Page 1

DTx-EZ

Getting Started Manual

DTXEZ-903-01 Rev. A / January 2005

www.keithley.com

A GR

EATER MEASURE OF CONFIDENCE

Page 2

WARRANTY

Keithley Instruments, Inc. warrants this product to be free from defects in material and workmanship for a period of 3 years from

date of shipment.

Keithley Instruments, Inc. warrants the following items for 90 days from the date of shipment: probes, cables, rechargeable batteries,

diskettes, and documentation.

During the warranty period, we will, at our option, either repair or replace any product that proves to be defective.

To exercise this warranty, write or call your local Keithley representative, or contact Keithley headquarters in Cleveland, Ohio.

You will be given prompt assistance and return instructions. Send the product, transportation prepaid, to the indicated service facility. Repairs will be made and the product returned, transportation prepaid. Repaired or replaced products are warranted for the balance of the original warranty period, or at least 90 days.

LIMITATION OF WARRANTY

This warranty does not apply to defects resulting from product modification without Keithley’s express written consent, or misuse

of any product or part. This warranty also does not apply to fuses, software, non-rechargeable batteries, damage from battery leakage, or problems arising from normal wear or failure to follow instructions.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE. THE REMEDIES PROVIDED HEREIN

ARE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

NEITHER KEITHLEY INSTRUMENTS, INC. NOR ANY OF ITS EMPLOYEES SHALL BE LIABLE FOR ANY DIRECT,

INDIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE USE OF ITS INSTRUMENTS AND SOFTWARE EVEN IF KEITHLEY INSTRUMENTS, INC., HAS BEEN ADVISED IN ADVANCE OF THE

POSSIBILITY OF SUCH DAMAGES. SUCH EXCLUDED DAMAGES SHALL INCLUDE, BUT ARE NOT LIMITED TO:

COSTS OF REMOVAL AND INSTALLATION, LOSSES SUSTAINED AS THE RESULT OF INJURY TO ANY PERSON,

OR DAMAGE TO PROPERTY.

A G R E A T E R M E A S U R E O F C O N F I D E N C E

Keithley Instruments, Inc.

Corporate Headquarters • 28775 Aurora Road • Cleveland, Ohio 44139

440-248-0400 • Fax: 440-248-6168 • 1-888-KEITHLEY (534-8453) • www.keithley.com

12/04

Page 3

DTx-EZ

Getting Started Manual

©2005, Keithley Instruments, Inc.

All rights reserved.

First Printing, January 2005

Cleveland, Ohio, U.S.A.

Document Number: DTXEZ-903-01

Rev. A

Page 4

Manual Print History

The print history shown below lists the printing dates of all Revisions and Addenda created for this manual. The Revision Level letter increases alphabetically as the manual undergoes subsequent updates. Addenda, which are released

between Revisions, contain important change information that the user should incorporate immediately into the manual.

Addenda are numbered sequentially. When a new Revision is created, all Addenda associated with the previous Revision

of the manual are incorporated into the new Revision of the manual. Each new Revision includes a revised copy of this

print history page.

Revision A (Document Number DTXEZ-903-01A) ........................................................................... January 2005

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their respective holders.

Page 5

Safety Precautions

The following safety precautions should be observed before using

this product and any associated instrumentation. Although some instruments and accessories would normally be used with non-hazardous voltages, there are situations where hazardous conditions

may be present.

This product is intended for use by qualified personnel who recognize shock hazards and are familiar with the safety precautions required to avoid possible injury. Read and follow all installation,

operation, and maintenance information carefully before using the

product. Refer to the manual for complete product specifications.

If the product is used in a manner not specified, the protection provided by the product may be impaired.

The types of product users are:

Responsible body is the individual or group responsible for the use

and maintenance of equipment, for ensuring that the equipment is

operated within its specifications and operating limits, and for ensuring that operators are adequately trained.

Operators use the product for its intended function. They must be

trained in electrical safety procedures and proper use of the instrument. They must be protected from electric shock and contact with

hazardous live circuits.

Maintenance personnel perform routine procedures on the product to keep it operating properly, for example, setting the line voltage or replacing consumable materials. Maintenance procedures

are described in the manual. The procedures explicitly state if the

operator may perform them. Otherwise, they should be performed

only by service personnel.

Service personnel are trained to work on live circuits, and perform

safe installations and repairs of products. Only properly trained service personnel may perform installation and service procedures.

Keithley products are designed for use with electrical signals that

are rated Measurement Category I and Measurement Category II, as

described in the International Electrotechnical Commission (IEC)

Standard IEC 60664. Most measurement, control, and data I/O signals are Measurement Category I and must not be directly connected to mains voltage or to voltage sources with high transient overvoltages. Measurement Category II connections require protection

for high transient over-voltages often associated with local AC

mains connections. Assume all measurement, control, and data I/O

connections are for connection to Category I sources unless otherwise marked or described in the Manual.

Exercise extreme caution when a shock hazard is present. Lethal

voltage may be present on cable connector jacks or test fixtures.

The American National Standards Institute (ANSI) states that a

shock hazard exists when voltage levels greater than 30V RMS,

42.4V peak, or 60VDC are present. A good safety practice is to ex-

pect that hazardous voltage is present in any unknown circuit

before measuring.

Operators of this product must be protected from electric shock at

all times. The responsible body must ensure that operators are prevented access and/or insulated from every connection point. In

some cases, connections must be exposed to potential human contact. Product operators in these circumstances must be trained to

protect themselves from the risk of electric shock. If the circuit is

capable of operating at or above 1000 volts, no conductive part of

the circuit may be exposed.

Do not connect switching cards directly to unlimited power circuits.

They are intended to be used with impedance limited sources.

NEVER connect switching cards directly to AC mains. When connecting sources to switching cards, install protective devices to limit

fault current and voltage to the card.

Before operating an instrument, make sure the line cord is connected to a properly grounded power receptacle. Inspect the connecting

cables, test leads, and jumpers for possible wear, cracks, or breaks

before each use.

When installing equipment where access to the main power cord is

restricted, such as rack mounting, a separate main input power disconnect device must be provided, in close proximity to the equipment and within easy reach of the operator.

For maximum safety, do not touch the product, test cables, or any

other instruments while power is applied to the circuit under test.

ALWAYS remove power from the entire test system and discharge

any capacitors before: connecting or disconnecting cables or jumpers, installing or removing switching cards, or making internal

changes, such as installing or removing jumpers.

Do not touch any object that could provide a current path to the common side of the circuit under test or power line (earth) ground. Always

make measurements with dry hands while standing on a dry, insulated

surface capable of withstanding the voltage being measured.

The instrument and accessories must be used in accordance with its

specifications and operating instructions or the safety of the equipment may be impaired.

Do not exceed the maximum signal levels of the instruments and accessories, as defined in the specifications and operating information, and as shown on the instrument or test fixture panels, or

switching card.

When fuses are used in a product, replace with same type and rating

for continued protection against fire hazard.

Chassis connections must only be used as shield connections for

measuring circuits, NOT as safety earth ground connections.

If you are using a test fixture, keep the lid closed while power is applied to the device under test. Safe operation requires the use of a

lid interlock.

5/03

Page 6

If a screw is present, connect it to safety earth ground using the

wire recommended in the user documentation.

!

The symbol on an instrument indicates that the user should refer to the operating instructions located in the manual.

The symbol on an instrument shows that it can source or measure 1000 volts or more, including the combined effect of normal

and common mode voltages. Use standard safety precautions to

avoid personal contact with these voltages.

The symbol indicates a connection terminal to the equipment

frame.

The WARNING heading in a manual explains dangers that might

result in personal injury or death. Always read the associated information very carefully before performing the indicated procedure.

The CAUTION heading in a manual explains hazards that could

damage the instrument. Such damage may invalidate the warranty.

Instrumentation and accessories shall not be connected to humans.

Before performing any maintenance, disconnect the line cord and

all test cables.

To maintain protection from electric shock and fire, replacement

components in mains circuits, including the power transformer, test

leads, and input jacks, must be purchased from Keithley Instruments. Standard fuses, with applicable national safety approvals,

may be used if the rating and type are the same. Other components

that are not safety related may be purchased from other suppliers as

long as they are equivalent to the original component. (Note that selected parts should be purchased only through Keithley Instruments

to maintain accuracy and functionality of the product.) If you are

unsure about the applicability of a replacement component, call a

Keithley Instruments office for information.

To clean an instrument, use a damp cloth or mild, water based

cleaner. Clean the exterior of the instrument only. Do not apply

cleaner directly to the instrument or allow liquids to enter or spill on

the instrument. Products that consist of a circuit board with no case

or chassis (e.g., data acquisition board for installation into a computer) should never require cleaning if handled according to instructions. If the board becomes contaminated and operation is affected,

the board should be returned to the factory for proper cleaning/servicing.

Page 7

Table of Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

What You Should Learn from this Manual. . . . . . . . . . . . . . . . . xiii

Organization of this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . xiv

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Where to Get Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Chapter 1: Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What is DTx-EZ?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Conforms to the DT-Open Layers Standard . . . . . . . . . . . . . . 2

Provides Custom Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

The Data Acquisition Custom Control . . . . . . . . . . . . . . 3

The DT Plot Custom Control . . . . . . . . . . . . . . . . . . . . . . . 3

Provides Properties, Methods, and Events . . . . . . . . . . . . . . . 4

Provides Function and Subroutine Libraries . . . . . . . . . . . . . 5

Follows Object-Oriented Design. . . . . . . . . . . . . . . . . . . . . . . . 6

Provides Extensive Example Programs . . . . . . . . . . . . . . . . . . 6

Provides Multiple Board Support. . . . . . . . . . . . . . . . . . . . . . . 6

Provides High Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adding DTx-EZ Custom Controls to Your Project . . . . . . . . . . . 10

Adding to a Visual Basic 6.0 Project . . . . . . . . . . . . . . . . . . . . 10

Adding to a Visual C++ 6.0 Project. . . . . . . . . . . . . . . . . . . . . 11

Creating an Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using the DTx-EZ Online Help . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

vii

Page 8

Contents

Chapter 2: Using the DTx-EZ Examples . . . . . . . . . . . . . . . 15

About the Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Running the Examples as Applications. . . . . . . . . . . . . . . . . 17

Opening the Examples from within Visual Basic. . . . . . . . . 18

Opening the Examples from within Visual C++ . . . . . . . . . 19

A/D Burst Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DAC Waveform Generator Example. . . . . . . . . . . . . . . . . . . . . . . 25

Continuous A/D Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Single-Value Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

About-Trigger Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Digital I/O Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DDE Server and Client Examples . . . . . . . . . . . . . . . . . . . . . . . . . 37

Waveform Generator Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Continuous FFT Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ChartIt Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Scope Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

viii

Chapter 3: Property, Method, Function, and Subroutine

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Data Acquisition Custom Control . . . . . . . . . . . . . . . . . . . . . . . . . 47

Information Properties and Methods. . . . . . . . . . . . . . . . . . . 47

Initialization Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configuration Properties and Functions . . . . . . . . . . . . . . . . 58

Operation Properties, Methods, Functions, and

Subroutines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Data Management DLLs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Buffer Management Functions and Subroutines . . . . . . . . . 64

Conversion Functions and Subroutines. . . . . . . . . . . . . . . . . 67

DT Plot Custom Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Plot Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Page 9

Plot Pre-Display Operational Parameters . . . . . . . . . . . . . . . 70

Grids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Markers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

x-Axis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

y-Axis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Plotting Operation Control Parameters. . . . . . . . . . . . . . . . . 73

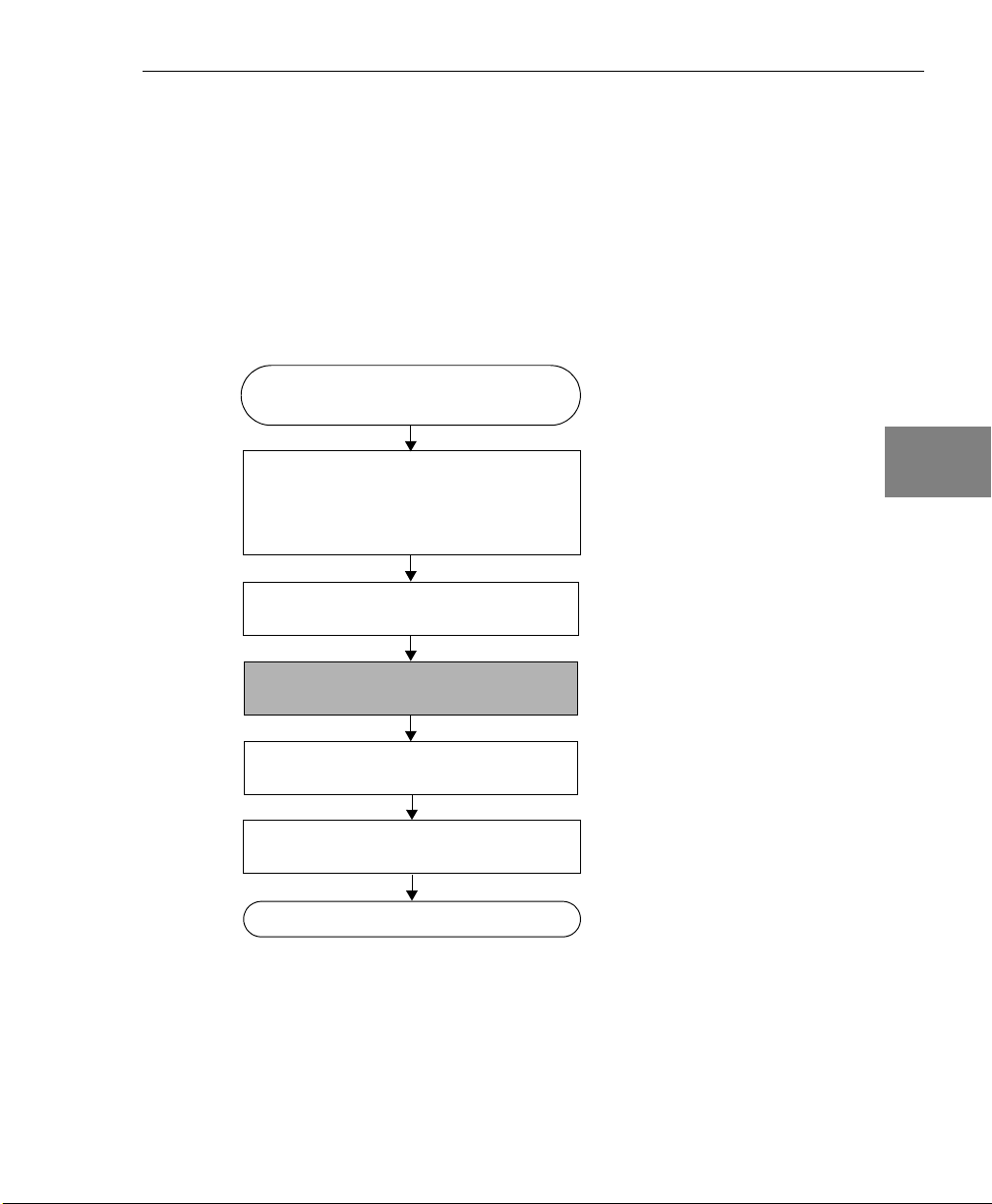

Chapter 4: Programming Flowcharts. . . . . . . . . . . . . . . . . . 75

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Single-Value Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Continuous Buffered Input Operations . . . . . . . . . . . . . . . . . . . . 79

Continuous Buffered Output Operations. . . . . . . . . . . . . . . . . . . 81

Event Counting Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Frequency Measurement Operations . . . . . . . . . . . . . . . . . . . . . . 85

Pulse Output Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Plotting Control Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Chapter 5: Software Architecture. . . . . . . . . . . . . . . . . . . . . 91

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

System Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Initializing and Specifying a Board . . . . . . . . . . . . . . . . . . . . 93

Specifying a Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Configuring a Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Handling Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Handling Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Halting the Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Analog and Digital I/O Operations . . . . . . . . . . . . . . . . . . . . . . . 99

Data Encoding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Specifying the Channel Type . . . . . . . . . . . . . . . . . . . . . 101

Contents

ix

Page 10

Contents

Specifying a Single Channel . . . . . . . . . . . . . . . . . . . . . 102

Specifying One or More Channels . . . . . . . . . . . . . . . . 102

Specifying the Channel List Size . . . . . . . . . . . . . . 103

Specifying the Channels in the Channel List . . . . 104

Inhibiting Channels in the Channel List . . . . . . . . 105

Specifying Synchronous Digital I/O Values

in the Channel List . . . . . . . . . . . . . . . . . . . . . . . . . 106

Ranges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Specifying the Gain for a Single Channel . . . . . . . . . . 109

Specifying the Gain for One or More Channels . . . . . 109

Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Data Flow Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Single-Value Operations . . . . . . . . . . . . . . . . . . . . . . . . . 112

Continuous Operations . . . . . . . . . . . . . . . . . . . . . . . . . 113

Continuous (Post-Trigger) Mode . . . . . . . . . . . . . . 114

Continuous Pre-Trigger Mode . . . . . . . . . . . . . . . . 115

Continuous About-Trigger Mode. . . . . . . . . . . . . . 116

Triggered Scan Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Scan-Per-Trigger Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Internal Retrigger Mode . . . . . . . . . . . . . . . . . . . . . . . . . 120

Retrigger Extra Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Clock Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Internal Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

External Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Extra Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Trigger Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Software (Internal) Trigger Source . . . . . . . . . . . . . . . . 125

External Digital (TTL) Trigger Source . . . . . . . . . . . . . 125

External Analog Threshold (Positive) Trigger Source 126

x

Page 11

External Analog Threshold (Negative) Trigger

Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Analog Event Trigger Source . . . . . . . . . . . . . . . . . . . . . 127

Digital Event Trigger Source . . . . . . . . . . . . . . . . . . . . . 127

Timer Event Trigger Source . . . . . . . . . . . . . . . . . . . . . . 127

Extra Trigger Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Buffers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Ready Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Done Queue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Buffer and Queue Management . . . . . . . . . . . . . . . . . . 133

Buffer Wrap Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

DMA Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Counter/Timer Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Counter/Timer Operation Mode . . . . . . . . . . . . . . . . . . . . . 138

Event Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Frequency Measurement . . . . . . . . . . . . . . . . . . . . . . . . 140

Using the Windows Timer. . . . . . . . . . . . . . . . . . . . 140

Using a Pulse of a Known Duration . . . . . . . . . . . 142

Rate Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

One-Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Repetitive One-Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

C/T Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Internal C/T Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

External C/T Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Internally Cascaded Clock . . . . . . . . . . . . . . . . . . . . . . . 156

Extra C/T Clock Source . . . . . . . . . . . . . . . . . . . . . . . . . 157

Gate Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Software Gate Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

High-Level Gate Type . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Low-Level Gate Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Contents

xi

Page 12

Contents

Low-Edge Gate Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

High-Edge Gate Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Any Level Gate Type . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

High-Level, Debounced Gate Type . . . . . . . . . . . . . . . 160

Low-Level, Debounced Gate Type . . . . . . . . . . . . . . . . 160

High-Edge, Debounced Gate Type . . . . . . . . . . . . . . . . 160

Low-Edge, Debounced Gate Type . . . . . . . . . . . . . . . . 161

Level, Debounced Gate Type . . . . . . . . . . . . . . . . . . . . . 161

Pulse Output Types and Duty Cycles . . . . . . . . . . . . . . . . . 162

Simultaneous Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Plot Control Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Plotting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Data Identification Properties . . . . . . . . . . . . . . . . . . . . 166

Plotting Mechanics Properties . . . . . . . . . . . . . . . . . . . . 167

Appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Stripchart Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Specifying a Grid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Specifying Markers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

xii

Appendix A: Flowcharts for Substeps . . . . . . . . . . . . . . . 171

Chapter 6: Product Support . . . . . . . . . . . . . . . . . . . . . . . . 191

General Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Service and Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Page 13

This manual describes how to get started using DTx-EZ™ to develop

application programs for data acquisition boards that conform to the

DT-Open Layers

TM

Intended Audience

This document is intended for engineers, scientists, technicians, or

others responsible for developing application programs using the

Microsoft Visual Basic™ or Visual C++™ compiler to perform data

acquisition operations.

It is assumed that you are a proficient programmer, that you are

experienced programming in the Windows® 98, Windows NT,

Windows Me (Millennium Edition), or Windows 2000 operating

environment on the IBM PC or compatible computer platform, that

you have familiarity with data acquisition principles, and that you

have clearly defined your requirements.

About this Manual

standard.

What You Should Learn from this Manual

This manual provides installation instructions, summarizes the

functions provided by the DTx-EZ, and describes how to use the

properties, methods, functions, and subroutines to develop a data

acquisition program. Using this manual, you should be able to

successfully install the DTx-EZ software and get started writing an

application program for data acquisition.

This manual is intended to be used with the online help for the

DTx-EZ, which you can find in the same program group as the

DTx-EZ software. The online help for the DTx-EZ contains all of the

specific reference information for each of the properties, methods,

functions, subroutines, error codes, and Windows messages (events).

xiii

Page 14

About this Manual

Organization of this Manual

This manual is organized as follows:

• Chapter 1, “Overview,” provides an overview of DTx-EZ.

• Chapter 2, “Using the DTx-EZ Examples,” describes how to use

the example programs provided with DTx-EZ.

• Chapter 3, “Property, Method, Function, and Subroutine

Summary,” summarizes the properties, methods, functions, and

subroutines provided with DTx-EZ.

• Chapter 4, “Programming Flowcharts,” provides programming

flowcharts for using the properties, methods, functions, and

subroutines provided with DTx-EZ.

• Chapter 5, “Software Architecture,” describes the architecture

and concepts of DTx-EZ software.

• Chapter 6, “Product Support,” describes how to get help if you

have trouble using DTx-EZ.

• Appendix A, “Flowcharts for Substeps,” provides additional

flowcharts for performing substeps required for an operation.

xiv

• An index completes this document.

Conventions Used in this Manual

The following conventions are used in this manual:

• Notes provide useful information that requires special emphasis,

cautions provide information to help you avoid losing data or

damaging your equipment, and warnings provide information to

help you avoid catastrophic damage to yourself or your

equipment.

• Items that you select or type are shown in bold. Property,

method, function, and subroutine names also appear in bold.

• Code fragments appear in courier font.

Page 15

• In syntax, items inside square brackets are optional.

• In syntax, a vertical bar between braces indicates that you must

choose between two or more items. You must choose an item

unless all of the items are also enclosed in curly brackets. For

example, { True | False } indicates that you must select one of

these choices.

• When navigating the screens, an instruction such as Configure >

Board means to select “Board” from the drop-down menu under

“Configure.”

Related Information

Refer to the following documentation for more information on using

DTx-EZ:

• DTx-EZ Online Help. This Windows help file is located in the

same program group as the DTx-EZ software and contains all of

the specific reference information for each of the properties,

methods, subroutines, functions, error codes, and Windows

messages (events) provided by DTx-EZ. Refer to page 13 for

information on how to launch this help file.

About this Manual

• Device Driver documentation for your board. This

documentation describes the capabilities supported by the device

driver for your board. Refer to this documentation as you

develop application programs using DTx-EZ.

• User manual for your data acquisition board. This manual

describes the capabilities of the hardware as well as how to set up

and install your board.

• For Visual Basic and Visual C++ programmers, see the online

help in your programming environment.

• Windows programming documentation.

xv

Page 16

About this Manual

Where to Get Help

Should you run into problems installing or using DTx-EZ, the

Keithley Technical Support Department is available to provide

technical assistance.

xvi

Page 17

1

Overview

What is DTx-EZ?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adding DTx-EZ Custom Controls to Your Project . . . . . . . . . . . 10

Creating an Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Using the DTx-EZ Online Help . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1

Page 18

Chapter 1

What is DTx-EZ?

DTx-EZ is a set of Object-Linking and Embedding (OLE) controls that

facilitate rapid data acquisition application development in Visual

Basic and Visual C++ environments.

DTx-EZ supplies the programming tools to transform Visual Basic

and Visual C++ into a powerful data acquisition application

development environment. With DTx-EZ, you can quickly develop

applications with analog and digital I/O, real-time data display, and

a graphical user interface (GUI), while operating in a true Windows

environment.

Conforms to the DT-Open Layers Standard

DTx-EZ is fully compatible with DT-Open Layers.

DT-Open Layers is a set of open standards for developing integrated,

modular software under Microsoft Windows. Because it is modular

and uses Windows DLLs, DT-Open Layers is easily expanded to

support new, more powerful hardware devices without re-linking or

rebuilding applications. Therefore, you do not need to rewrite your

code when adding new data acquisition boards that have DT-Open

Layers-compliant device drivers. DT-Open Layers protects your

software investment now and in the future.

Provides Custom Controls

The DTx-EZ provides two custom controls:

• Data Acquisition Custom Control, and

• Plotting Custom Control.

The following subsections describe these controls.

2

Page 19

The Data Acquisition Custom Control

Overview

The Data Acquisition Custom Control facilitates performing data

acquisition functions. Each copy of the Data Acquisition Custom

Control operates on a single subsystem of the supported board at a

time. However, Visual Basic and Visual C++ lets you use multiple

copies of this control operating simultaneously, controlling different

subsystems on the same board or even on different boards.

DTx-EZ determines the capabilities of each subsystem for your data

acquisition board. The board’s supported capabilities are listed in the

custom control’s Properties window. You can control the subsystem's

operation by manipulating the subsystem's properties. You can

change the properties at design time in the Properties window or at

run time using simple Visual Basic or Visual C++ code.

Each subsystem may have multiple channels. For example, the A/D

subsystem on the DataAcq-EZ boards has 16 available channels. To

access multiple channels, you must set up a list of channels you want

to sample. The DataAcq-EZ boards also provide programmable

gains. To program the gains on the channels, you need to set up a

gain list to accompany the channel list.

The DT Plot Custom Control

1

1

1

1

1

1

The DT Plot Custom Control is a high-speed plotting control, useful

for plotting fixed- or floating-point data in your Visual Basic or Visual

C++ application. Since the DT Plot Custom Control works directly

with DT-Open Layers hBuf data, the need to copy the buffer to an

array is eliminated.

1

1

1

3

Page 20

Chapter 1

You fill a buffer with data you want to plot and assign it to the plot’s

Buffer property. You can plot from 1 to 16 channels of data at a time,

all with different colors. You may also choose from a variety of line

styles and the following features:

• x and y grid lines that you can set to automatically scale to your

data or to remain at fixed spacing intervals.

• x and y markers that can be used to indicate a zoom-in section of

the data or to determine the data value at that position.

• A stripchart mode so you can plot many buffers of

rapidly-changing, continuous data and see all of them on the

plot’s display.

• A single-point feature when in strip charting mode that allows

you to add one point of data at a time to the display.

At design time, the DT Plot Custom Control displays a

randomly-generated data plot that shows you what your plots will

look like. Whenever you change a property, the plot immediately

displays the effects of your changes. For some properties, you can

enter new data for the plot at either design time or run time.

Provides Properties, Methods, and Events

The Data Acquisition and DT Plot Custom Controls have unique

properties, methods, and events, described as follows:

• Properties represent the variables that allow you to configure the

data acquisition or plotting operation. Many read/write

properties are accessible in the Properties window at design time

or at runtime. Some read/write properties are lists that may be

accessed through the control’s custom property pages. Other

properties are read-only; you can access them only at runtime.

These read-only properties represent variables that you can use

to determine data acquisition or plotting capabilities.

4

Page 21

Overview

Note: Each Data Acquisition Custom Control can be associated

with a single subsystem at a time. This means that you must first

select the board and subsystem you want to use before you can configure

the subsystem's properties. When a custom control is created, its

properties are set to the default settings. You must modify the

properties if you want to change their values from the default

settings.

• Methods are tools that are used in the Visual Basic or Visual C++

code to provide runtime control of data acquisition operations;

no methods are associated with the DT Plot Custom Control.

• Events have procedures that execute code when the specified

data acquisition event occurs during runtime in the case of the

Data Acquisition Custom Control or when the specified mouse or

keyboard event occurs during runtime in the case of the DT Plot

Custom Control. Most OLE custom control events are based on

user interactions.

Note, however, that the Data Acquisition Custom Control events

are based on specific data acquisition events that could occur

within your application. Most of the Data Acquisition Custom

Control events are used for either continuous acquisition

operation or for error tracking.

1

1

1

1

1

1

All of the DT Plot Custom Control events are standard Microsoft

events. Refer to your Visual Basic or Visual C++ online help for

more information about them.

Provides Function and Subroutine Libraries

In addition to custom controls, DTx-EZ provides a library of

DT-Open Layers functions and subroutines for Visual Basic and for

Visual C++. These libraries add facilities for managing buffers,

simultaneously starting multiple subsystems, and performing FFT

analysis.

1

1

1

5

Page 22

Chapter 1

Follows Object-Oriented Design

For easy programming, DTx-EZ’s Application Programming

Interface (API) emphasizes polymorphism — it uses nearly identical

interface functions to communicate with each type of data acquisition

subsystem: analog input (A/D), analog output (D/A), digital input

(DIN), digital output (DOUT), and counter/timer (C/T).

The features provided by each supported data acquisition board

vary; for a complete list of capabilities supported by your board, refer

to board's driver documentation.

The API provides a full set of functions to query and set all possible

device capabilities. The library hides device details and presents a

consistent interface to each subsystem.

Provides Extensive Example Programs

To get your application up and running quickly, a comprehensive set

of Visual Basic and Visual C++ example programs is provided. You

can use these examples as tutorials to learn how DTx-EZ operates, or

you can modify one or more examples to form the basis of your own

custom data acquisition application. Source code is included, so you

can customize the examples to complete your Visual Basic or Visual

C++ application.

Provides Multiple Board Support

The DTx-EZ is hardware-independent. You can add support for new

boards without altering or recompiling code at the application level

simply by adding a new DT-Open Layers device driver. You install

the device driver separately (in the Windows environment); refer to

your board and/or device driver documentation for more

information on installing device drivers.

The library functions are designed to fully support all board features.

6

Page 23

Provides High Performance

Overview

DTx-EZ was designed with an intimate knowledge of the Windows

operating environment and the IBM PC computer system. As a result,

it takes unique advantage of the Windows architecture to achieve

maximum performance. By using sophisticated software buffering

(part of the DT-Open Layers standard), and the PCI bus, USB bus, or

DMA capabilities of the hardware, the software can achieve

continuous throughput to or from memory at greater than 1 MHz.

1

1

1

1

1

1

1

1

1

7

Page 24

Chapter 1

What You Need

To use DTx-EZ, you need the following:

• Pentium or higher-based PC with a CD-ROM drive and a

minimum of 32 Mbytes of RAM;

• One or more supported data acquisition boards;

• Microsoft Windows 2000 or XP.

• Microsoft Visual C++ 6.0 or Microsoft Visual Basic 6.0.

8

Page 25

Installation

DTx-EZ is installed automatically when you install the device driver

for the module. Refer to the getting started manual for your module

for more information.

Overview

1

1

1

1

1

1

1

1

1

9

Page 26

Chapter 1

Adding DTx-EZ Custom Controls to Your Project

The following subsections describe how to add DTx-EZ Custom

Controls to:

• A Visual Basic 6.0 project (this page),

• A Visual C++ 6.0 project (page 11).

Adding to a Visual Basic 6.0 Project

Before you begin using the DT-EZ, add the DTx-EZ Data Acquisition

and DT Plotting Custom Controls and definition files. Add the files

DTACQ32.OCX, DTPLOT32.OCX, OLMEMDEFS.BAS,

OLDADEFS.BAS and OLDSPDEFS.BAS to your project file as follows

from Visual Basic 6.0:

1. Select Project > Components.

The Components dialog box appears.

2. Click the Controls tab.

10

3. Click DTAcq32 OLE Custom Control module and/or DTPlot32

OLE Custom Control module, then click OK.

4. Choose Project > Add Module.

The Add Module dialog box appears.

5. Select the Existing tab.

6. Select OLMEMDEFS.BAS, OLDEFS.BAS, and/or

OLDSPDEFS.BAS from the \DTx-EZ\INCLUDE directory, and

click Open.

Page 27

When the DTx-EZ custom controls are loaded, the DTACQ32 and

DTPLOT32 icons appear in the Toolbox as follows:

Adding to a Visual C++ 6.0 Project

Overview

1

1

Before you begin using the DT-EZ, add the DTx-EZ Data Acquisition

and DT Plotting Custom Controls.

1. Start Windows 95 and launch Microsoft Visual C++ 6.0.

2. Create a new MFC project using the application wizard.

Ensure you add support for ActiveX controls in Step 2.

3. Select Project > Add to Project > Components and Controls.

The “Component and Controls Gallery” appears.

4. Double-click the Registered ActiveX Controls folder.

5. Select the DTPlot32 Control and click Insert.

The program prompts you to insert the component and to confirm the

creation of a wrapper class for accessing the control through Visual

C++.

6. Repeat step 5 for the DTAcq32 Control.

1

1

1

1

1

1

1

11

Page 28

Chapter 1

Creating an Application

You can use the Data Acquisition Custom Control and DT Plot

Custom Control just like other ActiveX or OLE custom controls to

integrate data acquisition into your Windows application. Create

your application as follows:

1. Add the Data Acquisition or DT Plot Custom Control to your

form by selecting it from the toolbox and placing it on your form.

For information on adding a DTx-EZ Custom Control to a project, see

page 10. Once added to your project, you can select the DTx-EZ

Custom Control from the toolbox.

2. Configure your control object for the desired function by setting

values in the Properties window.

Refer to Chapter 5, “Software Architecture,” for more information.

Context-sensitive online help is available for the DTx-EZ Custom

Controls as well. To access online help, simply press F1, and

information related to the current operation appears on the screen.

3. Add code, as needed, using the Code window to

− Respond to user actions,

12

− Change the properties at run time, or

− Control data acquisition operations.

Refer to Chapter 2, “Using the DTx-EZ Examples,” for more

information.

4. When you are ready to run your application outside your

development environment, create an executable file (.EXE) by

choosing Make EXE file from the File menu.

Note: When you create and distribute applications that use the

Data Acquisition Custom Control and DT Plot Custom Control,

review the licensing material included in the DTx-EZ online help.

Page 29

Using the DTx-EZ Online Help

This manual is intended to be used with the online help for DTx-EZ.

The online help contains all of the specific reference information for

each of the functions, error codes, and Windows messages not

included in this manual.

To launch this online help, double-click the DTx-EZ help icon in the

KUSB Series program group or folder.

Overview

1

1

1

1

1

1

1

1

1

13

Page 30

Chapter 1

14

Page 31

2

Using the DTx-EZ Examples

About the Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

A/D Burst Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DAC Waveform Generator Example. . . . . . . . . . . . . . . . . . . . . . . 25

Continuous A/D Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Single-Value Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

About-Trigger Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Digital I/O Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DDE Server and Client Examples . . . . . . . . . . . . . . . . . . . . . . . . . 37

Waveform Generator Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Continuous FFT Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ChartIt Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Scope Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

15

Page 32

Chapter 2

About the Examples

DTx-EZ provides the software tools to create Visual Basic and

Visual C++ data acquisition applications quickly and easily. A

comprehensive set of examples shows you how to use DTx-EZ's Data

Acquisition and DT Plotting Custom Controls in the Visual Basic or

Visual C++ environment. If your needs are simple, choose one of the

example programs; DTx-EZ will perform data acquisition right out of

the box. Since all example source code is included, you can easily

modify the examples to suit your needs, combine two or more

examples, or extend the examples with your own code.

The following examples are provided:

• A/D Burst Example − Acquires data to disk; demonstrates

channel-gain list setup (page 20).

• DAC Waveform Generator Example − Generates sine, square, or

triangle output waveforms. It also demonstrates “zooming in”

using the plot control (page 25).

• Continuous A/D Example − Continuously samples and displays

multiple data points (page 29).

16

• Single Value Example − Acquires a single value from an A/D

subsystem; outputs a single value to a D/A subsystem (page 31).

• About-Trigger Example − Acquires data to disk from

initialization until the trigger event occurs and then for one

second after (page 33).

• Digital I/O Example − Controls digital I/O lines (page 35).

• DDE Server and Client Example − Moves data to or from other

applications using Window's Dynamic Data Exchange (page 37).

• Waveform Generator Example − Demonstrates the use of

counter/timers to generate square waves (page 39).

• Continuous FFT Example − Computes and displays FFTs of the

input data (page 40).

Page 33

Using the DTx-EZ Examples

• ChartIt Example − Demonstrates how to use the stripchart mode

to display single points of data (page 41).

• Scope Example − Generates and displays analog input channels

including typical oscilloscope functions (page 42).

2

This chapter explains how to use each example. To see actual signals

being acquired, connect a signal source to the analog inputs of your

data acquisition board. (You can choose to run the examples without

connecting a signal source to the board.)

You can run the examples as applications. However, if you wish to

view or modify the source code for the examples, open the associated

.VBP files from within Visual Basic (see page 18), or open the

associated .MDP files from within Visual C++ (see page 19).

Note: Before running the examples, make sure the device driver for

your data acquisition board has been installed.

Running the Examples as Applications

If you wish to use them as tutorials to learn how DTx-EZ operates,

you can run the examples as applications as follows:

1. Start your operating system.

2. In the start menu, select the icon for the desired example from the

DTx-EZ program group.

2

2

2

2

2

2

2

2

17

Page 34

Chapter 2

Opening the Examples from within Visual Basic

To customize the DTx-EZ example code for your own application,

you must open the example’s build file, .VBP, from within Visual

Basic as follows:

1. Start your operating system, and start Visual Basic.

2. Choose File > Open Project.

3. Select the examples from the directory DTx-EZ\examples\vb.

(The examples have a .VBP extension.)

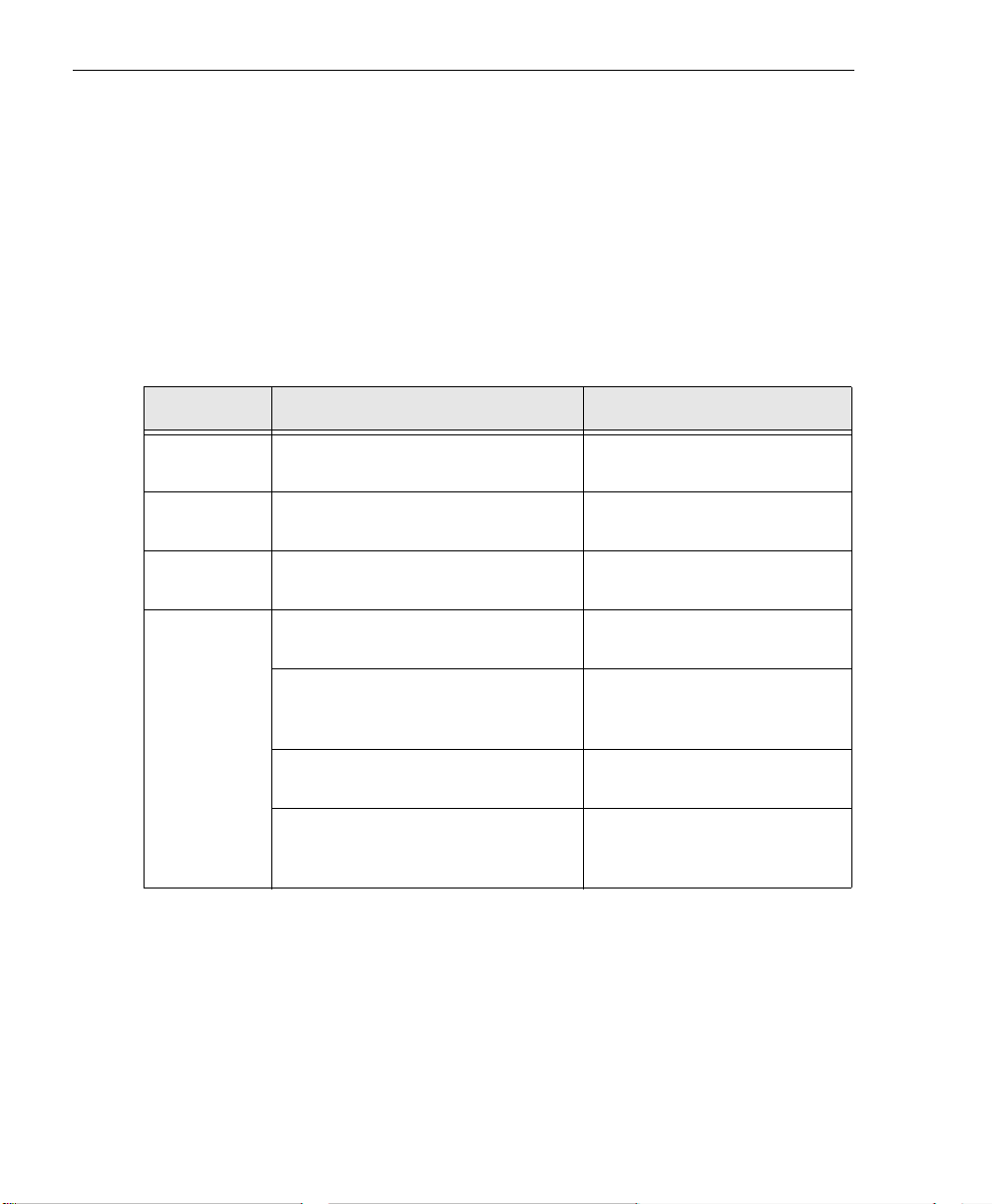

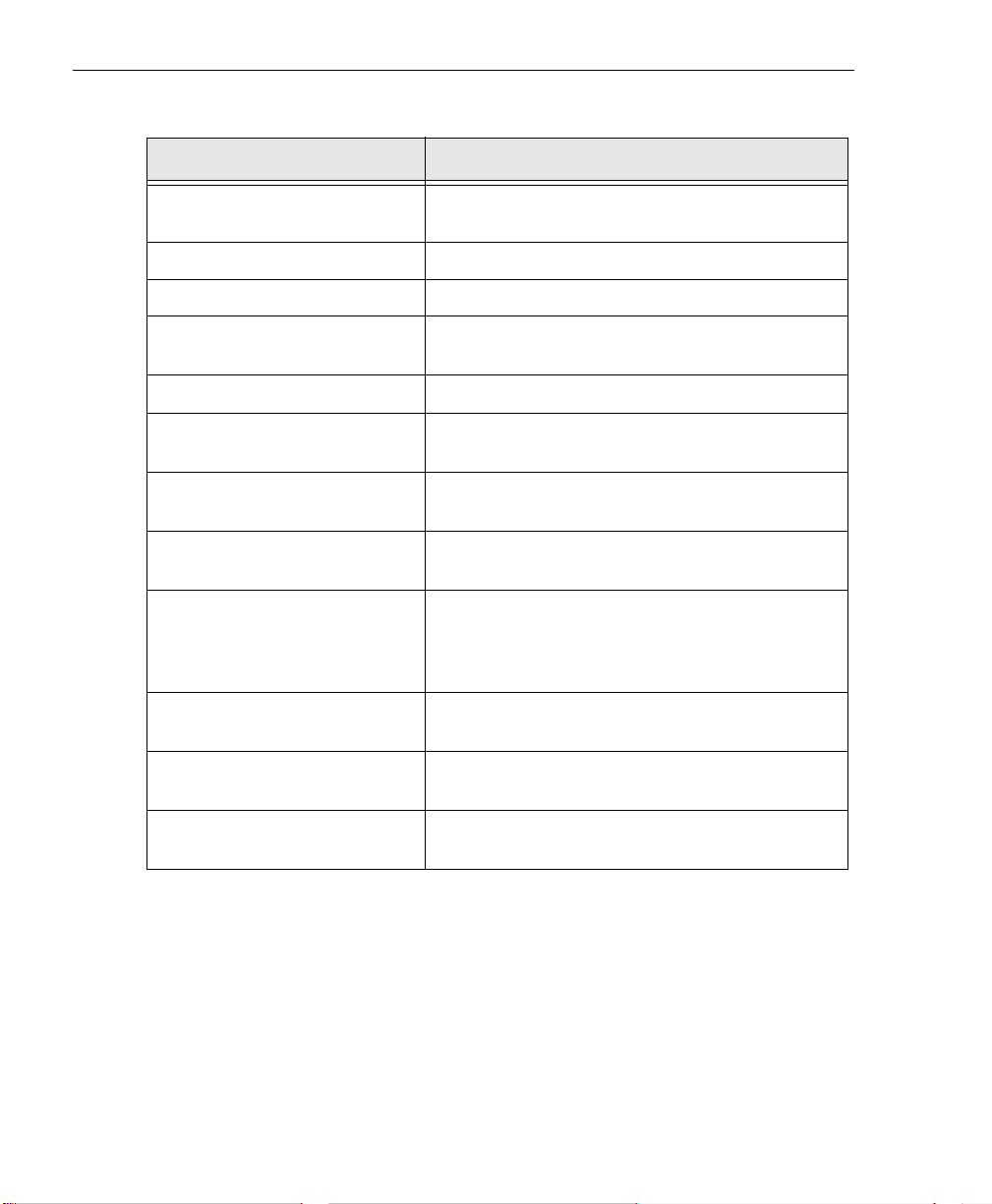

Table 1: Visual Basic Example Programs and Their .VBP Files

Example Directory

A/D Burst \adburst\adburst.vbp

DAC Waveform \dacwave\dacwave.vbp

Continuous A/D \contdisp\contdisp.vbp

Single value \sv\sv.vbp

18

Digital I/O \dio\dio.vbp

DDE Server \dde\server.vbp

DDE Client \dde\client.vbp

Wave Generator \wavegen\wavegen.vbp

About-Trigger \abouttrigger\abouttrigger.vbp

Continuous FFT \contfft\contfft.vbp

ChartIt \chartit\chartit.vbp

Scope \scope\scope.vbp

4. Select Run > Start to run each example.

Page 35

Using the DTx-EZ Examples

Opening the Examples from within Visual C++

To customize the DTx-EZ example code for your own application,

you must open the example’s build file, .MDP, from within

Visual C++ as follows:

1. Start your operating system, and start Visual C++.

2. Choose File > Open Workspace.

3. Select the examples from the directory DTx-EZ\examples\cpp.

(The examples have a .MDP extension.)

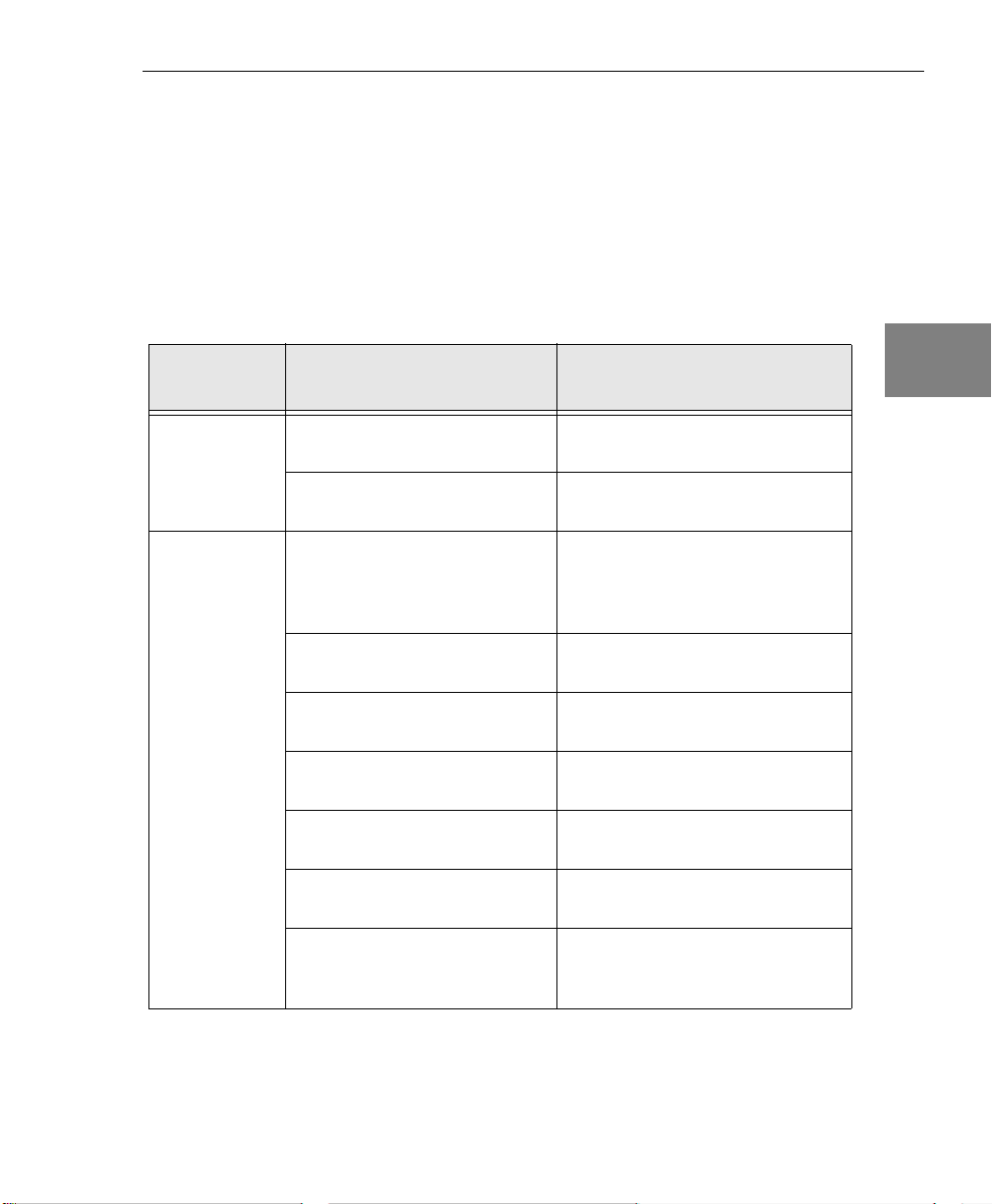

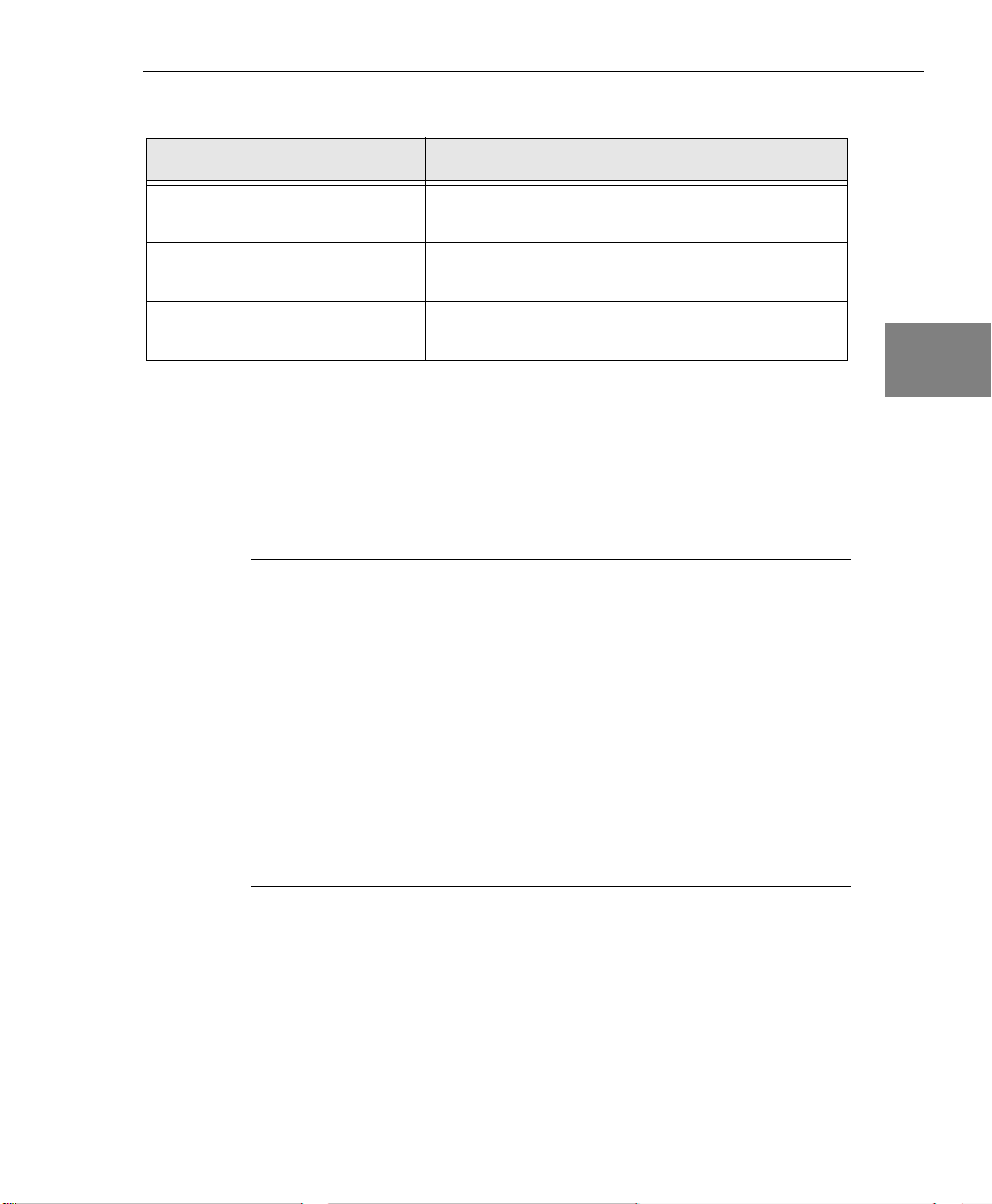

Table 2: Visual C++ Example Programs and Their .MDP Files

Example Directory

A/D Burst \adburst\adburst.mdp

DAC Waveform \dacwave\dacwave.mdp

Continuous A/D \contdisp\contdisp.mdp

Single value \sv\sv.mdp

Digital I/O \dio\dio.mdp

DDE Server \dde\server\server.mdp

2

2

2

2

2

2

DDE Client \dde\client\client.mdp

Wave Generator \wavegen\wavegen.mdp

About-Trigger \abouttrigger\abouttrigger.mdp

Continuous FFT \contfft\contfft.mdp

ChartIt \chartit\chartit.mdp

Scope \scope\scope.mdp

4. Select Run > Start to run each example.

2

2

2

19

Page 36

Chapter 2

A/D Burst Example

This example (adburst.vbp or adburst.mdp) samples multiple analog

input channels and places the resulting data in a disk file for

archiving and post-acquisition analysis. This example also

demonstrates how to configure a channel-gain list and the A/D

subsystem for a data acquisition board. You could use this example

once your application is debugged to store actual data values.

When you run the example, the “Select Board” dialog box appears.

The A/D Buffer To File screen is shown in Figure 1.

20

Figure 1: A/D Buffer To File Screen

Follow these steps:

1. Select Configure > Board to select a board from the list.

2. Select Configure > CGL to set up your board's channel-gain list.

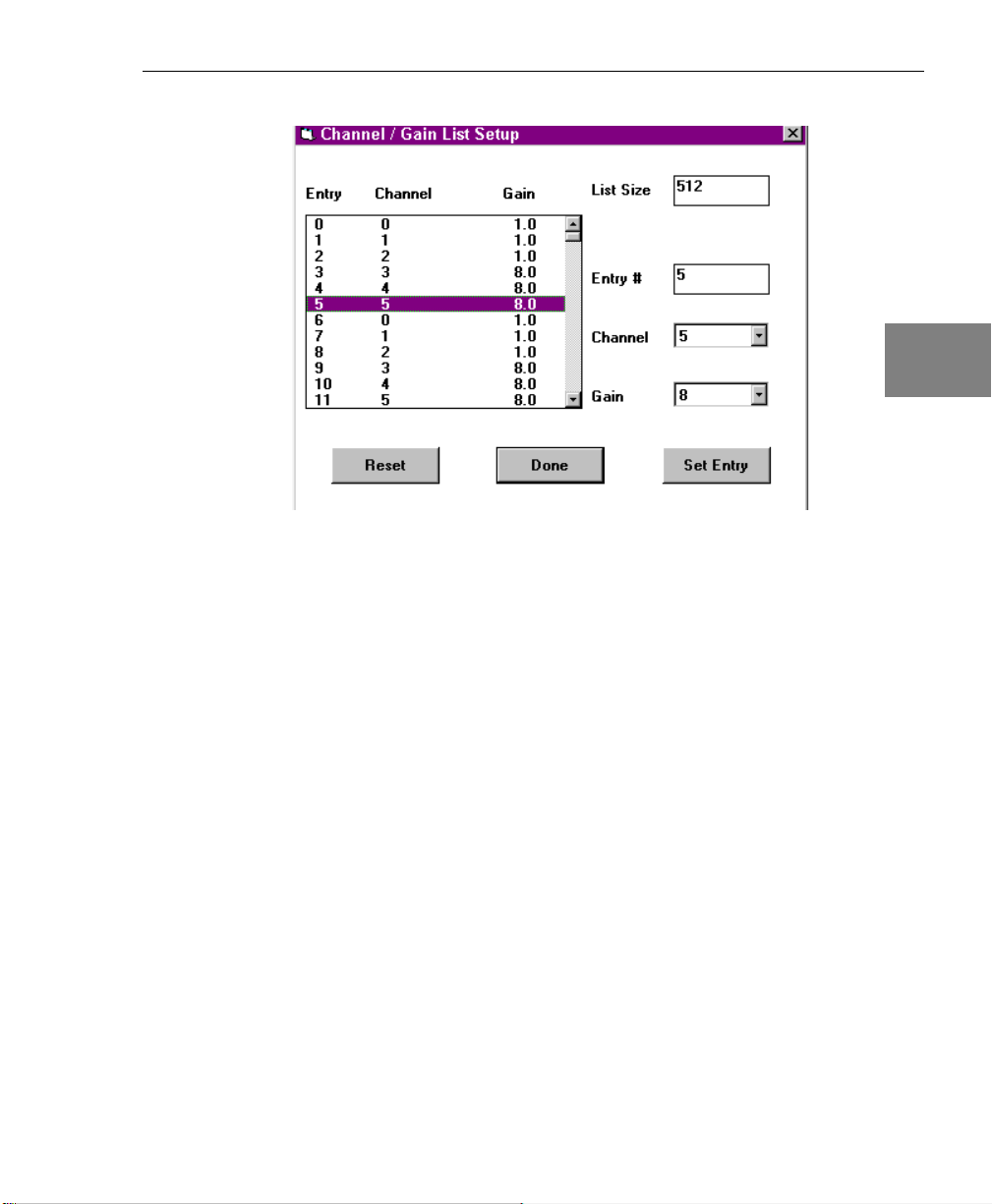

The Channel/Gain List Setup dialog box, shown in Figure 2, appears.

Page 37

Figure 2: Setting Up a Channel-Gain List

Using the DTx-EZ Examples

2

2

2

2

2

During data acquisition, the channel-gain list automatically

selects channel and gain values without compromising

throughput. You can configure the list with channel numbers and

associated gains.

To set up the channel-gain list, perform the following steps:

a. Select the list size, and then choose channel and gain values

for each entry in the list.

b. After changing each item, click Set Entry to confirm the

setting.

c. When you have completed the setup, click Done to return to

the main menu.

2

2

2

2

21

Page 38

Chapter 2

The screen shown in Figure 2 illustrates a 512-entry channel-gain

list that repeatedly scans channels 0 through 5 using a gain of 1

for channels 0-2 and a gain of 8 for channels 3-5.

3. Select Configure > Input to configure the analog input settings

for your data acquisition board.

The Input Options dialog box, shown in Figure 3, appears.

22

Figure 3: Configure the Analog Input Settings

Page 39

Using the DTx-EZ Examples

Any settings that are not software-configurable for your board

are inactive. The available settings are as follows:

− Interface Mode — allows you to select either single-ended or

differential inputs. Most data acquisition boards can be

configured for either 16 single-ended or 8 differential input

channels. Single-ended inputs share a common ground.

Differential inputs use a separate ground for each channel

(which halves the channel capacity). Differential inputs can

improve accuracy where long cables, low-level input ranges

(< 1 V full-scale), or high resolution converters (> 12 bits) are

used.

2

2

2

Note: If your board uses an onboard jumper to set the input

mode, do not change this setting until you remove the board and

change the jumper configuration to correspond with the new

selection. If your board provides software-configurable input

mode selection, you do not need to change any jumper settings.

− Clock Source and Trigger Source — You can select either an

internal or an external clock source and trigger source. Clock

frequency sources and triggers help you synchronize data

conversions with off-board events. External frequency sources

can also be used to produce clock frequencies that cannot be

achieved with the board’s onboard oscillator.

− Range — allows you to select the input voltage range. Ranges

can be unipolar or bipolar.

− Encoding — lets you choose the input data encoding format.

2

2

2

2

2

2

23

Page 40

Chapter 2

Note: Because older boards use an onboard jumper to set the

input voltage range and data encoding format, these settings

cannot be changed until you remove the board and change the

jumper configuration to correspond with the new selections. (If

your board provides software-configurable settings, you do not

need to change any jumper settings.)

− Triggered Scan — You can enable this mode on boards that

support this feature. (Refer to your board’s driver

documentation to determine if it is supported on your board.)

Triggered scan mode performs scans through the

channel-gain list, where each scan is initiated by the onboard

trigger. On some boards, the interval between the scans is

programmable.

4. Select the desired options and click OK.

5. When you have completed the configuration, select Start! to

begin acquiring data.

Note that the menu name changes to Stop! until the operation is done.

You can choose Stop! to halt the operation at any time.

24

When the acquisition is complete, a message indicates that a

buffer of data was collected and where the file was created.

Page 41

Using the DTx-EZ Examples

DAC Waveform Generator Example

The DAC (digital-to-analog converter) waveform generator example

(dacwave.vbp or dacwave.mdp) uses the D/A subsystem to

continuously output a sine wave, square wave, or triangle wave. You

can specify waveform frequency and the board on which to output

the signal. You could use this example to supply a test signal for

circuit evaluation or a stimulus to your experiment.

2

2

When you run the example, the Select Board dialog box appears.

Choose the desired board from the list and click OK. The DAC

Waveform Generator screen, shown in Figure 4, appears.

Figure 4: DAC Waveform Generator Screen

2

2

2

2

2

2

2

25

Page 42

Chapter 2

Follow these steps:

1. Select Configure > Board to choose a data acquisition board from

the list.

2. Select Configure > Output to configure the analog output

settings for your board.

The Output Options dialog box, shown in Figure 5, appears. Refer to

the A/D Burst example in the previous section for information on these

settings.

26

Figure 5: Configure the Analog Output Settings

3. Select Configure > Acquisition to configure your output

waveform.

The Acquisition Options dialog box, shown in Figure 6, appears.

Page 43

Using the DTx-EZ Examples

Figure 6: Configure Output Waveform

− Click Use DMA to enable direct memory access (DMA) for

data transfer operations. (For optimum speed, DMA should

be enabled on boards that support it.)

− Select the type of waveform you wish to produce, and then

select the waveform’s peak voltage, the wave frequency, and

the board’s sample frequency.

2

2

2

2

2

2

4. When you've completed the setup, click OK.

5. Select Start! to begin outputting a continuous waveform.

Note that the name changes to Stop! until the operation completes. You

can choose Stop! to halt the operation at any time.

6. Select ViewOutput! to display the waveform on your screen.

Figure 7 shows a typical sine wave.

2

2

2

27

Page 44

Chapter 2

Figure 7: Displaying a Waveform

You can zoom in on a portion of the data by right-clicking on the

plot and then dragging the red dotted selection bars.

Double-click the left mouse button to zoom out again.

28

Page 45

Continuous A/D Example

This example (contdisp.vbp or contdisp.mdp) continuously samples

a single analog input channel to memory and plots the data on screen

using pre-defined buffer and frequency settings. You could use this

example to detect data trends by immediately viewing the effect of

changing stimulus.

Click Start to begin the acquisition; click Stop to end it. Figure 8

shows a typical acquisition.

Using the DTx-EZ Examples

2

2

2

2

2

Figure 8: Continuous A/D Display

2

2

2

2

29

Page 46

Chapter 2

The Y-axis setting (volts) corresponds to the minimum and maximum

voltage settings for the selected board. The X-axis setting (seconds) is

determined by the data buffer size and selected sampling frequency.

(You can modify these properties within the example’s form_load()

event subroutine.)

30

Page 47

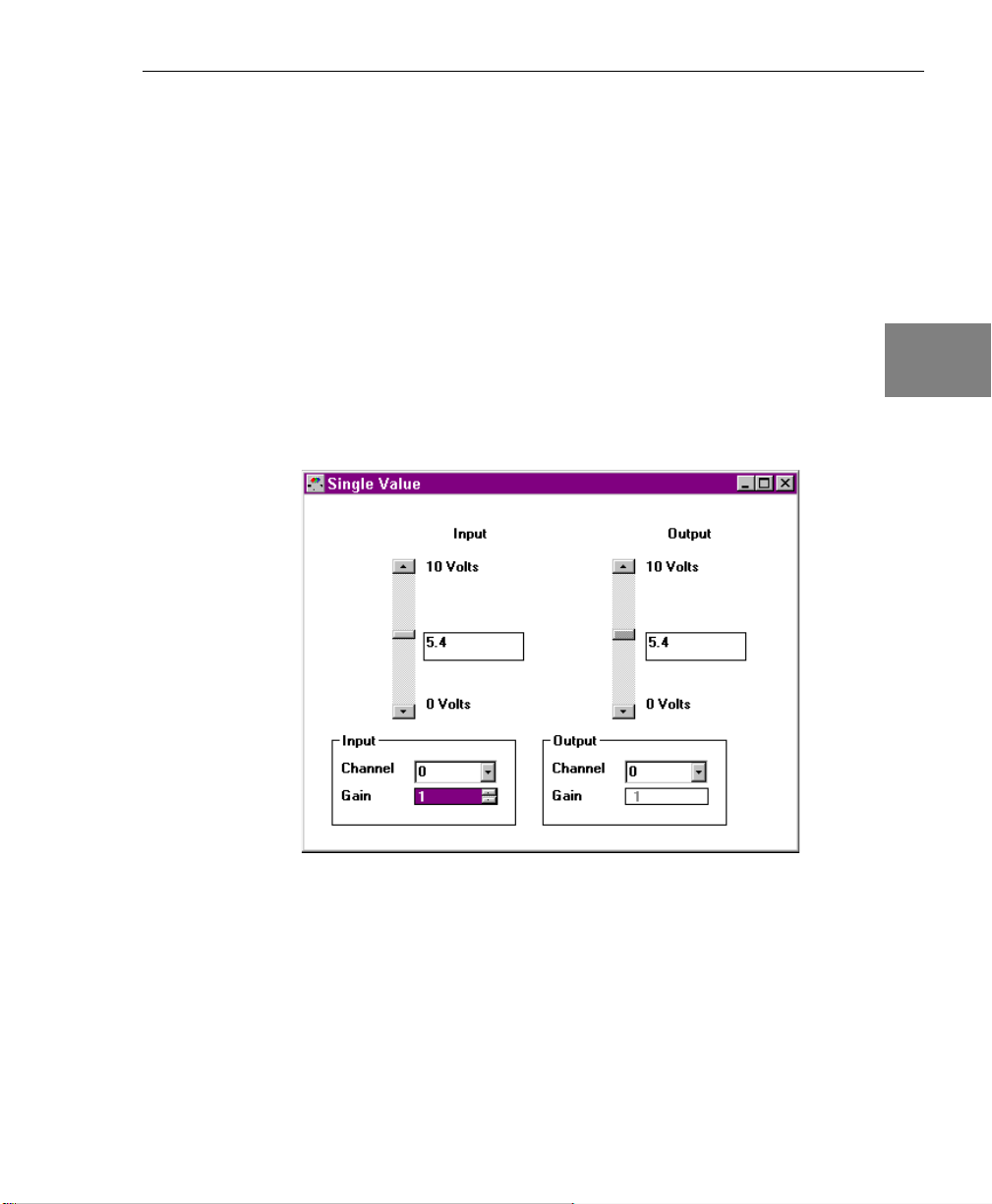

Single-Value Example

This example (sv.vbp or sv.mdp) acquires a single sample from a

single analog input channel and outputs a single value on the DAC

you specify. You can use this example to check for correct

configuration, to monitor slowly-changing inputs, or to provide a

constant or slowly-varying voltage output.

When you run it, the example prompts you for the board’s name.

After the board is located, a display allows you to monitor inputs and

generate outputs. A single value is continuously input and displayed

in a text box and on the scroll bar, as shown in Figure 9.

Using the DTx-EZ Examples

2

2

2

2

2

Figure 9: Monitoring Inputs and Outputs for a Single-Value Operation

2

2

2

2

31

Page 48

Chapter 2

A single value can also be output continuously. You can change the

output voltage setting by entering a new value in the text box or by

adjusting the scroll bar.

Note: The actual read and write rate is set (to 100 ms) by the timer

control. The clock timer control runs from the system clock.

32

Page 49

About-Trigger Example

This example (abouttrig.vbp or abouttrig.mdp) samples a single

analog input channel to memory and plots the data on screen using

pre-defined buffer and frequency settings until the main trigger

event. After the trigger, the example samples the channel for one

second and then stops. You could use this example to collect data

before and after a specific event (trigger) occurs. In this example, the

marker is used to show the first point collected after the trigger event,

so you can see the triggering point.

This example also demonstrates using the stripchart mode to plot

entire buffers of data rather than single points, one at a time.

Using the DTx-EZ Examples

2

2

2

Click Start to begin the acquisition; click Stop to end it. Figure 10

shows a typical acquisition.

Figure 10: About-Trigger A/D Display

2

2

2

2

2

2

33

Page 50

Chapter 2

The y-axis setting (volts) corresponds to the minimum and maximum

voltage settings for the selected board. The x-axis setting (number of

samples) is determined by the data buffer size and selected sampling

frequency. (You can modify these properties within the example’s

form_load() event subroutine.)

34

Page 51

Digital I/O Example

This example (dio.vbp or dio.mdp) demonstrates the use of a single

value operation with DIN and DOUT subsystems. You could use this

example to interface with sensors and control devices that use digital

signals.

After selecting the board, the screen shown in Figure 11 appears.

Using the DTx-EZ Examples

2

2

2

2

2

Figure 11: Monitoring Digital I/O Operations

The “light bulbs” represent the digital input and output data. A timer

control reads the digital input data at regular intervals. The light

bulbs turn “on” and “off” to indicate the value read from the DIN

subsystem.

You can change the digital output value by clicking the light bulbs in

the bottom half of the display. As you turn them on and off, the new

values are written to the DOUT subsystem.

2

2

2

2

35

Page 52

Chapter 2

Note: The actual read and write rate is set (to 100 ms) by the timer

control. The timer control runs from the system clock.

36

Page 53

DDE Server and Client Examples

The DDE server and client examples demonstrate the use of

Windows Dynamic Data Exchange (DDE) between applications. In

Visual Basic, these examples (server.vbp and client.vbp) reside in the

same directory; in Visual C++, these examples (server.mdp and

client.mdp) reside in their own directories. In either platform, the two

examples are designed to be used together. These examples allow you

to send acquired voltage values to other applications for analysis and

display and to move voltage values calculated in another application

to DTx-EZ for conversion and output. You could use this example for

report generation and data analysis or data generation using any

Windows spreadsheet, word processing, or analysis package.

Using the DTx-EZ Examples

2

2

2

For more information on DDE operation, refer to your development

environment’s programming guide.

Open the Server and Client examples to display the forms shown in

Figure 12.

Figure 12: DDE Forms

2

2

2

2

2

2

37

Page 54

Chapter 2

These forms allow you to share data between the two examples. The

Server represents the A/D subsystem and the Client represents the

D/A subsystem. The Server continuously updates the input data

values in the scroll bar and text box.

Follow these steps:

1. Click Copy Link on the Server form to copy the data link to the

clipboard.

2. Click Paste Link on the Client form to continuously output data

from the clipboard and to display it in the Client form’s scroll bar

and text box.

Note that the Paste Link command has toggled to Close DDE Link.

3. Click Close DDE Link to stop the data exchange into the D/A

subsystem.

38

Page 55

Waveform Generator Example

This example (wavegen.vbp or wavegen.mdp) generates a square

wave from counter/timer 0. Set the frequency by entering the value

(in hertz) in the text box at runtime, as shown in Figure 13.

Using the DTx-EZ Examples

2

2

2

2

Figure 13: Setting the Waveform Frequency

2

2

2

2

2

39

Page 56

Chapter 2

Continuous FFT Example

This example (contfft.vbp or contfft.mdp) acquires data from a single

analog input channel, performs frequency analysis on the data using

an FFT (Fast Fourier Transform), and plots the result of the analysis.

You could use this example for vibration analysis, to calculate

transfer functions, or to monitor the frequency content of an audio

signal.

Click Start to begin the FFT; click Stop to end it. A typical FFT display

is shown in Figure 14.

40

Figure 14: FFT Display

Page 57

ChartIt Example

This example (chartit.vbp or chartit.mdp) acquires data using the

GetSingleValue method and plots the data using the plotting

control’s SinglePoint property in stripchart mode.

Using the DTx-EZ Examples

2

Click Start to begin sampling. A timer control samples and plots each

data point every 500 ms. Click Stop to halt sampling. A typical

stripchart display is shown in Figure 15.

Figure 15: Stripchart Display

2

2

2

2

2

2

2

2

41

Page 58

Chapter 2

Scope Example

This example generates and displays data from one to four analog

input channels. It includes typical oscilloscope functions such as

single sweep or continuous scan, horizontal and vertical offsets, and

adjustable time and amplitude settings. The example also operates as

a single-channel spectrum analyzer with a number of popular

windowing selections.

You may apply gains and filters (if available) and even invert

Channel 2 data and add it to Channel 1 data. Both manual and auto

triggering as well as external triggering are possible. By clicking the

mouse on the plot display, an exact voltage reading for each channel

and the time of acquisition is displayed.

For further analysis, you can apply various windowing formulas as

well as FFTs to a single channel of data. Both of these are performed at

a user-selected acquisition rate.

Starting the example produces a screen similar to that shown in

Figure 16.

42

Page 59

Figure 16: Sample Scope Screen

Using the DTx-EZ Examples

2

2

2

2

2

2

2

2

2

43

Page 60

Chapter 2

44

Page 61

3

Property, Method, Function,

and Subroutine Summary

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Data Acquisition Custom Control . . . . . . . . . . . . . . . . . . . . . . . . . 47

Data Management DLLs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

DT Plot Custom Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

45

Page 62

Chapter 3

Introduction

This chapter summarizes the properties, methods, functions, and

subroutines provided by the Data Acquisition and the DT Plot

Custom Controls in DTx-EZ.

46

Page 63

Property, Method, Function, and Subroutine Summary

Data Acquisition Custom Control

The Data Acquisition Custom Control provides the following

categories of data acquisition tools:

• Information properties and methods (page 47);

• Initialization properties (page 57);

• Configuration properties and functions (page 58); and

3

3

• Operation properties, methods, functions, and subroutines (page

61).

The following subsections briefly describe these tools.

Note: For specific information about each of these tools, refer to the

DTx-EZ online help. See page 13 for information on launching the

online help file.

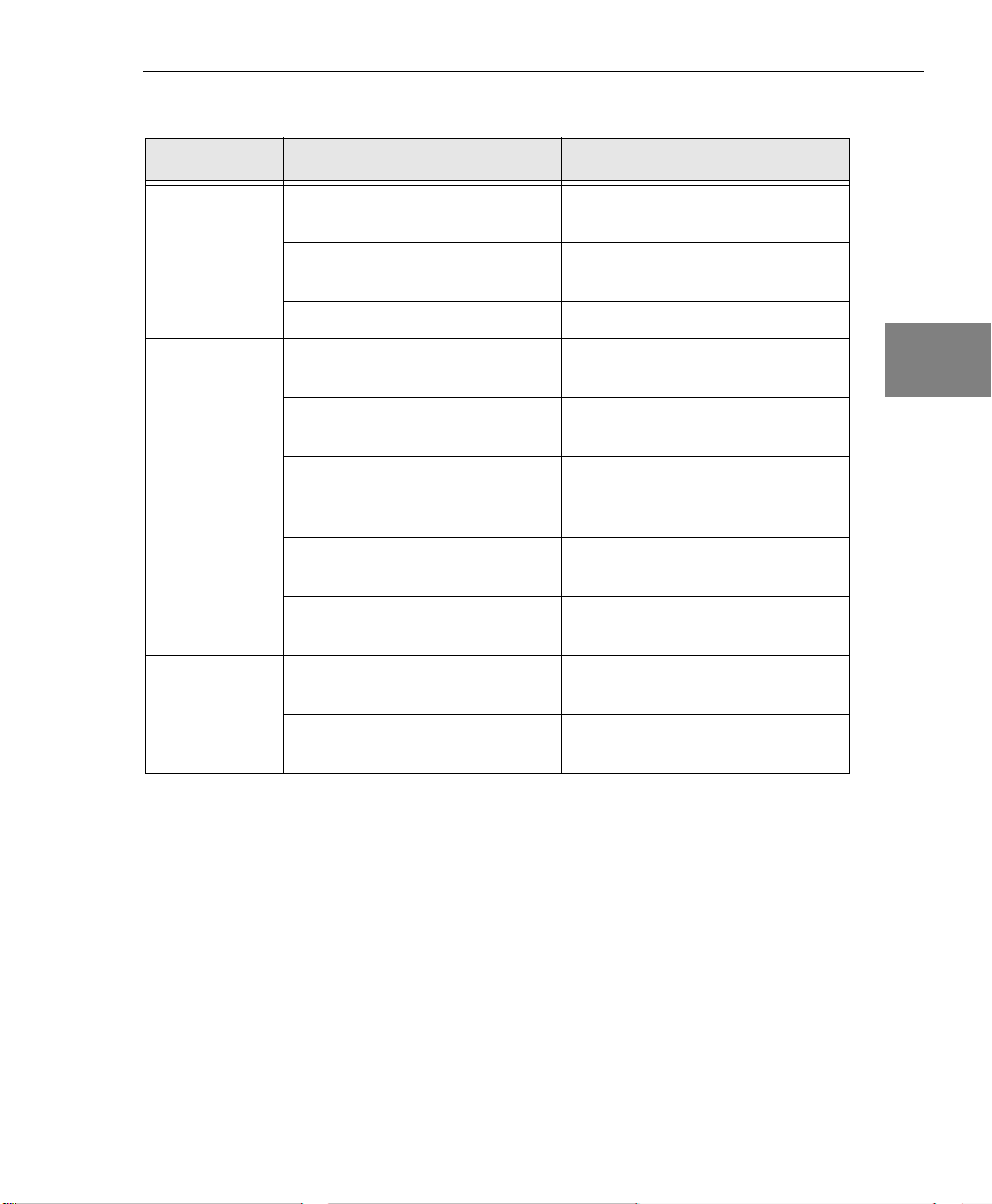

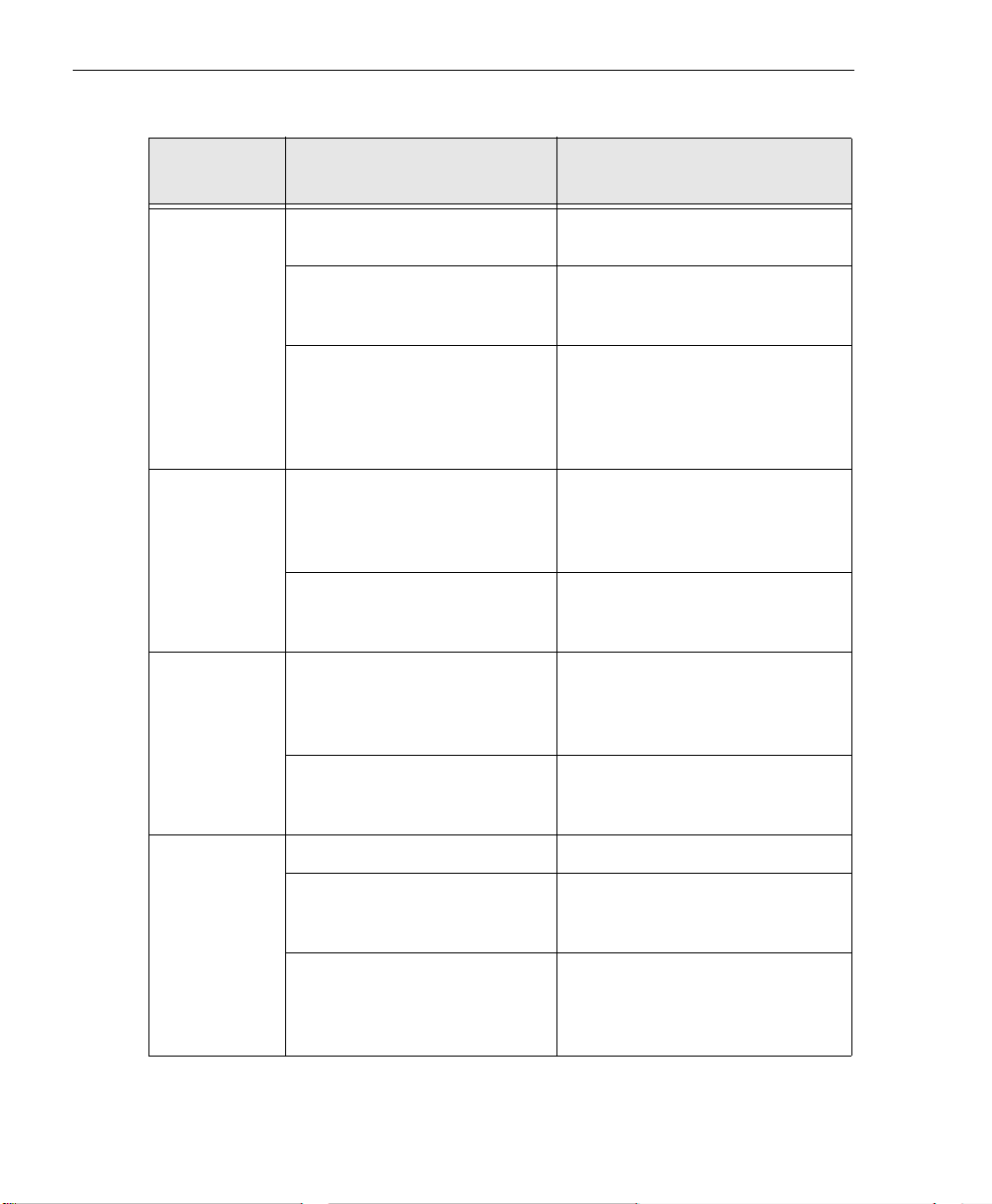

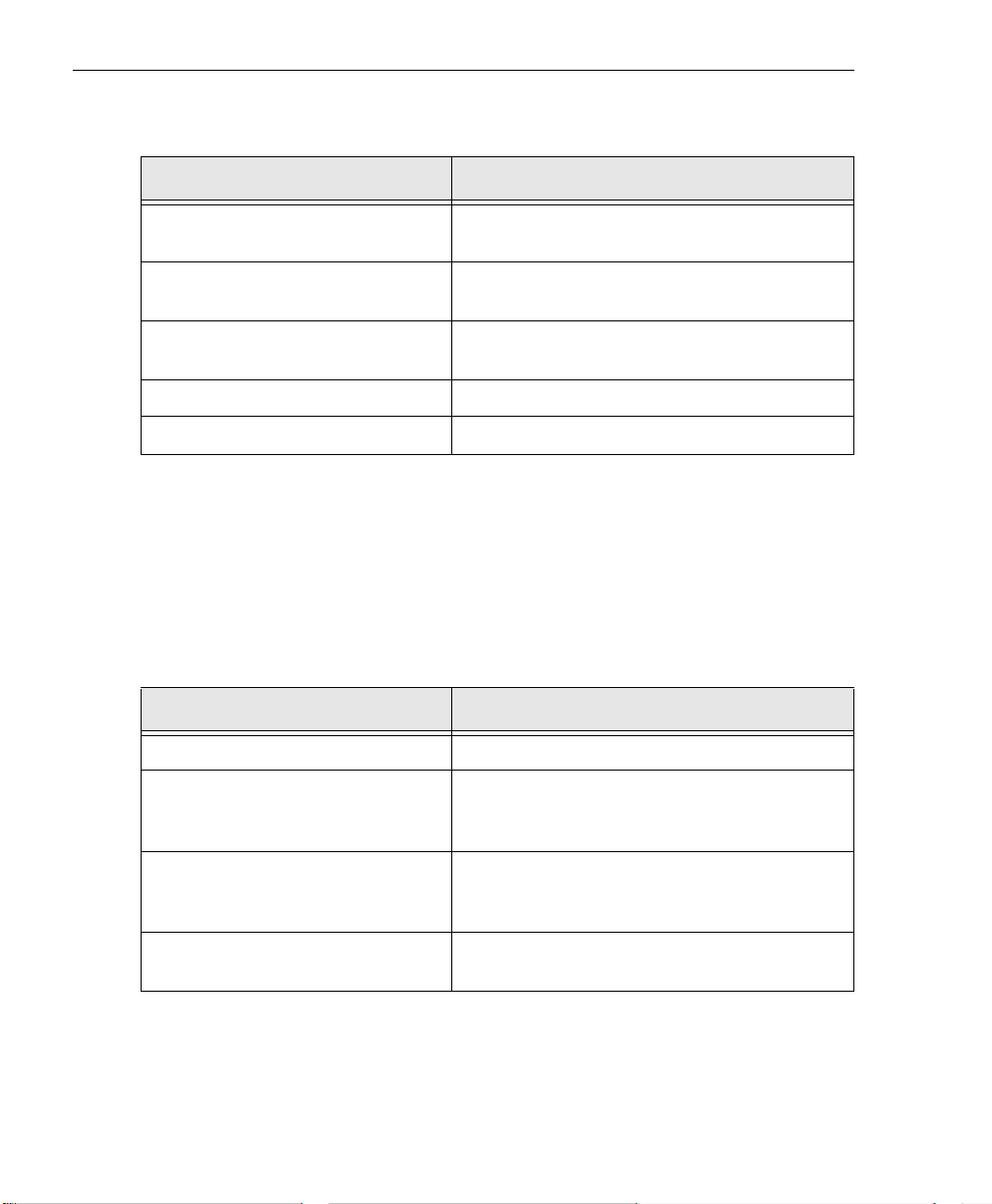

Information Properties and Methods

To determine the capabilities of your installed boards, subsystems on

each board, and software, use the information properties and

methods listed in Table 4.

3

3

3

3

3

3

3

47

Page 64

Chapter 3

Table 4: Information Properties and Methods

Query About Properties and Methods Description

Boards and

Devices

Subsystems numSubSystems Property Returns the number of available

BoardList Property Lists all currently-installed DT-Open

Layers data acquisition boards

(devices).

numBoards Property Returns the number of DT-Open

Layers boards currently installed in

the system.

EnumBoards Method Invokes the board enumeration

sequence.

DeviceName Property Gets the full name of the specified

device (this name is set by the driver

as part of the installation procedure).

hDev Property Returns the handle of the current

subsystem’s device.

subsystems for the selected

DT-Open Layers board.

SubSystemList Property Lists the subsystems available for

the selected DT-Open Layers board.

EnumSS Method Lists the names, types, and element

number for each subsystem

supported by the specified device.

48

GetDevCaps Method Returns the number of elements for

a specified subsystem type on a

specified device.

Page 65

Property, Method, Function, and Subroutine Summary

Table 4: Information Properties and Methods (cont.)

Query About Properties and Methods Description

Subsystems

(cont.)

GetSSCaps Method Returns whether a specified

subsystem capability is supported

and/or the number of capabilities

supported. Refer to Ta bl e 5 for a list

of possible capabilities and return

values.

GetSSCapsEx Method Gets information about extended

subsystem capabilities including the

minimum and maximum throughput,

retrigger frequency, clock divider

value, and base clock frequency.

EnumSSCaps Method Lists the possible settings for

specified subsystem capabilities

including filters, ranges, gains, and

resolution.

numFilters Property Returns the number of available filter

settings for a subsystem.

FilterValues Property Lists filters available to the selected

subsystem.

numGains Property Returns the number of available gain

settings for a subsystem.

3

3

3

3

3

3

GainValues Property Lists the subsystem’s available gain

values.

numResolutions Property Returns the number of available

resolution settings for a subsystem.

ResolutionValues Property Lists a subsystem’s available

resolution values.

numRanges Property Returns the number of available

range settings for a subsystem.

MaxRangeValues Property Lists a subsystem’s maximum

voltage range values.

3

3

3

49

Page 66

Chapter 3

Table 4: Information Properties and Methods (cont.)

Query About Properties and Methods Description

Subsystems

(cont.)

Software LastError Property Retrieves the last known DT-Open

MinRangeValues Property Lists a subsystem’s minimum voltage

range values.

hDass Property Returns the handle of the current

subsystem.

Layers error generated by the

DTAcq32 Control.

LastErrorDescription

Property

Retrieves a string representation of

the last known DT-Open Layers error

generated by the DTAcq32 Control.

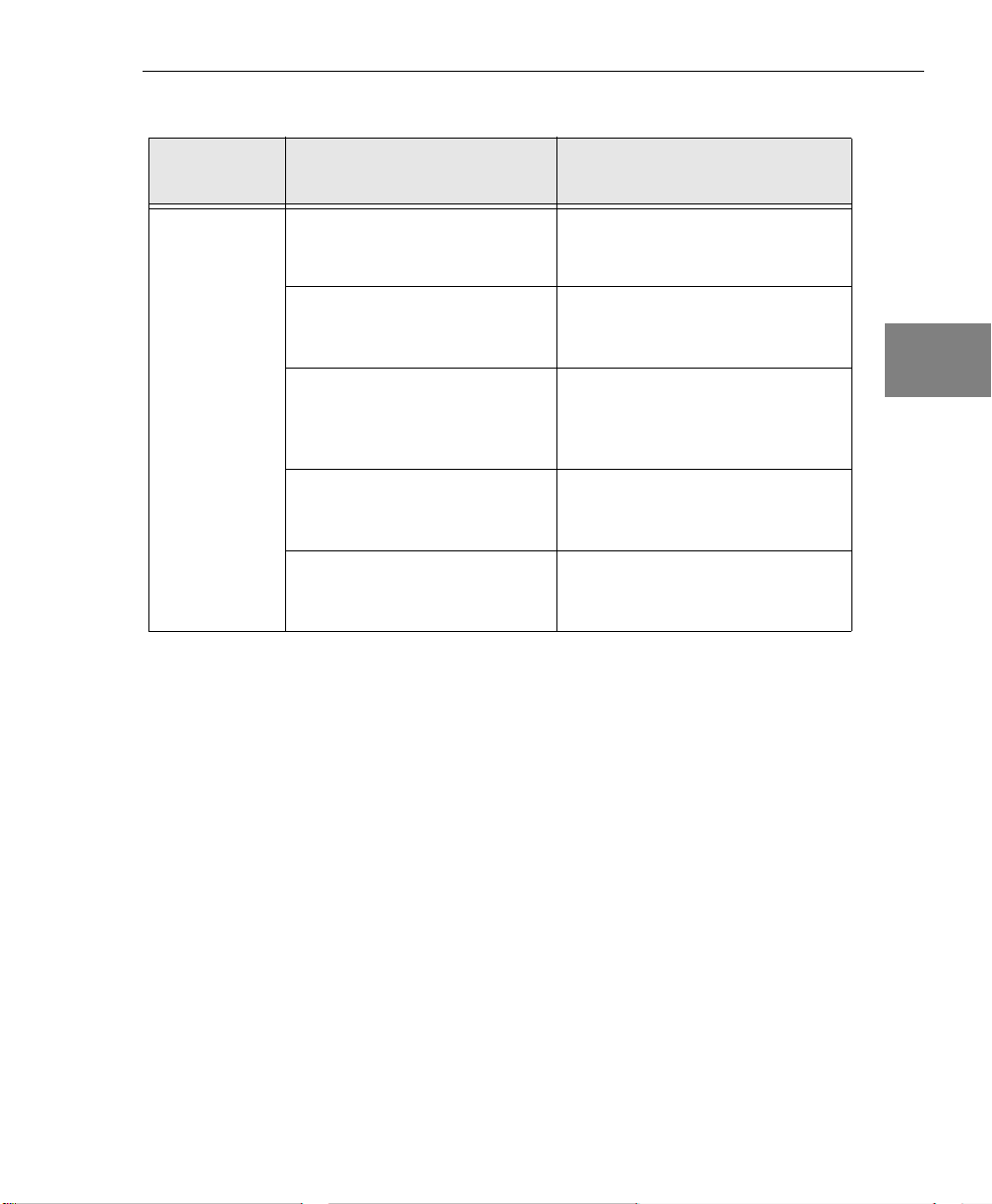

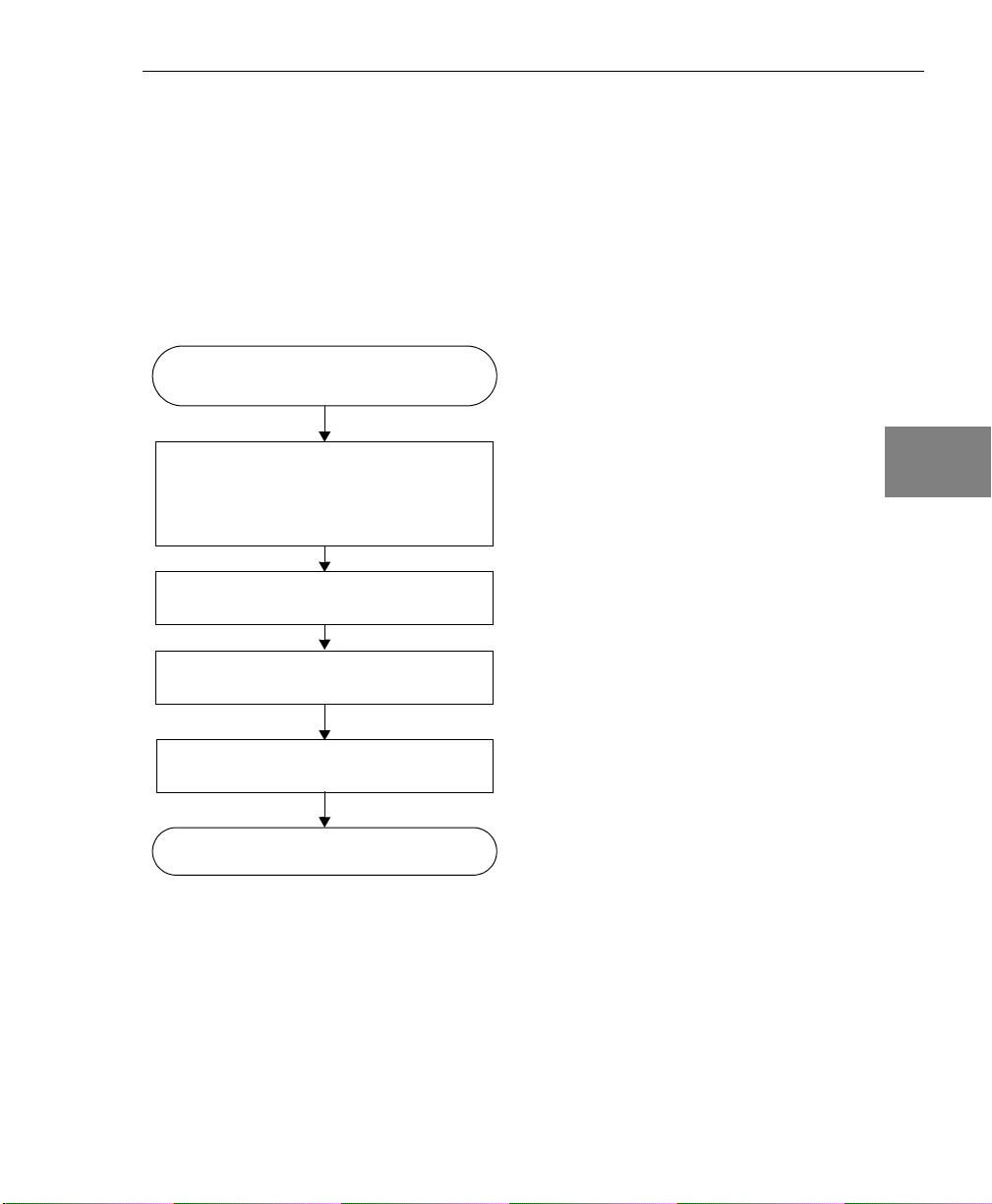

Tabl e 5 lists the subsystem capabilities that you can query using the

GetSSCaps method. Note that capabilities may be added as new

boards are developed; for the most recent set of capabilities, refer to

the DTx-EZ online help.

Table 5: Capabilities to Query with the GetSSCaps Method

Query About Capability Method Returns

Data Flow

Mode

OLSSC_SUP_SINGLEVALUE Non-zero if subsystem supports

single value operations.

50

OLSSC_SUP_CONTINUOUS Non-zero if subsystem supports

continuous (post-trigger)

operations.

OLSSC_SUP_CONTINUOUS_

PRETRIG

OLSSC_SUP_CONTINUOUS_

ABOUTTRIG

Non-zero if subsystem supports

continuous pre-trigger operations.

Non-zero if subsystem supports

continuous about-trigger (both

pre- and post-trigger) operations.

Page 67

Property, Method, Function, and Subroutine Summary

Table 5: Capabilities to Query with the GetSSCaps Method (cont.)

Query About Capability Method Returns

Simultaneous

Operations

Pausing

Operations

Windows

Messaging

Buffering OLSSC_SUP_BUFFERING Non-zero if subsystem supports

DMA OLSSC_NUMDMACHANS Number of DMA channels

OLSSC_SUP_

SIMULTANEOUS_START

OLSSC_SUP_PAUSE Non-zero if subsystem supports

OLSSC_SUP_POSTMESSAGE Non-zero if subsystem supports

OLSSC_SUP_WRPSINGLE Non-zero if subsystem supports

OLSSC_SUP_WRPMULTIPLE Non-zero if subsystem supports

OLSSC_SUP_INPROCESS_

FLUSH

Non-zero if subsystem can be

started simultaneously with

another subsystem on the device.

pausing during continuous

operation.

asynchronous operations.

buffering.

single buffer wrap mode.

multiple buffer wrap mode.

Non-zero if subsystem supports

copying a buffer on subsystem’s

inprocess queue.

supported.

3

3

3

3

3

3

OLSSC_SUP_GAPFREE_

NODMA

DMA (cont.) OLSSC_SUP_GAPFREE_

SINGLEDMA

OLSSC_SUP_GAPFREE_

DUALDMA

Non-zero if subsystem supports

gap-free continuous operation

with no DMA.

Non-zero if subsystem supports

gap-free continuous operation

with a single DMA channel.

Non-zero if subsystem supports

gap-free continuous operation

with two DMA channels.

3

3

3

51

Page 68

Chapter 3

Table 5: Capabilities to Query with the GetSSCaps Method (cont.)

Query About Capability Method Returns

Triggered

Scan Mode

Channel-Gain

List

OLSSC_SUP_TRIGSCAN Non-zero if subsystem supports

triggered scans.

OLSSC_MAXMULTISCAN Maximum number of scans per

trigger or retrigger supported by

the subsystem.

OLSSC_SUP_RETRIGGER_

SCAN_PER_TRIGGER

OLSSC_SUP_RETRIGGER_

INTERNAL

OLSSC_SUP_RETRIGGER_

EXTRA

OLSSC_CGLDEPTH Number of entries in channel-gain

OLSSC_SUP_RANDOM_CGL Non-zero if subsystem supports

Non-zero if subsystem supports

scan-per-trigger triggered scan