Page 1

xx

H600 RFHawk &

ZZZ

SA2600 Spectrum Analyzer

Service Manual

*P071264101*

071-2641-01

Page 2

Page 3

xx

H600 RFHawk &

ZZZ

SA2600 Spectrum Analyzer

Service Manual

Revision A

www.tektronix.com

071-2641-01

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are c overed by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

NetTek is a registered trademark of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. Box 50 0

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

In North America, call 1-800-833-9200.

Worl dwid e, v isit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement pr oducts used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

General Safety Summary .......................................................................................... v

Service Safety Summary.......... ................................ .................................. ............. vii

Preface .............................................................................................................. ix

Manual Content . .................................. ................................ ............................ ix

Manual Conventions.................................. ................................ ........................ ix

Related User Documents...................................................................................... x

Operating Information

Installation......................................................................................................... 1-1

Operating Information ........................................................................................... 1-2

Performance Verification . ................................ .................................. ..................... 1-3

Preparation......................................... ................................ ........................... 1-3

Test Record...... ................................ .................................. ........................... 1-4

Procedures .................................................................................................... 1-6

Test Descriptions........................ ................................ ................................ ..... 1-7

Verify Performance........................................................................................ 1-12

Theory of Operation

Theory of Operation. ................................ ................................ ............................. 2-1

Platform.. ................................ .................................. ................................ ... 2-1

Measurement Module .............. ................................ ................................ ......... 2-9

Adjustment Procedures

Adjustment Procedures .......................................................................................... 3-1

Maintenance

Cleaning .. .................................. ................................ ................................ ....... 4-1

Removal and Replacement Procedures ........................................................................ 4-2

Preparation......................................... ................................ ........................... 4-2

Preventing Electrostatic Damage .......................................................................... 4-3

Removal Procedures......................................................................................... 4-3

Troubleshooting................................................................................................. 4-13

Power On Self Test ................. ................................ ................................ ....... 4-14

Display Does Not Operate ... .................................. ................................ ........... 4-14

Display Image Inverted (Rotated 1

Touch Screen Does Not Operate .................. .................................. ..................... 4-15

Signal and Connector Information ....................................................................... 4-15

80°) ................................................................. 4-15

H600 & SA2600 Service Manual i

Page 8

Table of Contents

Lithium-Ion Ba

H600 and SA2600 Instrument-Specific Battery Maintenance . ................................ ....... 4-26

Repackaging for Shipment .................................................................................... 4-30

ttery Maintenance ..... .................................. ................................ ..... 4-24

Replaceable Parts

Replaceabl

Parts Ordering Information ...................... .................................. ......................... 5-1

Using the Replaceable Parts List........................................................................... 5-1

e Parts ............ .................................. ................................ ................... 5-1

Specifications

Specifica

tions ...................... ................................ .................................. ............. 6-1

ii H600 & SA2600 Service Manual

Page 9

List of Figures

Figure 4-1: Processor and backlight inverter board input and output connections...................... 4-13

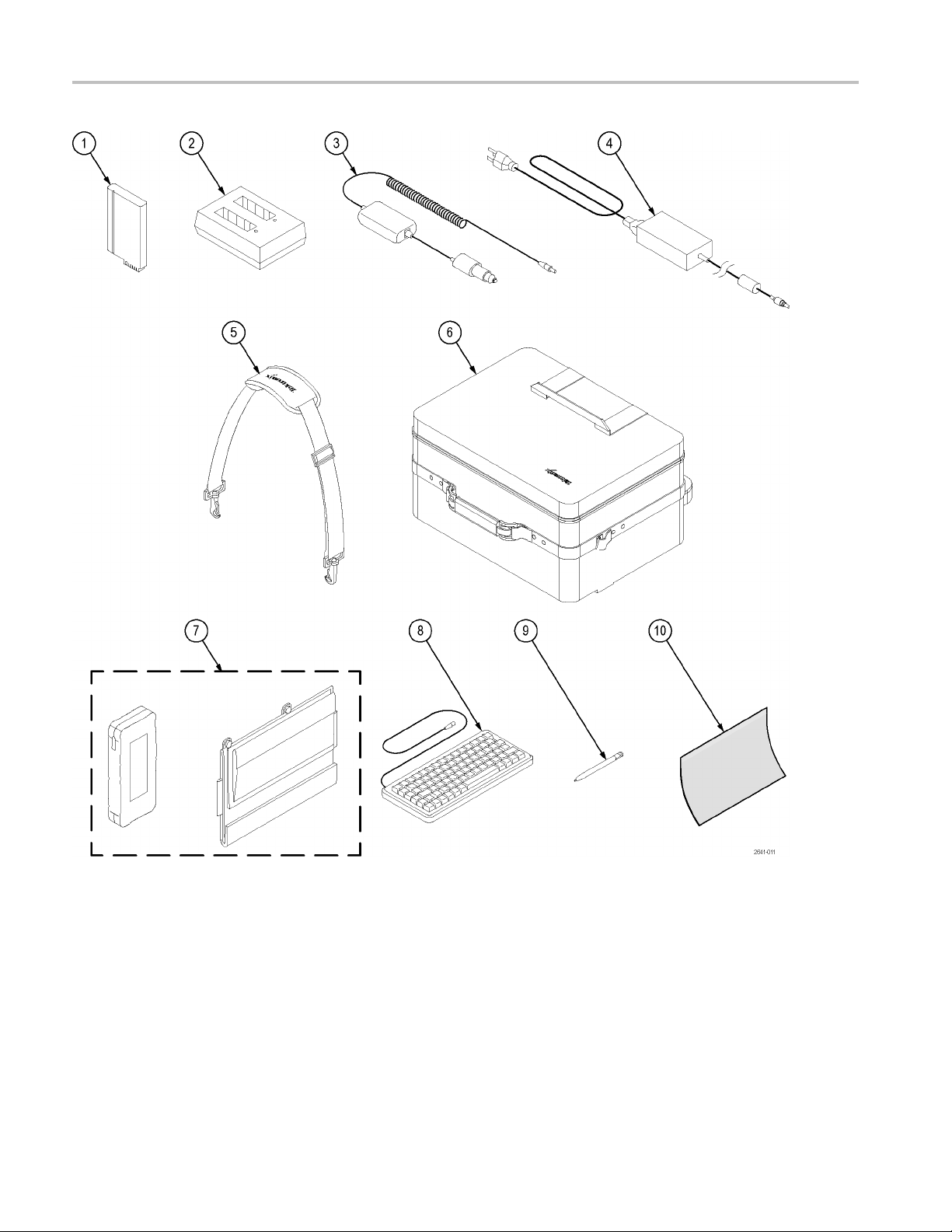

Figure 5-1: Module and cover replaceable parts .............................................................. 5-2

Figure 5-2: Mainframe replaceable parts ...................................................................... 5-4

Figure 5-3:

H600 and SA2600 accessories.................................................................... 5-6

H600 & SA2600 Service Manual iii

Page 10

Table of Contents

List of Tables

Table 1-1: DB- 9F serial loop-back connector pin-out ........ ................................ ............. 1-10

Table 1-2: T

Table 2-1: External ports and buses ............................................................................ 2-4

Table 2-2: Internal ports and buses ........ ................................ ................................ ..... 2-4

Table 2-3: Platform voltage supplies to module ....................... ................................ ....... 2-7

Table 4-1: Tools required ........................................................................................ 4-2

Table 4-2: Backlight-related voltages ............................... ................................ ......... 4-14

Table 4-3

Table 4-4: Application module connector JR170 .... .................................. ..................... 4-16

Table 4-5: Internal speaker connector J110......................................... ......................... 4-17

Table 4-6: External microphone connector J200............................................................ 4-18

Table 4-7: Power connector J240 ............................................................................. 4-18

Table 4-8: Front-panel switch/LED connector J120................................... ..................... 4-19

Table

Table 4-10: JTAG port connector J670....................................................................... 4-19

Table 4-11: PS/2 keyboard connector J700.................................................................. 4-20

Table 4-12: Headphone connector J300...................................................................... 4-20

Table 4-13: TFT color display connector J660.............................................................. 4-20

Table 4-14: TFT backlight connector CN2 (Backlight Inverter Board) .................................. 4-21

ble 4-15: Touch screen connector J4 and J2 .............................................................. 4-21

Ta

Table 4-16: Ethernet connector J400.......... ................................ ............................... 4-21

Table 4-17: USB 1.1 series A host connector J701........................ ................................ . 4-22

Table 4-18: USB 1.1 series B slave connector J800................... ................................ ..... 4-22

Table 4-19: Backlight connector JR1 ... ................................ .................................. ... 4-22

Table 6-1: General performance characteristics............................................................... 6-1

Table 6-2: Spectrum analyzer characteristics............................... .................................. . 6-3

Table 6-3: DPX measurement processing characteristics ............... .................................. ... 6-5

Table 6-4: General purpose RF measurement characteristics ............................................... 6-6

Table 6-5: Amplitude vs. Time measurement characteristics ............................................... 6-6

Table 6-6: Signal analysis and monitoring characteristics ................................................... 6-8

Table 6-7: Environmental characteristics ..... .................................. ............................... 6-9

Table 6-8: Physical characteristics ............................................................................. 6-9

Table 6-9: Miscellaneous characteristics ....................... .................................. ............. 6-9

est voltages and limits .................... ................................ ....................... 1-11

: PCMCIA interface connectors JR420, JR520 .................................................. 4-15

4-9: Serial port connector J500 ........................................................................ 4-19

iv H600 & SA2600 Service Manual

Page 11

General Safety Summary

General Safet

To Avoid Fire or Personal

Injury

ySummary

Review the fo

this product or any products connected to it.

To avoid pot

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of a larger system.

Read the safety sections of the other component manuals for warnings and

cautions r

Use proper power cord. Use only the power cord specified for this product and

certified for the country of use.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product. Consult the product manual for further ratings

information before making connections to the product.

The inputs are not rated for connection to mains or Category II, III, or IV circuits.

Power disconnect. The power cord disconnects the product from the power source.

Do not block the power cord; it must remain accessible to the user at all times.

llowing safety precautions to avoid injury and prevent damage to

ential hazards, use this product only as specified.

elated to operating the system.

Do not operate without covers. Do not operate this product with covers or panels

removed.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Avoid exposed circuitry. Do not touch exposed connections and components when

power is present.

Replace batteries properly. Replace batteries only with the specified type and

rating.

Recharge batteries properly. Recharge batteries for the recommended charge cycle

only.

Use proper AC adapter. Use only the AC adapter specified for this product.

Do not operate in an explosive atmosphere.

H600 & SA2600 Service Manual v

Page 12

General Safety Summary

TermsinThisManual

Symbols and Terms on the

Product

These terms may

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER in

the marking.

WARNING

read the marking.

CAUTIO

The following symbol(s) may appear on the product:

appear in this manual:

dicates an injury hazard immediately accessible as you read

indicates an injury hazard not immediately a ccessible as you

N indicates a hazard to property including the product.

vi H600 & SA2600 Service Manual

Page 13

Service Safety Summary

Service Safet

y Summary

Only qualifie

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, switch off the instrument power, then

disconnect the power cord from the mains power.

UseCareWhenServicingWithPowerOn. Dangerousvoltagesorcurrentsmay

exist in

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

d personnel should perform service procedures. Read this Service

this product. Disconnect power, remove battery (if applicable), and

H600 & SA2600 Service Manual vii

Page 14

Service Safety Summary

viii H600 & SA2600 Service Manual

Page 15

Preface

Preface

Manual Content

Manual Conventions

This service

Analyzer.

This manual contains information related to servicing the mainframe part of the

H600 RFHawk and SA2600 Spectrum Analyzer, and running a performance

verification on the whole instrument. The module part of the instrument has no

user-serviceable parts or adjustments. The entire instrument must be returned to

Tektronix if service is required.

For information related to installing and operating the instrument, or for a list of

instrument specifications, refer to the appropriate user document as described in

Related

Be sure to read the introductions to all procedures. These introductions provide

import

efficiently.

This manual uses certain conventions that you should become familiar with

before attempting service.

manual is for servicing the H600 RFHawk and SA2600 Spectrum

User Documents below.

ant information needed to perform the service correctly, safely, and

Module

Replaceable Parts

Safety

term module refers to a collection of items that are replaceable as a unit. A

The

module may contain electrical and mechanical asse mblies, circuit boards, and

interconnecting cables.

his manual refers to any field-replaceable assembly or mechanical part by its

T

name or generically as a replaceable part. In general, a replaceable part is any

circuit board or assembly that is listed in the Replaceable Parts section.

Symbols and terms related to safety appear in the General Safety Summary found

at the beginning of this manual. Be sure to read both the General Safety Summary

and Service Safety Summary before performing any service to this instrument.

H600 & SA2600 Service Manual ix

Page 16

Preface

Related User Documents

The following related English user documents are available if you need more

information about operating the instrument. The user manuals can be downloaded

from the Tektronix Web site (www.tektronix.com).

User manual. Tektronix part number 071-2464-xx (for the H600 RFHawk)

and Tektronix part number 071-2465-xx (for the SA2600 Spectrum Analyzer)

contain general information about how to put the instrument into service,

guides to u

Online Help. The H600 RFHawk and SA2600 Spectrum Analyzer

applicat

information appropriate for the active screen or the selected help button.

ser interface controls, and application examples.

ions contain online help that is context sensitive, displaying

x H600 & SA2600 Service Manual

Page 17

Operating Information

Page 18

Page 19

Installation

The Specifications section contains information on instrument operation

environment requirements. (See Table 6-7 on page 6-9.)

H600 & SA2600 Service Manual 1–1

Page 20

Operating Information

Operating Inf

ormation

Refer to the i

nstrument user manual for operation instructions.

1–2 H600 & SA2600 Service Manual

Page 21

Performance Verification

Performance V

Preparation

erification

This section

warranted characteristics.

Before you perform the procedures in this manual, do the following steps:

Ensure tha

who have read the General Safety Summary at the front of this manual.

Ensure th

to the product user manual).

Obtain t

additional cables and adapters, depending on the actual test equipment you use.

Description Minimum requirements Examples

Signal generator

Frequency standard

Power meter with head 0.009 to 6200 MHz, -52 dBm

Oscilloscope

10 dB fixed attenuator

50 ohm N-type RF cable 0.009 to 6200 MHz

50 ohm BNC cables

N-type barrel

female-to-female adapter

enables you to verify that the instrument performs according to its

t the procedures are performed only by qualified service personnel

at the service personnel are familiar with system operation (refer

he equipme nt described in the following table. You may also need

0.009 to 6200 MHz,

phase noise better than

-110 dBc/Hz at 10 kHz offset

10 MHz (or any frequency in

therange1MHzto20MHz

in 1 MHz increments), ±0.05

ppm

to +3 dBm

300MHz band width

0.009 to 6200 MHz

None Tektronix part number

0.009 MHz to 6200 MHz

Anritsu MG3692B with

option 22 (low frequency),

option 3 (low phase noise,

main band), and option 4

(low phase noise, low band)

Fluke 910/910R GPS

Controlled Frequency

Standards

Agilent E4418B

Agilent E9304A

Tektronix TDS3034B

RLC Electronics A-8-10-N

Florida RF Labs NMS 290 AN - 36.0 - NMS

012-0482-00

SRI Connector Gage Co.

P/N 53-953-0003-00

H600 & SA2600 Service Manual 1–3

Page 22

Performance Verification

Test Record

Serial number Procedure performed by

Date

Test Passed Failed

Self Test

Performance checks

Carrier Frequency

and Timebase Error

External Lock Time

Tested at 6 GHz

10 MHz (typical) Reference

Low limit Test result High limit

-3010 Hz

-9010 Hz

-15010 Hz

1

2

3

-

Frequency

RF Channel Power

Accuracy

50 MHz, -5 dBm Input - 0.75 dB +0.75 dB

3200 MHz, -5 dBm Input - 0 .75 dB +0.75 dB

5000 MHz, -5 dBm Input - 0 .75 dB +0.75 dB

6199 MHz, -5 dBm Input - 0 .75 dB +0.75 dB

50 MHz, -20 dBm Input -1.25 dB +1.25 dB

3200 MHz, -20 dBm Input -1.25 dB +1.25 dB

5000 MHz, -20 dBm Input -1.25 dB +1.25 dB

6199 MHz, -20 dBm Input -1.25 dB +1.25 dB

50 MHz, -35 dBm Input -1.25 dB +1.25 dB

3200 MHz, -35 dBm Input -0.75 dB +0.75 dB

5000 MHz, -35 dBm Input -0.75 dB +0.75 dB

6199 MHz, -35 dBm Input -1.5 dB +1.5 dB

Phase N oise

100 MHz Input,

-

10 kHz, offset

3000 MHz Input, 10 kHz offset

5000 MHz Input,

-

-

10 kHz offset

6000 MHz Input,

-

10 kHz offset

Displayed Average

Noise Level

1MHzto4GHz(1)

1MHzto4GHz(2)

4 GHz to 5 GHz

5GHzto6.2GHz

Residual Spurs -60 dBm ref level

1

Use this limit if testing shortly after instrument calibration.

2

Use this limit if testing one year after instrument calibration.

3

Use this limit if testing two years after instrument calibration.

3010 Hz

9010 Hz

15010 Hz

15 s

-95 dBc/Hz

-95 dBc/Hz

-95 dBc/Hz

-95 dBc/Hz

-153 dBm

-153 dBm

-151 dBm

-145 dBm

-105 dBm

1–4 H600 & SA2600 Service Manual

Page 23

Performance Verification

Instrument Warmup

Equipment Setup

Before perform

operating continuously for at least twenty (20) minutes in an environment that

meets the operating range specifications for temperature and humidity:

The H600 or SA2600 under test

All test equ

Setup the test equipment as follows:

1. Reset all the test instruments to their factory default settings before starting a

test.

2. Connect the RF cable to the output of the Signal Generator; all test instructions

make this assumption.

3. Connect the AC adapter to the H600 or SA2600 instrument. Do not attempt to

do the procedure steps while the instrument is powered from the batteries.

ing these procedures, the following equipment must have been

ipment

H600 & SA2600 Service Manual 1–5

Page 24

Performance Verification

Procedures

A test record table is provided. (See page 1-4, Test Record.) You can photocopy

the page and record your test results in the table.

Diagnostic Tests

This section contains procedures to verify that the instrument platform is

functioning properly.

1. Select Start > Programs > Tektronix Utilities > Diagnostics.

2. Tap the Dia

3. To view the test selections, tap the + symbol in front of All Modules, All

Tests.Th

4. Select the test(s) to run. The default selection runs all tests. However,

some diagnostic tests require special equipment or custom fixtures (such as

aDBPS/2-compatible keyboard, Microphone, USB Flash Memory Device, and a

network interface connected to a DHCP-enabled network server). Clear the

box next to any test that requires equipment or custom fixtures that you do not

have available for the tests, otherwise these tests will indicate that they fail.

gnostics tab.

en tap the + symbol in front of Platform.

9F serial loopback connector, PCMCIA ATA flash memory cards,

5. Select one of the test run options:

Loop. Use the up/down arrows to set how many times to repeat the test(s).

Until Fail. Run the selected test(s) until a failure occurs or the user selects

Stop.

Continuous. Run the selected test(s) until the user selects Stop.

6. Tap Run to begin the tests.

1–6 H600 & SA2600 Service Manual

Page 25

Performance Verification

Test Descr

Vertica

iptions

lLineTest

Test Results Re

report the results of each test.

The Last Resul

The Fail Count column lists the number of times a test failed.

The Loop Count field reports the number of times the test ran.

To see details on failed tests, select the Failure Log tab and read the Message

column.

Some diagnostic tests require special equipment or custom fixtures. These

requirements are noted under each description.

Observe a full screen of moving vertical lines.

1. Look for inconsistent line widths and lengths.

2. Report a Pass or Fail when prompted.

A Test

response when prompted.

failed is recorded in the Failure Log if the user does not enter a pass/fail

porting. The Diagnostics window contains columns and fields to

t column lists the Pass or Fail status of each test.

Horizontal Line Test

Color Range Test

Observe a full screen of moving horizontal lines.

1. Look for inconsistent line widths and lengths.

2. Report a Pass or Fail.

A Test faile d is recorded in the Failure Log if the user does not enter a pass/fail

response when prompted.

Observe two different color test patterns.

attern 1, look for color fading and inconsistencies while observing red,

1.P

green, and blue color bands on a white background.

2. Pattern 2, look for color inconsistencies (failed pixels) while observing three

different full color screens (red, green, blue).

3. Report a Pass or Fail when prompted.

A Test faile d is recorded in the Failure Log if the user does not enter a pass/fail

response when prompted.

H600 & SA2600 Service Manual 1–7

Page 26

Performance Verification

Brightness Test

LED Test

Touch S

creen Test

Observe a full s

1. Look for adequate brightness at each level.

2. Report a Pass or Fail when prompted.

A Test faile d is recorded in the Failure Log if the user does not enter a pass/fail

response when prompted.

The display returns to its original brightness at test completion.

Observe a series of front-panel LED color cycles.

1. Look for t

2. Report a Pass or Fail when prompted.

A Test faile d is recorded in the Failure Log if the user does not enter a pass/fail

response when prompted.

Observe a c rosshair cursor that moves from screen center to top-left, top-right,

bottom-right, and bottom-left.

1. At each position, press on the center of the crosshair icon until it moves.

Use the stylus or your finger.

creen checker-board pattern that changes brightness.

he color and position indicated: left-right, green, red, and amber.

Keyboard Test

Pass is reported if the sequence is completed within the a llotted time.

Test failed is recorded in the Failure Log if no user interaction is detected or the

user presses outside of the crosshair area.

Check the keyboard cable connection to the instrument; check the function of

each key.

NOTE. This test requires an external PS/2 keyboard.

1. Connect a PS/2-compatible keyboard to the keyboard port. Refer to the user

manual for port location.

2. Select Keyboard Test; then select Run.

3. Enter the requested text on the keyboard when prompted; then select OK.

The text must be duplicated exactly or the test will fail.

This test reports a Fail if a keyboard is not connected or the user misspells the

message.

1–8 H600 & SA2600 Service Manual

Page 27

Performance Verification

Audio Test

PCMCIA Slot 1 Test

Check the exter

1. Plug a microphone into the external microphone jack.

2. Select Audio Test; then select Run.

3. When prompted, speak into the microphone for approximately 5 seconds.

The device will then automatically play back your message.

4. Listen to the playback and verify its accuracy. The test fails if there is no

output or if the audio is significantly distorted.

5. Report a Pass or Fail when prompted.

A Test fai

response when prompted.

CheckthePCMCIAcontrollerconnectiontoanATAflash card in Slot 1. The test

uses sta

read the file back, and validate the data.

NOTE. This test requires two PCMCIA ATA flash memory cards. Both cards must

be installed for the test to run successfully.

ndard API functions to create a file on the device, write data to the file,

nal microphone and speaker operation.

led is recorded in the Failure Log if the user does not enter a pass/fail

PCMCIA Slot 2 Test

1. Install two PCMCIA ATA flash memory cards, one in each of the PCMCIA

card slots.

2. Select PCMCIA Slot 1 Test,thentapRun.

A Test failed is recorded in the Failure Log if a memory card is not installed

when prompted.

eck the PCMCIA controller connection to an ATA flash card in Slot 2. Uses

Ch

standard API functions to create a file on the device, write data to the file, read the

file back, and validate the data.

NOTE. NOTE. This test requires two PCMCIA ATA flash memory cards. Both

cards m ust be installed for the test to run successfully.

1. Install two PCMCIA ATA flash memory cards in the PCMCIA card slots.

2. Select PCMCIA Slot 2 Test; then select Run.

A Test failed is recorded in the Failure Log if a memory card is not installed

when prompted.

H600 & SA2600 Service Manual 1–9

Page 28

Performance Verification

Network Port Test

Serial Port Test

Checks the Ethe

rnet network port. Requires a network connection with a DHCP

server.

1. Connect the Ne

tTek Analyzer Platform RJ45 Ethernet port to a DHCP-enabled

network server.

2. Select Netw

ork Port Test; then select Run.

A Test failed is recorded in the Failure Log if the NetTek Analyzer cannot obtain

an I.P. addr

ess from the DHCP-enabled network server.

Check the serial port signal lines by setting the output control lines and reading

the corresponding status lines. Writes, reads, and validates a data pattern at

varying b

aud rat es.

NOTE. This test requires a custom DB-9F serial loop-back connector.

Table 1-1: DB- 9F serial loop-back connector pin-out

Connect pin

1 (DCD) 4 (DTR)

6 (DSR) 4 (DTR)

2(RX) 3(TX)

5(SGND) NC

8(CTS) 7(RTS)

9(RI) 7(RTS)

To p in

1. Install the custom DB-9 loop-back connector on the RS-232 serial port. Refer

to the user manual for port location.

2. Select Serial Port Test; then select Run.

A Test failed is recorded in the Failure Log if the loop-back connector is not

installed when prompted.

1–10 H600 & SA2600 Service Manual

Page 29

Performance Verification

USB Flash Memory Device

Test

SPI Test

Tests the USB po

NOTE. This test requires a USB Flash Memory Device inserted into the USB slot.

If a Flash Memory Device is not installed when the test is initiated, the user is

prompted to insert a Flash Memory Drive or fail the test. The test consists of

the following:

Creating a data file

Writing a fixed size pattern to the file

Closing the file

If an error occurs during any portion of the test, the test terminates and reports a

Test failed in the Failure Log. A Test failedisalsorecordedifaFlashMemory

Drive is not install

Check the external connectivity and function by setting the instrument module

interface port to loop back mode and sending, receiving, and validating device

selects and frequency changes.

No user interaction required. Select Run.

rtusingaFlashMemorydrive.

ed when prompted.

SMBus Te

st

Flash File System Test

Power Test

Verify communications between the host and power management processor.

No user interaction required. Select Run.

Check the read/write function and data integrity of the internal flash file system.

The test uses standard API functions to create a file, write a data pattern to the

file, read the file, and validate the data.

Verify the instrument platform processor board and application module voltages

are within their nominal range. See Table 3-2 for voltage limits.

NOTE. The Power Test does not chec k battery voltages.

This test uses internal voltage sensing. No user interaction required. Select Run.

Table 1-2: Test voltages and limits

Source Voltage (VDC) Limits (VDC)

Processor board +1.5

Processor board +3.3

10%

10%

H600 & SA2600 Service Manual 1–11

Page 30

Performance Verification

Table 1-2: Test voltages and limits (cont.)

Verify Performance

Processor board

Application module +3.4

Application module +13

Application module -13

This test

reports a fail if the detected voltages exceed ±10% of their nominal

+5

10%

10%

10%

10%

values.

Before continuing these procedures, warm up the instrument and all other test

equipment for at least twenty (20) minutes in an environment that meets the

operating range specifications for temperature and humidity.

To warm up the instrument:

1. Connect the AC adapter to the H600 or SA2600 instrument. Do not attempt to

do the procedure steps while powered from the batteries.

2. Power on the instrument. Wait until it completes the power-on sequence.

3. Dou

ble-tap the H600 or SA2600 application icon on the screen to open and

run the instrument application. Leave the application running.

Check Carrier Frequency

d Time-base

an

This test checks the accuracy of the carrier frequency measurement and the

ccuracy of its internal time-base.

a

1. Remove any cable attached to instruments Freq Ref BNC.

2. Reset the instrument application:

a. Select Tools > Factory Reset.

b. Tap Reset All.

3. Connect the Signal Generator output to the H600 under test RF INPUT

connector through the RF cable.

1–12 H600 & SA2600 Service Manual

Page 31

Performance Verification

4. Set the Signal G

a. Reset the Signal Generator.

b. Connect the Frequency Standard output to the frequency reference input

of the Signal Generator marked REF.

c. Set the Signal Generator lock to the external reference input.

d. Verify that the Signal Generator displays is locked to the external

reference.

e. Set frequency to 6 GHz.

f. Set the amplitude to 10dBm.

5. On the H600 or SA2600 application:

a. Tap the S

b. Tap the Freq button to open the Meas Freq form and enter 6GHz.

c. Ta p t he Auto Level button.

d. If you don’t see the signal, tap on the Span: field right arrow button to

increase the signal span.

e. Tap the Meas Freq marker readout box just a bove the Start button to

ensure the red triangle is the selected marker; the red triangle will be

displayed on the marker button in the Spectrum drawer.

enerator as follows:

pectrum drawer.

f. Using the marker drop-down box in the Spectrum drawer, select "Marker

to max peak" then select "Marker to center freq".

g. Reduce the displayed signal span by tapping the arrow icon on the left of

the Span: field.

h. Repeat steps g through h until the signalpeakiscenteredinthedisplay

and the span is 0.010 MHz.

i. Read the marker frequency value from the Meas Freq marker readout box.

j. Write down the FREQ: measurement.

k. Subtract 6 GHz from the measured frequency. Check that the result is

within the limits listed in the Test Record.

H600 & SA2600 Service Manual 1–13

Page 32

Performance Verification

Check External Lock Time

This test check

1. Reset the H600 or SA2600 application:

a. Select Tools > Factory Reset.

b. Tap Reset All.

2. On the Signal Generator:

a. RESET the Signal Generator.

b. Connect a B

generator.

3. On the H60

a. Make sure that the reference oscillator indicator, near the upper right

corner o

b. Connect the BNC cable from the signal generator’s 10 MHz Reference

Out to t

time.

c. Wa t ch

Ext, record the time.

s the lock time of the external frequency reference input.

NC cable to the external reference output of the Signal

0 or SA2600:

f the screen, is indicating FInt.

he H600 FREQUENCY REFERENCE INPUT andrecordthe

the reference oscillator indicator; when it changes from FIntto F

Check RF Channel Power

racy

Accu

d. The di

This test checks the accuracy of the RF channel power measurement.

1. Reset the H600 or SA2600 application:

a. Select Tools > Factory Reset.

b. Tap Reset All.

2. Set the H600 or SA2600 application to read channel power:

a.D

b. Tap the RF Measure drawer.

c. Select Channel Power from the Measurement drop-down list, tap the

3. Connect a 10 dB attenuator to the RF cable. (The attenuator improves the

impedance match between the Signal Generator and the H600/SA2600 under

test.)

4. Connect an N-type barrel adapter (female-to-female) to the attenuator.

fference between the two times is the result of the test. The time

should be 15 seconds or less.

isplay a Spectrum measurement.

Meas BW field, tap the keypad icon on the Meas BW dialog box, and

enter 10 kHz.

1–14 H600 & SA2600 Service Manual

Page 33

Performance Verification

5. Set the Signal G

a. Reset the Signal Generator.

b. Set the frequency to 50 MHz.

c. Set the output level to +5 dBm.

6. Push the ZERO buttononthepowermeter.

7. Connect the power meter head to the barrel adapter.

8. Perform a p

a. Set the power meter correction factor for 50 MHz.

b. Read the power.

9. Adjust the output level of the Signal Generator until the power meter reads

-5 dBm.

10. Disconnect the power meter head and the barrel adapter from the cable/10 dB

attenuator assembly.

11. Connect the RF cable with the 10 dB attenuator to the RF INPUT of the

H600 or SA2600 under test.

enerator as follows:

ower measurement using the power m eter:

H600 & SA2600 Service Manual 1–15

Page 34

Performance Verification

12. On the H600 or SA

a. Tap t he Freq buttontoopentheMeas Freq dialog and enter 50 MHz.

b. If you don’t see the signal, tap on the Span: field right arrow button to

increase the signal span.

c. Ta p the Auto Level button.

d. Tap the Meas Freq marker readout box (just above the Windows CE

Start button) to set the red measurement triangle as the selected (active)

marker. The red triangle will be displayed on the Marker-To button in

the Spectr

e. Ta p the Spectrum drawer button.

f. Tap the down arrow button next to the Marker-To button and select

Marker to max peak. Then select Marker to center freq to move the

peak of t

g. Reduce the displayed signal span by tapping the arrow icon on the left of

the Spa

h. Repeat steps f through g until the signal peak is centered in the display

and th

i. Read the Channel Power in dBm; the Channel Power is displayed in the

trac

Power tab if the RF Measure drawer is open.

he test signal to the center of the display.

n: field.

espanis10 kHz.

e area if the Spectrum drawer is open or displayed on the Channel

2600:

um drawer.

j. Sub

k. Di

13.Re

Record.

tract the nominal power (-5 dBm) from the measurement value and

write it down in the Test Record; this is the result of the test.

sconnect the RF cable with the 10 dB attenuator from the RF INPUT

of the H600 or SA2600 under test.

peat steps 3 through 12 for all frequencies and levels listed in the Test

1–16 H600 & SA2600 Service Manual

Page 35

Performance Verification

Check Phase Noise

This test deter

Signal Generator used in the test should have significantly less phase noise than

the H600 or SA2600 under test.

NOTE. The peak detector is used to measure narrowband signals such as the

CW signal from the signal source and the average detector is used to measure

wideband signals such as noise floor.

Signal Generator setup.

1. Reset the signal generator.

2. Set the frequency to 100 MHz (center frequency).

3. Set the output power level to +10 dBm.

4. Connect the RF cable from the signal generator output to the H600 or SA2600

under test RF INPUT connector.

H600/SA2600 setup.

1. Disconnect the cable from the H600/SA2600 FREQ REF connector if present.

2. Select Tools > Factory Reset

mines the phase noise of the H600 or SA2600 under test. The

3. Tap Reset All.

Phase noise verification.

Do the following steps from the H600/SA2600:

1. Tap the Spectrum drawer.

2. Tap t he More buttonintheSpectrumdrawer.

3. Tap t he Freq/Span tab and set Span to 100.000 kHz and Center Freq to

100.000 MHz.

4. Tap th e Tr ace tab and set the following:

Type to Aver age

Number of Averages to 20 (default)

Detector to +Peak

5. Tap the AutoLevel button.

6. Tap the Meas Freq marker readout box (just above the Windows CE Start

button) to set the red measurement triangle as the selected (ac tive) marker.

The application also updates the Marker-To button in the Spectrum drawer

to show the red measurement triangle icon, indicating that the Marker-To

button will act on the Meas Freq marker.

H600 & SA2600 Service Manual 1–17

Page 36

Performance Verification

7. Tap the down arr

ow button next to the Marker-To button and select Marker

to max peak. ThentapthedownarrowbuttonnexttotheMarker-Tobutton

again and select Marker to center freq to move the peak of the test signal

to the center of the display.

8. Verify that the Span is still 100 kHz and the Meas Freq marker box and center

frequency readouts are both 100 MHz.

9. Write down the level of the signal as shown in the Meas Freq marker readout

box; this is the carrier level value L

.

c

10. Tap the Tr ace tab and set the following:

Type to Aver age

Number of

Aver age s to 100

Detector to Avg ( VRM S)

11. Write down the center frequency.

12. Tap the M1 marker readout box on the bottom of the screen to open the M1

input control.

13. Tap the keypad icon in the M1 control and enter the center frequency

minus 10 kHz (offset). For example, a minus 10 kHz offset for 100 MHz

is 99.990 MHz.

14. Tap the M2 marker readout box on the bottom of the screen to open the M2

input control.

15. Tap the keypad icon in the M2 control and enter the center frequency

plus 10 kHz (offset). For example, a plus 10 kHz offset for 100 MHz is

0.010 MHz.

10

16. Determine the total sideband noise level:

a. Tap t he Reset display-control button (the X button located along the right

side of the waveform plot) to reset the measurement, then wait until the

nstrument averages the 100 measurements.

i

b. Write down the M1 marker value; this is the lower sideband noise level

LN

.

ssb1

c. Write down the M2 marker value; this is the upper sideband noise level

LN

ssb2

.

1–18 H600 & SA2600 Service Manual

Page 37

Performance Verification

17. Determine the n

oise floor levels:

a. Turn off the signal generator.

b. Tap the Reset display-control button (the X button located along the right

side of the waveform plot) to reset the measurement, then wait until the

instrument

averages the 100 measurements.

c. Write down the M1 marker value; this is the lower sideband noise floor

LNF

ssb1

.

d. Write down the M2 marker value; this is the upper sideband noise floor

ssb2

.

LNF

18. Obtain the signal generator phase noise level at 10 kHz offset for 100 MHz

N

output (L

). This may be the typical phase noise performance stated in the

sg

signal generator user manual or specification sheet, or it may be the actua l

measured phase noise data for the signal generator. The signal generator’s

guaranteed specification limit should not be usedsincethatmayleadtoan

underestimate of the H600 or SA2600 phase noise.

For the Agilent signal generator shown in the Required Equipment list, use the

following values for the signal generator phase noise level LN

:

sg

100 MHz: -143 dBc

3to6GHz: -113dBc

19. Write down the Resolution Bandwidth displayed in the Spectrum drawer

below RBW, in Hz. Use this RBW value, and values obtained earlier in this

procedure, to calculate the phase noise by using the following formulas:

[in dBc/Hz]

[in dBc/Hz]

20. Verify that the phase noise is less t han -95 dBc/Hz.

21. Repeat Phase Noise Verification steps 1 through 20, readjusting the signal

generator for all center frequencies noted in the Test Record.

H600 & SA2600 Service Manual 1–19

Page 38

Performance Verification

Check GPS function

This test deter

NOTE. The GPS antenna should be placed so that it has an unobstructed view of

the sky. If the antenna is inside a building, it may not be able to locate any GPS

signals due to signal attenuation caused by the building.

1. Reset the H600 or SA2600 application:

a. Select Tools > Factory Reset.

b. Tap Reset A

2. Connect the GPS antenna to the GPS connector on the instrument and position

the anten

a. Tap the GPS button on the main screen.

b. Roll down the menu and select Tek Internal GPS from the GPS Receiver

c. Wait until five or more green bars show in the Satellite Signal Strength

d. Check that the GPS Lock icon turns green.

mines if the H600 or SA2600 built-in GPS functions properly.

ll.

na so that it has a clear view of the sky.

drop-down list.

window.

e. Check that the Satellites in Use status field readout is ≥ 5.

1–20 H600 & SA2600 Service Manual

Page 39

Performance Verification

Check Displayed Average

Noise Level (DANL)

This test check

bandwidth).

NOTE. The DANL measurement is a measure of average noise and does not

include spurious signals. If the marker is placed on a spurious signal, it should be

moved slightly to the left or right to avoid the spurious signal.

1. Reset the H600 or SA2600 application:

a. Select Tools > Factory Reset.

b. Tap Reset All.

2. Connect a 50 Ω RF terminator to the H600 or SA2600 under test RF INPUT

connector. Disconnect the external reference.

a. Tap t he Freq button and enter 1000 MHz.

b. Set the SPAN to 10 kHz.

c. Set the

d. Tap t he Spectrum drawer.

e. Ta p t he More button.

s the H600 or SA2600 DANL with 10 Hz RBW (resolution

Ref Level to -60 dBm.

f. Tap the Trace tab.

g. Change the detector to Av era ge mode.

h. Select Average from the Trac e 1 typ e: drop-down men.

i. Tap

j. Place a marker near the center frequency and read the marker dBm value.

3. Change the Freq to 3200 MHz, 5000 MHz and 6199 MHz and repeat step j.

the x button to close the tabs.

the marker is on a spurious signal, the marker should be moved slightly

If

to the left or right to avoid the spurious signal. Record this value in the

test record.

H600 & SA2600 Service Manual 1–21

Page 40

Performance Verification

Check Residual Spurs

This test check

manual test, it is simplified to look for gross defects instead of a more rigorous

check.

1. Reset the H600 or SA2600 application:

a. Select To o l

b. Tap Reset All.

2. Connect a 50 Ohm RF terminator to the H600 or SA2600 under test RF

INPUT connector. Disconnect the external reference.

a. Tap the Spectrum drawer.

b. Tap the More button.

c. Ta p the Trace tab.

d. Change Type to Avera ge.

e. Change

f. Tap the Ampl tab.

g. Set the Ref Level to -60 dBm.

h. Tap the Freq/Span tab.

s for residual spur signals with the preamp on. Because this is a

s > Factory Reset.

the detector to Av era ge mode.

i. Set the Start frequency to 10 MHz.

j. Set the Stop frequency to 6200 MHz.

k. Set

3. Note any single frequencies that extend more than about 5 dB above the

ad

a. For any single frequencies found, adjust the span and center frequency to

b. If this single frequency exceeds the residual spur high limit of the test

c. Repeat steps a and b for any other suspect frequencies.

End of performance verification procedures.

the RBW to 100 KHz.

jacent noise floor.

duce the span to 20 MHz centered around the suspect frequency.

re

ecord, write the frequency and amplitude of this spur in the test record.

r

1–22 H600 & SA2600 Service Manual

Page 41

Theory of Operation

Page 42

Page 43

Theory of Operation

This section of the manual describes the theory of operation for the instrument

platform. As the instrument module is not user-serviceable, there is no theory

of operation

Platform

for the module.

Refer to th

e following figure while reading this section.

Display

H600 & SA2600 Service Manual 2–1

The color display is a TFT type transflective with backlight. The display inverter

mplemented on the Processor board. The color display has the following

is i

characteristics:

.4 inch diagonal size, 640 x 480 resolution, 256-color display

10

Transflective backing for indoor and outdoor viewability

Power consumption: logic 1.98 W, backlight: 5.76 W (dual cold cathode

fluorescent lamps)

Page 44

Theory of Operation

Touch Screen

LCD Controls

Processor System

The 8-wire, 10.

to the graphical user interface. It functionally replaces a mouse for Windows

navigation, substituting point and click with a touch. The touch screen has an

anti-reflective coating that reduces glare when the platform is used outdoors.

Backlighting is used for indoor viewing, and a combination of backlighting and

ambient light is used for outdoor viewing. To control brightness, use the soft keys

available on the Control Panel (Start > Settings > Control Panel > Backlight),

or double tap the backlight icon (lower-right corner of display).

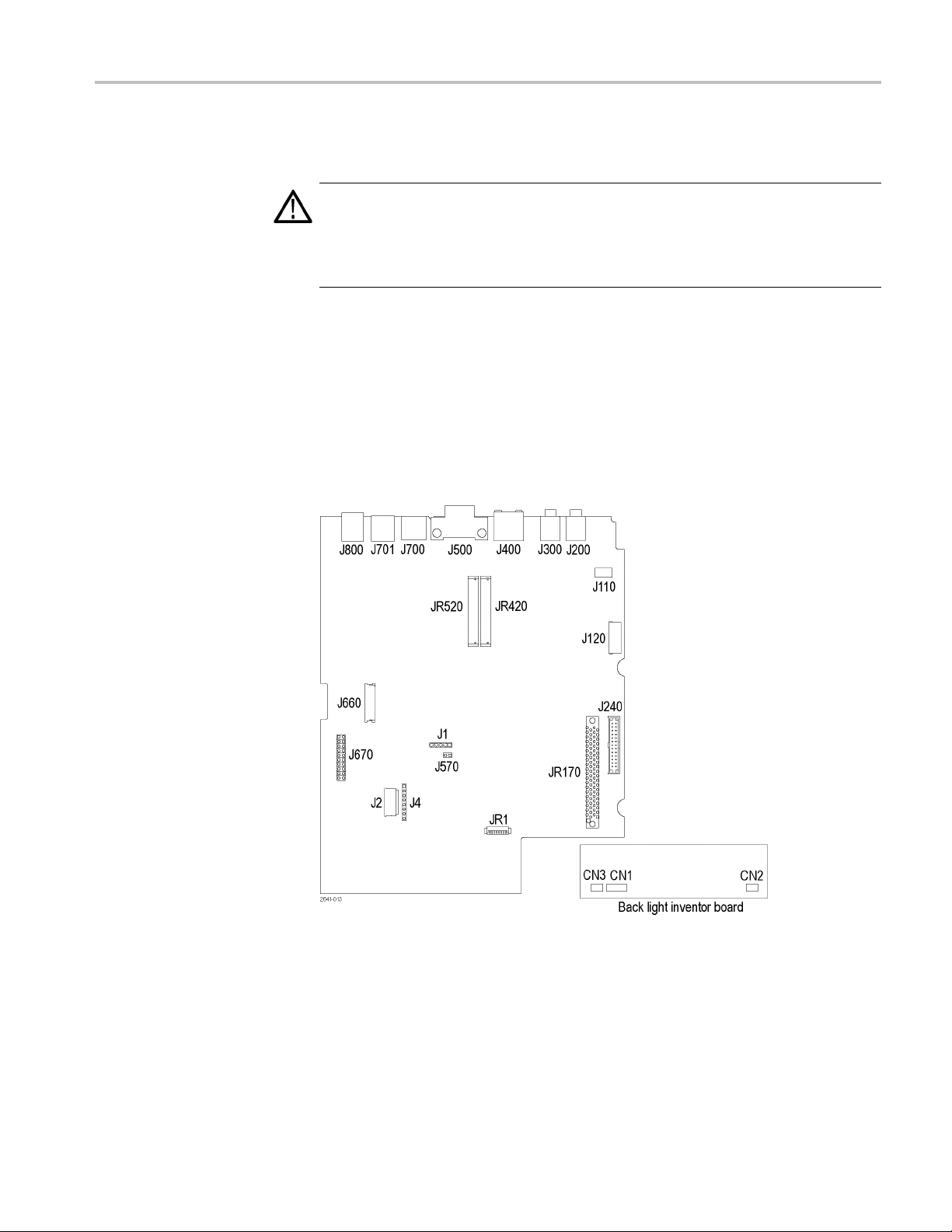

Backlighting is continuously adjustable, with the default level set to 66%. The

backlight is extinguished during screen saver, suspend, and power down modes.

The instrument processor architecture is similar to that of a handheld PC with the

following exceptions:

640 x 480 TFT color display

8-wire touch screen

SPI bu

SMBus battery interface that supports two rechargeable battery packs

4 in, resistive touch-screen module provides a touch-based access

s

Expanded power management system

USB slave/host ports

Dual PCMCIA ports standard

PS/2 keyboard port

ash file system ROM for optional software and system backup

Fl

Automatic Windows CE registry restoration during cold boot up

Instrument module power management system and additional power supplies

Foreign language support

Network support

Processor Bus. The PXA255 processor external bus width is 32 bits and operates

at 100 MHz.

Temperature Sensor. The Processor board has an internal temperature sensor to

monitor the temperature of the platform.

Real-time Clock. The Processor board real-time clock operates from a separate

Lithium coin cell battery. The battery life expectancy is 7 years.

2–2 H600 & SA2600 Service Manual

Page 45

Theory of Operation

Built-in Drive

Windows CE drivers for all ports. You can reinstall these drivers by reloading

the operating system.

Flash ROM. The Processor board has the following flash ROM:

32 MB Flash ROM for the operating system and built-in drivers

32 MB Flash ROM for the nonvolatile file system memory (\BuiltInDisk)

SDRAM. The Processor board has 64 MB of DRAM. The Windows CE Control

panel provides SDRAM allocation of program and data storage memory (Start

> Setting

NOTE. When entering the Suspend state, registry information is automatically

backeduptotheflash ROM file system from SDRAM. During the suspend state,

the SDRAM retains its contents. After approximately 2 hours, the analyzer

powers down the SDRAM and enters the Shutdown (power down) state. User

application data is lost when entering the shutdown state unless previously stored

in nonv

Firmware Upgrade. You can upgrade platform firmware over the RS-232 and

USB p

rs. The Processor board is configured with vendor supplied

s > Control Panel > System > Memory).

olatile memory.

orts,aswellasbyusingaPCMCIAflashmemorycard.

Hardware and Software Configuration Data. To check the hardware and software

configurations of the platform, do the following:

1. Select Start > Programs > Tektronix Utilities > System Configuration.

2. Open the Software or Hardware tab.

lect the item of interest from the list and then select Properties.

3. Se

Electronic Keying. The platform supports electronic keying from the instrument

modules to maintain the registry. The registry is updated at each power up.

Registry information includes module name, module type, module description,

and HW/SW/FW version numbers and location. If the platform detects

configuration incompatibilities, the user is notified.

Firmware Backup. The platform backs up the the system registry to flash memory

during the power down process.

H600 & SA2600 Service Manual 2–3

Page 46

Theory of Operation

External I/O Ports and

Buses

All external po

rts are protected against electrostatic discharge and their power

supplies against shorts.

Table 2-1: External ports and buses

External por

bus Description

RS-232 port EIA/TIA-574 compliant DTE interface with modem control

USB slave, host ports Standard USB slave and host ports that support USB 1.1

Ethernet port

PCMCIA ports Supports a single type III or dual type II PCMCIA cards. Any

Keyboar

DC supp

Headphone jack A 3.5 mm jack. Inserting a headphone disables the internal

Microphone jack

t, signal, or

d port

ly jack

lines. The Baud Rate is 115.2 kbps.

standard.

Standard R

100BaseT Ethernet standards.

application software must be H600 & SA2600 platform and

Windows

5 V PC cards.

Supports PS/2 keyboards with Mini DIN connectors.

Keyboards can be plugged in without shutting down the

platfo

Accept

operation or to charge the internal batteries. Nominal supply

voltage is 24 VDC "10% .

speaker and microphone in the platform.

A 3.5 mm jack. 1.5 V bias supply, for 2 kΩ electret-type

micr

J-45 connector that supports 10BaseT and

CE compatible. This port accepts both 3.3 V and

rm.

s power from the AC power adapter for normal

ophone.

Internal I/O Ports and

Buses

internal ports are used to interface with the instrument module, display

The

modules, and development ports.

Table 2-2: Internal ports and buses

Internal port, s ig nal, or

bus Description

Color LCD Port Interface: 3.3 V, 9-bit data (8 bits used), Red, Green, and Blue

LCD Connector: 15 pin

Backlight Connector: 4 pin

Touch screen port

SMBus port Interfaces to two SMART Li-Ion battery packs. Compatible

Supports 8-wire, resistive, touch-screen panel with firmware

calibration

Touch-Screen connector: 8 pin

with Smart battery Interfaces from Inspired Energy and

others. This bus is not available to the instrument module.

(See page 2-6, Power System.) (See page 4-24, Lithium-Ion

Battery Maintenance.)

2–4 H600 & SA2600 Service Manual

Page 47

Table 2-2: Internal ports and buses (cont.)

Internal port, s ig nal, or

bus Description

Speaker port

Application interface port

Interrupt signals

Audio input signal

Audio output signal

-3 dB bandwidth: 100 Hz to 15 kHz

Speaker: 28 mm diameter, 8 W, 1 W nominal, water resistant

Connector: 2-pin header

Connects to the internal speaker. Outputs platform and

instrument module generated audio. A volume control is

available on the Control Panel (Start > Settings > Volum e &

Sounds).

Logic Levels: 3.3 V signals, 5 V tolerant

Connector: 80-pin blind mate, Molex type

SPI bus signal lines: SPIMISO (master-in-slave-out),

SPIMOSI (master-out-slave-in), SPICLK<6... 1> (SPI clock),

and SPISEL<6... 1> (instrument module select, active low).

The Application Interface port is a full duplex Serial Peripheral

Interface (SPI) bus interface between the platform and the

instrument module.

SPIMISO and SPIMOSI signals are tied together. SPISEL

and SPICLK signals are unique for a module. The platform

signals are always master; all other signals are slave.

The platform addresses the module with a unique SPISEL

signal. The instrument module picks up its SPISEL signal

from the lowest numbered SPISEL pin of the interface

connector on its front case.

The instrument modules use MODINTR<4... 1> signals for

requesting service from the platform. These signals are

open collector 3.3 V, active low, TTL-level. The instrument

module generates the MODINTR1 signal on the Processor

board. All m odule interrupt signals are OR-logic wired to form

one interrupt to the CPU. The CPU can then decode which

module a sserted the interrupt. Pull-up resistors for these

signals are located on the Processor board.

Signals: AUDIP, AUDIN

Level: 1 Vrms, maximum

Load: 10 kW

Bandwidth: -3 dB, 100 Hz to 15 kHz

A differential analog audio output signals from the instrument

module input to the platform volume control.

Signals: AUDOP, AUDON

Level: 1 Vrms, maximum

Load: 40 kW per module, 10 kW minimum impedance

Bandwidth: -3 dB, 100 Hz to 15 kHz

A differential analog output signal from the platform built-in

microphone to the input of an instrument modules.

Theory of Operation

H600 & SA2600 Service Manual 2–5

Page 48

Theory of Operation

Table 2-2: Internal ports and buses (cont.)

Internal port, s ig nal, or

bus Description

Power bus

System clock 5 MHz, 3.3 V, TTL-level (SYSCLK) for use by the instrument

Timer signal 3.3 V, TTL-level, implemented in hardware only.

Supplies power and controls the shut down of individual

instrument modules to conserve battery power.

MODON<4... 1>: 3.3 V CMOS-level s ignals. An active high

turns on the corresponding instrument module. The module

is MODON1. Only one CMOS load per line is allowed. A low

level on this signal isolates all supplies from the instrument

module. The signal must be active before addressing a

module.

module.

Programmable from 25 ms to 500 ms in 25 ms intervals.

This signal can be used to synchronously accumulate

measurement results to derive time correlated data.

Power System

The power system consists of an internal ba ttery charger and power supplies for

the internal boards and instrument module. The Processor board implements

all power management operations. The battery board controls battery charging,

battery selection, and the V

r Management. The platform processor system, peripheral devices, and I/O

Powe

main

value.

implement power management techniques similar to those used in hand-held

HPCs. This includes powering down I/O ports, power supplies, and peripherals

to a shutdown state while running the CPU in sleep mode; power to all circuits

except the real-time clock and the power system micro-controller is turned off.

The power management strategy also inc ludes a screen-saver mode. In this

ate, power to the LCD logic and backlight are shut down while maintaining

st

operation of the I/Os.

he platform uses a non-latching type power switch on the front-panel to

T

implement power on/off and suspend/resume operations similar to an HPC.

Unlike the HPC however, the platform manages power to the instrument module.

The platform shuts down power to the instrument module by pulling their

respective MODON control signals low and then cutting the power. During power

on from the suspend or shutdown state, the instrument module power supplies are

turned on first and then the module is turned on using the MODON signals.

2–6 H600 & SA2600 Service Manual

Page 49

Theory of Operation

The power modes

are:

Suspend mode. The platform automatically enters shutdown mode to save

battery power

following a period of instrument inactivity, or when you press

the front panel power button. You can set the length of this inactivity from the

Start > Settings > Control Panel > Power Management > Power Saver

tab. Before entering this mode, registry information and nonvolatile memory

are backed up and all nonessential power supplies shut down. LCD backlights

are turned off and the touch-screen display is inactivated. The instrument

module wil

l also be shut down.

During suspend mode, the real-time clock and SDRAM refresh remain active.

To return

from this state, you must press the front-panel power switch to

power up the platform, which takes approximately one minute.

Display

Power Saver mode . The front-panel status indicator changes from

Green to Amber to indicate the display Power Saver mode. In this state, the

display and backlight are turned off to save power. Instrument modules

remain powered on. Pressing the front-panel power switch cancels the Power

Saver mode and returns the platform to an active state. Measurements that are

running when you enter this mode continue to run.

Automatic Shutdown mode. If a voltage is present on fine-pitched

component pins under humid conditions, corrosion can occur over time.

ing the internal circuitry in shutdown mode when not in use can minimize

Plac

this problem. If the platform remains in shutdown mode for more than two

hours, the processor system, with the exception of the real-time clock, is

completely powered off.

Transition to the power-down state occurs when the shutdown state timer

times-out or the internal batteries becomes critically low. Pressing the

front-panel power switch reactivates the internal circuitry and returns the

platform to an active s tate.

Internal Supplies to Module. In addition to the power requirements of the internal

circuit boards, the platform provides the following voltages to the instrument

module.

Table 2-3: P latform voltage supplies to module

Characteristic Description

Voltages

Instrument Power Supply

Noise (peak-to-peak) for

1 Megahertz bandwidth

+3.4 V DC ±0.14 V, 5 A at 17 W

–13 V DC ±0.5 V, 1 A at 13 W

+13VDC±0.5V,1Aat13W

< 250 mV for ±13 V

< 100 mV for +3.4 V

1

H600 & SA2600 Service Manual 2–7

Page 50

Theory of Operation

Table 2-3: Platform voltage supplies to module (cont.)

Characteristic Description

Transient Response

Supply Monitoring The built-in diagnostics verify the instrument module power

1

The 3.4 V s

to account for the voltage drops across the connectors and Power FET switch used to control power to the

instrument module.

upply may also be referred to as the 3.3 V supply in the rest of this document. 3.4 V is specified

For 50% to 75% step load, the initial transients are ≤10% of

the initial voltage set point. Recovery is ≤2% of the set value

within 0.5 ms.

supply status while running power diagnostics. If a problem

is detected, the platform displays an out-of-tolerance warning

message.

Power Sources. The p latform and module can operate from the following

supplies:

Batteries. Powers the instrument using up to two Inspired Energy type

NI2020HD24 10.8 V, 7200 mAH, Li-ion batteries.

External Supply (DC or AC): Powers the instrument from a 24 VDC ±10%

external source. If the external supply is connected while the platform is

ting, the internal batteries will be disconnected without interrupting

opera

service. If the externa l supply is disconnected during service, the internal

batteries are connected without disrupting service.

Fuse Protection is provided by an automatic resetting fuse device. This fuse is

located in the external DC supply line on the Battery board. Requires no user

intervention.

Internal Charger. The sequential internal charger will charge a single 7200 mAH

ttery in approximately 4.5 hrs (two batteries requires approximately 9 hrs) if the

ba

platform is in shutdown mode. If the platform is operating, charging takes place

at a reduced rate in order to maintain internal temperatures within limits and to

avoid exceeding the capacity of the external supply. The charger is capable of

determining the battery technology type and appropriate charging sequence, and

is optimized for battery packs with nominal terminal voltages of between 7.2 and

12 volts. The maximum charging current is approximately 1.8 A in shutdown

mode and 0.8 A in the power on mode.

If the Desktop Power Supply or In-Vehicle Power Adapter is connected, the

internal batteries will charge if their capacity is low.

Charge Status Indicator. Low Battery Warning: Red indicates a low battery (less

than 20% remaining capacity). Green indicates battery charging. The platform

backs up current data and executes an orderly shutdown before complete loss

of battery power.

2–8 H600 & SA2600 Service Manual

Page 51

Theory of Operation

Each Li-Ion bat

level. To check the battery status, remove the battery from the analyzer. Then

press the PUSH button on the side of the battery and note the charge value on the

LED charge indicator.

Taskbar Power Status Icon. A battery icon appears in the taskbar when the

instrument

in 10% increments. If two batteries are installed, the icon displays the average

charge level of the two combined batteries. When the instrument operates from

AC power (from the Desktop Power Supply) a plug icon appears in the Taskbar

status area.

Battery S

10.8 V, 7200 mAH, Li-ion batteries. You do not need special tools to replace the

batteries. (See page 4-24, Lithium-Ion Battery Maintenance.)

Battery operation characteristics include:

The bat

watts load) from two Li-Ion batteries and approximately 4.5 hrs from a single

battery. Run time for the platform plus application varies depending on the

applications being run.

Only one of two batteries will be in use at any given time when two batteries

are installed.

tery pack has an internal microprocessor that monitors its charge

operates from battery power. The icon displays the battery charge level

ystem. The instrument uses up to two Inspired Energy type NI2020HD24

tery power system operates the platform for approximately 9 hrs (12

Measurement Module

If two batteries are installed, you can remove and replace either battery

without disrupting service.

If a second battery is installed, the platform automatically switches operation

to the second battery when the first battery reaches cut off capacity (5%

reserve) or is removed. The transition is transparent and does not interrupt

service.

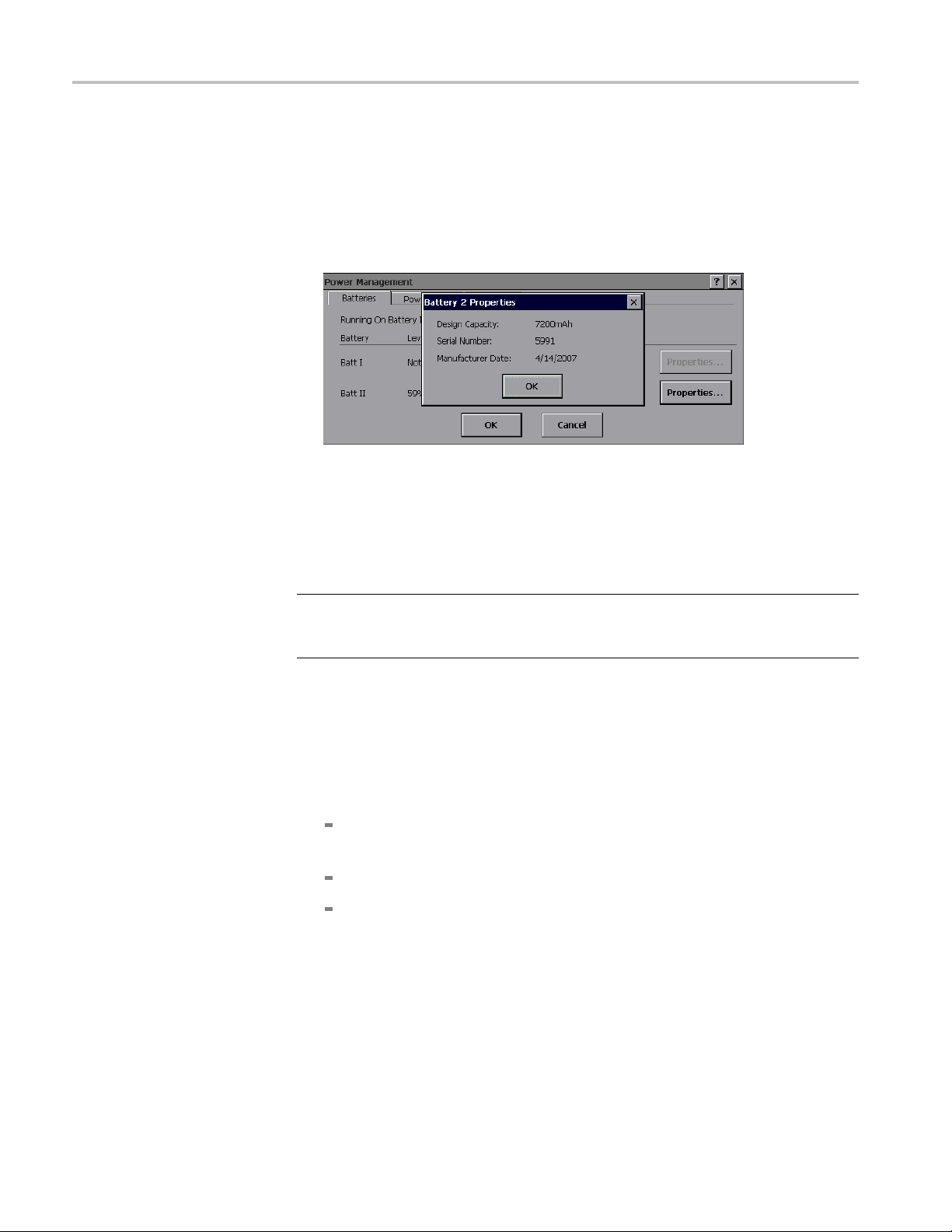

Battery Power Management Utility. The Batteries tab in the Power Management

dialog box provides general information on battery status. This is the most accurate

information to determine battery charge status and probable manufacture dates.

(See page 4-26, H600 and SA2600 Instrument-Specific Battery Maintenance.)

The Measurement module contains no user-servicable parts. There are also no user

adjustments on the Measurement module. The entire instrument must be returned

for service. Service for the measurement module is not independently a vailable.

H600 & SA2600 Service Manual 2–9

Page 52

Theory of Operation

2–10 H600 & SA2600 Service Manual

Page 53

Adjustment Procedures

Page 54

Page 55

Adjustment Procedures

There are no manual or software adjustment procedures for the H600 RFHawk or

SA2600 Spectrum Analyzer instruments.

H600 & SA2600 Service Manual 3–1

Page 56

Adjustment Procedures

3–2 H600 & SA2600 Service Manual

Page 57

Maintenance

Page 58

Page 59

Cleaning

To clean the instrument, close or cover all instrument connectors, c onnector doors,

and battery doors. Then use a soft cloth dampened with a solution of water and

mild deterge

display touch screen.

CAUTION. To prevent damage to external surfaces, avoid using chemicals that

contain benzene, toluene, xylene, acetone, or similar solvents. Do not use bleach

or ammonia solutions for cleaning.

To prevent damage to internal components, do not allow moisture to get into

the instrument.

nt to clean the instrument. Do not apply heavy pressure or scrub the

H600 & SA2600 Service Manual 4–1

Page 60

Removal and Replacement Procedures

Removal and Replacement Procedures

This subsection contains procedures for the removal and replacement of all

replaceable mechanical and electrical modules.

Preparation

NOTE. The in

strument does not require calibration after removal and replacement

of the indicated parts.

WARNING.

Before doing this or any other procedure in this manual, read the

Safety Summary found at the beginning of this manual. Also, to prevent possible

damage to the instrument components, read Preventing ESD in this section. (See

page 4-3.)

This subsection contains the following items:

This preparatory information that you need to properly do the procedures

that follow.

List of tools required to remove and disassemble all modules.

dures for removal and reinstallation of the electrical and mechanical

Proce

modules.

CAUTION. Disconnect the power adapter and remove all batteries from the

instrument before disassembling the instrument.

Equipment Required

Table 4-1: Tools required

Item

no. Name Description General Tool number

1.

2. T-9 Torx tip

3. T-10 Torx tip

4. T-15 Torx tip

5.

Screwdriver handle

P0 Pozi tip

Accepts Torx-driver and

Pozi bits

Used for removing

instrument screws

Used for removing

instrument screws

Used for removing

instrument screws

Used for removing

instrument screws

620-440

640-234

640-235

640-247

640-234

4–2 H600 & SA2600 Service Manual

Page 61

Table 4-1: Tools required (cont.)

Item

no. Name Description General Tool number

6.

7.

1/4 inch nut driver

Torque driver Accepts Torx tips, Pozi

Preventing Electrostatic Damage

Electrostatic discharge (ESD) can damage components in the instrument. To

prevent, ESD:

Do not touch exposed components or connector pins unless you are using

ESD protective measures, such as wearing a properly grounded antistatic

wrist strap.

Handle boards and modules little as possible.

Removal and Replacement Procedures

Used to remove

standoffs

tips, and open-end

wrenches

Standard tool

Standard tool

Removal Procedures

Do not slide boards or modules across work surfaces.

port and store boards and modules in a static-protected bag or container.

Trans

NOTE. U nle ss directed otherwise, installation is the reverse of the removal

procedure. Note cable routing when disassembling so that you can route the

cables correctly during assembly.

NOTE. The instrument does not require calibration after removal and replacement

of the indicated parts.

H600 & SA2600 Service Manual 4–3

Page 62

Removal and Replacement Procedures

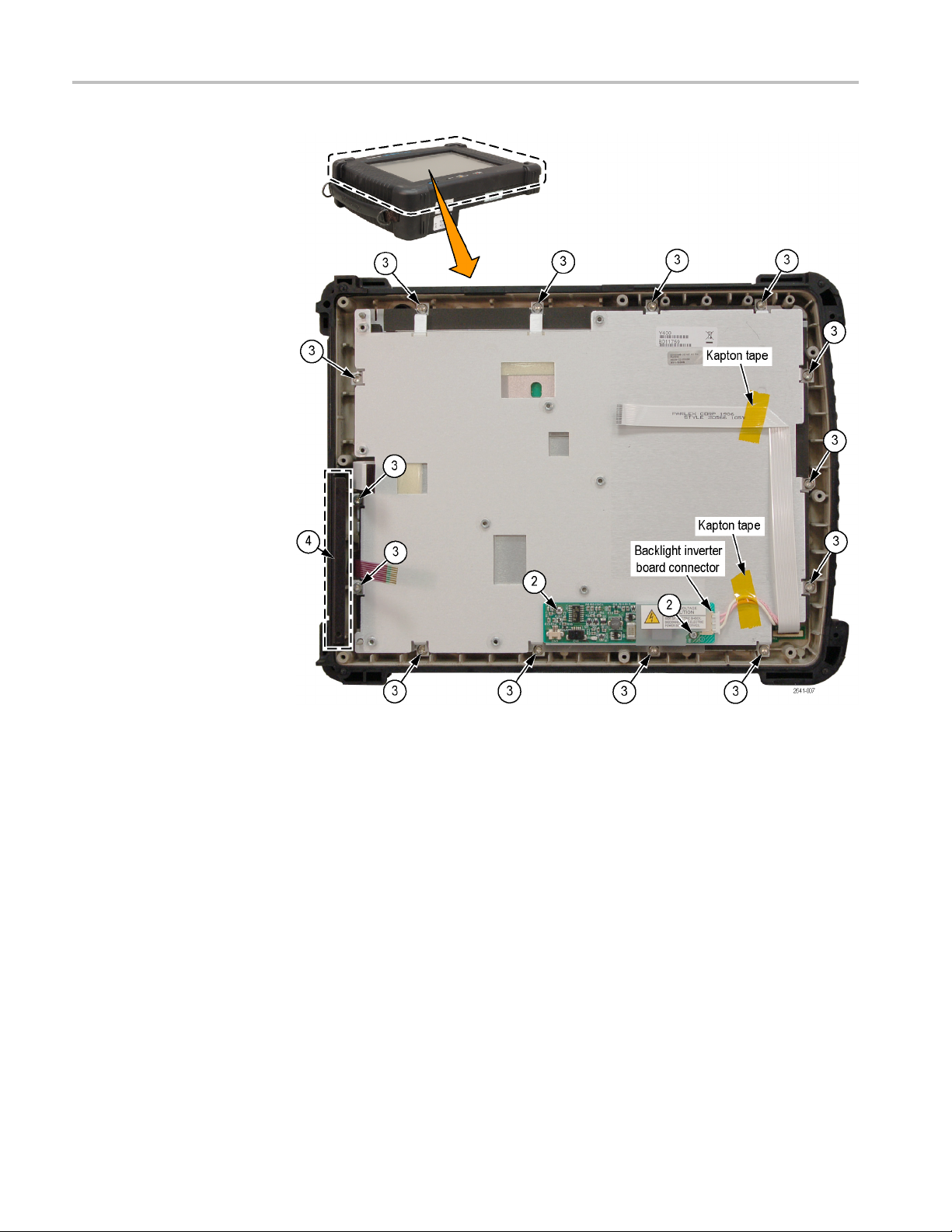

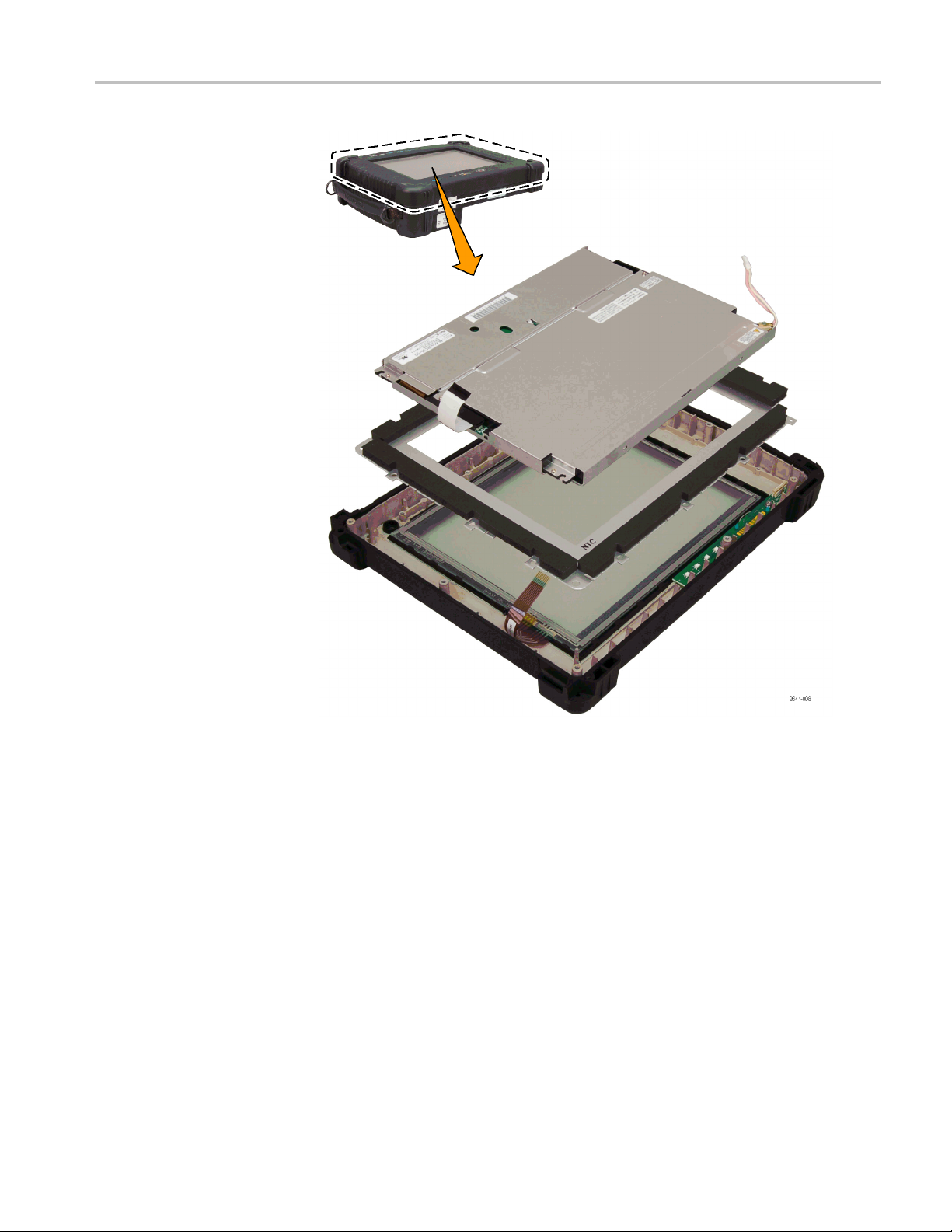

Remove Module F

Platform

rom

1. Remove the four 1/4” standoff posts.

When reinstalling these standoffs, torque them to 8 in/lb.

2. Remove the cosmetic cover.

3. Remove the four 1/4” standoff posts that secure the module to the mainframe

chassis.

When reinstalling these standoffs, torque them to 12 in/lb.

4. Remove the module from the platform.

CAUTION. Do not open the module. There are no user-serviceable parts. If

the module is opened, you must return the entire instrument to Tektronix for

calibration.

4–4 H600 & SA2600 Service Manual

Page 63

Removal and Replacement Procedures

Remove Platfor

m Rear

Cover

1. Remove th

When reinstalling these screws, torque them to 8 in/lb.

2. Remove the five screws from the bottom, side, and top edge of the rear case.

When reinstalling these screws, torque them to 8 in/lb.

e three screws from the side of the rea r case above the battery area.

3. Remove the four screws from the battery compartment area.

When reinstalling these screws, torque them to 8 in/lb.

4. Lift c

ase one to two inches and remove the carrying strap and strap pins. Also

remove the strap pins from the other corners of the case.

H600 & SA2600 Service Manual 4–5

Page 64

Removal and Replacement Procedures

Separate Front

and Rea r

Cases

Separa

Disconnect J110 and J240.

te the front and back instrument cases enough to access connecting cables.

4–6 H600 & SA2600 Service Manual

Page 65

Removal and Replacement Procedures

Rear Case: Remo

ve

Battery Compartment

H600 & SA2600 Service Manual 4–7

Page 66

Removal and Replacement Procedures

1. Remove the five s

the battery compartment towards the bottom of the instrument to access

connecting cables