Page 1

Technical Reference

Tektronix Logic Analyzer Series

Product Specifications

071-1344-02

This document applies to TLA System Software

version 4.3 and above.

www.tektronix.com

*P071134402*

071134402

Page 2

Copyright © Tektronix, Inc. All rights reserved.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Spec ifications and price change privileges reserved.

Tektronix, Inc., P.O. Box 500, Beaverton, OR 97077

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Page 3

Specifications and Characteristics

This document lists the specifications for the Tektronix Logic Analyzer family

products.

Characteristic Tables

All specifications are guaranteed unless noted Typical. Typical characteristics

describe typical or average performance and provide useful reference information.

Specifications that are marked with the n symbol are checked directly (or

indirectly) in the Performance Verification chapter of module’s or mainframe

service manual.

For mainframes and modules, the performance limits in this specification are

valid with these conditions:

H The logic analyzer must be in an environment with temperature, altitude,

humidity, and vibration within the operating limits described in these

specifications.

H The logic analyzer must have had a warm-up period of at least 30 minutes.

For modules, the performance limits in this specification are valid with these

conditions:

H The modules must be installed in a Logic Analyzer Mainframe.

H The module must have been calibrated/adjusted at an ambient temperature

between +20

H The DSO module must have had its signal-path-compensation routine

(self calibration or self cal) last executed after at least a 30 minute warm-up

period.

H After the warm-up period, the DSO module must have had its signal-path-

compensation routine last executed at an ambient temperature within ±5 _C

of the current ambient temperature.

For optimum performance using an external oscilloscope, please consult the

documentation for any external oscilloscopes used with your Tektronix Logic

Analyzer to determine the warm-up period and signal-path compensation

requirements.

_C and +30 _C.

TLA Specifications and Characteristics

1

Page 4

Specifications and Characteristics

Atmospheric Characteristics for the Tektronix Logic Analyzer Family

Table 1 lists the Atmospheric characteristics of all components in the Tektronix

Logic Analyzer family.

Table 1: Atmospheric characteristics

Characteristic Description

Temperature:

Operating and nonoperating

Operating (no media in floppy disk drive):

+5 _Cto+50_C, 15 _C/hr maxim um gradient, non-condensing

(derated 1 _C per 1000 ft above 5000 foot altitude)

1

Nonoperating (no media in floppy disk drive or CD ROM drive):

-- 2 0 _Cto+60_C, 15 _C/hr maximum gradient, non-condensing.

Relative Humidity:

Operating and nonoperating

Altitude:

Operating and nonoperating

1

TLA7Axx series module operating temperature is +40 _C maximum.

2

TLA7Axx series module operating humidity is 5% to 90% up to +30 _C, 75% from +30 to +40 _C, noncondensing.

Maximum wet- bulb temperature is +29.4 _C.

3

TLA7NAx series module operating humidity is 5% to 90% up to +30 _C, 75% from +30 to +40 _C,45%from+40to

+50 _C, noncondensing. Maximum wet- bulb temperature is +29.4 _C.

4

TLA7Axx/TLA7NAx series module nonoperating humidity is 5% to 90% limited by a wet bulb temperature of

+40 _C.

Operating (no media in floppy disk drive or CD ROM drive):

20% to 80% relative humidity, non-condensing. Maximum wet bulb temperature: +29 _C

(derates relative humidity to approximately 22% at +50 _C)

.

2, 3

Nonoperating (no media in floppy disk drive or CD ROM drive):

8% to 80% relative humidity, non-condensing. Maximum wet bulb temperature: +29 _C (derates

relative humidity to approximately 22% at +50 _C).

4

Operating:

To 10,000 ft (3040 m), (derated 1 _C per 1000 ft (305 m) above 5000 ft

(1524 m) altitude)

Nonoperating:

40,000 ft (12190 m).

2

TLA Specifications and Characteristics

Page 5

Certifications and Compliances

g

A

/

A

a

fetyreq

c

alequip

AdditionalComplianceIEC610101/A2:1995Safetyrequirementsforelectricalequipmentformeasurement

Table 2 lists the certifications and compliances of the Tektronix Logic Analyzer

family. The certifications and compliances apply to all components of the

Tektronix Logic Analyzer family unless noted otherwise.

Table 2: Certifications and compliances

Category Standards or description

Specifications and Characteristics

EC Declaration of Conformity -EMC

Australia / New Zealand

Declaration of Conformity-EMC

EC Declaration of Conformity -Low Voltage

U.S. Nationally Recognized

Testing Laboratory Listing

Canadian Certification CAN/CSA C22.2 No. 1010.1 Safety requirements for electrical equipment for measurement,

dditionalCompliance IEC61010-1

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European

Communities:

EN 61326 EMC requirements for Class A electrical equipment for

measurement, control and laboratory use.

IEC 61000--4--2 Electrostatic discharge immunity (Performance criterion B)

IEC 61000--4--3 RF electromagnetic f ield im munity (Performance criterion A)

IEC 61000--4--4 Electrical fast transient / burst immunity (Performance criterion B)

IEC 61000--4--5 Power line surge immunity (Performance criterion B)

IEC 61000--4--6 Conducted RF immunity (Performance criterion A)

IEC 61000--4--11 Voltage dips and interruptions immunity (Performance criterion B)

EN 61000--3--2 AC power line harmonic emissions

Complies with EMC provision of Radiocommunications Act per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

Compliance was demonstrated to the following specification as listed in the Official Journal of t he

European Communities:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1/A2:1995 Safety requirements for electrical equipment for measurement

control and laboratory use.

UL3111-1 Standard for electrical measuring and test equipment.

control, and laboratory use.

2:1995 S

control, and laboratory use.

uirementsfor electri

1

ment for measurement,

,

Installation (Overvoltage)

Category

1

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test

object.

TLA Specifications and Characteristics

Terminals on this product may have different installation (overvoltage) category designations. The

installation categories are:

CAT II Local-level mains (wall sockets). Equipment at this level includes appliances, portable

tools, and similar products. Equipm ent i s usuall y cord-connected.

3

Page 6

Specifications and Characteristics

Table 2: Certifications and compliances (Cont.)

Category Standards or description

Pollution Degree A measure of the contaminates that could occur in the environment around and within a product.

Typically the internal environment inside a product is considered to be the same as the external.

Products should be used only in the environment for which they are rated.

Pollution Degree 2 Normally only dry, nonconductive pollut ion occurs. Occasionally a

temporary conductivity that is caused by condensation must be

expected. This location is a typical office/hom e environment.

Temporary condensation occurs only when the product is out of

service.

Safety Certification Compliance

Equipment Type Test and measuring

Safety Class Class 1 (as defined in IEC61010-1, Annex H) -- grounded product

Overvoltage Category Overvoltage Category II (as defined in IEC61010-1, Annex J)

Pollution Degree Pollution Degree 2 (as defined in IEC61010-1). Note: Rated for indoor use only.

4

TLA Specifications and Characteristics

Page 7

TLA600 Series Logic Analyzer Specifications

Tables 3 through 17 list the specifications for the TLA600 series logic analyzer.

Table 3: TLA600 input parameters with probes

Characteristic Description

n Threshold Accuracy ±100 mV

Threshold range and step size Settable from +5 V to --2 V in 50 mV steps

Threshold channel selection 16 threshold groups assigned to channels.

P6417 and P6418 probes have two threshold settings, one for the clock/qualifier

channel and one for the data channels.

P6434 probes have four threshold settings, one for each of the clock/qualifier

channels and two for the data channels (one per 16 data channels).

n Channel-to-channel skew ≤ 1.6 ns maximum

Channel-to-channel skew

(Typical)

Sample uncertainty

Asynchronous: Sample period

Synchronous: 500 ps

Probe input resistance

(Typical)

Probe input capacitance: P6417, P6434

(Typical)

Probe input capacitance: P6418

(Typical)

Minimum slew rate

(Typical)

Maximum operating signal 6.5 V

Probe overdrive:

P6417, P6418

P6434

Maximum nondestructive input signal to probe ±15 V

Minimum input pulse width signal

(single channel)

(Typical)

Delay time from probe tip to input probe

connector

(Typical)

≤ 1.0 ns

20 kΩ

2pF

1.4 pF data channels

2 pF CLK/Qual channels

0.2 V/ns

p-p

--3.5 V absolute input voltage minimum

6.5 V absolute input voltage maximum

±250 mV or ±25% of signal swing minimum required beyond threshold, whichever is

greater

±300 mV or ±25% of signal swing minimum required beyond threshold, whichever is

greater

±4 V maximum beyond threshold

2ns

7.33 ns

Specifications and Characteristics

TLA Specifications and Characteristics

5

Page 8

Specifications and Characteristics

Table 4: TLA600 timing latencies

Characteristic Description

System Trigger and External Signal Input

Latencies

1

(Typical)

External System Trigger Input to LA Probe

2

Tip

External Signal Input to LA Probe Tip via

Signal 3, 4

3

External Signal Input to LA Probe Tip via

Signal 1, 2

3, 4

--266 ns

--212 ns + Clk

--208 ns + Clk

System Trigger and External Signal Output

Latencies (Typical)

LA Probe Tip to External System Trigger

5

Out

376 ns + SMPL

LA Probe Tip to External Signal Out via

Signal 3, 4

5

OR function 366 ns + SMPL

AND function 379 ns + SMPL

LA Probe Tip to External Signal Out via

Signal 1, 2

4, 5

normal function 364 ns + SMPL

inverted logic on backplane 364 ns + SMPL

1

All system trigger and external signal input latencies are measured from a falling-edge transition (active true low) with

signals measured in the wired-OR configuration.

2

In the Waveform window, triggers are always marked immediately except when delayed to the first sample. In the Listing

window, triggers are always marked on the next sample period following their occurrence.

3

“Clk” represents the time to the next master clock at the destination logic analyzer. In the asynchronous (or internal)

clock mode, this represents the delta time to the next sample clock beyond the minimum asynchronous rate of 4 ns. In

the synchronous (or external) clock mode, this represents the time to the next master clock generated by the setup of the

clocking state machine and the supplied system under test clocks and qualification data.

4

Signals 1 and 2 (ECLTRG0, 1) are limited to a “broadcast” mode of operation, where only one source is allowed to drive

the signal node at any one time. That single source may be utilized to drive any combination of destinations.

5

SMPL represents the time from the event at the probe tip inputs to the next valid data sample. In the Normal Internal clock

mode, this represents the delta time to the next sample clock. In the MagniVu Internal clock mode, this represents 500 ps

or less. In the External clock mode, this represents the time to the next master clock generated by the setup of the

clocking state machine, the system-under-test supplied clocks, and the qualification data.

6

TLA Specifications and Characteristics

Page 9

Specifications and Characteristics

Table 5: TLA600 external signal interface

Characteristic Description

System Trigger Input TTL compatible input via rear panel mounted BNC connectors

Input Levels

V

IH

V

IL

Input Mode Falling edge sensitive, latched (active low)

Minimum Pulse Width 12 ns

Active Period Accepts system triggers during valid acquisition periods via real-time gating, resets system

Maximum Input Voltage 0 to +5 V peak

External Signal Input TTL compatible input via rear panel mounted BNC connectors

Input Destination Signal 1, 2, 3, 4

Input Levels

V

IH

V

IL

Input Mode Active (true) low, level sensitive

Input Bandwidth

1

Signal 1, 2

Signal 3, 4

Active Period Accepts signals during valid acquisition periods via real-time gating

Maximum Input Voltage 0 to +5 V peak

System Trigger Output TTL compatible output via rear panel mounted BNC connectors

Source Mode Active (true) low, falling edge latched

Active Period Outputs system trigger state during valid acquisition period, resets system trigger output to false

Output Levels

V

OH

TTL compatible input

≥ 2.0 V

≤ 0.8 V

trigger input latch between valid acquisition periods

TTL compatible input

≥ 2.0 V

≤ 0.8 V

50 MHz square w ave minimum

10 MHz square w ave minimum

state between valid acquisitions

50 Ω back terminated TTL-compatible output

≥4 V into open circuit

≥ 2Vinto50Ω to ground

V

OL

≤ 0.7Vsinking10mA

Output Protection Short-circuit protected (to ground)

External Signal Output TTL compatible outputs via rear panel mounted BNC connectors

Source Selection Signal 1, 2, 3, 4, or 10 MHz clock

Output Modes

Level Sensitive

Output Levels

V

OH

User definable

Active (true) low or acti ve (true) high

50 Ohm back terminated TTL output

≥ 4 V into open circuit

≥ 2Vinto50Ω to ground

V

OL

≤ 0.7Vsinking10mA

TLA Specifications and Characteristics

7

Page 10

Specifications and Characteristics

Table 5: TLA600 external signal interface (Cont.)

Characteristic Description

Output Bandwidth

Signal 1, 2

Signal 3, 4

Active Period Outputs signals during valid acquisition periods, resets signals to false state between valid

Output Protection Short-circuit protected (to ground)

1

The Input Bandwidth specification only applies to signals to the modules; it does not apply to signals applied to the

External Signal Input and sent back to the External Signal Output.

2

The Output Bandwidth specification only applies to signals from the modules; it does not apply to signals applied to the

External Signal Input and sent back to the External Signal Output.

2

50 MHz square w ave minimum

10 MHz square w ave minimum

acquisitions

Outputs 10 MHz clock continuously

Table 6: TLA600 channel width and depth

Characteristic Description

Number of channels Product Channels

TLA601, TLA611, TLA621 32 data and 2 clock

TLA602, TLA612, TLA622 64 data and 4 clock

TLA603, TLA613, TLA623 96 data, 4 clock, and 2 qualifier

TLA604, TLA614, TLA624 128 data, 4 clock, and 4 qualifier

Acquisition memory depth Product Memory depth

TLA601, TLA602, TLA603, TLA604 64 K or 256 K samples

TLA611, TLA612, TLA613, TLA614 64 K or 256 K samples

TLA621, TLA622, TLA623, TLA624 1 M samples

1

PowerFlex options

1

1

8

TLA Specifications and Characteristics

Page 11

Table 7: TLA600 clocking

Characteristic Description

Asynchronous clocking

n Internal sampling period

n Minimum recognizable word

(across all channels)

Synchronous clocking

Number of clock channels

Number of qualifier channels

n Setup and hold window size

(data and qualifiers)

1

4 ns to 50 ms in a 1--2--5 sequence

2 ns in 2x Clocking mode

2

Channel-to-channel skew + sample uncertainty

Example: for a P6417, P6418, or P6434 Probe anda4nssampleperiod=

3

Product Clock channels

TLA601, TLA611, TLA621 2

TLA602, TLA612, TLA622 4

TLA603, TLA613, TLA623 4

TLA604, TLA614, TLA624 4

5

Product Qualifier channels

TLA601, TLA611, TLA621 0

TLA602, TLA612, TLA622 0

TLA603, TLA613, TLA623 2

TLA604, TLA614, TLA624 4

Maximum window size = Maximum channel-to-channel skew + (2 x sample

Maximum setup time = User interface setup time + 0.8 ns

Maximum hold time = User interface hold time + 0.2 ns

Specifications and Characteristics

1.6ns+4ns=5.6ns

uncertainty) + 0.4 ns

Examples: for a P6417 or a P6418 probe and user interface

setup and hold of 2.0/0.0 typical:

Maximum window size = 1.6 ns + (2 x 500 ps) + 0.4ns = 3.0 ns

Maximum setup time = 2.0 ns + 0.8 ns = 2.8 ns

Maximum hold time = 0.0 ns + 0.2 ns = 0.2ns

Setup and hold window size

(data and qualifiers)

(Typical)

Channel-to-channel skew (typical) + (2 x sample uncertainty)

Example: for P6417 or P6418 Probe = 1 ns + (2 x 500 ps) = 2 ns

Setup and hold window range For each channel, the setup and hold window can be moved from +8.5 ns (Ts) to

--7.0 ns (Ts) in 0.5 ns steps (setup time). Hold time follows the setup time by the setup

and hold window size.

n Maximum synchronous clock rate

4

200 MHz in full speed mode (5 ns minimum between active clock edges)

100 MHz (10 ns minimum between active clock edges)

Demux clocking

TLA603, TLA613, TLA623

TLA604, TLA614, TLA624

Channels multiplex as follows:

A3(7:0) to D3(7:0)

A2(7:0) to D2(7:0)

A1(7:0) to D1(7:0)

A0(7:0) to D0(7:0)

TLA Specifications and Characteristics

9

Page 12

Specifications and Characteristics

Table 7: TLA600 clocking (Cont.)

Characteristic Description

TLA601, TLA611, TLA621

TLA602, TLA612, TLA622

Channels multiplex as follows:

A3(7:0) to C3(7:0)

A2(7:0) to C2(7:0)

A1(7:0) to D1(7:0) TLA602, TLA612, TLA622

A0(7:0) to D0(7:0) TLA602, TLA612, TLA622

Time between DeMux clock edges

(Typical)

Time between DeMux store clock edges

(Typical)

Data Rate

4

(Typical)

4

5 ns minimum between Demux clock edges in full-speed mode

10 ns minimum between Demux clock edges in half-speed mode

4

10 ns minimum between Demux master clock edges in full-speed mode

20 ns minimum between Demux master clock edges in half-speed mode

400 MHz (200 MHz option required) half channel.

(Requires channels to be multiplexed.)

These multiplexed channels double the memory depth.

Clocking state machine

Pipeline delays Each channel can be programmed with a pipeline delay of 0 through 3 active clock

edges.

1

It is possible to use storage control and only store data when it has changed (transitional storage).

2

Applies to asynchronous clocking only. Setup and hold window specification applies to synchronous clocking only.

3

Any or all of the clock channels may be enabled. For an enabled clock channel, either the rising, falling, or both edges

can be selected as the active clock edges. The clock channels are stored.

4

Full and half speed modes are controlled by PowerFlex options and upgrade kits.

5

All qualifier channels are stored. For custom clocking there are an additional 4 qualifier channels on C2 3:0 regardless of

channel width.

Table 8: TLA600 trigger system

Characteristic Description

Triggering Resources

Word/Range recognizers 16 word recognizers. The word recognizers can be combined to form full width, doubl e

bounded, range recognizers. The fol lowing selections are available:

16 word recognizers 0 range recognizers

13 word recognizers 1 range recognizer

10 word recognizers 2 range recognizers

7 word recognizers 3 range recognizers

4 word recognizers 4 range recognizers

Range recognizer channel order From most-significant probe group to least-significant probe group: C3 C2 C1 C0 E3

E2 E1 E0 A3 A2 D3 D2 A1 A0 D1 D0 Q3 Q2 Q1 Q0 CK3 CK2 CK1 CK0

Missing channels for modules with fewer than 136 channels are omitted.

Glitch detector

10

1,2

Each channel group can be enabled to detect a glitch

TLA Specifications and Characteristics

Page 13

Table 8: TLA600 trigger system (Cont.)

Characteristic Description

Specifications and Characteristics

Minimum detectable glitch pulse width

2.0 ns (single channel with P6417, P6418, or a P6434 probe)

(Typical)

Setup and hold violation detector

1,3

Each channel can be enabled to detect a setup and hold violation. The range is from

8 ns before the clock edge to 8 ns after the cl ock edge. The range can be selected in

0.5 ns increments.

The setup and hold violation of each window can be individually programmed.

Transition detector

1

Each channel group can be enabled or disabled to detect a transition between the

current valid data sample and the previous valid data sample.

This mode can be used to create transitional storage selections where all channels

are enabled.

Counter/Timers 2 counter/timers, 51 bits wide, can be clocked up to 250 MHz.

Maximum count is 2

Maximum time is 9.007 X 10

51

.

6

seconds or 104 days.

Counters and timers can be set, reset, or tested and have zero reset latency.

External Signal In

1

A backplane input signal

External Trigger In A backplane input signal that causes the main acquisition and the MagniVu

acquisition to trigger if they are not already triggered

Active trigger resources 16 maximum (excluding counter/timers)

Word recognizers are traded off one-by-one as External Signal In, glitch detection,

setup and hold detection, or transition detect ion resources are added.

Trigger States 16

n Trigger State sequence rate Same rate as valid data samples received, 250 MHz maximum

Trigger Machine Actions

Main acquisition trigger Triggers the main acquisition memory

Main trigger position Trigger position is programmable to any data sample (4 ns boundaries)

MagniVut acquisi tion trigger Triggering of MagniV memory is controlled by t he mai n acquisition trigger

MagniVut trigger position The MagniV trigger position is programmable within 4 ns boundaries and separate

from the main acquisition memory trigger position.

Increment counter Either of the two counter/timers used as counters can be increased.

Start/Stop timer Either of the two counter/timers used as timers can be started or stopped.

Reset counter/timer Either of the two counter/timers can be reset.

When a counter/timer is used as a timer and is reset, the timer continues from the

started or stopped state that it was in prior to the reset.

Signal out A signal sent to the backplane to be used by other instruments

Trigger out A trigger out signal sent to t he backplane to trigger other instruments

TLA Specifications and Characteristics

11

Page 14

Specifications and Characteristics

Table 8: TLA600 trigger system (Cont.)

Characteristic Description

Storage Control

Global storage Storage is allowed only when a specif ic condition is met. This condition can use any

of the trigger machine resources except for the counter/timers. Storage commands

defined in the current trigger state will override the global storage control.

Global storage can be used to start the acquisition with storage initially turned on

(default) or turned off.

By event Storage can be turned on or off; only the current sample can be stored. The event

storage control overrides any global storage commands.

Block storage When enabled, 31 samples are stored before and after the valid sample.

Not allowed when glitch storage or setup and hold violation is enabled.

Glitch violation storage The acquisition memory can be enabled to store glitch violation information with each

data sample when asynchronous clocking is used. The probe data storage size is

reduced by one half (the other half holds the violation information). The fastest

asynchronous clocking rate is reduced to 10 ns.

Setup and hold violation storage The acquisition memory can be enabled to store setup and hold violation information

with each data sample when synchronous clocki ng is used. The probe data storage

size is reduced by one half (the other half holds the violation information). The

maximum clock rate is reduced by half.

1

Each use of External Signal In, glitch detector, setup and hold violation detector, or transition detector requires a trade-off

of one word recognizer resource.

2

Any glitch is subject to pulse width variation of up to the channel-to-channel skew specification + 0.5 ns.

3

Any setup value is subject to variation of up to 1.8 ns; any hold value is subject to variation of up to 1.2 ns.

12

TLA Specifications and Characteristics

Page 15

Specifications and Characteristics

Table 9: TLA600 MagniVut feature

Characteristic Description

MagniVu memory depth 2016 samples per channel

MagniVu sampling period Data is asynchronously sampled and stored every 500 ps in a separate high resolution

memory. There are no clocking options.

Table 10: TLA600 Data handling

Characteristic Description

Nonvolatile memory retention time

(Typical)

Battery is integral to the NVRAM. Battery life is > 10 years.

Table 11: TLA600 internal controller

Characteristic Description

Operating System Microsoft Windows

Microprocessor Intel Celeron, 566 MHz

Main Memory SDRAM

Style 168 pin DIMM, 2 Sockets

Speed 100 MHz

Installed Configurations Minimum 256 MB loaded in one socket

Maximum 512 MB with both sockets loaded

Real-Time Clock and CMOS Setups,

Plug & Play NVRAM Retention Time

Hard Disk Drive Standard PC compatible IDE (Integrated Device Electronics) hard disk drive residing on an

Size Minimum 10 GByte

Battery life is typic ally > 3 years when the logic analyzer is not connected to line voltage. When

connected to line voltage the life of the battery is extended.

Lithium battery, CR3032

EIDE interface.

Maximum 30 GByte

Continually subject to change due to the fast-moving PC component environment.

These storage capacities valid at product introduction.

CD-RW Drive Standard PC compatible IDE (Integrated Device Electronics)

24x-10x-40x CD-RW drive residing on an EIDE interface.

Continually subject to change due to the fast-moving PC component environment.

Floppy Disk Drive Standard 3.5 inch 1.44-MB PC compatible high-density, double-sided floppy disk drive.

TLA Specifications and Characteristics

13

Page 16

Specifications and Characteristics

Table 12: TLA600 display system

Characteristic Description

Classification Standard PC graphics accelerator technology (bitBLT-based); capable of supporting both

internal color LCD display and external color SVGA/XGA monitor

Display Memory DRAM-based frame-buffer memory

Size 2 MB

Display Selection Both front panel and external displays can be used simultaneously, each with independent

resolutions. Supports Windows dual-moni tor capability.

External Display Drive One SVGA/XGA-compatible analog output port

Display Size Selected via Windows

Plug and Play support for DDC1 and DDC2 A and B

Resolution (Pixels) Colors

640 x 480 256, 64 K, 16.8 M

800 x 600 256, 64 K, 16.8 M

1024 x 768 256, 64 K, 8 M

1280 x 1024 256, 64 K, 8 M

Internal Display

Classification Thin Film Transistor (TFT) 10.4 inch active-matrix color LCD display; CCFL backlight; intensity

controllable via software

Resolution 800 x 600 pixels

Color Scale 262,144 colors (6-bit RGB)

Table 13: TLA600 front-panel interface

Characteristic Description

QWERTY Keypad ASCII keypad to support naming of files, traces, and keyboard equivalents of pointing device

inputs for menus

Special Function Knobs Various functions

14

TLA Specifications and Characteristics

Page 17

Specifications and Characteristics

Table 14: TLA600 rear-panel interface

Characteristic Description

Parallel Interface Port (LPT) 36-pin high-density connector supports standard Centronics mode, Enhanced Parallel Port

(EPP), or Microsoft high-speed mode (ECP)

Serial Interface Port (COM 1) 9-pin male sub-D connector to support RS-232 serial port

Single USB Ports One USB (Universal Serial Bus) compliant port

SVGA Output Port (SVGA OUT) 15-pin sub-D SVGA connector

Mouse Port PS/2 compatible mouse port utilizing a mini DIN connector

Keyboard Port PS/2 compatible keyboard port utilizing a mini DIN connector

Type I and II PC Card Port Standard Type I and II PC-compatible PC card slot

Type I, II, and III PC Card Port Standard Type I, II , and III PC-compatible PC card slot

Table 15: TLA600 AC power source

Characteristic Description

Source Voltage and Frequency 90--250 V

100--132 V

45--66 Hz, continuous range CAT II

RMS,

360--440 Hz, continuous range CAT II

RMS,

Fuse Rating

90 V -- 132 V Operation

(2 required)

90 V - 250 V Operation

(2 required)

UL198/CSA C22.2

0.25 in × 1.25 in, Fast Blow, 8 A, 250 V

IEC 127/Sheet 1

5mm× 20 mm, Fast Blow, 6.3 A, 250 V

Maximum Power Consumption 600 Watts line power maximum

Steady-State Input Current 6A

RMS

maximum

Inrush Surge Current 70 A maximum

Power Factor Correction Yes

On/Standby Switch and Indicator Front Panel On/Standby switch, with indicator.

The power cord provides main power disconnect.

Table 16: TLA600 cooling

Characteristic Description

Cooling System Forced air circulation (negative pressurization) utilizing six fans operating in parallel

Cooling Clearance 2 in (51 mm), sides and rear; unit should be operated on a flat, unobstructed surface

TLA Specifications and Characteristics

15

Page 18

Specifications and Characteristics

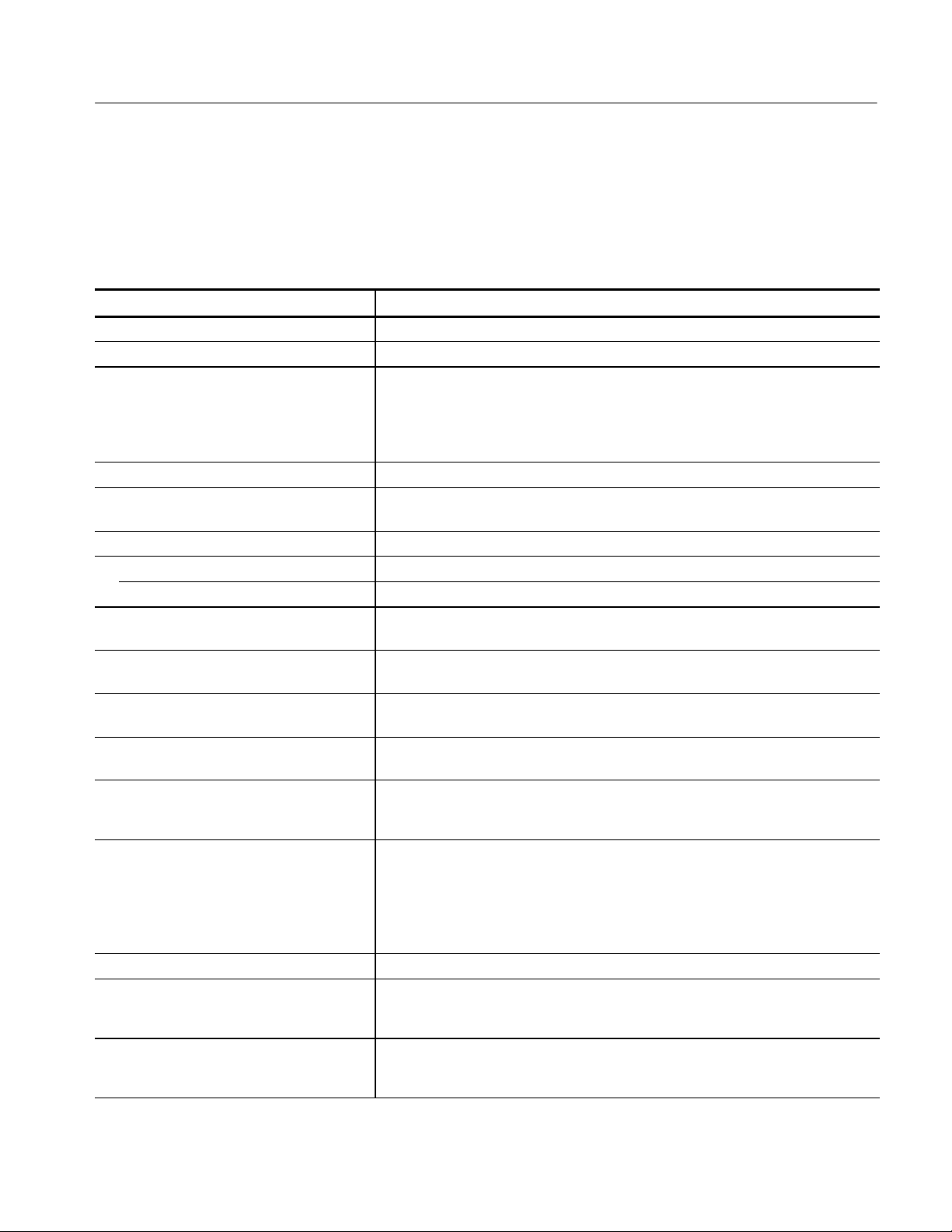

Table 17: TLA600 mechanical characteristics

Characteristic Description

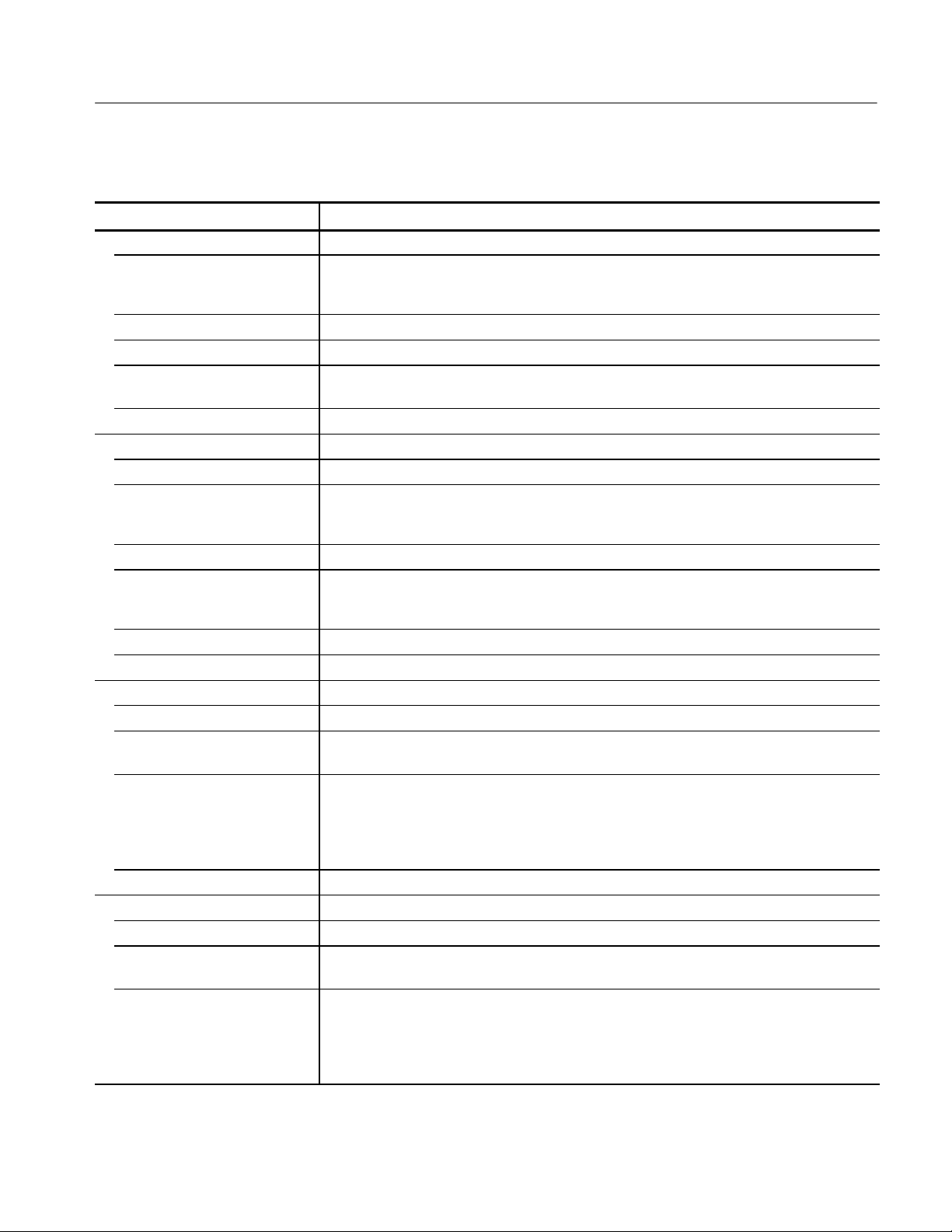

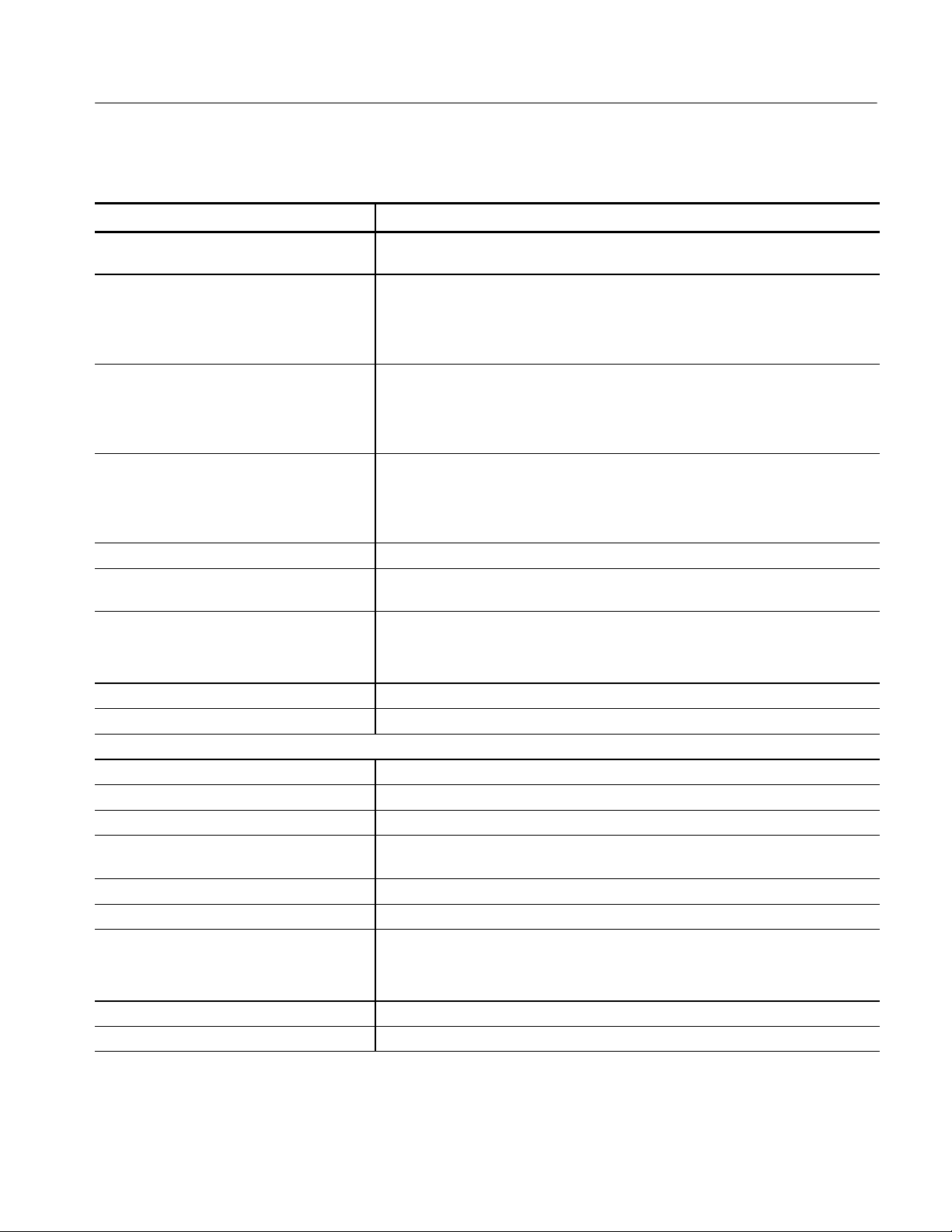

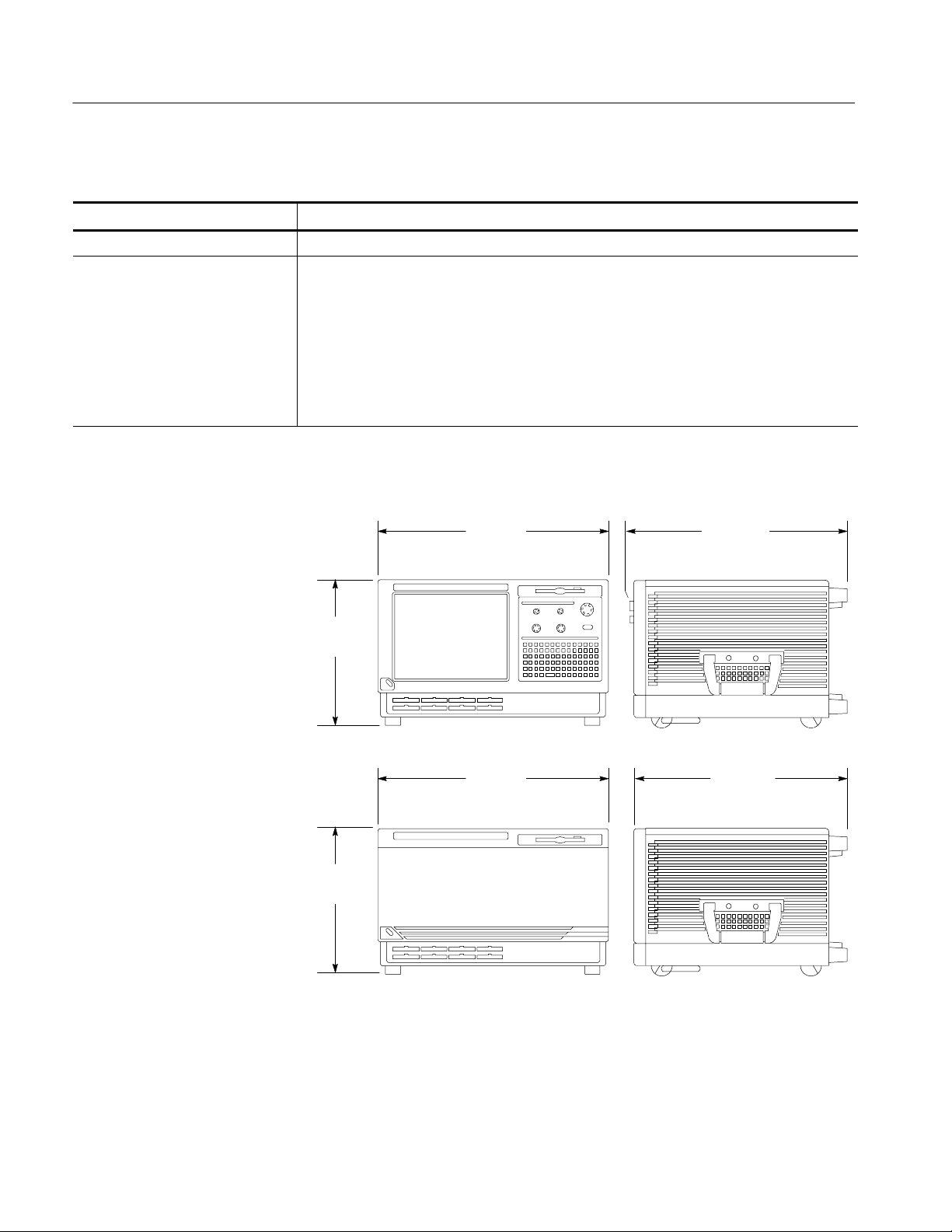

Overall Dimensions See Figure 1 for overall chassis dimensions

Weight Includes empty accessory pouch and front cover

TLA614, TLA624,

18.1 Kg (40 lbs)

TLA613, and TLA623

TLA612, TLA622,

18 Kg (39.75 lbs)

TLA611, and TLA621

TLA604 and TLA603 17.6 Kg (38.75 lbs)

TLA602 and TLA601 17.5 Kg (38.5 lbs)

281.94 mm

(11.10 in)

457.20 mm

(18.00 in)

421.64 mm

(16.60 in)

16

457.20 mm

(18.00 in)

281.94 mm

(11.10 in)

Figure 1: Dimensions of the TLA600 series logic analyzer

TLA Specifications and Characteristics

414.02 mm

(16.30 in)

Page 19

TLA5000 Series Logic Analyzer Specifications

Tables 18 through 32 list the specifications for the TLA5000 series logic

analyzer.

Table 18: TLA5000 input parameters with probes

Characteristic Description

n Threshold Accuracy ±100 mV

Threshold range and step size Settablefrom+4.5Vto--2Vin5mVsteps

Threshold channel selection 16 threshold groups assigned to channels.

P6417, P6418 and P6419 probes have two threshold settings, one for the clock/qualifier channel and one for the data channels.

P6434 probes have four threshold settings, one for each of the clock/qualifier

channels and two for the data channels (one per 16 data channels).

n Channel-to-channel skew ≤ 1 ns maximum

Channel-to-channel skew

(Typical)

Sample uncertainty

Asynchronous: Sample period

Synchronous: 125 ps

Probe input resistance

(Typical)

Probe input capacitance: P6417, P6434

(Typical)

Probe input capacitance: P6418

(Typical)

P6419 input capacitance: P6419

(Typical)

Minimum slew rate

(Typical)

Maximum operating signal 6.0 V

Probe overdrive:

P6417, P6418, P6419

P6434

Maximum nondestructive input signal to probe ±15 V

≤ 0.9 ns

20 kΩ

2pF

1.4 pF data channels

2 pF CLK/Qual channels

<0.7pF

0.2 V/ns

p-p

--3.5 V absolute input voltage minimum

6.5 V absolute input voltage maximum

±250 mV or ±25% of signal swing minimum required beyond threshold, whichever is

greater

±300 mV or ±25% of signal swing minimum required beyond threshold, whichever is

greater

±4 V maximum beyond threshold

Specifications and Characteristics

TLA Specifications and Characteristics

17

Page 20

Specifications and Characteristics

Table 18: TLA5000 input parameters with probes (Cont.)

Characteristic Description

Minimum input pulse width signal

(single channel)

1.5 ns (P6434)

1.25 ns (P6417, P6418, P6419)

(Typical)

Delay time from probe tip to module input

7.33 ns ±100ps

probe connector

(Typical)

Table 19: TLA5000 timing latencies

Characteristic Description

System Trigger and External Signal Input

Latencies

System Trigger and External Signal Output

Latencies (Typical)

1

(Typical)

External System Trigger Input to LA Probe

Tip

External Signal Input to LA Probe Tip via

Signal 3, 4

External Signal Input to LA Probe Tip via

Signal 1, 2

2

--594 ns

--594 ns + Clk

--594 ns + Clk

LA Probe Tip to External System Trigger

3

Out

760 ns + SMPL

LA Probe Tip to External Signal Out via

Signal 3, 4

3

OR function 760 ns + SMPL

AND function 760 ns + SMPL

LA Probe Tip to External Signal Out via

Signal 1, 2

2, 3

normal function 760 ns + SMPL

inverted logic on backplane 760 ns + SMPL

1

All system trigger and external signal input latencies are measured from a falling-edge transition (active true low) with

signals measured in the wired-OR configuration.

2

Signals 1 and 2 (ECLTRG0, 1) are limited to a “broadcast” mode of operation, where only one source is allowed to drive

the signal node at any one time. That single source may be utilized to drive any combination of destinations.

3

SMPL represents the time from the event at the probe tip inputs to the next valid data sample. In the Normal Internal clock

mode, this represents the delta time to the next sample clock. In the MagniVu Internal clock mode, this represents 500 ps

or less. In the External clock mode, this represents the time to the next master clock generated by the setup of the

clocking state machine, the system-under-test supplied clocks, and the qualification data.

18

TLA Specifications and Characteristics

Page 21

Specifications and Characteristics

Table 20: TLA5000 external signal interface

Characteristic Description

System Trigger Input TTL compatible input via rear panel mounted BNC connectors

Input Levels

V

IH

V

IL

Input Mode Falling edge sensitive, latched (active low)

Minimum Pulse Width 12 ns

Active Period Accepts system triggers during valid acquisition periods via real-time gating, resets system

Maximum Input Voltage 0 to +5 V peak

External Signal Input TTL compatible input via rear panel mounted BNC connectors

Input Destination Signal 1, 2, 3, 4

Input Levels

V

IH

V

IL

Input Mode Active (true) low, level sensitive

Input Bandwidth

1

Signal 1, 2, 3, 4 50 MHz square wave minimum

Active Period Accepts signals during valid acquisition periods via real-time gating.

Maximum Input Voltage 0 to +5 V peak

System Trigger Output TTL compatible output via rear panel mounted BNC connectors

Source Mode Active (true) low, falling edge latched

Active Period Outputs system trigger state during valid acquisition period, resets system trigger output to false

Output Levels

V

OH

TTL compatible input

≥ 2.0 V

≤ 0.8 V

trigger input latch between valid acquisition periods.

TTL compatible input

≥ 2.0 V

≤ 0.8 V

state between valid acquisitions.

50 Ω back terminated TTL-compatible output

≥4 V into open circuit

≥ 2Vinto50Ω to ground

V

OL

≤ 0.7Vsinking10mA

Output Protection Short-circuit protected (to ground)

External Signal Output TTL compatible outputs via rear panel mounted BNC connectors

Source Selection Signal 1, 2, 3, 4, or 10 MHz clock

Output Modes

Level Sensitive

Output Levels

V

OH

User definable

Active (true) low or acti ve (true) high

50 Ohm back terminated TTL output

≥ 4 V into open circuit

≥ 2Vinto50Ω to ground

V

OL

Output Bandwidth

1

≤ 0.7Vsinking10mA

Signal 1, 2, 3, 4 50 MHz square wave minimum

TLA Specifications and Characteristics

19

Page 22

Specifications and Characteristics

Table 20: TLA5000 external signal interface (Cont.)

Characteristic Description

Active Period Outputs signals during valid acquisition periods, resets signals to false state between valid

acquisitions.

Outputs 10 MHz clock continuously

Output Protection Short-circuit protected (to ground)

1

The Output Bandwidth specification only applies to signals from the modules; it does not apply to signals applied to the

External Signal Input and sent back to the External Signal Output.

Table 21: TLA5000 channel width and depth

Characteristic Description

Number of channels Product Channels

TLA5201 32 data and 2 clock

TLA5202 64 data and 4 clock

TLA5203 96 data, 4 clock, and 2 qualifier

TLA5204 128 data, 4 clock, and 4 qualifier

Acquisition memory depth Product Memory depth

TLA520X 512 K or optionally either 2 or 8 M samples

1

PowerFlex options

1

20

TLA Specifications and Characteristics

Page 23

Specifications and Characteristics

Table 22: TLA5000 clocking

Characteristic Description

Asynchronous clocking

n Internal sampling period

n Minimum recognizable word

(across all channels)

Synchronous clocking

Number of clock channels

Number of qualifier channels

n Setup and hold window size

(data and qualifiers)

Setup and hold window size

(data and qualifiers)

(Typical)

Setup and hold window range For each channel, the setup and hold window can be moved from +8.0 ns (Ts) to

n Maximum synchronous clock rate 235 MHz in full speed mode (4. 25 ns minimum bet ween active clock edges)

1

500 ps to 50 ms in a 1-2-5 sequence. Storage control can be used to only store data

when it has changed (transitional storage)

2 ns minimum for all channels

1 ns minimum for half channels (using 2:1 demultiplex mode)

0.5 ns minimum for quarter channels (using 4:1 demultiplex mode)

2

Channel-to-channel skew + sample uncertainty

Example: for a P6419, or P6434 Probe anda2nssampleperiod=

1ns+2ns=3ns

3

Product Clock channels

TLA5201 2

TLA5202 4

TLA5203 4

TLA5204 4

4

Product Qualifier channels

TLA5201 0

TLA5202 0

TLA5203 2

TLA5204 4

Maximum window size = Maximum channel-to-channel skew + (2 x sample

uncertainty) + Margin = 1.875 ns

Channel-to-channel skew (typical) + (2 x sample uncertainty) = 1.5 ns

--8.0 ns (Ts) in 0.125 ns steps (setup time). Hold time follows the setup time by the

setup and hold window size.

TLA Specifications and Characteristics

21

Page 24

Specifications and Characteristics

Table 22: TLA5000 clocking (Cont.)

Characteristic Description

2X Demux clocking

TLA5203

TLA5204

TLA5201

TLA5202

Time between Demultiplex clock edges

(Typical)

4X Demux clocking

TLA5203

TLA5204

TLA5201

TLA5202

Time between Demultiplex clock edges

(Typical)

Any individual channel may be demultiplexed wit h it s partner channel. Channels

demultiplex as folllows:

A3(7:0) to/from D3(7:0)

A2(7:0) to/from D2(7:0)

A1(7:0) to/from D1(7:0)

A0(7:0) to/from D0(7:0)

C3(7:0) to/from C1(7:0)

C2(7:0) to/from C0(7:0)

E3(7:0) to/from E1(7:0) TLA5204 only

E2(7:0) to/from E0(7:0) TLA5204 only

CK3 to/from Q2 TLA5204 only

CK2 to/from Q3) TLA5204 only

CK1 to/from Q0

CK0 to/from Q1

Any individual channel may be demultiplexed wit h it s partner channel. Channels

demultiplex as folllows:

A3(7:0) to/from C3(7:0)

A2(7:0) to/from C2(7:0)

A1(7:0) to/from D1(7:0) TLA5202 only

A0(7:0) to/from D0(7:0) TLA5202 only

Same limitations as normal synchronous acquisition

Unlike 2X demultiplexing, the channels within a group of four cannot arbitrarily drive

the others.

E3(7:0) to E2(7:0), E1(7:0), E0(7:0) TLA5204 only

A3(7:0) to A2(7:0), D3(7:0), D2(7:0)

A1(7:0) to A0(7:0), D1(7:0), D0(7:0)

C3(7:0) to C2(7:0), C1(7:0), C0(7:0)

CK3 to CK2, Q3, Q2 TLA5204 only

CK1 to CK0, Q1, Q0

Unlike 2X demultiplexing, the channels within a group of four cannot arbitrarily drive

the others.

A1(7:0) to A0(7:0), D1(7:0), D0(7:0) TL:A5202 only

C3(7:0) to C2(7:0), A3(7:0), A2(7:0)

Same limitations as normal synchronous acquisition

22

TLA Specifications and Characteristics

Page 25

Specifications and Characteristics

Table 22: TLA5000 clocking (Cont.)

Characteristic Description

Clocking state machine

Pipeline delays Each channel can be programmed with a pipeline delay of 0 through 7 active clock

edges.

1

It is possible to use storage control and only store data when it has changed (transitional storage).

2

Applies to asynchronous clocking only. Setup and hold window specification applies to synchronous clocking only.

3

Any or all of the clock channels may be enabled. For an enabled clock channel, either the rising, falling, or both edges

can be selected as the active clock edges. The clock channels are stored.

4

All qualifier channels are stored. For custom clocking there are an additional 4 qualifier channels on C2 3:0 regardless of

channel width.

Table 23: TLA5000 trigger system

Characteristic Description

Triggering Resources

Word/Range recognizers 16 word recognizers. The word recognizers can be combined to form full width, doubl e

bounded, range recognizers. The fol lowing selections are available:

16 word recognizers 0 range recognizers

13 word recognizers 1 range recognizer

10 word recognizers 2 range recognizers

7 word recognizers 3 range recognizers

4 word recognizers 4 range recognizers

Range recognizer channel order From most-significant probe group to least-significant probe group: C3 C2 C1 C0 E3

E2 E1 E0 A3 A2 D3 D2 A1 A0 D1 D0 Q3 Q2 Q1 Q0 CK3 CK2 CK1 CK0

Missing channels for modules with fewer than 136 channels are omitted.

Glitch detector

1,2

Channel groups can be enabled to detect glitches.

Glitches are subject to pulse width variations of up to ±125 ps

Minimum detectable glitch pulse width

(Typical)

Setup and hold violation detector

1,3

1.25 ns (single channel with P6434 probe)

1.0 ns (P6417, P6418, P6419 probe)

Any channel can be enabled to detect a setup or hold violation. The range is from 8.0

ns before the clock edge to 8.0 ns after the clock edge in 0.125 ns steps. The channel

setup and hold violation size can be individually programmed.

The range can be shifted towards the positive region by 0 ns, 4 ns, or 8 ns. With a 0

ns shift, the range is +8 ns to --8 ns; witha4nsshift,therange is +12 ns to --4 ns;

with an 8 ns shift, the range is +16 ns to 0 ns. The sample point selection region is the

same as the setup and hol d window.

TLA Specifications and Characteristics

Any setup value is subject to variation of up to the channel skew specification. Any

hold value is subject to variation of up to the channel skew specification.

23

Page 26

Specifications and Characteristics

Table 23: TLA5000 trigger system (Cont.)

Characteristic Description

Transition detector

Counter/Timers 2 counter/timers, 51 bits wide, can be clocked up to 500 MHz.

External Signal In

External Trigger In A backplane input signal that causes both the main acquisition and the MagniVu

Active trigger resources 16 maximum (excluding counter/timers)

Trigger States 16

n Trigger State sequence rate Same rate as valid data samples received, 500 MHz maximum.

Trigger Machine Actions

Main acquisition trigger Triggers the main acquisition memory.

Main trigger position Trigger position is programmable to any data sample (2 ns boundaries).

MagniVut acquisi tion trigger Triggering of MagniV memory is controlled by t he mai n acquisition trigger machine.

MagniVut trigger position The MagniV trigger position is programmable within 2 ns boundaries and separate

Increment & decrement counter Either of the two counter/timers used as counters can be increased or decreased.

Reloadable word recognizer Loads the current acquired data sample into the reference value of the word

Reloadable word recognizer latency 378 ns

Start/Stop timer Either of the two counter/timers used as timers can be started or stopped.

Reset counter/timer Either of the two counter/timers can be reset.

1

16 transition detectors.

Any channel group can be enabled or disabled to detect a rising transition, a falling

transition, or both rising and falling transitions between the current valid data sample

and the previous valid data sample.

51

Maximum count is 2

Maximum time is 4.5 X 10

-- 1 .

6

seconds or 52 days.

Counters and timers can be set, reset, or tested and have zero reset latency.

1

A backplane input signal.

acquisition to trigger if they are not already triggered.

Word recognizers are traded off one-by-one as External Signal In, glitch detection,

setup and hold detection, or transition detect ion resources are added.

from the main acquisition memory trigger position.

recognizer via a trigger machine action. All data channels are loaded into their

respective word recognizer reference register on a one-to-one manner.

When a counter/timer is used as a timer and is reset, the timer continues from the

started or stopped state that it was in prior to the reset.

Signal out A signal sent to the backplane to be used by other instruments.

Trigger out A trigger out signal sent to t he backplane to trigger other instruments.

24

TLA Specifications and Characteristics

Page 27

Specifications and Characteristics

Table 23: TLA5000 trigger system (Cont.)

Characteristic Description

Storage Control

Global storage Storage is allowed only when a specif ic condition is met. This condition can use any

of the trigger machine resources except for the counter/timers. Storage commands

defined in the current trigger state will override the global storage control.

Global storage can be used to start the acquisition with storage initially turned on

(default) or turned off.

By event Storage can be turned on or off; only the current sample can be stored. The event

storage control overrides any global storage commands.

Block storage When enabled, 31 samples are stored before and after the valid sample.

Not allowed when glitch storage or setup and hold violation is enabled.

Glitch violation storage The acquisition memory can be enabled to store glitch violation information with each

data sample when asynchronous clocking is used. The probe data storage size is

reduced by one half (the other half holds the violation information). The fastest

asynchronous clocking rate is reduced to 4 ns.

Setup and hold violation storage The acquisition memory can be enabled to store setup and hold violation information

with each data sample when synchronous clocki ng is used. The probe data storage

size is reduced by one half (the other half holds the violation information). The

maximum clock rate in this mode is 235 MHz.

1

Each use of External Signal In, glitch detector, setup and hold violation detector, or transition detector requires a trade-off

of one word recognizer resource.

2

Any glitch is subject to pulse width variation of up to the channel-to-channel skew specification + 0.25 ns.

3

Any setup value is subject to variation of up to the channel skew specification. Any hold value is subject to variation of

the channel skew specifications.

TLA Specifications and Characteristics

25

Page 28

Specifications and Characteristics

Table 24: TLA5000 MagniVut feature

Characteristic Description

MagniVu memory depth 16,000 samples per channel

MagniVu sampling period Data is asynchronously sampled and stored every 125 ps in a separate high resolution

memory. The storage speed may be changed (by software) to 250 ps, 500 ps, or

1000 ps so that MagniVu memory covers more time at a lower resolution.

Table 25: TLA5000 Data handling

Characteristic Description

Nonvolatile memory retention time

(Typical)

Battery is integral to the NVRAM. Battery life is > 10 years.

Table 26: TLA5000 internal controller

Characteristic Description

Operating System Microsoft Windows

Microprocessor Intel Celeron, 2 GHz

Main Memory PC2100 DDR SDRAM

Style 184 pin DIMM, 2 Sockets

Speed 100 MHz

Installed configuration 512 MB loaded in one socket

Real-Time Clock and CMOS Setups,

Plug & Play NVRAM Retention Time

Hard Disk Drive Standard PC compatible IDE (Integrated Device Electronics) hard disk drive residing on an

Size Formatted capacity 80 GByte

Battery life is typic ally > 3 years when the logic analyzer is not connected to line voltage. When

connected to line voltage the life of the battery is extended.

Lithium battery, CR2032

EIDE interface.

Continually subject to change due to the fast-moving PC component environment.

These storage capacities valid at product introduction.

CD-RW Drive Standard PC compatible IDE (Integrated Device Electronics)

CD-RWdriveresidingonanEIDEinterface.

Continually subject to change due to the fast-moving PC component environment.

Floppy Disk Drive Standard 3.5 inch 1.44-MB PC compatible high-density, double-sided floppy disk drive.

26

TLA Specifications and Characteristics

Page 29

Specifications and Characteristics

Table 27: TLA5000 display system

Characteristic Description

Classification Standard PC graphics accelerator technology (bitBLT-based); capable of supporting both

internal color LCD display and external color SVGA/XGA monitor.

Display Memory SDRAM-onboard the ATI Mobility I video controller clocked up to 100 MHz.

Size 8 MB

Display Selection Both front panel and external displays can be used simultaneously, each with independent

resolutions. Supports Windows dual-moni tor capability.

External Display Drive Two XGA-compatible analog output ports

Primary Display Size

(RAGE M1 chip)

Secondary Display Size

(845GV chip)

Internal Display

Classification Thin Film Transistor (TFT) 10.4 inch active-matrix color LCD display; CCFL backlight; intensity

Resolution 1024 x 768 pixels

Color Scale 256K

Selected via Windows

Resolution (Pixels) Colors

1024 x 768 256, 64 K, 16.8 M

Selected via Windows

Resolution (Pixels) Colors

640 x 480 256, 64 K, 16.8 M

800 x 600 256, 64 K, 16.8 M

1024 x 768 256, 64 K, 16.8 M

1280 x 1024 256, 64 K, 16.8 M

1600 x 1200 256, 64 K, 16.8 M

1920 x 1440 256, 64K

controllable via software.

Table 28: TLA5000 front-panel interface

Characteristic Description

QWERTY Keypad ASCII keypad to support naming of files, traces, and keyboard equivalents of pointing device

inputs for menus.

Special Function Knobs Various functions

TLA Specifications and Characteristics

27

Page 30

Specifications and Characteristics

Table 29: TLA5000 rear-panel interface

Characteristic Description

Parallel Interface Port (LPT) 25-pin sub-D Parallel Port Connector, Extended Parallel Port (EPP), or Enhanced Capabilities

Port (ECP)

Serial Interface Port (COM 1) 9-pin male sub-D connector to support RS-232 serial port

Two USB Ports Two USB 2.0 (Universal Serial Bus) compliant ports

SVGA Output Ports (SVGA OUT) 15-pin sub-D SVGA connectors (two each, one Primary, one Secondary)

Mouse Port PS/2 compatible mouse port utilizing a mini DIN connector

Keyboard Port PS/2 compatible keyboard port utilizing a mini DIN connector

Table 30: TLA5000 AC power source

Characteristic Description

Source Voltage and Frequency 100--240 VAC ±10%, 47--63 Hz, continuous range CAT II

Maximum Power Consumption 225 Watts line power maximum

Steady-State Input Current 4A

Inrush Surge Current 65 A maximum

Power Factor Correction Yes

On/Standby Switch and Indicator Front Panel On/Standby switch, with indicator.

maximum

RMS

The power cord provides main power disconnect.

Table 31: TLA5000 cooling

Characteristic Description

Cooling System Forced air circulation (negative pressurization) utilizing two fans operating in parallel

Cooling Clearance 51 mm (2 in), sides and rear; unit should be operated on a flat, unobstructed surface

28

TLA Specifications and Characteristics

Page 31

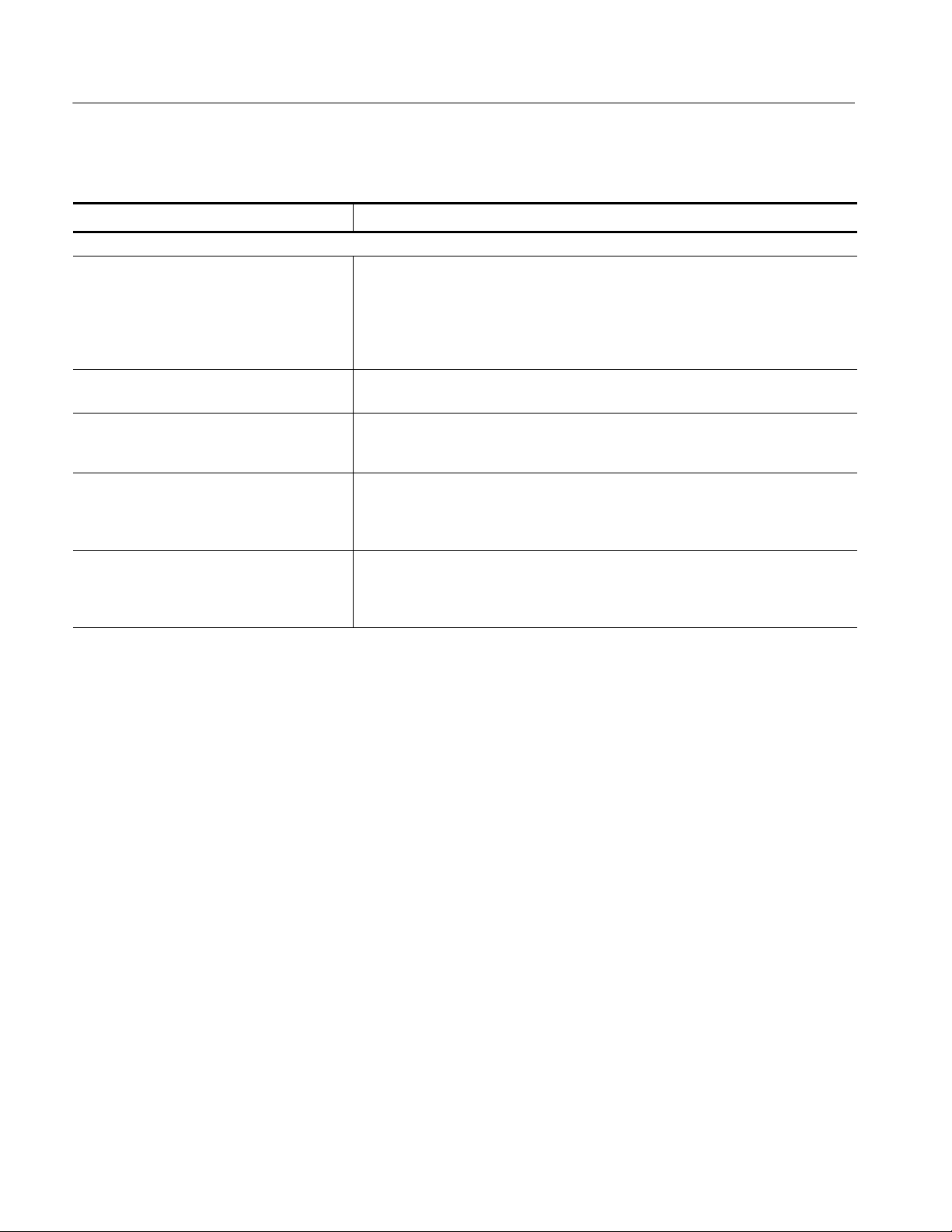

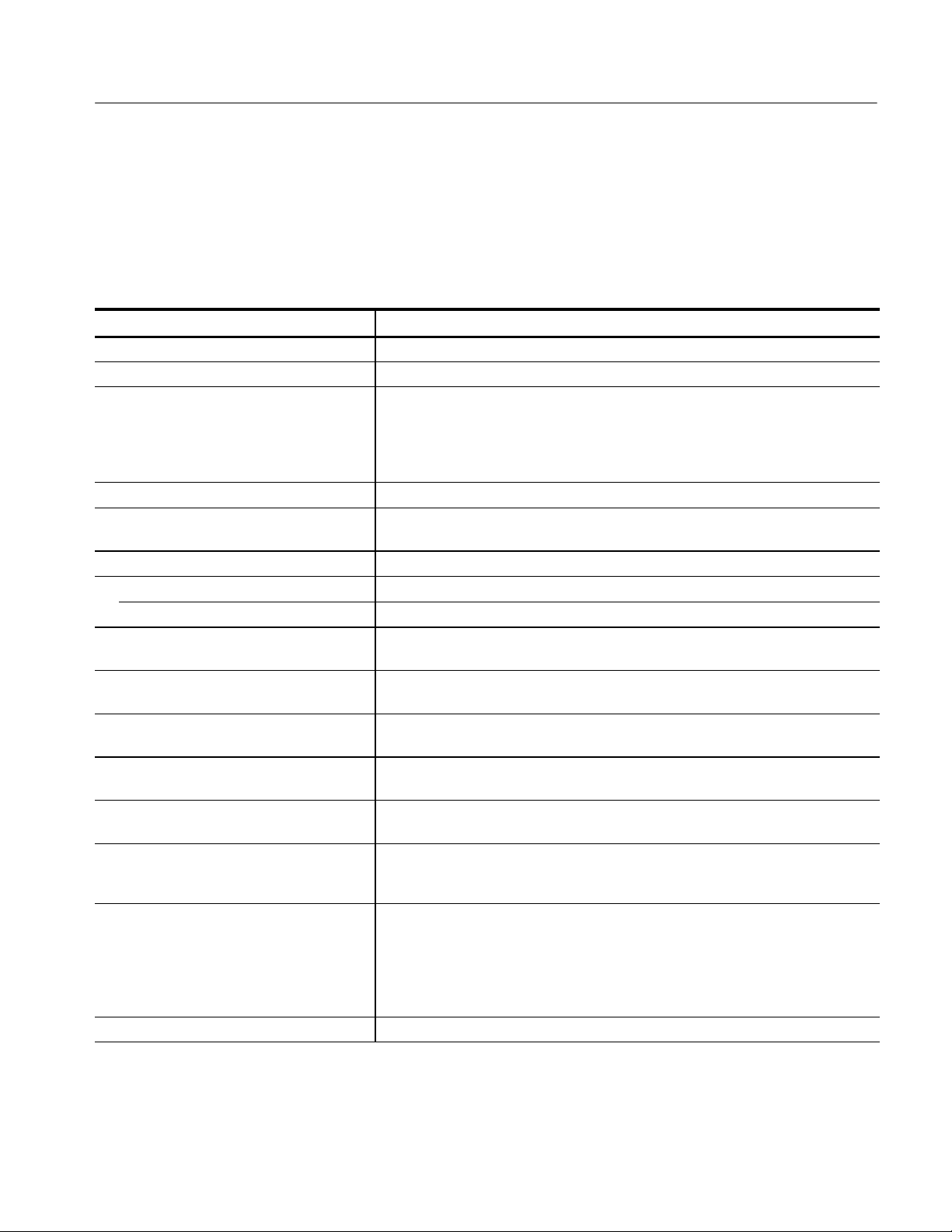

Table 32: TLA5000 mechanical characteristics

Characteristic Description

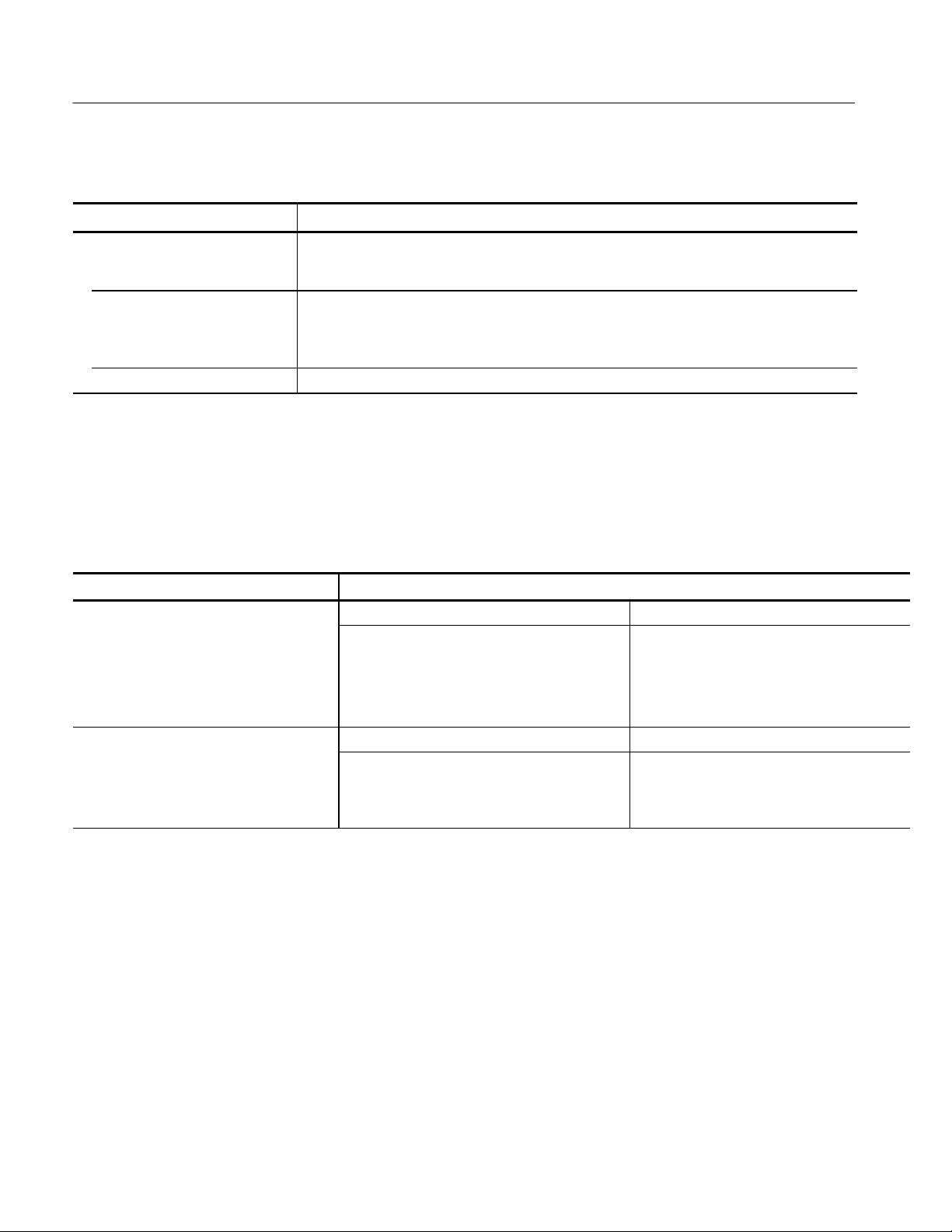

Overall Dimensions See Figure 1 for overall chassis dimensions

Weight Includes empty accessory pouch and front cover

TLA5201 11.8 Kg (25 lb 15 oz)

TLA5202 11.85 Kg (26 lb 2 oz)

TLA5203 11.9 Kg (26 lb 4 oz)

TLA5204 12Kg (26lb7oz)

Specifications and Characteristics

288.29 mm

(11.350 in)

284.48 mm

(11.200 in)

444.5 mm

(17.500 in)

Figure 2: Dimensions of the TLA5000 series logic analyzer

TLA Specifications and Characteristics

29

Page 32

Specifications and Characteristics

TLA700 System Specifications

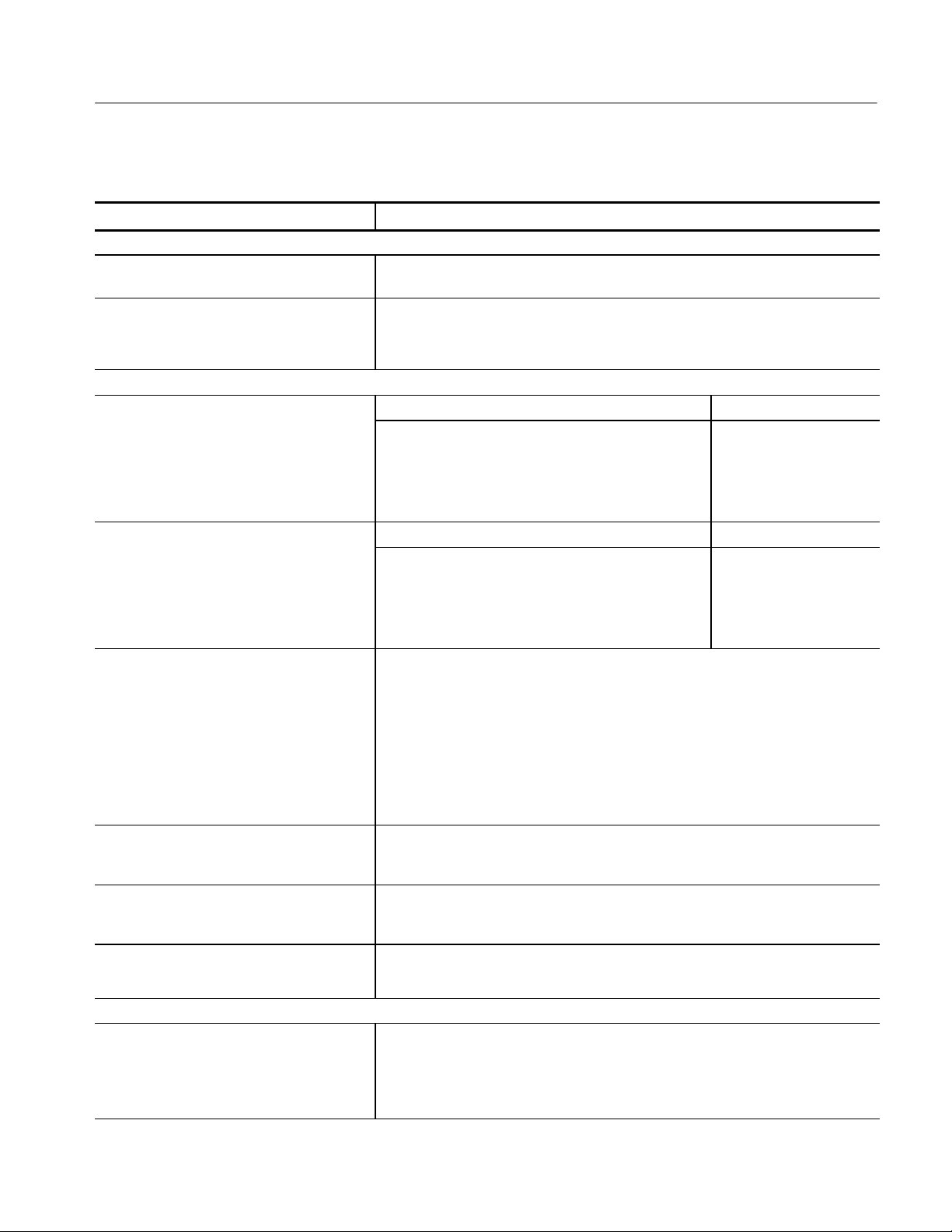

Tables 33 through 35 list the specifications common to the TLA715, TLA714,

TLA720, and TLA721 logic analyzers. Detailed specifications for the individual

logic analyzers begin on page 38.

Table 33: TLA700 Backplane interface

Characteristic Description

Slots

Portable mainframe 4

Benchtop mainframe 10 (three slots taken up by the controller module)

Expansion mainframe 13

CLK10 Frequency 10 MHz ±100 PPM

n

Relative Time Correlation Error

TLA7Lx/Mx/Nx/Px/Qx to TLA7Lx/Mx/Nx/Px/Qx “MagniVu” data 2 ns

1,2

(Typical)

TLA7Axx/TLA7NAx to TLA7AxxTLA7NAx “MagniVu” data 2ns

TLA7Axx/TLA7NAx to TLA7Lx/Mx/Nx/Px/Qx “MagniVu” data -- 3 n s

TLA7Lx/Mx/Nx/Px/Qx to TLA7Lx/Mx/Nx/Px/Qx “normal” data using an internal

clock

TLA7Axx/TLA7NAx to TLA7Axx “normal” data using an internal clock 1 TLA7Axx/TLA7NAx sample -- 0.5 ns

TLA7Axx/TLA7NAx to TLA7Lx/Mx/Nx/Px/Qx “normal” data using an internal

clock

TLA7Lx/Mx/Nx/Px/Qx to TLA7Lx/Mx/Nx/Px/Qx “normal” data using an external

clock

TLA7Axx/TLA7NAx to TLA7Axx/TLA7NAx “normal” data using an external

clock

TLA7Axx/TLA7NAx to TLA7Lx/Mx/Nx/Px/Qx “normal” data using an external

clock

1 TLA7Lx/Mx/Nx/Px/Qx sample -- 0.5 ns

1 TLA7Lx/Mx/Nx/Px/Qx sample -- 0.5 ns

2ns

2ns

4ns

30

TLA Specifications and Characteristics

Page 33

Table 33: TLA700 Backplane interface (Cont.)

Characteristic Description

TLA7Lx/Mx/Nx/Px/Qx “MagniVu” to DSO data 3ns

TLA7Axx/TLA7NAx “MagniVu” to DSO data 2ns

TLA7Lx/Mx/Nx/Px/Qx to DSO “normal” data using an internal clock

TLA7Axx/TLA7NAx to DSO “normal” data using an internal clock

TLA7Lx/Mx/Nx/Px/Qx to DSO “normal” data using an external clock

TLA7Axx/TLA7NAx to DSO “normal” data using an external clock

DSO to DSO

1

3

Includes typical jitter, slot-to-slot skew, and probe-to-probe variations to provide a “typical” number for the measurement. Assumes standard accessory probes are utilized.

2

For time intervals longer than 1 s between modules, add 0.01% of the difference between the absolute time

measurements to the relative time correlation error to account for the inaccuracy of the CLK10 source.

3

The DSO module time correlation is measured at the maximum sample rate on one channel only.

3

3

3

3

1 TLA7Lx/Mx/Nx/Px/Qx sample + 2 ns

1 TLA7Axx/TLA7NAx sample + 2 ns

3ns

2ns

3ns

Specifications and Characteristics

TLA Specifications and Characteristics

31

Page 34

Specifications and Characteristics

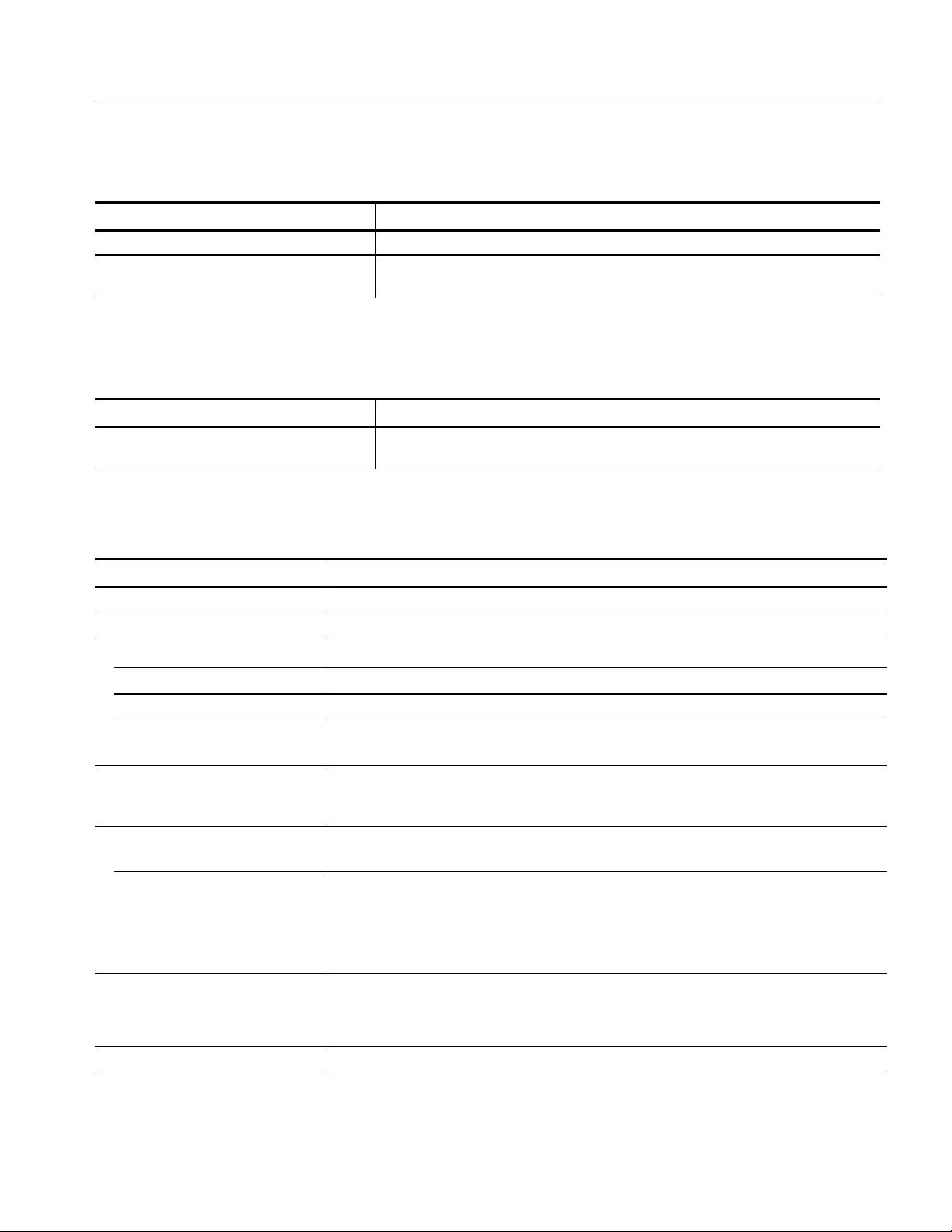

Table 34: TLA700 Backplane latencies

Characteristic Portable mainframe and

benchtop mainframe

System trigger and external signal input latencies

2

(Typical)

External system trigger input to TLA7Lx/Mx/Nx/Px/ Qx

probe tip

External system trigger input to TLA7Axx probe tip

4

4

External signal input to TLA7Lx/Mx/Nx/Px/Qx probe tip

via Signal 3, 4

5

External signal input to TLA7Axx/TLA7NAx probe tip via

Signal 3, 4

5

External signal input to TLA7Lx/Mx/Nx/Px/Qx probe tip

via Signal 1, 2

5, 6

External signal input to TLA7Axx/TLA7NAx probe tip via

Signal 1, 2

External system trigger input to DSO probe tip

5, 6

4

--266 ns --230 ns

--653 ns --617 ns

--212 ns + Clk --176 ns + Clk

--212 ns + Clk --176 ns + Clk

--634 ns + Clk --596 ns + Clk

--636 ns + Clk --615 ns + Clk

--25 ns 11 ns

System trigger and external signal output latencies1(Typical)

TLA7Lx/Mx/Nx/Px/Qx probe tip to external system trigger

376 ns + SMPL 412 ns + SMPL

out

TLA7Axx/TLA7NAx probe tip to external system trigger

794 ns + SMPL 830 ns + SMPL

out

Expansion

mainframe

TLA7Lx/Mx/Nx/Px/Qx probe tip to external signal out via

Signal 3, 4

3

OR function 366 ns + SMPL 402 ns + SMPL

AND function 379 ns + SMPL 415 ns + SMPL

TLA7Axx/TLA7NAx probe tip to external signal out via

Signal 3, 4

3

OR function 792 ns + SMPL 828 ns + SMPL

AND function 800 ns + SMPL 836 ns + SMPL

TLA7Lx/Mx/Nx/Px/Qx probe tip to external signal out via

Signal 1, 2

3, 6

normal function 364 ns + SMPL 385 ns + SMPL

inverted logic on backplane 364 ns + SMPL 385 ns + SMPL

TLA7Axx/TLA7NAx probe tip to external signal out via

Signal 1, 2

3, 6

normal function 796 ns + SMPL 817 ns + SMPL

inverted logic on backplane 796 ns + SMPL 817 ns + SMPL

32

TLA Specifications and Characteristics

Page 35

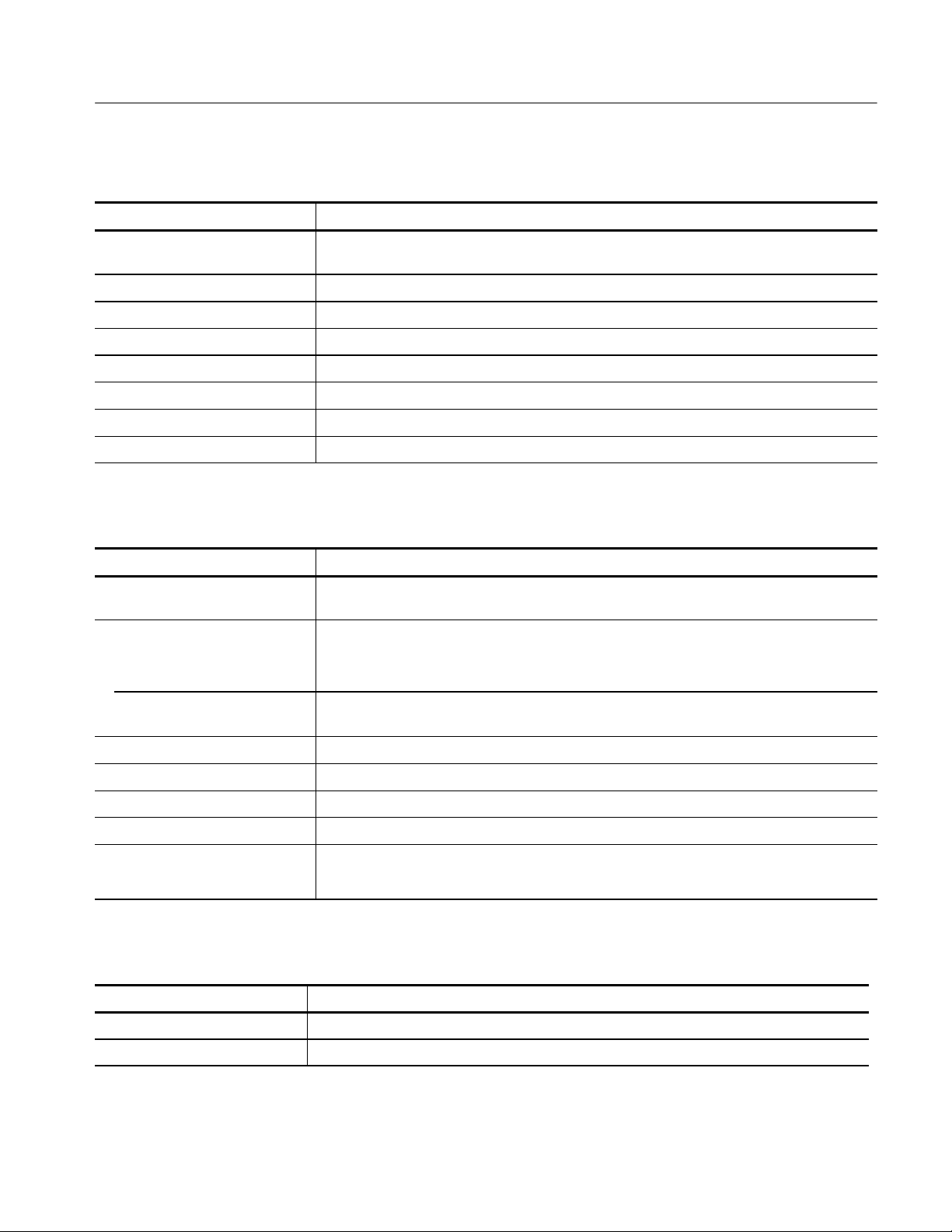

Table 34: TLA700 Backplane latencies (Cont.)

Specifications and Characteristics

Characteristic Expansion

Portable mainframe and

benchtop mainframe

mainframe

DSO probe tip to external system trigger out 68 ns 104 ns

DSO Probe tip to external signal out via Signal 3, 4

3

OR function 65 ns 101 ns

AND function 75 ns 111 ns

DSO probe tip to external signal out via Signal 1, 2

3,6

normal function 68 ns 89 ns

inverted logic on backplane 71 ns 92 ns

Inter-module latencies (Typical)

TLA7Lx/Mx/Nx/Px/Qx to DSO inter-module system

1,4

trigger

TLA7Axx/TLA7NAx to DSO inter-module system

1,4

trigger

TLA7Lx/Mx/Nx/Px/Qx to TLA7Lx/Mx/Nx/Px/Qx

inter-module system trigger

1,4

TLA7Axx/TLA7NAx to TLA7Lx/Mx/Nx/Px/Qx inter-module

system trigger

1,4

TLA7Axx/TLA7NAx to TLA7Axx/TLA7NAx inter-module

system trigger

TLA7Lx/Mx/Nx/Px/Qx to DSO inter-module ARM

TLA7Axx/TLA7NAx to DSO inter-module ARM

1,4

1

1

358 ns + SMPL 394 ns + SMPL

772 ns + SMPL 808 ns + SMPL

66 ns + SMPL 102 ns + SMPL

479 ns + SMPL 515 ns + SMPL

116 ns + SMPL 152 ns + SMPL

360 ns + SMPL 396 ns + SMPL

779 ns + SMPL 815 ns + SMPL

TLA7Lx/Mx/Nx/Px/Qx to TLA7Lx/Mx/Nx/Px/Qx

inter-module ARM

1,5

TLA7Axx/TLA7NAx to TLA7Lx/Mx/Nx/Px/Qx inter-module

1,5

ARM

TLA7Axx/TLA7NAx to TLA7Axx inter-module ARM

TLA7Lx/Mx/Nx/Px/Qx to TLA7Lx/Mx/Nx/Px/Qx

inter-module via Signal 1, 2

1,5,6

TLA7Axx/TLA7NAx to TLA7Axx inter-module via Signal

1,5,6

1, 2

TLA7Axx/TLA7NAx to TLA7Lx/Mx/Nx/Px/Qx inter-module

via Signal 1, 2

1,5,6

TLA7Lx/Mx/Nx/Px/Q to TLA7Lx/Mx/Nx/Px/Qx

inter-module via Signal 3, 4

1,5

TLA7AxxTLA7NAx to TLA7Axx inter-module via Signal 3,

1,5

4

TLA Specifications and Characteristics

1,5

108 ns + SMPL + Clk 144 ns + SMPL + Clk

479 ns + SMPL + Clk 533 ns + SMPL + Clk

111 ns + S M PL + Clk 147 ns + SMPL + Clk

116 ns + SMPL + Clk 137 ns + SMPL + Clk

113 ns + SMPL + Clk 134 ns + SMPL + Clk

534 ns + SMPL + Clk 555 ns + SMPL + Clk

116 ns + SMPL + Clk 152 ns + SMPL + Clk

124 ns + SMPL + Clk 160 ns + SMPL + Clk

33

Page 36

Specifications and Characteristics

Table 34: TLA700 Backplane latencies (Cont.)

Characteristic Expansion

TLA7Axx/TLA7NAx to TLA7Lx/Mx/Nx/Px/Qx inter-module

via Signal 3, 4

1,5

TLA7Lx/Mx/Nx/Px/Qx to TLA7Axx/TLA7NAx inter-module

System Trigger

1,4

DSO to TLA7Lx/Mx/Nx/Px/Qx inter-module System

4

Trigger

DSO to TLA7Axx/TLA7NAx inter-module System

4

Trigger

DSO to DSO inter-module System Trigger

4

TLA7Lx/Mx/Nx/Px/Qx to TLA7Axx/TLA7NAx inter-module

1,5

ARM

DSO to TLA7Lx/Mx/Nx/Px/Qx inter-module ARM

DSO to TLA7Axx/TLA7NAx inter-module ARM

5

5

Portable mainframe and

benchtop mainframe

mainframe

545 ns + SMPL + Clk 581 ns + SMPL + Clk

--287 ns + SMPL --251 ns + SMPL

--240 ns --204 ns

--598 ns --562 ns

50 ns 86 ns

--300 ns + SMPL + Clk --264 ns + SMPL + Clk

--192 ns + Clk --156 ns + Clk

--600 ns + Clk --564 ns + Clk

DSO to DSO inter-module ARM 59 ns 95 ns

DSO to TLA7Lx/Mx/Nx/Px/Qx inter-module via

Signal 1, 2

5,6

TLA7Lx/Mx/Nx/Px/Qx to TLA7Axx/TLA7NAx inter-module

via Signal 1, 2

1,5,6

--179 ns + Clk --158 ns + Clk

--294 ns + SMPL + Clk --273 ns + SMPL + Clk

DSO to TLA7Axx/TLA7NAx inter-module via Signal 1,

5,6

2

TLA7Lx/Mx/Nx/Px/Qx to TLA7Axx/TLA7NAx inter-module

via Signal 3, 4

1,5

--598ns + Clk --577 ns + Clk

--294 ns + SMPL + Clk --258 ns + SMPL + Clk

34

TLA Specifications and Characteristics

Page 37

Table 34: TLA700 Backplane latencies (Cont.)

Specifications and Characteristics

Characteristic Expansion

DSO to TLA7Lx/Mx/Nx/Px/Qx inter-module via

Signal 3, 4

5

Portable mainframe and

benchtop mainframe

mainframe

--184 ns + Clk --148 ns + Clk

DSO to TLA7Axx/TLA7NAx inter-module via Signal 3, 45--598 ns + Clk --562 ns + Clk

1

SMPL represents the time from the event at the probe tip inputs to the next valid data sample of the LA module. In the

Normal Internal clock mode, this represents the delta time to the next sample clock. In the Magni Vu Internal clock mode,

this represents 500 ps or less. In the External clock mode, this represents the time to the next master clock generated by

the setup of the clocking state machine, the system-under-test supplied clocks, and the qualification data.

2

All system trigger and external signal input latencies are measured from a falling-edge transition (active true low) with

signals measured in the wired-OR configuration.

3

All signal output latencies are validated to the rising edge of an active (true) high output.

4

In the Waveform window, triggers are always marked immediately except when delayed to the first sample. In the Listing

window, triggers are always marked on the next sample period following their occurrence.

5

“Clk” represents the time to the next master clock at the destin ation logic analyzer. In the asynchronous (or internal)

clock mode, this represents the delta time to the next sample clock beyond the minimum asynchronous rate of 4 ns. In

the synchronous (or external) clock mode, this represents the time to the next master clock generated by the setup of the

clocking state machine and the supplied system under test clocks and qualification data.

6

Signals 1 and 2 are limited to a “broadcast” mode of operation, where only one source is allowed to d rive the signal node

at any one time. That single source may be utilized to drive any combination of destinations.

TLA Specifications and Characteristics

35

Page 38

Specifications and Characteristics

Table 35: TLA700 External signal interface

Characteristic Description

System Trigger Input TTL compatible input via rear panel mounted BNC connectors (portable mainfram e) or front

panel mounted SMB connectors (benchtop mainframe)

Input Levels

V

IH

V

IL

Input destination System trigger

Input Mode Falling edge sensitive, latched (active low)

Minimum Pulse Width 12 ns

Active Period Accepts system triggers during valid acquisition periods via real-time gating, resets system

Maximum Input Voltage 0 to +5 V peak

External Signal Input TTL compatible input via rear panel mounted BNC connectors (portable mainframe) or front

Input Destination Signal 1, 2

Input Levels

V

IH

V

IL

Input Mode Active (true) low, level sensitive

Input Bandwidth

1

Signal 1, 2

Signal 3, 4

Active Period Accepts signals during valid acquisition periods via real-time gating

Maximum Input Voltage 0 to +5 V peak

System Trigger Output TTL compatible output via rear panel mounted BNC connectors (portable mainf rame) or front

Source selection System trigger

Source Mode Active (true) low, falling edge latched

Active Period Outputs system trigger state during valid acquisition period, resets system trigger output to false

Output Levels

V

OH

TTL compatible input

≥ 2.0 V

≤ 0.8 V

trigger input latch between valid acquisition periods

panel mounted SMB connectors (benchtop mainframe)

Signal 3, 4

TTL compatible input

≥ 2.0 V

≤ 0.8 V

50 MHz square w ave minimum

10 MHz square w ave minimum

panel mounted SMB connectors (benchtop mainframe)

state between valid acquisitions

50 Ω back terminated TTL-compatible output

≥4 V into open circuit

≥ 2Vinto50Ω to ground

V

OL

≤ 0.7Vsinking10ma

Output Protection Short-circuit protected (to ground)

36

TLA Specifications and Characteristics

Page 39

Specifications and Characteristics

Table 35: TLA700 External signal interface (Cont.)

Characteristic Description

External Signal Output TTL compatible outputs via rear panel mounted BNC connectors (portable mainframe) or front

panel mounted SMB connectors (benchtop mainframe)

Source Selection Signal 1, 2

Signal 3, 4

10 MHz clock

Output Modes

Level Sensitive

Output Levels

V

OH

User definable

Active (true) low or acti ve (true) high

50 Ω back terminated TTL output

≥ 4 V into open circuit

≥ 2Vinto50Ω to ground

V

OL

Output Bandwidth

Signal 1, 2

Signal 3, 4

2

≤ 0.7Vsinking10ma

50 MHz square w ave minimum

10 MHz square w ave minimum

Active Period Outputs signals during valid acquisition periods, resets signals to false state between valid

acquisitions

Outputs 10 MHz clock continuously

Output Protection Short-circuit protected (to ground)

Intermodule signal line bandwidth Minimum bandwidth up to which the intermodule signals are specified to operate correctly

Signal 1, 2

Signal 3, 4

1

The Input Bandwidth specification only applies to signals to the modules; it does not apply to signals applied to the

50 MHz square w ave minimum

10 MHz square w ave minimum

External Signal Input and sent back to the External Signal Output.

2

The Output Bandwidth specification only applies to signals from the modules; it does not apply to signals applied to the

External Signal Input and sent back to the External Signal Output.

TLA Specifications and Characteristics

37

Page 40

Specifications and Characteristics

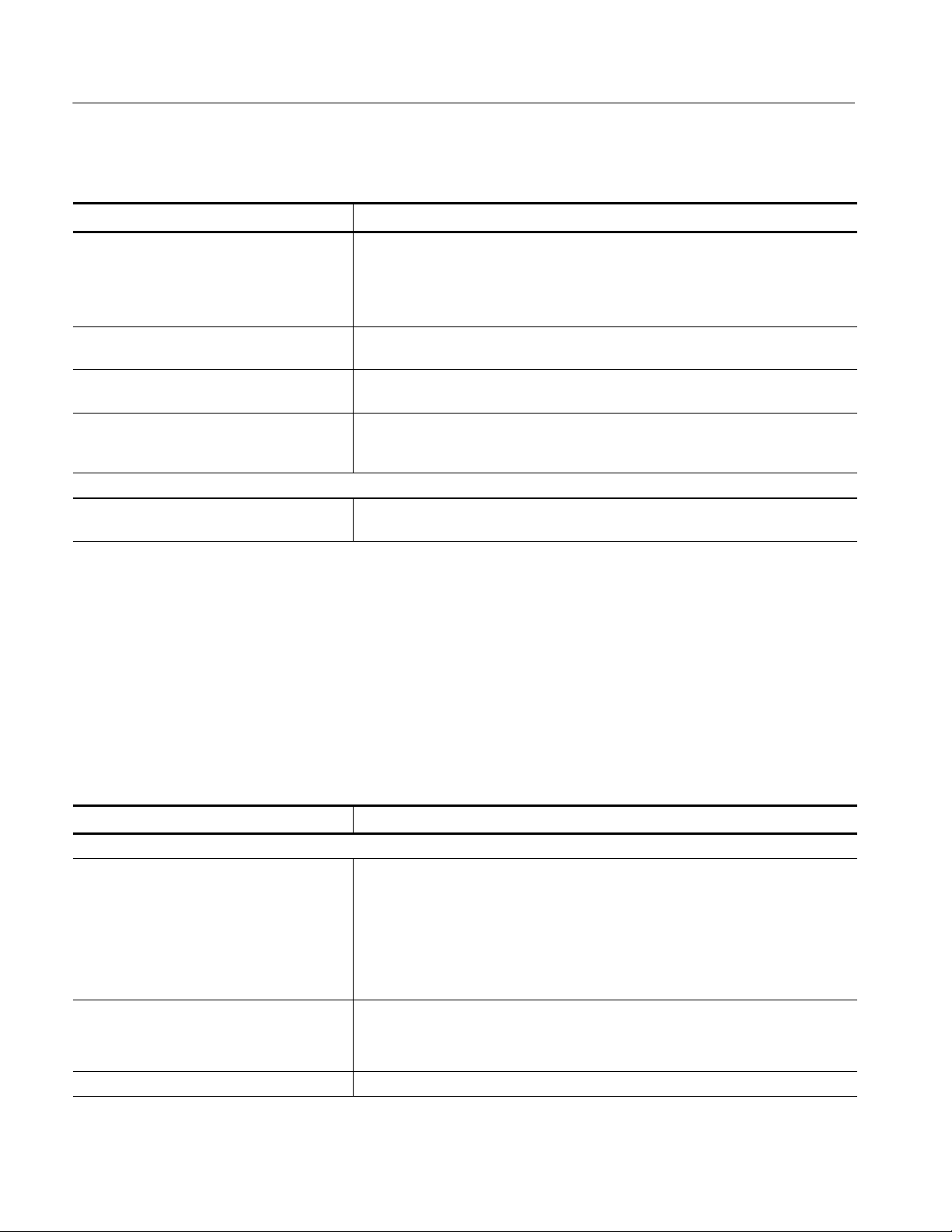

TLA715 Dual Monitor Portable Mainframe Characteristics

Tables 36 through 43 describe the specifications for the TLA715 Dual Monitor

Portable Mainframe.

Table 36: TLA715 Internal controller

Characteristic Description

Operating system Microsoft Windows 2000

Microprocessor Intel Pentium PC-AT configuration with an Intel 815E chip-set and a 733 MHz Pentium III

processor

Main memory SDRAM

Style 144 pin SO DIMM, 2 sockets, gold plated, 1.25-inch (3.175 cm) maximum height

Speed 133 MHz

Available configurations 32, 64, 128, 256 MByte per SO DIMM

Installed configurations 512 MB with both sockets loaded

Cache memory 256 KByte Level 2 (L2) write-back cache

Flash BIOS 256 KByte

Real-time clock and CMOS setups

NVRAM

RTC, CMOS setup, & PNP NVRAM

retention time (typical)

Floppy disk drive St andard 3.5 inch 1.44-MB PC compatible high-density, double-sided floppy disk drive,

Bootable replaceable hard disk drive Standard PC compatible IDE (Integrated Device Electronics) hard disk drive resi ding on an

Size 40 GB

Interface ATA --5/enhanced IDE (EIDE)

Average seek time Read, 12 ms

Average latency 7/ 14 ms

I/O data transfer rate 33.3 MBytes/sec maximum (U-DMA mode 2)

Cache buffer 2 MBytes (30 GB) /512 KBytes (10GB)

CD-RW drive Standard PC compatible IDE (Integrated device Electronics) 8x-8x-24x CD-RW drive residing on

Real-time clock/calendar, standard and advanced PC CMOS setups; see BIOS specification

> 10 years bat tery life, lithium battery

500 Kbits/sec transfer rate

EIDE interface.

Continually subject to change due to the fast-moving PC component environment.

These storage capacities valid at product introduction.

an IDE interface.

38

Continually subject to change due to the fast-moving PC component environment.

TLA Specifications and Characteristics

Page 41

Specifications and Characteristics

Table 37: TLA715 display system

Characteristic Description

Classification Standard PC graphics-accelerator technology capable of supporting both internal color LCD

display and two external color VGA, SVGA, or XGA monitors

Display memory 4 MB SDRAM clocked up to 100 MHz, no external video memory

Display selection Hardware sense of external SVGA monitor during BIOS boot sequence; defaults to internal

color LCD display (indicated by two beeps); automatically switches to external SVGA monitor, if

attached (indicated by one beep).

Dual (simultaneous) display of external SVGA monitor and internal color LCD is possible via

special CMOS “simulscan” setup, as long as internal and external displays operate at same

resolution (limited to 800x600 on current LCD) and display rates (simulscan mode indicated by

three beeps).

Four beeps during the BIOS boot indicates a monochrome LCD was found (not supported). Five

beeps indicates no recognizable LCD or external monitor was found.

Dynamic Display Configuration 1 (DDC1) support for external SVGA monitor is provided.

External display drive Two VGA, SVGA, or XGA-compatible analog output ports. Display size is selected via Win2000

display applet.

Display Size

(Primary video port with Silicon

motion chip)

(Secondary video port with 815E

chip set)

Internal display

Classification TFT (Thin Film Transistor) 26 cm active-matrix color LCD displ ay, CCFL backlight, intensity

Resolution 800 X 600, 262, 144 colors with 211.2 mm (8.3 in) by 158.4 mm (6.2 in) of viewing area

Color scale 262, 144 colors (6-bit RGB) with a color gamut of 42% at center to NTSC

Resolution (Pixels

640 x 480 256, 64 K, 16.8 M 60, 75, 85

800 x 600 265, 64 K, 16.8 M 60, 75, 85

1024 x 768 256, 64 K, 16.8 M 60, 75, 85

1280 x 1024 256, 64 K, 16.8 M 60

1600 x 600 256, 64 K 60

1600 x 1200 256, 64 K 60

Resolution (Pixels) Colors Refresh Rates

640 x 480 256, 64 K, 16.8 M 60, 75, 85

800 x 600 256, 64 K, 16.8 M 60, 75, 85

1024 x 768 256, 64 K, 16.8 M 60, 75, 85

1280 x 1024 256, 64 K, 16.8 M 60, 75, 80

1600 x 1200 256 60, 75

controllable via software

) Colors Refresh Rates

TLA Specifications and Characteristics

39

Page 42

Specifications and Characteristics

Table 38: TLA715 front-panel interface

Characteristic Description

QWERTY keypad 31-key ASCII keypad to support naming of files, traces, and keyboard equival ents of pointing

device inputs for menus

HEX keypad 25-key HEX keypad supporting standard DSO and LA entry functions

Special function knobs

Multi-function knob Various increment/decrement functions dependent on screen or window type

Vertical position Scrolling and positioning dependent on display type

Vertical scale Scales waveform displays only

Horizontal position Scrolling and positioning dependent on display type

Horizontal scale Scales waveform displays only

Integrated pointing device Vertically mounted Trackball with two keypad control buttons (SELECT and MENU)

USB port Front panel (lower left-hand side) dual USB connector

Mouse Port PS/2 compatible pointing device port

Keyboard Port PS/2 compatible keyboard port

Table 39: TLA715 rear-panel interface

Characteristic Description

Parallel interface port 36-pin high-density connector supports Output only, Enhanced Parallel Port (EPP), or Microsoft

high-speed mode (ECP)

Complies with IEEE P1284-C/D2 for bi-directional Parallel Peripheral Interface for Personal

Computers (draft) style 1284-C

Serial interface port 9-pin male sub-D connector to support RS-232 serial port

SVGA output Port 1 and Port 2 Two 15-pin sub-D SVGA connectors

PC CardBus32 port Standard Type I, II, III PC-compatible, PC card slot