Page 1

KPCI-1800HC Series

PCI Bus Data Acquisition Board

User’s Manual

A GREATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Hardware

Keithley Instruments, Inc. warrants that, for a period of three (3) years from the date of shipment, the Keithley Hardware product will be free from defects

in materials or workmanship. This warranty will be honored provided the defect has not been caused by use of the Keithley Hardware not in accordance

with the instructions for the product. This warranty shall be null and void upon: (1) any modification of Keithley Hardware that is made by other than Keithley and not approved in writing by Keithley or (2) operation of the Keithley Hardware outside of the environmental specifications therefore.

Upon receiving notification of a defect in the Keithley Hardware during the warranty period, Keithley will, at its option, either repair or replace such

Keithley Hardware. During the first ninety days of the warranty period, Keithley will, at its option, supply the necessary on site labor to return the

product to the condition prior to the notification of a defect. Failure to notify Keithley of a defect during the warranty shall relieve Keithley of its obligations and liabilities under this warranty.

Other Hardware

The portion of the product that is not manufactured by Keithley (Other Hardware) shall not be covered by this warranty, and Keithley shall have no

duty of obligation to enforce any manufacturers' warranties on behalf of the customer. On those other manufacturers’ products that Keithley purchases for resale, Keithley shall have no duty of obligation to enforce any manufacturers’ warranties on behalf of the customer.

Software

Keithley warrants that for a period of one (1) year from date of shipment, the Keithley produced portion of the software or firmware (Keithley Software)

will conform in all material respects with the published specifications provided such Keithley Software is used on the product for which it is intended

and otherwise in accordance with the instructions therefore. Keithley does not warrant that operation of the Keithley Software will be uninterrupted or

error-free and/or that the Keithley Software will be adequate for the customer's intended application and/or use. This warranty shall be null and void

upon any modification of the Keithley Software that is made by other than Keithley and not approved in writing by Keithley.

If Keithley receives notification of a Keithley Software nonconformity that is covered by this warranty during the warranty period, Keithley will review

the conditions described in such notice. Such notice must state the published specification(s) to which the Keithley Software fails to conform and the

manner in which the Keithley Software fails to conform to such published specification(s) with sufficient specificity to permit Keithley to correct such

nonconformity. If Keithley determines that the Keithley Software does not conform with the published specifications, Keithley will, at its option, provide

either the programming services necessary to correct such nonconformity or develop a program change to bypass such nonconformity in the Keithley

Software. Failure to notify Keithley of a nonconformity during the warranty shall relieve Keithley of its obligations and liabilities under this warranty.

Other Software

OEM software that is not produced by Keithley (Other Software) shall not be covered by this warranty, and Keithley shall have no duty or obligation

to enforce any OEM's warranties on behalf of the customer.

Other Items

Keithley warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries, diskettes, and documentation.

Items not Covered under Warranty

This warranty does not apply to fuses, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to

follow instructions.

Limitation of Warranty

This warranty does not apply to defects resulting from product modification made by Purchaser without Keithley's express written consent, or by

misuse of any product or part.

Disclaimer of Warranties

EXCEPT FOR THE EXPRESS WARRANTIES ABOVE KEITHLEY DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING WITHOUT LIMITATION, ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. KEITHLEY DISCLAIMS ALL WARRANTIES WITH RESPECT TO THE OTHER HARDWARE AND OTHER SOFTWARE.

Limitation of Liability

KEITHLEY INSTRUMENTS SHALL IN NO EVENT, REGARDLESS OF CAUSE, ASSUME RESPONSIBILITY FOR OR BE LIABLE FOR:

(1) ECONOMICAL, INCIDENTAL, CONSEQUENTIAL, INDIRECT, SPECIAL, PUNITIVE OR EXEMPLARY DAMAGES, WHETHER

CLAIMED UNDER CONTRACT, TORT OR ANY OTHER LEGAL THEORY, (2) LOSS OF OR DAMAGE TO THE CUSTOMER'S DATA OR

PROGRAMMING, OR (3) PENALTIES OR PENALTY CLAUSES OF ANY DESCRIPTION OR INDEMNIFICATION OF THE CUSTOMER

OR OTHERS FOR COSTS, DAMAGES, OR EXPENSES RELATED TO THE GOODS OR SERVICES PROVIDED UNDER THIS WARRANTY.

Keithley Instruments, Inc. 28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168

1-888-KEITHLEY (534-8453) • www.keithley.com

Sales Offices:BELGIUM: Bergensesteenweg 709 • B-1600 Sint-Pieters-Leeuw • 02-363 00 40 • Fax: 02/363 00 64

CHINA: Yuan Chen Xin Building, Room 705 • 12 Yumin Road, Dewai, Madian • Beijing 100029 • 8610-6202-2886 • Fax: 8610-6202-2892

FINLAND: Tietäjäntie 2 • 02130 Espoo • Phone: 09-54 75 08 10 • Fax: 09-25 10 51 00

FRANCE: 3, allée des Garays • 91127 Palaiseau Cédex • 01-64 53 20 20 • Fax: 01-60 11 77 26

GERMANY: Landsberger Strasse 65 • 82110 Germering • 089/84 93 07-40 • Fax: 089/84 93 07-34

GREAT BRITAIN: Unit 2 Commerce Park, Brunel Road • Theale • Berkshire RG7 4AB • 0118 929 7500 • Fax: 0118 929 7519

INDIA: Flat 2B, Willocrissa • 14, Rest House Crescent • Bangalore 560 001 • 91-80-509-1320/21 • Fax: 91-80-509-1322

ITALY: Viale San Gimignano, 38 • 20146 Milano • 02-48 39 16 01 • Fax: 02-48 30 22 74

JAPAN: New Pier Takeshiba North Tower 13F • 11-1, Kaigan 1-chome • Minato-ku, Tokyo 105-0022 • 81-3-5733-7555 • Fax: 81-3-5733-7556

KOREA: 2FL., URI Building • 2-14 Yangjae-Dong • Seocho-Gu, Seoul 137-888 • 82-2-574-7778 • Fax: 82-2-574-7838

NETHERLANDS: Postbus 559 • 4200 AN Gorinchem • 0183-635333 • Fax: 0183-630821

SWEDEN: c/o Regus Business Centre • Frosundaviks Allé 15, 4tr • 169 70 Solna • 08-509 04 679 • Fax: 08-655 26 10

SWITZERLAND: Kriesbachstrasse 4 • 8600 Dübendorf • 01-821 94 44 • Fax: 01-820 30 81

TAIWAN: 1FL., 85 Po Ai Street • Hsinchu, Taiwan, R.O.C. • 886-3-572-9077• Fax: 886-3-572-9031

4/02

Page 3

KPCI-1800HC

PCI Bus Data Acquisition Board

User’s Manual

Windows and WindowsNT are registered trademarks of Microsoft Corporation.

DriverLINX is a registered trademark of Scientific Software Tools, Inc.

©1999, Keithley Instruments, Inc.

All rights reserved.

Cleveland, Ohio, U.S.A.

Second Printing, March 1999

Document Number: 98220 Rev. B

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision

Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released between Revisions, contain important change information that the user should incorporate immediately into the manual. Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision of the manual are

incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this print history page.

Revision A (Document Number 98220) ............................................................................................February 1999

Revision B (Document Number 98220) ................................................................................................March 1999

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product

to keep it operating properly, for example, setting the line voltage

or replacing consumable materials. Maintenance procedures are described in the manual. The procedures explicitly state if the operator

may perform them. Otherwise, they should be performed only by

service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Installation Category I and Installation Category II, as described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Installation Category I and must not be directly connected

to mains voltage or to voltage sources with high transient over-voltages. Installation Category II connections require protection for

high transient over-voltages often associated with local AC mains

connections. Assume all measurement, control, and data I/O connections are for connection to Category I sources unless otherwise

marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures. The

American National Standards Institute (ANSI) states that a shock

hazard exists when voltage levels greater than 30V RMS, 42.4V

peak, or 60VDC are present. A good safety practice is to expect

that hazardous voltage is present in any unknown circuit before

measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

5/02

Page 6

If or is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill

on the instrument. Products that consist of a circuit board with no

case or chassis (e.g., data acquisition board for installation into a

computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected, the board should be returned to the factory for proper

cleaning/servicing.

Page 7

Table of Contents

1 Overview

Preface ................................................................................................................................................................ 1-2

Hardware characteristics .................................................................................................................................... 1-3

Specifications ..................................................................................................................................................... 1-4

System requirements .......................................................................................................................................... 1-4

Software ........................................................................................................................................................... 1-4

Accessories ......................................................................................................................................................... 1-5

2 Functional Description

Analog input features ......................................................................................................................................... 2-2

Understanding and choosing analog input modes ...................................................................................... 2-3

Throughput ................................................................................................................................................. 2-8

Data conversion modes ............................................................................................................................ 2-11

Clock sources ........................................................................................................................................... 2-12

Triggers .................................................................................................................................................... 2-13

Gates ......................................................................................................................................................... 2-18

Analog output features ..................................................................................................................................... 2-19

Digital input and output features ..................................................................................................................... 2-19

General purpose digital inputs and outputs .............................................................................................. 2-19

External pacer clock (XPCLK) digital control input ............................................................................... 2-19

Trigger in (TGIN) digital control input .................................................................................................... 2-19

Strobe (DOSTB) digital control output .................................................................................................... 2-20

Trigger-out (TGOUT) digital control output ........................................................................................... 2-20

Power ............................................................................................................................................................... 2-21

3 Installation

Installing the software ........................................................................................................................................ 3-2

Software options ........................................................................................................................................ 3-2

Installing DriverLINX ................................................................................................................................ 3-3

Installing application software and drivers ................................................................................................ 3-3

Installing and wiring to the KPCI-1800HC Series board ................................................................................... 3-4

Installing the board ..................................................................................................................................... 3-5

Checking the combined board and DriverLINX installations .................................................................... 3-6

Identifying I/O connector pin assignments for KPCI-1800HC series ....................................................... 3-7

Connecting interface accessories to a KPCI-1800HC Series board ......................................................... 3-10

Wiring analog input signals ..................................................................................................................... 3-17

Wiring analog output signals ................................................................................................................... 3-24

Wiring digital input and output signals .................................................................................................... 3-25

i

Page 8

Synchronizing multiple boards ................................................................................................................. 3-28

Wiring +5V and ±15V power to external circuits ................................................................................... 3-30

4 DriverLINX Test Panels

DriverLINX Analog I/O Panel ........................................................................................................................... 4-2

Starting the Analog I/O Panel ..................................................................................................................... 4-5

Using the Analog I/O Panel ........................................................................................................................ 4-6

DriverLINX Calibration Utility .......................................................................................................................... 4-6

DriverLINX Digital I/O Test Panel .................................................................................................................... 4-7

Starting the Digital I/O Test Panel ............................................................................................................. 4-8

Using the Digital I/O Test Panel ................................................................................................................ 4-8

5 Calibration

Introduction ........................................................................................................................................................ 5-2

Objectives ................................................................................................................................................... 5-2

Calibration summary .................................................................................................................................. 5-2

Equipment ................................................................................................................................................... 5-2

Calibration procedure ......................................................................................................................................... 5-3

Preparing for the calibrations ..................................................................................................................... 5-3

Calibrating the analog inputs .................................................................................................................... 5-4

Calibrating the analog outputs ................................................................................................................... 5-6

Finishing ..................................................................................................................................................... 5-8

6 Troubleshooting

Identifying symptoms and possible causes ......................................................................................................... 6-2

Systematic problem isolation ............................................................................................................................. 6-3

Specified hardware I/O tests ............................................................................................................................. 6-25

Analog input hardware test ....................................................................................................................... 6-25

Analog output hardware test .................................................................................................................... 6-31

Digital I/O hardware test .......................................................................................................................... 6-35

Specified software I/O tests .............................................................................................................................. 6-40

Analog input software test ........................................................................................................................ 6-40

Analog output software test ...................................................................................................................... 6-42

Digital I/O software test ........................................................................................................................... 6-45

Technical support ............................................................................................................................................. 6-49

A Specifications

KPCI-1801HC specifications ............................................................................................................................ A-2

Analog Inputs, KPCI-1801HC .................................................................................................................. A-2

Analog Outputs, KPCI-1801HC ................................................................................................................ A-4

Clock/Timer, KPCI-1801HC ..................................................................................................................... A-4

Digital I/O, KPCI-1801HC ........................................................................................................................ A-5

Power, KPCI-1801HC ............................................................................................................................... A-5

Environment, KPCI-1801HC .................................................................................................................... A-6

Accessories, KPCI-1801HC ...................................................................................................................... A-6

KPCI-1802HC specifications ............................................................................................................................ A-7

Analog Inputs, KPCI-1802HC .................................................................................................................. A-7

Analog Outputs, KPCI-1802HC ................................................................................................................ A-9

Clock/Timer, KPCI-1802HC ..................................................................................................................... A-9

ii

Page 9

Digital I/O, KPCI-1802HC ..................................................................................................................... A-10

Power, KPCI-1802HC ............................................................................................................................ A-10

Environment, KPCI-1802HC .................................................................................................................. A-10

Accessories, KPCI-1802HC .................................................................................................................... A-11

B Connector pin assignments

Pin assignments for KPCI-1800HC Series I/O connector ................................................................................ B-2

Pin assignments for STA-1800HC and CONN-1800HC 37-pin D connectors ................................................ B-4

C Glossary

iii

Page 10

List of Illustrations

2 Functional Description

Figure 2-1 Block diagram of KPCI-1800HC board ..................................................................................................... 2-2

Figure 2-2 Multiplexing of 32 channels in differential input mode ............................................................................ 2-4

Figure 2-3 Multiplexing of 64 channels in single-ended input mode .......................................................................... 2-5

Figure 2-4 Channel-gain queue example ..................................................................................................................... 2-7

Figure 2-5 Paced mode and burst mode timing for a queue of channels 4 to 7 ......................................................... 2-12

Figure 2-6 Enabling conversions with software triggers ........................................................................................... 2-14

Figure 2-7 Enabling conversions with hardware triggers .......................................................................................... 2-15

Figure 2-8 Trigger acquisition modes ........................................................................................................................ 2-17

Figure 2-9 Enabling conversions with gates .............................................................................................................. 2-18

Figure 2-10 Timing relationship between data from DO0 to DO7 and latch strobe DOSTB ..................................... 2-20

Figure 2-11 Timing for the generation of TGOUT ...................................................................................................... 2-21

3 Installation

Figure 3-1 Connectors on the KPCI-1800HC Series board ......................................................................................... 3-4

Figure 3-2 Pin assignments for the I/O connector of the KPCI-1800HC Series boards ............................................. 3-7

Figure 3-3 Connecting an STP-100 screw terminal accessory .................................................................................. 3-11

Figure 3-4 Pin assignments for the I/O connector of the STP-100 accessory and the main

I/O connectors of the STA-1800HC and CONN-1800HC accessories ............................................. 3-12

Figure 3-5 Connecting an STA-1800HC screw terminal accessory to a KPCI-1800HC Series board ..................... 3-13

Figure 3-6 CJC temperature circuit ........................................................................................................................... 3-14

Figure 3-7 Location of CJC circuit screw terminals (TB11) on STA-1800HC accessory ........................................ 3-15

Figure 3-8 Connecting a CONN-1800HC accessory to a KPCI-1800HC Series board ............................................ 3-16

Figure 3-9 Connecting MB01 module racks (backplanes) to an STA-1800HC or a CONN-1800HC ...................... 3-17

Figure 3-10 Analog and digital ground path ................................................................................................................ 3-18

Figure 3-11 Wiring a signal source to a board configured for single-ended inputs .................................................... 3-19

Figure 3-12 Wiring a floating signal source to differential inputs: three common examples ..................................... 3-20

Figure 3-13 Satisfactory differential input connections for ground-referenced signals that avoid a ground loop ...... 3-22

Figure 3-14 Improper differential input connection, which creates a ground loop error ............................................ 3-23

Figure 3-15 Analog and digital ground path ................................................................................................................ 3-24

Figure 3-16 Analog and digital ground path ................................................................................................................ 3-26

Figure 3-17 Contact de-bounce circuit ........................................................................................................................ 3-26

Figure 3-18 Two connection schemes for synchronizing multiple boards .................................................................. 3-28

Figure 3-19 Analog and digital ground path ................................................................................................................ 3-30

v

Page 11

4 DriverLINX Test Panels

Figure 4-1 Analog I/O Panel oscilloscope utility ......................................................................................................... 4-2

Figure 4-2 Analog I/O Panel digital voltmeter utility .................................................................................................. 4-3

Figure 4-3 Analog I/O Panel function generator utility ............................................................................................... 4-3

Figure 4-4 Analog I/O Panel output level control utility ............................................................................................. 4-4

Figure 4-5 Analog I/O Panel digital I/O utility ............................................................................................................ 4-4

Figure 4-6 Analog I/O Panel setup screen when only a KPCI-1800HC series board is

installed under DriverLINX ................................................................................................................. 4-5

Figure 4-7 Analog I/O Panel setup screen example when multiple board types are installed under DriverLINX ...... 4-6

Figure 4-8 DriverLINX Digital I/O Test Panel ............................................................................................................ 4-7

Figure 4-9 Open DriverLINX dialog box .................................................................................................................... 4-8

5 Calibration

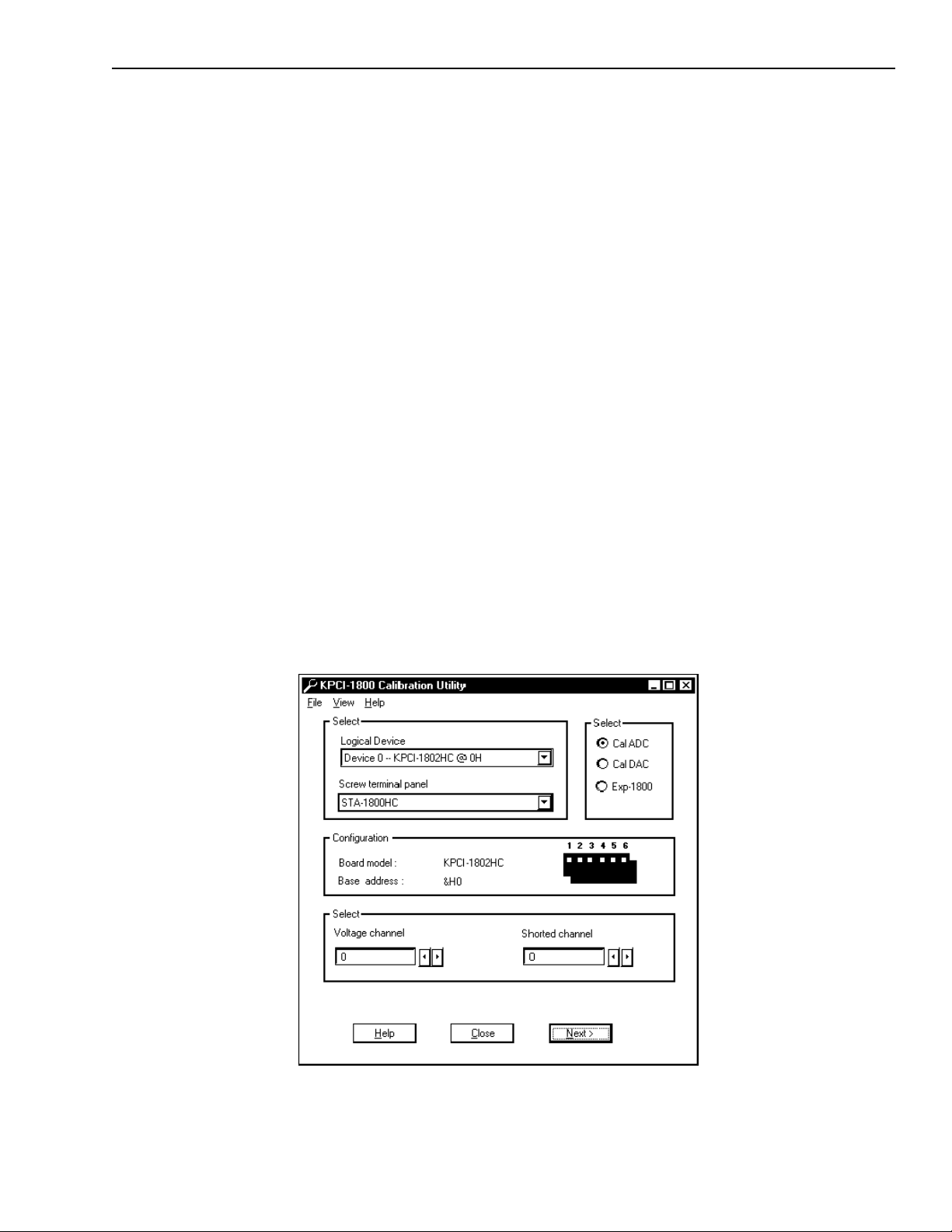

Figure 5-1 KPCI-1800 Calibration Utility dialog box example ................................................................................... 5-3

Figure 5-2 Example of a Calibrate A/D dialog box ..................................................................................................... 5-4

Figure 5-3 Example of a Calibrate DAC dialog box .................................................................................................... 5-7

6 Troubleshooting

Figure 6-1 Problem isolation Scheme A: basic system ................................................................................................ 6-5

Figure 6-2 Problem isolation Scheme B: installation ................................................................................................... 6-8

Figure 6-3 Analog I/O Panel setup screen when only KPCI-1800HC series boards are

installed under DriverLINX ................................................................................................................. 6-9

Figure 6-4 Analog I/O Panel example setup screen when multiple board types are installed under DriverLINX .... 6-10

Figure 6-5 Listing of improperly configured/installed KPCI-1800HC Series board ................................................. 6-11

Figure 6-6 Appearance of device manager listing when KPCI-1800HC Series board is

properly configured/installed ............................................................................................................. 6-12

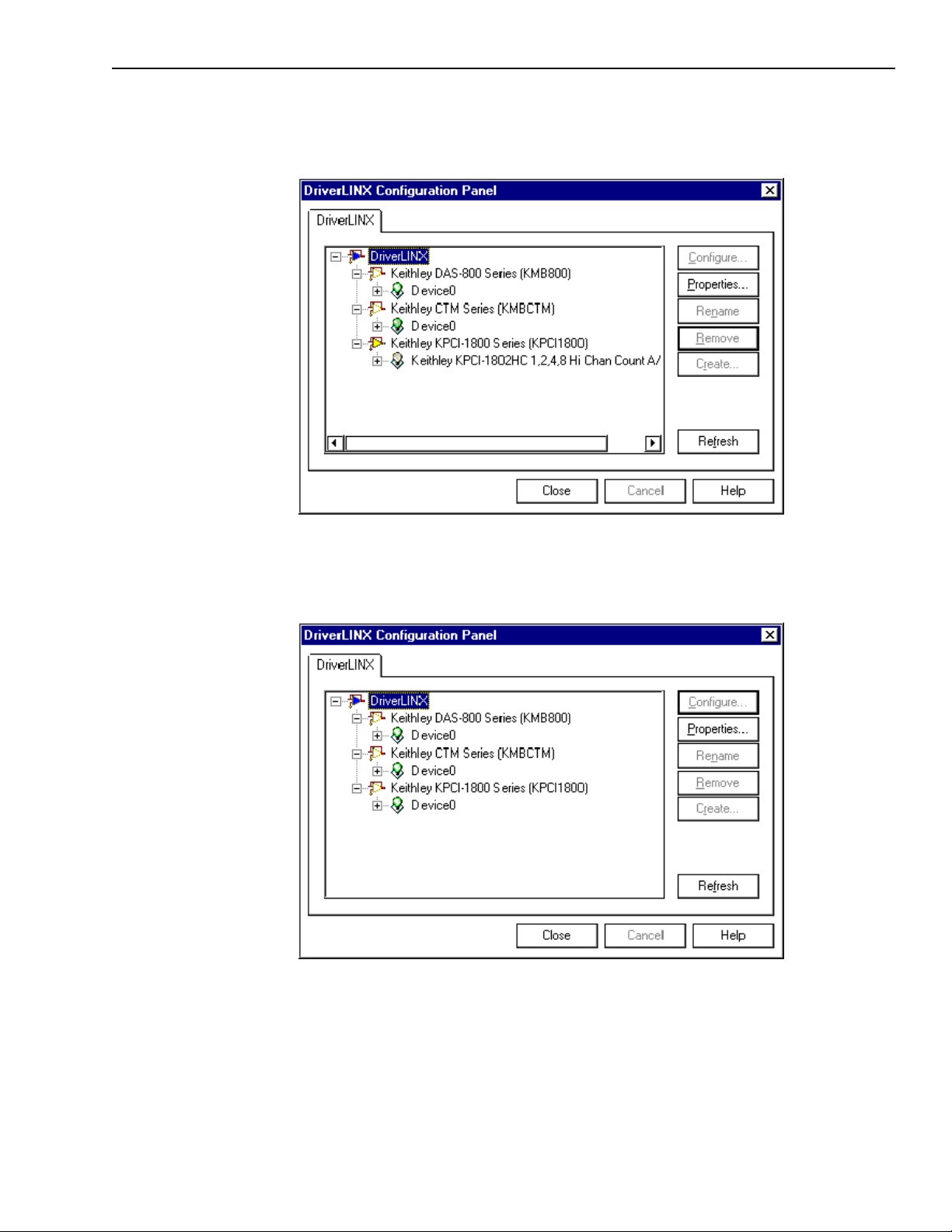

Figure 6-7 Example of a DriverLINX Configuration Panel before a KPCI-1800HC Series board is configured ..... 6-13

Figure 6-8 Example of a DriverLINX Configuration Panel after a KPCI-1800HC Series board is configured ....... 6-13

Figure 6-9 Selecting the logical device number ......................................................................................................... 6-14

Figure 6-10 Configure DriverLINX Device dialog box example ................................................................................ 6-15

Figure 6-11 Device Change message ........................................................................................................................... 6-15

Figure 6-12 Problem isolation Scheme C: application software .................................................................................. 6-18

Figure 6-13 Problem isolation Scheme D: expansion slot connectors ......................................................................... 6-21

Figure 6-14 Problem isolation Scheme E: user wiring ................................................................................................ 6-22

Figure 6-15 Problem isolation Scheme F: the board .................................................................................................... 6-23

Figure 6-16 Problem isolation Scheme G: verification of problem solution ............................................................... 6-24

Figure 6-17 Analog I/O Panel setup screen when only a KPCI-1800HC series board is

installed under DriverLINX ............................................................................................................... 6-27

Figure 6-18 Analog I/O Panel setup screen example when multiple board types are installed under DriverLINX .... 6-28

Figure 6-19 On-screen digital voltmeter display example: channel 0 connected to ground ........................................ 6-29

Figure 6-20 On-screen digital voltmeter display example: channel 1 connected to flashlight battery ........................ 6-30

Figure 6-21 Analog I/O Panel setup screen when only a KPCI-1800HC series board is

installed under DriverLINX ............................................................................................................... 6-32

Figure 6-22 Analog I/O Panel setup screen example when multiple board types are installed under DriverLINX .... 6-33

Figure 6-23 On-screen analog-output level control ..................................................................................................... 6-34

Figure 6-24 Example of Open DriverLINX dialog box ............................................................................................... 6-37

Figure 6-25 DriverLINX Digital I/O Test Panel .......................................................................................................... 6-37

Figure 6-26 Output bit pattern 1 of digital I/O hardware test ...................................................................................... 6-38

Figure 6-27 Proper input-bit responses to bit pattern 1 of digital I/O hardware test ................................................... 6-38

Figure 6-28 Output bit pattern 2 of digital I/O hardware test ...................................................................................... 6-38

Figure 6-29 Proper input-bit responses to bit pattern 2 of digital I/O hardware test ................................................... 6-39

vi

Page 12

Figure 6-30 Output bit pattern 3 of digital I/O hardware test ...................................................................................... 6-39

Figure 6-31 Proper input-bit responses to bit pattern 3 of digital I/O hardware test ................................................... 6-39

Figure 6-32 Output bit pattern 4 of digital I/O hardware test ...................................................................................... 6-40

Figure 6-33 Proper input-bit responses to bit pattern 4 digital I/O hardware test ....................................................... 6-40

Figure 6-34 Output bit pattern 1 of digital I/O software test ....................................................................................... 6-46

Figure 6-35 Proper input-bit responses to bit pattern 1 of digital I/O software test .................................................... 6-46

Figure 6-36 Output bit pattern 2 of digital I/O software test ....................................................................................... 6-47

Figure 6-37 Proper input-bit responses to bit pattern 2 of digital I/O software test .................................................... 6-47

Figure 6-38 Output bit pattern 3 of digital I/O software test ....................................................................................... 6-47

Figure 6-39 Proper input-bit responses to bit pattern 3 of digital I/O software test .................................................... 6-48

Figure 6-40 Output bit pattern 4 of digital I/O software test ....................................................................................... 6-48

Figure 6-41 Proper input-bit responses to bit pattern 4 of digital I/O software test .................................................... 6-48

B Connector pin assignments

Figure B-1 Pin assignments for the main I/O connector of KPCI-1800HC Series boards ......................................... B-2

Figure B-2 Pin assignments for the main I/O connectors of the STA-1800HC, STP-100, and CONN-1800HC ....... B-3

Figure B-3 Connector J1 ............................................................................................................................................. B-4

Figure B-4 Connector J2 ............................................................................................................................................. B-4

Figure B-5 Connector J3 ............................................................................................................................................. B-5

Figure B-6 Accessory Connector J4 ............................................................................................................................ B-5

vii

Page 13

List of Tables

1 Overview

Table 1-1 System requirements .................................................................................................................................. 1-4

Table 1-2 Interface accessories for KPCI-1800HC Series boards ............................................................................. 1-5

2 Functional Description

Table 2-1 Gains, ranges, and resolutions for the KPCI-1801HC ............................................................................... 2-6

Table 2-2 Gains, ranges, and resolutions for the KPCI-1802HC ............................................................................... 2-7

Table 2-3 Maximum throughput for channel-to-channel sampling at fixed gain: bipolar mode ............................... 2-9

Table 2-4 Maximum throughput for channel-to-channel sampling at fixed gain: unipolar mode ............................. 2-9

Table 2-5 Maximum KPCI-1801HC throughput when changing gain between channels: bipolar mode ................ 2-10

Table 2-6 Maximum KPCI-1801HC throughput when changing gain between channels: unipolar mode .............. 2-10

Table 2-7 Maximum KPCI-1802HC throughput when changing gain between channels: bipolar mode ................ 2-10

Table 2-8 Maximum KPCI-1802HC throughput when changing gain between channels: unipolar mode .............. 2-11

3 Installation

Table 3-1 Descriptions for A side pins ....................................................................................................................... 3-8

Table 3-2 Descriptions for B side pins ....................................................................................................................... 3-9

Table 3-3 Interface accessories for KPCI-1800HC Series boards ........................................................................... 3-10

Table 3-4 CAB-1800 Series cables .......................................................................................................................... 3-11

Table 3-5 Analog output terminals on STA-1800HC and STP-100 accessories ..................................................... 3-25

Table 3-6 General purpose and control digital I/O terminals for STA-1800HC and STP-100 accessories ............. 3-27

Table 3-7 Power output terminals for STA-1800HC and STP-100 accessories ...................................................... 3-31

6 Troubleshooting

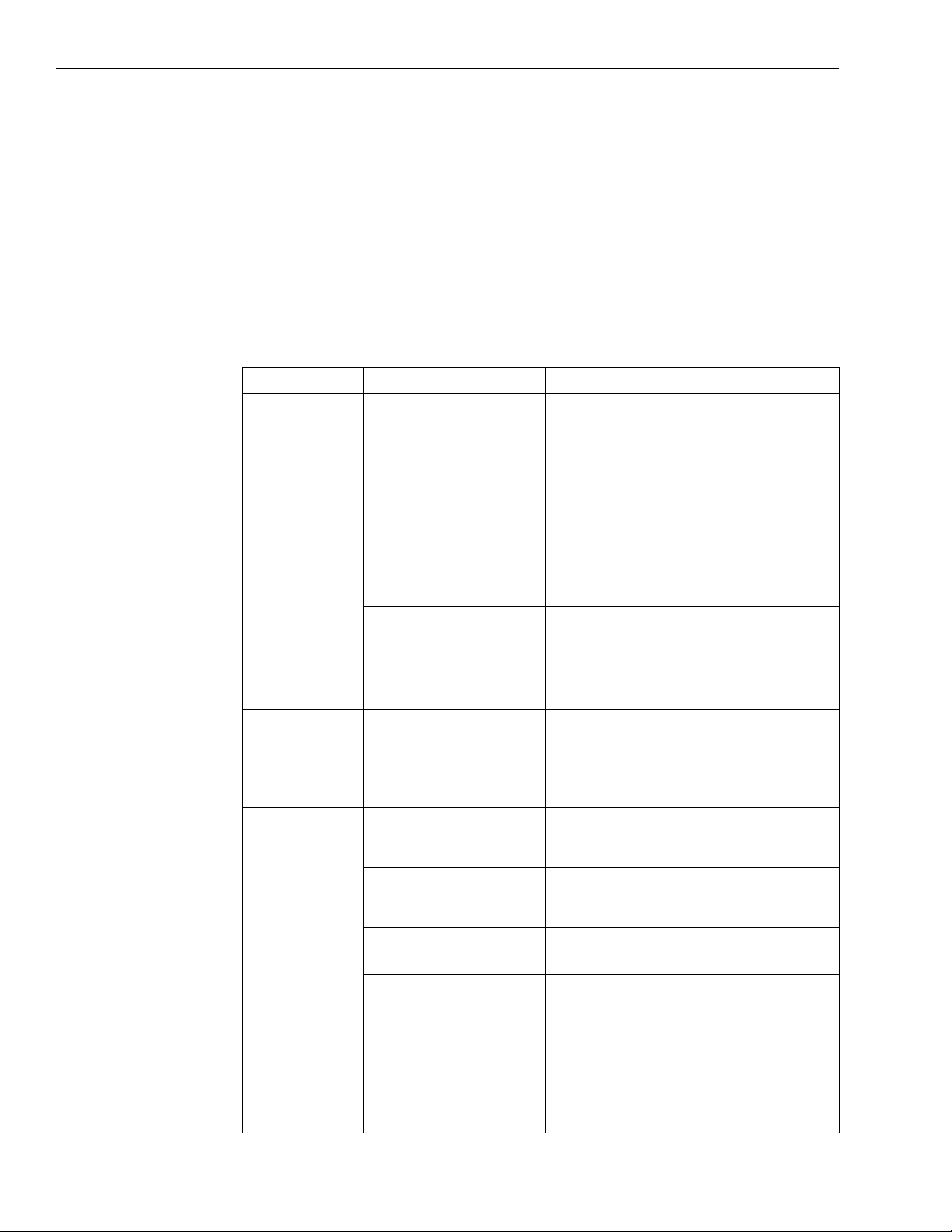

Table 6-1 Basic troubleshooting information ............................................................................................................. 6-2

Table 6-2 Wiring for analog input hardware test ..................................................................................................... 6-26

Table 6-3 Screw terminals to which DVM/DMM is connected in analog output hardware test ............................. 6-31

Table 6-4 Test connections and correct readings for zero-voltage analog output .................................................... 6-34

Table 6-5 Test connections and correct readings for mid-range analog output,

during analog output hardware tests .................................................................................................. 6-35

Table 6-6 Wiring for digital I/O hardware test ......................................................................................................... 6-36

Table 6-7 Wiring for analog input software test ....................................................................................................... 6-41

Table 6-8 Screw terminals to which DVM/DMM is connected in analog output software test .............................. 6-43

Table 6-9 Test connections and correct readings for zero-voltage analog output .................................................... 6-44

Table 6-10 Test connections and correct readings for mid-range analog output

during analog output software tests ................................................................................................... 6-44

Table 6-11 Wiring for digital I/O software test .......................................................................................................... 6-45

ix

Page 14

1

Overview

Page 15

•

•

•

•

•

•

•

•

•

•

1-2 Overview KPCI-1800HC Series User’s Manual

Preface

This manual is provided for persons needing to understand the installation, interface requirements, functions, and operation of the KPCI-1801HC and KPCI-1802HC boards. The two models differ only in available gains. Unless this manual refers specifically to a KPCI-1801HC board

or a KPCI-1802HC board, it refers to the two models collectively as a KPCI-1800HC Series

board.

This manual focuses primarily on describing the KPCI-1800HC Series boards and their capabilities, setting up the boards and their associated software, making typical hookups, and operating

the test-panel software. There are also sections on calibration and troubleshooting.

To follow the information and instructions contained in this manual, you must be familiar with

the operation of Windows 95, 98, or NT, with basic data-acquisition principles, and with your

application. However, if you find unfamiliar terms in this manual, check the glossary in Appendix C. To locate topics discussed in this manual, search the index.

The

KPCI-1800HC Series User's Manual is organized as follows:

Section 1 describes general features and system requirements and summarizes supporting

software and accessories for the KPCI-1800HC Series boards.

Section 2 describes operating features of the boards in more detail. This section contains a

block diagram and brief descriptions of the features as they relate to setting up and using the

board.

Section 3 contains software descriptions and installation notes and instructions for the following: inspecting the board, installing the board, checking the board and software installation, installing accessories, and connecting signals.

Section 4 summarizes the test panels that are available in the DriverLINX software.

Section 5 discusses how to calibrate your board using the DriverLINX calibration utility.

Section 6 contains detailed procedures for isolating problems with your data acquisition sys-

tem. This section also contains instructions for obtaining technical support.

Appendix A contains specifications for the KPCI-1800HC Series boards.

Appendix B provides pin assignments for the KPCI-1800HC Series board I/O connector and

for the four 37-pin accessory connectors of the STA-1800HC and CONN-1800HC

accessories.

Appendix C is a glossary of key terms used in this manual.

A detailed index completes this manual.

Page 16

•

•

-

-

•

-

-

-

-

-

-

•

•

•

•

•

•

KPCI-1800HC Series User’s Manual Overview 1-3

This section summarizes general hardware characteristics of the KPCI-1800HC board, computer

system requirements to run the board, and software that can be used with the board.

Hardware characteristics

The KPCI-1801HC and KPCI-1802HC are high-performance PCI-bus data acquisition boards

for PC-compatible computers running Windows 95, 98, or NT. The KPCI-1801HC is a highgain board, while the KPCI-1802HC is a low-gain board.

PCI-bus data acquisition boards such as the KPCI-1800HC Series, have two major advantages

over ISA-bus data acquisition boards:

The PCI-bus Plug and Play feature allows a user to install the data acquisition board without

making manual system configurations. Upon system power-up or reset, the PCI-bus Plug and

Play feature automatically configures the board for your system, eliminating the need to set

DIP switches on the board.

Cleaner, faster, direct data transfer to and from memory using bus mastering to bypass the

CPU.

Data transfer occurs at speeds up to 132 MB/sec rate for the PCI bus, versus 8.33 MB/sec

maximum for the ISA bus, due to the 32 bit width and 33 MHz clock speed of the PCI

bus.

Data transfer causes minimal interruptions to normal processing.

Major features of KPCI-1800HC Series boards include the following:

The following analog input characteristics:

Software-configurable for 64 single-ended or 32 differential analog input channels.

Software-configurable individual gains for each analog input channel. The

KPCI-1801HC provides gains of 1, 5, 50, and 250. The KPCI-1802 provides gains of 1,

2, 4, and 8.

Analog data conversion speeds up to 333 ksamples/s with 12-bit resolution.

A 64-location channel/gain queue which supports high-speed sampling of analog input

channels at identical or different gains in any desired sequence.

A 2048 sample FIFO (First In First Out) data buffer for the A/D converter that ensures

data integrity at high sampling rates.

Software-selectable edge-polarity detection for hardware trigger and gate signals which

are used to start and stop analog-to-digital data conversions.

Two analog outputs from two independent 12-bit DACs (Digital-to-Analog Converters).

Two general-purpose digital inputs and two combination digital inputs which can be config-

ured by software as either general-purpose inputs or control inputs.

Eight general-purpose digital outputs and three digital control outputs. The control outputs

include a strobe output to coordinate data movement from the outputs and latching into the

registers of other equipment.

Optional target-mode (pass-through) data transfer capability in addition to bus mastering.

Both target-mode data transfer, which is sometimes referred to as pass-through operation,

and bus mastering data transfer are software-configurable. To maximize the speed of analog

I/O, the KPCI-1800HC Series boards normally implement the bus mastering mode. The target mode provides a simple access port to the PCI bus for digital I/O.

Very fast board control via a field-programmable gate array (FPGA) instead of a microprocessor. (Refer to glossary for more information about FPGAs).

100-pin I/O connector that requires only one slot on the rear panel of the PC.

For more detailed information on these features, refer to Section 2, Functional Description .

Page 17

•

•

•

1-4 Overview KPCI-1800HC Series User’s Manual

Specifications

General specifications are listed in Appendix A. I/O connections are identified in Section 3 and

Appendix B.

System requirements

The system capabilities required to run the KPCI-1800HC Series board, and to use the DriverLINX software supplied with the board, are listed in Table 1-1.

Table 1-1

System requirements

CPU Type

Operating system

Pentium or higher processor on motherboard with PCI bus version 2.1

Windows 95 or 98

Windows NT version 4.0 or higher

Software

Memory

Hard disk space

Other

* Any CD-ROM drive that came installed with the required computer should be satisfactory. However, if you have

post-installed an older CD-ROM drive or arrived at your present system by updating the microprocessor or replacing

the motherboard, some early CD-ROM drives may not support the long file names often used in 32 bit Windows files.

The user can select a fully integrated data acquisition software package such as TestPoint or

LabVIEW or write a custom program supported by DriverLINX.

DriverLINX is the basic Application Programming Interface (API) for the KPCI-1800HC series

boards:

It supports programmers who wish to create custom applications using Visual C/C++, Visual

Basic, or Delphi.

It accomplishes foreground and background tasks to perform data acquisition.

It is the needed interface between TestPoint and LabVIEW and a KPCI-1800HC Series

board.

16 MB or greater RAM when running Windows 95 or 98

32 MB or greater RAM when running Windows NT

4 MB for minimum installation

50 MB for maximum installation

A CD-ROM drive*

A free PCI-bus expansion slot capable of bus mastering

Enough reserve computer power supply capacity to power the

KPCI-1800HC Series board, which draws 10W at 5VDC and 6W at

+12VDC.

DriverLINX software and user’s documentation on a CD-ROM are included with your board.

TestPoint is an optional, fully featured, integrated application package with a graphical dragand-drop interface which can be used to create data acquisition applications without

programming.

Page 18

KPCI-1800HC Series User’s Manual Overview 1-5

LabVIEW is an optional, fully featured graphical programming language used to create virtual

instrumentation.

Refer to Section 3, Installation , for more information about DriverLINX, TestPoint, and

LabView.

Accessories

Accessories available to interface your KPCI-1800HC board to external circuits are listed in

Table 1-2.

Table 1-2

Interface accessories for KPCI-1800HC Series boards

Category

Primary interfaces to

KPCI-1800HC Series

boards.

They connect to

KPCI-1800HC Series

boards via CAB-1800

series cables.

CAB-1800 Series

cables.

Secondary, signal

conditioning

interfaces.

They connect to

primary interfaces via

cables listed below.

Cables to connect

secondary interfaces

to primary interfaces.

Other accessories. RMT-04 Rack-mount enclosure for the STA-1800HC.

Part number Description

STP-100 Basic screw-terminal accessory. Interfaces each

KPCI-1800HC Series I/O connector-pin to a

corresponding screw terminal.

STA-1800HC Screw-terminal accessory and secondary connector

interface. Interfaces KPCI-1800HC Series I/O

connector-pins both to screw terminals and to four

secondary connectors. The secondary connectors

interface signal conditioning modules to a

KPCI-1800HC Series board. Also provides a

breadboarding area for user circuits and an onboard

temperature measurement circuit that facilitates

thermocouple Cold-Junction Compensation (CJC).

CONN-1800HC Secondary connector interface only. Effectively an

STA-1800HC without the screw terminals, the

breadboarding area, or the CJC temperature

measurement circuit. Interfaces signal conditioning

modules to a KPCI-1800HC Series board.

CAB-1800 18-inch, 100-wire ribbon cable.

CAB-1801 36-inch, 100-wire ribbon cable.

CAB-1800/S

CAB-1801/S

MB Series

modules and

MB01

backplanes

C-16MB1 Cable for connecting an STA-1800HC or

18-inch, 100-wire, shielded, ribbon cable.

36-inch, 100-wire, shielded, ribbon cable.

Plug-in, isolated, signal-conditioning modules and

the backplanes that hold them.

CONN-1800HC to an MB01 signal-conditioning

backplane.

Page 19

2

Functional Description

Page 20

2-2 Functional Description KPCI-1800HC Series User’s Manual

This section describes features of the following KPCI-1800HC Series board sections: the analog

input, the analog output, and the digital I/O. These descriptions help familiarize you with operating options and enable you to make the best use of your board.

NOTE

The block diagram in Figure 2-1 represents both the KPCI-1801HC and the KPCI-1802HC.

Figure 2-1

Block diagram of KPCI-1800HC board

AMCC S5933

PCI BUS

Boot

ROM

PCI

Interface

Circuitry

Control

Pass-

Through

Data

PassThrough

Address

FIFO

Timer

82C54

ROM

Decode

Module

PCI/S5933

Handshake

&

Control

Timing

Control

Prescaler

÷2, ÷10, ÷5

Boot

Field Programmable

Gate Array

10MHz

Clock

Features described in this section are typically configured using custom

or commercial application software which interfaces to your

KPCI-1800HC Series board via DriverLINX. For information on how to

configure and apply these features, consult the appropriate manuals.

Application software developers should consult your DriverLINX manuals located on the DriverLINX CD-ROM shipped with your board.

Application software users should consult the manuals provided by the

vendor or developer of your software.

Input

Multiplexer

DAC Out

0

± 10V Out

DAC Out

1

64 Single-Ended

. . . . . . .

QRAM

Analog to

Digital

Control

Digital

To Analog

Control

Digital I/O

Control

Data

Control

FIFO

FIFO

DAC0

12 Bits

DAC1

12 Bits

Mux & Gain Control

Data

Control

Analog

To

Digital

Converter

12 Bits

Buffer

Latch

+

-

Instrumentation

Amplifier

Data In

DI [3...0]

Data Out

DO [7...0]

TGIN

SSHD

XPCLK

TGOUT

Analog Inputs

32 Differential

or

. . . . . . .

Input

Protection

Analog input features

This section discusses the following:

•

Understanding and choosing the software-configurable analog input modes.

•

Maximum data throughput specifications and tips on optimizing throughput.

•

Signal conversion modes.

•

Signal conversion clock sources.

•

The use of triggers and gates to start and stop signal conversions.

Page 21

KPCI-1800HC Series User’s Manual Functional Description 2-3

Understanding and choosing analog input modes

Using software, you can select between various analog input options as follows:

• The differential input mode or the single-ended input mode for all channels.

• The unipolar input mode or the bipolar input mode for all channels.

• The input channels to be scanned to the instrumentation amplifier, in any order or

combination.

• The instrumentation amplifier gain to be used at each step in the input scan.

The next four subsections, as well as the subsequent section entitled Optimizing throughput,

explain these options and provide guidance for making choices.

Understanding the analog inputs

Each KPCI-1800HC Series board provides 64 analog input terminals. These terminals are configurable by software either as single-ended inputs or, in pairs, as differential inputs. Each

single-ended or differential input is commonly referred to as an input channel. The characteristics of single ended and differential inputs are as follows:

• A single-ended input measures the voltage at one input terminal relative to a common

ground. When the 64 analog input terminals are configured as single-ended, you can connect

each of the 64 input terminals to 64 external signals, maximum. In other words, each

KPCI-1800HC Series board provides up to 64 single-ended input channels.

• A differential input measures the difference between the voltages at two input terminals, designated input-high and input-low. Signals at both the input-high and input-low terminals are

referenced to a common ground. When the 64 analog input terminals are configured for differential input, you can connect 32 external signals, maximum, because a pair of input terminals is needed for each differential input. In other words, each KPCI-1800HC Series board

provides up to 32 differential input channels.

Differential inputs reject the common mode voltage, the voltage that each “sees” in common,

except for a small fraction determined by the common mode rejection ratio (refer to the glossary in Appendix C). Differential inputs are commonly used to:

- Reject noise and other unwanted voltages in a signal ground.

- Reject a common power supply voltage, such as the excitation voltage of a bridge circuit.

A single-ended input cannot reject these voltages. Refer to Section 3, Wiring analog input

signals for more information about using differential inputs.

Signals from all 64 single-ended inputs or 32 differential inputs are amplified by one instrumentation amplifier — a type of high performance differential amplifier — and are digitized by one

12-bit analog-to-digital converter (A/D converter or ADC). This is made possible by a

time-sharing arrangement in which inputs are scanned and connected intermittently to the

instrumentation amplifier and A/D converter according to a user-defined sequence. The inputs

are connected through a pair of 32-channel multiplexers, each of which is effectively a solidstate 32-pole, single-throw switch. Additional solid-state switches connecting the multiplexer to

the instrumentation amplifier determine whether inputs are configured as differential or singleended.

Page 22

2-4 Functional Description KPCI-1800HC Series User’s Manual

When the inputs are configured as differential inputs, the two multiplexers act together as a

32-pole, double throw switch, connecting one input signal at a time to both the high and low terminals of the instrumentation amplifier. See Figure 2-2.

Figure 2-2

Multiplexing of 32 channels in differential input mode

NOTE: Channel 31 is shown connected

to the instrumentation amplifier

and A/D converter.

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

+

Inputs

(Multiplexer)

–

Signal

Source #31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

MUX1

AGND (Analog Ground), which may be tied

to the [–] terminal of source. Refer to Section 3,

Wiring analog inputs,

about grounding with differential inputs.

59

60

61

62

63

Inputs

MUX2

(Multiplexer)

for more information

V

V

1

2

Hi

Lo

Ground)

Instrumentation

amplifier*

*Programmable-Gain

Instrumentation

Amplifier (PGIA)

AGND

(Analog

analog-to-digital

= –

V

O

To 12-bit

converter

V

V

1

V

O

2

Page 23

KPCI-1800HC Series User’s Manual Functional Description 2-5

When the inputs are configured as single-ended inputs, the input-low terminal of the instrumentation amplifier is connected to ground. At any given time, only one multiplexer is active. The

active multiplexer connects only one pole of a signal source to the input-high terminal of the

instrumentation amplifier. See Figure 2-3.

Figure 2-3

Multiplexing of 64 channels in single-ended input mode

To 12-bit

analog-to-digital

converter

V

1

Hi

Instrumentation

V

2

amplifier*

Lo

= –

V

V

O

*Programmable-Gain

Instrumentation

Amplifier (PGIA)

AGND

(Analog

Ground)

NOTE: Channel 31 is shown connected

to the instrumentation amplifier

and A/D converter.

V

O

V

2

1

+

–

Signal

Source #31

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Inputs

AGND

(Analog

Ground)

MUX1

(Multiplexer)

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

+

Inputs

MUX2

(Multiplexer)

–

Signal

Source #63

AGND

(Analog

Ground)

Page 24

2-6 Functional Description KPCI-1800HC Series User’s Manual

Choosing between the differential and single-ended input modes

Generally, you should use a differential input for a low-level signal having a significant noise

component and/or for a signal having a non-zero common-mode voltage. You should use a

single-ended input for a high-level signal having a relatively small noise component.

There is no absolute level at which one of these input configurations becomes more effective

than the other. However, you should generally use a differential input for a voltage range of

100mV or below.

NOTE You must specify all analog inputs to be either all differential or all

single-ended. You cannot use a mixture of differential and single-ended

inputs.

Choosing between the unipolar and bipolar input modes

Using software, you can configure the KPCI-1800HC Series boards to operate in either the unipolar or bipolar input mode. A unipolar signal is always positive (0 to +5V, for example). A

bipolar signal can swing between positive and negative values (±5V maximum, for example).

For exapmle, an unbiased sinusoidal AC signal is bipolar.

For maximum resolution, use the bipolar mode only if you must measure signals having both

positive and negative polarity. The KPCI-1800HC Series boards represent a unipolar signal as an

unsigned 12 bit number and a bipolar signal as a 2’s complement 12 bit number. Because one bit

of a 2’s complement number is effectively used up as a sign bit, a bipolar range provides only

half the resolution of a unipolar range of the same magnitude. Looked at another way, the dual

polarity of the bipolar range effectively doubles the magnitude that must be covered by the same

12 bits. For example, the 12 bits must cover a span of 10V for a ±5V, bipolar range

[+5V – (-5V) = 10V]. However, the 12-bits must only cover a span of 5V for a 0 to 5V, unipolar

range [+5V – (0V) = 5V].

Resolutions for unipolar and bipolar inputs are listed in the next section in Tables 2-1 and 2-2.

NOTE You must specify all analog inputs to be either all unipolar or all bipo-

lar. You cannot use a mixture of unipolar and bipolar inputs.

Table 2-1

Gains, ranges, and resolutions for the KPCI-1801HC

Unipolar Bipolar

Gain

1 0 to 5V 1.2mV −5.0 to +5.0V 2.4mV

5 0 to 1V 240µV −1.0 to +1.0V 490µV

50 0 to 100mV 24µV −100 to +100mV 49µV

250 0 to 20mV 4.9µV −20 to +20mV 9.8µV

Range Resolution Range Resolution

Page 25

KPCI-1800HC Series User’s Manual Functional Description 2-7

Table 2-2

Gains, ranges, and resolutions for the KPCI-1802HC

Unipolar Bipolar

Gain

Range Resolution Range Resolution

1 0.0 to +10.0V 2.4mV −10 to +10V 4.9mV

2 0.0 to +5.0V 1.2mV −5.0 to +5.0V 2.4mV

4 0 to 2.5V 610µV −2.5 to + 2.5V 1.2mV

8 0 to 1.25V 310µV −1.25 to +1.25V 610µV

Choosing channel gains and positions in the scan sequence

Each channel may be assigned an individual gain and a particular position in a channel-gain

queue. The channel gain queue is a user-defined scan sequence that specifies both the position in

the sequence and the gain at which each channel is scanned. Up to sixty-four gains and positions

may be specified in the channel-gain queue, without regard to sequential channel number. Channel numbers may be skipped or be repeated in the queue if desired. For example, by repeating a

channel number in the queue, you can do the following:

• Sample some channels more frequently than others.

• Provide extra settling time to wash out residual signals between gain changes.

• Provide extra samples for averaging.

Figure 2-4 illustrates use of a channel-gain queue.

Figure 2-4

Channel-gain queue example

Position

in queue

Channel

number

Channel

gain*

* Note: Gains available on the KPCI-1801HC are used in this illustration. Though gains available on the

1st2nd3rd4th5th6th7th8th9th10

21 03 11 11 21 09 25 25 21 07 00 29 17

250 250 50 50 50 50 5 5 5 5 1 1 1

KPCI-1802HC are different, the capabilities of the channel-gain queue are otherwise identical.

th

49th50th51

st

All 64 combinations of gain and position in the channel-gain queue are held in a 64-position

RAM. You need not specify channels and gains for all 64 positions of the channel-gain queue.

Available gains and corresponding input ranges are listed in Table 2-1 for the KPCI-1801HC and

in Table 2-2 for the KPCI-1802HC.

NOTE Optimum selection and sequencing of channel gains may be affected by

your required throughput and by noise and other stray signals. Refer to

“Optimizing throughput” for general recommendations about channelgain selection and sequencing. Refer to “Avoiding wiring problems at

high gain” in Section 3 for recommendations to minimize signal errors

at high gains.

The gains and positions in the channel-gain queue are specified using software.

Page 26

2-8 Functional Description KPCI-1800HC Series User’s Manual

Throughput

Throughput is the maximum rate at which the data acquisition card can perform repetitive conversions within a specified accuracy. Signal throughput depends on the gain settings for individual channels and for adjacent channels in the channel-gain queue. This section discusses general

recommendations to optimize throughput and lists KPCI-1800HC Series throughput for specific

conditions.

Optimizing throughput

Because you can change input ranges on a per-channel basis, throughput is likely to drop if you

group channels with varying gains in sequence. This throughput drop occurs for two reasons.

Firstly, channels with low-level inputs (100mV or less) are inherently slower than channels with

high-level inputs signals left by high-level inputs. Secondly, extra settling time is required for

low-level inputs to wash out residual signals. The best way to maximize throughput is to use a

combination of sensible channel grouping and external signal conditioning. When using the

channel-gain queue, consider the following suggestions:

• Put all channels that use the same range in the same group, even if you must arrange the

channels out of sequence.

• To acquire low-level signals at high-speeds, preamplify the signal to the maximum input

range of the board using external signal. External amplification increases total system

throughput and reduces noise.

• If low-level inputs are relatively slow and high-level inputs are relatively fast, maintain two

channel lists: one for slow inputs and the other for fast inputs.

• If some channels are not used, you can provide extra settling time for a channel that is used,

as follows:

- Assign two (or more) consecutive, identical channel-gain entries to this channel.

- Ignore the measurement results from the first channel-gain entry.

This approach allows the input signal measured through the first entry to largely wash out

residuals before the same input signal is measured through the second entry.

You must take special care when directly measuring low-level signals with the KPCI-1801HC.

When using the ±20mV, 0 to 20mV, ±100mV, or 0 to 100mV ranges, measurement throughput

drops for two reasons:

• The amplifier settles more slowly (particularly in the ±20mV and 0 to 20mV ranges).

• Noise in the measurements is higher and therefore requires post-acquisition filtering (averag-

ing) to achieve accurate results.

Because the KPCI-1801HC has a very high bandwidth — about 8 to 10MHz for low level signals — any noise is amplified and digitized. Therefore, you must measure low-level signals carefully to minimize noise effects.

Low-level transducers are best used with signal conditioning. Always use the differential input

mode when making measurements with the ±20mV, 0 to 20mV, ±100mV, and 0 to 100mV

ranges.

Page 27

KPCI-1800HC Series User’s Manual Functional Description 2-9

Subsequent sections show throughput for various configurations. Note that these throughputs are

based on driving an input with an ideal voltage source. The output impedance and drive capabilities of the source are far more critical when making large gain changes between two channels,

especially when the gains are at opposite extremes of the input range. Examples follow:

• Consider the measurement of a signal near −20mV just after measurement of a signal near

+5V. You get better performance when driving adjacent channels at the same gain.

• The source must be able to drive both the capacitance of the cable and the RC for the multiplexer and board (the product of the multiplexer resistance and output capacitance). The

multiplexer typically presents about 1kΩ (2kΩ maximum) in series with 150pF output

capacitance.

Throughput for channel-to-channel sampling at fixed gain

If you are sampling at only one channel at any gain, the maximum throughput is 333 ksamples/s.

If you are sampling multiple channels at a fixed gain, the maximum throughput for channel-tochannel sampling is as listed in Table 2-3 for bipolar mode and in Table 2-4 for unipolar mode.

In both cases, a 0.024% maximum error applies, assuming an ideal voltage source.

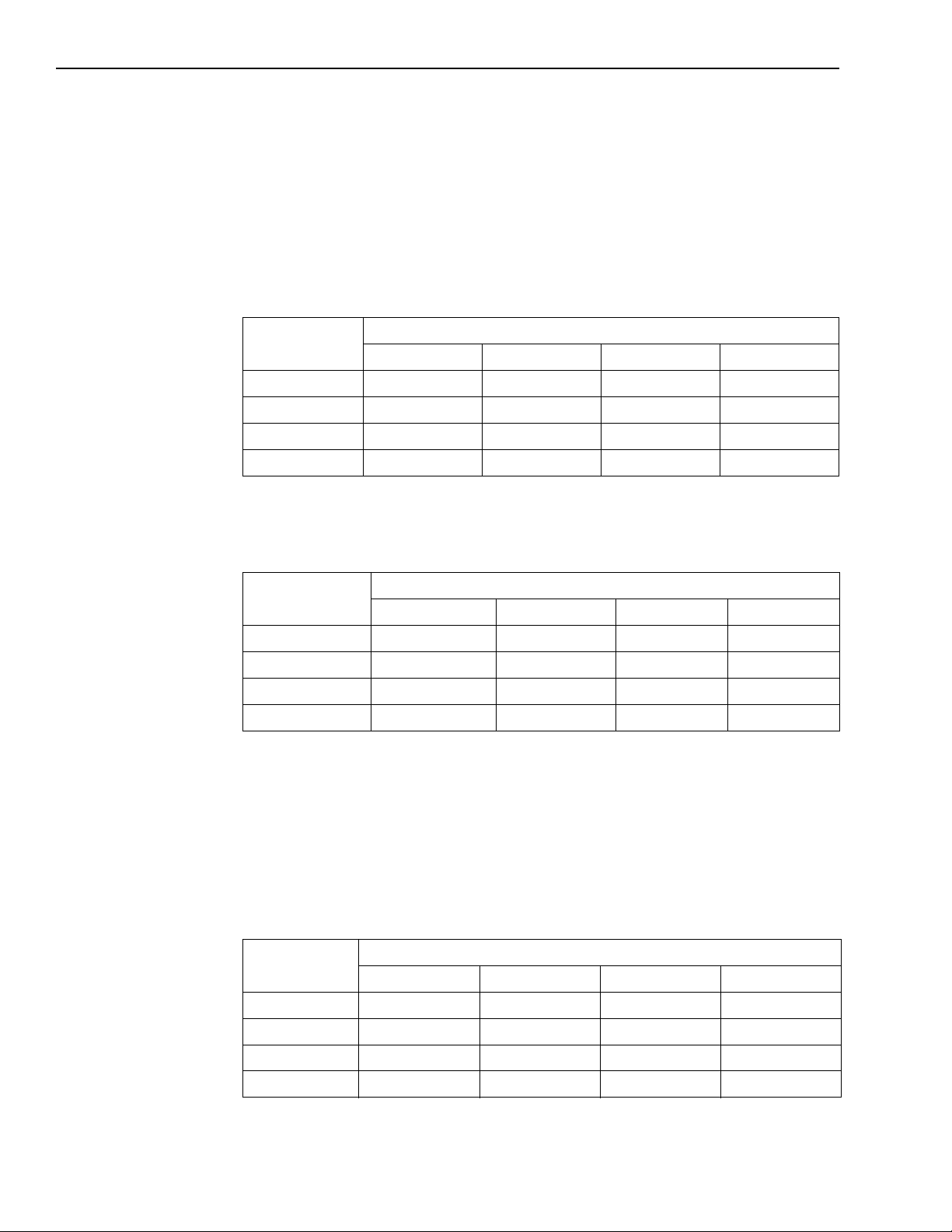

Table 2-3

Maximum throughput for channel-to-channel sampling at fixed gain: bipolar mode

KPCI-1801HC Range KPCI-1802HC Range Throughput

— ±10.0V 312.5 ksamples/s

±5.00V ±5.00V 312.5 ksamples/s

— ±2.50V 312.5 ksamples/s

— ±1.25V 312.5 ksamples/s

±1.00V — 312.5 ksamples/s

±100mV — 312.5 ksamples/s

±20mV — 75 ksamples/s

Table 2-4

Maximum throughput for channel-to-channel sampling at fixed gain: unipolar mode

KPCI-1801HC range KPCI-1802HC range Throughput

— 0 to 10.0V 312.5 ksamples/s

0 to 5.00V 0 to 5.00V 312.5 ksamples/s

— 0 to 2.50V 312.5 ksamples/s

— 0 to 1.25V 312.5 ksamples/s

0 to 1.00V — 312.5 ksamples/s

0 to 100mV — 200 ksamples/s

0 to 20mV — 60 ksamples/s

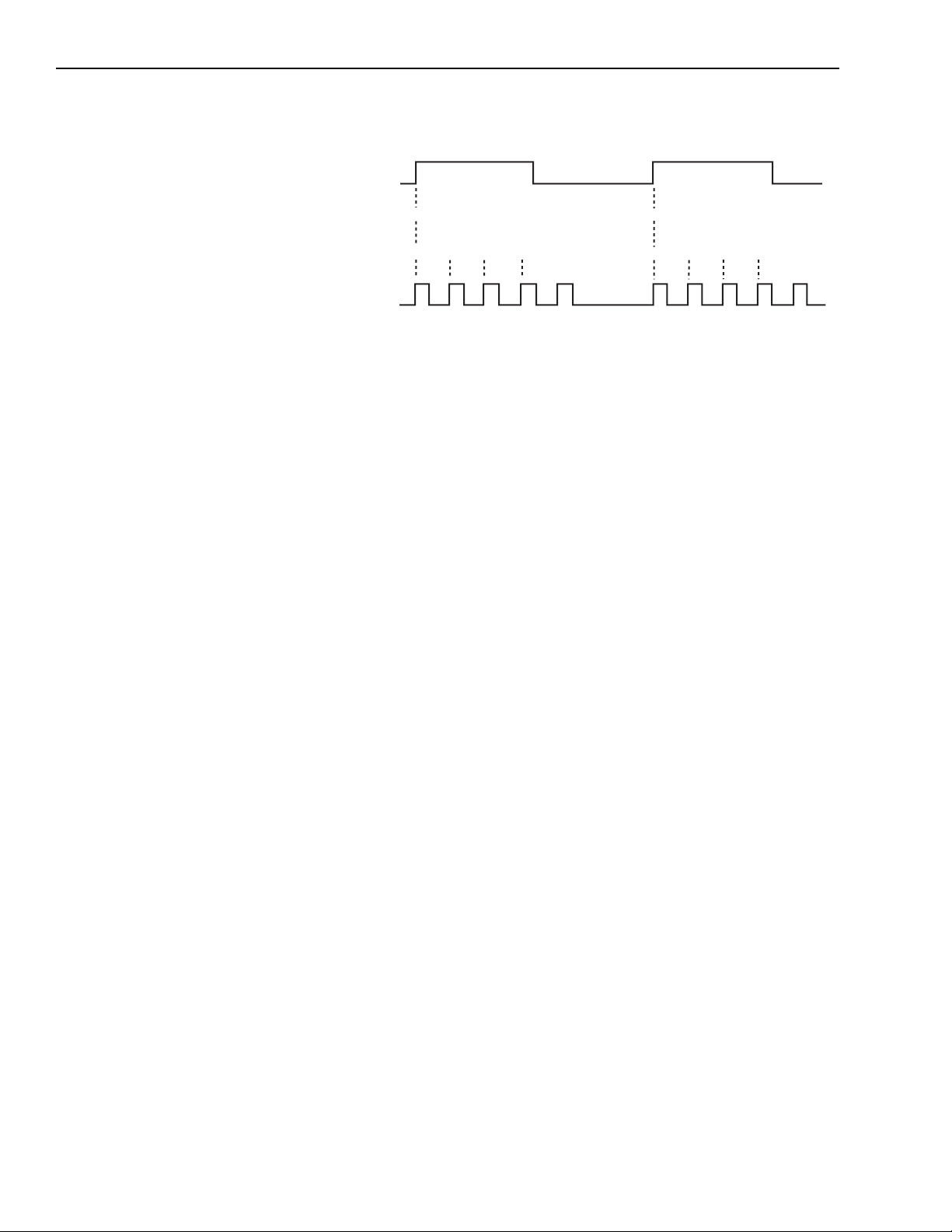

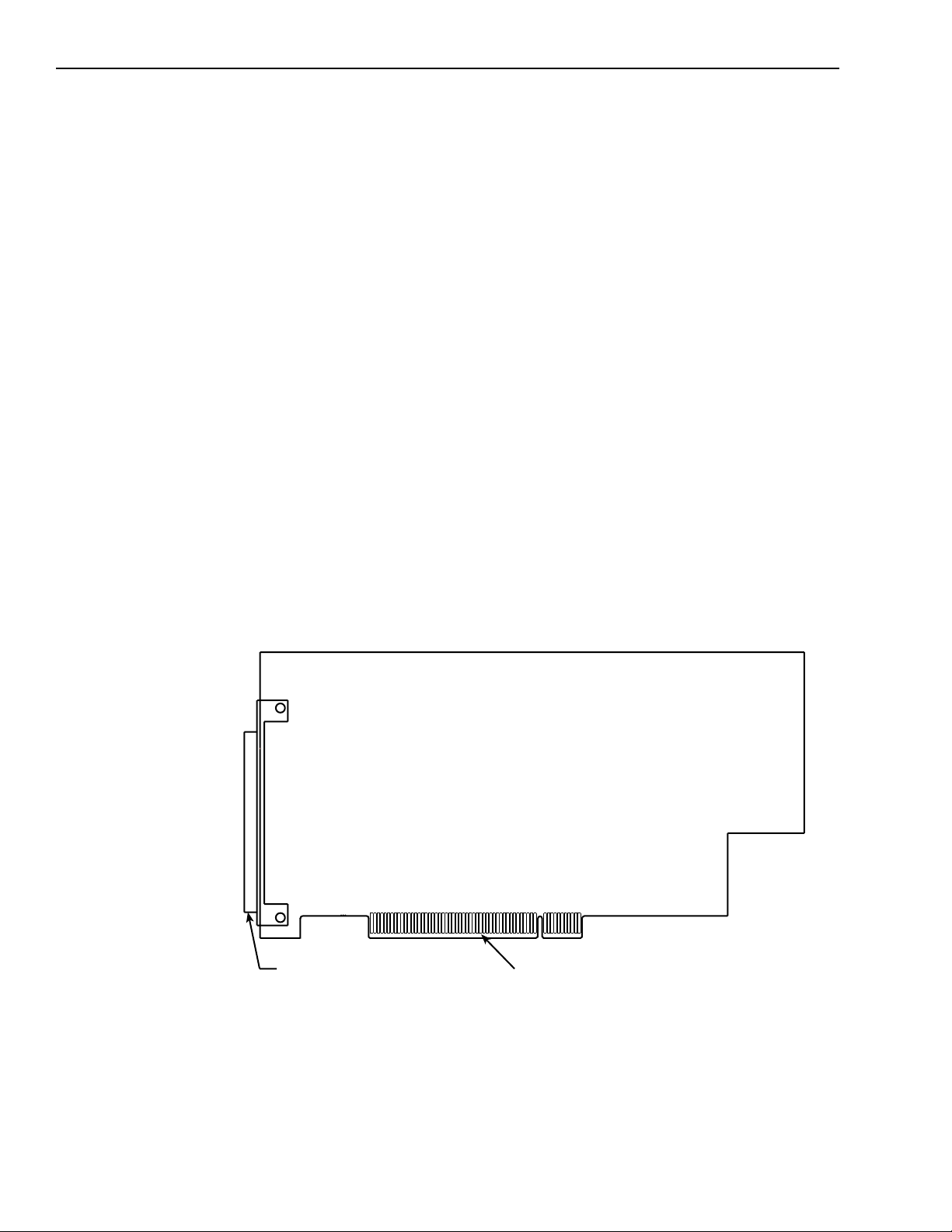

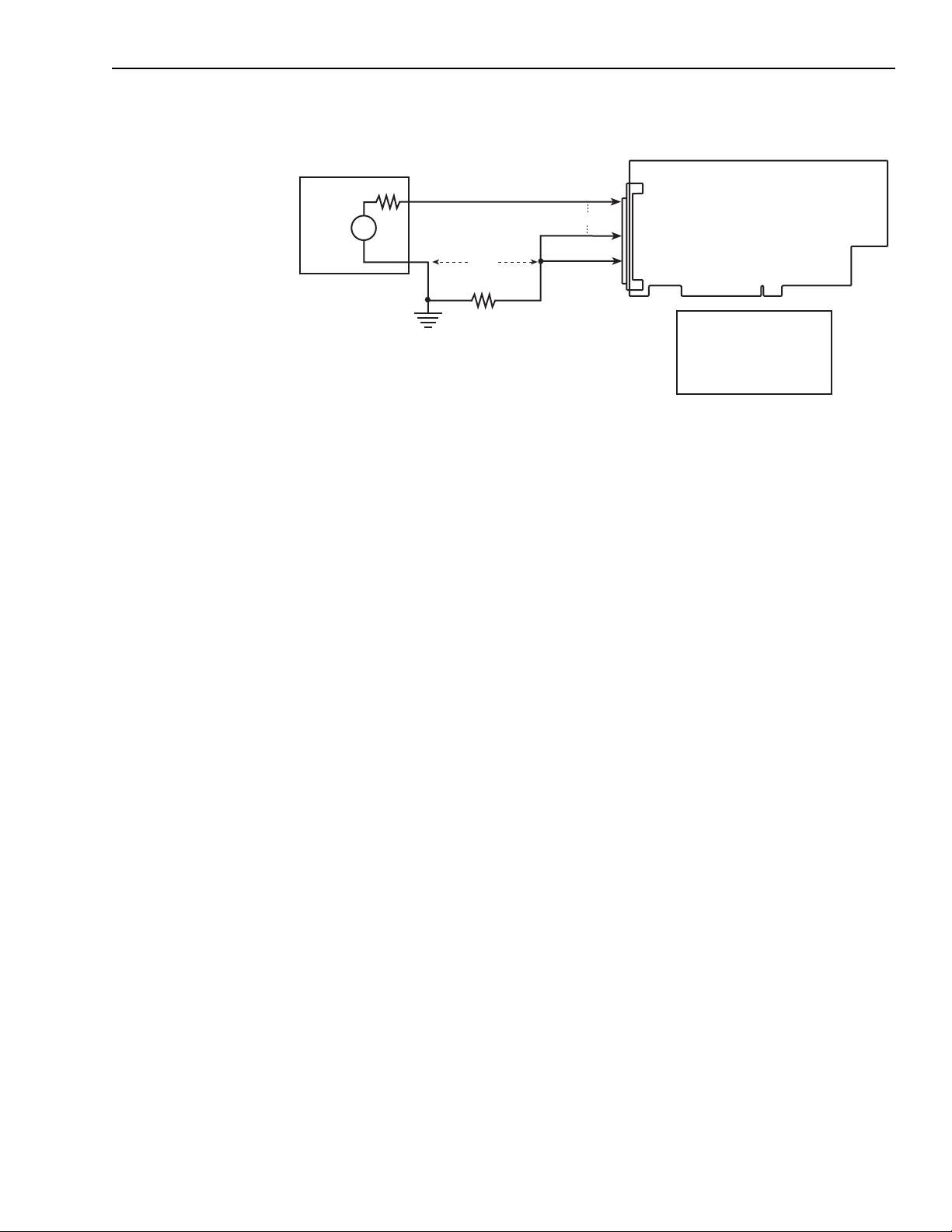

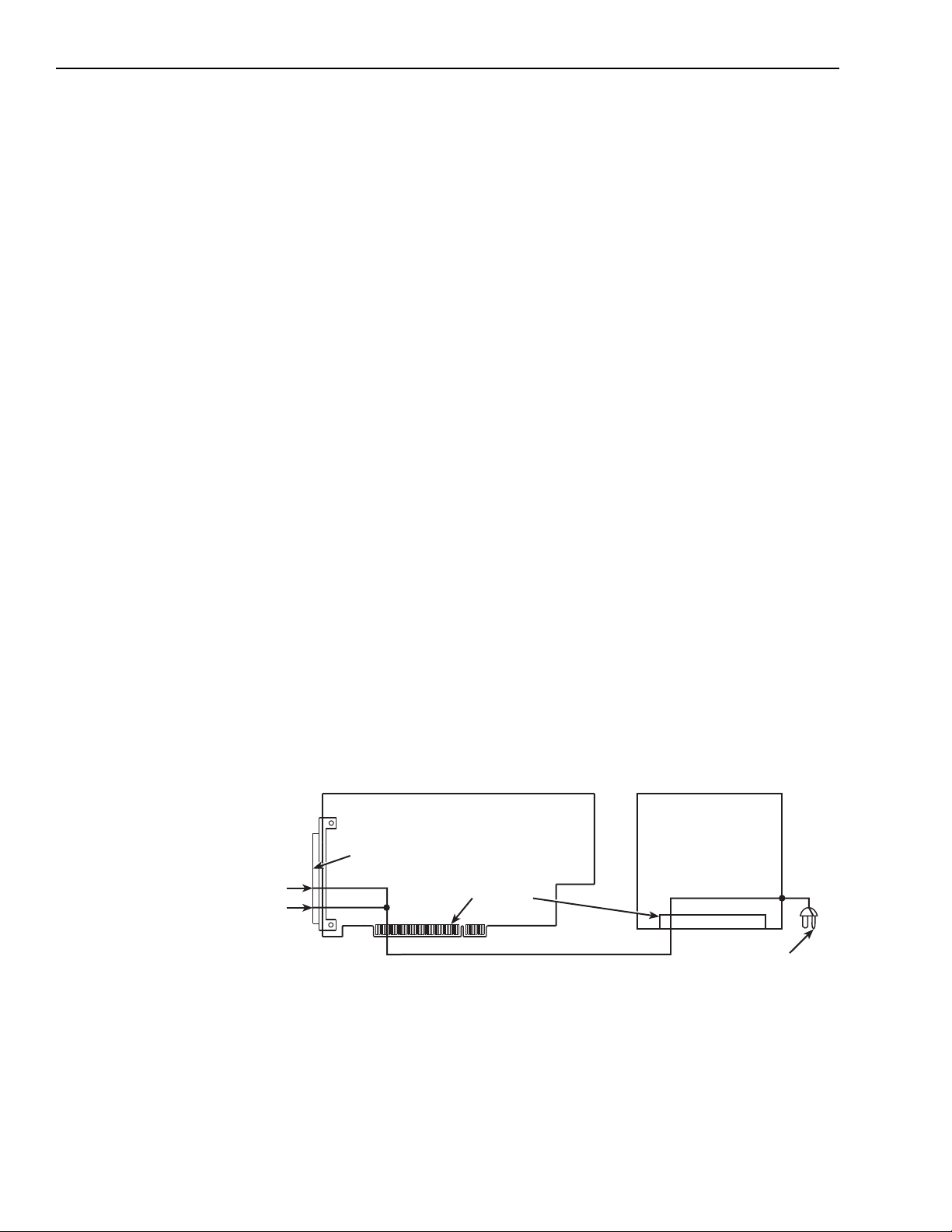

Page 28