Page 1

KUSB-3100

Getting Started Manual

KUSB3100-903-01 Rev. A / January 2005

www.keithley.com

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 3 years from

date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facil

ity. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse

of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leak

age, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN

ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

-

-

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRU

MENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE

POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO:

COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON,

OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

-

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/04

Page 3

KUSB-3100

Getting Started Manual

©2005, Keithley Instruments, Inc.

All rights reserved.

First Printing, January 2005

Cleveland, Ohio, U.S.A.

Document Number: KUSB3100-903-01

Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released

between Revisions, contain important change information that the user should incorporate immediately into the manual.

Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number KUSB3100-903-01A) ...................................................................... January 2005

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some in

struments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for en

suring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instru

ment. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or replacing consumable materials. Maintenance procedures

are described in the manual. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed

only by service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained ser

vice personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O sig

nals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient overvoltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless other

wise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present. A good safety practice is to ex-

-

pect that hazardous voltage is present in any unknown circuit

before measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are pre

vented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human con

tact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When con

necting sources to switching cards, install protective devices to limit

fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connect-

ed to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

-

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power dis

connect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jump

ers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

-

Do not touch any object that could provide a current path to the

common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a

dry, insulated surface capable of withstanding the voltage being

measured.

-

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equip

ment may be impaired.

Do not exceed the maximum signal levels of the instruments and ac-

-

cessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

-

-

-

-

-

-

5/03

Page 6

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

The ! symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment

frame.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that se

lected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on

the instrument. Products that consist of a circuit board with no case

or chassis (e.g., data acquisition board for installation into a com

puter) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/ser

vicing.

-

-

-

Page 7

Table of Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

How this Manual is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . x

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Where To Get Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Key Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Getting Started Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Preparing to Use a Module. . . . . . . . . . . . . . . . . . 5

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Checking the System Requirements . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3: Setting Up and Installing the Module . . . . . . . . 11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Attaching Modules to the Computer. . . . . . . . . . . . . . . . . . . . . . . 14

Connecting One or Two Modules Directly to the USB

Ports of Your Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connecting Multiple Modules Using an Expansion Hub . . 16

Changing the Name of a Module (Optional) . . . . . . . . . . . . . . . . 18

Chapter 4: Wiring Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Preparing to Wire Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Wiring Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

vii

Page 8

Contents

Connecting Single-Ended Analog Input Signals . . . . . . . . . . . . . 24

Connecting Analog Output Signals. . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting Digital I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting Counter/Timer Signals . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting Signals for an Event Counting Operation . . . . 28

Connecting Signals for a Frequency Measurement

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting Signals for an Edge-to-Edge Measurement

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connecting Signals for a Rate Generation Operation . . . . . 34

Chapter 5: Verifying the Operation of a Module . . . . . . . . . 35

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Running the Quick Data Acq Application . . . . . . . . . . . . . . . . . . 38

Performing a Single-Value Analog Input Operation . . . . . . 39

Performing a Single-Value Analog Output Operation . . . . 40

Performing a Continuous Analog Input Operation. . . . . . . 41

Performing a Single-Value Digital Input Operation . . . . . . 42

Performing a Single-Value Digital Output Operation. . . . . 42

Performing a Frequency Measurement Operation. . . . . . . . 43

Performing a Pulse Output Operation. . . . . . . . . . . . . . . . . . 44

viii

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Page 9

About this Manual

This manual describes how to install and set up your KUSB-3100

module and device driver, and verify that your module is working

properly.

Intended Audience

This document is intended for engineers, scientists, technicians, or

others responsible for installing and setting up a KUSB-3100 module

to perform data acquisition operations. It is assumed that you are

familiar with the requirements of your application. It is also assumed

that you are familiar with the Microsoft

Windows XP.

How this Manual is Organized

This manual is organized as follows:

• Chapter 1, “Overview,” describes the key features of the

KUSB-3100 hardware and software, and provides an overview of

the getting started procedure.

®

Windows® 2000 or

• Chapter 2, “Preparing to Use a Module,” describes how to

unpack the module, check the system requirements, and install

the software using Windows 2000 or Windows XP.

• Chapter 3, “Setting Up and Installing the Module,” describes

how to set up the KUSB-3100 module and configure the device

driver.

ix

Page 10

About this Manual

Conventions Used in this Manual

• Chapter 4, “Wiring Signals,” describes how to wire signals to the

module.

• Chapter 5, “Verifying the Operation of a Module,” describes how

to verify the operation of the module with the Quick Data Acq

application.

An index completes this manual.

The following conventions are used in this manual:

• Notes provide useful information that requires special emphasis,

cautions provide information to help you avoid losing data or

damaging your equipment, and warnings provide information to

help you avoid catastrophic damage to yourself or your

equipment.

• Items that you select or type are shown in bold.

• Courier font is used to represent source code.

Related Information

Refer to the following documents for more information on using the

KUSB-3100 module:

• KUSB-3100 User’s Manual provided with the module. This

manual describes the features of the KUSB-3100 module and

device driver.

• DataAcq SDK User’s Manual. For programmers who are

developing their own application programs using the Microsoft

C compiler, this manual describes how to use the DT-Open

TM

Layers

access the capabilities of your module.

x

DataAcq SDKTM in Windows 2000 or Windows XP to

Page 11

• DTx-EZ Getting Started Manual. This manual describes how to use

the ActiveX controls provided in DTx-EZ

capabilities of your module in Microsoft Visual Basic® or Visual

C++®.

• DT-LV Link Getting Started Manual. This manual describes how to

use DT-LV Link

language to access the capabilities of your module.

• Microsoft Windows 2000 or Windows XP documentation.

• USB web site (http://www.usb.org).

Where To Get Help

Should you run into problems installing or using your KUSB-3100

module, please call the Keithley Technical Support Department.

About this Manual

TM

to access the

TM

with the LabVIEW® graphical programming

xi

Page 12

About this Manual

xii

Page 13

1

Overview

Key Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Getting Started Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1

Page 14

Chapter 1

Key Hardware Features

Table 1 lists the key features of the KUSB-3100 module.

Table 1: Key Features of the KUSB-3100 Module

Analog

Inputs

Analog

Outputs

Resolution

I/O

Range

Sample

Rate

Digital

I/O

Counter/

a

Timer

8 SE

a. This counter/timer channel allows you to perform event counting, frequency

measurement, edge-to-edge measurement, and continuous pulse output (rate generation)

operations.

2

12-bit ±10 V

50 kS/s 8

input,

8

output

1

2

Page 15

Software

The software for the KUSB-3100 module, which is shipped on the

Keithley CD that is provided with the module, includes the following

software components:

Overview

1

• Device Driver − This software must be installed and loaded

before you can use a KUSB-3100 module with any of the

supported software packages or utilities.

• The Quick Data Acq application − This application provides a

quick way to get your module up and running. Using the Quick

Data Acq application, you can verify the features of the module,

display data on the screen, and save data to disk.

• DataAcq SDK − This DT-Open Layers Software Develop Kit

(SDK) allows programmers to develop application programs for

the KUSB-3100 using the Microsoft C compiler in Windows 2000

or Windows XP.

• DTx-EZ − This software package contains ActiveX controls that

allow Microsoft Visual Basic® or Visual C++® programmers to

access the capabilities of the KUSB-3100 module.

• DT-LV Link − This software package allows LabVIEW®

programmers to access the capabilities of the KUSB-3100 module.

1

1

1

1

1

1

1

1

3

Page 16

Chapter 1

Getting Started Procedure

The flow diagram shown in Figure 1 illustrates the steps needed to

get started using the KUSB-3100 module. This diagram is repeated in

each chapter; the shaded area in the diagram shows you where you

are in the getting started procedure.

Preparing to Use a Module

(see Chapter 2 starting on page 5)

Set Up and Install the Module

(see Chapter 3 starting on page 11)

Wire Signals to the Module

(see Chapter 4 starting on page 19)

Verify the Operation of the Module

(see Chapter 5 starting on page 35)

Figure 1: Getting Started Flow Diagram

4

Page 17

2

Preparing to Use a

Module

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Checking the System Requirements . . . . . . . . . . . . . . . . . . . . . . . . 8

Installing the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5

Page 18

Chapter 2

Prepare to Use a Module

(this chapter)

Set Up and Install the Module

(see Chapter 3 starting on page 11)

Wire Signals to the Module

(see Chapter 4 starting on page 19)

Verify the Operation of the Module

(see Chapter 5 starting on page 35)

6

Page 19

Unpacking

Open the shipping box and verify that the following items are

present:

• KUSB-3100 module,

•USB cable, and

• Keithley CD.

Preparing to Use a Module

2

2

If an item is missing or damaged, contact Keithley Technical Support.

Once you have unpacked your module, check the system

requirements, as described in the next section.

2

2

2

2

2

2

2

7

Page 20

Chapter 2

Checking the System Requirements

For reliable operation, your KUSB-3100 module requires the

following:

• Windows 2000 or Windows XP (Professional Edition) operating

system.

For USB Ver. 2.0 support, make sure that you install Service Pack

1 (for Windows XP) or Service Pack 4 (for Windows 2000). In

addition, for some systems, you may have to disable standby

mode. If you are not sure whether you are using USB Ver. 1.1 or

Ver. 2.0, run the Open Layers Control Panel applet, described on

page 13.

• One or more USB ports (Ver. 2.0 or Ver. 1.1). USB Ver. 2.0 is

recommended for optimal performance.

•One CD-ROM drive.

Once you have verified that your system meets the system

requirements, install the software, as described in the next section.

8

Page 21

Installing the Software

To install the driver software, Data Acq SDK, DTx-EZ, and the Quick

Data Acq software, perform the following steps:

Preparing to Use a Module

2

1. Insert the Keithley CD into your CD-ROM drive.

2. Click Start from the Task Bar, then click Run.

The Run dialog box appears.

3. In the Command Line edit box, enter D:\Setup.Exe.

If your CD-ROM is not in drive D:, enter the letter of the drive where

your CD-ROM is located. The welcome screen appears.

4. Click Install Drivers and SDK.

5. Click Install now!

The installation wizard appears.

6. Click Next.

You are prompted for the destination location.

7. Either change the directory path and/or name using Browse or

accept the default directory, then click Next.

8. Click Next to copy the files.

9. Click Finish.

10. Click Quit Installer.

2

2

2

2

2

2

2

2

9

Page 22

Chapter 2

10

Page 23

3

Setting Up and Installing

the Module

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Attaching Modules to the Computer. . . . . . . . . . . . . . . . . . . . . . . 14

Changing the Name of a Module (Optional) . . . . . . . . . . . . . . . . 18

11

Page 24

Chapter 3

Prepare to Use a Module

(see Chapter 2 starting on page 5)

Set Up and Install the Module

(this chapter)

Wire Signals to the Module

(see Chapter 4 starting on page 19)

Verify the Operation of the Module

(see Chapter 5 starting on page 35)

Note: The KUSB-3100 module is factory-calibrated. You can recalibrate

the module using the instructions in the KUSB-3100 User's Manual.

12

Page 25

Overview

You can attach a KUSB-3100 module to the host computer in one of

two ways:

• Connect directly to a USB port of the host computer, described on

• Connect to one or more self-powered USB hubs, described on

Setting Up and Installing the Module

page 13. Use this method if one or two modules are sufficient for

your application.

page 16. Use this method if your application requires more than

two modules connected to the host computer.

3

3

3

Note: The KUSB-3100 module is a low-power device (using less

than 200

supply.

mA); therefore, it does not require an external power

3

3

3

3

3

3

13

Page 26

Chapter 3

Attaching Modules to the Computer

This section describes how to attach a KUSB-3100 module to the host

computer.

Note: Most computers have two USB ports that allow direct

connection to USB devices. If your application requires more than

two KUSB-3100 modules, you can expand the number of USB

devices attached to a single USB port by using expansion hubs. For

more information, refer to page 16.

You can unplug a module, then plug it in again, if you wish, without

causing damage. This process is called hot-swapping. Your

application may take a few seconds to recognize a module once it is

plugged back in.

Connecting One or Two Modules Directly to the USB Ports of Your Computer

14

To connect one or two KUSB-3100 modules directly to the USB ports

of your computer, perform the following steps:

1. Attach one end of the USB cable to the USB port on the module.

2. Attach the other end of the USB cable to one of the USB ports on

the host computer, as shown in Figure 2.

The operating system automatically detects the USB module. If the

module is attached correctly, the LED on the module turns green.

Page 27

Setting Up and Installing the Module

Host Computer

Figure 2: Attaching the Module to the Host Computer

3. Repeat the steps to attach another KUSB-3100 module to the host

computer, if desired.

USB Ports

USB Cable

KUSB-3100 Modules

3

3

3

3

3

3

3

3

3

15

Page 28

Chapter 3

Connecting Multiple Modules Using an Expansion Hub

Expansion hubs are powered by their own external power supply.

Theoretically, you can connect up to five expansion hubs to a USB

port on the host computer. However, the practical number of

KUSB-3100 modules that you can connect to a single USB port

depends on the throughput you want to achieve. Each of the hubs

supports up to four modules.

Note: The bandwidth of the USB Ver. 1.1 bus is 12 Mbits/second;

the bandwidth of the USB Ver. 2.0 bus is 480 Mbits/second.

Particularly if you are using the USB Ver. 2.0 bus, you may be limited

in the number of modules that you can connect to a single USB port.

To connect multiple KUSB-3100 modules to an expansion hub,

perform the following steps:

16

1. Attach one end of the USB cable to the module and the other end

of the USB cable to an expansion hub.

2. Connect the power supply for the expansion hub to an external

power supply.

3. Connect the expansion hub to the USB port on the host computer

using another USB cable.

The operating system automatically detects the USB device. If the

module is attached correctly, the LED on the module turns green.

Page 29

Setting Up and Installing the Module

4. Repeat these steps until you have attached the number of

expansion hubs (up to five) and modules (up to four per hub)

that you require. Refer to Figure 3.

The operating system automatically detects the USB devices as they are

installed.

3

3

Host Computer

KUSB-3100 Module

USB Cables

USB Cable

Power Supply

for Hub

KUSB-3100 Module

USB Cables

Figure 3: Attaching Multiple KUSB-3100 Modules

Using Expansion Hubs

KUSB-3100 Module

USB Cable

Expansion Hubs

KUSB-3100 Module

Power Supply

for Hub

3

3

3

3

3

3

3

17

Page 30

Chapter 3

Changing the Name of a Module (Optional)

To change the name of a KUSB-3100 module, configure the device

driver by performing the following steps:

1. From the Windows Start menu, select Settings|Control Panel.

2. From the Control Panel, double-click Open Layers Control

Panel.

The Data Acquisition Control Panel dialog box appears.

3. If you want to rename the module, click the KUSB-3100 module

that you want to rename, then click Edit Name.

4. Enter a new name for the module, then click OK. The name is

used to identify the module in all subsequent applications.

5. When you are finished configuring the module, click Close.

6. Repeat steps 3 to 5 for the other modules that you want to

configure.

7. Close the Data Acquisition Control Panel dialog box.

18

Continue with the instructions on wiring in Chapter 4 starting on

page 19.

Page 31

4

Wiring Signals

Preparing to Wire Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connecting Single-Ended Analog Input Signals . . . . . . . . . . . . . 24

Connecting Analog Output Signals. . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting Digital I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting Counter/Timer Signals . . . . . . . . . . . . . . . . . . . . . . . 28

19

Page 32

Chapter 4

Preparing to Use a Module

(see Chapter 2 starting on page 5)

Set Up and Install the Module

(see Chapter 3 starting on page 11)

Wire Signals

(this chapter)

Verify the Operation of the Module

(see Chapter 5 starting on page 35)

20

Page 33

Preparing to Wire Signals

Note: To avoid electrostatic sensitivity, it is recommended that you

unplug your KUSB-3100 module from the computer before wiring

signals.

This section provides recommendations and information about

wiring signals to a KUSB-3100 module.

Wiring Recommendations

Keep the following recommendations in mind when wiring signals to

an ECONseries module:

• Use individually shielded twisted-pair wire (size 16 to 26 AWG)

in highly noisy electrical environments.

• Separate power and signal lines by using physically different

wiring paths or conduits.

Wiring Signals

4

4

4

4

4

• To avoid noise, do not locate the box and cabling next to sources

that produce high electromagnetic fields, such as large electric

motors, power lines, solenoids, and electric arcs, unless the

signals are enclosed in a mumetal shield.

• Prevent electrostatic discharge to the I/O while the box is

operational.

• Connect all unused analog input channels to analog ground.

4

4

4

4

21

Page 34

Chapter 4

Wiring Method

You wire signals to the KUSB-3100 module using the screw terminals

on the module.

modules.

Table 2: KUSB-3100 Screw Terminal Assignments

Table 2 lists the screw terminal assignments for the

Screw

Terminal

20 USB +5 V Out 40 Ext Trig In

19 Ground 39 Ext Clock In

18 Counter 0 In 38 Ground

17 Counter 0 Out 37 Digital Output 7

16 Counter 0 Gate 36 Digital Output 6

15 Ground 35 Digital Output 5

14 DAC 1 34 Digital Output 4

13 DAC 1 Return 33 Digital Output 3

12 DAC 0 32 Digital Output 2

11 DAC 0 Return 31 Digital Output 1

10 2.5 V Reference 30 Digital Output 0

9 Analog Ground 29 Ground

8 Analog Input CH7 High 28 Digital Input 7

7 Analog Input CH6 High 27 Digital Input 6

Signal

Screw

Terminal

Signal

22

6 Analog Input CH5 High 26 Digital Input 5

5 Analog Input CH4 High 25 Digital Input 4

4 Analog Input CH3 High 24 Digital Input 3

Page 35

Table 2: KUSB-3100 Screw Terminal Assignments (cont.)

Wiring Signals

Screw

Terminal

3 Analog Input CH2 High 23 Digital Input 2

2 Analog Input CH1 High 22 Digital Input 1

1 Analog Input CH0 High 21 Digital Input 0

Signal

Screw

Terminal

Signal

4

4

4

4

4

4

4

4

4

23

Page 36

Chapter 4

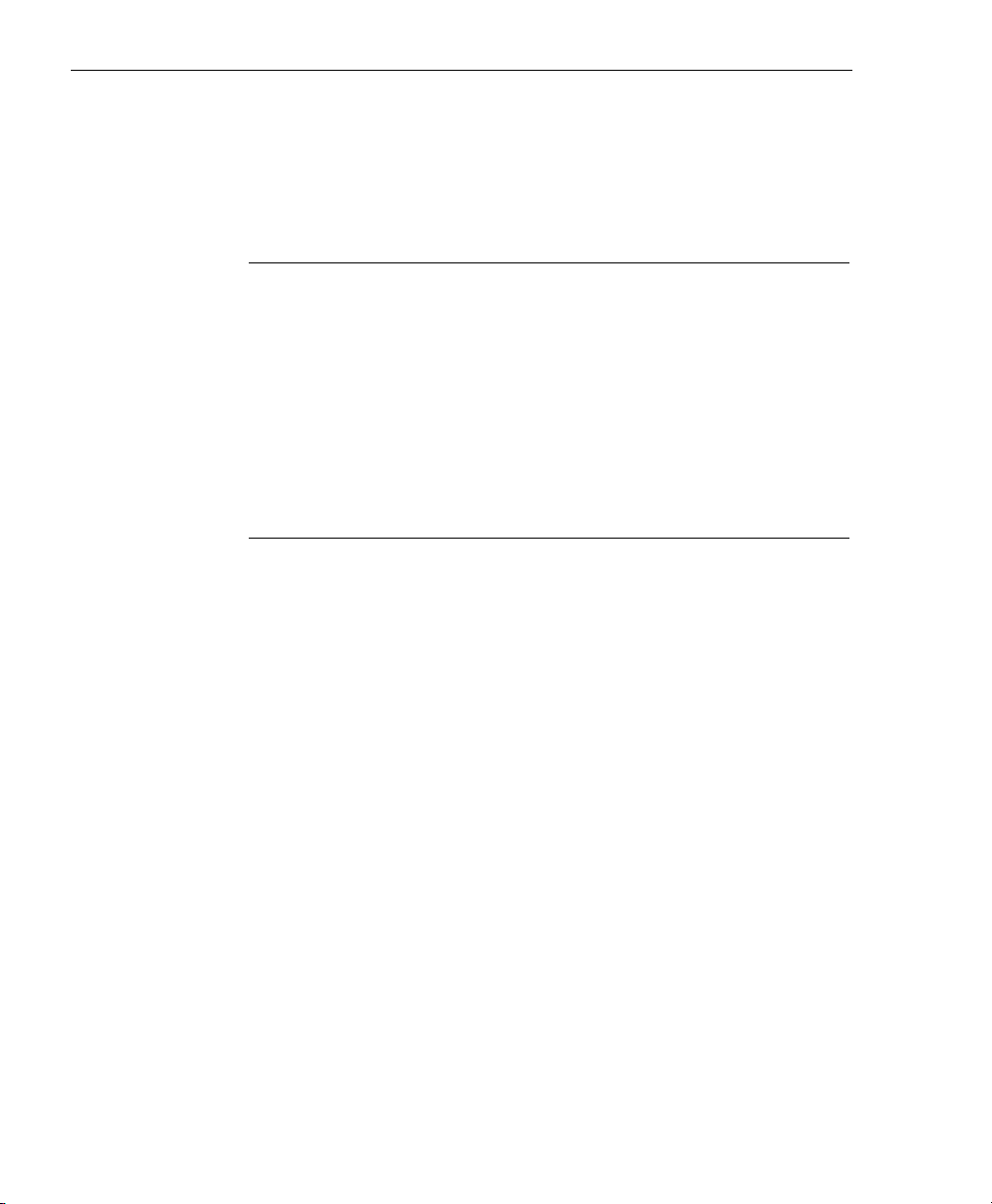

Connecting Single-Ended Analog Input Signals

The KUSB-3100 module supports 8 single-ended analog input

channels.

signals (channels 0 and 1, in this case) to the screw terminals of the

module.

Figure 4 shows how to connect single-ended voltage input

-

source 1

V

-

Vsource 0

Signal Source

Analog Ground

+

Analog In 1 High

+

Analog In 0 High

9

2

1

KUSB-3100 Module

Figure 4: Connecting Single-Ended Inputs

24

Page 37

Connecting Analog Output Signals

The KUSB-3100 module supports two analog output channels (DAC0

and DAC1).

signal (DAC0, in this case) to the KUSB-3100 module.

Figure 5 shows how to connect an analog output voltage

Wiring Signals

4

4

DAC0

Load

Figure 5: Connecting Analog Outputs to a Screw Terminal Panel

DAC0 Return

12

11

KUSB-3100 Module

4

4

4

4

4

4

4

25

Page 38

Chapter 4

Connecting Digital I/O Signals

The KUSB-3100 module supports eight, fixed digital input lines and

eight, fixed digital output lines.

digital input signals (lines 0 and 1, in this case) to the screw terminals

of a KUSB-3100 module.

Figure 6 shows how to connect

29

22

21

KUSB-3100 Module

Ground

Digital Input 1

Digital Input 0

Figure 6: Connecting Digital Inputs

TTL Inputs

26

Page 39

Wiring Signals

Figure 7 shows how to connect digital output signals (line 0, in this

case) to the screw terminals of aKUSB-3100 module.

4

38

30

KUSB-3100 Module

Figure 7: Connecting Digital Outputs

Ground

Out = LED On

Digital Output 0

500 Ω

4

+

5 V

-

4

4

4

4

4

4

4

27

Page 40

Chapter 4

Connecting Counter/Timer Signals

The KUSB-3100 module provides one counter/timer channel that you

can use to perform the following operations:

• Event counting,

• Frequency measurement,

• Edge-to-edge measurement, and

• Continuous pulse output (rate generation).

This section describes how to connect counter/timer signals for these

operation modes. Refer to the KUSB-3100 User’s Manual for more

information about using the counter/timers.

Connecting Signals for an Event Counting Operation

Figure 8 shows how to connect counter/timer signals to the screw

terminals on the KUSB-3100 module to perform an event counting

operation using an external gate.

28

In this example, the counter counts the number of rising edges that

occur on the Counter 0 In signal when the Counter 0 Gate signal is in

the active state (as specified by software). Refer to the KUSB-3100

User’s Manual for more information.

Page 41

Wiring Signals

Ground

Signal

Source

Counter 0 In

External

Gating

Switch

Figure 8: Connecting Counter/Timer Signals for an Event Counting

Operation Using an External Gate

Figure 9 shows how to connect counter/timer signals to the screw

terminals on the KUSB-3100 module to perform an event counting

operation without using a gate (also called a software gate). The

counter counts the number of rising edges that occur on the Counter

0 In signal.

Counter

0 Gate

Ground

19

18

16

KUSB-3100 Module

4

4

4

4

4

4

4

4

4

29

Page 42

Chapter 4

Signal

Source

KUSB-3100 Module

Ground

19

Counter 0 In

18

Figure 9: Connecting Counter/Timer Signals for an Event Counting

Operation Without Using a Gate

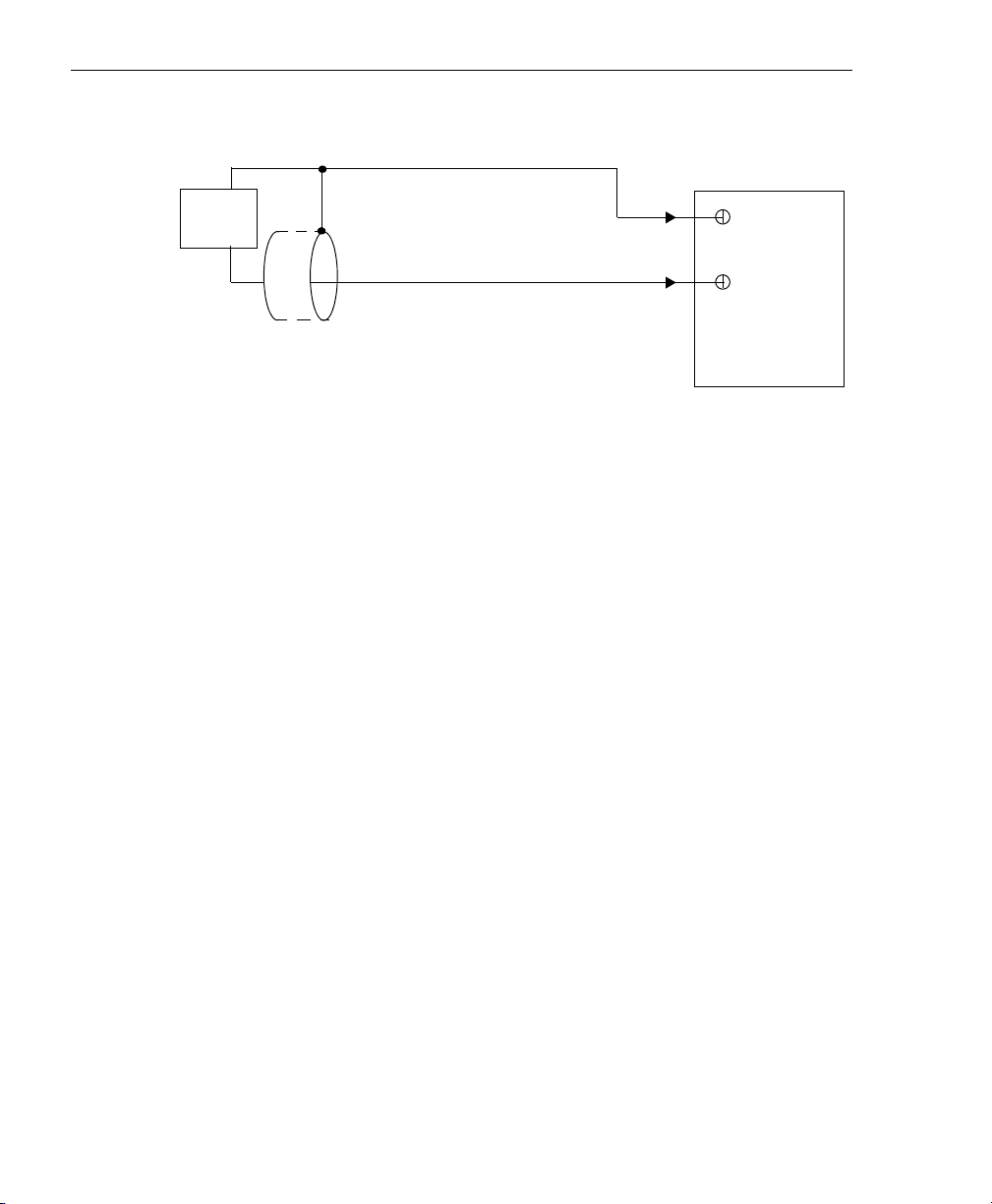

Connecting Signals for a Frequency Measurement Operation

One way to measure frequency is to use the same wiring as a

standard event counting application that does not use a gate (see

Figure 9 on page 30), then use the Windows timer to determine the

duration over which to count the number of pulses connected to the

Counter 0 In signal. The frequency of the Counter 0 In signal is the

number of counts divided by the duration of the Windows timer.

If you need more accuracy than the Windows timer can provide, you

can connect a pulse of a known duration to the Counter 0 Gate signal,

as shown in

signal is the number of counts divided by the period of the signal

connected to the Counter 0 Gate input.

Figure 10. In this case, the frequency of the Counter 0 In

30

Page 43

Signal

Source

Ground

Counter 0 In

(Number of pulses counted

during gate period)

Wiring Signals

4

KUSB-3100 Module

19

4

18

Counter 0 Gate

Known Signal

Source

Figure 10: Connecting Counter/Timer Signals for a Frequency Measurement

Operation Using an External Pulse

(Determines period

for count)

16

4

4

4

4

4

4

4

31

Page 44

Chapter 4

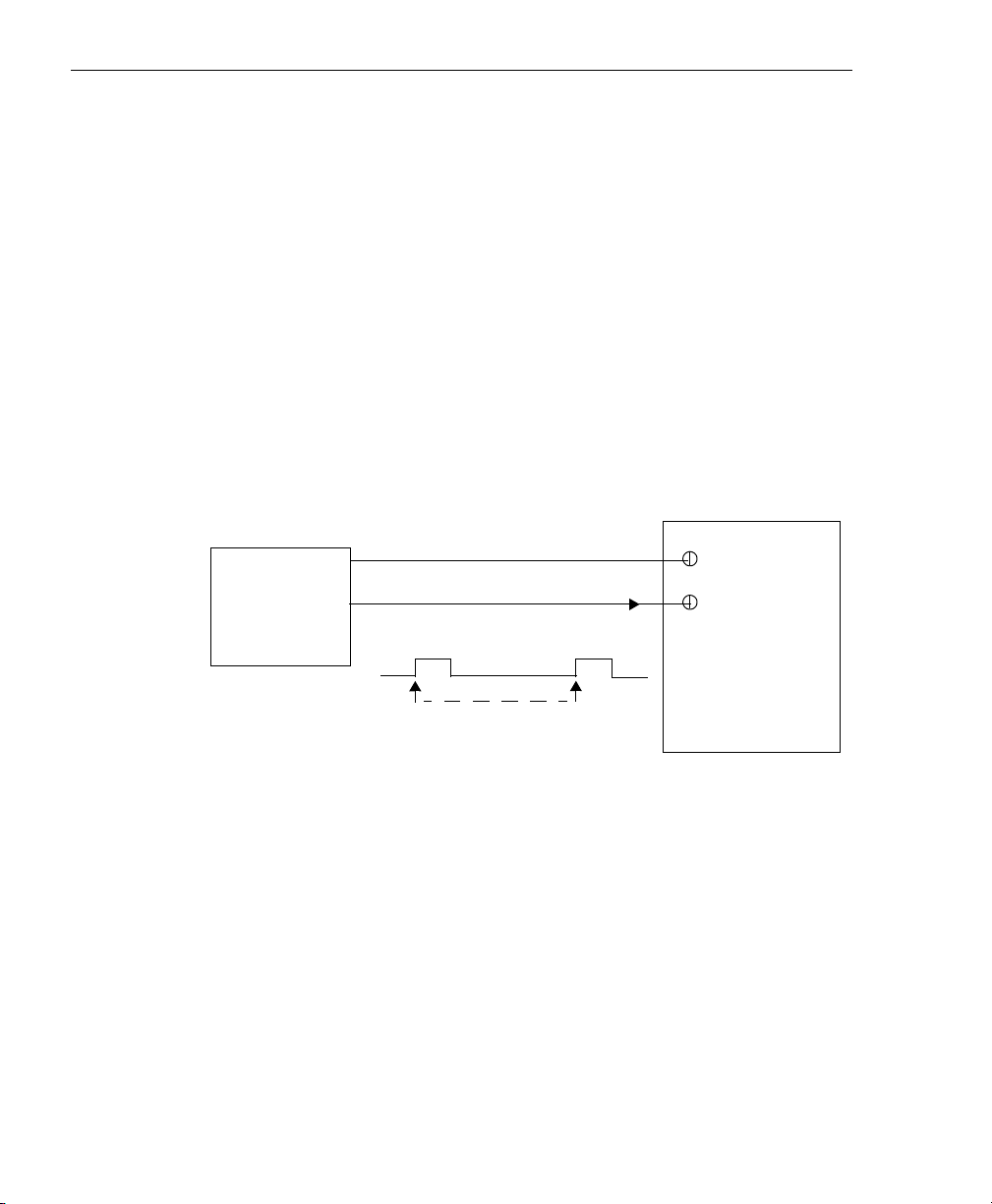

Connecting Signals for an Edge-to-Edge Measurement Operation

Figure 11 shows how to connect counter/timer signals to the

KUSB-3100 module to perform an edge-to-edge measurement

operation on one signal sources. The counter measures the number of

counts between the start edge (in this case, a rising edge on the

Counter 0 Gate signal) and the stop edge (in this case, another rising

edge on the Counter 0 Gate signal).

You specify the start edge and the stop edge in software. Refer to the

KUSB-3100 User’s Manual for more information.

KUSB-3100 Module

Digital Ground

Signal Source

Counter 0 Gate

In this example, the software

returns the number of counts

between the two rising edges

Figure 11: Connecting Counter/Timer Signals for an

Edge-to-Edge Measurement Operation

19

16

32

Page 45

Wiring Signals

You can use edge-to-edge measurement to measure the following

characteristics of a signal:

• Pulse width – The amount of time that a signal pulse is in a high

or a low state, or the amount of time between a rising edge and a

falling edge or between a falling edge and a rising edge. You can

calculate the pulse width as follows:

− Pulse width = Number of counts/24 MHz

• Period – The time between two occurrences of the same edge

(rising edge to rising edge, or falling edge to falling edge). You

can calculate the period as follows:

− Period = 1/Frequency

4

4

4

− Period = Number of counts/24 MHz

• Frequency – The number of periods per second. You can calculate

the frequency as follows:

− Frequency = 24 MHz/Number of Counts

4

4

4

4

4

4

33

Page 46

Chapter 4

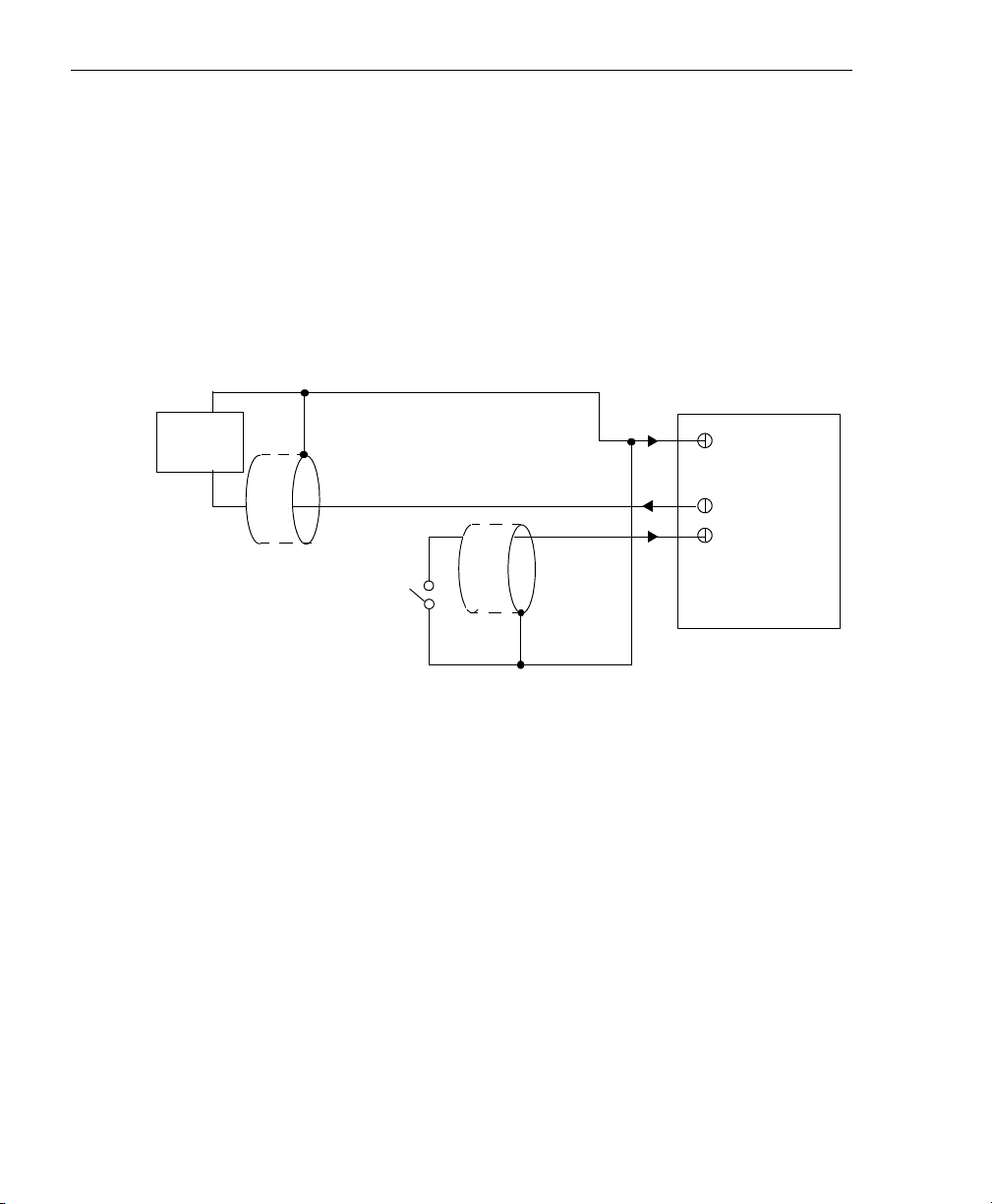

Connecting Signals for a Rate Generation Operation

Figure 12 shows how to connect counter/timer signals to the screw

terminals of a KUSB-3100 module to perform a rate generation

(continuous pulse output) operation; in this example, an external gate

is used.

Heater

Controller

Ground

Counter 0 Out

External

Gating

Switch

Counter 0

Gate

Ground

KUSB-3100 Module

19

17

16

Figure 12: Connecting Counter/Timer Signals for a Rate Generation

Operation Using an External Gate

34

Page 47

5

Verifying the Operation of a

Module

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Running the Quick Data Acq Application . . . . . . . . . . . . . . . . . . 38

35

Page 48

Chapter 5

Prepare to Use a Module

(see Chapter 2 starting on page 5)

Set Up and Install the Module

(see Chapter 3 starting on page 11)

Wire Signals to the Module

(see Chapter 4 starting on page 19)

Verify the Operation of the Module

(this chapter)

36

Page 49

Overview

Quick Data Acq allows you to perform the following operations:

• Acquire data from a single analog input channel or digital input

• Acquire data continuously from one or more analog input

Verifying the Operation of a Module

5

port;

5

channels using an oscilloscope, strip chart, or Fast Fourier

Transform (FFT) view;

• Measure the frequency of events (using the Windows system

timer);

• Output data from a single analog output channel or digital

output port;

• Output pulses continuously; and

• Save the input data to disk.

Quick Data Acq is installed automatically when you install the driver

software, described on

page 9.

5

5

5

5

5

5

5

37

Page 50

Chapter 5

Running the Quick Data Acq Application

To run the Quick Data Acq application, perform the following steps:

1. If you have not already done so, power up your computer and

any attached peripherals.

2. Select Quick Data Acq from the Keithley Instruments\Quick

Data Acq program group.

Note: The Quick Data Acq application allows you to verify basic

operations on the module; however, it may not support all of the

module’s features.

For information on each of the features provided, use the online help

for the Quick Data Acq application by pressing F1 from any view or

selecting the Help menu.

For detailed information on the supported features of the module,

refer to the KUSB-3100 User’s Manual.

38

Page 51

Verifying the Operation of a Module

Performing a Single-Value Analog Input Operation

To verify that the module can read a single analog input value,

perform the following steps:

1. Connect a voltage source, such as a function generator, to analog

input channel 0 (single-ended mode) on the module. Refer to

page 24 for an example of how to connect a single-ended analog

input.

2. Click the Acquisition menu.

3. Click Single Analog Input.

4. Select the appropriate module from the Board list box.

5. In the Channel list box, select analog input channel 0.

6. In the Range list box, select the range for the channel (±10 V,

±5

V, ±2.5 V, or ±1.25 V). The default is ±10 V.

7. Select Single-ended.

8. Click Get to acquire a single value from analog input channel 0.

The value is displayed on the screen in both text and graphical form.

5

5

5

5

5

5

5

5

5

39

Page 52

Chapter 5

Performing a Single-Value Analog Output Operation

To verify that the module can output a single analog output value,

perform the following steps:

1. Connect an oscilloscope or voltmeter to DAC 0 on the module.

Refer to page 25 for an example of how to connect analog output

signals.

2. Click the Control menu.

3. Click Single Analog Output.

4. Select the appropriate module from the Board list box.

5. In the Channel list box, select analog output channel 0.

6. In the Range list box, select the output range of DAC 0.

The default is ±10 V.

7. Enter an output value, or use the slider to select a value to output

from DAC0.

8. Click Send to output a single value from DAC 0.

The value that is output is displayed on the screen in both text and

graphical form.

40

Page 53

Verifying the Operation of a Module

Performing a Continuous Analog Input Operation

To verify that the module can perform a continuous analog input

operation, perform the following steps:

1. Connect known voltage sources, such as the outputs of a function

generator, to analog input channels 0 and 1 on the module (using

the single-ended configuration). Refer to page 24 for an example

of how to connect a single-ended analog input.

2. Click the Acquisition menu.

3. For this example, click Scope.

4. Select the appropriate module from the Board list box.

5. In the Sec/Div list box, select the number of seconds per division

(.1 to .00001) for the display.

6. In the Channels list box, select analog input channel 1, then click

Add to add the channel to the channel list.

Note that, by default, channel 0 is included in the channel list.

7. Click Config from the Toolbar.

8. From the Config menu, select ChannelType, then select

Single-ended.

9. From the Config menu, select Range, then select Bipolar.

This is the default configuration.

5

5

5

5

5

5

10. From the Scope view, double-click the input range of the channel

to change the input range of the module (±10 V, ±5 V, ±2.5 V, or

±1.25

V). The default is ±10 V.

The display changes to reflect the selected range for all the analog input

channels on the module.

11. In the Trigger box, select Auto to acquire data continuously from

the specified channels or Manual to acquire a burst of data from

the specified channels.

5

5

5

41

Page 54

Chapter 5

12. Click Start from the Toolbar to start the continuous analog input

operation.

The values acquired from each channel are displayed in a unique color

on the oscilloscope view.

13. Click Stop from the Toolbar to stop the operation.

Performing a Single-Value Digital Input Operation

To verify that the module can read a single digital input value,

perform the following steps:

1. Connect a digital input to digital input line 0 of port A on the

module. Refer to page 26 for an example of how to connect a

digital input.

2. Click the Acquisition menu.

3. Click Digital Input.

4. Select the appropriate module from the Board list box.

5. Select digital input port A by clicking Port A.

42

6. Click Get.

The value of each digital input line in port A is displayed on the screen

in both text and graphical form.

Performing a Single-Value Digital Output Operation

To verify that the module can output a single digital output value,

perform the following steps:

1. Connect a digital output to digital output line 0 of digital output

port A on the module. Refer to page 26 for an example of how to

connect a digital output.

2. Click the Control menu.

3. Click Digital Output.

4. Select the appropriate module from the Board list box.

Page 55

Verifying the Operation of a Module

5. Select digital output port A by clicking Port A.

6. Click the appropriate bits to select the type of signal to write from

the digital output lines. If the bit is selected, a high-level signal is

output from the digital output line; if the bit is not selected, a

low-level signal is output from the digital output line.

Optionally, you can enter an output value in the Hex text box.

7. Click Send.

The value of each digital output line of digital output port A is output

and displayed on the screen in both text and graphical form.

Performing a Frequency Measurement Operation

To verify that the module can perform a frequency measurement

operation (using the Windows timer), perform the following steps:

1. Wire an external clock source to counter/timer 0 on the module.

Refer to page 30 for an example of how to connect an external

clock.

2. Click the Acquisition menu.

3. Click Frequency Counter.

4. Select the appropriate module from the Board list box.

5

5

5

5

5

5

5. In the Count Duration text box, enter the number of seconds

during which events will be counted.

6. Click Start to start the frequency measurement operation.

The operation automatically stops after the number of seconds you

specified has elapsed, and the frequency is displayed on the screen.

If you want to stop the frequency measurement operation when it is

in progress, click Stop.

5

5

5

43

Page 56

Chapter 5

Performing a Pulse Output Operation

To verify that the module can perform a pulse output operation,

perform the following steps:

1. Connect a scope to counter/timer 0 on the module. Refer to page

34 for an example of how to connect a scope (a pulse output) to

counter/timer 0.

2. Click the Control menu.

3. Click Pulse Generator.

4. Select the appropriate module from the Board list box.

5. Select Continuous to output a continuous pulse stream.

6. Click Start to generate the pulse(s).

The results are displayed both in text and graphical form.

7. Click Stop to stop a continuous pulse output operation.

44

Page 57

Index

A

analog input operations 24

analog inputs 39, 41

analog output operations 25

analog outputs 40

applet, Open Layers Control Panel 8

application wiring

analog inputs 24

analog outputs 25

digital inputs and outputs 26

edge-to-edge measurement 32

event counting 28

frequency measurement 30

period measurement 32

pulse output 34

attaching the module to the computer

13, 14

C

cables, USB 14, 16

changing the name of a module 18

configuring the device driver 18

connecting signals

analog inputs 24

analog outputs 25

digital inputs and outputs 26

edge-to-edge measurement 32

event counting 28

frequency measurement 30

period measurement 32

pulse output 34

connecting to the host computer 14

using an expansion hub 16

Control Panel applet 8

conventions used x

counter/timers

connecting edge-to-edge signals 32

connecting event counting signals 28

connecting frequency measurement

signals

connecting pulse output signals 34

30

D

DataAcq SDK 3

device driver 3

configuring 18

digital inputs 26, 42

digital outputs 26, 42

DT-LV Link 3

DTx-EZ 3

E

edge-to-edge measurement, wiring 32

event counting, wiring 28

F

frequency measurement 30, 33, 43

H

hot-swapping 14

45

Page 58

Index

L

LEDs 14, 16

O

Open Layers Control Panel applet 8

output pulses 34, 44

P

period measurement 32, 33

preparing to wire signals 21

pulse outputs 34, 44

pulse width 33

Q

Quick Data Acq 3

running 38

R

recommendations for wiring 21

related documents x

requirements 8

running the Quick Data Acq

application

38

W

wiring signals

analog inputs 24

analog outputs 25

digital inputs and outputs 26

edge-to-edge measurement 32

event counting 28

frequency measurement 30

methods 22

period measurement 32

preparing 21

pulse output 34

recommendations 21

S

software supported 3

system requirements 8

U

unpacking 7

USB cable 14, 16

46

Page 59

All Keithley trademarks and trade names are the property of Keithley Instruments, Inc.

Specifications are subject to change without notice.

All other trademarks and trade names are the property of their respective companies.

A GREATER MEASUR E OF CONFIDENCE

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/04

Loading...

Loading...