Page 1

KUSB-3102 and KUSB-3108

User’s Manual

KUSB3102/8-900-01 Rev. A / January 2005

www.keithley.com

A GR

EATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 3 years from

date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio. You

will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility.

Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance

of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse

of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN

ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE

POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO:

COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON, OR

DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/04

Page 3

KUSB-3102 and KUSB-3108

User’s Manual

©2005, Keithley Instruments, Inc.

All rights reserved.

First Printing, January 2005

Cleveland, Ohio, U.S.A.

Document Number: KUSB3102/8-900-01A Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released

between Revisions, contain important change information that the user should incorporate immediately into the manual.

Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number KUSB3102/8-900-01A)................................................................... January 2005

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or replacing consumable materials. Maintenance procedures

are described in the manual. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed

only by service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient overvoltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present. A good safety practice is to ex-

pect that hazardous voltage is present in any unknown circuit

before measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit

fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

5/03

Page 6

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment

frame.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on

the instrument. Products that consist of a circuit board with no case

or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

Page 7

Table of Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

What You Should Learn from this Manual. . . . . . . . . . . . . . . . . . xi

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . xii

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Where To Get Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Supported Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2: Principles of Operation . . . . . . . . . . . . . . . . . . . . 5

Analog Input Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Input Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analog Input Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Specifying a Single Channel . . . . . . . . . . . . . . . . . . . . . . . 8

Specifying One or More Channels . . . . . . . . . . . . . . . . . . 9

Specifying Digital Input Lines in the Analog Input

Channel List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Performing Dynamic Digital Output Operations . . . . 10

Input Ranges and Gains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specifying the Gain for a Single Channel . . . . . . . . . . . 13

Specifying the Gain for One or More Channels . . . . . . 13

A/D Sample Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Internal A/D Sample Clock . . . . . . . . . . . . . . . . . . . . . . . 14

External A/D Sample Clock . . . . . . . . . . . . . . . . . . . . . . 15

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

vii

Page 8

Contents

Analog Input Conversion Modes . . . . . . . . . . . . . . . . . . . . . . 16

Continuously Paced Scan Mode . . . . . . . . . . . . . . . . . . . 17

Triggered Scan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Internally Retriggered Scan Mode . . . . . . . . . . . . . . 19

Externally Retriggered Scan Mode. . . . . . . . . . . . . . 21

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Analog Output Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Output Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Analog Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Output Ranges and Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Conversion Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Digital I/O Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Digital I/O Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Operation Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Counter/Timer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

C/T Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Internal C/T Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

External C/T Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Internally Cascaded Clock . . . . . . . . . . . . . . . . . . . . . . . . 37

Gate Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Pulse Output Types and Duty Cycles . . . . . . . . . . . . . . . . . . 39

Counter/Timer Operation Modes . . . . . . . . . . . . . . . . . . . . . 40

Event Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . . 42

Rate Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

viii

Page 9

One-Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Repetitive One-Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 3: Supported Device Driver Capabilities. . . . . . . . 53

Chapter 4: Programming Flowcharts. . . . . . . . . . . . . . . . . . 65

Single-Value Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Continuous A/D Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Event Counting Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Frequency Measurement Operations . . . . . . . . . . . . . . . . . . . . . . 73

Pulse Output Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 5: Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Running the Calibration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Calibrating the Analog Input Subsystem . . . . . . . . . . . . . . . . . . . 92

Configuring for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Calibrating the Analog Input Circuitry . . . . . . . . . . . . . . . . . 93

Using the Auto-Calibration Procedure . . . . . . . . . . . . . 93

Using the Manual Calibration Procedure . . . . . . . . . . . 94

Calibrating the Thermocouple Circuitry . . . . . . . . . . . . . . . . 95

Calibrating the Analog Output Subsystem . . . . . . . . . . . . . . . . . 98

Contents

Chapter 6: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . 101

General Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Service and Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Appendix A: Specifications . . . . . . . . . . . . . . . . . . . . . . . . 107

Appendix B: Connector Pin Assignments . . . . . . . . . . . . 117

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

ix

Page 10

Contents

x

Page 11

About this Manual

This manual describes the features of the KUSB-3102 and KUSB-3108

modules, the capabilities of the device driver, and how to program

these modules using DT-Open Layers™ software. Calibration and

troubleshooting information is also provided.

Intended Audience

This document is intended for engineers, scientists, technicians, or

others responsible for using and/or programming the KUSB-3102 or

KUSB-3108 modules for data acquisition operations in Microsoft®

Windows 2000 or Windows XP. It is assumed that you have some

familiarity with data acquisition principles and that you understand

your application.

What You Should Learn from this Manual

This manual provides detailed information about the features of the

KUSB-3102 and KUSB-3108 modules and the capabilities of the

device driver. The manual is organized as follows:

• Chapter 1, “Overview,” describes the major features of the

modules, as well as the supported software and accessories for

the modules.

• Chapter 2, “Principles of Operation,” describes all of the features

of the modules and how to use them in your application.

• Chapter 3, “Supported Device Driver Capabilities,” lists the data

acquisition subsystems and the associated features accessible

using the device driver.

xi

Page 12

About this Manual

Conventions Used in this Manual

• Chapter 4, “Programming Flowcharts,” describes the processes

you must follow to program the subsystems on the KUSB-3102

and KUSB-3108 modules using DT-Open Layers-compliant

software.

• Chapter 5, “Calibration,” describes how to calibrate the analog

I/O circuitry of the modules.

• Chapter 6, “Troubleshooting,” provides information that you can

use to resolve problems with the modules and the device driver,

should they occur.

• Appendix A, “Specifications,” lists the specifications of the

modules.

• Appendix B, “Connector Pin Assignments,” shows the pin

assignments for the connectors and the screw terminal

assignments for the modules.

• An index completes this manual.

xii

The following conventions are used in this manual:

• Notes provide useful information or information that requires

special emphasis, cautions provide information to help you avoid

losing data or damaging your equipment, and warnings provide

information to help you avoid catastrophic damage to yourself or

your equipment.

• Items that you select or type are shown in bold.

Page 13

Related Information

Refer to the following documents for more information on using the

KUSB-3102 or KUSB-3108 module:

• KUSB-3102 and KUSB-3108 User’s Manual provided with the

module. This manual describes the features of the KUSB-3102

and KUSB-3108 modules and device driver.

• DataAcq SDK User’s Manual. For programmers who are

developing their own application programs using the Microsoft

C compiler, this manual describes how to use the DT-Open

TM

Layers

access the capabilities of your module.

• DTx-EZ Getting Started Manual. This manual describes how to use

the ActiveX controls provided in DTx-EZ

capabilities of your module in Microsoft Visual Basic® or Visual

C++®.

• DT-LV Link Getting Started Manual. This manual describes how to

use DT-LV Link

language to access the capabilities of your module.

DataAcq SDKTM in Windows 2000 or Windows XP to

About this Manual

TM

to access the

TM

with the LabVIEW® graphical programming

• Microsoft Windows 2000 or Windows XP documentation.

• USB web site (http://www.usb.org).

• Omega Complete Temperature Measurement Handbook and

Encyclopedia®. This document, published by Omega Engineering,

provides information on how to linearize voltage values into

temperature readings for various thermocouple types.

Where To Get Help

Should you run into problems installing or using your KUSB-3102 or

KUSB-3108 module, please call the Keithley Technical Support

Department.

xiii

Page 14

About this Manual

xiv

Page 15

1

Overview

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Supported Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1

Page 16

Chapter 1

Features

The KUSB-3102 and KUSB-3108 are low-cost, multifunction data

acquisition modules for the Universal Serial Bus (USB). Ta b le 1 lists

their key features.

Module

Analog Inputs

# of

Table 1: Key Features

Sample

Rate

# of Analog

Outputs

# of DIO

Lines

# of

Counter/

Timers

KUSB3102

KUSB3108

16 single-ended/ or

8 differential

16 single-ended/

8 differential/ or

7 thermocouples

and 1 CJC

100 kS/s 2 8 in,

8 out

50 kS/s 2 8 in,

8 out

2

2

The KUSB-3102 provides input gains of 1, 2, 4, and 8. The KUSB-3108

provides input gains of 1, 10, 100, and 500 to support thermocouples

and low-level analog input capability.

Both modules share the following major features:

• USB compatibility;

• Software configurable termination resistance for differential

inputs on a channel-by-channel basis.

• Continuously paced and triggered scan capability;

• A 32-location channel-gain list that supports sampling analog

input channels at the same or different gains in sequential or

random order;

• Internal and external clock sources for the analog input

subsystem;

2

Page 17

• Digital TTL triggering for the analog input subsystem;

Overview

• One 8-bit digital input port and one 8-bit digital output port; the

digital input lines can be included as part of the analog input

channel-gain list to correlate the timing of analog and digital

events; digital outputs can drive external solid-state relays; and

• One dynamic digital output line;

• Two 16-bit user counter/timers programmable for event

counting, frequency measurement, rate generation (continuous

pulse output), one-shot, and repetitive-one shot pulse output

operations.

• Programmable gate types and pulse output types.

• Software calibration for the analog I/O subsystems.

1

1

1

1

1

1

1

1

1

3

Page 18

Chapter 1

Supported Software

The following software is provided with the KUSB-3102 and

KUSB-3108 modules:

• Device Driver − This software must be installed and loaded

before you can use a KUSB-3102 and KUSB-3108 module with

any of the supported software packages or utilities.

• The Quick Data Acq application − This application provides a

quick way to get your module up and running. Using the Quick

Data Acq application, you can verify the features of the module,

display data on the screen, and save data to disk.

• Calibration Utility − This software allows you to calibrate the

analog I/O circuitry of the module. Refer to the KUSB-3102 and

KUSB-3108 User’s Manual for information on using this utility.

• DataAcq SDK − This DT-Open Layers Software Develop Kit

(SDK) allows programmers to develop application programs for

the KUSB-3102 and KUSB-3108 using the Microsoft C compiler in

Windows 2000 or Windows XP.

• DTx-EZ − This software package contains ActiveX controls that

allow Microsoft Visual Basic® or Visual C++® programmers to

access the capabilities of the KUSB-3102 and KUSB-3108

modules.

• DT-LV Link − This software package allows LabVIEW®

programmers to access the capabilities of the KUSB-3102 and

KUSB-3108 modules.

4

Page 19

2

Principles of Operation

Analog Input Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Analog Output Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Digital I/O Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Counter/Timer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5

Page 20

Chapter 2

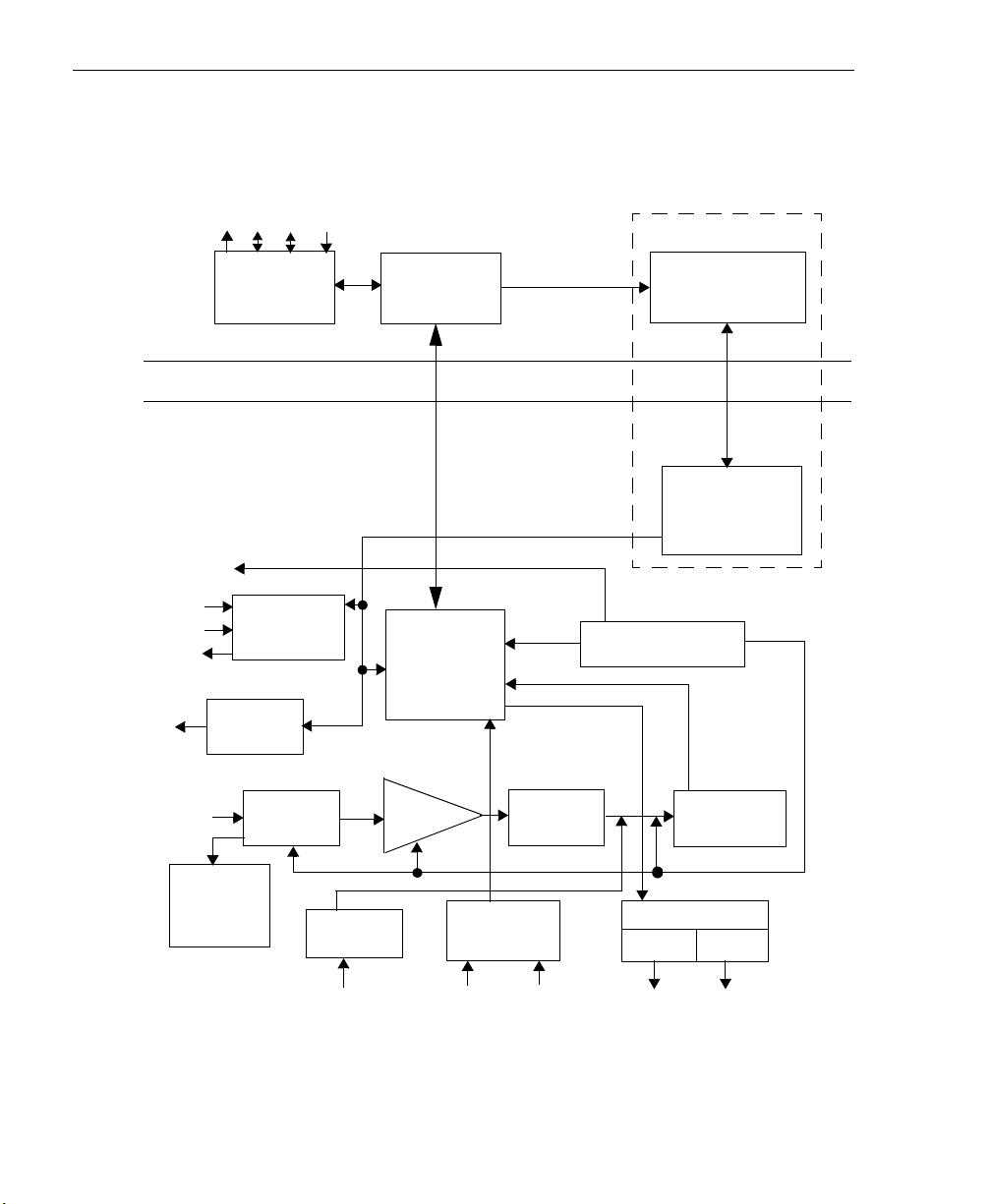

Figure 1 shows a block diagram of the KUSB-3102 and KUSB-3108

modules. Note that bold entries indicate signals you can access.

+5 V

D+

D−

Ground

USB

Interface

500 V Isolation Barrier *

Dynamic

Digital Out

Clock

Gate

Out

16 SE/8 DI

Analog

Inputs

Two 16-bit

User

Counter/Timers

8 Digital

Outputs

Analog Input

MUX

MicroController

High-Speed

Isolated Data Path

Isolated Side

Control Logic*

PGA

12- or 16-Bit

ADC

Isolated DC-DC

and Power Control*

Isolated

Powe r*

Channel Gain List

(32) Entries

Sample FIFO

10 kΩ Bias

Return

Termination

Resistors

8 Digital

Inputs

External

Clock and

Trigger Logic

Tri gger

Clock

12-or 16-Bit D/A

DAC0

DAC1

Figure 1: Block Diagram of the KUSB-3102 and KUSB-3108 Modules

6

Page 21

Analog Input Features

This section describes the features of the analog input (A/D)

subsystem, including the following:

• Input resolution, described on this page;

• Analog input channels, described on page 7;

• Input ranges and gains, described on page 12;

Principles of Operation

2

2

• A/D sample clock sources, described on page 14;

• Analog input conversion modes, described on page 16;

• Triggers, described on page 16;

• Data formats, described on page 23;

• Data transfer, described on page 25; and

• Error conditions, described on page 26.

Input Resolution

The input resolution of the KUSB-3102 is 12-bits, while the input

resolution of the KUSB-3108 module is 16-bits. Note that the

resolution is fixed; it cannot be programmed in software.

Analog Input Channels

Both the KUSB-3102 and KUSB-3108 modules support 16

single-ended or pseudo-differential analog input channels, or eight

differential analog input channels.

2

2

2

2

2

2

In addition, the KUSB-3108 module provides a cold junction

compensation (CJC) circuit on channel 0 at 10 mV/

you can connect seven thermocouple inputs (in differential mode) to

the KUSB-3108 module.

° C. Using the CJC,

2

7

Page 22

Chapter 2

You configure the channel type as single-ended or differential

through software. Using software, you can also select whether to use

10 kΩ termination resistance between the low side of each differential

channel and isolated analog ground. This feature is particularly

useful with floating signal sources. Refer to the KUSB-3102 and

KUSB-3108 Getting Started Manual for more information on wiring to

inputs and configuring the driver to use bias return termination

resistance.

Note: For pseudo-differential inputs, specify single-ended in

software; in this case, how you wire these signals determines the

configuration.

The KUSB-3102 and KUSB-3108 modules can acquire data from a

single analog input channel or from a group of analog input

channels. Channels are numbered 0 to 15 for single-ended and

pseudo-differential inputs, and 0 to 7 for differential inputs. The

following subsections describe how to specify the channels.

Specifying a Single Channel

The simplest way to acquire data from a single channel is to specify

the channel for a single-value analog input operation using software;

refer to page 16 for more information on single-value operations.

You can also specify a single channel using the analog input channel

list, described in the next section.

Note: If you want to perform a single-value digital input operation

while the A/D subsystem is configured, specify channel 16 (which

corresponds to the digital input port) in the A/D single-value

operation.

8

Page 23

Specifying One or More Channels

Principles of Operation

You can read data from one or more analog input channels using an

analog input channel list. You can group the channels in the list

sequentially (starting either with 0 or with any other analog input

channel) or randomly. You can also specify a single channel or the

same channel more than once in the list.

Using software, specify the channels in the order you want to sample

them. You can enter up to 32 entries in the channel list. The channels

are read in order (using continuously paced scan mode or triggered

scan mode) from the first entry to the last entry in the channel list.

Refer to page 16 for more information on the supported conversion

modes.

Specifying Digital Input Lines in the Analog Input Channel List

In addition to the analog input channels, the KUSB-3102 and

KUSB-3108 modules allow you to read eight digital input lines (Port

A, lines 0 to 7) using the analog input channel list. This feature is

particularly useful when you want to correlate the timing of analog

and digital events.

2

2

2

2

2

2

To read these eight digital input lines, specify channel 16 in the

analog input channel list. You can enter channel 16 anywhere in the

list and can enter it more than once, if desired.

Note: If channel 16 is the only channel in the channel-gain list, the

module can read this channel at the maximum A/D sampling rate.

2

2

2

9

Page 24

Chapter 2

The digital channel is treated like any other channel in the analog

input channel list; therefore, all the clocking, triggering, and

conversion modes supported for analog input channels are

supported for these digital input lines, if you specify them this way.

Performing Dynamic Digital Output Operations

Using software, you can enable a synchronous dynamic digital

output operation for the A/D subsystem. This feature is particularly

useful for synchronizing and controlling external equipment.

One dynamic digital output line (0) is provided (screw terminal 46).

This line is set to a value of 0 on power up; a reset does not affect the

values of the dynamic digital output line. Note that this line is

provided in addition to the other eight digital output lines; see page

32 for more information on the digital I/O features.

You specify the value (0 or 1) to write from the dynamic digital

output line using a digital channel list. A value of 0 indicates a

low-level signal; a value of 1 indicates a high-level signal.

10

The digital channel list corresponds to the analog input channel list.

As each entry in the analog input channel list is read, the

corresponding value you specified in the digital channel list is output

to the dynamic digital output line.

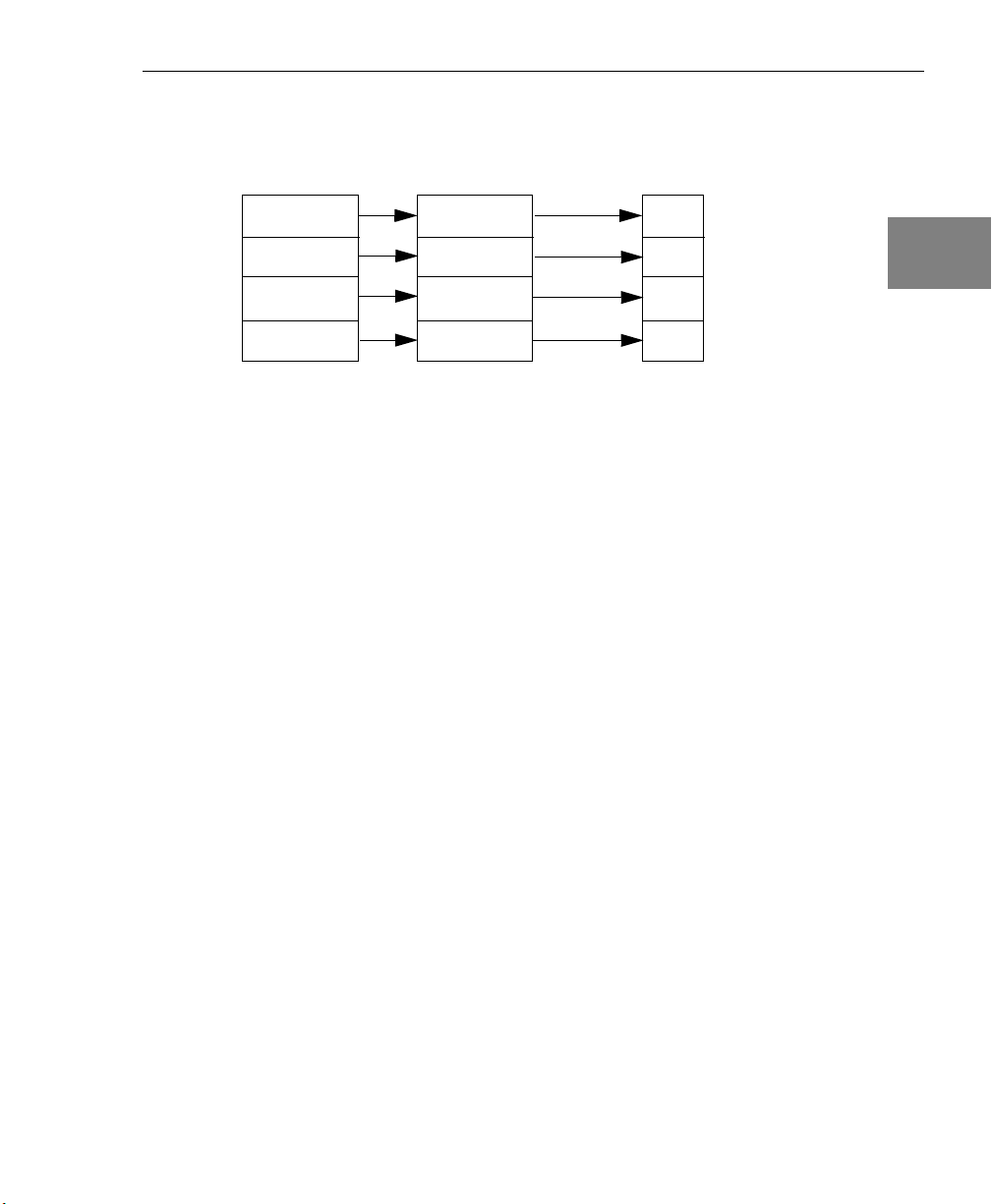

For example, assume that the analog input channel list contains

channels 0, 1, 2, and 3; that dynamic digital output operations are

enabled; and that the values in the digital channel list are 1, 0, 0, 1.

Figure 2 shows this configuration.

Page 25

Principles of Operation

Analog

Channel List

0

1

2

3

Figure 2: An Example Using Dynamic Digital Outputs

As analog input channel 0 is read, a high-level signal is output to the

dynamic digital output line. As analog input channels 1 and 2 are

read, a low-level signal is output to the dynamic digital output line.

As analog input channel 3 is read, a high-level signal is output to the

dynamic digital output line.

On power up, a value of 0 is written to the dynamic digital output

line.

Digital

Channel List

1

0

0

1

Dynamic Digital

Output Line 0

1

0

0

1

2

2

2

2

2

2

2

2

2

11

Page 26

Chapter 2

Input Ranges and Gains

Table 2 lists the supported gains and effective input ranges of the

KUSB-3102 and KUSB-3108 modules.

Table 2: Effective Input Ranges

Unipolar Input

Module Gain

KUSB-3102 1 0 to 10 V ±10 V

2 0 to 5 V ±5 V

4 0 to 2.5 V ±2.5 V

8 0 to 1.25 V ±1.25 V

KUSB-3108 1 − ±10 V

10 − ±1 V

100 − ±0.10 V

500 − ±0.020 V

Range

Bipolar Input

Range

Using software, specify 0 to 10 V for unipolar ranges or −10 V to +10 V

for bipolar ranges. Note that you specify the range for the entire

analog input subsystem, not the range per channel.

For each channel, choose the gain that has the smallest effective range

that includes the signal you want to measure. For example, if you are

using a KUSB-3102 and the range of your analog input signal is

±1.05 V, specify a range of −10 V to +10 V for the module and use a

gain of 8 for the channel; the effective input range for this channel is

then ±1.25 V, which provides the best sampling accuracy for that

channel.

12

The way you specify gain depends on how you specified the

channels, as described in the following subsections.

Page 27

Principles of Operation

Note: For single-value operations, the KUSB-3108 module supports

autoranging, where the module determines the appropriate gain for

your range rather than you having to specify it. Refer to page 16 for

more information on using autoranging.

Specifying the Gain for a Single Channel

The simplest way to specify gain for a single channel is to specify the

gain for a single-value analog input operation using software; refer to

page 16 for more information on single-value operations.

You can also specify the gain for a single channel using an analog

input gain list, described in the next section.

Specifying the Gain for One or More Channels

For the KUSB-3102 and KUSB-3108 modules, you can specify the gain

for one or more analog input channels using an analog input gain list.

Using software, set up the gain list by specifying the gain for each

entry in the channel list. (The two lists together are often referred to

as the channel-gain list.)

2

2

2

2

2

2

For example, assume the analog input channel list contains three

entries: channels 5, 6, and 7; the gain list might look like this: 2, 4, 1,

where a gain of 2 corresponds to channel 5, a gain of 4 corresponds to

channel 6, and a gain of 1 corresponds to channel 7.

Note: For analog input channel 16 (the eight digital input lines) in

the channel list, specify a gain of 1 in the gain list.

2

2

2

13

Page 28

Chapter 2

A/D Sample Clock Sources

The KUSB-3102 and KUSB-3108 modules allow you to use one of two

clock sources for pacing analog input operations in continuous mode:

• The internal A/D sample clock, which uses the 24-bit A/D

Counter on the module, or

• An external A/D sample clock, which you can connect directly to

the screw terminals on the module.

You use an A/D sample clock to pace the acquisition of each channel

in the channel-gain list; this clock is also called the A/D pacer clock.

Note: If you enter digital input channel 16 in the channel-gain list,

the A/D sample clock (internal or external) also paces the

acquisition of the eight digital input lines.

The following subsections describe the internal and external A/D

sample clocks in more detail.

14

Internal A/D Sample Clock

The internal A/D sample clock uses a 12 MHz time base.

Conversions start on the rising edge of the counter output; the output

pulse is active low.

Using software, specify the clock source as internal and the clock

frequency at which to pace the operation. The minimum frequency

supported is 0.75 Hz (0.75 Samples/s).

The maximum frequency of the KUSB-3102 module is

100 kSamples/s.

Page 29

Principles of Operation

For the KUSB-3108 module, the maximum frequency is

50 kSamples/s for a single channel or a channel scan when the gain is

1 or 10. When the gain is 100, the maximum frequency is

10 kSamples/s. When the gain is 500, the maximum frequency is 2

kSamples/s.

2

According to sampling theory (Nyquist Theorem), specify a

frequency that is at least twice as fast as the input’s highest frequency

component. For example, to accurately sample a 20 kHz signal,

specify a sampling frequency of at least 40 kHz. Doing so avoids an

error condition called aliasing, in which high frequency input

components erroneously appear as lower frequencies after sampling.

External A/D Sample Clock

An external A/D sample clock is useful when you want to pace

acquisitions at rates not available with the internal A/D sample clock

or when you want to pace at uneven intervals.

Connect an external A/D sample clock to screw terminal TB25 on the

module (pin 25 on connector J1). Conversions start on the rising edge

of the external A/D sample clock input signal.

Using software, specify the clock source as external. The clock

frequency is always equal to the frequency of the external A/D

sample clock input signal that you connect to the module.

2

2

2

2

2

2

2

2

15

Page 30

Chapter 2

Triggers

A trigger is an event that occurs based on a specified set of

conditions. KUSB-3102 and KUSB-3108 modules support the

following trigger sources:

• Software trigger − A software trigger event occurs when you start

the analog input operation (the computer issues a write to the

module to begin conversions). Using software, specify the trigger

source as a software trigger.

• External trigger − An external digital trigger event occurs when

the module detects a rising edge on the Ext A/D Trigger input

signal connected to screw terminal TB24 on the module (pin 24 of

connector J1). The trigger signal is TTL-compatible. Using

software, specify the trigger source as a external digital trigger

(external for DataAcq SDK users).

Analog Input Conversion Modes

The KUSB-3102 and KUSB-3108 modules support the following

conversion modes:

16

• Single-value operations are the simplest to use. Using software,

you can either specify the range, gain, and analog input channel,

or you can specify the range and analog input channel and have

the software determine the best gain for the range (called

autoranging). The board acquires the data from the specified

channel and returns the data immediately. Data can be returned

as both counts and voltage. For a single-value operation, you

cannot specify a clock source, trigger source, scan mode, or

buffer.

Single-value operations stop automatically when finished; you

cannot stop a single-value operation.

Page 31

Principles of Operation

• Scan mode takes full advantage of the capabilities of the

KUSB-3102 and KUSB-3108 modules. In a scan, you can specify a

channel-gain list, clock source, trigger source, scan mode, buffer,

and buffer wrap mode using software. Two scan modes are

supported: continuously paced scan mode and triggered scan

mode (often called burst mode). These modes are described in

the following subsections.

Using software, you can stop a scan by performing either an

orderly stop or an abrupt stop. In an orderly stop, the module

finishes acquiring the data, stops all subsequent acquisition, and

transfers the acquired data to host memory; all subsequent

triggers or retriggers are ignored.

In an abrupt stop, the module stops acquiring samples

immediately; the acquired data is not transferred to host memory,

and all subsequent triggers or retriggers are ignored.

2

2

2

2

Continuously Paced Scan Mode

Use continuously paced scan mode if you want to accurately control

the period between conversions of individual channels in a scan.

When it detects an initial trigger, the module cycles through the

channel-gain list, acquiring and converting the value for each entry in

the list (this process is defined as the scan). The module then wraps to

the start of the channel-gain list and repeats the process continuously

until either the allocated buffers are filled or until you stop the

operation. Refer to page 25 for more information on buffers.

The conversion rate is determined by the frequency of the A/D

sample clock; refer to page 14 for more information on the A/D

sample clock. The sample rate, which is the rate at which a single

entry in the channel-gain list is sampled, is determined by the

frequency of the A/D sample clock divided by the number of entries

in the channel-gain list.

2

2

2

2

2

17

Page 32

Chapter 2

To select continuously paced scan mode, use software to specify the

dataflow as continuous and to specify a trigger source to start the

operation. Refer to page 16 for more information on the supported

trigger sources.

Figure 3 illustrates continuously paced scan mode using a

channel-gain list with three entries: channel 0, channel 1, and channel

2. In this example, analog input data is acquired on each clock pulse

of the A/D sample clock. When it reaches the end of the channel-gain

list, the module wraps to the beginning of the channel-gain list and

repeats this process. Data is acquired continuously.

Chan 0

Chan 1

A/D

Sample

Clock

Trigger event occurs

Figure 3: Continuously Paced Scan Mode

Chan 2

Chan 0

Data acquired continuously

Chan 2

Chan 1

Chan 0

Chan 1

Chan 2

Chan 0

Chan 1

Chan 2

18

Page 33

Triggered Scan Mode

Principles of Operation

KUSB-3102 and KUSB-3108 modules support two triggered scan

modes: internally retriggered and externally retriggered. These

modes are described in the following subsections.

Internally Retriggered Scan Mode

Use internally retriggered scan mode if you want to accurately

control both the period between conversions of individual channels

in a scan and the period between each scan. This mode is useful when

synchronizing or controlling external equipment or when acquiring a

buffer of data on each trigger or retrigger.

When it detects an initial trigger (either a software trigger or an

external trigger), the module scans the channel-gain list once, then

waits for an internal retrigger to occur. When it detects an internal

retrigger, the board scans the channel-gain list once again, then waits

for another internal retrigger to occur. The process repeats

continuously until either the allocated buffers are filled or until you

stop the operation; refer to page 25 for more information on buffers.

The sample rate is determined by the frequency of the A/D sample

clock divided by the number of entries in the channel-gain list; refer

to page 14 for more information on the A/D sample clock. The

conversion rate of each scan is determined by the frequency of the

internal retrigger clock. The internal retrigger clock is the Triggered

Scan Counter on the board; the Triggered Scan Counter is a 24-bit

counter with a 12 MHz clock.

2

2

2

2

2

2

2

Figure 4 illustrates triggered scan mode. In this example, post-trigger

analog input data is acquired on each clock pulse of the A/D sample

clock until the channel-gain list has been scanned once; then, the

board waits for the retrigger event. When the retrigger event occurs,

the board scans the channel-gain list once again, acquiring data on

each pulse of the A/D sample clock. The process repeats

continuously with every specified retrigger event.

2

2

19

Page 34

Chapter 2

Chan 0

Chan 1

A/D

Sample

Clock

Trigger event occurs;

data acquired for one

scan of the CGL.

Specify the frequency of the internal retrigger clock using software.

The minimum retrigger frequency is 0.75 Hz (0.75 Samples/s).

The maximum retrigger rate of the KUSB-3102 module is 100 kHz.

For the KUSB-3108 module, the maximum retrigger frequency is

50 kHz for a single channel or a channel scan when the gain is 1 or 10.

When the gain is 100, the maximum retrigger frequency is 10 kHz.

When the gain is 500, the maximum retrigger frequency is 2 kHz.

Chan 2

Board waits for

retrigger event.

Chan 0

Retrigger event occurs;

data acquired for one

scan of the CGL.

Figure 4: Triggered Scan Mode

Chan 2

Chan 1

20

The appropriate retrigger frequency depends on a number of factors,

determined by the following equations:

Min. Retrigger = # of CGL entries + 2 µs

Period A/D sample clock frequency

Max. Retrigger = 1

Frequency Min. Retrigger Period

Page 35

Principles of Operation

For example, if you are using 16 channels in the channel-gain list, and

using an A/D sample clock with a frequency of 50 kHz, set the

maximum retrigger frequency to 3.106 kHz, since

3.106 kHz = 1

16 + 2 µs

50 kHz

To select internally retriggered scan mode, use software to specify the

following parameters:

• The dataflow as continuous;

• Triggered scan mode usage as enabled;

2

2

2

• The retrigger mode as internal;

• The number of times to scan per trigger or retrigger (also called

the multiscan count) as 1;

• The frequency of the retrigger clock; and

• The initial trigger source; refer to page 16 for more information

on the supported trigger sources.

Externally Retriggered Scan Mode

Use externally retriggered scan mode if you want to accurately

control the period between conversions of individual channels and

retrigger the scan based on an external event.

When a module detects an initial trigger (either a software trigger or

an external trigger), the module scans the channel-gain list once, then

waits for an external retrigger to occur. The external retrigger occurs

when a rising edge is detected on the Ext A/D Trigger input screw

terminal (TB24) on the module.

2

2

2

2

2

2

21

Page 36

Chapter 2

When the retrigger occurs, the module scans the channel-gain list

once, then waits for another external retrigger to occur. The process

repeats continuously until either the allocated buffers are filled (if

buffer wrap mode is none) or until you stop the operation (if buffer

wrap mode is single or multiple); refer to page 25 for more

information on buffers.

The conversion rate of each channel is determined by the frequency

of the A/D sample clock; refer to page 14 for more information on the

A/D sample clock. The conversion rate of each scan is determined by

the period between external retriggers; therefore, it cannot be

accurately controlled. The module ignores external triggers that occur

while it is acquiring data. Only external retrigger events that occur

when the module is waiting for a retrigger are detected and acted on.

To select externally retriggered scan mode, use software to specify the

following parameters:

• The dataflow as continuous;

• The triggered scan mode usage as enabled;

• The retrigger mode as an external retrigger (retrigger extra for

DataAcq SDK users);

22

• The number of times to scan per trigger or retrigger (also called

the multiscan count) to 1; and

• The retrigger source as the external trigger (external for DataAcq

SDK users).

Note: For DataAcq SDK users, if you want to use the same trigger

source as both the initial trigger and the retrigger source, specify the

external trigger as the initial trigger source and specify the retrigger

mode as scan-per-trigger. In this case, you need not specify the

retrigger source; the module uses the initial trigger source as the

retrigger source.

Page 37

Data Format

Principles of Operation

The KUSB-3102 module uses straight binary data encoding. The

KUSB-3108 module uses offset binary data encoding.

In software, the analog input value is returned as a code. To convert

the code to voltage, use the following formulas:

LSB = FSR

Vin = Code * LSB + Offset

where,

• LSB is the least significant bit.

• FSR is the full-scale range. The full-scale range is 10 for the

• N is the input resolution (12-bits for the KUSB-3102 and 16-bits

• Vin is the analog voltage.

• Code is the raw count used by the software to represent the

N

2

unipolar range or 20 for the bipolar range.

for the KUSB-3108).

voltage.

2

2

2

2

2

2

• Offset is the actual minus full-scale value. The minus full-scale

value is 0.0 V for the unipolar input range and −10 V for the

bipolar input range.

2

2

2

23

Page 38

Chapter 2

For example, assume that you are using a KUSB-3102 with a unipolar

input range. If the software returns a code of 2010 for the analog

input operation, determine the analog input voltage as follows:

LSB = 10 = 0.002441 V + 0.0 V

4096

Vin = 2010 * 0.002441 + 0 V

Vin = 4.906 V

Similarly, assume that you are using a KUSB-3108 module with a

bipolar input range. The actual minus full-scale value is −10.0 V. If

the software returns a code of 2010 for the analog input operation,

determine the analog input voltage as follows:

LSB = 20 = 0.000305 V

65536

Vin = 2010 * 0.000305 + −10.0 V

24

Vin = −9.370 V

Table 3 lists the values that are returned when the KUSB-3102 or

KUSB-3108 module is overrange.

Table 3: Overrange SIgnal Values

Module

Name

KUSB-3102 FFFh

KUSB-3108 FFFFh

Above-Range

Signals

(plus full-scale)

(plus full-scale)

Below-Range

000h

(minus full-scale)

0000h

(minus full-scale)

Signals

Page 39

Data Transfer

Principles of Operation

The module packs two bytes into each transfer to the host computer.

Even samples (corresponding to entries 0, 2, 4, and so on, in the

channel-gain list) are packed into the low bytes; odd samples

(corresponding to entries 1, 3, 5, and so on, in the channel-gain list)

are packed into the high bytes.

Both the KUSB-3102 and KUSB-3108 modules contain a 2048-sample

FIFO. During a continuous analog input operation, the hardware

interrupts the firmware on the module when the FIFO is half full. The

module then transfers 2048 samples to a circular buffer, which is

dedicated to the hardware, in the host computer.

The device driver accesses the hardware circular buffer to fill user

buffers that you allocate in software. Keep the following

recommendations in mind when allocating user buffers for

continuous analog input operations on the module:

• Allocate a minimum of three user buffers.

• Specify a buffer size at least as large as the sampling rate; for

example, if you are using a sampling rate of 100 kSamples/s

(100 kHz), specify a buffer size of 100,000. The minimum buffer

size that you should specify is 256 samples.

2

2

2

2

2

2

Note: If you are using a slow clock data rate, such as .75 Hz, and

a 256 sample user buffer, you will have to wait over 5 minutes for

any data since data is transferred only when 256 samples have

been read.

2

2

2

25

Page 40

Chapter 2

• Specify one of the following buffer wrap modes:

− If the wrap mode is none, data is written to the allocated

buffers until no more empty buffers are available; at that

point, the operation stops.

− If wrap mode is multiple, data is written to the allocated

multiple buffers continuously; when no more empty buffers

are available, the module overwrites the data in the filled

buffers starting with the first location of the first buffer. This

process continues indefinitely until you stop it.

− If wrap mode is single, data is written to a single buffer

continuously; when the buffer is filled, the module overwrites

the data in the buffer starting with the first location of the

buffer. This process continues indefinitely until you stop it.

Error Conditions

The KUSB-3102 and KUSB-3108 modules report an error if one of the

following conditions occurs:

26

• A/D Over Sample error − The A/D sample clock rate is too fast.

This error is reported if a new A/D sample clock pulse occurs

while the ADC is busy performing a conversion from the

previous A/D sample clock pulse. The host computer can clear

this error.

To avoid this error, use a slower sampling rate.

• A/D FIFO Full Flag set to 1 − The data was not read fast enough

by the host computer. The host computer can clear this error.

To avoid this error, ensure that you allocated at least three

buffers, each at least as large as the sampling rate; for example, if

you are using a sampling rate of 100 kSamples/s (100 kHz),

specify a buffer size of 100,000 samples for each buffer.

If one of these error conditions occurs, the module reports the

error but continues to acquire and transfer data to the host

computer.

Page 41

Principles of Operation

Note: The LED on the front panel will not blink green if the

hardware detects an error.

2

2

2

2

2

2

2

2

2

27

Page 42

Chapter 2

Analog Output Features

Both the KUSB-3102 and KUSB-3108 modules contain an analog

output (D/A) subsystem. This section describes the following

features of the D/A subsystem:

• Output resolution, described on this page;

• Analog output channels, described on page 28;

• Output ranges and gains, described on page 29;

• Conversion modes, described on page 30; and

• Data format, described on page 30.

Output Resolution

The KUSB-3102 module provides an output resolution of 12-bits. The

KUSB-3108 module provides an output resolution of 16-bits. Note

that the resolution is fixed; it cannot be programmed in software.

28

Analog Output Channels

Both the KUSB-3102 and KUSB-3108 modules support two DC-level

analog output channels (DAC0 and DAC1). Refer to the KUSB-3102

and KUSB-3108 Getting Started Manual for information on how to wire

analog output signals to the module. You configure the channel type

through software.

Within each DAC, the digital data is double-buffered to prevent

spurious outputs, then output as an analog signal. Both DACs power

up to a value of 0 V ±10 mV. Resetting the module does not clear the

values in the DACs.

Page 43

Principles of Operation

The module can output data from a single analog output channel

only. Specify the channel for a single-value analog output operation

using software; refer to “Conversion Modes,” on page 30 for more

information on single-value operations.

2

Output Ranges and Gains

Table 4 lists the output ranges supported by the KUSB-3102 and

KUSB-3108 modules. The gain is always 1.

Table 4: Output Ranges

Unipolar Output

Module

KUSB-3102 0 to 10 V or

KUSB-3108

Specify the range using software.

Range

0 to 5 V

−

Bipolar Input

Range

±10 V or ±5 V

±10 V

2

2

2

2

2

2

2

2

29

Page 44

Chapter 2

Conversion Modes

KUSB-3102 and KUSB-3108 modules can perform single-value analog

output operations only. Use software to specify the range, gain, and

analog output channel, then output the data from the specified

channel. You cannot specify a clock source, trigger source, or buffer.

Note: You cannot perform a single-value analog output operation

while the A/D subsystem is running.

The settling time for each DAC is 50 µs (20 V steps).

Single-value operations stop automatically when finished; you

cannot stop a single-value operation.

Data Format

30

Data from the host computer must use offset binary data encoding for

analog output signals. Using software, specify the data encoding as

binary.

In software, you need to supply a code that corresponds to the analog

output value you want the module to output. To convert a voltage to

a code, use the following formulas:

LSB = FSR

Code = Vout - offset

N

2

LSB

Page 45

where,

Principles of Operation

• LSB is the least significant bit.

• FSR is the full-scale range (10).

• N is the output resolution (12-bits for the KUSB-3102 module and

16-bits for the KUSB-3108 module).

• Code is the raw count used by the software to represent the

voltage.

• Vout is the analog voltage.

• Offset is the minus full-scale value, or −10 V.

For example, assume that you are using a KUSB-3108 module. If you

want to output a voltage of 4.7 V, determine the code value as

follows:

LSB = 10 V = 0.0001526 V

65536

Code = 4.7 V - (-10 V)

0.0001526 V

Code = 96330 = 1784Ah

2

2

2

2

2

2

2

2

2

31

Page 46

Chapter 2

Digital I/O Features

This section describes the following features of the digital I/O

subsystem:

• Digital I/O lines, described on this page;

• Resolution, described on this page; and

• Operation modes, described on page 33.

Digital I/O Lines

KUSB-3102 and KUSB-3108 modules support eight digital input lines

(Port A, lines 0 to 7) through the DIN subsystem and eight digital

output lines (Port B, lines 0 to 7) through the DOUT subsystem.

For fast, clocked digital input operations, you can enter the digital

input lines from Port A as channel 16 in the analog input channel list;

refer to page 9 for more information.

Both modules also provide a dynamic digital output line that you can

update when an analog input channel is read. Note that the dynamic

digital output line is in addition to the digital output lines in Port B.

Refer to page 10 for more information on dynamic digital output

operations.

32

On power up or module reset, no digital data is output from the

modules. All the outputs include diode protection to the isolated

ground and the isolated +5 V.

Resolution

The resolution of the digital input port is fixed at 8 bits; the resolution

of the digital output port is also fixed at 8 bits.

You cannot program the digital I/O resolution in software.

Page 47

Operation Modes

Principles of Operation

KUSB-3102 and KUSB-3108 modules support the following digital

I/O operation modes:

• Single-value operations are the simplest to use but offer the least

flexibility and efficiency. You use software to specify the digital

I/O port and a gain of 1 (the gain is ignored). Data is then read

from or written to the digital I/O lines. For a single-value

operation, you cannot specify a clock or trigger source.

Single-value operations stop automatically when finished; you

cannot stop a single-value operation.

• Continuous digital input takes full advantage of the capabilities

of the modules. In this mode, enter all eight digital input lines of

Port A as channel 16 of the analog input channel-gain list;

program this mode through the A/D subsystem. Using this

mode, you can specify a clock source, scan mode, trigger source,

buffer, and buffer wrap mode for the digital input operation.

Refer to page 9 for more information on specifying digital input

lines for a continuous digital input operation.

• Dynamic digital output is useful for synchronizing and

controlling external equipment and allows you to output data to

the dynamic digital output line each time an analog input value

is acquired. This mode is programmed through the A/D

subsystem; refer to page 10 for more information.

2

2

2

2

2

2

2

2

2

33

Page 48

Chapter 2

Counter/Timer Features

The counter/timer circuitry on the module provides the clocking

circuitry used by the A/D and D/A subsystems as well as several

user counter/timer features. This section describes the following user

counter/timer features:

• Units, described on this page;

• C/T clock sources, described on page 35;

• Gate types, described on page 37;

• Pulse types and duty cycles, described on page 39; and

• Counter/timer operation modes, described on page 40.

Units

Two 16-bit counter/timers (0 and 1) are supported by the KUSB-3102

and KUSB-3108 modules.

Each counter accepts a clock input signal and gate input signal and

outputs a clock output signal (also called a pulse output signal), as

shown in Figure 5.

34

Clock Input SIgnal

(internal, external,

or internally

cascaded)

Counter

Gate Input Signal

(software or

external input)

Figure 5: Counter/Timer Channel

Pulse Output

Signal

Page 49

Principles of Operation

Each counter corresponds to a counter/timer (C/T) subsystem. To

specify the counter to use in software, specify the appropriate C/T

subsystem. Counter 0 corresponds to C/T subsystem element 0;

counter 1 corresponds to C/T subsystem element 1.

2

C/T Clock Sources

The following clock sources are available for the user counters:

• Internal C/T clock,

• External C/T clock, and

• Internally cascaded clock.

Refer to the following subsections for more information on these

clock sources.

Internal C/T Clock

The internal C/T clock uses a 12 MHz time base. Counter/timer

operations start on the rising edge of the clock input signal.

Through software, specify the clock source as internal and the

frequency at which to pace the counter/timer operation (this is the

frequency of the clock output signal). The maximum frequency that

you can specify for the clock output signal is 750 kHz. The minimum

frequency that you can specify for the clock output signal for each

16-bit counter is 183.1 Hz. The rising edge of the clock is the active

edge.

2

2

2

2

2

2

2

2

35

Page 50

Chapter 2

External C/T Clock

An external C/T clock is useful when you want to pace

counter/timer operations at rates not available with the internal C/T

clock or if you want to pace at uneven intervals. The rising edge of

the external C/T clock input signal is the active edge.

Using software, specify the clock source as external and the clock

divider used to determine the frequency at which to pace the

operation. The minimum clock divider that you can specify is 2.0; the

maximum clock divider that you can specify is 65,536. For example, if

you supply an external C/T clock with a frequency of 700 kHz and

specify a clock divider of 2, the resulting frequency of the external

C/T clock output signal is 350 kHz. The resulting frequency of the

external C/T clock output signal must not exceed 750 kHz.

Table 5 lists the screw terminals of the modules that correspond to

the external C/T clock signals of each counter/timer.

Table 5: External C/T Clock Signals

36

Counter/

Timer

0 TB54 54

1 TB50 50

Screw Terminal

on Module

Number

J1 Pin

Page 51

Internally Cascaded Clock

Principles of Operation

You can also internally route the clock output signal from

counter/timer 0 to the clock input signal of counter/timer 1 to

internally cascade the counters. In this way, you can create a 32-bit

counter without externally connecting two counters together.

Specify internal cascade mode in software. The rising edge of the

clock input signal is active.

Through software, specify the clock source as internal and the

frequency at which to pace the counter/timer operation (this is the

frequency of the clock output signal). The maximum frequency that

you can specify for the clock output signal is 750 kHz. For a 32-bit

cascaded counter, the minimum frequency that you can specify for

the clock output signal is 0.0028 Hz.

Gate Types

The active edge or level of the gate input to the counter enables

counter/timer operations. The operation starts when the clock input

signal is received. Specify the gate type in software.

KUSB-3102 and KUSB-3108 modules provide the following gate

input types:

2

2

2

2

2

2

• None − A software command enables any specified

counter/timer operation immediately after execution. This gate

type is useful for all counter/timer modes; refer to page 40 for

more information on these modes.

• Logic-low level external gate input − Enables a counter/timer

operation when the external gate signal is low, and disables the

counter/timer operation when the external gate signal is high.

Note that this gate type is used only for event counting,

frequency measurement, and rate generation; refer to page 40 for

more information on these modes.

2

2

2

37

Page 52

Chapter 2

• Logic-high level external gate input − Enables a counter/timer

operation when the external gate signal is high, and disables a

counter/timer operation when the external gate signal is low.

Note that this gate type is used only for event counting,

frequency measurement, and rate generation; refer to page 40 for

more information on these modes.

• Falling-edge external gate input − Enables a counter/timer

operation on the transition from the high level to the low level

(falling edge). In software, this is called a low-edge gate type.

Note that this gate type is used only for one-shot and repetitive

one-shot mode; refer to page 40 for more information on these

modes.

• Rising-edge external gate input − Enables a counter/timer

operation on the transition from the low level to the high level

(rising edge). In software, this is called a high-edge gate type.

Note that this gate type is used only for one-shot and repetitive

one-shot mode; refer to page 49 for more information on these

modes.

Table 6 lists the screw terminals and pin numbers on the modules

that correspond to the gate input signals of each counter/timer.

38

Table 6: Gate Input Signals

Counter/

Timer

0 TB52 52

1 TB48 48

Screw Terminal

on Module

Number

J1 Pin

Page 53

Pulse Output Types and Duty Cycles

Principles of Operation

KUSB-3102 and KUSB-3108 modules can output pulses from each

counter/timer. Table 7 lists the screw terminals of the modules that

correspond to the pulse output signals of each counter/timer.

Table 7: Pulse Output Signals

Counter/

Timer

0 TB53 53

1 TB49 49

Both modules support the following pulse output types on the clock

output signal:

• High-to-low transitions − The low portion of the total pulse

output period is the active portion of the counter/timer clock

output signal.

• Low-to-high transitions − The high portion of the total pulse

output period is the active portion of the counter/timer pulse

output signal.

Screw Terminal

on Module

J1 Pin

Number

2

2

2

2

2

2

You specify the pulse output type in software.

The duty cycle (or pulse width) indicates the percentage of the total

pulse output period that is active. A duty cycle of 50, then, indicates

that half of the total pulse is low and half of the total pulse output is

high. You specify the duty cycle in software.

Note: The minimum pulse width must be 650 ns.

2

2

2

39

Page 54

Chapter 2

Figure 6 illustrates a low-to-high pulse with a duty cycle of

approximately 30%.

Active Pulse Width

high pulse

low pulse

Total Pulse Period

Figure 6: Example of a Low-to-High Pulse Output Type

Counter/Timer Operation Modes

KUSB-3102 and KUSB-3108 modules support the following

counter/timer operation modes:

40

• Event counting,

• Frequency measurement,

• Rate generation,

• One-shot, and

• Repetitive one-shot.

The following subsections describe these modes in more detail.

Page 55

Event Counting

Principles of Operation

Use event counting mode to count events (clock pulses) from the

counter’s associated clock input source.

If you are using one counter, you can count a maximum of 65,536

events before the counter rolls over to 0 and starts counting again. If

you are using a cascaded 32-bit counter, you can count a maximum of

4,294,967,296 events before the counter rolls over to 0 and starts

counting again.

In event counting mode, use an external C/T clock source; refer to

page 36 for more information on the external C/T clock source.

Using software, specify the counter/timer mode as event counting

(count), the C/T clock source as external, and the gate type that

enables the operation as logic high. Refer to page 39 for information

on gates.

Ensure that the signals are wired appropriately. Refer to the

KUSB-3102 and KUSB-3108 Getting Started Manual for wiring

examples.

Figure 7 shows an example of an event counting operation using a

logic-high gate type.

2

2

2

2

2

2

2

2

2

41

Page 56

Chapter 2

Gate Input

Signal

External C/T

Clock

Input Signal

high level

enables operation

low level

disables operation

3 events are counted while

the operation is enabled

event counting

operation starts

event counting

operation stops

Figure 7: Example of Event Counting

Frequency Measurement

Use frequency measurement mode to measure the frequency of the

signal from counter’s associated clock input source over a specified

duration. In this mode, use an external C/T clock source; refer to

page 35 for more information on the external C/T clock source.

One way to perform a frequency measurement is to use the same

wiring as an event counting application that does not use an external

gate signal. Refer to the KUSB-3102 and KUSB-3108 Getting Started

Manual for wiring examples.

42

Page 57

Principles of Operation

In this configuration, use software to specify the counter/timer mode

as frequency measurement or event counting (count), and the

duration of the system timer over which to measure the frequency.

(The system timer uses a resolution of 1 ms.) In this configuration,

frequency is determined using the following equation:

2

Frequency Measurement = Number of Events

Duration of the System Timer

If you need more accuracy than the system timer provides, you can

connect a pulse of a known duration (such as a one-shot output of

another user counter) to the external gate input. Refer to the

KUSB-3102 and KUSB-3108 Getting Started Manual for wiring

examples.

In this configuration, use software to set up the counter/timers as

follows:

1. Set up one of the counter/timers for one-shot mode, specifying

the clock source, clock frequency, gate type, type of output pulse

(high or low), and duty cycle.

2. Set up the counter/timer that will measure the frequency for

event counting mode, specifying the clock source to count, and

the gate type (this should match the pulse output type of the

counter/timer set up for one-shot mode).

3. Start both counters (events are not counted until the active period

of the one-shot pulse is generated).

4. Read the number of events counted. (Allow enough time to

ensure that the active period of the one-shot occurred and that

events have been counted.)

5. Determine the measurement period using the following

equation:

2

2

2

2

2

2

2

Measurement period = 1 * Active Pulse Width

Clock Frequency

2

43

Page 58

Chapter 2

External C/T

Clock

Input Signal

6. Determine the frequency of the clock input signal using the

following equation:

Frequency Measurement = Number of Events