grating provides maximum dispersion while the very short

cavity maximizes mode-spacing. This design avoids mode competition and

guarantees spectrally pure, single-mode operation. The high-performance optical

isolator and the angle-polished fiber on the output work to protect the laser

cavity from interference and ensure optimum power and spectral purity. A

dihedral reflector in the rear of the laser cavity acts as a two-dimensional corner

cube to keep the resonator in tune.

The LPB 1300 and LPB 1550 Tunable Laser Sources offer the following

benefits:

H Precise wavelength tuning. Provides a 1 pm resolution.

H Digitally-controlled analog fine tuning. Extends resolution beyond the 1 pm

steps into the MHz domain.

H Mode hop-free operation. Ensures smooth and accurate wavelength sweep

for reliable testing of narrow band components (mode hop spacing > 70 nm

on the LPB 1550 laser and > 40 nm on the LPB 1300 laser).

H High output power. Delivers the rated output power over the entire wave-

length range: 0 dBm (standard), 6 dBm (Option P6), or 10 dBm (Option PX,

LPB 1550 only).

H Outstanding long-term stability. Keeps the resonator in tune with a self-

aligning optical layout, reliable design, and thermally stable construction.

Prevents small changes caused by shock, vibration, temperature, or

mechanical drift from affecting operation.

H Intuitive, user-friendly controls. Simplifies operation with easy-to-use

keypad or multi-speed rotary control.

H Modulation possibilities. Analog and digital modulation of the optical power

from DC to 1 GHz with mode-locked operation at 5 GHz. The 150 kHz

linewidth can go to 100 MHz when high coherence is a problem.

H Remote operation and easy system integration. Provides IEEE-488.1 and

RS-232-C computer interfaces, modulation inputs, and monitor outputs.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–1

Page 16

Getting Started

Unpacking

Handle the instrument carefully when unpacking. Keep the instrument in a lateral

position at all times.

CAUTION. This instrument contains delicate optical components. To avoid

misalignment of the optical components, use both handles on the sides of the

instrument and keep the instrument in a lateral position during unpacking and

handling.

Do not set the instrument on the rear bumpers. These bumpers are only for

purposes of protecting the rear panel from contact with adjacent surfaces and

should not be used as feet when transporting or storing the instrument.

After unpacking, set the instrument on a stable surface that is free of excessive

vibration.

Standard Accessories

The following accessories are standard with the LPB 1300 and LPB 1550

Tunable Laser Sources:

H Certificate of traceable calibration

H Calibration data (Option D1 test report)

H FC/PC-to-FC/APC adapter cable

H Safety lock key

H Instruction manual

H Power Cord

For a list of replaceable part numbers, see the Replaceable Parts section that

begins on page 2–21.

1–2

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 17

Options

Getting Started

The following options are available at the time of purchase:

H Option A1, A2, or A3 Power Cord, see Figure 2–4 on page 2–22

H Option C3 Three years calibration service

H Option D3 Three years calibration data

H Option 1L Labview driver

H Option P6 6 dBm output power (LPB 1550 only)

H Option R3 Three years extended warranty

H Option PX 10 dBm output power (LPB 1550 only)

H Option 1M Polarization maintaining fiber and adapter cable (blue)

H Option 1W Modified wavelength range

H Option 2W Modified wavelength range (LPB 1550 only)

H Option 3W Modified wavelength range (LPB 1550 only)

NOTE. The range of each wavelength (W) option varies according to the model

and power (P) option. See the Specifications section on page 1–37 for details.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–3

Page 18

Getting Started

Installation

First Time Operation

Install the LPB 1300 and LPB 1550 Tunable Laser Sources as follows:

1. Use the proper power cord for your location.

2. Keeping the instrument in a lateral position, transport the instrument using

the handles on both sides.

3. Place the instrument on a stable surface that is free of excessive vibration.

4. Make sure the keyed switch on the front panel is in the standby mode before

applying power.

5. Allow air for the cooling fan to flow freely around the instrument; move any

equipment or papers that could impede air flow.

Cleaning the Optical

Connections

Connecting the Laser

Output

WARNING. To avoid eye damage, do not look into the laser output or into the end

of an optical cable. Even though the laser radiation is not visible, the intense

infrared light can still cause eye damage.

Always disable laser output while connecting and disconnecting the optical fiber.

For the best performance, optical connections must be clean and free of

contamination. Cleaning instructions for optical connections are on page 2–17.

To connect the laser output, remove the protective cap and use a fiber with a

FC/APC type connector.

CAUTION. To avoid damage to the laser output, always use a FC/APC type

connector. To connect other styles, use the FC/PC to FC/APC jumper.

To help protect the laser output, leave a jumper cable in place when making

connections to other devices. When the laser output is not connected, the

protective cover should be over the laser output.

1–4

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 19

Getting Started

Initializing the Laser

For safe operation, use the following procedure to initialize the laser:

1. Make sure the key on the front panel is in the Standby position.

2. Connect line cord to the socket on the rear panel and then to the proper

mains supply.

3. Set the rear panel MAINS switch to on ( I ). See Figure 1–2 on page 1–12.

4. Turn the front panel POWER key to the right (ON). During the initialization

phase, the message “Initializing....” displays. This message clears once the

laser is initialized and ready for operation.

At the end of the initialization, the message “Disabled...” appears on the display

signifying that the laser output is ready to enable.

CAUTION. Avoid switching the laser off before the laser is fully initialized.

After initialization, the cavity tunes to a wavelength near the center of the

wavelength range.

The optical power setting initializes to zero when the laser is enabled.

Enabling the Output

Shutting Down the Laser

For safety reasons, the laser provides an Enable button to enable or disable the

output.

H To enable the laser output, press the Enable button. The Enable key lights.

H To disable the laser output, press the Enable button and check that the Enable

light is out.

To shut down the laser, turn the front panel key left to the standby position. The

message “Parking...” displays and the optical head automatically moves to the

parking position. After a few seconds, the laser shuts down by itself.

CAUTION. Avoid switching the power to standby before the laser is fully

initialized. After turning the power to standby, wait at least thirty seconds before

initializing the laser again.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–5

Page 20

Getting Started

1–6

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 21

Operating Basics

Front Panel

This section provides an overview of the controls, connectors, and functions of

the LPB 1300 and LPB 1550 Tunable Laser Sources.

Figure 1–1 shows the front panel features.

l,f

Figure 1–1: Front panel

Power

The front panel is divided into five areas:

H Power

H Data

H Mode

H Setup

H Optical Output

After switching on the mains switch (rear panel), the power switch initializes the

laser head in the ON position or parks the laser head in the STBY (standby)

position. When the message “Disabled...” appears, the laser is ready to enable by

using the ENABLE key located in the data area.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–7

Page 22

Operating Basics

CAUTION. Avoid switching the power to standby before the tunable laser is fully

initialized. After turning the power to standby, wait at least thirty seconds before

initializing the laser again.

Data, Mode, and Setup

The Data area displays wavelength or frequency (l, f) and the output power

(mW/dBm) as selected by the data keys. The instrument also uses this area to

display messages.

Mode keys select instrument functions and work with keys in the Setup area to

enter numerical values, access advanced functions, and set scan steps.

Table 1–1 lists the display and mode keys along with a description of the

function they perform. For more instructions, see the section Entering Numerical

Values on page 1–10.

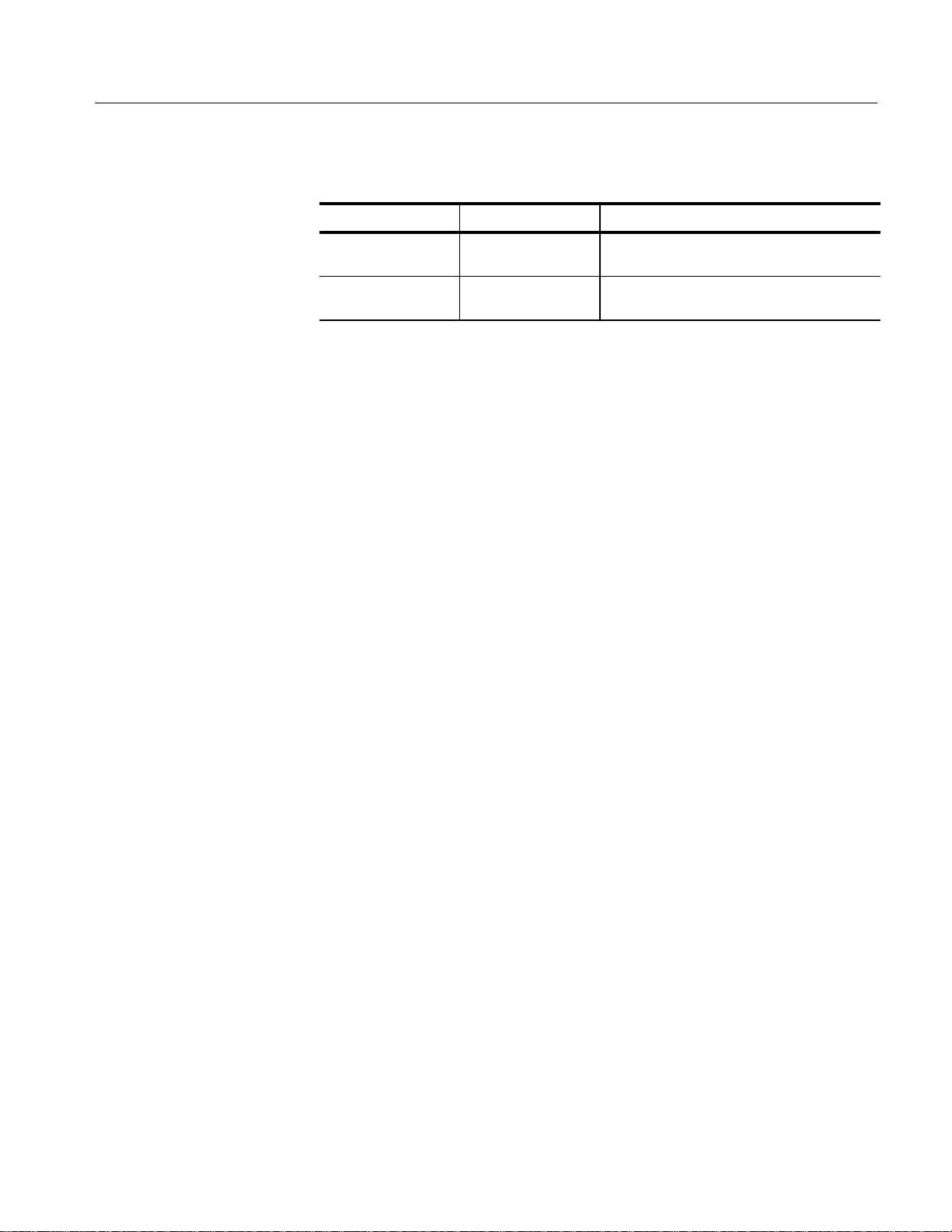

T able 1–1: Description of Display, Mode, and Setup keys

Name Description

nm/GHz Displays the wavelength in nm or the optical frequency in GHz.

mW/dBm Displays the power in dBm or mW.

l,f Enables entry of a new value for the wavelength.

P Enables entry of a new value for the power output and switches to the

constant power mode.

I Enables entry of a new value for the diode current and switches to the

constant current mode.

1–8

ENABLE Enables/Disables the optical output. When disabled, the message

“Disabled...” is displayed. When enabled, the Enable light is on.

REMOTE Enables front panel (local) operation. The Remote button has no effect when

the light is off during local operation.

The Remote key lights and Remote operation begins when the laser

receives data on either the RS-232-C or the IEEE-488.1nterface.

FSC (Fine Scanning mode.) Enables a quasi-continuous sweep of the

wavelength on a ± 2 GHz range. Once this mode is selected, the

wavelength can be continuously adjusted with the rotating knob. The

wavelength sweep is displayed in GHz. To exit the fine scanning mode,

press the FSC key again.

APC (Automatic Power Control.) Switches between constant current (APC light

off) and constant power (APC light on) modes. See Automatic Power

Control on page 1–1 1.

² or ³ Increases or decreases the wavelength by the value of the STEP parameter.

Backspaces or forward spaces to correct numbers during keypad entry.

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 23

Operating Basics

T able 1–1: Description of Display, Mode, and Setup keys (Cont.)

Name Description

± or ° Decreases or increases the elementary step of the control knob. The

message, “Scroll...” indicates which digit relative to the decimal point the

control knob changes.

ENTER Enters the numerical value.

STEP Changes the STEP parameter.

2ND Accesses advanced functions.

2ND > l,f Initiates wavelength calibration.

2ND > P Initiates power calibration.

2ND > STEP Enables wavelength scan mode.

2ND > 1 Disables/Enables backlash suppression of the micrometer screw.

2ND > 2 Displays software release.

2ND > REMOTE Changes GPIB address.

Optical Output

2ND > FSC Enables linewidth coherence control.

The Optical Output area includes the angle polished connector (APC) output

with protective cover. The ENABLE key that enables and disables the optical

output is located in the data area.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–9

Page 24

Operating Basics

Entering Numerical Values

Using the basic procedure in this section, you can use the keypad or control knob

to edit the parameters for the following functions:

H Emission wavelength (l,f)

H Optical power (P)

H Diode Current (I)

H Wavelength step (STEP)

Information on editing the parameters for other functions begins on page 1–15.

Basic Procedure

Use the keypad or control knob to enter numerical values as follows:

1. Press the appropriate key function (l, f, I, or P).

a. The related indicator lights and the display shows the present setting for

the chosen parameter.

b. The equal sign (=) on the display blinks to show that this parameter can

be changed.

2. Change the present setting with the keypad or the control knob.

a. To correct a number during entry, back space or forward space using the

z or ! keys.

b. To exit the edit mode without saving the new value, press the same

parameter key (l, f, I, or P) as the function.

3. If you are using the keypad, press the ENTER key to enter the new value. If

you are using the control knob, the value is updated in real time.

4. If the value is outside the range of acceptable settings, the message “Lim”

displays and the setting remains the same.

For instance, to enter a power of 0.5 mW, key in the following sequence:

1–10

P Parameter selection

0.5 New value ( .5 is also valid)

ENTER Validation of the new value

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 25

Operating Basics

NOTE. If the new value is outside the valid range for the parameter, an error

message displays (“Value error Press ENTER”). Pressing ENTER retains the

former setting and suspends scanning or calibration.

For a listing of the valid ranges for each system parameter, refer to Appendix A

on page A–1.

Arrow Keys

Backlash Suppression

The z and ! keys decrease or increase the wavelength by the step value. To

change the step value, press STEP and use the control knob or keypad to enter

the new value (STEP > new value in nm > ENTER). The keys also allow you to

forward or backspace during keypad entry.

The # and " keys below the control knob decrease or increase the elementary

step of the control knob. In the message “Scroll 0.01,” for example, the 1

indicates which digit in relation to the decimal point the control knob changes.

To select a different digit, press either arrow key repeatedly until the 1 is in the

same place as the digit you wish to change, and then turn the control knob.

When the using the keypad or the z and ! arrow keys to set the wavelength

value, the software of the tunable laser suppresses the mechanical backlash of the

tuning mechanism.

When using the control knob to change the wavelength value, the value changes

in real time and the backlash suppression is not active. A dot (“.”) at the right

end of the wavelength display indicates the absence of backlash suppression.

Example : “l=1555.000 nm

The backlash suppression procedure activates the next time you use the keypad

or the z and ! arrow keys to enter a value.

.”

Automatic Power Control

The Automatic Power Control (APC) button on the front panel switches between

constant current and constant power modes. In the constant current mode, the

APC light is off and the I parameter indicates the diode current. When the APC

light is on, the diode current is controlled to deliver optical power equal to the P

parameter.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–11

Page 26

Operating Basics

Rear Panel

NOTE. In some cases, it may not be possible to reach the required power even

with the maximum allowable current. When this happens, the current limits at

the maximum value and the message “Lim” appears at the right end of the

displayed power.

(Example : P = 5.4 mW Lim )

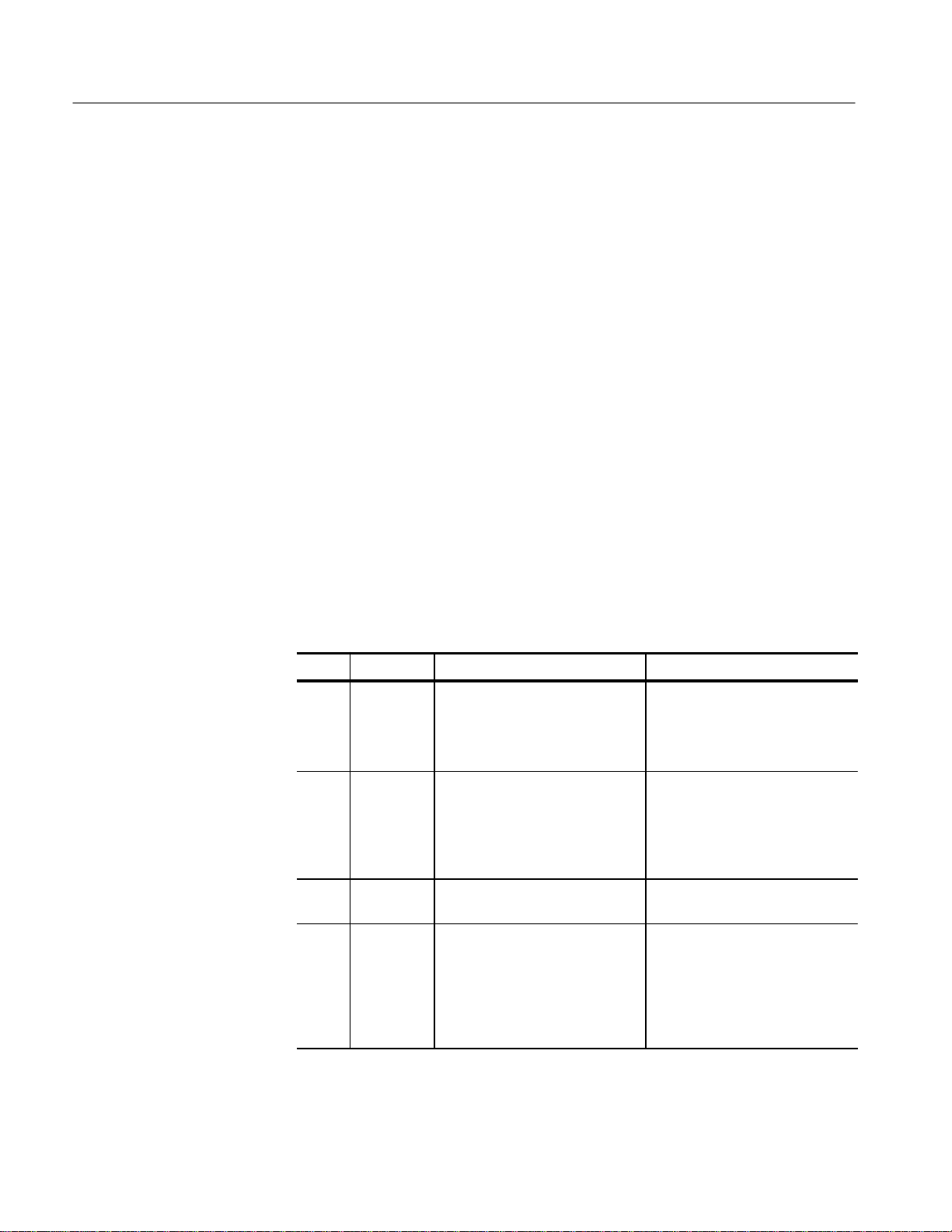

Figure 1–2 shows the rear panel of the LPB 1300 and LPB 1550 Tunable Laser

Sources.

Figure 1–2: Rear panel

1–12

The MAINS module includes the mains power switch, power cord connection,

and fuse drawer.

In addition to the MAINS module and two remote control connectors (RS-232-C

and IEEE-488.1), ten auxiliary IN/OUT connectors are available on the rear

panel:

Analog and TTL outputs:

H Mod. Sync. (modulation sync) TTL output

H Mod. Out (modulation output) TTL output

Monitor (scaled) outputs:

H Sync (motor sync)

H l (wavelength)

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 27

Operating Basics

H P (power)

H I (current)

Inputs:

H FSC (fine scanning and coherence control)

H HF Mod (high frequency modulation)

H LF Mod (low frequency modulation)

H Remote interlock connection as required by Class IIIb.

For a discussion of these connectors, see Auxiliary Inputs and Outputs on

page 1–18.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–13

Page 28

Operating Basics

1–14

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 29

Reference

Advanced Functions

This section describes the advanced functions, RS-232-C and IEEE-488.1

interfaces, and auxiliary inputs and outputs of the LPB 1300 and LPB 1550

Tunable Laser Sources.

Press the 2ND key on the front panel (which functions like a shift key) to access

the following functions:

H Wavelength scanning

H Wavelength calibration

H Power calibration

H Backlash suppression of the micrometer screw

H Changing the GPIB address

Wavelength Scanning

Wavelength scanning presets the tunable laser to emit a range of different

wavelengths for selected intervals of time.

1. To activate the scan mode, press 2ND > STEP.

The tunable laser requests the first of the following scan parameters:

H The first scan wavelength

H The last scan wavelength

H The scan increment

H The pause time between two steps

2. To progress through the scan parameters, you must confirm or modify each

parameter in order:

a. To modify a parameter, press the numeric keys followed by the ENTER

key.

b. To keep a parameter, press the ENTER key without entering a new

value.

c. To cancel the entire scan procedure and retain the previous parameters,

press the STEP key a second time before entering the value.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–15

Page 30

Reference

After you enter the last parameter, the tunable laser goes to the first wavelength.

The wavelength increments step by step (applying the scan step parameter value)

until the tunable laser reaches the last wavelength. At each step the wavelength

remains constant during the pause time parameter.

3. To suspend scanning, press the STEP key during wavelength scanning. The

message: “Stop scan (1/0) ?” asks the operator to confirm termination of the

scan.

a. To stop scanning, press 1, scanning stops and the emission wavelength

remains at the displayed value.

b. To resume scanning, press 0.

For all modes except the remote mode, the tunable laser goes back to the first

wavelength and scanning repeats indefinitely after reaching the upper wavelength.

In the remote mode, scanning ends when the tunable laser reaches the upper

wavelength.

Wavelength Calibration

The wavelength calibration procedure calibrates the wavelength setting of the

laser output. The procedure requires the use of an optical wavemeter.

CAUTION. This procedure erases factory calibration data for the optical

wavelength settings. Do not use this procedure unless you intend to erase this

data.

1. Connect the output of the tunable laser to a wavemeter.

2. Press the 2ND key followed by the l key to initiate wavelength calibration.

The tunable laser moves to a short wavelength of the tuning range and

displays the default value corresponding to the calibration data.

3. Measure the first wavelength with the wavemeter.

4. Enter the reading after the display prompt (l = ).

The tunable laser moves to a long wavelength of the tuning range, and

displays the default value corresponding to the actual calibration data.

5. Measure the second wavelength with the wavemeter.

6. Enter the reading after the display prompt (l = ).

1–16

The wavelength calibration is now complete and all wavelength settings are

referenced to the new data.

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 31

Reference

Power Calibration

The power calibration procedure calibrates the laser output power. The procedure

requires the use of an optical power meter.

CAUTION. This procedure erases factory calibration data for optical power. Do

not use this procedure unless you intend to erase this data.

1. Connect the output of the tunable laser to a power meter.

2. Press the 2ND key followed by the P key to initiate power calibration.

3. The tunable laser moves to a short wavelength of the tuning range and

displays the power level corresponding to the calibration data.

4. Measure the power level at the first wavelength.

5. Enter the reading after the display prompt (P = ).

6. The tunable laser moves to a long wavelength of the tuning range, and

displays the power level corresponding to the actual calibration data.

7. Measure the power level at the second wavelength.

8. Enter the reading after the display prompt (P = ).

Backlash Suppression of

the Micrometer Screw

Changing the GPIB

Address

The power calibration is now complete and all power settings are referenced to

the new data.

The software of the tunable laser uses a procedure to eliminate the effect of the

backlash of the tuning micrometer screw.

1. To cancel backlash suppression, press 2ND > 1.

A dot “.” at the right end of the wavelength display indicates backlash

suppression is inactive.

Example : “l=1555.000 nm

2. To reactivate backlash suppression, press 2ND > 1 again.

By default, the GPIB address of the tunable laser is 10.

To change the default address, press 2ND > REMOTE. The tunable laser

displays the actual address and prompts for the new value.

.”

LPB 1300 and LPB 1550 Tunable Laser Sources

1–17

Page 32

Reference

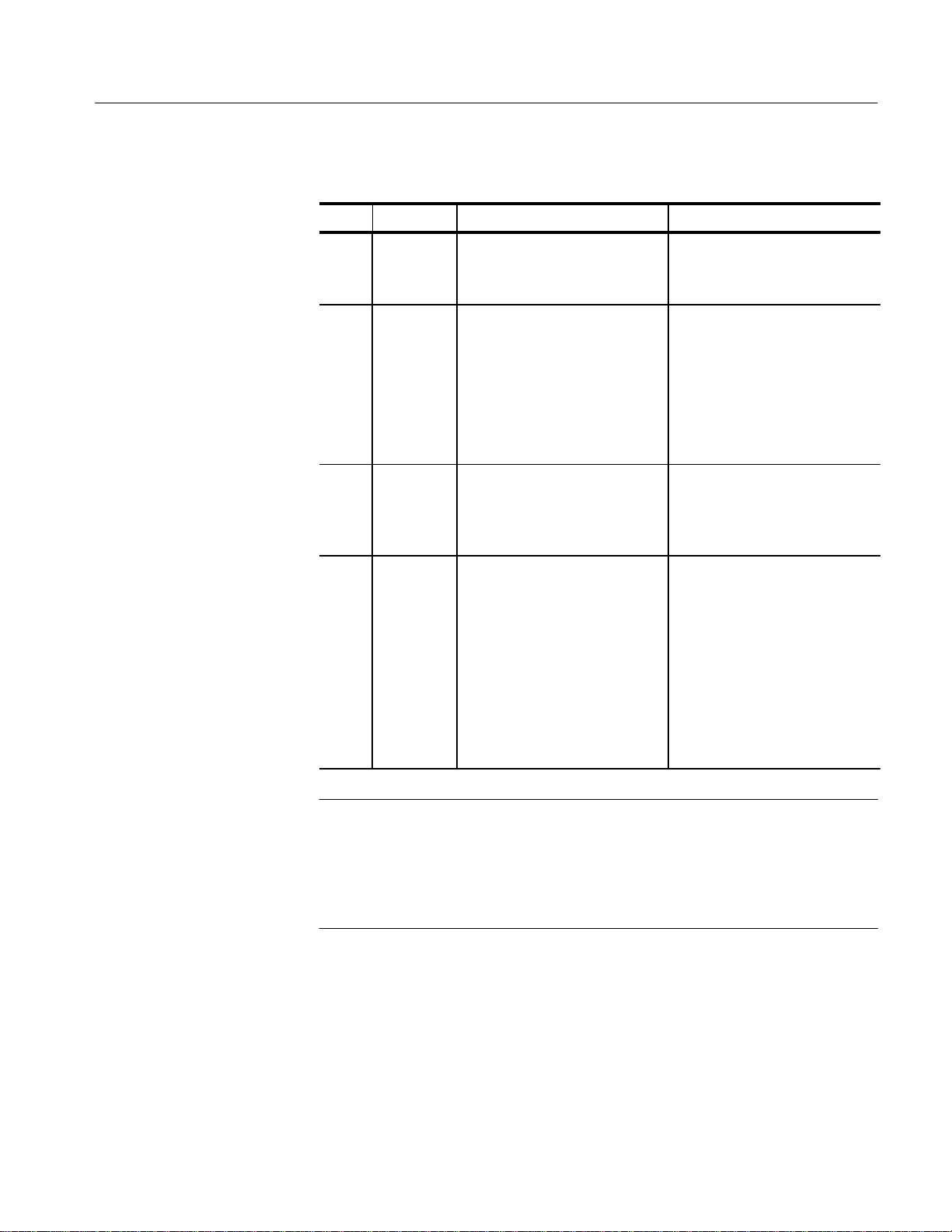

Auxiliary Inputs and Outputs

Figure 1–3 shows the auxiliary input and output connectors on the rear panel.

Monitor Outputs

Figure 1–3: Auxiliary connectors

The outputs that allow continuous monitoring of the tunable laser are l

(wavelength), P (power), I (current), and Sync (motor). The scaling of the signal

voltage at these outputs is as follows:

T able 1–2: Voltage scaling of monitor outputs

Name Voltage scaling

l 66.66 mV/nm, typical

P 0.3 mV/mW , typical

I 20 mV/mA , typical

0 V corresponds to 1400 nm (LPB 1550) or

1200 nm (LPB 1300)

Sync 0 V: motor moving

5 V: motor not moving

Mod. Out Modulation output (TTL)

Mod. Sync Modulation synchronization (TTL, same signal

as Mod. Out)

1–18

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 33

Reference

NOTE. To minimize noise levels on the diode control and on the monitor output

circuits, the BNC connectors for the monitor outputs are isolated from chassis

common and earth ground. To prevent increasing the noise levels, connect the

monitor outputs to devices with differential inputs that are also isolated from

ground. Otherwise, the tunable laser optical output may have higher than

normal power fluctuations.

Remote Interlock

Figure 1–4 show the pin out of the Sub-D9 connector on the rear panel labeled

Remote Interlock. The remote interlock connector is a safety feature required by

the Laser Class IIIb standard.

9

7

6

5

2

1

Figure 1–4: Remote interlock connector

To use the interlock feature, the user must supply a mating connector that shorts

pins 1 and 2 and connects a normally open safety switch between pins 6 and 7.

The switch must be electrically isolated from all other circuits including earth

ground. The switch disables the laser output when open.

Without any connections to the interlock, normal operation of the tunable laser is

unaffected.

Wavelength Fine Tuning

and Coherence Control

On the front panel, the tunable laser has a wavelength fine tuning function (FSC)

and a coherence control function (2nd > FSC). The fine tuning function enables

the control knob to precisely adjust the wavelength or optical frequency. The

coherence control function broadens the linewidth.

On the rear panel, the wavelength fine tuning and coherence control functions are

available through the FSC connector. When a voltage is applied to this connector, the optical frequency shifts by 200 MHz per applied volt on the LPB 1300

and by 300 MHz per applied volt on the LPB 1550. The maximum input voltage

is ±10 volts. This input also allows wavelength modulation, by applying a

modulation signal whose frequency is lower than 1 kHz.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–19

Page 34

Reference

BNC

If a noise signal is directly injected in the FSC input to modulate the optical

frequency, it will induce an apparent broadening of the linewidth of the laser

leading to a reduction of the coherence length. One application of this technique

is to wash out parasitic interference in the user setup.

Optical Power Modulation

The LF Mod (BNC) and HF Mod (SMA) inputs are connected to the laser diode

and allow the user to add an external current to the bias current of the diode. By

modulating this extra current, it is possible to modulate the optical power output

as shown in Table 1–3.

T able 1–3: Range of frequencies for modulating the optical power

Input Connector APC Frequency range

LF Mod (

HF Mod (SMA connector) On or off 30 kHz to 1 GHz

connector)

Off DC to 8 MHz

On 10 kHz to 8 MHz

In the APC mode, the tunable laser monitors the average power of the optical

output and constantly adjusts the bias current so that the output power is

constant. If a DC or low-frequency signal below 1 kHz is applied to the LF Mod

input, it will have no effect on the output power. However, if the frequency of the

signal applied to the LF Mod input is well above 1 kHz, the output signal will

modulate around an average power determined by the settings of the tunable

laser. For this reason, the modulation frequency should be above 10 kHz.

1–20

CAUTION. To avoid damaging the laser diode, do not over drive the modulation

input. See the conditions that follow.

The Mod inputs are directly connected to the laser diode chip, so the user must

ensure that the input voltage (|V|

) meets the following two conditions:

max

1. The diode laser is forward biased.

< 50 × I

|V|

max

bias

2. The current flowing through the diode is lower than the maximum admissi-

ble current (I

< 50 × (I

|V|

max

) indicated in the acceptance test report.

max

– I

bias

)

max

The best way to determine the system bias current is to measure the voltage on

the current monitor output. The voltage scaling on the current monitor output is

20 mV/mA.

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 35

Reference

Remote Control

The maximum and minimum values of V

current (I

rent (I

) remains positive and lower than the maximum admissible cur-

t

):

max

< I

0 < I

t

max

should be chosen so that the total

in

The Mod Out (modulation out) and Mod Sync (modulation sync) connectors

provide identical 31.2 kHz TTL signals. The Mod out signal can be used to drive

the LF Mod input and the sync signal is available to synchronize another piece of

test equipment.

When the tunable laser receives data from the RS-232-C or the IEEE-488.1

interfaces, it enters the remote mode and the indicator light on the REMOTE key

switches ON.

H When the tunable laser is operating in the remote mode, all keys are disabled

except the REMOTE key.

H To exit the remote mode, press the REMOTE key.

NOTE. If the tunable laser receives a message through the serial interface ending

with a return character (↵ ), the remote mode automatically activates even if the

message itself is invalid.

RS-232-C Remote Control

The tunable laser is in the remote mode when the REMOTE key light is on. The

remote mode disables all the keyboard keys and allows the tunable laser to

receive commands through the RS-232-C interface. Additional specific

commands are also available using this interface.

Physical Interface

The cable link is a three-wire RS-232-C type using a SUB-D9 plug. The serial

port is configured in the terminal mode: data sent to the serial port is on pin 2 of

the connector and return messages are on pin 3. The ground is through pin 5. No

other connector pin is used.

The serial port is configured as follows:

Data transmission rate 9600 baud

Number of bits 8

Parity no

Stop bits 1

LPB 1300 and LPB 1550 Tunable Laser Sources

1–21

Page 36

Reference

Message Format

All commands sent by the computer to the tunable laser are composed of a string

of ASCII alphanumeric characters followed by a return (ASCII code 13). When

such an instruction is received, the character string is decoded and the relevant

procedure is carried out.

After completion, a message informs the computer that the requested procedure

has been performed or that an error situation has been encountered. This

response message is always terminated by the same group of three characters:

return character (↵)

greater than character (>)

space character ( )

These three characters indicate that the tunable laser is ready to receive a new

instruction. Table 1–4 gives an example of dialog between the computer and the

tunable laser.

T able 1–4: Example of dialog between the controller and the tunable laser (RS-232-C)

Message

to tunable laser

↵ Set constant power (APC) on ↵

Meaning

Response

from tunable laser

Meaning

Instruction performed

Change diode current to 160 mA ↵

↵ What is the actual wavelength value? ↵

The message syntax described above eases the management of the interface since

the computer must await the acknowledgment before sending a new instruction.

To easily detect the end of the message, the response from the tunable laser is

always terminated by the same three characters.

Other considerations include the following:

H The tunable laser does not distinguish between lower and upper case

alphabetical characters.

H It is possible to send a series of instructions in a single string: successive

instructions should be separated by a semicolon (;), and the string should end

The tunable laser is ready to receive

another instruction

Current level is over permitted

maximum

The tunable laser is ready to receive

another instruction

Actual wavelength value is

1523.325 nm

The tunable laser is ready to receive

another instruction

1–22

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 37

Reference

with a return character (↵ ). The different instructions will be analyzed as

soon as the ↵ character is received and will be executed in sequence.

H The input buffer length is 255 characters; if more than 255 characters are

sent in a single string, or before previous strings have been analyzed, the

buffer will be cleared, all received instructions lost, and the message

“command error” sent.

H Space characters are allowed in some places inside the strings: they can be

placed at the beginning of an instruction; after an instruction; or before, after,

or in place of the equal sign (=). They cannot be inserted within an instruction mnemonic, within a numeric, or between a mnemonic and the question

mark (?).

H On the RS-232-C interface, all characters with ASCII codes lower than or

equal to 32, except the return character (ASCII code 13) are considered as

space characters.

Response Messages

Format of Numerics

All instructions requesting a parameter reset or a change of operating mode give

rise to an “OK” acknowledgment (terminated by ↵, >, and a space) from the

tunable laser when the command has correctly executed. The only exception to

this general rule is the SCAN command, since the acknowledgment in this case

is “Scanning...” which is sent as soon as scanning has begun, followed by “End

of scan” when scanning has terminated.

If a command is not recognized, the message returned is “Command error”. If a

command requesting a new parameter setting is correctly formulated but the

specified value is outside the allowed limits for that parameter, the setting will

remain unchanged and the response is “Value error”.

Some command messages include a numeric. The format rules are as follows:

H No spaces are allowed within the numeric.

H Leading zero (0) characters are allowed at the beginning of a numeric.

H After the decimal point, trailing zero (0) characters may be included or

omitted.

H Either a period (.) or comma (,) character designates the decimal point.

H The return character (↵) terminates the numeric. No unit abbreviations are

allowed after the numeric.

Table 1–5 gives some correct and incorrect examples of the message formats that

include numerics.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–23

Page 38

Reference

T able 1–5: Examples of message formats with numerics (RS-232-C)

Entry Correct/Incorrect Meaning

P=0.22 Correct Set power to 0.22 mW

L=1530.2 Correct Set wavelength to

1530.200 nm

P=01 Correct Set power to 1 mW

Changing Parameter

Settings

I= 25 Correct, spaces are before the

numeric

I=25 mA Incorrect, unit abbreviations

not allowed

Smin=1 520.31 Incorrect, space between “1”

and “5” not allowed

Set diode current to 25 mA

Command error

Command error

Table 1–6 lists the commands for each parameter setting of the tunable laser.

Each “n” represents an integer from 0 to 9. All commands must be terminated by

the return character.

T able 1–6: Command parameters (RS-232-C)

Command Action

I=nn.n Sets the laser current level (mA) and switches to the constant current mode.

P=nn.nn Sets the the optical power (mW). See MW in Table 1–8.

P=±n.nn Sets the the optical power (dBm). See DBM in Table 1–8.

L=nnnn.nnn Sets the wavelength (nm). The “OK” acknowledgment is sent when the

emission wavelength is stabilized.

f=nnnnnn.n Sets the optical frequency (GHz). The “OK” acknowledgment is sent when

the emission wavelength is stabilized.

1–24

FSCL=nn.n Switches to the Fine Scanning mode. The numeric nn.n is the change in

wavelength (pm).

(Also available with the fine scanning option.)

FSCF=n.nn Switches to the Fine Scanning mode. The numeric n.nn is the change in

optical frequency (GHz).

(Also available with the fine scanning option.)

Smin=nnnn.nnn Sets the lower limit scanning wavelength (in nm).

Smax=nnnn.nnn Sets the upper limit scanning wavelength (in nm).

Step=n.nnn Sets the wavelength scan step (in nm).

Stime=nn.n Sets the stop time (in seconds) between each scan step.

LCAL1=nnnn.nnn Defines the first calibration wavelength.

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 39

T able 1–6: Command parameters (RS-232-C) (Cont.)

Command Action

LCAL2=nnnn.nnn Defines the second calibration wavelength.

PCAL1=nn.nn Defines the calibration power (first wavelength),

PCAL2=nn.nn Defines the calibration power (second wavelength).

B_SUPPR=1 Enables backlash suppression irrespective of the previous state.

B_SUPPR=0 Enables backlash suppression irrespective of the previous state.

Table 1–7 lists the possible command responses from the tunable laser.

T able 1–7: Command responses (RS-232-C)

Response Meaning

OK Command executed

Reference

Changing the Operating

Mode

Value error Value outside valid limits

Command error Syntax error

Table 1–8 lists the commands that change the operating mode.

T able 1–8: Operating mode commands (RS-232-C)

Command Action

APCON Switch to constant power mode.

APCOFF Switch to constant current mode.

SCAN Initiate wavelength scanning. the laser response message is “Scanning...”

when scanning starts, followed by “End of scan” when scanning is

terminated.

NOTE: Unlike scanning initiated locally using the laser controller keypad,

once the upper wavelength scan limit has been reached, scanning

terminates; it does not start again at the lower wavelength scan limit. Each

parameter can be altered individually without changing the others and the

previous parameters are retained from one scan session to the next.

STOP Stop scan. When scanning is terminated, the message “End of scan” is sent

by the laser.

DBM Selects dBm unit for transmission of optical power values to and from the

LPB 1300 and LPB 1550 Tunable Laser Sources

NOTE: While scan is running, all commands are disabled (this is indicated

by the response message “Command error”), with the exception of

parameter value requests and the STOP instruction.

laser, and for displayed values.

1–25

Page 40

Reference

T able 1–8: Operating mode commands (RS-232-C) (Cont.)

Command Action

MW Selects mW unit for displayed values and for transmission of optical power

values to and from the laser.

INIT Initialize the optical head.

ENABLE Enable the optical output.

DISABLE Disable the optical output.

Reading the System

Parameters

Table 1–9 lists the queries for system parameters of the tunable laser.

T able 1–9: System parameters (RS-232-C)

Query Action System response

I? Request the present current level. “I=nn.n” (mA) or “disabled” if the

Enable mode is not active.

P? Request the present power output

level.

L? Request the present wavelength

value.

f? Request the present optical

frequency value.

LIMIT? Request the status of the current

limit.

B_SUPPR? Request the status of the backlash

suppression.

“P=nn.nn” (mW) or “P=+nn.nn”

(dBm) or “disabled” if the Enable

mode is not active.

“L=nnnn.nnn” (nm).

“L=nnnn.nnn” (nm).

The answer is “Y es” if the current is

limited and “No” otherwise.

The answer is B_SUPPR=1 if the

backlash suppression is active and

B_SUPPR=0 if it is disabled.

1–26

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 41

Reference

Other System Commands

Table 1–10 lists the other system commands of the LPB 1300 and LPB 1550

Tunable Laser Sources.

T able 1–10: Other system commands (RS-232-C)

Command Action

ECHON When this mode is active, the laser sends an echo of each character

ECHOFF Cancels “echo” mode.

IEEE-488.1 Remote Control

The General Purpose Interface Bus (GPIB) of the LPB 1300 and LPB 1550

Tunable Laser Sources is compatible with the IEEE-488.1 standard.

The controller sends instructions over the GPIB with one string of ASCII

characters for each instruction. These instructions can be either definition

instructions for the operation of the tunable laser (for example, “I=35” means

“Set the level of the current to 35 mA”) or requests of a parameter value (for

example, “I?” to ask for the value of the current level). The microprocessor of

the tunable laser immediately handles each instruction/request.

received back through the serial cable. Since some terminals and terminal

emulation programs do not feature local echo, this function can be useful for

visual monitoring of the characters keyed in at the terminal.

NOTE: The default option is ECHOFF. Specifically, anytime you cancel the

remote mode using the REMOTE key then re-activate it, the echo mode

switches to ECHOFF.

The computer must address the tunable laser as the “talker” to read the value

transmitted by the tunable laser over the GPIB. For example, if the computer

requests the value of the current (“I?”) and addresses the tunable laser as “talker,”

the transmitted response on the bus will be in the form “I=35”.

NOTE. To accelerate and secure the exchange of informations between the

controller and the tunable laser, use a serial poll command to check the value of

the status word. (See Definition of Status Word on page 1–32).

This status word contains the information that allows the controller to know the

status of commands received by the tunable laser, and determines when the

controller can send a new instruction or read a parameter. In particular, when the

controller reads a parameter value, the bit MAV (message available) indicates

that the tunable laser has measured the requested parameter and that the answer

message is available.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–27

Page 42

Reference

Protocol of Messages

The following protocol applies for the transmission and reception of messages:

H Each message sent by the controller to the tunable laser must end either with

the line-feed character (LF, ASCII code10), or with the end-or-identify (EOI)

message, or with both of them.

H Each message may contain one instruction or more. If more than one

instruction is sent, successive instructions should be separated with the

semicolon (;) character.

H Numerics must be transmitted in a fixed-decimal-point format for non-inte-

ger values (values of the current, for example) and without a decimal point

for integer values (the validation byte of the request condition for service of

the SRE instruction, for example).

H Space characters can be placed within a message at certain positions; they

can be placed before an instruction or at the end of an instruction; or instead

of, after, or before the equal (=) sign. It cannot be placed within a mnemonic,

nor within a numeric, nor between a mnemonic and the question mark (?)

character.

H All alphabetic characters can be either upper or lower case letters.

H The instructions for parameter modification are composed of the name of the

parameter, the (=) sign, and the value of the parameter. The parameter-request instructions are composed of the name of the parameter and the

question mark (?). A value’s unit must never be indicated. (The unit

applicable to each parameter is indicated in Table 1–12.)

Operating Commands,

Parameters, and Queries

1–28

Tables 1–11, 1–12, and 1–13 list the operating mode commands, command

parameters, and queries of the LPB 1300 and LPB 1550 Tunable Laser Sources.

T able 1–11: Definition of operating commands (GPIB)

Mode

command

SCAN Starts a wavelength scan. The scan will use the Smin, Smax, Step and

STOP Interrupts an ongoing wavelength scan.

DBM Switches to the dBm mode.

MW Switches to the mW mode.

ENABLE Enables the laser output.

DISABLE Disables the laser output.

Action

Stime values.

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 43

Reference

Table 1–12 gives the parameters for the commands. Each “n” represents an

integer from 0 to 9.

T able 1–12: Command parameters (GPIB)

Parameter

command

I=nn.n Sets the laser diode current (mA) and switches to the constant current

P=nn.nn Sets the emitted power (mW). See MW, Table 1–11.

P=±n.nn Sets the the emitted power (dBm). See DBM, Table 1–11.

L=nnnn.nnn Sets the emission wavelength (nm).

f=nnnnnn.n Sets the emission optical frequency (GHz).

FSCL=nn.n Switches to the Fine Scanning mode. The numeric nn.n is the delta change

Action

mode.

in wavelength (pm).

(Also available with the fine scanning option.)

FSCF=n.nn Switches to the Fine Scanning mode. The numeric n.nn is the change in

optical frequency (GHz).

(Also available with the fine scanning option.)

Smin=nnnn.nnn Sets the lower limit scanning wavelength (nm).

Smax=nnnn.nnn Sets the upper limit scanning wavelength (nm).

Step=n.nnn Sets the wavelength scan step (nm).

Stime=nn.n Sets the stop time (seconds) between each scan step.

*SRE=nnn Defines the conditions under which the tunable laser will automatically send

a service request (SRQ) to the controller.

GP AD=nn Defines the GPIB address of the tunable laser.

LCAL1

=nnnn.nnn

LCAL2

=nnnn.nnn

PCAL1 =nn.nn Defines the calibration power (mW) of the first wavelength.

PCAL2 =nn.nn Defines the calibration power (mW) of the second wavelength.

B_SUPPR=1 Enables backlash suppression irrespective of the previous state.

B_SUPPR=0 Disables backlash suppression irrespective of the previous state.

Defines the first calibration wavelength (nm).

Defines the second calibration wavelength (nm).

LPB 1300 and LPB 1550 Tunable Laser Sources

1–29

Page 44

Reference

Table 1–13 lists the queries that ascertain the parameter settings and software

version.

T able 1–13: Queries (GPIB)

Query Action

I? Asks for the value of the diode current (mA).

P? Asks for the value of the optical power (mW or dBm). The unit is selected by

the commands DBM or MW. See Definition of Operating Modes in

Table 1–14.

L? Asks for the value of the emission wavelength (nm).

f? Asks for the value of the optical frequency (GHz).

*IDN? Queries the tunable laser for the software version. The tunable laser returns

the message

“xxxxxx,n.nn”

where n.nn is the software version number.

Definition of Operating

Modes

Table 1–14 lists the operating mode commands.

T able 1–14: Operating mode commands (GPIB)

Command Action

APCON Switch to constant power mode.

APCOFF Switch to constant current mode.

SCAN Initiate a wavelength scan. The scan uses the Smin, Smax, Step, and Stime

values.

STOP Stop scan.

DBM Selects dBm unit for transmission of optical power values to and from the

laser, and for displayed values.

MW Selects mW unit for transmission of optical power values to and from the

laser, and for displayed values.

ENABLE Enables the optical output.

DISABLE Disables the optical output.

1–30

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 45

Reference

Conditions of Use

GPIB Standard

Synchronization of

Messages

Some instructions can only be used under specific conditions:

H During a wavelength scan (SCAN instruction), only the request instructions

for parameter’s value and the instruction STOP are valid. All other commands will be ignored and will activate the ERRC (command error)

indication.

H The STOP instruction is only valid during a wavelength scan. If this

instruction is transmitted without a scan in process, the ERRC (command

error) indication will be activated.

The messages corresponding to the IEEE-488.1 standard are normally processed

by the tunable laser, and are not specifically described here (refer to the

IEEE-488.1 standard). All messages concerning the parallel polling are not

executed by the tunable laser. Also, the tunable laser does not offer the extended

addressing capability.

If successive instructions in a message do not interact (for example, setting all

the scan parameters), several instructions can be contained in a single message.

Several messages can be transmitted, even if previous messages have not been

executed. If a given state is to be reached before some instruction is to be

executed, it is preferable to make sure this state has been reached by reading the

status word through the serial poll instruction.

Provided that the tunable laser is not busy at another task, the tunable laser

executes each instruction as soon it receives a complete instruction. (The

instruction is completed with a semicolon (;), line feed (LF), or end-or-identify

(EOI).) This implies that the tunable laser can execute some instructions even

though the message is not completely transmitted. The tunable laser executes

each successive instruction in sequence. To execute each instruction, the tunable

laser decodes the character string and performs the following operations as

necessary:

H Modify the operating state

H Elaborate a response string

H Modify some bits of the status word

If the previous message included a request for the value of a parameter, the serial

polling repeats until the MAV indicator in the status word is activated

(MAV = 1). Only then can the computer read the requested value. If a single

message contains several requests, the MAV bit stays true (1) until the computer

reads all the response messages.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–31

Page 46

Reference

Errors

Two types of errors can arise in the transmission of instructions: command errors

and value errors.

The tunable laser detects command errors when the received string of characters

does not correspond to an authorized instruction (syntax error or unknown

mnemonic). The ERRC indicator in the status word is then activated.

A value error arises when the command is valid, but the value of the parameter is

incorrect, either because it could not be read or because it is outside the valid

range. In both cases, the received message is ignored and the ERRV indicator in

the status word is activated.

Definition of the Status

Word

The 8-bit status word contains a number of binary indicators which can be used

by the controller for an optimal synchronization between the tunable laser and

the controller. They indicate to the controller the nature of the current operations

as well as the errors encountered. These binary indicators are contained in the

word sent by the tunable laser when the computer performs a serial polling.

Table 1–15 gives the definition of each bit in the status word and when each bit

is activated or deactivated.

T able 1–15: Bits in status word (GPIB)

Bit # Mnemonic Meaning When activated/deactivated

7

(MSB)

6 SRQ Service request: request for

5 ESB (Reserved for future use) (Reserved for future use; value is

SCANNING Wavelength scan in progress Activated at the beginning of a

wavelength scan.

Deactivated at the end of the

scan.

Activated when an occurrence

controller intervention

defined by the instruction *SRE

arises.

Deactivated when it has been read

by a serial poll.

always 0)

1–32

4 MAV Message available: a message is

available for reading

LPB 1300 and LPB 1550 Tunable Laser Sources

Activated when the response to a

parameter request is ready to be

sent.

Deactivated when the response

has been read and no other

answer message is available.

Page 47

Reference

T able 1–15: Bits in status word (GPIB) (Cont.)

Bit # When activated/deactivatedMeaningMnemonic

3 LIM Current limitation Activated when the tunable laser

is current-limited

Deactivated in all other cases.

2 ERRV Error in received parameter value Activated upon receipt of a

parameter value which either has

not been read, is erroneously

formatted (e.g., the units have

been indicated), or is outside the

acceptable range (e.g., I=160).

Deactivated upon the reception of

a correct instruction.

1 ERRC Error in received command Activated when an erroneous

command has been received.

Deactivated when a valid

command is received.

0 OPC Operation complete: the operation

has been completed; the laser is

ready to receive a new instruction

Activated when no operation is in

progress in the tunable laser.

Deactivated during the handling of

commands (and also, during

shifting of the drive to modify the

wavelength emission). In

particular, during scan operation,

OPC bit is set to 0 each time the

motor is moving and set back to 1

during the pause between

successive steps.

NOTE. To detect errors that might occur after messages that contain only one

instruction, test the ERRV and ERRC bits of the status word. When the message

contains several instructions, the ERRV and ERRC flags are relevant to the last

instruction only. To detect errors in messages with multiple instructions, activate

the SRE bits corresponding to ERRC and ERRV, so that the tunable laser

requests service as soon as it encounters an error.

LPB 1300 and LPB 1550 Tunable Laser Sources

1–33

Page 48

Reference

Reading the Status Word

The computer can read the status word at any time by performing a serial poll.

The computer checks the state of the different binary indicators to perform the

next operation accordingly. Note the following recommendations for reading

various bits of the status word:

H To be certain that changes to the wavelength, current, or power settings have

stabilized, the computer should check the condition of the OPC indicator

before sending an instruction that changes the settings again.

H After each instruction, check that the indicators ERRV and ERRC are

deactivated (= 0) to verify that there were no transmission errors.

H When the computer requests a parameter value, check the state of the MAV

indicator before reading the value. (If the reading is made before the message

is available, the response of the tunable laser will be a string of empty

characters ending with the line-feed character.)

The tunable laser updates the different indicators for the status word according to

the state of the internal functions. When the computer reads the status word, the

value corresponds to the actual state of the tunable laser and no memorization is

performed. The different indicators are automatically activated or deactivated

according to the criteria described above, even if no message is transmitted on

the GPIB.

Service request (SRQ)

However, if the tunable laser activates a service request, the status word will not

update until the serial poll is performed. (See below.)

The SRQ (service request) line is a part of the definition of the IEEE-488.1

standard. This line can be activated by all devices on the bus to alert the central

controller that a particular device requires a particular operation.

When the controller detects that the SRQ line is active, it can question all of the

devices present on the bus to determine which one has initiated the service

request and for what reason. For this, it performs a serial poll, during which it

will read the status word of each device (see Table 1–15 on page 1–32) which

regroups the indicators permitting the controller to monitor the progress of the

polling.

The IEEE-488.1 standard imposes the condition that Bit # 6 of the status word

be set to 1 if the interrogated device has sent a service request. The other bits can

reflect the state of different logical indicators of the tunable laser.

To facilitate the synchronization between the operations initiated by the

computer and by the tunable laser, the computer can request the tunable laser to

activate a service request when certain indicators move to 1 by using the

instruction *SRE. In this fashion, the computer will be warned that a particular

occurrence has happened, without having to repetitively read the status word of

the tunable laser to detect this occurrence.

1–34

LPB 1300 and LPB 1550 Tunable Laser Sources

Page 49

Reference

The command *SRE permits the definition of the conditions in which the

tunable laser will perform a service request. The transmitted parameter with the

instruction *SRE must be an integer value between 0 and 255. If you write this

value in the form of a binary byte of 8 bits, the binary elements (bits) which are

at 1 validate the service request upon activation of the corresponding indicators

of the status word.

For example, if the instruction *SRE=16 is received by the tunable laser, this

corresponds to the binary value 00010000. Since indicator #4 is set to one

(indicator #4 = MAV = message available), the SRQ line will be automatically

activated each time a message is available.

Different indicators can be set to 1 (true):

SCANNING 128 indicator #7

MAV 16 indicator #4

LIM 8 indicator #3

ERRV 4 indicator #2

ERRC 2 indicator #1

OPC 1 indicator #0

To calculate the parameter value to send with the instruction *SRE, you must

add the corresponding value of each of the indicators (bits) for which you wish a

service request in case of activation. For example, to obtain a service request

each time an error is made, you must send the instruction “*SRE=6”, (obtained

by adding the corresponding values of the two error indicators, which are ERRV

(4) and ERRC(2)).

Once a service request has been activated by the tunable laser, the status word is

no longer modified, as long as the controller does not perform a serial poll on the

GPIB to read the status word of the tunable laser. This will allow the tunable

laser’s indicators to remain in the state which they have had from the moment of

the service request, so that the computer can analyze the cause of the service

request.

NOTE. When a service request is received by the computer, a serial poll will be

performed as soon as possible. No new instruction can be treated until the

computer has performed the serial poll, since the processing of an instruction

begins with the deactivation of the OPC indicator.

Once the status word is read, the service request is deactivated, and the normal

activity of the tunable laser resumes.

Changing the GPIB

Address

LPB 1300 and LPB 1550 Tunable Laser Sources

At the time of the tunable laser’s factory configuration, its address on the GPIB

is 10. To enter a new GPIB address, press 2ND > REMOTE > new address >

ENTER.

1–35

Page 50

Reference

This modification can also be performed with the IEEE-488.1 command:

“GPAD=nn”.

When the GPIB address has been modified, the new value is stored in protected

memory, and it is therefore retained even if the tunable laser is turned off. This

new value then replaces the initial value of the address, which is lost.

Local Lockout

When the tunable laser receives a message through its IEEE-488.1 interface, it

switches automatically to the remote mode of operation and the REMOTE

indicator on the front panel lights up. In this operating mode, all keys of the front

panel are deactivated. The local operating mode can be re-activated by pressing

the REMOTE key.

If the message “Local lockout” is sent to the tunable laser through the GPIB, the

Remote mode cannot be deactivated through the keys, and only the computer can

set the tunable laser to the Local mode by sending the message “Go to local”. In