Page 1

www.keithley.com

KPXI 48-Channel General Purpose Card

User’s Manual

KPXI-DIO-900-01 Rev. A / January 2007

A GREATER MEASURE OF CONFIDENCE

ECA 42912

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of

1 year from date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables,

rechargeable batteries, diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley Instruments representative, or contact

Keithley Instruments headquarters in Cleveland, Ohio. You will be given prompt assistance and return instructions.

Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product

returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original

warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley Instruments’ express

written consent, or misuse of any product or part. This warranty also does not apply to fuses, software,

non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES

PROVIDED HEREIN ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF

ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN

ADVANCE OF THE POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT

ARE NOT LIMITED TO: COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT

OF INJURY TO ANY PERSON, OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/06

Page 3

KPXI

48-Channel General Purpose Card

User’s Manual

©2007, Keithley Instruments, Inc.

Document Number:

All rights reserved.

Cleveland, Ohio, U.S.A.

KPXI-DIO-900-01 Rev. A / January 2007

Page 4

Manual Print History KPXI 48-Channel General Purpose Card User’s Manual

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this

manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent

updates. Addenda, which are released between Revisions, contain important change information that

the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a

new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number KPXI-DIO-900-01) ............................................January 2007

All Keithley Instruments product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand names are trademarks or registered trademarks of their respective holders.

KPXI-DIO-900-01 Rev. A / January 2007

Page 5

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions

required to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using

the product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state

if the operator may perform them. Otherwise, they should be performed only by service personnel.

Safety Precautions

Service personnel are trained to work on live circuits, and perform safe installations and repairs of products. Only properly

trained service personnel may perform installation and service procedures.

Keithley Instruments products are designed for use with electrical signals that are rated Measurement Category I and

Measurement Category II, as described in the International Electrotechnical Commission (IEC) Standard IEC 60664. Most

measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or

to voltage sources with high transient over-voltages. Measurement Category II connections require protection for high transient

over-voltages often associated with local AC mains connections. Assume all measurement, control, and data I/O connections are

for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30V RMS, 42.4V peak, or 60VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock.

If the circuit is capable of operating at or above 1000 volts, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to

limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

12/06

Page 6

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground.

Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the voltage being

measured.

The instrument and accessories must be used in accordance with its specifications and operating instructions or the safety of the

equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating

information, and as shown on the instrument or test fixture panels, or switching card.

When fuses are used in a product, replace with same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to safety earth ground using the wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of

normal and common mode voltages. Use standard safety precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

The WARNING heading in a manual explains dangers that might result in personal injury or death. Always read the associated

information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could damage the instrument. Such damage may invalidate the

warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits, including the power transformer,

test leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety

approvals, may be used if the rating and type are the same. Other components that are not safety related may be purchased

from other suppliers as long as they are equivalent to the original component. (Note that selected parts should be purchased only

through Keithley Instruments to maintain accuracy and functionality of the product.) If you are unsure about the applicability of a

replacement component, call a Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that consist of a circuit board with

no case or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled

according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the

factory for proper cleaning/servicing.

Page 7

Table of Contents

Section Topic Page

1 Introduction............................................................................................. 1-1

Introduction ................................................................................................. 1-2

Features ............................................................................................... 1-2

Applications.......................................................................................... 1-2

Safety symbols and terms .......................................................................... 1-2

Specifications.............................................................................................. 1-3

Unpacking and inspection........................................................................... 1-3

Inspection for damage.......................................................................... 1-3

Shipment contents ............................................................................... 1-3

Instruction manual................................................................................ 1-3

Repacking for shipment........................................................................ 1-4

Supporting software.................................................................................... 1-4

Programming library KDIO-DRVR........................................................ 1-4

KDAQ-LVIEW LabVIEW® driver .......................................................... 1-4

2 Installation............................................................................................... 2-1

Introduction ................................................................................................. 2-2

Handling precautions .................................................................................. 2-2

PXI configuration ........................................................................................ 2-2

Plug and play ....................................................................................... 2-2

Configuration........................................................................................ 2-2

Troubleshooting.................................................................................... 2-2

Installation................................................................................................... 2-3

Jumper description ..................................................................................... 2-5

Termination boards connection................................................................... 2-6

PCB layout.................................................................................................. 2-7

3 Operation and Connection .................................................................. 3-1

Digital I/O ports........................................................................................... 3-2

Introduction ......................................................................................... 3-2

8255 Mode 0 ........................................................................................ 3-2

Special function of the DIO signals ..................................................... 3-2

Digital I/O port programming ............................................................... 3-2

Control word......................................................................................... 3-2

Power on configuration ....................................................................... 3-3

Output data concern............................................................................. 3-4

Timer/counter operation.............................................................................. 3-4

Introduction ......................................................................................... 3-4

General purpose timer/counter ............................................................ 3-4

Cascaded 32 Bits Timer ..................................................................... 3-5

Event counter and edge control ........................................................... 3-5

Interrupt multiplexing .................................................................................. 3-5

Architecture .......................................................................................... 3-5

IRQ level setting................................................................................... 3-5

Dual interrupts concerns ...................................................................... 3-6

Interrupt source control ........................................................................ 3-6

12V and 5V power supply ......................................................................... 3-7

Connector pin assignment.......................................................................... 3-7

Pin assignment of Model KPXI-DIO-48................................................ 3-7

Page 8

Table of Contents KPXI 48-Channel General Purpose Card User’s Manual

Section Topic Page

4 Registers .................................................................................................. 4-1

Introduction ................................................................................................. 4-2

PCI PnP registers ................................................................................. 4-2

I/O address map ................................................................................... 4-2

Appendix Topic Page

A KDIO-DRVR User’s Guide ................................................................... A-1

Introduction to KDIO-DRVR ....................................................................... A-2

About the KDIO-DRVR software.......................................................... A-2

KDIO-DRVR hardware support............................................................ A-2

KDIO-DRVR language support............................................................ A-2

KDIO-DRVR overview ................................................................................ A-3

General configuration function group .................................................. A-3

Actual sampling rate function group .................................................... A-4

Analog output function group............................................................... A-4

Digital input function group .................................................................. A-4

Digital output function group ................................................................ A-6

Timer/counter function group............................................................... A-7

DIO function group .............................................................................. A-8

Creating a KDIO-DRVR application ........................................................... A-9

Contiguous memory allocation in driver for continuous operation....... A-9

Fundamentals of building Windows XP/2000 Application.......................... A-9

Microsoft® Visual Basic (Version 6.0) .................................................. A-9

Using Microsoft Visual Basic.NET ...................................................... A-11

Microsoft Visual C/C++....................................................................... A-11

KDIO-DRVR application hints ................................................................... A-11

Digital input programming hints ......................................................... A-12

Digital output programming hints....................................................... A-17

DAQ event message programming hints........................................... A-21

Interrupt event message programming hints ..................................... A-22

Continuous data transfer in KDIO-DRVR ................................................. A-23

Continuous data transfer mechanism................................................ A-23

Double-buffered / multiple-buffered DI operation............................... A-23

KDIO-DRVR utilities for Win32................................................................. A-25

KDIO-DRVR configuration utility (configdrv)...................................... A-25

KDIO-DRVR data file converter utility (KIDAQCvt)............................ A-26

B KDIO-DRVR Function Reference....................................................... B-1

Function description................................................................................... B-2

Data types............................................................................................ B-2

Function reference............................................................................... B-2

Status Codes............................................................................................ B-38

Data file format......................................................................................... B-40

Header............................................................................................... B-40

ChannelRange................................................................................... B-41

Data Block ......................................................................................... B-42

Function Support...................................................................................... B-43

C KIDAQ®-LabVIEW Compatible Interface Guide............................. C-1

Introduction to KIDAQ®-LabVIEW ............................................................. C-2

Overview.............................................................................................. C-2

Using KIDAQ LabVIEW VIs in LabVIEW............................................. C-2

KIDAQ LabVIEW Programming........................................................... C-3

Device Driver Handling .............................................................................. C-4

Windows XP/2000 Device Driver......................................................... C-4

Driver Utility ......................................................................................... C-4

KIDAQ Utilities ........................................................................................... C-4

KIDAQ Registry/Configuration utility.................................................... C-4

ii KPXI-DIO-900-01 Rev. A / January 2007

Page 9

KPXI 48-Channel General Purpose Card User’s Manual Table of Contents

Appendix Topic Page

C KIDAQ®-LabVIEW Compatible Interface Guide (continued)

KIDAQ Device Browser ....................................................................... C-4

KIDAQ LabVIEW VIs Overview.................................................................. C-5

Analog Input VIs .................................................................................. C-6

Analog Output VIs................................................................................ C-6

Digital I/O VIs....................................................................................... C-7

Timer/Counter VIs................................................................................ C-7

Calibration and Configuration VIs ........................................................ C-8

Error Handler VI................................................................................... C-8

Distribution of Applications......................................................................... C-8

Windows XP/2000 ............................................................................... C-8

D KIDAQ®-LabVIEW Compatible Function Reference..................... D-1

Introduction ................................................................................................ D-2

Hardware support....................................................................................... D-2

KPXI-DIO series: ................................................................................. D-2

KPXI-DAQ series: ................................................................................ D-2

Digitizer series: .................................................................................... D-2

Analog input VIs......................................................................................... D-3

Easy analog input VIs.......................................................................... D-3

Intermediate analog input VIs.............................................................. D-7

Analog output VIs..................................................................................... D-21

Easy analog output VIs...................................................................... D-21

Intermediate analog output VIs.......................................................... D-24

Advanced analog output VIs.............................................................. D-32

Digital I/O VIs ........................................................................................... D-33

Easy Digital I/O VIs............................................................................ D-33

Intermediate Digital I/O VIs................................................................ D-37

Advanced Digital I/O VIs.................................................................... D-45

Counter VIs .............................................................................................. D-46

Easy Counter VIs .............................................................................. D-46

Intermediate Counter VIs .................................................................. D-50

Advanced Counter VIs ...................................................................... D-63

Calibration and Configuration VIs ............................................................ D-67

Calibration VIs .................................................................................. D-67

Other Calibration and Configuration VIs............................................ D-68

Service VIs ............................................................................................... D-70

Error Codes ............................................................................................. D-71

AI Range Codes ...................................................................................... D-73

AI Data Format ....................................................................................... D-76

Service Form

KPXI-DIO-900-01 Rev. A / January 2007 iii

Page 10

Table of Contents KPXI 48-Channel General Purpose Card User’s Manual

This page left blank intentionally.

iv KPXI-DIO-900-01 Rev. A / January 2007

Page 11

List of Figures

Section Figure Title Page

2 Figure 2-1 Typical PXI module installation...................................................... 2-4

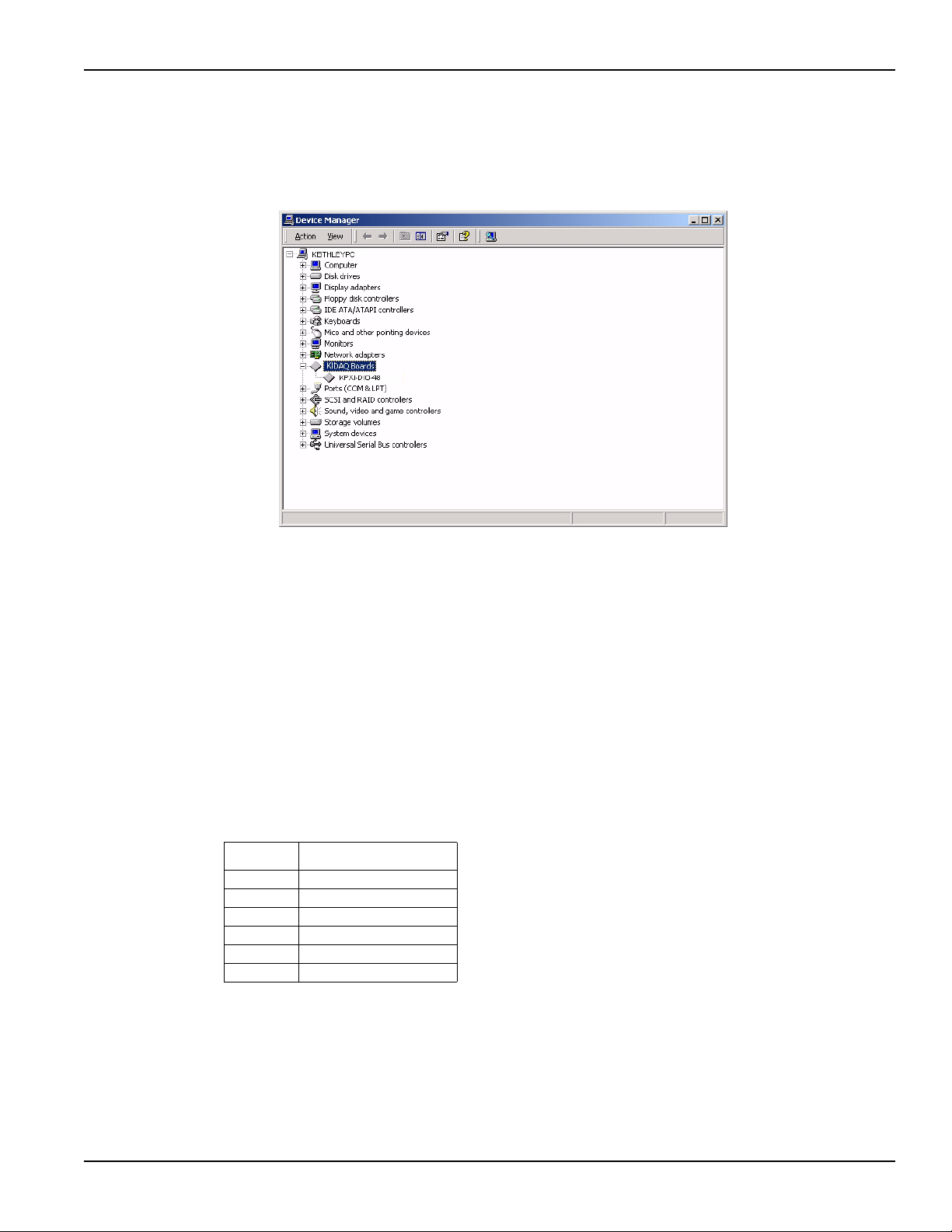

Figure 2-2 Device manager (successful installation) ...................................... 2-5

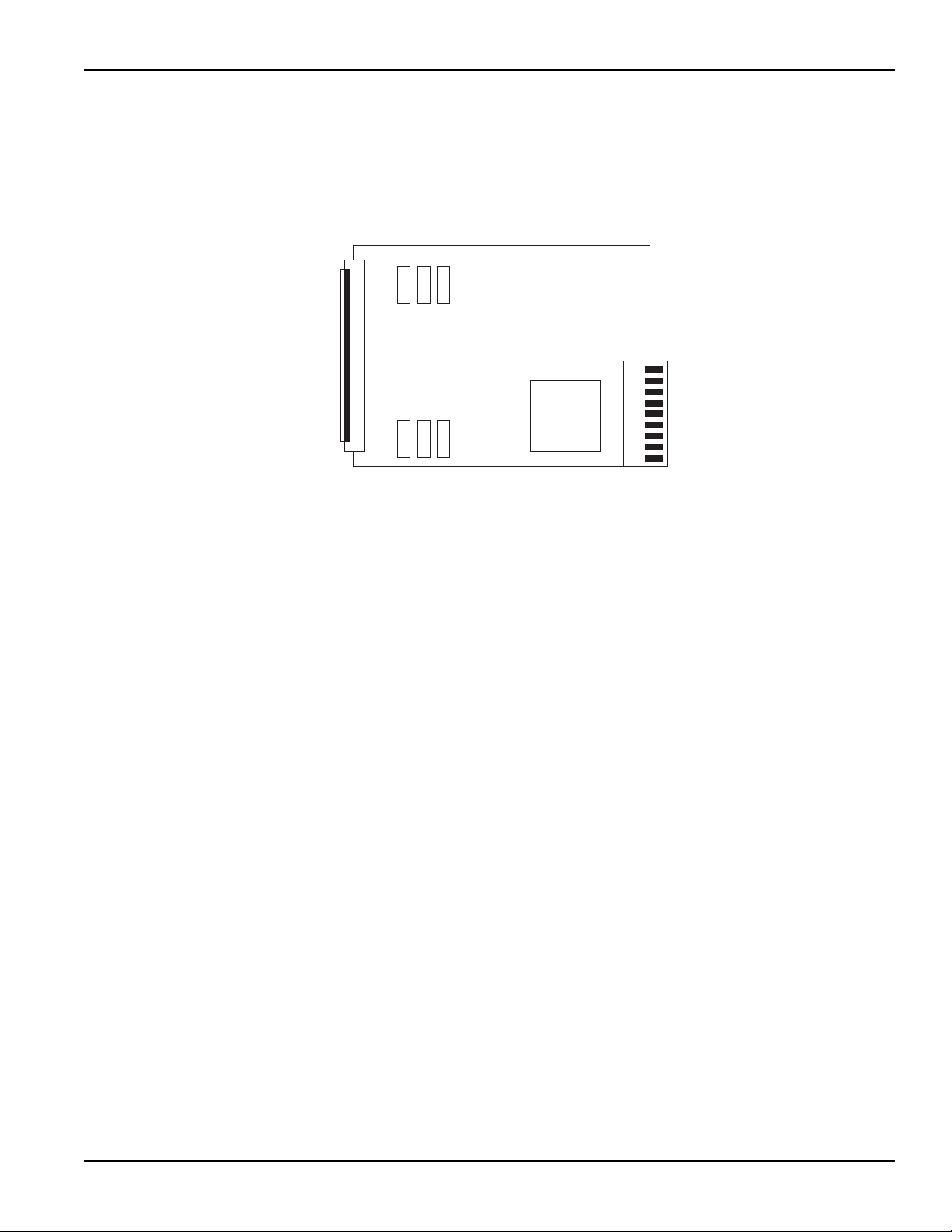

Figure 2-3 Model KPXI-DIO-48 PCB Layout................................................... 2-7

3 Figure 3-1 Control Word Format .................................................................... 3-3

Figure 3-2 Timer/counter system of Model KPXI-DIO-48................................ 3-4

Figure 3-3 Dual Interrupt System Model KPXI-DIO-48 ................................... 3-5

Appendix Figure Title Page

A Figure A-1 Open Project dialog box .............................................................. A-10

Figure A-2 Basic KDIO-DRVR building blocks .............................................. A-12

Figure A-3 One-shot digital input programming............................................. A-13

Figure A-4 Synchronous continuous digital input programming.................... A-14

Figure A-5 Non-multiple-buffered asynchronous continuous digital input ..... A-15

Figure A-6 Multiple-buffered asynchronous continuous digital input ............. A-16

Figure A-7 Synchronous continuous digital output programming.................. A-18

Figure A-8 Asynchronous continuous digital output programming ................ A-18

Figure A-9 Pattern generation digital output programming ........................... A-19

Figure A-10 Multiple-buffered asynchronous continuous digital output ........... A-20

Figure A-11 Double/multiple buffer mode principle ......................................... A-24

Figure A-12 Driver configuration window......................................................... A-25

Figure A-13 DAQ File Conversion Utility ......................................................... A-26

Figure A-14 Loading source binary data file.................................................... A-27

B Figure B-1 TOGGLE_OUTPUT mode timing .................................................. B-4

Figure B-2 PROG_ONE_SHOT mode timing.................................................. B-4

Figure B-3 RATE_GENERATOR mode timing ................................................ B-5

Figure B-4 SQ_WAVE_RATE_GENERATOR mode timing............................. B-5

Figure B-5 SOFT_TRIG mode timing .............................................................. B-5

Figure B-6 HARD_TRIG mode timing ............................................................. B-5

Figure B-7 DAQ File Conversion Utility ......................................................... B-42

C Figure C-1 Function Browser Options ............................................................. C-2

Figure C-2 Functions palette ........................................................................... C-3

Figure C-3 Keithley PXI Devices Explorer....................................................... C-5

D Figure D-1 Analog input palette ....................................................................... D-3

Figure D-2 Analog output palette................................................................... D-21

Figure D-3 Digital I/O palette ......................................................................... D-33

Page 12

List of Figures KPXI 48-Channel General Purpose Card User’s Manual

This page left blank intentionally.

vi KPXI-DIO-900-01 Rev. A / January 2007

Page 13

List of Tables

Section Table Title Page

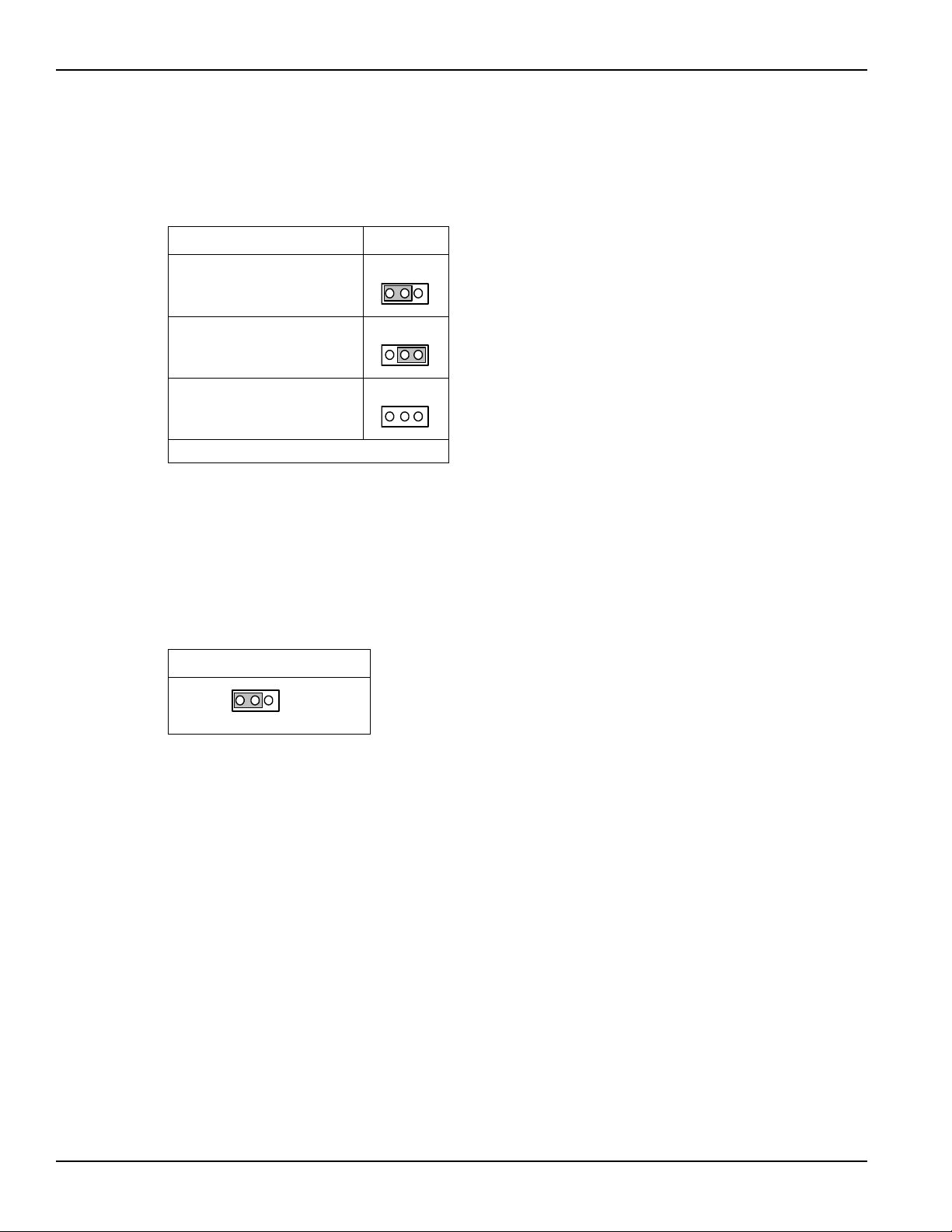

2 Table 2-1 Jumpers and Port names list ......................................................... 2-5

Table 2-2 JA1 jumper setting ......................................................................... 2-6

Table 2-3 JP1 12V Power Supply Configuration........................................... 2-6

3 Table 3-1 I/O Port Names.............................................................................. 3-2

Table 3-2 Summary of control word (D0 - D4)............................................... 3-3

Table 3-3 ISC register format......................................................................... 3-6

Table 3-4 IRQ Trigger conditions................................................................... 3-6

Table 3-5 Pinout and power signals of Model KPXI-DIO-48.......................... 3-7

4 Table 4-1 Model KPXI-DIO-48 I/O Address Map ........................................... 4-2

Appendix Table Title Page

B Table B-1 Suggested data types.................................................................... B-2

Table B-2 Channel_Pn data format.............................................................. B-16

Table B-3 Status codes returned by KDIO-DRVR........................................ B-38

Table B-4 Data file header ........................................................................... B-40

Table B-5 Data structure of ChannelRange unit .......................................... B-41

Table B-6 KDIO-DRVR model function ........................................................ B-43

D Table D-1 KI AI acquire waveform.................................................................. D-3

Table D-2 KI AI acquire waveforms ................................................................ D-4

Table D-3 KI AI sample channel..................................................................... D-6

Table D-4 KI AI sample channels ................................................................... D-6

Table D-5 KI AI clear ...................................................................................... D-7

Table D-6 KI AI config .................................................................................... D-9

Table D-7 2-byte binary array....................................................................... D-12

Table D-8 Scaled and Binary Arrays ............................................................ D-14

Table D-9 Scaled Array ................................................................................ D-16

Table D-10 KI AI single scan .......................................................................... D-17

Table D-11 KI AI start ..................................................................................... D-19

Table D-12 KI AO generate waveform ........................................................... D-22

Table D-13 KI AO generate waveforms.......................................................... D-22

Table D-14 KI AO update channel.................................................................. D-23

Table D-15 KI AO update channels................................................................ D-24

Table D-16 KI AO clear .................................................................................. D-25

Table D-17 KI AO Config................................................................................ D-25

Table D-18 KI AO start ................................................................................... D-27

Table D-19 KI AO wait.................................................................................... D-28

Table D-20 KI AO write binary array............................................................... D-29

Table D-21 KI AO write binary array scaled array.......................................... D-30

Table D-22 KI AO Trigger and Gate Config.................................................... D-32

Table D-23 KI Read from Digital Line............................................................. D-34

Table D-24 KI Read from Digital Port............................................................. D-34

Page 14

List of Tables KPXI 48-Channel General Purpose Card User’s Manual

Appendix Table Title Page

D Table D-25 KI Write to Digital Line................................................................. D-35

Table D-26 KI Write to Digital Port................................................................. D-36

Table D-27 KI DIO Clear................................................................................ D-37

Table D-28 KI DIO Config .............................................................................. D-38

Table D-29 KI DIO Read................................................................................ D-40

Table D-30 KI DIO Start................................................................................. D-42

Table D-31 KI DIO Write ................................................................................ D-43

Table D-32 KI DIO Port Config ...................................................................... D-45

Table D-33 KI Count Events or Time ............................................................. D-46

Table D-34 KI Generate Delayed Pulse......................................................... D-47

Table D-35 KI Generate Pulse-Train.............................................................. D-48

Table D-36 KI Measure Pulse-Width or Period.............................................. D-49

Table D-37 KI Continuous Pulse Generator Config ....................................... D-50

Table D-38 KI Counter Divider Config ........................................................... D-52

Table D-39 KI Counter Read ......................................................................... D-53

Table D-40 KI Counter Start........................................................................... D-54

Table D-41 KI Counter Stop........................................................................... D-55

Table D-42 KI Delayed Pulse Generator Config ............................................ D-56

Table D-43 KI Down Counter or Divider Config............................................. D-58

Table D-44 KI Event or Time Counter Config ................................................ D-59

Table D-45 KI Pulse-Width or Period Measurement Config .......................... D-61

Table D-46 KI UpDown Counter Config......................................................... D-62

Table D-47 KI ICTR Control........................................................................... D-63

Table D-48 KI KPXI-DAQ series devices and Digitizer Series Calibrate ...... D-67

Table D-49 KI Route Signal .......................................................................... D-68

Table D-50 KI SSI Control ............................................................................ D-69

Table D-51 KI Error Handler ......................................................................... D-70

Table D-52 Error Codes: KIDAQ LabVIEW VIs ............................................. D-71

Table D-53 Analog Input Range .................................................................... D-73

Table D-54 Valid analog input ranges (specified by module)......................... D-75

Table D-55 Analog Input data format (by Model)........................................... D-76

viii KPXI-DIO-900-01 Rev. A / January 2007

Page 15

In this section:

Top ic Pa ge

Introduction......................................................................................... 1-2

Safety symbols and terms .............................................................. 1-2

Specifications..................................................................................... 1-3

Unpacking and inspection .............................................................. 1-3

Section 1

Introduction

Features ........................................................................................... 1-2

Applications ...................................................................................... 1-2

Inspection for damage ...................................................................... 1-3

Shipment contents............................................................................ 1-3

Instruction manual ............................................................................ 1-3

Repacking for shipment.................................................................... 1-4

Supporting software ......................................................................... 1-4

Programming library KDIO-DRVR .................................................... 1-4

KDAQ-LVIEW LabVIEW® driver....................................................... 1-4

Page 16

Section 1: Introduction KPXI 48-Channel General Purpose Card User’s Manual

Introduction

The Model KPXI-DIO-48 is a general purpose, 48 channel digital input / output (DIO) product. The

KPXI-DIO-48 emulates two industry standard Programmable Peripheral Interface (PPI) chips

operated under mode zero configuration. The cards are compatible in hardware connections as

well as software programming.

Each PPI connector has 3 ports: PA, PB, and PC. The PC can also be subdivided into 2 nibblewide (4-bit) ports - PC Upper and PC Low. Each connector is corresponding to one PPI chip with

24 DIO points. The Model KPXI-DIO-48 is equipped with one 100-pin SCSI-type connector.

Features

Model KPXI-DIO-48 products provide the following advanced features:

Digital I/O ports

• 48 TTL/DTL compatible digital I/O lines

• Emulates industry standard mode 0 of 8255 PPI

• Buffered circuits for higher driving

• Output status read-back

Timer/counter and interrupt system

• A 32 bit timer to generate watchdog timer interrupt

• A 16 bit event counter to generate event interrupt

• Programmable interrupt source

• Dual interrupt system

Miscellaneous

• On board fuses that can be reset protect the power supply from external devices

Applications

• Programmable mixed digital input & output

• Industrial monitoring and control

• Digital I/O control

• Contact closure, switch/keyboard monitoring

• Useful with A/D and D/A to implement a data acquisition & control system

Safety symbols and terms

The following symbols and terms may be found on the KPXI DIO series module or used in this

manual.

The symbol indicates that the user should refer to the operating instructions located in the

!

manual.

The symbol shows that high voltage may be present on the terminal(s). Use standard safety

precautions to avoid personal contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to

prevent burns.

1-2 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 17

KPXI 48-Channel General Purpose Card User’s Manual Section 1: Introduction

The WARNING heading used in this manual explains dangers that might result in personal injury

or death. Always read the associated information very carefully before performing the indicated

procedure.

The CAUTION heading used in this manual explains hazards that could damage the unit. Such

damage may invalidate the warranty.

Specifications

Refer to the product data sheet for updated KPXI DIO card specifications. Check the Keithley

Instruments website at www.keithley.com for the latest updates to the specifications.

Unpacking and inspection

Inspection for damage

CAUTION Your KPXI DIO series module contains electro-static sensitive components

that can be easily be damaged by static electricity.

Therefore, handle the card on a grounded anti-static mat. The operator should

be wearing an anti-static wristband, grounded at the same point as the

antistatic mat.

The KPXI General Purpose DIO series module was carefully inspected electrically and

mechanically before shipment.

Inspect the module carton for obvious damages. Shipping and handling may damage the module.

Make sure there are no shipping and handling damages on the module’s carton before continuing.

After opening the card module carton, extract the system module and place it only on a grounded

anti-static surface with component side up. Save the original packing carton for possible future

shipment.

Again, inspect the module for damages. Report any damage to the shipping agent immediately.

Shipment contents

The following items are included with every Model KPXI DIO series order:

• Model KPXI DIO series module

• CD containing required software and manuals

Instruction manual

A CD-ROM containing this User’s Manual and required software is included with each Model KPXI

General Purpose DIO series order. If a hardcopy of the Model KPXI-DIO Series User’s Manual is

required, you can order the Manual Package (Keithley Instruments Part Number Model KPXI-DIO900-01). The Manual Package includes an instruction manual and any pertinent addenda.

Always check the Keithley Instruments’ website at www.keithley.com for the latest revision of the

manual. The latest manual can be downloaded (in PDF format) from the website.

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 1-3

Page 18

Section 1: Introduction KPXI 48-Channel General Purpose Card User’s Manual

Repacking for shipment

Should it become necessary to return the Model KPXI General Purpose DIO series module for

repair, carefully pack the unit in its original packing carton or the equivalent, and follow these

instructions:

• Call Keithley Instruments’ repair department at 1-888-KEITHLEY (1-888-534-8453) for a

Return Material Authorization (RMA) number.

• Let the repair department know the warranty status of the Model KPXI General Purpose

DIO series module.

• Write ATTENTION REPAIR DEPARTMENT and the RMA number on the shipping label.

• Complete and include the Service Form located at the back of this manual.

Supporting software

This section contains information on provided software. Keithley Instruments’ provides versatile

software drivers and packages for different systems. Keithley Instruments not only provides

programming libraries such as DLL’s for most Windows

software packages such as LabVIEW.

All software options are included in the Keithley Instruments’ CD.

1

®

based systems, but also drivers for other

Programming library KDIO-DRVR

KDIO-DRVR includes device drivers and DLL’s for Windows XP® and Windows 2000®. Therefore,

all applications developed with KDAQ-DRVR are compatible on Windows XP/2000. The

developing environment can be VB, VC++, BC5, or any Windows programming language that

allows calls to a DLL. Documentation includes a User's Guide (refer to

User’s Guide), and a Function Reference (refer to Appendix B: KDIO-DRVR Function Reference).

KDAQ-LVIEW LabVIEW® driver

KDAQ-LVIEW contains the VI’s, which are used to interface with National Instrument's Lab-VIEW®

software package. The KDAQ-LVIEW supports Windows XP/2000. The LabVIEW

shipped free with the board — you can install and use them without a license. Documentation

includes an Interface Guide (refer to

and an interface Function Reference (refer to Appendix D: KIDAQ®-LabVIEW Compatible

Function Reference).

Appendix C: KIDAQ®-LabVIEW Compatible Interface Guide),

Appendix A: KDIO-DRVR

®

driver is

1. National Instruments™, NI, and LabVIEW are trademarks of the National Instruments Corporation.

1-4 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 19

In this section:

Top ic Pa ge

Introduction......................................................................................... 2-2

Handling precautions ....................................................................... 2-2

PXI configuration............................................................................... 2-2

Installation........................................................................................... 2-3

Jumper description........................................................................... 2-5

Section 2

Installation

Plug and play.................................................................................... 2-2

Configuration .................................................................................... 2-2

Troubleshooting................................................................................ 2-2

Termination boards connection..................................................... 2-6

PCB layout........................................................................................... 2-7

Page 20

Section 2: Installation KPXI 48-Channel General Purpose Card User’s Manual

Introduction

This section contains information about handling and installing Keithley Instruments’ KPXI series

cards:

• Handling precautions

• PXI configuration

• Installation

• Jumper description

• Termination boards connection

• PCB layout

Handling precautions

CAUTION Use care when handling the KIDAQ

When handling, make sure to observe the following guidelines:

• Only handle the card on a grounded anti-static mat.

• Wear an an anti-static wristband that is grounded at the same point as the anti-static mat.

PXI configuration

Plug and play

As a plug and play component, the board requests an interrupt number via its cPCI controller. The

system BIOS responds with an interrupt assignment based on the board information and system

parameters. These system parameters are determined by the installed drivers and the hardware

load recognized by the system. If this is the first time a KIDAQ

on your Windows

detailed information.

Configuration

Configuration is done on a board-by-board basis for all PCI boards on your system. Configuration

is controlled by the system and software. There is no jumper setting required (or available) for

base address, DMA, and interrupt IRQ.

®

KPXI series cards. KIDAQ® KPXI series

cards contain electro-static sensitive components that can be easily damaged

by static electricity.

®

®

system, a hardware driver needs to be installed. Refer to Installation for

KPXI series card will be installed

The configuration is not static, but is subject to change with every boot of the system as new

boards are added or removed.

Troubleshooting

If your system doesn't boot or if you experience erratic operation with your PCI board in place, it's

likely caused by an interrupt conflict (perhaps the BIOS Setup is incorrectly configured). In

general, the solution, is to consult the BIOS documentation that came with your system.

2-2 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 21

KPXI 48-Channel General Purpose Card User’s Manual Section 2: Installation

Installation

Step 1. Install driver software

Windows® will find the new module automatically. If this is the first time a KPXI series digital I/O

card has been installed, a hardware driver needs to be installed. Use the following installation

procedure as a guide.

NOTE Keithley Instruments controllers are pre-loaded with the necessary drivers.

For Windows XP/2000:

1. Insert the CD shipped with the module. The CD should auto load. From the base menu

install the KDIO-DRVR. This is the hardware driver that recognizes the KPXI series

modules. If the CD does not auto load run, then under x:\KDIO-DRVR\DISK1\, you will find

SETUP.EXE (x is the drive letter of your CDROM). This will run the CD menu. On the CD

menu, click the driver for your model to install.

2. When you complete driver installation, turn off the system.

Step 2. Inspect module

Keeping the “Handling precautions” information in mind, inspect the module for damage. With the

module placed on a firm flat surface, press down on all socketed IC's to make sure that they are

properly seated.

If the module does not pass the inspection, do not proceed with the installation.

CAUTION Do not apply power to the card if it has been damaged.

The card is now ready for installation.

Step 3. Install module

Remove power from the system and install the KPXI card in an available slot.

The PXI connectors are rigid and require careful handling when inserted and removed. Improper

handling of modules can easily damage the backplane.

To insert the module into a PXI chassis, use the following procedure as a guide:

1. Read through this manual and setup required jumpers (as needed). Refer to Jumper

description for additional information.

2. Turn off the system.

3. Align the module's edge with the card guide in the PXI chassis.

4. Slide the module into the chassis until resistance is felt from the PXI connector.

5. Push the ejector upwards and fully insert the module into the chassis. Once inserted, a

"click" can be heard from the ejector latch.

6. Tighten the screw on the front panel.

7. Turn on the system.

To remove a module from a PXI chassis, use the following procedure as a guide:

1. Turn off the system.

2. Loosen the screw on the front panel.

3. Push the ejector downwards and carefully remove the module from the chassis.

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 2-3

Page 22

Section 2: Installation KPXI 48-Channel General Purpose Card User’s Manual

Figure 2-1

Typical PXI module installation

Typical PXI

chassis

Card guide

Front panel

screw

Modules edge

Ejector latch

Step 4. Verify installation

When the system is turned on for the first time with a new module present (or a module in a new

slot), Windows Add New Hardware Wizard attempts to locate the correct driver. If it cannot find

the correct driver, even after you have loaded the driver above in Step 1, then force the Add New

Hardware Wizard to look in Windows system32 directory. The driver files should be in this

location. If they are not, shutdown the system, remove the module, and restart the installation

process.

When the Add New Hardware Wizard finishes, the window will verify whether or not installation

was successful. To confirm if the module is installed correctly at a later time, use Windows Device

Manager. In the Device Manager under KIDAQ Boards, look for a device name matching the

model number of the newly installed board (see

installation is complete. If the board appears with a exclamation point or warning in Device

Manager, the installation was unsuccessful. If unsuccessful, use Device Manager to update the

2-4 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Figure 2-2 for an example). If it is found,

Page 23

KPXI 48-Channel General Purpose Card User’s Manual Section 2: Installation

driver or un-install the module, power down the system, remove the module, and attempt

installation again from Step 1.

Figure 2-2

Device manager (successful installation)

Jumper description

Model KPXI-DIO-48 DIO cards are plug-and-play, which makes it unnecessary to setup the card

configurations to fit the computer system. However, to fit users’ versatile operation environment,

there are still a few jumpers to set the power-on status of ports and the usage of the +12V output

pin.

Power on Status of Ports

For every port on a Model KPXI-DIO-48 card, the power-on status is set as input, therefore, the

voltage could be pulled high, pulled low, or floating. It is dependent on the jumper setting.

Table 2-1 lists jumper reference numbers and corresponding port names.

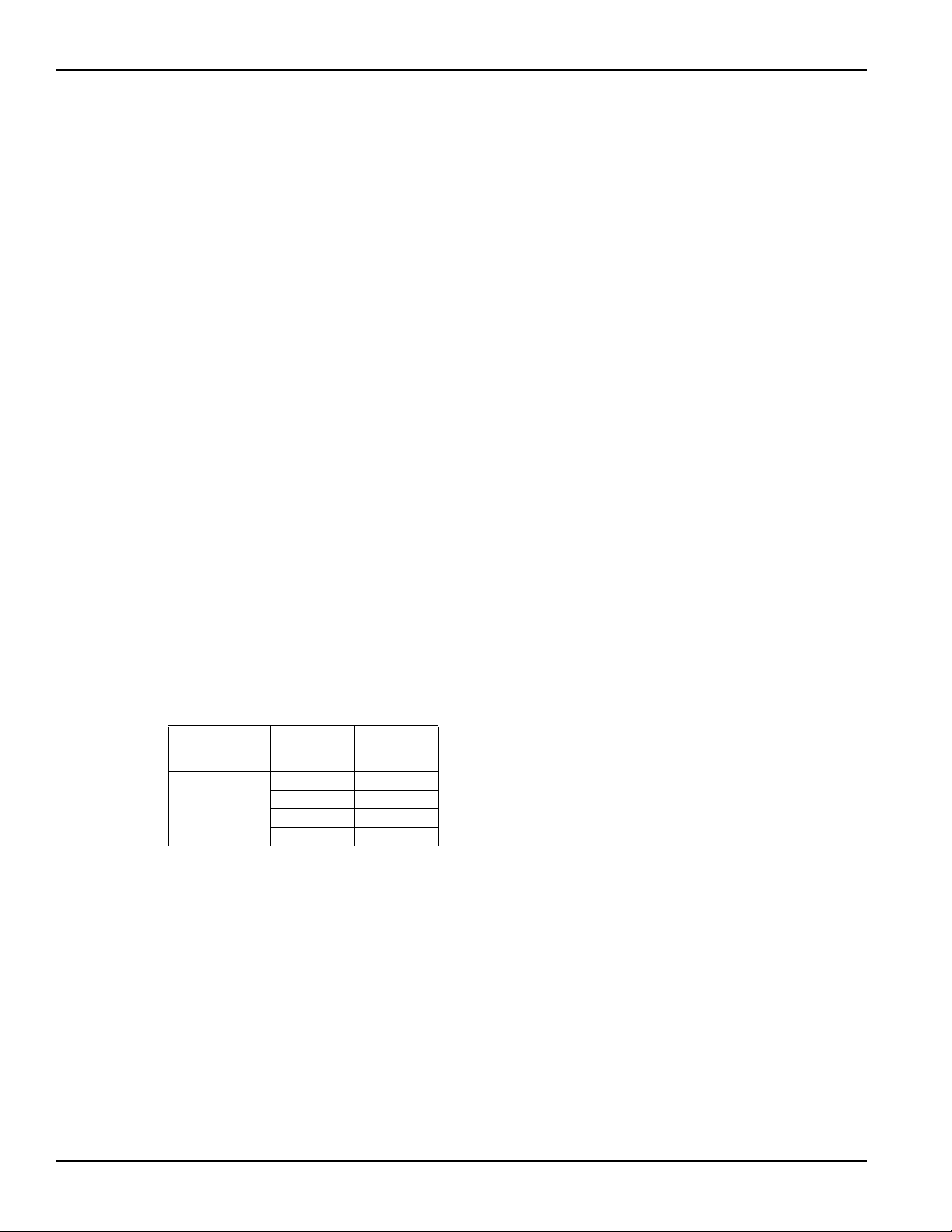

Table 2-1

Jumpers and Port names list

Jumper Port Name

JA1 P1A (Port A of PPI1)

JB1 P1B (Port B of PPI1)

JC1 P1C (Port C of PPI1)

JA2 P2A (Port A of PPI2)

JB2 P2B (Port B of PPI2)

JC2 P2C (Port C of PPI2)

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 2-5

Page 24

Section 2: Installation KPXI 48-Channel General Purpose Card User’s Manual

The physical meaning of all the jumpers are identical. The power on status of each port can be set

independently. The default is to pull all signals high. The following diagram use JA1 as an

example to show the possible configurations.

Table 2-2

JA1 jumper setting

Port A (PPI1 connector) JA1

Power-on pulled high 1 2

Power-on pulled low 1 2

Power-on floating* 1 2

*Jumper is removed

12V Power Supply Configuration

Pin 50 on connector CN1 can be configured as a 12V power supply or ground (refer to Connector

pin assignment contained in Section 3 for detalied connector information). Refer to Table 2-3 for

the 12 volts power supply position. JP1 sets the pin to be 12V or ground. Connections with ground

are set as default. The following diagram shows the setting of JP1, connecting pin 50 to 12 volts.

Table 2-3

JP1 12V Power Supply Configuration

JP1 through JP2

(12V)1 2 (Ground)

Termination boards connection

There are two termination boards that can connect with Model KPXI-DIO-48 for I/O expansion:

Model KPXI-32-DIO-TB

Model KPXI-32-DIO-TB is equipped with a 50-pin ribbon connector. They are used for

general-purpose applications. Two of these can be used together along with a KPXI-DIO-CAB2 to

connect with the KPXI-DIO-48.

Model KPXI-DIO-TB

Model KPXI-DIO-TB is equipped with 100-pin SCSI-type connector. It can connect with the

Model KPXI-DIO-48 via the KPXI-DIO-CAB cable.

2-6 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 25

KPXI 48-Channel General Purpose Card User’s Manual Section 2: Installation

PCB layout

Model KPXI-DIO-48 PCB layout

Figure 2-3

Model KPXI-DIO-48 PCB Layout

PPI2

JC2 JB2

JA2

PCI

Controller

Chip

JA1 JB1 JC1

PPI1

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 2-7

Page 26

Section 2: Installation KPXI 48-Channel General Purpose Card User’s Manual

This page left blank intentionally.

2-8 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 27

In this section:

Top ic Pa ge

Digital I/O ports................................................................................... 3-2

Timer/counter operation.................................................................. 3-4

Section 3

Operation and Connection

Introduction ...................................................................................... 3-2

8255 Mode 0..................................................................................... 3-2

Special function of the DIO signals .................................................. 3-2

Digital I/O port programming ............................................................ 3-2

Control word ..................................................................................... 3-2

Power on configuration .................................................................... 3-3

Output data concern ......................................................................... 3-4

Introduction ...................................................................................... 3-4

General purpose timer/counter ......................................................... 3-4

Cascaded 32 Bits Timer .................................................................. 3-5

Event counter and edge control........................................................ 3-5

Interrupt multiplexing....................................................................... 3-5

Architecture ...................................................................................... 3-5

IRQ level setting ............................................................................... 3-5

Dual interrupts concerns................................................................... 3-6

Interrupt source control..................................................................... 3-6

12V and 5V power supply ............................................................... 3-7

Connector pin assignment.............................................................. 3-7

Pin assignment of Model KPXI-DIO-48 ............................................ 3-7

Page 28

Section 3: Operation and Connection KPXI 48-Channel General Purpose Card User’s Manual

Digital I/O ports

Introduction

Model KPXI-DIO-48 can emulate one/two/four mode 0 configuration of 8255 programmable

peripheral interface (PPI) chips. There are 24 DIO signals for every PPI.

8255 Mode 0

The basic functions of 8255 mode 0 are:

• Two 8-bit I/O ports−−port A (PA) and port B (PB)

• Two nibble-wide (4-bit) ports C−−PC upper and PC lower

• Each port can be used as either input or output

• Outputs are latched whereas inputs are buffered

• 16 different input/output configurations are available

Special function of the DIO signals

Two I/O signals (PC0 and PC3) of PPI1 and PPI2 can be used to generate hardware interrupt.

Refer to

can be used as an input signal of an event counter.

Interrupt multiplexing for details about the interrupt control. In addition, the P1C4 signals

Digital I/O port programming

Users can write the digital output value to or read back the digital signal level from the PPI ports by

using the software library. Here we define the port name in Table 4.1. These port names are used

both in software library and all through this manual.

Table 3-1

I/O Port Names

Connector

Number PPI1 PPI2

P1A P2A

Port

Name

There are four ports on every 8255 PPI, including port A,B,C and the control port. PA, PB and PC

could be written or read but the control port is write only.

P1B P2B

P1C P2C

P1CTRL P2CTRL

Control word

The control word written in the control port is used to setup PA, PB and PC as input or output port.

Figure 3-1 shows the format of the control word. Table 3-2 shows the 16 possible control words

and the respective I/O configurations .

3-2 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 29

KPXI 48-Channel General Purpose Card User’s Manual Section 3: Operation and Connection

Figure 3-1

Control Word Format

D7 D6 D5 D4 D3 D2 D1 D0

X X

X

?

??X

?

1/0 : Input/Output of Port C low nibble

1/0 : Input/Output of Port B

1/0 : Input/Output of Port C high nibble

1/0 : Input/Output of Port A

X : don't care

Table 3-2

Summary of control word (D0 - D4)

Control

Word D4 D3 D1 D0 PORTA

00H 0 0 0 0 O/P O/P O/P O/P

01H 0 0 0 1 O/P O/P O/P I/P

02H 0 0 1 0 O/P O/P I/P O/P

03H 0 0 1 1 O/P O/P I/P I/P

08H 0 1 0 0 O/P I/P O/P O/P

09H 0 1 0 1 O/P I/P O/P I/P

0AH 0 1 1 0 O/P I/P I/P O/P

0BH 0 1 1 1 O/P I/P I/P I/P

10H 1 0 0 0 I/P O/P O/P O/P

11H 1 0 0 1 I/P O/P O/P I/P

12H 1 0 1 0 I/P O/P I/P O/P

13H 1 0 1 1 I/P O/P I/P I/P

18H 1 1 0 0 I/P I/P O/P O/P

19H 1 1 0 1 I/P I/P O/P I/P

1AH 1 1 1 0 I/P I/P I/P O/P

1BH* 1 1 1 1 I/P I/P I/P I/P

PORT C

UPPER

PORT BPORT C

LOWER

* Power on default configuration

Power on configuration

The default configuration after power on, hardware reset or software reset sets all ports as input

ports, therefore the users don’t have to worry about damaging the external devices when system

is power on. In addition, the default signal level can be pulled high or pulled low by setting the

jumpers. Refer to

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 3-3

Jumper description for setting the power on status of the DIO ports.

Page 30

Section 3: Operation and Connection KPXI 48-Channel General Purpose Card User’s Manual

Output data concern

CAUTION Be careful of the initial condition of digital output signals. If users set the con-

trol word as output port after power on, the previous uncertain output value

will be put on the output pins immediately. Therefore, BE SURE TO WRITE A

SAFE VALUE TO THE PORTS BEFORE CONFIGURING THEM AS OUTPUT

PORTS.

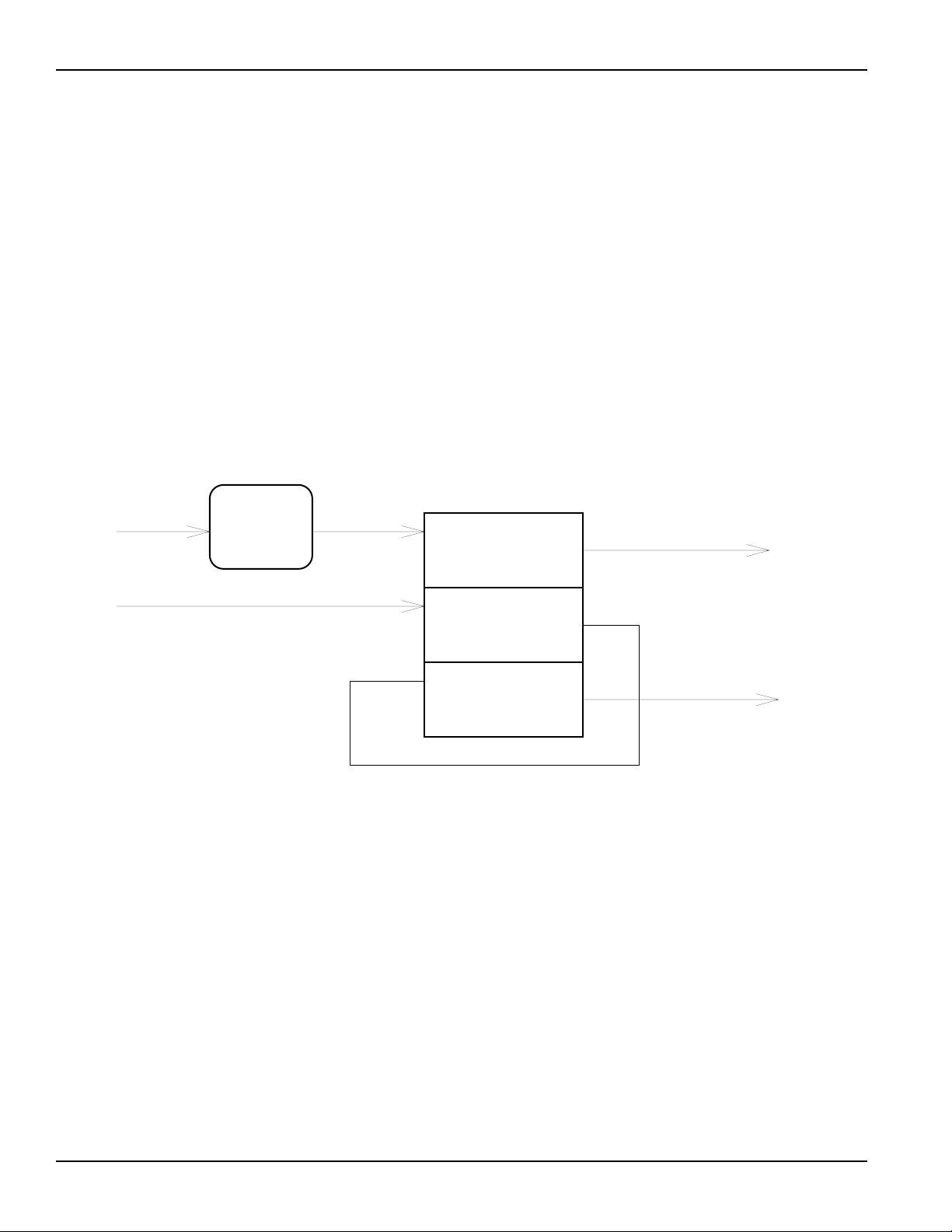

Timer/counter operation

Introduction

One 8254 programmable timer/counter chip is installed Model KPXI-DIO-48. There are three

counters in one 8254 chip and 6 possible operation modes for each counter. The block diagram of

the timer /counter system is shown in

Figure 3-2

Timer/counter system of Model KPXI-DIO-48

Figure 3-2.

P1C4

Trigger

Edge

Control

2 MHz Clock

The timer #1 and timer #2 of the 8254 chip are cascaded as a 32-bit programmable timer. In

software library, the timer #1 and #2 are always set as mode 2 (rate generator).

In software library, the counter #0 is used as an event counter, that is, interrupt on terminal count of

8254 mode 0.

General purpose timer/counter

The counter 0 is a general purpose timer/counter for users applications. It can be used as an event

counter, or used for measuring frequency, or other functions. The following modes are provided by

the 82C54 chip.

'H'

'H'

'H'

8254 Chip

C

Counter #0

G

C

Timer #1

G

C

Timer #2

G

Event IRQ

O

O

Timer IRQ

O

• Mode 0: Interrupt on Terminal Count

• Mode 1: Programmable One-Shot.

• Mode 2: Rate Generator.

• Mode 3: Square Wave Rate Generator.

• Mode 4: Software Triggered Strobe.

• Mode 5: Hardware Triggered Strobe.

3-4 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 31

KPXI 48-Channel General Purpose Card User’s Manual Section 3: Operation and Connection

The 8254 timer/ counter IC occupies 4 I/O address.

Cascaded 32 Bits Timer

The input clock frequency of the cascaded timers is 2MHz. The output of the timer is send to the

interrupt circuit (refer to

timer interrupt frequency is (2MHz)/(2*2)=500KHz and (2MHz)/(65535*65535)= 0.000466Hz

respectively.

Interrupt multiplexing). Therefore, the maximum and minimum watchdog

Event counter and edge control

The counter #0 of the 8254 chip can be used as an event counter. The input of counter #0 is PC4

of PPI1 (P1C4). The counter clock trigger direction (H to L or L to H) is programmable. The gate

control is always enabled. The output is sent to the interrupt system which is named as event IRQ.

If counter #0 is set as 8254 mode 0, the event counter IRQ will trigger when the counter value is

counting down to zero.

Interrupt multiplexing

Architecture

Model KPXI-DIO-48 has a powerful and flexible interrupt multiplexing circuit which is suitable for

many applications. The board can accept

generate two interrupt request signals at the same time and the software can service these two

request signals by ISR. Note that the dual interrupts do not mean that the card occupies two IRQ

levels.

The two interrupt request signals (INT1 and INT2) comes from digital input signals or the timer/

counter output. An interrupt source multiplexer (MUX) is used to select the IRQ sources.

Figure 3-3 shows the interrupt system.

IRQ level setting

There is only one IRQ level requested by this card, although it is a dual interrupt system. The

mother board circuits will transfer INTA# to one of the PC IRQ levels. The IRQ level is set by the

PCI plug and play BIOS and saved in the PCI controller. Users can get the IRQ level setting by

software library.

Figure 3-3

Dual Interrupt System Model KPXI-DIO-48

Dual Interrupts, which means the hardware can

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 3-5

Page 32

Section 3: Operation and Connection KPXI 48-Channel General Purpose Card User’s Manual

Dual interrupts concerns

The PCI controller of Model KPXI-DIO-48 can receive two hardware IRQ sources. However, a PCI

controller can generate only one IRQ to PCI bus, the two IRQ sources must be distinguished by

ISR of the application software if the two IRQs are both used.

The application software can use a function to distinguish which interrupt is inserted. After an ISR

is completed, users must check if another IRQ is also asserted, then clear the current IRQ to allow

the next IRQ coming in.

The two IRQs are named as INT1 and INT2. In Model KPXI-DIO-48, INT1 comes from P1C0,

P1C3 or the event counter interrupt. INT2 comes from P2C0, P2C3 or the timer interrupt. The

sources of INT1 and INT2 is selectable by the Interrupt Source Control (ISC) Register.

Interrupt source control

In the ISC register (offset 0x20), there are four bits to control the IRQ sources of INT1 and INT2.

If the application needs only one IRQ, you can disable one of the IRQ sources by software. If your

application does not need any IRQ source, you can disable both interrupts. However, the PCI

BIOS will still assign an IRQ level to the PCI card and occupy the PC resource if you only disable

the IRQ sources without changing the initial condition of the PCI controller.

It is not recommended to change the initial condition of the PCI card by users‘ own application

software.

Table 3-3 shows the register format of the ISC (address offset 0x20). This register is write only.

The 4 LSBs are used to control the source of INT1 and INT2.

Table 3-3

ISC register format

INT INT1 D3 D2 D1 D0 IRQ Sources IRQ Trigger Condition

1 Disable X X 0 0 INT1 disable --

Mode 1 X X 0 1 ~P1C0 falling edge of P1C0

Mode 2 X X 1 0 P1C0 OR ~P1C3 (see following)

Mode 3 X X 1 1 Event Counter Counter count down to 0

2 Disable 0 0 X X INT2 disable --

Mode 1 0 1 X X ~P2C0 falling edge of P2C0

Mode 2 1 0 X X P2C0 OR ~P2C3 (see following)

Mode 3 1 1 X X Timer Output Timer count down to 0

Then the IRQ sources is set as “P1C0 OR ~P1C3”, the IRQ trigger conditions are summarized in

Table 3-4.

Table 3-4

IRQ Trigger conditions

P1/2C0 P1/2C3 IRQ Trigger Condition

High X PC0=‘H’ disable all IRQ

X Low PC3=‘L’ disable all IRQ

Low 1->0 PC3 falling edge trigger when PC0=L

0->1 High PC0 rising edge trigger when PC3=H

Because the P1/P2C0 and P1/P2C3 are external signals, the users can utilize the combination of

the four signals to generate a proper IRQ.

3-6 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 33

KPXI 48-Channel General Purpose Card User’s Manual Section 3: Operation and Connection

12V and 5V power supply

The maximum current for 5 volts on every connector is 0.5 A. If the load current is larger than 0.5

A, the resistance of re-settable fuses will increase because of rising temperature. The rising

resistance will cause the power supply drop and reduce current. If the overload or short condition

is removed, the fuse will get to normal condition. It is not necessary to repair or re-install the fuse.

The maximum current of 12 volts for all the four connectors is also 0.5 A. The action of the fuse is

the same as which used for +5V power. The limitation is more restrictive than 5V power supply

because the PXI bus can not provide large current.

Connector pin assignment

Pin assignment of Model KPXI-DIO-48

The Model KPXI-DIO-48 is equipped a SCSI-type 100-pin connector. The pin assignment is

described in

Table 3-5

Pinout and power signals of Model KPXI-DIO-48

Table 3-5.

Pin location Pin description

(2) P1A1 (27) P2A1 (52) GND (77) GND

(1)

(2)

(3)

(48)

(49)

(50)

(3) P1A2 (28) P2A2 (53) GND (78) GND

(51)

(4) P1A3 (29) P2A3 (54) GND (79) GND

(52)

(53)

(5) P1A4 (30) P2A4 (55) GND (80) GND

(6) P1A5 (31) P2A5 (56) GND (81) GND

(7) P1A6 (32) P2A6 (57) GND (82) GND

(8) P1A7 (33) P2A7 (58) GND (83) GND

(9) P1B0 (34) P2B0 (59) GND (84) GND

(10)P1B1 (35) P2B1 (60) GND (85) GND

(11)P1B2 (36) P2B2 (61) GND (86) GND

(12) P1B3 (37) P2B3 (62) GND (87) GND

(13) P1B4 (38) P2B4 (63) GND (88) GND

(14) P1B5 (39) P2B5 (64) GND (89) GND

(15) P1B6 (40) P2B6 (65) GND (90) GND

(16) P1B7 (41) P2B7 (66) GND (91) GND

(17) P1C0 (42) P2C0 (67) GND (92) GND

(18) P1C1 (43) P2C1 (68) GND (93) GND

(19) P1C2 (44) P2C2 (69) GND (94) GND

(20) P1C3 (45) P2C3 (70) GND (95) GND

(98)

(99)

(21) P1C4 (46) P2C4 (71) GND (96) GND

(100)

(22) P1C5 (47) P2C5 (72) GND (97) GND

(23) P1C6 (48) P2C6 (73) GND (98) GND

(24) P1C7 (49) P2C7 (74) GND (99) GND

(25) V5V (50) +12V (75) V5V (100) +12V

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 3-7

Page 34

Section 3: Operation and Connection KPXI 48-Channel General Purpose Card User’s Manual

The DIO pin names described in Table 3-5 are specified as PnXb,

where:

P: DIO pin

n: PPI reference number n=1 or 2.

X: port name, X= ‘A’ , ‘B’ or ‘C’

b: bit number of a port, b=0~7

For example, P1C4 means bit 4 of port C on connector PPI1.

NOTE The power supply pins are protected by re-settable fuses. Refer to 12V and 5V power

supply for details of the power supply.

3-8 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 35

In this section:

Top ic Pa ge

Introduction......................................................................................... 4-2

Section 4

Registers

PCI PnP registers ............................................................................. 4-2

I/O address map ............................................................................... 4-2

Page 36

Section 4: Registers KPXI 48-Channel General Purpose Card User’s Manual

Introduction

This section describes the details of the registers and its structure. This information is important

for programmers who want to control the hardware with low-level programming

However, we suggest users become familiar with the PCI interface before starting low-level

programming. In addition, the contents of this section can help users understand how to use

software driver to manipulate this card.

NOTE Direct register access can be difficult to program. All users are encouraged to use the

KDIO-DRVR driver interface instead of direct access to the registers. This section is

included only as a reference for customers who absolutely require the efficiency of

register access.

PCI PnP registers

This PCI card functions as a 32-bit PCI target device to any master on the PCI bus. There are

three types of registers: PCI Configuration Registers (PCR), Local Configuration Registers (LCR)

and registers.

The PCR, which is PCI-bus specifications compliant, is initialized and controlled by the plug & play

(PnP) PCI BIOS. Users may obtain more information on the PCI BIOS specification to better

understand the operation of the PCR. Please contact PCISIG to acquire the specifications of the

PCI interface.

The PCI bus controller PCI-9050 is provided by PLX technology Inc. (www.plxtech.com). For

more information about the LCR, please visit PLX technology’s web site to download relative

information. It is not necessary for users to fully understand the details of the LCR if the software

library provided is used. The PCI PnP BIOS assigns the base address of the LCR. The assigned

address is located at an offset of 14h from the PCR.

Please do not try to modify the base address and interrupt which assigned by the PCI PnP BIOS,

it may cause resource confliction in your system.

I/O address map

All Model KPXI-DIO-48 registers are 8 bits. The users can access these registers only by 8 bits I/

O instructions.

addresses relative to the base address. Please refer to the Section 3 for detailed register

operation.

Table 4-1

Model KPXI-DIO-48 I/O Address Map

Offset Write Read

0x00 P1A P1A

0x01 P1B P1B

0x02 P1C P1C

0x03 P1Ctrl Not used

0x04 P2A P2A

0x05 P2B P2B

0x06 P2C P2C

0x07 P2Ctrl Not used

0x10 Timer/Counter #0 Timer/Counter #0

0x11 Timer/Counter #1 Timer/Counter #1

0x12 Timer/Counter #2 Timer/Counter #2

Table 4-1 shows the registers map, including descriptions and their offset

4-2 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 37

KPXI 48-Channel General Purpose Card User’s Manual Section 4: Registers

Table 4-1 (continued)

Model KPXI-DIO-48 I/O Address Map

Offset Write Read

0x13 Timer/Counter

Mode Control

0x20 ISC: Interrupt

Source Control

0x30 Clear Interrupt Not used

Timer/Counter

Mode Status

Not used

KPXI-DIO-900-01 Rev. A / January 2007 Return to Section Topics 4-3

Page 38

Section 4: Registers KPXI 48-Channel General Purpose Card User’s Manual

This page left blank intentionally.

4-4 Return to Section Topics KPXI-DIO-900-01 Rev. A / January 2007

Page 39

In this appendix:

Top ic Page

Introduction to KDIO-DRVR ............................................................ A-2

About the KDIO-DRVR software.......................................................A-2

KDIO-DRVR hardware support.........................................................A-2

KDIO-DRVR language support......................................................... A-2

KDIO-DRVR overview ....................................................................... A-3

General configuration function group ...............................................A-3

Actual sampling rate function group .................................................A-4

Analog output function group............................................................ A-4