Page 1

TM 9-6625-474-14&P-2

TECHNICAL MANUAL

OPERATOR, ORGANIZATIONAL,

DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS)

FOR

FUNCTION GENERATOR

TEKTRONIX, MODEL FG 501A

(6625-01-106-9873)

DEPARTMENT OF THE ARMY

27

DECEMBER 1984

Page 2

TM 9-6625-474-14&P-2

WARNING

RA PD 404264

DANGEROUS VOLTAGE

is used in the operation of this equipment

DEATH ON CONTACT

may result if personnel fail to observe safety precautions

Never work on electronic equipment unless there is another person nearby who is familiar with the

operation and hazards of the equipment and who is competent in administering first aid. When the

technician is aided by operators, he must warn them about dangerous areas.

Whenever possible, the power supply to the equipment must be shut off before beginning work on the

equipment. Take particular care to ground every capacitor likely to hold a dangerous potential. When

working inside the equipment, after the power has been turned off, always ground every part before

touching it.

Be careful not to contact high-voltage connections when installing or operating this equipment.

Whenever the nature of the operation permits, keep one hand away from the equipment to reduce the

hazard of current flowing through vital organs of the body.

WARNING

Do not be misled by the term “low voltage.”

conditions.

COMMON and probe ground straps are electrically connected. Herefore, an elevated reference applied to

any is present on each - as indicated by the yellow warning bands under the probe retractable hook tips.

For Artificial Respiration, refer to FM 21-11,

Potentials as low as 50 volts may cause death under adverse

Power Source

This product is intended to operate in a power module connected to a power source that will not apply more

than 250 volts rms between the supply conductors or between either supply conductor and ground. A

protective ground connection by way of the grounding conductor in the power cord is essential for safe

operation.

a/(b blank)

Page 3

TECHNICAL MANUAL

No. 9-6625-474-14&P-2

You can help improve this manual. If you find any mistakes or if you know of a way

to improve the procedures, please let us know. Mail your letter or DA Form 2028

(Recommended Changes to Publications and Blank Forms), direct to: Command-

er, US Army Missile Command, ATTN: DRSMI-SNPM, Redstone Arsenal, AL

35898-5238. A reply will be furnished to you.

TM 9-6625-474-14&P-2

Copyright 1980 Tektronix, Inc. All rights reserved

Reproduced by permission of copyright owner.

HEADQUARTERS

DEPARTMENT OF THE ARMY

Washington, D.C., 27 December 1984

OPERATOR, ORGANIZATIONAL, DIRECT SUPPORT,

AND GENERAL SUPPORT MAINTENANCE MANUAL

(INCLUDING REPAIR PARTS)

FOR

FUNCTION GENERATOR

TEKTRONIX, MODEL FG 501A

(6625-01-106-9873)

REPORTING OF ERRORS

LIST OF ILLUSTRATIONS

LIST OF TABLES

SECTION 0.

SECTION 1.

SECTION 2.

SECTION 3.

SECTION 4.

SECTION 5.

TABLE OF CONTENTS

Page

iii

iv

0-1

0-1

0-1

0-1

0-1

0-1

0-1

1-1

2-1

2-1

2-2

2-4

2-5

2-6

2-9

3-1

4-1

4-1

4-8

5-1

5-1

5-4

This manual is, in part, authenticated manufacturer’s commercial literature. Recommended Spare Parts List has been added to supplement the commercial

literature, The format of this manual has not been structured to consider levels of maintenance.

i

Page 4

TM 9-6625-474-14&P-2

SECTION 6.

SECTION 7.

SECTION 8.

SECTION 9.

APPENDIX A.

APPENDIX B.

APPENDIX C.

APPENDIX D.

OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REPLACEABLE ELECTRICAL PARTS, . . . . . . . . . . . . . . .

DIAGRAMS AND CIRCUIT BOARD ILLUSTRATIONS . . . . . . .

REPLACEABLE MECHANICAL PARTS . . . . . . . . . . .

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE ALLOCATION CHART (MAC) . . . . . .

RECOMMENDED SPARE PARTS LIST..... . . . . . . . . . . . . . . . . . . .

MANUAL CHANGE INFORMATION. . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .

TABLE OF CONTENTS (CONT)

Page

6-1

7-1

8-1

9-1

A-1

B-1

C-1

D-1

ii

Page 5

LIST OF ILLUSTRATIONS

TM 9-6625-474-14&P-2

Fig. No.

0-1

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

4-1

4-2

4-3

4-4

4-5

5-1

5-2

5-3

5-4

Title

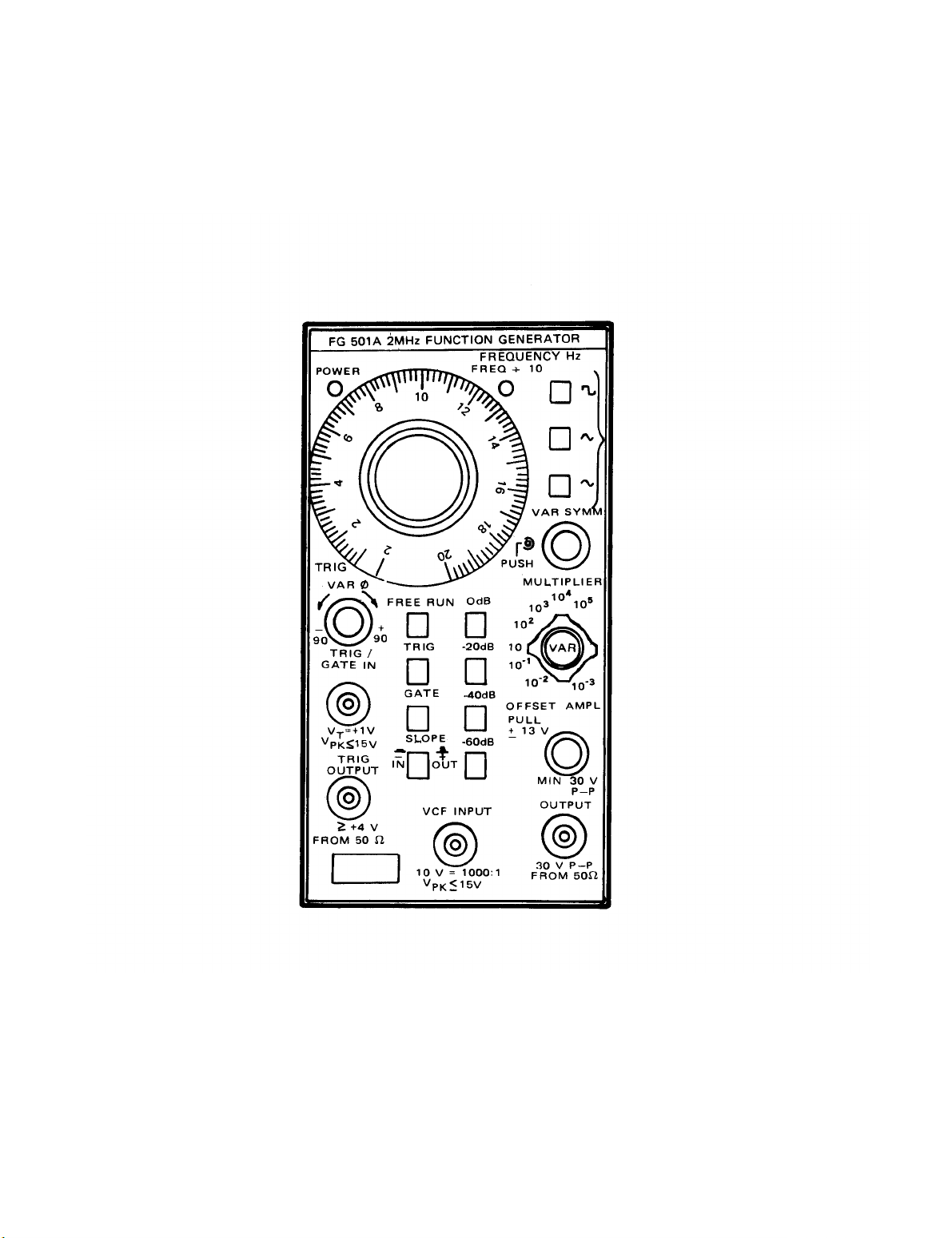

FG 501A 2 MHz Function Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Swept Frequency Range (VCF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

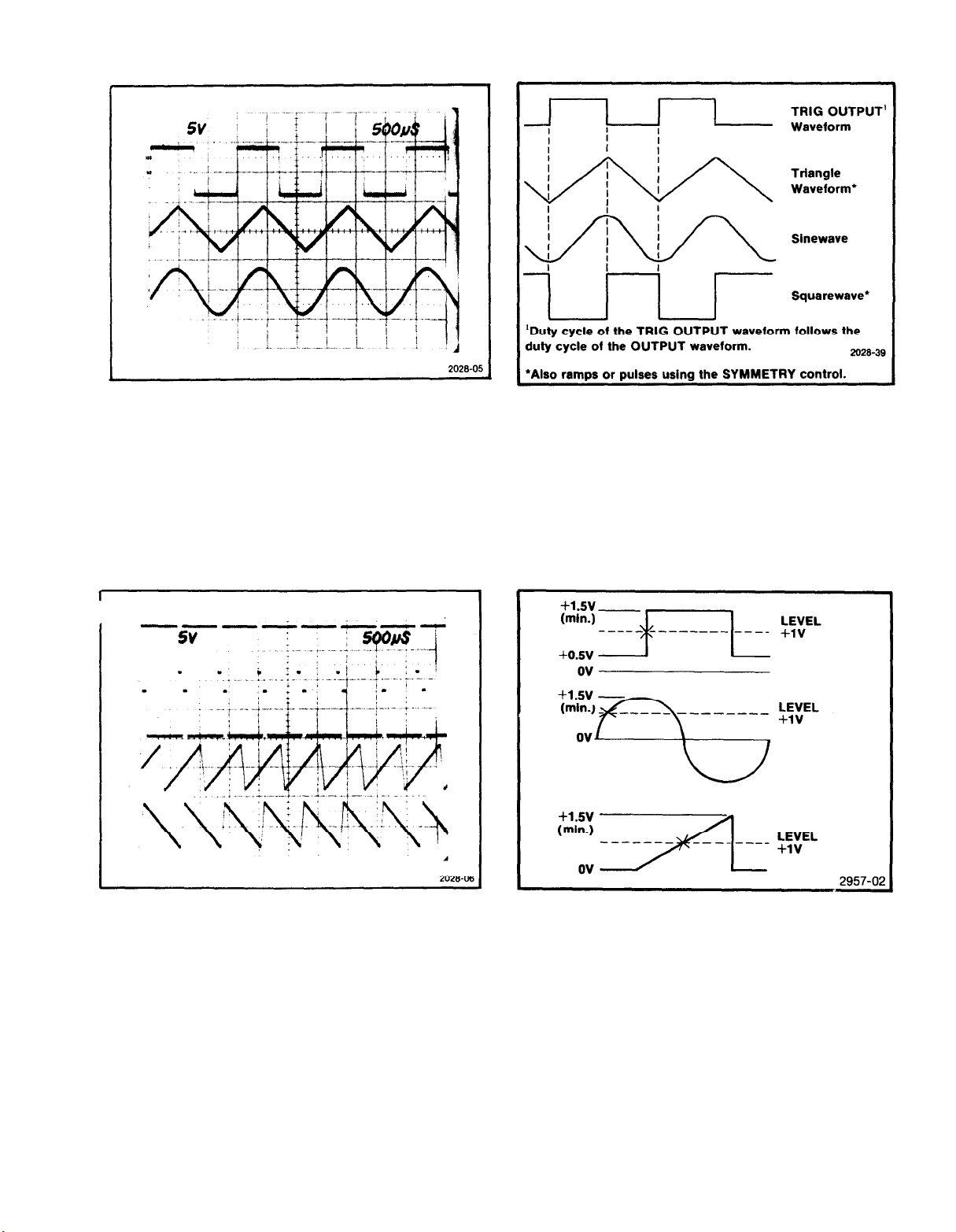

Basic Functions (Waveforms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ramps and Pulses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phase Relationships (Output and Trig) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Signal Amplitude Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gated Operation (Waveforms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triggered Operation (Waveforms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phase Control (Waveforms) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analyzing Circuit or System Response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

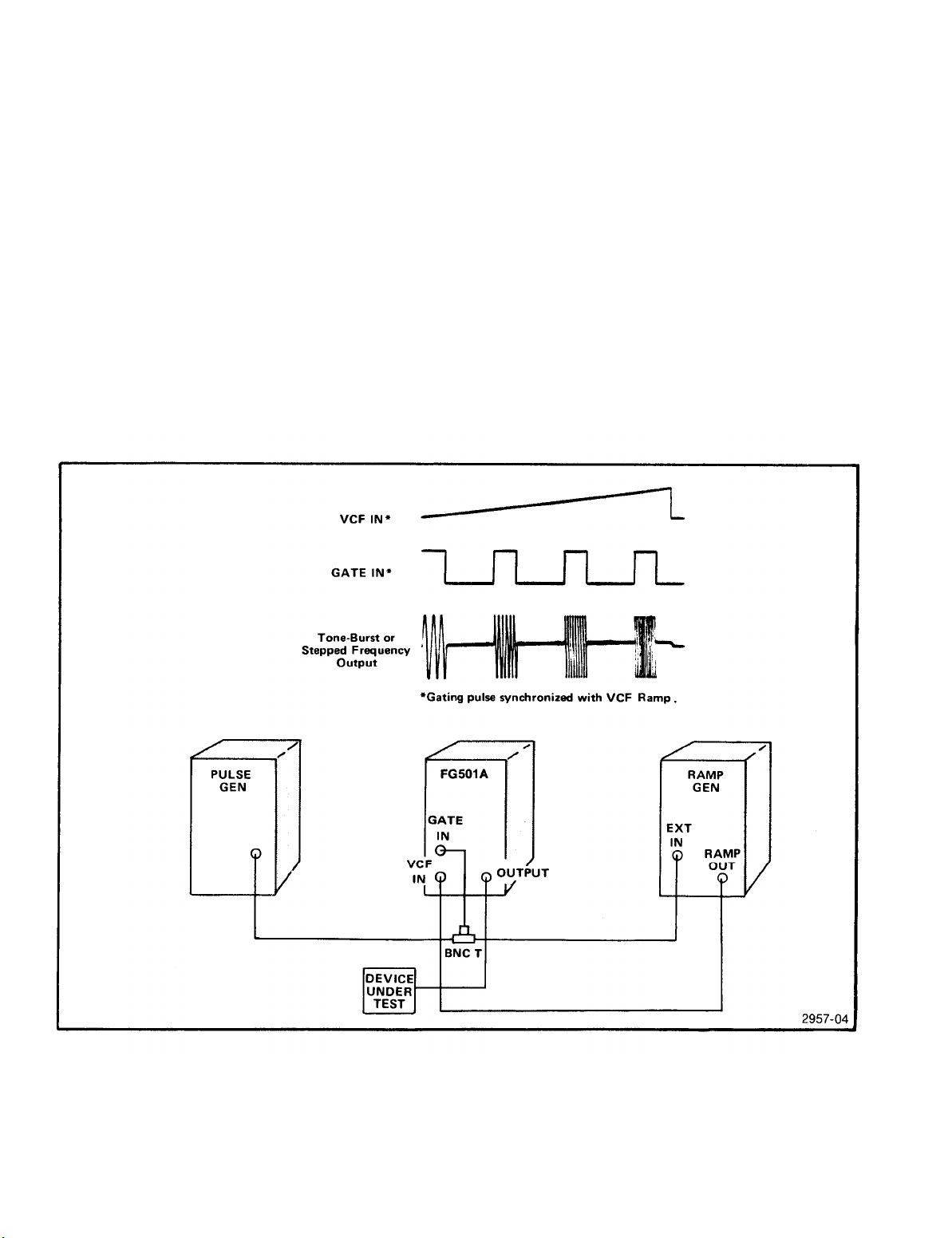

Tone Burst Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Setup for Dial Alignment and Offset Adjustment . . . . . . . . . . . . . . . . . . . . .

Test Setup for Sine Distortion Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Setup for Offset and Sine/SquareAmplitude

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Setup for Squarewave Comp/Rise and Falltime

Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Setup for Dial Cal and Loop Delay Adjustment . . . . . . . . . . . . . . . . . . . . . . .

Coaxial End Lead Connector Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Orientation and Disassembly of Multipin Connectors . . . . . . . . . . . . . . . . . . . . . .

Extension Shaft and Pushbutton Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Interface Connector Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0-2

2-1

2-3

2-6

2-7

2-7

2-7

2-7

2-8

2-8

2-8

2-9

2-10

4-9

4-11

4-12

4-13

4-14

5-3

5-3

5-4

5-5

iii

Page 6

TM 9-6625-474-14&P-2

LIST OF TABLES

Table No.

1-1

1-2

1-3

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Title Page

1-4 Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

5-1

Test Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relative Susceptibility to Static Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4

1-4

1-5

4-1

5-1

iv

Page 7

SECTION 0

GENERAL INFORMATION

TM 9-6625-474-14&P-2

0-1. Scope. This manual contains instructions for

the operator, organizational, direct support, and general support maintenance of and calibration procedures for Tektronix Function Generator, Model FG

501A. Throughout this manual, Tektronix Function

Generator, Model FG 501A is referred to as the FG

501A.

0-2. Indexes of publications. a. DA Pam 310-4.

Refer to the latest issue of DA Pam 310-4 to determine whether there are new editions, changes, or

additional publications pertaining to Tektronix Function Generator, Model FG 501A.

b. DA Pam 310-7. Refer to the latest issue of DA

Pam 310-7 to determine whether there are modification work orders (MWO’S) pertaining to Tektronix

Function Generator, Model FG 501A.

0-3. Forms, Records, and Reports. Department of

Army forms and procedures used for equipment maintenance and calibration are those prescribed by TM

38-750, The Army Maintenance Management System.

Accidents involving injury to personnel or damage to

materiel will be reported on DA Form 285,

Report, in accordance with AR 385-40.

Accident

0-4. Reporting Equipment Improvement Recommendations (EIR). If your FG 501A needs im-

provement, let us know. Send us an EIR. You, the

user, are the only one who can tell us what you don’t

like about your equipment. Let us know why you don’t

like the design. Tell us why a procedure is hard to

perform. Put it on an SF 368 (Quality Deficiency

Report). Mail it to Commander, U.S. Army Missile

Command, ATTN: DRSM1-CIMD, Redstone Arsenal,

AL 35898-5290. We’ll send you a reply.

0-5. Administrative Storage. To prepare the Tektronix Function Generator, Model FG 501A for placement into and removal from administrative storage,

refer to Section 3, Chapter 4, AR 750-25-1, Maintenance of Equipment and Supplies. Temporary storage

should be accomplished in accordance with TB 75025-1, Section 2, Maintenance of Supplies and

Equipment.

0-6.

Materiel. Destruction of Tektronix Function

Generator, Model FG 501A to prevent enemy use shall

be in accordance with TM 750-244-2.

Destruction

of Army Electronics

0-1

Page 8

TM 9-6625-474-14&P-2

.

0-2

FIG.0-1. FG 501A 2MHz FUNCTION GENERATOR

Page 9

SECTION 1

SPECIFICATION

TM 9-6625-474-14&P-2

INTRODUCTION

This section of the manual contains a general description of the FG 501A and complete electrical, environmental, and physical specifications. Standard accessories are

also listed. Instrument option information is located in the

back of this manual in a separate section.

INSTRUMENT DESCRIPTION

The FG 501A Function Generator provides low distortion sine, square, triangle, ramp, and pulse waveforms

over the frequency range 0.002 Hz to 2 MHz in eight

decade steps. Dc offset up to ±13 V is available. Waveform

triggering and gating functions, in addition to being slope

(+ or –) selectable, are provided with variable phase

control capable of up to ±90° phase shift. The symmetry

of the output waveform may also be varied from 5 to 95%.

Step attenuators provide up to 60 dB of attenuation in

20 dB steps. A variable amplitude control provides an

additional 20 dB attenuation.

A voltage-controlled frequency (VCF) input is provided

to control the output frequency from an external voltage

source. The output frequency can be swept above and

below the selected frequency to a maximum of 1000:1

depending on the polarity and amplitude of the VCF input

signal and the selected output frequency.

ACCESSORIES

The only accessory shipped with the FG 501A is the

Instruction Manual.

PERFORMANCE CONDITIONS

The electrical characteristics are valid with the follow-

ing conditions:

1. The instrument must have been adjusted at an

ambient temperature between +20° C and +30° C and

operating at an ambient temperature between 0° C and

+50° C.

The instrument must be in a non-condensing en-

2.

vironment whose limits are described under Environmen-

tal.

3. Allow twenty minutes warm-up time for operation to

specified accuracy; sixty minutes after exposure to or

storage in high humidity (condensing) environment.

Items listed in the Performance Requirements column

of the Electrical Characteristics are verified by completing

the Performance Check in this manual. Items listed in the

Supplemental Information column may not be verified in

this manual; they are either explanatory notes or performance characteristics for which no limits are specified.

1-1

Page 10

TM 9-6625-474-14&P-2

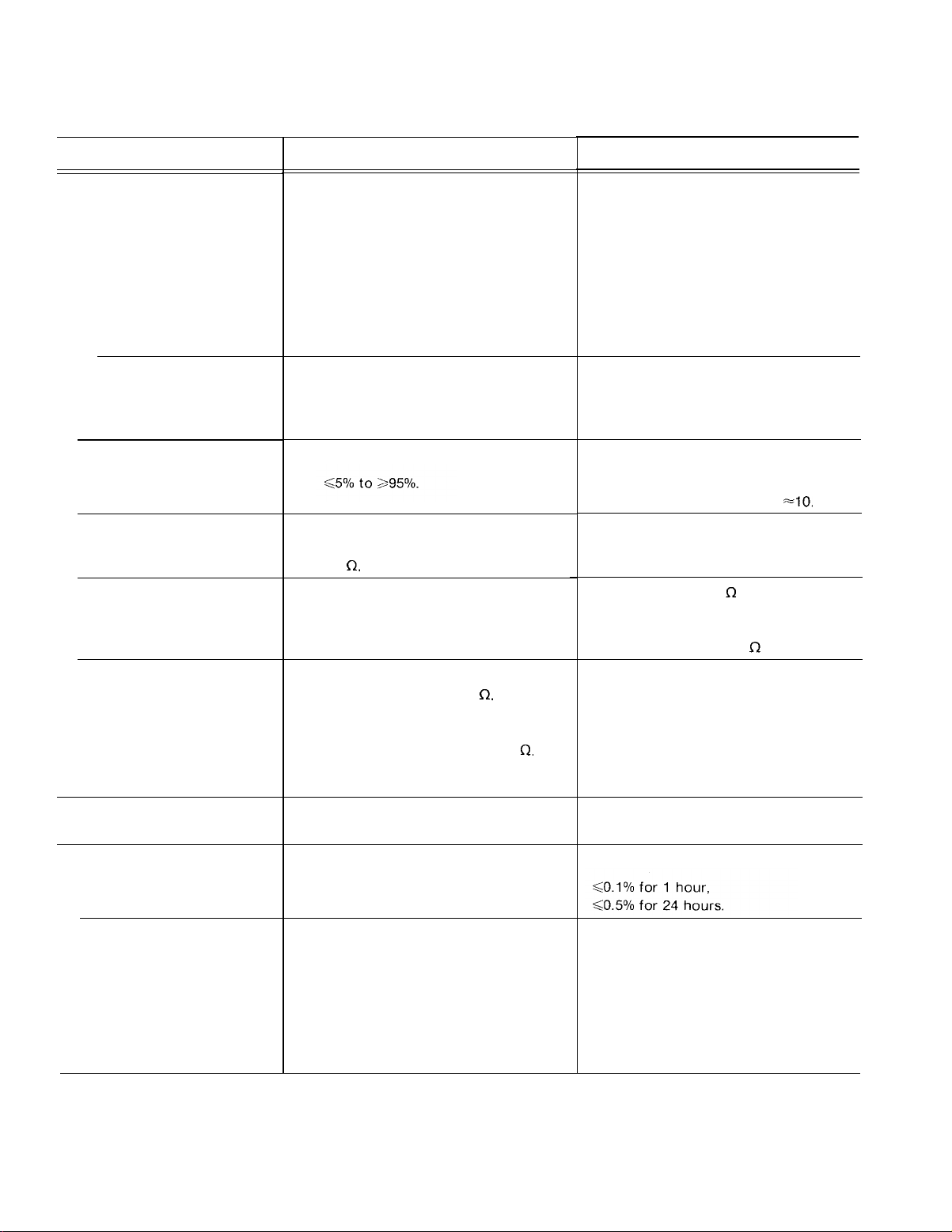

Table 1-1

ELECTRICAL CHARACTERISTICS

Characteristics

Frequency

Range

Sine-wave, square-wave,

and triangle

Ramp and Pulse

Variable Symmetry

Duty Cycle

Output Amplitude

Output Impedance

Performance Requirements

.002 Hz to 2 MHz

.002 Hz to 200 kHz ± 10% calibrated

portion of dial.

At least

30 V P-P into an open

circuit, at least 15 V p-p into

50

Cl,

(Front panel only.)

Supplemental Information

Provided in eight decade steps plus

variable, with overlap on all

ranges.

Calibrated portion of dial extends

from 20 to 2. Portion of dial from

2 to .2 is uncalibrated

.0002 Hz to .002 Hz uncalibrated

portion of dial.

Measured at 50% duty cycle.

.0002 Hz to .002 Hz uncalibrated

portion of dial.

Activation of Symmetry control

divides output frequency by

=10.

Offset control off.

Front panel z

= 50 (2 ±10%

o

ATTEN in 0 dB position.

Offset Range

Frequency Resolution

Stability (Frequency)

Time

Temperature

At least ±13 V into open circuit,

at least ±6.5 V into 50

Q.

Maximum peak signal plus offset

cannot exceed ±15 V into an

open circuit, or ±7.5 into 50

Q.

(Front panel only,) Offset reduced

by attenuators.

Rear interface z

1 part in 10

= 600 Cl –10%.

O

4

of full scale with

frequency vernier control.

Within 2% from .2 Hz to 2 MHz, and

within 10% from .002 Hz to .2 Hz. The

FREQUENCY Hz dial must be on the

calibrated portion. The instrument

must be in a temperature between

0° C and +50° C and checked

after a 1 hour warmup. VAR SYMM

control disabled,

1-2

Page 11

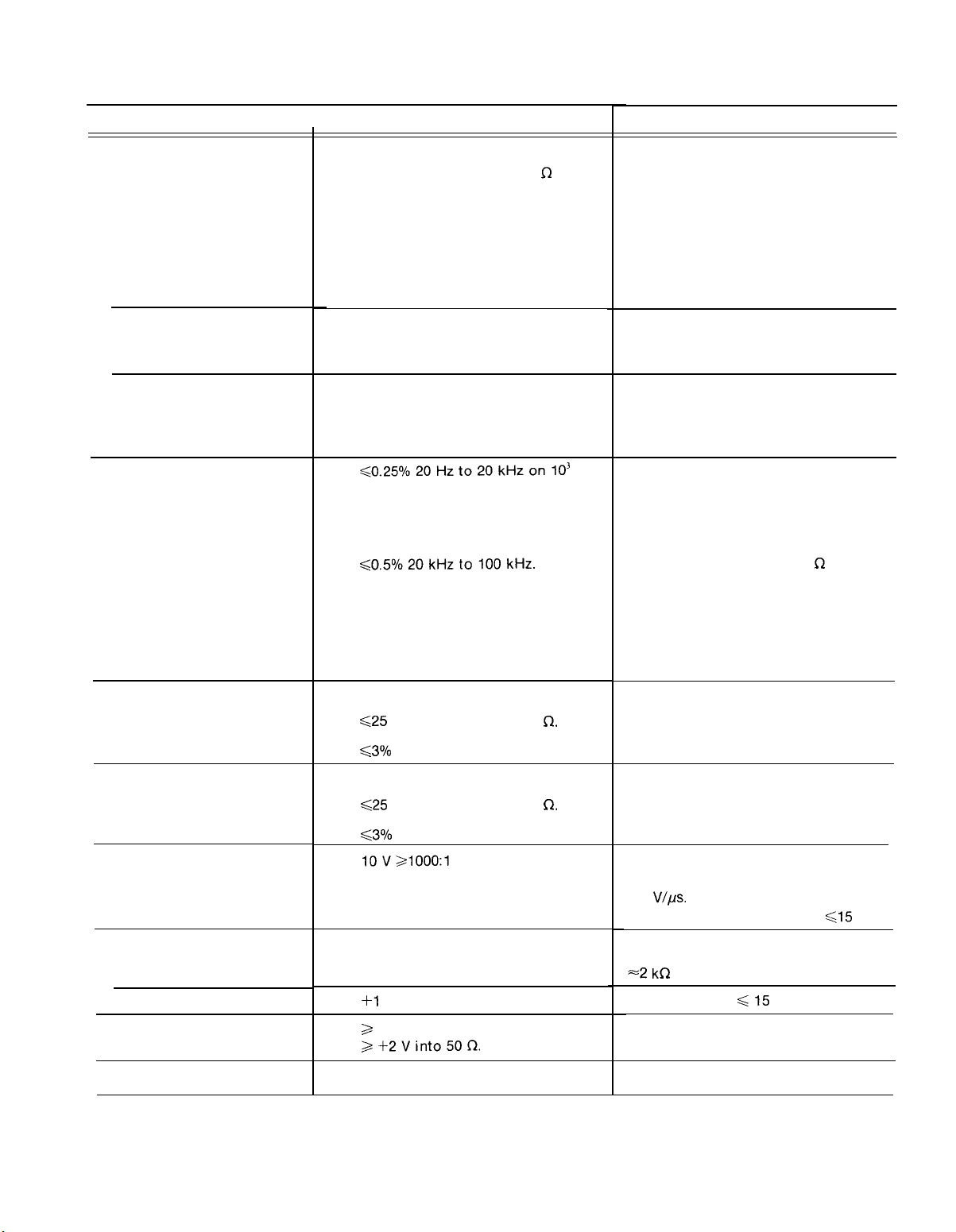

Table 1-1 (cont)

TM 9-6625-474-14&P-2

Characteristics

Amplitude Flatness

Sinewave

(10 kHz Sinewave Ref)

Squarewave

(10 kHz Squarewave Ref)

Triangle

(10 kHz Triangle Ref)

Sinewave Distortion

Performance Requirements

Measured with 0 dB ATTEN button

“IN” and output driving 50

(Front panel only.)

±0.1 dB 20 Hz to 20 kHz

±0.5 dB 20 kHz to 1 MHz

±1 dB 1 MHz to 2 MHz

Peak to peak amplitude within

±0.5 dB of squarewave reference

amplitude 20 Hz to 2 MHz.

Peak to peak amplitude within

±0.5 dB of triangle wave reference amplitude 20 Hz to 200 kHz.

Within 2 dB 200 kHz to 2 MHz.

range and below.

Cl

load.

Supplemental Information

Typically ±.5 dB .002 Hz to 20 Hz

Typically within ±.5 dB .002 Hz

to 20 Hz.

Typically within ±.5 dB .002 Hz

to 20 Hz.

20° to 30° C. Measured with

with average responding THD meter.

Measurement bandwidth limited to

approximately 300 kHz.

Q

Verified at 15 V p-p into 50

Must be on calibrated portion of

dial. VAR SYMM control off, Offset

control off.

load.

Squarewave Output

Risetime and Falltime

Aberrations (p-p)

Pulse Output

Risetime and Falltime

Aberrations (p-p)

VCF Input

Ext Trig/Gate Input

Impedance

Threshold Level

Trigger Output

Variable Phase Range

All harmonics at least 30 dB below

fundamental from 100 kHz to 2 MHz

Step ATTEN in 0 dB position.

<25 ns at 15 V p-p into 50

s30/o (Front panel only. )

Step ATTEN in 0 dB position.

<25 ns at 15 V p-p into 50

<30/o (Front panel only.)

+1

V ±20%.

>

+4 V into open circuit

>+2Vinto50f2.

At Ieast ±90°

Q

Q,

Trig output driving open circuit.

Positive going voltage increases

frequency. Maximum Slew Rate =

0.5

V/Ps.

VCF must not exceed

range limits, Maximum input

=2

kf2

Maximum input

Sine and Triangle only.

<15

V pk.

<15 V pk.

1-3

Page 12

TM 9-6625-474-14&P-2

Table 1-1 (cont)

Characteristics

Attenuators

Accuracy

Dial Accuracy

Triangle

Linearity

Time Symmetry

Characteristics

Power Consumption

Performance Requirements

±1 dB.

Within 3% of full scale 20 to 2.

Better than 1% 20 Hz to 200 kHz.

5% 200 kHz to 2 MHz (calibrated).

Table 1-2

MISCELLANEOUS

12 W or less. (plug-in only)

Supplemental Information

60 dB in 20 dB steps. >20 dB

additional attenuation with amplitude

control.

Verified at 20 kHz.

2 to .2 Uncal.

Greater than or equal to 99% 20 Hz to

200 kHz. 97% 200 kHz to 2 MHz (calibrated). Measured from 10% to

90% of waveform.

Description

Recommended Adjustment

Interval

Warm-up Time

Characteristics

Temperature

Operating

Non-operating

Humidity

Altitude

Operating

Non-operating

Vibration

1000 hours or 6 months, whichever occurs first.

20 minutes.

Table 1-3

ENVIRONMENTAL’

Description

Meets MlL-T-28800B, class 5.

0° C to +50° C

–55° C to +75° C

95% RH, 0° C to 30° C

Exceeds MlL-T-28800B, class 5.

75% RH to 40° C

45% RH to 50° C

Exceeds MIL-T-28800B, class 5.

4.6 Km (15,000 ft)

15 Km (50,000 ft)

0.38 mm (0.015") peak to peak,

5 Hz to 55 Hz, 75 minutes.

Exceeds MlL-T-28800B, class 5,

when installed in qualified

power modules.

b

1-4

Page 13

Table 1-3 (cont)

TM 9-6625-474-14&P-2

Characteristics

Shock

Bench Handling

Transportation

C

c

EMC

Electrical Discharge

a

With power module.

b

Refer to TM 500 power module specifications.

c

Without power module.

Description

30 G’s (1/2 sine), 11 ms duration, 3 shocks in each direction along 3 major axes, 18

Meets MlL-T-28800B, class 5,

when installed in qualified

power modules.

b

total shocks.

12 drops from 45°, 4“ or

Meets MlL-T-28800B, class 5.

equilibrium, whichever occurs

first.

Qualified under National Safe Transit Association Preshipment Test

Procedures 1A-B-1, and 1A-B-2.

Within limits of MIL-461A, and F.C.C. Regulations, Part 15, Subpart J,

Class A.

20 kV maximum charge applied to instrument case.

Table 1-4

Characteristics

Finish

Net Weight

Overall Dimensions

PHYSICAL CHARACTERISTICS

Description

Plastic/aluminum laminate front panel. Anodized aluminum chassis.

1.88 Ibs (.85 kg)

Height 5 in (126mm)

Width 2.6 in (67mm)

Length 11.9 in (303mm)

1-5/(1-6 blank)

Page 14

TM 9-6625-474-14&P-2

SECTION 2

OPERATING INSTRUCTIONS

INTRODUCTION

This section of the manual provides operating information required to obtain the most effective performance

from the FG 501A. Included are installation and removal

instructions, a functional description of the front panel

controls, and a general description of the operating

modes. Some basic applications of the instrument are also

briefly discussed.

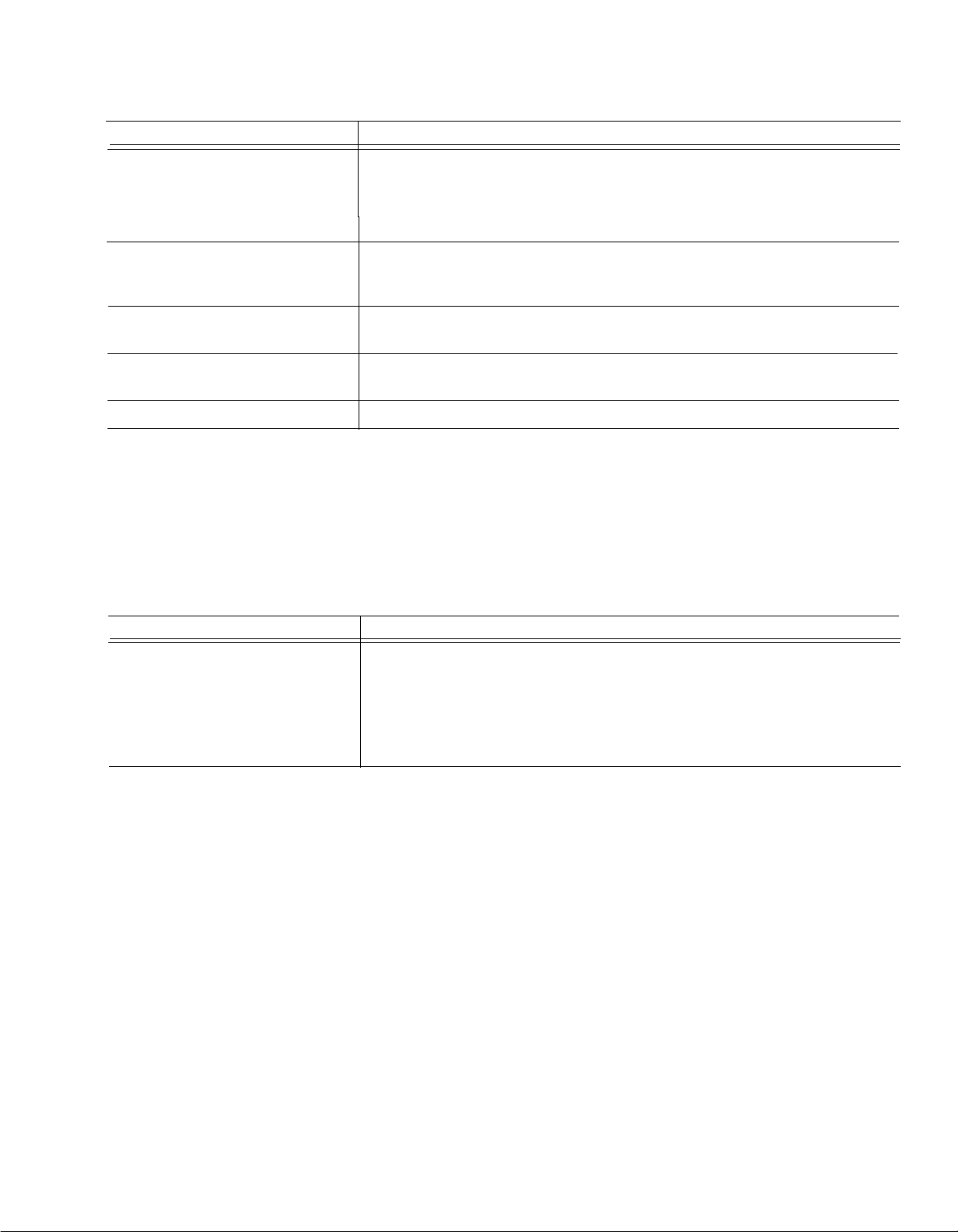

INSTALLATION AND REMOVAL

The FG 501A is calibrated and ready to use when

received. It operates in one compartment of any TM 500series power module. Refer to the power module instruc-

tion manual for line voltage requirements and power

module operation.

CAUTION

To prevent damage to the FG 501A, turn the power

module off before installation or removal of the

instrument from the mainframe. Do not use excessive force to install or remove.

showing: owner (with address) and the name of an

individual at your firm that can be contacted. Include

complete instrument serial number and a description of

the service required.

If the original package is not fit for use or not available,

repackage the instrument as follows:

Surround the instrument with polyethylene sheeting, or

other suitable material, to protect the exterior finish.

Obtain a carton of corrugated cardboard of adequate

strength and having inside dimensions no less than six

inches more than the instrument dimensions. Cushion

the instrument by tightly packing dunnage or urethane

foam between the carton and the instrument, on all

sides. Seal the carton with shipping tape or an industrial stapler.

The carton test strength for your instrument is 200

pounds.

Check to see that the plastic barriers on the interconnecting jack of the selected power module compartment match the cutouts in the FG 501 A circuit board edge

connector. If they do not match, do not insert the

instrument until the reason is found. When the units are

properly matched, align the FG 501A chassis with the

upper and lower guides of the selected compartment (see

Fig. 2-1). Insert the FG 501A into the compartment and

press firmly to seat the circuit board edge connector in the

power module interconnecting jack. Apply power to the

FG 501A by operating the power switch on the power

module.

To remove the FG 501A from the power module, pull

the release latch (located in the lower left corner) until the

interconnecting jack disengages. The FG 501A will now

slide straight out.

REPACKAGING FOR SHIPMENT

If the Tektronix instrument is to be shipped to a

Tektronix Service Center for service or repair, attach a tag

Fig. 2-1. Plug-in installation and removal.

2-1

Page 15

TM 9-6625-474-14&P-2

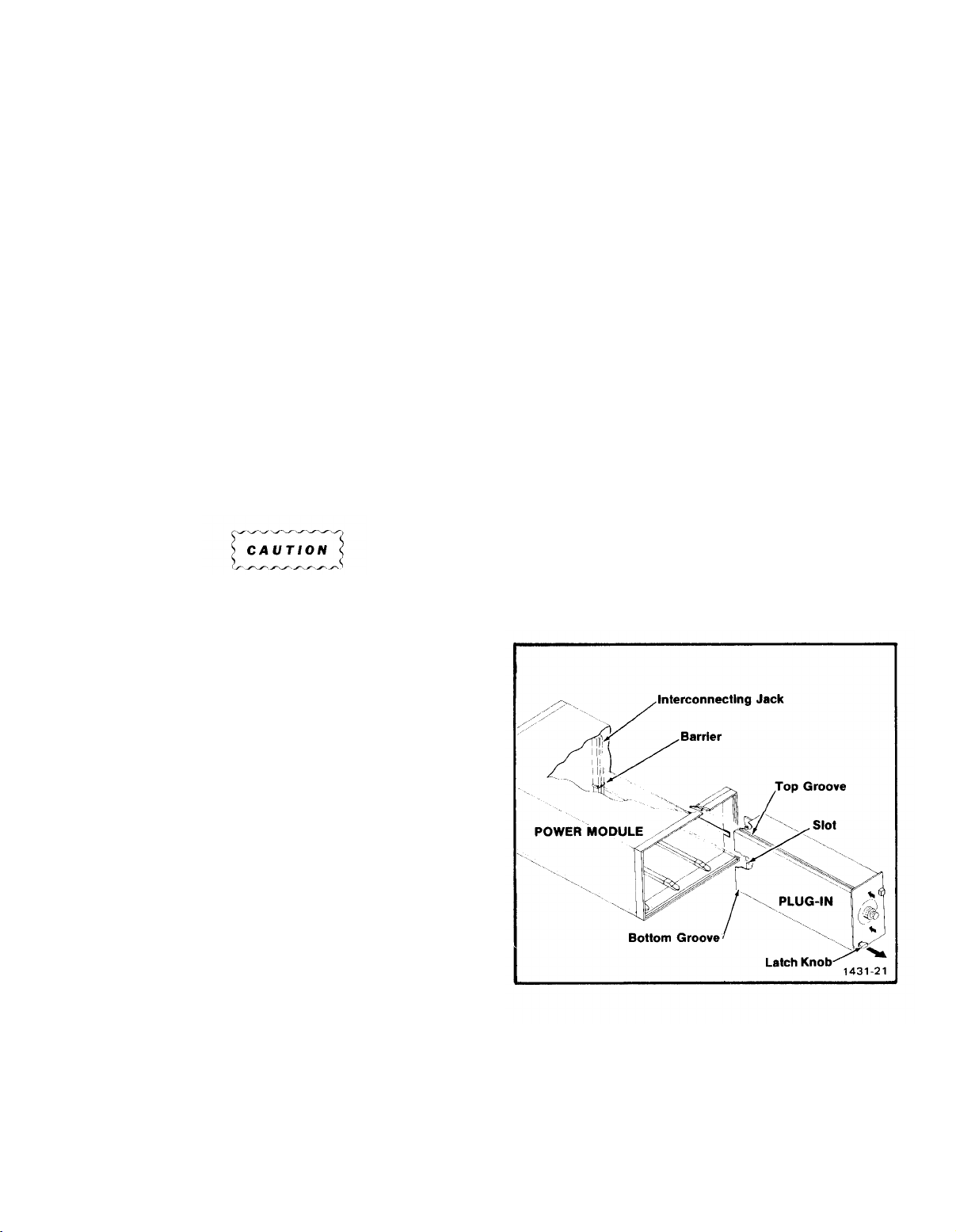

CONTROLS AND CONNECTORS

Although the FG 501A is calibrated and ready to use,

the functions and actions of the controls and connectors

should be reviewed before attempting to use it. All

controls necessary for operation of the instrument are

located on the front panel. A brief description of these

controls follows. Refer to Fig. 2-2.

2-2

Fig. 2-2. Controls and connectors.

Page 16

TM 9-6625-474-14&P-2

POWER - llluminated when power is applied to the

FG 501A.

FREQUENCY CONTROL AND FUNCTION

SELECTION

FREQUENCY Hz - Selects the frequency of the

output waveform

MULTIPLIER control.

FREQ + 10 - Illuminated when the variable symmetry function is activated.

FUNCTION BUTTONS - Select square, triangle,

and sine waveforms.

VAR SYMM - (push to enable) adjusts time-based

symmetry of the selected output waveform. Reduces

the frequency of the output waveform by a factor

= 10 and illuminates the FREQ + 10 indicator.

FREQUENCY VERNIER - For fine adjustment of

output frequency to at least 1 part in 10

MULTIPLIER - Selects the output frequency in eight

decade steps in conjunction with the FREQUENCY

Hz control.

in

conjunction with the

4

of full scale.

TRIGGER AND GATE CONTROLS

GATE - When pressed causes continuous output of

the selected waveform for the duration of the gating

pulse.

SLOPE - Button selects, in TRIG mode, the slope of

the input signal which will trigger the selected

output waveform. In GATE mode, whether output

gating will occur when the level of the input signal is

above or below the threshold level of +1 V.

TRIG/GATE lN - Bnc connector used to apply the

external trigger or gating signal.

VCF lNPUT - Bnc connector for applying an exter-

nal voltage for controlling the output frequency of

the generator.

TRIGGER OUTPUT - Bnc connector which outputs

one positive pulse for each cycle of the selected

output waveform.

OUTPUT CONTROLS

ATTENUATOR BUTTONS - Attenuate the ampli-

tude of the selected output waveform in 20 dB steps

to a maximum of 60 dB when pressed.

AMPL - Varies the amplitude of the selected output

waveform, between steps of the attenuator buttons.

VAR

0

relative to input trigger or gate waveform.

FREE RUN - When pressed causes continuous

waveform output.

TRIG - When pressed causes output of one cycle of

selected waveform for each trigger pulse applied to

the TRIG/GATE IN connector.

- Selects phase lead or lag, up to ±90°,

OFFSET - Pull and turn control, concentric with the

AMPL control, provides up to ±13 V dc offset of the

output waveform.

OUTPUT - Bnc connector for output of the selected

waveform.

RELEASE LATCH - Pull to disengage the FG 501A

from the power module.

2-3

Page 17

TM 9-6625-474-14&P-2

OPERATING CONSIDERATIONS

OUTPUT CONNECTIONS

The output of the FG 501A is designed to operate as a

50

fl

voltage source working into a 50 Q load. At higher

frequencies, an unterminated or improperly terminated

output will cause aberrations on the output waveform.

Loads less than 50

Excessive distortion or aberrations, due to improper

termination, are less noticeable at the lower frequencies

(especially with sine and square waveforms). To ensure

waveform purity, observe the following precautions:

1. Use good quality 50

tors.

2. Make all connections tight and as short as possible.

3. Use good quality attenuators if it is necessary to

reduce waveform amplitude applied to sensitive circuits.

4. Use terminations orimpedance matching devices to

avoid reflections when using long cables (6 feet or more).

~

will reduce the waveform amplitude.

Q

coaxial cables and connec-

capacitance) of the vertical input of an oscilloscope,

Q

connect the transmission line to a 50

termination, and then to the oscilloscope input. The

attenuator isolates the input capacitance of the device,

and the FG 501A is properly terminated.

attenuator, 50

FIRST TIME OPERATION

The Controls and Connectors pages give a description

of the front panel controls and connectors, The waveform

selection and frequency determining control sareoutlined

in blue, the trigger function controls and inputs are

outlined in green, and the output controls are outlined in

black.

The following exercise will familiarize the operator with

most functions of the FG 501A.

NOTE

If any discrepancies are encountered during the

exercise, refer the condition to qualified service

personnel,

Q

5. Ensure that attenuators, terminations, etc. have

adequate power handling capabilities for the output

waveform.

If there is a dc voltage across the output load, use a

coupling capacitor in series with the load. The time

constant of the coupling capacitor and load must be long

enough to maintain pulse flatness.

RISETIME AND FALLTIME

If the FG 501A is used to measure the rise or falltime of

a device, the riestime characteristics of associated equipment should be considered. If the risetime of the device

under test is at least 10 times greater than the combined

risetimes of the FG 501A and associated equipment, the

error introduced will not exceed

ignored. When the rise or falltime of the test device is less

than 10 times as long as the combined risetimes of the

testing system, the actual risetime of the system must be

calculated. The risetime of the device under test can be

determined once the risetime of the system is known.

1%, and generally can be

IMPEDANCE MATCHING

If the FG 501A is driving a high impedance such as the

1

MQ

input impedance (paralleled by a stated

Preset the controls as follows:

Blue section:

FREQUENCY Hz

MULTIPLIER

FREQUENCY VERNIER

WAVEFORM—SINE

VAR SYMM

Green section:

FREE RUN

Black section:

ATTENUATOR

AMPL (variable)

OFFSET

Connect a 50

the vertical input of an oscilloscope. Set the oscilloscope

controls to:

Vertical

Horizontal (Time Base)

The oscilloscope should display 1 complete cycle per

division of the sine waveform ( approximately 10 cycles

across the graticule),

Q

bnc coaxial cable terminated in 50 f2to

10

10

Fully CW

in

off

in

-20 dB

Centered

off

1 V/Div DC Coupled

1 ms/Div

2-4

Page 18

TM 9-6625-474-14&P-2

1. Alternately press the square, triangle and sine

buttons and observe the different waveshapes. Return to

the preset condition.

2. Alternately press the four attenuator buttons and

rotate the AMPL (variable) control to verify that the

waveform amplitude changes. Return these controls to the

preset condition.

3. Pull the OFFSET knob out and rotate it. Notice the

change in dc level of the displayed waveform. Return the

OFFSET knob to the in position.

OPERATING MODES

FREE-RUNNING OUTPUT

The following procedure will provide a free-running

output with variable frequency and amplitude.

1. Select the desired waveform.

4. Push the VAR SYMM button to release it to the out

position. Observe that the FREQ

luminated and only one cycle of the output waveform is

displayed. Rotate the VAR SYMM control through its

range and notice the change in shape of the square,

triangle, and sine waveforms (with the appropriate buttons

pushed in). Return the controls to the preset condition.

5. Rotate the FREQUENCY control and the

MULTIPLIER switch while observing the change in frequency of the displayed

to the preset condition,

If more than one cycle of the output waveform is

desired, push the GATE button. The output will now be

continuous for the duration of the gating waveform. The

number of cycles per burst can be approximated by

dividing the gating signal duration by the period of

FG 501A output frequency,

waveform, Return these controls

+

10 indicator is il-

2. Set the AMPL control fully counterclockwise. Check

that the VAR SYMM and OFFSET controls are in the off

(in) position.

3. Select the desired frequency with the FREQUENCY

Hz dial and MULTIPLIER switch. Frequency equals dial

setting times multiplier setting.

4. Connect the load to the FG 501A output connector

and adjust the AMPL control for the desired output

amplitude.

TRIGGERED OR GATED (BURST)

OPERATION

With the FG 501A set for free-running operation, as

described in previous paragraphs, apply the triggering or

gating signal to the TRIG/GATE IN connector.

If only one cycle of the output waveform per trigger is

desired, push the TRIG button and select + or – slope.

One output cycle will now be generated for each input

trigger cycle.

In triggered or gated operation the PHASE control

varies the start of the output waveform by ±90°. This

phase change is measured from the 0 V, 0° point on the

output waveform.

VOLTAGE CONTROLLED FREQUENCY

(VCF) OPERATION

The output frequency of any selected waveform can be

swept within a range of 1000:1 by applying an external

voltage to the VCF INPUT connector. The polarity of the

VCF input signal determines which direction the output

frequency sweeps from the selected frequency, A positive

(+) going signal increases the frequency while a negative

(–) going signal decreases the frequency. The amplitude

and polarity of the input voltage can be selected within a

range of ±10 V depending on the FREQUENCY Hz dial

setting.

The maximum swept frequency range of 1000:1 encom-

passes the uncalibrated portion of the FREQUENCY Hz

dial (<.2 to 2). To ensure that the frequency does sweep at

least a range of 1000:1, it is recommended that the

FREQUENCY Hz dial be set at .2 and a 0 to +10 V signal be

applied to the VCF INPUT connector. It may be necessary

2-5

Page 19

TM 9-6625-474-14&P-2

to vary the FREQUENCY VERNIER control to obtain the

full 1000:1 swept range or the lowest swept frequency

desired.

Since the VCF input amplitude is a linear relationship,

the frequency output range can be determined from the pulse is generated for each negative cycle of the output

VCF input amplitude.

A +4 V square wave is available from the TRIG

OUTPUT connector. The frequency of the trigger output

is determined by the frequency of the selected output

waveform. One trigger pulse is generated for each positive

cycle of the output signal except when square waves are

selected. When generating square waves, one trigger

signal. Trigger output impedance is

TRIGGER OUTPUT

50’(2.

BASIC WAVEFORM CAPABILITIES

The following photographs illustrate the basic waveform capabilities of the FG 501A.

2-6

Fig. 2-3. Swept Frequency range with 10 V signals applied to VCF IN connector.

Page 20

TM 9-6625-474-14&P-2

Fig. 2-4. BASIC FUNCTIONS. Square, triangle, and sine

waveforms selected by front panel pushbuttons.

Fig. 2-6. Phase relationships between OUTPUT waveforms and

the TRIG OUT waveform.

Fig. 2-5. RAMPS AND PULSES. These are obtained from the Fig. 2-7. Trigger Signal amplitude requirements and triggering

basic waveforms by using the SYMMETRY control.

points.

2-7

Page 21

TM 9-6625-474-14&P-2

Fig. 2-8. GATED OPERATION. The top three traces are various

output waveforms and the bottom trace is the gating waveform

applied to the trigger INPUT connector with the GATE

pushbutton pressed in. Note the additional cycle completed after

the waveforms are gated off.

Fig. 2-10. PHASE CONTROL OPERATION. This photograph

illustrates PHASE control usage in the triggered mode. The five

super-imposed traces illustrate the effect of the phase control.

This control provides ±90° of shift. The bottom trace is the

triggering waveform.

Fig. 2-9. TRIGGERED OPERATION. The top three traces are the

various out put traces selected. The bottom trace is the triggering

waveform applied to the trigger INPUT connector with the TRIG

mode selected. Note that only one cycle of the output waveforms

is completed.

2-8

Page 22

APPLICATIONS

TM 9-6625-474-14&P-2

RESPONSE ANALYSIS

The FG 501A is particularly suited for determining

resIponse characteristics of circuits or systems. This

application utilizes the VCF input of the FG 501 Ato sweep

the generator over a range of frequencies. Refer to the

Voltage Controlled Frequency (VCF) Operation discussion under Operating Modes for additional information.

1. Connect the equipment as shown in Fig. 2-11.

5. Observe the response characteristics on the

monitoring oscilloscope.

The frequency at which a displayed response

characteristic occurs can be determined by first removing

the VCF input waveform, then manually adjusting the

FREQUENCY Hz dial to again obtain the particular

characteristic observed in the swept display and reading

that frequency on the FREQUENCY Hz dial.

TONE-BURST GENERATION OR

2. Set the MULTIPLIER selector and FREQUENCY Hz

dial for the desired upper or lower frequency limit

(depending on the direction you wish to sweep).

The FG 501A can be used as atone-burst generator or

frequency multiplier for checking tone-controlled

3. Apply the desired waveform to the VCF INPUT

connector. (A positive-going waveform will increase the

frequency while a negative-going waveform will decrease

it. )

4. Adjust the amplitude of the VCF input waveform for

the desired output frequency range. obtaining a tone-burst or frequency multiplied output

devices. This application utilizes a ramp generator, such

as the TEKTRONIX RG 501, as a VCF signal source and a

pulse generator, such as the TEKTRONIX PG 501, as a

gating signal source.

The following procedure describes a technique for

STEPPED FREQUENCY

MULTIPLICATION

Fig. 2-11. Analyzing circuit or system response.

2-9

Page 23

TM 9-6625-474-14&P-2

from the FG 501A. Refer to the Gated (burst) Output and

Variable Phase and the Voltage-controlled Frequency

(VCF) Output discussions under Operation for additional

information.

1. Connect the equipment as shown in Fig. 2-12.

2. Push the GATE button in and set the PHASE control

to the desired phase.

3. Set the ramp generator for the desired ramp dura-

tion and polarity.

4. Adjust the pulse generator period for the desired

number of bursts within the selected ramp duration. input waveforms, i.e., triangle, sine, square, etc.

Adjust the pulse generator duration for the desired burst

width.

5. Select the sweep frequency range by adjusting the

FREQUENCY Hz dial for one end of the sweep range

(upper or lower limit depending on the polarity of the

ramp). Then, adjust the ramp generator amplitude for the

other swept frequency limit.

Various other tone-burst or frequency multiplied

characteristics can be obtained by using different gating

2-10

Fig. 2-12. Tone-burst generation or stepped frequency multiplication.

Page 24

TM 9-6625-474-14&P-2

SECTION 3

THEORY OF OPERATION

INTRODUCTION

This section of the manual contains a description of the

electrical circuits in the FG 501A. Refer to the block throughout this section refer to the schematic diagram on

diagram and schematic diagrams on the fold out pages in which the circuit being discussed is located.

the back of the manual to aid in understanding this

LOOP

FREQUENCY CONTROL AND SUMMING

AMPLIFIER

The voltage developed across the frequency control

divider string, R1429, R1321, R500 and R510, is applied to

pin 5 of operational amplifier U1540B. This voltage is

buffered by the amplifier and. a current is developed

through R1551. This current is applied top in 2 of summing

amplifier U1540A where it is summed with any currents

developed by a voltage applied tothe VCF inputs. The VCF

inputs are J510 (front panel) through R1553, and pin 21B

(rear interface) through R1103. These summed currents

are buffered by Q1445 and flow through R1543. The

voltage developed across R1543 is proportional to the

frequency.

CURRENT SOURCES AND SWITCH

The voltage developed across R1543 is buffered by

U1440 and Q1541 which form the negative current source

for the main Ioop timing circuitry. This same voltage is also

buffered by U1540C and Q1543 which form a current

source identical to U1440 and Q1541. The output current

from Q1543 flows through Q1527, Q1525, and Q1421,

which form a current mirror that inverts this current to

provide the positive current source for the main loop

timing circuitry. The current through R1521 is the timing

capacitor charging current; the current through R1536 is

the discharging current. The Top Dial Symmetry Cal,

R1421, adjusts the balance between these two currents so

they are equal in magnitude.

description. Diamond enclosed numbers appearing

@

positive and negative current sources. In this manner the

symmetry of the waveform generated by the loop is varied.

These currents are switched into the junction of CR1531

and CR1533 where they alternately charge and discharge

the timing capacitor, producing a triangle waveform, The

current switch is formed by Q1531, CR1531, Q1433 and

CR1533.

TIMING CAPACITORS AND

@

@

5

(C1631)

0

down to

CAPACITANCE MULTIPLIER

The timing capacitors provide for triangle generation in

the five fastest MULTIPLIER ranges. They are switched

into and out of the circuit in decade stepsfrom 10

down to 10

For the four lower MULTIPLIER ranges, 10

10-’,

C1741 is switched into the feedback loop of U1930

forming an integrator. Current from the current switch is

applied to operational amplifier U1940. A voltage is

developed at the output of this amplifier that is propor-

tional to the applied current times the value of R1941

(1

kfl).

resistors, to the input of U1930. These resistors, R1831,

R1841, R1842, and R1843, are switched into and out of the

circuit in decade steps with the MULTIPLIER switch

S1731. This arrangement provides very large values of

effective capacitance. The output of U1930 is now the

triangle that is applied to the buffer stage.

1

(C1741).

This voltage is applied, across one of four

TRIANGLE BUFFER

In the normal mode of operation (fixed symmetry) R520

and R540 are in the emitter circuit of Q1541 and Q1543. In

this condition, equal amounts of current will flow in both

the positive and negative current sources. When S500,

VAR SYMM, is activated, R530 is switched into the current

source emitter circuits. As R530 is varied from one end to

the other, unequal amounts of current flow through the

The voltage developed by the timing capacitor or

multiplier (U1930) is applied to the triangle buffer. Q1725

and Q1723 form the differential input stage of this circuit.

Q1821 serves as a constant current source for the input

differential pair. Q1721 and Q1712 complete the feedback

for the amplifier such that the voltage at the emitter of

Q1712 is equal to the voltage at the Gate of Q1725.

3-1

Page 25

TM 9-6625-474-14&P-2

Loop delay compensation is provided by a network

comprised of R1712, R1812, C1712, and C1714. The

buffered timing capacitor voltage is applied through this

network to the level comparators.

(~)

low and pin 8

to the current switch, Q1531 will be turned off and Q1433

turned on. This allows the timing capacitor to charge in the

positive direction.

to go high. Taking this high at pin 8 back

LEVEL COMPARATORS

The level comparators detect upper and lower

threshold levels. U1700A is the upper level detector and

U1700B the lower. The reference level for these comparators is supplied by U1400B and C. As the threshold

levels are detected, the respective comparator triggers

U1600B.

REFERENCE VOLTAGES

The reference voltage supplies are composed of

U1400B (–) and U1400C (+) and associated components.

The upper (positive) level threshold voltage is established

by adjusting R1412. This resistor is in a voltage divider

string from zener diode VR1413. The voltage developed

across R1412 is buffered by U1400C and set to approximately +400 mV at the output. This voltage is applied

to pin 5 of U1700A as the upper threshold level reference.

This same voltage is also applied to pin 9 of inverter

U1400B. R1511 is used to adjust the gain of this stage so

that the output is nominally –400 mV. This voltage is

applied to pin 13 of U1700B as the lower threshold level

reference.

LOOP LOGIC

When a rising voltage at pin 6 of U1700A passes

through the threshold level set at pin 5, the output (pin 8)

goes low pulling pin 10 of U1600Blow. This action sets the

flip-flop causing pin 9 (Q) to go high and pin 8 (Q) to go

low. Pin 8 of U1600B is tied back, through R1403, to the

junction of CR1431 and VR1532. VR1532 serves as a level

shifter to change the TTL output gate to the correct level to

drive the current switch (Q1531, CR1531, Q1433,

CR1533).

As the voltage at the junction of R1532 and R1534

drops, it pulls the bases of Q1531 and Q1433 low. Q1531 is

turned on and Q1433 is turned off. Any current from the

positive current source, through R1521, now flows

through Q1531 and is shunted to the –15 V supply. With

Q1433 turned off, any current flow through the negative

current source must come from the positively charged

timing capacitor through CR1533.

The falling voltage on the timing capacitor is buffered

through the triangle buffer and applied to the level

comparators U1700A and U1700B. As the voltage at pin 12

of U1700B falls through the threshold level set at pin 13,

the output (pin 1) goes low pulling pin 13 of U1600Blow.

This action resets the flip-flop causing pin 9

(Q) tonowgo

The action just described generates one entire cycle of

a triangle wave.

TRIGGER GENERATOR

The square wave output at pin 8

drives the trigger output amplifier. This circuit is composed of emitter follower Q1431 and associated components. Q1440, in conjunction with R1440, serves as

output short circuit protection. The output of this circuit

(at J2043) is a square wave 180° out of phase with the main

loop signal. The output amplitude is greater than +4 V into

an open circuit, and at least +2 V into a 50

(~)

of U1600B also

f2

load.

SQUARE WAVE GENERATOR

The output at pin 9 (Q) of U1600B is a square wave, but

180° out of phase with that at pin 8. This signal is used to

drive the square wave generator composed of differential

pair Q1801, Q1901, and associated components. The base

of Q1901 is held at a constant voltage by divider network

R1815 and R1818. R1728 and R1816 form a constant

current source for the differential pair. The square wave

from U1600B alternately switches this constant current to

ground through Q1801 or through R1819 and Q1901. In

this manner, a square wave voltage is developed with dc

levels sufficient to drive the output amplifier for the square

wave function.

PHASE CLAMP THRESHOLD DETECTOR

The output of the triangle buffer, in addition to possibly

being fed to the Output Amplifier through S1901B, is

connected to the base of Q1711. Q1711 and Q1611 form a

differential amplifier. Q1621 and associated components

provide a constant current source for the differential pair.

This amplifier senses the level of the triangle waveform

and compares it to the output voltage of U1400A. The

output voltage of U1400A is determined by the setting of

the VAR 0 control, R550. The voltage range of R550 is

established by reference voltage supplies U1400B (–) and

U1400C (+). These are the same reference voltages

supplied to the Level Comparators. This arrangement

permits comparison of the triangle voltage with the

maximum possible positive and negative levels, and all

levels between.

When the triangle voltage exceeds the reference

voltage set by the VAR 0 control, Q1711 turns off. Any

current flowing through Q1621 now flows through Q1611.

3-2

Page 26

TM 9-6625-474-14&P-2

CURRENT AMPLIFIER

Current flowing through Q1611 also flows through

R1622 and is amplified by Q1521. Temperature compensation for this amplifier is provided by CR1621. Differential

pair Q1511 and Q1523 serve as a current switch. With

Q1511 turned off, any current amplified by Q1521 passes

through Q1523 to the junction of CR1531 and CR1533.

When the timing capacitor voltage rises to the threshold

TRIG/GATE AMP AND SINE SHAPER

TRIG/GATE AMP AND LOGIC

The input trigger amplifier consists of an emitter

coupled differential pair (Q1320 and Q1322), current

amplifier Q1324, and the required logic circuitry to control

the operation of the main loop phase clamp. Input circuit

protection is provided by R1203, R1204, CR1220 and

CR1221. Triggering signals are applied either through

front panel connector J520 or interface connections on

the rear edge of the Main circuit board.

The differential pair, Q1320-Q1322, responds to the

input signal when the voltage rises above (+ SLOPE) the

reference voltage at the base of Q1320. This reference

voltage is established by divider network R1312 and

R1314, The position of S1400D, SLOPE switch, determines whether a positive or negative going input will

cause the amplifier Q1324 to conduct. When the threshold

level is exceeded and conduction starts, current flow

through the circuit causes a voltage to be developed

across R1322. This voltage is applied to the base of Q1324.

The output at the collector of Q1324 is a TTL compatible

waveform to drive the logic circuit, U1310. CR1320

provides temperature compensation for Q1324.

level set by the VAR 0 control, R550, it is clamped. Q1523

now draws exactly the amount of current that the positive

current source supplies. Because the square wave at pin 5

(Q) of U1600A drives the base of Q1511, the clamping

action only happens during the positive edge of the

triangle wave. On the negative transition, Q1523 is shut

off, and Q1511 is on. In this manner, the timing capacitor

voltage can be clamped at any desired positive level.

@

as long as this condition exists. As soon as the level at the

input connector drops below the threshold, the output

voltage of U1310A rises. This high level causes the

generator to again stop running when the phase clamp

reaches its threshold level at the end of the last complete

cycle.

In the FREE RUN mode, S1400A is positioned such that

pin 4 of U1600A is held low. The generator now outputs

continuous waveforms.

SINE SHAPER

The Sine Shaper is composed of three separate circuit

functions: a Transconductance Amplifier, the Shaper

Circuitry, and an Output Buffer.

Transconductance Amplifier. Emitter coupled tran-

sistors Q1210 and Q1212 along with current source Q1200

form the Transconductance Amplifier. The amplifier con-

verts the triangle voltage at the base of Q1212 to a

differential current. This current flows through two sets of

diode wired transistors, U1120C, U1120D, U1220C, and

U1220D, to the input of the shaper.

Three modes of operation are selectable with S1400;

Triggered, Gated, and Free Running.

In the TRIG mode, S1400A and S1400C are positioned

such that the output, pin 6, of U1310B is connected to pin

4, set input, of U1600A. In this mode, a very narrow,

negative going voltage pulse is developed by U1310B each

time the input waveform passes through the trigger

threshold. This low sets U1600A, which deactivates the

phase clamp until the triangle generator again starts in the

positive direction, and allows the generator to complete

one full cycle.

In the GATE mode, S1400A and S1400C are positioned

such that the output, pin 3, of U1310A is connected to pin

4, set input, of U1600A. In this mode, a low level is

produced whenever the input waveform exceeds the

threshold if + SLOPE is selected. The generator free runs

Shaper. The active portion of the Shaper is formed by

two sets of emitter coupled transistors U1220A, U1220B,

U1120A and U1120B. These devices have their inputs

wired in series and their outputs cross coupled. U1120E

and U1220E are current sources for these devices. The

circuit operates by generating a power series approximation to the sine function. The devices in U1120 generate

the first order term while those in U1220 generate the

second order term in the approximation.

Output Buffer. The Output Buffer is an operational

amplifier that converts the differential current from Q1010

and U1020D to a single ended voltage that is applied,

through the function switch, to the output amplifier.

U1020E is a current source for the emitter coupled

differential input pair U1020A and U1020B. Q1012 serves

as a current mirror for U1020A and as an active load for

U1020B. U1020C is the output emitter follower and R1020

is the feedback resistor.

3-3

Page 27

TM 9-6625-474-14&P-2

OUTPUT AMPLIFIER & ATTENUATORS

The output amplifier is basically a noninverting

operational amplifier whose plus input is the base of

Q2101 and minus input is the base of Q2113.

The three basic waveforms are selected by S1901 and

applied across R560B and R2335 to the input stage of the

amplifier. R560B varies the amplitude of the selected

waveform. The feedback network consists of R2011 and

R2012, connected from the output to the minus input of

the amplifier. C2011 provides high frequency compensation for the feedback, and is used to adjust the squarewave

front corner. The input pair, Q2101 and Q2113, amplify the

difference between the input waveform and the fedback

waveform.

An offset current is also summed with the feedback

signal at the base of Q2113 when S510A is closed. This

allows R560A to control the dc offset of the output signal.

POWER SUPPLY

The FG 501A receives its power from the power module

via interface connections on the rear edge of the Main

circuit board. The power module supplies plus (+) and

minus (–) 33.5 Vdc (unregulated) from which the following regulated voltages are generated.

+20 V SUPPLY

The +33.5 V from the power module is filtered and

applied to voltage regulator U1210 (pins 11 and 12). This

regulator contains its own reference, operational

amplifier, and current Iimiting elements. The output of the

regulator is applied to Q1231 which serves as a driver the

the series pass transistor located in the power module.

The +20 V output is applied across voltage divider R1201,

R1301, and R1315. The output level of the supply is set by

R1301 (+15 V Adj) which compares the supply output to

the internal reference level of the regulator. This supply is

current limited through the action of R1121 and the

current limiting element in the regulator. When excessive

amounts of current are drawn from the supply, the voltage

developed across R1121 turns on the current limiting

element in the regulator (U1210). This action reduces the

base drive, through Q1231, to the series pass transistor

causing the supply to reduce output, This supply is the

reference for other supplies in the FG 501A.

@

The output of Q2101 is applied directly to Q2111 which

is cascoded with Q2011. The output of Q2113 passes

through an inverting amplifier, Q2211, before passing to

Q2213 cascoded with Q2311. CR2111 provides temperature compensation for Q2211. The two cascodes form

drivers for the amplifier output stage.

The output stage consists of Q2013 and Q2123 in

parallel with Q2121 for amplification of positive going

signals. Q2321 and Q2323 in parallel with Q2325 form the

amplifier for negative going signals. The output is taken at

the junction of R2026 and R2228. The 50

impedance is determined by parallel 100

R2033 and R2131. C2121 in this network provides high

frequency compensation for the output impedance, The

attenuator circuit is a constant impedance resistive divider

network, switch selectable in 20 dB steps.

f2

output

Q

resistors

@

+20 V supply. Since this supply is sourced from the +20 V,

it is inherently current limited by the +20 V supply.

+5 V SUPPLY

The +5 V supply consists of U1230C and Q1331.

U1230C serves as an error amplifier which compares the

+5 V output to a +5 V reference developed by divider

network R1231, R1232 and R1233 from the +20 V supply.

Since this supply is sourced from the +15 V and referenced

to the +20 V supply, it is inherently current limited under

the same conditions that limit those supplies.

–20 V SUPPLY

The –20 V supply is derived from –33.5 V supplied by

the power module. The output of operational amplifier

U1230A is applied, through Q1245, to the base of Q1241,

which serves as a driver for the series pass transistor

located in the power module. This supply is also referenced to the +20 V. The supply is current limited through the

action of R1141 and Q1243. When excessive amounts of

current are drawn through R1141, a voltage sufficient to

turn Q1243 on develops across R1141. This action reduces

the base drive to the series pass transistor causing the

supply to reduce output.

–15 V SUPPLY

+15 V SUPPLY

The +15 V supply consists of U1230D and Q1221.

U1230D serves as an error amplifier which compares the

F15 Voutput of the supply to a +15 Preference developed

by divider network R1231, R1232 and R1233 from the

3-4

The –15 V supply consists of operational amplifier

(U1230B) and a series pass feedback regulator (Q1345),

The output of the supply is fed back through divider

network R1247, R1341, and R1245. The output level is

adjusted by R1341. Because this supply is sourced from

the –20 V supply, it is current limited by the –20 V supply.

Page 28

SECTION 4

CALIBRATION

PERFORMANCE CHECK

TM 9-6625-474-14&P-2

INTRODUCTION

This procedure checks the Electrical Performance

Requirements as listed in the Specification section in this

manual. Perform the internal adjustment procedure if the

instrument fails to meet these checks. If recalibration does

not correct the discrepancy, circuit troubleshooting is

indicated. Also, use this procedure to determine acceptability of performance in an incoming inspection facility, The test equipment, or equivalent, listed in Table 4-1 is

For convenience, many steps in this procedure check the

performance of this instrument at only one value in the

Table 4-1

TEST EQUIPMENT REQUIRED

Minimum Application

Item Description Specifications

1

Power Module Five compartments or more.

2

Oscilloscope System

3

Differential Comparator Minimum Vertical deflection

Amplifier

Minimum Vertical deflection

Sweep Rate .5

factor .1 V/div

PS.

specified performance range. Any value within the

specified range, within appropriate limits, may be substituted.

TEST EQUIPMENT REQUIRED

suggested to perform the performance check and the

adjust ment procedure.

Perf Adj

Check

X X

X X

X X

Proc

TEKTRONIX TM 515 or

TM 506

TEKTRONIX 7704/4/

7A16A/7B50

TEKTRONIX 7A13

Example

4

Sampling System

5

Spectrum Analyzer

Distortion Analyzer Frequency range from 20 Hz

6

to at least 300 kHz. Distortion

resolution <0.25%

7

Frequency Counter Frequency range 0.002 Hz

to above 2 MHz. Accuracy within

one part in 10

8

Digital Multi meter

Pulse Generator 0 to 2 V square wave

9

10

Power Supply

Range to ±30 V 5 1/2 digits

Accuracy 0.1%.

output into 50

Period 2

0 to 10 V range

Accuracy ±10%

,US;

Duration .1

4

±1 count.

f2

load.

ps

X

X

X

X X

X

X

X

Tektronix 7704/7S11/

7T11/S-1

TEKTRONIX 7L12

X

TEKTRONIX AA 501

X

TEKTRONIX DC 504

TEKTRONIX DM 501

TEKTRONIX PG 501

TEKTRONIX PS 501-1

4-1

Page 29

TM 9-6625-474-14&P-2

Minimum

Item Description Specifications

11

Flexible Extender Compatible with TM 500-

Series Power Modules

Black

12

Cable

Meter Lead

Table 4-1 (cont)

Application

Perf Adj

Check

X

Proc

X

X

Example

Tektronix Part No,

067-0645-02

Tektronix Part No.

012-0462-00

13

Meter Lead

14

Oscilloscope Probe

15

Coaxial Cable 50 !2 BNC Connectors

16

Termination 50 Cl BNC Connectors

X10 Attenuator

17

X5 Attenuator

18

19

Adapter BNC Female to Dual Banana

Red

X10 10

50

Cl

(20 dB) BNC

50

~

(14 dB) BNC

Mf2

1. Check Frequency Range

a. Connect the OUTPUT connector of the FG 501 to the

counter input.

b. Press the FEE RUN and 0 dB pushbuttons.

X X

Tektronix Part No.

012-0462-01

X X

Tektronix Part No.

010-6053-13

X X

Tektronix Part No.

012-0057-01

X

X

Tektronix Part No.

011-0049-01

X

Tektronix Part No.

011-0059-02

X

Tektronix Part No.

011-0060-02

X X

Tektronix Part No.

103-0090-00

i. Adjust the VAR SYMM control for a 50% duty cycle

pulse waveform.

j. CHECK - that the counter reads from 180 kHz to

220 kHz.

c. Press either the

W , ~ or N pushbuttons.

d. Make certain the VAR SYMM and OFFSET controls

are off.

e. Set the FREQUENCY Hz dial to 20 and the

MULTIPLIER control to the 10

5

position.

f. Adjust the AMPLITUDE control for a stable counter

display.

g. CHECK - that the counter reads

>2

MHz.

h. Activate the VAR SYMM control.

4-2

k. Change the MULTPLIER to 10-3.

l. CHECK - for an output frequency of between 0.0019

Hz and 0.0021 Hz.

m

Disable the VAR SYMM control.

n.

Change the FREQUENCY Hz dial to 2.

CHECK - that the FREQUENCY Hz dial can be ad-

o.

justed to obtain 0.0002 Hz.

p. Disconnect the counter for the next step

Page 30

2. Check Variable Symmetry Duty Cycle

Press the FREE RUN, 0 dB and ~ pushbuttons.

a.

d. Adjust the VAR

dmm.

TM 9-6625-474-14&P-2

0

control for a 0 V reading on the

Release the VAR SYMM pushbutton.

b.

Connect the OUTPUT connector through a 50

c.

coaxial cable to the oscilloscope vertical input:

d. Adjust the START, MULTIPLIER, AMPLITUDE, and

oscilloscope controls to display a squarewave that occupys exactly 10 major divisions for one cycle.

e. Rotate the VAR SYMM control from fully cw to fully

CCW.

f. CHECK - that the oscilloscope display varies each

squarewave half cycle from

<1/2

major division to >9.5

major divisions.

g. Leave these connections for the next step.

3.

Check Output Amplitude

a. Using the same setup as in the previous step, turn

the AMPLITUDE control fully

CW.

e. Pull and turn the OFFSET control fully cw to fully

CCW.

Q

f. CHECK - that the dmm reads

propriate stops for the OFFSET control.

g. Remove the coaxial cable from the dmm and insert a

50

f)

termination.

h. CHECK - that the dmm reads at least ±6.5 V at the

appropriate stops of the OFFSET control.

i. Remove the connections from the dmm for the next

step.

5. Check Amplitude Flatness

a. Press the FREE RUN, 0 dB and \ pushbuttons.

b. Make certain the OFFSET is off.

>+13

V at the ap-

b. CHECK - that the waveform on the oscilloscope

display is

>30 V peak to peak.

c. Remove the coaxial cable from the oscilloscope

vertical input and connect a 50

f2termination in series with

the cable.

d. CHECK - that the oscilloscope display is

peak to peak.

e. Disconnect the 50

f)

cable and remove the 50

termination from the oscilloscope for the next step.

4.

Check Offset Range

Press the TRIG 0 dB, and N pushbuttons.

a.

Make certain the VAR SYMM pushbutton is in.

b.

Connect a dmm set to read ±15 V to the output

c.

connector.

>15 V

c. Set the FREQUENCY Hz dial to 10 and the

MULTIPLIER to 10

d. Connect the OUTPUT connector through a 50

3

.

Q

cable and 50 Cl termination to the vertical input of the

differential oscilloscope plug-in.

e. Adjust the AMPLITUDE control and the gain of the

vertial amplifier for an 8 major division peak to peak

display.

f)

f. Increase the vertical amplifier gain by a factor of 10.

g. Adjust the vertical amplifier plug-in offset voltage so

that the waveform peaks are on the oscilloscope graticule

center line.

h. Change the output to any frequency from 20 Hz to

20 kHz.

i. CHECK - that the display is within 0.46 major

divisions from graticule center.

4-3

Page 31

TM 9-6625-474-14&P-2

j. Change the output to any frequency from 20 kHz to

1 MHz.

k. CHECK - that the display is within 2.37 major

divisions from graticule center.

l. Decrease the vertical gain of the oscilloscope by a

factor of 10 and adjust the offset voltage to 0.

m. Adjust the output frequency to 10 kHz.

n. Adjust the oscilloscope vertical gain and the

AMPLITUDE control for a 6 major division peak to peak

display.

o. Change the output to any frequency from 1 MHz to

2 MHz.

p. CHECK - that the peak to peak display amplitude is

from 5.36 to 6.73 major divisions.

aa. Adjust the vertical plug-in offset voltage to 0.

bb. Adjust the AMPLITUDE control and the vertical

plug-in gain for an 8 major division oscilloscope display of

the triangle waveform.

cc. Increase the plug-in gain by a factor of 10.

dd. Adjust the offset voltage so that the positive peak

of the triangle waveform is at graticule center.

ee. Change the output to any frequency from 20 Hz to

200 kHz.

ff. CHECK - that the positive peak of the triangle

waveform is 2.37 major divisions or Iess from the graticule

center.

gg. Decrease the vertical amplifier gain by a factor of

10.

.

q. Press

r. Set the output frequency to 10 kHz.

s. Adjust the AMPLITUDE control and the vertical

comparator oscilloscope plug-in for an 8 major division

peak to peak display.

t. Increase the oscilloscope vertical plug-in gain by a

factor of 10.

u. Adjust the vertical plug-in offset voltage so that the

positive peaks of the squarewaves are at graticule center.

v. Change the output to any frequency from 20 Hz to

2 MHz.

w. CHECK—that the positive squarewave peaks are

within ±2.37 major divisions from graticule center.

x.

y.

the\

pushbutton.

Press the N pushbutton.

Change the output frequency to 10 kHz.

hh. Remove the comparison voltage from the vertical

plug-in.

ii. Adjust the AMPLITUDE control and the vertical

plug-in gain for a peak to peak triangle waveform display

of 6 major divisions.

jj. Change the output to any frequency from 200 kHz

to 2 MHz.

kk. CHECK - that the peak to peak display reads from

4.4 major divisions to 7.6 major divisions in amplitude.

ll. Disconnect the oscilloscope for the next step.

6. Check Sinewave Distortion

a. Press the FREE RUN, 0 dB, and

The VAR SYMM, and OFFSET controls must be off (in).

b. Connect the OUTPUT connector through a 50

coaxial cable and 50 Q termination to the distortion

anal yzer.

I

pushbuttons.

Q

z.

Decrease the oscilloscope vertical plug-in gain by a

factor of 10.

4-4

c. Set the distortion analyzer to measure total har-

monic distortion plus noise with average response.

Page 32

TM 9-6625-474-14&P-2

d. Make certain the function generator is in an ambient

temperature from 20° C to 30° C.

e. Select any frequency from 20 Hz to 20 kHz with the

FREQUENCY Hz and MULTIPLIER controls. The FREQUENCY Hz control must be on the calibrated portion of

the dial and the MULTIPLIER control must be on the 10

range or below.

f. Adjust the AMPLITUDE control for a 15 V peak to

peak signal at the input of the distortion analyzer.

g. CHECK - that the distortion is

<0.25°/0.

h. Select any frequency from 20 kHz to 100 kHz. The

FREQUENCY Hz control must be on the calibrated portion

of the dial.

i. CHECK - that the distortion is

<0.5%.

j. Disconnect the distortion analyzer and the 50

termination from the coaxial cable.

k. Connect the coaxial cable to the input of the

spectrum analyzer.

b. Set the FREQUENCY Hz dial and the MULTIPLIER

control for any calibrated frequency. (For ease, the

FREQUENCY Hz dial at 20 and the MULTIPLIER at 10

recommended. )

3

c. Turn the AMPLITUDE control fully cw.

d. Connect the OUTPUT connector through a 50

coaxial cable and the necessary attenuators to obtain a 5

division display to the 50

fl

vertical input of the sampling

oscilloscope.

e. Connect the TRIG OUTPUT connector through a

50

Q

coaxial cable and the necessary attenuators to the

external trigger input on the sampling oscilloscope.

f. Obtain a stable rise and fall time display on the

oscilloscope.

g. CHECK - that the rise time and fall time is

from the 10% to the 90% amplitude points.

S2

h. CHECK - that the peak to peak amplitude of the

front corner ringing does not exceed 3% of the total

squarewave amplitude. (If the squarewave amplitude is 8

major divisions, maximum aberrations allowed are 0.24

major divisions. )

5

are

<25 ns

Q

l. Set the FREQUENCY Hz dial at 10 and the

MULTIPLIER at 10

4

.

m. Adjust the AMPLITUDE control and the spectrum

analyzer controls so that amplitudes 30 dB or greater

below the fundamental amplitude are easily viewed on the

spectrum analyzer.

n. Rotate the FREQUENCY Hz dial to 20, change the

MULTIPLER to 10

5

, and rotate the FREQUENCY Hz dial

from 20 to 2.

o. CHECK - that all harmonics from 100 kHz to 2 MHz

are at least 30 dB below the fundamental amplitude.

p. Remove the connections to the spectrum analyzer

for the next step.

7. Check Squarewave and Pulse Output

a. Press the FREE RUN, 0 dB and

~

pushbuttons. All

other pushbuttons out.

Release the VAR SYMM pushbutton.

i.

Adjust the VAR SYMM control for a pulse waveform.

j.

Repeat steps f and g.

k.

l. Remove all connections for the next step.

8. Check VCF Input

a. Press the FREE RUN, 0 dB and

~

pushbuttons. The

VAR SYMM and OFFSET pushbuttons should be in. Set

the FREQUENCY Hz dial to 20 and the MULTPLlER to 10

b. Connect the OUTPUT connector through a 50

coaxial cable to the input of the frequency counter.

c. Obtain a stable counter display.

d. Apply -10 Vdc to the VCF INPUT connector.

5

.

Q

4-5

Page 33

TM 9-6625-474-14&P-2

CHECK - that the frequency decreases by a factor

of

>1000.

f. Remove all connections for the next step.

9.

Check External Trigger/Gate Input

a. Press the TRIG, 0 dB, and I pushbuttons.

b. Connect the OUTPUT connector to the vertical

input of the oscilloscope.

c. Connect the pulse generator through a 50 Q coaxial

cable and 50

f

termination to the TRIG/GATE IN connec-

tor.

d. Set the pulse generator for a 0 to 1.2 V positive

going

50% duty cycle pulse at 1/2 the frequency of the

FG 501A.

e. CHECK - for one cycle of a sine waveform for each

trigger pulse.

11. Check Variable Phase Range

a. Press the FREE RUN, 0 dB, and ~ pushbuttons.

b. Connect the OUTPUT connector to the vertical

input of the oscilloscope. Set the oscilloscope for

automatic triggering.

c. Obtain a sine waveform on the oscilloscope

centered around 0 V. Determine the peak-to-peak

amplitude of the waveform.

d. Press the TRIG pushbutton.

e. Rotate the VAR 0 from stop to stop and observe the

position of the free running trace on the oscilloscope

display.

f. CHECK - that the straight line can be positioned at

the peak amplitudes of the sine waveform.

g. Remove all connections for the next step.

f. Press the GATE pushbutton.

g. CHECK - for an output waveform that lasts for the

duration of the gating waveform.

h. Remove all connections for the next step.

10. Check Trigger Out put

a. Press the FREE RUN pushbutton.

b. Connect the TRIG OUTPUT connector through a

50

Q

c. CHECK - for

coaxial cable to the vertical input of the oscilloscope.

a>+4

V waveform on the oscilloscope

display.

d. Insert a 50

~

termination from the coaxial cable to

the oscilloscope vertical input.

e. CHECK - for

a>+2

V waveform on the oscilloscope

display.

12. Check Attenuator Accuracy

a. Press the FREE RUN, 0 dB and ~ pushbuttons.

b. Set the FREQUENCY Hz dial to 20.

c. Set the MULTIPLIER to the 10

3

position.

d. Set the AMPLITUDE control fully cw.

e. Connect the OUTPUT connector thorugh a 50

coaxial cable and 50 Q termination to the input of the dB

ratio meter (AA 501).

f. Set the AA 501 for automatic level ranging.

g. Push the 0 dB REF button on the AA 501.

h. Push the -20 dB pushbutton.

i. CHECK - that the ratio meter reads from -19 dB to

-21 dB.

Q

f. Remove all connections for the next step.

4-6

j. Push the -40 dB pushbutton.

Page 34

TM 9-6625-474-14&P-2

k. CHECK-that the display reads from -39 dB to

-41 dB.

l. Push the -60 dB pushbutton.

m. CHECK-that the display reads from -59 dB to

-61 dB.

n. Remove all connections for the next step.

12A. Alternate Procedure for Checking Attenuator

Accuracy

a. Press the FREE RUN, 0 dB, and I pushbuttons.

b. Set the FREQUENCY Hz dial to 20.

c. Set the MULTIPLIER to 10

3

position. Connect the

output through a coaxial cable to the oscilloscope vertical

input.

j. CHECK-for a waveform amplitude from 0.0267 V to

0.0337 v.

k. Remove all connections for the next step.

13. Check Triangle Time Symmetry

a. Press the FREE RUN pushbutton.

b. Set the FREQUENCY Hz and MULTIPLIER control

for any frequency from 20 Hz to 200 kHz in the calibrated

portion of the dial. Connect the counter through a coaxial

cable to the TRIG OUTPUT connector.

c. Trigger the counter to read the time of the positive-

going half cycle of the trigger waveform (+ slope).

d. Record this reading.

e. Trigger the counter to read the negative-going half