Page 1

Technical Reference

InfiniBand Serial Data Compliance and Analysis

Application

Methods of Implementation (MOI)

071-2043-00

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its suppliers

and are protected by United States copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supercedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX, TEK and RT-Eye are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive or P.O. Box 500

Beaverton, OR 97077 USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Table of Contents

Table of Contents

1 Introduction to RT-Eye InfiniBand Compliance Module......................1

2 Background on InfiniBand Compliance Testing....................................1

2.1 Compliance Statements and Test Definitions (TDs)...............................1

2.2 Integrator List Tests for InfiniBand........................................................4

3 InfiniBand Driver Compliance Measurements (MOIs).........................5

3.1 Required Equipment.................................................................................5

3.2 Connecting to the driver under test.........................................................5

3.2.1 SMA Connection .............................................................................6

3.2.2 ECB pad connection........................................................................7

4 Configuring a Device Under Test (DUT) for Compliance

Measurements ............................................................................................7

5 Initial Oscilloscope Setup..........................................................................8

6 Running the RT-Eye Software .................................................................9

6.1 DC Common Mode Measurement MOI................................................10

6.2 AC Common Mode Measurement MOI................................................11

6.3 Transmitter Peak-Peak Measurement MOI.........................................12

6.4 Rise/Fall Time Measurements................................................................14

6.5 Driver Jitter Measurements....................................................................15

6.6 Combining Driver Measurements..........................................................17

7 InfiniBand Cable Measurements............................................................17

7.1 Required Equipment...............................................................................17

7.2 Connecting to the Driver Under Test.....................................................18

7.3 Configuring the Device Under Test (DUT) for Compliance

Measurements.....................................................................................................18

7.4 Initial Oscilloscope Setup........................................................................18

7.5 Running the RT-Eye Software ...............................................................18

7.6 Cable Connected Minimum Differential Voltage.................................19

7.7 Combining Cable Measurements...........................................................20

8 Giving a Device an ID..............................................................................20

9 Creating a Compliance Report...............................................................20

10 Appendix A – Measurement Algorithms...............................................21

InfiniBand Compliance Measurements i

Page 4

Table of Contents

ii InfiniBand Compliance Measurements

Page 5

Methods of Implementation

1 Introduction to RT-Eye InfiniBand Compliance Module

This document provides the procedures for making InfiniBand compliance measurements with Tektronix

TDS/CSA7000, DSA/DPO 70000 and TDS6000 series real time oscilloscopes (4 GHz models and above).

The InfiniBand Compliance Module (Opt. IBA) is an optional software plug-in to the RT-Eye Serial Data

Compliance and Analysis application (Opt. RTE). The InfiniBand Compliance module provides Amplitude,

Timing, and Jitter measurements described in the electrical specification sections of the InfiniBand

Architecture Specification.

The IBTA-CIWG (InfiniBand Trade Association - Compliance and Interoperability Working Group) has

defined a suite of electrical measurements that InfiniBand devices must pass to qualify for the InfiniBand

Integrators List (IL). Manufacturers periodically perform these measurements on their InfiniBand devices at

InfiniBand plugfests. The RT-Eye InfiniBand Compliance Module automates and provides Pass/Fail limit

testing on many of these required IL measurements, as well as additional measurements that appear in the

electrical specification.

In the subsequent sections, step-by-step procedures are described to help you perform these measurements

on your InfiniBand devices. Measurements that are required to qualify for the IL are noted as such and

appear in the IBTA CIWG Subgroup Method of Implementation (MOI) document available for

download to IBTA members at

www.infinibandta.com.

2 Background on InfiniBand Compliance Testing

2.1 Compliance Statements and Test Definitions (TDs)

Compliance statements appear in the InfiniBand architecture specification.

Chapter 6 - driver characteristics compliance statement are as follows:

C6-7: All output ports SHALL comply with the parameters and notes of the Table 16 Driver

Characteristics using appropriate parameters as noted.

From compliance statements, the CIWG-PHY (Compliance and Interoperability Working Group –

Physical Layer Subgroup) has developed Test Definitions (TDs) for measurements in Table 16. Test

Definition assertions that have been given the following designations.

InfiniBand Compliance Measurements 1

Page 6

Methods of Implementation

Table 1 – Chapter 6 Driver Test Definitions (TDs) from Table 16 of the Specification

CIWG-PHY

Measurement Symbol in

TD

Assertion

V2c6-

Common Mode Voltage VCM 0.5V 1.0V

007#01

V2c6-

Pk-Pk Differential Voltage Vdiff Table19

007#02

V2c6-

Disable Mode Output pk-pk Vdisable 0 85mV

007#03

V2c6-

Disable Mode Output max Vdisable 0 1.6V

007#03

V2c6-

Standby Mode Output pk-pk Vstandby 0 85mV

007#04

V2c6-

Standby Mode Output max Vstandby 0 1.6V

007#04

V2c6-

Driver Rise/Fall Time (20-80%) t

007#05

AC Common Mode Voltage V

V2c6-

Driver Total Jitter JT Table19*

007#14

Chap. 6, Table 16

100ps

DRF

25mV

ACCM

Min

Max

1

1.6V

V2c6-

Driver Deterministic l Jitter JD 0.17UI

007#14

1

Minimum Differential Pk-Pk Voltage and Jitter @ 10

specification. Test Points (compliance points) are defined based on where in the system the measurement is being made.

-12

BER is dependent on Table 19 in Chapter 6 of the InfiniBand

2 InfiniBand Compliance Measurements

Page 7

Methods of Implementation

Figure 1 – Compliance Points from InfiniBand Specification

Chapter 7 Cable characteristics compliance statement is as follows:

C7-16: Cable assemblies to be used for InfiniBand shall meet the electrical requirements listed in Table 30

for all link widths for port type 1.

Table 2 – Chapter 7 Cable Test Definitions (TDs) from Table 30 of the Spec ification

CIWG-PHY TD

Assertion

V2c7-002#09 Cable Connector Near End Cross Talk

V2c7-002#010 Cable Assembly Min Differential Voltage VCout 316mV

V2c07-016#01

V2c07-016#02

V2c07-016#05 Cable Connection Jitter Jca .25UI

Measurement

Cable Differential Impedance Zdca(nom)

Symbol in

Min

Max

InfiniBand Compliance Measurements 3

Page 8

Methods of Implementation

2.2 Integrator List Tests for InfiniBand

Table 3 shows the measurements that are available in the RT-Eye InfiniBand Compliance Module and how

they map to electrical measurements in Chapter 6 and Chapter 7 of the InfiniBand Architecture

Specification. Also shown is whether or not the measurement is an Integrator List (IL) test. IL tests are

required to have your device certified as InfiniBand compliant. Other measurements are useful, but not

required.

Table 3 – RT-Eye Measurements Mapped to Chapter 6 and Chapter 7 Measurements

Measurement

Electrical Driver Measurements (Chapter 6 of IBA Specification)

Waveform Eye Height Yes Yes

Waveform Eye Width No Yes

Common Mode DC Voltage No Yes

Common Mode AC Voltage No Yes

Transmitter Peak-Peak Voltage Yes Yes

Integrator List Tests

Available in RT-Eye InfiniBand

Compliance Module

Transmitter Transition Time

(20-80 Rise/FallTime)

Driver Total Jitter @ e

Electrical Cable Measurements (Chapter 7 of IBA Specification)

Cable Connected Eye Height No Yes

Cable Connected Eye Width No Yes

Cable Connection Jitter (TIE) Yes Yes

Cable Connector Minimum Differential

Voltage

Cable Connector Near End CrossTalk Yes

Cable Differential Impedance Yes

-12

BER Yes Yes

Yes Yes

Yes Yes

No (Use TDS8000 series sampling

oscilloscopes)

4 InfiniBand Compliance Measurements

Page 9

Methods of Implementation

A

A

A

A

3 InfiniBand Driver Compliance Measurements (MOIs)

This section applies Methods of Implementation (MOI) to the Test Definitions as they relate to Tektronix

real-time oscilloscopes, probing solutions, and RT-Eye Serial Compliance and Analysis software.

3.1 Required Equipment

The following equipment is required to take the measurements in this document.

• TDS/CSA7404 or TDS6000 series oscilloscope equipped with TDS RT-Eye software (Opt. RTE) and

InfiniBand Compliance Module (IBA).

• Probes – probing configuration is MOI specific. Refer to each MOI for proper probe configuration.

• InfiniBand breakout cable (available from Fujikura Ltd.)

Figure 2 - Fujikura InfiniBand 4X Break-out harness

3.2 Connecting to the driver under test

The first step is to probe the link. Connect your probes based on one of the four methods described below.

Table 4 – Probing Configurations for an InfiniBand Link

Break

Serial

Link

Channels

Used

2

1

2

2

2

1

Probe

A

SMA

Connection

ECB

Pad

Connection

2 x TCA-SMA Y

B

1 x P7350SMA Y

2 x P7260

C

2 x P7350

2 x P7240

1 x P7350 Y/N

D

Y/N

Y/N

Y/N

Captured WaveformsProbing Configurations

Differential

Mode

Pseudo

True No 5GHz 65ps 4GHz 75ps

Pseudo

Pseudo

Pseudo

True No 5GHz 65ps 4GHz 75ps

Common

Mode

C 6GHz 53ps 4GHz 75ps

C/DC 6GHz 53ps 4GHz 75ps

C/DC 5GHz 65ps 4GHz 75ps

C/DC na na 4GHz 75ps

System Specifications

Band

Width

*Typical

Rise*

Time

(20-80)

TDS/CSA7404TDS6604

Band

Width

Rise*

Time

(20-80)

InfiniBand Compliance Measurements 5

Page 10

Methods of Implementation

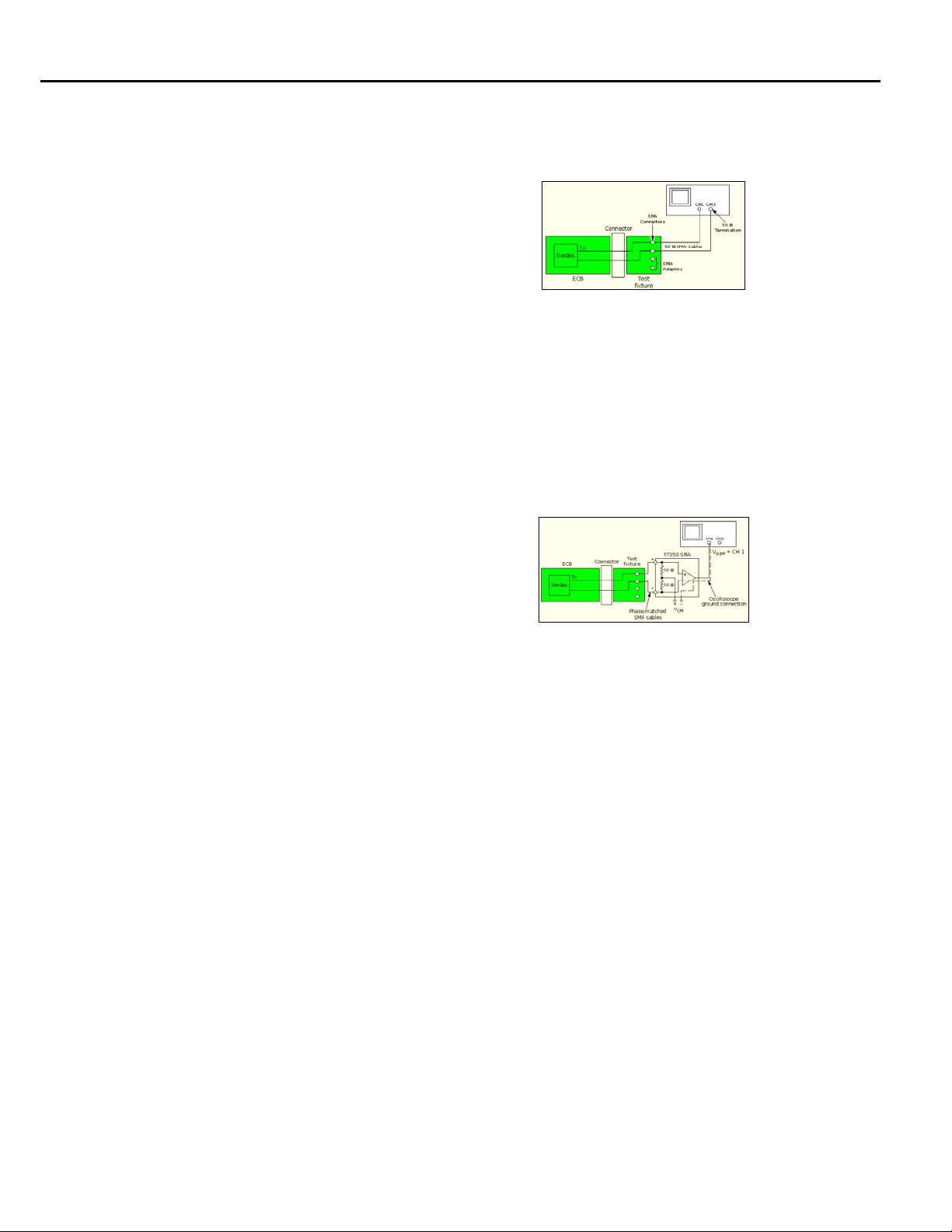

3.2.1 SMA Connection

1. Two TCA-SMA inputs using SMA

cables (Ch1) and (Ch3)

The differential signal is created by the

RT-Eye SW from the math waveform

Ch1-Ch3. The Common mode AC

measurement is also available in this

configuration from the common mode

waveform (Ch1+Ch3)/2. This probing

technique requires breaking the link

and terminating into the 50 Ω/side

termination into the oscilloscope. While

in this mode, the InfiniBand SerDes

will transmit the 320 bit Jitter test

pattern designed to maximize data

dependent jitter. Ch-Ch deskew is

required using this technique because

two channels are used.

2. One P7350SMA differential active

probe (Ch1)

The differential signal is measured

across the termination resistors inside

the P7350SMA probe. This probing

technique requires breaking the link.

While in this mode, the InfiniBand

SerDes will transmit the 320 bit Jitter

test pattern designed to maximize data

dependent jitter. Matched cables are

provided with the P7350 probe to avoid

introducing de-skew into the system.

Only one channel of the oscilloscope is

used.

Probe Configuration A

SMA Psuedo-differential

Probe Configuration B

SMA Input Differential Probe

6 InfiniBand Compliance Measurements

Page 11

Methods of Implementation

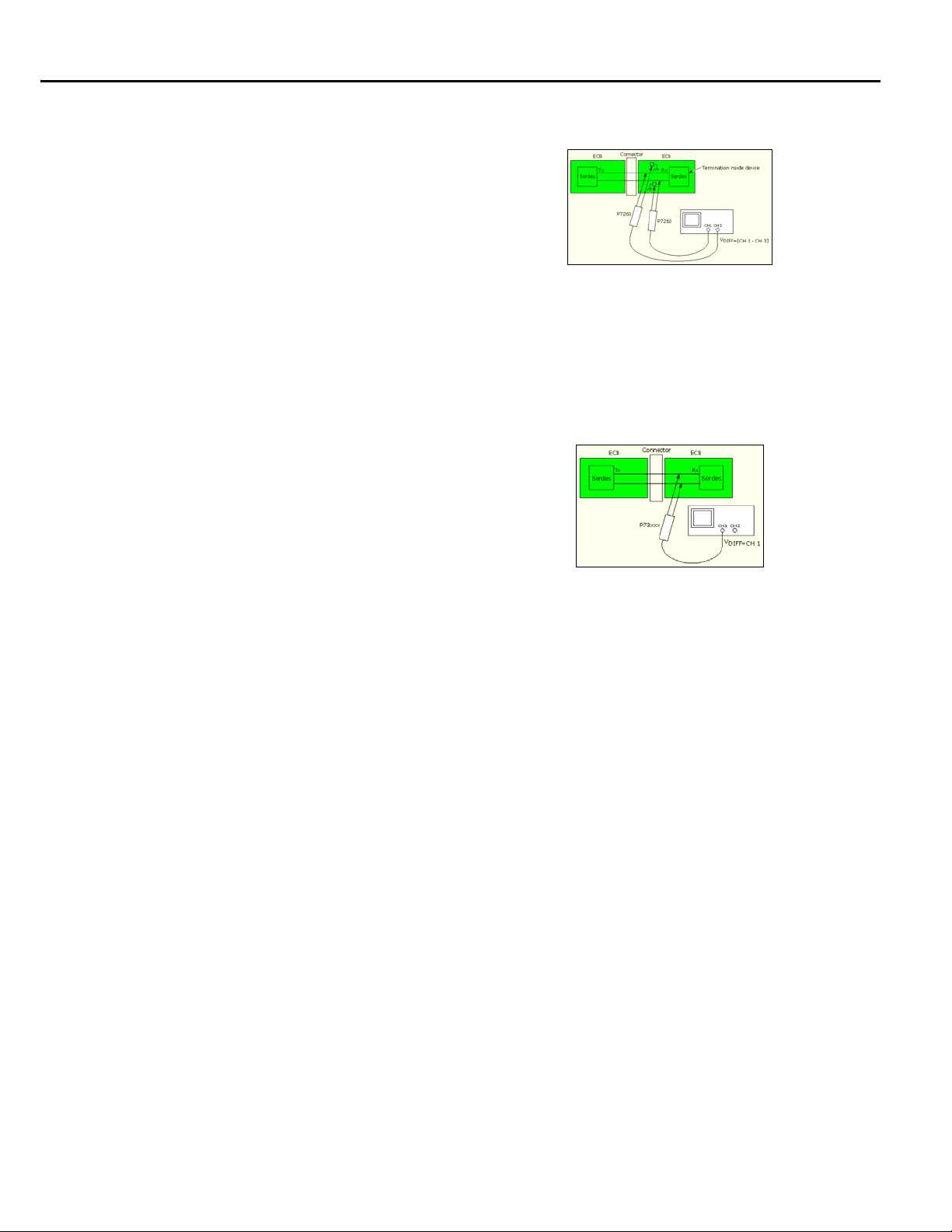

3.2.2 ECB pad connection

3. Two P7260 single ended active probes (Ch1)

and (Ch3)

The differential signal is created by the RTEye SW from the math waveform Ch1-Ch3.

The Common mode AC measurement is also

available in this configuration from the

common mode waveform (Ch1+Ch3)/2. This

probing technique can be used for either a live

link that is transmitting data, or a link

terminated into a “dummy load.” In both cases,

the single ended signals should be probed as

close as possible to the termination resistors on

both sides with the shortest ground connection

possible. Ch-Ch deskew is required using this

technique because two channels are used.

4. One Differential probe

The differential signal is measured directly

across the termination resistors. This probing

technique can be used for either a live link that

is transmitting data, or a link terminated into a

“dummy load.” In both cases, the signals

should be probed as close as possible to the

termination resistors. A single channel of the

oscilloscope is used, so de-skew is not

necessary. Two P7350 differential probes can

be used to create probing configuration shown

in configuration “C” above.

Probe Configuration C

Two Single Ended Active Probes

Probe Configuration D

One Differential Active Probe

4 Configuring a Device Under Test (DUT) for Compliance

Measurements

To perform compliance measurements on an InfiniBand link, it is required that the link be configured to

generate Back to Back TS1 (BTBTS1) test pattern. The following describes various methods of obtaining a

TS1 signal out of ones HCA/TCA.

Beacon Method. The InfiniBand beacon signal is the default signal which is broadcast on a repeating basis

when there is no form of link established. The Beacon is comprised of 100 mSec of sleep state followed by

1 mSec of TS1’s back to back. A simple edge trigger on an instrument is capable of triggering on the leading

edge of this 1 mSec interval of TS1’s. It is recommended however that one use a delayed trigger of at least

50 uSec ensure the RC ramping found on the leading edge of this TS1 beacon be excluded from any

measurements. The trigger menu setup from TDS oscilloscopes to establish this delay is shown in Figure 3.

InfiniBand Compliance Measurements 7

Page 12

Methods of Implementation

Figure 3 – Beacon method

Loop-Back Method. This method loops back the transmit line from an un-used lane into the receive lane 0

(Figure 4). This results in a periodic (100 mSec) link state training machine stimulus into IbtxIn(0) which

triggers a state change into the LTSM’s "configuration" state. The LTSM will broadcast 100 mSec of TS1’s

in a back to back form. This is the simplest method for generating the BTBTS1 pattern.

Note: The LTSM’s Config.RcvrCfg state generally cycles back around immediately into the

Config.debounce state in this configuration with no non-deterministic intervals introduced. Some systems

handle the transition through the LinkDown Default Idle state differently, and this transition can lead to a

short non-deterministic delay of ~30mSec before recycling into the Config.debounce state. In these systems

use the Instruments timeout trigger capability (dial in 10mSec timeout) combined with a trigger delay to

ensure this region of non-determinstic pre Donfig.debounce idle state does not appear in the region of data

over which jitter computations would occur. Failure to do this can result in an “insufficient number of

pattern repeats” warning.

Figure 4 – Loop back method

5 Initial Oscilloscope Setup

After hooking up to the DUT with the proper probing configuration for the test, press the DEFAULT frontpanel button and then the AUTOSET button to display the serial data bit stream.

8 InfiniBand Compliance Measurements

Page 13

Methods of Implementation

6 Running the RT-Eye Software

1. Go to File > Run Application > RT-Eye Serial Compliance and Analysis.

Figure 5 – Default menu of the RT-Eye software

Figure 5 shows the oscilloscope display. The default mode of the software is the Serial Analysis module

(Opt. RTE). This software is intended for generalized Serial Data analysis on 8B/10B encoded copper links.

2. Select the InfiniBand Compliance Module from the Modules pull down list.

Figure 6 – Choosing the InfiniBand Compliance Module

Note: If InfiniBand does not appear in the list, the InfiniBand Compliance Module (Opt. IBA) has not been

installed.

The rest of this document details use of the RT-Eye InfiniBand Compliance Module to perform electrical

compliance measurements.

Online Help is available under the Help Menu for the software when it’s in the Serial Analysis Module. For

information not contained in this document, refer to the RT-Eye online help or the printable format.

InfiniBand Compliance Measurements 9

Page 14

Methods of Implementation

6.1 DC Common Mode Measurement MOI

This test checks DC common mode voltage from the driver using Tektronix real-time oscilloscope, probes,

and RT-Eye compliance software. This test checks the common mode voltage level of the transmitter

output signal, is defined for a single physical bit lane, and must be repeated for each bit lane of each port

on the DUT.

• TD Assertion covered: V2c6-007.

• V

CM is defined in Vol. 2, Section 6.4, table Differential Output DC Characteristics,

Maximum V

• Integrator List Test: No.

• DUT Signaling: The test is performed on the TS1 ordered-sets captured by the oscilloscope while the

DUT is in the Polling Active state described in section 3.3

• Probing Configuration: Probe Configuration C - Use two P7260 or two P7240 active probes.

• Test Procedure is as follows:

• Connect the probe for the positive leg of the differential to Ch1 and the negative leg to Ch3.

CM=1.0V and Minimum VCM=0.50V.

• In the RT-Eye InfiniBand compliance module, select Single Ended as the Probe Type.

• Select CM Voltage as the measurement.

• Select the Configure Button to access the Configuration menu.

• Select the Source Tab and set up that menu as follows:

o Live as the Source Type.

o Select Ch1, Ch3 as the D+, D-.

• Select the Start button.

The RT-Eye application gives measurement results along with a Pass /Fail indication of the measurement.

See Figure 7.

Figure 7 - Result of the DC Common Mode Measurement

10 InfiniBand Compliance Measurements

Page 15

Methods of Implementation

6.2 AC Common Mode Measurement MOI

This test checks the AC common mode voltage from the driver using a Tektronix real-time oscilloscope

and RT-Eye software. This test checks the common mode voltage level of the transmitter output signal, is

defined for a single physical bit lane, and must be repeated for each bit lane of each port on the DUT.

• TD Assertion covered: None.

• V

CM is defined in Vol. 2, Section 6.4, table Differential Output DC Characteristics,

Maximum VAC

• Integrator List Test: No.

• DUT Signaling: The test is performed on the TS1 ordered-sets captured by the oscilloscope while the

DUT is in the Polling Active state described in section 3.3.

• Probing Configurations (from section 3.2):

• Configuration A – Use TCA-SMA connectors with blocking capacitors.

• Configuration C - Use two P7260 or two P7240 active probes.

• Test Procedure as follows:

CM =25 mV RMS.

• Connect the probe for the positive leg of the differential to Ch1 and the negative leg to Ch3.

• In the RT-Eye InfiniBand compliance module, select Single Ended as the Probe Type.

• Select AC CM Voltage as the measurement.

• Select the Configure button to access the Configuration menus.

• Select the Source tab and set up that menu as follows:

o Live as the Source Type.

o Select Ch1, Ch3 as the D+, D-.

• Select the Start button.

The RT-Eye application gives measurement results along with a Pass /Fail indication of the measurement.

See Figure 8.

Figure 8 - Result of AC Common Mode Measurement

InfiniBand Compliance Measurements 11

Page 16

Methods of Implementation

6.3 Transmitter Peak-Peak Measurement MOI

This test checks the Pk-Pk voltage from the driver using a Tektronix real-time oscilloscope and RT-Eye

software. This test checks the Pk-Pk differential voltage level of the transmitter output signal, is defined for

a single physical bit lane, and must be repeated for each bit lane of each port on the DUT. An eye diagram

is displayed to give additional information on the health of the transmitter.

• TD Assertion covered: V2c6-007#02

• Vdiff is defined in Vol. 2, Section 6.4, table Differential Output Differential Pk-Pk Voltage

Characteristics.

Maximum Vdiff = 1.6 V Pk-Pk, Minimum Vdiff is dependent on the test point.

Table 5 – Chapter 6 Test Point Descriptions, from Table 19 of the Specification*

Test

point

TP1 Transmitted signal at the board side of the backplane connector .800 250 ps

TP2 Transmitted signal at the backplane side of the backplane connector .750 240 ps

Description

Unsigned

Waveform

Amplitude

(IEEE181)

Eye Width

TP3 Received signal at the board side of the connector .316 150 ps

TP4 Received signal at the backplane side of the connector .335 160 ps

TP5 Transmitted signal at the board side of the cable connector .890 250 ps

TP6 Transmitted signal at the cable side of the cable connector .820 240 ps

TP7 Received signal at the board side of the cable connector .282 150 ps

TP8 Received signal at the cable side of the cable connector .300 160 ps

TP9 Transmitted signal at the board side of the pluggable interface socket .890 296 ps

TP10 Received signal at the board side of the pluggable interface socket .282 126 ps

* Measurements will require de-embedding or other compensation technique for properties of measurement

fixtures and test equipment.

• Integrator List Test: Yes

• DUT Signaling: The test is performed on the TS1 ordered-sets captured by the oscilloscope while the

DUT is in the Polling Active state described in section 3.3.

• Probing Configurations (from section 3.2):

• Configuration A – Use TCA-SMA connectors with blocking capacitors.

• Configuration B – Use P7350SMA probe (recommended).

• Connect via port breakout (Fujikura fixture in 4X case) to SMA inputs of probe configuration.

12 InfiniBand Compliance Measurements

Page 17

Methods of Implementation

• Test Procedure is as follows:

• Connect the SMA connectors from the Break-out Harness to Ch1 and Ch3 of the oscilloscope, or

to Ch1 depending on the probe configuration used.

• In the RT-Eye InfiniBand compliance module, select Single Ended as the Probe Type if using

probe configuration (A), or Differential as the Probe Type if using probe configuration (B).

• Select Eye Height and Differential Voltage as the measurements.

• Select the Configure button to access the Configuration menus.

• Select the Source tab and set up that menu as follows:

o Live as the Source Type.

o Select Ch1, Ch3 as the D+, D- if using probe configuration (A) or select Ch1 if using probe

configuration (B).

• Select the Start button.

The RT-Eye application gives measurement results along with a Pass /Fail indication of the measurement.

See Figure 9.

Figure 9 - Result of the Differential Amplitude Measurement

The last two lines report Pass/Fail on Min and Max of Diff Voltage Pk-Pk. The waveform is also compared

to a waveform mask where the vertical and horizontal dimensions are defined by amplitude and jitter eye

width. Note that the Lower Limit on the voltage is listed as 986 mV. The specification indicates 890 mV as

the lower limit to TP5. Care should be taken to properly account and compensate for (Instruments external

attenuation menu) for all line losses between the test-point and the instrument inputs.

The signal tested in this example exhibited 989 mV Pk-Pk amplitude. The measurement is a cycle-cycle

differential voltage measurement on a 101 or a 010 bit combination. Note that this voltage is higher than

the measured Eye Height in the eye diagram (960 mV).

InfiniBand Compliance Measurements 13

Page 18

Methods of Implementation

This is typical, since the eye diagram adds a “smearing affect” that hides the true minimum differential PkPk number. If you select the Details button in the RT-Eye software, it can be seen that the Min and Max

Pk-Pk measurement were derived from 23,283 valid measurements within the real time acquisition. See

Figure 10.

Figure 10 - Details View of Pk-Pk measurement

6.4 Rise/Fall Time Measurements

This test checks the Transition Times from the driver using Tektronix real-time oscilloscope and RT-Eye

software. This test checks the 20-80% Rise/Fall times of the transmitter output signal and compares them

against the specified limits. This test is defined for a single physical bit lane and must be repeated for each

bit lane of each port on the DUT.

• TD Assertion covered: V2c6-007#05

• tDRF is defined in Vol. 2, Section 6.4, Table 16 of the specification, Characteristics

Minimum tDRF = 100 ps.

• Integrator List Test: Yes

• DUT Signaling: The test is performed on the TS1 ordered-sets captured by the oscilloscope while the

DUT is in the Polling Active state described in section 3.3.

• Probing Configurations (from section 3.2):

• Configuration A – Use TCA-SMA connectors with blocking capacitors.

• Configuration B – Use P7350SMA probe (recommended).

• Connect via port breakout (Fujikura fixture in 4X case) to SMA inputs of probe configuration.

• Test Procedure is as follows:

• Connect the SMA connectors from the Break-out Harness to Ch1 and Ch3 of the oscilloscope, or

to Ch1 depending on the probe configuration used.

• In the RT-Eye InfiniBand compliance module, select Single Ended as the Probe Type if using

probe configuration (A) or Differential as the Probe Type if using probe configuration (B).

• Select Eye Height and Differential Voltage as the measurements.

• Select the Configure button to access the Configuration menus.

• Select the Source tab and set up that menu as follows:

o Live as the Source Type.

o Select Ch1, Ch3 as the D+, D- option if using probe configuration (A), or select Ch1 if using

probe configuration (B).

14 InfiniBand Compliance Measurements

Page 19

Methods of Implementation

• Select the Meas Params tab and set up that menu as follows:

o TP6 (Transmitted signal at the cable side of the cable connector) as the Test Point.

o Stand By or Disable as the Differential Voltage Mode.

• Select the Start button.

The RT-Eye application gives measurement results along with a Pass /Fail indication of the measurement.

See Figure 11.

Figure 11 - Results of Transition Time Test

6.5 Driver Jitter Measurements

This test checks the Total Jitter from the driver using Tektronix real-time oscilloscope and RT-Eye

software. This test checks the values of Total Jitter @ 10

-12

BER and Deterministic Jitter and compares

them against the specified limits. This test is defined for a single physical bit lane and must be repeated for

each bit lane of each port on the DUT.

• TD Assertion covered: V2c6-007#14

• Total Jitter (J

) and Deterministic Jitter (JD) for the driver are defined in Vol. 2, Section 6.4, Table

T

16 Driver Characteristics. Jitter Eye Opening at different compliance points are defined in Table 5.

• Integrator List Test: Yes

• DUT Signaling: The test is performed on the TS1 ordered-sets captured by the oscilloscope while the

DUT is in the Polling Active state described in section 3.3.

• Probing Configurations (from section 3.2):

• Configuration A – Use TCA-SMA connectors with blocking capacitors.

• Configuration B – Use P7350SMA probe (recommended).

• Connect via port breakout (Fujikura fixture in 4X case) to SMA inputs of probe configuration.

• Test Procedure is as follows:

• Connect the SMA connectors from the Break-out Harness to Ch1 and Ch3 of the oscilloscope, or

to Ch1 depending on the probe configuration used.

• In the RT-Eye InfiniBand compliance module, select Single Ended as the Probe Type if using

probe configuration (A) or Differential as the Probe Type if using probe configuration (B).

• Select Jitter @ BER as the measurement.

• Select the Configure button to access the Configuration menus.

InfiniBand Compliance Measurements 15

Page 20

Methods of Implementation

• Select the Source tab and set up that menu as follows:

o Live as the Source Type.

o Select Ch1, Ch3 as the D+, D- option if using probe configuration (A), or select Ch1 if using

probe configuration (B).

• Select the Meas Params tab and set up that menu as follows:

o TP6 (Transmitted signal at the cable side of the cable connector) as the Test Point.

o Stand By or Disable as the Differential Voltage Mode.

• Select the Start button.

The RT-Eye application gives measurement results along with a Pass /Fail indication of the measurement.

See Figure 12.

Figure 12 - Results of the Jitter Eye Opening @ 10

-12

BER Measurement

The results of the Total Jitter can be directly compared to Table 5, where:

Total Jitter + Jitter Eye Opening = 400ps (1UI)

Deterministic Jitter can be viewed by selecting it in the Measurement Details menu as shown in Figure 13.

Figure 13 – Deterministic jitter results

16 InfiniBand Compliance Measurements

Page 21

Methods of Implementation

6.6 Combining Driver Measurements

Using the RT-Eye InfiniBand Compliance Module (Opt. IBA). all measurements can be made in a single

acquisition. Measurements that can be combined into a single acquisition are as follows:

• Eye Height/Eye Width

• Rise Time/Fall Time

• Unit Interval

• Jitter @ BER (RJ, DJ, TJ, and Jitter Eye Opening)

• Differential Voltage

7 InfiniBand Cable Measurements

7.1 Required Equipment

The following equipment is required to make the measurements in this document.

• TDS/CSA7404 or TDS6000 series oscilloscope equipped with TDS RT-Eye software (Opt. RTE)

and InfiniBand Compliance Module (IBA).

• DTG5000 series or AWG710 signal generator

• Probes – Probing configuration is MOI specific. Refer to each MOI for proper probe configuration.

• InfiniBand cable test fixture (available from Gore; see Figure 14)

Figure 14 – Gore cable test fixture

InfiniBand Compliance Measurements 17

Page 22

Methods of Implementation

7.2 Connecting to the Driver Under Test

The connection method to the Device Under test is shown in Figure 15.

Low Jitter

(<30pSec Pk)

Signal Source

2.5Gb/Sec Aggressor Signal

IB Connector

Figure 15 – Test Setup for IB cable testing

This test setup shows the use of a P7350SMA Differential Active probe with SMA inputs. Alternatively,

each leg of the differential signal being tested can be connected to Ch1 and Ch3 of the oscilloscope and the

measurement can be made in a pseudo-differential manner.

7.3 Configuring the Device Under Test (DUT) for Compliance Measurements

The signal generator is setup to transmit a repeating CJTPAT (Compliance Jitter Test Pattern).

7.4 Initial Oscilloscope Setup

After connecting to the DUT with the proper probing configuration for the test, press the DEFAULT frontpanel button and then the AUTOSET button to display the serial data bit stream.

7.5 Running the RT-Eye Software

Go to File > Run Application > RT-Eye Serial Compliance and Analysis. The result should be similar to

Figure 3.

18 InfiniBand Compliance Measurements

Page 23

Methods of Implementation

7.6 Cable Connected Minimum Differential Voltage

This test checks cable assembly minimum differential voltage using Tektronix real-time oscilloscope and

signal source. This test checks the minimum differential output voltage peak to peak of the Cable

connector output signal. This test is defined for a single physical bit lane and must be repeated for each bit

lane on the DUT(differential pair of cable).

• TD Assertion covered: V2c7-002#010

• Total Jitter (J

) and Deterministic Jitter (JD) for the driver are defined in Vol. 2, Section 6.4, Table

T

16 Driver Characteristics. Jitter Eye Opening at different compliance points are defined in Table 19

of the specification.

Notes:

• The test applies to the cable connector and to the cable assembly (ambiguously defined in the

InfiniBand Architecture Specification 1.1)

• Required instruments:

• Oscilloscope: TDS6604, TDS7404 or CSA7404 with SM option

• Signal source: Arbitrary Waveform Generator AWG610, AWG710, or DTG5000 Series.

• Differential Amplitude = 1 Vpp

• VCout (peak-peak), minimum differential output Voltage (peak-peak) limits defined in Vol.2,

Section 7.9.2, table Cable assembly electrical performance requirements.

• Vmeas is the minimum differential voltage measured at the center of the eye Diagram (Eye

Height).

• Test must be performed on each lane on the DUT.

• Integrator List Test: Yes

• DUT Signaling: The test is performed on the CJTPAT Ordered Sets captured by the oscilloscope.

The voltage measurement is taken for 1 Vpp Fibre Channel CJTPAT stimulus for 1000 waveforms or

equivalent.

• Probing Configurations (from section 3.2):

• Configuration A – Use TCA-SMA connectors with blocking capacitors.

• Configuration B – Use P7350SMA probe (recommended).

• Connect via port breakout (Fujikura fixture in 4X case) to SMA inputs of probe configuration.

• Test Procedure:

• Connect SMA connectors from Break-out Harness to Ch1 and Ch3 of the oscilloscope, or to Ch1

depending on the probe configuration used.

• In the RT-Eye InfiniBand compliance module, select Single Ended as the Probe Type if using

probe configuration (A) or Differential as the Probe Type if using probe configuration (B).

• Select Eye Width/Eye Height as the measurement.

• Select the Configure button to access the Configuration menus.

InfiniBand Compliance Measurements 19

Page 24

Methods of Implementation

• Select the Source tab and set up that menu as follows:

o Live as the Source Type.

o Select Ch1, Ch3 as the D+, D- if using probe configuration (A) or select Ch1 if using probe

configuration (B).

• Select the Start button.

The RT-Eye application gives measurement results along with a Pass /Fail indication of the measurement.

See Figure 16.

Figure 16 - Results of the Cable Connected Minimum Differential test

7.7 Combining Cable Measurements

Using the RT-Eye InfiniBand Compliance Module (Opt. IBA). All measurements can be made in a single

acquisition. Measurements that can be combined into a single acquisition are as follows:

8 Giving a Device an ID

The InfiniBand Compliance Module provides a graphical user interface for entering a Device ID and

Description. Data entered here will appear on the compliance report and is recommended for device

tracking.

9 Creating a Compliance Report

To create a compliance report, select Utilities > Reports. The Report Generator utility can create a complete

report of the compliance test.

20 InfiniBand Compliance Measurements

Page 25

Methods of Implementation

10 Appendix A – Measurement Algorithms

This section is under development.

InfiniBand Compliance Measurements 21

Page 26

Methods of Implementation

22 InfiniBand Compliance Measurements

Loading...

Loading...