Page 1

Keithley Instruments

KTTI-RS232 Communication and Digital I/O

28775 Aurora Road

Cleveland, Ohio 44139

1-800-935-5595

tek.com/keithley

Accessory Instruction Sheet

Introduction

The KTTI-RS232 Communication and Digital I/O Accessory provides instruments with an accessory card slot

with an RS-232 interface.

The card provides six independently configurable digital input/output lines that can be used to control external

digital circuitry, for example, a handler that is used to perform binning operations. The digital I/O port is a

standard female DB-9 connector. You can also use these lines for triggering. The instrument can generate

output trigger pulses and detect input trigger pulses.

Figure 1: KTTI-RS232 communications card

077143600 / April 2018 *P077143600* 1

The item shipped may vary from model pictured.

Page 2

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

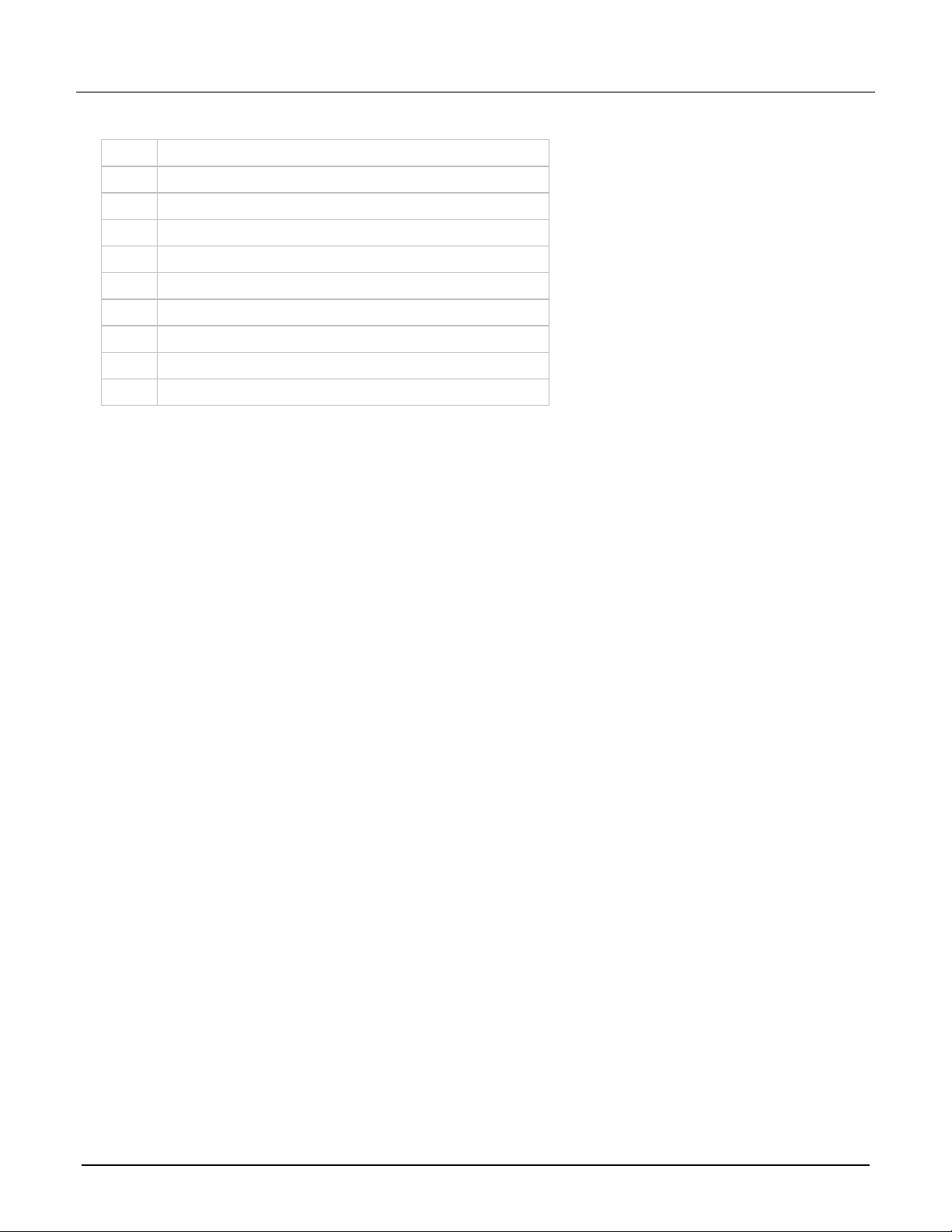

General specifications

General ratings for the KTTI-RS232 are lis ted in the fol low ing tab le.

Category Specification

Serial interface I/O connector: DB-9, female connector

Compliance Conforms to European Union EMC Directive

Compliance with CE and NRTL listed to UL61010-1 and UL61010-2-30

Conforms with European Union Low Voltage Directive

Environmental conditions I/O connector: DB-9, female connector

Operating temperature: 0 °C (32 °F) to 55 °C (131 °F)

Storage temperature: –20 °C (–4 °F) to 80 °C (176 °F)

Relative humidity: 5% to 95%, noncondensing

Power consumption: +5.0 V: 250 mA (typical), 300 mA (maximum)

Dimensions, (not including connectors): 120 mm (4.72 in.) x 64.5 mm

(2.54 in.)

Digital I/O Connector: 9-pin female D.

5V Power Supply Pin: Limited to 500 mA at > 4 V (solid-state fuse protected).

Lines: Six input/output, user-defined, for digital I/O or triggering.

Input Signal Levels: 0.7 V (maximum logic low), 3.7 V (minimum logic high).

Input Voltage Limits: –0.25 V (absolute minimum), +5.25 V (absolute

maximum).

Maximum Source Current: +2.0 mA at >2.7 V (per pin).

Maximum Sink Current: –50 mA at 0.7 V (per pin, solid-state fuse protected).

Environmental conditions Operating environment: Temperature 23 ºC ± 5 ºC, 5% to 80% relative

humidity, noncondensing

Storage environment: –25 ºC to 65 ºC

Unpack and inspect

Make sure to handle the KTTI-RS232 carefully. Always grasp the card by the side edges. Do not touch board

surfaces, components, or areas adjacent to electrical contacts. Contamination from foreign materials such as

dirt, dust, and body oils can substantially degrade card performance.

To unpack and inspect your instrumen t:

1. Inspect the box for damage.

2. Open the box.

3. Remove the card and inspect for any obvious signs of physical damage.

4. Report any damage to the shipping agent im mediately.

Installation

Slot covers must be installed on unused slots to prevent personal contact with high-voltage

circuits. Failure to recognize and observe standard safety precautions could result in

personal injury or death due to electric shock.

2 077143600 / April 2018

Page 3

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

To install the communications car d :

1. Turn the instrument off and disconnect the power line cord and any other cables connected to the rear

panel.

2. Position the instrument so that you are facing the rear panel.

3. Remove the slot cover plate from the slot on the back of the instrument. Retain the plate and screws for

future use.

4. Align the card with the connector toward the inside edge of the slot and slide the card into the chassis. For

the last ¼ inch, press in firmly to mate the card to the connector.

5. On each side of the card, there is a spring-loaded mounting screw. Tighten these two screws, either by

hand or with a Phillips-head screwdriver, to secure the card in the case. Do not overtighten.

6. Reconnect the power line cable and any other cables to the rear panel.

7. Turn on the instrument.

Making connections

The RS-232 serial port can be connected to the serial port of a controller using a straight-through RS232 cable

terminated with DB-9 connectors. Do not use a null modem cable.

The serial port uses the transmit (TXD), receive (RXD), and signal ground (GND) lines of the RS232 standard.

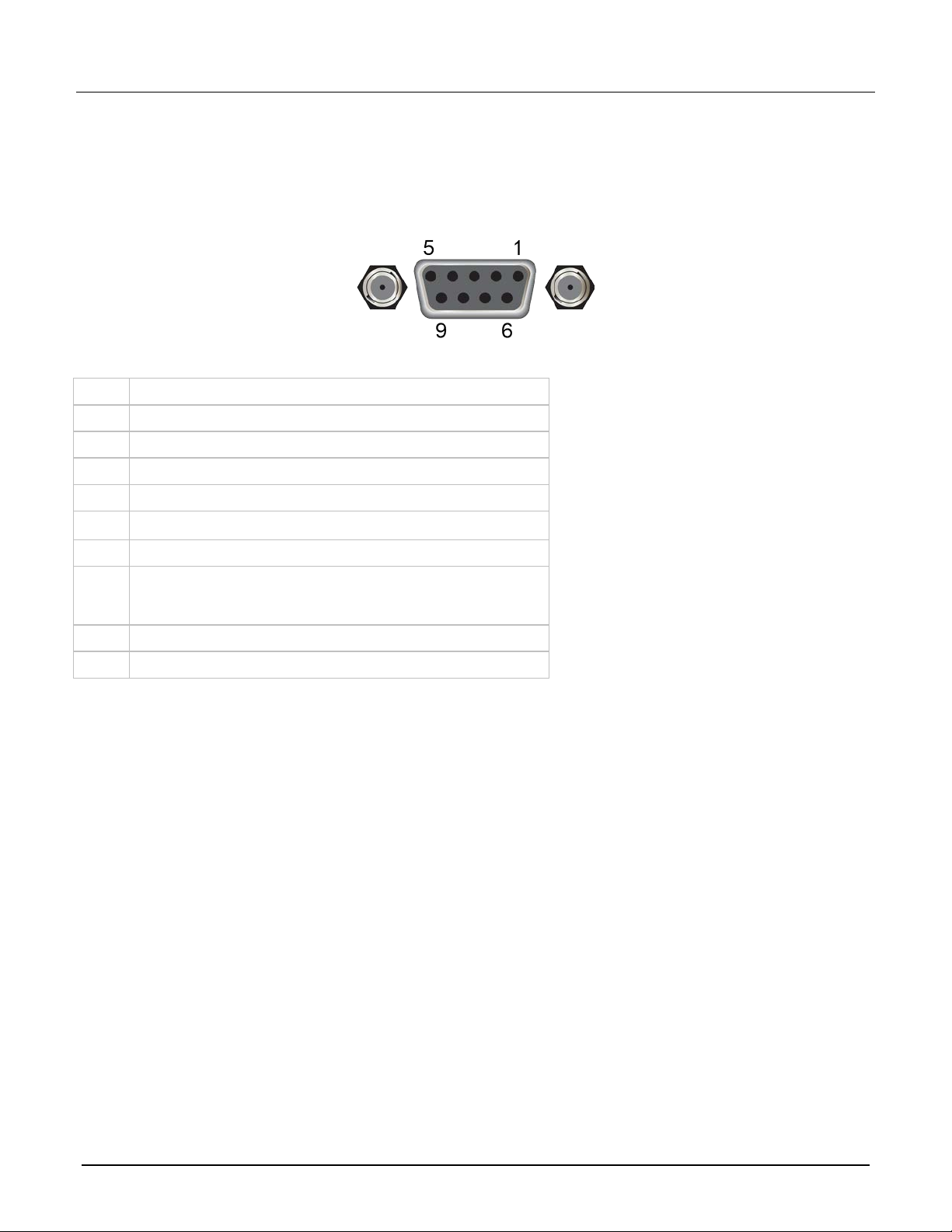

The figure below shows the rear panel connector for the RS232 interface. The table below shows the pinouts

for the connector.

Figure 2: KTTI-RS232 panel view

Figure 3: RS-232 panel connector

077143600 / April 2018 3

Page 4

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Pin Description

1 No connection

2 TXD, transmit data

3 RXD, receive data

4 No connection

5 GND, signal ground

6 No connection

7 No connection

8 No connection

9 No connection

Operation

This section provides information needed to use the KTTI-RS232.

When the communications card is installed, the instrument recognizes the card when the power is turned on.

The KTTI-RS232 interface transfers data using eight data bits, one stop bit, and no parity. Make sure the

device you connect to the instrument also uses these settings .

You can break data transmissions by sending the ^C or ^X character string. This clears any pending operations

and discards any pending output.

Refer to the instrument reference manual for information about controlling the instrument from a remote

interface.

4 077143600 / April 2018

Page 5

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Configuration

The baud rate is the rate at which the instrument and the attached device communicate. The factory-selected

baud rate is 9600, but you can choose from any of these available rates.

115200

57600

38400

19200

9600

4800

2400

1200

600

300

When you choose a baud rate, make sure the attached device can support the selected rate. The instrument

and the attached device must be configured for the same baud rate.

To configure the RS-232 card:

1. Press the MENU key.

2. Select Communication.

3. Set the Baud Rate option.

4. Set Flow Control.

Digital I/O

The KTTI-RS232 digital I/O port provides six independently configurable digital input/output lines.

You can use these lines for digital control by writing a bit pattern to the digital I/O lines. Digital control is used

for applications such as providing binning codes to a component handler. Digital control uses the state of the

line to determine the action to take.

You can also use these lines for triggering by using the transition of the line state to initiate an action. The

instrument can generate output trigger pulses and detect input trigger pulses. Triggering is used for applications

such as synchronizing the operations of a measurement instrument with the operations of other instruments.

You cannot configure or directly control the digital I/O lines from the front panel. To configure and control any of

the six digital input/output lines, you need to send commands to the KTTI-RS232 over a remote interface. You

can use either the SCPI or TSP command set.

See Remote communications interfaces in the instrument reference manual for information about setting up a

remote interface and choosing a command set.

077143600 / April 2018 5

Page 6

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Digital I/O connector and pinout s

The digital I/O port uses a standard female DB-9 connector, located on the rear panel of the KTTI-RS232. You

can connect to the KTTI-RS232 digital I/O using a standard male DB-9 connector. The port provides a

connection point to each of the six digital I/O lines and other connections, as shown in the following table.

Figure 4: Digital I/O communication port

KTTI-RS232 digital I/O port pinouts

Pin Description

1 I/O line #1

2 I/O line #2

3 I/O line #3

4 I/O line #4

5

6 I/O line #5

7 +5 V line. Use this pin to drive external logic circuitry. Maximum

8 I/O line #6

9 Ground

line (relay flyback diode protection; maximum 33 V)

V

ext

current output is 500 mA. This line is protected by a

self-resetting fuse (one-hour recovery time).

6 077143600 / April 2018

Page 7

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Digital I/O port configura t ion

The following figure shows the basic configuration of the digital I/O port.

To set a line high (nominally +5 V), write a 1 to it; to set a line low (nominally 0 V), write a 0 to it. To allow a

external device to control the state of the line, the line must be set to input mode or open-drain mode. An

attached device must be able to sink at least 50 µA from each I/O line.

F

igure 5: Digital I/O port configuration

n

For additional details about the digital output, see the KTTI-RS232 specifications, available at the

Keithley Instruments support website

.

077143600 / April 2018 7

Page 8

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Vext line

The digital I/O port provides a line (V

) with a flyback diode clamp that you can use when controlling inductive

ext

circuitry such as relay coils or low-power solenoids. You can use the built-in 5 V supply or an external vo lta g e

supply for these types of applications. The externally supplied voltage can be up to +33 V.

Do not apply more than 50 mA (maximum current) or exce ed +33 V (maximum voltage) on the

digital I/O lines. Applying current or voltage exceeding these limits may damage the

instrument.

Refer to the following figure for a simplified schematic of a sample control circuit for a relay. You can externally

power a different device by replacing the relay coil with the other device. The relay is actuated by configuring

the corresponding digital output line. Most of these types of applications use an active-low (set the bit to 0) to

turn the relay on (ON = 0 V). In the low state (0 V), the output transistor sinks current through the external

device. In the high state, the output transistor is off (transistor switch is open). This interrupts current flow

through the external device.

igure 6: Digital I/O port (example external circuit)

F

+5 V line

The digital I/O port provides a +5 V output. You can use this line to drive external circuitry. The maximum

current output for this line is 500 mA. A self-resetting fuse with a one-hour recovery time protects this line.

If you are using this supply to drive a relay, it should be connected to the V

by the flyback diode clamp.

8 077143600 / April 2018

line so that the relay is protected

ext

Page 9

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Digital I/O lines

You can place each digital I/O line into one of the following modes:

Digital open-drain, output, or input

Trigger open-drain, output, or input

Trigger synchronous master or acceptor

When you configure the digital I/O lines for triggering applications, configure the output lines before

the input lines. This prevents possible false input trigger detection in certain situations.

Digital control modes

If you are setting a line for digital control, you can set the line to be open-drain, output, or input, as described in

the following topics.

Open-drain

When you place a line in open-drain mode, the line is configured to be an open-drain signal with a 100 kΩ

pull-up resistor. This makes the line compatible with other instruments that use open-drain digital I/O lines, such

as other Keithley Instruments products that only support open-drain for its digital I/O. In this mode, the line can

serve as an input, an output, or both. You can read from the line or write to it. When a digital I/O line is used as

an input in open-drain mode, you must write a 1 to the line to enable it to detect logic levels that are generate

f

rom external sources.

d

Output

When you place a line in output mode, you can set the line as logic high (+5 V) or as logic low (0 V). The

default level is logic low (0 V). When the instrument is in output mode, the line is actively driven high or low.

Unlike the input or open-drain modes, it will not respond to externally generated logic levels.

When you read the line, it shows the present output status and an event message is generated.

Input

The input mode is similar to the open-drain mode, except that a line in this mode is intended to be used strictly

as an input. When you place a line in input mode, the instrument automatically writes a 1 to the line to enable it

to detect externally generated logic levels.

You can read an input line, but you cannot write to it. You also cannot change the logic level while the line is in

input mode. If you attempt to change the logic level of a line that is in input mode, an event message is

generated.

077143600 / April 2018 9

Page 10

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Trigger control modes

You can use the trigger control modes to synchronize instrument operation with the operation of other

instruments. These modes either detect or generate transitions in the state of the line, from high to low (falling

edge) or from low to high (rising edge). The input edge detection setting of the instrument determines which

type of transition is detected as an input trigger. Output triggers are typically generated in the form of a pulse.

The type of transition that occurs on the leading edge of the pulse is determined by an output logic setting. The

duration of the pulse is determined by a pulse width setting.

You can use the trigger control modes with interactive triggering or with the trigger model. For more information

about the trigger modes and triggering, refer to the triggering section of the instrument reference manual.

Open-drain

When you set the instrument to trigger mode and place a line in open-drain mode, the line is configured to be

an open-drain signal with a 100 kΩ pull-up resistor. This makes the line compatible with other instruments that

use open-drain trigger signals, such as other Keithley Instruments products that only support open-drain for its

digital I/O. In this mode, you can use the line to detect input triggers or generate output triggers, or both. To use

this mode successfully, you must carefully configure the input edge and output logic settings because both of

these affect the initial state of the trigger line. It is recommended that you reset the line before selecting and

configuring this mode.

To use the line only as a trigger input:

1. Reset the line.

2. Set the input trigger edge detection type to falling, rising, or either.

The command that sets the detection type automatically sets the line high. This enables the line to respond to

and detect externally generated trigg er s .

Do not set the output trigger logic type to positive after setting the edge detection type. This sets the line low,

which will prevent the line from operating correctly as a trigger input.

To use the line only as a trigger output:

1. Reset the line.

2. Set the output trigger logic type to negative (falling edge) or positive (rising edge).

When you set the logic type to negative, the instrument automatically sets the line high. Setting the logic type to

positive automatically sets the line low.

Do not set the input trigger edge detection type after setting the positive logic type. This will set the line high,

which will prevent the line from operating correctly as a trigger output.

To use the line as both a trigger input and a trigger output (falling edge triggers on ly):

1. Reset the line.

2. Set the output trigger logic type to negative (falling edge).

3. Set the input trigger edge detection type to falling, rising, or either.

You can use these settings for triggering applications that use Keithley Instrument products featuring Trigger

Link.

Output

When you place a line in output mode, it is autom atically set high or low depending on the output logic setting .

Use the negative logic setting when you want to generate a falling edge trigger. Use the positive logic setting

when you want to generate a rising edge trigger. You cannot detect incoming triggers on a line configured as a

trigger output.

10 077143600 / April 2018

Page 11

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Input

When you place a line in input mode, it is automatically set high to allow it to respond to and detect externally

generated triggers. Depending on the input edge detection setting, the line can detect falling-edge triggers,

rising-edge triggers, or both.

The line cannot generate an output trigger if it is set to the trigger input mode.

Synchronous triggering

The synchronous triggering modes allow you to:

Implement bidirectional triggering on a single trigger line

Start operations on one or more external instruments using a single trigger line

Wait for all instruments to complete all triggered actions

To coordinate non-Keithley instrumentation with synchronous triggering, the non-Keithley instrument must have

a trigger mode that is similar to the synchronous acceptor or synchronous master trigger mode.

To use synchronous triggering, configure the triggering master to synchronous master trigger mode or the

non-Keithley equivalent. Configure all other instruments in the test system to the synchronous acceptor trigger

mode or equivalent.

Synchronous master

Use the synchronous master trigger mode with the synchronous acceptor mode or its non-Keithley equivalent.

Configure only one instrument as a synchronous master. Configure all other instruments that are connected to

the synchronization line as synchronous acceptors.

When a digital I/O line is set to the synchronous master mode, it generates falling edge output triggers and

detects rising edge input triggers on the same trigger line.

Instruments that are configured as synchronous acceptors detect the falling-edge trigger and begin their

triggered actions. At the same time, they latch the line low and hold it in that state until their trigg ered ac tio ns

complete. Each instrument configured as an acceptor releases the line upon completion of its triggered actions.

When all instruments have released the line, the line changes state and generates a rising edge trigger. This

trigger is detected by the synchronous master, which then performs its next triggered action.

077143600 / April 2018 11

Page 12

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Input characteristics:

All rising edges are input triggers.

When all external drives release the physical line, the rising edge is detected as an input trigger.

A rising edge is not detected until all external drives release the line and the line floats high.

Figure 7: Synchronous master input trigger

Output characteristics:

In addition to trigger events from other trigger objects, the TSP comm

ger.digout[N].assert() generates a low pulse that is similar to the falling-edge trigger mode.

trig

An action overrun occurs if the physical line state is low when a stimulus event occurs.

Figure 8: Synchronous master output trigger

Synchronous acceptor

Use the synchronous acceptor trigger mode with the synchronous master mode or its non-Keithley equivalent.

Only one instrument should be configured as a synchronous master. All other instruments connected to the

synchronization line must be configured as synchronous acceptor or equivalent.

and

A line that is set to the synchronous acceptor mode detects falling edge input triggers and generates rising

edge output triggers on the same trigger line. When a line that is configured as synchronous acceptor detects

the falling edge trigger, it latches the line low and holds it in that state until all triggered actions for that

instrument are complete. When the triggered actions are complete, the synchronous acceptor line releases the

line. When all connected instruments have released the line, the line changes state and generates a rising

edge trigger.

12 077143600 / April 2018

Page 13

Input characteristics:

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

The falling edge is detected as the external drive pulses the line low, and the internal drive latches the li

l

ow.

Figure 9: Synchronous acceptor input tri g ger

Output characteristics:

In addition to trigger events from other trigger objects, the TSP comm

trigger.digout[

The physical line state does not change until all drives (internal and external) release the line.

Action overruns occur if the internal drive is not latched low and a source event is received.

N].assert() triggers events as well.

Figure 10: Synchronous acceptor output trigger

and

ne

077143600 / April 2018 13

Page 14

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

:DIGital:LINE<n>:MODE

*RST

:DIGital:LINE<n>:STATe

:DIGital:READ?

:DIGital:WRITe <n>

:TRIGger:DIGital<n>:IN:CLEar

:TRIGger:DIGital<n>:IN:EDGE

:TRIGger:DIGital<n>:IN:OVERrun?

trigger.digout[N].assert()

Remote digital I/O comma nds

Commands for both SCPI and TSP are summarized in the following table. You can use the digital I/O port to

perform the following actions:

Perform basic steady-state digital I/O operations, suc h as readi ng and writing to indi vidua l I/O lines or

reading and writing to the entire port

Trigger the instrument when external trigger pulses are applied to the digital I/O port

Provide trigger pulses to external devices

For detailed descriptions and sample applications, see the instrument reference manual.

SCPI command

TSP command Description

This command sets the mode of the digital I/O line

digio.line[N].mode

to be a digital line, trigger line, or synchronous line

and sets the line to be input, output, or open-drain.

A line reset is not available in SCPI; however, the line

is reset when a global reset (

) is sent

digio.line[N].reset()

digio.line[N].state

digio.readport()

digio.writeport()

trigger.digin[N].clear()

trigger.digin[N].edge

This command resets digital I/O line values to their

factory defaults.

This command sets a digital I/O line high or low

when the line is set for digital control and returns

the state on the digital I/O lines.

This command reads the digital I/O port. All six lines

must be configured as digital control lines. If not,

this command generates an error.

This command writes to all digital I/O lines. All six

lines must be configured as digital control lines. If

not, this command generates an error.

This command clears the trigger event on a digital

input line.

This command sets the edge used by the trigger

event detector on the given trigger line.

trigger.digin[N].overrun

Not available in SCPI This command waits for a trigger.

trigger.digin[N].wait()

Not available in SCPI This command asserts a trigger pulse on one of the

14 077143600 / April 2018

This command returns the event detector overrun

status.

digital I/O lines.

Page 15

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

:TRIGger:DIGital<n>:OUT:LOGic

:TRIGger:DIGital<n>:OUT:PULSewidth

:TRIGger:DIGital<n>:OUT:STIMulus

SCPI command

TSP command Description

This command sets the output logic of the trigger

trigger.digout[N].logic

trigger.digout[N].pulsewidth

Not available in SCPI This command releases an indefinite length or

trigger.digout[N].release()

trigger.digout[N].stimulus

event generator to positive or negative for the

specified line.

This command describes the length of time that the

trigger line is asserted for output triggers.

latched trigger.

This command selects the event that causes a

trigger to be asserted on the digital output line.

To use the trigger model as a stimulus to a digital I/O line, you can use the trigger model Notify

block. For information on the Notify block, see the reference manual for your instrument.

Digital I/O bit weighting

Bit weighting for the digital I/O lines is shown in the following table. Line 1 is the least significant bit.

Line # Bit Pin Decimal Hexadecimal Binary

1 B1 1 1 0x01 000001

2 B2 2 2 0x02 000010

3 B3 3 4 0x04 000100

4 B4 4 8 0x08 001000

5 B5 6 16 0x10 010000

6 B6 8 32 0x20 100000

Digital I/O programming examples

These examples provide typical methods you can use to work with the digital I/O port.

Outputting a bit pattern

The programming examples below illustrate how to output the bit pattern 110101 at the digital I/O port. Line 1

(bit 1) is the least significant bit.

077143600 / April 2018 15

Page 16

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Using SCPI commands to configure all six lines as digital outputs:

:DIGital:LINE1:MODE DIGital, OUT

:DIGital:LINE2:MODE DIGital, OUT

:DIGital:LINE3:MODE DIGital, OUT

:DIGital:LINE4:MODE DIGital, OUT

:DIGital:LINE5:MODE DIGital, OUT

:DIGital:LINE6:MODE DIGital, OUT

Using SCPI commands to set the state of each line individually:

:DIGital:LINE6:STATe 1

:DIGital:LINE5:STATe 1

:DIGital:LINE4:STATe 0

:DIGital:LINE3:STATe 1

:DIGital:LINE2:STATe 0

:DIGital:LINE1:STATe 1

Using SCPI commands to set all six lines at onc e by writing the decimal equivalent of the bit pattern to

the port:

:DIGital:WRITe 53

Using TSP commands to configure all six lines a s digital outputs:

-- Send for loop as a single chunk or include in a script.

for i = 1, 6 do

digio.line[i].mode = digio.MODE_DIGITAL_OUT

end

Using TSP commands to set the state of each line individually:

digio.line[1].state = digio.STATE_HIGH

digio.line[2].state = digio.STATE_LOW

digio.line[3].state = digio.STATE_HIGH

-- You can use 0 instead of digio.STATE_LOW.

digio.line[4].state = 0

-- You can use 1 instead of digio.STATE_HIGH.

digio.line[5].state = 1

digio.line[6].state = 1

Using TSP commands to set all six lines at once by writing the decimal equivalent of the bit pattern to

the port:

-- You can write binary, decimal or hexadecimal values, as shown below.

-- Use binary value.

digio.writeport(0b110101)

-- Use decimal value.

digio.writeport(53)

-- Use hexadecimal value.

digio.writeport(0x35)

16 077143600 / April 2018

Page 17

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Reading a bit pattern

The programming examples below illustrate how to read part or all of a bit pattern that has been applied to the

digital I/O port by an external instrument. The binary pattern is 111111 (63 decimal). Line 1 (bit 1) is the least

significant bit.

Using SCPI commands:

Configure all six lines as digital inputs:

DIGital:LINE1:MODE DIGital, IN

DIGital:LINE2:MODE DIGital, IN

DIGital:LINE3:MODE DIGital, IN

DIGital:LINE4:MODE DIGital, IN

DIGital:LINE5:MODE DIGital, IN

DIGital:LINE6:MODE DIGital, IN

Read the state of Line 2:

DIGital:LINE2:STATe?

Value returned is 1.

Read the state of Line 3:

DIGital:LINE3:STATe?

Value returned is 1.

Read the value applied to the entire port:

DIGital:READ?

Value returned is 63, which is the decimal equivalent of the binary bit pattern.

Using TSP commands:

-- Configure all six digital I/O lines as digital inputs.

-- You can also use a for loop.

digio.line[1].mode = digio.MODE_DIGITAL_IN

digio.line[2].mode = digio.MODE_DIGITAL_IN

digio.line[3].mode = digio.MODE_DIGITAL_IN

digio.line[4].mode = digio.MODE_DIGITAL_IN

digio.line[5].mode = digio.MODE_DIGITAL_IN

digio.line[6].mode = digio.MODE_DIGITAL_IN

-- Read and then print the state of Line 2 (bit 2).

b2 = digio.line[2].state

print(b2)

The value returned is digio.STATE_HIGH.

-- Print the state of Line 3 (bit 3).

print(digio.line[3].state)

The value returned is digio.STATE_HIGH.

-- Read and then print the value applied to the entire port.

port = digio.readport()

print(port)

The value returned is 63, which is the decimal equivalent of the binary bit pattern.

077143600 / April 2018 17

Page 18

KTTI-RS232 Communication and Digital I/O Accessory Instruction Sheet

Upgrading the firmware

You will periodically update the instrument firmware. During the upgrade pr oces s , the instr ument verifies that

the version you are loading is newer than what is on the instrument. If the version is older or at the same

revision level, no changes are made.

If you have a KTTI-RS232 communications accessory card installed in the instrument, the firmware on the card

is upgraded.

You can load the file from the front-panel USB port or you can use Test Script Builder (TSB) using a file saved

to the computer on which TSB is running.

The firmware file must be in the root subdirectory of the flash drive and must be the only firmware file in that

location.

If you want to return to a previous version or reload the present version of the firmware, select Downgrade to

Older. This forces the instrument to load the firmware regardless of the version.

The upgrade process normally takes about five minutes.

Upgrade files are available on tek.com/keithley

.

Accessories

The KTTI-RS232 requires a shielded RS-232 cable with a male DB-9 connector at one end and a female DB-9

connector on the other (wired as a straight-through, not as a null modem cable).

Model 7009-5 1.5 m (5 ft), male DB-9 to female DB-9

18 077143600 / April 2018

Page 19

Safety precaut ions

The following safety precautions should be observed before using this produ ct and any associa ted ins t rum enta tion. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circ uit may be ex posed.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

077143600 / April 2018 19

Page 20

The CAUTION heading in the user documentation explains h az ards that coul d dama ge the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pollution degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2017.

20 077143600 / April 2018

Loading...

Loading...