Page 1

xx

ZZZ

Tektronix Instrument Switch

Instruction Manual

www.tektronix.com

077-0589-00

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX, TEK, and BERTScope are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit http://www.tektronix.com to find contacts in your area.

Page 3

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one

(1) year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at

its option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be new or reconditioned to like new performance. All replaced parts, modules and products become the

property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix, with

shipping charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a

location within the country in which the Tektronix service center is located. Customer shall be responsible for

paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE

VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

Page 4

Table of Contents

General Safety Summary ........................................................................................................................................ iv

Service Safety Summary .......................................................................................................................................... v

Compliance Information ......................................................................................................................................... vi

EMC Compliance .................................................................................................................................................. vi

Environmental Considerations ............................................................................................................................ vii

Getting Started.......................................................................................................................................................... 1

Standard Accessories .............................................................................................................................................. 2

Operating Basics ....................................................................................................................................................... 3

Power On Status ..................................................................................................................................................... 3

Setup ....................................................................................................................................................................... 3

Instrument Switch Operation .................................................................................................................................. 4

Installing the Instrument Switch in a Test Setup ................................................................................................... 4

Switch Signal Paths ................................................................................................................................................ 4

Manual Switch Control ............................................................................................................................................ 6

Switch Front Panel Controls and Connectors ......................................................................................................... 6

Channel Select .................................................................................................................................................... 6

Trigger Select ..................................................................................................................................................... 7

Switch Rear Panel Connectors ............................................................................................................................... 8

USB Switch Control ................................................................................................................................................. 9

Switch Control Software ........................................................................................................................................ 9

USB 3.0 Testing Software .................................................................................................................................... 10

Specifications .......................................................................................................................................................... 12

Maintenance ............................................................................................................................................................ 13

Troubleshooting ...................................................................................................................................................... 14

ii Tektronix Instrument Switch Instruction Manual

Page 5

List of Figures

Figure 1: The Tektronix Instrument Switch ..............................................................................................................1

Figure 2: Example Test Setup – Jitter Tolerance Test Cabling Diagram .................................................................4

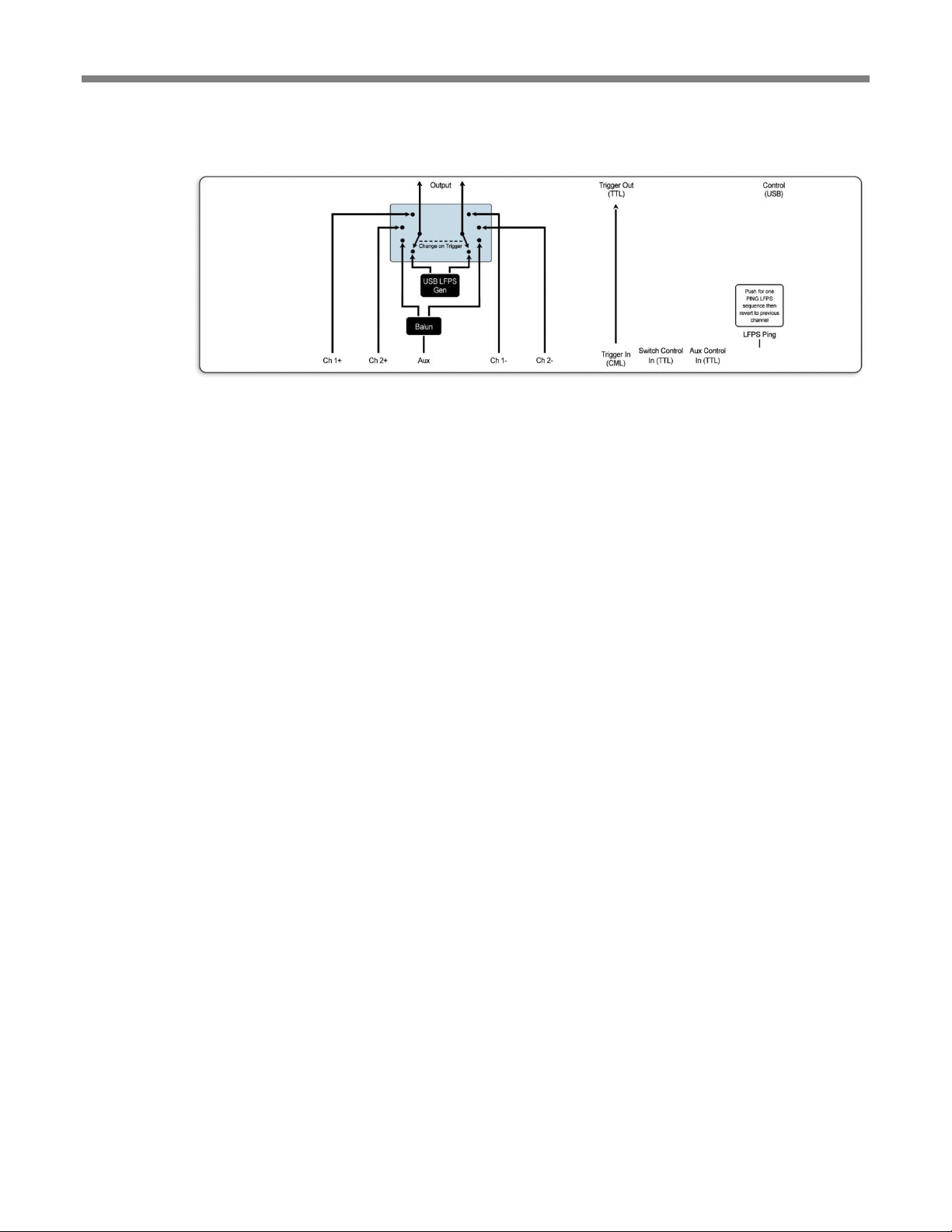

Figure 3: Instrument Switch signal paths ..................................................................................................................5

Figure 4: Instrument Switch front panel controls and connectors .............................................................................6

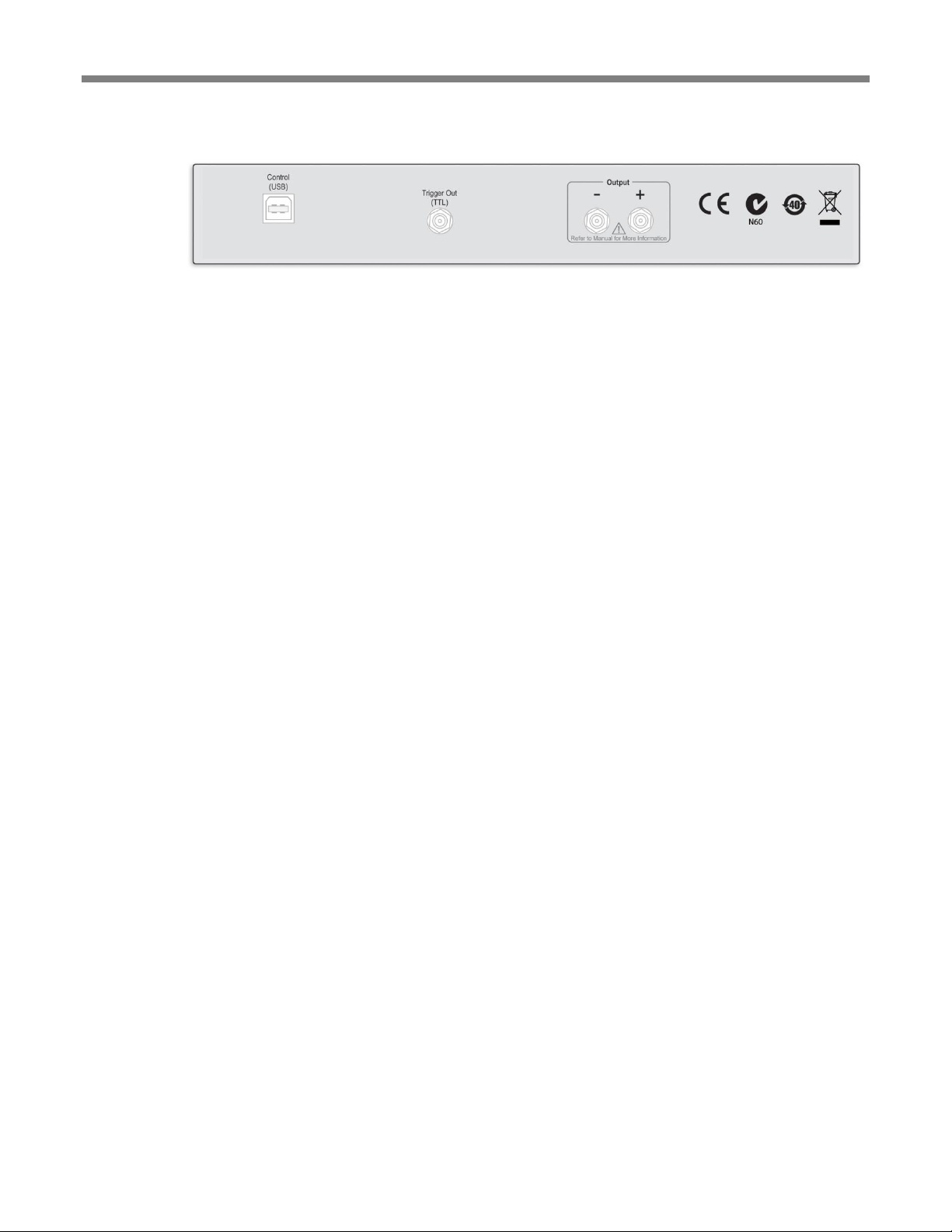

Figure 5: Instrument Switch rear panel connectors ...................................................................................................8

Figure 6: Switch Control Software user interface .....................................................................................................9

Figure 7: Tektronix USB 3.0 Testing Software user interface ................................................................................. 10

Page 6

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to this

product or any products connected to it.

To avoid potential hazards, use this product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and cautions

related to operating the system.

To Avoid Fire or

Personal Injury

Connect and Disconnect Properly. Do not connect or disconnect test leads while

they are connected to a voltage source.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or

panels removed.

Do Not Operate With Suspected Failures. If you suspect that there is damage to

this product, have it inspected by qualified service personnel.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate in Wet/Damp Conditions

Do Not Operate in an Explosive Atmosphere

Keep Product Surfaces Clean and Dry

General Safety Summary

iv Tektronix Instrument Switch Instruction Manual

Page 7

Service Safety Summary

Terms in this Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that

could result in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that

could result in damage to this product or other property.

Symbols and Terms

on the Product

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power,

then disconnect the power cord from the mains power.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

CAUTION

Refer to Manual

Service Safety Summary

Tektronix Instrument Switch Instruction Manual v

Page 8

Compliance Information

EMC Compliance

EC Declaration of

Conformity – EMC

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the

Official Journal of European Communities:

EN 61326-1 2006. EMC requirements for electrical equipment for measurement,

control, and laboratory use.

1234

CISPR 11:2003. Radiated and conducted emissions, Group 1, Class A

IEC61000-4-2:2001. Electrostatic discharge immunity

IEC61000-4-3:2002. RF electromagnetic field immunity

IEC61000-4-4:2004. Electrical fast transient / burst immunity

IEC61000-4-5:2001. Power line surge immunity

IEC61000-4-6:2003. Conducted RF immunity

IEC61000-4-11:2004. Voltage dips and interruptions immunity

EN61000-3-2:2006. AC power line harmonic emissions

EN61000-3-3:1995. Voltage changes, fluctuations, and flicker

European Contact

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

Australia / New

Zealand Declaration

of Conformity–EMC

Complies with the EMC provision of the Radiocommunications Act per the

following standard, in accordance with ACMA:

CISPR 11:2003. Radiated and Conducted Emissions, Group 1, Class A, in

accordance with EN61326-1:2006.

Compliance Information

1

This product is intended for use in nonresidential areas only. Use in residential areas may cause electromagnetic interference.

2

Emissions which exceed the levels required by this standard may occur when this equipment is connected to a test object.

3

To ensure compliance with the EMC standards listed here, high quality shielded interface cables should be used.

4

EMC performance is dependent upon the USB host device to which the Tektronix Instrument Switch is connected. Performance has

been verified when connected to a BERTScope Analyzer.

vi Tektronix Instrument Switch Instruction Manual

Page 9

Compliance Information

Environmental Considerations

This section provides information about the environmental impact of the product.

Product End-of-Life Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. In order to avoid release of such substances into the environment and to

reduce the use of natural resources, we encourage you to recycle this product in an

appropriate system that will ensure that most of the materials are reused or recycled

appropriately.

This symbol indicates that this product complies with the

applicable European Union requirements according to Directives

2002/96/EC and 2006/66/EC on waste electrical and electronic

equipment (WEEE) and batteries. For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Restriction of

Hazardous

Substances

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive.

Tektronix Instrument Switch Instruction Manual vii

Page 10

Page 11

Getting Started

The Tektronix Instrument Switch is a flexible device usable for general purpose

applications and specific inclusion in USB 3.0 compliance testing. For USB 3.0

testing, the switch features a pattern generator for generation of Low Frequency

Periodic Signaling (LFPS), used to ensure devices achieve loopback. Other features

include:

Manual switching between channels with front panel controls

Automated control via USB

Flexible triggering with multiple control choices

Two main input channels (Ch 1, Ch 2) with >10 GHz analog bandwidth

Single-ended to differential input channel for easily adding low frequency

signal generators to test setups

USB control and power with no need for additional external power

Figure 1: The Tektronix Instrument Switch

Manual Control

The Instrument Switch can be operated manually, using the pushbuttons and

connectors, with power supplied through the USB connection to a host instrument.

The Switch Control program and instrument drivers must be installed on the host

instrument to properly power the switch.

Switch Control

Program

Software control communication is through USB connection to a control host (such

as a Windows PC or BERTScope Analyzer).

The Switch Control software provides additional control features, including:

Duty Cycle setting for LFPS sequences

LFPS Polling/Ping/Reset selection

Custom LFPS type setup

The Switch Control program and instrument drivers must be installed on the host

instrument prior to connecting the USB cable.

Tektronix USB 3.0

Receiver Testing

Software

This Tektronix USB 3.0 Receiver Testing solution software is available for use with

the BERTScope Analyzer. Once installed on a PC, the testing software

communicates directly with the Switch Control program, for seamless operation

through the user interface.

The USB 3.0 Receiver Testing software also includes a detailed remote control

protocol for automated testing.

Getting Started

Tektronix Instrument Switch Instruction Manual 1

Page 12

Getting Started

Standard USB 2.0 cable

Instrument Switch Control Software CD-ROM

Driver and application/socket-server programs to be installed on a control host

(BERTScope Analyzer or Windows PC) connected to the Switch via USB.

Standard Accessories

2 Tektronix Instrument Switch Instruction Manual

Page 13

Operating Basics

The Instrument Switch is intended to be operated in a controlled laboratory

environment. It is intended to operate on a bench top, or on top of another

instrument such as the BERTScope Analyzer. There are four shock-absorbing feet

located on the bottom of the instrument.

This instrument draws operating power through a USB connection to a host

instrument, such as the BERTScope Analyzer or a Windows PC. No other power

source is required.

Note: The Instrument Switch drivers must be installed on the host instrument in

order to correctly supply power to the switch.

Connect the Instrument Switch to a BERTScope Analyzer or host PC via the USB

connector on the rear panel.

Press the Power button on the front panel. A lit green LED on the button indicates

that power is on.

Note: If you will be using a software switch control program, it should be installed

on the control host prior to connecting the switch.

The Instrument Switch serves as a regulated gateway for passing test signals to a

DUT. It can be operated using:

The physical pushbuttons and connectors

Switch Control software, installed on a control host

Tektronix USB 3.0 Receiver Testing software, installed on a control host

Software control communication is through USB 2.0 connection to a control host

(such as a BERTScope Analyzer or a Windows PC). The Switch Control program

should be installed on this control instrument prior to connecting the USB cable.

The Switch Control software is distributed on the CD-ROM supplied as a standard

accessory with the Instrument Switch.

Operating Basics

Power On Status

Setup

Tektronix Instrument Switch Instruction Manual 3

Page 14

Instrument Switch Operation

Figure 2 illustrates an example test setup incorporating the Instrument Switch.

Figure 2: Example Test Setup – Jitter Tolerance Test Cabling Diagram

The Instrument Switch allows the selection of one of four RF signals as its output:

Channel 1, through connectors on the front panel.

Channel 2, through connectors on the front panel.

Single-ended AUX Input, through a connector on the front panel. This

single-ended source is split into a differential signal by a balun internal to

the switch.

Built-in Low Frequency Periodic Signal (LFPS) generator, which provides

different types of USB 3.0 LFPS signals that are useful during USB 3.0

application testing. For instance, the USB 3.0 Receiver Testing solution

software uses this fourth source to initiate loopback training.

Once Primary, Secondary, and Trigger sources are set, the input Primary channel is

passed directly to output until a Trigger event occurs, prompting a change to the

Secondary channel.

Instrument Switch Operation

Installing the Instrument Switch in a Test Setup

Switch Signal Paths

4 Tektronix Instrument Switch Instruction Manual

Page 15

Instrument Switch Operation

The following diagram (which appears on the top panel of the Instrument Switch) is

a straightforward depiction of the switching options.

Figure 3: Instrument Switch signal paths

Tektronix Instrument Switch Instruction Manual 5

Page 16

Manual Switch Control

Testing signals are routed through the switch using the connectors on the front and

rear panels. Use the front panel pushbuttons set the Primary and Secondary

channels, select the Trigger source, and insert a one-time LFPS Ping.

The Instrument Switch is powered through USB connection to a host PC or

BERTScope Analyzer. The switch software drivers must be installed on the host

instrument in order to correctly power the switch.

Figure 4: Instrument Switch front panel controls and connectors

Channel Select

Primary

Secondary

Use these pushbuttons to select Primary and Secondary input channels. The Primary

channel is the source normally passed to the switch outputs. Upon a trigger event,

input switches to the Secondary channel, if one is selected.

Press the button to advance to the next channel in sequence: Channel 1 – Channel 2

– AUX – LFPS Generator. Hold the button down to cycle through the channels. The

switch will not physically change position until the button is released, allowing you

to change from, for example, Channel 1 to AUX, without enabling Channel 2 in

between.

Pressing the Primary Channel Select button clears any Secondary channel selection,

effectively ‘locking’ the switch to the Primary channel until a new Secondary

channel is selected.

When the switch is powered on, Channel 1 is selected as the Primary channel and

the LFPS generator as the Secondary channel.

Channel LEDs

An illuminated green LED indicates the Primary channel.

A red LED may be illuminated, indicating the Secondary channel if one is selected.

Channel 1 (+) In

SMA connector for a single-ended or differential (+) Channel 1 input, internally

AC-coupled.

Channel 2 (+) In

SMA connector for a single-ended or differential (+) Channel 2 input, internally

AC-coupled.

Auxiliary In

SMA connector; internally AC-coupled.

Limited to a maximum frequency of 100 MHz; an internal balun converts the

single-ended signal to a differential pair of signals for transmission to the switch

outputs. This is intended for use with an AFG or AWG, to generate custom lowspeed signaling.

Manual Switch Control

Switch Front Panel Controls and Connectors

6 Tektronix Instrument Switch Instruction Manual

Page 17

Manual Switch Control

LFPS Generator

Selects the internal LFPS generator as the channel source.

Channel 1 (–) In

SMA connector for a differential Channel 1 (–) input, internally AC-coupled.

Channel 2 (–) In

SMA connector for a differential Channel 2 (–) input, internally AC-coupled.

Trigger Select

This pushbutton selects a trigger input: Trigger In – Switch Control – AUX Control.

Only one trigger is enabled at a time, indicated by an illuminated green LED. Press

the button to enable the next trigger in sequence.

Hold the button down to cycle through the sources; the switch will not enable a new

trigger until the button is released, allowing you to change from, for example,

Trigger In to AUX Control, without enabling Switch Control in between.

Trigger LED

One of three green LEDs is illuminated to indicate the active Trigger Input.

Trigger In

(CML)

SMA connector. A rising edge will cause a switch to the Secondary channel, if one

has been selected.

Expected signal levels are CML, with nominal input voltages of 0 V for V(ih) and 400 mV for V(il). This input has protection circuitry that prevents the 3.3 V TTL

input trigger signal from causing damage to the switch.

Switch Control In

(3.3 V TTL)

SMA connector. A rising or falling edge of this 3.3 V TTL-level input will cause a

switch to the Secondary channel, if one has been selected.

Aux Control In

(3.3 V TTL)

SMA connector. A rising or falling edge of this 3.3 V TTL-level input will cause a

switch to the Secondary channel, if one has been selected.

LFPS Ping

The Ping pushbutton immediately switches output to the internal LFPS generator,

transmits a single LFPS sequence (a ‘Ping’), and immediately returns to the

previously selected Primary channel.

If the LFPS generator is selected as the Primary channel when a ping is instigated,

the switch will go from tri-state to LFPS to tri-state output.

If the LFPS generator is selected as the Secondary channel, a ping will switch from

whatever state the primary channel is in to LFPS, and then back to the previous

state of the Primary channel.

Power Button/LED

Press to power-on. A green LED in the button will light. Press the button again to

turn off power.

Tektronix Instrument Switch Instruction Manual 7

Page 18

Manual Switch Control

Figure 5: Instrument Switch rear panel connectors

Control (USB)

A USB B-type connector on the rear panel provides power and software control

through USB 2.0 connection to a host instrument.

Trigger Out

(3.3 V TTL)

The Trigger Out connector on the rear panel outputs a 3.3 V TTL-level signal that

has been internally converted from the CML-level Trigger In. This can be used to

trigger additional external equipment.

The source of the output signal(s) is determined by the Primary, Secondary, and

Trigger selections.

Output (–)

The Output (–) connector on the rear panel outputs a differential (–) signal. SMA

connector; internally AC-coupled.

Output (+)

The Output (+) connector on the rear panel outputs a differential (+) signal. SMA

connector; internally AC-coupled.

Switch Rear Panel Connectors

8 Tektronix Instrument Switch Instruction Manual

Page 19

USB Switch Control

Through the USB connection, software programs installed on a host instrument can

be used to manage switch operation.

The included Switch Control software program (on the Software CD-ROM shipped

with the Instrument Switch) provides options in addition to manual operation,

including:

Duty Cycle setting for LFPS sequences

LFPS Polling/Ping/Reset selection

Custom LFPS type setup

Figure 6: Switch Control Software user interface

USB Switch Control

Switch Control Software

Tektronix Instrument Switch Instruction Manual 9

Page 20

USB Switch Control

The Instrument Switch is an integral part of the Tektronix USB 3.0 Receiver Testing

solution. The USB 3.0 Receiver Testing software communicates directly with the

Switch Control program, managing all aspects of switch operation through one

interface.

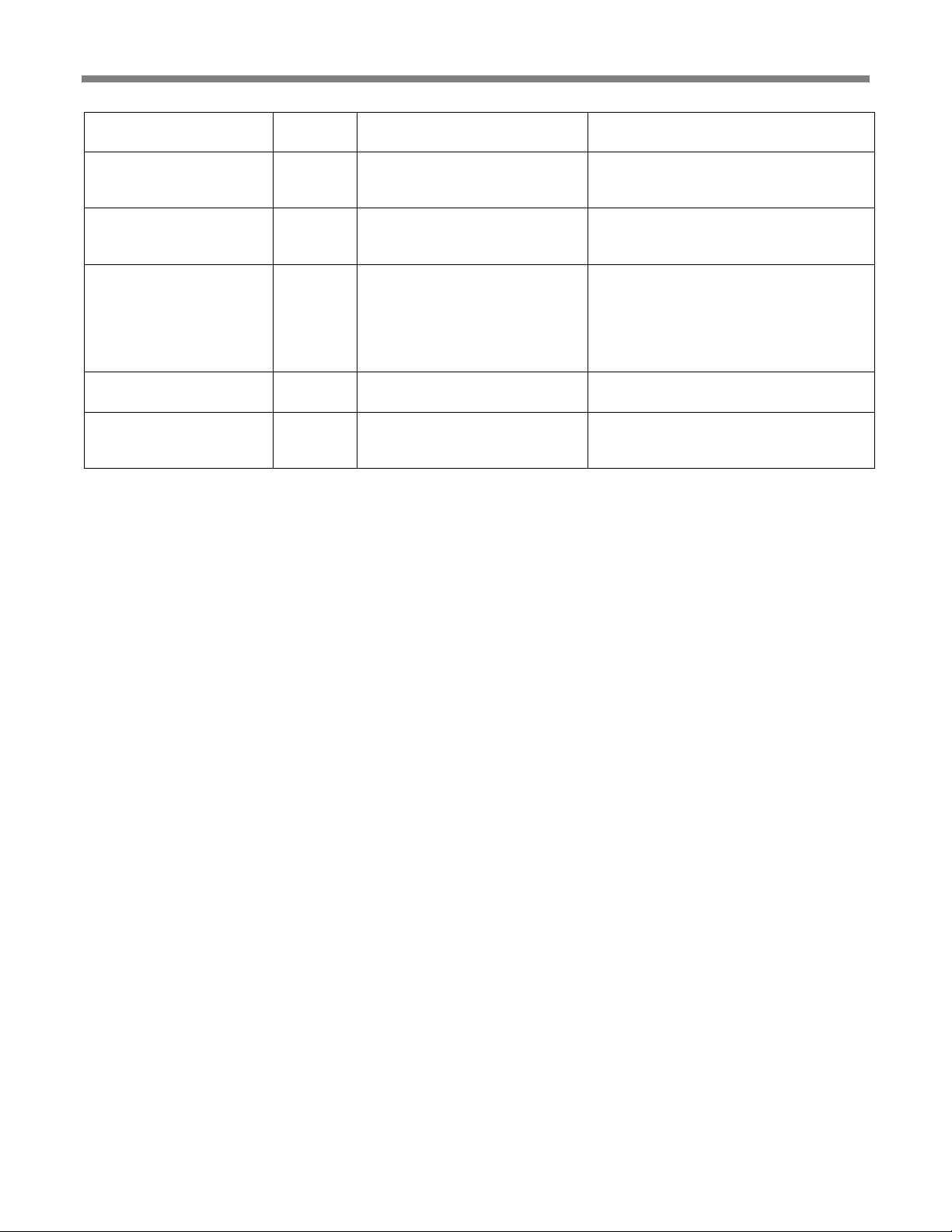

Figure 7: Tektronix USB 3.0 Testing Software user interface

Remote Control

The USB 3.0 Testing software includes a detailed remote control protocol for

automated USB 3.0 receiver testing.

Remote control commands specifically for configuring and controlling the

Instrument Switch are listed here. A complete command protocol is included in the

USB 3.0 Receiver Testing software’s online Help System.

Protocol

Type

Description

Parameter(s)

CONN:SWITCH [bool]

R/W

Property

Connects or disconnects TCP/IP

communications to Switch using

default IP address and port

Boolean value indicating whether to connect (1)

or disconnect (0)

PREF:SAVE

Command

Save Preferences

PREF:SW:IP "text"

R/W

Property

Instrument Switch communications

TCP/IP Address

String IP address in the form 192.168.99.99

PREF:SW:PORT <int>

R/W

Property

Instrument Switch communications

TCP/IP Port

Decimal integer port number

PREF:SW:TO <int>

R/W

Property

Instrument Switch communications

Timeout

Decimal integer representing seconds

RXTEST:SW:COUNT

R-Only

Property

Returns number of frequencies in

receiver testing

Decimal integer value representing the number

of frequencies tested

USB 3.0 Testing Software

10 Tektronix Instrument Switch Instruction Manual

Page 21

USB Switch Control

RXTEST:SW:DISPL [enum]

R/W

Property

Selects whether to display a chart or

table during receiver testing

Possible values include: 0 = table, 1 = chart

RXTEST:SW:PROGRESS

R-Only

Property

Returns the index of the frequency

currently being tested

Decimal integer value representing the 0-based

index of the frequency being tested, or -1 if

testing is not being performed.

RXTEST:SW:RCOUNT

R-Only

Property

Returns number of rows in test results

from receiver test system

Decimal integer value representing the number

of test results contained in the receiver test

system results table

RXTEST:SW:RESULT [int]

R-Only

Property

Returns specified table row from the

receiver test system results table

Returns 5 values for specified row: Test

amplitude, Bits, Errors, BER, and Status strings.

Status values include: Blank, Skipped,

InProgress, Passed, NoSync, BERFailure,

ClockError, DataError, LimitReached,

Unknown.

RXTEST:SW:RUN [bool]

R/W

Property

Controls the run state of the receiver

test system.

Boolean value indicating whether the receiver

test system is running or not.

RXTEST:SW:STATUS

R-Only

Property

Returns receiver test system status

Possible return values include: NotRunning,

TestStarted, TestingFreq, and

LoopbackRequired.

Tektronix Instrument Switch Instruction Manual 11

Page 22

Specifications

Specifications

Analog Bandwidth (Ch 1, Ch 2) ................... >10 GHz

Max. Input Voltage (Ch 1, Ch 2, AUX) ....... 3 V p-p per channel

Insertion Loss (Ch 1, Ch 2) ........................... 3 dB

Impedance ..................................................... 50 Ω

Switching Speed ........................................... 400 ns (typical)

Input/Output Connectors ............................... SMA 3.5 mm female

Power Supply ................................................ Via USB connection to a control host

(BERTScope Analyzer or Windows PC)

Software Control ........................................... Via USB connection to a control host

INPUTS

Channel 1+ ............................................. Single-ended / Differential (+)

Internally AC-coupled

Channel 2+ ............................................ Single-ended / Differential (+)

Internally AC-coupled

AUX In ................................................... Internally converted to differential

output

Internally AC-coupled

Max. Frequency ............................... 100 MHz

LFPS ....................................................... Internal LFPS generator

Max. Frequency ............................... 100 MHz

Channel 1– ............................................. Differential (–)

Internally AC-coupled

Channel 2–.............................................. Differential (–)

Internally AC-coupled

Trigger In................................................ CML

Nominal Voltage .............................. V(ih) 0 V

V(il) –400 mV

Switch Control........................................ 3.3 V TTL

AUX Control .......................................... 3.3 V TTL

OUTPUTS

Output – .................................................. Differential (–)

Output + ................................................. Single-ended / Differential (+)

Trigger Out ............................................. 3.3 V TTL (internally converted from

CML Trigger In)

ENVIRONMENTAL

Temperature, Operating ......................... +10 to 40 °C

Humidity ................................................ Non-condensing at 40 °C, 15 to 95%

12 Tektronix Instrument Switch Instruction Manual

Page 23

Maintenance

The exterior of the instrument may be cleaned using a soft cloth dampened with a

‘glass and office desk surface’ type cleaner. Do not use solvent or abrasive cleaning

agents.

The Channel and Trigger inputs and outputs use 3.5 mm SMA connectors. Should a

connector become damaged, replacements can be ordered from Tektronix.

Maintenance

Cleaning

Connector Replacement

Tektronix Instrument Switch Instruction Manual 13

Page 24

Troubleshooting

This normally means that the switch is not receiving power from the USB port to

which it is connected. Verify that the USB cable is securely connected between the

host PC/BERTScope Analyzer and the Tektronix Instrument Switch, and that the

host instrument is not in a low power (suspend) state.

When the Tektronix Instrument Switch is first powered on, the default configuration

is as follows:

The Primary channel is set to Channel 1.

The Secondary channel is set to the LFPS Generator channel.

The Trigger In (CML) input is selected.

The selection LEDs for these inputs should be lit. If the green power LED is the

only LED lit, this normally means that the Tektronix Instrument Switch was not

recognized and configured correctly by the host PC, typically because the switch

driver has not been installed on the host PC. Verify that the switch driver has been

installed on the host PC, or if necessary, reinstall the driver on the host system.

This behavior occurs if the currently selected trigger input is receiving a fast,

repeating trigger signal. The switch will continuously oscillate between the primary

and secondary channels in this case, and their LEDs will be perceived as orange

(actually oscillating between green and red).

Troubleshooting

Symptom #1: Power button pressed, green power LED does not light.

Symptom #2: Power button pressed, green power LED lights but the Channel 1

LED (green), LFPS LED (red) and/or Trigger In LED (green) are not lit.

Symptom #3: Two of the Channel Input Select LEDs are lit orange.

14 Tektronix Instrument Switch Instruction Manual

Loading...

Loading...