Service Manual

HFS 9009

Stimulus System

070-8366-03

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to the Safety Summary prior to

performing service.

Copyright T ektronix, Inc. 1991, 1994. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Table of Contents

Specifications

Operating Information

Theory of Operation

General Safety Summary vii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Safety Summary xi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal Traits 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

W arranted Characteristics 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ypical Characteristics 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Selections 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resetting the HFS 9009 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Time Base 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The UNDO Button 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Output 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Descriptions 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backplane 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fans 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cards 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Card 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Base Card 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Generator Cards 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Time Generator Cards 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification

Required Test Equipment 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T est Record 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verification Sequence 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Procedures 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HFS 9009 Service Manual

Self Test 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Instrument Setup 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Level Checks (HFS 9DG1 Card Only) 4–13. . . . . . . . . . . . . . . . . . . . . . .

Output Level Checks (HFS 9DG2 and HFS 9PG2 Cards Only) 4–16. . . . . . . . .

Output Level Checks (HFS 9PG1 Card Only) 4–19. . . . . . . . . . . . . . . . . . . . . . .

Trigger Output Level 4–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rise Time and Fall T ime Checks (HFS 9PG1 and HFS 9DG1 Cards Only) 4–22

Rise Time and Fall T ime Checks (HFS 9PG2 and HFS 9DG2 Cards Only) 4–25

Edge Placement Checks 4–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Accuracy Check 4–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phase Lock Check 4–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Contents

Adjustment Procedures

Maintenance

Adjustments 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Replacement 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Keypad and Encoder Switch 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display Module 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T op Panel Circuit Board and Trim Bezel 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ON/ST ANDBY Switch 6–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cards 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mainframe T op Cover 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply (lower back panel) 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fans (upper back panel) 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan (side panel) 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-On Diagnostics 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Kernel-T est Diagnostics 6–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller-Test Diagnostics 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Test Diagnostics 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Test Diagnostics 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Indications 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Assignments For Diagnostic LEDs 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Procedure 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options Electrical Parts List Diagrams

Mechanical Parts List

Block Diagram 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Parts List 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Ordering Information 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Replaceable Parts List 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

HFS 9009 Service Manual

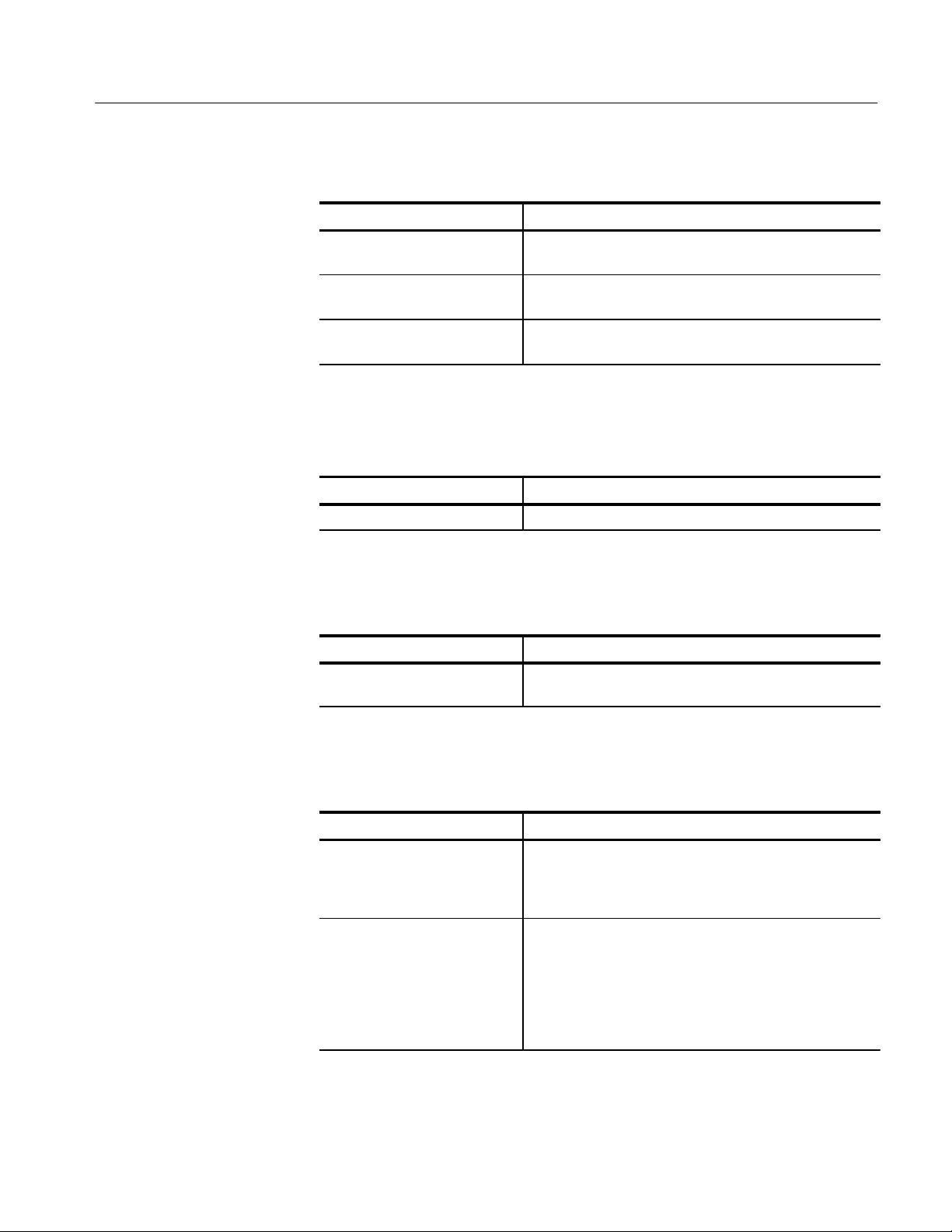

List of Figures

Contents

Figure 2–1: HFS 9009 Mainframe, Cards, and Front Panel 2–1. . . . . . . .

Figure 2–2: MAIN MENU, SELECT, and Arrow Button Locations 2–2.

Figure 2–3: Main Menu Display 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: The Time Base Menu 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: Mode set to Auto-Burst 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–6: Controls and Connectors for the Pulse Generator, Data

Generator, and Time Base Cards 2–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6–1: Clock Distribution Cable Location 6–6. . . . . . . . . . . . . . . . . .

Figure 6–2: HFS 9009 Power Supply (rear view) 6–8. . . . . . . . . . . . . . . . .

Figure 6–3: The Location of LEDs on the CPU Card 6–14. . . . . . . . . . . . .

Figure 6–4: Bit Assignments for Diagnostic LEDs 6–15. . . . . . . . . . . . . . . .

Figure 6–5: Diagnostic Procedure Flowchart 6–17. . . . . . . . . . . . . . . . . . . .

Figure 9–1: Module Block and Interconnection Diagram 9–2. . . . . . . . . .

Figure 10–1: Cabinet 10–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–2: Front Panel 10–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10–3: Mainframe and Chassis Parts 10–9. . . . . . . . . . . . . . . . . . . . .

Figure 10–4: Power Supply and Fan Assembly 10–11. . . . . . . . . . . . . . . . . .

Figure 10–5: Circuit Cards 10–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HFS 9009 Service Manual

iii

Contents

List of Tables

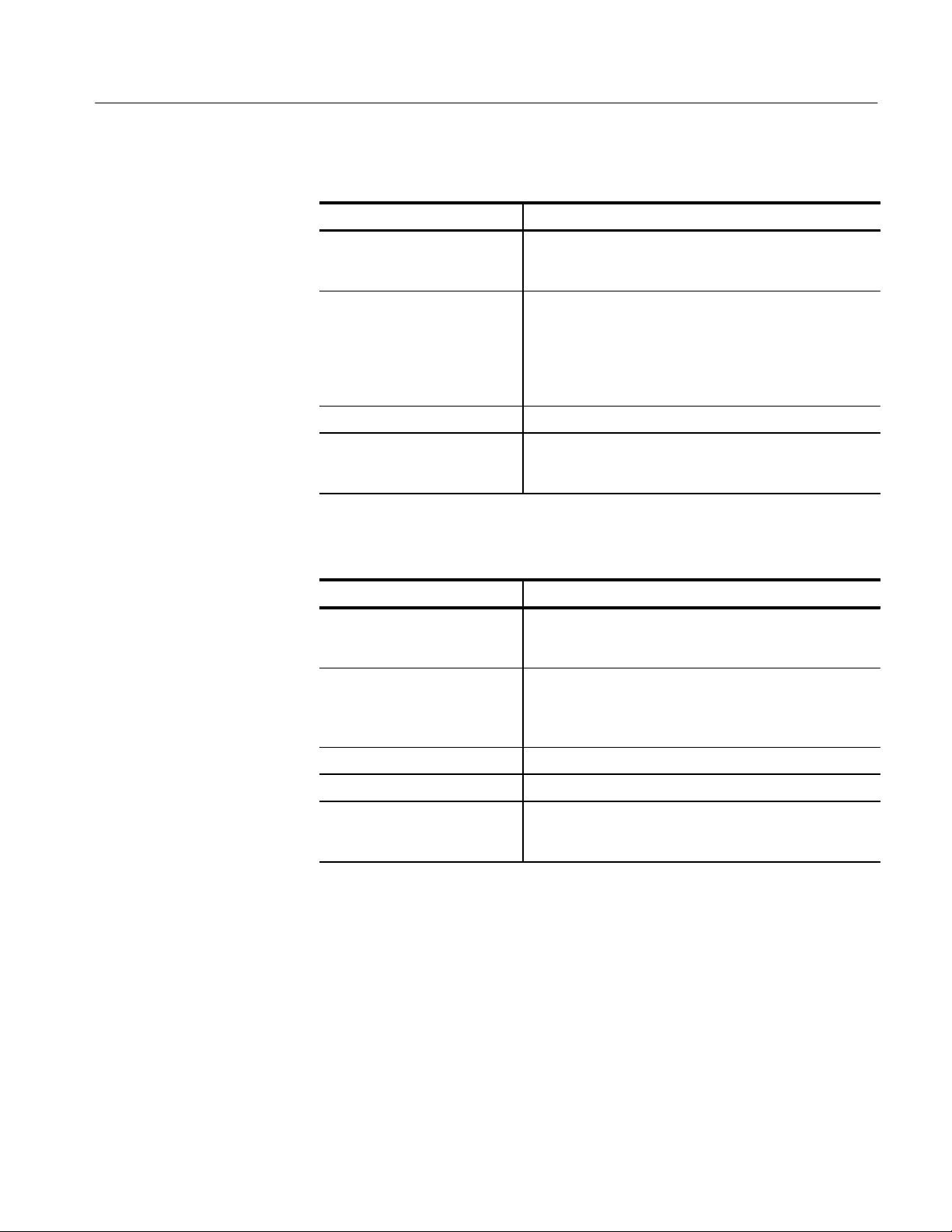

Table 1–1: Nominal Traits — HFS 9PG1 Output Performance 1–1. . . .

Table 1–2: Nominal Traits — HFS 9PG2 Output Performance 1–2. . . .

Table 1–3: Nominal Traits — HFS 9DG1 Output Performance 1–3. . . .

Table 1–4: Nominal Traits — HFS 9DG2 Output Performance 1–3. . . .

Table 1–5: Nominal Traits — Time Base 1–4. . . . . . . . . . . . . . . . . . . . . . .

Table 1–6: Nominal Traits — Performance to External Frequency

Reference 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Nominal Traits — Output Edge Placement Performance 1–5

Table 1–8: Nominal Traits — Transducer In Performance 1–5. . . . . . . .

Table 1–9: Nominal Traits — Skew Cal In Performance 1–5. . . . . . . . . .

Table 1–10: Nominal Traits — Trigger In Performance 1–6. . . . . . . . . . .

Table 1–11: Nominal Traits — Trigger Out Performance 1–6. . . . . . . . .

Table 1–12: Nominal Traits — Power Requirements 1–6. . . . . . . . . . . . .

Table 1–13: Nominal Traits — System Memory Performance 1–6. . . . .

Table 1–14: Nominal Traits — HFS 9003 Mechanical 1–7. . . . . . . . . . . .

Table 1–15: Nominal Traits — HFS 9009 Mechanical 1–7. . . . . . . . . . . .

Table 1–16: Warranted Characteristics — HFS 9PG1 Output

Performance 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–17: Warranted Characteristics — HFS 9PG2 Output

Performance 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–18: Warranted Characteristics — HFS 9DG1 Output

Performance 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–19: Warranted Characteristics — HFS 9DG2 Output

Performance 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–20: Warranted Characteristics — Time Base 1–9. . . . . . . . . . . .

Table 1–21: Warranted Characteristic — Performance to External

Frequency Reference 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–22: Warranted Characteristics — Output Edge Placement

Performance 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–23: Warranted Characteristics — Trigger Out Performance 1–10

Table 1–24: Warranted Characteristics — Power Requirements 1–10. . .

Table 1–25: Warranted Characteristics — Environmental and

Safety 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–26: Typical Characteristics — Time Base 1–11. . . . . . . . . . . . . . .

Table 1–27: Typical Characteristics — HFS 9PG1 Output

Performance 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

HFS 9009 Service Manual

Contents

Table 1–28: Typical Characteristics — HFS 9PG2 Output

Performance 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–29: Typical Characteristics — HFS 9DG1 Output

Performance 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–30: Typical Characteristics — HFS 9DG2 Output

Performance 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–31: Typical Characteristics — Performance to External

Frequency Reference 1–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–32: Typical Characteristics — Transducer In Performance 1–13

Table 1–33: Typical Characteristics — Trigger In Performance 1–13. . . .

Table 1–34: Typical Characteristics — Trigger Out Performance 1–14. .

Table 1–35: Typical Characteristics — Power Requirements 1–14. . . . . .

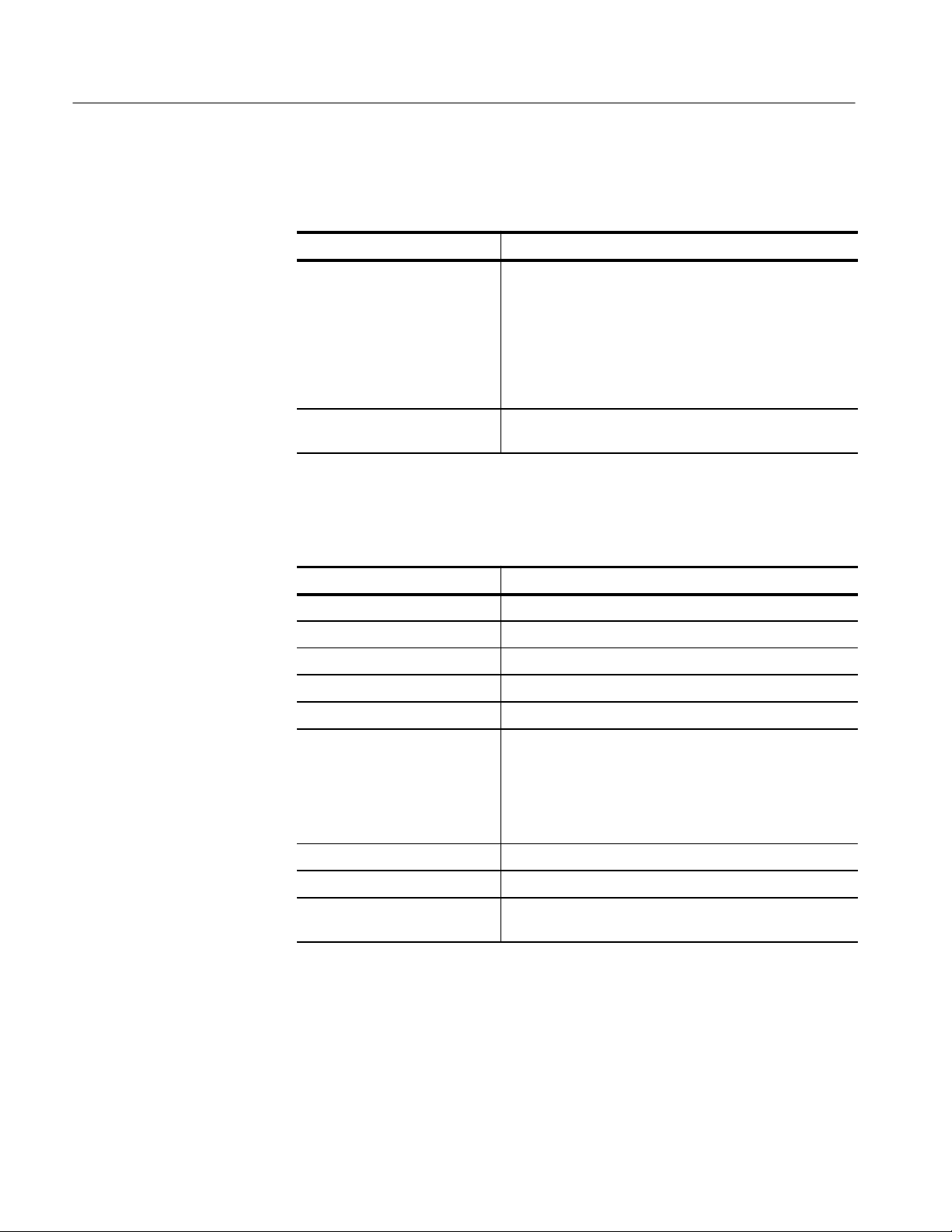

Table 4–1: Required Test Equipment 4–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–2: Trigger Output Level and Phase Lock Test 4–3. . . . . . . . . . . .

Table 4–3: Test Record for HFS 9DG1 Card 4–4. . . . . . . . . . . . . . . . . . . .

Table 4–4: Test Record for HFS 9DG2 Card 4–6. . . . . . . . . . . . . . . . . . . .

Table 4–5: Test Record for HFS 9PG1 Card 4–7. . . . . . . . . . . . . . . . . . . .

Table 4–6: Test Record for HFS 9PG2 Card 4–9. . . . . . . . . . . . . . . . . . . .

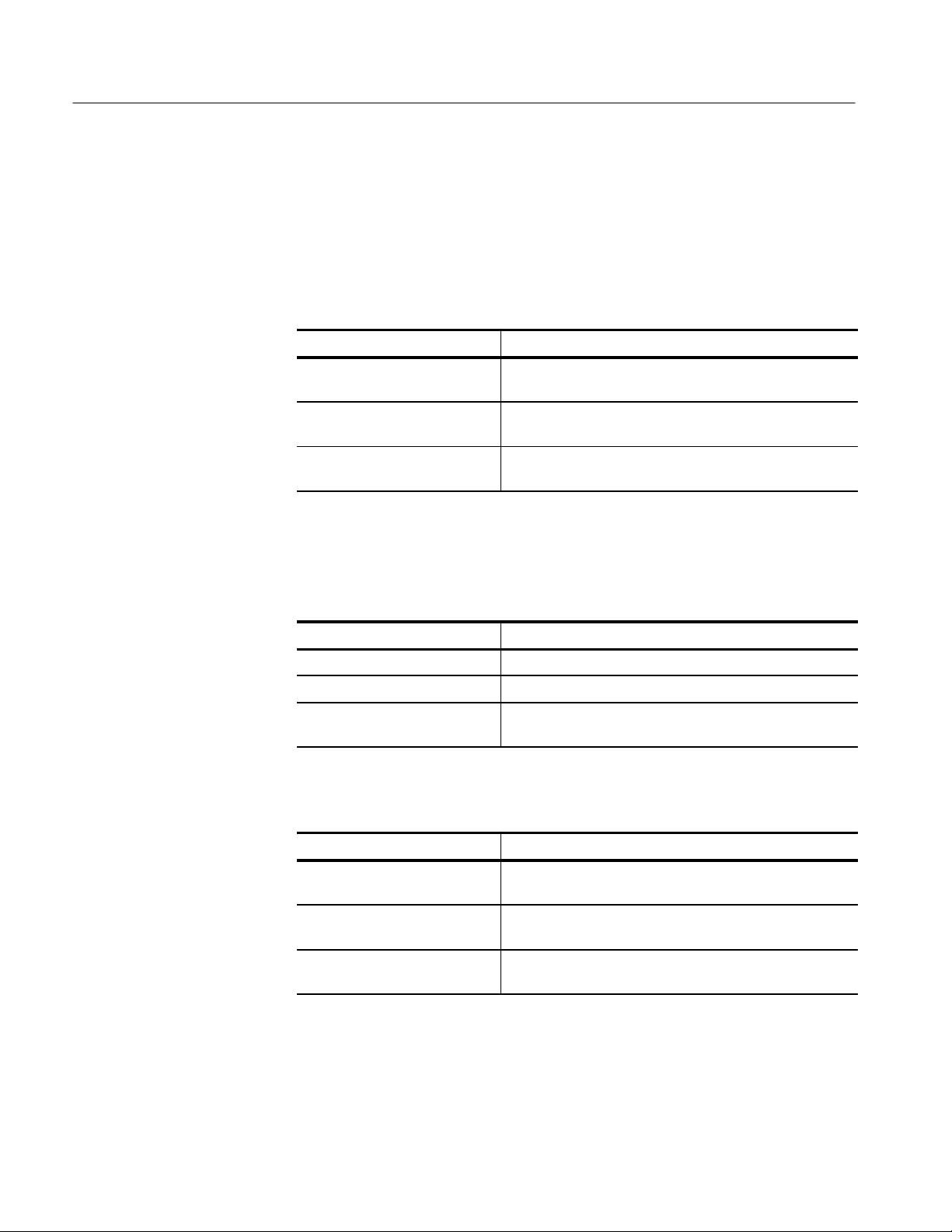

Table 4–7: HFS 9DG1 Output Level Checks, First Settings 4–14. . . . . . .

Table 4–8: HFS 9DG1 Output Level Checks, Second Settings 4–14. . . . .

Table 4–9: HFS 9DG1 Output Level Checks, Third Settings 4–15. . . . . . .

Table 4–10: HFS 9DG1 Output Level Checks, Fourth Settings 4–15. . . . .

Table 4–11: HFS 9DG2 and HFS 9PG2 Output Level Checks, First

Settings 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–12: HFS 9DG2 and HFS 9PG2 Output Level Checks, Second

Settings 4–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4–13: HFS 9PG2 Output Level Checks, Third Settings 4–18. . . . . .

Table 4–14: HFS 9PG2 Output Level Checks, Fourth Settings 4–18. . . . .

Table 4–15: HFS 9PG1 Output Level Checks, First Settings 4–19. . . . . . .

Table 4–16: HFS 9PG1 Output Level Checks, Second Settings 4–20. . . . .

Table 4–17: HFS 9PG1 Output Level Checks, Third Settings 4–20. . . . . .

Table 4–18: HFS 9PG1 Output Level Checks, Fourth Settings 4–21. . . . .

Table 4–19: Settings for Trigger Output Check 4–22. . . . . . . . . . . . . . . . .

Table 4–20: Settings for Rise Time and Fall Time Checks 4–23. . . . . . . . .

Table 4–21: DSO Settings for Rise/Fall Time Checks 4–24. . . . . . . . . . . . .

Table 4–22: Settings for Rise Time and Fall Time Checks 4–25. . . . . . . . .

Table 4–23: DSO Settings for Rise/Fall Time Checks 4–26. . . . . . . . . . . . .

Table 4–24: Settings for Edge Placement Checks 4–27. . . . . . . . . . . . . . . .

Table 4–25: Lead Delay Limits for HFS 9PG1 and HFS 9PG2 4–28. . . . .

HFS 9009 Service Manual

v

Contents

Table 4–26: Lead Delay Limits for HFS 9DG1 and HFS 9DG2 4–29. . . .

Table 4–27: Width Variance Limits for HFS 9PG1 4–29. . . . . . . . . . . . . . .

Table 4–28: Width Variance Limits for HFS 9DG1 4–30. . . . . . . . . . . . . .

Table 4–29: Width Limits for HFS 9PG1 and HFS 9PG2 4–30. . . . . . . . .

Table 4–30: Width Limits for HFS 9DG1 4–30. . . . . . . . . . . . . . . . . . . . . .

Table 4–31: Width Limits for HFS 9DG2 4–31. . . . . . . . . . . . . . . . . . . . . .

Table 4–32: Frequency Limits (HFS 9PG1 & HFS 9DG1) 4–32. . . . . . . . .

Table 4–33: Frequency Limits (HFS 9PG2) 4–32. . . . . . . . . . . . . . . . . . . . .

Table 4–34: Frequency Limits (HFS 9DG2) 4–33. . . . . . . . . . . . . . . . . . . .

Table 6–1: Results from *TST? 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6–2: Troubleshooting From the Error Index Code 6–16. . . . . . . . . .

vi

HFS 9009 Service Manual

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Use Proper Power Cord

Avoid Electric Overload

Ground the Product

Do Not Operate Without

Covers

Use Proper Fuse

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

To avoid fire hazard, use only the power cord specified for this product.

To avoid electric shock or fire hazard, do not apply a voltage to a terminal that is

outside the range specified for that terminal.

This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid fire hazard, use only the fuse type and rating specified for this product.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

Product Damage Precautions

Use Proper Power Source

Provide Proper Ventilation

HFS 9009 Service Manual

Do not operate this product from a power source that applies more than the

voltage specified.

To prevent product overheating, provide proper ventilation.

vii

General Safety Summary

Do Not Operate With

Suspected Failures

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Safety Terms and Symbols

Terms in This Manual

Terms on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

Symbols on the Product

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

DANGER

High Voltage

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

Double

Insulated

viii

HFS 9009 Service Manual

Certifications and Compliances

General Safety Summary

CSA Certified Power

Cords

Compliances

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

Consult the product specifications for IEC Installation Category, Pollution

Degree, and Safety Class.

HFS 9009 Service Manual

ix

General Safety Summary

x

HFS 9009 Service Manual

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

To avoid electric shock, do not touch exposed connections.

HFS 9009 Service Manual

xi

Service Safety Summary

xii

HFS 9009 Service Manual

Preface

This Service Manual provides you with limited service information for the

HFS 9009 Precision Pulse Generator.

Use the Specifications section as a reference for all nominal, typical, and

specified characteristics.

Use the Operating Information section to learn about each of the front panel

controls and how to input simple settings for basic operation.

Use the Theory of Operation section to help you understand the operation of

each of the replaceable modules in the HFS 9009.

Use the Performance Verification section to verify the specified performance of

the instrument.

The Adjustment Procedures section lists the adjustment that can be made to the

instrument.

Use the Maintenance section to learn how to perform general preventive

maintenance of the instrument. Removal and replacement and troubleshooting

procedures are also described in this section.

Notation Conventions

The Options section lists the options available from the factory. This section also

describes the procedure for installing field updates to the internal programmed

code of the instrument.

The Diagrams section describes and illustrates the major electrical sections of

the HFS 9009.

The Mechanical Parts List section lists all of the replaceable parts and describes

how to order these parts.

The following conventions are used in this manual:

H Signal names are printed in bold capital letters; for example, SENSE IN.

H A signal active in the low state is shown with a tilde (~) in front of the signal

name; for example, ~ACFAIL.

H Labels of front panel buttons and connectors are shown in bold capital

letters; for example, ENTER.

H Labels of menu items are shown in mixed case bold text; for example, the

Pulse menu Amplitude item.

HFS 9009 Service Manual

xiii

Preface

Related Manuals

Refer to the HFS 9000 User Manual (070-8365-01) for additional operating

information.

xiv

HFS 9009 Service Manual

Specifications

Nominal Traits

The HFS 9000 family of high-speed logic signal source instruments have a

modular architecture with factory-configurable cards. The channels are digitally

synthesized from a common clock resulting in highly accurate independent

placement of rising and falling edges. The instruments are optimized for digital

device characterization with unique triggering capabilities and a variety of pulse

outputs. The product family also features low RMS jitter, the ability to compensate for external cable skews, and an easy-to-use graphical human interface.

This section contains the complete specifications for the HFS 9000 Stimulus

System and Modules. These specifications are classified as either nominal traits,

warranted characteristics, or typical characteristics.

Nominal traits are described using simple statements of fact such as “+2.6 V” for

the trait “Maximum high level,” rather than in terms of limits that are performance requirements.

T able 1–1: Nominal Traits — HFS 9PG1 Output Performance

Each channel and complement driving a 50 load to ground, except as noted.

Name

Maximum high level +2.6 V

Minimum low level –2.00 V

Maximum amplitude 3.00 V

Minimum amplitude 0.50 V

Level resolution 0.01 V

Operation when terminated

through 50 to –2 V

Description

Output levels will be approximately 1 V more negative than

the values programmed, specified, and displayed. Actual

output levels more negative than –2 V may cause

malfunction. Level accuracy specifications do not apply

when terminating to –2 V. Both true and complement

outputs must be terminated to the same voltage.

HFS 9009 Service Manual

1–1

Specifications

T able 1–1: Nominal Traits — HFS 9PG1 Output Performance (Cont.)

Each channel and complement driving a 50 load to ground, except as noted.

Name Description

Operation when terminated to

high impedance loads

Output limits One high limit and one low limit may be enabled or disabled

Output level range will double until certain internal limits are

achieved. Since the programmed, specified, and displayed

output levels do not match the actual output levels, level

accuracy specifications do not apply when terminating to a

high impedance load. Because of the larger voltage swings

associated with doubled level range, output transition time

specifications do not apply when driving a high impedance

load.

together.

T able 1–2: Nominal Traits — HFS 9PG2 Output Performance

Each channel and complement driving a 50 load to ground, except as noted.

Name

Maximum high level +5.50 V

Minimum low level –2.00 V

Maximum amplitude 5.50 V

Minimum amplitude 0.50 V

Level resolution 0.01 V

Operation when terminated

through 50 to –2 V

Transition time 20% to 80% V ariable from 800 ps to 5 ns

Transition time resolution 10 ps

Output limits One high limit and one low limit may be enabled or disabled

Description

Output levels will be approximately 1 V more negative than

the values programmed, specified, and displayed. Actual

output levels more negative than –2 V may cause

malfunction. Level accuracy specifications do not apply

when terminating to –2 V. Both true and complement

outputs must be terminated to the same voltage.

together.

1–2

HFS 9009 Service Manual

T able 1–3: Nominal Traits — HFS 9DG1 Output Performance

Each channel and complement driving a 50 load to ground, except as noted.

Specifications

Name

Maximum high level +5.0V

Minimum low level –2.5 V

Maximum amplitude 3.00 V

Minimum amplitude 0.01 V

Level resolution 0.01V

Operation when terminated

through 50 to –2 V

Operation when terminated to

high impedance loads

Output limits One high limit and one low limit may be enabled or

Description

Output levels will be approximately 1 V more negative than

the values programmed, specified, and displayed. Actual

output levels more negative than –2 V may cause

malfunction. Level accuracy specifications do not apply

when terminating to –2 V. Both true and complement

outputs must be terminated to the same voltage.

Output level range will double until certain internal limits

are achieved. Since the programmed, specified, and

displayed output levels do not match the actual output

levels, level accuracy specifications do not apply when

terminating to a high impedance load. Because of the

larger voltage swings associated with doubled level range,

output transition time specifications do not apply when

driving a high impedance load.

disabled together.

HFS 9009 Service Manual

T able 1–4: Nominal Traits — HFS 9DG2 Output Performance

Each channel and complement driving a 50 load to ground, except as noted.

Name

Maximum high level +5.50 V

Minimum low level –2.00 V

Maximum amplitude 5.50 V

Minimum amplitude 0.01 V

Level resolution 0.01 V

Operation when terminated

through 50 to –2 V

Transition time 20% to 80% V ariable from 800 ps to 6 ns

Description

Output levels will be approximately 1 V more negative than

the values programmed, specified, and displayed. Actual

output levels more negative than –2 V may cause

malfunction. Level accuracy specifications do not apply

when terminating to –2 V. Both true and complement

outputs must be terminated to the same voltage.

1–3

Specifications

T able 1–4: Nominal Traits — HFS 9DG2 Output Performance (Cont.)

Each channel and complement driving a 50 W load to ground, except as noted.

Name Description

Transition time resolution 10 ps

Output limits One high limit and one low limit may be enabled or disabled

together.

T able 1–5: Nominal Traits — Time Base

Name Description

Frequency range HFS 9PG1, HFS 9DG1: 50 kHz to 630 MHz

HFS 9PG2, HFS 9DG2: 50 kHz to 300 MHz

Frequency resolution ≤ 0.1% of frequency setting

1

Minimum frequency setting when

using half, quarter, or eighth

pulse rate modes

2

Number of pulse periods in burst

half pulse rate: 100 kHz

quarter pulse rate: 200 kHz

eighth pulse rate: 400 kHz

User selectable from 1 to 65,536

or auto-burst modes

1

If the HFS 9PG2 or HFS 9DG2 is operated in half pulse rate mode, frequency can be

extended to 600 MHz for the HFS 9PG2 and 630 MHz for the HFS 9DG2.

2

All pulse rate modes result in 50 kHz output frequency.

T able 1–6: Nominal Traits — Performance to External Frequency Reference

Name Description

PHASE LOCK IN input charac-

teristic

Phase lock output frequency

range

FRAME SYNC IN Initiates a burst when using phase lock mode

FRAME SYNC IN input charac-

teristic

0.1 mF DC blocking capacitor followed by 50W termination

to ground

Any 2n multiple or sub-multiple of the phase lock frequency

that is within the allowed frequency range for the card being

used

50 W terminated to –2V

1–4

HFS 9009 Service Manual

T able 1–7: Nominal Traits — Output Edge Placement Performance1

Name Description

Channel deskew (Chan Delay)

range, channels relative to time

zero reference

Channel deskew (Chan Delay)

resolution

–60 ns to 2.0ms

HFS 9PG1, HFS 9PG2: 5 ps

HFS 9DG1, HFS 9DG2: 1 ps

Specifications

Delay (Lead Delay) adjustment

range

Delay (Lead Delay, Trail Delay)

adjustment resolution

Pulse width adjustment range HFS 9PG1, HFS 9PG2: Zero to (one period – 790 ps)

Pulse width adjustment resolution

Fine knob resolution of timing 5 ps

1

Measured at 50% levels, each channel independent.

Zero to 20 ms

HFS 9PG1, HFS 9PG2: 5 ps

HFS 9DG1, HFS 9DG2: 1 ps

inclusive

HFS 9DG1, HFS 9DG2: Zero to (one period × 65,536)

inclusive

HFS 9PG1, HFS 9PG2: 5 ps

HFS 9DG1, HFS 9DG2: 1 ps

T able 1–8: Nominal Traits — Transducer In Performance

Name Description

TRANSDUCER IN input charac-

teristic

HFS 9PG1: 1000 pF DC blocking capacitor followed by

50 W termination to ground

HFS 9PG2: 100 pF DC blocking capacitor followed by 50 W

termination to ground

HFS 9009 Service Manual

T able 1–9: Nominal Traits — Skew Cal In Performance

Name Description

SKEW CAL IN usage Calibration use only . No signal, except from a channel

OUTPUT connector during the calibration process, should

ever be applied to this input.

1–5

Specifications

1

T able 1–10: Nominal Traits — Trigger In Performance

Name Description

Input Voltage range ±5 V maximum

Trigger level range ±4.70 V

Trigger level resolution 100 mV

T able 1–11: Nominal Traits — Trigger Out Performance

Name Description

Pretrigger range, TRIGGER OUT

before time zero reference

TRIGGER OUT pulse width in

auto mode

Zero to 70 ns

00

10

Width

(ns)

1

0.1

0.01 0.1 1 10 100 1000

Output Frequency (MHz)

T able 1–12: Nominal Traits — Power Requirements

Name HFS 9003 Description HFS 9009 Description

Fuse ratings 5 A, 250V, type 3AG,

(Tektronix part 159-0014-00),

and

15 A, 250 V, type 3AG, fast

blow, (Tektronix part

159-0256-00)

4 A, 250 V, type 3AG, fast

blow, (Tektronix part

159-0017-00)

T able 1–13: Nominal Traits — System Memory Performance

Name Description

Non-volatile memory retention

time

Instrument settings and calibration constants are retained

in non-volatile memory for 5 years or more. Card

identification is retained for 10 years. Extended storage

above 50_ C may degrade the life of all non-volatile

memory .

1–6

HFS 9009 Service Manual

Specifications

T able 1–14: Nominal Traits — HFS 9003 Mechanical

Name Description

Weight, in 12-channel configuration. (Shipping weight includes all

standard accessories.)

Overall Dimensions Cabinet Rackmount

Cooling Method Forced-air circulation with no air filter, maximum 318 cfm

Construction Material Chassis parts are constructed of aluminum alloy; bezel is

Net weight: 45 lbs. (20.5 kg) 51 lbs. (23.2 kg)

Shipping weight: 60 lbs. (27.3 kg) 66 lbs. (30.0 kg)

Width: 16.3 in. (414 mm) 19.0 in (483 mm)

Height: 7.0 in. (178 mm) 7.0 in. (178 mm)

Depth: 24.75 in. (629 mm) 24.75 in. (629 mm)

Depth behind

rack flange: — 22.0 in. (559 mm)

glass-filled polycarbonate with Lexan plastic inserts; cabinet

is aluminum with textured epoxy paint.

Cabinet Rackmount

T able 1–15: Nominal Traits — HFS 9009 Mechanical

Name Description

Weight, in 36-channel configuration. (Shipping weight includes all

standard accessories.)

Overall Dimensions Rackmount

Cooling Method, mainframe Forced-air circulation with air filter, maximum 318 cfm

Cooling Method, power supply Forced-air circulation, maximum 106 cfm

Construction Material Chassis parts are constructed of aluminum alloy with Lexan

Net weight: 81 lbs. (33.7 kg)

Shipping weight: 100 lbs. (45.3 kg)

Width: 16.75 in (425.79 mm)

Height: 14.00 in. (355.89 mm)

Depth: 24.00 in. (610.11 mm)

plastic inserts; cabinet is aluminum with textured epoxy

paint.

Rackmount

HFS 9009 Service Manual

1–7

Specifications

Warranted Characteristics

Warranted characteristics are described in terms of quantifiable performance

limits which are warranted. Names of characteristics that appear in boldface type

have checks for verifying the specifications in the Check Procedures section.

T able 1–16: Warranted Characteristics — HFS 9PG1 Output Performance

Name Description

High level accuracy (amplitude

≥ 1 V or high level ≥ 0 V)

1

±2% of level, ±50 mV

Low level accuracy (amplitude

≥ 1 V or high level ≥ 0 V)

Transition time 20% to 80%

(amplitude ≤ 1V)

1

If amplitude < 1 V and high level < 0 V, accuracy typically meets the specification but

is not guaranteed

1

±2% of high level, ±2% of amplitude, ±50 mV

≤ 200ps

T able 1–17: Warranted Characteristics — HFS 9PG2 Output Performance

Name Description

High level accuracy ±2% of level, ±50 mV

Low level accuracy ±2% of high level, ±2% of amplitude, ±50 mV

Transition time accuracy 20%

to 80% (amplitude ≤ 1V)

±10% of setting, ±300 ps

T able 1–18: Warranted Characteristics — HFS 9DG1 Output Performance

Name Description

High level accuracy (amplitude

1

≥ 0.5 V)

±2% of level, ±50 mV

1–8

Low level accuracy (amplitude

1

≥ 0.5 V)

Transition time 20% to 80%

(amplitude ≤ 1V)

1

If amplitude < 0.5 V , accuracy typically meets the specification but is not guaranteed

±2% of high level, ±2% of amplitude, ±50 mV

≤ 250ps

HFS 9009 Service Manual

Specifications

T able 1–19: Warranted Characteristics — HFS 9DG2 Output Performance

Name Description

High level accuracy (amplitude

1

≥ 0.5 V)

±2% of level, ±50 mV

Low level accuracy (amplitude

1

≥ 0.5 V)

Transition time accuracy 20%

±2% of high level, ±2% of amplitude, ±50 mV

±10% of setting, ±300 ps

to 80% (amplitude ≤ 1V)

1

If amplitude < 0.5 V , accuracy typically meets the specification but is not guaranteed.

T able 1–20: Warranted Characteristics — Time Base

Name Description

Frequency accuracy ±1%

T able 1–21: Warranted Characteristic — Performance to External Frequency

Reference

Name Description

PHASE LOCK IN frequency

range

6 MHz to 630 MHz

HFS 9009 Service Manual

T able 1–22: Warranted Characteristics — Output Edge Placement

Performance

Name Description

Delay of pulses relative to time

zero reference (Lead Delay)

accuracy

Pulse width accuracy HFS 9PG1: 1% of width ±300 ps

1

Measured at 50% levels, each channel independent.

1

HFS 9PG1, HFS 9PG2: 1% of (Lead Delay + Chan Delay)

±300 ps

HFS 9DG1, HFS 9DG2: 1% of (Lead Delay + Chan Delay)

±50 ps

HFS 9PG2: 1% of width ±300 ps [for widths 20 ns]; 1%

of width300 ps, –500 ps [for widths 20 ns]

HFS 9DG1: 1% of width 50 –75 ps

HFS 9DG2: 1% of width50 ps, –250 ps [for widths

20 ns]; 1% of width50 ps, –450 ps [for widths

20 ns]

1–9

Specifications

T able 1–23: Warranted Characteristics — Trigger Out Performance

Name Description

TRIGGER OUT signal levels Amplitude ≥ 300 mV (–0.5 V ≥ offset ≥ –1.5 V, driving 50

to ground)

T able 1–24: Warranted Characteristics — Power Requirements

Name Description

Primary circuit dielectric breakdown voltage

Primary Grounding 0.1 maximum from chassis ground and protective earth

1500 VAC

ground

, 60 Hz for 10 seconds without breakdown

RMS

T able 1–25: Warranted Characteristics — Environmental and Safety

Name HFS 9003 Description HFS 9009 Description

Temperature Operating: 0_ C to +50_ C

(32_ F to 122_ F)

Non-operating (storage):

–40_ C to +75_ C (–40_ F

to 167_ F)

Altitude Operating: 4 hours at 3,048 m (10,000 feet). Derate

maximum operating temperature by –1_ C (–1.8_ F) for

each 304.8 m (1,000 feet) above 1,524 m (5,000 feet)

Non-operating: 2 hours at 12,192 m (40,000 feet)

Humidity Operating: 95% RH, non-condensing, from 0_ C to

30_ C (32_ F to 86_ F)

75% RH, non-condensing, from 31_ C to 40_ C (88_ F

to 104_ F)

(MIL-T-28800E, para 4.5.5.1.2.2, Type III, Class 5)

Shock (non-operating) MIL-T-28800E, para 4.5.5.4.1, Type III, Class 5

Resistance to mishandling during

bench use (operating)

Resistance to packaged trans-

portation vibration, sinusoidal, in

shipping package

Resistance to packaged transportation vibration, sinusoidal, in

shipping package

Resistance to packaged transportation random vibration

MIL-T-28800E, para 4.5.5.4.3, Type III, Class 5

Drops of 36 inches on all edges, faces, and corners

National Safe Transit Association, test procedure 1A-B-2

Packaged sinusoidal vibration

National Safe Transit Association, test procedure 1A-B-1

MIL-STD-810D, method 514.3, category I, Figure 514.3-1

Operating: 0_ C to +40_ C

(32_ F to 104_ F)

Non-operating (storage):

–40_ C to +75_ C (–40_ F

to 167_ F)

1–10

HFS 9009 Service Manual

Typical Characteristics

Specifications

T able 1–25: Warranted Characteristics — Environmental and Safety (Cont.)

Name HFS 9009 DescriptionHFS 9003 Description

Safety Listed to UL1244

Certified to CAN/CSA-C22.2 No. 231–M89

IEC Specifications Installation Category II

Pollution Degree 2

Safety Class I

Typical characteristics are described in terms of typical or average performance.

Typical characteristics are not warranted.

T able 1–26: Typical Characteristics — Time Base

Name Description

RMS jitter 15 ps, ±0.05% of interval

Recovery time between bursts or

auto-bursts

15 ms

T able 1–27: Typical Characteristics — HFS 9PG1 Output Performance

Name Description

Transition time 20% to 80% Amplitude ≤ 1V: 150 ps

1 V < Amplitude ≤ 2 V: 190ps

2 V < Amplitude ≤ 3 V: 225ps

Output aberrations (beginning

200 ps after 50% point of transition)

Overshoot: +15%, +20 mV

Undershoot: –10%, –20 mV

HFS 9009 Service Manual

1–11

Specifications

T able 1–28: Typical Characteristics — HFS 9PG2 Output Performance

Name Description

Operation when terminated to

high impedance loads

Output level range will double until certain internal limits are

achieved. Since the programmed, specified, and displayed

output levels do not match the actual output levels, level

accuracy specifications do not apply when terminating to a

high impedance load. Because of the larger voltage swings

associated with doubled level range, output transition time

specifications do not apply when driving a high impedance

load.

Transition time accuracy 20% to

80%

Output aberrations Overshoot: +15%, +20 mV

±10% of setting, ±300 ps

Undershoot: –10%, –20 mV

T able 1–29: Typical Characteristics — HFS 9DG1 Output Performance

Name Description

Transition time 20% to 80% Amplitude ≤ 1V: ≤ 250 ps, 250 ps

1 V < Amplitude < 2 V: 250ps

2V ≤ Amplitude ≤ 3V: 260 ps

Output aberrations Overshoot: +15%, +20 mV

Undershoot: –10%, –20 mV

T able 1–30: Typical Characteristics — HFS 9DG2 Output Performance

Name Description

Operation when terminated to

high impedance loads

Output level range will double until certain internal limits are

achieved. Since the programmed, specified, and displayed

output levels do not match the actual output levels, level

accuracy specifications do not apply when terminating to a

high impedance load. Because of the larger voltage swings

associated with doubled level range, output transition time

specifications do not apply when driving a high impedance

load.

1–12

Transition time accuracy 20% to

80%

Output aberrations Overshoot: +15%, +20 mV

±10% of setting, ±300 ps

Undershoot: –10%, –20 mV

HFS 9009 Service Manual

Specifications

T able 1–31: Typical Characteristics — Performance to External Frequency

Reference

Name Description

PHASE LOCK IN amplitude

range

0.8 V to 1.0 V peak-to-peak

PHASE LOCK IN transition time

requirement

FRAME SYNC IN signal level –1.810V ≤ V

Setup time, rising edge of

FRAME SYNC IN signal to rising

edge of PHASE LOCK IN

Hold time, high level of FRAME

SYNC IN after rising edge of

PHASE LOCK IN

Time from frame sync qualified

phase lock clock cycle to timezero reference

20% to 80% in ≤ 10 ns

≤ –1.475 V

–1.165 V ≤ V

(standard 100 K ECL levels)

650 ps minimum

650 ps minimum

70 ns minimum, 130 ns

low

≤ –0.810 V

high

T able 1–32: Typical Characteristics — Transducer In Performance

Name Description

TRANSDUCER IN useful fre-

quency range

TRANSDUCER IN amplitude

requirement

HFS 9PG1: 25 MHz to > 1GHz

HFS 9PG2: 5 MHz to 300 MHz

1.0 V to 1.5 V peak-to-peak

HFS 9009 Service Manual

T able 1–33: Typical Characteristics — Trigger In Performance

Name Description

Input resistance 50

Trigger level accuracy ±100 mV ±5% of trigger level

Trigger input rise/fall time re-

quirement

Minimum trigger input pulse

width

Trigger sensitivity ≤ 500mV

Time from trigger in to time-zero

reference

≤ 10 ns

1ns

70 ns minimum, 130 ns typical

1–13

Specifications

T able 1–34: Typical Characteristics — Trigger Out Performance

Name Description

Pretrigger resolution 250 ps

T able 1–35: Typical Characteristics — Power Requirements

Name HFS 9003 Description HFS 9009 Description

Line Voltage 90VAC

or 180 V AC

250 VAC

switched automatically

Line frequency 48 Hz to 63 Hz

to 130 VAC

RMS

RMS

, range

RMS

to

90 V AC

RMS

with maximum 7 cards

installed, 104 V AC

132 VAC

9 cards installed, or

180 VAC

250 VAC

switched automatically

to 104 VAC

RMS

with maximum

RMS

to

RMS

, range

RMS

RMS

RMS

to

Power consumption 540 W maximum 1190 W with maximum of 9

cards installed

Inrush surge current 50 A maximum up to 40 ms at 110 VAC

100 A maximum up to 40 ms at 220 VAC

1–14

HFS 9009 Service Manual

Operating Information

The HFS 9009 is built in a C-size VXI card-modular mainframe. It has a CPU

card, a time base card, and up to nine pulse and data generator cards. A front

panel module provides a keyboard and a flat-panel display (see Figure 2–1).

NOTE. Even though the HFS 9009 is built in a VXI mainframe, the instrument

does not follow all VXI standards and therefore is not a true VXI instrument.

Menu Selections

CPU

Time Base

Figure 2–1: HFS 9009 Mainframe, Cards, and Front Panel

This section shows how to input simple settings for basic operation. For a more

thorough explanation of how to set up the instrument, refer to the HFS 9000

Series User Manual.

The front panel MAIN MENU button, shown in Figure 2–2, displays the

top-level menu. Each item in this menu leads to a second-level menu. You can

move through all menus using the arrow keys surrounding the SELECT button.

Each arrow button moves the selection to the next menu item in the direction

indicated. When the desired menu item is highlighted, press the SELECT button

to activate that selection.

Generator Cards

HFS 9009 Service Manual

2–1

Operating Information

Resetting the HFS 9009

MAIN MENU ButtonSELECT and

Arrow Buttons

Figure 2–2: MAIN MENU, SELECT, and Arrow Button Locations

To reset all user-selected parameters to known default settings:

1. Press the MAIN MENU button (see Figure 2–2).

2. Use the arrow buttons to highlight the Save/Recall Menu item in the main

menu (see Figures 2–2 and 2–3). Press the SELECT button.

Figure 2–3: Main Menu Display

3. Highlight the Reset item and press SELECT again.

4. Verify the reset selection by highlighting Yes in the subsequent dialog box,

then press SELECT. (To select options in the dialog box, use the up and

down arrow keys, or turn the knob.)

Setting the Time Base

2–2

All pulse and data generator channels are governed by a single time base. Follow

these steps to set up the time base to self-trigger repeatedly and to specify the

number of pulses to be output from the pulse or data generators.

HFS 9009 Service Manual

Operating Information

1. Press the MAIN MENU button.

2. Highlight the Time Base Menu item in the main menu. Press the SELECT

button.

The time base normally waits for a trigger event, then specifies the number

of pulses (Count) to be generated (see Figure 2–4). After that, the time base

pauses for a rearm time, then waits for the next trigger event. The display

screen above the Time Base menu graphically depicts this sequence.

Figure 2–4: The Time Base Menu

3. Use the arrow keys to highlight the Mode item. Press the SELECT button

twice to select Auto-Burst in the menu item (see Figure 2–5).

Figure 2–5: Mode set to Auto-Burst

The Period and Count settings control the generated pulses. When either of

these items are highlighted, the waveform display above the menu is updated

to illustrate the parameter being adjusted.

4. Select the Period item. Use the knob to adjust the period. To get finer

resolution, press the FINE button. The FINE light illuminates to indicate

that fine mode is selected.

You may also enter numeric values with the keypad. Type in the number and,

if necessary, press a key to specify units. Then finish by pressing the

ENTER key.

HFS 9009 Service Manual

5. Select the Count item. Set a value using the knob or type a value using the

keypad. Press ENTER to terminate keypad entry.

2–3

Operating Information

The UNDO Button

Pulse Output

The Period item can also be used to specify Frequency. When Period is

highlighted, the SELECT button alternates between Period and Frequency.

Use the knob or keypad to set values.

6. Highlight the Period item and press the SELECT button. Observe that the

period setting changes to a reciprocal frequency setting.

The HFS 9009 is now set up to enable the output of pulses. Since the HFS 9009

is in auto-burst mode, no trigger input is required to generate pulses.

Whenever a setting is changed, the HFS 9009 remembers the old setting as well.

Pressing the UNDO button at the right of the display panel restores the last

setting. Pressing it twice undoes the undo.

The following procedure demonstrates how to turn the pulse generator channels

on. Any channel can be turned on from the Pulse menu Output item, but it is

more convenient to turn on a channel from the front panel. Depending on the

configuration of the HFS 9009, up to nine pulse and data generator cards can be

installed, each with at least two channels. The controls for each type of card are

shown in Figure 2–6. (Figure 2–1 shows the placement of the generator cards in

the mainframe.)

1. Select a channel to use for the output by pressing the OUTPUT button for

that channel. Observe that the associated light illuminates. If you want to use

OUTPUT

separately.

The HFS 9009 is now creating pulse bursts. It generates the number of

pulses entered for the count value at the frequency entered for the corresponding period value (or frequency value). When the pulse train is

completed, it automatically starts over again after the rearm time.

2. Connect a cable to the output to access the generated pulses.

3. To select normal burst mode operation, highlight the Mode item of the Time

Base menu. Use the SELECT button to select Burst mode. If burst is

selected, the output is no longer triggered unless a suitable trigger signal is

applied to the time base card TRIGGER IN connector. Press the MANUAL

TRIGGER button at the right of the display panel to initiate a single burst

from the HFS 9009.

for any generator channel, you must turn on the OUTPUT

2–4

HFS 9009 Service Manual

Operating Information

SMA Connector OUTPUT ButtonLight

HFS 9DG1 HFS 9DG2HFS 9PG2TIME BASE

HFS 9009 Service Manual

Figure 2–6: Controls and Connectors for the Pulse Generator, Data Generator, and

Time Base Cards

2–5

Operating Information

2–6

HFS 9009 Service Manual

Module Descriptions

This section describes the operation of each of the replaceable modules in the

HFS 9009 Precision Pulse Generator. Refer to the Diagrams section of this

manual for a block diagram of the HFS 9009.

Mainframe

The mainframe consists of a backplane, a power supply, and four fans.

Power Supply

Front Panel

Backplane

Fans

The backplane complies with the VXIbus System Specification Rev. 1.2, dated

June 21, 1989. The backplane is VXI standard C size and has 13 slots; a

maximum of 11 slots may be used for the HFS 9000 configuration. The

backplane is not a replaceable part.

The HFS 9009 power supply is a single modular assembly located at the back of

the mainframe. The power supply is a replaceable part.

Four fans provide cooling for the power supply modules and the VXI modules

installed in the card cage. Each fan can be replaced. All fans draw their power

from the +12 V fan control of the power supply and draw a total of approximately 3 Amps.

The factory setting for the fan is variable speed. If the HFS 9009 is in a

rackmount with reduced airflow, set the fan speed to high.

The front panel contains several modules. One module consists of the numeric

keypad and encoder. This module is used to interact with the menus that appear

on the electro-luminescent display. A second module contains a scan pushbutton

matrix and LEDs, and mechanically supports the electro-luminescent display.

The third module is the electro-luminescent display itself.

Cards

HFS 9009 Service Manual

Six types of cards plug into the mainframe: the CPU card, time base card, high

speed pulse generator card (HFS 9PG1), variable rate pulse generator card

(HFS 9PG2), high speed data generator card (HFS 9DG1), and variable rate data

3–1

Module Descriptions

generator card (HFS 9DG2). Each HFS 9009 has one CPU card, one time base

card, and up to nine generator cards.

CPU Card

Time Base Card

Pulse Generator Cards

The CPU receives commands for pulse output parameters from the front panel,

the GPIB, or RS-232 interfaces. The CPU creates a series of time base and

generator card commands which are then transmitted via the VXI Bus to set up

the generator outputs.

The CPU card contains all product code in read-only memory (ROM). The CPU

card also has volatile and nonvolatile random-access memory (RAM), as well as

video display and bus timing circuitry.

The time base contains a voltage-controlled oscillator (VCO) which is tunable

from 325 MHz to 650 MHz. The time base also contains the trigger in, trigger

out, and phase lock circuits.

The VCO output is connected to the generator cards through clock distribution

cables. Clock distribution cables are located at the front of the cards. The time

base card provides several connections for clock distribution cables, one of

which is connected to each pulse and data generator card. The clock distribution

cables provide a high-speed signal path for the clock because the VXI backplane

cannot carry signals of sufficiently high frequency.

Each pulse generator card provides two independent output channels. Each

channel provides standard and logically-complemented outputs.

The pulse generator card channels divide the master clock signal into the

requested frequency, and format the output signals. The pulse generator card

controls the channel output levels, the channel delay, and the channel rising and

falling edge time.

The pulse generator card transducer input can be used to bypass the VCO and

timing generation circuits in the HFS 9009. When transducer in is enabled, a sine

wave can be applied to the transducer input. You can use the channel output

levels and rise and fall times to reshape the input signal.

High Speed Pulse Generator Cards (HFS 9PG1) run at a top speed of 630 MHz and

have a fixed rise and fall time of 200 ps.

Variable Rate Pulse Generator Cards (HFS 9PG2) run at a top speed of 300 MHz.

The rise time and fall times can be independently programmed from less than

one nanosecond to five nanoseconds, which allows the user to adjust the speed of

the pulse edges.

3–2

HFS 9009 Service Manual

Module Descriptions

Data Time Generator

Cards

Each data time generator card provides four independent output channels. The

high speed data time generator card provides standard and logically-complemented outputs. The variable rate data time generator card provides only a single

output for each channel. The data time generator card channels work in the same

way as the pulse generator card channels. The master clock signal is divided into

the requested frequency and format output signals by controlling the output

levels, channel delay, and rising and falling edge time.

High Speed Data Time Generator Cards (HFS 9DG1) run at a top speed of 630 MHz

and have a fixed rise and fall time of 200 ps.

Variable Rate Data Time Generator Cards (HFS9DG2) run at a top speed of

300 MHz. The rise and fall times can be independently programmed from less

than one nanosecond to five nanoseconds, which allows the user to adjust the

speed of the pulse edges.

HFS 9009 Service Manual

3–3

Module Descriptions

3–4

HFS 9009 Service Manual

Performance Verification

The following tests verify that the HFS 9000 Stimulus System achieves its

specified performance.

Required Test Equipment

Refer to Table 4–1 for a list of the test equipment required to verify performance.

T able 4–1: Required Test Equipment

Item Number and

Description

Minimum Requirements Example Purpose

1 Digital Volt Meter DC volt accuracy:

± 0.1% from 0.40 V to 5.5 V

2 BNC female to dual

banana plug

3 Cable, Precision

Coaxial, BNC

4 Precision Feed-

through Terminator

5 Digital Sampling

Oscilloscope

6 Sampling Head Rise time: ≤ 60 ps (10% to 90%) Tektronix SD-22, SD-24, or SD-26 Used with Tektronix Digital Sam-

7 Attenuator, 5X,

SMA

8 Cable, Coaxial,

SMA (two required)

9 Generator, Leveled

Sine Wave

— Tektronix part number

36-inch, 50 W Tektronix part number

50 W, 0.1% at DC Tektronix part number

D time accuracy:

± (0.25% + 10 ps) from 100 ps to

1 ms

Freq. Measurement accuracy:

± 0.10% from 50 kHz to 630 MHz

50 W, ≥ 12 GHz bandwidth Tektronix part number

20-inch, 50 W Tektronix part number

Capable of producing 0.8 V

amplitude up to 600 MHz into

50 W

p-p

Tektronix DM 511 Output level and amplitude checks

Output level and amplitude checks

103-0090-00

Output level and amplitude checks

012-0482-00

Output level and amplitude checks

01 1-0129-00

Tektronix 11801B Digital Sampling

Oscilloscope or CSA803A Communication Signal Analyzer

015-1002-00

174-1427-00

Tektronix SG 504 Phase lock check

Trigger Output Check,

Rise and fall time checks,

Edge placement checks,

Frequency accuracy check

pling Oscilloscope (item 5)

Rise and fall time checks

Trigger Output Check,

Rise and fall time checks,

Edge placement check,

Frequency accuracy check

HFS 9009 Service Manual

4–1

Performance Verification

T able 4–1: Required Test Equipment (Cont.)

Item Number and

Description

PurposeExampleMinimum Requirements

10 BNC female to

SMA male adapter

11 Threaded SMA

female to SMA

male slip-on connector

Test Record

— Tektronix part number

015-1018-00

— Tektronix part number

015-0553-00

Identify the type of cards you will be testing and photocopy the appropriate

tables from pages 4–3 to 4–9. Use these tables to record the performance test

results for the instrument.

Output level and amplitude

checks, Phase lock check

SMA quick disconnect

4–2

HFS 9009 Service Manual

Performance Verification

OutputMa

High Level

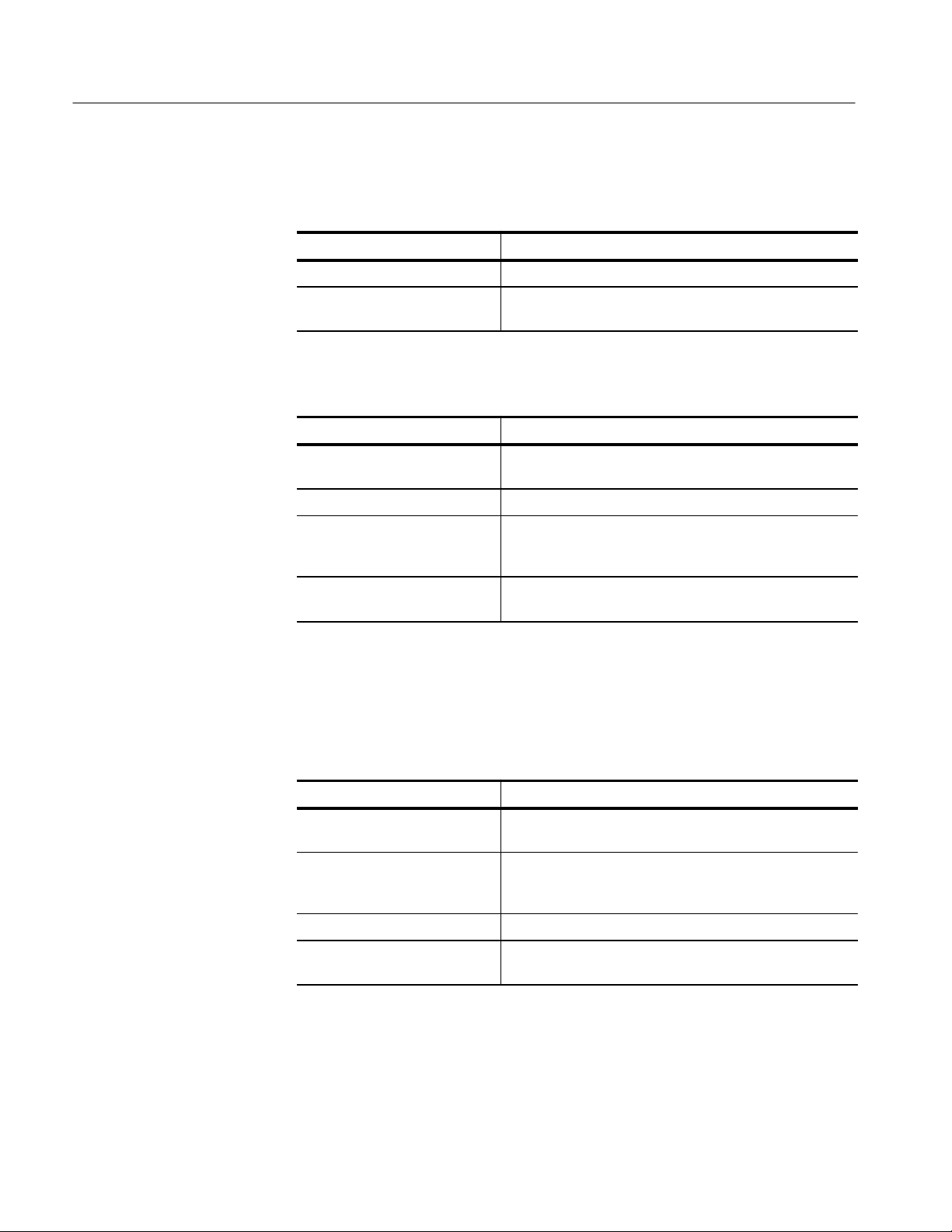

T able 4–2: Trigger Output Level and Phase Lock Test

Page of

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance Test Minimum Incoming Outgoing Maximum

Trigger Output Level Amplitude ≥ 300 mV (–0.5 V ≥ offset ≥ –1.5 V, driving 50 to ground)

ximum

N/A __________ __________ ≤ –0.5 V

Minimum Low Level

Minimum Amplitude

Phase Lock Test 1% (frequency set accuracy of generator)

Output 0.8 V, 250 MHz

Channel 0.8 V, 594 MHz

250 MHz

594 MHz

≥ –1.5 V

≥ 300 mV

247.5

588.1

__________ __________ N/A

__________ __________ N/A

p–p

__________

__________

__________

__________

252.5

599.9

HFS 9009 Service Manual

4–3

Performance Verification

T able 4–3: Test Record for HFS 9DG1 Card

Channel: Page of

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance Test Nominal Minimum Incoming Outgoing Maximum

Output High Level: ± 2% of level, ± 50 mV Low Level: ± 2% of High Level, ± 2% of amplitude (p-p), ± 50 mV

Output Complement

Channel Normal

Normal

Complement

Not Output Normal

Channel Complement

Complement

Normal

Rise Time / Fall Time ≤ 250ps for Amplitude ≤ 1V

Output Normal, 1V, Tr

Channel Complement, 1 V, Tf

Not Output Normal, 1V, Tf

Channel Complement, 1 V, Tr

Edge Placement Pulse Delay Time 1% of (Lead Delay + Chan Delay) ±50 ps

Output Normal

Channel

Not Output Normal

Channel

Edge Placement Pulse Width Variance 1% of width ± 50ps

Output Normal

Channel

Not Output Normal

Channel

+5.0 V

+2.0 V

–2.5 V

–1.5 V

+5.0 V

+2.0 V

–2.5 V

–1.5 V

250 ps

250 ps

250 ps

250 ps

100 ps

500 ps

1 ns

5 ns

10 ns

50 ns

100 ns

100 ps

500 ps

1 ns

5 ns

10 ns

50 ns

100 ns

500 ps

750 ps

1 ns

500 ps

750 ps

1 ns

+4.850

1.790

–2.680

–1.580

+4.850

1.790

–2.680

–1.580

N/A

N/A

N/A

N/A

49

445

0.940

4.900

9.850

49.45

98.95

49

445

0.940

4.900

9.850

49.45

98.95

445

693

0.940

445

693

0.940

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

+5.150

+2.210

–2.320

–1.420

+5.150

+2.210

–2.320

–1.420

250 ps

250 ps

250 ps

250 ps

151

555

1.060

5.100

10.150

50.55

101.05

151

555

1.060

5.100

10.150

50.55

101.05

555

808

1.060

555

808

1.060

4–4

HFS 9009 Service Manual

T able 4–3: Test Record for HFS 9DG1 Card (Cont.)

Channel: Page of

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance Test MaximumOutgoingIncomingMinimumNominal

Pulse Width Limits 1% of width +50 –75ps

Output Normal

Channel

Not Output Normal

Channel

Frequency Accuracy ± 1%

Output

Channel

5 ns

10 ns

50 ns

100 ns

500 ns

1 ms

5 ns

10 ns

50 ns

100 ns

500 ns

1 ms

50 kHz

324 MHz

326 MHz

400 MHz

433 MHz

466 MHz

500 MHz

533 MHz

566 MHz

600 MHz

630 MHz

4.875

9.825

49.425

98.925

494.925

0.990

4.875

9.825

49.425

98.925

494.925

0.990

49.50

320.8

322.7

396.0

428.7

461.3

495.0

527.7

560.3

594.0

623.7

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

Performance Verification

5.100

10.150

50.55

101.05

505.05

1.010

5.100

10.150

50.55

101.05

505.05

1.010

50.50

327.2

329.3

404.0

437.3

470.7

505.0

538.3

571.7

606.0

636.3

HFS 9009 Service Manual

4–5

Performance Verification

T able 4–4: Test Record for HFS 9DG2 Card

Channel: Page of

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance Test Nominal Minimum Incoming Outgoing Maximum

Output High Level: ± 2% of level, ± 50 mV Low Level: ± 2% of High Level, ± 2% of amplitude (p-p), ± 50 mV

Output Complement

Channel Normal

Normal

Complement

Rise Time / Fall Time ± 10% of setting ± 300 ps for Amplitude ≤ 1V

Output Normal, 1V, Tr

Channel Complement, 1 V, Tf

Normal, 1 V , Tr

Complement, 1 V , Tf

Edge Placement Pulse Delay Time 1% of (Lead Delay + Chan Delay) ±50 ps

Output Normal

Channel

Edge Placement Pulse Width Limits (1% + 50 ps, –450 ps) for widths 20 ns (1% + 50 ps, –250 ps) for widths 20 ns

Output

Channel

Frequency Accuracy ± 1%

Output

Channel

+5.5 V

0.0 V

–2.0 V

–1.0 V

0.8 ns

0.8 ns

5 ns

5 ns

100 ps

500 ps

1 ns

5 ns

10 ns

50 ns

100 ns

5 ns

10 ns

50 ns

100 ns

500 ns

1 s

50 kHz

162 MHz

163 MHz

200 MHz

216.5 MHz

233 MHz

250 MHz

266.5 MHz

283 MHz

300 MHz

+5.340

–0.270

–2.090

–1.070

0.420

0.420

4.200

4.200

49

445

0.940

4.900

9.850

49.45

98.95

4.500

9.450

49.25

98.75

494.8

0.990

49.50

160.4

161.4

198.0

214.3

230.7

247.5

263.8

280.2

297.0

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

+5.660

+0.270

–1.910

–0.930

1.180

1.180

5.800

5.800

151

555

1.060

5.100

10.150

50.55

101.05

5.100

10.150

50.55

101.05

505.1

1.010

50.50

163.6

164.6

202.0

218.7

235.3

252.5

269.2

285.8

303.0

4–6

HFS 9009 Service Manual

Performance Verification

T able 4–5: Test Record for HFS 9PG1 Card

Channel: Page of

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance Test Nominal Minimum Incoming Outgoing Maximum

Output High Level: ± 2% of level, ± 50 mV Low Level: ± 2% of High Level, ± 2% of amplitude (p-p), ± 50 mV

Output Complement

Channel Normal

Normal

Complement

Not Output Normal

Channel Complement

Complement

Normal

Rise Time / Fall Time ≤ 200ps for Amplitude ≤ 1V

Output Normal, 1V, Tr

Channel Complement, 1 V, Tf

Not Output Normal, 1V, Tf

Channel Complement, 1 V, Tr

Edge Placement Pulse Delay Time 1% of (Lead Delay + Chan Delay) ±300 ps

Output Normal

Channel

Not Output Normal

Channel

Edge Placement Pulse Width Variance 1% of width ± 300ps

Output Normal

Channel

Not Output Normal

Channel

+2.6 V

–0.4 V

–2 V

–1 V

+2.6 V

–0.4 V

–2 V

–1 V

200 ps

200 ps

200 ps

200 ps

100 ps

500 ps

1 ns

5 ns

10 ns

50 ns

100 ns

100 ps

500 ps

1 ns

5 ns

10 ns

50 ns

100 ns

500 ps

750 ps

1 ns

500 ps

750 ps

1 ns

+2.498

–0.562

–2.090

–1.070

+2.498

–0.562

–2.090

–1.070

N/A

N/A

N/A

N/A

–201

195

0.690

4.650

9.600

49.20

98.70

–201

195

0.690

4.650

9.600

49.20

98.70

195

443

0.690

195

443

0.690

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

+2.702

–0.238

–1.910

–0.930

+2.702

–0.238

–1.910

–0.930

200 ps

200 ps

200 ps

200 ps

401

805

1.310

5.350

10.400

50.80

101.30

401

805

1.310

5.350

10.400

50.80

101.30

805

1060

1.310

805

1058

1.310

HFS 9009 Service Manual

4–7

Performance Verification

T able 4–5: Test Record for HFS 9PG1 Card (Cont.)

Channel: Page of

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

Performance Test MaximumOutgoingIncomingMinimumNominal

Pulse Width Limits 1% of width ± 300 ps

Output Normal

Channel

Not Output Normal

Channel

Frequency Accuracy ± 1%

Output

Channel

5 ns

10 ns

50 ns

100 ns

500 ns

1 ms

5 ns

10 ns

50 ns

100 ns

500 ns

1 ms

50 kHz

324 MHz

326 MHz

400 MHz

433 MHz

466 MHz

500 MHz

533 MHz

566 MHz

600 MHz

630 MHz

4.650

9.600

49.20

98.70

494.70

0.990

4.650

9.600

49.20

98.70

494.70

0.990

49.50

320.8

322.7

396.0

428.7

461.3

495.0

527.7

560.3

594.0

623.7

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________