Page 1

xx

Tektronix Logic Protocol Analyzer Solutions

ZZZ

for PCI Express 3.0

Instruction Manual

TektronixLogic Protocol Analyzer Solutions for PCI Express 3.0

TLA7012/16 Mainframes

TLA Application Software V5.7+

TMS160PCIE3 Software

TLA7SAxx Logic Protocol Analyzer Modules

P67SAxxx Serial Analyzer Probes

www.tektronix.com

P077040001*

*

077-0400-01

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

DPOJET is a registered trademark of Tektronix, Inc.

PCI Express is a registered trademark of PCI-SIG®.

G3PO is a trademark of Corning Gilbert Inc.

Contacting Tektronix

Tektroni

14150 SW Karl Braun Drive

P.O . B o x 5 00

Beaverton, OR 97077

USA

For pro

x, Inc.

duct information, sales, service, and technical s upport:

In North America, call 1-800-833-9200.

World w i de, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable a rrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 4

Warranty

Tektronix warrants that the media on which this software product is furnished and the encoding of the programs on

the media will be free from defects in materials and workmanship for a period of three (3) months from the date of

shipment. If any such medium or encoding proves defective during the warranty period, Tektronix will provide

a replacement in exchange for the defective medium. Except as to the media on which this software product is

furnished,

Tektronix does not warrant that the functions contained in this software product will meet Customer’s requirements

or that the operation of the programs will be uninterrupted or error-free.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period. If Tektronix is unable to provide a replacement that is free from defects in materials and

workmanship within a reasonable time thereafter, Customer may terminate the license for this software product

and return this software product and any associated materials for credit or refund.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRO

PAYMENT IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH

OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT,

SPECIAL, INCIDENTAL, O R CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX

OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W9b – 15AUG04]

this software product is provided “as is” without warranty of any kind, either express or implied.

NIX’ RESPONSIBILITY TO REPLACE DEFECTIVE MEDIA OR REFUND CUSTOMER’S

Page 5

Ta ble of Contents

General Safety Summary .......................................................................................... x

Service Safety Summary.................. ................................ .................................. ..... xii

Compliance Information ......................................................................................... xiii

EMC Compliance......... ................................ .................................. ................. xiii

Safety Compliance........................................................................................... xiii

Environmental Considerations ................ ................................ .............................. xv

Preface ............................................................................................................ xvii

Related Documentation .................................................................................... xvii

Product Description ....... .................................. ................................ ....................... 1

TLA7SA16 x8 Logic Protocol Analyzer Module .................................. ................... 1

TLA7SA08 x4 Logic Protocol Analyzer Module .................................. ................... 1

Midbus Probes...... .................................. ................................ ..................... 2

Slot Interposer Probes ............................... ................................ ..................... 2

Solder-Down Probe ............................ ................................ ........................... 3

Logic Protocol Analyzer Module Controls and Connectors ............... ............................... 4

Front Panel................................ ................................ ................................ . 4

LED Indicators ............................................................................................ 7

Rear Panel ................................................................................................. 9

Logic Protocol Analyzer and Logic Analyzer Compatibility .... . . . . . . . . . . . . .................... . . . . . . . . . 9

Options and Accessories.......................................................................................... 10

Install Common Hardware........................................................................................ 13

Connecting the Instrument to the SUT ............................ .................................. ............ 14

Clock Cable ................................................................................................... 16

Connecting a Clock Cable .............. ................................ ................................ 16

Connecting a Clock Jumper Cable..................................................................... 16

Connecting a Probe to the Logic Protocol Analyzer Module.............. .............................. 17

Connect the Midbus Probe................................................................................... 17

Handling the Probe Head ....................... .................................. ...................... 18

Connect the Probe........................................................................................ 19

Arranging the Midbus Probe Cables. ................................ ................................ .. 20

Connect the Slot Interposer Probe .......................................................................... 21

Handling the Probe Head ....................... .................................. ...................... 21

Connect the Probe........................................................................................ 21

Connecting a Probe to a x16 Link.......................... ................................ ............ 23

Installing the Slot SUT Card Support Bracket . . . . . . . . .................. . . . . . . . . . . ............... . . . . . 24

Connect the Solder Down Probe ............................................................................ 26

Connect to the Logic Protocol Analyzer Module..................................................... 26

P75TLRST Solder Tip........... ................................ .................................. ...... 27

Applying and Removing Power............................................................................. 30

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual i

Page 6

Table of Contents

Install the TMS

Using the Logic Protocol Analyzer Software .................................................................. 33

Logic Protocol Analyzer Setup Window ................................................................... 33

Open the Setup Window ..................................................................................... 33

Monitoring Signal Activity .... ................................ .................................. ............ 35

Defining the Link . ................................ .................................. .......................... 36

Selecting a Clock Signal Source ........................... .................................. .......... 36

Storage Settings ................ . . . . . . . . . . . . . . . . .. .......................... . . . . . . . . . . . . . . . . .. ............ 37

Descramble and Deskew ........ ................................ .................................. ...... 37

Defining a Data Filter.. . . . . . . . . . . . . . . ...................... . . . . . . . . . . . . . . ................... . .. . . . . . . . . . . 37

Assigning Lanes.. ................................ .................................. ...................... 37

Changing the Maximum Electrical Idle Timeout.............. ................................ ............ 39

Trigger Window............................... ................................ ................................ 39

Open the Trigger Window ............................. ................................ ...................... 39

Adding States, Clauses, Events, and Actions ......................................................... 40

Deleting States, Clauses, Events, and Actions........ ................................ ................ 41

Trigger Events............................................................................................ 41

Trigger Actions........................................................................................... 47

Acquiring and Viewing Data ..................................................................................... 48

Setting Up the Data Windows . . . . . .................... . . . . . . . . . . . . . . .................... . . . . . . . . . . . . ........ 49

Acquiring Data ................................................................................................ 49

Transaction Window...................................... .................................. .................. 49

Opening the Transaction Window...................................................................... 49

Transaction Window Elements ............................... .................................. ........ 50

Physical Layer View....... ................................ ................................ .............. 52

Using the Transaction Window with the Listing Window........................................... 52

Summary Profile Window . .................................. ................................ ................ 53

Summary Statistics Tab Notebook ..................................................................... 54

Element Table ................ .................................. ................................ .......... 55

Using the Custom Element.............................................................................. 56

Listing Window ... .................................. ................................ .......................... 57

Adding two Sides of a Link to a Single Listing Window............................................ 58

Changing How Data is Displayed........................................................................... 58

Bus-Specific Fields ...................................................................................... 59

10-Bit Mode Acquisition .................. . . . . . . . . . . ............... . . . . . . . . . . . .................. . . . . . . . . 60

Changing from Binary Listing Symbol Tables to 10-Bit Mode..................................... 60

Special Messages ........... ................................ .................................. ................ 60

Vendor Defined Message (VDM) Support...................................................................... 62

Probe Dimensions ........... .................................. ................................ .................... 63

P67SA08 Midbus Probe Head Dimensions ........................................................... 64

P67SA16 Midbus Probe Head Dimensions ........................................................... 65

160PCIe3 Support Software ................................................................... 31

ii Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 7

Table of Contents

Circuit Board D

Mechanical Design ........................................................................................... 71

Footprint Dimensions and Keep-Out Area ................................ ............................ 71

Routing Considerations for the Midbus Probe Footprint ............................................ 77

Midbus Probe CAD Symbols for PCB Layout ............................................................ 79

P67SA01SD Probe Solder Tips ............................................................................. 80

TriMode Resistor Solder Tip ........................................................................... 81

Tip Topology ............................................................................................. 81

Soldering the Tips.................. ................................ ................................ ...... 82

Reference Clock Cable Three-Pin Connector ............................. ................................ 85

Electrical Design.............................................................................................. 87

Measuring Signal Eye ................................................................................... 87

P67SAxx Midbus Probe Circuit Impact ............................................................... 88

P67SA16G2 x8 Midbus Probe Circuit Impact.................. .................................. .... 89

P67SAxx Slot Interposer Probe Circuit Impact..................................... .................. 90

P67SA01SD Solder-Down Probe Circuit Impact .............................. ...................... 91

Reference Clock Signal ...................................................................................... 93

Recognize the Reference Clock Signal by Directly Connecting to the SUT with a Reference Clock

Recognize the Clock Signal Embedded in the Data Stream......................................... 94

Midbus Footprint Pin and Probe Input Assignments ................ .................................. ........ 95

General Guidelines for Lane Mapping ..................................................................... 96

x8 PCI Express Midbus Pin Assignments............... ................................ .............. 97

x4 PCI Express Midbus Pin Assignments............... ................................ ............ 100

P67SA1

Diagnostics............. ................................ .................................. ........................ 105

Power-On Diagnostics ....................... ................................ .............................. 105

Extended Diagnostics ...................................................................................... 105

Troubleshooting.................................................................................................. 107

General Troubleshooting............. .................................. ................................ .... 107

Probe Troubleshooting ..................... ................................ ................................ 108

Using the P67UHDSMA Probe .......... .................................. .......................... 108

Care and Maintenance ...................... ................................ .................................. .. 113

Exterior Inspection ..................... ................................ ................................ .... 113

Inspection and Cleaning...................................... .................................. ............ 114

Module Exterior Cleaning Procedure.................................... ............................ 114

Probe Retention Mechanism Cleaning Procedure.................................................. 114

Probe Cleaning Procedure ............................ ................................ ................ 114

Cleaning the Probe Head.......... ................................ .................................. .. 115

Storing the Probe............................................ ................................ ................ 115

Repackaging Instructions .............................. ................................ .................... 115

esign.............................................................................................. 71

Cable.................................................................................................. 93

6G2 x8 Midbus ProbePin Assignments.................................................... 103

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual iii

Page 8

Table of Contents

Appendix A: TLA

Updating the Logic Protocol Analyzer Module Firmware ............................................. 117

Appendix B: File Attachments ....................... .................................. ........................ 119

Probe Electrical Simulation Models.. .................................. ................................ .. 119

Midbus Probe CAD Symbols for PCB Layout .......................................................... 120

Midbus Probe 3D CAD Models........................................................................... 121

DSP Filter F

Appendix C: Installing the Midbus Retention M echanism . .............................. .. .. . . . . . . . . . . . . . . 123

Cleaning the Footprint ................... ................................ .................................. 123

Installing the Midbus Retention Mechanism . . . . . ................... . . . . . . . . . . .................... . . . . . . 123

Installing the Retention Mechanism for the P67SA08 or P67SA16 Midbus Probes . . . . . . . .... 123

Installing the Retention Mechanism for the P67SA16G2 x8 Midbus Probes . .................. 125

Appendi

Appendix E: Rearranging Wires in the Probe Connector ................. ................................ .. 133

Appe

Appendix G: Solder-Down Probe Bullets..................................................................... 139

Glossary

In

x D: System Design Review Checklist.............................................................. 129

General Considerations ............................ .................................. ...................... 129

Midbus Probe Configuration .............................................................................. 129

Mechanical Considerations.......... ................................ .................................. .... 129

Electrical Considerations ...................... ................................ ............................ 131

ndix F: Adding Probes to the P67SA01SD Probe Connector ........................................ 137

Removing the Bullets ...................... ................................ ................................ 139

Inspecting the Bullets and Connectors ................................. ................................ .. 141

Installing the Bullets..... . . . . . . . . . . . . . .................... . . . . . . . . . . . . .................. . . . . . . . . . . . . ........ 141

dex

Application Software ........... ................................ .......................... 117

iles for Probe Troubleshooting . ................................ ............................ 121

iv Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 9

List of Figures

Figure 1: P67SA16 x8 midbus probe............................................ ................................. 2

Figure 2: P67SA08S x8 Slot interposer probe ....... ................................ ........................... 3

Figure 3: P67SA01SD Solder-Down probe ..................................................................... 4

Figure 4: TLA7SA08 logic protocol analyzer front panel ... .................................. ............... 5

Figure 5: TLA7SA16 logic protocol analyzer front panel ... .................................. ............... 6

Figure 6: TLA7SA16 rear panel .................................................................................. 9

Figure 7: Installing a module. .................. . . . . . . . . . . .................. . . . . . . . . . . .................. . . . . . . . . . . 13

Figure 8: Installation overview .................................................................................. 14

Figure 9: Clock cable and clock jumper cable ................... .................................. ............ 16

Figure 10: Connecting a probe to the retention mechanism .................................................. 19

Figure 11: Arranging the midbus probe cables................................................................. 20

Figure 12: Connecting a slot interposer probe ................................................................. 22

Figure 13: Slot SUT card support bracket configurations..................................................... 25

Figure 14: Installing the P67SA01SD probe . . . . . . . ................. . . . . . . . . . . . . . .................. . . . . . . . . . . . . 27

Figure 15: Connecting the P75TLRST tip to the probe head................................................. 28

Figure 16: Connecting wires to the circuit........................................ .............................. 29

Figure 17: Connecting the tip to the circuit................... ................................ .................. 30

Figure 18: Default Setup window ............................................................................... 34

Figure 19: Channel-lane connectors............................................................................. 38

Figure 20: Default Trigger window ............................................................................. 40

Figure 21: Specifying a TLP event .............................................................................. 42

Figure 22: Defining a TLP ....................................................................................... 42

Figure 23: Specifying a DLLP event............................................................................ 43

Figure 24: Defining a DLLP ..................................................................................... 43

Figure 25: Specifying a Link event................................ ................................ .............. 44

Figure 26: Defining a Link event .......... ................................ ................................ ...... 44

Figure 27: Specifying a symbol sequence ...................................................................... 45

Figure 28: Defining a symbol sequence................................. ................................ ........ 45

Figure 29: Event counter . ................................ ................................ ........................ 46

Figure 30: Specifying a global counter ............................... ................................ .......... 46

Figure 31: Specifying a timer .......... ................................ ................................ .......... 46

Figure 32: Transaction window.................................................................................. 50

Figure 33: Side-by-side Transaction window and Listing window .......................................... 52

Figure 34: Opening the Summary Profile window ............................................................ 53

Figure 35: Summary Profile window............................................................................ 54

Figure 36: Summary Profile window (Summary Statistics Tab Notebook)................................. 55

Figure 37: Define Packet window for a Custom element in the Summary Profile window ............... 56

Figure 38: Data displayed in the Listing window.............................................................. 57

Figure 39: P67SA08 and P67SA16 cable length dimensions ................................................ 63

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual v

Page 10

Table of Contents

Figure 40: P67S

Figure 41: P67SA16 midbus probe head dimensions ......................................................... 65

Figure 42: P67SA16S, P67SA08S, P67SA04S and P67SA01S Slot Interposer probe cable lengths ... . 66

Figure 43: P67SA16S Slot Interposer Probe dimensions

Figure 44: P67SA01S, P67SA04S, and P67SA08S Slot Interposer probe dimensions...... . . . . . . . . . . .... 67

Figure 45: PCI Express Compliance Load Board (CLB1).............. .................................. .... 68

Figure 46: P75TLRST Solder Tip dimensions ................................................................. 68

Figure 47: TriMode Resistor Solder Tip dimensions.......................................................... 69

Figure 48: Connecting the P67SA01SD Solder-Down probe ................................................ 70

Figure 49: x8 midbus footprint dimensions and keep-out area (front side of circuit board) ... . . . . . . . . . . . 72

Figure 50: x8 midbus footprint dimension and keep-out area (back side of circuit board) ............. . . 73

Figure 51: Footprint pad details for x8 and x4 midbus probes ............................................... 73

Figure 52: x4 midbus footprint dimensions and keep-out area (front side of circuit board) ... . . . . . . . . . . . 74

Figure 53: x4 midbus footprint dimension and keep-out area (back side of circuit board) ............. . . 75

Figure 54: P67SA16G2 x8 midbus footprint dimensions and keep-out area ......................... ...... 76

Figure 55: Recommended trace routing on the primary surface layer................... .................... 78

Figure 56: P67SA08 x4 midbus probe CAD symbol.......................................................... 79

Figure 57: P67SA16 x8 midbus probe CAD symbol.......................................................... 79

Figure 58: P75TLRST TriMode Long Reach Solder Tip..................................................... 80

Figure 59: TriMode Resistor Solder Tip ........................................................................ 81

Figure 60: Typical wire length from probe tip to circuit ...................................................... 82

Figure 61: P75TLRST solder tip with 0.010 inch of tip wire .................. .............................. 83

Figure 62: P75TLRST solder tip with 0.050 inch of tip wire .................. .............................. 83

Figure 63: P75TLRST solder tip with 0.100 inch of tip wire .................. .............................. 84

Figure 64: P75TLRST solder tip with 0.200 inch of tip wire .................. .............................. 84

Figure 65: Reference clock cable connector dimensions ..................................................... 86

Figure 66: Signal eye measurements (time versus voltage) .................................................. 87

Figure 67: Probe impact of the P67SAxx midbus probe...................................................... 89

Figure 68: S-parameter data of retention mechanism only ................................................... 89

Figure 69: S-parameter data of retention mechanism plus P67SA16G2 x8 Midbus probe ............... 90

Figure 70: Probe impact of the P67SAxxS slot probe......................... ................................ 91

Figure 71: S-parameter data of P67SA01SD Solder-Down probe ........................................... 92

Figure 72: Slot interposer probe with a reference clock cable connected ............................. ...... 93

Figure 73: P67SA16 x8 midbus probe footprint pin assignments ................. .......................... 95

Figure 74: P67SA08 x4 midbus probe footprint pin assignments ................. .......................... 95

Figure 75: x8 midbus footprint connections for an upstream or downstream configuration .............. 97

Figure 76: x8 midbus footprint connections in an upstream and downstream configuration ............. 98

Figure 77: x8 midbus footprint connections for an upstream and downstream configuration ............ 99

Figure 78: x4 midbus footprint connections for an upstream or downstream configuration ............ 100

Figure 79: x4 midbus footprint connections for an upstream and downstream configuration .......... 101

Figure 80: x4 midbus footprint connections for an upstream and downstream configuration. ......... 102

A08 midbus probe head dimensions ......................................................... 64

..................................................... 66

vi Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 11

Table of Contents

Figure 81: P67S

Figure 82: P67SA16G2 x8 midbus footprint connection module connector ............................. 103

Figure 83: P67UHDSMA probe connected to the inputs of a Tektronix oscilloscope (example 1) . . . . 110

Figure 84: P67UHDSMA probe connected to the inputs of a Tektronix oscilloscope (example 2) . . . . 111

Figure 85: x8 footprint.......................................................................................... 123

Figure 86: Connecting the P67SA16 midbus probe to the retention mechanism on the circuit board . 124

Figure 87: C

Figure 88: Installing the retention mechanism ............... . . . . . . . . . . . . .................. . . . . . . . . . . . . ...... 126

Figure 89: Soldering the anchoring posts to the circuit board (PCB).................................. .... 127

Figure 90: Opening the probe connector...................................................................... 134

Figure 91: Removing the probe sleeve........................................................................ 134

Figure 92: Probe labels ......................................................................................... 135

Figure 9

Figure 94: Inserting additional probe wires .................... . . . . . . . . . . . . ................... . . . . . . . . . . . . . .. 137

Figure 95: Replaceable bullets and tool....................................... ................................ 139

Figure 96: Removing the bullet contacts ......................... ................................ ............ 140

Figure 97: Inspect the bullet contacts ......................................................................... 141

Figure 98: Installing the bullet contacts. . . .................... . . . . . . . . . . . . . . ................... . . . . . . . . . . . . . . . 142

3: Removing individual wires........................................................................ 135

A16G2 midbus probe footprint pin assignments.......................................... 103

onnecting the P67SA08 midbus probe to the retention mechanism on the circuit board . 125

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual vii

Page 12

Table of Contents

List of Tables

Table 1: Front panel indicators and connectors .................... ................................ ............. 7

Table 2: Status LEDs............................................................................................... 8

Table 3: TLA7SAxx logic protocol analyzer module standard accessories........................... ...... 10

Table 4: P67SA16 and P67SA08 midbus probes standard accessories...................................... 10

Table 5: P67SA16 and P67SA08 midbus probes optional accessories.............. ........................ 10

Table 6: P67SAxxS slot probes standard accessories ......................................................... 11

Table 7: P67SA01SD solder-down probe standard accessories ........ ................................ ...... 11

Table 8: P67SA01SD solder-down probe

Table 9: TLA7SAxx logic protocol analyzer module and P67SAxxx probes service options .... . . . . . . . . 12

Table 10: P67UHDSMA standard accessories ................................................................. 12

Table 11: TLA Modules and midbus probes per link.......................................................... 15

Table 12: TLA Modules and slot interposer probes per link ..................... ............................ 15

Table 13: TLA Modules and solder down probes per link.................................................... 15

Table 14: Status indicators in the Setup window............................................................... 35

Table 15: Trigger events .......................................................................................... 41

Table 16: Trigger event recognizer resources ...................... ................................ ............ 41

Table 17: Trigger actions ......................................................................................... 47

Table 18: Special characters in the Listing window ........... ................................ ................ 57

Table 19: Logic protocol analyzer disassembly display options ............................................. 59

Table 20: Training sequence messages.......................................................................... 60

Table 21: Packet framing messages ............. ................................ ................................ 60

Table 22: DLLP messages............ ................................ ................................ ............ 60

Table 23: TLP header messages ................................................................................. 61

Table 24: CRC checking messages .......................... ................................ .................... 61

Table 25: General acquisition messages . . .................... . . . . . . . . . . . . ................... . . . . . . . . . . . . . ...... 61

Table 26: Recommended circuit board design criteria ........................................................ 71

Table 27: Trace cha

Table 28: Reference clock cable three-pin connector pin assignments.................................. .... 86

Table 29: Reference clock electrical requirements ............................ ................................ 94

Table 30: Failure symptoms and possible causes ............................................................ 107

Table 31: Internal inspection checklist........................................................................ 113

Table 32: Probes and related electrical simulation models ................................................. 119

Table 33: Midbus Probe CAD Symbols for PCB Layout ................... ................................ 120

Table 34: Midbus Probe 3D CAD Models.................................... ................................ 121

Table 35: Probes and related DSP filter files ....................... ................................ .......... 121

Table 36: P67SA16 midbus probe retention assembly kits................................................. 124

Table 37: P67SA08 midbus probe retention assembly kits................................................. 125

Table 38: 6P67SA16G2 x8 midbus probe retention assembly kit........................................ .. 127

optional accessories .. ................................ ............ 11

racterisitics ............ .................................. ................................ .... 77

viii Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 13

Table of Contents

Table 39: Midbu

Table 40: Midbus probe......................................................................................... 129

Table 41: Slot interposer probe ................................................................................ 130

Table 42: Reference clock connector.......................... .................................. .............. 130

Table 43: Midbus probe......................................................................................... 131

Table 44: Slot interposer probe ................................................................................ 132

Table 4 5: Re

s probe configuration ........................................................................ 129

ference clock connector...................... ................................ .................... 132

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual ix

Page 14

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Use proper voltage setting. Before applying power, ensure that the line selector

is in the proper position for the source being used.

Connect and disconnect properly. Do not connect or disconnect probes or test

leads while they are connected to a voltage source.

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product o nly as specified.

elated to operating the system.

Observe all terminal ratings. To a void fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the p roduct.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Connect the probe reference lead to earth ground only.

Do not apply a potential to any terminal, including the common terminal, that

exceeds the maximum rating of that terminal.

Power disconnect. The power cord disconnects the product from the power source.

Donotblockthepowercord;itmustremain accessible to the user at all times.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

x Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 15

General Safety Summary

TermsinThisManual

Symbols and Terms on the

Product

Do not operate i

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

Provide prop

details on installing the product so it has proper ventilation.

These terms may appear in this manual:

WAR NING.

in injury or loss of life.

CAUTION

damage to this product or other property.

These t

erms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the ma

n wet/damp conditions.

er ventilation. Refer to the manual’s installation instructions for

Warning statements identify conditions or practices that could result

. Caution statements identify conditions or practices that could result in

rking.

WARNING indicates an injury hazard not immediately accessible as you

the marking.

read

CAUTION indicates a hazard to property including the product.

The following symbol(s) may appear on the product:

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual xi

Page 16

Service Safety Summary

Service Safet

y Summary

Only qualifie

Safety Summary and the General Safety Summary befor e performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person c apable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

d personnel should perform service procedures. Read this Service

this product. Disconnect power, remove battery (if applicable), and

xii Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 17

Compliance Information

This section lists the EMC (electromagnetic compliance), safety, and

environmental standards with which the instrument complies.

EMC Compliance

EMC Compliance

Australia / New Zealand

Declaration of

Conformity – EMC

Safety Compliance

Equipment Type

Meets the intent of Directive 2004/108/EC for Electromagnetic Compatibility

when it is used with the product(s) stated in the specifications table. Refer to the

EMC specification published for the stated products. May not meet the intent of

the directive if used with other products.

European contact.

Tektronix UK, Ltd.

Western Peninsula

West e rn Road

Bracknell, RG12 1RF

United Kingdom

Complies with the EMC provision of the Radiocommunications Act per the

following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in

accordance with EN 61326-1:2006.

Test and measuring equipment.

Safety Class

Pollution Degree

Description

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual xiii

Class1–groundedproduct.

A measure of the contaminants that could occur in the environment around

and within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs.

Products in this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution Degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

Page 18

Compliance Information

Pollution Degree

Installation (Overvoltage)

Category Descriptions

Pollution Degr

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution Degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, or s now. Typical outdoor locations.

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Terminals on this product may have different installation (overvoltage) category

designations. The installation categories are:

Measurement Category IV. For measurements performed at the source of

low-voltage installation.

Measurement Category III. For measurements performed in the building

installation.

Measurement Category II. For measurements performed on circuits directly

connected to the low-voltage installation.

Measurement Category I. For measurements performed on circuits not

directly connected to MAINS.

ee 3. Conductive pollution, or dry, nonconductive pollution

Overvoltage Category

Overvoltage Category I (as defined in IEC 61010-1)

xiv Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 19

Compliance Information

Environmenta

l Considerations

Product End-of-Life

Handling

Restriction of Hazardous

Substances

This section provides information about the environmental impact of the product.

Observe the following guidelines when recycling an instrument or component:

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could b e

harmful to

end of life. In order to avoid release of such substances into the environment and

to reduce the use of natural resources, we encourage you to recycle this product

in an appropriate system that will ensure that most of the materials are reused or

recycled appropriately.

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive.

the environment or human health if improperly handled at the product’s

This sym

Union requirements according to Directives 2002/96/EC and 2006/66/EC

on waste electrical and electronic equipment (WEEE) and batteries. For

informa

Tektronix Web site (www.tektronix.com).

bol indicates that this product complies with the applicable European

tion about recycling options, check the Support/Service section of the

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual xv

Page 20

Compliance Information

xvi Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 21

Preface

Preface

Related Documentation

This manual d

escribes how to install and use a TLA7SA16 or TLA7SA08 Logic

Protocol Analyzer, probes, and software with your PCI Express 3 system.

The following table lists related documentation, available f rom the Tektronix

Web site (www.tektonix.com/manuals).

The TLA7SA08 & TLA7SA16 PCIe3 Product Specifications and Performance

Ver i fication Technical Reference Manual (Tektronix part number

077-0402-xx) lists the product specifications and high-level functional check

procedures for your TLA7SA16 or TLA7SA08 Logic Protocol Analyzer

Module and probes.

d documentation

Relate

Item Purpos

TLA Qui

Onlin

Inst

Installation Manuals

XYZ

Dec

Application notes

P

Verification Procedures

T

Field upgrade kits

Optional Service Manuals Self-service documentation for modules and

ck Start User Manuals

eHelp

allation Reference Sheets

s of Logic Analyzers

lassification and Se curities instructions

roduct Specifications & Performance

PI.NET Documentation

e

High-level operational overview

In-depth operation and UI help

-level installation information

High

iled first-time installation information

Deta

Logic analyzer basics

a security concerns specific to sanitizing

Dat

or removing memory devices from Tektronix

products

Collection of logic analyzer application

ecific notes

sp

LA Product specifications and performance

T

verification procedures

Detailed information for controlling the logic

analyzer using .NET

Upgrade information for your logic analyzer

mainframes

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual xvii

Page 22

Preface

xviii Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 23

Product Description

Tektronix provides two different logic protocol analyzer modules and probes. The

logic protocol analyzer modules have acquisition rates of 8.0 GT/s, 5.0 GT/s, and

2.5 GT/s to acquire PCIe3, PCIe2, and PCIe1 data. They provide packet-level

triggering, sequence triggering, and error triggering. The modules acquire up

to 160 milli

the modules are the number of inputs.

on 8b/10b symbols or bytes-per-line. The main difference between

TLA7SA16 x8 Logic

Protocol A

nalyzer Module

TLA7SA08 x4 Logic

Protocol Analyzer Module

The TLA7SA16 Logic Protocol Analyzer Module has 16 differential inputs and

supports x

The TLA7SA08 Logic Protocol Analyzer Module has 8 differential inputs and

supports x1, x2, and x4 links.

1, x2, x4, and x8 links.

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 1

Page 24

Product Description

Midbus Probes

A midbus probe c

You must install the retention mechanism to either a PCI Express Gen3, Gen2,

or Gen 1 footprint on your circuit board. (See page 123, Installing the Midbus

Retention Mechanism.) Tektronix offers the following midbus probes:

P67SA16 x8 Midbus probe

P67SA08 x4 Midbus probe

P67SA16G2 x

onnects to a retention mechanism installed on your circuit board.

8 Midbus probe

re 1: P67SA16 x8 midbus probe

Figu

Slot Interposer Probes

2 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

A slot interposer probe connects to a PCI Express slot on your SUT. Tektronix

ers the following slot interposer probes:

off

P67SA16S PCI Express x16 slot interposer probe

P67SA08S PCI Express x8 slot interposer probe

P67SA04S PCI Express x4 slot interposer probe

P67SA01S PCI Express x1 slot interposer probe

Page 25

Product Description

Solder-Down Probe

Figure 2

The P67SA01SD probe connects to your SUT through the differential solder-down

tip (P7

each signal connector to the logic protocol module. (See page 137, Adding Probes

to the P67SA01SD Probe Connector.)

: P67SA08S x8 Slot interposer probe

5TLRST). Up to four probes (one differential pair each) can be installed in

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 3

Page 26

Product Description

Figure 3: P67SA01SD Solder-Down probe

Logic Protocol Analyzer Module Controls and Connectors

section briefly describes the logic protocol analyzer controls and connectors.

This

Front Panel

The front panel provides indicators for checking the status of the logic protocol

analyzer. It includes probe connectors, two probe power connectors, and four

nectors for a reference clock. The TLA7SA08 has two probe connectors.

con

(See Figure 4.) The TLA7SA16 has four probe connectors. (See Figure 5.) A

description of the indicators and connectors is provided. The functions of the

indicators and connectors are the same for both modules except where noted.

(See Table 1 on page 7.)

4 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 27

Product Description

Figure 4: TLA7SA08 logic protocol analyzer front panel

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 5

Page 28

Product Description

Figure 5: TLA7SA16 logic protocol analyzer front panel

6 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 29

Product Description

Table 1: Front p

Item

number Indicator or connector Description

1 READY indicat

2

3 ARM’D indic

4

5

6

7

8LEDind

9 Probe connectors

anel indicators and connectors

or

ACCESSED in

TRIG’D indicator The TRIG’D indicator lights when the logic protocol analyzer module triggers and stays on

Reference Clock Output

connecto

Reference Clock Input

connectors

Probe Power connectors The probe power connectors provide power to the probes.

dicator

ator

rs

icators

The READY indicator lights continuously after the logic protocol analyzer module

successfully completes the power-on process. If the indicator fails to light within five

seconds of po

The ACCESSE

analyzer module.

The ARM’D in

an acquisition.

until the module finishes acquiring data.

The Reference Clock Output SMA connectors (labeled + and – ) provide a means of

passing t

external module.

Two SMA connectors (labeled + and – ) provide differential clock input connections from

the SUT or from another module.

Three groups of LED indicators provide different information. (See page 7, LED

Indicators.)

Four connectors for the TLA7SA16 module (two for the TLA7SA08 module) provide the

probe

for the TLA7SA16 module (A or B for the TLA7SA08 module). The letters correspond to

the graphic display in the Setup window.

he differential clock signal from the Reference Clock Input connectors to another

connections for the module. Each connector is labeled with a letter A, B, C, or D

wer-on, an internal module failure may be present.

D indicator lights anytime the controller accesses the logic protocol

dicator lights when the logic protocol analyzer module is armed during

LED Indicators

The TLA7SA16 x8 modules have 32 front panel LEDs that provide information

on the status of the SUT. The TLA7SA08 x4 modules have 15 LEDs.

Link Rate LEDs. ThetopsetofLEDsaretheLink Rate LEDs. They monitor the

current rate of the SUT and indicate the most-recent rate detected by the module.

The TLA7SA16 x8 module has two columns of LEDs; the TLA7SA08 x4 module

has one.

The top LEDs (Row 1) show that the SUT is operating at 2.5 GT/s.

The center LEDs (Row 2) show that the SUT is operating at 5.0 GT/s.

The bottom LEDs (Row 3) show that the SUT is operating at 8.0 GT/s.

TheLEDshelpidentifyproblemsonthelink. The link might not be operating at

the highest-reported rate detected by the module on at least one direction of the

link. The rate of each link is determined from Lane 0; there is no indication if

other lanes are running at different rates.

Status LEDs. The Status LEDs provide an indication that the system is operating

as expected after the first turn-on. If the top two LEDs are turned on, the system is

working as expected.

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 7

Page 30

Product Description

Table 2: Status

Row / LED Description

TLA7SA16 and TLA7SA08

Top r ow

Diagnostics passed

Reference

Second row

Link Locked Down

Link Locked Up

TLA7SA16 only

Third, fourth, and fifth rows

Acquisition progress These LEDs progressively light in a downward

LEDs

Clock found

The left LED

the diagnostics. If the LED is off, check the Module

diagnostics to determine which diagnostics have

failed. If t

Diagnostics dialog box appears on the screen. If it

does not, select Calibratio n and Diagnostics from

the System

The right LED turns on when the module has locked

onto a refe

external. This LED should always be on unless an

external reference clock is selected and is not present.

This LED monitors the Serdes status of all lanes of the

Down lin

locked or in the EIDLE state. If the link is in the EIDLE

state, the LED blinks at a s teady rate.

This LED monitors the Serdes status of all lanes of

theUpl

locked or in the EIDLE state. If the link is in the EIDLE

state, the LED blinks at a s teady rate.

direction after an acquisition has started (the RUN

ton was pressed or clicked). The fifth row indicates

but

that the link is aligned (deskewed).

is on when the module has passed

he Power On diagnostics fail, the Power On

menu to display the dialog box.

rence clock. The clock can be internal or

k. The LED is on when all lanes are symbol

ink. The LE D is on when all lanes are symbol

tivity LEDs. The lower set of LEDs show the current Serdes status of each lane.

Ac

The LEDs track the status of the Dn/Up settings in the Setup window. An LED is

on when the corresponding lane is symbol locked. The LEDs a re on when the

lane is in the EIDLE state (and the EIDLE timeout counter has not expired). The

lanes are logically numbered to indicate their position in the link.

If there is a problem, you can quickly see which logical lane has the problem.

A blinking LED indicates an invalid condition, such as the lane not achieving

a symbol lock. For another example, if a problem occurs that causes the link

to downgrade to a x4 link, LEDs 4 through 7 will turn off. Refer to the Setup

window to determine which physical lane is associated with the logical lane.

NOTE. The Up and Dn indications on the front panel do not apply when all lanes

are capturing a single unidirectional link.

8 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 31

Product Description

Rear Panel

The rear panel p

The rear panel includes two logical address switches. (See Figure 6 on page 9.)

Tektronix recommends that you leave the switches at the default switch setting

of FF (Dynamic Auto Configuration). When the switches are set to FF, the

instrument automatically sets the address to an u nused value.

NOTE. Do not set any module to logical address 00. Logical address 00 is

reserved ex

rovides connectors to connect the module to the mainframe.

clusively for the controller.

Figure 6: TLA7SA16 rear panel

Logic Protocol Analyzer and Logic Analyzer Compatibility

Install the TLA7SA08 & TLA7SA16 Logic Protocol Analyzer modules in either a

A7012 portable mainframe logic analyzer, or a TLA7016 benchtop mainframe

TL

logic analyzer. The logic analyzer must have TLA Software V5.7 or higher

installed, and the latest version of the TMS160PCIe3 Tektronix PCI Express

Support Software.

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 9

Page 32

Options and A ccessories

Options and Ac

cessories

The followin

Analyzer Modules and TLA7SA16 Logic Protocol Analyzer Modules.

Table 3: TLA

Accessory

Reference clock cable, SMA-to-3 pin header

Cable assembly, reference clock jumper

The following table lists the accessories for the P67SA16 and P67SA08 midbus

probes. F

refer to the information in Appendix C. (See page 123, Installing the Midbus

Retention Mechanism.)

Table 4: P67SA16 and P67SA08 midbus probes standard accessories

Accessory

Probe case 016-1994-xx

x8 Bolster assembly kit (includes

x8 Retention mechanism 131-8616-xx

x4 Bolster assembly kit (includes1/16-inch hex wrench)

x4 Retention mechanism 131-8617-xx

Probe head jack screw adjustment tool 003-1890-xx

Probe cable straps (two straps)

g table lists the accessories for the TLA7SA08 Logic Protocol

7SAxx logic protocol analyzer module standard accessories

Tektr onix

part number

672-6285-x

174-5392-

or descriptions of the bolster assembly kits and retention mechanisms

Tektr onix

part number

1

/16-inch hex wrench)

020-3056-xx

020-3057-xx

346-0300-xx

x

xx

Table 5: P67SA16 and P67SA08 midbus probes optional accessories

Tektr onix

cessory

Ac

8 Retention assembly kit, P67SA16

x

Consisting of the x8 retention mechanism (Tektronix part number,

131-8616-xx) and the bolster assembly kit (Tektronix part number,

20-3056-xx)

0

x4 Retention assembly kit, P67SA08

Consisting of the x4 retention mechanism (Tektronix part number,

131-8617-xx) and the bolster assembly kit (Tektronix part number,

020-3057-xx)

rt number

pa

020-4016-xx

020-4008-xx

10 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 33

Options and Accessories

The following t

able lists the accessories for the P67SAxxS slot probes.

Table 6: P67SAxxS slot probes standard accessories

Tektronix

Accessory

Probe case, P67SA16S

Probe case, P67SA08S, P67SA04S, P67SA01S

Tall support bracket, P67SA16S

Short support bracket, P67SA04S, P67SA08S

Probe cable straps (two straps)

part number

016-2002-xx

016-1994-xx

407-5559-xx

407-5560-xx

346-0300-xx

The following table lists the standard accessories for the P67SA01SD solder-down

probe.

Table 7: P67SA01SD solder-down probe standard accessories

Tektronix

ory

Access

Probe case 016-2009-xx

Solder kit, ROHS-compliant (two spools w ire, one spool solder)

G3PO bullet removal tool

Bullet contacts (QTY 4)

Solder tip P75TLRST

Probe cable straps (package of 2 straps)

mber

part nu

020-2754-xx

003-1896-xx

013-0359-xx

016-1953-xx

The following tables list the optional accessories for the P67SA01SD solder-down

probe.

Table 8: P67SA01SD solder-down probe optional accessories

Tektronix

Accessory

Probe power adapter (one required to power up to eight P67SA01SD

probes)

Solder tip tape (strip of 10)

Solder kit, ROHS-compliant (two spools w ire, one spool solder)

Probe cable straps (package of 2 straps)

G3PO bullet removal tool

Bullet contacts (QTY 4)

Probe power adapter 878-0509-xx

Solder tip P75TLRST

Trimode resistor solder tip, with resistor leads 020-2936-xx

Resistor conversion kit to add resistor leads to P75TLRST trimode solder tip

part number

P67SA01SD

Option 1P

066-8237-xx

020-2754-xx

016-1953-xx

003-1896-xx

013-0359-xx

020-2937-xx

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 11

Page 34

Options and A ccessories

The following t

able lists the service options for the modules and probes.

Table 9: TLA7SAxx logic protocol analyzer module and P67SAxxx probes service

options

Option

Service Offerings

Repair warranty extended to cover three years (including warranty)

Repair warranty extended to cover five years (including warranty)

Single calibration event or coverage CA1

Calibration services extended to cover three years C3

Calibration services extended to cover five years C5

number

R3

R5

The following table lists the accessories for the P67UHDSMA four-differential

inputs, x2, UHD-to-SMA probe leadset for use with the P67xx and P67SAxx

series probes.

Table 10: P67UHDSMA standard accessories

Tektr onix

Accessory

50 Ω SMA terminator (QTY 8)

SMA connector, female-to-female (QTY 8)

part number

015-1022-xx

015-1012-xx

12 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 35

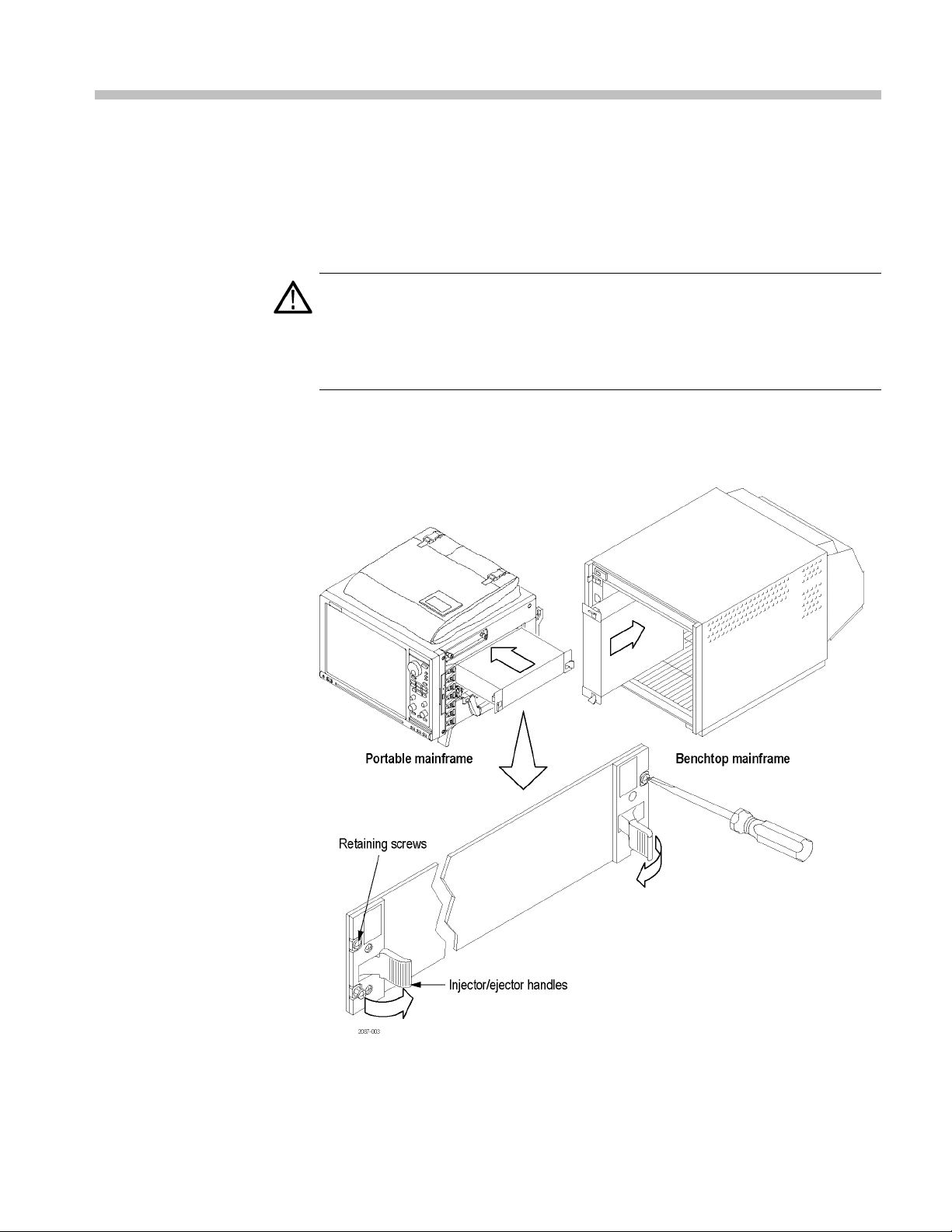

Install Common Hardware

This manual is written assuming that your logic analyzer mainframe is already

installed properly. However, a high-level module installation overview is

provided. If

TLA7000 Series Logic Analyzers Installation Manual.

CAUTION. To avoid damaging the mainframe, do not install or remove any

modules while the mainframe is powered on. Always power off the instrument

before installing or removing modules.

Cover any empty module slots with a blank cover (Tektronix part number,

333-4206-xx).

Install the modules in the mainframe. (See Figure 7.) Use a screwdriver to tighten

the retaining screws to 2.5 in-lbs after seating the modules in place.

you need additional help installing your mainframe, refer to the

Figure 7: Installing a module

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 13

Page 36

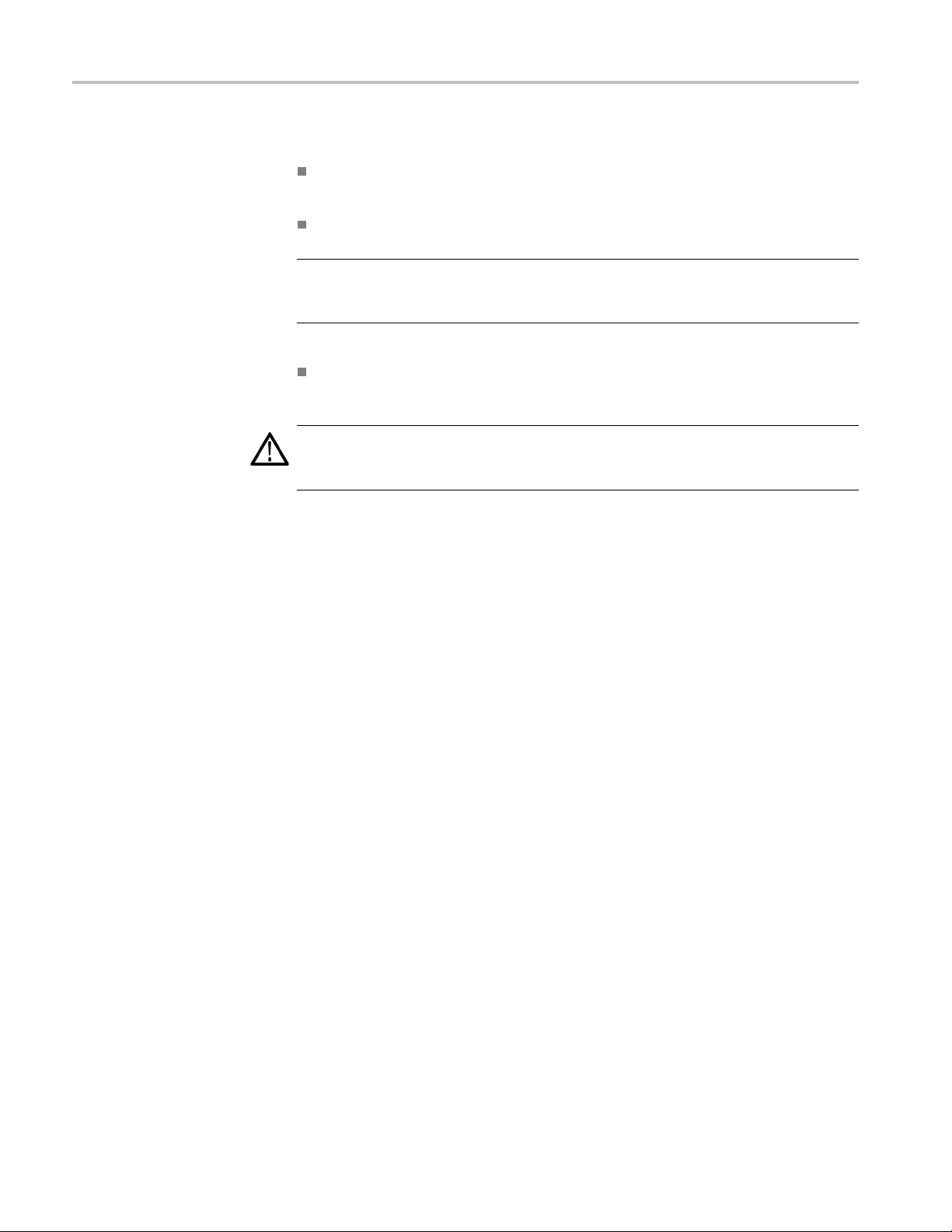

Connecting the Instrument to the SUT

Connecting th

e Instrument to the SUT

The probes co

following illustration shows possible connections to your SUT. Choose the

probing scheme that works for your application.

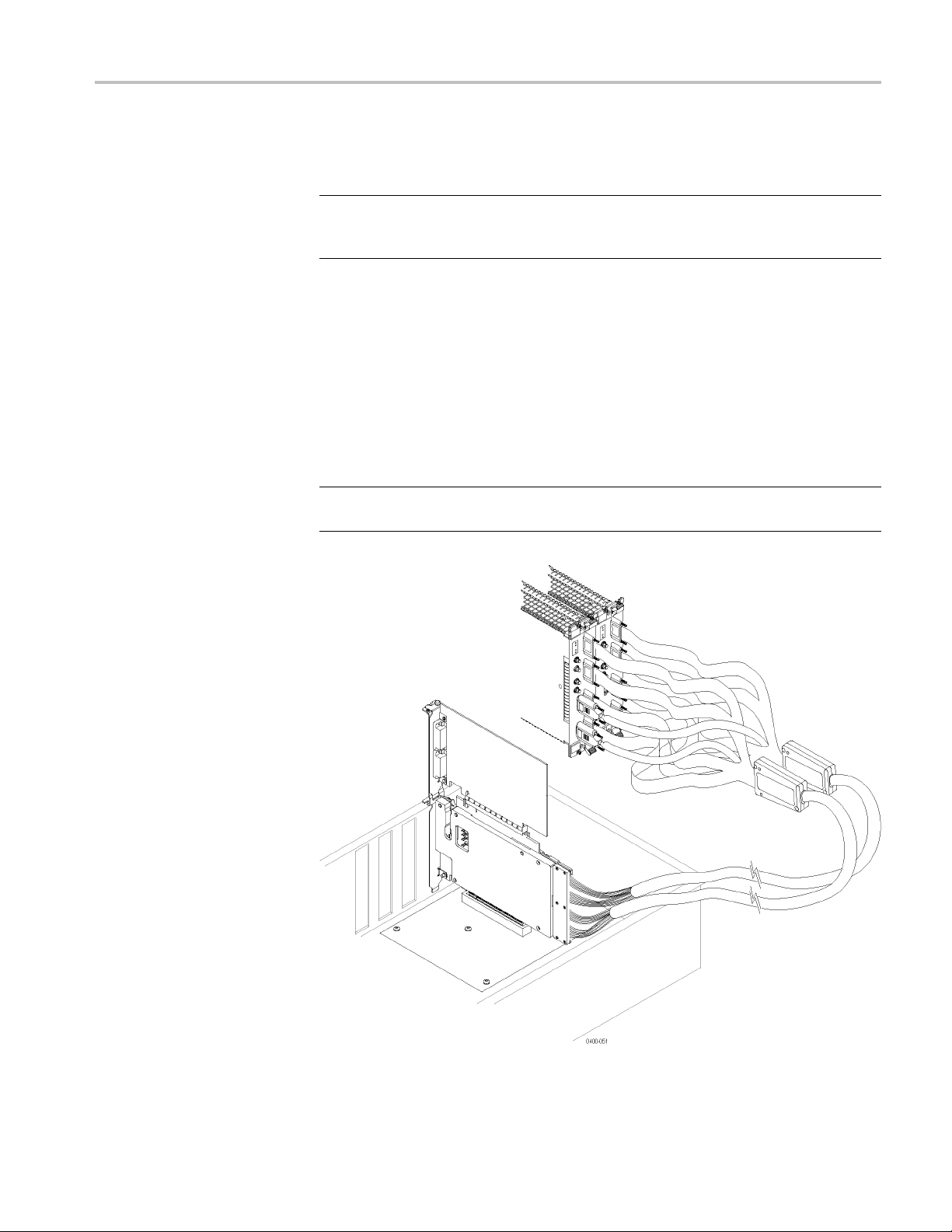

nnect your logic protocol analyzer module to the SUT. The

Figure 8: Installation overview

14 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 37

Connecting the Instrument to the SUT

The following t

ables list the number of probes needed per module to connect to a

link. Refer to the previous illustration for an overview of the connections to the

logic analyzer and SUT. (See Figure 8 on page 14.)

Additional probe connection information is provided later in this document; refer

to those sections for additional information.

Table 11: TLA Modules and midbus probes per link

Link TLA M od ules Probes

x16

x8

x4, x2, or

x1

Table 12

Link TLA Modu

x16

x8

x4, or x2

x1

2 TLA7SA16 2 P67SA16

1 TLA7SA16 1 P67SA16

1 TLA7SA16 or 1 TLA7SA08 1 P67SA16 or P67SA08

: TLA Modules and slot interposer probes per link

les

2 TLA7SA

1 TLA7S

1 TLA7

1 TLA7

16

A16

SA16 or 1 TLA7SA08

SA16 or 1 TLA7SA08

Probes

1 P67SA1

1 P67SA

A04S

1 P67S

A01S

1 P67S

08S

6S

Table 13: TLA Modules and solder down probes per link

Link TLA M od ules Probes

x16

x8

x4

x1

2TLA7SA16 32 P67SA01SD

1 TLA7SA16 16 P67SA01SD

1 TLA7SA16 or 1 TLA7SA08 8 P67SA01SD

1 TLA7SA16 or 1 TLA7SA08 2 P67SA01SD

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 15

Page 38

Connecting the Instrument to the SUT

Clock Cable

Two clock connection cables are included with your logic protocol analyzer

module. One is for connecting the reference clock input of the module to the

SUT or slot in

module to another.

terposer probe, and the other is a jumper cable for connecting one

Connecting a Cloc k Cable

Connecting a Clock

Jumper Cable

Figure 9

Connect a clock cable by following these steps:

1. Connect one end of the cable to the Ref Clock input connectors (+ and –) on

2. Connect the other end of the correct cable to the SUT three-pin connector or

1. Connect one end of the cable to the Ref Clock input connectors (+ and –) on

2. Connect the other end of the cable to the Ref Clock output connectors

NOTE. Clock Reference Source must be set to SUT if either clock cable is used.

(See page 36, Selecting a Clock Signal Source.)

: Clock cable and clock jumper cable

the logic protocol analyzer module; screw the SMA connectors down until

re snug.

they a

lot interposer probe three-pin connector.

the s

the logic protocol analyzer module; screw the SMA connectors down until

yaresnug.

the

and–)onanothermodule.

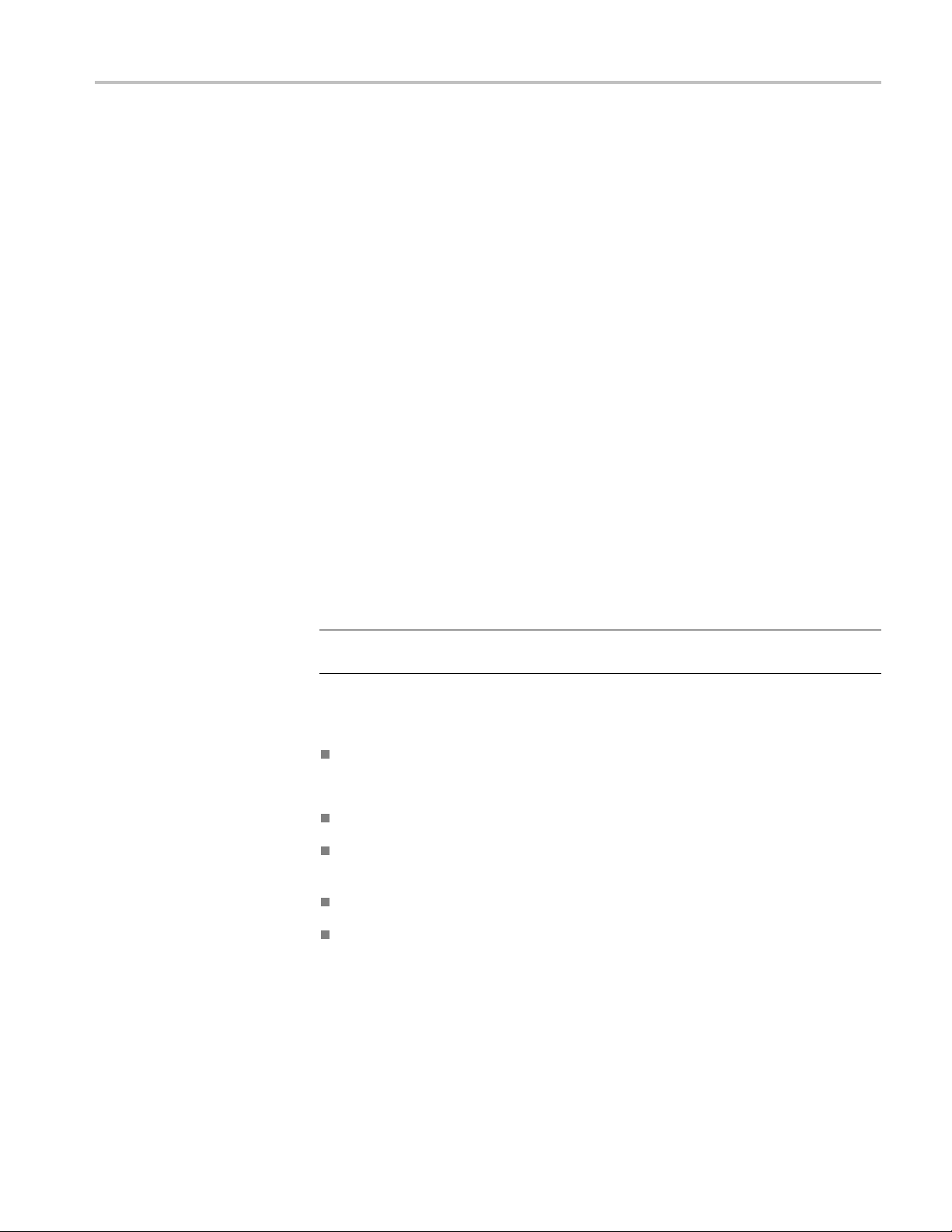

(+

16 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 39

Connecting the Instrument to the SUT

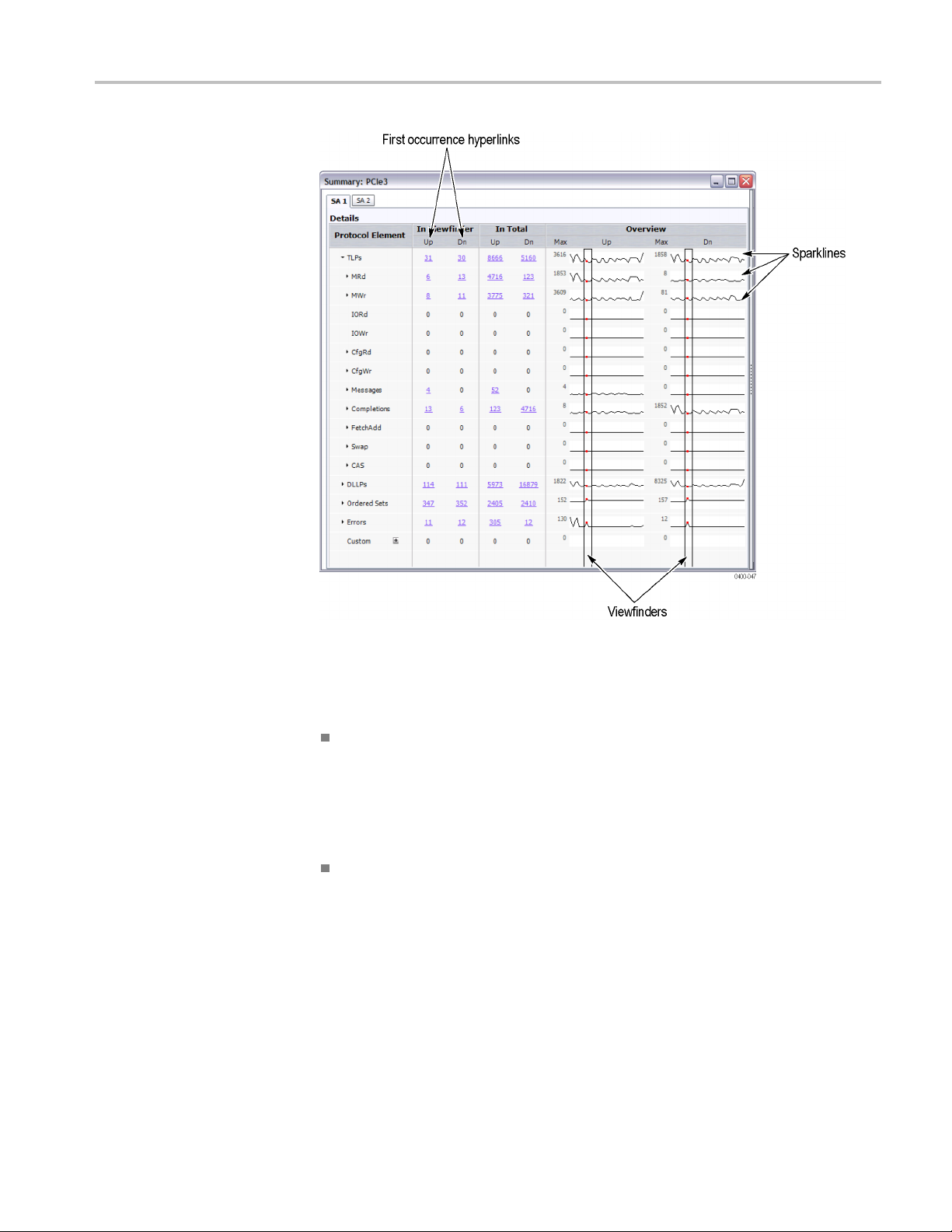

Connecting a P

robe to the Logic Protocol Analyzer Module

Follow these steps to connect a probe to the logic protocol analyzer:

1. Note the label on the module-end of the probe connector and connect the

2. Connect the probe power connector to one of the power connectors on logic

3. Tighten the connector screws using the adjustment tool included with your

Connect the Midbus Probe

The P67S

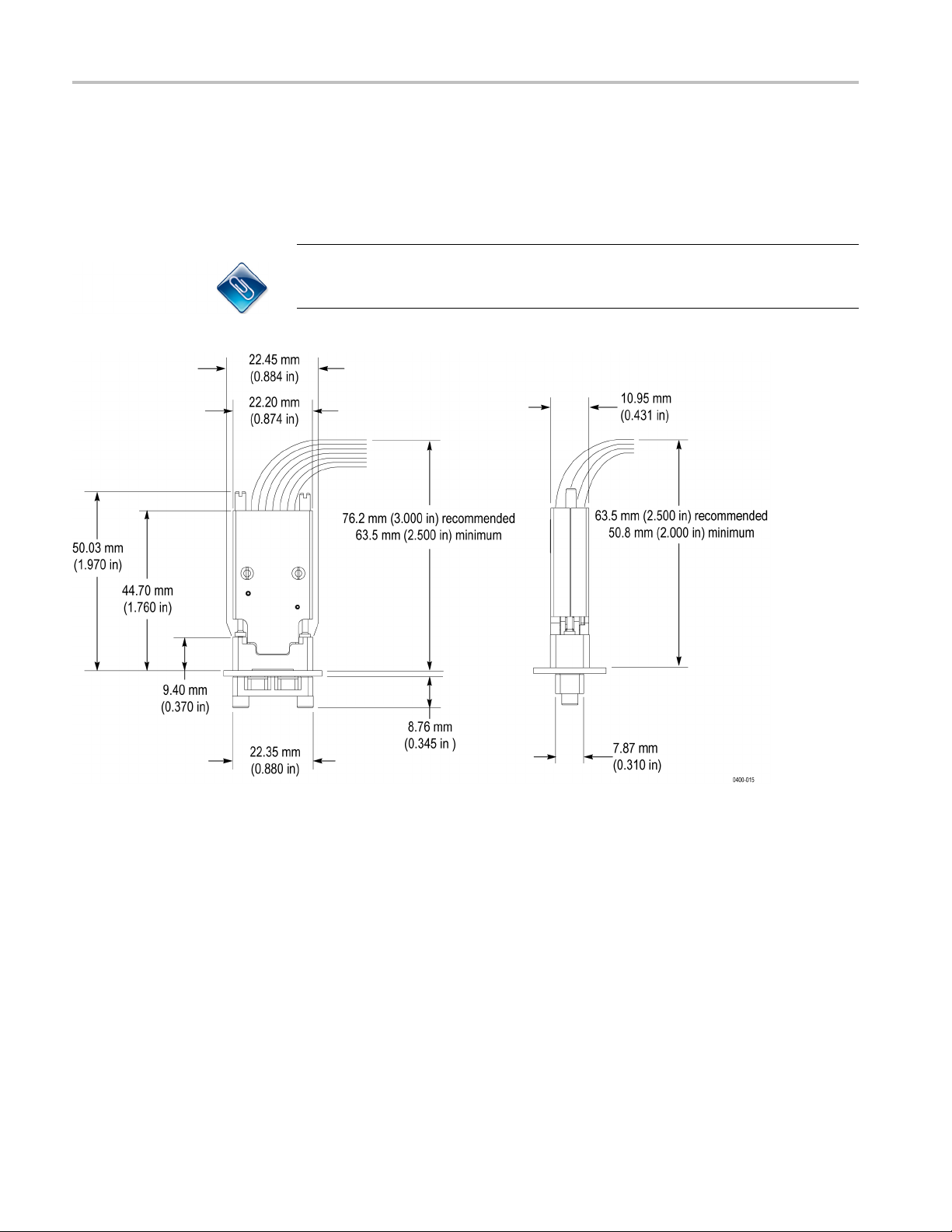

TLA7SA08 and TLA7SA16 Logic Protocol Analyzer modules to capture PCIe3,

PCIe2, and PCIe1 data from PCIe3 footprints. The P67SA16G2 x8 midbus probes

are designed to connect the TLA7SA08 and TLA7SA16 Logic Protocol Analyzer

modules to signals using PCIe2 footprints. The general probe connection

procedures are the same for all the midbus probes; however the P67SA16G2

x8 mi

probe to the appropriate connector on the logic protocol analyzer (for example

connect the probe with the A connector label to the A connector on the logic

protocol an

protocol a

probe.

dbus probes require a different type of retention m echanism.

alyzer).

nalyzer.

A08 and P67SA16 midbus probes are designed for use w ith the

Connect the midbus probe from the logic protocol analyzer to a retention

hanism on your circuit board. Instructions for installing a retention

mec

mechanism are provided in Appendix B. (See page 123, Installing the Midbus

Retention Mechanism.)

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 17

Page 40

Connecting the Instrument to the SUT

Handling the Probe Head

Handle the prob

Handle the probe head by the outer casing. Do not touch the contacts in the

center with fin

Do not expose the connector to liquids or dry chemicals.

NOTE. Be car

connected to a powered module. The probe head may become warm to the touch;

the probe is operating normally.

When connecting the probe, be careful not to touch the probe head contacts to

any other surfaces or components on your circuit board.

CAUTION. Static discharge can damage the probe head. Always wear a grounded

antistatic wrist strap whenever handling the probe head. Also verify that anything

to which the probe head is connected does not carry a static charge.

e head with care. Keep the following points in mind:

gers, tools, wipes, or any other devices.

eful when handling the probe head while the midbus probe is

18 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 41

Connecting the Instrument to the SUT

Connect the Probe

Follow these st

your circuit board:

1. Locate the cor

your PCB has multiple retention mechanisms. Be careful to select the correct

one.

2. Align the probe h ead with the retention mechanism. Both are keyed so that

the probe can only be inserted one way.

3. Press the probe head into the retention mechanism.

eps to connect a midbus probe to the retention mechanism on

rect retention m echanism. If you intend to use multiple probes,

Figure 10: Connecting a probe to the retention mechanism

4. Startbothmountingscrewsintheposts, and tighten them evenly to ensure

that the probe approaches and mates squarely to the PCB. Use the adjustment

tool included with your probe. Proper installation torque is 1 in-lb.

Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual 19

Page 42

Connecting the Instrument to the SUT

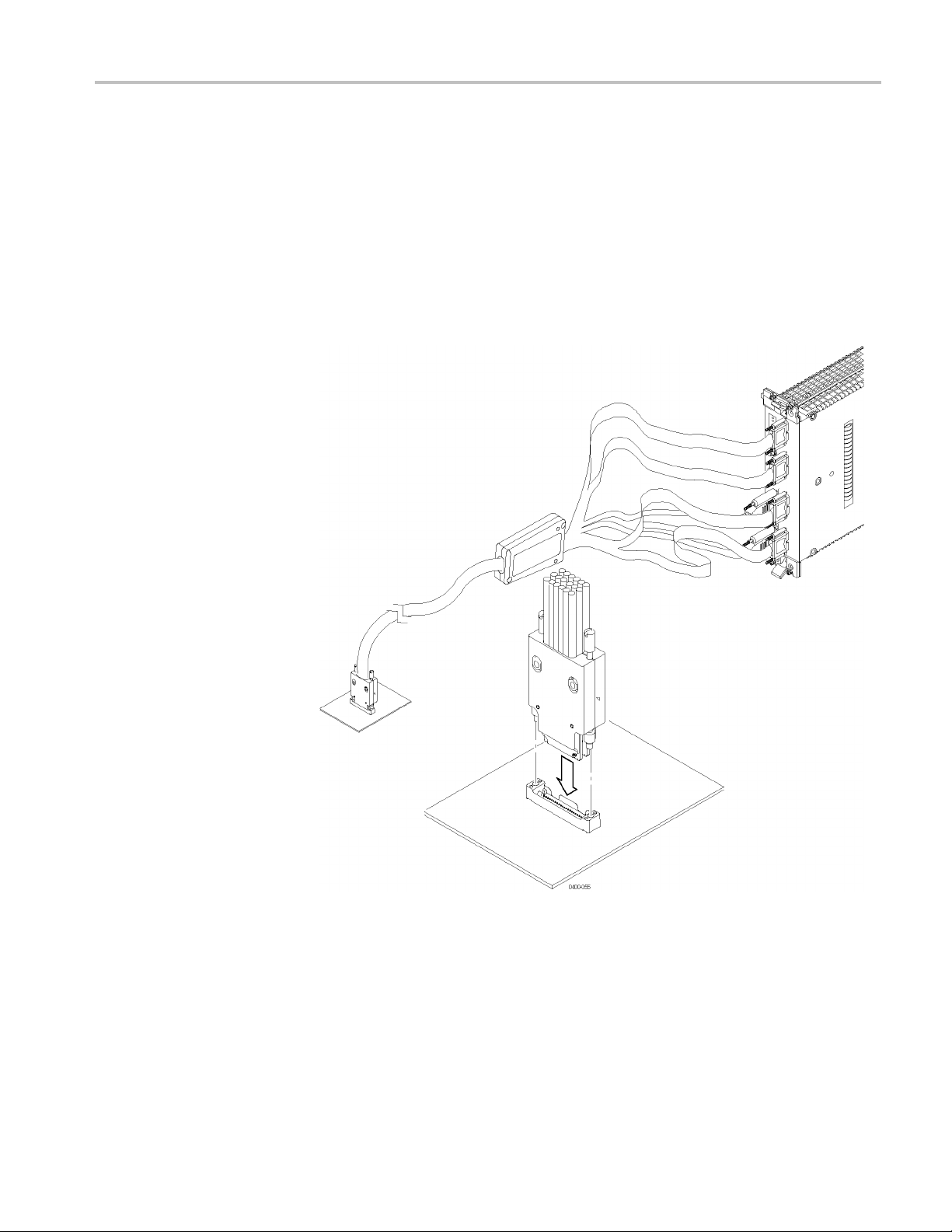

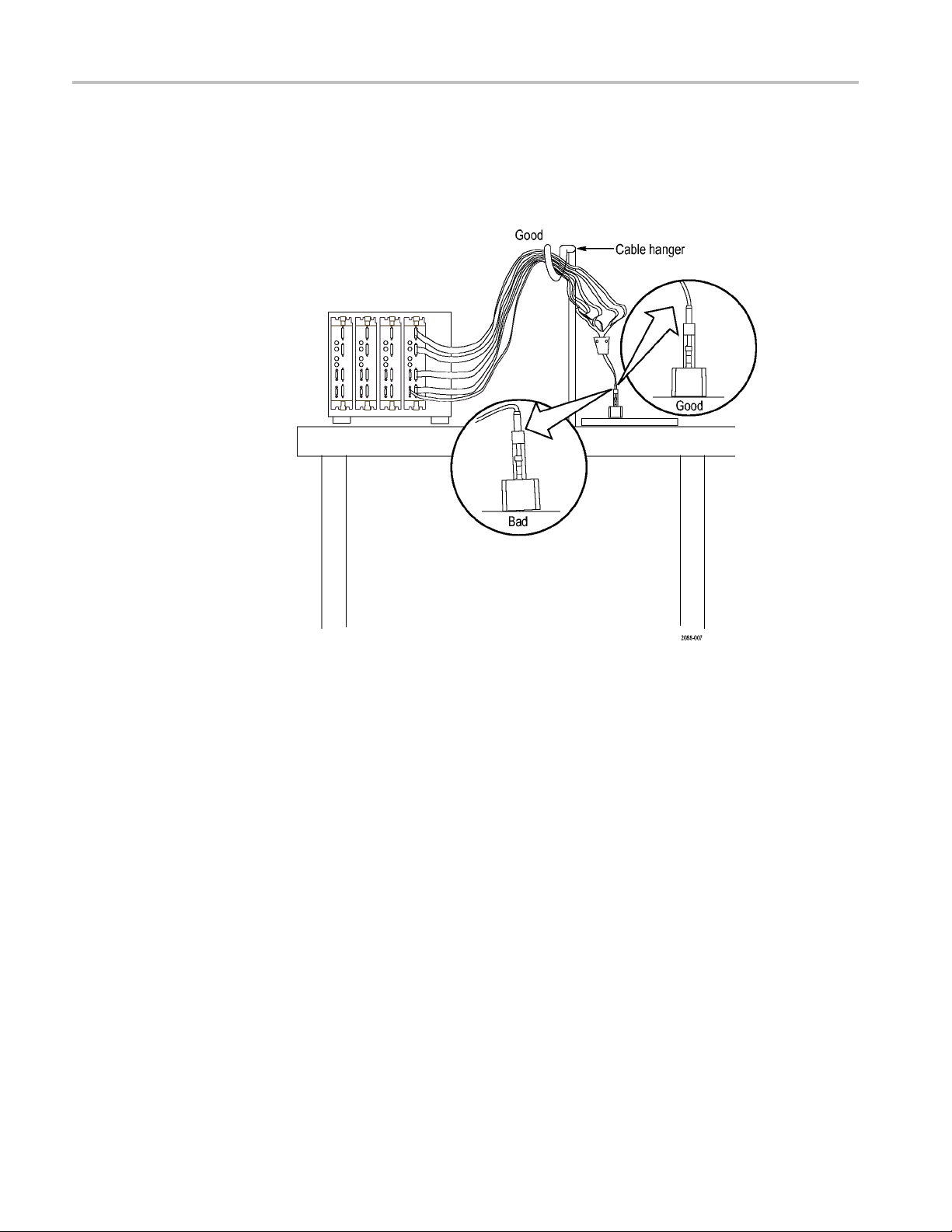

Arranging the Midbus

Probe Cables

Hang the probe c

and tension on the retention mechanism is minimized. Route the cables as straight

as possible, maximizing the bend radius, and making sure that a 90 degree bend

does not occur within three inches of the circuit board surface. (See Figure 11.)

ables so that the probe head is perpendicular to the circuit board,

Figure 11: Arranging the midbus probe cables

20 Tektronix Logic Protocol Analyzer Solutions for PCI Express 3.0 Instruction Manual

Page 43

Connecting the Instrument to the SUT

Connect the Sl

ot Interposer Probe

Handling the Probe Head

Connect the Probe

Connect the slot interposer probe to a PCI Express slot on your SUT.

Handle the probe head with care. Keep the following points in mind:

Handle the probe head by the outer casing. Do not touch the contacts with

fingers, tools, wipes, or any other devices.

Do not expose the connector to liquids or dry chemicals.

When connecting the probe, be careful not to touch the probe head contacts to

any other surfaces or components on your circuit board.

CAUTION. Static discharge can damage the probe head. Always wear a grounded

antistatic wrist strap whenever handling the probe head. Also verify that anything

to which the probe head is connected does not carry a static charge.

Connect a slot interposer probe to a PCI Express slot on your SUT by following

these steps:

NOTE. Although you do not need to power off the TLA before connecting the slot

probe to the SUT, Tektronix recommends that you DO NOT connect the probe

power to the TLA until after making all other connections.

1. Disconnect the power supply to your SUT. Disconnect the PC power supply if

your SUT is connected to one.

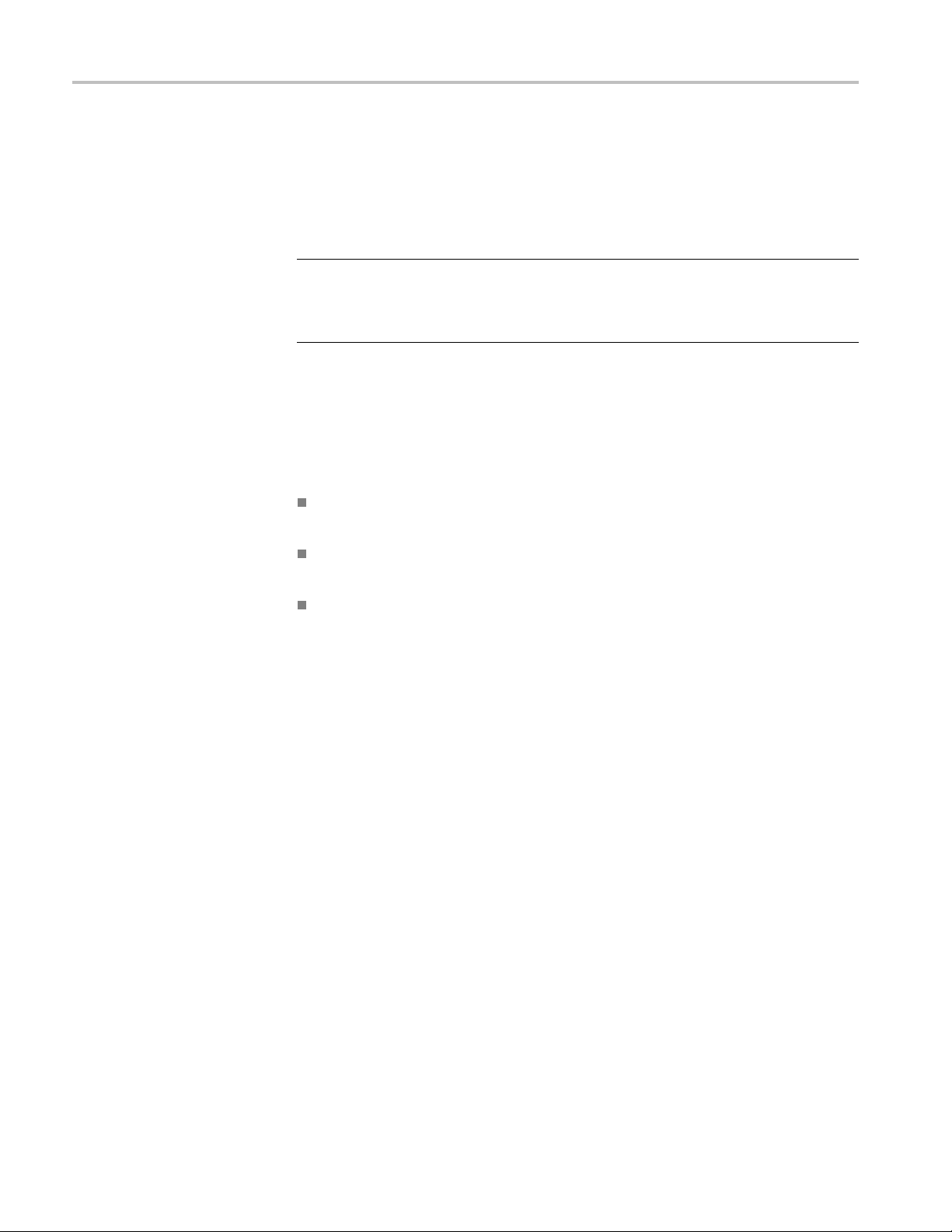

NOTE. To provide additional mechanical support for the PCI Express c ard w hen it

connected to the slot probe, install the slot probe bracket. (See page 24, Installing

the Slot SUT Card Support Bracket.)

2. Locate the correct PCI Express slot.

3. Remove the PCI Express card that is in the PCI Express slot of the SUT.

4. Align the probe with the slot.

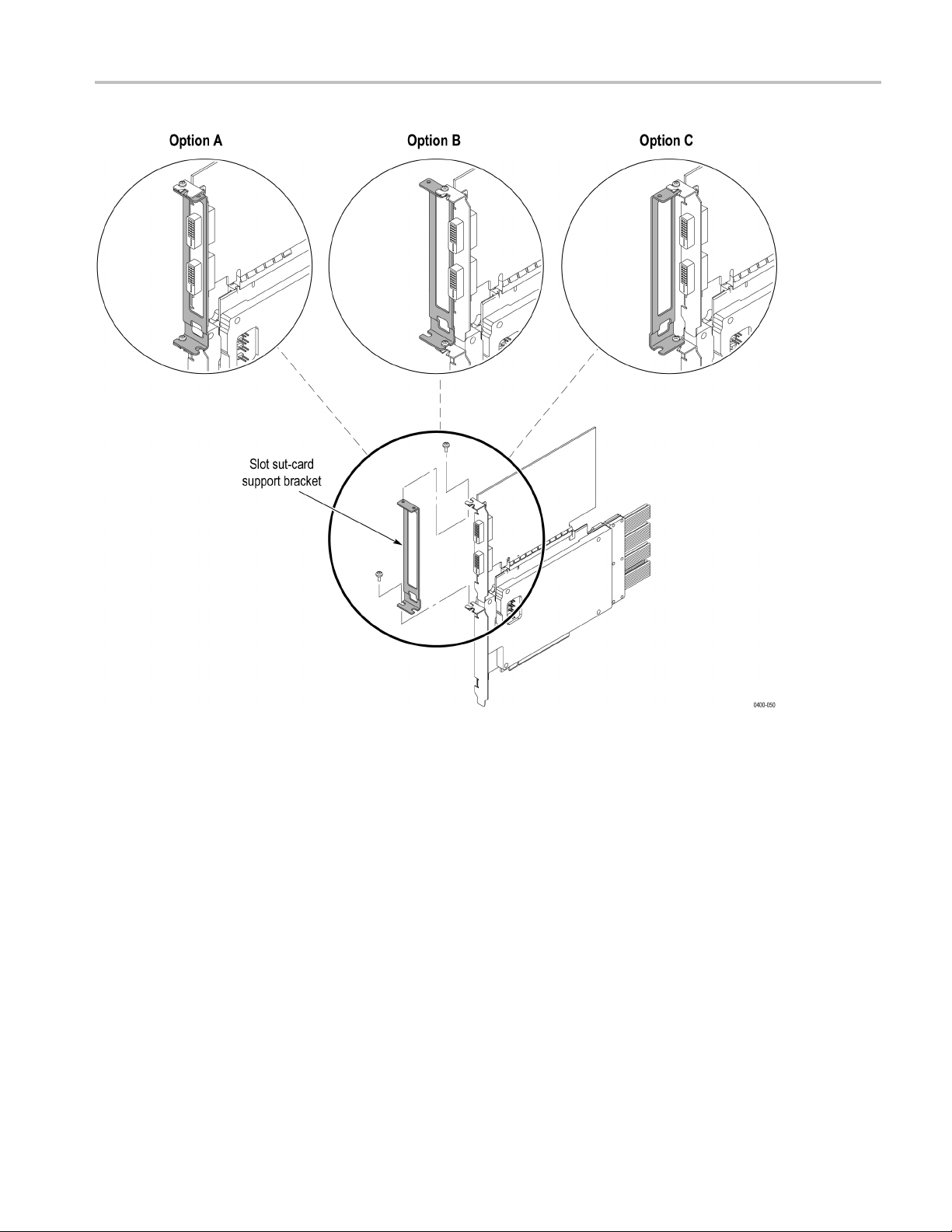

5. Press the probe head into the slot.