Page 1

Service Manual

HDVG1

HDTV Digital Video Generator

071-0594-51

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

www.tektronix.com

Page 2

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its suppliers and are

protected by United States copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patent s, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty 2

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year

from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product. Parts, modules and replacement products used by Tektronix for warranty work may be new or

reconditioned t o like new performance. All replaced parts, modules and products become the property of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepa id.

Tektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

Tektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than Tektronix repre sentatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; c) to repair any damage or malfunction

caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or integrated with other

products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO

REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO

THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS WILL NOT BE

LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE

OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary v...................................

Service Safety Summary vii....................................

Environmental Consid erations ix...............................

Preface xi...................................................

About This Manual xi...............................................

Related Manuals xii.................................................

Product Description 1--1..............................................

Characteristics 1--2..................................................

Certification and Compliances 1--3......................................

Installation 2--1...............................................

Preventing Component Damage 2--1.....................................

Module Installation 2--2...............................................

Signal and Logo Backup and Module Removal 2--8........................

Functional Overview 2--11.......................................

Operating Procedures 2--13......................................

Power On and Select the Module 2--14....................................

Select the Output Signal 2--15...........................................

Active Signal Parameters 2-- 17..........................................

Module Parameters 2--21...............................................

Theory of Operation

Signal Memory 3--2..................................................

Embedded Audio 3--4................................................

Performance Verification

Required Equipment 4--1..............................................

Calibration Data Report 4--2...........................................

Preparation for Performance Verification 4--3.............................

Performance Verification Procedures 4--5.................................

HDVG1 HDTV Digital Video Generator Service Manual

i

Page 6

Table of Contents

Maintenance

Option

Preparation 5--1.....................................................

Inspection and Cleaning 5--3...........................................

Repackaging Instructions 5--3..........................................

Removal and Replacement 5--7..................................

Tools Required 5--7..................................................

Removing the Rear Panel 5--7..........................................

Replacing the Shie ld 5--8..............................................

Replacing the Rear Panel Connectors 5--8................................

Troubleshooting Procedures 5--9.................................

Equipment Required 5--9..............................................

General Troubleshooting 5--10..........................................

Fault Symptom Table 5--11.............................................

Troubleshooting Flowcharts 5--12........................................

Option D1 Description 6--1............................................

Diagram

Replaceable Parts List

Diagram 7--1.................................................

Replaceable Parts List 8--1......................................

Parts Ordering Information 8--1.........................................

Using the Replaceable Parts List 8--2....................................

ii

HDVG1 HDTV Digital Video Generator Service Manual

Page 7

List of Figures

Table of Contents

Figure 2--1: TG2000 Platform mainframe rear panel, showing slot

numbering 2--2............................................

Figure 2--2: Top cover removal 2--3...............................

Figure 2--3: Removing the rear panel 2--4.........................

Figure 2--4: Module flange 2--4..................................

Figure 2--5: Installing the module 2--5............................

Figure 2--6: Top screw 2--6......................................

Figure 2--7: Menu structure for the HDVG1 Generator module 2--11...

Figure 3--1: Simplified block diagram of the HDVG1 Generator

module 3--2...............................................

Figure 3--2: Signal memory layout 3--3............................

Figure 4--1: SDI correctness and digital audio output check

connection 4--6............................................

Figure 4--2: Eye pattern check connection 4--9.....................

Figure 4--3: Example of eye pattern for an acceptable output signal 4--10

Figure 4--4: Trigger output check connection 4--11...................

Figure 5--1: Placing the module in the protective wrapping 5--4.......

Figure 5--2: Placing the module in the shipping carton 5--5...........

Figure 5--3: Flowchart for major difficulties with module 5--12........

Figure 5--4: Flowchart for checking the current module installation

slot 5--13...................................................

Figure 5--5: Flowchart for checking the module in a different slot 5--14..

Figure 5--6: Flowchart for failure to power up 5--15..................

Figure 5--7: Flowchart for signals lost after power down 5--16.........

Figure 5--8: Measuring the battery charging circuit 5--17.............

Figure 5--9: Flowchart for wrong signal on output 5--17..............

Figure 5--10: Flowchart for missing output signal 5--18...............

Figure 7--1: HDVG1 Generator module connections 7--1.............

Figure 8--1: Exploded view 8--4..................................

HDVG1 HDTV Digital Video Generator Service Manual

iii

Page 8

Table of Contents

List of Tables

Table 1--1: Electrical specifications (typical) 1--2...................

Table 1--2: Certifications and compliances 1--3....................

Table 2--1: Module slot assignments 2--2..........................

Table 3--1: Supported embedded audio frequencies 3--4.............

Table 4--1: Equipment required for Performance Verification 4--1....

Table 4--2: HDVG1 Calibration Data Report 4--2..................

Table 5--1: Required tools 5--7..................................

Table 5--2: Equipment required for troubleshooting 5--9............

Table 5--3: Fault symptom table 5--11.............................

iv

HDVG1 HDTV Digital Video Generator Service Manual

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. T o avoid potential hazards, use this

product only as specified.

Only qualified personnel should perform service procedures.

To Avoid Fire or

Personal Injury

Use Proper Power Cord. Use only the power cord specified for this product and

certified for the country of use.

Ground the Product. This product is grounded t hrough the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Observe All Terminal Ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product m anual for further ratings

information before making connections to the product.

Do Not Operate Without Covers. Do not operate this product with covers or panels

removed.

Avoid Exposed Circuitry. Do not touch exposed connections and components

when power is present.

Do Not Operate With Suspect ed Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

Do Not Operate in Wet/Damp Conditions.

Do Not Operate in an Explosive Atmosphere.

Keep Product Surfaces Clean and Dry.

Provide Proper Ventilation. Refer to the manual’s installation instructions for

details on installing the product so it has proper ventilation.

HDVG1 HDTV Digital Video Generator Service Manual

v

Page 10

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

CAUTION

Refer to Manual

WARNING

High Voltage

Double

Insulated

Protective Ground

(Earth) Terminal

vi

HDVG1 HDTV Digital Video Generator Service Manual

Page 11

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the mains power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

HDVG1 HDTV Digital Video Generator Service Manual

vii

Page 12

Service Safety Summary

viii

HDVG1 HDTV Digital Video Generator Service Manual

Page 13

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Restriction of Hazardous

Substances

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful t o the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown t o the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of t he

Tektronix Web site (www.tektronix.com).

This product has been classified as Monitoring and C ontrol equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product complies

with the RoHS Directive requirements expect for the presence of hexavalent

chromium in the surface coating of the aluminum chassis parts, assembly

hardware, and 63/37 tin/lead solder used in the fabrication of the circuit boards.

HDVG1 HDTV Digital Video Generator Service Manual

ix

Page 14

Environmental C onsiderations

x

HDVG1 HDTV Digital Video Generator Service Manual

Page 15

Preface

About This Manual

You have purchased this optional service manual for the HDVG1 HDTV Digital

Vi deo Generator module. To optimize troubleshooting capability, you should

also purchase t he service manual for the TG2000 Platform mainframe.

This manual contains information for servicing the HDVG1 HDTV Digital

Vi deo Generator module to a module level. The information is designed only for

qualified service technicians, with moderate experience in analog circuits, digital

circuits, and television technology.

This manual is composed of the following sections:

H Specifications provides instrument specifications tables.

H Operating Information provides basic operating information.

H Theory of Operation is an overview of the module’s design.

H Performance Verification contains procedures to perform the operation tests.

H Maintenance contains installation, removal and replacement, and trouble-

shooting instructions.

H Option contains a description of available option for the HDVG1 Generator

module.

H Diagram contains interconnect diagram showing the connections between

the HDVG1 Generator module, the mainframe, and other modules.

H Replaceable Parts list the part numbers for replacement parts that you can

order. Exploded view illustrations help you to identify t he parts.

HDVG1 HDTV Digital Video Generator Service Manual

xi

Page 16

Preface

Related Manuals

The following documents are related to the HDVG1 Generator module.

H The TG2000 Signal Generation Platform Service Manual describes how to

service the mainframe to the module level, and includes a troubleshooting

disk that is required for all module and mainframe troubleshooting. This

optional manual must be ordered separately, and is recommended before

beginning any troubleshooting.

H The TG2000 Signal Generation Platform User Manual describes how to use

the TG2000 Platform. It also contains information about SCPI commands,

programming structure, and status and events for the TG2000 S i gnal

Generation Platform. Some of this information applies to all generator

modules, including the HDVG1 Generator module.

H The HDVG1 HDTV Digital Video Generator User Manual contains

operating information and information about SCPI commands for the

HDVG1 Generator module.

xii

HDVG1 HDTV Digital Video Generator Service Manual

Page 17

Specifications

Page 18

Page 19

Specifications

Product Description

This section contains a general product description of the HDVG1 Generator

module followed by the operating specifications of the module.

The HDVG1 Generator module is an HDTV test signal generator which

provides 1.485 Gb/s serial digital video signals in various formats. The module

contains the following features:

H Produces custom test signals using SDP2000 software package

H Three serial digital video outputs

H Signal parameters such as active video gain and chroma/luma gain are

adjustable in real-time from the front panel.

H Rear-panel trigger output, used to trigger an oscilloscope or other video

equipment

H Overlay of circles, text, or logo on the video signal

H Up to 8 channels of Embedded Audio

H Full remote control using GP IB or RS-232C interface

Embedded Audio. The HDVG1 Generator module can generate video signals with

20-bit or 24-bit embedded digital audio with a sample rate of 48 kHz. Multiple

user-selectable frequencies and amplitudes are available with channel and status

independence.

HDVG1 HDTV Digital Video Generator Service Manual

1- 1

Page 20

Specifications

Characteristics

This section contains the specifications for the HDVG1 Generator module.

Specifications are only valid when the module is installed in a TG2000 P l atform

mainframe. For installation instructions, refer to Module Installation on

page 2--2.

For a list of environmental specifications, refer to the TG2000 Signal Generation

Platform Service Manual.

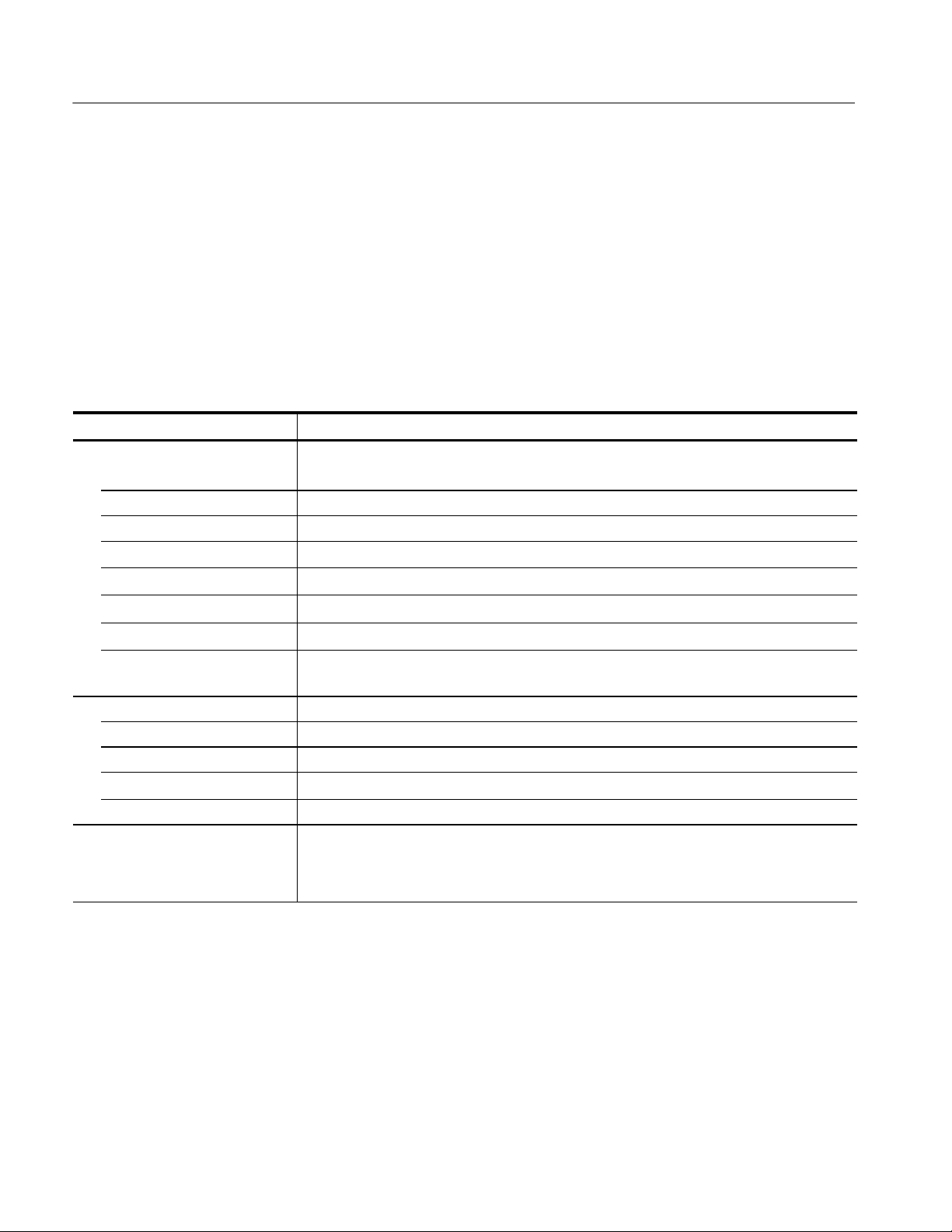

Table 1- 1: Electrical specifications (typical)

Characteristics Description

Serial Connector

Number of Outputs 3 (BNC)

Signal Amplitude 800 mV typical, into 75 Ω load

Data Rate 1.485 Gbps or 1.485/1.001 Gbps nominal

Overshoot

Rise and Fall Times

DC Offset (Ac coupled)

Jitter

Return Loss

(75 Ω, AC coupled)

Trigger Output

Connector BNC

Amplitude TTL compatible if unterminated

Rise Time

Output Impedance 75 Ω

Typical Power Consumption +5 Volts: 14.0 Watts

≤10%

≤270 ps (Measured at 20% and 80% points)

0.0 V 0.5 V (Into DC termination)

≤135 ps p-p (Alignment jitter)

≥15 dB, 5 MHz to 742.5 MHz

≥10 dB, 742.5 MHz to 1.485 GHz

≤10 ns

-5 Volts: 1.0 Watts

-2 Volts: 1.0 Watts

Battery: 30 mA maximum

1- 2

HDVG1 HDTV Digital Video Generator Service Manual

Page 21

Certification and Compliances

The certification and compliances for the HDVG1 Generator module are listed in

Tab l e 1- -2 .

Table 1- 2: Certifications and compliances

Category Standards or description

Specifications

EC Declaration of Conformity -EMC

Australia/New Zealand

Declaration of Conformity -- EMC

FCC Compliance Emissions comply with FCC Code of Federal Regulations 47, Part 15, Subpart B, Class A Limits.

EC Declaration of Conformity -Low Voltage

Safety Complies with the following safety standards:

Meets intent of Directive 89/336/EEC for Electromagnetic Compatibility. Compliance was

demonstrated to the following specifications as listed in the Official Journal of the European Union:

EN 55022 Class B Radiated and Conducted Emissions

EN 55103-1 Emissions:

Annex A Magnetic Loop Antenna

EN 55103-2 Immunity:

EN 61000-4-2 Electrostatic Discharge Immunity

EN 61000-4-3 Radiated RF Electromagnetic Field Amplitude Modulated

EN 61000-4-4 Electrical Fast Transient Immunity

EN 61000-4-5 Surge Immunity

EN 61000-4-6 Conducted RF Common Mode Immunity

EN 61000-4-11 Power Line Interruption Immunity

Annex A Magnetic Immunity

Complies with EMC provision of Radiocommunications Act per the following standard(s):

AS/NZS 2064.1/2 Industrial, Scientific, and Medical Equipment: 1992

Compliance was demonstrated to the following specification as listed in the Official Journal of the

European Union:

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC

EN 61010-1:1993 Safety requirements for electrical equipment for measurement control and

laboratory use.

UL3111- 1

CAN/CSA C22.2 No. 1010.1

IEC61010-1

1

1

Standard for electrical measuring and test equipment.

1

Safety requirements for electrical equipment for measurement, control, and

laboratory use.

Safety requirements for electrical equipment for measurement, control,

and laboratory use.

1

UL3111-1, CSA C22.2 No. 1010.1, and IEC61010-1 Safety Certification Compliance Altitude (maximum operating) :

2000 meters

HDVG1 HDTV Digital Video Generator Service Manual

1- 3

Page 22

Specifications

1- 4

HDVG1 HDTV Digital Video Generator Service Manual

Page 23

Operating Information

Page 24

Page 25

Installation

This section contains instructions for installing the HDVG1 Generator module

into the TG2000 Platform mainframe and instructions for operating the module.

Listed below are the major topics in this section.

H Preventing component damage

H Module installation, including signal sets and output configuration

H Signal backup and module removal

Preventing Component Damage

CAUTION. Electrostatic discharge (ESD) can damage components on this module

and mainframe. To prevent ESD or other component damage, follow the steps

below when installing, removing, or handling modules:

1. Wear a grounded antistatic wrist strap to discharge the static voltage from

your body while installing or removing modules from the TG2000 Pl atform

mainframe.

2. Transport and store modules in a static-protected bag or container.

3. Do not slide the module over any surface.

4. Handle modules as little as possible.

5. Do not touch module components or connector pins.

6. Do not use any devices capable of generating or holding a static charge in the

work area where you remove, install, or handle modules.

7. Avoid handling modules in areas that have a floor or work-surface covering

capable of generating a static charge.

8. Do not remove the module circuit board assembly from the shield. The

shield is an important stiffener which prevents damage to surface-mount

components.

HDVG1 HDTV Digital Video Generator Service Manual

2- 1

Page 26

Installation

Module Installation

A T-10 torx tip screwdriver is the only tool you need to install the module. A

T-10 torx tip is supplied with the module.

Hardware Installation

To install the module i nto the TG2000 Platform mainframe, perform these steps:

1. Set the TG2000 Platform mainframe rear-panel power switch to off.

2. Unplug the power cord.

3. Select the slot you will use to install the module. Table 2--1 lists the slot

restrictions. Figure 2--1 shows a sample configuration with slot numbers.

Table 2- 1: Module slot assignments

Module Slots in which the module can be installed

AGL1 Genlock module Slot 2 or 3

A VG1 Generator module Slots 2 through 10

AWVG1 Generator module Slots 2 through 10

BG1 Generator module Slots 2 through 10

Clock module Slot 1

CPU module Slot 11

DVG1 Generator module Slots 2 through 10

GP1 GPIB Interface module Slot 10

HDVG1 Generator module Slots 2 through 10

2- 2

Power

Supply

CPU

Module

GPIB

Module

111098 76 5 432 1

DVG1

Module

AVG 1

Module

AWVG 1

Module

HDVG1

Module

AGL1

Module

BG1

Module

Figure 2- 1: TG2000 Platform mainframe rear panel, showing slot numbering

HDVG1 HDTV Digital Video Generator Service Manual

Clock

Module

Page 27

Installation

WARNING. To avoid a shock hazard, always remove the power cord before

removing the top cover. Failure to remove the power cord can result in serious

injury or death.

4. Refer to Figure 2--2 and remove or loosen all screws to remove the top cover.

Top cover

Loosen screws (12)

Top cover

Remove

screws

(23)

Figure 2- 2: Top cover r e moval

HDVG1 HDTV Digital Video Generator Service Manual

2- 3

Page 28

Installation

5. Remove the appropriate rear panel as shown in Figure 2--3. Loosen, but do

not remove the bottom screw. You will use it later to secure the module.

Loosen screw

Figure 2- 3: Removing the r ear panel

6. While ensuring correct alignment of the module flange as shown i n

Figure 2--4, lower the module into the desired slot as shown in Figure 2--5.

Flange

2- 4

Figure 2- 4: Module flange

HDVG1 HDTV Digital Video Generator Service Manual

Page 29

Installation

Figure 2- 5: Installing the module

7. Ensure that the connectors on the Backplane board and the module exactly

match before seating the module.

CAUTION. The connectors must exactly match before you attempt to press the

module firmly in place. If the connectors do not match you could bend a pin that

could damage the module, mainframe, or both when power is applied.

8. Press down evenly on the module until it is firmly in place.

9. Refer to Figure 2--6 and insert and tighten the top screw, which comes with

your module, and tighten the rear panel screw.

HDVG1 HDTV Digital Video Generator Service Manual

2- 5

Page 30

Installation

Signal Set Installation

Figure 2- 6: Top screw

10. Reinstall the top cover and insert and tighten all top cover screws.

11. Plug in the instrument power cord. Power on the mainframe by setting the

rear-panel power switch to ON and pressing the front-panel power switch.

Wait for the instrument to perform self tests.

12. If you previously moved or removed a module and backed up the instrument,

perform Instrument Restore from Backup now (page 4--12).

If this module was installed in t he TG2000 Platform mainframe at the factory,

signal sets are already i nstalled. If a generator module i s ordered separately, the

user must install signal sets when installing the module. If you need to install

signal sets, use one of the two following procedures: Installing Signals to the

Default Destination or Installing Signals to a Non-default Destination. To

replace signal sets, refer to the TG2000 Signal Generation Platform User

Manual.

2- 6

HDVG1 HDTV Digital Video Generator Service Manual

Page 31

Installation

Installing Signals to the Default Destination.

1. Insert the test signal disk into the TG2000 Platform mainframe disk drive.

2. Push the DISK button.

3. Touch Add S ignals when the Disk menu appears.

4. Touch Select Source.

5. Move the browse ring to the .DNL you want to load and push t he Select key.

6. Select all of t he signal sets at the module level and push the Select button.

7. Touch Quit/Load. The previous menu appears.

8. Touch Quit/Load again. The Add Signals window reappears, showing the

module as the selected destination.

NOTE. The Add Signals window shows the amount of Kbytes selected (Total

Tagged) and the amount available on the module. If the tagged total is greater

than the amount available, the signal sets will not load.

9. Touch Start Load. The signal sets are automatically loaded into the module.

A pop-up menu tells you when the transfer is complete.

Installing Signals to a Non-default Destination.

1. Insert the test signal disk into the TG2000 Platform mainframe disk drive.

2. Push the DISK button.

3. Touch Add S ignals when the Disk menu appears.

4. Touch Select Source.

5. Move the browse ring to the .DNL you want to load and push t he Select key.

6. Move the browse ring t o a particular test signal and push t he Select button.

7. Touch Quit/Load. The previous menu appears.

8. Touch Quit/Load again. The Add Signals window reappears.

NOTE. The Add Signals window shows the amount of Kbytes selected (Total

Tagged) and the amount available on the module. If the tagged total is greater

than the amount available, the signal sets will not load.

9. Touch Select Destination.

HDVG1 HDTV Digital Video Generator Service Manual

2- 7

Page 32

Installation

10. Move the cursor to t he signal’s field and place the cursor where you want the

test signal to be installed. Be sure to chose a destination that i s one level

above the source. Press the Select key.

11. Touch Start Load. A pop-up menu tells you when the transfer is complete.

Signal and Logo Backup and Module Removal

Before removing a generator module, you should save the signal sets and logos

to a disk. The module will lose its signal memory 30 seconds after you remove it

from the platform. You will need a blank, DOS formatted 3.5 inch disk.

Signal Backup

Logo Backup

Save the signal sets as follows:

1. Insert a DOS formatted disk into the platform’s disk drive.

2. Push the Disk button and touch Save Signals to Disk.

3. Touch Select Source and select the HDVG1. Use the cursor arrows to select

the HDVG1 module in the signals column.

4. Select Quit/Save.

5. Touch Select Destination. If desired, create a new directory for the signals

by selecting New Dir and entering a DOS compatible name.

6. Create a new file by touching New File.

7. Select Quit/Save to complete the transfer of signal sets to the disk.

8. Touch Start Save. Saving signals may take several minutes, depending on

the number and size of test signals.

Save the logos as follows:

1. Push the Test Signals button.

2- 8

2. Touch Module Parameters.

3. Touch Logo Overlay.

4. Touch File Utils.

5. Touch Save Logo to Disk.

6. Touch Select Source.

7. Select the logo you want to save a disk file.

8. Touch Quit /Save.

HDVG1 HDTV Digital Video Generator Service Manual

Page 33

Installation

9. Touch Select Destination. If desired, create a new directory for the logos by

selecting New Dir and entering a DOS compatible name.

10. Create a new file by touching New File. (The original l ogo name is

preserved inside the logo file.)

11. Touch Quit/Save to begin the save process.

12. Repeat for each logo you want to save.

Module Removal

To remove the module, follow these steps:

1. Turn off the platform by pressing the front-panel On/Standby switch and

switching the rear panel power switch to off.

2. Unplug the power cord.

WARNING. To avoid a shock hazard always unplug the power cord before

removing the top cover. Failure to unplug the power cord can result in serious

injury or death.

3. Remove all top-cover screws and remove the top cover. See Figure 2--2 on

page 2--3.

4. Remove the appropriate rear panel as shown in Figure 2--3 on page 2--4.

Loosen, but do not remove the bottom screw. You will use it later to secure

the rear panel.

5. Refer to Figure 2--6 on page 2 --6 and remove the top screw.

6. Remove the module. To leave the slot empty, proceed to step 8 of this

procedure.

7. To install a module in the empty slot, proceed to Module Installation on

page 2--2.

8. To ensure proper cooling and adherence to EMI shielding requirements,

install a blank panel to cover any empty slots in the rear panel. A spare blank

panel is included in the TG2000 Platform mainframe accessories kit.

9. Tighten the screws on the blank rear panel.

10. Reinstall the top cover and insert and tighten all top cover screws.

HDVG1 HDTV Digital Video Generator Service Manual

2- 9

Page 34

Installation

2- 10

HDVG1 HDTV Digital Video Generator Service Manual

Page 35

Functional Overview

This section provides an overview of the HDVG1 Generator module. If you are

not familiar with the operation of the TG2000 S i gnal Generation Platform, refer

to the TG2000 Signal Generation Platform User Manual before reading this

section.

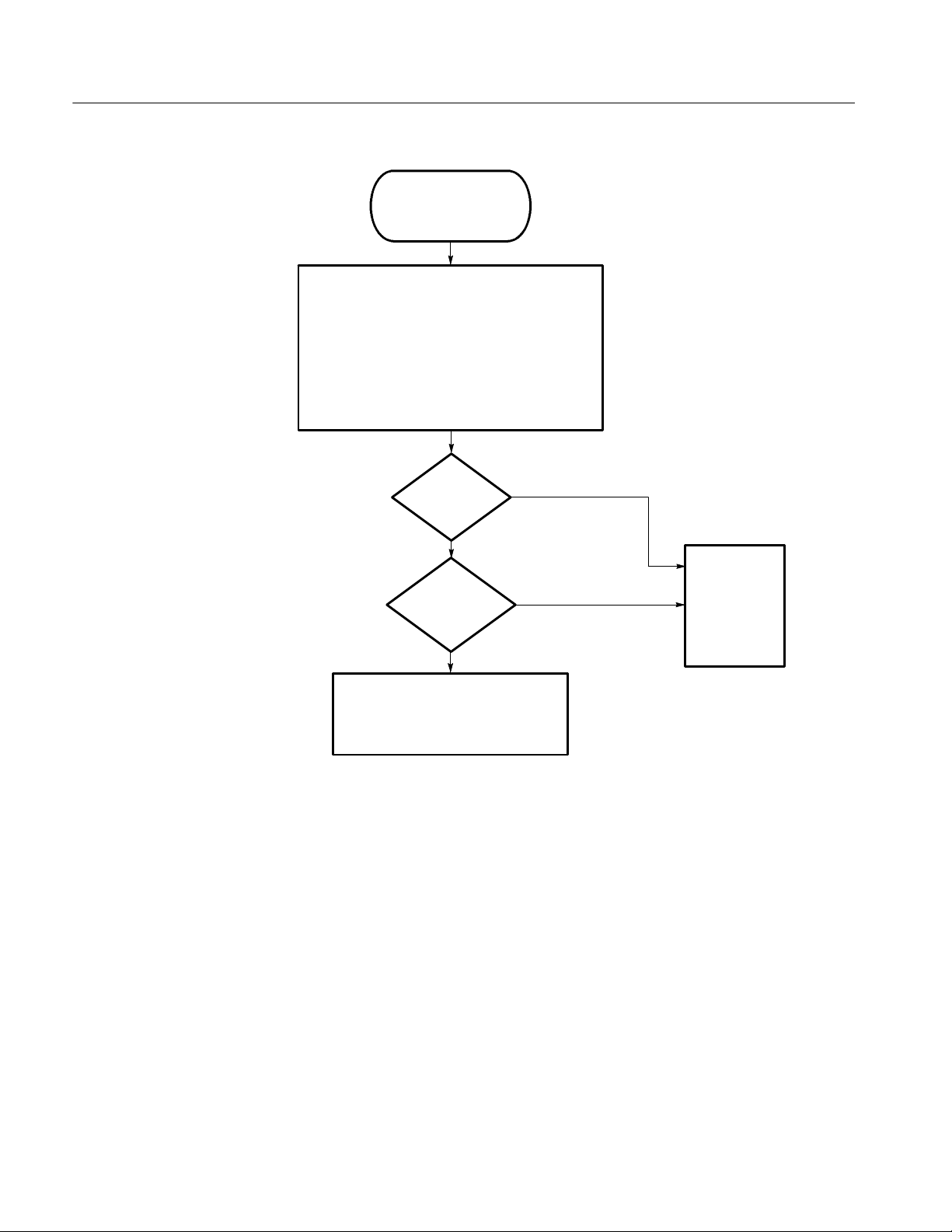

Figure 2--7 shows the menu structure for basic module operations.

Modules window

Edit Module window

Touch Rename

Module

Rename Module window

Enter new name for

module

Module Parameters window

Touch Output enable/disable, Module Timing,

Circle Overlay, Trigger Output, Embedded Audio,

Touch Module

Parameters

Touch Module

Parameters

or Logo Overlay.

Touch desired module

Signal Sets window

Touch desired signal set

(usually represents format)

Test Signals window

Touch desired Test Signal icon

until correct signal is selected

Touch Active

Signal Parameters

Parameters window

Touch Video, Text Overlay

or Signal Information

Push Modules

button

Push Edit

button

Push Signal

Sets button

Push Test

Signals button

Active Signal

Module Timing, Circle Overlay, Trigger Output,

Embedded Audio, or Logo Overlay window

Set module timing with respect to the BG1

module. Create circle overlay or Logo Overlay.

Configure trigger output, or embedded audio.

Figure 2- 7: Menu structure for the HDVG1 Generator module

HDVG1 HDTV Digital Video Generator Service Manual

Video Parameters, Text Overlay,

or Signal Information window

Set video parameters, adjust text

on signal, or view information

about the selected signal

2- 11

Page 36

Functional Overview

Outputs

Online Help

The HDVG1 Generator module has four outputs: three serial outputs and one

trigger output.

Serial Outputs. Outputs 1, 2 and 3 are serial signal outputs (BNC).

Trigger Output. The trigger output (BNC) can be used to trigger an oscilloscope

or other video equipment.

Push the front-panel HELP button to display a help window. The help window

describes the window you were using when you pushed HELP.

2- 12

HDVG1 HDTV Digital Video Generator Service Manual

Page 37

Operating Procedures

This section is organized into the following main topics:

H Power on the mainframe and select the module

H Select the output signal

H Active signal parameters

H Module parameters

Refer to Figure 2--7 on page 2--11 for the menu structure.

HDVG1 HDTV Digital Video Generator Service Manual

2- 13

Page 38

Operating Procedures

Power On and Select the Module

After the module is installed in the mainframe, and the mainframe is installed in

the rack or other location where it will be used, power on the mainframe, and

select the module by following these steps:

1. Set the rear-panel power switch to the ON position.

2. Press the front-panel POWER switch if necessary.

3. Wait for a few seconds as the mainframe executes confidence tests on the

mainframe and modules. Check for any error messages t hat might appear.

4. When self tests are complete, the instrument displays icons representing the

generator modules. If an installed module is not represented, refer to

Troubleshooting Procedures, starting on page 5--9.

NOTE. The illustrations in these procedures show the factory default name

(HDVG1:X where X represents the slot number in which the module is installed).

However, because you can rename the module, your icons may display a different

name. Refer to the TG2000 Signal Generation Platform User Manual for

information about editing the module name.

5. Since you have just powered on the platform, the Modules window is

displayed. To open this window at other times, push the Modules button.

6. Touch the module icon on the display (or push the Signal Sets button if the

desired icon is already highlighted). The installed signal sets for the module

appear. Selections you make after this will pertain to the HDVG1 Generator

module.

2- 14

HDVG1 HDTV Digital Video Generator Service Manual

Page 39

Select the Output Signal

The output signal is supplied on the three rear-panel serial outputs. Use the

following procedure to select the module’s output test signal. You can select any

of the HDVG1 signals that are loaded in your instrument.

1. Push the Signal Sets button to open the window shown below. Check that

Operating Procedures

there is an icon for each installed signal set. If your signal sets are not

installed, refer to Signal Set Installation on page 2--6.

2. Touch the desired signal set on the display. The Test Signals window for t he

selected signal set appears. In the following example, 1920X1080 60 2:1 is

selected.

List box

HDVG1 HDTV Digital Video Generator Service Manual

2- 15

Page 40

Operating Procedures

3. Each test signal icon in the Test Si gnals window represents one or more

signals that the module can generate. In this example, the Color Bar test

signal icon is selected, and the 75% SMPTE Color Bars signal is being

generated.

4. To change to another Color Bar s ignal, touch the Color Bar repeatedly to

browse through all available signals. You can also display the complete list

of test signals available under a selected test-signal icon by touching the list

box or by rotating t he Navigation knob, and then select a signal by pressing

the front-panel Select button.

5. To change to a different signal type, such as Linearity, touch the correspondingicononthedisplay.Thenselectthesignalasshowninstep4.

6. To select the output signal using the List window, display the list of test

signals by pushing the front-panel List button. Use the Navigation arrow

keys to highlight the module and signal, and then push the Select button.

2- 16

HDVG1 HDTV Digital Video Generator Service Manual

Page 41

Active Signal Parameters

The following procedures discuss windows that are accessed through the Active

Signal Parameters window, shown below. Changes that you make to parameters

in any of these windows affect only the active signal.

To enter the Active Signal Parameters window for the HDVG1 Generator

module, follow these steps:

1. Select the module, if not already selected.

2. Push the Test Signals button.

3. Touch Active Signal Parameters at the bottom of the screen. The Active

Operating Procedures

Signal Parameters window appears, as shown below.

HDVG1 HDTV Digital Video Generator Service Manual

2- 17

Page 42

Operating Procedures

Video Parameters

You can adjust the signal parameters of the currently selected (active) test signal

by modifying the parameters and then saving the signal with a new name. There

are no factory defaults. Factory signals may be reinstalled, if needed.

NOTE. To modify and save a Tektronix generated signal, you must rename it.

When you rename and save a signal, both the original and the modified signals

are saved. If you modify any signal that was shipped on the factory disks, the

platform adds an underscore to the front of the name.

You can change the signal parameters in the Video Parameters window, shown

below. This is accessed through the Active Signal Parameters window, shown on

page 2--17. Different signals may display a different list in this window. Use the

Navigation arrow keys to select the parameter you want to change. Detailed

information can be found in the HDVG1 HDTV Digital Video Generator User

Manual.

2- 18

HDVG1 HDTV Digital Video Generator Service Manual

Page 43

Operating Procedures

Text Overlay

You can enter text that overlays your displayed t est signal. When turning text on

or off, you are turning text on or off for all test signals that have overlaid text.

Touching Reset returns the text, horizontal and vertical to previously saved

values.

Text Overlay is controlled through the Signal Text window, shown below.

Access this window by touching Text Overlay in the Active Signal Parameters

window, shown on page 2--17. Detailed information about adding and positioning overlaid text can be found in the HDVG1 HDTV Digital Video Generator

User Manual.

HDVG1 HDTV Digital Video Generator Service Manual

2- 19

Page 44

Operating Procedures

Signal Information

You can view detailed information about the selected signal in the Signal

Information window, accessed through the Active Signal Parameters window

shown on page 2--17.

2- 20

HDVG1 HDTV Digital Video Generator Service Manual

Page 45

Module Parameters

Operating Procedures

The following pages discuss windows that are accessed through the Module

Parameters window, shown below. Changes that you make to parameters in any

of these windows affect the entire module.

To enter the Module Parameters window for the HDVG1 Generator module,

follow these steps:

1. Select the HDVG1 Generator module, if not already selected.

2. Push the Test Signals button.

3. Touch Module Parameters at the bottom of the screen. The Module

Parameters window appears, as shown below.

4. Another way to access this window is as follows:

a. Push the Modules button.

b. Ensure that the module is highlighted.

c. Push the Edit button.

d. Touch Module Parameters.

HDVG1 HDTV Digital Video Generator Service Manual

2- 21

Page 46

Operating Procedures

Enable/Disable the

Output Signal

Timing

If you disable the module output, it releases all system resources used by this

module. To disable the module output, select the module and then touch the

Output icon in the Module Parameters window shown on page 2--21.

You can set the horizontal and vertical timing of this module with respect to the

BG1 Generator module. Changes you make to timing affect all signals for the

HDVG1 Generator module. In the Module Parameters window, shown on

page 2--21, touch the module timing icon.

Touch Reset All if you want to return horizontal and vertical timing to the

defaults.

2- 22

HDVG1 HDTV Digital Video Generator Service Manual

Page 47

Operating Procedures

Circle Overlay

You can create a circle that is overlaid on the output test signal. The circle

overlay parameters will affect all test signals from this module. Entered values

are constant, regardless of which test signal or video standard you use.

You can define a circle overlay in the Circle Overlay window, accessed through

the Module Parameters window, shown on page 2--21. The Circle Overlay

window is shown in the following illustration. Touch On/Off to turn on the

circle overlay.

If you want to reset the values, touch Reset All. This will set the diameter,

horizontal, and vertical to 90%, 0, and 0 respectively.

HDVG1 HDTV Digital Video Generator Service Manual

2- 23

Page 48

Operating Procedures

Trigger Output

You can generate three types of Trigger signals to the rear panel BNC. In the

Module Parameters window, shown on page 2--21, touch Trigger to enter the

Trigger window, shown below. Turn on the cursor by touching the On/Off on the

display. Touch Reset All if you want to set all the parameters to the default

settings (H Pos to zero and V Pos to 1).

NOTE. Triggers are active throughout the line. However, cursors are only active

during active video.

2- 24

HDVG1 HDTV Digital Video Generator Service Manual

Page 49

Operating Procedures

Embedded Audio

You can turn embedded audio on or off, select which channel groups to enable,

and which of the enabled groups to send first. You can also adjust the frequency

and amplitude of the embedded audio signal. Changes you make affect all

signals for this module. Detailed information can be found in the HDVG1

HDTV Digital Video Generator User Manual.

HDVG1 HDTV Digital Video Generator Service Manual

2- 25

Page 50

Operating Procedures

Logo Overlay

You can provide a logo that is overlaid on the output test signal. The logo

overlay parameters will affect all test signals from this module. Entered values

are constant, regardless of which test signal or video standard you use.

You can define a logo overlay in the Logo Overlay window, accessed through the

Module Parameters window, shown on page 2--21. The Logo Overlay window is

shown in the following illustration. Touch On/Off to turn on the logo overlay.

You can also save logos to a floppy disk, add logos to the module, and delete

logos from the module using the File Utilities window.

If you want to reset the values, touch Reset. This will set the horizontal and

vertical position to 0.

2- 26

HDVG1 HDTV Digital Video Generator Service Manual

Page 51

Theory of Operation

Page 52

Page 53

Theory of Operation

This discussion provides an overview of the HDVG1 Generator module. For

information about the TG2000 Platform mainframe, refer to the TG2000 Signal

Generation Platform Service Manual.

The HDVG1 Generator module is a 10-bit precision, digital video test signal

generator for HDTV digital signals. Output signal data is stored in fast access

memory (Line Memory) which has been loaded from the NVRAM over the CPU

bus. An overlay data modifier (which is actually an integral part of the fast

access memory) inserts data from the overlay memory into the fast access

memory data stream to create circular patterns, cursors, text characters, and logo.

For HDTV signal generation, Cb and Cr data are multiplexed in the data memory

and then further multiplexed with the Y data to produce the HDTV formatting.

The multiplex switching causes the data mux to output the data sequence in the

following form: Y--Cb--Y--Cr.

The Audio Coprocessor adds embedded audio data.

The coprocessor output containing all the added data is serialized for the module

serial output. There are three serial outputs.

HDVG1 HDTV Digital Video Generator Service Manual

3- 1

Page 54

Theory of Operation

mP Interface

Flash

NVROM

Address

Generator

Line Memory

A

Line Memory

B

74.25/2 MHz

20 bits X 2

Bank

Mux

Data

Mux

74.25 MHz

10 bits X 2

Overlay

Engine

Frame

Memory

A

Frame

Memory

B

74.25 MHz

10 bits X 2

Audio

RAM

Y

Cb/Cr

Audio

Co--

Processor

Serializer

Figure 3- 1: Simplified block diagram of the HDVG1 Generator module

Signal Memory

Overlay

Memory

Serial

Output

Module

3- 2

The HDVG1 module uses two levels of memory to generate signals in real time

(See Figure 3--2). Each level of memory puts constraints on the maximum

complexity of a signal that can be generated.

The Line Memory holds the actual sample points which define the signal. The

Line holds approximately 1M samples for Y, 512K samples for Cb, and 512K

samples for Cr (1048576 samples total). The equation to determine the maximum number of unique video lines that can be stored in the Line Memory is as

follows:

HDVG1 HDTV Digital Video Generator Service Manual

Page 55

Theory of Operation

1048576 samples / # of samples per line = # of unique video lines

1080I 1048576 samples / 2200 per line = 476 unique video lines.......

720P 1048576 samples / 1650 per line = 632 unique video lines........

The Frame Memory contains a series of pointers which control the order in

which the video lines that are stored in Line Memory are used to produce HDTV

signals. The maximum number of pointers is 174762. The equation to determine

the maximum length (in seconds) of a video sequence is:

Line length × 174762 = maximum sequence length (in seconds)

1080I [1 / (30*1125)] × 174762 = 5. 1 seconds [155 Frames].......

720P [1 / (60*750)] × 174762 = 3.8 seconds [233 Frames]........

NOTE. The limit on number of unique video lines means that HDVG1 Generator

module cannot generate an arbitrarily complex full frame image (i.e., it cannot

replicate a captured video image). The lines consumed by the logo are not

included in the unique line counts, nor are the lines consumed by overlaid text.

Frame Memory

Line 1

Pointer

Line 2

Pointer

Line 3

Pointer

Line 4

Pointer

¯

¯

¯

Figure 3- 2: Signal m emory layout

Line Memory

Y

Y

Y

Cr

Cr

Cr

Resulting Image:

Y’

Y’

Y’

Cb

Cb

Cb

Y

Y

Y

Cr

Cr

Cr

¯¯¯

¯¯¯

¯¯¯

HDVG1 HDTV Digital Video Generator Service Manual

3- 3

Page 56

Theory of Operation

Embedded Audio

The HDVG1 can generate video signals with embedded digital audio. The

embedded signal is 24 (or 20) bit audio data with a sample rate of 48 kHz. The

data can be made up of multiple frequencies and amplitudes, with channel and

status independence. The supported audio frequencies are listed in Table 3--1.

Table 3- 1: Supported embedded audio frequencies

50 Hz 750 Hz 3200 Hz

100 Hz 800 Hz 4000 Hz

150 Hz 1000 Hz 4800 Hz

200 Hz 1200 Hz 6000 Hz

250 Hz 1500 Hz 8000 Hz

300 Hz 1600 Hz 9600 Hz

400 Hz 2000 Hz 12000 Hz

500 Hz 2400 Hz 16000 Hz

600 Hz 3000 Hz

3- 4

HDVG1 HDTV Digital Video Generator Service Manual

Page 57

Performance Verification

Page 58

Page 59

Performance Verification

Perform the following procedure to verify that your HDVG1 Generator module

is meeting the requirements listed in the Specifications section.

NOTE. All values checked in this procedure represent typical characteristics and

are not absolutely guaranteed.

Required Equipment

Test Equipment

Table 4--1 lists the equipment required for this procedure.

Table 4- 1: Equipment required for Performance Verification

Item No. Required precision Recommended equipment

Digital Television Waveform

Monitor

HDTV Picture Monitor 1 Sony HDM1220J

Digital Audio Monitor 1 Tektronix 764

Oscilloscope 1 Bandwidth: 200 MHz or higher Tektronix TDS740D

Sampling oscilloscope with

head

75 Ω coaxial cable

50 Ω BNC to SMA adapter

75 Ω BNC terminator

75 Ω Signal Adapter 2

1 Tektronix WFM1125 Option 0C or 0D

1 Bandwidth: 6 GHz or higher Tektronix 11801C with SD-22

5 Tektronix part number 012-0159-01

2 Tektronix part number 015-1018-00

4 Tektronix part number 011-0102-00

5

Tektronix AMT75

HDVG1 HDTV Digital Video Generator Service Manual

4- 1

Page 60

Performance Verification

Calibration Data Report

Photocopy this form and use it to record the performance test results.

T abl e 4- 2: HDVG1 Calibration Data Report

Serial Number: Cal Date: Temperature: Humidity:

Step Function Tested Minimum Cal Data Maximum

1. Serial Output Rise Time (20% to 80% amplitude points)

Output 1 ps 270 ps

Output 2 ps 270 ps

Output 3 ps 270 ps

2. Serial Output Fall Time (20% to 80% amplitude points)

Output 1 ps 270 ps

Output 2 ps 270 ps

Output 3 ps 270 ps

3. Trigger Output Level into 75Ω

Low OK 0.25V

High 1.00V OK

4- 2

HDVG1 HDTV Digital Video Generator Service Manual

Page 61

Preparation for Performance Verification

Follow all instructions for power on, instrument warm-up, and loading test and

logo signals. The 1920X1080 60 2:1 signal set is used in this procedure.

Performance Verification

Overview

Power On and Warm Up

This is a list of the steps that you will follow while preparing for and performing

the Performance Verification procedure:

H Power on and warm up, page 4--3

H Create Preset, page 4--3

H Recall the Factory Preset, page 4--4

H Complete the Performance Verification procedure, page 4--5

Power on and warm up the mainframe as follows:

1. Connect the TG2000 Platform mainframe to an AC power source.

2. Set the rear-panel power switch to the ON position.

3. Press the front-panel POWER switch if necessary.

4. Wait for a few seconds as the mainframe executes confidence tests on the

mainframe and modules. Check to see if any error messages appear.

5. When the self tests are complete, the instrument will display icons representing each of the installed generator modules. If an installed module is not

represented on the display, proceed to Troubleshooting Procedures on

page 5--9.

6. Allow 20 minutes of warm-up time before performing Performance

Verification.

7. During warm-up time, you can perform the remaining preparation steps.

Create Preset

HDVG1 HDTV Digital Video Generator Service Manual

Before beginning the Performance Verification procedure, create a preset to save

your instrument settings as follows:

1. Push the Presets button.

2. Touch Presets on the display.

3. Touch Create on the display.

4. Touch letters on the display to spell out a name for the new preset, and then

touch OK.

5. Use the Navigation arrows to move the cursor to the new preset. Press the

Select key.

6. Touch Save To. Your current instrument settings are saved to the new preset.

4- 3

Page 62

Performance Verification

Instrument Backup

Determine whether you will replace signals or add signals (refer to Signal Set

Installation on page 2--6). If you will replace signals, perform the following

Instrument Backup first. During this procedure, you create disks that you will use

to restore the module signals after you finish the Performance Verification

procedure. You need blank 3.5 inch disks, DOS formatted, approximately one

disk for each module.

If you do not wish to perform the backup, you can choose to restore the standard

HDVG1 test signals instead, using the HDVG1 Test Signals disks that were

shipped with the module’s user manual.

T o perform Instrument Backup, follow these steps:

1. Insert the Troubleshooting disk supplied with TG2000 Signal Generation

Platform Service Manual into the mainframe disk drive and push the

front-panel Sequences button.

2. Touch File Utilities on the display, and then touch Add Sequences from

Disk.

3. Select the tgbackup.seq sequence file, and then touch Start Load.

4. When you see the message, “The Load is Complete”, touch OK.

5. Touch Quit, and then touch Quit again.

Recall the Factory Preset

6. Touch Sequences and then select the tgbackup.seq file to run (use the touch

screen and the Select key). Be sure this file name appears in the box at the

top of the window.

7. Touch Run. A popup menu will tell you how many disks are needed. Touch

Quit.

8. When you see the message, “Insert a Floppy Disk”, remove the troubleshoot-

ing disk and insert a blank formatted disk. Touch Quit.

9. After each backup disk is complete, a popup menu will tell you to insert a

disk. Replace the completed disk with a new disk, and touch Quit.

10. After the last backup disk is complete, touch Quit and then Quit again.

Recall the Factory Preset as follows:

1. Push the Presets button.

2. Touch Presets on the display.

3. Use the Navigation arrows to move the cursor to the Factory preset. Press

the Select button.

4. Touch

Recall. The instrument is set to factory presets.

4- 4

HDVG1 HDTV Digital Video Generator Service Manual

Page 63

Performance Verification Procedures

Be sure you have performed the Preparation for Performance Verification before

proceeding.

Performance verification procedures can be performed individually if desired.

WARNING. Dangerous electric shock hazards exist inside the TG2000 mainframe.

Only qualified service personnel should perform these procedures.

Performance Verification

SDI Output Correctness

and Digital Audio Output

Check

Equipment

required

Five 75 Ω coaxial cables

Four 75 Ω terminators

WFM1125 Digital TV Waveform Monitor Option 0C or 0D

HDM1220J HDTV Picture Monitor

764 Digital Audio Monitor

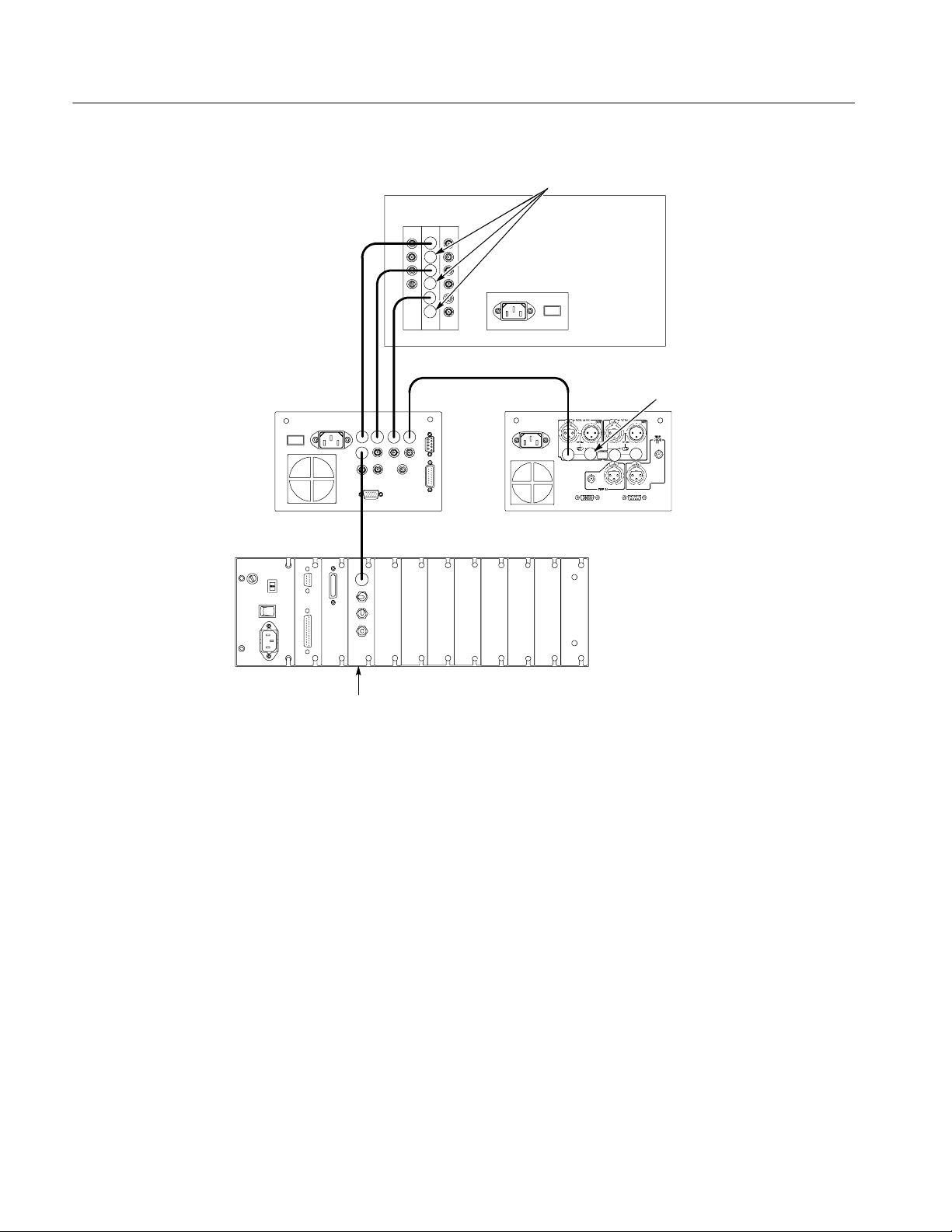

Connections. Refer to Figure 4--1 for connections.

Use the 75 Ω coaxial cables to make the following connections:

H Connect OUTPUT 1 connector on the HDVG1 Generator module to the

CHA connector on the digital TV waveform monitor rear panel.

H Connect Pr, Pb, and Y ANALOG OUT connectors on the digital TV

waveform monitor rear panel to INPUT A R/P

,B/PB, G/Y connectors,

R

respectively, on the HDTV picture monitor rear panel.

H Connect AUDIO CHA connector on the digital TV waveform monitor rear

panel to CH1--2 BNC connector on the digital audio monitor rear panel.

Use the 75 Ω terminators to make following connections:

H Terminate the other loop through to R/P

HDTV picture monitor rear panel.

H Terminate the other loop through to CH1--2 BNC connector on the digital

audio monitor rear panel.

HDVG1 HDTV Digital Video Generator Service Manual

,B/PB, and G/Y connectors on the

R

4- 5

Page 64

Performance Verification

75 Ω coaxial cable

75 Ω terminator

Pr

Y

Pb

HDM1120J HDTV

Picture Monitor

rear panel

75 Ω coaxial cable

WFM1125 Waveform

Monitor Option 0C

rear panel

75 Ω coaxial cable

HDVG1 module

Figure 4- 1: SDI correctness and digital audio output check connection

Setup. Set the digital TV waveform monitor as indicated below:

75 Ω terminator

764 Digital Audio

Monitor rear panel

TG2000 Signal Generation

Platform rear panel

4- 6

Input .......................... CHA

Display......................... Parade

Format ......................... 240M/274M (for SMPTE 274M) (Opt 0C)

Interlaced/Progressive .............. Interlaced(Opt0D)

Procedure.

1. Select the 75% SMPTE Color Bars signal as follows:

a. Push the Signal Sets button on the TG2000 Signal Generation Platform.

b. Touch 1920X1080 60 2:1 on the display. Load from floppy if necessary.

HDVG1 HDTV Digital Video Generator Service Manual

Page 65

Performance Verification

c. Touch Color Bars on the display until the 75% SMPTE Color Bars

signal is selected.

2. Enter the text and turn on the text overlay as follows:

a. Touch Active Signal Parameters on the display.

b. Touch Text Overlay on the display.

c. Touch Edit Text on the display.

d. In the text entry window, touch the o, v, e, r, l, a, y,andOK in that

order.

e. Touch Text On/Off to turn on the text overlay.

f. Save the text overlay when prompted.

3. Set the audio frequency for the channel 1 and channel 2 to 1 kHz as follows:

a. Press the Test Signal button on the TG2000 Signal Generation Platform.

b. Touch Module Parameters on the display.

c. Touch Embedded Audio on the display.

d. Touch Group1 on the display.

e. Touch the list box for the channel 1. A list box appears for you to select

the desired frequency.

f. Select 1000 Hz using the cursor keys and the Select button.

g. Perform steps c and d for the channel 2.

4. Check the displayed waveform and CRC error:

a. Confirm that t he waveform and “overlay” text are correctly displayed on

the digital TV waveform monitor.

b. Check that the CRC ERROR LED on the digital TV waveform monitor

does not light.

5. Check the digital audio:

a. On the digital audio monitor front panel, press t he MENU button to

display the menu.

b. Select the Input item from the menu, and select CH1--2 input:

BNC--unbalanced item from the submenu.

c. On the digital audio monitor front panel, press the CLEAR button t o

clear the menu.

HDVG1 HDTV Digital Video Generator Service Manual

4- 7

Page 66

Performance Verification

d. On the digital audio monitor front panel, press the CH STATUS button

to display CHANNEL STATUS view.

e. In the view, check CRC errors are not displayed.

f. On the digital audio monitor front panel, press the Audio View button.

g. Check that the digital audio monitor bar graphs show both Channel 1

and Channel 2 at --20 dBfs.

6. Check that the correct color bar and “overlay” text are displayed on the

HDTV picture monitor.

7. Change the coaxial cable connection from OUTPUT 1 connector to

OUTPUT 2 connector on the HDVG1 Generator module and repeat step 4

andstep5.

8. Change the coaxial cable connection from OUTPUT 2 connector to

OUTPUT 3 connector on the HDVG1 Generator module and repeat step 4

andstep5.

Eye Pattern Check

Equipment

required

Two 75 Ω coaxial cables

One AMT75

Two SMA-to-BNC adapters

Sampling oscilloscope with sampling head

Connections. Refer to Figure 4--2 for connections.

Use the AMT75, 75

Ω coaxial cables, and SMA-to-BNC adaptors to make the

following connections:

NOTE. Some sampling oscilloscopes do not automatically adjust their readouts

to account for the

5 attenuation of t he AMT75. You must remember to account

for this attenuation while viewing the oscilloscope readouts if you are using an

oscilloscope of this type.

H Connect the OUTPUT 1 connector on the HDVG1 Generator module to the

AMT75 and then to the CH1 input connector on the oscilloscope sampling

head.

H Connect the OUTPUT 2 connector on the HDVG1 Generator module to the

TRIGGER INPUTS DIRECT connector on the oscilloscope sampling head.

4- 8

HDVG1 HDTV Digital Video Generator Service Manual

Page 67

75 Ω coaxial cable

Performance Verification

TG2000 Signal Generation Platform rear panel

HDVG1 module

Figure 4- 2: Eye pattern check connection

Setup. Set the sampling oscilloscope as indicated below:

11801C Sampling

Oscilloscope

BG1 module

75 Ω coaxial cable

ANT75

TRIGGER INPUTS

DIRECT

Vertical......................... CH1

Coupling.................... AC

Scale ...................... 20mV/div

Horizontal

Sweep ..................... 200ps/div

Trigger

Source ..................... ExternalDirect

Coupling.................... AC

Slope ...................... Positive

Level ...................... 0V

Mode ...................... Auto

Displaymode .................... ColorGradingorInfinite

SMA-to-BNC adaptor

SMA-to-BNC adaptor

procedure.

1. Select the 75% SMPTE Color Bars signal as follows:

a. Push the Signal Sets button on the TG2000 Signal Generation Platform.

b. Touch 1920X1080 60 2:1 on the display.

c. Touch Color Bars on the display until the 75% SMPTE Color Bars

signal is selected.

HDVG1 HDTV Digital Video Generator Service Manual

4- 9

Page 68

Performance Verification

2. Check that OUTPUT 1 eye pattern displayed on the sampling oscilloscope is

fully open. Figure 4--3 shows an example of the eye pattern for an acceptable

output signal

4- 10

Figure 4- 3: Example of eye pattern for an acceptable output signal

3. Use the sampling oscilloscope measurement functions to perform the

amplitude, rise and fall time measurement and check that these values are as

follows.

Amplitude : approximately 800 mV

Rise and fall time : < 270 ps (20% to 80%)

Alignment jitter : < 135 ps

4. Change the cable connection on the HDVG1 Generator Module.

a. Disconnect the coaxial cable from OUTPUT 1 connector on the HDVG1

Generator module.

HDVG1 HDTV Digital Video Generator Service Manual

Page 69

Performance Verification

b. Disconnect the coaxial cable from OUTPUT 2 connector on the HDVG1

Generator module, and then connect it to OUTPUT1 connector on the

HDVG1 Generator module.

c. Connect the coaxial cable disconnected in step 4.a. to OUTPUT 2

connector on the HDVG1 Generator module.

5. Check that OUTPUT 2 eye pattern displayed on the sampling oscilloscope is

fully open (see Figure 4--3 ) and repeat step 3.

6. Disconnect the coaxial cable from OUTPUT 2 connector on the HDVG1

Generator module, and then connect it to OUTPUT 3 connector on the

HDVG1 Generator module.

7. Check that OUTPUT 3 eye pattern displayed on the sampling oscilloscope is

fully open (see Figure 4--3 ) and repeat step 3.

Trigger Output Check

HDVG1 module

Equipment

required

75 Ω coaxial cable

75 Ω terminator

Oscilloscope

Connections. Refer to Figure 4--4 for connections.

Use the 75 Ω coaxial cable and 75 Ω terminator to make the following connections:

H Connect the TRIG OUT connector on the HDVG1 Generator Module to the

oscilloscope CH1 input connector.

TG2000 Signal Generation Platform rear panel

TDS740D Oscilloscope

75 Ω coaxial cable

Figure 4- 4: Trigger output check connection

HDVG1 HDTV Digital Video Generator Service Manual

75 Ω terminator

4- 11

Page 70

Performance Verification

Setup. Set the oscilloscope as indicated below:

Vertical......................... CH1

Coupling.................... DC

Scale ...................... 0.2V/div

Horizontal

Sweep ..................... 1ms/div

Trigger

Coupling.................... AC

Slope ...................... Positive

Level ...................... 0V

Mode ...................... Auto

procedure.

1. Select the 75% SMPTE Color Bars signal as follows:

a. Push the Signal Sets button on the TG2000 Signal Generation Platform.

Instrument Restore from

Backup

b. Touch 1920X1080 60 2:1 on the display.

c. Touch Color Bars on the display until the 75% SMPTE Color bars

signal is selected.

2. Generate the trigger signal as follows:

a. Touch Module Parameters on the display.

b. Touch Trigger on the display.

c. Touch Type to select Horizontal, Vertical,orPixel.

3. Use the oscilloscope measurement functions to perform the trigger output

signal amplituide and rise and fall time measurement and check that these

values are as follows.

Amplitude:

Low : < 0.25 V

High : > 1.0 V

Rise and fall time : < 10 ns

If you performed an instrument backup before beginning the Performance

Verification procedure, restore the signals by following these steps:

4- 12

1. Insert the Troubleshooting disk supplied with this manual into the mainframe

disk drive and press the front-panel Sequences key.

2. Select the tgrstore.seq file, and then touch Start Load.

HDVG1 HDTV Digital Video Generator Service Manual

Page 71

Performance Verification

3. When you see the message, “The Load is Complete”, touch OK.

4. Touch Quit, and then touch Quit again.

5. Touch Sequences and then select the tgbackup.seq file to run (use the touch

screen and the Select key). Be sure this file name appears in the box at the

top of the window.

6. Touch Run. Insert any of the backup disks that you created when you

performed the Instrument Backup procedure. Touch Quit.

7. Insert another disk and touch Quit each time you are prompted. (You can

insert the disks in any order.)

8. When the Restore Complete window appears, turn the mainframe power off

and then on again to cycle power.

Recall Preset

Recall the preset you created as follows:

1. Push the Presets button.

2. Touch Presets on the display.

3. Use the Navigation arrows to move the cursor to the preset that you created

before beginning the Performance Verification procedure. Press the Select

key.

4. Touch Recall. Your instrument settings are recalled.

This completes the Performance Verification procedure. If you require further

assistance, contact your nearest Tektronix Service Center.

HDVG1 HDTV Digital Video Generator Service Manual

4- 13

Page 72

Performance Verification

4- 14

HDVG1 HDTV Digital Video Generator Service Manual

Page 73

Maintenance

Page 74

Page 75

Maintenance

This section contains instructions and procedures for maintaining the HDVG1

Generator module. For information on servicing the mainframe, refer to the

TG2000 Signal Generation Platform Service Manual.

The following information can be found in this section:

H Preparation page 5--1

H Inspection and Cleaning (preventive maintenance) page 5--3

H Repackaging instructions page 5--3

H Removal and replacement procedures page 5--7

H Troubleshooting procedures page 5--9

If the instrument does not function properly, troubleshooting and corrective

measures should be taken immediately to prevent additional problems.

NOTE. Contact your local Tektronix representative for information on where to

return your instrument if it requires repair during the warranty period.

Preparation

Please read and follow these preparation instructions before attempting to

perform any maintenance or service to the instrument.

Servicing Prerequisites

HDVG1 HDTV Digital Video Generator Service Manual

Make sure of the following before beginning any instrument service:

H The maintenance or service of this instrument must be performed by

qualified service personnel only.

H Read the Service Safety Summary located at the beginning of this manual

before attempting to perform any maintenance or service to the instrument.

H Read the Operating Information section of this manual before attempting to

perform any maintenance or service to the instrument.

5- 1

Page 76

Maintenance

Electrostatic Damage

Prevention

This instrument contains electrical components that are susceptible to damage

from electrostatic discharge. Static voltages of 1 kV to 30 kV are common in

unprotected environments.

CAUTION. Static discharge can damage any semiconductor component in this

instrument.

Observe the following precautions to avoid static damage:

H Minimize handling of static-sensitive components.

H Transport and store static-sensitive components or assemblies in their

original containers, on a metal rail, or on conductive foam. Label any

package that contains static-sensitive assemblies or components.

H Discharge the static voltage from your body by wearing a wrist strap while

handling these components. Servicing static-sensitive assemblies or

components should only be performed at a static-free workstation by

qualified personnel.

H Nothing capable of generating or holding a static charge should be allowed

on the workstation surface.

H Keep the component leads shorted together whenever possible.

H Pick up components by the body, never by the leads.

H Do not slide the components over any surface.

H Avoid handling components in areas that have a floor or work surface

covering capable of generating a static charge.

H Use a soldering iron that is connected to earth ground.

H Use only special antistatic, suction-type or wick-type desoldering tools.

NOTE. A 2% RMA flux content solder is recommended for making repairs in this

instrument. Cleaning of rosin residue is not recommended. Most cleaning

solvents tend to reactivate the rosin and spread it under components where it

may cause corrosion under humid conditions. The rosin residue, if left alone,

does not exhibit these corrosive properties.

5- 2

HDVG1 HDTV Digital Video Generator Service Manual

Page 77

Inspection and Cleaning

Preventive maintenance consists of cleaning, visual inspection, performance

checking, and, if needed, readjustment. The preventive maintenance schedule

established for the instrument should be based on the environment in which it is

operated and the amount of use. Under average conditions, scheduled preventive

maintenance should be performed every 2000 hours of operation.

Maintenance

General Care

Cleaning and Visual

Inspection

Performance Verification

Protect the module from adverse weather conditions. The module is not

waterproof.

CAUTION. To avoid damage to this module, do not expose it to sprays, liquids, or

solvents. Do not flex the circuit board if you remove the board from its mounting

shield. The circuit board can be damaged by flexing. The shield provides

necessary structural support to the circuit board.

Clean the mainframe and modules often enough to prevent dust or dirt from

accumulating. Refer to Cleaning and Visual Inspection in the TG2000 Signal

Generation Platform Service Manual.

Check module performance after each 2000 hours of operation or every

12 months. This will help to ensure maximum performance and assist in locating

defects that may not be apparent during regular operation. Performance

verification procedures are included in this m anual.

Repackaging Instructions

Use the following instructions to prepare your instrument for shipment t o a

Tektronix, Inc., Service Center:

1. Attach a tag to the instrument showing: the owner, complete address and

phone number of someone at your firm who can be contacted, the instrument

serial number, and a description of t he required service.

2. Package the instrument in the original packaging materials. Figures 5--1 and

5--2 illustrate how to repackage the module in the original packaging