Page 1

Keithley Instruments

KPCI-488LPA GPIB Controller Interface Card

28775 Aurora Road

Cleveland, Ohio 44139

1-800-935-5595

tek.com/keithley

Quick Start Guide

Welcome

Thank you for choosing a Keithley Instruments product. The KPCI-488LPA has the following features:

Full compatibility with the IEEE48 8.2 st and ar d

Up to 1.5 MB per second data transfer rates

Supports a 32-bit 3.3 V or 5 V PCI bus

A built-in 1 KB first-in first-out (FIFO) for read/write operations

Half-sized printed circuit board

Supports up to 14 stand-alone instruments

An interactive utility for testing and diagnostics

Command-compatible driver API (application program interfaces) for Keithley Instruments, National

TM

Instruments NI

, and VISA (Virtual Instrument Software Architecture) libraries.

Contact and support information

This guide is designed to help you to install your KPCI-488LPA. For more detailed information, refer to the

Models KPCI-488LPA and KUSB-488B Reference Manual (part number KI488-901-01), available from the

Keithley Instruments website (tek.com/keithley

From the website, you can also access updated drivers and information about related products.

Your local Field Applications Engineer can help you with product selection, configuration, and usage. Check the

website for contact infor mation.

).

Inspection for damage

The KPCI-488LPA was carefully inspected electrically and mechanically before shipment. After unpacking all

items from the shipping carton, check for any obvious signs of physical damage that may have occurred during

transit. Report any damage to the shipping agent immediately. Save the original packing carton for possible

future shipment.

KPCI-488LPA-903-01 Rev. B / January 2020 *PKPCI-488LPA-903-01B* 1

Page 2

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

Repacking for return shi pme nt

Should it become necessary to return the KPCI -488LPA for repair, carefully pack the entire instrument in its

original packing carton or the equivalent, and follow these instructions:

Call Keithley Instruments’ repair department at 1-800-935-5595 for a Return Material Authorization (RMA)

number.

Let the repair department know the warranty status of the KPCI-488LPA.

Write ATTENTION REPAIR DEPARTMENT and the RMA number on the shipping label.

Software and hardware installation

To download the latest software drivers, visit tek.com/keithley.

You must install the software driver before you connect the KPCI-488LPA to your computer.

Driver installation

Make sure that your user account has Administrator privileges, or log into your computer's

Administrator account before installing the driver

To install the drivers:

1. Remove any existing GPIB interfaces and GPIB drivers from your computer.

2. Download the latest KPCI-488LPA software from the Product Support web page (tek.com/product-support

The software is available in a compressed (.zip) format.

3. Extract the files to your computer.

4. Launch setup.exe to begin the driver installation.

Figure 1: Selecting setup.exe from the extracted files

).

2 KPCI-488LPA-903-01 Rev. B / January 2020

Page 3

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

5. The driver installation dialog window opens, as shown in the following figure.

Figure 2: KUSB-488 driver installation screen

6. Install one of the following drivers. The InstallShield Wizard provides guidance on which driver to install.

NI command-compatible driver (32- or 64-bit)

Keithley command-compatible driver (32-bit)

You can install either a Keithley command-compatible driver or an NI command-compatible driver.

See the Models KPCI-488LPA and KUSB-488B Reference Manual (part number KI488-901-01) for

the available functions of each driver.

For LabVIEW™ and LabWindows/CVI™ support, Keithley Instruments recommends that you install

the NI command-compatible driver. For LabVIEW programming, you can also install the LabVIEW

GPIB virtual instruments (VIs) that are optimized for use with the KPCI-488LPA.

For ACS and ACS Basic support, insta ll the Ke ith ley command-compatible driver.

To use VISA or an application that uses VISA (such as KickStart Instrument Control Software), install

either driver.

7. Follow the prompts to complete the setup procedure.

8. When the installation finishes, select Yes to restart your system.

KPCI-488LPA-903-01 Rev. B / January 2020 3

Page 4

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

Hardware installation

The KPCI-488LPA contains sensitive components that can easily be damaged by static

electricity. Handle the module on a grounded anti-static mat. The operator should be wearing

an anti-static wristband, grounded at the same point as the anti-static mat.

You must install the drivers before installing the hardware. See Driver installation (on page 2).

To install the KPCI-488LPA:

1. Turn off your computer and all accessories connected to your computer.

2. Disconnect the power cord from the power source.

3. Open your computer case.

4. Select a vacant PCI slot.

5. Discharge any static buildup on your body by touching the metal case of the computer before touching the

KPCI-488LPA card.

6. Position the board into the PCI slot you selected.

7. Secure the card in place at the rear panel of the system.

8. Replace your computer's case.

®

In most Microsoft Windows

operating system when you power on your computer. However, previous versions of Windows may display the

Found New Hardware Wizard.

You can initiate the wizard manually with older versions of Windows.

To manually initiate the Found New Hard ware Wizard:

1. From the Control Panel on your computer, select Add Hardware. The Add Hardware Wizard dialog box

displays.

2. Select Next. The wizard searches for an y new hardware that has not yet been installed.

3. The Found New Hardware Wizard will display. Click Next and follow the prompts.

If the wizard does not find any new hardware, turn your computer off and turn it on again. Once it has rebooted,

the Found New Hard war e Wizard should launch.

10 configurations, the KPCI-488LPA hardware is automatically configured by the

4 KPCI-488LPA-903-01 Rev. B / January 2020

Page 5

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

Cabling

For optimal GPIB throughput, adhere to the following cabling guidelines:

The longest distance between two devices cannot exceed 4 m.

The average GPIB bus distance between all devices should be less than 2 m.

The total GPIB bus distance should be less than 20 m.

The total number of connected devices must be less than 15 (including your computer) with at least

two-thirds of all devices powered on.

You can connect devices in a linear configuration, star configuration, or a combination of the two configurations.

See the next figures.

Figure 3: Linear connection configurati o n

To lower the total current load of the configuration, limit the number of cable connections on each

individual instrument to three or less. For example, to lower the required current load when using the

configuration shown in the next figure, move one of the cable connections from Instrument A to a

different instrument. This makes the configuration a combination of linear and star configurations.

KPCI-488LPA-903-01 Rev. B / January 2020 5

Page 6

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

Figure 4: Star connection configuration

GPIB connection configuration

The GPIB has 24 lines. These lines consist of 16 signal lines and eight ground-return or shield-drain lines . The

16 signal lines can be divided into a set of eight parallel (8-bit) data transfer bus lines and a set of eight control

lines. The eight control lines contain five system management lines and handshake lines.

Figure 5: Standard GPIB connector

6 KPCI-488LPA-903-01 Rev. B / January 2020

Page 7

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

Pin

Number

Description

SIGNAL

GROUND

GPIB BUS Type Function

1 DIO1

2 DIO2

3 DIO3

24 lines

16 signal lines

8 data lines

5 system management lines

8 control lines

3 handshake lines

1 shield drain line 12 SHIELD

4 DIO4

13 DIO5

14 DIO6

15 DIO7

16 DIO8

5 EOI

9 IFC

10 SRQ

11 ATN

17 REN

6 DAV

7 NRFD

8 NDAC

18 GND

19 GND

8 ground lines

7 ground return lines

20 GND

21 GND

22 GND

23 GND

24

Data lines

DIO1 to DIO8 carry both data and command messages. All commands (and most data) use 7-bit ASCII code.

The 8th bit (DIO8), is either unused or used for parity check.

KPCI-488LPA-903-01 Rev. B / January 2020 7

Page 8

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

Handshake lines

Three handshake lines control the transfer of data/messages between devices:

DAV (Data Valid): Used to indicate the availability and validity of information on the DIO signal lines.

NRFD (Not Ready For Data): Used to indicate readiness of devices to accept data.

NDAC (Not Data Accepted): Used to indicate acceptance of data by device.

System management lines

The following five system management lines manage the flow of control and data bytes across the interface:

EOI (End or Identify): Used (by a talker) to indicate the end of a multiple-byte transfer sequence or, in

conjunction with ATN (by a controller), to execute a polling sequence.

IFC (Interface Clear): Used (by a controller) to place the interface system, portions of which are

contained in all interconnected devices, in a known quiescent state.

SRQ (Service Request): Used by a device to indicate the need for attention and to request an

interruption of the current sequence of events.

ATN (Attention): Used (by a controller) to specify how data on the Digital I/O signal lines are to be

interpreted, and which devices must respond to the data.

REN (Remote Enable): Used (by a controller) in conjunction with other messages to enable or disable

one or more local controls that have corresponding remote controls.

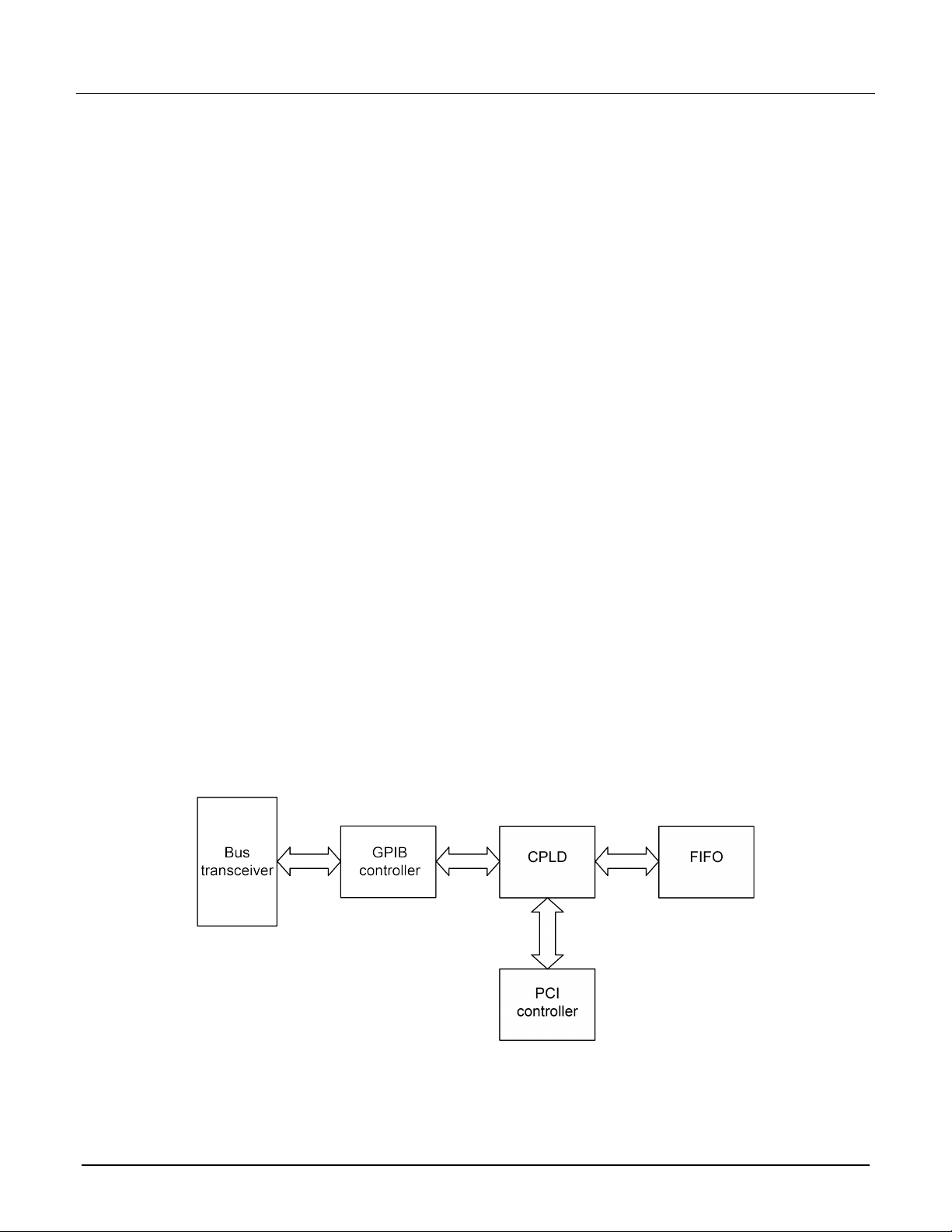

KPCI-488LPA blo ck diagram

The KPCI-488LP A has a 1 KB on-board FIFO buffer (First In First Out) to maximize the data transfer rate. The

CPLD (Complex Programmable Logical Device) coordinates the data flow between the PCI controller

(Peripheral Component Interconnect), FIFO buffer, and GPIB bus.

Figure 6: KPCI-488LPA block diagram

The FIFO can buffer data from the master (either from the KPCI-488LPA or external device) when the target is

busy. Therefore, the efficiency will be significantly improved when transferring large blocks of data.

8 KPCI-488LPA-903-01 Rev. B / January 2020

Page 9

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

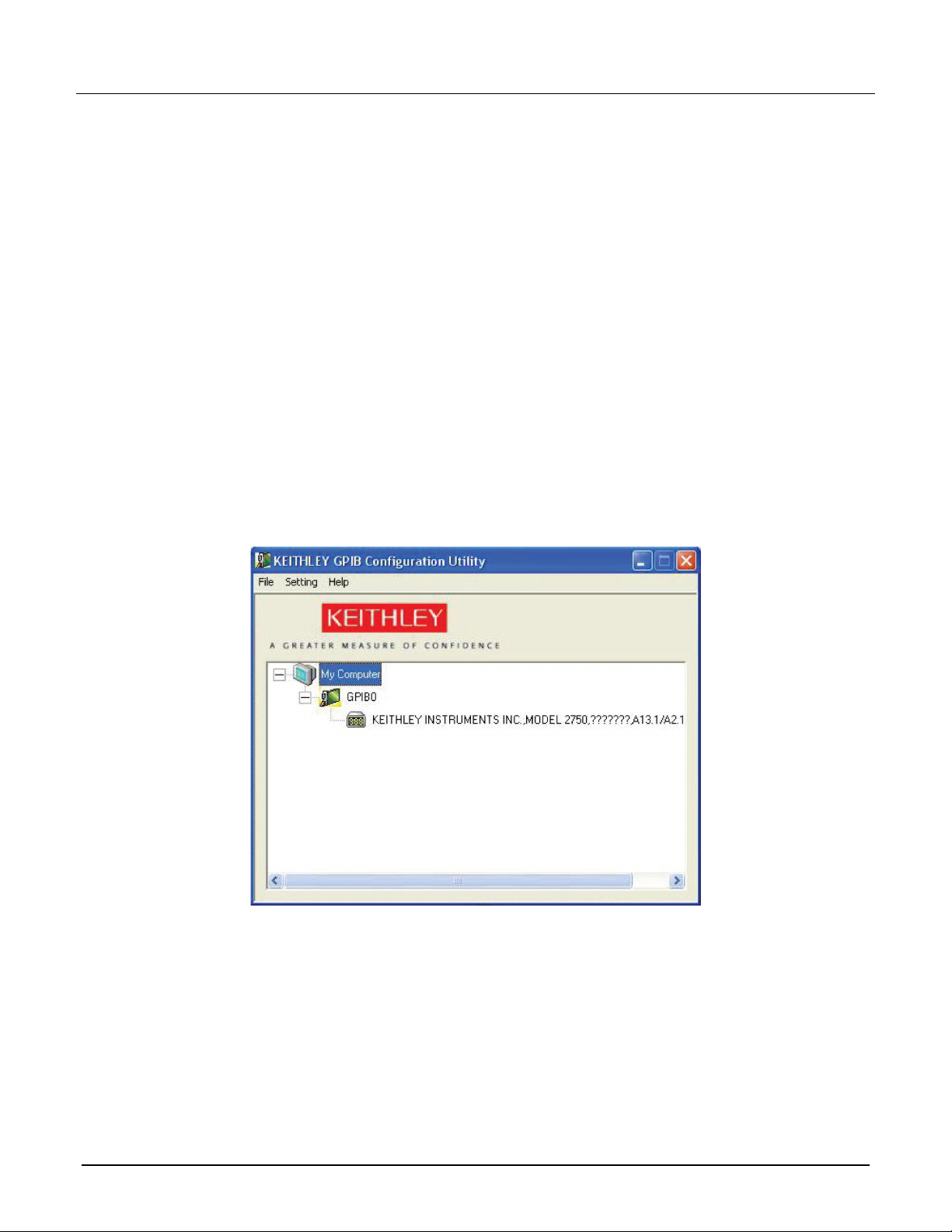

Using the Keithley GPIB Configuration Utility

The Keithley GPIB Configuration Utility allows you to configure the following settings:

KPCI-488LPA bus address

Bus timing

I/O timeout

Set the KPCI-488LPA to be a system controller

Enable autopolling

To launch the configuration utility:

1. From Microsoft Windows, select Start > All Programs.

2. From the programs selection, select Keithley Instruments > KI-488 > KI-488 Configuration Utility. The

Keithley GPIB Configuration Utility window will open. The utility queries the GPIB bus for instruments and

displays the response to the identification query for any discovered instruments.

Figure 7: Keithley GPIB Configuration Utili ty

KPCI-488LPA-903-01 Rev. B / January 2020 9

Page 10

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

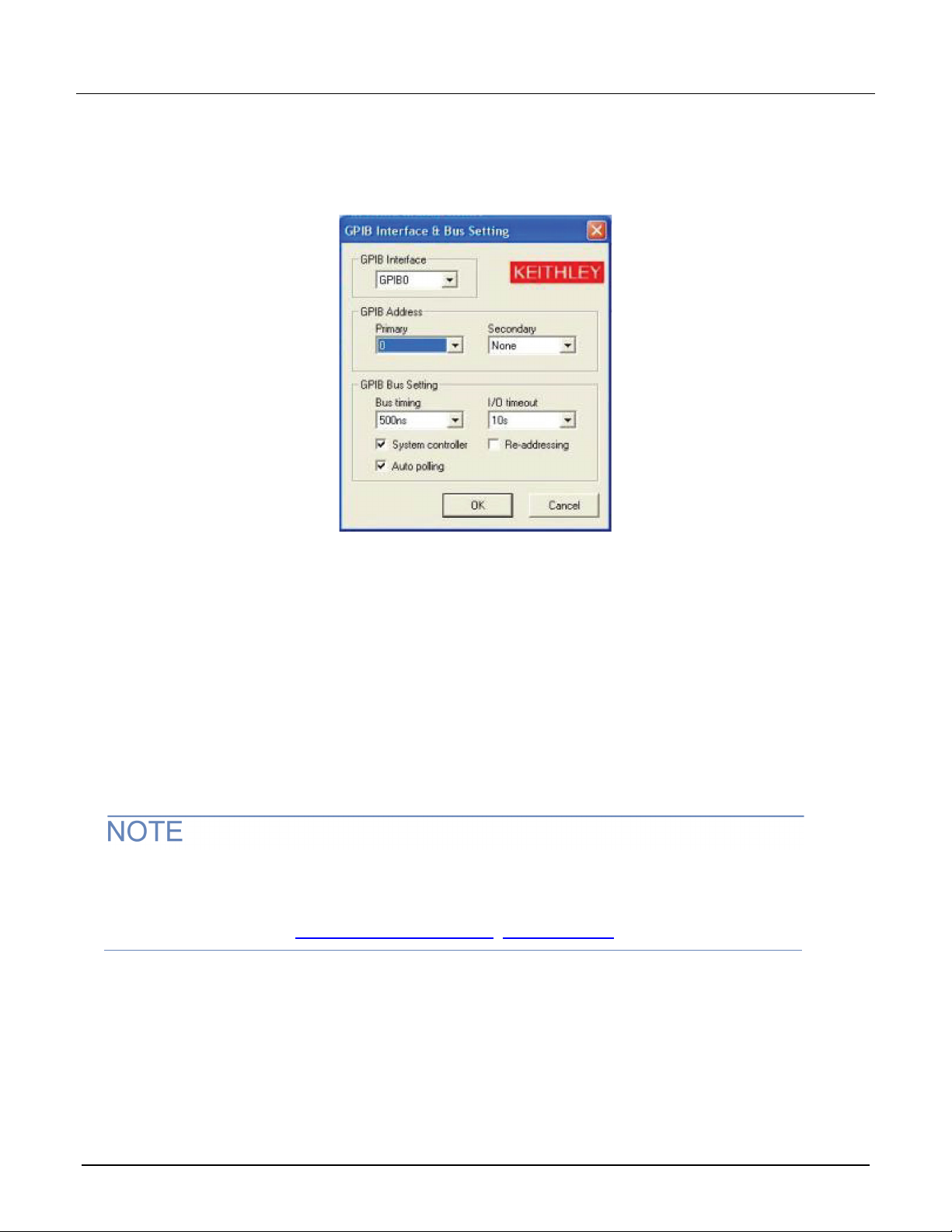

3. Double-click the interface icon to open the GPIB Interface & Bus Setting dialog box.

4. Make any changes to the configuration, then select OK.

Figure 8: GPIB interface and bus configuration

5. Save these configuration changes by selecting Setting > Save Configuration in the Keithley GPIB

Configuration Utility window.

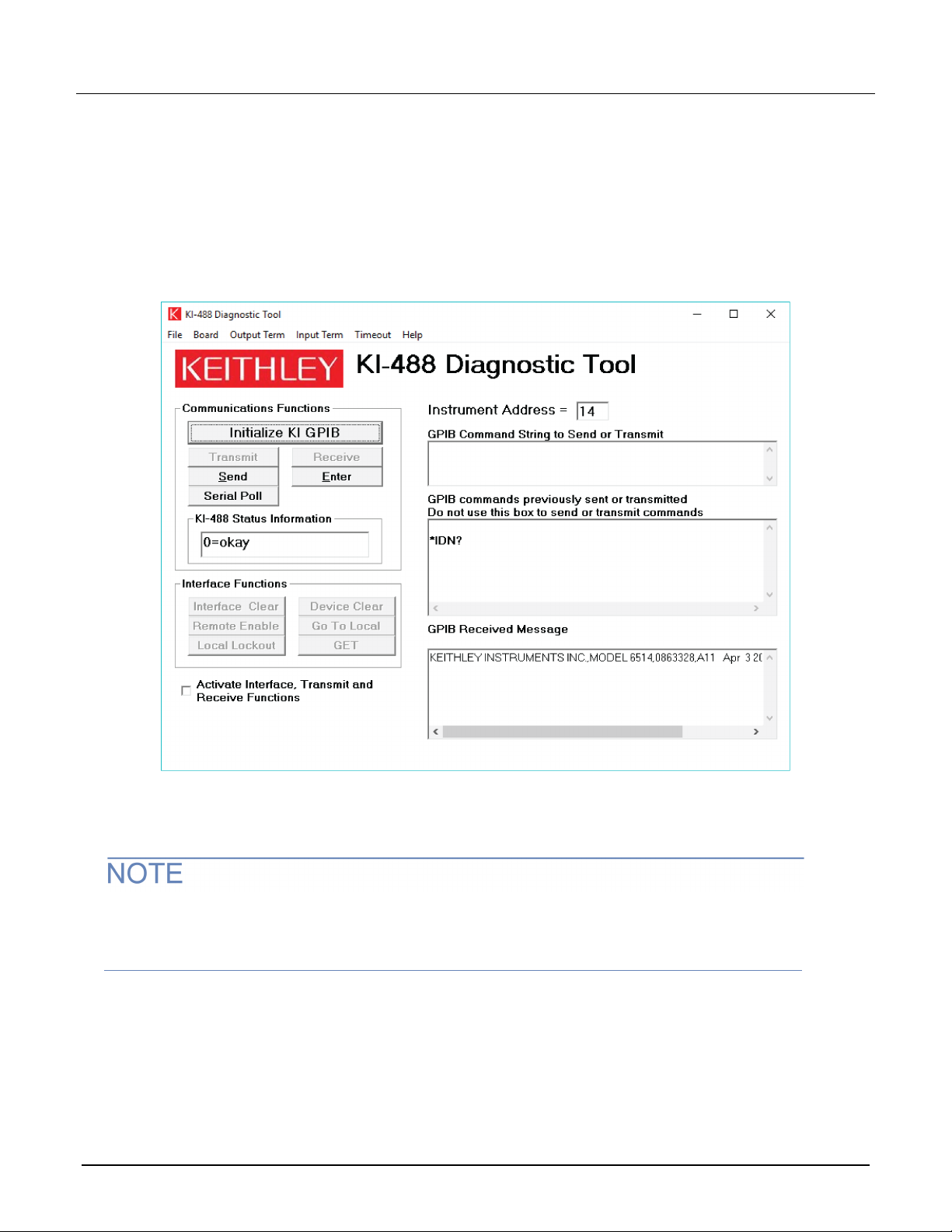

Using the Keithley Instruments KI-488 Diagnostic Tool

The KI-488 Diagnostic Tool lets you communicate with any GPIB instrument by writing command strings to

your instrument and reading the results.

Before you launch the diagnostic tool, make sure that the KPCI-488LPA is connected to both your computer

and your instrument, and verify that both are powered-on. Make sure that your instrument is set for remote

GPIB communication, and verify the assigned GPIB address.

The following example demonstrates how to send a single command and receive a response from a

GPIB-connected instrument. For detailed information about using command strings with the KPCI488LPA, refer to the Models KPCI-488LPA and KUSB-488B Refer ence Man ual (part number KI488901-01), available from the Keithley Instruments website (tek.com/keithley

).

10 KPCI-488LPA-903-01 Rev. B / January 2020

Page 11

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

To use the diagnostic tool:

1. From Windows, select Start > All Prog ram s .

2. From the programs selection, select Keithley Instruments > KI-488 Diagnostic Tool. The KI-488

Diagnostic Tool window will open.

Figure 9: KI-488 Diagnostic Tool

To initialize your GPIB interface accessory:

1. Select Initialize KI GPIB. The Initialize GPIB Interface Board dialog is displayed.

You must select Initialize KI GPIB

Diagnostic Tool. To initialize the communication interface, select a GPIB address that is not assigned

to any instrument connected to your GPIB bus.

before communic ating with your instrument using the KI-488

KPCI-488LPA-903-01 Rev. B / January 2020 11

Page 12

KPCI-488LPA GPIB Controller Interface Card Quick Start Guide

Figure 10: Specifying the GPIB bo ar d address

2. Enter the address to assign to your GPIB interface. The default is 21.

3. Select OK.

To communicate with a GPIB-connected instrument:

1. Enter the instrument GPIB address .

Figure 11: Specifying the instrument address

2. Type any commands to send to your instrument in the GPIB Command String to Send or Transmit field.

For example, you can send *IDN? to query the identification of an instrument.

3. Under Communications Functions, select Send. The command string will appear in the GPIB Commands

Previously Sent or Transmitted field.

To read the instrument response to a query:

Select Enter under Communications Functions. Any instrument responses are displayed in the GPIB Received

Message field. In this example, sending the *IDN? command to the instrument returns the manufacturer,

model number, and other information about the instrument.

Figure 12: GPIB Received Message field

12 KPCI-488LPA-903-01 Rev. B / January 2020

Page 13

Safety precaut ions

The following safety precautions should be observed before using this product and any associated instrumentation. Although

some instruments and accessories would normally be used with nonhazardous voltages, there are situations where hazardous

conditions may be present.

This product is intended for use by personnel who recognize shock hazards and are familiar with the safety precautions required

to avoid possible injury. Read and follow all installation, operation, and maintenance information carefully before using the

product. Refer to the user documentation for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product warranty may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use and maintenance of equipment, for ensuring that the

equipment is operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be trained in electrical safety procedures and proper use of the

instrument. They must be protected from electric shock and contact with hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line

voltage or replacing consumable materials. Maintenance procedures are described in the user documentation. The procedures

explicitly state if the operator may perform them. Otherwise, they should be performed only by service personnel.

Service personnel are trained to work on live circuits, perform safe installations, and repair products. Only properly trained

service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that are measurement, control, and data I/O connections, with low

transient overvoltages, and must not be directly connected to mains voltage or to voltage sources with high transient

overvoltages. Measurement Category II (as referenced in IEC 60664) connections require protection for high transient

overvoltages often associated with local AC mains connections. Certain Keithley measuring instruments may be connected to

mains. These instruments will be marked as category II or higher.

Unless explicitly allowed in the specifications, operating manual, and instrument labels, do not connect any instrument to mains.

Exercise extreme caution when a shock hazard is present. Lethal voltage may be present on cable connector jacks or test

fixtures. The American National Standards Institute (ANSI) states that a shock hazard exists when voltage levels greater than

30 V RMS, 42.4 V peak, or 60 VDC are present. A good safety practice is to expect that hazardous voltage is present in any

unknown circuit before measuring.

Operators of this product must be protected from electric shock at all times. The responsible body must ensure that operators

are prevented access and/or insulated from every connection point. In some cases, connections must be exposed to potential

human contact. Product operators in these circumstances must be trained to protect themselves from the risk of electric shock. If

the circuit is capable of operating at or above 1000 V, no conductive part of the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits. They are intended to be used with impedance-limited

sources. NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective

devices to limit fault current and voltage to the card.

Before operating an instrument, ensure that the line cord is connected to a properly-grounded power receptacle. Inspect the

connecting cables, test leads, and jumpers for possible wear, cracks, or breaks before each use.

When installing equipment where access to the main power cord is restricted, such as rack mounting, a separate main input

power disconnect device must be provided in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any other instruments while power is applied to the circuit under

test. ALWAYS remove power from the entire test system and discharge any capacitors before: connecting or disconnecting

cables or jumpers, installing or removing switching cards, or making internal changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth)

ground. Always make measurements with dry hands while standing on a dry, insulated surface capable of withstanding the

voltage being measured.

KPCI-488LPA-903-01 Rev. B / January 2020 13

Page 14

For safety, instruments and accessories must be used in accordance with the operating instructions. If the instruments or

accessories are used in a manner not specified in the operating instructions, the protection provided by the equipment may be

impaired.

Do not exceed the maximum signal levels of the instruments and accessories. Maximum signal levels are defined in the

specifications and operating information and shown on the instrument panels, test fixture panels, and switching cards.

When fuses are used in a product, replace with the same type and rating for continued protection against fire hazard.

Chassis connections must only be used as shield connections for measuring circuits, NOT as protective earth (safety ground)

connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use

of a lid interlock.

If a screw is present, connect it to protective earth (safety ground) using the wire recommended in the user documentation.

The symbol on an instrument means caution, risk of hazard. The user must refer to the operating instructions located in the

user documentation in all cases where the symbol is mark ed on the instr u ment .

The symbol on an instrument means warning, risk of electric shock. Use standard safety precautions to avoid personal

contact with these voltages.

The symbol on an instrument shows that the surface may be hot. Avoid personal contact to prevent burns.

The symbol indicates a connection terminal to the equipment frame.

If this s ymbol is on a product, it indicates that mercury is present in the display lamp. Please note that the lamp must be

properly disposed of according to federal, state, and local laws.

The WARNING heading in the user documentation explains hazards that might result in personal injury or death. Always read

the associated information very carefully before performing the indicated procedure.

The CAUTION heading in the user documentation explains h az ards that coul d dama ge the instrument. Such damage may

invalidate the warranty.

The CAUTION heading with the symbol in the user documentation explains hazards that could result in moderate or minor

injury or damage the instrument. Always read the associated information very carefully before performing the indicated

procedure. Damage to the instrument may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and all test cables.

To maintain protection from electric shock and fire, replacement components in mains circuits — including the power

transformer, test leads, and input jacks — must be purchased from Keithley. Standard fuses with applicable national safety

approvals may be used if the rating and type are the same. The detachable mains power cord provided with the instrument may

only be replaced with a similarly rated power cord. Other components that are not safety-related may be purchased from other

suppliers as long as they are equivalent to the original component (note that selected parts should be purchased only through

Keithley to maintain accuracy and functionality of the product). If you are unsure about the applicability of a replacement

component, call a Keithley office for information.

Unless otherwise noted in product-specific literature, Keithley instruments are designed to operate indoors only, in the following

environment: Altitude at or below 2,000 m (6,562 ft); temperature 0 °C to 50 °C (32 °F to 122 °F); and pol luti on degree 1 or 2.

To clean an instrument, use a cloth dampened with deionized water or mild, water-based cleaner. Clean the exterior of the

instrument only. Do not apply cleaner directly to the instrument or allow liquids to enter or spill on the instrument. Products that

consist of a circuit board with no case or chassis (e.g., a data acquisition board for installation into a computer) should never

require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board

should be returned to the factory for proper cleaning/servicing.

Safety precaution revision as of June 2017.

14 KPCI-488LPA-903-01 Rev. B / January 2020

Loading...

Loading...