Page 1

www.keithley.com

KPXI Compact GPIB Controller

Quick Start Guide

KPXI-488-903-01 Rev. A / January 2007

A GREATER MEASURE OF CONFIDENCE

ECA 42912

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF

ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT

OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/06

Page 3

KPXI

Compact GPIB Controller

Quick Start Guide

©2007, Keithley Instruments, Inc.

Document Number:

All rights reserved.

Cleveland, Ohio, U.S.A.

KPXI-488-903-01 Rev. A / January 2007

Page 4

Manual Print History KPXI Compact GPIB Controller Quick Start Guide

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this

manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between Revisions, contain important change information that the

user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new

Revision is created, all Addenda associated with the previous Revision of the manual are incorporated

into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number KPXI-488-903-01)................................... January 2007

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

KPXI-488-903-01 Rev. A / January 2007

Page 5

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Safety Precautions

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

trained service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and

Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most

measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or

to voltage sources with high transient over-voltages. Measurement Category II connections require protection for high transient

over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are

for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to

limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

12/06

Page 6

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being

measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

The WARNING heading in a manual explains dangers that might result in personal injury or death. Always read the associated

information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety

approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased

from other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a

replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Page 7

Table of Contents

Section Topic Page

1 Introduction............................................................................................. 1-1

Introduction ................................................................................................. 1-2

Overview .............................................................................................. 1-2

Performance......................................................................................... 1-2

Compatibility......................................................................................... 1-2

Features ............................................................................................... 1-2

Manual addenda......................................................................................... 1-3

Safety symbols and terms .......................................................................... 1-3

Specifications.............................................................................................. 1-3

GPIB bus properties............................................................................. 1-3

Certificates ........................................................................................... 1-3

General specifications.......................................................................... 1-4

Unpacking and inspection........................................................................... 1-4

Inspection for damage.......................................................................... 1-4

Shipment contents ............................................................................... 1-4

Instruction manual................................................................................ 1-4

Repacking for shipment........................................................................ 1-5

Software support......................................................................................... 1-5

2 Installation and configuration ............................................................ 2-1

Introduction ................................................................................................. 2-2

Software installation description ................................................................. 2-2

Installation requirements............................................................................. 2-2

Driver installation ........................................................................................ 2-3

Hardware installation .................................................................................. 2-4

Installation procedure........................................................................... 2-4

PXI configuration.................................................................................. 2-4

Cabling........................................................................................................ 2-5

Using the Keithley GPIB Configuration Utility ............................................. 2-8

Using the Keithley Instruments KPXI-488 Diagnostic Tool ......................... 2-9

3 Using a GPIB........................................................................................... 3-1

Introduction ................................................................................................. 3-2

GPIB connection configuration ................................................................... 3-2

Data lines ............................................................................................. 3-3

Handshake lines................................................................................... 3-3

System management lines................................................................... 3-3

Model KPXI-488 block diagram .................................................................. 3-4

Appendix Topic Page

A Specifications......................................................................................... A-1

Index ........................................................................................................................... I-1

Page 8

Table of Contents KPXI Compact GPIB Controller Quick Start Guide

This page left blank intentionally.

ii KPXI-488-903-01 Rev. A / January 2007

Page 9

List of Figures

Section Figure Title Page

2 Figure 2-1 InstallShield® Wizard ..................................................................... 2-3

Figure 2-2 Restart system............................................................................... 2-4

Figure 2-3 Linear connection configuration..................................................... 2-6

Figure 2-4 Star connection configuration ........................................................ 2-7

Figure 2-5 Keithley GPIB Configuration Utility ................................................ 2-8

Figure 2-6 GPIB Interface & Bus Setting ........................................................ 2-8

Figure 2-7 Keithley KPXI-488 Diagnostic Tool ................................................ 2-9

3 Figure 3-1 Standard GPIB connector .............................................................. 3-2

Figure 3-2 Model KPXI-488 block diagram ..................................................... 3-4

Page 10

List of Figures KPXI Compact GPIB Controller Quick Start Guide

This page left blank intentionally.

iv KPXI-488-903-01 Rev. A / January 2007

Page 11

List of Tables

Section Figure Title Page

1 Table 1-1 Power requirements....................................................................... 1-4

3 Table 3-1 GPIB connector line....................................................................... 3-3

Page 12

List of Tables KPXI Compact GPIB Controller Quick Start Guide

This page left blank intentionally.

vi KPXI-488-903-01 Rev. A / January 2007

Page 13

In this section:

Top ic Pa ge

Introduction ....................................................................................... 1-2

Manual addenda ................................................................................ 1-3

Safety symbols and terms ............................................................... 1-3

Specifications.................................................................................... 1-3

Section 1

Introduction

Overview....................................................................................... 1-2

Performance ................................................................................. 1-2

Compatibility ................................................................................. 1-2

Features ....................................................................................... 1-2

GPIB bus properties ..................................................................... 1-3

Certificates.................................................................................... 1-3

General specifications .................................................................. 1-4

Unpacking and inspection ............................................................... 1-4

Inspection for damage .................................................................. 1-4

Shipment contents........................................................................ 1-4

Instruction manual ........................................................................ 1-4

Repacking for shipment ................................................................ 1-5

Software support............................................................................... 1-5

Page 14

Section 1: Introduction KPXI Compact GPIB Controller Quick Start Guide

Introduction

This section contains general information about the Keithley Instruments Model KPXI-488 GPIB

Controller Interface Card.

If you have any questions after reviewing this information, contact your local Keithley Instruments

representative or call one of our applications engineers. Find current contact information at

www.keithley.com.

Overview

Keithley Instruments’ Model KPXI-488 GPIB Controller Interface Card is fully compatible with the

IEEE488.2 instrumentation control and communication standard. The interface card is capable of

controlling up to 14 stand-alone instruments via IEEE488 cables. Designed to meet the

requirements for high performance and maximum programming portability, the 1KB on-board FIFO

buffer (First In First Out) and block transfer mode provide up to 1.5MB per second GPIB transfer

rate.

With the Keithley Command Compatible driver, the National Instruments™ (NI)1 Command

Compatible driver, and VISA support (Virtual Instrument Software Architecture), the

Model KPXI-488 provides extensive compatibility with your existing applications and instrument

drivers.

Performance

This newly-designed Model KPXI-488 GPIB Controller Interface Card works with all PXI standard

2.2 compliant controllers and chassis. An on-board 1KB FIFO is placed between the GPIB bus and

PCI controller to buffer GPIB read/write operations. The FIFO eliminates the gap between the

slower GPIB bus (which is about 1.5MB per second) and the fast PXI bus (132MB per second),

dramatically increasing overall system performance.

Compatibility

The Model KPXI-488 provides complete software support, including a driver API (application

program interface) that is command compatible with Keithley Instruments' and Capital Equipment

Corporations' IEEE_32M.DLL, and a driver API that is NI command compatible with GPIB32.DLL

(programs written based on these DLL's can be executed on the Model KPXI-488 without any

major modification, often no modifications at all). Industry-standard VISA libraries are also

supported to ensure compatibility with applications utilizing VISA. Through design, the Model

KPXI-488 is plug-and-play compatible with your existing applications.

Features

The Model KPXI-488 GPIB Controller Interface Card provides the following advanced features:

• Fully compatible with the IEEE488.2 standard

• Supports a 32-bit PXI bus

• Up to 1.5MB per second data transfer rates

• On-board 1KB FIFO for read/write operations

• Command compatible driver API for Keithley Instruments, NI, and VISA.

• Interactive utility for testing and diagnostics

1. National Instruments™ and NI are trademarks of the National Instruments Corporation.

1-2 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 15

KPXI Compact GPIB Controller Quick Start Guide Section 1: Introduction

Manual addenda

Any improvements or changes concerning the Model KPXI-488 or manual will be explained in an

addendum included with the manual. Be sure to note these changes and incorporate them into the

manual.

Safety symbols and terms

The following symbols and terms may be found on the Model KPXI-488 or used in this manual:

The symbol indicates that the user should refer to the operating instructions located in the

!

manual.

The symbol shows that high voltage may be present on the terminal(s). Use standard safety

precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to

prevent burns.

The WARNING heading used in this manual explains dangers that might result in personal injury

or death. Always read the associated information very carefully before performing the indicated

procedure.

The CAUTION heading used in this manual explains hazards that could damage the switch. Such

damage may invalidate the warranty.

Specifications

Detailed Model KPXI-488 specifications are included in Appendix A; a specification overview is

presented below. Check the Keithley Instruments website (www.keithley.com) for latest updates to

the specifications.

GPIB bus properties

• Up to 14 instruments can be connected to one controller

• Maximal 1.5MB per second data transfer rate

• Cable length:

– 2 meters between each instrument (suggested)

– 20 meters total cable length

• Data transfer mode: 8 bits parallel

• Handshake: 3-wire handshake, reception of each data byte is acknowledged

Certificates

• Safety: European Directive 73/23/EEC, EN60950

• EMC/EMI: European Directive 89/336/EEC, EN55022, EN55024

KPXI-488-903-01 Rev. A / January 2007 Return to Section Topics 1-3

Page 16

Section 1: Introduction KPXI Compact GPIB Controller Quick Start Guide

General specifications

• I/O connector: IEEE488 standard 24-pin connector

• Operating temperature: 0°C to 55ºC

• Storage temperature: -20°C to 80ºC at 5% to 95% humidity

• Relative humidity: 5% to 95%, non-condensing

Table 1-1

Power requirements

Current

400mA (typical)

750mA (maximum)

• Dimensions (not including connectors): 135mm x 107mm

Unpacking and inspection

CAUTION The Model KPXI-488 contains electro-static sensitive components that can

easily be damaged by static electricity. Handle the module on a grounded antistatic mat. The operator should be wearing an anti-static wristband, grounded

at the same point as the anti-static mat.

Inspection for damage

The Model KPXI-488 was carefully inspected electrically and mechanically before shipment. After

unpacking all items from the shipping carton, check for any obvious signs of physical damage that

may have occurred during transit. Report any damage to the shipping agent immediately. Save the

original packing carton for possible future shipment.

Shipment contents

The following items are included with every Model KPXI-488 order:

• Model KPXI-488

• A CD (KPXI-488-950-01) that contains drivers, manual, and software for all KPXI Series

products

Instruction manual

The product CD-ROM contains this Quick Start Guide and a Reference Manual for the Model

KPXI-488. The reference manual provides programming information on Keithley Command

Compatible functions and NI command compatible functions (syntax as well as examples in C/

C++, Visual Basic, etc.).

Always check the Keithley Instruments website (www.keithley.com) for the latest revision of the

manual. The latest manual can be downloaded (in PDF format) from the website.

1-4 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 17

KPXI Compact GPIB Controller Quick Start Guide Section 1: Introduction

Repacking for shipment

Should it become necessary to return the Model KPXI-488 for repair, carefully pack the unit in its

original packing carton or the equivalent, and follow these instructions:

• Call the Repair Department for a Return Material Authorization (RMA) number. Call the

Repair Department toll-free at 1-800-552-1115 (US only). Outside of the US, Worldwide

Service Centers contact information is available at www.keithley.com.

• Advise as to the warranty status of the Model KPXI-488.

• Write ATTENTION REPAIR DEPARTMENT and the RMA number on the shipping label.

• Fill out and include the Service Form located at the back of this manual.

Software support

The Model KPXI-488 provides device drivers for Windows® XP/2000 operating systems. The

Keithley Instruments GPIB driver package provides a diagnostic utility to test your

Model KPXI-488 GPIB card, as well as programming samples and source codes for Microsoft®

Visual Basic and Visual C++. The Model KPXI-488 also offers support for

National Instruments™ LabVIEW™ and LabWindows/CVI™. Find the Keithley Instruments GPIB

driver package located on the supplied CD. Refer to

for detailed software installation instructions. Refer to Section 3 for a description of the operational

theory of a GPIB (General Purpose Interface Bus) and the basic architecture of Keithley

Instruments Model KPXI-488 GPIB interface card. Contact Keithley Instruments for other

operating system support.

Software installation description in Section 2

For LabVIEW™ and LabWindows/CVI™ support, Keithley Instruments recommends the

installation of the NI Command Compatible Driver. For LabVIEW programmers, Keithley

Instruments supplies a set of LabVIEW GPIB VIs that are optimized for use with the

KPXI-488.

KPXI-488-903-01 Rev. A / January 2007 Return to Section Topics 1-5

Page 18

Section 1: Introduction KPXI Compact GPIB Controller Quick Start Guide

This page left blank intentionally.

1-6 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 19

In this section:

Top ic Pa ge

Introduction ....................................................................................... 2-2

Software installation description..................................................... 2-2

Installation requirements ................................................................. 2-2

Driver installation.............................................................................. 2-3

Hardware installation........................................................................ 2-4

Cabling............................................................................................... 2-5

Section 2

Installation and configuration

Installation procedure ................................................................... 2-4

PXI configuration .......................................................................... 2-4

Using the Keithley GPIB Configuration Utility ............................... 2-8

Using the Keithley Instruments KPXI-488 Diagnostic Tool........... 2-9

Page 20

Section 2: Installation and configuration KPXI Compact GPIB Controller Quick Start Guide

Introduction

This section describes unpacking information and describes how to install the Model KPXI-488. To

install the Model KPXI-488 in a system, after reviewing the

Installation requirements, complete (in this order):

1. Driver installation

2. Hardware installation

3. Cabling

See Using the Keithley GPIB Configuration Utility and Using the Keithley Instruments KPXI-488

Diagnostic Tool for information on using these supplied utilities.

WARNING The procedures in this section are intended only for qualified service

personnel. Do not perform these procedures unless you are qualified to do so.

Failure to recognize and observe normal safety precautions could result in

personal injury or death.

CAUTION The Model KPXI-488 contains electro-static sensitive components that can

easily be damaged by static electricity. Handle the module on a grounded

anti-static mat. The operator should be wearing an anti-static wristband,

grounded at the same point as the anti-static mat.

Software installation description and

CAUTION Do not apply power to the card if it has been damaged.

Software installation description

This section describes the software installation for the Keithley Instruments Model KPXI-488.

Driver installation is outlined along with information on using the Keithley GPIB Configuration

Utility and the KPXI-488 Diagnostic Tool.

The Keithley Instruments Model KPXI-488 is delivered with a GPIB driver package that supports

Windows

compatible with your current applications. They provide both Keithley Command Compatible

NI2 command compatible APIs3 and software support for program developers using Microsoft®

programming languages like Visual Basic®, Visual C, as well as LabVIEW™ and LabWindows/

CVI™.

Instruments Model KPXI-488 Reference Manual (KPXI-488-901-01) for complete function and

programming information.

®

XP/2000 Operating Systems. The KPXI-488 drivers are designed to be command

4

The KPXI-488 also supports industry-standard VISA5 libraries. Refer to the Keithley

Installation requirements

Review the following list of important requirements that must be taken into account prior to

installing the Model KPXI-488:

I. The KPXI-488 is not compatible with Dynamic Link Libraries (DLL) from other IEEE

interface board suppliers. Due to the KPXI-488's command compatibility with National

Instruments™ and Capital Equipment Corporation (CEC), the installation program for the

KPXI-488 will install a DLL that has the same name as those provided by National

1

and

1. Derived from the Capital Equipment Corporation (CEC) command set.

2. National Instruments™ and NI™ are trademarks of the National Instruments Corporation. Other brand names are

trademarks or registered trademarks of their respective holders.

3. API—Application Program Interface

4. CVI—C for Virtual Instrumentation

5. VISA—Virtual Instrument Software Architecture

2-2 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 21

KPXI Compact GPIB Controller Quick Start Guide Section 2: Installation and configuration

Instruments (GPIB32.DLL) and CEC (and previous Keithley) interfaces (IEEE_32M.DLL).

For proper installation of the KPXI-488 hardware and software, you must remove any

existing GPIB interfaces from your PC and uninstall any currently installed GPIB

drivers. Failure to uninstall any existing GPIB drivers before installing the KPXI-488

command compatible drivers can, and likely will cause system problems.

II. For LabVIEW™ and LabWindows/CVI™ support, Keithley Instruments recommends

the installation of the NI Command Compatible Driver. For LabVIEW programmers,

Keithley Instruments supplies a set of LabVIEW GPIB VIs that are optimized for use with the

KPXI-488.

The procedure to install the KPXI-488 driver package and utilities is outlined in Driver installation.

Driver installation

Use the following procedure as a guideline to install the GPIB Driver Package on your computer:

1. Insert the Keithley Instruments KPXI driver CD.

2. Allow the CD to auto run and begin the setup program. If setup does not start, open the CD

using Windows Explorer and execute setup.exe to launch the setup program. Once the

setup screen appears, click on GPIB in the left navigation menu (shown in Figure 2-1).

3. You may choose to install the Keithley Command Compatible Driver or the NI command

compatible driver. Refer to Model KPXI-488 Reference Manual (KPXI-488-901-01) for

available functions of either compatible driver.

Figure 2-1

InstallShield® Wizard

4. Follow the InstallShield® Wizard prompts to complete the setup procedure.

5. When setup finishes, please reboot your system.

KPXI-488-903-01 Rev. A / January 2007 Return to Section Topics 2-3

Page 22

Section 2: Installation and configuration KPXI Compact GPIB Controller Quick Start Guide

Figure 2-2

Restart system

Hardware installation

CAUTION The Model KPXI-488 contains electro-static sensitive components that can

easily be damaged by static electricity. Handle the module on a grounded

anti-static mat. The operator should be wearing an anti-static wristband,

grounded at the same point as the anti-static mat.

NOTE Install software before installing the hardware (refer to Software installation description).

Installation procedure

The following instructions outline Model KPXI-488 installation:

1. Turn off your PXI controller.

2. Turn off all accessories (printer, modem, monitor, etc.) connected to your PXI controller.

3. Make a PXI peripheral slot available by removing a slot cover if necessary.

4. Before handling the PXI cards, discharge any static buildup on your body by touching the

metal case of the PXI chassis. Hold the handle and do not touch the components.

5. Position the board into the PXI slot you selected.

6. Secure the card in place by lifting the handle and tightening the top and bottom screws on

the faceplate.

After completing the hardware installation procedure, install cables as desired (refer to Cabling for

information).

PXI configuration

Plug-and-play

As a plug-and-play component, the card requests an interrupt number via its PCI controller

(Peripheral Component Interconnect). The system BIOS (Basic Input Output System) responds

with an interrupt assignment based on the card information and on known system parameters.

These system parameters are determined by the installed drivers and the hardware load seen by

the system.

Configuration

The board configuration is done on a board-by-board basis for all PXI boards on your system.

Because configuration is controlled by the system and software, there is no jumper setting

required for base-address, DMA (Direct Memory Access), and interrupt IRQ (Interrupt Request).

2-4 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 23

KPXI Compact GPIB Controller Quick Start Guide Section 2: Installation and configuration

The configuration is subject to change with every boot of the system as new boards are added or

removed.

Troubleshooting

If your system doesn't boot or if you experience erratic operation with your PXI board in place, it's

likely caused by an interrupt conflict (perhaps the BIOS setup is incorrectly configured). In general,

the solution — once you determine it is not a simple oversight — is to consult the BIOS

documentation that comes with your system or computer.

In Windows 2000 or WinXP, if your KPXI-488 shows up in Device Manager, but has an error code

which indicates that no resources are in use, a simple change in the BIOS may resolve the

matter. The BIOS setting for Plug-and-Play Aware OS should be set to NO. This setting will allow

the PnP BIOS and motherboard chipset hardware to assign hardware resources to cards such as

the KPXI-488. Windows 2000 or WinXP will then make use of these assigned resources.

Cabling

For optimal GPIB throughput, adhere to the following bulleted cabling guidelines. These cabling

guidelines include instrument number and cable distance:

• The longest distance between two devices is 4 meters; the average GPIB bus distance

between all devices should be less than 2 meters.

• The total GPIB bus distance should be less than 20 meters.

• The total number of connected devices must be less than 15 (including computer itself), with

at least two-thirds of the devices powered on (in a power-on status).

Users can connect devices in a linear configuration (refer to Figure 2-3), star configuration (refer to

Figure 2-4), or combination of the two configurations.

NOTE To lower the total current load of the configuration, limit the number of cable connections

on each individual instrument to three or less. For example, to lower the required current

load when using the configuration shown in

connections on Instrument A. Move one of the cable connections from Instrument A to a

different instrument, thus making this configuration into a combination of linear and star

configurations.

Figure 2-4, reduce the number of

KPXI-488-903-01 Rev. A / January 2007 Return to Section Topics 2-5

Page 24

Section 2: Installation and configuration KPXI Compact GPIB Controller Quick Start Guide

Figure 2-3

Linear connection configuration

Model KPXI-488

GPIB Controller Card

PXI Controller

Instrument A

Instrument B

Instrument C

2-6 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 25

KPXI Compact GPIB Controller Quick Start Guide Section 2: Installation and configuration

Figure 2-4

Star connection configuration

Model KPXI-488

GPIB Controller Card

PXI Controller

Instrument C

Instrument A

Instrument B

Instrument D

KPXI-488-903-01 Rev. A / January 2007 Return to Section Topics 2-7

Page 26

Section 2: Installation and configuration KPXI Compact GPIB Controller Quick Start Guide

Using the Keithley GPIB Configuration Utility

The driver package provides a configuration utility program (Keithley Instrument's GPIB

Configuration Utility) to let you configure the KPXI-488's bus address, bus timing, I/O timeout,

whether the board is a system controller, and to enable auto-polling.

To launch the configuration utility:

1. From Windows® Start, select All Programs.

2. From the programs selection, select Keithley Instruments => KPXI-488 =>

KPXI-488 Configuration Utility. The utility window as shown in Figure 2-5 will open.

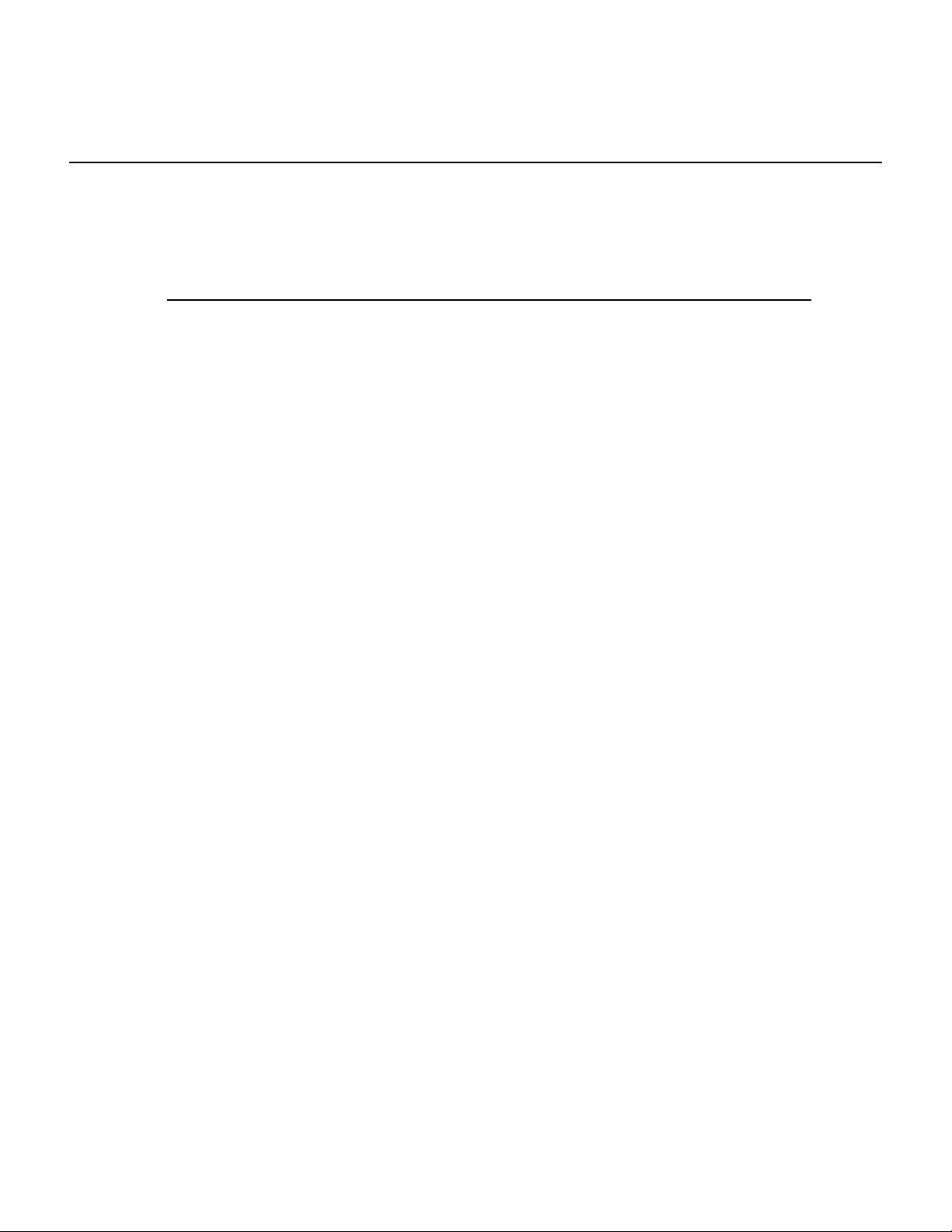

Figure 2-5

Keithley GPIB Configuration Utility

Double-clicking on the interface icon such as GPIB0 as shown in Figure 2-5 opens up the

KPXI-488 configuration dialog window as shown in Figure 2-6. From this dialog window, you can

set a variety of parameters for operating your interface board.

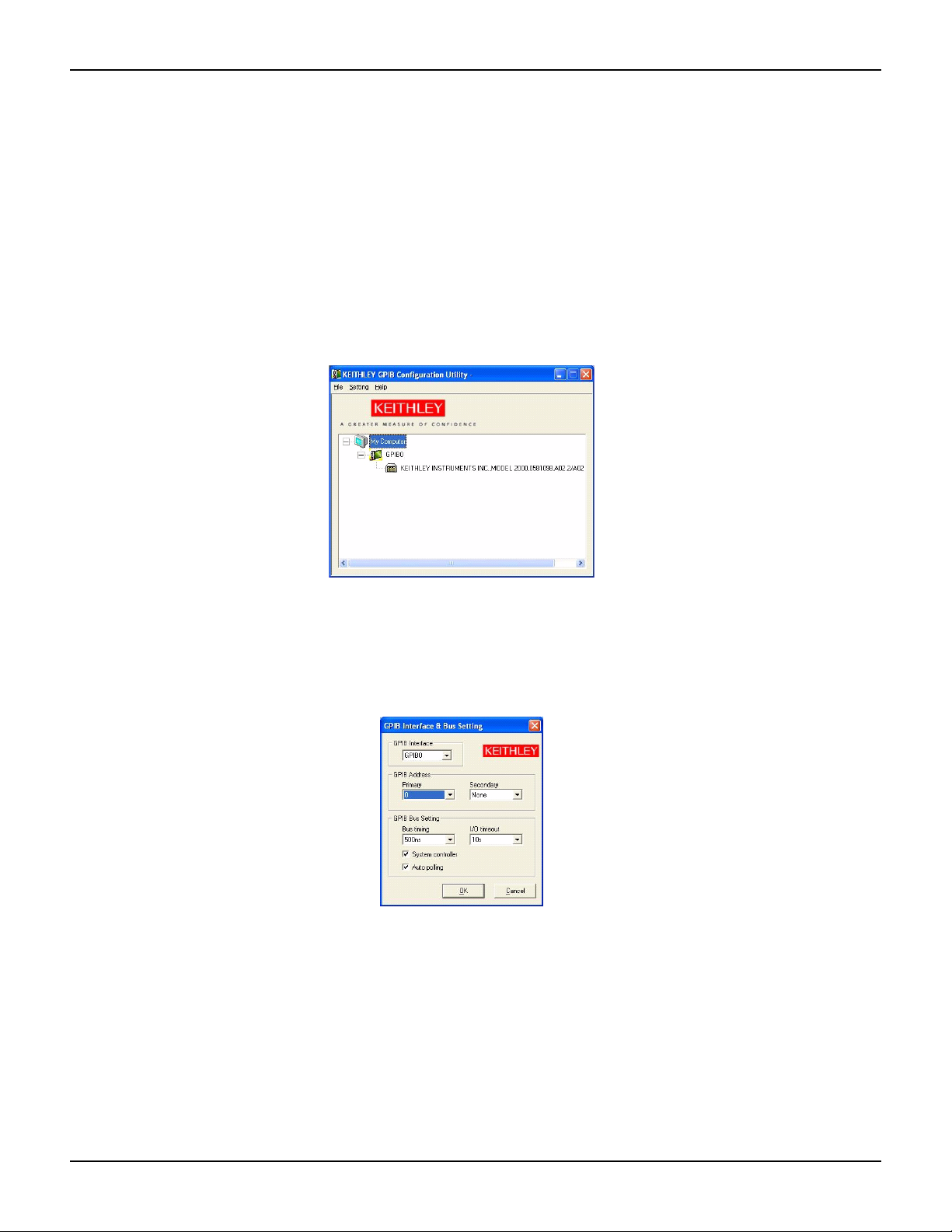

Figure 2-6

GPIB Interface & Bus Setting

If you change any settings, press OK to set the changes. Make sure to save configuration changes

by going to: Setting => Save Configuration in the KPXI-488 Configuration Utility window.

2-8 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 27

KPXI Compact GPIB Controller Quick Start Guide Section 2: Installation and configuration

Using the Keithley Instruments KPXI-488 Diagnostic Tool

The KPXI-488 Diagnostic Tool lets you communicate with any GPIB instrument by writing

command strings to your instrument and reading the results.

To launch the diagnostic tool:

1. From Windows® Start, select All Programs.

2. From the programs selection, select Keithley Instruments => KPXI-488 => KPXI-488

Diagnostic Tool.

The diagnostic tool window as shown in Figure 2-7 will open.

Figure 2-7

Keithley KPXI-488 Diagnostic Tool

Prior to communicating with your instrument using the KPXI-488 Diagnostic Tool, press the

Initialize KPXI-488 button and set the required parameters. This must be done before any of the

other feature buttons are enabled.

Type command strings to send to your instrument into the GPIB Command String to Send or

Tra nsmit box. Data returned from the instrument will be displayed in the GPIB Received

Message box. All data strings that you send to instruments will be logged in the GPIB commands

previously sent or transmitted box.

KPXI-488-903-01 Rev. A / January 2007 Return to Section Topics 2-9

Page 28

Section 2: Installation and configuration KPXI Compact GPIB Controller Quick Start Guide

This page left blank intentionally.

2-10 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 29

In this section:

Top ic Page

Introduction ....................................................................................... 3-2

GPIB connection configuration ....................................................... 3-2

Model KPXI-488 block diagram........................................................ 3-4

Section 3

Using a GPIB

Data lines...................................................................................... 3-3

Handshake lines ........................................................................... 3-3

System management lines ........................................................... 3-3

Page 30

Section 3: Using a GPIB KPXI Compact GPIB Controller Quick Start Guide

Introduction

This section describes the operational theory of a GPIB (General Purpose Interface Bus) and the

basic architecture of Keithley Instruments Model KPXI-488 GPIB Controller Interface Card.

GPIB connection configuration

The GPIB has 24 lines (refer to Figure 3-1). These lines can be divided into 16 signal lines and

8 ground-return or shield-drain lines (refer to Table 3-1). The 16 signal lines can be divided into

a set of 8 parallel (8-bit) data transfer bus lines and a set of 8 control lines. These 8 control lines

contain 5 system management lines and 3 handshake lines.

Figure 3-1

Standard GPIB connector

3-2 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 31

KPXI Compact GPIB Controller Quick Start Guide Section 3: Using a GPIB

Table 3-1

GPIB connector line

GPIB

BUS

24 lines

Type Function

8 data lines

16

signal

lines

8

ground

lines

8 control

lines

1 shield drain line 12 SHIELD

7 ground return lines

5 system

management

lines

3 handshake

lines

No. Description

1 DIO1

2 DIO2

3 DIO3

4 DIO4

13 DIO5

14 DIO6

15 DIO7

16 DIO8

5 EOI

9 IFC

10 SRQ

11 ATN

17 REN

6 DAV

7 NRFD

8 NDAC

18 GND

19 GND

20 GND

21 GND

22 GND

23 GND

24 SIGNAL GROUND

Pin

Data lines

DIO1 to DIO8 carry both data and command messages. All commands (and most data) use 7-bit

ASCII code; the 8th bit (DIO8), is either unused or used for parity check.

Handshake lines

Three handshake lines control the transfer of data/messages between devices:

• DAV (Data Valid): used to indicate the availability and validity of information on the DIO

signal lines.

• NRFD (Not Ready For Data): used to indicate readiness of device(s) to accept data.

• NDAC (Not Data Accepted): used to indicate acceptance of data by device.

System management lines

The following five system management lines manage the flow of control and data bytes across the

interface:

• EOI (End or Identify): used (by a talker) to indicate the end of a multiple-byte transfer

sequence or, in conjunction with ATN (by a controller), to execute a polling sequence.

• IFC (Interface Clear): used (by a controller) to place the interface system, portions of which

are contained in all interconnected devices, in a known quiescent state.

• SRQ (Service Request): used by a device to indicate the need for attention and to request

an interruption of the current sequence of events.

• ATN (Attention): used (by a controller) to specify how data on the Digital I/O signal lines

are to be interpreted, and which devices must respond to the data.

KPXI-488-903-01 Rev. A / January 2007 Return to Section Topics 3-3

Page 32

Section 3: Using a GPIB KPXI Compact GPIB Controller Quick Start Guide

• REN (Remote Enable): used (by a controller) in conjunction with other messages to enable

or disable one or more local controls that have corresponding remote controls.

Model KPXI-488 block diagram

Keithley Instruments Model KPXI-488 has a 1KB on-board FIFO buffer (First In First Out) to

maximize the data transfer rate (refer to

Programmable Logical Device) coordinates the data flow between PCI controller (Peripheral

Component Interconnect), FIFO buffer, and GPIB bus.

Figure 3-2

Model KPXI-488 block diagram

Figure 3-2). Its state-of-the-art CPLD (Complex

Bus

Transceiver

GPIB

Controller

CPLD FIFO

PCI

Controller

The FIFO can buffer data from the master (either from the Model KPXI-488 controller or external

device) when the target is busy. Therefore, the efficiency will be significantly improved when

transferring large blocks of data.

3-4 Return to Section Topics KPXI-488-903-01 Rev. A / January 2007

Page 33

Appendix A

Specifications

Page 34

Model KPXI-488

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, Ohio 44139

(440) 248-0400

www.keithley.com

GPIB Controller Interface Card Specifications

BASIC SPECIFICATIONS

GPIB Bus Specifications:

• Up to 14 instruments connected

• Maximal 1.5MB/s data transfer rate

• Cable length:

1. Two meters between each instrument (suggested)

2. Twenty meters total cable length

• Data transfer mode: 8 bits parallel

• Handshake: 3-wire handshake; reception of each data byte is acknowledged

Compliance:

• Safety: European Directive 73/23/EEC,EN60950

• EMC/EMI: European Directive 89/336/EEC,EN55022, EN55024

Operating System:

®

• Microsoft

Windows® XP/2000

General Specifications:

• I/O connector: IEEE 488 standard 24-pin

• Operating temperature: 0°C to 55°C

• Storage temperature: -20°C to 80°C

• Relative humidity: 5% to 95%, non-condensing

• Power consumption: 400mA (typical), 750mA (maximum)

• Dimensions: 135mm x 107mm (not including connectors)

Specifications are subject to change without notice.

SPEC-KPXI-488 Rev. A / December 2006 Page 1 of 1

Page 35

Index

A

Addenda ................................................... 1-3

ATN (Attention) ......................................... 3-3

Average GPIB BUS distance ....................2-5

B

Block diagram ........................................... 3-4

Bus properties, GPIB ................................ 1-3

C

Cabling .....................................................2-5

CD-ROM ................................................... 1-4

Certificates ...............................................1-3

Compatibility ............................................. 1-2

Configuration (PCI) ................................... 2-4

Connector, Standard GPIB ....................... 3-2

D

Damage, Inspection for ............................1-4

Data lines .................................................3-3

Device drivers ...........................................1-5

Diagnostic utility .......................................1-5

Dimensions ............................................... 1-4

Driver installation ...................................... 2-3

Drivers, device ..........................................1-5

E

EOI (End or Identify) ................................. 3-3

I

I/O Connector ........................................... 1-4

IFC (Interface Clear) ................................ 3-3

Inspection for damage ............................. 1-4

Installation Procedure

Hardware ......................................... 2-4

Software ........................................... 2-2

Instruction manual .................................... 1-4

L

Linear connection configuration ....... 2-5, 2-6

O

ON ........................................................... 1-3

On-board FIFO

Buffer, FIFO ..................................... 3-4

Operating temperature ............................. 1-4

P

Performance ............................................ 1-2

Plug-and-play ........................................... 2-4

Polling sequence ...................................... 3-3

Power requirements ................................. 1-4

R

Relative humidity ...................................... 1-4

REN (Remote Enable) ............................. 3-4

Repacking ................................................ 1-5

F

Features ...................................................1-2

G

General Purpose Interface Bus ................ 3-1

General specifications .............................. 1-4

GPIB (General Purpose Interface Bus) .... 3-2

Distance ...........................................2-5

Properties ......................................... 1-3

H

Handshake lines ....................................... 3-3

Hardware installation ................................2-1

S

Safety symbols and terms ........................ 1-3

Shipment contents ................................... 1-4

Specifications ........................................... A-1

SRQ (Service Request) ........................... 3-3

Standard GPIB connector ........................ 3-2

Star connection configuration .................. 2-7

Storage temperature ................................ 1-4

Symbols and terms .................................. 1-3

System management lines ....................... 3-3

T

Troubleshooting ....................................... 2-5

U

Using a GPIB ........................................... 3-1

KPXI-488-903-01 Rev. A / January 2007 I-1

Page 36

Index KPXI Compact GPIB Controller Quick Start Guide

This page left blank intentionally.

I-2 KPXI-488-903-01 Rev. A / January 2007

Page 37

Service Form

Model No. _______________ Serial No. _______________ Date _______________________________

Name and Telephone No. _____________________________________________________________________

Company _____________________________________________________________________________________

List all control settings, describe problem and check boxes that apply to problem._____________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

Intermittent Analog output follows display Particular range or function bad; specify

____________________________________________

IEEE failure Obvious problem on power-up Batteries and fuses are OK

Front panel operational All ranges or functions are bad Checked all cables

Display or output (check one)

Drifts Unable to zero Unstable

Overload Will not read applied input

Calibration only Certificate of calibration required Data required

(attach any additional sheets as necessary)

Show a block diagram of your measurement including all instruments connected (whether power is turned on or not).

Also, describe signal source.

Where is the measurement being performed? (factory, controlled laboratory, out-of-doors, etc.)__________________________

____________________________________________________________________________________________________

What power line voltage is used? ___________________________ Ambient temperature? __________________________ °F

Relative humidity? ______________________________________ Other? _________________________________________

Any additional information. (If special modifications have been made by the user, please describe.)

____________________________________________________________________________________________________

____________________________________________________________________________________________________

Be sure to include your name and telephone number on this service form.

Page 38

Page 39

12/06

Specifications are subject to change without notice.

All Keithley trademarks and trade names are the property of Keithley Instruments, Inc.

All other trademarks and trade names are the property of their respective companies.

A GREATER MEASURE OF CONFIDENCE

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY • www.keithley.com

Loading...

Loading...