Page 1

AOM4

Programmable Excitation Module

The AOM4 Programmable Excitation Module provides four channels of high-speed

anaIog voltage output. Each channel has an independent D/A converter.

The D/A converters offer true X&bit resolution with a maximum nonlinearity of *.0X!%.

A single 0-10.2375V output range has a resolution of 2.5mV and a maximum output current of 4OmA.

Each output stage can be supplied either by the internal +l5V supply, or by an external

supply of +l5 (+2, -0) VDC.

A system strobe feature, supported by two levels of data latching in the D/A converters,

allows any number of D/A channels to be updated simultaneously.

Signals are connected directly to the module via screw terminals mounted on the righthand side of the module board.

The AOM4 module may be placed in any available slot in the system. To install the

module, first turn off power and remove the top cover of the mainframe. Insert the

module in the desired slot with the component side facing the power supply. Generally, analog modules should be placed in the low-numbered slots to isolate them from

power supply thermal and noise effects.

CAUTION: Always turn off the system power before installing or removing modules.

To avoid possible EM1 radiation never operate the system with the top cover removed.

User-Configured Components

All output connections are made to screw terminals located on the module. Two terminals are provided for each channel: signal output and common ground.

Table 1. User-Configured Components on the AOM4

Name

Screw Terminals Jl7’l Output Connection Channels O-3

Jumper 101

Designation Function

Part of Jl.7l External Power Connections

WlOl Select Internal/External Supply

Document Number: 500-932-01 Rev. C

AOM4-1

Page 2

AOM42

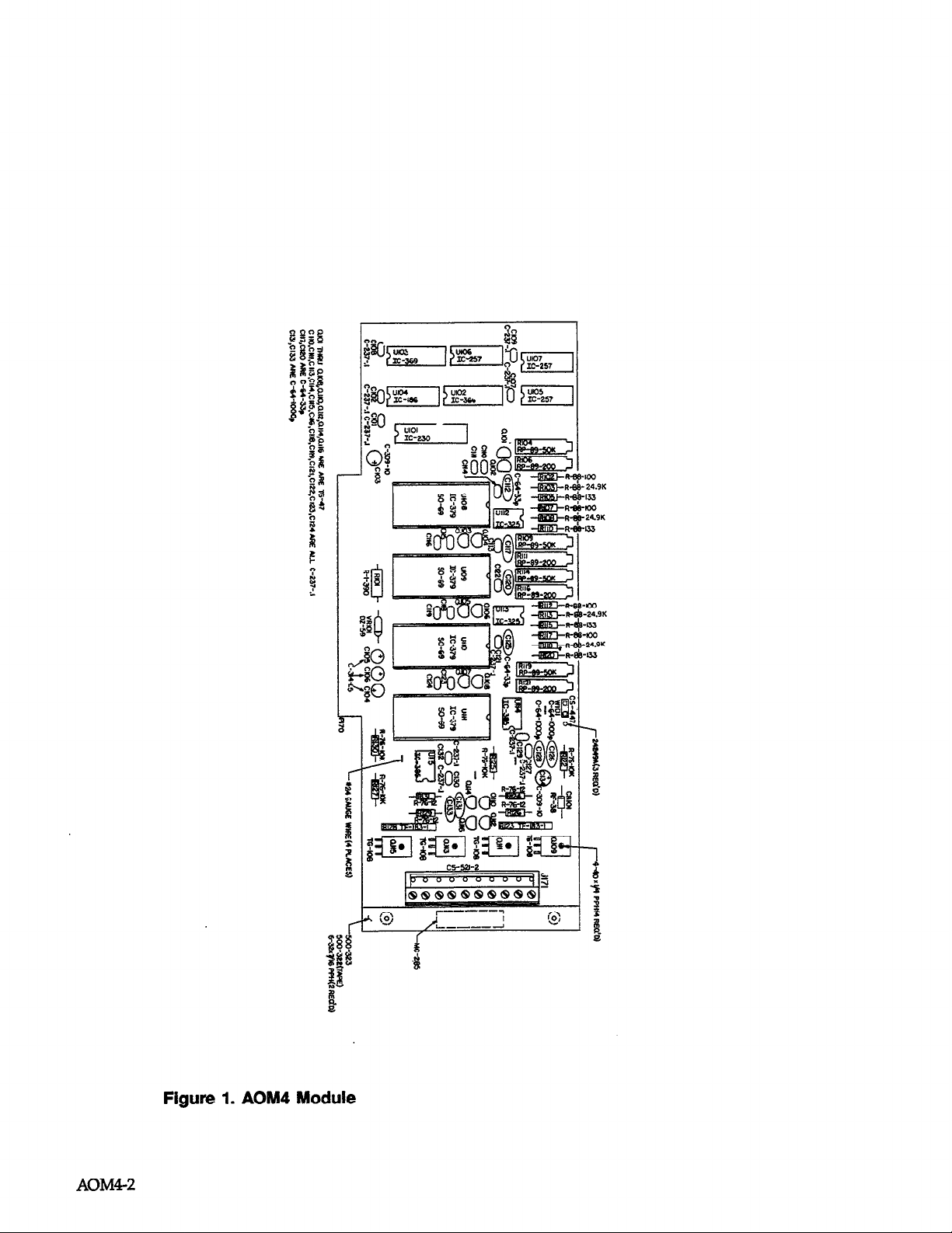

Figure 1. AOM4 Module

Page 3

Connections

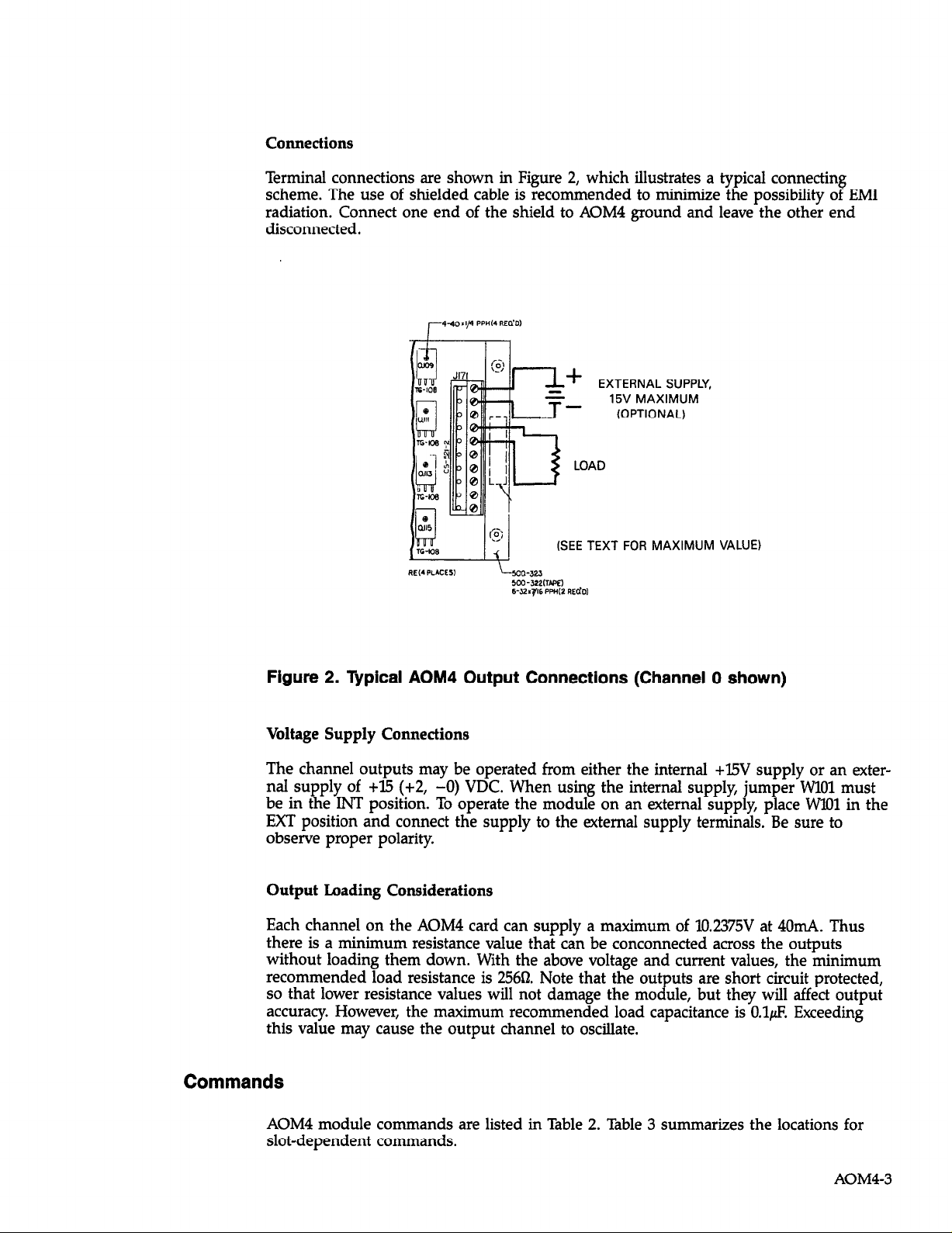

Terminal connections are shown in Figure 2, which illustrates a typical connecting

scheme. The use of shielded cable is recommended to minimize the possibility of EM1

radiation. Connect one end of the shield to AOM4 ground and leave the other end

disconnected.

IL!8

J---J-+

I“,” I

EXTERNAL SUPPLY,

(SEE TEXT FOR MAXIMUM

VALUE)

Figure 2. Typical AOM4 Output Connections (Channel 0 shown)

Voltage Supply Connections

The channel outputs may be operated from either the internal +l5V supply or an exter-

nal supply of +l5 (+2,

be in the INT position. To operate the module on an external supply, place WlOl in the

EXT position and connect the supply to the external supply terminals. Be sure to

observe proper polarity.

-0) VDC. When using the internal supply, jumper WlOl must

Output Loading Considerations

Each channel on the AOM4 card can supply a maximum of lO.2375V at 40mA. Thus

there is a minimum resistance value that can be conconnected across the outputs

without loading them down. With the above voltage and current values, the minimum

recommended load resistance is 25612. Note that the outputs are short circuit protected,

so that lower resistance values will not damage the module, but they will affect output

accuracy. However, the maximum recommended load capacitance is O.&S. Exceeding

this value may cause the output channel to oscillate.

Commands

AOM4 module commands are listed in Table 2. Table 3 summarizes the locations for

slot-dependent commands.

AOM4-3

Page 4

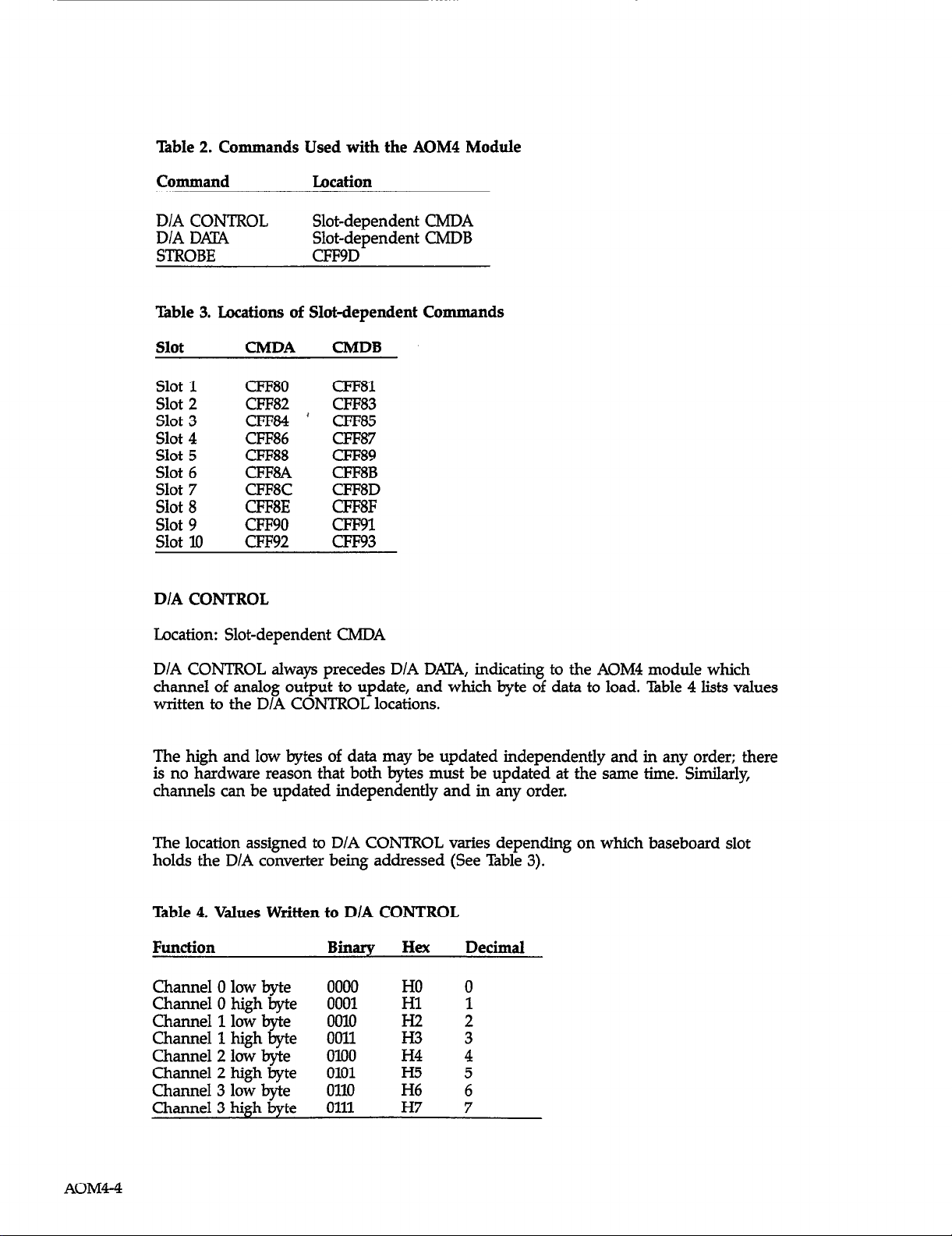

Table 2. Commands Used with the AOM4 Module

Command

D/A CONTROL

D/A DAL4

STROBE

Table 3. Locations of Slot-dependent Commands

Slot CMDA CMDB

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Slot 8

Slot 9

Slot lo

D/A CONTROL

CFFSO

CFF82

cFF84

CFF86

CEE88

cFF8A

CFF8C

CFF8E

CFF90

CFF92

Location

Slot-dependent CMDA

Slot-dependent CMDB

CFF9D

Location: Slot-dependent CMDA

D/A CONTROL always precedes D/A DATA, indicating to the AOM4 module which

channe1 of analog output to update, and which byte of data to load. Table 4 lists values

written to the D/A CONTROL locations.

The high and low bytes of data may be updated independently and in any order; there

is no hardware reason that both bytes must be updated at the same time. Similarly,

channels can be updated independently and in any order.

The location assigned to D/A CONTROL varies depending on which baseboard slot

holds the D/A converter being addressed (See Table 3).

Table 4. Values Written to D/A CONTROL

Function Binary Hex

Channel 0 low byte 0000

Channel 0 high byte 0001

Channel 1 low byte 0010

Channel 1 high byte 0011

Channel 2 low byte 0100

Channel 2 high byte 0101

ChanneI 3 low byte 0110

Channel 3 high byte 0111

HO 0

Hl 1

H2 2

H3 3

H4 4

H5 5

iz; 7 6

Decimal

AOM4-4

Page 5

DIA Dp;TA

Location: Slot-dependent CMDB

D/A DATA is used to load data values into the D/A converter. This command should

always be preceded by D/A CONTROL, which selects the channel and the byte to be

loaded. The data must be separated into low and high bytes prior to loading, and each

byte must be prefaced by D/A CONTROL.

When the strobe feature is not enabled, the output of the converter is updated immediately. Thus, when the strobe is not used, the low and high bytes are updated independently. When the strobe is enabled, outputs are not updated until the STROBE

command is issued with the value 1 (to issue data).

To determine the digital value to input for a given voltage, it is necessary to know the

output range of the D/A converter. With a l2-bit digital converteI; there are 4096 possible voltage levels, specified with digital values O-4095. Therefore the actual voltage of

each step equals the range divided by 4095. For an input range of 0 to 10.237V the

voltage of each step is 10237V/4095 or 2.5mV: thus a BASIC formula for each voltage

value can be derived:

Where V is voltage and D is the digital value in counts loaded into the converter.

Similarly, the following BASIC equation determines the digital value to use when a particular voltage is required:

V

D= INT (

2.5 x 10-j

Again, D is the digital value, while V is the voltage.

The digital values may be separated into low byte (LB) and high byte (HB) values with

the following equations:

HB

= INT (D/256)

LB =(D/256-HB) l 256

STROBE

Location: CFF9D

The STROBE command is used to make possible the synchronous updating of two or

more analog output channels. STROBE is issued in three modes: strobe enable, strobe

disable and issue data. The STROBE feature must either be enabled or disabled at the

start of any program, or the D/A converters will not function (see Table 5).

When any strobe feature is disabled, all data given to a D/A converter is immediately

placed in that converter’s primary data latch, and the current output updated. The low

byte and high byte are thus updated asynchronously

AOM4-5

Page 6

When the strobe is enabled, no data is updated until the STROBE command has been

issued in the issue data mode. New data is placed in a secondary data latch within the

D/A converter. When the STROBE command (to issue data) is given, new data is released to the primary data latch, updating the voltage output, and old data in other channels is reissued, leaving the voltage output of these channels unchanged. The strobe is

completely flexible. Any amount of data-from a single byte to any number of channelscan be updated when the strobe is enabled.

To use the strobe, issue the strobe enable command early in the program. Use the D/A

CONTROL and D/A DATA commands to load the secondary latches of the appropriate

converters. This can be done as far in advance as required. To issue the new data, load

STROBE with 1 (to issue data), releasing all data loaded since the last issue data command and leaving unchanged the outputs of other channels.

The STROBE feature is global, affecting all D/A modules installed in the Series 500

simultaneously.

Table 5. Values Written to STROBE

Function BillarV

Strobe Enable 01000000 H40 64

Strobe Disable 10000000 H80 128

Issue Data 00000001 HO1 1

AOM4 Module Calibration

Calibration of the AOM4 module is very similar to the procedure used to calibrate the

AOMl. This module has only a single range, howevel; so the complexity is reduced

considerably. Figure 3 shows calibration adjustment locations for the AOM4 Program 1

lists a calibration program intended for use with this module.

1.

Place the module to calibrated in slot 5 of the system baseboard.

Unless an external voltage source is connected to the module, place the supply

2.

jumper in the internal position.

3.

Connect the DMM high (or current input)lead to the signal output terminal of the

channel being calibrated. Connect the DMM low signal lead to module ground.

4.

Select an appropriate function and range on the DMM. Remember that the AOM4

output signal is a voltage in the range of 0 to +10.2375V.

5.

Enter program 1 into the computer.

Run the program and follow the instructions given. The program will prompt for

6.

module type and output channel, and then display the correct offset and gain adjustment values in that order.

HeX Decimal

AOM46

Page 7

CHAN 0 OFFSET

CHAN 0 GAIN

CHAN 1 OFfWFT

CHAN 1 GAIN

&g-J

,, CHAN 2 GAIN

CHAN 2 OFFSET

CHAN 3 OFFSET

CHAN 3 GAIN

Figure 3. AOM4 Calibration Adjustments

AOM47

Page 8

Program 1. AOM4 Calibration

10 DEF SEG=&HCFFO:CLS

20 CA=&H88:CB=&H89:ST=&H9D

30 POKE ST,64

40 PRINT”1-AOM3”

50 PRINT”2-AOM4’

60 PRINTzINPUT ‘MODULE TYPE (1 OR 2)“;M

70 IF M<l OR M>2 THEN 60

80 IF M=l THEN M$=“AOM3”:R$=“CURRENT”

90 IF M=2 THEN M$=‘AOM4”:R$=“VOLTAGE”

100 PRINT “INSERT”;M$:“INTO SLOT 5”

110 PRINT:INI’UT “CHANNEL (0-3)“;CH

120 IF CH<O OR CH>3 THEN 110

130 PRINTPRINT “CONNECT DMM To CHANNEL’;CH

140 PRINT “SET DMM TO MEASURE”;R$

150 ON M GOSUB 300,320

160 POKE CA,2*CH:POKE C&LB

170 POKE CA,TCH+lzPOKE CB,HB

180 POKE ST,1

190 PRINTPRINT’ADJUST CHANNEL’;CH;“OFFSET FOR”; L$;“READING ON DMM”

200 INPUT “PRESS RETURN To CONTINUE”;A$

210 ON M GOSUB 310,330

220 POKE CA,2*CH:POKE CB,LB

230 POKE CA,2*CH+l:POKE CB,HB

240 POKE ST,1

250 PRINTPRINT’ADJUST CHANNEL”;CH;“GAIN FOR”;H$; ‘READING ON DMM”

260 INWT’TRESS RETURN To CONTINUE”;A!$

270 PRINTzINI’UT’AGAIN”;A!$

280 IF LEFl?§(A!$,1)=“Y” THEN 110

290 END

300 LB=1:HB=O:I$=“5@‘:RETURN

310 LB=255:HB=15:H$=“20.475m.A’:RETURN

320 LB==l:HB=O:I$=“2.5mV”:RETURN

330 LB=255:HB=15:H$=“10238V”:RETURN

Theory of Operation

The AOM4 schematic is located on drawing number 500-416.

The circuitry on the module can be divided into three groups: D/A conversion circuitry

for each of the four channels, command development circuitry, and data buffering

circuitry.

D/A conversion centers around the complete Y&bit D/A converters (AD567JN) one for

each channel of the module. These converter ICs are designated UlO8 through Ulll for

channels 0 to 3 respectively. The converters contain precision voltage references, high

speed analog switches, two levels of data latching, and a precision resistor ladder. Each

D/A converter is supplemented by a high-speed, high accuracy, operational amplifier,

Ull2A and Ull2B for channels 0 and 1, and Ull3A and Ull3B for channels 2 and 3

respectively.

Two potentiometers calibrate the gain and offset for each D/A converter: potentiometers

R106, Rlll and Rl21 calibrate the gain for channels O-3 respectively. Transistors QlO9,

AOM4-8

Page 9

4111, 4113 and 4115 are the output transistors for channels O-3, while QllO, 4112, 4114

and 4116 provide short circuit protection for those channels, Each op amp has a 0

OOluF capacitor in the feedback loop to prevent oscillation with large capacitive loads.

Components U102-U107 comprise the command development circuitry. A quad

transparent data latch, U102 (74LS75) stores the 3 bit command selected data (a number

between 0 and 7). This latch is refreshed by a negative pulse of the D/A CONTROL

command line (CMDA). CMDA is buffered and inverted by a hex inverter segment of

Ul.04 (74LSO4). U103, a binary-to-decimal decoder (74LS42), generates eight separate

command lines based on the 3 bit binary word from UlO2. The eight command lines

are then gated by quad OR gate segments of U105-Ul.07 to control data latching in

U108-Ulll.

The eight data lines are buffered by UlOl, an octal buffer (74LS244). The operation of

UlOl is controlled by the CMDA and CMDB lines through elements of U104 and U105.

UlOl will be enabled if either CMDA or CMDB is low.

AOM4 Specifications

Number of Channels: 4

Range of Output: 0 to 10.2375V

Resolution: 12 bits

Maximum Output Current: 4OmA

The AOM4 consists of 4 voltage-output channels. Each channel has a nominal output

voltage range of 0 to lO2375V with K&bit resolution. This corresponds to 2.5mV per

LSB. The output power supply can be provided either by the internal +l5V supply or

by an external +I!W supply. The output stage is short-circuit protected and can drive a

capacitive load of up to .l$.

AOM4-9

Page 10

I

0.101 THRU QUX~,~IK~,~~IZ,CUI~,QL~ ARE ARE TG-47

C IK).CIII.C~~~.C~~~.C~~~.CIL.C~B.C~~~.C~ZI~.C~~,CIW.C~~~ nRE ALL C-237-d

C117,ClX)ARE‘C-‘ii-33p

CuI,CI33 ARE C-~~-UDC’P

I

n,....

L W24 GA”GE WIRE (4 PLACES)

&QO-323

SDD-322 A

6-32x v2 PPH(2 RED!D)b

Page 11

I

iii

/!//i//l///l/

AOM4 SCHEMATIC DIAGRAM

AOM4-ll/AOM4-12

Loading...

Loading...