Tektronix KDAC500 Data Acquisition,Control Software Compiler Version Rev. C (UNSUPPORTED) User manual

Page 1

KDAC500

Compiler Version for IBM, COMPAQ, and

100% Compatible Personal Computers

Data Acquisition and Control Software

Publication Date: October 1991

Document Number: 501-915-01 Rev. C

Page 2

Copyright Notice

The KDAC500 software and this documentation are copyrighted with all rights reserved by

Keithley Instruments, Inc., Cleveland, Ohio. No part of this product may be copied or reproduced by any mechanical, photographic, electronic or other method without prior written

consent of Keithley Instruments, Inc.

The KDAC500 software, including all files and data, and the diskettes on which it is contained (the “Licensed Software”), is licensed to you, the end user, for your own use. You do

not obtain title to the licensed software. You may not sublicense, rent, lease, convey, modify,

translate, convert to another programming language, decompile, or disassemble the licensed

software for any purpose.

You may: a) use the software on a single machine; b) copy the software into any machinereadable or printed form only for backup in support of your use of the program on the single

machine; and, c) transfer the programs and license to use to another party if the other party

agrees to accept the terms and conditions of the licensing agreement. If you transfer the programs, you must at the same time transfer all copies whether in printed or in machinereadable form to the same party or destroy any copies not transferred.

The KDAC500 software has been thoroughly tested and the documentation reviewed. However, Keithley Instruments, Inc. does not warrant that the KDAC500 software will operate as

described in this manual in every hardware and software environment. Further, Keithley Instruments, Inc. does not warrant the performance of the product for any particular purpose.

In no event is Keithley Instruments, Inc. liable for any damages resulting, directly or indirectly, from the use of this product.

Copyright (0) July 1989

Keithley Metrabyte/Asyst/DAC

Data Acquisition Division

440 Myles Standish Blvd.

Taunton, MA 02780

1-508-880-3000

All Keithley product names are trademarks or registered trademarks of Keithley Instruments, Inc.

Other brand and product names are trademarks or registered trademarks of their representative holders.

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Chapter 1

- Getting Started

WhatYouWillNeedtoRunKDAC500.. ...................................

InstallingKDAC500 ...................................................

Running the CONFIG Program

Methods of Creating a KDAC500 Program

Methods of R unning a KDACSOO Program

Operating more than One Data Acquisition System on a Single Computer

Initializing Hardware at Power-up with HARDINIT

...........................................

Chapter 2 - KDACSOO System Features

KDAC500 Memory Management

Background/Foreground ...............................................

Triggering ..........................................................

Engineering Units Conversion

Chapter 3 -

Brief Listing of KDAC500 Functions

General Considerations

CommandFormat

KDAC500 Functions

................................................

....................................................

.........................................

...........................................

.......................................

..................................

..................................

...........................

...........

1-3

1-5

l-19

l-29

l-35

l-37

l-39

2-3

2-7

2-11

2-19

3-3

3-5

3-9

Chapter 4 Appendix A Appendix B Appendix C -

Appendix D Appendix E -

KDACSOO Commands

Summary of KDAC500 Commands and Parameters

KDAC500 Error Messages

KDAC500 Function List

Engineering Unit Conversions

Running KDAC500/M Under the Microsoft QuickBASIC

Environment

Page 4

Upgrade Notes For

KDAC500 Version 1.4

Changes in KDACSOO Version 1.4

The following changes have been made in KDACSOO Version 1.4. This information collectively covers interpreter

and compiler versions of the software as noted.

Enhanced language support in KDAGOO/M - The following Microsoft languages are supported by

KDACSOO/M:

Microsoft

Microsoft

Microsoft

Microsoft

Enhanced language support in KDACSOO/B - The following Borland languages are now supported by

KDACSOO/B:

Turbo Pascal

Turbo Pascal

Turbo Pascal

Documentation changes - The contents of previous KDACSOO/B and /M addenda have been integrated into the

KDACSOO Compiler Manual. There is no additional documentation other than this manual.

NOTES ON TURBO PASCAL:

The Turbo Pascal Unit for Turbo Pascal 5.0 is named KDAC5OO.T50.

The Turbo Pascal Unit for Turbo Pascal 5.5 is named KDAC5OO.T55.

The Turbo Pascal Unit for Turbo Pascal 6.0 is named KDACSWTPU.

In order for Turbo Pascal to find the KDACSOO TPU files they MUST have a .TPU extension. If you are

using Turbo Pascal 5.x you should delete KDACSOO.TPU from your installed version of the software and

rename KDACSOO.TSx to KDACSOO.TPU. DO NOT delete KDACSOO.TPU from the distribution disks!

If you use the wrong version of TPU file the Turbo Pascal compiler will generate an error message and

will not be able to compile your program.

QuickBASIC 4.0

QuickBASIC 4.5

QuickPascal 1.0

C 5.0,5.1,6.0

5.0 Turbo

5.5 Turbo

6.0 Turbo

Microsoft Fortran 5.0

Microsoft BASIC P.D.S. 7.0

Microsoft BASIC P.D.S. 7.1

C 1.0

C 1.5

C+ + 1.0

The functional interface between all versions of Turbo Pascal is exactly the same. The format of the TPU

file is different, however.

KDACSOO 1.4 Upgrade Notes - 1

Page 5

NOTES ON TURBO C+ +:

Turbo C+ + 1.0 is supported by KDACSOO/B. However, the KDAC500 interface library is a C style

library and not a C+ + library. In order to prevent Turbo C+ + from “mangling” the KDACSOO function

names you will need to include the following statements when including the KDAC500 header file:

#ifdef cplusplus

extern Y? {

#endif

#include “kdac5OO.h”

#ifdef _cplusplus

1

#endif

Since Turbo C+ + is also a C compiler, you can create C programs using KDACSOO with the same library

file. The Turbo C+ + library tile for KDACSOO is named TURB05OO.LIB. The file TURB05OO.LIB is

used for all versions of Turbo C as well as Turbo C+ + .

NOTES ON MICROSOFT BASIC PDS:

KDACSOO Version 1.4 is compatible with the Microsoft BASIC Professional Development System Version

7.0 and 7.1 for operation under DOS only. KDACSOO will not run under OS/2 or Microsoft Windows.

Libraries are included on the KDACSOO/M diskettes to facilitate running KDACSOCI under the BASIC 7

QBX environment:

KDACQBX.LIB

KDACQBX.QLB

The file KDACQBX.LlB contains the object modules that make up the KDACSOO interface. The file

KDACQBX.QLB is a quick library for the QuickBASIC Extended (QBX) environment. These files are

NOT compatible with Microsoft QuickBASIC.

All BASIC 7.x modules that are compiled for use with KDACSOO must use FAR STRINGS. This means

that they must be compiled using the /Fs option. According to the BASIC PDS Programmer’s Guide, “If

you are linking new code containing far strings with older code containing near strings, you must recompile

the old code using the /Fs option. Otherwise the program will return an error message “LOW LEVEL

INITIALIZATION and terminate.”

NOTES ON MICROSOFT QuickPascal:

KDACSOO Version 1.4 is compatible with the Microsoft Quick Pascal Version 1.0. Every place that Turbo

Pascal is referred to in the Kdac5OO/M manual also applies to QuickPascal. QuickPascal is functionally

equivalent to Turbo Pascal. All the Language Syntax statements for Turbo Pascal also apply to QuickPas-

cal.

The support unit for QuickPascal is named KDACSOO.QPU. This file should either be in your working

directory (it will automatically be copied there during installation) or in the QuickPascal UNIT

directory.

KDACSOO 1.4 Upgrade Notes - 2

Page 6

CHANGES TO KDACSOO/I

The only significant changes in KDACSOO Version 1.4 apply to Borland Turbo Pascal support for

KDACSOO/B, and Microsoft Professional BASIC support for KDACSOO/M. The KDACSOO/I Version 1.3

manual, Revision C, also covers KDACSOO/I Version 1.4.

Changes in KDAC500 Version 1.3

The following changes have been made in KDACSOO Version 1.3. This information collectively covers interpreter

and compiler versions of the software as noted. The contents of the addenda for KDAC5OO/I and

KDACSOO/B/M differ slightly.

SUPPORT FOR THE WAVl MODULE (all versions) - KDACSOO V1.3 includes new commands for program-

ming the WAVl waveform generator module.

REVISED DOCUMENTATION -

Installation Section:

NEW INSTALL SECTION (all versions) - Previous addenda concerning the installation of KDACSOO

have been incorporated into a revised installation section for KDACSOO V1.3. Replace your existing

installation information with this new section.

“Methods...” Sections:

GENERAL NOTES, PLUS NEW INFORMATION FOR USING FORTRAN (KDACSOO/B/M only) The “Methods of Creating a KDAC500 Program” and “Methods of Running a KDAC500 Program” sections have been updated. Replace your existing pages with these new pages.

Command Section:

INTON (all versions) - Revised pages are included for the INTON command. Replace your existing

INTON pages with the new pages.

KDCLOCK (KDACSOO/B/M only) - A revised page for the KDCLCOK command is included for compiler versions of KDACSOO. The page includes an example for KDACSOO/M and QuickBASIC. Replace

your existing KDCLOCK page with this new page.

WAV and WAVSETUP (all versions) - New pages are included for the WAV and WAVSETUP commands. Insert these pages at the end of the KDACSOO command section.

KDACSOO/M EXAMPLE PROGRAMS NOW INCLUDED (KDACSOO/B/M only) - An application note and

examples covering programming with KDACSOO/M and Microsoft QuickBASIC 4.5 have been added to

the KDACSOO/B/M (compiler version) manual. This information also discusses running KDACSOO/M

under the QuickBASIC environment. Add these pages to the end of the KDACSOO command section.

ENHANCEMENTS IN CONFIG.EXE (all versions) - The WAVl now appears in CONFIG’s list of available

modules.

KDACSOO 1.4 Upgrade Notes - 3

Page 7

MICROSOFT BASIC 7 IS NOT SUPPORTED (KDACSOO/B/M only) - None of the Microsoft Professional

Development System BASIC Versions (6.0,7.0,7.1) are not supported for use with KDACSOO/M. You

can, however, use Microsoft Professional BASIC to perform low-level access to the Keithley hardware by

PEEKing and POKEing the data acquisition system command registers. In this case, KDACSOO is not

used.

TRIGGER/KDTIMER BUG FIXED (all versions) - A bug which prevented KDTIMER from waiting for a back-

ground trigger has been fried.

ANINQ BUG FIXED (all versions) - For multi-channel acquisition, the ANINQ command sometimes returned

incorrect data to the fust width in the data array. This has been faed.

PASSING PARAMETERS TO BASICA WORKS AS DOCUMENTED (KDACSOO/I only) - KDACSOO/I V1.3

now permits passing the BASIC interpreter start-up parameters such as number of files open, buffer size,

etc. These modifiers are added to the batch command used to start KDACSOO, e.g. “KDACSOO /F:5

/s:32”.

Changes in KDACSOO Version 1.2

The following changes were made in KDACSOCI Version 1.2. This information covers interpreter and compiler

versions of the software as noted.

KDACSOO/I EXAMPLE PROGRAMS NOW INCLUDED (KDAC5OO/I only) - The KDACSOO/I distribution dis-

kettes include several example programs which exercise most KDACSOO/I commands. The programs are

stored on both the 5 ” KDACSOO/I Library disk and the 3 ’ combined disk under the directory “EXAMPLES”. The programs are also listed in the KDACSOO/I manual (Rev. B or later) at the end of the command section.

SIMPLIFIED INSTALLATION (all versions) - The installation process now uses a single INSTALL.EXE tile to

copy files, test the system environment, and generate the necessary KDACSOO files. Previous KDAC500

versions used INSTALL.BAT and KINSTALLBXE to perform these functions.

NOTE: If you choose NM1 as the interrupt method, you must select and execute the NM1 Interlock Test.

On 2%-based (AT) computers, the NM1 Interlock Test will cycle the NM1 while displaying a window

showing test counts and remaining time. On SOS% and SO3%-based computers, INSTALL will set the

interrupt mask information, and then exit the test without exercising the interrupt test.

CHANGES IN THE INSTALL SCREEN (all versions) - The installation environment screen now shows the

speed determined for the master IBIN interface, rather than the system bus or clock speed. This information is for reference, and will not affect how you perform the installation. If the installation environment

screen shows a negative amount for system memory, you have insufficient memory to do an installation.

640k of system RAM is recommended. Abort INSTALL by pressing <Escape > . Check your DOS

AUTOEXEC.BAT and CONPIG.SYS files for resident programs or other memory users, and eliminate

as many as possible. Rerun INSTALL.

KDACSOO 1.4 Upgrade Notes - 4

Page 8

MORE ACCURATE ASSESSMENT OF PROCESSOR SPEED (all

versions) - The new installation program

more accurately determines the computer processor speed, particularly in faster 2% and 3&based

machines. KDACSOO has been tested on 25MHz 3%based computers, and should be compatible with

33Mhz systems as well.

INTERNAL CHANGES IN KINSTALLKIF AND CLKSPD.COM (all versions) - The installation “KIF’ file

includes new parameters which record additional diagnostic information concerning system timing. The

new installation is not compatible with KIF files from earlier KDACSOO versions. If you have an earlier

version of the software, do not install KDACSOO 1.2 in the same directory or you may mix old and new

files.

The structure of the CLKSPD.COM file in KDAC.500 V1.2 differs from CLKSPD.COM in older versions.

Information concerning the location of various operating parameters and variables within older

CLKSPD.COM files is not valid for the V1.2 CLKSPD.COM.

ENHANCEMENTS IN CONFIG.EXE (all versions) - The CONFIG.EXE file has been recompiled for greater

speed. The handling of some modules has been improved. Minor problems in CONFIG have been corrected.

Additional modules appear in the hardware set-up screen.

The AMMl module selection provides choices for AMMl or AMMlA.

The AIM3 module selection provides choices for AIM3 and AIM3A.

The single module designation “DIOl” covers both the DIOl and DIOlA.

IMPROVED HANDLING OF THE AIM3A IN CONFIG (all versions) - Previous versions of CONFIG permitted

the AIM3A to be assigned a cold-junction reference IONAME even though the AIM3A has no CJR or

channel 32. This could result in problems at run time. The V1.2 CONFIG program will no longer accept a

reference junction IONAME for the AIM3A. You may use an older CONFIG.TBL fde with KDACSOO

V1.2. However, any IONAMEs which reference channel 32 on an AIM3A will be ignored.

A bug affecting KDACSOO’s recognition of IONAMEs for the AIM3A has been fued.

CHANGES IN THE HANDLING OF THE TRGl MODULE IN CONFIG (all versions) - Two changes have been

made in how CONFIG handles the TRGl module:

Fist, KDACSOO V1.2 treats the TRGl module as an analog module. Previous KDACSOO versions treated

the TRGl as a digital module because of the TRGl’s digital trigger output signal.

If you are using a TRGl with KDACSOO V1.2, you must reinstall the module in CONFIG, and recreate the

TRGl IONAMEs. You may use an older CONFIG.TBL file with KDACSOO V1.2. However, any IONAMEs

which reference a TRGl will cause an error message when KDINIT is executed.

Second, the TRIG1 module can now be used as a single channel of differential analog input. Set up an

IONAME which references the TRIG1 input channel, and then include the IONAME in an analog input

command. The IONAME can include the following set-up parameters:

KDACSOO 1.4 Upgrade Notes - 5

Page 9

Local gain of xl or x10. Default = xl.

Global gain of xl, x2, x5, or x10. Default = xl.

AC or DC coupling. Default = DC.

Filter of 3OOHz - 1Mhz. Default = 1MHz.

ENHANCEMENTS TO INTON (all versions) - The INTON command now accepts Hertz (HZ) and millihertz

(MILHZ) as time units. The legal ranges are O-65535 Hertz and O-65,535 millihertz. The maximum achievable rate on a 3%-based computer is approximately 6,OOOHz; slower on 2% and XT type systems. Specifying

too high an interrupt rate may lock up the computer.

IMPROVED ACCURACY FOR TEMPERATURE CONVERSIONS (all versions) - In KDACSOO Vl.2, tempera-

ture EUF routines dynamically select temperature conversion constants based on thermocouple and

reference junction output voltages.

FIX IN GRAPHIC OVERLAYS (all versions) - When two identical graphics commands were issued consecutively

in a program, the second graphics command might not produce a graph. For example, if HGRAPHRT commands were called in two consecutive program lines, only the first HGRAPHRT would plot a graph. This

problem has been corrected.

BACKING UP YOUR KDACSOO DISKE’ITES (all versions) - If you need to make back-up copies of the original

KDACSOO diskettes, do so with the DOS DISKCOPY command. Using a simple DOS COPY or XCOPY

command produces backups which will not function correctly when INSTALLEXE is executed.

KDACSOO 1.4 Upgrade Notes - 6

Page 10

Updates and Errata

Please observe the following notes, errors, and updates pertaining to the KDACSOO manual.

Chapter 1, Getting Started:

1. * New Installation Section (all versions) - integrates all previous changes to the installation procedure into

a new replacement installation section for the manual.

2. * Methods of Creating a KDAC500 Program (KDACSOO/B/M only) - additional instructions have been

included for programming with Microsoft FORTRAN. These are contained in a new replacement section

for the manual.

3. * Methods of Running a KDACSOO Program (KDACSOO/B/M only) - notes and changes have been

included in a new replacement section for the manual.

Chapter 2, “Engineering Units Conversion” (KDACSOO/I only):

1. The Engineering Unit Flag for LVDT/RVDT sensors under KDACSOO/I is “C.AIM9.D” rather than

“CXM9D” which is shown in the KDACSCMl/I manual.

Chapter 4, “KDACSOO Commands” (all versions):

1. ARLOAD - A dummy string (up to 255 characters) must be created for the array name prior to running

ARLOAD. If the actual array name is shorter than the dummy string, the resulting array name will be

padded by spaces, with length equal to that of the dummy string.

For example, if the dummy name is defined as ARN$ = SPACE$(12) and the actual name is “DATA%“,

ARN$ will equal “DATA%” plus 7 spaces ( “DATA%

2. ARGET/ARPUT - The ION$ parameter takes precedence over the WID% parameter. To identify a par-

ticular data set by its width parameter, set the ION$ parameter to “’ (two adjacent double quotes).

3. ARSAVE - The legal time units for ARSAVE now include HZ and MILHZ. If the file is saved in one of

the non-KDAC data formats using HZ or MILHZ as the time base, the time units column in the output file

will be represented as fractions of a second.

4. ARSTATUS - A dummy string (up to 255 characters) must be created for the array label prior to running

ARLOAD. If the actual array label is shorter than the associated dummy string, the resulting array label will

be padded by spaces, with length equal to that of the dummy string. See ARLOAD command information

listed above for similar requirements concerning the array name.

’ ) after the ARLOAD.

KDACSOO 1.4 Upgrade Notes - 7

Page 11

5. INTON - The fast data point acquired after INTON is issued will be taken after the specified interrupt

period has elapsed.

6. KDCLOCK - Data returned for the year consists of four digits, e.g. “1990” rather than “90”.

7. KDINIT - a DIOlA module and the digital section of a Model 575 will be initialized as follows when

KDINIT is called: Ports A and B to logic 0; ports C and D to logic 1.

8. BGREAD and ARGET - If you intend to apply engineering units conversion, you should not mix

IONAMEs for different types of modules (e.g. AIM7 and AIMS) in the same BGREAD command. This will

cause the data from both types of modules to be stored in one KDACSOO array. When you issue an ARGET

command with engineering units conversion, an error will be generated. Separate BGREAD commands

should be used. If you plan to work exclusively in A/D counts or voltage, this limitation does not apply.

9. TRIGGER - The CHM parameter in the KDACSOO manual shows the values “OFF” and “ON” for digital

input. For interpreter BASIC and QuickBASIC only, these should be “OFF.” and “ON.”

10. KDCLOCK - The last line of the TIME%() parameter shows “Time%(50 year....“. This should read

“Tie%(S) year...“.

11. FGRE+AD - The RANGE$ parameter shows W.READ_RESET” and “P2.READ ONLY” for pulse

reading modes with PIMl and PIMZ. Correct syntax for BASICA and QuickBASIC is’P2.READ.RESET”

and “P2.READ.ONLY”.

Appendix A, “Installation of KDAC500/1 on a Dual 360K System” (KDACSOO/I only):

1. Under Step 3, Item 3 - KINSTALL.EXE is now INSTALL-EXE.

2. Under Step 4, Item 2 - KINSTALL.EXE is now INSTALLEXE.

KDACSOO 1.4 Upgrade Notes - 8

Page 12

Introduction

Welcome to the world of workstation data acquisition and control with Keithley’s KDAC500,

and thank you for selecting a Keithley product.

WHAT IS KDACZOO?

KDAC500 is a family of software products for data acquisition and control using Keithley’s

5OOA, 5OOP, 575 and 570 Measurement and Control Systems and IBM, Compaq, or 100% compatible personal computers. The KDAC500 family consists of the following individual packages:

KDAC500/1- an interpreter-based version which runs under Microsoft GWBASIC, IBM Advanced BASIC (BASICA) and Compaq Advanced BASIC. KDAC500/1 is bundled with certain Keithley hardware.

KDAC5OO/B - a compiler version of KDAC500 which runs under Borland’s Turbo C and

Turbo Pascal. KDAC500/B is available as an option.

KDAC5OO/M - a compiler version of KDAC500 which runs under Microsoft’s C, QuickC,

Quick Pascal, QuickBASIC, and FORTRAN. KDAC5OO/M is available as an option.

Each package adds a number of new commands to its respective compatible language. Since

KDAC500/1 runs under BASICA, it provides an easy, entry-level approach to data acquisition programs under a language that is well-known and widely used. KDAC500/B and

KDAC5OO/M provide an easy migration path for users who wish to upgrade from BASICA

to faster, more structured compiler languages.

USING THIS MANUAL

In this manual you will find a complete description of the KDAC500 software package. This

manual does not duplicate information in the computer hardware documentation or programming manuals except where necessary to explain specific features of KDAC500. This

manual will not teach you how to program. If you need more help with programming, consult your local bookstore. There are numerous books available on programming languages

and personal computers.

Many users of KDAC500/B and KDAC500/M will have had experience programming in

Soft500, Quick500, or KDAC500/1. While these products are similar to KDAC500, there are

important differences. This manual will make occasional reference to older software packages

in order to call out some of those differences, and, hopefully, eliminate points of confusion for

the user who is converting to KDAC500/B or KDAC500/M. If this is your first experience in

programming for Keithley’s data acquisition systems, these comments will not concern you.

i

Page 13

The first three chapters of this manual provide a quick introduction to the KDAC500 software, and cover topics such as installation, creating the hardware configuration table, running KDAC500, etc. Chapter 4 includes a description of KDAC500 commands and an explanation of how each command is used. The commands are referenced alphabetically, and a list

of all KDAC500 commands is included in the Appendix section. We recommend that you

read your compiler manual and the Keithley KDAC500 manual before you begin installation

and programmin g.

Later, you can return to specific sections of the appropriate manual for

more careful study. After a while, most users of KDAC500 will only need to use the command reference section for finding the command, format, and the parameters to use with

KDAC500 commands.

Some Typographical Conventions

1. In this manual, ah KDAC500 command parameters and reserved words are given in upper case characters. Quoted strings, remarks and data statements will remain in the form

input by the programmer.

2. Any items enclosed by square brackets [...I are optional. However, none of the KDAC500

commands contain options within their parameter lists.

3. The characters “<‘I and ‘I>” delimit keystroke combinations, or file names which you

must include as part of a keyboard entry. The “<” and ‘I>” marks themselves must not be

entered. Examples include:

<ct.&c>

<Enter>

<Ctrl-Ah-Del>

<filename.ext>

<configuration table file name>

4. Any other punctuation that appears in the KDAC500 command format line must be entered as shown. However, there is some flexibility in the delimiters used to separate parameters in a KDAC500 list. Valid delimiters are commas, spaces and tabs.

Page 14

CHAPTER 1

Getting Started

What You Will Need to Run KDAC500

Installing KDAC500

Running the CONFIG Program

Operating Modes for KDAC500

Methods of Creating a KDAC500 Program

Methods of Running a KDAC500 Program

Operating more than One Data Acquisition System on a Single

Computer

Initializing Hardware at Power-up with HARDINIT

Page 15

What You Will Need to Run KDAC500

You will require the following items to install and run KDAC500:

DOS

You should have a DOS version which is approved by the manufacturer for use with your

computer. Keithley recommends IBM PC-DOS 3.1 or later for IBM computers, Compaq DOS

3.0 or later for Compaq computers, and a manufacturer-approved version of MS-DOS 3.0 or

later for compatibles. All versions of MS-DOS are not alike. A version which is optimized for

use on one compatible may not operate properly on another. Versions of DOS earlier than the

recommended versions may cause problems and should not be used.

COMPUTER

The KDAC500 Software System was developed to run on IBM PC, XT, AT, and PS/2 computers, Compaq computers, and most compatibles. The INSTALL program used with KDAC500

performs an in-depth analysis of the computer, DOS, RAM workspace, and other hardware

parameters. INSTALL then creates batch files named KLOAD.BAT and KRUNBAT, and a

CLKSPD.COM file customized for the hardware environment. If INSTALL cannot accommodate the hardware, it will abort the installation process and issue an error message. If this

happens, contact the Keithley DAC applications department for assistance.

Your computer should have 640K of random access memory (RAM). A smaller RAM space

will detract from the amount of data that can be acquired. Since you will also be running a

compiler, make sure that your RAM space is also sufficient for that purpose. KDAC500 will

not run on a system which has less than 512K of RAM. KDAC500 will not take advantage of

L&l/EMS expanded memory or extended memory.

Your computer should have a fixed disk KDAC500 Compiler versions must be installed with,

and have ready access to, the compiler you’ve chosen. The total storage space for a typical

installation of KDAC500 plus compiler may be three megabytes or more. It is not realistic to

operate these packages from floppy-based systems.

To take advantage of the graphics capabilities of KDAC500, your computer should have a

suitable graphics adapter. This adapter may be an IBM Color Graphics Adapter, Hercules

Color Card, IBM Enhanced Graphics Adapter, IBM Video Graphics Array, or 100% equivalent. If the adapter is non-IBM, it must be 100% compatible with its IBM counterpart. Compaq

portable computers and some Compaq desktop machines have a built-in combined text-andgraphics adapter. This is also suitable for displaying KDAC500 graphics.

Some standard color graphics adapters have an NTSC composite color output which will display graphics (without color) on a composite input monochrome monitor. These adapter/

monitor combinations are also suitable, although some adapters may translate certain color

combinations into invisible or unreadable monochrome shades. Monochrome adapters can be

used with KDAC500, although they will not support graphics. This includes Hercules (mono-

chrome) Graphics cards and similar monochrome graphics cards.

l-3

Page 16

Graphics adapters which require special driver programs, or which make non-standard use

of the computer’s non-maskable interrupt (NMI) will cause problems when KDAC500 is run.

A math coprocesser chip for the computer is optional. It will improve the speed of execution

of some KDAC500 commands, notably the commands which manipulate KDAC500 arrays

and do engineering units conversions. Compilers often take advantage of coprocessors, and

will deliver various performance improvements.

Page 17

Installing KDAC500

Follow these instructions to in&ill the KDAC500 software on your computer system. These

steps cover all versions of KDAC500, including the interpreter and compiler versions. The

references to BASICA or GWBASIC concern installation of the interpreter version only, and

are noted as such where they appear. Reference to compilers concern only the /B and /M

versions.

Install the Keithley Data Acquisition Interface Card

Installation of the KDAC500 software is a dynamic process which actively checks various parameters within the computer. If you have not done so already,,open your computer and in-

stall your IBIN-A, IBIN-IS/Z, or System 570 interface card. Be sure to note all CAUTIONS

and WARNINGS for relevant safety information. If necessary, get a technician to assist you.

1

A

WARNING: UNPLUG ALL POWER CORDS TO THE COMPUTER AND DATA AC-

QUISITION HARDWARE BEFORE YOU ATTEMPT INSTALLATION.

KDAC500 is normally shipped as two 5-l /4”, 360K diskettes and one 3-l/2” 720K floppy

diskette. One of the 5-l/4” diskettes is labeled “Program Disk” and the other is labeled “Library Disk”. Both volumes are combined on the single 3-l/2” disk. The KDAC500 diskettes

and software manual contain all the support needed to make full use of your Keithley data

acquisition hardware.

The following instructions presume the use of 5-l/4” KDAC500 distribution diskettes unless

otherwise noted. References to 720K or 1.4M diskettes as drives A: or B: presume that your

computer’s standard A: or B: drives are 3-l /2” units.

You should not use the original KDAC500 diskettes for day-to-day operations. Install

KDAC500 on to another floppy diskette or hard disk as described below, If you anticipate

doing several installations, make and use a backup copy of the originals. In any case, store the

originals in a safe place.

You should use the DOS version recommended for your computer, but no version before

DOS 3.1 for IBM systems, DOS 3.0 for Compaq, or DOS 3.0 for compatibles running Microsoft

DOS.

The Installation Files

Installing KDAC500 involves running “INSTALL.EXE”. INSTALL.EXE may use other support files on the KDAC500 diskette set. The INSTALL.EXE file copies the necessary files to

destination disk, then configures the software.

the

1-5

Page 18

Pre-installation

Before you begin the actual installation of KDAC500, make sure that any other computer configuration or memory-resident software has been installed and is operating properly.

KDAC500 can coexist with many other types of programs, but compatibility problems may

occur with some programs.

When you install KDAC500, you will specify an amount of system memory to be used for

data. T,his memory will be allocated when you run KDAC500. If you add memory resident

software to your operating environment after you have installed KDACSOO, you may have

insufficient memory left to nm KDAC500 with the designated array space. Keep track of

memory usage if you add memory-resident programs to your system, and reinstall KDAC500

if necessary.

Turn on your computer and load DOS.

Installations on Computers with Multiple Processing Speeds

Some computers have switchable CPU clock speeds. If your computer has a switchable CPU

clock speed, perform data acquisition only at the CPU clock speed which was set at the time

of installation.

Advanced BASIC (KDAC/I Only)

During installation of KDAC500/1, you will be prompted for the name and location of your

Advanced or GW-BASIC interpreter file. At that time, enter the disk drive letter, path (if any),

and complete filename of the BASIC interpreter. During installation, BASIC must be where

you specify or you will receive an error message.

Approved Compilers (KDAC/M and /B Only)

The KDAC500/B and KDAC500/M packages are designed to run under any of several approved compilers. The “/B” package is designed for Borland Turbo C and Turbo Pascal,

while the “/M” package is intended for Microsoft C, QuickC, QuickBASIC, Quick Pascal, and

FORTRAN. The supported revisions include:

KDAC500/B

Borland Turbo C Version 2.0

Borland Turbo Pascal

KDAC500/M

Versions 5.0 and 5.5

l-6

Microsoft C: Versions 5.0 and 5.1

Microsoft Quickc: Versions 1.0 and 2.0

Page 19

Microsoft QuickBASIC: Versions 4.0 and 4.5

Microsoft Quickl%scah Version 1 .O

Microsoft FORTRAN: Version 5.0

Earlier versions of these products are not supported and should not be used. Borland Turbo

BASIC is also not supported.

Support for other compilers will be added from time to time. If you are considering a compiler or version other than those listed, please call Keithley DAC for more information. The

KDAC500 packages do not include the compiler. You are free to purchase an approved compiler package for the language you desire.

Note that the installation for each of the various compilers may involve specialized path parameters, environment variables, library directories, or other special configurations needed

by the compiler. Make sure that your compiler is installed and operating properly before you

attempt to run KDAC500. Ideally, your system path, directories, and environment variables

should be organized such that you can run your compiler while working in the KDAC500

directory. See your compiler manual for more information on installing the compiler.

Disk Preparation

Most personal computers share one of a relatively few disk drive configurations. The drive

configuration will dictate which drive receives the installation, and which drive serves as the

source.

Installing KDAC500 requires two disk drives. The drive receiving the installation should be a

fixed disk, or a 720K, XXVI, or l&I floppy drive. The diskette drive holding the KDAC500

product diskette may be any type.

Depending on the compiler, KDAC500 may be run from a fixed disk or a high-capacity

floppy disk drive such as a 720K, 1 Z&I, or 1.4M drive.

Running KDAC500/1 from two 360K floppy diskette is not recommended. However, an installation for dual 360K floppies is outlined in the Appendix section of the KDAC500/1 manual. A single 360K floppy does not have enough room for a working copy of KDAC500.

For KDAC500/B or /M, note that some compilers require a fixed disk because floppy disks

do not have enough room

Installing to a High-Capacity Floppy Diskette (KDAC50011, only)

These instructions assume that you have a 1.2M or 1.4M diskette drive as A: and any type of

drive as B:. If your high capacity diskette drive is Drive B: rather than A:, switch the A: and B:

designations in the following procedure.

l-7

Page 20

These instructions also assume that you are installing KDAC500/1. Compiler versions plus

the required compiler will not fit on one floppy disk.

The HC diskette which receives KDAC500 must be formatted and should also be bootable.

KDACSOO may also be installed to a non-bootable floppy diskette. Doing so will save the

space on the diskette normally taken by the DOS system files at the expense of operating convenience. To format without copying the system files, omit the “/S” option.

To format a HC floppy diskette, place the blank HC diskette in the HC drive A: and your

DOS diskette in drive B:. Make B: the default drive and run FORMAT:

B: <Enten

FORMAT A: /S <Entee

Unless told otherwise, FORMAT assumes that a diskette formatted in a HC drive is a high-capacity diskette. The system will format the diskette in drive A: and copy over the DOS system

files.

Install KDACSOO/I in its own directory on the HC diskette. When you run INSTALL, the desired target directory will be created automatically if it does not already exist.

Replace your DOS diskette in Drive B: with the KDAC500/1 Program Disk and continue with

the section ‘The INSTALL Environment”.

Installing KDACSOO on a Fixed Disk

Normally, the bootable fixed disk on a personal computer is drive C:. If you have two fixed

disks, or if your disk is divided into ‘logical” drives, you may also have drives D:, E:, F:, etc.

KDAC500 may be installed on any drive.

Fixed disk installation is recommended for all versions of KDAC, and provides maximum

convenience.

You should install KDAC500 in a separate directory on the fixed disk. When you run INSTALL, the desired target directory will be created automatically if it does not already exist.

Place the KDAC500 Program Disk in Drive A: and continue with the section ‘The INSTALL

Environment”.

The INSTALL Environment

l-8

The INSTALL program initially checks the computer hardware and then generates an information screen with pull-down menus (see Figure l-1). The INSTALL environment will

Page 21

prompt you for information. Some responses will require that you enter alpha or numeric

characters, while other responses will be simple menu selections. In both cases, the available

entries will be obvious or self explanatory. Figure l-2 is a map of the installation process. Interpretive BASIC will appear only for KDAC500/1.

Modify New Save Load Config Wit

Allows user to modify displayed parameters.

Keithley DAC KDACSDD Installation

Array Space / Maximun Size:

Master IBIN Timer Speed:

Machine Type:

Processor Type: 80286

RTMDS Graphics: Disabled

Interface Board(s):

IBIN Address

cff8H

KDACSOO Uorking Directory:

C:\KEITHLEY\

Interpretive BASIC:

C:\DOS\BASICA.CW

IBM AT or compatible

CONFIG File Name

-*-

CONFIG

Figure l-l. Main Installation Screen

I

64K / 182K

1.00 MHz

(int lev = NMI)

(ni mask = 08)

(NM1 interlock fix OFF)

l-9

Page 22

r

1

Modify

I

New

(Restart INSTALL

at @%heck System"

I

(Write .BAT Files to Disk)

(Write .KIF File to Disk)

INSTALL Dnodifiersl

(Copy'Files)

(Check System1

Specify Name‘of BASIC (2)

I

I

Save

I

I

LOi

ad Config Quit

I

I I

I

(Run CONFIG.EXE) (End INSTALL)

Specify harduare (Auto reboot

configuration and if NM1 Interlock

IONAMES was detected)

I

I I

I

t Specify

array space (Load .K

F from Disk)

I

k RTM Graphics -,- Enable/Disable rtm

k Select Display (3) , CGA

/-- Specify Address L Select Display Size

c Interface Card(s) -I- Add - Specify address - (Check for card)

k Delete -

I

I

I

l- Change BASIC (2)

NOTES:

1.

Processes in parentheses ( ) are performed by the installation software.

2.

KDACSOO/I interpreter version, only. BASIC interpreter name may be respecified through the

Whange BASIC@@ option.

3.

Installation automatically determines type of primary display, and will show WNKND~JN~~ if

display type is not recognized. VGA is not cospatible with RTM card.

4.

IRQ is set only for the first interface card. IRP9 on an AT = IRQ2 on a PC/XT.

5.

Must be performed by user if NW has been selected. See manual for details.

6.

Hay also be modified manually.

/- Modify CONFIG

II

- Set IRP Level (4)

c

+ Clock

k9or2 L (Set NM1 Interlock Fix ON/OFF) (6)

t:

-,- 400 x 200 E

400 x 350 t_

+

640 x 200 L

+

640 x 350

L

Select address

NMI I Test for NM1 interlock (5)

k (Set NM1 Reset Mask) (6)

:::

VGA (3)

Unknown

I

l-10

Figure 1-2. Main Install Map

Page 23

Running Install

The simplest method for running INSTALL is to make the floppy diskette holding the

KDAC500 distribution diskette the default, and then execute “INSTALL” at the DOS command line.

If you are using the 5-l/4” diskettes, insert the diskette marked “Program” into the disk

drive. Later, INSTALL will prompt you to change to the “Library” diskette. The 3-l/2” diskette contains all the KDAC500 Program and Library files, and will not require a disk change.

The floppy disk volumne will typically be A: or B:. Change to the appropriate drive and run

INSTALL:

A: <Enter>

INSTALL <Enter>

The INSTALL program wilI respond with the following screen. If the source and destination

are correct, press <Enter>. If not, chang ‘9”’ to “N” and press <Enter>. You will then have an

opportunity to change the source and destination.

Data Acquisition & Control Install C2.00)

The Source Drive is: A:

The Destination Path is: C:\KEITHLEY\

1 Is this correct? (Y/N) fYl,l[

Setup

KDACSOO Installation Screen

When you accept the indicated setup, the INSTALL program will copy the files from the

KDAC500 diskette(s) to the target, and then run the remainder of the installation program.

Proceed to the next section “Modifying the Installation Parameters”.

l-11

Page 24

You may specify the source and destination for the installation as part of the INSTALL command line. If you elect to use this method, you should specify source, destination, and direc-

tory on the INSTALL command line. The following optional syntax may be used:

NOTE: You must leave a space between all items entered in the INSTALL command line or

the installation will not be completed properly.

Make the drive holding the source diskette the default drive.

A: <Enter>

Enter the INSTALL command. The optional format is:

INSTALL <Source Drive7 [Destination Drive [Destination Path]]

where:

<Source Drive> is the drive containing the KDACSOO diskette (A:, B:, etc.). Source Drive

is required.

[Destination Drive] is the drive to which KDAC500 will be installed (C:, D:, etc.) Destina-

tion Drive is optional. If it is omitted, “C:” will be assumed.

[Destination Path] is the path to KDAC500. The path name must begin with the “\‘I backslash. Destination Path is optional. If it is omitted, KDAC500 will be installed to directory

KEITHLEY off the root directory of the destination drive.

If you want to install to a root directory, use “\” as the destination path. This is not recommended for fixed disks, but may be desirable for a floppy disk installation.

If this is a floppy disk installation with the destination in drive A: and the source in Drive B:,

you can start the installation with the command:

INSTALL B: A:

If this is an installation to the root directory of a floppy disk in drive B: and the source is

Drive A:, start the installation with the command:

INSTALL A: B: \

Entering the Name and Path of Interpreter BASIC (KDACII, only)

For an installation of KDAC500/1, INSTALL will ask you for the name and location of your

BASIC interpreter. Typical names are BASICA.COM, BASICA.EXE, GWBASIC.EXE and GW-

l-12

Page 25

BASICEXE. Specify the drive letter, complete path, and complete BASIC filename, then press

<Enter>. The installation will check your version of BASIC, during which the computer

screen will briefly go blank.

Modifying the Installation Parameters

SELECT “MODIFY” FROM THE PULL-DOWN MENU: After you have specified the name

and location of your BASIC interpreter, you will see the screen in Figure 2-1. If the menu is

not visible, it can be invoked by pressing the cEso key.

Once visible, any menu choice can be invoked by using the cursor keys to move the cursor to

the desired choice, and then pressing <Enter>. You may also press the first letter of the menu

word.

Select MODIFY - The cursor will drop down into the information screen and let you change

selected installation parameters. You may change any or all of the following items.

ARRAY SPACE - The Array Space line shows the following information:

Array Space / Maximum Size

“Array Space” shows what you have specified for the desired array workspace. “Maxi-

mum RAM” is a suggested maximum amount of RAM available for data arrays.

NOTE: For KDAC500/1, the suggested maximum is based on the sizes of IBM PC-DOS

3.3, GWBASIC 3.2, and the KDAC500 software. Your DOS and BASIC versions may require slight adjustment of the suggested maximum. Under some circumstances, you may

enter more than the suggested RAM size.

NOTE: If you specify too large an amount of RAM, you will receive an error message

when you run KDAC500, or run into other problems. For a first installation, it is best to

select a small array memory size, e.g. 64k for KDAC500/1, or 8-16k for a compiler version.

After you become familiar with the software, you can change the memory size.

Select ARRAY SPACE and press <Enter>. A box will appear on the screen, Type the size

of the array space you want and press <Enter>.

RTM GRAPHICS - If you have an RTM (Dataq WFS-200) waveform scroller card installed in your computer and would like to use it for KDAC500 graphics, select RTM

GRAPHICS and press <Enter>.

ENABLE/DISABLE - to enable use of the RTM card, move the cursor to this choice

and press <Enter>. The feature will toggle on or off. RTM cannot be enabled if the

detected monitor adapter is VGA.

l-13

Page 26

SET DISPLAY TYPE - move the cursor to this option and Press <Enter>. Select the

type of monitor you will be using with the RTM (Dataq) WFS-200 waveform scroller

card. VGA video is not compatible with the WFS-200.

ADDRESS - select this option and press <Enter>. Type the hardware address of the

RTM card as installed in your system (see the RTM manual for more information)

DISPLAY SIZE - select this option and press <Enter>. Move the cursor to the desired display size and press <Enter>. The only valid choice if you are using a CGA

card with the RTM card is 640x200. Note messages on the INSTALL screen for more

information.

INTERFACE CARD(S) -You must specify the address of each Keithley hardware

interface board installed in your computer. If you do not specify a hardware interface, the software will not be able to access the data acquisition system connected to

that interface card. Select INTERFACE CARD(S) and press <Enter>.

NOTE: If you are installing to a ES/2 with Microchannel bus (I’S/2 Model 50,60,70,

and 80), the only parameter you may change under INTERFACE CARD(S) is “MODIFY CONFIG”. The interrupt is set as part of the hardware installation using the ES/2

Reference Diskette.

ADD - Selecting “INTERFACE CARD(S)” when there are no cards shown will automatically move to “ADD” and prompt you for an address. For additional interfaces,

select ADD and press <Enter>.

You will be prompted for the first two characters (in hexadecimal) of the boards address. For example, if a board is installed at address CFF80 (hex), you would enter

“CF’.

After you add the first card, the menu moves directly to the “SET INTERRUPT

LEVEL” option.

Repeat the ADD step for each interface installed in your computer,

DELETE - to remove a board from the configuration, select DELETE and press <Enter>. Use the cursor keys to select the board for deletion and press <Enter>. Repeat

this step for each interface you want to remove from the configuration process.

MODIFY CONFIG - The default name of the configuration table file for the first in-

terface you identify is “CONFIG.TBL”. Additional boards will be named “CONFIGlTBL”, “CONFIG2.TBL”, etc. To specify a different name, select MODIFY CONFIG and press <Enter>. Use the cursor keys to select the name to be changed and

press <Enter>. Type the desired name and press <Enter>.

1-14

Page 27

SET INTERRUPT LEVEL - This option selects a hardware interrupt within the PC

which will be used to control background (timed) data acquisition. The choices, in

order of system priority, are “NMI”, ” CLOCK”, 9,3, and 5. NMI is the computer’s

non-maskable (highest priority) interrupt. CLOCK is the computer system clock. If

you are using an 8088-based PC or XT, Level 9 corresponds to IRQ2 in the PC.

NM1 is the suggested method, but may not be compatible with all types of PC hardware. Specifically, the NMI is used by some video adapters and by 80386 systems operating in virtual 8086 mode. These systems will conflict with KDAC500 if it also attempts to use the NMI.

NOTE: For non-Microchannel computers, you must select an interrupt method as

part of the installation. If you do not select an interrupt system, operating errors will

result when you run KDAC500.

Move the cursor over the desired choice and press <Enter>. If you select “NMI”, you

will receive a submenu with the following choices:

TEST FOR NMI INTERLOCK - This choice will check the computer microprocessor for compatibility with use of NMI and Keithley interface, and then install

the NMI as the interrupt system for KDAC500.

SET NMI RESET MASK - The previous option “TEST FOR NMI INTERLOCK”

will normally set this parameter automatically if it is required. This option should

not normally be selected unless an installation problem requires you to manually

adjust an installation’s parameters. The NMI RESET MASK sets up an installation parameter which helps determine the software’s use of the computer’s nonmaskable interrupt.

NMI INTERLOCK FIX ON/OFF - The option “TEST FOR NMI INTERLOCK’

will normally set this parameter automatically if it is required. Some early 80286

microprocessors have an internal problem which causes background data acquisition to spontaneously abort. NMI FIX will correct the problem through soft-

ware. NMI fix also disables the system clock, so BASIC commands such as

“TIMER” will not work when the NMI fix is in place.

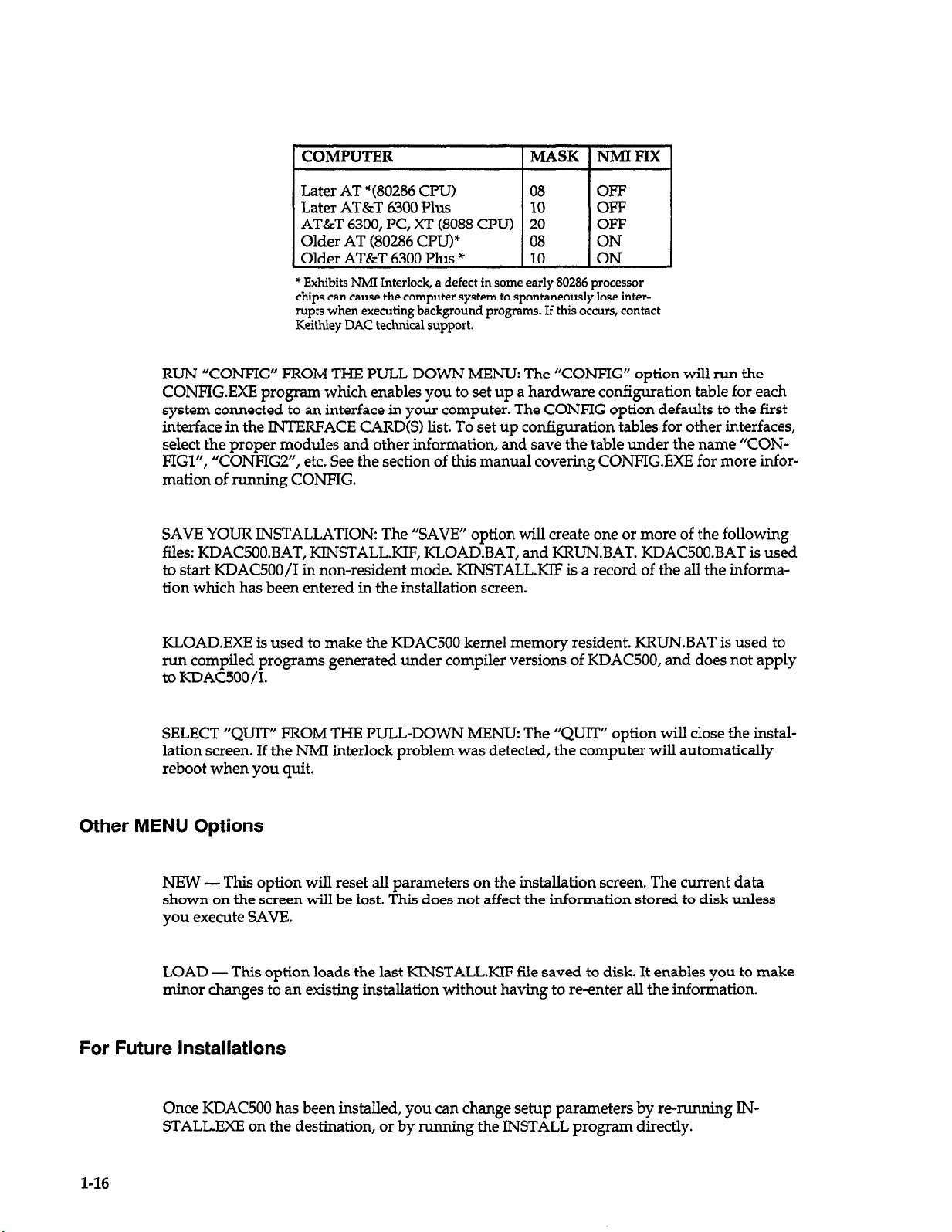

CAUTION: You should not change the NM1 RESET MASK or NM1 FIX unless

you have experienced trouble with the installation, and have been instructed

by Keithley DAC technical support to do so. The following chart is for refer-

ence only.

NOTE: If the NMI interlock is detected on your computer, you may also choose

CLOCK or Level 9,3, or 5.

l-15

Page 28

1 COMPUTER IMASK INMIFIX]

* Exhibits NMI Interlock, a defect in some early 80286 processor

chips can cause the computer system to spontaneously lose interrupts when executing background programs. If this occurs, contact

Keithley DAC technical support.

RUN “CONFIG” FROM THE FULL-DOWN MENU: The “CONFIG” option will run the

CONFIG.EXE program which enables you to set up a hardware configuration table for each

system connected to an interface in your computer. The CONFIG option defaults to the first

interface in the INTERFACE CARD(S) list. To set up configuration tables for other interfaces,

select the proper modules and other information, and save the table under the name “CONFIGl”, “CONFIG2”, etc. See the section of this manual covering CONFIG.EXE for more information of running CONFIG.

SAVE YOUR INSTALLATION: The “SAVE” option will create one or more of the following

files: KDAC500.BAT, KINSTALLKIF, KLOAD.BAT, and KRUN.BAT. KDAC500.BAT is used

to start KDAC500/1 in non-resident mode. KINSTALLKIF is a record of the all the information which has been entered in the installation screen.

KLOAD.EXE is used to make the KDAC500 kernel memory resident. KRUN.BAT is used to

run compiled programs generated under compiler versions of KDAC500, and does not apply

to KDAC500/1.

SELECT “QUIT” FROM THE PULL-DOWN MENU The “QUIT” option will close the instal-

lation screen. If the NMI interlock problem was detected, the computer will automatically

reboot when you quit.

Other MENU Options

NEW - This option will reset all parameters on the installation screen. The current data

shown on the screen will be lost. This does not affect the information stored to disk unless

you execute SAVE.

LOAD - This option loads the last KINSTALLKIF file saved to disk. It enables you to make

minor changes to an existing installation without having to re-enter all the information.

For Future Installations

1-16

Once KDAC500 has been installed, you can change setup parameters by re-running IN-

STALL.EXE on the destination, or by

running the INSTALL program directly.

Page 29

The syntax for the INSTALL command is:

INSTALL 1 -f I [ -mono I [ -rtm<display_area><wfs_200_address> ]

Any or all the modifiers may be used.

Details on the INSTALL command line modifiers are as follows:

-f

-mono

-RTM

The “-f” modifier tells KINSTALL to automatically load and use the set-up

information in the KINSTALLKIF file, rather than rechecking the system.

This option will permit you to modify parts of an installation without having

to re-enter all the information..

The “-mono” modifier selects monochrome output. Normally, the program

is able to sense what type of display adaptor the computer has and adjust the

display accordingly. Where a composite monochrome monitor is being

driven by a CGA, the color pallet is translated into various shades and patterns which may be unreadable under some circumstances. In these cases the

-mono modifier overrides the sensing of a display adaptor and improves the

readability of the screen.

The “-RTM” modifier can be used to specify all the set up information for the

RTM (Dataq WFS-ZOO) waveform scroller card. The full syntax for the RTM

modifier is:

-rtmcdisplay_area><wfs-ZOO_address>

There are four possible values for the display area:

LL = 400 pixels horizontal x 200 pixels vertical

HL = 640 pixels horizontal x 200 pixels vertical

LH = 400 pixels horizontal x 350 pixels vertical

HH = 640 pixels horizontal x 350 pixels vertical

The KINSTALL.KIF File

When you write an installation to disk with SAVE, a file named “KINSTALL.KIF” is also

written to disk. This file is a record of the information entered in the installation screen. This

information is valuable when you contact the applications department for help.

When operating on a CGA the only valid display area specification is HL.

When no display area is specified a default of HI-I (for EGA or MONO) is

used.

The scroller card address is a number from 0 to 3f8 (hex) which must be

evenly divisible by 8. The default address is 308.

NOTE: in order to specify an alternate address, a display area must also be

specified.

1-17

Page 30

Installations Involving the 500GPIB Module

If your system includes a 5OOGPIB module, note that KDAC500 does not perform installation

steps for this module. The 500GPIB driver installation is outlined in the 500GPIB manual. It

requires that the user manually edit the DOS AUTOEXEC.BAT file to insert the required

command line.

If You Have Problems Installing KDACSOO

If you experience any problems with INSTALL, first review your work. If you must call

Keithley DAC for assistance, have available a printout of your KDAC500.BAT file

(KDAC500/1 only) and KINSTALLKIF (if they exist).

You should also have available the make and model of your computer and type of monitor

adapter. Also print out copies of your AUTOEXEC.BAT file and CONBIG.SYS file. If possible,

be near your computer so that you can supply additional information if it is requested.

l-18

Page 31

Running the CONFIG Program

This section of the KDAC500 manual covers the creation of hardware configuration table

“CONFIG.TBL” with the KDAC500 program “CONFIG.EXE”. The following paragraphs discuss the purpose of the “CONFIG.TBL” file, explain the important run-time features of CON-

FIG, and provide a tutorial session using CONF’IG.

The Function of CONFIG.TBL

Keithley data acquisition and control systems are modular and expandable. The possible

combinations of modules, ranges, gains, and I/O configurations are practically unlimited.

KDAC500 must know the module names, switch settings, and related information in order to

control the hardware and acquire data. During installation, the INSTALL program can create

up to four configuration table filenames

system. These names are CONFIG.TBL, CONFIGl.TBL,...CONFIG4.TBL. You must run CONFIG to create a configuration table file for each of the file names.

Setting Up Channel Information (IONAMEs)

-- one for each interface card located in the computer

The CONFIG.TBL file must also include the channel information for each channel accessed by

KDAC500. This information establishes a name for a channel, as well as the slot, channel

number, gain, and other parameters needed to fully describe the channel for input or output,

hence the term “IONAME”. KDAC500 itself does not provide for an IONAME command to

be used within the programming environment.

An important function of IONAMEs in the CONFIG.TBL file is that they set programmable

functions in many modules which otherwise lack hardware switches. An important example

is the programmable local gain on the AMMlA and AMM2 modules. In this case, IONAME

enables you to set the both local gain and global gain for any channel input of the AMM module.

Menu Screens, Cursor Control, and Special Function Keys

All the functions of CONFIG are performed menu-style using tabular screens and the computer’s cursor and special function keys. The screens are “HARDWARE SETUP” and

“CHANNEL SETUP” (see figures 1-3 and figure l-4). Each screen contains several columns

or windows which show instructions and menu choices for configuration.

Selections are made with various special function keys Fl-FlO. Each key controls one or more

functions depending on which screen or window is active. Some keys are not used.

The cursor appears as flashing text in reverse video block. Cursor keys on the right side of the

keyboard control the movement of the cursor around the screen. The left and right arrow

1-19

Page 32

keys function only where choices are arranged in two or more columns. The up arrow and

down arrow keys control vertical movement, and will automatically move the cursor through

multiple columns.

==========================

HARDWARE SETUP ===I============~~========

AMM2: 16SE/8DI than analog in, 16 bit A/D, global mux. Slot 1 only.

SLOT

--

CARD SWITCH CONFIGURATION

AMM2

1

TRGl

2

NONE

3

AOM5

4

DIOl Port : A) IN B) IN C)OUT D)OUT

5

Range: lO.B, Filt: 100 KHZ, SING

Default Range: -10. to 10.V

6 EXT

MODULES

auto AIM6 AOM3

ADMl AIM7 AOM4 PIMl

ADM2 AIM8 AOM5 PIM2

AIM1 AIM9 DIM1 PROT

AIM2 AMMl DIOl STPl

AIM3 AMM2 DOMl STP2

AIM4 AOMl GPIB TRGl

AIM5 AOM2 PCMl NONE

FZ-FILE F3-MODULE

F9-LIST

Wed Jul 5 13:39

FlO-EXIT TO DOS

Path: D:\KDAC500\

F4-SWITCHES F5-CHANNELS

Figure 1-3 Hardware Setup

PCM2

l-20

==========================

CHANNEL SETUP

ANALOG1 : AMMZ, SL 1, CH 0, 16 BIT,

, A FP 7.2

SLOT CHANNEL

PORT IONAMES CHANNEL SETUP

1 0 8 ANALOG1

2 19

3 2 10

4 3 11

5 4 12

6 5 13

6 14

7 15

I

F2-SLOT

F3-CHAN/PORT

F4-IONAME

FlO-RETURN

Wed Jul 5 13:40 Path: D:\KDACSOOj

Figure Z-4. Channel Setup

==============I===========

LOCxl, GLOxl

1) ADD IONAME

8) RESISTOR

2) COPY IONAME 9) FILTER

3) DELETE IONAME

4) RENAME IONAME

5) ACCURACY

6) LOCAL GAIN

10) OFFSET

11) MODE/RANGE

12) CONVERSION

13) DISPLAY FORMAT

7) GLOBAL GAIN

FS-CHANNELS

Page 33

Special Considerations for the Model 575 and System 570

The CONFIG program contains an option which automaticahy creates a configuration table

for the Model 575-1, Model 575-2, or System 570. This configuration table contains the factory

default module assignments, ranges, gains, and other setup information for these systems.

To automatically create a Model 575-l configuration table, type:

CONFIG 575-l

To automatically create a Model 575-2 configuration table, type:

CONFIG 575-2

To automatically create a System 570 configuration table, type:

CONFIG 570

Press <Enter>. CONFIG loads a default configuration table. Refer to the specific hardware

manual for more details on setting up the system hardware.

The modules in the Model 575 and System 570 cannot be changed, except for the option slot.

However, you can change hardware switches (if present), and other set-up information for

the virtual slots. If you add an option module or change the hardware configuration, run

CONFIG and update the configuration table to show these changes.

The CONFIG commands shown above should be run only once to create the desired configuration table. Make subsequent changes to the table by running CONFIG. Then LOAD CONFIG.TBL, or the appropriate configuration table.

Running A Sample Configuration Session

The following instructions are a step-by-step tutorial through a typical configuration of

AMM2, AlM3, and DIOl modules installed in a 500A System. This exercise does not cover all

possible menu selections, and may not cover the particular hardware installed in your system. However, it will provide enough familiarity with CONFIG that you can create any configuration table that you will need.

This tutorial has five objectives:

1. Set up an AMM2 module in slot 1 with single-ended input, and +lOV A/D range.

2. Set up an AIM3 module in slot 6 with 16 differential inputs and a hardware gain of x100.

3. Set up a DIOl in slot 8 with channels O-15 configured as outputs and channels 1631 configured as inputs.

4. Create several IONAMES within the configuration table, including a digital output

IONAME for the DIOl port A and a digital input IONAMX for channel 31.

1-21

Page 34

This exercise will create a configuration table starting with a blank table, as is normally done

for a 500A.

Assigning Modules to Slots

To begin a practice session

KDAC500 Working Disk or fixed disk. From the DOS prompt, type:

CONFIG <Enter>

CONFIG will run and present the HARDWARE SETUP screen without any modules.

1. The cursor should be over 1 in the SLOT column. If necessary, use the cursor keys to

move the cursor to 1.

2. Press the special function F3 key to SELECT MODULE. The cursor will move to the

MODULES window.

3. Use the cursor keys to move the cursor over AMM2.

4. Press <Enter>. The cursor moves back to 1 in the SLOT column.

5. Move the cursor to the 6 position in the SLOT column.

6. Press F3 to SELECT MODULE. The cursor moves to the MODULES window.

7. Use the cursor keys to move the cursor over AIM3.

8. Press <Enter>. The cursor moves back to 6 in the SLOT column.

9. Move the cursor to the 8 position in the SLOT column.

10. Press F3 to SELECT MODULE. The cursor moves to the MODULES window.

11. Use the cursor keys to move the cursor over DIOl.

12. Press <Enter>. The cursor moves back to 8 in the SLOT column.

This completes the selection of modules for the configuration table.

running CONFIG, make sure you have booted the system from a

Setting Configuration Switches and Options

The following instructions describe the entry of switch information for the modules already

entered into the configuration table.

1. This step begins the assignment of the flOV A/D range for the AMM2 analog inputs. The

cursor should be over 1 in the SLOT column. If necessary move the cursor to 1.

2. Press special function key F4 to SET SWITCHES. GAIN information replaces the MODULES window.

3. Use the cursor keys to move through the available range settings to -10. to +lO.V. The

Ah4M2 module is software-programmable for gain and range, so there are no hardware

switches to be set. Gain is set in the IONAME commands.

4. Press <Enter>. The filter selection window will appear. Move the cursor to 1OOkHz.

5. Press <Enter>. The SINGLE-ENDED/DIFFERENTIAL choices appear. Use the cursor

keys to toggle the cursor to SINGLE-ENDED.

6. Press <Enter>. This concludes setting for AMMZ.

7. This step begins the setting of switches on the AIM3. Configuration of the AIM3A module is similar. Move the cursor to the 6 position in the SLOT column.

l-22

Page 35

8. Press special function key F4 to SET SWITCHES. GAIN information replaces the MODULES window. Switch setting information appears in the AIM3 manual.

9. Use cursor keys to move through the available gain settings to x 100. Set the gain

switches on the AIM3 according to the switch information at the top of the screen.

10. Press <Enter>. The SINGLE-ENDED/DIFFERENTIAL choices appear in the GAIN window. Use the cursor keys to toggle the cursor to DIFFERENTIAL. Set the input mode

switches on the AIM3 for differential operation (both switches up).

11. Press <Enter>. The window shows a choice between AIM3 and AIM3A. Move the cursor

to AIM3 and press <Enter>. This concludes set-up of the AIM3 switches.

12. This step begins the setting of switches on the DIOl. Move the cursor to the 8 position in

the SLOT column.

13. Press F4 to SET SWITCHES. PORT information replaces the MODULES window. (A port

is 8 input or output channels.)

14. The cursor will rest on either INPUT or OUTPUT according to the present setting for port

A. The port or channel being affected is listed at the top of the PORT window. Use the

cursor keys to toggle to OUTPUT, and then press <Enter>.

15. Repeat step 17 to set port B to OUTPUT. Repeat step 17, except with the cursor on “INPUT”, for ports C and D. After you configure the last port, the cursor will move back to 8

in the SLOT column.

The DIOl has a 4-bank DIP switch which is labeled “IN” and “OUT”. Set the DIP switches

for channels O-15 to “OUT”, and channels 16-31 to “IN”. This information is not repeated at

the top of the screen. The DIOlA module is software-programmable for I/O and does not

have switches.

This concludes switch settings for the system.

Programming IONAMES as Part of the Configuration Table

The next instructions explain how to program IONAMEs directly in the configuration table.

KDAC500 does not provide for an IONAME statement, so all channel information must be

set up through CONFIG.

Three IONAME’s will be set up:

l One IONAME for channel 2 of the AIM3 in slot 6 with differential input and global gain

(GA%) of 10.

l One IONAME for DIOl port A. KDAC500 will program these 8 lines for output as individ-

ual bits in a byte.

l One IONAME for the individual DIOl input channel 31.

During this operation, new options will appear in the CHANNEL SETUP window. These options deserve special note since some of their functions are not immediately obvious.

ADD IONAME - adds an IONAME for a slot/channel. Make sure the cursor is on ADD

IONAME. Press <Enter>. CONFIG prompts for the new IONAME. Type the name and press

<Enter>.

l-23

Page 36

COPY IONAME - copies the contents of an existing IONAME to the IONAME which is

highlighted in the IONAME column. To select an IONAME for copying, press F4-SELECT

IONAME. Move the cursor to the desired IONAME. Press F5-CHANNEL SETUP to return to

the CHANNEL SETUP window. Move the cursor to COPY IONAME and press <Enter>.

CONFIG will prompt for the IONAME to be copied to the highlighted IONAME. Type the

name and press <Enter>.

DELETE IONAME - deletes the IONAME highlighted in the IONAME column. To select an

IONAME for deletion, press F4SELECT IONAME. Move cursor to the desired IONAME.

Press F5-CHANNEL SETUP to return to the CHANNEL SETUP window. Move the cursor to

DELETE IONAME and press <Enter>. CONFIG will prompt for a confirmation before it deletes the selected IONAME.

RENAME IONAME - renames the IONAME highlighted in the IONAME column. To select

an IONAME for renaming, press F4-SELECT IONAME. Move cursor to the desired

IONAME. Press F5-CHANNEL SETUP to return to the CHANNEL SETUP window. Move

the cursor to RENAME IONAME and press <Enter>. CONEIG will prompt for the new name.

Type the name and press <Enter>.

ACCURACY - specifies A/D resolution - 1214, or 16 bits. Move the cursor to ACCURACY

and press <Enter>. Toggle to 12,14, or 16 with the cursor keys and press <Enter>.

LOCAL GAIN - specifies hardware gain selected for analog input modules which have onboard gain amplifiers. For gains which are set by hardware switches, CONFIG reads the

switch information you previously entered and updates LOCAL GAIN automatically. For

modules with software-programmable gain, LOCAL GAIN shows legal gain values. Move

the cursor to LOCAL GAIN and press <Enter>. Move the cursor to the desired gain and press

<Enter>.

GLOBAL GAIN - Gain applied by the master analog module global gain amplifier, but programmed on a slot-and-channel basis for any analog input modules. Legal values are xl, x2,

x5, and x10. Move the cursor to GLOBAL GAIN and press <Enter>. Move the cursor to the

desired gain and press <Enter>.

RESISTOR - The value of a resistor which you have installed on an analog input module for

current-to-voltage conversion. Move the cursor to RESISTOR and press <Enter>. CONFIG

will prompt for the resistor value in ohms. Type in the value (integer) and press <Enter>.

FILTER - For modules with software-programmable filters. Move the cursor to FILTER and

press <Enter>. Move the cursor to the desired filter and press <Enter>.

OFFSET - Enables or disables adjustable input offset feature of the AIM8. Move the cursor

to OFFSET and press <Enter>. Move the cursor to ENABLED or DISABLED as desired, and

press <Enter>.

l-24

MODE/RANGE - This menu selection set the mode of the PIM2 as either READ only, or

READ and RESET. This will either allow totalizing or not, depending on your application.

This command also sets the range of the AOM5 module.

Page 37

CONVERSION - In general, this function allows you to define the type of conversion that

should be performed on the input signal. It currently does not cause the conversion to take

place but can be used for documentation of the type of signal or tranducer that you are using.

For AIM8 and AIM9 you can set the calibration factor and calibration measurement units

used to calibrate the card and transducer. Move cursor to CONVERSION and press <Enter>.

Then move to SPECIAL and press <Enter>. Then select either LVDT/RVDT or STRAIN

GAGE. CONFIG then prompts for the calibration factor in millivolts per volt excitation. Type

in factor to three decimal places and press <Enter>. CONFIG prompts for calibrating units of

measure. Type in units (integer) and press <Enter>.

DISPLAY FORMAT - This function does nothing for KDAC500. It will be used in future

products to allow you to define the data formats for hard copy printouts of data, and for communication with analysis packages.

NOTE: The AIM6 module is supported in a different fashion from previous versions of CONFIG. To select the proper mode of operation for the AIM6, simply use the LOCAL gain menu

selection.

1. Before continuing, make sure the cursor is in the SLOT column of the initial HARD-

WARE SETUP screen. Press Esc several times if necessary to return to the HARDWARE

SETUP screen.

2. Use the cursor keys to move the cursor over 6 in the SLOT column. Press special function

key F5 for the CHANNEL SETUP screen.

3. Press F3 to SELECT CHAN/PORT. The cursor will move to 0 in the CHANNEL column.

4. Use the cursor keys to move the cursor to 2 in the CHANNEL column.

5. Press <Enter>. The cursor will move to ADD IONAME in the CHANNEL SETUP window.

6. Press <Enter>. CONFIG will prompt for an IONAME. This name can contain up to 8 letters and numbers. In this case, type in ‘TEST” and press <Enter>.

7. Move the cursor to ACCURACY in the CHANNEL SETUP window.

8. Press <Enter>. A/D menu choices appear in the CHANNEL SETUP window. Use the

cursor keys to select 16 BIT and press <Enter>. The CHANNEL SETUP choices will reappear.

9. Use the cursor keys to move the cursor to GLOBAL GAIN.

10. Press <Enter>. Global Gain choices will appear in the CHANNEL SETUP window. Use

the cursor keys to move the cursor to the x10 position. Press <Enter>.

11. This completes the configuration of IONAME parameters for the AIM3 module. Go directly to creating an IONAME for another slot by pressing F2 for SELECT SLOT.

12. The following instructions set up IONAME’s for the DIOl module port A and Channel

15. Use the cursor keys to move the cursor to 8 in the SLOT column.

13. Press F3 for SELECT CHAN/PORT. The cursor will move to the C

HANNEL column.

Press F3 again to move to the PORT column.

14. Use the cursor keys to move the cursor to A in the PORT column.

15. Press <Enter>. The cursor will move to ADD IONAME in the CHANNEL SETUP column.

16. Press <Enter>. CONFIG will prompt for an IONAME. In this case, type in “OUTA” and

press <Enter>. (The only parameter you can enter for digital I/O is the name.)

17. Press F3 for SELECT CHAN/PORT. The cursor will return to the PORT column.

18. Press F3 for SELECT CHAN/PORT again. The cursor will move to the CHANNEL column.

19. Use the cursor keys to move the cursor to 31.

20. Press <Enter>. The cursor moves to ADD IONAME in the CHANNEL SETUP column.

21. Press <Enter>. CONFIG will prompt for an IONAME. In this case, type in “IN15” and

press <Enter>. (The only parameter you can enter for digital I/O is the name.)

1-25

Page 38

22. This completes the assignment of IONAMES for the DIOl. Press F10 to return to the

HARDWARE SETUP screen.

File I/O

- Saving the Configuration Table

These steps will save the configuration table to disk.

1. Press F2 for FILE operations. The MODULE window will be replaced by a FILE I/O

menu. It includes choices for loading, saving, and deleting files, and for changing default

drives and directory.

2. Use the cursor keys to move the cursor to SAVE FILE.

3. Press <Enter>. The FILE I/O window will show the drive, directory, and one or more