Page 1

DPP-25 and DPP-45 Series Printers

User’s Guide

Page 2

DPP-25 and DPP-45 Series Printers

User’s Guide

Revision A - March 1996

Part Number: 40420

Page 3

New Contact Information

Keithley Instruments, Inc.

28775 Aurora Road

Cleveland, OH 44139

Technical Support: 1-888-KEITHLEY

Monday – Friday 8:00 a.m. to 5:00 p.m (EST)

Fax: (440) 248-6168

Visit our website at http://www.keithley.com

Page 4

The information contained in this manual is believed to be accurate and reliable. However, Keithley

Instruments, Inc., assumes no responsibility for its use or for any infringements of patents or other rights

of third parties that may result from its use. No license is granted by implication or otherwise under any

patent rights of Keithley Instruments, Inc.

KEITHLEY INSTRUMENTS, INC., SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES RELATED TO THE USE OF THIS PRODUCT. THIS

PRODUCT IS NOT DESIGNED WITH COMPONENTS OF A LEVEL OF RELIABILITY

SUITABLE FOR USE IN LIFE SUPPORT OR CRITICAL APPLICATIONS.

Refer to your Keithley Instruments license agreement for specific warranty and liability information.

All brand and product names are trademarks or registered trademarks of their respective companies.

© Copyright Keithley Instruments, Inc., 1996.

All rights reserved. Reproduction or adaptation of any part of this documentation beyond that permitted

by Section 117 of the 1976 United States Copyright Act without permission of the Copyright owner is

unlawful.

Acculex

A Unit of Keithley Instruments, Inc.

440 Myles Standish Blvd. Taunton, MA 02780

Telephone: (508) 880-3660 ● FAX: (508) 880-0179

Page 5

Preface

This document describes the features and operation of the DPP-25 and

DPP-45 Series printers.

The manual is intended for users responsible for setting up, installing, and

operating these printers.

The DPP-25 and DPP-45 Series User’s Guide is organized as follows:

● Chapter 1 provides an overview of the features, specifications, and

dimensions of the DPP-25 and DPP-45 Series printers.

● Chapter 2 describes how to set up the printers.

● Chapter 3 describes how to operate the printers.

● Chapter 4 describes how to change the configuration of the printers.

An index completes this manual.

v

Page 6

Table of Contents

Preface

1 Overview

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

2 Setting up the Printer

Connecting I/O Devices to the Printer. . . . . . . . . . . . . . . . . . . . .2-1

Connecting Power to the Printer . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Loading or Changing the Paper Roll . . . . . . . . . . . . . . . . . . . . . .2-3

Changing the Ribbon Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Mounting the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

3 Operating the Printer

Performing a Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Using Control Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Using Escape Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Using Bit Image Graphics Mode . . . . . . . . . . . . . . . . . . . . . . . . .3-4

4 Changing the Printer Configuration

Locating the Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Connecting Power - P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Feeding the Paper, Resetting the Printer, or Performing a

Self Test - P3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Changing the Communication Parameters - SW1

(Serial Printers Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Connecting I/O - P4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

RS-232 Serial Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Centronics and Parallel Interfaces. . . . . . . . . . . . . . . . . . . . . .4-8

Index

iii

Page 7

List of Figures

Figure 1-1. Printer Model Numbers . . . . . . . . . . . . . . . . . . . . .1-2

Figure 1-2. Printer Dimensions (Front View without Front

Cover) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Figure 1-3. Printer Dimensions (Rear View with Cover). . . . .1-5

Figure 1-4. Printer Dimensions (Side View without

Rear Cover) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Figure 1-5. Printer Dimensions (Side View with Rear Cover).1-7

Figure 2-1. Connecting to the Printer. . . . . . . . . . . . . . . . . . . .2-2

Figure 2-2. Removing the Front Cover . . . . . . . . . . . . . . . . . .2-3

Figure 2-3. Removing the Paper Spindle . . . . . . . . . . . . . . . . .2-3

Figure 2-4. Loading the Paper into the Paper Feed

Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Figure 2-5. Feeding the Paper through the Paper Feed

Mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Figure 2-6. Replacing the Spindle . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-7. Feeding Paper through the Front Cover. . . . . . . . .2-5

Figure 2-8. Ejecting the Ribbon Cartridge . . . . . . . . . . . . . . . .2-6

Figure 2-9. Mounting the Printer . . . . . . . . . . . . . . . . . . . . . . .2-7

Figure 4-1. Rear View of Serial Printers . . . . . . . . . . . . . . . . .4-2

Figure 4-2. Rear View of the Centronics and Parallel Printers 4-2

Figure 4-3. Serial Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Figure 4-4. Centronics and Parallel Timing . . . . . . . . . . . . . . .4-9

List of Tables

Table 1-1. General Specifications. . . . . . . . . . . . . . . . . . . . . .1-3

Table 3-1. Control Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Table 3-2. Escape Sequences . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Table 4-1. P1 - Power Connector Pin Assignments . . . . . . . .4-3

Table 4-2. P3 - Paper Feed and Reset Connector

Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Table 4-3. DIP Switch Settings (Serial Printers Only) . . . . . .4-5

Table 4-4. Baud Rate Settings. . . . . . . . . . . . . . . . . . . . . . . . .4-6

Table 4-5. P4 Connector, RS-232 Interface Pin Assignments 4-7

Table 4-6. P4 Connector, Centronics and Parallel Interfaces .4-8

iv

Page 8

Table 1-1. General Specifications. . . . . . . . . . . . . . . . . . . . . .1-3

Table 3-1. Control Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Table 3-2. Escape Sequences . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Table 4-1. P1 - Power Connector Pin Assignments . . . . . . . .4-3

Table 4-2. P3 - Paper Feed and Reset Connector

Pin Assignments4-4

Table 4-3. DIP Switch Settings (Serial Printers Only) . . . . . .4-5

Table 4-4. Baud Rate Settings. . . . . . . . . . . . . . . . . . . . . . . . .4-6

Table 4-5. P4 Connector, RS-232 Interface Pin Assignments 4-7

Table 4-6. P4 Connector, Centronics and Parallel Interfaces .4-8

Page 9

Figure 1-1. Printer Model Numbers . . . . . . . . . . . . . . . . . . . . .1-2

Figure 1-2. Printer Dimensions (Front View without Front Cover)

1-4

Figure 1-3. Printer Dimensions (Rear View with Cover). . . . .1-5

Figure 1-4. Printer Dimensions (Side View without Rear Cover)

1-6

Figure 1-5. Printer Dimensions (Side View with Rear Cover).1-7

Figure 2-1. Connecting to the Printer. . . . . . . . . . . . . . . . . . . .2-2

Figure 2-2. Removing the Front Cover . . . . . . . . . . . . . . . . . .2-3

Figure 2-3. Removing the Paper Spindle . . . . . . . . . . . . . . . . .2-3

Figure 2-4. Loading the Paper into the Paper Feed Mechanism .

2-4

Figure 2-5. Feeding the Paper through the Paper Feed Mechanism

2-4

Figure 2-6. Replacing the Spindle . . . . . . . . . . . . . . . . . . . . . .2-5

Figure 2-7. Feeding Paper through the Front Cover. . . . . . . . .2-5

Figure 2-8. Ejecting the Ribbon Cartridge . . . . . . . . . . . . . . . .2-6

Figure 2-9. Mounting the Printer . . . . . . . . . . . . . . . . . . . . . . .2-7

Figure 4-1. Rear View of Serial Printers . . . . . . . . . . . . . . . . .4-2

Figure 4-2. Rear View of the Centronics and Parallel Printers 4-2

Figure 4-3. Serial Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Figure 4-4. Centronics and Parallel Timing . . . . . . . . . . . . . . .4-9

Page 10

Features

1

Overview

This chapter describes the features, general specifications, and

dimensions of the DPP-25 and DPP-45 Series printers.

The DPP-25 and DPP-45 Series printers provide the following standard

features:

● 5 VDC input power operation.

● 6912 Character input buffer.

● Paper feed/reset/self-test input.

● Normal or inverted print.

● Underlined text.

● Double-wide, double-high, or double-wide AND double-high

characters. You can mix normal and double-wide characters on any

line.

● Bit image graphics mode using the EPSON line printer, ESC K

protocol.

● Fast paper feed through the Paper Feed switch or through the

"immediate feed command" (ESC J +n).

● Serial RS-232 interface, available on the DPP-25xxS and DPP-45xxS

printers.

Features 1-1

Page 11

● Centronics interface, available on the DPP-25xxC and DPP-45xxC

printers.

● Parallel interface, available on the DPP-25xxP and DPP-45xxP

printers.

The following features are optional:

● 12 VDC power input (includes a linear regulator), available on the

DPP-2512x and DPP-4512x printers.

● 120 VAC power input (includes the linear regulator and a 14 VAC,

20 VA wall mount transformer), available on the DPP-25ACx and

DPP-AC12x printers.

The interface type and the power input used are indicated in the model

number for the printer, as shown in Figure 1-1.

For example, a DPP-25 Series printer with the 12 VDC power input and

the RS-232 serial interface is model number DPP-2512S. A DPP-45

Series printer with the 5 VDC power input and the parallel interface is

model number DPP-4505P.

DPP-25xxx

C = Centronics

5 VDC = 05

12 VDC = 12

120 VAC = AC

P = Parallel

S = Serial

DPP-45xxx

C = Centronics

5 V DC = 05

12 V DC = 12

120 VAC = AC

Figure 1-1. Printer Model Numbers

1-2 Overview

P = Parallel

S = Serial

Page 12

Specifications

Table 1-1 lists the general specifications of the DPP-25 and DPP-45

Series printers.

Table 1-1. General Specifications

Feature DPP-25 Series

Paper Width 57.5 mm

Dots per line 166 252

Characters per line 24 42

Lines per second 1.7 1.0

Dimensions

DPP-45 Series

Specifications

2.25 inches

Specifications

57.5 mm

2.25 inches

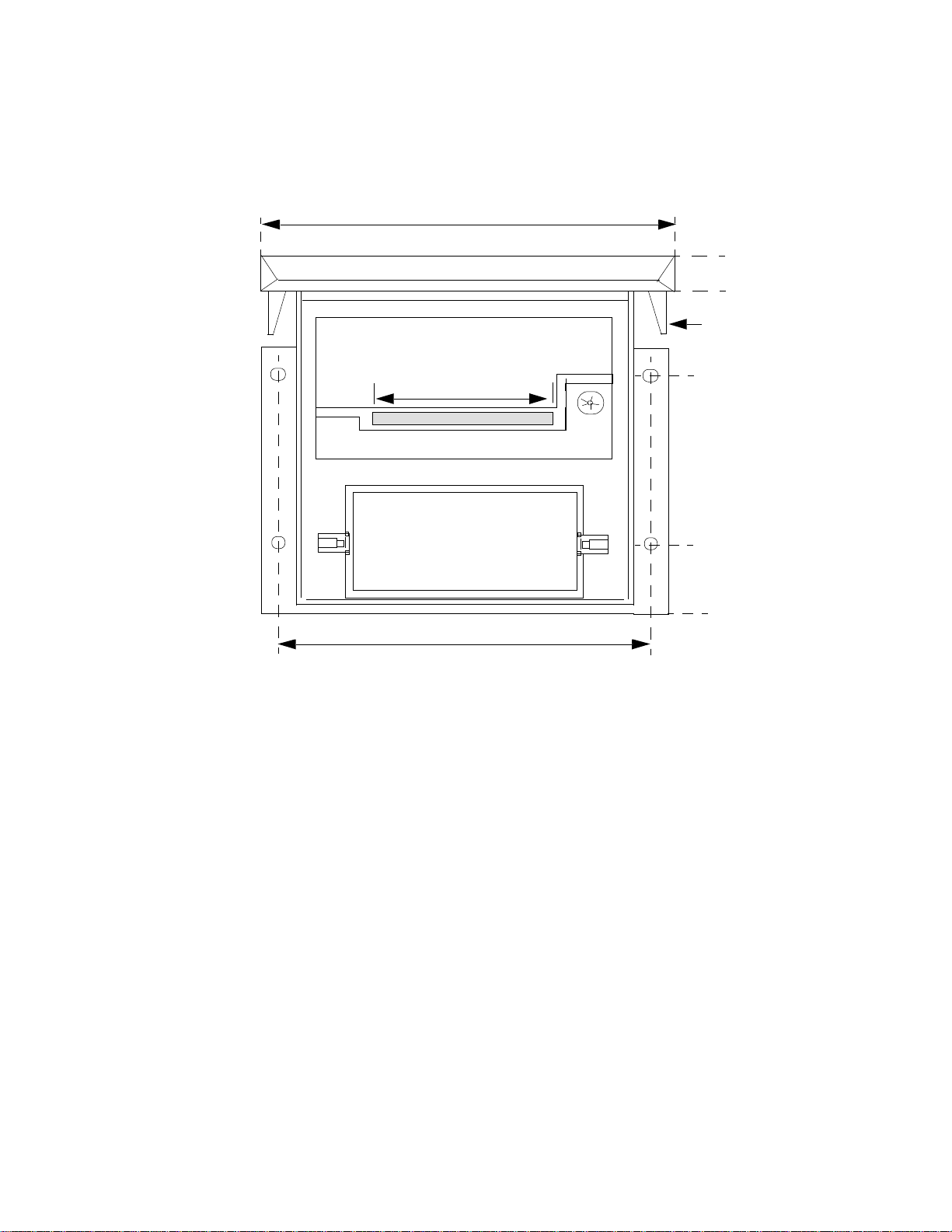

Figure 1-2 shows the dimensions of the printers from the front with the

front cover removed. Figure 1-3 shows the dimensions of the printers

from the rear with the rear cover installed. Figure 1-4 shows the

dimensions of the printers from the side with the rear cover removed.

Figure 1-5 shows the dimensions of the printers from the side with the

rear cover installed.

Specifications 1-3

Page 13

4.50

4.350

4.0 (Ref)

Printer Mechanism

Paper Path

Ribbon Cartridge

Paper Roll

Paper Roll

4.125

Figure 1-2. Printer Dimensions (Front View without Front Cover)

Latch

Cover

2.720

0.920

0.0

1-4 Overview

Page 14

3.375 inches

1.55

inches

Paper Feed Switch

(Wiring Access)

25-pin Serial or

Parallel

Connector

(depends on

printer)

36-pin,

Centronics

Connector

Not used

Power

Jack

3.775

inches

4-40 Screws

(4 PLCS)

DIP Switch

Access (on serial

printers only)

Figure 1-3. Printer Dimensions (Rear View with Cover)

Dimensions 1-5

Page 15

3.8 Ref

0.0

Panel Mounting

Plane

1.65

3.50

Behind Panel Depth to

Allow Cable Access

Figure 1-4. Printer Dimensions (Side View without Rear Cover)

1-6 Overview

Page 16

Behind Panel Dimensions

3.45-inches with 25-pin, Sub D Serial Connector

3.60-inches with 36-pin, Parallel Connector

Printer Case

Panel Mounting

Plane

Printer

Cover

Printer

Cover

User-supplied

cable

Figure 1-5. Printer Dimensions (Side View with Rear Cover)

Dimensions 1-7

Page 17

Setting up the Printer

This chapter describes how to set up the printer, including how to

● Connect an I/O device to the printer

● Connect power to the printer

● Load or change the paper roll

● Change the ribbon cartridge

● Mount the printer in a panel

Refer to Chapter 3 for information on how to operate the printer; refer to

Chapter 4 for information on how to change the printer configuration.

Connecting I/O Devices to the Printer

2

Refer to Figure 2-1 for the location of the I/O connectors on the printer.

If you are using a serial printer, connect the 25-pin, male connector end of

the serial cable to the I/O connector on the rear panel of the printer;

connect the other end to the I/O device.

If you are using a Centronics printer, connect the 36-pin, male connector

end of the cable to the I/O connector on the rear panel of the printer;

connect the other end to the I/O device.

If you are using a parallel printer, connect the 25-pin, female connector

end of the cable to the I/O connector on the rear panel of the printer;

connect the other end to the I/O device.

Connecting I/O Devices to the Printer 2-1

Page 18

25-pin Serial or

Parallel

Connector

(depends on

printer)

36-pin,

Centronics

Connector

Figure 2-1. Connecting to the Printer

Connecting Power to the Printer

1. Attach the red and black wires of the supplied power cord to the

corresponding terminals of the appropriate power supply:

Power

Jack

– 5 VDC power supply for printer models DPP-2505x and

DPP-4505x

– 12 VDC power supply for printer models DPP-2512x and

DPP-4512x

– 120 VAC power supply for printer models DPP-25ACx and

DPP-45ACx

2. Insert the other end of the power cord into the power jack on the rear

panel of the printer, as shown in Figure 2-1.

2-2 Setting up the Printer

Page 19

Loading or Changing the Paper Roll

To load or change the paper roll, perform the following steps:

1. Slide the front cover down as far as it will go (about 1/2 inch), as

shown in Figure 2-2, and lift it off.

Front Cover

Figure 2-2. Removing the Front Cover

2. Locating the paper roll, use a rotating motion to lift first the left then

the right end of the paper spindle, as shown in Figure 2-3.

Slide down

1/2 inch from top

and lift off

Paper Roll

Paper

Remove left side

of spindle first

Paper Spindle

Right side of

spindle

Figure 2-3. Removing the Paper Spindle

Loading or Changing the Paper Roll 2-3

Page 20

3. Insert the end of the new roll of paper into the paper slot of the printer

mechanism with the paper coming off the roll at the bottom, as shown

in Figure 2-4.

Top of paper feed

Insert paper

in paper

feed

mechanism

Feed paper from

bottom of roll

mechanism

Silver paper feed

guide

Figure 2-4. Loading the Paper into the Paper Feed Mechanism

4. With power supplied to the printer, press the Paper Feed switch until

at least 3 inches of paper extend above the printer, as shown in

Figure 2-5.

Press the Paper Feed

switch until the paper

extends at least

3 inches through the

top of the paper feed

mechanism.

Figure 2-5. Feeding the Paper through the Paper Feed Mechanism

5. Slide the spindle into the new paper roll, being sure that the end with

two shafts is on the left.

2-4 Setting up the Printer

Page 21

6. Place the spindle into its holder by inserting the right side first,

followed by the left side, as shown in Figure 2-6.

Ensure that the left side snaps into place.

Paper Roll

Paper

Replace right side

of spindle first

Figure 2-6. Replacing the Spindle

7. Feed the loose end of paper through the paper slot of the front cover

and rest the cover flush on the base, 1/2 inch from the top, as shown in

Figure 2-7.

Feed paper

through the

front cover

Paper

Slide cover up

until closed

Figure 2-7. Feeding Paper through the Front Cover

8. Slide the front cover up and snap it into position.

Loading or Changing the Paper Roll 2-5

Page 22

Changing the Ribbon Cartridge

Note: Ignore this section unless your ribbon cartridge needs to be

replaced.

To change the ribbon cartridge, perform the following steps:

1. Remove the front cover, as shown in Figure 2-2 on page 2-3.

2. With at least 3 inches of paper extending from the printer, press down

on the left end of the ribbon cartridge to eject it, as shown in Figure

2-8.

Paper Feed

Mechanism

Ribbon cartridge;

push this side to

eject

Paper Roll

Paper

Turn knob to

adjust ribbon

tension

Figure 2-8. Ejecting the Ribbon Cartridge

3. Lift both ends of the ribbon cartridge to remove it.

4. Lower the new ribbon cartridge over the extended paper, turning the

knob on the right end of the ribbon cartridge, as needed, to keep the

ribbon tight.

5. Snap the new ribbon cartridge in place.

6. Replace the front cover as shown in Figure 2-5 on page 2-4.

2-6 Setting up the Printer

Page 23

Mounting the Printer

If you want to mount the printer into a panel, ensure that you choose a

convenient location on the front panel for the Paper Feed switch. Figure

2-9 shows the dimensions required to mount the printer.

0.076 diameter

hole for 2-56

self-tapping screws

(supplied)

0.089 diameter

clearance hole for

2-56 machine

screws (optional)

TYP (4 PLCS)

Use a .50 diameter hole to mount the

supplied Paper Feed switch

3.950

2.66

Printer Cutout

0.860

4.125

4.038

3.95

Ref

0.0

0.0

0.088

Figure 2-9. Mounting the Printer

Mounting the Printer 2-7

Page 24

Operating the Printer

This chapter describes how to operate the printer, including how to

● Perform a self test

● Use control codes

● Use escape sequences

● Use binary image graphics mode

Performing a Self Test

The self-test feature prints the version of the software installed, the model

of the printer connected, various setup parameters (such as the interface

type and communication parameters), followed by the entire alphabet.

3

To perform the self test, press the Paper Feed switch when turning on

power or use the ESC T command, described on page 3-3.

Performing a Self Test 3-1

Page 25

Using Control Codes

Table 3-1 describes the codes you can use to control the DPP-25 and

DPP-45 Series printers.

Table 3-1. Control Codes

Hexadecimal

Value

0A 10 LF Prints the contents of the printer buffer without moving

0D 13 CR Prints the contents of the printer buffer, moves the

0E 14 SO Sets double-wide1 print mode for text. Single-wide and

0F 15 SI Sets double-high2 print mode for text and/or bit image

14 20 DC4 Clears double-wide print mode.

15 21 NAK Clears double-high print mode.

Decimal

Value Name Description

the column pointer, and clears double-high mode.

column pointer to the left margin, and clears double-high

mode.

double-wide print can be intermixed on any print line.

Double-wide stays in effect until the clear double-wide

command is received.

graphics (see page 3-4). Double-high printing is on a

line-by-line basis. The line is single-high or double-high

depending on the mode when a line is printed.

Double-high print mode is cleared when the clear

double-high command is received or whenever a line is

printed. The print can be due to any of the print

commands or to a line length overflow.

1B 27 ESC Escapes header. See the next section for more

information.

Notes

1

You can mix double-wide and normal-wide characters on any line.

2

Double-high print mode causes the entire line to be double high.

3-2 Operating the Printer

Page 26

Using Escape Sequences

An escape sequence is the ESC character immediately followed by the

appropriate byte(s) to complete the sequence, where +n refers to another

byte and +s refers to more than 1 byte to complete the command

sequence. Abbreviations used are as follows:

● NC = Number Of Characters per line

● ND = Number Of Dots per line

● DL = Dot Line

● CL = Character Line

● LM = Left Margin (default = 1)

● RM = Right Margin (default = NC)

● BI = Bit Image graphics

The escape sequences supported by the DPP-25 and DPP-45 Series

printers are described in Table 3-2.

Table 3-2. Escape Sequences

Hexadecimal

Value

Decimal

Value Name Description

+n 20 32 (sp) Tabs to character position n. Range = 1 to RM.

This command is ignored if n is out of range. n is for

single-wide character positions even if double-wide mode

is selected at the time.

+n 24 36 $ Tabs to dot position n. Range = 1 to RM*6. This command

is ignored if n is out of range.

1

+n 2D 45 - Selects underline mode. OFF is n=0 , ON is n=1.

30 48 0 Sets line spacing to 9 DL/CL (default).

31 49 1 Sets line spacing to 8 DL/CL (no BI space).

32 50 2 Sets line spacing to 12 DL/CL.

40 64 @ Initializes printer.

Using Escape Sequences 3-3

Page 27

Table 3-2. Escape Sequences (cont.)

Hexadecimal

Value

+n 41 65 A Sets line spacing to n DL/CL.

+n 43 67 C Causes a pause while the controller tries to activate an

+n 4A 74 J Prints, if needed, then fast feeds paper n DL. The column

+s 4B 75 K Selects bit image mode. See “Using Bit Image Graphics

54 84 T Runs a self test. See “Performing a Self Test” on page 3-1

+s 58 X Sets margins. +s = two more bytes (n1 and n2), which

Decimal

Value Name Description

n = 0 to 8 is treated as n = 8.

n = 9 to 127 is treated as n.

n > 127 is treated as (n − 128).

autocutter. These printers have no provision for driving an

autocutter.

counter is not changed.

Mode” on page 3-4 for more information.

for more information.

defines the leftmost and rightmost character positions to

use for printing. Range = 1 to NC.

This command is ignored if either n1 or n2 = 0, or if n1 =

n2 and both are in range.

One byte greater than NC is treated as n = NC. If both bytes

are greater than N, the right margin is set to NC and the left

margin is set to NC − 1.

Notes

1

If the margins are changed with the ESC X +s command, either tab command can still tab back to

position 1, but RM sets the right limit of printing.

Using Bit Image Graphics Mode

Bit image (BI) graphics mode uses the ESC K protocol. This protocol is

similar to EPSON line printers; however, because DPP-25 and DPP-45

Series printers have a fixed number of dot positions (ND), limitations

exist.

3-4 Operating the Printer

Page 28

If more data is specified than the printer is capable of printing, the first

ND (left part) is printed and the remaining columns of data are ignored

(truncated to ND). If you change the margins with the ESC X +s

command, then the effective ND is also changed.

The protocol is as follows:

ESC K n1 n2 (n2*256 + n1 bytes of data) PRINT

For example, the following line prints 272 columns of bit image graphics

(truncated at ND columns):

1Bhex K 16dec 1dec (272 bytes of data) 0Dhex

If the number of bytes = N, the values of n1 and n2 are as follows:

● n1 (LSB) is the remainder of dividing N by 256 (N MOD 256).

The range is 0 (decimal) to 255 (decimal) but any number larger than

the number of dots per line is truncated.

● n2 (MSB) is the integer quotient of dividing N by 256 (INT(N/256)).

Any data for n2 > 0 (decimal) is truncated.

The character line spacing remains in effect; therefore, if you want to

print the graphics on adjacent character lines with no blank dot lines in

between, set the line spacing by sending ESC 1 (8 DL/CL).

The first byte of data is printed in the current dot position as a vertical

group of 8 dots, defined by the data byte. The most significant bit of the

byte is printed at the top of the group of dots; the least significant bit is

printed at the bottom of the group of dots. (If the appropriate bit is a

logical 1, a dot is printed. If the bit is 0, nothing is printed at that

position).

The second byte is printed in the next dot position and so on, until byte n1

+ (n2 x 256) is printed. Printing does not occur until a print command is

received or until more than ND bytes of data are received.

Graphics data and ASCII text data can be printed on the same line by

printing only when all the required data is in the printer's input buffer.

Printing occurs if a print command is received or if the ND counter is

greater than the ND for the printer.

Using Bit Image Graphics Mode 3-5

Page 29

Paper is automatically advanced one dot line as each dot line is printed.

The printer’s motor is turned off anytime the next line of data is not ready

to be printed or when the printer completes the previous character line.

Before any printing can be done, the motor must be turned on for one

shuttle to synchronize the printer; this causes the paper to feed one dot

line.

Note: To avoid blank dot lines from occurring between each 8 dot lines

of bit image graphic data, the data must be sent at a rate fast enough to

stay ahead of the printer.

An IBM PC/XT (8088 at 4.8 MHz) running a BASICA program does not

send data fast enough, even to the parallel port. Sending a few print

commands before a routine to print bit image graphic data can keep the

printer busy long enough for the computer to send several lines of data to

the printer's buffer.

3-6 Operating the Printer

Page 30

Changing the Printer

This chapter describes how to change the configuration of the printer for

various operations.

Locating the Components

Figure 4-1 shows the rear view of the serial printers with the rear cover

removed.

Figure 4-2 shows the rear view of the Centronics and parallel printers

with the rear cover removed.

4

Configuration

Locating the Components 4-1

Page 31

9

stop

bits, parity, baud

rate

O

P3

Paper Feed, Reset,

and Self Test

1

1 2 3

P1

Power

8K SRAM

E2

E1

P4 - Serial I/O

13

26

MPU

1

SW 1

1

8

Figure 4-1. Rear View of Serial Printers

9

P3

Paper Feed, Reset,

and Self Test

1

E1

1 2 3

P1

Power

8K SRAM

MPU

Data bits,

E2

P4 - Parallel I/O

18

36

1

19

Figure 4-2. Rear View of the Centronics and Parallel Printers

4-2 Changing the Printer Configuration

Page 32

Notes: For the serial printers, the 26-pin serial connector (P4) mates to a

DB25, 25-pin connector on the rear cover.

For the Centronics printers, the 36-pin connector (P4) mates to a 36-pin

Centronics connector on the rear cover.

For the parallel printers, the 36-pin connector (P4) mates to a 25-pin

parallel connector on the rear cover.

The following subsections describe how to adjust the printer settings

using the components shown.

Connecting Power - P1

Power is available through the P1 power connector. The pin assignments

of connector P1 are described in Table 4-1.

Table 4-1. P1 - Power Connector Pin Assignments

Pin Name I/O Description

1 GND Input Common

2 5 Input +5 V

3 +V Input Strapped through E2 to +5 V.

E2 can be cut and +V can be applied at this pin, if

desired, to power the mechanism separately from

the +5 V logic supply.

The power requirement is regulated +5 VDC voltage.

The current requirements are as follows:

● Standby, which means ON but not printing, requires 25 mA typical

(CMOS logic).

● With DPP-25xxx series printers, printing typical ASCII text requires

4.5 A peak and 1.0 A average.

Connecting Power - P1 4-3

Page 33

Average current varies depending on the density of dots printed.

Note: The P1 connector is available from Molex as part# 09-74-103. The

posts of the connector are 1 x 3, 0.045-inch square, L/R.

Feeding the Paper, Resetting the Printer, or

Performing a Self Test - P3

The paper feed, reset, and self-test functions are available through

connector P3. The pin assignments of connector P3 are described in Table

4-2.

Table 4-2. P3 - Paper Feed and Reset Connector

Pin Assignments

1

Pin

Name I/O Description

2

9

7 - Input No connection.

6

4 PE Input Normally connected to ground by a strap at E1. If the strap

1 IS Output Current source for PE LED.

Notes

1

Pins 2, 3, 5, and 8 are grounds.

2

By default, this pin is connected to the Paper Feed switch, described on page 4-5.

/PF Input Low = paper feed;

Low at power on = self test (see page 3-1).

/RST Input Low pulse yields reset.

is cut, a high input at this pin means the printer is out of

paper.

No paper-out sensor is furnished. If you add a paper-out sensor, you must

cut the etch between the two pads at jumper pad E1. This allows you to

use pin 4 of connector P3 as a paper-out input signal from the paper-out

sensor you supply.

4-4 Changing the Printer Configuration

Page 34

A 12-inch cable assembly, which includes the mating connector for P3

and a push button Paper Feed switch, is furnished with all printers. The

Paper Feed switch is required to load paper.

Note: Connector P3 is available from Molex as part# 22-03-2091. The

posts of the connector are 1 x 9 0.025-inch square.

Changing the Communication Parameters - SW1

(Serial Printers Only)

DIP switch SW1 is provided for serial printers only. Use DIP switch SW1

to change the communication parameters for the DPP-25xxS and

DPP-45xxS printers. Table 4-3 describes the DIP switch settings.

Table 4-3. DIP Switch Settings (Serial Printers Only)

Position ON = OFF =

8 Normal (default) Inverted print

7 − DPP-25 or DPP-45 Series printer (default)

6 7 data bits 8 data bits (default)

5 odd parity even parity (default)

4 enable parity disable parity (default)

3 BR32 on

2 BR22 on BR2 off (default)

1 BR12 on (default) BR1 off

Notes

1

This setting is ignored by default since the default setting disables parity.

2

See Table 4-4 on page 4-6. The default baud rate is 9600.

Changing the Communication Parameters - SW1 (Serial Printers Only) 4-5

BR3 off (default)

1

Page 35

Note: 7 data bits, no parity, and 1 stop bit is NOT a valid combination to

send to the printer.

Table 4-4 describes the available baud rate settings that you can set using

DIP switch SW1.

Table 4-4. Baud Rate Settings

Baud

Rate

150 on on on

300 on on off

600 on off on

1200 on off off

2400 off on on

4800 off on off

9600

(default)

19200 off off off

Connecting I/O - P4

Connector P4 provides the I/O interface to your printer, but uses different

hardware and has different functionality depending on the printer you are

using.

BR3

Setting

off off on

BR2

Setting

BR1

Setting

The following subsections describes the implementation of the P4

connector and the timing for each I/O interface.

4-6 Changing the Printer Configuration

Page 36

RS-232 Serial Interface

For the DPP-25xxS and DPP-45xxS printers, connector P4 provides an

RS-232 serial interface. Table 4-5 describes the pin assignments of

connector P4 for these printers.

Table 4-5. P4 Connector, RS-232 Interface Pin Assignments

Pin Name I/O Description

2 XD output RS-232 transmitted data (no function)

3 RD input RS-232 received data

7 GND - Logic ground

20 DTR output Hardware handshake line

The serial timing of the RS-232 interface is shown in Figure 4-3.

st d0 d1 d2 d3 d4 d5 d6 d7 p sp

1 Character Time

Figure 4-3. Serial Timing

The definitions of these bits is as follows:

● st = start bit

● sp = stop bit

● p = parity bit (optional)

● d0 to d7 = data bits. d7 is optional unless needed for graphics. The

width of each bit depends on the baud rate.

The length of the data byte must be 10 bits minimum. 7 data bits, no

parity, and 1 stop bit is not a valid combination to send to the printer. The

polarity shown (start bit high and stop bit low) is for RS-232 voltage

levels of serial data stream.

Connecting I/O - P4 4-7

Page 37

Note: For serial printers, connector P4 uses 2 x 13, 0.025-inch square

posts.

Centronics and Parallel Interfaces

For the DPP-25xxC and DPP-45xxC printers, connector P4 provides a

Centronics interface; for the DPP-25xxP and DPP-45xxP printers,

connector P4 provides a parallel interface. Table 4-6 describes the pin

assignments of connector P4 for these printers.

Table 4-6. P4 Connector, Centronics and Parallel Interfaces

1,2

Pin

1 /STB input Active low pulse to send data to printer

2 D0 input ASCII data bit 0 (LSB)

3 D1 input ASCII data bit 1

4 D2 input ASCII data bit 2

5 D3 input ASCII data bit 3

Name I/O Description

6 D4 input ASCII data bit 4

7 D5 input ASCII data bit 5

8 D6 input ASCII data bit 6

9 D7 input ASCII data bit 7 (MSB)

10 /ACK output Active low pulse when data is accepted

11 BUSY output High level when printer cannot accept data

12 PE output High level when printer is out of paper (no

paper out sensor is furnished)

31 /INIT input Low pulse resets the printer

32 /ERROR output Normally high, low = error condition

Notes

1

For the Centronics interface, pins 13 and 35 are pulled up to +5 V; pins 16, 17,

19 to 30, and 33 are grounds; pins 14, 15, 18, 34, and 36 are not connected.

2

For the parallel interface, pins 13 and 15 are pulled up to +5 V; pins 18 to 25 are

grounds; pins 14, 16, and 17 are not connected.

4-8 Changing the Printer Configuration

Page 38

The timing used for the Centronics and parallel printers is shown in

Figure 4-4.

DATA . . .

/STB

/ACK

BUSY

Data Valid

su

= 50 ns

(min)

hold

= 50 ns

(min)

. . .

. . .

. . .

Figure 4-4. Centronics and Parallel Timing

The terms used in Figure 4-4 are described as follows:

● su = setup time

DATA VALID to /STB LOW = 50 ns (min)

● hold = hold time

/STB LOW to DATA can change = 50 ns (min)

● /STB width = 20 ns (min)

● /ACK width = 0.5 µs (typical)

● /STB LOW to BUSY high = 40 ns (typical)

Note: For the Centronics printers, connector P4 uses 2 x 18, 0.025-inch

square posts.

Connecting I/O - P4 4-9

Page 39

Index

Numerics

12 VDC 2-2

120 VAC 2-2

5 VDC 2-2

B

baud rate 4-5, 4-6

bit image graphics mode 3-3, 3-4

C

cartridge, ribbon 2-6

Centronics interface 4-8

Centronics printers 2-1

Centronics timing 4-9

changing the communication parameters 4-5

changing the paper roll 2-3

changing the printer configuration 4-1

changing the ribbon cartridge 2-6

character line 3-3

characters 3-3

communication parameters 4-5

components 4-1

configuration 4-1

connecting I/O devices 2-1, 4-6

connecting power 2-2, 4-3

control codes 3-2

cover

front 2-3

rear 1-5

current requirements 4-3

D

dimensions 1-3

DIP switch S1 4-5

dot line 3-3

dots 3-3

E

escape sequences 3-3

F

features 1-1

feeding paper 2-4, 4-4

front cover 2-3

G

graphics 3-4

I

I/O devices 2-1, 4-6

interface

Centronics 4-8

parallel 4-8

serial 4-7

L

left margin 3-3

loading the paper roll 2-3

locating the components 4-1

X-1

Page 40

M

models 1-2

mounting the printer 2-7

N

number of characters 3-3

number of dots 3-3

O

operating the printer 3-1

options 1-2

P

P1 4-3

P3 4-4

P4 4-6

paper feed mechanism 1-4, 2-4

Paper Feed switch 2-4, 4-5

paper path 1-4

paper roll 1-4, 2-3

paper spindle 2-3

paper, feeding 4-4

paper-out sensor 4-4

parallel interface 4-8

parallel printers 2-1

parallel timing 4-9

parameters, communication 4-5

parity 4-5

performing a self test 3-1, 4-4

pin assignments

Centronics interface 4-8

parallel interface 4-8

RS-232 serial interface 4-7

power 2-2, 4-3

power cord 2-2

power jack 2-2

power requirements 4-3

printer

Centronics 2-1

changing the communication parameters

4-5

changing the configuration 4-1

changing the paper roll 2-3

changing the ribbon cartridge 2-6

connecting I/O devices 2-1, 4-6

connecting power 2-2, 4-3

dimensions 1-3

feeding the paper 4-4

loading the paper roll 2-3

locating the components 4-1

mounting 2-7

operating 3-1

parallel 2-1

performing a self test 3-1, 4-4

resetting 4-4

serial 2-1

setup 2-1

specifications 1-3

using bit image graphics mode 3-4

using control codes 3-2

using escape sequences 3-3

printer models 1-2

R

rear cover 1-5

removing the front cover 2-3

resetting the printer 4-4

ribbon cartridge 1-4, 2-6

right margin 3-3

RS-232 serial interface 4-7

X-2 Index

Page 41

S

self test 3-1, 4-4

sequences, escape 3-3

serial interface 4-7

serial printers 2-1

serial timing 4-7

setting up the printer 2-1

specifications 1-3

specifying a printer model 1-2

spindle 2-3

switch

DIP switch S1 4-5

Paper Feed 2-4, 4-5

T

testing 3-1

timing

Centronics interface 4-9

parallel 4-9

serial 4-7

U

using bit image graphics mode 3-4

using control codes 3-2

using escape sequences 3-3

X-3

Loading...

Loading...