Page 1

KUSB-3116

Getting Started Manual

KUSB3116-903-01 Rev. A / January 2005

www.keithley.com

A GR

EATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 3 years from

date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse

of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN

ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE

POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO:

COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON,

OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/04

Page 3

KUSB-3116

Getting Started Manual

©2005, Keithley Instruments, Inc.

All rights reserved.

First Printing, January 2005

Cleveland, Ohio, U.S.A.

Document Number: KUSB3116-903-01A Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released

between Revisions, contain important change information that the user should incorporate immediately into the manual.

Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number KUSB3116-903-01A) ...................................................................... January 2005

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or replacing consumable materials. Maintenance procedures

are described in the manual. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed

only by service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient overvoltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present. A good safety practice is to ex-

pect that hazardous voltage is present in any unknown circuit

before measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit

fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

5/03

Page 6

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment

frame.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on

the instrument. Products that consist of a circuit board with no case

or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

Page 7

Table of Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

How this Manual is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . xii

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Where To Get Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Supported Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Getting Started Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 2: Preparing to Use a Module. . . . . . . . . . . . . . . . . . 7

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Checking the System Requirements . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 3: Setting Up and Installing a Module . . . . . . . . . . 13

Applying Power to the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Configuring the Device Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Attaching Modules to the Computer. . . . . . . . . . . . . . . . . . . . . . . 18

Connecting One or Two Modules. . . . . . . . . . . . . . . . . . . . . . 18

Connecting Multiple Modules Using an Expansion Hub . . 20

Chapter 4: Wiring Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Preparing to Wire Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

vii

Page 8

Contents

Wiring Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wiring Signals to the BNC Connectors . . . . . . . . . . . . . 28

Wiring Signals to the D-Sub Connectors on the BNC

Connection Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Analog Input Connector . . . . . . . . . . . . . . . . . . . . . . 28

Digital In/Out Connector . . . . . . . . . . . . . . . . . . . . . 30

C/T, DAC, Clk, Trig Connector . . . . . . . . . . . . . . . . 31

Connecting Analog Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connecting Single-Ended Voltage Inputs . . . . . . . . . . . . . . . 34

Connecting Pseudo-Differential Voltage Inputs . . . . . . . . . . 35

Connecting Differential Voltage Inputs . . . . . . . . . . . . . . . . . 37

Connecting Current Loop Inputs . . . . . . . . . . . . . . . . . . . . . . 40

Connecting Analog Output Signals. . . . . . . . . . . . . . . . . . . . . . . . 41

Connecting Digital I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting Counter/Timer Signals . . . . . . . . . . . . . . . . . . . . . . . 43

Connecting Signals for Event Counting Operations . . . . . . 43

Connecting Signals for Up/Down Counting Operations . . 45

Connecting Signals for Frequency Measurement

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Connecting Signals for Period/Pulse Width Measurement

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Connecting Signals for Edge-to-Edge Measurement

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Connecting Signals for Pulse Output Operations . . . . . . . . 49

viii

Chapter 5: Verifying the Operation of a Module . . . . . . . . . 51

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Running the Quick Data Acq Application . . . . . . . . . . . . . . . . . . 54

Performing a Single-Value Analog Input Operation . . . . . . 54

Performing a Single-Value Analog Output Operation . . . . 55

Performing a Continuous Analog Input Operation. . . . . . . 56

Page 9

Performing a Single-Value Digital Input Operation . . . . . . 57

Performing a Single-Value Digital Output Operation. . . . . 58

Performing a Frequency Measurement Operation. . . . . . . . 59

Performing a Pulse Output Operation. . . . . . . . . . . . . . . . . . 60

Appendix A: Ground, Power, and Isolation Connections . 61

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Contents

ix

Page 10

Contents

x

Page 11

About this Manual

This manual describes how to install and set up your KUSB-3116

module and device driver, and verify that your module is working

properly.

Intended Audience

This document is intended for engineers, scientists, technicians, or

others responsible for installing and setting up a KUSB-3116 module

to perform data acquisition operations. It is assumed that you are

familiar with the requirements of your application. It is also assumed

that you are familiar with the Microsoft

Windows XP operating system.

How this Manual is Organized

This manual is organized as follows:

• Chapter 1, “Overview,” describes the key features of the

KUSB-3116 hardware and software, and provides an overview of

the getting started procedure.

®

Windows® 2000 or

• Chapter 2, “Preparing to Use a Module,” describes how to

unpack the KUSB-3116 package, check the system requirements,

and install the software under Windows 2000 or Windows XP.

• Chapter 3, “Setting Up and Installing a Module,” describes how

to install a KUSB-3116 module, how to apply power to the

module, and how to configure the device driver.

• Chapter 4, “Wiring Signals,” describes how to wire signals to a

KUSB-3116 module.

• Chapter 5, “Verifying the Operation of a Module,” describes how

to verify the operation of the KUSB-3116 module with the Quick

Data Acq application.

xi

Page 12

About this Manual

Conventions Used in this Manual

• Appendix A, “Ground, Power, and Isolation Connections,”

describes the internal ground, power, and isolation connections

on the KUSB-3116 module.

An index completes this manual.

The following conventions are used in this manual:

• Notes provide useful information that requires special emphasis,

cautions provide information to help you avoid losing data or

damaging your equipment, and warnings provide information to

help you avoid catastrophic damage to yourself or your

equipment.

• Items that you select or type are shown in bold.

• Courier font is used to represent source code.

xii

Related Information

Refer to the following documents for more information on using the

KUSB-3116 module:

• KUSB-3116 User’s Manual, included on the CD provided with the

KUSB-3116 module. This manual describes the features of the

KUSB-3116 module and the device driver in detail.

• DataAcq SDK User’s Manual. For programmers who are

developing their own application programs using the Microsoft

C compiler, this manual describes how to use the DT-Open

TM

Layers

access the capabilities of your module.

DataAcq SDKTM in Windows 2000 or Windows XP to

Page 13

• DTx-EZ Getting Started Manual. This manual describes how to use

the ActiveX controls provided in DTx-EZ

capabilities of your module in Microsoft Visual Basic® or Visual

C++®.

• DT-LV Link Getting Started Manual. This manual describes how to

use DT-LV Link

language to access the capabilities of your module.

• Microsoft Windows 2000 or Windows XP documentation.

• USB web site (http://www.usb.org).

Where To Get Help

Should you run into problems installing or using your KUSB-3116

module, please call the Keithley Technical Support Department.

About this Manual

TM

to access the

TM

with the LabVIEW® graphical programming

xiii

Page 14

About this Manual

xiv

Page 15

1

Overview

Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Supported Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Getting Started Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1

Page 16

Chapter 1

Hardware Features

The KUSB-3116 is a high-performance, multifunction data acquisition

modules for the USB (Ver. 2.0 or Ver. 1.1) bus. The key hardware

features of the module is as follows:

• Installed in a metal BNC box to provide easy connections.

• Simultaneous operation of analog input, analog output, digital

I/O, and counter/timer subsystems.

• Analog input subsystem:

− 16-bit A/D converter.

− Throughput rate up to 500 kSamples/s.

− 16 single-ended or 8 differential analog input channels.

− Programmable gain of 1, 2, 4, or 8 provides input ranges of

±10, ±5, ±2.5, and ±1.25 V.

− 1024-location channel-gain list. You can cycle through the

channel-gain list using continuous scan mode or triggered

scan mode. The maximum sampling rate when using the

channel-gain list is 500 kSamples/s.

• Analog output subsystem:

− Four 16-bit D/A converters.

− Output rate up to 500 kSamples/s.

− Output range of ±10 V.

− The DACs are deglitched to prevent noise from interfering

with the output signal.

− Output channel list. You can cycle through the output channel

list using continuous output mode or waveform mode. For

waveform generation mode, you can simultaneously update

all four DACs at 500 kS/s per channel; for continuous output

mode, you can simultaneously update all four DACs at

250 kS/s per channel.

2

Page 17

• Digital I/O subsystem:

Overview

− One digital input port, consisting of 16 digital input lines. You

can program any of the first eight digital input lines to

perform interrupt-on-change operations. You can read the

value of the digital input port using the analog input

channel-gain list.

− One digital output port, consisting of 16 digital output lines.

You can output the value of the digital output port using the

output channel list.

− An additional dynamic digital output line that changes state

whenever an analog input channel is read.

• Five 32-bit counter/timer (C/T) channels that perform event

counting, up/down counting, frequency measurement,

edge-to-edge measurement, continuous pulse output, one-shot,

and repetitive one-shot operations. You can read the value of one

or more of the C/T channels using the analog input channel-gain

list.

• External or internal clock source.

• Trigger operations using a software command, an analog

threshold value, or an external digital input value as the trigger

event.

1

1

1

1

1

1

• 500 V galvanic isolation barrier that prevents ground loops to

maximize analog signal integrity and protect your computer.

1

1

1

3

Page 18

Chapter 1

Supported Software

The KUSB-3116 software, which is shipped on the CD provided with

the module, includes the following software components:

• Device Driver − This software must be installed and loaded

before you can use a KUSB-3116 module with any of the

supported software packages or utilities.

• Quick Data Acq application − This application provides a quick

way to get a KUSB-3116 module up and running. Using the

Quick Data Acq application, you can verify the features of the

module, display data on the screen, and save data to disk.

• DataAcq SDK − This DT-Open Layers Software Develop Kit

(SDK) allows programmers to develop application programs for

the KUSB-3116 using the Microsoft C compiler in Windows 2000

or Windows XP.

• DTx-EZ − This software package contains ActiveX controls that

allow Microsoft Visual Basic® or Visual C++® programmers to

access the capabilities of the KUSB-3116 module.

• DT-LV Link − This software package allows LabVIEW®

programmers to access the capabilities of the KUSB-3116 module.

4

Page 19

Getting Started Procedure

The flow diagram shown in Figure 1 illustrates the steps needed to

get started using the KUSB-3116 module. This diagram is repeated in

each chapter; the shaded area in the diagram shows you where you

are in the getting started procedure.

Prepare to Use the Module

(see Chapter 2 starting on page 7)

Set Up and Install the Module

(see Chapter 3 starting on page 13)

Overview

1

1

1

Wire Signals to the BNC Connection Box

(see Chapter 4 starting on page 23)

Verify the Operation of the Module

(see Chapter 5 starting on page 51)

Figure 1: Getting Started Flow Diagram

1

1

1

1

1

1

5

Page 20

Chapter 1

6

Page 21

2

Preparing to Use a Module

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Checking the System Requirements . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7

Page 22

Chapter 2

Prepare to Use the Module

(this chapter)

Set Up and Install the Module

(see Chapter 3 starting on page 13)

Wire Signals

(see Chapter 4 starting on page 23)

Verify the Operation of the Module

(see Chapter 5 starting on page 51)

8

Page 23

Unpacking

Open the shipping box and verify that the following items are

present:

• KUSB-3116 BNC module,

•USB cable,

• Power supply,

Preparing to Use a Module

2

2

• Keithley CD.

If an item is missing or damaged, contact Keithley Technical Support.

Once you have unpacked your module, check the system

requirements, as described in the next section.

2

2

2

2

2

2

2

9

Page 24

Chapter 2

Checking the System Requirements

For reliable operation, your KUSB-3116 module requires the

following:

• PC with Pentium 233 MHz (or higher) processor.

• Windows 2000 or Windows XP (Professional Edition) operating

system.

For USB Ver. 2.0 support, make sure that you install Service Pack

1 (for Windows XP) or Service Pack 4 (for Windows 2000). In

addition, for some systems, you may have to disable standby

mode. If you are not sure whether you are using USB Ver. 1.1 or

Ver. 2.0, run the Open Layers Control Panel applet, described on

page 16.

• One or more USB ports (Ver. 2.0 or Ver. 1.1). USB Ver. 2.0 is

recommended for optimal performance.

• 64 MB (or more) of RAM; 128 MB (or more) recommended.

• One or more CD-ROM drives.

10

• Super VGA (800 x 600 or higher resolution) display monitor.

Once you have verified that your system meets the system

requirements, install the software, as described in the next section.

Page 25

Installing the Software

To install the driver software, Data Acq SDK, DTx-EZ, and the Quick

Data Acq software, perform the following steps:

Preparing to Use a Module

2

1. Insert the Keithley CD into your CD-ROM drive.

2. Click Start from the Task Bar, then click Run.

The Run dialog box appears.

3. In the Command Line edit box, enter D:\Setup.Exe.

If your CD-ROM is not in drive D:, enter the letter of the drive where

your CD-ROM is located. The welcome screen appears.

4. Click Install Drivers and SDK.

5. Click Install now!

The installation wizard appears.

6. Click Next.

You are prompted for the destination location.

7. Either change the directory path and/or name using Browse or

accept the default directory, then click Next.

8. Click Next to copy the files.

9. Click Finish.

10. Click Quit Installer.

2

2

2

2

2

2

2

2

11

Page 26

Chapter 2

12

Page 27

3

Setting Up and

Installing a Module

Applying Power to the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Configuring the Device Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Attaching Modules to the Computer. . . . . . . . . . . . . . . . . . . . . . . 18

13

Page 28

Chapter 3

Prepare to Use the Module

(see Chapter 2 starting on page 7)

Set Up and Install the Module

(this chapter)

Wire Signals to the BNC Connection Box

(see Chapter 4 starting on page 23)

Verify the Operation of the Module

(see Chapter 5 starting on page 51)

Note: The KUSB-3116 module is factory-calibrated and requires no

further adjustment prior to installation.

14

Page 29

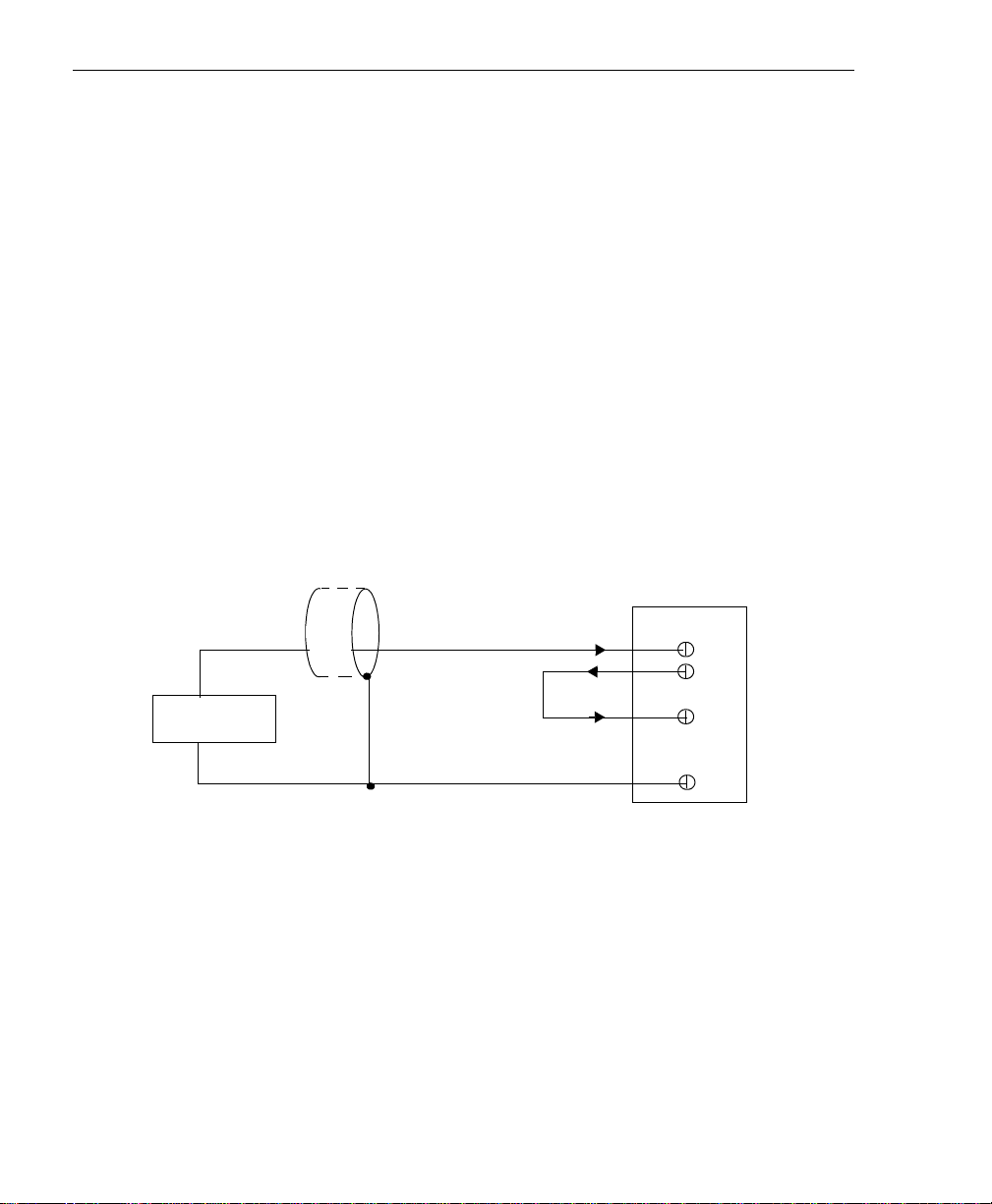

Applying Power to the Module

The KUSB-3116 module is shipped with a +5V power supply and

cable. To apply power to the KUSB-3116 module, perform the

following steps:

Setting Up and Installing a Module

3

+5 V Power

Supply

To wall outlet

1. Connect the +5 V power supply to the power connector on the

KUSB-3116 module. Refer to Figure 2.

Power Connector

LED

USB Port

Figure 2: Attaching a +5 V Power Supply to the Module

2. Plug the power supply to a wall outlet.

Continue by configuring the device driver, as described in the next

section.

KUSB-3116

Module

3

3

3

3

3

3

3

3

15

Page 30

Chapter 3

Configuring the Device Driver

To configure the device driver for the KUSB-3116 module, perform

the following steps:

1. If you have not already done so, power up the host computer and

all peripherals.

2. From the Windows Start menu, select Settings|Control Panel.

3. From the Control Panel, double-click Open Layers Control

Panel.

The Data Acquisition Control Panel dialog box appears.

4. Click the KUSB-3116 module that you want to configure, then

click Advanced.

The Control Panel dialog box appears.

5. If you are using differential analog input channels, it is

recommended that you select the 10k Ohm Resistor

Terminations checkbox for each analog input channel on the

module. This ensures that 10 kΩ of bias return termination

resistance is used for the analog input channels. (This is the

default configuration.) Bias return termination resistance is

particularly useful when your differential source is floating.

16

If you are using single-ended analog input channels, clear the

checkbox for each analog input channel so that bias return

resistance is not used.

6. If required, select the digital input line(s) that you want to use for

interrupt-on-change operations. When any of the selected lines

changes state, the module reads the entire 16-bit digital input

value and generates an interrupt.

7. Click OK.

8. If you want to rename the module, click Edit Name, enter a new

name for the module, then click OK. The name is used to identify

the module in all subsequent applications.

9. When you are finished configuring the module, click Close.

Page 31

Setting Up and Installing a Module

10. Repeat steps 4 to 8 for the other modules that you want to

configure.

11. Close the Data Acquisition Control Panel dialog box.

Continue by connecting the KUSB-3116 module to the computer, as

described in the next section.

3

3

3

3

3

3

3

3

3

17

Page 32

Chapter 3

Attaching Modules to the Computer

This section describes how to attach KUSB-3116 modules to the host

computer.

Notes: Most computers have two USB ports that allow direct

connection to USB devices. If your application requires more than

two KUSB-3116 modules, you can expand the number of USB

devices attached to a single USB port by using expansion hubs. For

more information, refer to page 20.

You can unplug a module, then plug it in again, if you wish, without

causing damage. This process is called hot-swapping. Your

application may take a few seconds to recognize a module once it is

plugged back in.

Connecting One or Two Modules

18

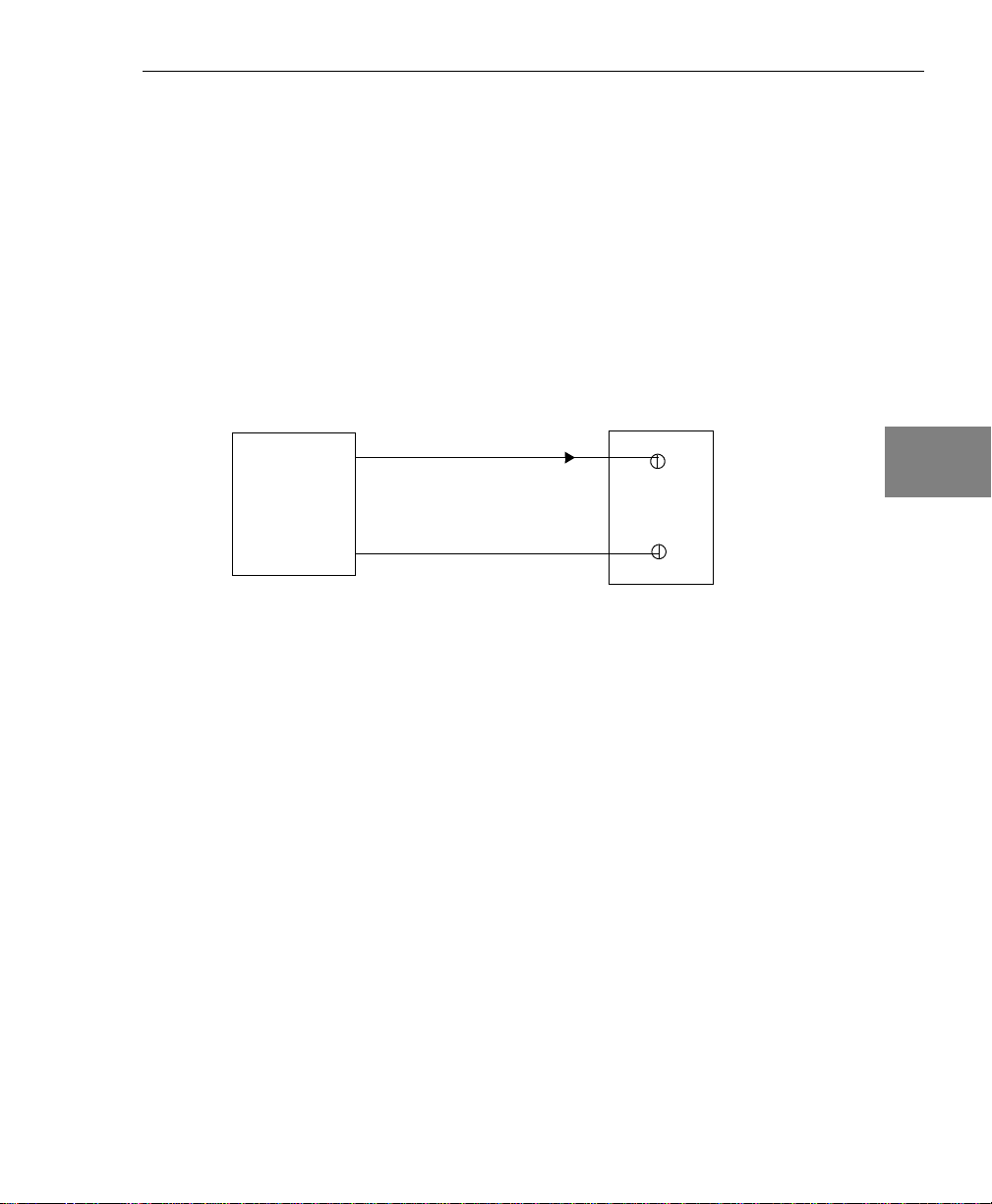

To connect one or two KUSB-3116 modules to a USB port of the

computer, perform the following steps:

1. Make sure that you have attached a power supply to the module.

2. Attach one end of the USB cable to the USB port on the module.

3. Attach the other end of the USB cable to one of the USB ports on

the host computer, as shown in Figure 3.

The operating system automatically detects the USB module. If the

power supply and module are attached correctly, the LED turns green.

Page 33

Setting Up and Installing a Module

Host Computer

Figure 3: Attaching the Module to the Host Computer

4. If you previously installed the device driver, ignore the

remaining steps, and repeat steps 1 and 2 to attach another

KUSB-3116 module to the host computer, if desired.

If you have not yet installed the device driver, the New

Hardware Found wizard appears. Click Next to have the wizard

search for the device driver, then proceed to step 5.

5. Click the option to search for the driver, then click Next.

USB Ports

USB Cable

Powe r Ca ble

KUSB-3116

Module

3

3

3

3

3

3

6. Click the option to specify the location, browse to the location on

the CD that contains the driver files, then click Next.

7. Click Next.

8. Click Finish.

A New Hardware Found dialog box appears indicating that Windows is

installing the driver for the USB module.

9. Repeat the steps 1 to 3 to attach another KUSB-3116 module to

the host computer, if desired.

3

3

3

19

Page 34

Chapter 3

Connecting Multiple Modules Using an Expansion Hub

Expansion hubs are powered by their own external power supply.

Theoretically, you can connect up to five expansion hubs to a USB

port on the host computer. However, the practical number of

KUSB-3116 modules that you can connect to a single USB port

depends on the throughput you want to achieve. Each of the hubs

supports up to four KUSB-3116 modules.

Note: The bandwidth of the USB Ver. 1.1 bus is 12 Mbits/second;

the bandwidth of the USB Ver. 2.0 bus is 480 Mbits/second.

Particularly if you are using the USB Ver. 2.0 bus, you may be

limited in the number of KUSB-3116 modules that you can connect

to a single USB port.

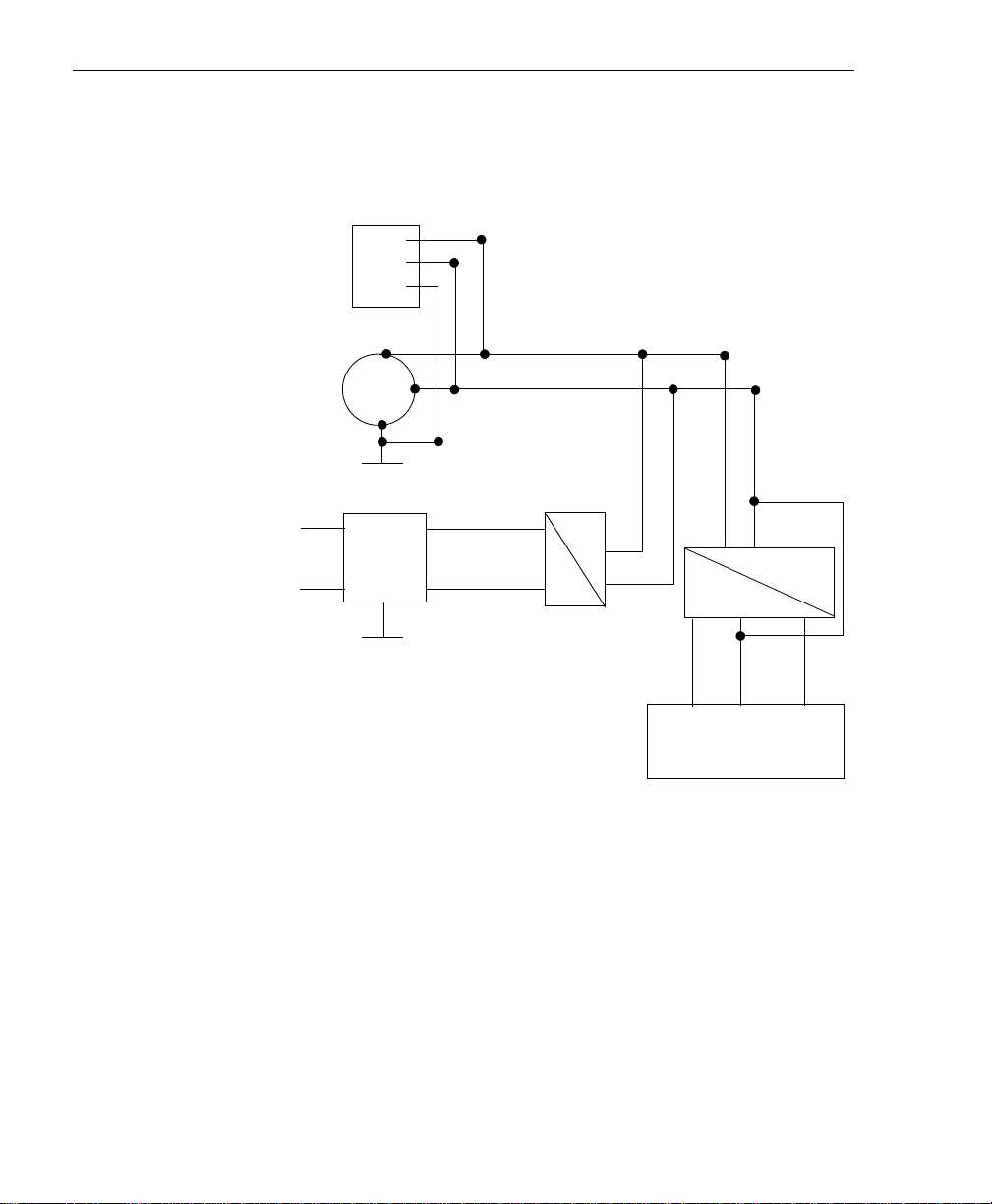

To connect multiple KUSB-3116 modules to an expansion hub,

perform the following steps:

20

1. Make sure that you have attached a power supply to the module.

2. Attach one end of the USB cable to the KUSB-3116 module and

the other end of the USB cable to an expansion hub.

3. Connect the power supply for the expansion hub to an external

power supply.

4. Connect the expansion hub to the USB port on the host computer

using another USB cable.

The operating system automatically detects the USB device. If the power

supply and module are attached correctly, the LED turns green.

5. If you have previously installed the device driver, ignore the

remaining steps, and repeat steps 1 to 3 until you have attached

the number of expansion hubs (up to five) and modules (up to

four per hub) that you require. Refer to Figure 4.

Page 35

Setting Up and Installing a Module

If you have not installed the device driver, the New Hardware

Found wizard appears. Click Next to have the wizard search for

the device driver. Proceed to step 6.

3

KUSB-3116

Module

Host Computer

USB Cable

Power Supply

for Hub

KUSB-3116

Module

USB Cables

Figure 4: Attaching Multiple KUSB-3116 Modules Using Expansion Hubs

Power Su pply

for Module

USB Cables

KUSB-3116

Module

USB Cable

Expansion Hubs

Power Supply

for Hub

KUSB-3116

Module

3

3

3

3

3

3

6. Click the option to search for the driver, then click Next.

7. Click the option to specify the location, browse to the location on

the CD that contains the driver files, then click Next.

8. Click Next.

9. Click Finish.

A New Hardware Found dialog box appears indicating that Windows is

installing the driver for the USB device.

3

3

21

Page 36

Chapter 3

10. Repeat steps 1 to 3 until you have attached the number of

expansion hubs (up to five) and modules (up to four per hub)

that you require.

The operating system automatically detects the USB devices as they are

installed.

Continue with the instructions on wiring in Chapter 4 starting on

page 23.

22

Page 37

4

Wiring Signals

Preparing to Wire Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting Analog Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connecting Analog Output Signals. . . . . . . . . . . . . . . . . . . . . . . . 41

Connecting Digital I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting Counter/Timer Signals . . . . . . . . . . . . . . . . . . . . . . . 43

23

Page 38

Chapter 4

Prepare to Use a Module

(see Chapter 2 starting on page 7)

Set Up and Install the Module

(see Chapter 3 starting on page 13)

Wire Signals

(this chapter)

Verify the Operation of the Module

(see Chapter 5 starting on page 51)

24

Page 39

Preparing to Wire Signals

CAUTION:

Wiring Signals

4

To avoid electrostatic sensitivity, it is recommended that you unplug

your KUSB-3116 module from the computer before wiring signals.

This section provides recommendations and information about

wiring signals to the KUSB-3116 module.

Wiring Recommendations

Keep the following recommendations in mind when wiring signals to

a BNC connection box:

• Use individually shielded twisted-pair wire (size 14 to 26 AWG)

in highly noisy electrical environments.

• Separate power and signal lines by using physically different

wiring paths or conduits.

• To avoid noise, do not locate the box and cabling next to sources

that produce high electromagnetic fields, such as large electric

motors, power lines, solenoids, and electric arcs, unless the

signals are enclosed in a mumetal shield.

• Prevent electrostatic discharge to the I/O while the box is

operational.

4

4

4

4

4

4

• Connect all unused analog input channels to analog ground.

4

4

25

Page 40

Chapter 4

Wiring Methods

The KUSB-3116 module contains both BNC connectors and 37-pin,

D-sub connectors, as shown in Figure 5.

Analog Input

AD Ch12

AD Ch8

AD Ch4

AD Ch0

AD Ch13 AD Ch14 AD Ch15 DAC Ch0

AD Ch9 AD Ch10 AD Ch11

AD Ch5 AD Ch7

AD Ch1 AD Ch2

AD Ch6

AD Ch3

DAC Ch1

DAC Ch2

DAC Ch3

DAC Cl ock

AD Clock

DAC Trig

AD Trig

Figure 5: KUSB-3116 Module

You can wire signals to the KUSB-3116 module in one of the

following ways:

• Analog input signals – You can wire analog input signals in one

of the following ways:

− Using the BNC connectors labelled AD Ch0 to AD Ch15.

− Using the appropriate pins on the Analog Input connector.

Refer to Appendix A in the KUSB-3116 User’s Manual for

information about the required mating connectors.

Digital I/O

C\T, DAC, Clk, Trig

26

Page 41

Wiring Signals

• Analog output signals – You can wire analog output signals in

one of the following ways:

− Using the BNC connectors labelled DAC Ch0 to DAC Ch3.

− Using the appropriate pins on the C\T, DAC, Clk, Trig

connector. Refer to Appendix A in the KUSB-3116 User’s

Manual for information about the required mating connectors.

• Digital I/O signals – To wire digital I/O signals, you must use

the appropriate pins on the Digital I/O connector. Refer to

Appendix A in the KUSB-3116 User’s Manual for information

about the required mating connectors.

• Counter/timer signals – To wire counter/timer signals, you must

use the appropriate pins on the C\T, DAC, Clk, Trig connector.

Refer to Appendix A in the KUSB-3116 User’s Manual for

information about the required mating connectors.

• External A/D clock or trigger signal – You can wire external

clock/trigger signals in one of the following ways:

− Using the BNC connectors labelled AD Clock and AD Trig.

− Using the appropriate pins on the C\T, DAC, Clk, Trig

connector. Refer to Appendix A in the KUSB-3116 User’s

Manual for information about the required mating connectors.

• External DAC clock or trigger signal – You can wire external

clock/trigger signals in one of the following ways:

4

4

4

4

4

4

− Using the BNC connectors labelled DAC Clock and DAC Trig.

− Using the appropriate pins on the C\T, DAC, Clk, Trig

connector. Refer to Appendix A in the KUSB-3116 User’s

Manual for information about the required mating connectors.

The following sections describe how to wire signals using the BNC

connectors and how to wire signals using the appropriate D-sub

connector.

4

4

4

27

Page 42

Chapter 4

Wiring Signals to the BNC Connectors

To wire signals using the BNC connectors, connect the appropriate

BNC connector to the appropriate input/output using a BNC cable.

The KUSB-3116 module, shown in Figure 5 on page 26, contains 24

BNC connectors (16 BNC connectors for single-ended analog inputs,

four BNC connectors for analog outputs, and four BNC connectors

for external clocks and triggers).

Wiring Signals to the D-Sub Connectors on the BNC Connection Box

If you do not want to use the BNC connectors or if you want to

connect digital I/O or counter/timer signals to the KUSB-3116

module, you can use the 37-pin, D-sub connectors. These connectors

are described in the following sections.

Analog Input Connector

28

The Analog Input connector allows you to access the analog input

signals. Tabl e 1 lists the pin assignments for the analog input

connector.

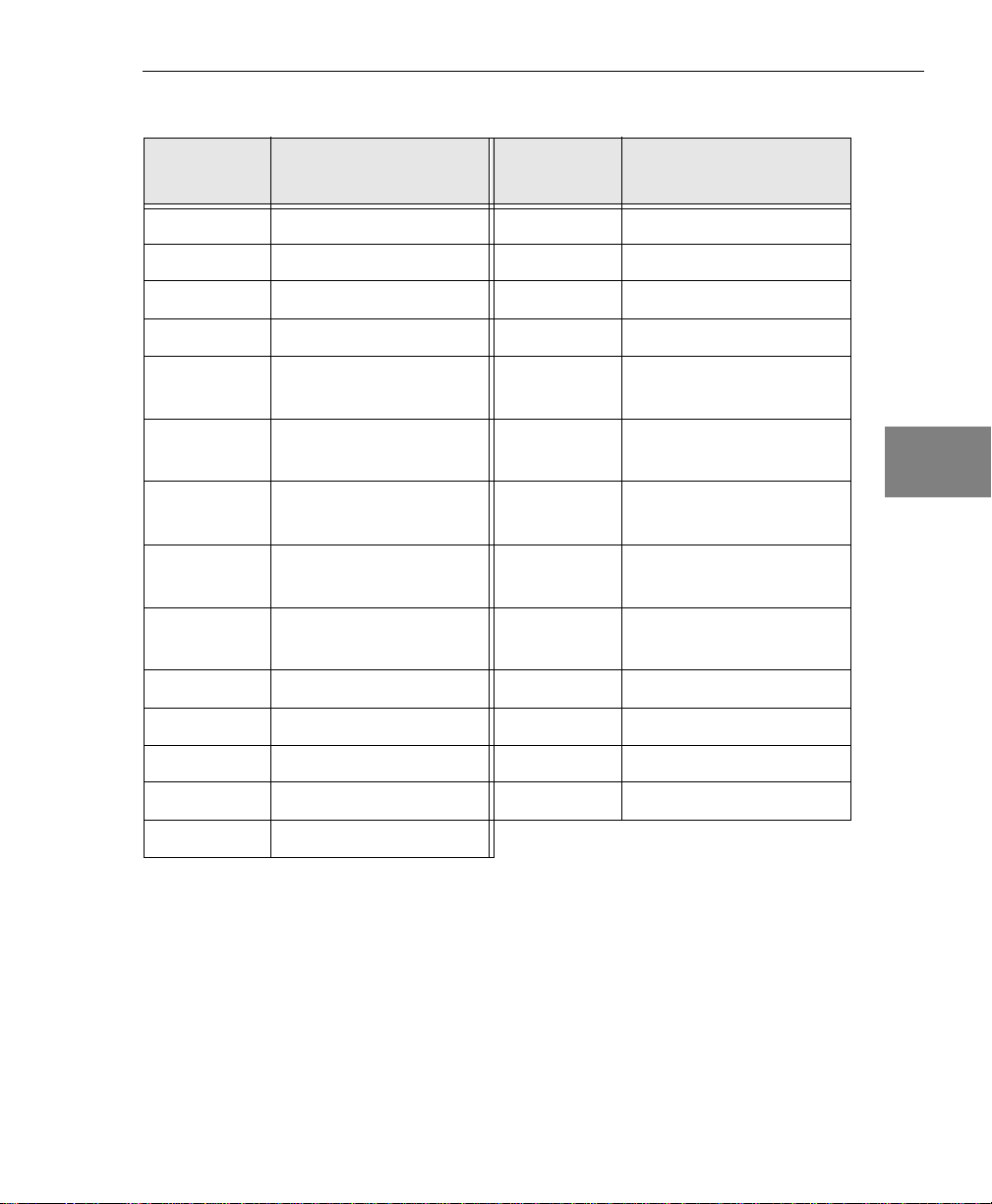

Table 1: Analog Input Connector Pin Assignments

Pin

Assignment

1 Analog Input 0 2 Analog Input 1

3 Analog Input 2 4 Analog Input 3

5 Analog Input 4 6 Analog Input 5

7 Analog Input 6 8 Analog Input 7

9 Analog Input 8 10 Analog Input 9

Signal Description

Pin

Assignment

Signal Description

Page 43

Table 1: Analog Input Connector Pin Assignments (cont.)

Wiring Signals

Pin

Assignment

11 Analog Input 10 12 Analog Input 11

13 Analog Input 12 14 Analog Input 13

15 Analog Input 14 16 Analog Input 15

17 Amplifier Low 18 +5 V Analog

19 Chassis Ground 20 Analog Input 0 Return/

21 Analog Input 1 Return/

23 Analog Input 3 Return/

25 Analog Input 5 Return/

27 Analog Input 7 Return/

29 Analog Input 9 Return

31 Analog Input 11 Returna32 Analog Input 12 Return

33 Analog Input 13 Returna34 Analog Input 14 Return

35 Analog Input 15 Returna36 Analog Ground

Signal Description

a

Analog In 9

Analog In 11

Analog In 13a

Analog In 15

a

a

a

Pin

Assignment

22 Analog Input 2 Return/

24 Analog Input 4 Return/

26 Analog Input 6 Return/

28 Analog Input 8 Return

30 Analog Input 10 Return

Signal Description

Analog In 8a

a

Analog In 10

Analog In 12

Analog In 14a

a

4

4

4

4

4

a

a

a

a

4

4

37 Digital Ground

a. The first signal description (Return) applies to the differential configuration for all modules.

The second signal description applies to the single-ended configuration for the module.

4

4

29

Page 44

Chapter 4

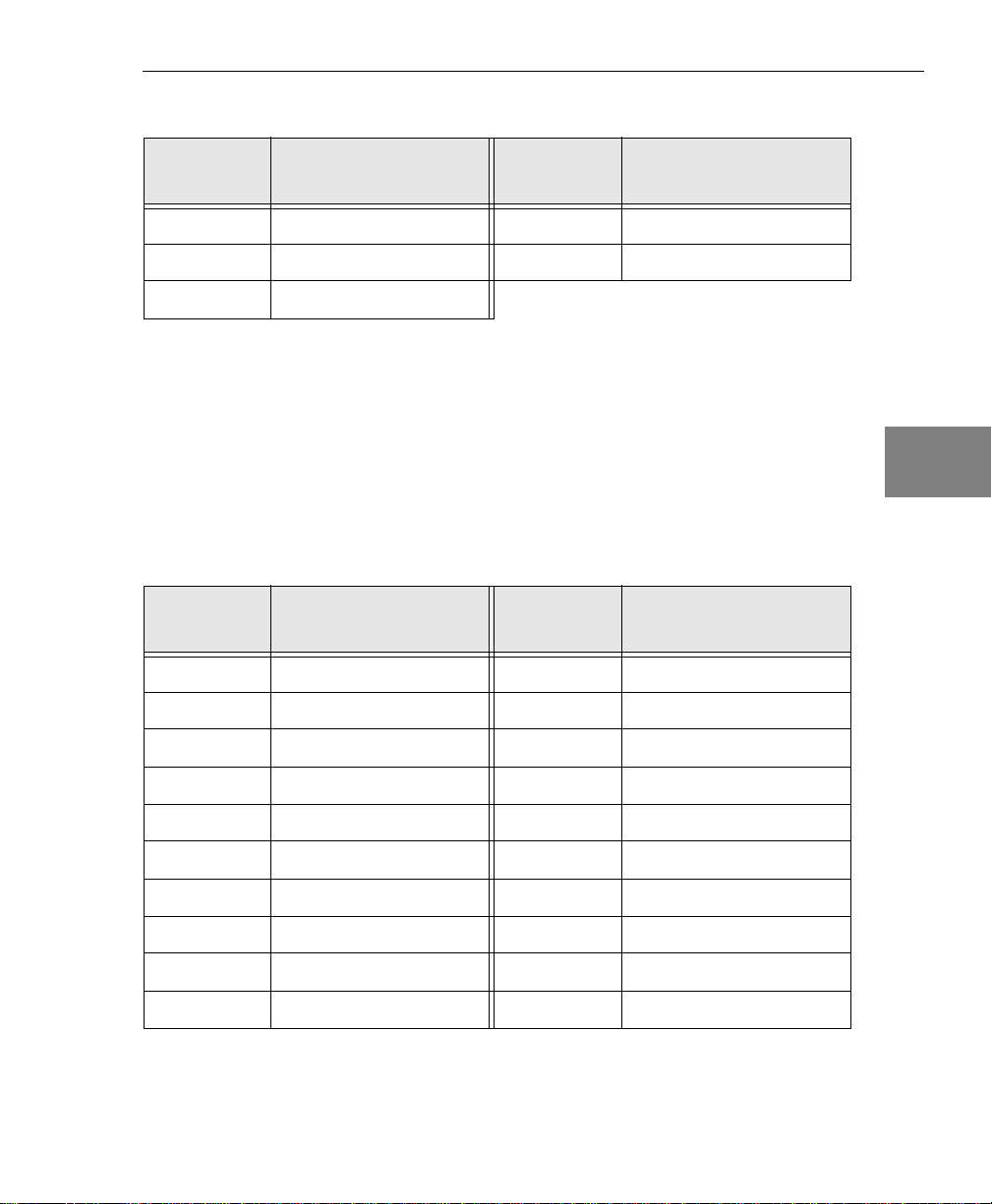

Digital In/Out Connector

The Digital In/Out connector allows you to access the digital I/O

signals. Tabl e 2 lists the pin assignments for the Digital In/Out

connector.

Table 2: Digital In/Out Connector Pin Assignments

Pin

Assignment

1 Digital Input 0 2 Digital Input 1

3 Digital Input 2 4 Digital Input 3

5 Digital Input 4 6 Digital Input 5

7 Digital Input 6 8 Digital Input 7

9 Digital Input 8 10 Digital Input 9

11 Digital Input 10 12 Digital Input 11

13 Digital Input 12 14 Digital Input 13

15 Digital Input 14 16 Digital Input 15

17 Digital Ground 18 Digital Ground

19 Not Used 20 Digital Output 0

21 Digital Output 1 22 Digital Output 2

23 Digital Output 3 24 Digital Output 4

25 Digital Output 5 26 Digital Output 6

27 Digital Output 7 28 Digital Output 8

Signal Description

Pin

Assignment

Signal Description

30

29 Digital Output 9 30 Digital Output 10

31 Digital Output 11 32 Digital Output 12

Page 45

Table 2: Digital In/Out Connector Pin Assignments (cont.)

Wiring Signals

Pin

Assignment

33 Digital Output 13 34 Digital Output 14

35 Digital Output 15 36 Dynamic Digital Output

37 Digital Ground

Pin

Assignment

1 Analog Output 0 2 Analog Output 1

3 Analog Output 2 4 Analog Output 3

Signal Description

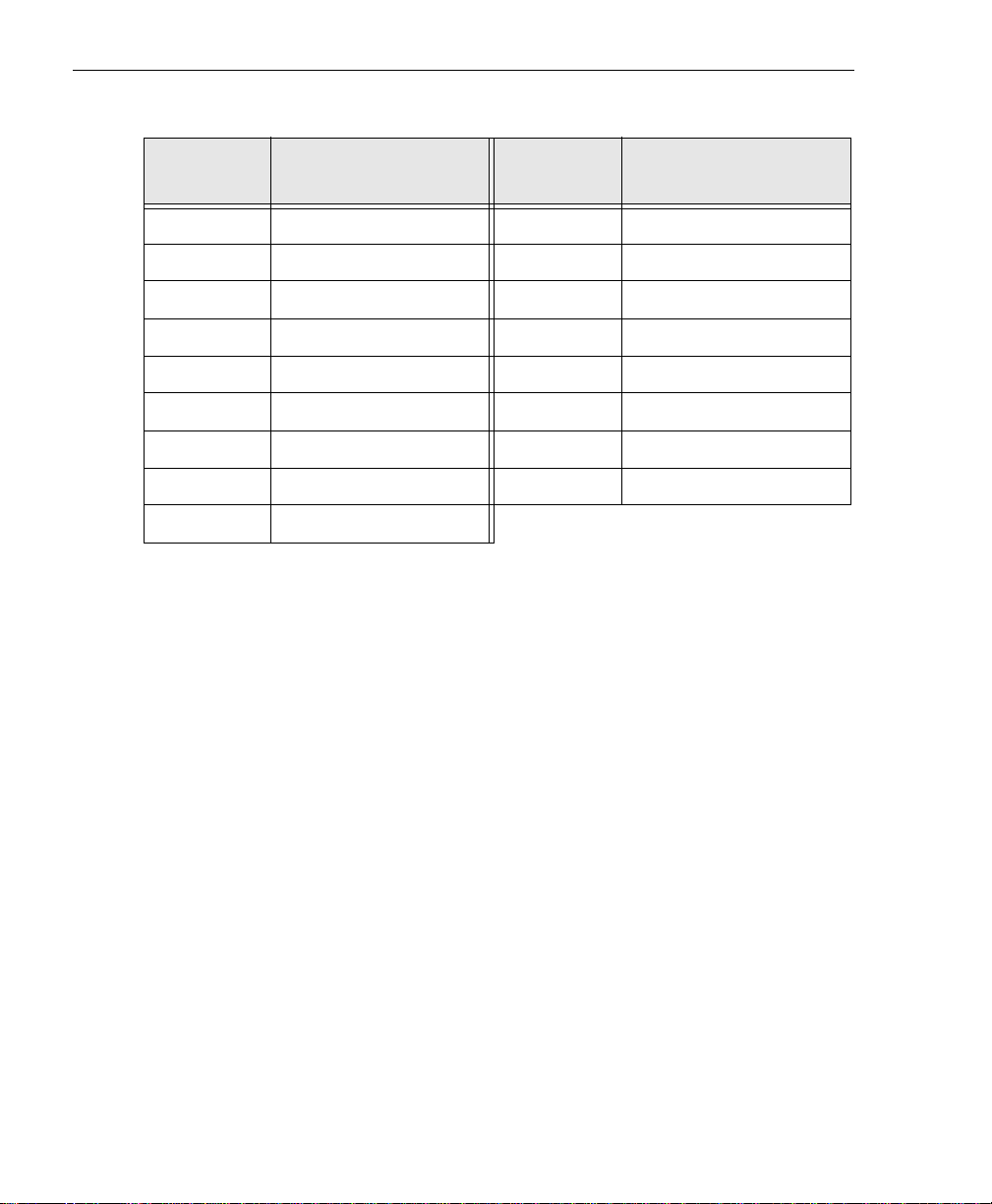

C/T, DAC, Clk, Trig Connector

The C/T, DAC, Clk, Trig connector allows you to access the

counter/timer, analog output, external clock, and external trigger

signals. Tabl e 3 lists the pin assignments for the C/T, DAC, Clk, Trig

connector.

Table 3: C/T, DAC, Clk, Trig Connector

Signal Description

Pin

Assignment

Pin

Assignment

Signal Description

Signal Description

4

4

4

4

4

4

5 Digital Ground 6 External DAC Clock

7 External ADC Clock 8 Counter 0 Clock

9 Counter 0 Out 10 Counter 1 Clock

11 Counter 1 Out 12 Counter 2 Clock

13 Counter 2 Out 14 Counter 3 Clock

15 Counter 3 Out 16 Counter 4 Clock

17 Counter 4 Out 18 Digital Ground

19 Not Used 20 Analog Output 0 Return

4

4

4

31

Page 46

Chapter 4

Table 3: C/T, DAC, Clk, Trig Connector (cont.)

Pin

Assignment

21 Analog Output 1 Return 22 Analog Output 2 Return

23 Analog Output 3 Return 24 Digital Ground

25 External DAC Trigger 26 External ADC Trigger

27 Digital Ground 28 Counter 0 Gate

29 Digital Ground 30 Counter 1 Gate

31 Digital Ground 32 Counter 2 Gate

33 Digital Ground 34 Counter 3 Gate

35 Digital Ground 36 Counter 4 Gate

37 Digital Ground

Signal Description

Pin

Assignment

Signal Description

32

Page 47

Connecting Analog Input Signals

The KUSB-3116 module supports both voltage and current loop

inputs. You can connect analog input signals to the module in the

following configurations:

Wiring Signals

4

• Single-ended − Choose this configuration when you want to

measure high-level signals, noise is not significant, the source of

the input is close to the module, and all the input signals are

referred to the same common ground.

• Pseudo-Differential − Choose this configuration when noise or

common-mode voltage (the difference between the ground

potentials of the signal source and the ground of the screw

terminal panel or between the grounds of other signals) exists

and the differential configuration is not suitable for your

application. This option provides less noise rejection than the

differential configuration; however, the number of analog input

channels available is the same as for single-ended configuration.

• Differential − Choose this configuration when you want to

measure low-level signals, noise is a significant part of the signal,

or common-mode voltage exists.

This section describes how to connect single-ended,

pseudo-differential, and differential voltage inputs, as well as current

loops, to the KUSB-3116 module.

4

4

4

4

4

4

4

4

33

Page 48

Chapter 4

Connecting Single-Ended Voltage Inputs

Note: If you are using single-ended inputs, make sure that bias

return resistance is disabled in the Open Layers Control Panel

applet. Refer to page 16 for more information.

Figure 6 shows how to connect single-ended voltage inputs (channels

0 and 1, in this case) to the BNC connectors on the KUSB-3116

module.

KUSB-3116 Module

Analog Input

Analog In 0

AD0

AD1

AD2

AD4

AD6 AD5

Signal

Source

Note that the BNC connection box

automatically connects the Analog

Ground and Amp Low signals together.

Analog In 1

AD8

AD9AD10

AD 12

AD13AD14

34

Figure 6: Connecting Single-Ended Inputs to the BNC Connectors

Figure 7 shows how to connect single-ended voltage inputs (channels

0 and 1, in this case) using your own cable/screw terminal panel.

Page 49

Wiring Signals

Signal Source

-

source 1

V

-

Vsource 0

Figure 7: Connecting Single-Ended Inputs to a Screw Terminal Panel

+

+

Analog Ground

Screw Terminal Panel

Analog In 0

Analog In 1

1

2

17

Amp Low (internally

connected to Analog Ground)

36

Connecting Pseudo-Differential Voltage Inputs

Figure 8 shows how to connect pseudo-differential voltage inputs

(channels 0 and 1, in this case) to the BNC connectors on the

KUSB-3116 module.

4

4

4

4

4

4

KUSB-3116 Module

Analog Input

Analog In 0

AD0

Signal

Source

Note that the BNC connection box

automatically connects the Analog

Ground and Amp Low signals together.

Figure 8: Connecting Pseudo-Differential Inputs to the BNC Connectors

Analog In 1

AD4

AD1

AD2

AD6 AD5

AD8

AD9AD10

AD 12

AD13AD14

4

4

4

35

Page 50

Chapter 4

Figure 9 shows how to connect pseudo-differential voltage inputs

(channels 0 and 1, in this case) using your own cable/screw terminal

panel.

Signal Source

−

Vsource 0

−

Vsource 1

V

CM

+

+

Analog Ground

Analog In 0

Analog In 1

Screw Terminal Panel

1

2

17

36

Amp Low (internally

connected to Analog Ground)

Figure 9: Connecting Pseudo-Differential Inputs to a Screw Terminal Panel

36

Page 51

Connecting Differential Voltage Inputs

Wiring Signals

Figure 10 shows how to connect differential voltage inputs (channels

0 and 1, in this case) to the BNC connectors on a KUSB-3116 module.

KUSB-3116 Module

Analog Input

Analog In 0

AD0

AD1

AD2

AD3

AD4

AD5AD7

AD6

Signal

Source

Note that the BNC connection box

automatically connects the Analog

Ground and Analog Input Return signals

appropriately.

Figure 10: Connecting Differential Inputs to the BNC Connectors

Analog In 1

4

4

4

4

4

4

Figure 11A shows how to connect a floating signal source to your

own screw terminal panel using differential inputs. (A floating signal

source is a voltage source that has no connection with earth ground.)

Note: For floating signal sources, it is recommended that you

provide a bias return path for the differential channels by using the

Open Layers Control Panel applet to enable 10 kΩ of termination

resistance. For more information, refer to page 16.

4

4

4

37

Page 52

Chapter 4

Figure 11B illustrates how to connect a nonfloating signal source to

your own screw terminal panel using differential inputs. In this case,

the signal source itself provides the bias return path; therefore, you

do not need to provide bias return resistance through software.

Rs is the signal source resistance while Rv is the resistance required to

balance the bridge. Note that the negative side of the bridge supply

must be returned to analog ground.

A)

Floating

Signal

Source

B)

R

v

+

DC Supply

Screw Terminal Panel

+

Analog In 0

R

s

Analog In 0 Return

-

Analog Ground

Bridge

Analog In 0

R

s

-

Analog In 0 Return

Analog Ground

Screw Terminal Panel

It is recommended that

1

you use the Open Layers

Control Panel applet to

enable 10 k

resistance to connect

the low side of channel 0

20

to analog ground (a

physical resistor is not

required). Refer to page

36

16 for more information.

1

20

36

Ω of

38

Figure 11: Connecting Differential Inputs to a Screw Terminal Panel

Page 53

Wiring Signals

Note that since they measure the difference between the signals at the

high (+) and low (−) inputs, differential connections usually cancel

any common-mode voltages, leaving only the signal. However, if you

are using a grounded signal source and ground loop problems arise,

connect the differential signals as shown as Figure 12. In this case,

make sure that the low side of the signal (−) is connected to ground at

the signal source, not at the screw terminal panel, and do not tie the

two grounds together.

4

4

Screw Terminal Panel

+

Analog In 0

Grounded

Signal

Source

Figure 12: Connecting Differential Voltage Inputs from a Grounded Signal

E

s

Signal Source

Ground V

g1

-

Analog In 0 Return

Analog Ground

Source to a Screw Terminal Panel

1

20

36

It is recommended that

you use the Open

Layers Control Panel

applet to enable 10 k

of resistance to connect

the low side of channel

0 to analog ground (a

physical resistor is not

required). Refer to page

16 for more information.

Ω

4

4

4

4

4

4

4

39

Page 54

Chapter 4

Connecting Current Loop Inputs

Note: You cannot connect a current loop input using the BNC

connectors.

Figure 13 shows how to connect a current loop input (channel 0, in

this case) to your own screw terminal panel.

+V

CC

4 to 20 mA

Analog Input 0

Analog Input 0 Return

Screw Terminal Panel

1

20

User-installed resistor

40

Analog Ground

The user-installed resistor connects the high side of the

channel to the low side of the corresponding channel,

thereby acting as a shunt. For example, if you add a 250

resistor and then connect a 4 to 20 mA current loop input

to channel 0, the input range is converted to 1 to 5 V.

It is recommended that you use the Open Layers Control

Panel applet to enable 10 k

connect the low side of channel 0 to analog ground (a

physical resistor is not required). Refer to page 16 for

more information.

36

Ω of termination resistance to

Figure 13: Connecting Current Inputs to a Screw Terminal Panel

Ω

Page 55

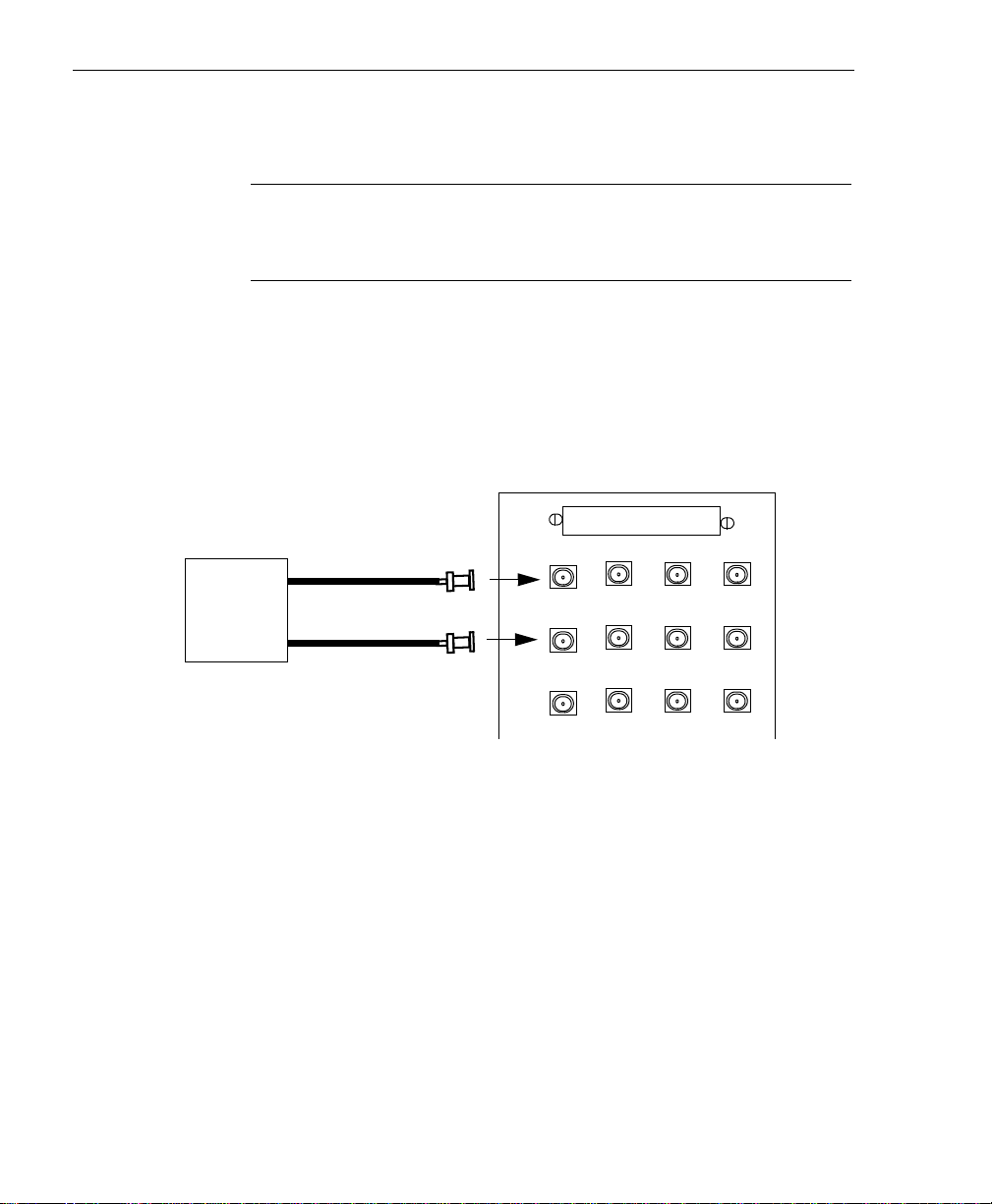

Connecting Analog Output Signals

Figure 14 shows how to connect an analog output voltage signal

(channel 0, in this case) to the BNC connectors on the KUSB-3116

module.

KUSB-3116 Module

Load

Analog Out 0

DAC0

DAC1

DACClock

ADClock

Wiring Signals

4

4

4

DAC2

Note that the BNC box automatically

connects the Analog Ground signal

appropriately.

Figure 14: Connecting Analog Outputs to the BNC Connectors

Figure 15 shows how to connect analog outputs to your own screw

terminal panel.

Analog Output 0

Load

Analog Output 0 Return

Figure 15: Connecting Analog Outputs to a Screw Terminal Panel

DAC3

DACTrig

ADTrig

Screw Terminal Panel

Digital I/O

1

20

C\T, DAC, Clk, Trig

4

4

4

4

4

4

41

Page 56

Chapter 4

Connecting Digital I/O Signals

Figure 16 shows how to connect digital input signals (lines 0 and 1, in

this case) to your own screw terminal panel.

Screw Terminal Panel

Digital Input 0

TTL Inputs

Digital Input 1

Digital Ground

Figure 16: Connecting Digital Inputs to a Screw Terminal Panel

Figure 17 shows how to connect a digital output (line 0, in this case)

to your own screw terminal panel.

Screw Terminal Panel

5 V

0 Out = LED On

500 Ω

+

-

Digital Out 0

Digital Ground

1

2

17

20

37

42

Figure 17: Connecting Digital Outputs to a Screw Terminal Panel

Page 57

Connecting Counter/Timer Signals

The KUSB-3116 module provides five counter/timer channels that

you can use to perform the following operations:

• Event counting,

•Up/down counting,

• Frequency measurement,

Wiring Signals

4

4

• Pulse width/period measurement,

• Edge-to-edge measurement, and

• Pulse output (continuous, one-shot, and repetitive one-shot).

This section describes how to connect counter/timer signals. Refer to

the KUSB-3116 User’s Manual for more information about using the

counter/timers.

Connecting Signals for Event Counting Operations

Figure 18 shows how to connect counter/timer signals either to your

own screw terminal panel to perform an event counting operation on

counter/timer 0 using an external gate. The counter counts the

number of rising edges that occur on the Counter 0 Clock input when

the Counter 0 Gate signal is in the active state (as specified by

software). Refer to the KUSB-3116 User’s Manual for more

information.

4

4

4

4

4

4

4

43

Page 58

Chapter 4

Signal

Source

External

Gating

Switch

Screw Terminal Panel

Counter 0 Clock

Counter 0 Gate

Digital Ground

8

28

29

Digital Ground

31

Figure 18: Connecting Counter/Timer Signals to a Screw Terminal Panel for

an Event Counting Operation Using an External Gate

Figure 19 shows how to connect counter/timer signals either to your

own screw terminal panel to perform an event counting operation on

counter/timer 0 without using a gate. The counter counts the number

of rising edges that occur on the Counter 0 Clock input.

Screw Terminal Panel

Counter 0 Clock

Signal Source

Digital Ground

8

18

Figure 19: Connecting Counter/Timer Signals to a Screw Terminal Panel for

an Event Counting Operation Without Using a Gate

44

Page 59

Connecting Signals for Up/Down Counting Operations

Figure 20 shows how to connect counter/timer signals to your own

screw terminal panel to perform an up/down counting operation on

counter/timer 0. The counter keeps track of the number of rising

edges that occur on the Counter 0 Clock input. The counter

increments when the Counter 0 Gate signal is high and decrements

when the Counter 0 Gate signal is low.

Wiring Signals

4

4

Screw Terminal Panel

Counter 0 Clock

Up/Down

Signal

Source

Figure 20: Connecting Counter/Timer Signals to a Screw Terminal Panel for

an Up/Down Counting Operation

Digital Ground

Counter 0 Gate

8

18

28

4

4

4

4

4

4

4

45

Page 60

Chapter 4

Connecting Signals for Frequency Measurement Operations

One way to measure frequency is to use the same wiring as a

standard event counting application that does not use a gate (see

Figure 19 on page 44), then use the Windows timer to determine the

duration of the frequency measurement. The frequency of the

Counter 0 Clock signal is the number of counts divided by the

duration of the Windows timer.

If you need more accuracy than the Windows timer can provide, you

can connect a pulse of a known duration (such as a one-shot output of

counter/timer 1) to the Counter 0 Gate input. Figure 21 shows how to

connect counter/timer signals to your own screw terminal panel. In

this case, the frequency of the Counter 0 clock input is the number of

counts divided by the period of the Counter 0 Gate input signal.

Screw Terminal Panel

46

Signal Source

Counter 0 Clock

Counter 1 Out

Counter 0 Gate

Digital Ground

8

11

28

33

Figure 21: Connecting Counter/Timer Signals to a Screw Terminal Panel for

a Frequency Measurement Operation Using an External Pulse

Page 61

Connecting Signals for Period/Pulse Width Measurement Operations

Figure 22 shows how to connect counter/timer signals to your own

screw terminal panel to perform a period/pulse width measurement

operation on counter/timer 0. You specify the active pulse (high or

low) in software. The pulse width is the percentage of the total pulse

period that is active. Refer to the KUSB-3116 User’s Manual for more

information about pulse periods and pulse widths.

Screw Terminal Panel

Wiring Signals

4

4

4

Counter 0 Clock

Signal Source

Digital Ground

Figure 22: Connecting Counter/Timer Signals to a Screw Terminal Panel for

a Period/Pulse Width Measurement Operation

8

18

4

4

4

4

4

4

47

Page 62

Chapter 4

Connecting Signals for Edge-to-Edge Measurement Operations

Figure 23 shows how to connect counter/timer signals to your own

screw terminal panel to perform an edge-to-edge measurement

operation on two signal sources. The counter measures the time

interval between the start edge (in this case, a rising edge on the

Counter 0 Clock signal) and the stop edge (in this case, a falling edge

on the Counter 0 Gate signal).

You specify the start edge and the stop edge in software. Refer to the

KUSB-3116 User’s Manual for more information.

Screw Terminal Panel

Signal Source 0

Signal Source 1

Counter 0 Clock

Digital Ground

Counter 0 Gate

8

18

28

Figure 23: Connecting Counter/Timer Signals to a Screw Terminal Panel for

an Edge-to-Edge Measurement Operation

48

Page 63

Wiring Signals

Connecting Signals for Pulse Output Operations

Figure 24 shows how to connect counter/timer signals to your own

screw terminal panel to perform a pulse output operation on

counter/timer 0; in this example, an external gate is used.

Screw Terminal Panel

Counter 0 Out

9

Heater

Controller

Figure 24: Connecting Counter/Timer Signals to a Screw Terminal Panel for

a Pulse Output Operation Using an External Gate

External

Gating

Switch

Counter 0 Gate

Digital Ground

Digital Ground

28

29

33

4

4

4

4

4

4

4

4

4

49

Page 64

Chapter 4

50

Page 65

5

Verifying the Operation

of a Module

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Running the Quick Data Acq Application . . . . . . . . . . . . . . . . . . 54

51

Page 66

Chapter 5

Prepare to Use a Module

(see Chapter 2 starting on page 7)

Set Up and Install the Module

(see Chapter 3 starting on page 13)

Wire Signals to the BNC Connection Box

(see Chapter 4 starting on page 23)

Verify the Operation of the Module

(this chapter)

52

Page 67

Overview

You can verify the operation of a KUSB-3116 module using the Quick

Data Acq application. Quick Data Acq allows you to perform the

following operations:

Verifying the Operation of a Module

5

• Acquire data from a single analog input channel or digital input

port;

• Acquire data continuously from one or more analog input

channels using an oscilloscope, strip chart, or Fast Fourier

Transform (FFT) view;

• Measure the frequency of events;

• Output data from a single analog output channel or digital

output port;

• Output pulses either continuously or as a one-shot; and

• Save the input data to disk.

Quick Data Acq is installed automatically when you install the driver

software, described on page 9.

5

5

5

5

5

5

5

5

53

Page 68

Chapter 5

Running the Quick Data Acq Application

To run the Quick Data Acq application, perform the following steps:

1. If you have not already done so, power up your computer and

any attached peripherals.

2. Select Quick Data Acq from the Keithley Instruments\Quick

Data Acq program group.

Note: The Quick Data Acq application allows you to verify basic

operations on the module; however, it may not support all of the

module’s features. For information about each of the supported

features, use the online help for the Quick Data Acq application by

pressing F1 from any view or selecting the Help menu, or refer to the

KUSB-3116 User’s Manual.

Performing a Single-Value Analog Input Operation

54

To verify that the module can read a single analog input value,

perform the following steps:

1. Connect a voltage source, such as a function generator, to analog

input channel 0 (differential mode) on the KUSB-3116 module.

Refer to page 37 for an example of how to connect a differential

analog input.

2. Click the Acquisition menu.

3. Click Single Analog Input.

4. Select the appropriate KUSB-3116 module from the Board list

box.

5. In the Channel list box, select analog input channel 0.

6. In the Range list box, select the range for the channel. The default

is ±10 V.

Page 69

7. Select Differential.

Verifying the Operation of a Module

8. Click Get to acquire a single value from analog input channel 0.

The value is displayed on the screen in both text and graphical form.

Performing a Single-Value Analog Output Operation

To verify that the module can output a single analog output value,

perform the following steps:

1. Connect an oscilloscope or voltmeter to analog output channel 0

on the module. Refer to page 41 for an example of how to connect

analog output signals.

2. Click the Control menu.

3. Click Single Analog Output.

4. Select the appropriate KUSB-3116 module from the Board list

box.

5. In the Channel list box, select analog output channel 0.

6. In the Range list box, select the output range of DAC0. The

default is ±10 V.

7. Enter an output value, or use the slider to select a value, to output

from DAC0.

5

5

5

5

5

5

8. Click Send to output a single value from analog output

channel 0.

The value that is output is displayed both on the slider and in the text

box.

5

5

5

55

Page 70

Chapter 5

Performing a Continuous Analog Input Operation

To verify that the module can perform a continuous analog input

operation, perform the following steps:

1. Connect known voltage sources, such as the outputs of a function

generator, to analog input channels 0 and 1 on the KUSB-3116

module (differential mode). Refer to page 37 for an example of

how to connect a differential analog input.

2. Click the Acquisition menu.

3. For this example, click Scope.

4. Select the appropriate KUSB-3116 module from the Board list

box.

5. In the Sec/Div list box, select the number of seconds per division

(.1 to .00001) for the display.

6. In the Channel list box, select analog input channel 1, then click

Add to add the channel to the channel list. Note that, by default,

channel 0 is included in the channel list.

56

7. Click Config from the Toolbar.

8. From the Config menu, select ChannelType, then select

Differential.

9. From the Config menu, select Range then select Bipolar.

10. Click OK to close dialog box

11. From the Scope view, double-click the input range of the channel

to change the input range of the module (±10 V, ±5 V, ±2.5 V, or

±1.25 V). The default is ±10 V.

The display changes to reflect the selected range for all the analog input

channels on the module.

12. In the Tr ig g e r box, select Auto to acquire data continuously from

the specified channels or Manual to acquire a burst of data from

the specified channels.

Page 71

Verifying the Operation of a Module

13. Click Start from the Toolbar to start the continuous analog input

operation.

The values acquired from each channel are displayed in a unique color

on the oscilloscope view.

14. Click Stop from the Toolbar to stop the operation.

Performing a Single-Value Digital Input Operation

5

5

To verify that the module can read a single digital input value,

perform the following steps:

1. Connect a digital input to digital input line 0 on the KUSB-3116

module. Refer to page 42 for an example of how to connect a

digital input.

2. Click the Acquisition menu.

3. Click Digital Input.

4. Select the appropriate KUSB-3116 module from the Board list

box.

5. Click Get.

The entire 16-bit digital input value (0 to FFFF) is displayed in both the

Data box and the Digital Input box.

In addition, the state of the lower eight digital input lines (lines 0 to 7)

is shown in the graphical display. If an indicator light is lit (red), the

line is high; if an indicator light is not lit (black), the line is low.

Note: Although the KUSB-3116 module contains 16 digital

input lines, the Quick Data Acq application shows indicator

lights for the lower eight digital input lines only. The 16-bit value

is the correct value for all 16 lines.

5

5

5

5

5

5

5

57

Page 72

Chapter 5

Performing a Single-Value Digital Output Operation

Note: Although the KUSB-3116 module contains 16 digital output

lines, the Quick Data Acq application allows you to perform a digital

output operation on the lower eight digital output lines (lines 0 to 7)

only.

To verify that the module can output a single digital output value,

perform the following steps:

1. Connect a digital output to digital output line 0 on the

KUSB-3116 module. Refer to page 42 for an example of how to

connect a digital output.

2. Click the Control menu.

3. Click Digital Output.

4. Select the appropriate KUSB-3116 module from the Board list

box.

58

5. Click the appropriate indicator lights to select the types of signals

to write from the digital output lines. If you select a light, the

module outputs a high-level signal; if you do not select a light,

the module outputs a low-level signal. You can also enter an

output value for the lower eight digital output lines (0 to FF) in

the Hex text box.

6. Click Send.

The values of the lower eight digital output lines are output

appropriately.

Page 73

Verifying the Operation of a Module

Performing a Frequency Measurement Operation

To verify that the module can perform a frequency measurement

operation, perform the following steps:

1. Wire an external clock source to counter/timer 0 on the

KUSB-3116 module. Refer to page 59 for an example of how to

connect an external clock.

Note: The Quick Data Acq application works only with

counter/timer 0.

2. Click the Acquisition menu.

3. Click Measure Frequency.

4. Select the appropriate KUSB-3116 module from the Board list

box.

5. In the Count Duration text box, enter the number of seconds

during which events will be counted.

6. Click Start to start the frequency measurement operation.

The operation automatically stops after the number of seconds you

specified has elapsed, and the frequency is displayed on the screen.

5

5

5

5

5

5

7. Click Stop to stop the frequency measurement operation.

5

5

5

59

Page 74

Chapter 5

Performing a Pulse Output Operation

To verify that the module can perform a pulse output operation,

perform the following steps:

1. Connect a scope to counter/timer 0 on the KUSB-3116 module.

Refer to page 49 for an example of how to connect a scope (a

pulse output) to counter/timer 0.

Note: The Quick Data Acq application works only with

counter/timer 0.

2. Click the Control menu.

3. Click Pulse Generator.

4. Select the appropriate KUSB-3116 module from the Board list

box.

5. Select either Continuous to output a continuous pulse stream or

One Shot to output one pulse.

60

6. Select either Low-to-high to output a rising-edge pulse (the high

portion of the total pulse output period is the active portion of

the signal) or High-to-low to output a falling-edge pulse (the low

portion of the total pulse output period is the active portion of

the signal).

7. Under Pulse Width, enter a percentage or use the slider to select

a percentage for the pulse width. The percentage determines the

duty cycle of the pulse.

8. Click Start to generate the pulse(s).

The results are displayed both in text and graphical form.

9. Click Stop to stop a continuous pulse output operation. One-shot

pulse output operations stop automatically.

Page 75

A

Ground, Power, and Isolation

Connections

61

Page 76

Appendix A

+5 V USB; used for

initialization only, not

for power.

Figure 25 illustrates how ground, power, and isolation are connected

internally on a KUSB-3116 module.

1

TB1

USB

2

3

USB Interface

Powe r

+5 V

DGND

DC

DC

DC

+5 V

+5 V

Earth GND

Interface

DGND USB

DC

62

Earth GND

A/D and D/A

Powe r

A/D and D/A

System

Figure 25: Ground, Power, and Isolation Connections

AGND-15 V +15 V

Page 77

Keep the following in mind:

Ground, Power, and Isolation Connections

• Earth ground on the KUSB-3116 module is not connected to

DGND or AGND.

• Earth ground is connected to the aluminum case of the BNC

connection box.

• You should connect earth ground to the power supply earth.

• You should isolate the +5V/DGND input. Note that the power