Page 1

www.keithley.com

KPXI Analog Output Module

Reference Manual

KPXI-AO-901-01 Rev. A / January 2007

A GREATER MEASURE OF CONFIDENCE

ECA 42912

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF

ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT

OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/06

Page 3

KPXI

Analog Output Module

Reference Manual

©2007, Keithley Instruments, Inc.

Document Number:

All rights reserved.

Cleveland, Ohio, U.S.A.

KPXI-AO-901-01 Rev. A / January 2007

Page 4

Manual Print History KPXI Analog Output Module Reference Manual

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this

manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between Revisions, contain important change information that

the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a

new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number KPXI-AO-901-01) ............................................. January 2007

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

KPXI-AO-901-01 Rev. A / January 2007

Page 5

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Safety Precautions

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

trained service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and

Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most

measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or

to voltage sources with high transient over-voltages. Measurement Category II connections require protection for high transient

over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are

for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to

limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

12/06

Page 6

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being

measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

The WARNING heading in a manual explains dangers that might result in personal injury or death. Always read the associated

information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety

approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased

from other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a

replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Page 7

Table of Contents

Section Topic Page

1 Introduction............................................................................................. 1-1

Introduction ................................................................................................. 1-2

Overview..................................................................................................... 1-2

Applications ................................................................................................ 1-2

Features...................................................................................................... 1-2

Manual addenda......................................................................................... 1-3

Safety symbols and terms .......................................................................... 1-3

Specifications.............................................................................................. 1-3

Unpacking and inspection........................................................................... 1-4

Inspection for damage.......................................................................... 1-4

Shipment contents ............................................................................... 1-4

Instruction manual................................................................................ 1-4

Repacking for shipment........................................................................ 1-4

Available accessories ................................................................................. 1-5

Connections................................................................................................ 1-5

Software introduction .................................................................................. 1-5

Programming library KDAQ-DRVR ...................................................... 1-5

KDAQ-LVIEW LabVIEW® driver .......................................................... 1-6

2 Installation............................................................................................... 2-1

Introduction ................................................................................................. 2-2

Handling precautions .................................................................................. 2-2

Mechanical drawing .................................................................................... 2-2

PCI configuration ........................................................................................ 2-2

Plug-and-Play....................................................................................... 2-2

Configuration........................................................................................ 2-3

Troubleshooting.................................................................................... 2-3

Installation................................................................................................... 2-3

3 Operation and connection................................................................... 3-1

Introduction ................................................................................................. 3-2

Signal connections...................................................................................... 3-3

Connectors pin assignment.................................................................. 3-3

A/D conversion ........................................................................................... 3-4

KPXI Analog Output Series A/D data format........................................ 3-5

Software polling mode.......................................................................... 3-5

Programmable scan mode ................................................................... 3-5

Trigger mode ........................................................................................ 3-7

Bus-mastering DMA data transfer........................................................ 3-9

D/A conversion ........................................................................................... 3-9

Architecture ........................................................................................ 3-10

Hardware controlled waveform generation ........................................ 3-10

Setting up the DACs........................................................................... 3-11

Utilizing multiplying characteristics of DACs ...................................... 3-11

Software update ................................................................................. 3-12

Waveform generation......................................................................... 3-12

Trigger modes .................................................................................... 3-14

Iterative waveform generation ............................................................ 3-15

Stop modes ........................................................................................ 3-16

Page 8

Table of Contents KPXI Analog Output Module Reference Manual

Section Topic Page

3 Operation and connection (continued)

General purpose digital I/O ....................................................................... 3-18

General purpose timer/counter operation ................................................. 3-18

Timer/Counter functions basics .......................................................... 3-18

General purpose timer/counter modes............................................... 3-19

Trigger sources ......................................................................................... 3-21

Software trigger .................................................................................. 3-22

External analog trigger ....................................................................... 3-22

Timing signal............................................................................................. 3-24

System synchronization interface ....................................................... 3-25

Calibration ................................................................................................. 3-25

Auto-calibration................................................................................... 3-25

Saving calibration constants............................................................... 3-26

Loading calibration constants ............................................................. 3-26

4 Waveform Generation Demonstration .............................................. 4-1

Waveform generation demonstration .......................................................... 4-2

Appendix Topic Page

A KDAQ-DRVR User’s Guide.................................................................. A-1

Introduction to KDAQ-DRVR...................................................................... A-2

About the KDAQ-DRVR software ........................................................ A-2

KDAQ-DRVR hardware support .......................................................... A-2

KDAQ-DRVR language support .......................................................... A-2

Fundamentals of building applications with KDAQ-DRVR ......................... A-3

Microsoft® Visual Basic (Version 6.0) .................................................. A-3

Using Microsoft Visual Basic.NET ....................................................... A-4

Microsoft Visual C/C++........................................................................ A-4

KDAQ-DRVR utilities for Win32 ................................................................. A-5

KDAQ-DRVR configuration utility (configdrv) ...................................... A-5

KDAQ-DRVR data file converter utility (KiDAQCvt)............................. A-6

KDAQ-DRVR overview .............................................................................. A-6

General configuration function group .................................................. A-7

Analog input function group................................................................. A-7

Analog output function group............................................................. A-10

Digital input function group ................................................................ A-12

Digital output function group .............................................................. A-13

General timer/counter function group ................................................ A-13

DIO function group ............................................................................ A-13

SSI function group ............................................................................. A-14

Calibration function group.................................................................. A-14

KDAQ-DRVR application hints................................................................. A-15

Analog input programming hints ........................................................ A-16

Analog output programming hints ............................................................ A-36

One-shot analog output programming scheme ................................. A-36

Digital input programming hints ......................................................... A-50

Digital output programming hints....................................................... A-51

DAQ event message programming hints........................................... A-52

Continuous data transfer in KDAQ-DRVR ............................................... A-53

Continuous data transfer mechanism................................................ A-53

Double-buffered AI/AO operation ...................................................... A-53

Single-buffered versus double-buffered data transfer ....................... A-54

Pre-trigger mode/middle-trigger data acquisition (AI)........................ A-54

ii KPXI-AO-901-01 Rev. A / January 2007

Page 9

KPXI Analog Output Module Reference Manual Table of Contents

Appendix Topic Page

B KDAQ-DRVR Function Reference ..................................................... B-1

Function description ................................................................................... B-2

Data types............................................................................................ B-2

Function reference............................................................................... B-2

Status Codes............................................................................................ B-94

AI range codes ......................................................................................... B-95

AI data format........................................................................................... B-97

DATA file format ....................................................................................... B-97

Header............................................................................................... B-98

ChannelRange................................................................................... B-99

Data Block ......................................................................................... B-99

C KIDAQ®-LabVIEW Compatible Interface Guide............................. C-1

Introduction to KIDAQ®-LabVIEW ............................................................. C-2

Overview.............................................................................................. C-2

Using KIDAQ LabVIEW VIs in LabVIEW............................................. C-2

KIDAQ LabVIEW Programming........................................................... C-3

Device Driver Handling .............................................................................. C-4

Windows XP/2000 Device Driver......................................................... C-4

Driver Utility ......................................................................................... C-4

KIDAQ Utilities ........................................................................................... C-4

KIDAQ Registry/Configuration utility.................................................... C-4

KIDAQ Device Browser ....................................................................... C-4

KIDAQ LabVIEW VIs Overview.................................................................. C-5

Analog Input VIs .................................................................................. C-6

Analog Output VIs................................................................................ C-6

Digital I/O VIs....................................................................................... C-7

Timer/Counter VIs................................................................................ C-7

Calibration and Configuration VIs ........................................................ C-8

Error Handler VI................................................................................... C-8

Distribution of Applications......................................................................... C-8

Windows XP/2000 ............................................................................... C-8

D KIDAQ®-LabVIEW Compatible Function Reference..................... D-1

Introduction ................................................................................................ D-2

Hardware support....................................................................................... D-2

KPXI-DIO series: ................................................................................. D-2

KPXI-DAQ series: ................................................................................ D-2

Digitizer series: .................................................................................... D-2

Analog input VIs......................................................................................... D-3

Easy analog input VIs.......................................................................... D-3

Intermediate analog input VIs.............................................................. D-7

Analog output VIs..................................................................................... D-21

Easy analog output VIs...................................................................... D-21

Intermediate analog output VIs.......................................................... D-24

Advanced analog output VIs.............................................................. D-32

Digital I/O VIs ........................................................................................... D-33

Easy Digital I/O VIs............................................................................ D-33

Intermediate Digital I/O VIs................................................................ D-37

Advanced Digital I/O VIs.................................................................... D-45

Counter VIs .............................................................................................. D-46

Easy Counter VIs .............................................................................. D-46

Intermediate Counter VIs .................................................................. D-50

Advanced Counter VIs ...................................................................... D-63

Calibration and Configuration VIs ............................................................ D-67

Calibration VIs .................................................................................. D-67

Other Calibration and Configuration VIs............................................ D-68

KPXI-AO-901-01 Rev. A / January 2007 iii

Page 10

Table of Contents KPXI Analog Output Module Reference Manual

Appendix Topic Page

D KIDAQ®-LabVIEW Compatible Function Reference (continued)

Service VIs ............................................................................................... D-70

Error Codes ............................................................................................. D-71

AI Range Codes ...................................................................................... D-73

AI Data Format ....................................................................................... D-76

iv KPXI-AO-901-01 Rev. A / January 2007

Page 11

List of Figures

Section Figure Title Page

1 Figure 1-1 Accessories configuration guide.................................................... 1-5

2 Figure 2-1 PCB layout of Model KPXI-AO-4-1M/Model KPXI-AO-8-1M ......... 2-2

Figure 2-2 Typical PXI module installation ...................................................... 2-4

Figure 2-3 Device manager (successful installation) ...................................... 2-5

3 Figure 3-1 Block diagram ................................................................................ 3-2

Figure 3-2 Connector pin assignment .......................................................... 3-3

Figure 3-3 Analog output series scan timing................................................... 3-6

Figure 3-4 Post trigger example...................................................................... 3-7

Figure 3-5 Trigger delay example ................................................................... 3-8

Figure 3-6 Post-trigger or delay-trigger acquisition with retrigger example..... 3-8

Figure 3-7 Scatter/gather DMA for data transfer............................................. 3-9

Figure 3-8 Block diagram of D/A group ......................................................... 3-10

Figure 3-9 Data format in FIFO and mapping ............................................... 3-11

Figure 3-10 Typical D/A timing of waveform generation ................................. 3-13

Figure 3-11 Post-trigger generation ................................................................ 3-14

Figure 3-12 Delay-trigger generation .............................................................. 3-15

Figure 3-13 Post-trigger with retrigger generation .......................................... 3-15

Figure 3-14 Finite iterative waveform generation with post-trigger ................. 3-16

Figure 3-15 Infinite iterative waveform generation with post-trigger ............... 3-16

Figure 3-16 Example mode I........................................................................... 3-17

Figure 3-17 Example mode II.......................................................................... 3-17

Figure 3-18 Example mode III......................................................................... 3-18

Figure 3-19 Mode 1 operation......................................................................... 3-19

Figure 3-20 Mode 2 operation......................................................................... 3-19

Figure 3-21 Mode 3 operation......................................................................... 3-20

Figure 3-22 Mode 4 operation......................................................................... 3-20

Figure 3-23 Mode 5 operation......................................................................... 3-20

Figure 3-24 Mode 6 operation......................................................................... 3-21

Figure 3-25 Mode 7 operation......................................................................... 3-21

Figure 3-26 Mode 8 operation......................................................................... 3-21

Figure 3-27 Analog trigger block diagram .................................................. 3-22

Figure 3-28 Below-low analog trigger condition .............................................. 3-23

Figure 3-29 Above-high analog trigger condition ............................................ 3-23

Figure 3-30 Inside-region analog trigger condition.......................................... 3-23

Figure 3-31 High-hysteresis analog trigger condition...................................... 3-24

Figure 3-32 Low-hysteresis analog trigger condition ...................................... 3-24

Figure 3-33 Routing of DAQ signals ............................................................... 3-25

Page 12

List of Figures KPXI Analog Output Module Reference Manual

Appendix Figure Title Page

A Figure A-1 Open Project dialog box................................................................ A-3

Figure A-2 Driver Configuration window ......................................................... A-5

Figure A-3 KDAQ-DRVR application building blocks.................................... A-15

Figure A-4 Typical function flow for all types of KDAQ-DRVR series............ A-16

Figure A-5 Fills channel gain queue first....................................................... A-17

Figure A-6 Synchronous operation ............................................................... A-18

Figure A-7 Non-double buffered asynchronous operation............................ A-19

Figure A-8 Double buffered asynchronous operation ................................... A-20

Figure A-9 All types of KPXI-DRVR series ................................................... A-22

Figure A-10 Fills channel gain queue first....................................................... A-23

Figure A-11 All types of KDAQ-DRVR series ................................................. A-25

Figure A-12 Fills channel gain queue first....................................................... A-26

Figure A-13 All types of KDAQ-DRVR series ................................................. A-27

Figure A-14 Fills channel gain queue first....................................................... A-29

Figure A-15 All types of KDAQ-DRVR series ................................................. A-31

Figure A-16 Fills channel gain queue first....................................................... A-32

Figure A-17 All types of KDAQ-DRVR series ................................................. A-33

Figure A-18 Fills channel gain queue first....................................................... A-35

Figure A-19 One-shot analog output programming ........................................ A-37

Figure A-20 One-shot analog output programming ........................................ A-38

Figure A-21 Non-double-buffered asynchronous continuous

analog output programming ........................................................ A-39

Figure A-22 Non-double-buffered asynchronous continuous

analog output programming ........................................................ A-40

Figure A-23 Double-buffered asynchronous continuous analog

output programming .................................................................... A-41

Figure A-24 Double-buffered asynchronous continuous analog

output programming .................................................................... A-43

Figure A-25 Typical flow of asynchronous analog output operation ............... A-44

Figure A-26 Typical flow of asynchronous analog output operation ............... A-45

Figure A-27 Typical flow of double-buffered asynchronous

analog output operation .............................................................. A-47

Figure A-28 Typical flow of double-buffered asynchronous

analog output operation .............................................................. A-49

Figure A-29 One-shot digital input programming ............................................ A-50

Figure A-30 Typical flow of non-buffered single-point digital output operation A-51

Figure A-31 Double buffer mode principle ...................................................... A-53

B Figure B-1 Scan timing example................................................................... B-13

Figure B-2 Scan timing example................................................................... B-15

Figure B-3 Scan timing example................................................................... B-17

Figure B-4 Scan timing example................................................................... B-20

Figure B-5 Scan timing example................................................................... B-22

Figure B-6 Scan timing example................................................................... B-25

Figure B-7 Scan timing example................................................................... B-27

Figure B-8 Scan timing example................................................................... B-30

Figure B-9 DATA file format .......................................................................... B-98

Figure B-10 DAQ File Conversion Utility....................................................... B-100

C Figure C-1 Function Browser Options............................................................. C-2

Figure C-2 Functions palette........................................................................... C-3

Figure C-3 Keithley PXI Devices Explorer ...................................................... C-5

vi KPXI-AO-901-01 Rev. A / January 2007

Page 13

KPXI Analog Output Module Reference Manual List of Figures

Appendix Figure Title Page

D Figure D-1 Analog input palette ...................................................................... D-3

Figure D-2 Analog output palette .................................................................. D-21

Figure D-3 Digital I/O palette......................................................................... D-33

KPXI-AO-901-01 Rev. A / January 2007 vii

Page 14

List of Figures KPXI Analog Output Module Reference Manual

This page left blank intentionally.

viii KPXI-AO-901-01 Rev. A / January 2007

Page 15

List of Tables

Section Table Title Page

3 Table 3-1 Connector pin assignment............................................................. 3-4

Table 3-2 Bipolar input range and converted digital codes............................ 3-5

Table 3-3 Unipolar input range and converted digital codes.......................... 3-5

Table 3-4 Summary of programmable scan counters.................................... 3-5

Table 3-5 Trigger modes and corresponding trigger sources ........................ 3-6

Table 3-6 D/A output versus digital codes ................................................... 3-11

Table 3-7 Trigger signals and corresponding signal sources....................... 3-12

Table 3-8 Summary of counters for waveform generation........................... 3-13

Table 3-9 Analog trigger SRC1(EXTATRIG) ideal transfer characteristics .. 3-22

4 Table 4-1 Various waveform samples............................................................ 4-2

Appendix Table Title Page

A Table A-1 Initial default channel configuration ............................................. A-18

Table A-2 Initial default AI configuration....................................................... A-18

Table A-3 Initial default channel configuration ............................................. A-38

Table A-4 Initial default DA configuration ..................................................... A-38

B Table B-1 Suggested data types .................................................................... B-2

Table B-2 Example trigger condition selection (KDAQ_AIO_Config) ........... B-46

Table B-3 Status codes returned by KDAQ-DRVR ...................................... B-94

Table B-4 Analog input range of digitizers ................................................... B-96

Table B-5 Valid values for each model......................................................... B-96

Table B-6 AI data format .............................................................................. B-97

Table B-7 Data file header ........................................................................... B-98

Table B-8 Data structure of ChannelRange unit (length: 2 bytes)................ B-99

D Table D-1 KI AI acquire waveform.................................................................. D-3

Table D-2 KI AI acquire waveforms................................................................ D-4

Table D-3 KI AI sample channel..................................................................... D-6

Table D-4 KI AI sample channels ................................................................... D-6

Table D-5 KI AI clear ...................................................................................... D-7

Table D-6 KI AI config .................................................................................... D-9

Table D-7 2-byte binary array....................................................................... D-12

Table D-8 Scaled and Binary Arrays ............................................................ D-14

Table D-9 Scaled Array ................................................................................ D-16

Table D-10 KI AI single scan .......................................................................... D-17

Table D-11 KI AI start ..................................................................................... D-19

Table D-12 KI AO generate waveform ........................................................... D-22

Table D-13 KI AO generate waveforms.......................................................... D-22

Table D-14 KI AO update channel.................................................................. D-23

Table D-15 KI AO update channels................................................................ D-24

Table D-16 KI AO clear .................................................................................. D-25

Table D-17 KI AO Config................................................................................ D-25

Page 16

List of Tables KPXI Analog Output Module Reference Manual

Appendix Table Title Page

D Table D-18 KI AO start................................................................................... D-27

Table D-19 KI AO wait ................................................................................... D-28

Table D-20 KI AO write binary array.............................................................. D-29

Table D-21 KI AO write binary array scaled array ......................................... D-30

Table D-22 KI AO Trigger and Gate Config ................................................... D-32

Table D-23 KI Read from Digital Line ............................................................ D-34

Table D-24 KI Read from Digital Port ............................................................ D-34

Table D-25 KI Write to Digital Line................................................................. D-35

Table D-26 KI Write to Digital Port................................................................. D-36

Table D-27 KI DIO Clear................................................................................ D-37

Table D-28 KI DIO Config .............................................................................. D-38

Table D-29 KI DIO Read................................................................................ D-40

Table D-30 KI DIO Start................................................................................. D-42

Table D-31 KI DIO Write ................................................................................ D-43

Table D-32 KI DIO Port Config ...................................................................... D-45

Table D-33 KI Count Events or Time ............................................................. D-46

Table D-34 KI Generate Delayed Pulse......................................................... D-47

Table D-35 KI Generate Pulse-Train.............................................................. D-48

Table D-36 KI Measure Pulse-Width or Period.............................................. D-49

Table D-37 KI Continuous Pulse Generator Config ....................................... D-50

Table D-38 KI Counter Divider Config ........................................................... D-52

Table D-39 KI Counter Read ......................................................................... D-53

Table D-40 KI Counter Start........................................................................... D-54

Table D-41 KI Counter Stop........................................................................... D-55

Table D-42 KI Delayed Pulse Generator Config ............................................ D-56

Table D-43 KI Down Counter or Divider Config............................................. D-58

Table D-44 KI Event or Time Counter Config ................................................ D-59

Table D-45 KI Pulse-Width or Period Measurement Config .......................... D-61

Table D-46 KI UpDown Counter Config......................................................... D-62

Table D-47 KI ICTR Control........................................................................... D-63

Table D-48 KI KPXI-DAQ series devices and Digitizer Series Calibrate ...... D-67

Table D-49 KI Route Signal .......................................................................... D-68

Table D-50 KI SSI Control ............................................................................ D-69

Table D-51 KI Error Handler ......................................................................... D-70

Table D-52 Error Codes: KIDAQ LabVIEW VIs ............................................. D-71

Table D-53 Analog Input Range .................................................................... D-73

Table D-54 Valid analog input ranges (specified by module)......................... D-75

Table D-55 Analog Input data format (by Model)........................................... D-76

x KPXI-AO-901-01 Rev. A / January 2007

Page 17

In this section:

Top ic Page

Introduction......................................................................................... 1-2

Overview .............................................................................................. 1-2

Applications........................................................................................ 1-2

Features ............................................................................................... 1-2

Manual addenda................................................................................. 1-3

Safety symbols and terms .............................................................. 1-3

Specifications..................................................................................... 1-3

Section 1

Introduction

Unpacking and inspection .............................................................. 1-4

Inspection for damage ...................................................................... 1-4

Shipment contents............................................................................ 1-4

Instruction manual ............................................................................ 1-4

Repacking for shipment.................................................................... 1-4

Available accessories....................................................................... 1-5

Connections........................................................................................ 1-5

Software introduction....................................................................... 1-5

Programming library KDAQ-DRVR................................................... 1-5

KDAQ-LVIEW LabVIEW® driver....................................................... 1-6

Page 18

Section 1: Introduction KPXI Analog Output Module Reference Manual

Introduction

This manual is designed to help you understand and use KPXI Analog Output Series

high-performance multi-function modules.

This section contains general information about the Keithley Instruments KPXI-AO-4-1M and

KPXI-AO-8-1M. The information is organized as follows:

• Overview

• Applications

• Features

• Manual addenda

• Safety symbols and terms

• Specifications

• Unpacking and inspection

• Available accessories

• Connections

• Software introduction

If you have any questions after reviewing this information, please contact your local Keithley

Instruments representative or call one of our Applications Engineers at 1-800-KEITHLEY. You can

also contact us through our website at www.keithley.com.

Overview

Keithley Instruments’ KPXI Analog Output Series provides advanced analog output cards based

on 32-bit PCI / PXI architecture (Peripheral Component Interconnect) / (PCI eXtensions for

Instrumentation). The Model KPXI-AO-4-1M provides up to four analog output channels while the

Model KPXI-AO-8-1M provides up to eight analog output channels.

Applications

High-performance designs and state-of-the-art technology make this card ideal for waveform

generation, industrial process control, and signal-analysis applications in medical, process control,

and other related fields. Specific applications are:

• Automotive testing

• Arbitrary waveform generator

• Transient signal measurement

• Laboratory automation

• Biotech measurement

Features

Key features and benefits include:

• 32-bit PCI/PXI-Bus, plug and play

• Up to 1MS/s analog output rate

• Up to 400KS/s analog input rate

• Output channels:

• Programmable bipolar/unipolar range for analog input channels and individual analog

Model KPXI-AO-4-1M — Up to four analog output channels

Model KPXI-AO-8-1M — Up to eight analog output channels

output channels

1-2 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 19

KPXI Analog Output Module Reference Manual Section 1: Introduction

• Programmable internal/external reference for individual analog output channels

• D/A FIFO size (Digital to Analog First In First Out):

Model KPXI-AO-4-1M — 8K samples

Model KPXI-AO-8-1M — 16K samples

• A/D FIFO (Analog to Digital) size (all models): 2K samples

• Versatile trigger sources: software trigger external digital trigger, analog trigger and trigger

from System Synchronization Interface (SSI)

• A/D data transfer: software polling and bus-mastering DMA with Scatter/Gather

• D/A data transfer: software update and bus-mastering DMA with Scatter/Gather

• A/D trigger modes: post-trigger, delay-trigger with re-trigger functionality

• D/A outputs with waveform generation capability

• System Synchronization Interface (SSI)

• A/D and D/A full auto-calibration

• Built-in programmable D/A external reference voltage compensator

• Jumper-less (software configurable)

Manual addenda

Any improvements or changes concerning the Model KPXI-AO-4-1M / KPXI-AO-8-1M or manual

will be explained in an addendum included with the manual. Be sure to note these changes and

incorporate them into the manual.

Safety symbols and terms

The following symbols and terms may be found on the Model KPXI-AO-4-1M / KPXI-AO-8-1M or

used in this manual.

The symbol indicates that the user should refer to the operating instructions located in the

!

manual.

The symbol shows that high voltage may be present on the terminal(s). Use standard safety

precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to

prevent burns.

The WARNING heading used in this manual explains dangers that might result in personal injury

or death. Always read the associated information very carefully before performing the indicated

procedure.

The CAUTION heading used in this manual explains hazards that could damage the unit. Such

damage may invalidate the warranty.

Specifications

Refer to the product data sheet for updated KPXI Analog Output Series analog output multifunction cards specifications. Check the Keithley Instruments website at www.keithley.com for the

latest updates to the specifications.

KPXI-AO-901-01 Rev. A / January 2007 Return to Section Topics 1-3

Page 20

Section 1: Introduction KPXI Analog Output Module Reference Manual

Unpacking and inspection

Inspection for damage

CAUTION Your Model KPXI-AO-4-1M / KPXI-AO-8-1M module contains electro-static

sensitive components that can easily be damaged by static electricity.

Therefore, handle the card on a grounded anti-static mat. The operator should

be wearing an anti-static wristband, grounded at the same point as the

anti-static mat.

The Model KPXI-AO-4-1M / KPXI-AO-8-1M was carefully inspected electrically and mechanically

before shipment.

Inspect the card module carton for obvious damages. Shipping and handling may damage the

module. Make sure there are no shipping and handling damages on the module’s carton before

continuing.

After opening the card module carton, extract the system module and place it only on a grounded

anti-static surface with component side up. Save the original packing carton for possible future

shipment.

Again, inspect the module for damages. Report any damage to the shipping agent immediately.

Shipment contents

The following items are included with every Model KPXI-AO-4-1M / KPXI-AO-8-1M order:

• Model KPXI-AO-4-1M / KPXI-AO-8-1M Portable RF PowerMeter

• CD containing required software and manuals

Instruction manual

A CD-ROM containing this Reference Manual and required software is included with each

Model KPXI-AO-4-1M / KPXI-AO-8-1M order. If a hardcopy of the Model KPXI-AO-4-1M / KPXIAO-8-1M Reference Manual is required, you can order the Manual Package (Keithley Instruments

Part Number Model KPXI-AO-901-01). The Manual Package includes an instruction manual and

any pertinent addenda.

Always check the Keithley Instruments website at www.keithley.com for the latest revision of the

manual. The latest manual can be downloaded (in PDF format) from the website.

Repacking for shipment

Should it become necessary to return the Model KPXI-AO-4-1M / KPXI-AO-8-1M for repair,

carefully pack the unit in its original packing carton or the equivalent, and follow these instructions:

• Call Keithley Instruments’ repair department at 1-888-KEITHLEY (1-888-534-8453) for a

Return Material Authorization (RMA) number.

• Let the repair department know the warranty status of the Model KPXI-AO-4-1M /

KPXI-AO-8-1M.

• Write ATTENTION REPAIR DEPARTMENT and the RMA number on the shipping label.

• Complete and include the Service Form located at the back of this manual.

1-4 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 21

KPXI Analog Output Module Reference Manual Section 1: Introduction

CAUTION The boards must be protected from static discharge and physical shock.

Never remove any of the socketed parts except at a static-free workstation.

Use the anti-static bag shipped with the product to handle the board. Wear a

grounded wrist strap when servicing.

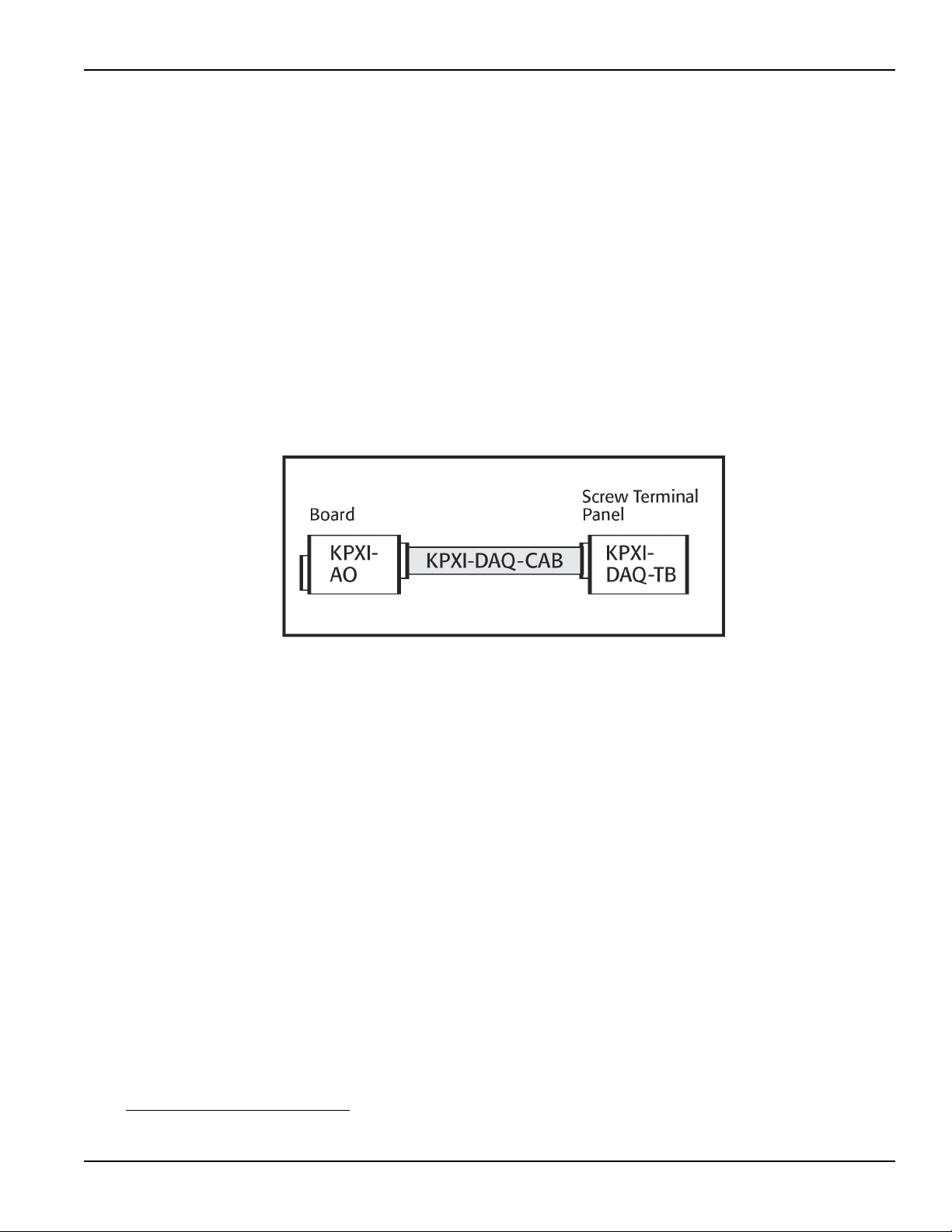

Available accessories

NOTE Check the Keithley Instruments website (www.keithley.com) for additional accessories

that may have been added to the Keithley Instruments product line for the

Model KPXI-AO-4-1M / KPXI-AO-8-1M.

Available accessories are listed below (also see Figure 1-1).

• KPXI-DAQ-TB: Terminal board with 68-pin SCSI-II connector.

• KPXI-DAQ-CAB: Cable connecting terminal block to KPXI-AO modules.

Figure 1-1

Accessories configuration guide

Connections

Keithley Instruments’ KPXI Analog Output Series is equipped with one 68-pin VHDCI-type

connector (AMP-787254-1). Use this for making connections (for example, connect digital input /

output, analog input / output, timer /counter signals, etc.).

NOTE Refer to Signal connections (contained in Section 3) for detailed information including pin

assignments.

Software introduction

Keithley Instruments’ provides versatile software drivers and packages for different systems.

Keithley Instruments not only provides programming libraries such as DLL’s for most Windows

based systems, but also drivers for other software packages such as LabVIEW.

All software options are included in the Keithley Instruments’ CD.

Programming library KDAQ-DRVR

KDAQ-DRVR includes device drivers and DLL’s for Windows XP® and Windows 2000®.

Therefore, all applications developed with KDAQ-DRVR are compatible on Windows XP/2000.

The developing environment can be VB, VC++, BC5, or any Windows programming language that

1. National Instruments™, NI, and LabVIEW are trademarks of the National Instruments Corporation.

®

1

KPXI-AO-901-01 Rev. A / January 2007 Return to Section Topics 1-5

Page 22

Section 1: Introduction KPXI Analog Output Module Reference Manual

allows calls to a DLL. Documentation includes a User's Guide (refer to Appendix A: KDAQ-DRVR

User’s Guide), and a Function Reference (refer to Appendix B: KDAQ-DRVR Function Reference).

KDAQ-LVIEW LabVIEW® driver

KDAQ-LVIEW contains the VI’s, which are used to interface with National Instrument's®

Lab-VIEW® software package. The KDAQ-LVIEW supports Windows XP/2000®. The LabVIEW

driver is shipped free with the board. Documentation includes an Interface Guide (refer to

Appendix C: KIDAQ®-LabVIEW Compatible Interface Guide), and an interface Function

Reference (refer to Appendix D: KIDAQ®-LabVIEW Compatible Function Reference).

1-6 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 23

In this section:

Top ic Page

Introduction......................................................................................... 2-2

Handling precautions ....................................................................... 2-2

Mechanical drawing.......................................................................... 2-2

PCI configuration............................................................................... 2-2

Installation........................................................................................... 2-3

Section 2

Installation

Plug-and-Play ................................................................................... 2-2

Configuration .................................................................................... 2-3

Troubleshooting................................................................................ 2-3

Page 24

Section 2: Installation KPXI Analog Output Module Reference Manual

Introduction

This section contains information about handling and installing Keithley Instruments’

KPXI Analog Output Series cards:

• Handling precautions

• Mechanical drawing

• PCI configuration

• Installation

Handling precautions

CAUTION Use care when handling the KPXI Analog Output Series module. KPXI Analog

Output Series modules contain electro-static sensitive components that can

be easily damaged by static electricity.

Follow these guidelines when handling:

• Only handle the card on a grounded anti-static mat.

• Wear an an anti-static wristband that is grounded at the same point as the anti-static mat.

Mechanical drawing

NOTE: See Figure 3-2 for a CN1 pinouts.

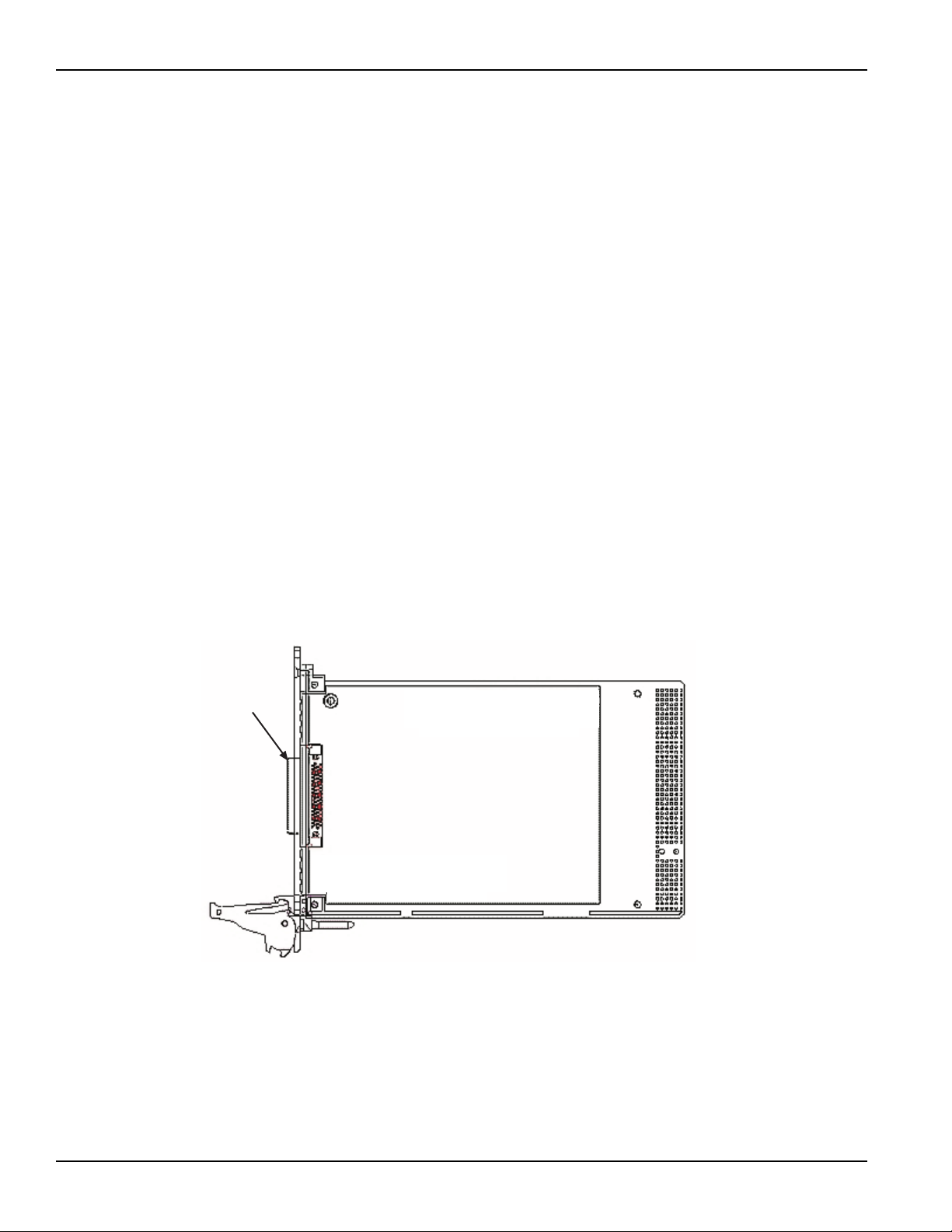

Figure 2-1

PCB layout of Model KPXI-AO-4-1M/Model KPXI-AO-8-1M

CN1

(68-Pin

Connector)

Board-to-board Connector

PCI configuration

Plug-and-Play

As a plug-and-play component, the board requests an interrupt number via its PCI controller. The

system BIOS responds with an interrupt assignment based on the board information and system

parameters. These system parameters are determined by the installed drivers and the hardware

2-2 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 25

KPXI Analog Output Module Reference Manual Section 2: Installation

load recognized by the system. If this is the first KIDAQ® KPXI Analog Output Series card installed

on your Windows

detailed information.

Configuration

Configuration is done on a board-by-board basis for all PCI boards on your system. Configuration

is controlled by the system and software. There is no jumper setting required (or available) for

base address, DMA, and interrupt IRQ.

The configuration is not static, but is subject to change with every boot of the system (as new

boards are added or removed).

Troubleshooting

If your system doesn't boot or if you experience erratic operation with your PXI board in place, it's

likely caused by an interrupt conflict (perhaps the BIOS Setup is incorrectly configured). In

general, the solution, is to consult the BIOS documentation that comes with your system.

Installation

Step 1. Install driver software

Windows® will find the new module automatically. If this is the first time a KIDAQ® KPXI Analog

Output Series card is running on your Windows system, you will need to install a hardware driver.

Use the following installation procedure as a guide.

®

system, you will also need to install a hardware driver. Refer to Installation for

NOTE: Keithley Instruments controllers are pre-loaded with the necessary drivers.

For Windows XP/2000:

1. Insert the CD shipped with the module. The CD should auto load. From the base menu

install the KDAQ-DRVR. This is the hardware driver that recognizes the KPXI Analog Output Series modules. If the CD does not auto load run, then under x:\KDAQ-DRVR\DISK1\,

you will find SETUP.EXE (x is the drive letter of your CDROM). This will also run the install.

2. When you complete driver installation, turn off the system.

Step 2. Inspect module

Keeping the “Handling precautions” information in mind, inspect the module for damage. With the

module placed on a firm, flat surface, press down on all socketed IC's to make sure that they are

properly seated.

If the module does not pass the inspection, do not proceed with the installation.

CAUTION Do not apply power to the card if it has been damaged.

The KIDAQ® KPXI Analog Output Series card is now ready for installation.

Step 3. Install module

Remove power from the system and install the KPXI Analog Output Series card in an available

slot.

The PXI connectors are rigid and require careful handling when inserted and removed. Improper

handling of modules can easily damage the backplane.

KPXI-AO-901-01 Rev. A / January 2007 Return to Section Topics 2-3

Page 26

Section 2: Installation KPXI Analog Output Module Reference Manual

To insert the module into a PXI chassis, use the following procedure as a guide:

1. Turn off the system.

2. Align the module's edge with the card guide in the PXI chassis.

3. Slide the module into the chassis until resistance is felt from the PXI connector.

4. Push the ejector upwards and fully insert the module into the chassis. Once inserted, a

"click" can be heard from the ejector latch.

5. Tighten the screw on the front panel.

6. Turn on the system.

To remove a module from a PXI chassis, use the following procedure as a guide:

1. Turn off the system.

2. Loosen the screw on the front panel.

3. Push the ejector downwards and carefully remove the module from the chassis.

Figure 2-2

Typical PXI module installation

Typical PXI

chassis

Card guide

Front panel

screw

Modules edge

Ejector latch

2-4 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 27

KPXI Analog Output Module Reference Manual Section 2: Installation

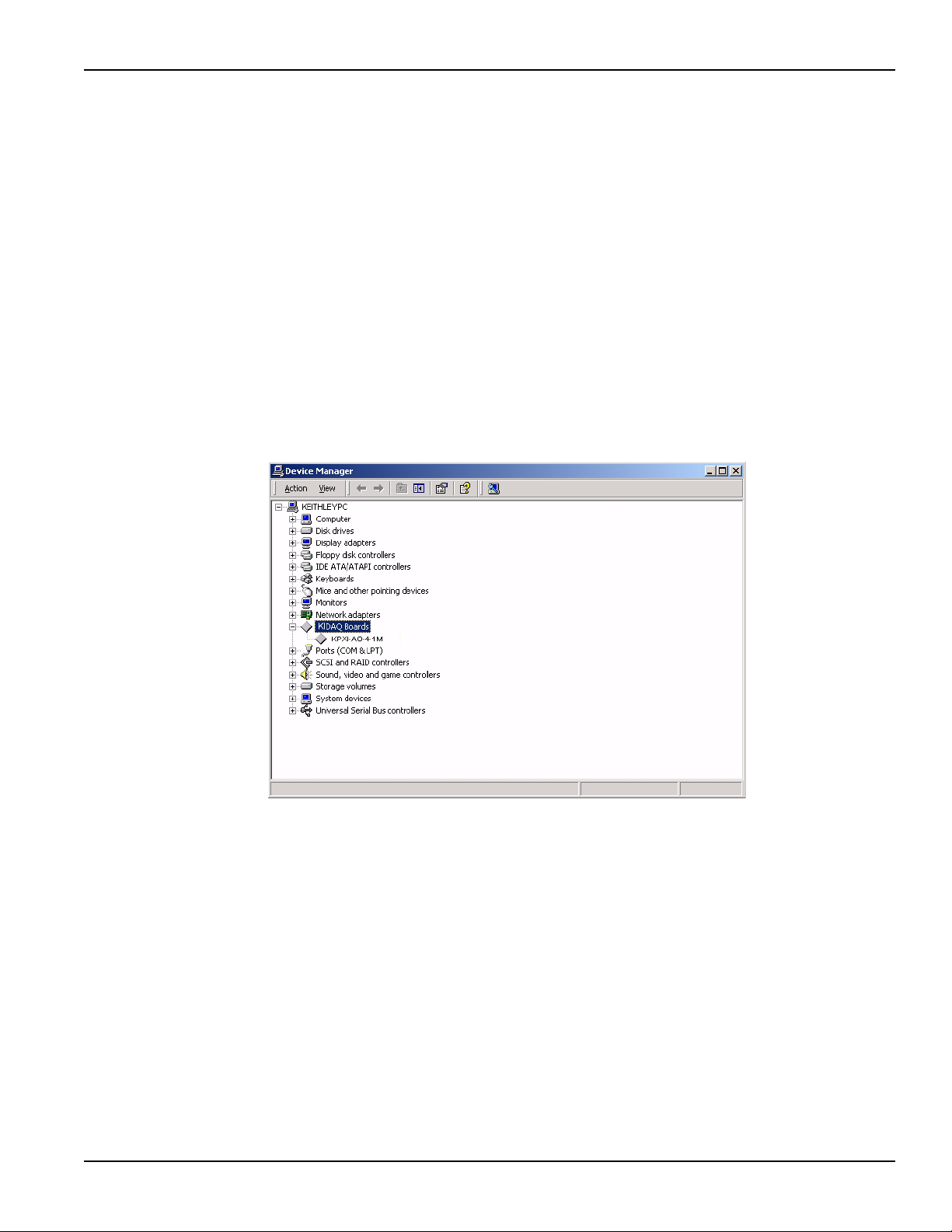

Step 4. Verify installation

When the system is turned on for the first time with a new module present (or a module in a new

slot), Windows Add New Hardware Wizard attempts to locate the correct driver. If it cannot find

the correct driver, even after you have loaded the driver above in Step 1, then force the Add New

Hardware Wizard to look in Windows system32 directory. The driver files should be in this

location. If they are not, shutdown the system, remove the module, and restart the installation

process.

When the Add New Hardware Wizard finishes, the window will verify whether or not installation

was successful. To confirm if the module is installed correctly at a later time, use Windows Device

Manager. In the Device Manager under KIDAQ Boards, look for a device name matching the

model number of the newly installed board. If it is found, installation is complete. If the board

appears with a exclamation point or warning in Device Manager, the installation was unsuccessful.

If unsuccessful, use Device Manager to update the driver or un-install the module, power down

the system, remove the module, and attempt installation again from Step 1.

Figure 2-3

Device manager (successful installation)

KPXI-AO-901-01 Rev. A / January 2007 Return to Section Topics 2-5

Page 28

Section 2: Installation KPXI Analog Output Module Reference Manual

This page left blank intentionally.

2-6 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 29

In this section:

Top ic Page

Introduction......................................................................................... 3-2

Signal connections ........................................................................... 3-3

A/D conversion................................................................................... 3-4

D/A conversion................................................................................... 3-9

Section 3

Operation and connection

Connectors pin assignment .............................................................. 3-3

KPXI Analog Output Series A/D data format .................................... 3-5

Software polling mode ...................................................................... 3-5

Programmable scan mode ............................................................... 3-5

Trigger mode .................................................................................... 3-7

Bus-mastering DMA data transfer .................................................... 3-9

Architecture .................................................................................... 3-10

Hardware controlled waveform generation ..................................... 3-10

Setting up the DACs ........................................................................3-11

Utilizing multiplying characteristics of DACs....................................3-11

Software update.............................................................................. 3-12

Waveform generation ..................................................................... 3-12

Trigger modes................................................................................. 3-14

Iterative waveform generation ........................................................ 3-15

Stop modes..................................................................................... 3-16

General purpose digital I/O........................................................... 3-18

General purpose timer/counter operation ................................ 3-18

Timer/Counter functions basics ...................................................... 3-18

General purpose timer/counter modes ........................................... 3-19

Trigger sources................................................................................ 3-21

Software trigger .............................................................................. 3-22

External analog trigger ................................................................... 3-22

Timing signal .................................................................................... 3-24

System synchronization interface................................................... 3-25

Calibration ......................................................................................... 3-25

Auto-calibration............................................................................... 3-25

Saving calibration constants........................................................... 3-26

Loading calibration constants ......................................................... 3-26

Page 30

Section 3: Operation and connection KPXI Analog Output Module Reference Manual

Introduction

This section contains operation information on KPXI Analog Output Series cards, including signal

connections. The operation theories described in this section include A/D conversion (Analog to

Digital), D/A conversion (Digital to Analog), Digital I/O (Input Output), and General Purpose

Counter / Timer (refer to

Analog Output Series modules.

Figure 3-1

Block diagram

Figure 3-1). Use this information to configure and program the KPXI

68 pin Mini-SCSI connector

DA GROUP B

Ext-WF-Trig, Ext-Dtrig, Ext-timebase

24-bit DIO / GPTC^2 / External Triggers

8255 24-bit DIO

MUX

14-bit

ADC

AD Control

and Timing

Logic

AD Control and

Trigger Logic

AD Control

FIFO (for Data

& Configuration)

Analog

Analog Trtigger Signals

Trigger Logic

Daughter Board FIFO Interface

Daughter Board

FIFO Interface

12-bit

DAC

12-bit

DAC

DA GROUP A

FIFO

Calibration

Board to Board Interface

DAQ

Bus

DAQ Bus

Interface

DAQ 2000

Control and

Trigger Logic

Local Bus

Interface

and DMA

Logic

DA Control

and Timing

Logic

DA Control and

Trigger Logic

DA Interface

FIFO

GRXXC0

GRXXC1

SSI XXXX PFI

OPAOPAOPA

12-bit

DAC

LATCHLATCHLATCH

OPA

12-bit

DAC

LATCH

CPLD

Analog

Trigger

General Purpose timer/Counter Signals

Programmabale Function Inputs

82CXXX

82CXXA

Control

Logic

Logic Bus

Interface

EEPROM

24-bit I/O

Power

Logic

Power

Circuit

Power

DMA

Local Bus Interface

PCI Bus Controller

Universal PCI Interface

Local Bus Signals

Configuration

and

Calibration

EEPROM

System Synchronization Interface

Universal 32-bit PCI Bus

3-2 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 31

KPXI Analog Output Module Reference Manual Section 3: Operation and connection

Signal connections

Signal connections describes the KPXI Analog Output Series card connectors and the signal

connection between KPXI Analog Output Series card and external devices.

Connectors pin assignment

KPXI Analog Output series cards are equipped with one 68-pin VHDCI-type connector (AMP787254-1) used for digital input / output, analog input / output, and timer/counter signals, etc.,.

Connector pin assignments are defined in

Figure 3-2

Connector pin assignment

AO_0 1 35 AGND

AO_1 2 36 AGND

AO_2 3 37 AGND

AO_3 4 38 AGND

AOEXTREF_A/AI_0 5 39 AGND

AI_1 6 40 AGND

EXTATRIG/AI_2 7 41 AGND

AOEXTREF_B/AI_3 8 42 AGND

AO_4/AI_4 9 43 AGND

AO_5/AI_5 10 44 AGND

AO_6/AI_6 11 45 AGND

AO_7/AI_7 12 46 AGND

AO_TRIG_OUTA 13 47 EXTWFTRG_A

AO_TRIG_OUTB 14 48 EXTWFTRG_B

GPTC1_SRC 15 49 VCC

GPTC0_SRC 16 50 DGND

GPTC0_GATE 17 51 GPTC1_GATE

GPTC0_OUT 18 52 GPTC1_OUT

GPTC0_UPDOWN 19 53 GPTC1_UPDOWN

RESERVED 20 54 DGND

AFI1 21 55 AFI0

PB7 22 56 PB6

PB5 23 57 PB4

PB3 24 58 PB2

PB1 25 59 PB0

PC7 26 60 PC6

PC5 27 61 PC4

DGND 28 62 DGND

PC3 29 63 PC2

PC1 30 64 PC0

PA7 31 65 PA6

PA5 32 66 PA4

PA3 33 67 PA2

PA1 34 68 PA0

Figure 3-2 and Table 3-1.

KPXI-AO-901-01 Rev. A / January 2007 Return to Section Topics 3-3

Page 32

Section 3: Operation and connection KPXI Analog Output Module Reference Manual

Table 3-1

Connector pin assignment

Pin # Signal Name Reference Direction Description

1-4 AO_<0 to 3> AGND Output Voltage output of DA channel <0 to 3>

5 AOEXTREF_A/AI_0 AGND Input External reference for AO channel <0 to 3> / AI

input 0 (pin is shared depending on configuration)

6 AI_1 AGND Input AI input 1

7 EXTATRIG/AI_2 AGND Input External analog trigger / AI input 2

8 AOEXTREF_B/AI_3 AGND Input External reference for AO channel <4 to 7> / AI

input 3 (pin is shared depending on configuration)

9 to 12 AO_<4 to 7> / AI_<4 to 7> AGND Output/Input KPXI-AO-8-1M:

Voltage output of DA channel <4 to 7>

KPXI-AO-4-1M: AI channel <4 to 7>

13, 14 AO_TRIG_OUT_<A, B> DGND Output AO trigger signal for channel <0 to 3> <4 to 7>

15, 16 GPTC<0, 1>_SRC DGND Input Source of GPTC<0, 1>

17, 51 GPTC<0, 1>_GATE DGND Input Gate of GPTC<0, 1>

18, 52 GPTC<0, 1>_OUT DGND Input Output of GPTC<0, 1>

19, 53 GPTC<0, 1>_UPDOWN DGND Input Up/down of GPTC<0, 1>

20 RESERVED -------- -------- Reserved Pin

21,55 AFI<1, 0> DGND Input Auxiliary Function Input

22, 56, 23,

57, 24, 58,

25, 59

26, 60, 27,

61, 29, 63,

30, 64

31, 65, 32,

66, 33, 67,

34, 68

35-46 AGND -------- -------- Analog ground

47, 48 EXTWFTRIG_<A, B> DGND Input External waveform trigger for AO channel <0 to 3>

49 VCC DGND Power (Output) +5V power source

28, 50, 54, 62DGND -------- -------- Digital ground

PB<7, 0> DGND PIO Programmable DIO of 8255 port B

PC<7, 0> DGND PIO Programmable DIO of 8255 port C

PA< 7 , 0 > DGND PIO Programmable DIO of 8255 port A

<4 to 7>

*PIO: Programmable Input/Output

A/D conversion

When using the A/D converter, determine the properties of the signal to be measured. Also, set up

the A/D configuration, which includes scan channels, input range, and polarities.

The A/D acquisition is initiated by a trigger signal. The data acquisition starts once the trigger

signal matches the trigger conditions. Converted data is queued into the FIFO buffer, and then

transferred to the host PC's memory for further processing.

KPXI Analog Output Series cards provide two acquisition modes: Software Polling and

Programmable Scan. These acquisition modes are described in the following paragraphs and

include timing, trigger modes, trigger sources, and transfer methods.

3-4 Return to Section Topics KPXI-AO-901-01 Rev. A / January 2007

Page 33

KPXI Analog Output Module Reference Manual Section 3: Operation and connection

KPXI Analog Output Series A/D data format

The data format of the acquired 14-bit A/D data is 2's Complement coding.

Table 3-2

Bipolar input range and converted digital codes

Magnitude Bipolar Input Range Digital code

FSR ±10V ±5V ±2.5V ±1.25V

LSB 112 0.78µV 610.39µV 305.19µV 152.60µV

FSR-1LSB 9.998779V 4.999389V 2.499694V 1.249847V 1FFF

Midscale + LSB 1120.78µV 610.39µV 305.19uV 152.60uV 0001

Midscale 0V 0V 0V 0V 0000

Midscale - LSB -1120.78µV -610.39µV -305.19µV -152.60uV 3FFF

-FSR -10V -5V -2.5V -1.25V 2000

Table 3-3

Unipolar input range and converted digital codes

Magnitude Unipolar Input Range Digital code

FSR 0V to 10V 0 to +5V 0 to +2.5V 0 to +1.25V

LSB 610.39µV 305.19µV 152.60µV 76.3µV

FSR - LSB 4.999389V 2.499694V 1.249847V 1.249923V 1FFF

Midscale + LSB 5.000611V 2.500306V 1.250153V 0.625076V 0001

Midscale 5V 2.5V 1.25V 0.625V 0000

Midscale - LSB 4.999389V 2.499694V 1.249847V 1.249923V 3FFF

-FSR 0V 0V 0V 0V 2000

Software polling mode

This is the easiest mode to acquire single A/D data. The A/D converter performs one conversion

whenever the software command is executed. The software polls the conversion status and reads

the A/D data back when it becomes available.

Use this mode when applications need to acquire A/D data in real time. In this mode, the timing of

the A/D conversion is fully software controlled. Note that this mode would cause difficulty

maintaining a fixed A/D sampling rate (refer to

Programmable scan mode

NOTE A scan is a sequential sampling of a group of multiple channels at a defined interval.

Use this mode when applications need to acquire A/D data at a precise and fixed rate. The scan

interval is defined by SI_counter. Likewise, the sample interval of multiple channels is defined by

SI2_counter. Refer to

Table 3-4