Page 1

KPCMCIA-12AIAOH

Type II PCMCIA Card

User’s Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Hardware

Keithley Instruments, Inc. warrants that, for a period of one (1) year from the date of shipment (3 years for Models 2000, 2001, 2002, 2010 and 2700), the

Keithley Hardware product will be free from defects in materials or workmanship. This warranty will be honored provided the defect has not been caused

by use of the Keithley Hardware not in accordance with the instructions for the product. This warranty shall be null and void upon: (1) any modification of

Keithley Hardware that is made by other than Keithley and not approved in writing by Keithley or (2) operation of the Keithley Hardware outside of the

environmental specifications therefore.

Upon receiving notification of a defect in the Keithley Hardware during the warranty period, Keithley will, at its option, either repair or replace such Keithley Hardware. During the first ninety days of the warranty period, Keithley will, at its option, supply the necessary on site labor to return the product to the condition prior to

the notification of a defect. Failure to notify Keithley of a defect during the warranty shall relieve Keithley of its obligations and liabilities under this warranty.

Other Hardware

The portion of the product that is not manufactured by Keithley (Other Hardware) shall not be covered by this warranty, and Keithley shall have no duty of

obligation to enforce any manufacturers' warranties on behalf of the customer. On those other manufacturers’ products that Keithley purchases for resale,

Keithley shall have no duty of obligation to enforce any manufacturers’ warranties on behalf of the customer.

Software

Keithley warrants that for a period of one (1) year from date of shipment, the Keithley produced portion of the software or firmware (Keithley Software) will

conform in all material respects with the published specifications provided such Keithley Software is used on the product for which it is intended and otherwise in accordance with the instructions therefore. Keithley does not warrant that operation of the Keithley Software will be uninterrupted or error-free and/

or that the Keithley Software will be adequate for the customer's intended application and/or use. This warranty shall be null and void upon any modification

of the Keithley Software that is made by other than Keithley and not approved in writing by Keithley.

If Keithley receives notification of a Keithley Software nonconformity that is covered by this warranty during the warranty period, Keithley will review the

conditions described in such notice. Such notice must state the published specification(s) to which the Keithley Software fails to conform and the manner

in which the Keithley Software fails to conform to such published specification(s) with sufficient specificity to permit Keithley to correct such nonconformity. If Keithley determines that the Keithley Software does not conform with the published specifications, Keithley will, at its option, provide either the

programming services necessary to correct such nonconformity or develop a program change to bypass such nonconformity in the Keithley Software.

Failure to notify Keithley of a nonconformity during the warranty shall relieve Keithley of its obligations and liabilities under this warranty.

Other Software

OEM software that is not produced by Keithley (Other Software) shall not be covered by this warranty, and Keithley shall have no duty or obligation to

enforce any OEM's warranties on behalf of the customer.

Other Items

Keithley warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes, and documentation.

Items not Covered under Warranty

This warranty does not apply to fuses, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow

instructions.

Limitation of Warranty

This warranty does not apply to defects resulting from product modification made by Purchaser without Keithley's express written consent, or by misuse

of any product or part.

Disclaimer of Warranties

EXCEPT FOR THE EXPRESS WARRANTIES ABOVE KEITHLEY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEITHLEY DISCLAIMS ALL WARRANTIES WITH RESPECT TO THE OTHER HARDWARE AND OTHER SOFTWARE.

Limitation of Liability

KEITHLEY INSTRUMENTS SHALL IN NO EVENT, REGARDLESS OF CAUSE, ASSUME RESPONSIBILITY FOR OR BE LIABLE FOR: (1)

ECONOMICAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR EXEMPLARY DAMAGES, WHETHER CLAIMED

UNDER CONTRACT, TORT OR ANY OTHER LEGAL THEORY, (2) LOSS OF OR DAMAGE TO THE CUSTOMER'S DATA OR PROGRAMMING, OR (3) PENALTIES OR PENALTY CLAUSES OF ANY DESCRIPTION OR INDEMNIFICATION OF THE CUSTOMER OR OTHERS FOR

COSTS, DAMAGES, OR EXPENSES RELATED TO THE GOODS OR SERVICES PROVIDED UNDER THIS WARRANTY.

Keithley Instruments, Inc. 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

Sales Offices: BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

4/02

Page 3

KPCMCIA-12AIAOH

Type II PCMCIA Card

User’s Manual

©1999, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, July 2002

Document Number: 98936 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 98936) ........................................................................................ September 1999

Revision B (Document Number 98936) ............................................................................................. July 2002

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

5/02

Page 6

If or is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Page 7

Table of Contents

1 Introduction

Getting started ...................................................................................................................................................... 1-2

Features ................................................................................................................................................................ 1-3

Technical support................................................................................................................................................. 1-4

2 Installation

Hardware setup ....................................................................................................................................................2-2

Software setup......................................................................................................................................................2-2

3 Theory of Operation

Introduction.......................................................................................................................................................... 3-2

DC/DC power supply...........................................................................................................................................3-2

Analog input multiplexer .....................................................................................................................................3-3

Programmable gain control.................................................................................................................................. 3-3

Scan list ................................................................................................................................................................ 3-3

Trigger circuit ......................................................................................................................................................3-4

A/D converter and data FIFO............................................................................................................................... 3-4

Interrupt and status...............................................................................................................................................3-5

Digital I/O ............................................................................................................................................................3-5

A/D state machine................................................................................................................................................ 3-6

D/A circuit............................................................................................................................................................ 3-7

Timer counter....................................................................................................................................................... 3-7

4 I/O Connections

Introduction.......................................................................................................................................................... 4-2

Cable assembly ....................................................................................................................................................4-2

5 Optional Accessories

i

Page 8

A Specifications

B PCMCIA Interface

Introduction .........................................................................................................................................................B-2

Configuration and option register (COR)............................................................................................................B-3

Card configuration and status register (CCSR) ................................................................................................... B-3

C I/O Registers

Introduction .........................................................................................................................................................C-2

Data FIFO register (base + 0)..............................................................................................................................C-3

Data FIFO operation modes ........................................................................................................................C-3

Mode setting ................................................................................................................................................ C-4

FIFO flags.................................................................................................................................................... C-5

Scan list queue register (base + 1, write only).....................................................................................................C-6

Scan list queue programming ...................................................................................................................... C-6

Channel configuration ................................................................................................................................. C-7

Analog input offset correction.....................................................................................................................C-8

Control register (base + 2, write only).................................................................................................................C-8

Clock source ................................................................................................................................................ C-8

Expansion mode ..........................................................................................................................................C-8

A/D interrupt enable .................................................................................................................................... C-8

Trigger mode ............................................................................................................................................... C-9

Trigger source.............................................................................................................................................. C-9

Trigger edge.................................................................................................................................................C-9

Analog trigger threshold..............................................................................................................................C-9

Status register (base + 2, read only) ..................................................................................................................C-10

Digital output register (base + 3, write only) ....................................................................................................C-11

Digital input register (base + 3, read only)........................................................................................................ C-11

Pacer clock (base + 4, + 5, + 6; write only)....................................................................................................... C-12

Command register (base + 7, write only) .......................................................................................................... C-12

Trigger/arm command ............................................................................................................................... C-13

Flush data FIFO command ........................................................................................................................ C-13

Flush scan list queue command.................................................................................................................C-13

Stop A/D command ................................................................................................................................... C-14

Latch timer/counter command................................................................................................................... C-14

Data FIFO program/access control............................................................................................................ C-14

Scan rate selection ..................................................................................................................................... C-15

D/A data port (base + 8, base + 9)..................................................................................................................... C-15

D/A channel output....................................................................................................................................C-15

D/A port interface......................................................................................................................................C-15

D/A update modes ..................................................................................................................................... C-16

Timer/counter port (base + 10, base + 11) ........................................................................................................C-17

Timer/counter operation modes................................................................................................................. C-17

Timer/counter clock source ....................................................................................................................... C-18

Reading the contents of the timer/counter.................................................................................................C-18

Timer divisor or counter modulus ............................................................................................................. C-18

Timer/counter overflow.............................................................................................................................C-18

Auxiliary control register (base + 15, write only) ............................................................................................. C-19

Auxiliary status register (base + 15, read only)................................................................................................. C-20

ii

Page 9

List of Illustrations

3 Theory of Operation

Figure 3-1 State transition diagram of A/D conversion process............................................................................................ 3-6

4 I/O Connections

Figure 4-1 KPCMCIA-12AIAOH PC card D-37 output connector, KCAB-AIAO..............................................................4-3

C I/O Registers

Figure C-1 Pacer clock block diagram ................................................................................................................................ C-12

iii

Page 10

List of Tables

4 I/O Connections

Table 4-1 KPCMCIA-12AIAOH PC card cable mapping ................................................................................................... 4-2

B PCMCIA Interface

Table B-1 PCMCIA configuration registers ........................................................................................................................ B-2

Table B-2 COR bit definitions ............................................................................................................................................. B-3

Table B-3 CCSR bit definitions ........................................................................................................................................... B-3

C I/O Registers

Table C-1 KPCMCIA-12AIAOH PC card register map...................................................................................................... C-2

Table C-2 Data FIFO register bit allocation ........................................................................................................................ C-3

Table C-3 Data FIFO operation mode ................................................................................................................................. C-3

Table C-4 Data FIFO threshold setting................................................................................................................................ C-4

Table C-5 Data FIFO flag status .......................................................................................................................................... C-5

Table C-6 Scan list queue entry bit definitions.................................................................................................................... C-6

Table C-7 Scan list queue programming example 1 ............................................................................................................ C-7

Table C-8 Scan list queue programming example 2 ............................................................................................................ C-7

Table C-9 Control register bit definitions ............................................................................................................................ C-8

Table C-10 Status register bit definitions............................................................................................................................. C-10

Table C-11 Digital output register bit definitions ................................................................................................................ C-11

Table C-12 Digital input register bit definitions .................................................................................................................. C-11

Table C-13 Command register bit definitions...................................................................................................................... C-13

Table C-14 Data FIFO threshold setting .............................................................................................................................. C-14

Table C-15 D/A data port definitions................................................................................................................................... C-15

Table C-16 D/A update modes............................................................................................................................................. C-16

Table C-17 Timer/counter mode .......................................................................................................................................... C-17

Table C-18 Auxiliary control register bit definitions........................................................................................................... C-19

Table C-19 Auxiliary status register bit definitions ............................................................................................................. C-20

v

Page 11

1

Introduction

Page 12

1-2 Introduction KPCMCIA-12AIAOH User’s Manual

Getting started

The KPCMCIA-12AIAOH PC card is a PCMCIA type II data acquisition system with four differential or eight single-ended analog input channels. The number of input channels can be

expanded to 128 with input expansion cards. Each channel has a bipolar input range from ±0.01V

(gain = 1000), ±0.1V (gain =100), ±1V (gain =10), and ±10V (gain = 1) with programmable gains

of 1, 10, 100, and 1000. The KPCMCIA-12AIAOH PC card supports sampling rates up to 100

kHz at either 12-bit or 16-bit resolution.

Equipped with a data FIFO of 2048 samples, the KPCMCIA-12AIAOH PC card can achieve full

speed data acquisition under Windows 95/98 and Windows NT. It also has a scan FIFO of the

same size that supports full-speed, random-order channel scanning and gain selection for all the

input channels (up to 128 channels when using the input expansion cards).

The KPCMCIA-12AIAOH PC card has a 24-bit pacer clock and a programmable divided-by-2,

by-10, or by-100 pre-scaler. The pacer clock can also be used with an external clock source. With

the 10MHz internal clock source, the pacer clock can generate accurate sampling rates from

0.006Hz to 100kHz.

The KPCMCIA-12AIAOH PC cards are also equipped with two independent 12-bit D/A output

channels with a bipolar output range from -5 to +5V. The D/A channels can be updated directly

when writing to the corresponding D/A port (direct mode) or simultaneously when a synchronization signal (timer overflow, gate control goes low to high, or pacer clock fires) comes.

The analog trigger and pre-trigger are two new features added to the KPCMCIA-12AIAOH PC

cards. One of the D/A channels (channel 1) can be used to set up the analog trigger level anywhere

in the full input range of the A/D converter (±10V). The pre-trigger mode, when enabled, keeps

the most recently received data samples in the data FIFO before the actual trigger comes so these

samples can be recorded together with those after the trigger.

The 16-bit timer/counter with auto-reload and read-out latch provides independent timing for the

D/A channels. It can also be used as an independent timer/counter for other purposes. The timer/

counter operates with internal or external clock sources and with internal or external gate control.

Its latched read-out guarantees the integrity whenever the timer/counter’s content is referenced.

The KPCMCIA-12AIAOH PC card also has four digital input and four digital output channels,

all are TTL compatible, which may be used for controlling or monitoring in addition to analog

data acquisition.

The DriverLINX software drivers provided support various programming languages including

Visual C/C++, Visual Basic and Delphi. A Dynamic Link Library (DLL) is provided for all types

of programming languages under Microsoft Windows and Visual Basic Controls (VBX). The

KPCMCIA-12AIAOH PC card also has turn-key software support for TestPoint with optional

software support for LabView.

The KPCMCIA-12AIAOH PC card is packaged with a cable terminating in a 37-pin

D-type female connector. Refer to Section 6 for a description of the connector pin assignments.

For applications requiring discrete wire hook-ups, an optional screw terminal adapter is also

available to convert the D-37 connector into 37 discrete screw terminal blocks.

Page 13

KPCMCIA-12AIAOH User’s Manual Introduction 1-3

Features

The KPCMCIA-12AIAOH PC card offers the following features:

•

12- or 16-bit A/D resolution.

Four differential or eight single-ended analog input channels, expandable to 128 channels.

•

•

Bipolar input range up to ±10V.

Truly programmable gains of 1, 10, 100, and 1000.

•

•

Programmable scan list with up to 2048 channels and gain entries. Selectable scan speed (10,

20, or 40µs).

Data FIFO of 2048 samples.

•

•

24-bit pacer clock with variable pre-scalers to generate sampling rates from 0.006Hz to

100kHz (0 to 100kHz with external clock source).*

Software, TTL, or analog trigger with programmable threshold. Pre-trigger capability up to

•

the size of the data FIFO.

•

Two 12-bit D/A channels with direct or synchronized update.

Additional 16-bit timer/counter with auto-reload, read-out latch, overflow latch, internal/

•

external gate control, and internal/external clock source.

•

Digital input/output channels.

Software drivers for Windows 95/98 and Windows NT, and TestPoint. An optional driver is

•

available for LABView.

*NOTE In “Paced” mode, the same input pin is shared between external clock

and external trigger, hence only one function can be used (not both simultaneously).

Page 14

1-4 Introduction KPCMCIA-12AIAOH User’s Manual

Technical support

Before returning any equipment for repair, call Keithley Instruments, Inc., for technical support

at:

1-888-KEITHLEY

Monday - Friday, 8:00 a.m. - 5:00 p.m., Eastern Time

An applications engineer will help you diagnose and resolve your problem over the telephone.

If a telephone resolution is not possible, the applications engineer will issue you a Return Material

Authorization (RMA) number and ask you to return the equipment. Include the RMA number

with any documentation regarding the equipment.

When returning equipment for repair, include the following information:

•

Your name, address, and telephone number.

The invoice or order number and date of equipment purchase.

•

•

A description of the problem or its symptoms.

The RMA number on the outside of the package.

•

Repackage the equipment using the original anti-static wrapping, if possible, and handle it with

ground protection. Ship the equipment to:

NOTES

ATTN: RMA #_________

Repair Department

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, OH 44139

Telephone 1-888-KEITHLEY

FAX (440) 248-6168

If you are submitting your equipment for repair under warranty, you

must include the invoice number and date of purchase.

To enable Keithley Instruments, Inc., to respond as quickly as possible,

you must include the RMA number on the outside of the package.

Page 15

2

Installation

Page 16

2-2 Installation KPCMCIA-12AIAOH User’s Manual

Hardware setup

To install a KPCMCIA-12AIAOH PC card, insert the adapter into any type II PCMCIA socket.

All other configuration options are determined by the DriverLINX software and operating

system, as discussed in your DriverLINX documentation.

Software setup

Refer to your DriverLINX documentation for a detailed description of the software

installation procedure.

Page 17

3

Theory of Operation

Page 18

3-2 Theory of Operation KPCMCIA-12AIAOH User’s Manual

Introduction

The KPCMCIA-12AIAOH PC card consists of four differential or eight single-ended analog

input channels, each having a bipolar input range of ±0.01V (gain = 1000), ±0.1V (gain = 100),

±1V (gain = 10), or ±10V (gain = 1) with programmable gains of 1, 10, 100, and 1000). The A/

D converter, either 12-bit or 16-bit, can be operated at its top speed of 100,000 samples per second

(10µs per sample).

The A/D converter uses left-justified 2’s complement coding. For the 16-bit version, its output

ranges from -32768 to 32767 as usual. However, the 12-bit version has its 12-bit result occupying

the most significant 12 bits and pads its least significant four bits with zeroes to make a 16-bit

output word for each converted input sample.

The KPCMCIA-12AIAOH PC card can be operated as an I/O device, occupying 16 consecutive

bytes in the I/O address space. It can also be configured to operate via memory mapped I/O. It

fully complies with the PCMCIA standard 2.1 as a type II card. The card does not have any jumpers or DIP switches; all of its configurable features are programmable.

Functionally, the KPCMCIA-12AIAOH PC card consists of the following components:

DC/DC power supply

•

•

Analog input multiplexer

Programmable gain control

•

•

A/D converter

Data FIFO

•

•

Scan list

Trigger control

•

•

Pacer clock

•

Interrupt and status

Digital I/O

•

•

D/A circuit

16-bit timer/counter circuit

•

•

Associated control circuits

DC/DC power supply

The KPCMCIA-12AIAOH PC card uses a standard 5V power supply for its digital circuit. The

±15V power supplies are used for the analog front end, and the analog +5V power supply is used

for the A/D converter. All are generated by a DC/DC converter off of the +5 digital input power

supply from the PCMCIA connector. The DC/DC converter takes 140mA, two-thirds of the

210mA total load current, from the input power supply.

According to the new PCMCIA specification, any card that takes more than 100mA must not be

blindly turned on when the card is inserted; the card must be intentionally accessed.The

KPCMCIA-12AIAOH PC card will support the new specification by providing a unique powerdown mode control. When the card is first plugged in, powered up, or reset, the DC/DC converter

shuts off so only the digital portion is up and running, taking only 70mA from the input +5 power

supply. Full-powered mode can then be activated by software.

Page 19

KPCMCIA-12AIAOH User’s Manual Theory of Operation 3-3

Analog input multiplexer

The differential or single-ended configuration is selected via software.The expansion cards can

only be used on single-ended channels. The single-ended/differential selection should be the

same for all the internal channels (e.g., all four channels as differential, or all eight channels as

single-ended). Having some channels configured as single-ended and others as differential, possible as it is, may cause confusion and unexpected signal errors.

In a differential configuration, there are, at most, four channels. However, if you specify channels

4 to 7 in a differential configuration, the inputs to ground for system offset measurement will

short. The readings taken under such a circumstance can be used for offset correction.

The input multiplexers have built-in protection against overvoltage when the board is both powered on and powered down. The protection mechanism isolates the input from the rest of the board

as long as the input voltage is within the protection range of ±30V.

Programmable gain control

Scan list

The KPCMCIA-12AIAOH PC card has an internal gain of 1, 10, 100, and 1000. The gain can be

changed “on the fly” from channel to channel when scanning through the channels. There is a programmable gain instrumentation amplifier with gains of 1, 10, 100, and 1000. The internal gain

selection is specified in the scan list entry via software.

The settling time of the analog front end meets the speed requirement. However, if the amplifier

is saturated, it may need a longer time to recover, which may cause distortion in the input signal

to the A/D converter. Amplifier saturation should be avoided (use low gains, attenuate the input

signal, etc.).

One entry to the scan list contains a 16-bit word, or two 8-bit bytes. It specifies the internal channel selection and gain selection (in the high byte, or MSB), the external channel and gain selection

(in the low byte, or LSB), and other control and configuration settings.

The external selections are used for channels on the expansion cards, while internal selections are

used for channels on the KPCMCIA-12AIAOH PC card.

The expansion cards are not included as part of the KPCMCIA-12AIAOH data acquisition system. However, they can be purchased separately from Keithley.

The number of entries in the scan list ranges from 1 to 2048. No dependencies are implied among

the entries of the scan list. You may choose any valid gain combinations for any channel, internal

or external. The channels can be scanned in any order as required, repeated or not, with the same

or different gain for each entry.

The differential/single-ended control bit (at bit 14, MSB) should be the same for all the entries in

the scan list, which is most likely the case for normal operations. Single-ended configurations

should be selected if one or more expansion cards are connected to the KPCMCIA-12AIAOH PC

card.

The synchronous sample hold bit (or SSH at bit 6, LSB) is reserved for the expansion cards.

Page 20

3-4 Theory of Operation KPCMCIA-12AIAOH User’s Manual

Trigger circuit

The KPCMCIA-12AIAOH PC card can be triggered by the software (i.e., an internal trigger), an

external TTL input,* the analog input passing through the preset threshold, or the pacer clock.

For the TTL or analog trigger, an active trigger edge can be selected for either the low-to-high

transition or the high-to-low transition.

In one-shot trigger mode, one trigger, either internal or external, starts one scan of all the channels

specified in the scan list. The pacer clock does not have any effect in this mode. Multiple scans

can be set up by issuing (or receiving) multiple triggers.

In continuous trigger mode (without pre-trigger), a software, TTL, or analog trigger starts a series

of scans in which the first is initiated immediately upon receiving the trigger and the rest occur

each time the pacer clock fires. The process continues until the software issues an A/D stop

command.

If the internal trigger (or the software trigger) is selected, a trig/arm command from software

serves as a trigger as soon as it is received by the PC card. For the external trigger sources (TTL

or analog), the same command is taken as an arm command, which arms the PC card so the first

proper trigger edge since the reception of the arm command serves as the trigger. Any trigger

edges before the first one will be ignored. Unexpected edge transitions during the configuration

of the trigger source and edge will not be taken as triggers as long as the PC card is not armed.The

pre-trigger option can be selected in continuous mode (not allowed in one-shot mode) with external trigger sources (TTL or analog but not with internal trigger). If the option is selected, the arm

command will actually start the pacer clock so the input channels specified in the scan list are

scanned each time the pacer clock fires and the scan results are placed in the data FIFO. However,

once the almost-full threshold (programmed as an integer multiple of the scan list length) of the

data FIFO is reached, the least recent scan is automatically discarded and the most recent one is

placed in the data FIFO. This filling and discarding continues until the external trigger (TTL or

analog) activates. At that point, no more discarding will be performed, and the normal data acquisition process starts with half FIFO full of data samples right before the trigger. A/D event bits

are not set until the trigger activates, guaranteeing that no interrupts can be sent before the trigger

eventually activates.

*NOTE In “Paced” mode, the same input pin is shared between external clock

and external trigger, hence only one function can be used (not both simultaneously).

A/D converter and data FIFO

The KPCMCIA-12AIAOH PC card always assumes a bipolar input range of ±10V if the gain is

one. The output data format will always be in 2’s complement (and left justified for 12-bit versions). The data acquisition time of the A/D converter is 2µs, while its conversion time is no more

than 8µs. The A/D converter output is fed into the data FIFO providing data buffering of 2048

samples.

The hardware design guarantees that the A/D converter, once triggered, will perform a conversion

for every analog input channel specified in the scan list at the selected scan speed and feed the

results into the data FIFO. In between scans, the PC card waits until another trigger activates (oneshot mode) or the pacer clock fires (continuous mode).

The data FIFO has two programmable thresholds: one for almost full and the other for almost

empty. The KPCMCIA-12AIAOH PC card only uses the almost-full threshold and ignores the

other. Upon power up or reset, the almost-full threshold is defaulted to 7 bytes to full (3.5 samples).

When the FIFO is full, no more samples can be written into the FIFO. At the end of each scan,

the KPCMCIA-12AIAOH PC card sets a data-lost flag if the data FIFO is already full.

Page 21

KPCMCIA-12AIAOH User’s Manual Theory of Operation 3-5

Interrupt and status

The KPCMCIA-12AIAOH PC card has three interrupt sources: the end-of-scan (EOS) interrupt,

the FIFO threshold interrupt, and the timer interrupt. These interrupts are used as follows:

•

When the EOS interrupt is enabled, an interrupt is sent to the host at the end of each scan of

the channel list. If only one channel is in the scan list, the EOS interrupt is reduced to an

EOC (end-of-conversion) interrupt.

•

The FIFO threshold interrupt, when enabled, is sent to the host when an almost-full flag is set

by the card. The host can then use the string input instruction to move a block of samples

from the FIFO.

When the timer interrupt is enabled, an interrupt is sent to the host each time the timer over-

•

flows.

Digital I/O

The KPCMCIA-12AIAOH PC card has one digital input port (base + 3, read only) of four bits

(bits 0 to 3) and one digital output port (base + 3, write only) of four output bits (bits 0 to 3). The

output port is latched, but the input port is not.

Four input lines are connected to the digital input port; each represents one bit in the port. When

reading the digital input port, the current status of the digital input lines are returned to the host.

All four input lines are shared with other functions. Bit 0 is shared as the external trigger and

external paced clock input. Bit 2 is shared as the external clock burst input. Bits 1 and 3 are taken

over as the external gain selection lines if one or more expansion cards are connected and an

expansion bit is set by software. However, the current status of the digital input lines is always

returned when the host reads the digital input port, whether the lines are shared or not.

The four digital output lines are taken over as the external channel selection lines if an expansion

bit is set by software. In this case, the digital output lines are driven by the external channel selection bits of the current scan list entry. Otherwise, they are connected to the latched bits 0 through

3 of the digital output port.

Page 22

3-6 Theory of Operation KPCMCIA-12AIAOH User’s Manual

A/D state machine

The KPCMCIA-12AIAOH PC card has an internal state machine (see Figure 3-1) that controls A/

D operation.

The state machine defaults to state S0 after power up or reset. The normal state flow is first S0 to

S3, initiated by a scan list (queue) flush command (RSTQ). Then, the queue is programmed.The

state machine then moves from S3 back to S0. The S3 to S0 step is initiated by issuing a flushdata FIFO command (RSTF)—which sets up the gain and channel selections for the first channel

in the scan list—and then waiting for a trigger to start the scan. When the trigger (ADCLK) activates, the state machine moves from S0 to S1, and the A/D conversion starts once it is moved to

S1. The state machine waits at S2 until the conversion is done. At this time, it moves to S4, where

the A/D conversion result is written into the data FIFO. The scan rate is determined by the time

the state machine moves from S1 to S4, which can be set to 10µs, 20µs, or 40µs. If there are more

channels to scan in the list, the state machine will skip to S1 for another conversion loop. Otherwise it will return to S0 and wait for another trigger (or a sampling pulse from the pacer clock if

it is in the continuous trigger mode). At any time during data acquisition, an A/D stop command

will clear RUN to zero and eventually stop the data acquisition by moving the state machine back

to S0.

Figure 3-1

State transition diagram of A/D conversion process

~RSTF

~ADCLK*

~RSTQ

S0

RSTF

RSTQ

ADCLK*

~RSTQ

~RUN + 1st

S3

S1

RUN*~1st

Wait A/D

Conversion

BUSY

S2

~BUSY

S4

The sequence of the first trip of S0-S3-S0, as previously described, is important. Software issues

two commands to the PC card: the flush scan list command (RSTQ) and then the flush data FIFO

command (RSTF). In between, the scan list is programmed. Once the flush data FIFO command

is issued, the PC card prepares the first channel in the scan list, and then goes back to state S0

waiting for the first trigger.This guarantees that the scan list and the data FIFO are flushed properly for the expected data acquisition.

Page 23

KPCMCIA-12AIAOH User’s Manual Theory of Operation 3-7

D/A circuit

The KPCMCIA-12AIAOH PC card is equipped with two D/A channels. The 12-bit serial D/A

converter (AD7249 from analog device) supports synchronous update. It is configured to have a

bipolar output range from -5 to +5V. The 12-bit output data format is always in 2’s complement

(right justified) with the upper four bits indicating the output channel number (binary 0000 for

channel 0 and 0001 for channel 1). The D/A data port occupies two bytes (write only) in the I/O

space.

The serial link from the D/A port to the D/A converter contains a 16-bit buffer register and a

16-bit shift register. A data word written into the D/A port is written into the buffer register, loaded

into the shift register, and sent to the input register of the corresponding D/A channel (inside the

D/A converter AD7249).

Inside the D/A converter, each channel also has a 16-bit shift register, a 12-bit input register, and

a 12-bit output register. The data loaded into the output register determines the analog output of

the D/A channel.

The KPCMCIA-12AIAOH PC card has four D/A operation modes (modes 0 to 3). Mode 0 is the

direct update mode. The corresponding D/A channel output register updates immediately after the

data word is written into the D/A port (if byte I/O is used, after the high byte is written). There is

no synchronization between the two channels in this mode.

Timer counter

Modes 1, 2, and 3 are all using synchronized update, in which the two D/A channels are updated

at the same time (synchronously) for certain events. In mode 1, the event is the timer overflow. In

mode 2, it is the external gate control (going from low to high). In mode 3, the event comes from

the pacer clock.

In the synchronous update modes, the data word written to each D/A channel is buffered in its

input register (inside the AD7249) first and then loaded into the output register (and therefore the

D/A output gets updated) when the corresponding event (depending on the mode) is received.

Synchronous update modes can be used to generate waveforms with accurate phase requirements,

such as orthogonal, sinusoidal waveforms (sine and cosine).

In addition to the 24-bit pacer clock, the KPCMCIA-12AIAOH PC card is equipped with an independent 16-bit timer/counter. The timer/counter has an internal clock source of 1MHz and an

external clock input (for counting or as an external clock source, shared with the pacer clock

external input).

The timer circuit contains a 16-bit reload register, a 16-bit up-counter, and a 16-bit read-latch register. The reload register holds the initial value for the counter. The counter is also loaded with the

same value each time it overflows. The read-latch register latches the current count of the counter

each time it receives a latch command. The integrity of the latched count is guaranteed by the logic

design.

The 16-bit reload register is accessed when writing into the port, while the read-latch register is

accessed when reading the port. The up-counter cannot be accessed directly.

Either the 1MHz internal clock source or the external clock source (or the counter pulse input) is

software selectable. Because of the I/O pin confinement, the timer external clock input is shared

with pacer clock external input (also shared as the digital input bit 2).

Page 24

3-8 Theory of Operation KPCMCIA-12AIAOH User’s Manual

There are four timer/counter modes: 0, 1, 2, and 3. In mode 0, the counter stops and reloads with

the initial value by the rising edge of the selected clock source. In mode 1, the counter pauses

counting but does not reload (as it does in mode 0). Mode 2 is the counting mode in which the

counter counts up the rising edge of the selected clock source. In mode 3, the counter is controlled

by the external gate (shared with D/A) signal. The counting proceeds when the signal is high and

pauses when the signal is low.

Three I/O pins are associated with the timer: the external clock source input (shared with the

pacer clock), external gate control (shared with D/A), and the timer overflow pulse output (TTL),

which goes high when the timer reaches its final count (hexadecimal FFFF).

The reload register can be set up for both counting and timing operations. The value written into

the reload register, denoted as X for the sake of the discussion, determines the divisor or modulus

for timing and counting. Since the final count before reloading is always 65535 (hexadecimal

FFFF) for the up-counter, the reload (initial) value determines from where the counting will start.

Therefore, 65536 - X will be the divisor for timing operations or the modulus for counting operations. For example, a divided-by-2 timer (or modulus 2 counter) can be configured by setting X

equal to 65534, while X = 0 implies the divisor is 65536 (or the modulus is 65536).

Avoid X = 65535 (hexadecimal FFFF) because the timer will be stuck at the final count and the

hardware will not reject or indicate such a setting.

Changing the reload register “on the fly” is allowed, but the setting will not take effect until the

up-counter reaches its final count (65535 or hexadecimal FFFF). The next clock rising edge will

load the counter with the new setting.

The timer interrupt is enabled and disabled by software. When enabled, an interrupt is sent each

time the up-counter overflows (passes through its final count).

Page 25

4

I/O Connections

Page 26

4-2 I/O Connections KPCMCIA-12AIAOH User’s Manual

Introduction

The KPCMCIA-12AIAOH PC card is fitted in with a 32-pin, 0.8mm shielded connector with the

pin assignment shown in Table 4-1.

Cable assembly

Table 4-1

KPCMCIA-12AIAOH PC card cable mapping

PC Card 32

pin connector

32 37 Channel 0 (+) Channel 0 A/D input, differential/single-ended

31 18,33 Channel 0 (-) Channel 4 A/D input, differential/single-ended

30 36 Channel 1 (+) Channel 1 A/D input, differential/single-ended

29 17,32 Channel 1 (-) Channel 5 A/D input, differential/single-ended

28 35 Channel 2 (+) Channel 2 A/D input, differential/single-ended

27 16,31 Channel 2 (-) Channel 6 A/D input, differential/single-ended

26 34 Channel 3 (+) Channel 3 A/D input, differential/single-ended

25 15,30 Channel 3 (-) Channel 7 A/D input, differential/single-ended

24 19 GND Signal ground (analog input)

23 9 DA0 D/A channel 0 output

22 27 DA1 D/A channel 1 output

20 7 GND Power supply ground return

19 24 ExtClk (shared with A/D) Timer/Counter external clock input

18 8 ExtGate Timer/Counter external gate control

17 11 ExtOut Timer/Counter overflow pulse output

16 7 GND Power supply ground return

15 1 FullPower (org. D/A 0 ref. in) 1/0 : Full power/Power down

14 26 SSH (org. D/A 1 ref. in) Synchronous sample hold

13 25 Digital in bit 0 (shared) External trigger (same as in DAS-16)

12 6 Digital in bit 1 (normal mode) External gain, LSB (expansion mode)

11 24 Digital in bit 2 (shared) External clock (org. DAS-16 Ctr 0 Gate)

10 5 Digital in bit 3 (normal mode) External gain, MSB (expansion mode)

9 23 Digital out bit 0 (normal mode) External channel bit 0 (expansion mode)

8 4 Digital out bit 1 (normal mode) External channel bit 1 (expansion mode)

7 22 Digital out bit 2 (normal mode) External channel bit 2 (expansion mode)

6 3 Digital out bit 3 (normal mode) External channel bit 3 (expansion mode)

5 28 GND Signal ground (D/A output)

4 28 GND Signal ground (D/A output)

3 29 GND Signal ground (digital)

2 29 GND Signal ground (digital)

1 N/C Reserved

D-37 pin

connector

Name Description

Page 27

KPCMCIA-12AIAOH User’s Manual I/O Connections 4-3

Note that the cable assembly for the KPCMCIA-12AIAOH PC card (KCAB-AIAO) in Figure 4-1 looks

very similar to the one for the KPCMCIA-12AI/16AI and KPCMCIA-12AIH PC cards (KCAB-AI). Do

not mistake one for the other; severe damage to the PC cards may occur. The cable assembly for the

KPCMCIA-12AIAOH PC cards have the name KCAB-AIAO on its 37-pin D-shell connector. If the

cable is not identified as such, do not use it with the KPCMCIA-12AIAOH PC cards.

Figure 4-1

KPCMCIA-12AIAOH PC card D-37 output connector, KCAB-AIAO

GND

Ch0- / Ch4

Ch1- / Ch5

Ch2- / Ch6

Ch3- / Ch7

N/C

N/C

N/C

N/C

N/C

D/A Ch0

ExtGate

GND

DI1 / GS0

DI3 / GS1

DO1 / CS1

DO3 / CS3

N/C

Full Power

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

37

Ch0+ / Ch0

36

Ch1+ / Ch1

35

Ch2+ / Ch2

34

Ch3+ / Ch3

33

Ch4+ / Ch4

32

Ch5+ / Ch5

31

Ch6+ / Ch6

30

Ch7+ / Ch7

29

GND

28

GND

27

D/A Ch1

26

SSH

25

DI0 / Ext. Trigger, Ext. Clock (paced mode)

24

DI2 / ExtClk (Burst mode)

23

DO0 / CS0

22

DO2 / CS2

21

N/C

20

ExtOut

Page 28

5

Optional Accessories

Page 29

5-2 Optional Accessories KPCMCIA-12AIAOH User’s Manual

The following optional accessories are available from Keithley:

•

STP-37

STA-U

•

•

EXP-1600

Page 30

A

Specifications

Page 31

A-2 Specifications KPCMCIA-12AIAOH User’s Manual

A/D converter 12-bit version 16-bit version

Acquisition + Conversion 2µs + 8µs 2µs + 8µs

Monotonicity No missing codes No missing codes

Integral linearity error ±1 LSB ±3 LSB

Differential linearity error ±1 LSB +3/-2 LSB

Full-scale error ±0.5% ±0.5%

Aperture delay 40ns 40ns

Analog input

Number of input channels Four differential/eight single-ended; expandable to 128

Input range ±10, ±1, ±0.1, and ±0.01V

Programmable gain 1, 10, 100,1000

Maximum overvoltage ±30V

Input impedance 100M Ω (DC)

A/D miscellaneous specifications

Data FIFO depth 2048 samples

Scan list length 2048 entries

Scan speed 10µs, 20µs, 40µs

Trigger source Internal (software)/external (TTL, analog)

Trigger mode Continuous/one-shot

Pre-trigger option Programmable, up to the data FIFO depth

TTL trigger 0.8V (low) / 2.2V (high), rising/falling edges

Analog trigger Threshold set in full A/D input range (±10V)

Rising/falling directions, 10mV hysteresis

Sampling rate 0.006Hz to 100kHz (with internal clock source)

External clock rate* DC - 5MHz

*NOTE In “Paced” mode, the same input pin is shared between external clock

and external trigger, hence only one function can be used (not both simultaneously).

D/A converter

Resolution 12-bit

Relative accuracy ±1 LSB

Bipolar zero error ±7 LSB max

Differential nonlinearity ±1 LSB max

Full scale error ±7 LSB max

Analog output

Number of output channels 2 (single-ended only)

Output settling time 10µs

Output range ±5V (bipolar only)

Output current ±2mA

DC output impedance 0.5 Ω (typical)

Timer/counter

Word length 16-bit, with auto reload and read latch

Clock source Internal (1MHz) / External (DC - 5MHz)

External clock input TTL, pulse width > 100ns, frequency < 5MHz

Overflow output TTL

Divisor/modulus range 2 - 65535

Digital I/O

Digital input channels 4 (no latch)

Digital output channels 4 (latched)

Maximum source current 0.5mA

Maximum sinking current 2.5mA

Minimum logic 1 level 2.4V

Maximum logic 0 level 0.8V

Page 32

KPCMCIA-12AIAOH User’s Manual Specifications A-3

General specifications

Power consumption 210mA (full power), 70mA (power down)

Operating temperature 0° to 50°C

Storage temperature 0° to 70°C

Humidity 0 to 95%, non-condensing

Size (cable not included) Standard PCMCIA type II

Weight 1.5 oz (for reference only)

Specifications subject to change without notice.

Page 33

B

PCMCIA Interface

Page 34

B-2 PCMCIA Interface KPCMCIA-12AIAOH User’s Manual

Introduction

NOTE

Information in this section is provided for those who need low-level PCMCIA interface details of

the KPCMCIA-12AIAOH PC card. The client driver or the enabler that comes with the PC card

is sufficient for most applications.

The KPCMCIA-12AIAOH PC card performs data acquisition for all host computers equipped

with a version 2.1 compliant PCMCIA interface. The PC card, which is the name given to all

PCMCIA interface cards, has a form factor of type II (5mm thick).

Due to the PCMCIA interface, the PC card is highly flexible with respect to addressing and interrupt level use. It can be configured either as a memory only interface or as an I/O interface and

can be powered up or down with the help of the PCMCIA card and socket services software. The

KPCMCIA-12AIAOH PC card provides a single interrupt that is routable to any system interrupt

via the PCMCIA socket controller.

Two sets of registers are on the KPCMCIA-12AIAOH PC card: the configuration registers and

program registers.

A typical user of this manual does not need to read the material in this

section. If you write a custom program, write it to work through DriverLINX,

using the many interface and support features of DriverLINX. Register-level

programming of the card is not recommended. This section is provided only

for an advanced programmer who must write a specialized driver.

The configuration registers are those defined in the PCMCIA 2.1 specification. The PCMCIA

configuration registers are located in the PC card’s configuration space at offset 8000H. Configuration space also contains the Card Information Structure (CIS). This memory is located at offset

0000H in the configuration space. The CIS memory contains information about the PC card as

defined by the PCMCIA 2.1 specification. The configuration and power-up/down control of the

PC card should be carried out through the standard card and socket services software even though

they can be achieved with an enabler.

Program registers are the registers that fall under program control and belong to the KPCMCIA12AIAOH PC card. The I/O location of these registers are controlled by the PCMCIA socket configuration and by the contents of the PCMCIA configuration registers. See the descriptions in

Appendix C for more information.

Two PCMCIA configuration registers are supported by the KPCMCIA-12AIAOH PC card: the

configuration option register and the card configuration and status register. Refer to Table B-1.

Table B-1

PCMCIA configuration registers

Offset

0x8000 R/W Configuration option register

0x8002 R/W Card configuration and status register

Access Description

Page 35

KPCMCIA-12AIAOH User’s Manual PCMCIA Interface B-3

Configuration and option register (COR)

Refer to Table B-2. Bits 6 and 7 of the configuration option register are defined by the PCMCIA

standard as the SRESET and the LevlREQ Bits. A 1 written into the SRESET bit puts the card

into a reset state, while a 0 moves it out of the reset state. When the card is in a reset state, it

behaves as if a hardware reset is received from the host. The LevlREQ bit controls the type of

interrupt signal generated by the PC card. Setting the configuration index bits to 0 makes the PC

card a memory-only card (accessed only by memory read/write operations), while setting it to 1

enables the card to be a standard I/O card.

Table B-2

COR bit definitions

Bit Name Description

7 SRESET 1 = Put the card into a reset state

0 = Get out of a reset state

6 LevlReq 1 = Level mode interrupt

0 = Edge mode interrupt

5-0 Index bits 000000 = Memory mode

000001 = I/O mode

Card configuration and status register (CCSR)

Refer to Table B-3. The KPCMCIA-12AIAOH PC card uses two bits in this register. When bit 1

is set to 1, it indicates a pending interrupt. The bit will remain as 1 until the software clears the

interrupt source. Bit 2 is used for power-down control. A 1 set to this bit puts the card into powerdown mode, while a 0 brings it back to full-powered mode. The rest of the bits are not used.

Table B-3

CCSR bit definitions

Bit Name Description

7-3 Not used Reserved, all 0 when writing and reading

2 PwrDwn 1 = Power-down mode

0 = Full-powered mode

1 Intr 1 = Interrupt pending

0 = No interrupt pending

0 Reserved Reserved as 0

Page 36

C

I/O Registers

Page 37

C-2 I/O Registers KPCMCIA-12AIAOH User’s Manual

Introduction

NOTE

The KPCMCIA-12AIAOH PC card uses eight consecutive I/O locations within the system I/O

address space. The base address of the adapter is determined by the client driver or enabler. The

eight I/O locations used by the PC card are summarized in Table C-1.

The D/A port and timer port registers can be accessed as 16-bit I/O registers. They can also be

accessed with 8-bit I/O instructions. The remaining registers are 8-bit wide. Each entry in

Table C-1 is discussed in detail in the following paragraphs.

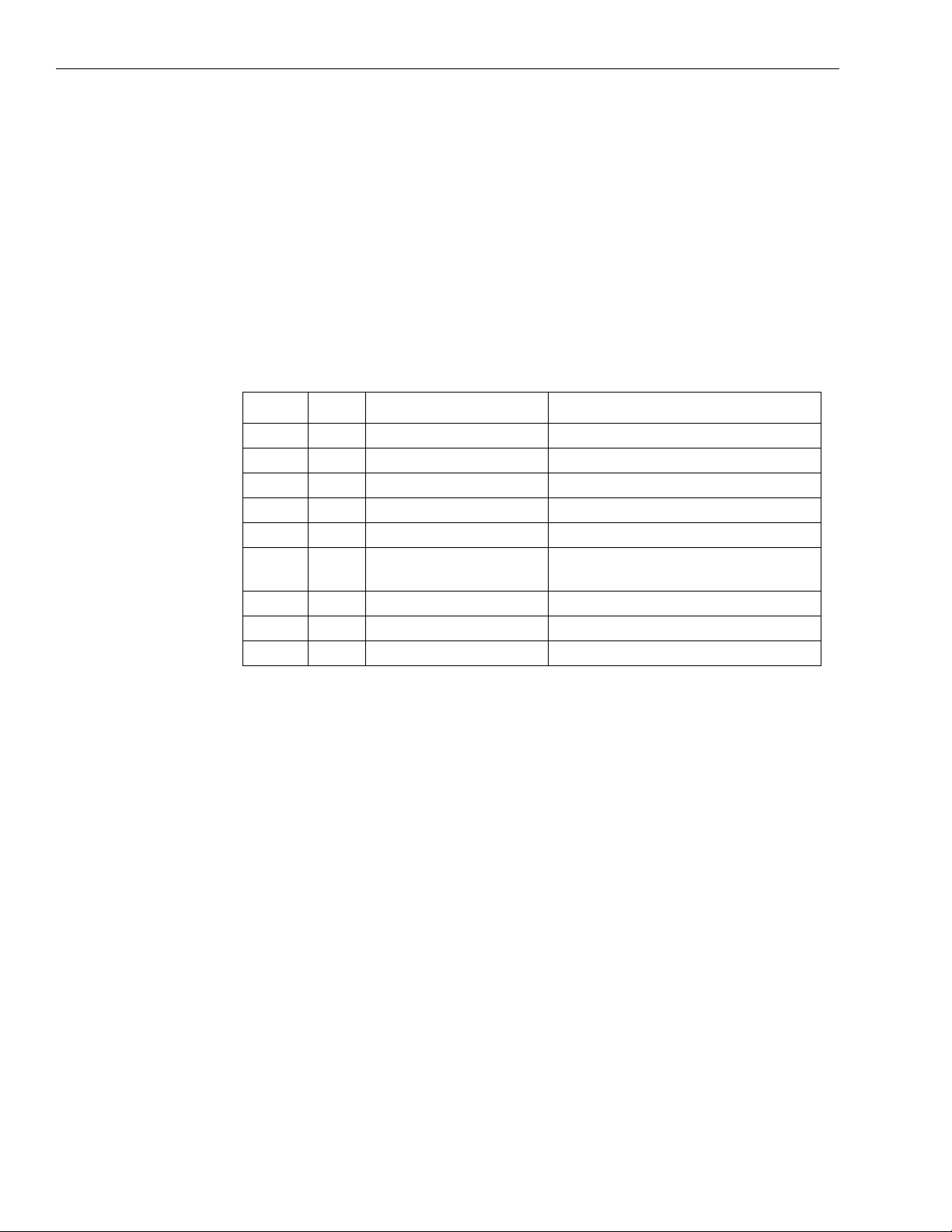

Table C-1

KPCMCIA-12AIAOH PC card register map

Address lines

(A3A2A1A0) I/O address Port access Register description

0000 base + 0 Read/Write Data FIFO

0001 base + 1 Write Only Scan list queue

0010 base + 2 Write

0011 base + 3 Write

0100 base + 4 Write Only Pacer clock, low byte

0101 base + 5 Write Only Pacer clock, middle byte

0110 base + 6 Write Only Pacer clock, high byte

0111 base + 7 Write Only Command register

1000-1001 base + 8,9 Write Only D/A port

1010-1011 base + 10,11 Write

1100-1110 base + 12,13,14 Reserved

1111 base + 15 Write

A typical user of this manual does not need to read the material in this

section. If you write a custom program, write it to work through

DriverLINX, using the many interface and support features of DriverLINX.

Register-level programming of the card is not recommended. This section is

provided only for an advanced programmer who must write a specialized

driver.

Control register

Read

Read

Read

Read

Status register

Digital output register

Digital input register

Timer port (reload)

Timer port (read latch)

Auxiliary control reg.

Auxiliary status reg.

Page 38

KPCMCIA-12AIAOH User’s Manual I/O Registers C-3

Data FIFO register (base + 0)

The data FIFO register can be considered the access port to the data FIFO, which can hold up to

2048 data words of the A/D conversion result. The port is also used to program the data FIFO

thresholds.

Two consecutive bytes should be read from (written into) the port each time it is accessed.

Table C-2 illustrates the bit allocation.

NOTE

Table C-2

Data FIFO register bit allocation

LSB

MSB

Although the data FIFO register is 8-bit wide, accessing the register

as a 16-bit word guarantees the integrity. The low byte (LSB, or the

least significant byte) should always be accessed first, followed by the

high byte (MSB, or the most significant byte).

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

D7 D6 D5 D4 D3 D2 D1 D0

D15 D14 D13 D12 D11 D10 D9 D8

Data FIFO operation modes

Depending on the mode of operation, the 16-bit word read from or written into the register has

different meanings, as described in Table C-3.

Table C-3

Data FIFO operation mode

Mode Selection bit A/D Access Operation

0 0, threshold Idle Read

1 1, data FIFO Idle Read

2 0, threshold Run Read

3 1, data FIFO Run Read

Write

Write

Write

Write

Verify data FIFO threshold

Program data FIFO threshold

Read data FIFO

Write data FIFO (diagnosis)

Verify data FIFO threshold

Not allowed

Read data FIFO

Not allowed

The selection bit in Table C-3 is also called the program/access control bit as defined in the command register (base + 7). Refer to “Command Register (base + 7, write only)” for details on setting the bit and issuing commands to change the status of the A/D conversion (from scan to idle

or vice versa).

Page 39

C-4 I/O Registers KPCMCIA-12AIAOH User’s Manual

Mode 0 is the FIFO program mode in which the two consecutive words (four bytes) written into

the register address will set the almost-full and almost-empty thresholds (in bytes). The first word

specifies the almost-empty threshold (not used; can be set to anything), while the second word

determines the almost-full threshold. The threshold should be set to a value from 1 to FIFO size

minus 1 (default is 7 when reset or powered up). Refer to Table C-4.

Table C-4

Data FIFO threshold setting

Threshold Default Threshold range Suggested value

Almost Empty 7 Irrelevant Irrelevant

Almost Full 7 1..4095 bytes* 2048 bytes*

* 2 bytes per sample/data word

Mode 1 is the FIFO test mode in which the data bytes can be written into the data FIFO and read

back from it. The FIFO flags (FIFO empty, almost-full, and full flags) will change according to

the data bytes available in the data FIFO and the configured threshold.

Mode 2 should be avoided. The data bytes cannot be written into the FIFO under this mode, while

the bytes read from the FIFO will be the same as in mode 0.

Mode 3 is the data transfer mode. Data bytes will be written into the FIFO by the A/D converter,

while the data byte read from the address is the first available byte in the data FIFO if it is not

empty. Otherwise, the most recent byte written into the FIFO will be returned. The data FIFO register is read-only under this mode. You cannot write data bytes into the data FIFO through I/O

instructions.

Mode setting

The FIFO operation mode setting is always initiated by the data FIFO flush command with the

access/program bit set to 0 (bit 0 at base + 7) before the data acquisition is started. See “Command

Register (base + 7, write only).” This will bring it to mode 0 (threshold setting mode). After the

threshold is programmed or verified, set the bit to 1 so the consequent read/write operations to the

FIFO will be taken as data access operations.

The A/D circuit is in idle mode before starting into the run mode by a trigger command (or an arm

command with pre-trigger). For one-shot operation, the A/D circuit will be set to run mode after

it receives the trigger signal. It will not return to the idle mode until the specified scan list is completed or an A/D stop command is received. See “Command register (base + 7, write only).” For

continuous trigger operation, the A/D circuit will stay in run mode after being triggered (or armed

with the pre-trigger option) until an A/D stop command is received.

Page 40

KPCMCIA-12AIAOH User’s Manual I/O Registers C-5

FIFO flags

When reading the register under mode 1 or 3, the first available data byte from the data FIFO will

be returned if it is not empty. Otherwise, the returned byte is not defined. The FIFO empty flag

will be set immediately after the last byte is read from the FIFO, while the FIFO full flag will be

cleared after reading the data FIFO register provided no more data bytes are written into the FIFO

by the A/D converter under mode 1 or 3. The same happens to the FIFO almost full flag, if the

data bytes available in the FIFO are less than the almost full threshold. Refer to Table C-5.

Table C-5

Data FIFO flag status

Data bytes in FIFO Empty Almost full Full

0 True False False

1 to (Threshold - 1) False False False

Threshold to (FIFO size - 1) False True False

FIFO size (4096 bytes*) False True True

*Note: Threshold is the almost-full threshold, and FIFO size is measured in bytes,

4096 (2048 samples/data words).

Page 41

C-6 I/O Registers KPCMCIA-12AIAOH User’s Manual

Scan list queue register (base + 1, write only)

The scan list queue register can be considered the access port to the scan list queue, which can

hold up to 2048 entries (each has two bytes), each specifying an analog input channel and its associated gain as well as other settings. The bit definition of an entry to the scan list queue is

explained in Table C-6.

NOTE

Table C-6