Page 1

COMMITTED TO EXCELLENCE

Tektronix, Inc.

p.10.

Box 500

Beaverton, Oregon 97077

INSTRUCTION

Serial Number

MANUAL

First printing August

1972

Page 2

Page 3

TABLE OF CONTENTS

Page

SECTION

SECTION

SEICTION

SE:CTION

SE:CTION

SE:CTION 6 OPTIONS 6-

SECTION

1

2

THE FOLLOWING SERVICING INSTRUCTIONS ARE FOR USE BY QUALIFIED PERSONNEL ONLY. TO A VOID PERSONAL INJURY, DO NOT PERFORM ANY SERVICING

OTHER THAN THAT CONTAINED IN OPERATING INSTRUCTIONS UNLESS YOU ARE

QUALIFIED TO DO SO.

3

4

5

7

OPERATING INSTRUCTIONS

SPECIFICATION AND PERFORMANCE CHECK

I

WARNING

ADJUSTMENT

MAINTENANCE AND INTERFACING INFORMATION

CIRCUIT DESCRIPTION

REPLACEABLE ELECTRICAL PARTS

)

1-1

2-

3- 1

4-

5-

7-

1

1

1

1

1

SEiCTlON

SEICTION

CHANGE INFORMATION

8

9

DIAGRAM AND CIRCUIT BOARD ILLUSTRATION

REPLACEABLE MECHANICAL PARTS AND EXPLODED VIEW

8- 1

9- 1

Page 4

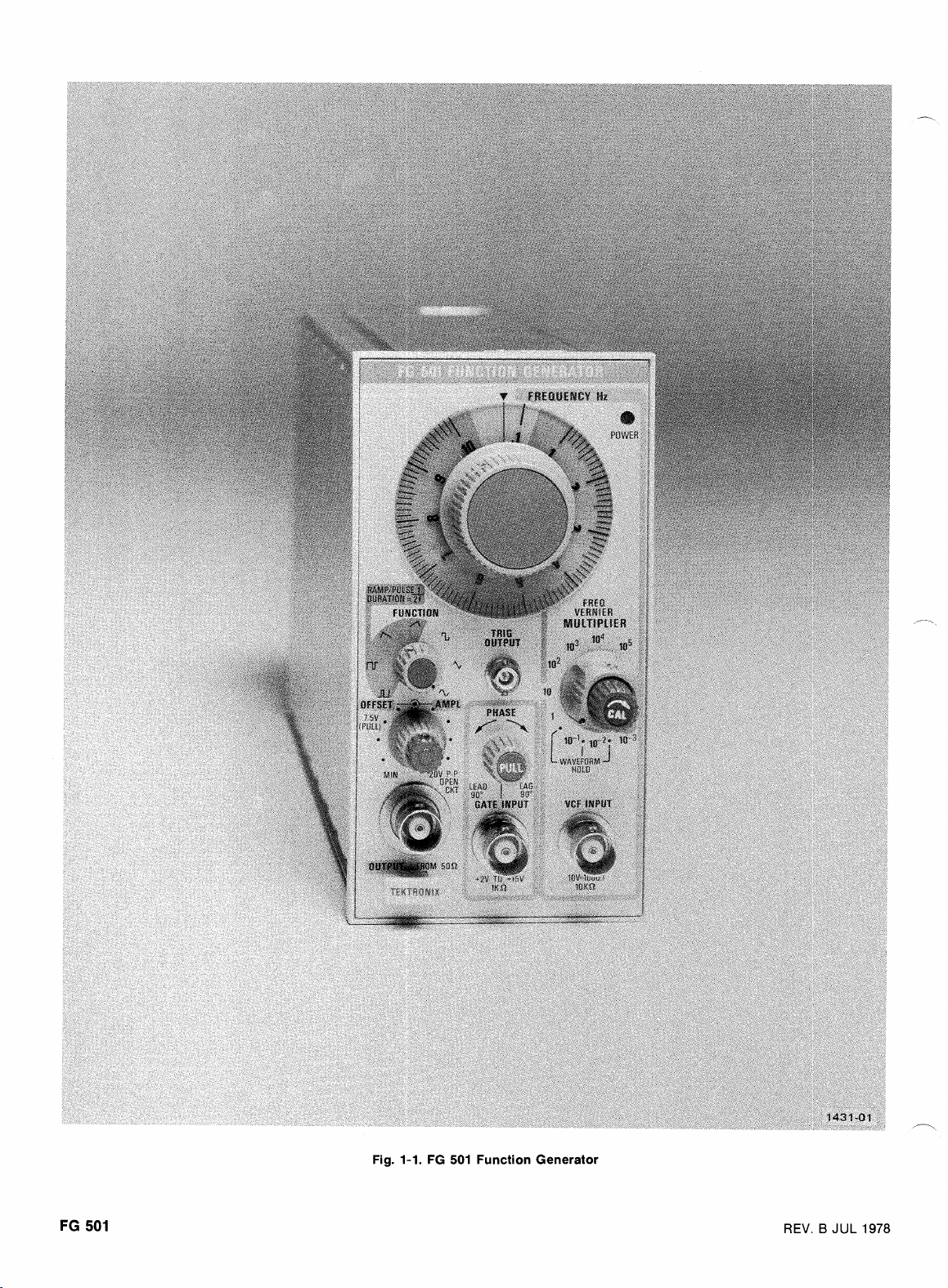

Fig.

1-1.

FG

501

Function Generator

REV.

B

JUL

1978

Page 5

INSTRUCTIONS

Section

1-FG

501

INTRODUCTION

The FG !501 Function Generator is designed to operate

TM

in a

square, tria~ngle, pulse, and ramp waveformsfrom 0.001

to 1

available at the front panel. Variable DC offset of k7.5 volts

is also provided. A "hold1' feature allows the generator

output to be abruptly halted at its instantaneous voltage

level and held there until manually switched on again.

to control the output frequency from an external voltage

source. The output frequency can be swept above or

below the selected frequency to a maximum of

depending on the polarity and amplitude of the VCF input

and the selected output frequency.

generator to be turned on for the duration of an externally

applied gating signal. This mode provides either a single

cycle output or a train (burst) of preselected waveforms

depending on the gating signal width and the generator

frequency setting. The phase (start level) of the waveform

burst can be varied

500-Series power module. Low distortion sine,

Hz

MHz

as well as a $2.5 volt square-wave trigger are

A voltage-controlled frequency (VCF) input is provided

1000:l

Also included is an external gate input that allows the

k90°

by a front-panel control.

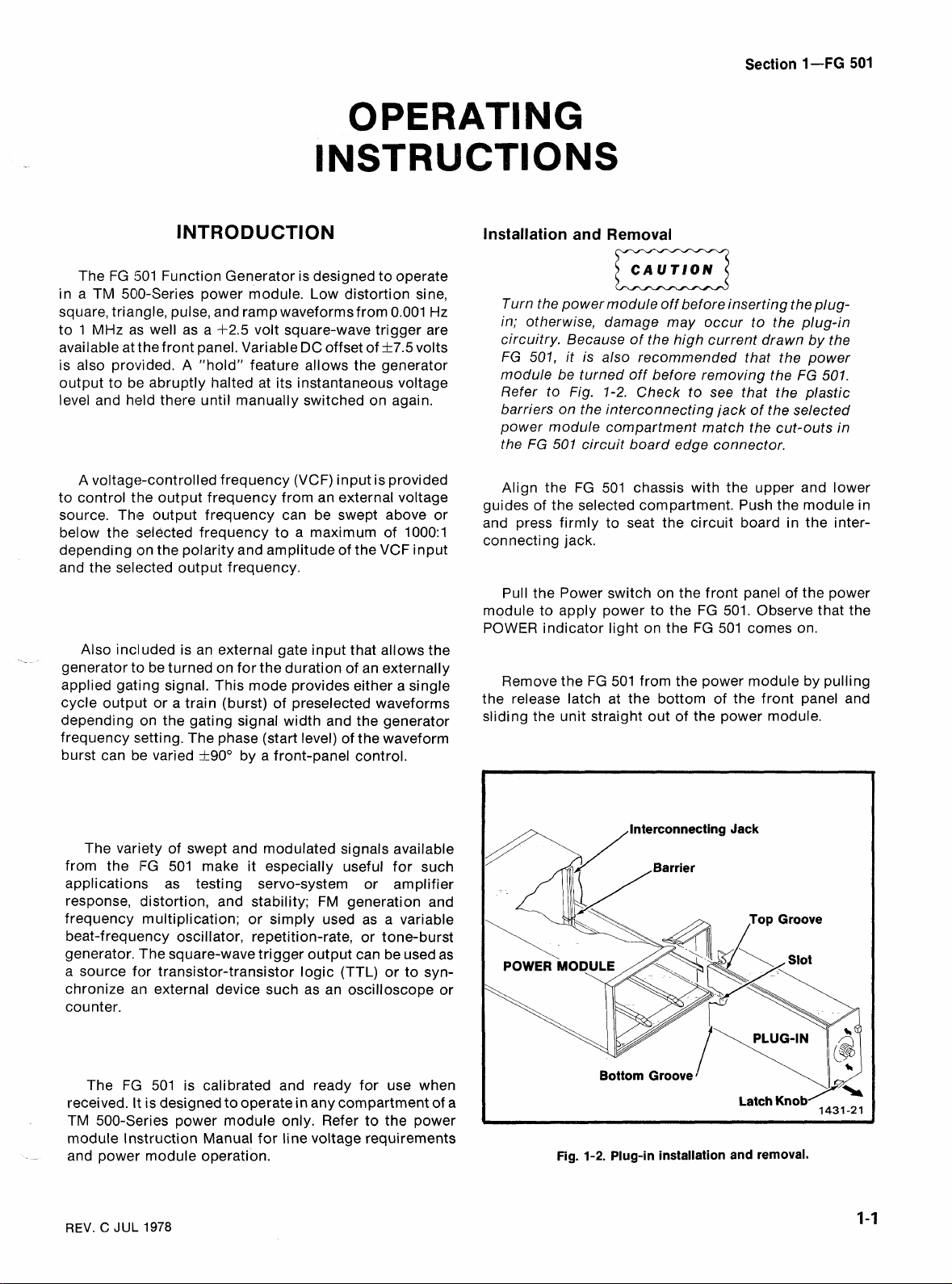

Installation and Removal

CAUTION

D

Turn the power module off before inserting the plugin; otherwise, damage may occur to the plug-in

circuitry. Because of the high current drawn by the

507,

FG

module be turned off before removing the FG

Refer to Fig.

barriers on the interconnecting jack of the selected

power module compartment match the cut-outs in

the

Align the FG 501 chassis with the upper and lower

guides of the selected compartment. Push the module in

and press firmly to seat the circuit board in the interconnecting jack.

Pull the Power switch on the front panel of the power

module to apply power to the FG 501. Observe that the

POWER indicator light on the FG 501 comes on.

Remove the FG 501 from the power module by pulling

the release latch at the bottom of the front panel and

sliding the unit straight out of the power module.

it is also recommended that the power

7-2.

FG

Check

501

circuit board edge connector.

to

see that the plastic

507.

The variety of swept and modulated signals available

from the IFG 501 make it especially useful for such

applications as testing servo-system or amplifier

response, distortion, and stability; FM generation and

frequency multiplication; or simply used as a variable

beat-f requency oscillator, repetition-rate, or tone- burst

generator. 'The square-wave trigger output can be used as

a source for transistor-transistor logic (TTL) or to synchronize

counter.

received. It is designed to operate in any compartment of

TM 500-Series power module only. Refer to the power

module Instruction Manual for line voltage requirements

-

and power module operation.

REV. C JUL

an external device such as an oscilloscope

The FG 501 is calibrated and ready for use when

1978

or

Interconnecting Jack

Bottom Groove

a

Fig.

1-2.

Plug-in installation and removal.

Page 6

Operating Instructions-FG

501

OPERATING CONSIDERATIONS

NOTE

Before using the

Operating Considerations in this section and the

description of the front-panel controls, connectors,

and indicators in Fig.

FG

501

for the first time, read the

1-3.

Output Connections

The output of the FG 501 is designed to operate as a

voltage source in series with 50

load. At the higher frequencies, an unterminated or

improperly terminated output will cause excessive

aberrations on the output waveform (see lmpedance

Matching discussion). Loads less than

waveform amplitude.

Excessive distortion or aberrations due to improper

termination is less likely to occur at the lower frequencies

(especially with sine and triangle waveforms). However, to

ensure that waveform purity is preserved, observe the

following precautions:

1. Use quality 50

2.

Make all connections tight and as short as possible.

3.

Use quality attenuators, if necessary, to reduce

waveform amplitude to sensitive circuits.

f2

coaxial cables and connectors.

f2

and working into a 50

50 R will reduce the

f2

When signal comparison measurements or time

difference determinations are made, the two siignals from

the test device should travel through coaxial cables with

identical loss and time-delay characteristics.

If there is a dc voltage across the output load, the output

pulse amplitude will be compressed; or in sorne cases, if

the voltage exceeds

prevent this from occurring, the output must be coupled

through a dc blocking capacitor to the load. The time

constant of the coupling capacitor and load must be long

enough to maintain pulse flatness.

f

10

V,

it may short the output. To

Risetime and Falltime

If the output pulse from the FG 501 is used for

measuring the rise or falltime of a device, the risetime

characteristics of associated equipment may have to be

considered. If the risetime of the device under test is at

least 10 times greater than the combined risetimes of the

FG 501 plus the monitoring oscilloscope and associated

cables, the error introduced will not exceed 1% and

generally can be ignored. If the rise or falltime of the test

device, however,

combined

risetime of the device will have to be determined from the

risetime of each component making up the system. This

equals the square root of the sum of the squares of the

individual risetimes. Conversely, the

under test can be found from the same relationship if all

the actual risetimes in the system are known except that of

the device under test.

risetimes of the testing system, the actual

is less than 10 times as long as the

risetime of the device

/-

4. Use terminators or impedance-matching devices to

avoid reflections when using long cables, i.e., six feet or

more.

5. Ensure that attenuators, terminations, etc. have

adequate power-handling capabilities for the output

waveform (approximately 0.5 W into a 50

Power output is determined by the selected waveform,

its amplitude, and the amount of offset voltage selected.

The physical and electrical characteristics of the pulse-

transmitting cable determine the characteristic im-

pedance, velocity of propagation, and amount of signal

loss. Signal loss, due to energy dissipation in the cable

dielectric, is proportional to the frequency; therefore, a

few feet of cable can attenuate high-frequency information in a fast-rise pulse. It is important to keep these cables

as short as possible.

f2

load).

lmpedance Matching

Reflections.

line, each time it encounters a mismatch, or an impedance

different than the transmission line, a reflection is

generated and sent back along the line to the source. The

amplitude and polarity of the reflections are determined

by the amount of the encountered impedance in relation

to the characteristic impedance of the cable. If the

mismatch impedance is higher than the line, the reflection

will be of the same polarity as the applied signal; if it is

lower, the reflection will be of opposite polarity. If the

reflected signal returns before the pulse is ended, it adds

to or subtracts from the amplitude of the pulse. This

distorts the pulse shape and amplitude.

Matching Networks.

for matching impedance networks into relatively low

impedances. If the FG 501 is driving a high impedance,

such as the 1 MR input impedance of the vertical input for

an oscilloscope, the transmission line must be terminated

As a pulse travels down a transmission

The following describes methods

REV.

B

JUL

1978

--

Page 7

Operating Instructions-FG

501

REV

C,

MAR

1979

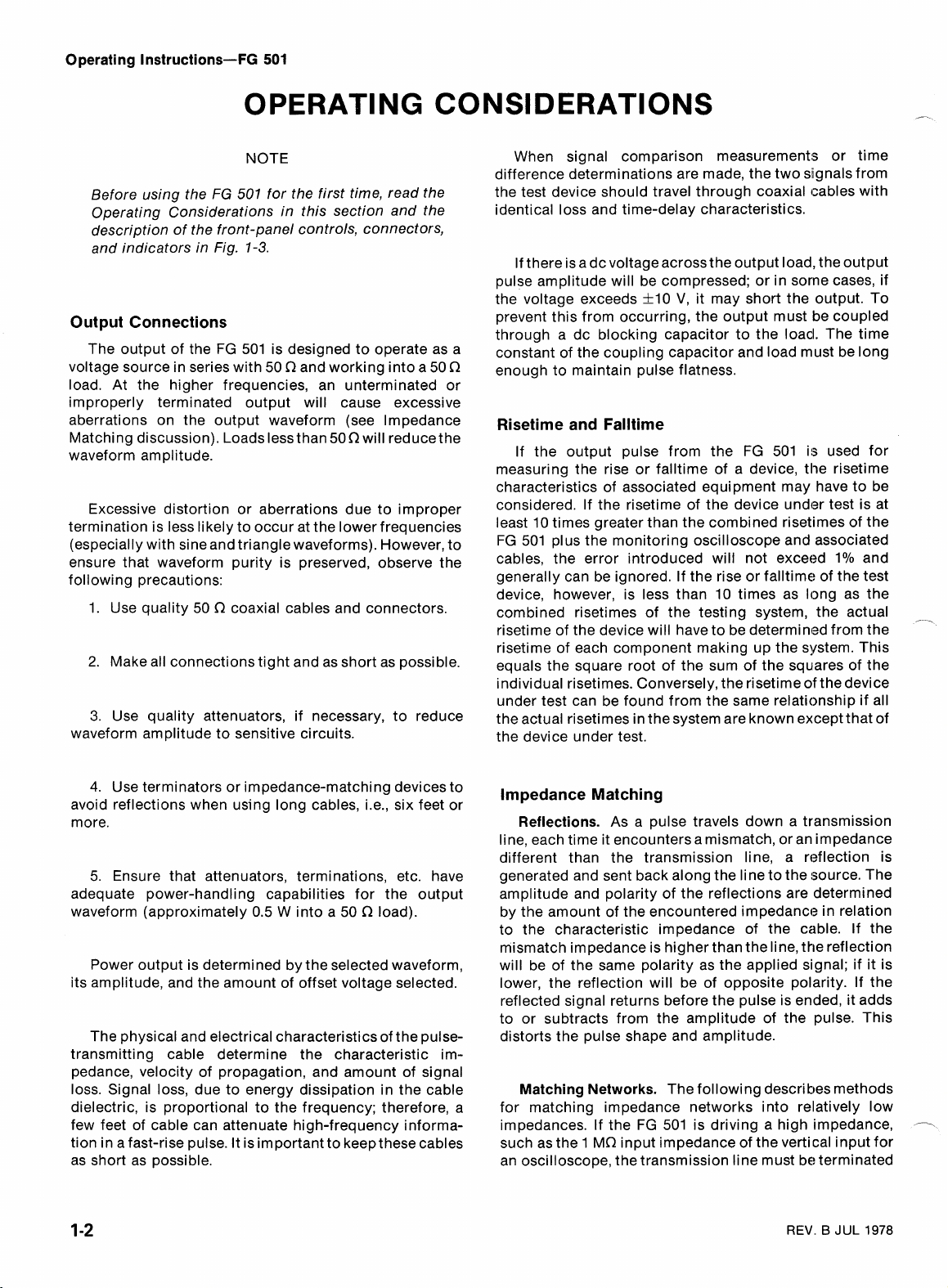

Fig.

1-3.

Operating controls and connectors.

Page 8

Operating Instructions-FG

501

into a 50

oscilloscope input. The attenuator isolates the input

capacity of the device. Distortion can be caused by this

input capacity.

A simple resistive impedance-matching network that

provides minimum attenuation is illustrated in Fig. 1-4. To

match impedance with the illustrated network, the follow-

ing conditions must exist:

and

Theref ore:

For example; to match a 50

Z1 equals 50

f2

attenuator and a 50

+

Z2)R2 must equal

(R1

Ri + Z2+ R2

RI

+

-

'IR2

ZI + R2

R1R2

=

2122; and RIZl = R2(Z2 - Z1)

Cl

and Z2 equals 125

f2

termination at the

must equal

f2

system to a 125

0.

zI

~2

f2

system,

Zl

-

(Low)

Fig.

1-4.

attenuation.

(22) encounters a greater voltage attenuation

greater than 1 and less than 2 (Z~IZI):

Impedance-matching network that provides minimum

A signal (E2) applied from the higher impedance source

-

(A2)

(High)

which is

2

Theref ore:

1

and R2

When constructing such a device, the environment

surrounding the components should also be designed to

provide a transition between the impedances. Keep in

mind that the characteristic impedance of a coaxial device

is determined by the ratio between the outside diameter of

the inner conductor to the inside diameter of the outer

z,

conductor.

diameter of the outer conductor, and d is the outside

diameter of the inner conductor. E is the dielectric constant (1 in air).

Attenuation Ratios.

provides minimum attenuation for a purely resistive

impedance-matching device, the attenuation as seen from

one end does not equal that seen from the other end.

signal (El) applied from the lower impedance source (Z1)

encounters a voltage attenuation (A1) which is greater

than 1 and less than

=

50dT 125 - 50 = 64.6

1381

E

loglo Dld, where D is the inside

Though the network in Fig. 1-4

2,

as follows:

f2

A

In the example of matching 50

The illustrated

different attenuation ratios by adding

(less than R1) between Z1 and the junction of R1 and R2.

network can be modified to provide

f2

to 125

anot.her resistor

f2.

Duration of Ramps and Pulses

The duration of ramp and pulse waveforrns is always

equal to the half-cycle time of the sine, square, or triangle

waveform frequency. For MULTIPLIER setti~ngs of 1 or

greater, the

a

duty cycle of approximately 80°/o, i.e., frequency equals

approximately 1.6X FREQUENCY

MULTIPLIER settings less than 1, the retrace/off time is

from 10 ms to 100 ms, which results in duty cycles

approaching 10O0/0; i.e., frequency equals approximately

2X FREQUENCY

retraceloff time is such that the waveform has

Hz

dial setting. For

Hz

dial setting.

---

REV.

B

JUL

1978

Page 9

OPERATION

Operating Instructions-FG

501

Free-Running Output

-A

The following procedure provides a free-running

waveform output with variable frequency and amplitude.

1. Set the AMPL control to the fully counterclockwise

position and the OFFSET control to the 0 (centered)

position. Check that the PHASE control is pushed in (off).

2.

Set the FUNCTION selector to the desired

waveform (see Fig. 1-5).

Gated (Burst) Output and Variable Phase

A gating signal of 2 to 15 V amplitude applied to the

GATE INPUT connector with the PHASE control pulled

out will provide a burst of cycles at the OUTPUT

connector. The duration of the burst and number of cycles

in the burst depend on the gating signal duration and the

output frequency selected. When the gating signal goes to

the zero level, the generator completes its last cycle and

remains quiescent until the next gating signal.

Single cycles can be obtained by applying a gating

signal with a period approximately equal to the period of

the FG 501 output waveform. The number of cycles per

burst can be approximated by dividing the gating signal

duration by the period of the FG 501 output frequency

GATE INPUT

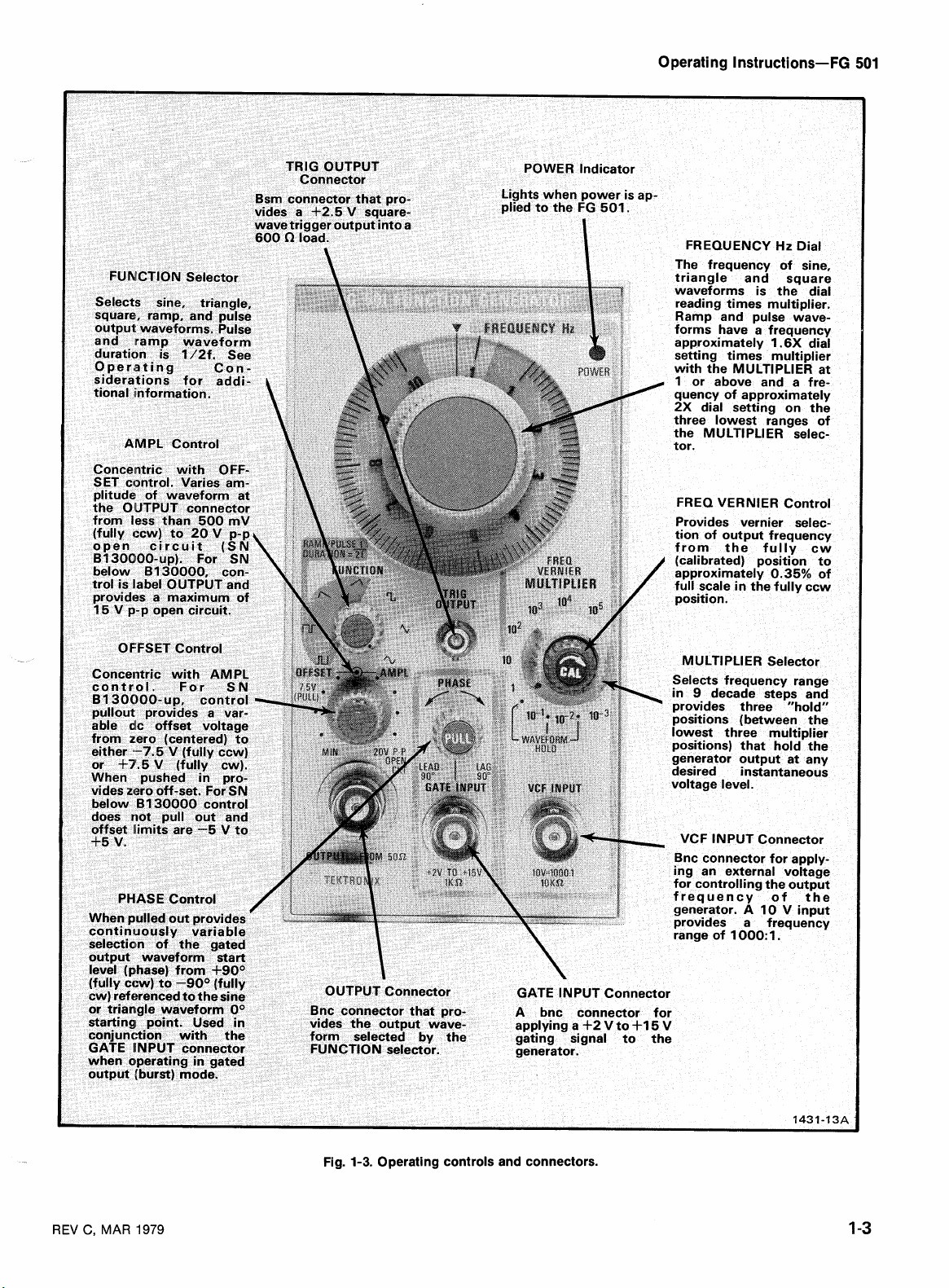

Fig.

1-5.

Output waveforms available from the

3.

Select the desired frequency with the MULTIPLIER

FG

501.

selector and FREQUENCY Hz dial. For example, if the

lo5

MULTIPLIER selector is set to the

position and the

FREQUENCY Hz dial is at 5, output frequency is 500 kHz;

X

i.e., MULTIPLIER setting

FREQUENCY Hz setting. The

output frequency is calibrated when the FREQUENCY

VERNIER control is in the fully clockwise position. The

duration of ramp and pulse waveforms is dependent on the

MULTIPLIER setting. See Duration of Ramps and Pulses

under Operating Considerations for further information.

4.

Connect the load to the OUTPUT connector and

adjust the AMPL control for the desired output amplituae.

Variable

DC

Offset

Pull outward on the OFFSETcontrol (pull switch added

at SN B020000) to position the dc level (baseline) of the

V

output waveform. For example,

+

the dc

+

12.5 V dc

dc

peak ac voltage of a 7.5 V p-p output to +5 and

.t

peak ac while -5 V of offset will reduce the

+

peak ac output to +2.5 V and -5

of offset will increase

$5

V.

GATE INPUT

GATE INPUT

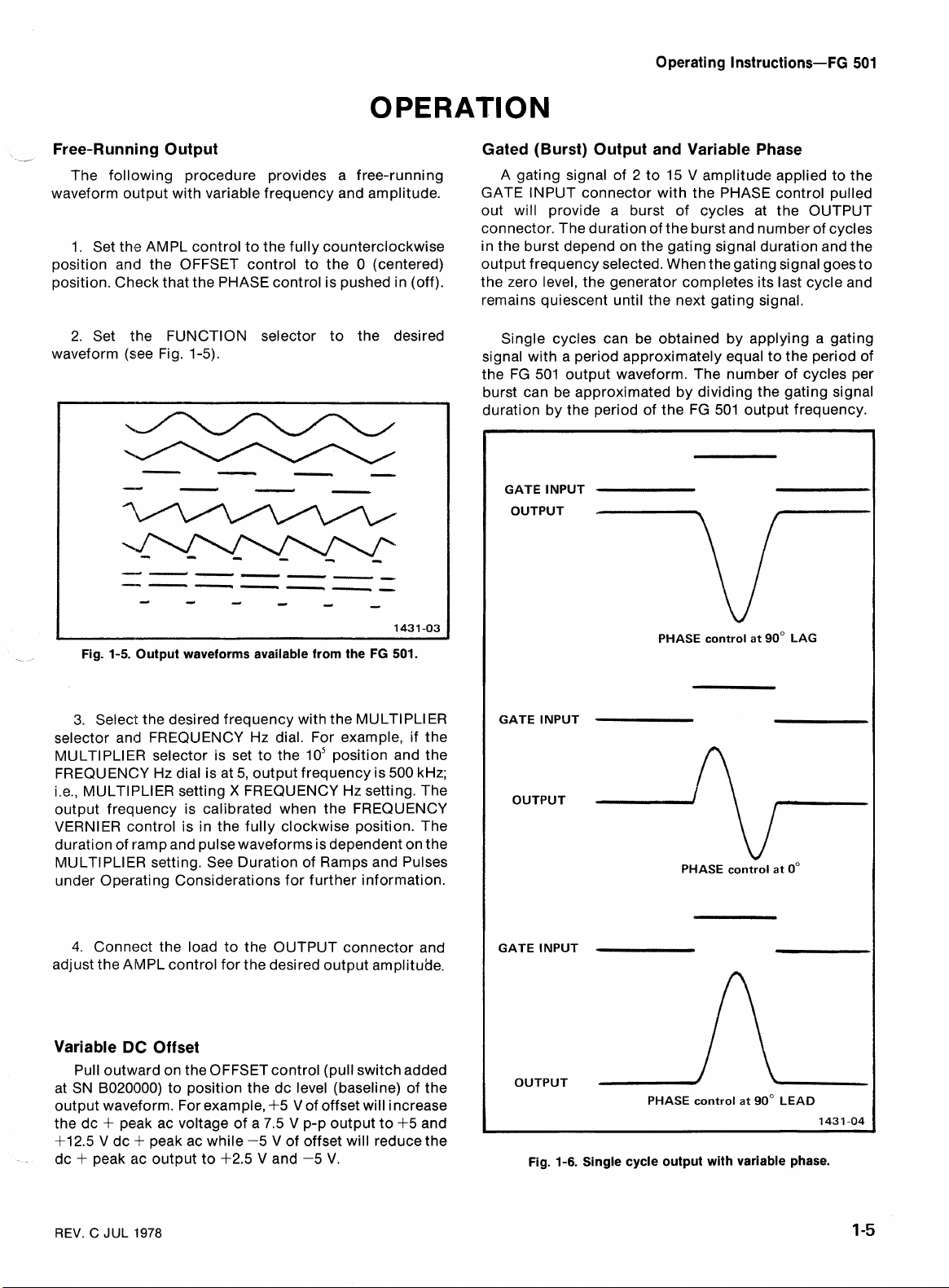

Fig.

1-6.

control at

PHASE

PHASE

PHASE

control at

Single cycle output with variable phase.

90"

control at

90"

LAG

0"

LEAD

1

43

1

-04

REV.

C

JUL

'1978

Page 10

Operating Instructions-FG

501

The phase (start level) of the waveform burst can be

varied +90° by pulling out and turning the PHASEcontrol

either counterclockwise or clockwise from the 0

(centered) position (see Fig. 1-6). The phase of theoutput

burst is referenced to the sine or triangle waveform 0° start

point.

Output frequency can be varied during the burst

duration by

applying a voltage-controlled frequency

(VCF) signal to the VCF INPUT connector.

Voltage-Controlled Frequency (VCF) Output

The output frequency of any selected waveform can be

swept within a range of 1000:l by applying a 0 to 10 V

signal to the VCF INPUT connector. The polarity of the

VCF input signal determines which direction the output

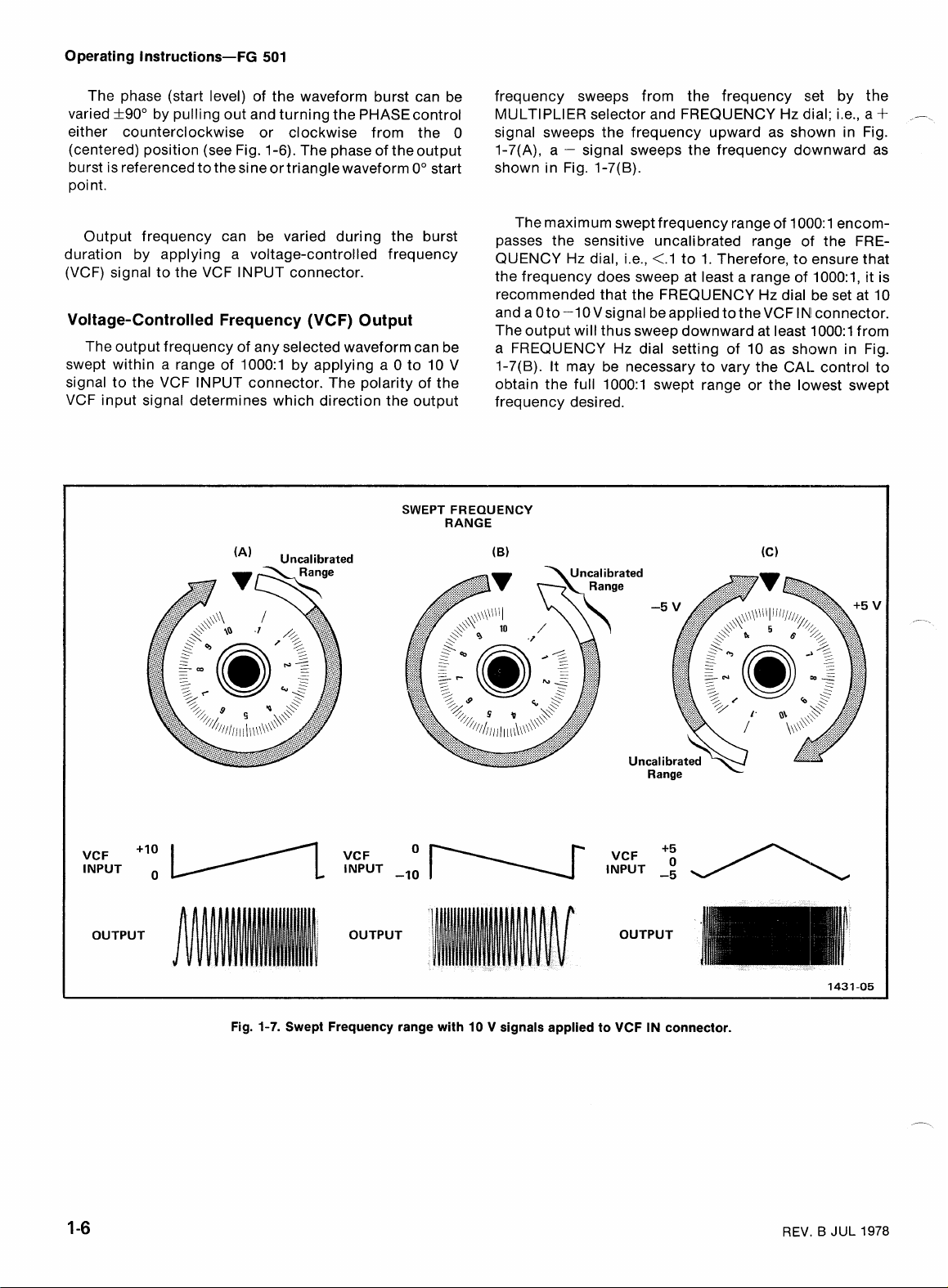

SWEPT FREQUENCY

RANGE

(A) Uncalibrated

frequency sweeps from the frequency

MULTIPLIER selector and FREQUENCY Hz dial; i.e., a

slet by the

+

signal sweeps the frequency upward as shown in Fig.

-

1-7(A), a

signal sweeps the frequency doiwnward as

shown in Fig. 1-7(B).

The maximum swept frequency range of 1000: 1 encompasses the sensitive uncalibrated range of the FREQUENCY Hz dial, i.e., <.l to 1. Therefore, to ensure that

the frequency does sweep at least a range of 1000:1, it is

recommended that the FREQUENCY Hz dial be set at 10

IN1

and a Oto -1OVsignal beapplied to theVCF

connector.

The output will thus sweep downward at least 1000:l from

a FREQUENCY Hz dial setting of 10 as shown in Fig.

1-7(B). It may be necessary to vary the CAL control to

obtain the full 1000:l swept range or the lowest swept

frequency desired.

,-,

VCF

INPUT INPUT

OUTPUT OUTPUT OUTPUT

Fig.

1-7.

Swept Frequency range with

10

V signals applied to VCF

INPUT

-5

IN

connector.

REV.

B

JUL

1978

Page 11

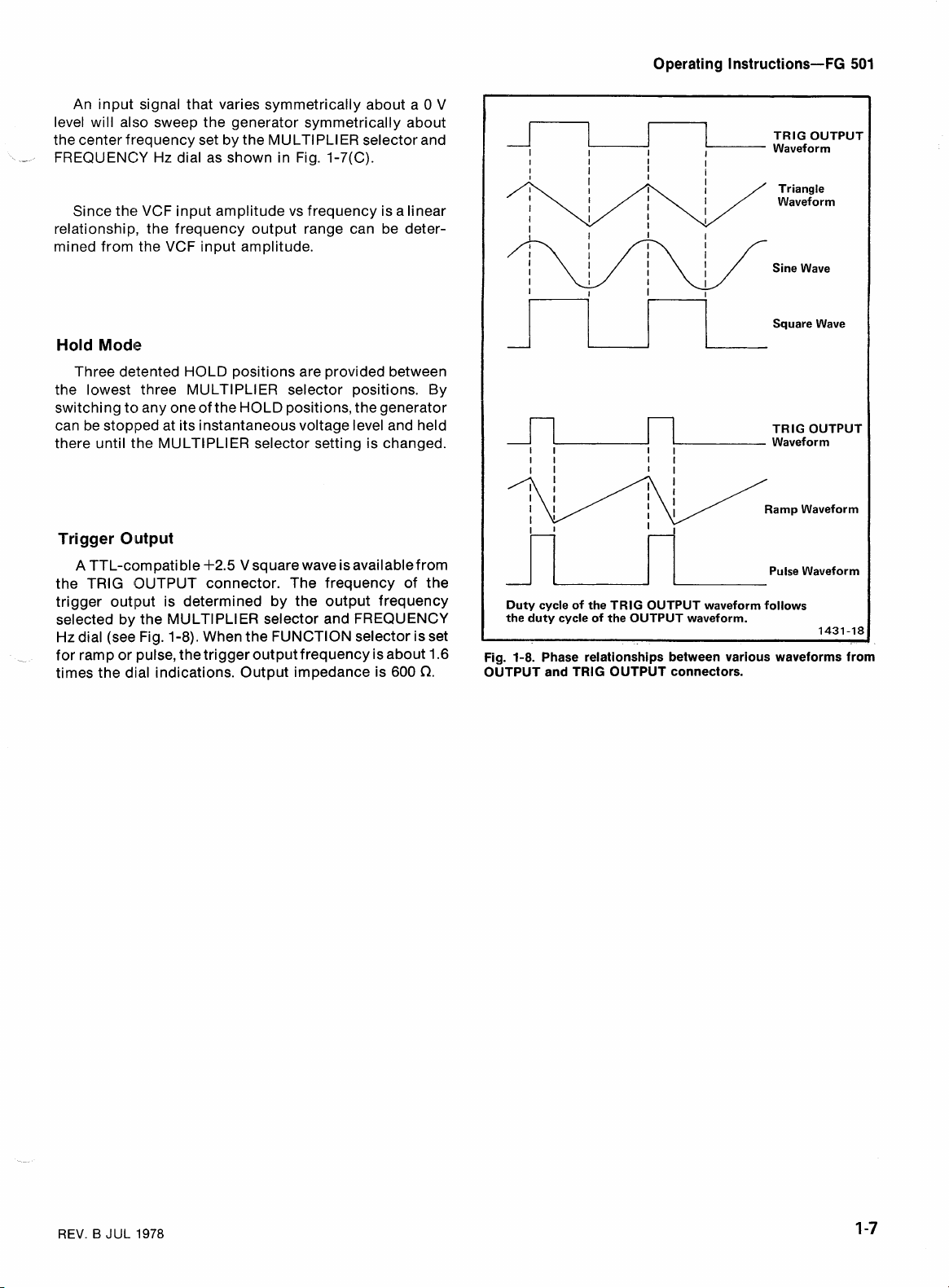

An input signal that varies symmetrically about a 0 V

level will also sweep the generator symmetrically about

the center frequency set by the MULTIPLIER selector and

-

FREQUENCY Hz dial as shown in Fig. 1-7(C).

Since the VCF input amplitude vs frequency is a linear

relationship, the frequency output range can be determined from the VCF input amplitude.

Operating Instructions-FG

Triangle

Waveform

I

I

I

I

I

I

I

Sine Wave

501

Hold

Mode

Three detented HOLD positions are provided between

the lowest three MULTl PLl ER selector positions. By

switching to any one of the HOLD positions, the generator

can be stop~ped at its instantaneous voltage level and held

there until the MULTIPLIER selector setting is changed.

Trigger

Olutput

A

TTL-corn pati

ble

+

2.5

V square wave is available from

the TRlG (OUTPUT connector. The frequency of the

trigger

outlput is determined by the output frequency

selected by the MULTIPLIER selector and FREQUENCY

Hz dial (see Fig. 1-8). When the FUNCTION selector is set

for ramp or pulse, the trigger output frequency

.

times the dial indications. Output impedance is 600

is

about 1.6

n.

I

I

I

Duty cycle of the TRlG OUTPUT waveform follows

the duty cycle of the OUTPUT waveform.

Fig. 1-8. Phase relationships between various waveforms from

OUTPUT

and

TRlG OUTPUT

I

I

connectors.

Square Wave

lG

OUTPUT

TR

Waveform

Ramp Waveform

1431-18

REV. B JUL

1978

Page 12

Operating Instructions-FG 501

APPLICATIONS

Response

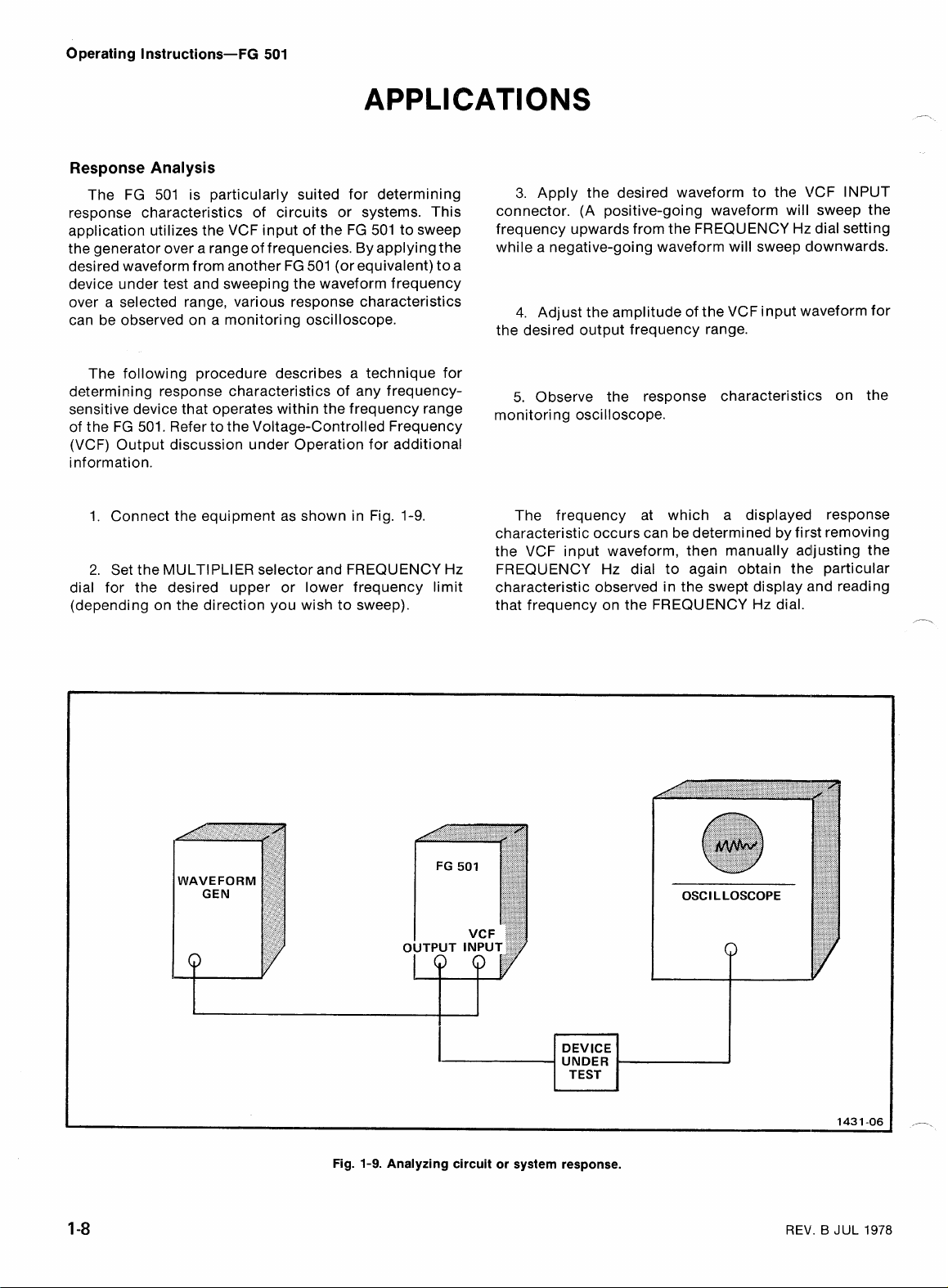

The FG 501 is particularly suited for determining

response characteristics of circuits or systems. This

application utilizes the VCF input of the FG 501 to sweep

the generator over a range of frequencies. By applying the

desired waveform from another FG 501 (or equivalent) to a

device under test and sweeping the waveform frequency

over a selected range, various response characteristics

can be observed on a monitoring oscilloscope.

The following procedure describes a technique for

determining response characteristics of any

sensitive device that operates within the frequency range

of the FG 501. Refer to the Voltage-Controlled Frequency

(VCF) Output discussion under Operation for additional

information.

1. Connect the equipment as shown in Fig. 1-9.

2.

dial for the desired upper or lower frequency limit

(depending on the direction you wish to sweep).

Analysis

frequency-

Set the MULTl PLl ER selector and FREQUENCY Hz

3.

Apply the desired waveform to the VCF INPUT

connector. (A positive-going waveform will sweep the

frequency upwards from the FREQUENCY Hz dial setting

while a negative-going waveform will sweep clownwards.

4.

Adjust the amplitude of the VCF input waveform for

the desired output frequency range.

5. Observe the response characteristics on the

monitori ng oscilloscope.

The frequency at whi

characteristic occurs can be determined by first removing

the VCF input waveform, then manually adljusting the

FREQUENCY Hz dial to again obtain the particular

characteristic observed in the swept display and reading

that frequency on the FREQUENCY Hz dial.

splayed respon

WAVEFORM

Fig.

I

,

1-9.

Analyzing circuit or system response.

UNDER

TEST

1

REV. B JUL

1978

Page 13

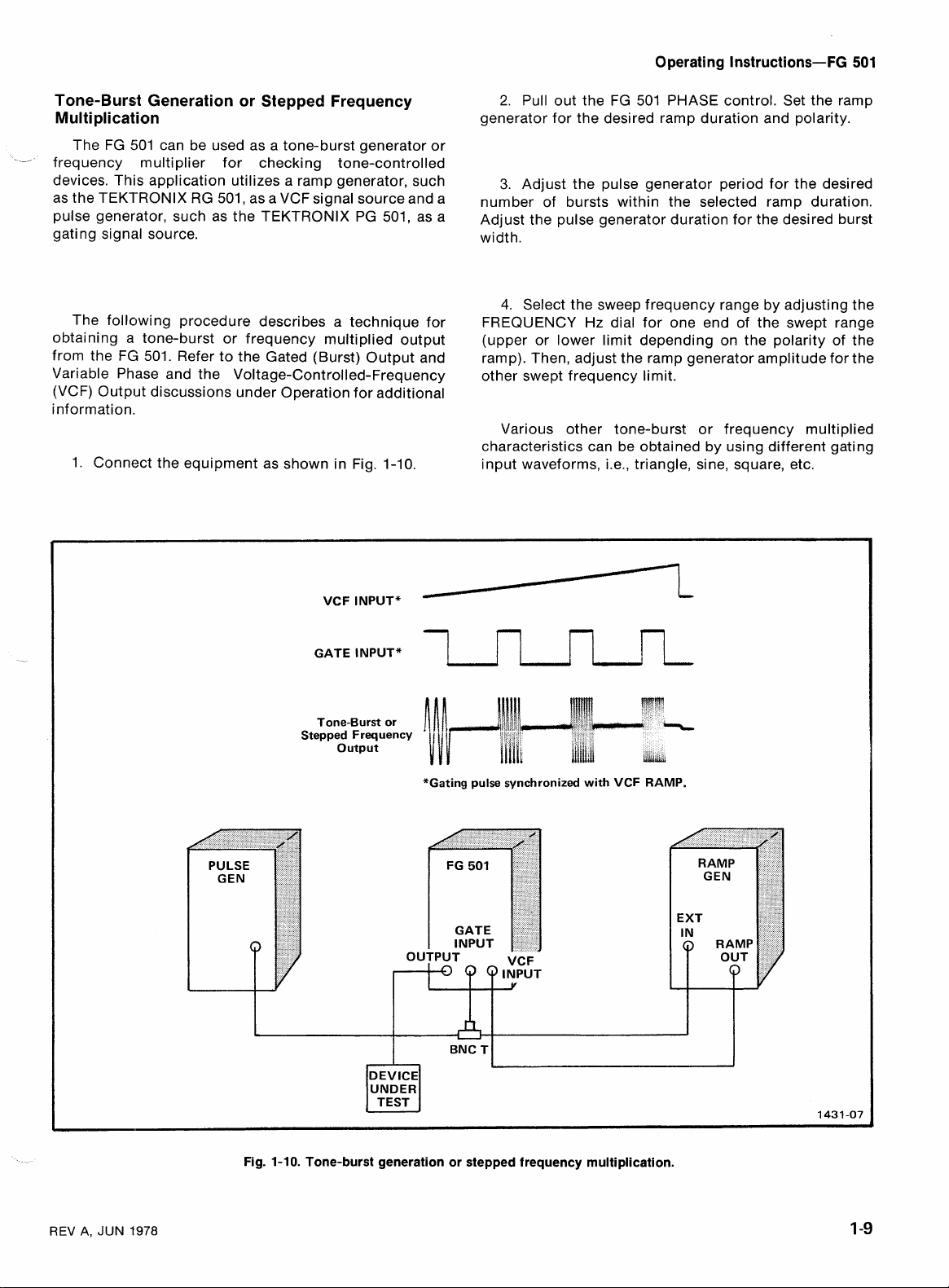

Tone-Burst Generation or Stepped Frequency

Multiplication

\

._

The FG 501 can be used as a tone-burst generator or

frequency multiplier for checking tone-controlled

devices. This application utilizes a ramp generator, such

as the TEKTRONIX RG 501, as a VCF signal source and a

pulse generator, such as the TEKTRONIX PG 501, as a

gating signal source.

Operating Instructions-FG

2.

Pull out the FG 501 PHASE control. Set the ramp

501

generator for the desired ramp duration and polarity.

3.

Adjust the pulse generator period for the desired

number of bursts within the selected ramp duration.

Adjust the pulse generator duration for the desired burst

width.

The following procedure describes a technique for

obtaining a tone-burst or frequency multiplied output

from the FG 501. Refer to the Gated (Burst) Output and

Variable Phase and the Voltage-Controlled-Frequency

(VCF) Output discussions under Operation for additional

information.

1. Connect the equipment as shown in Fig. 1-10.

VCF INPUT*

GATE INPUT*

Tone-Burst or

Stepped Frequency

Output

4. Select the sweep frequency range by adjusting the

Hz

FREQUENCY

dial for one end of the swept range

(upper or lower limit depending on the polarity of the

ramp). Then, adjust the ramp generator amplitude for the

other swept frequency limit.

Various other tone-burst or frequency multiplied

characteristics can be obtained by using different gating

input waveforms, i.e., triangle, sine, square, etc.

UUUL

REV

A,

JUN

1978

PULSE

GEN

Fig.

*Gating pulse synchronized with VCF RAMP.

DEVICE

UNDER

1-10.

Tone-burst generation or stepped frequency multiplication.

Page 14

Page 15

Section

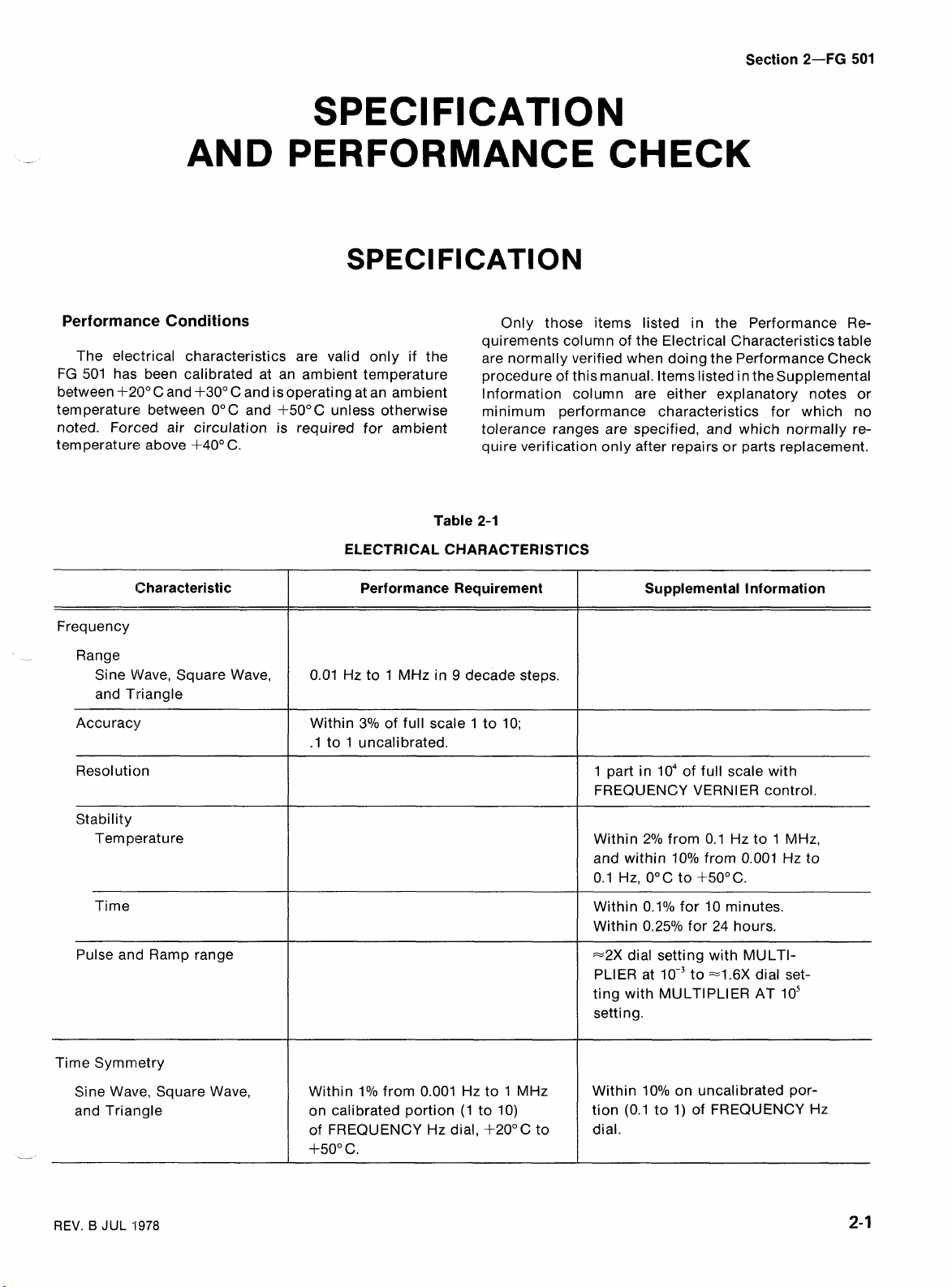

SPECIFICATION

AND PERFORMANCE CHECK

SPECIFICATION

2-FG

501

Performar~ce Conditions

The electrical characteristics are valid only if the

FG 501 has been calibrated at an ambient temperature

between +20° C and +30° C and is operating at an ambient

tem perature between 0" C and +50° C unless otherwise

noted. Forced air circulation is required for ambient

tem

perat ure above 4-40' C.

Table

ELECTRICAL CHARACTERISTICS

Characteristic

Frequency

Range

Sine VVave, Square Wave,

and Tiriangle

Accuracy

Resolution

--

Performance Requirement

0.01

Hz

to 1

Within 3% of full scale 1 to 10;

.1 to 1 uncalibrated.

-

MHz

in 9 decade steps.

Only those items listed in the Performance Requirements column of the Electrical Characteristics table

are normally verified when doing the Performance Check

procedure of this manual. Items listed in the Supplemental

lnformation column are either explanatory notes or

minimum performance characteristics for which no

tolerance ranges are specified, and which normally re-

quire verification only after repairs or parts replacement.

2-1

--

-

Supplemental lnformation

1 part in

FREQUENCY VERNl ER control.

lo4

of full scale with

Stability

Tem perature

Time

Pulse and Ramp range

Time

Symmetry

Sine Wave, Square Wave,

and Triangle

REV.

6

JUL

'1978

Within 1% from 0.001

on calibrated portion (1 to 10)

of FREQUENCY

+50° C.

Hz

to 1 MHz

Hz

dial, +20°C to

Within 2% from 0.1

and within 10% from 0.001

Hz,

0.1

Within 0.1% for 10 minutes.

Within 0.25% for 24 hours.

=2X dial setting with MULTI-

PLIER at

ting with MULTIPLIER AT

setting.

Within 10% on uncalibrated portion (0.1 to 1) of FREQUENCY

dial.

0° C to +SO0 C.

Hz

to 1 MHz,

Hz

to +.6X dial set-

lo5

to

Hz

Page 16

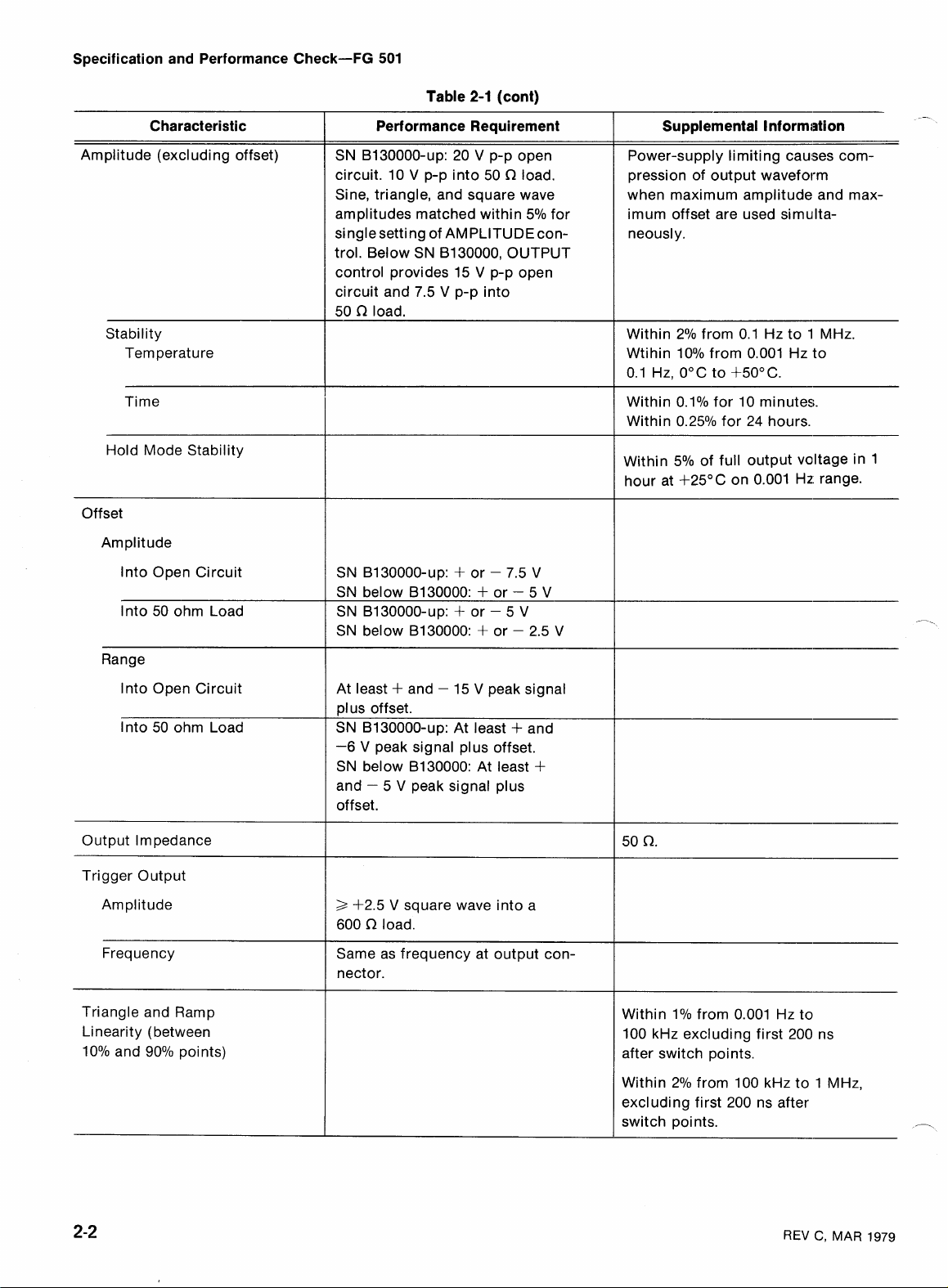

Specification and Performance Check-FG

Characteristic

501

Table

2-1

(cont)

Performance Requirement

Supplemental I nformiation

--

Amplitude (excluding offset)

Stability

Temperature

Time

Hold Mode Stability

Offset

Amplitude

Into Open Circuit

Into 50 ohm Load

SN B130000-up: 20 V p-p open

V

circuit. 10

Sine, triangle, and square wave

amplitudes matched within

single setting of AMPLlTUDEcontrol. Below SN B130000, OUTPUT

control provides 15

circuit and 7.5

fl

load.

50

SN B130000-up:

SN below 8130000: + or - 5

SN B130000-up: + or - 5

SN below B130000: + or - 2.5

p-p into 50

V

p-p into

+

fl

V

p-p open

or - 7.5

load.

5% for

V

V

V

V

Power-supply limiting causes compression of output waveform

when maximum amplitude and max-

imum offset are used

neousl y.

Within 2% from 0.1 Hz to 1 MHz.

Wtihin

0.1 Hz, 0°C to

Within 0.1% for 10 minutes.

Within 0.25% for 24 hours.

Within 5% of full output voltage in 1

hour at +25OC on 0.001

10% from 0.001 Hz to

+SO0

simu~lta-

C.

Hz:

range.

Range

Into Open Circuit

Into 50 ohm Load

Output Impedance

Trigger Output

Amplitude

Frequency

Triangle and Ramp

Linearity (between

10% and 90% points)

I

At least

plus offset.

SN B130000-up: At least

-6

SN below B130000: At least

and

offset.

3

600

Same as frequency at output

nector.

+

and - 15 V peak signal

V

peak signal plus offset.

-

5 V peak signal plus

+2.5 V square wave into a

n

load.

+

and

+

con-

I

n.

50

Within

100 kHz excluding first 200 ns

after switch points.

Within

excluding first 200 ns after

switch points.

1% from 0.081 Hz to

2% from 100 kHz to 1 MHz,

-

REV

C,

MAR

1979

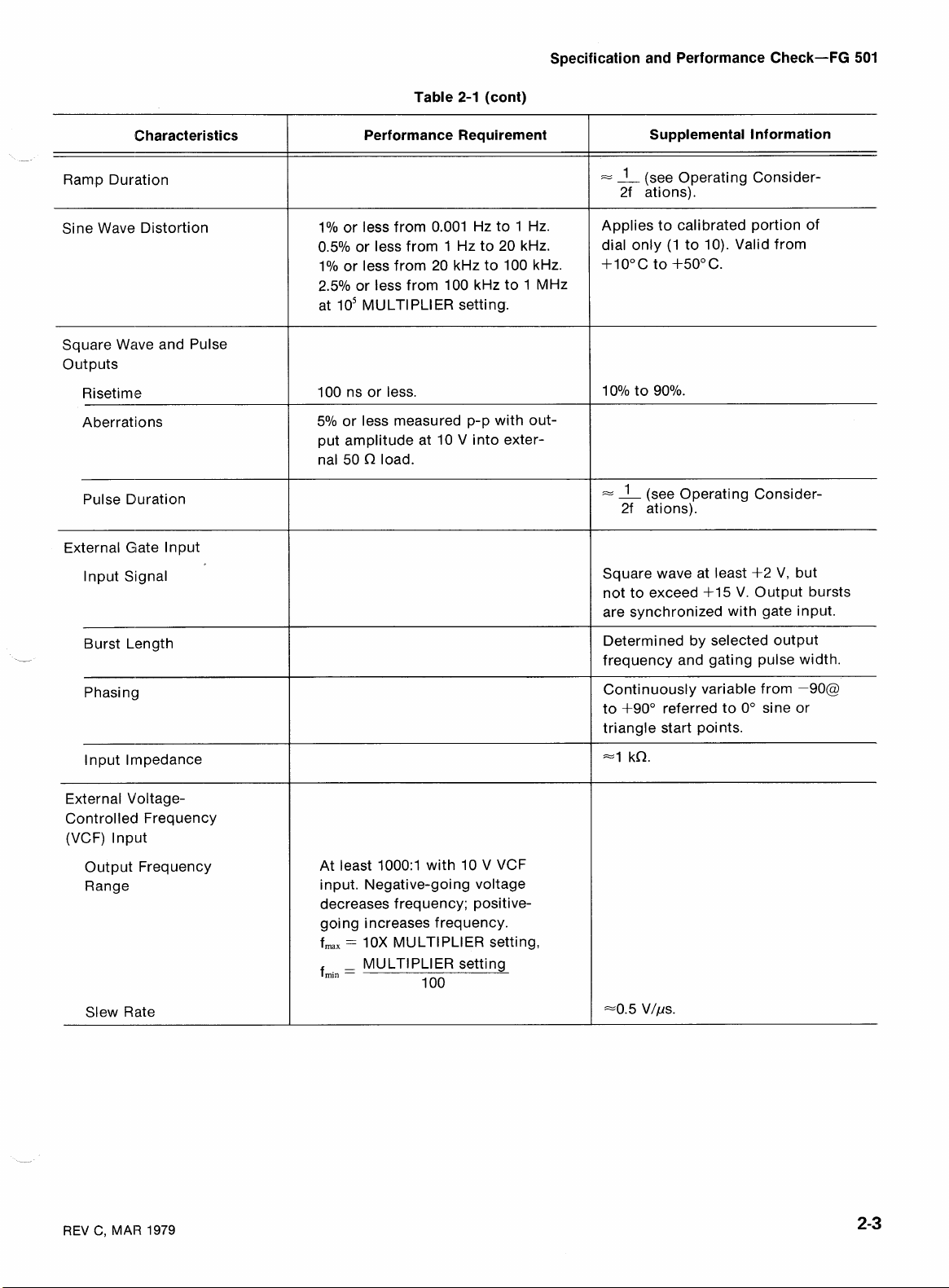

Page 17

Table

2-1

Specification and Performance Check-FG 501

(cont)

characteristics

-

Ramp Duration

Sine Wave Distortion

Square Wave and Pulse

Outputs

Aberrations

Pulse Dluration

External Gate lnput

lnput Signal

Performance Requirement

1% or less from 0.001 Hz to 1 Hz.

0.5% or less from 1 Hz to 20 kHz.

1% or less from 20 kHz to 100 kHz.

2.5% or less from 100 kHz to 1 MHz

at

10' MULTIPLIER setting.

100 ns or less.

5% or less measured p-p with out-

put amplitude at 10 V into exter-

0

nal 50

load.

Supplemental Information

--

(see Operating Consider-

2f ations).

Applies to calibrated portion of

dial only (1 to 10). Valid from

+lO°C to +50°C.

=

1

(see Operating Consider-

2f ations).

Square wave at least +2 V, but

not to exceed +15 V. Output bursts

are synchronized with gate input.

Burst Length

Phasing

lnput lrnpedance

External V'oltageControlled Frequency

(VCF) lnput

Output Frequency

Range

Slew Rate

At least 1000:l with 10 V VCF

input. Negative-going voltage

decreases frequency; positivegoing increases frequency.

f,,

=

10X MULTIPLIER setting,

MULTl PLl ER setting

f.

=

mln

100

Determined by selected output

frequency and gating pulse width.

Continuously variable from -90@

to +90° referred to 0° sine or

triangle start points.

REV

C,

MAR

1979

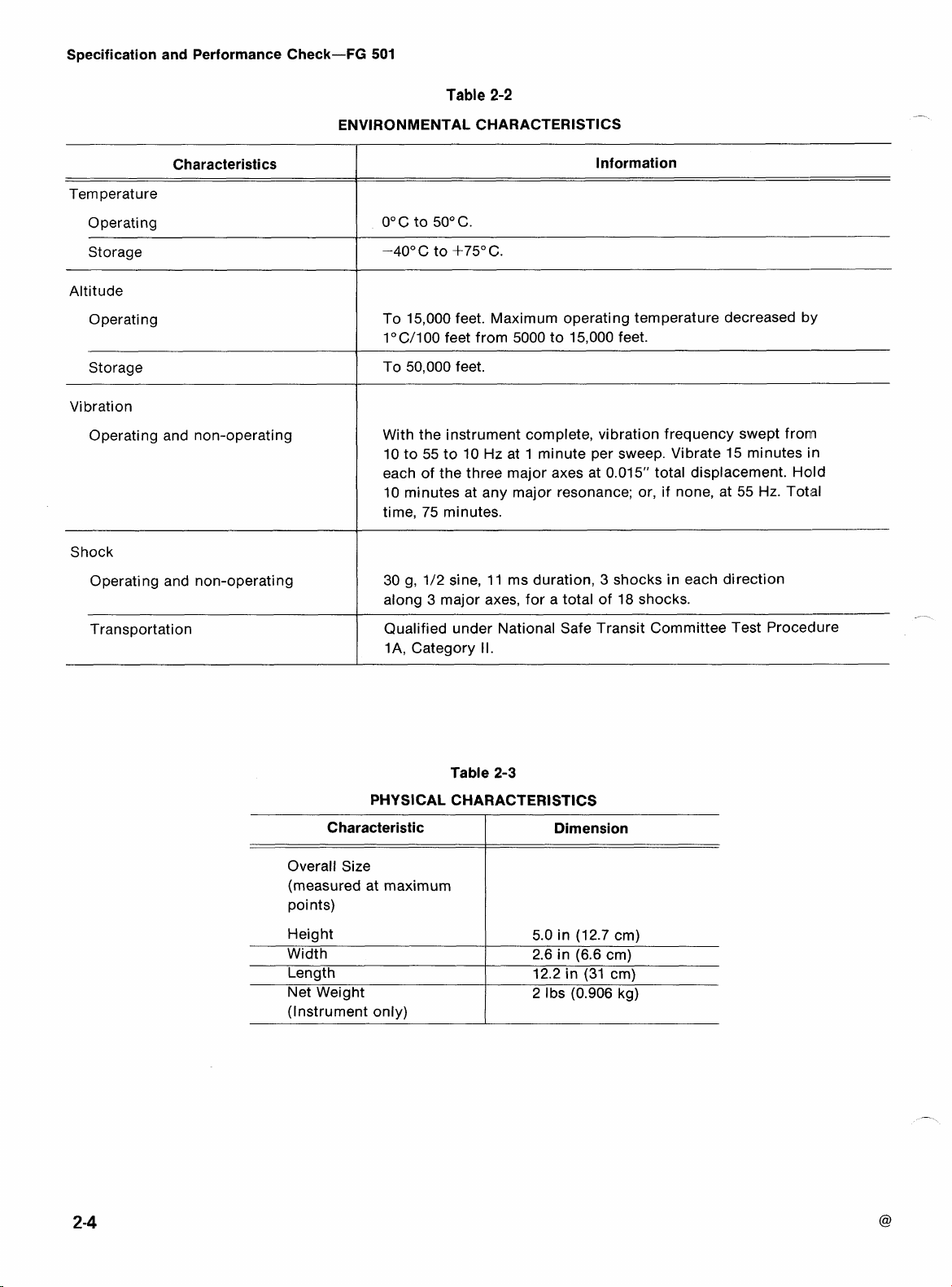

Page 18

Specification and Performance Check-FG

ENVIRONMENTAL CHARACTERISTICS

501

Table

2-2

Characteristics

Tern perat ure

Operating

Storage

Altitude

Operating

Storage

Vibration

Operating and non-operating

Shock

Operating and non-operating

Transportation

Information

To 15,000 feet. Maximum operating temperature decreased by

1

O

C/100 feet from 5000 to 15,000 feet.

-

To 50,000 feet.

With the instrument complete, vibration frequency swept from

10 to 55 to 10 Hz at 1 minute per sweep. Vibrate 15 minutes in

each of the three major axes at 0.015" total displacement. Holld

10 minutes at any major resonance; or, if none, at 55 Hz. Totid

time, 75 minutes.

30 g, 1/2 sine, 11 ms duration, 3 shocks in each direction

along 3 major axes, for a total of 18 shocks.

Qualified under National Safe Transit Committee Test Procedure

1A, Category

11.

-

-

PHYSICAL CHARACTERISTICS

Characteristic

Overall Size

(measured at maximum

points)

Height

Width

Length

Net Weight

(Instrument only)

Table 2-3

I

Dimension

5.0 in (12.7 cm)

2.6 in (6.6

12.2 in (31

cm)

em)

2 Ibs (0.906 kg)

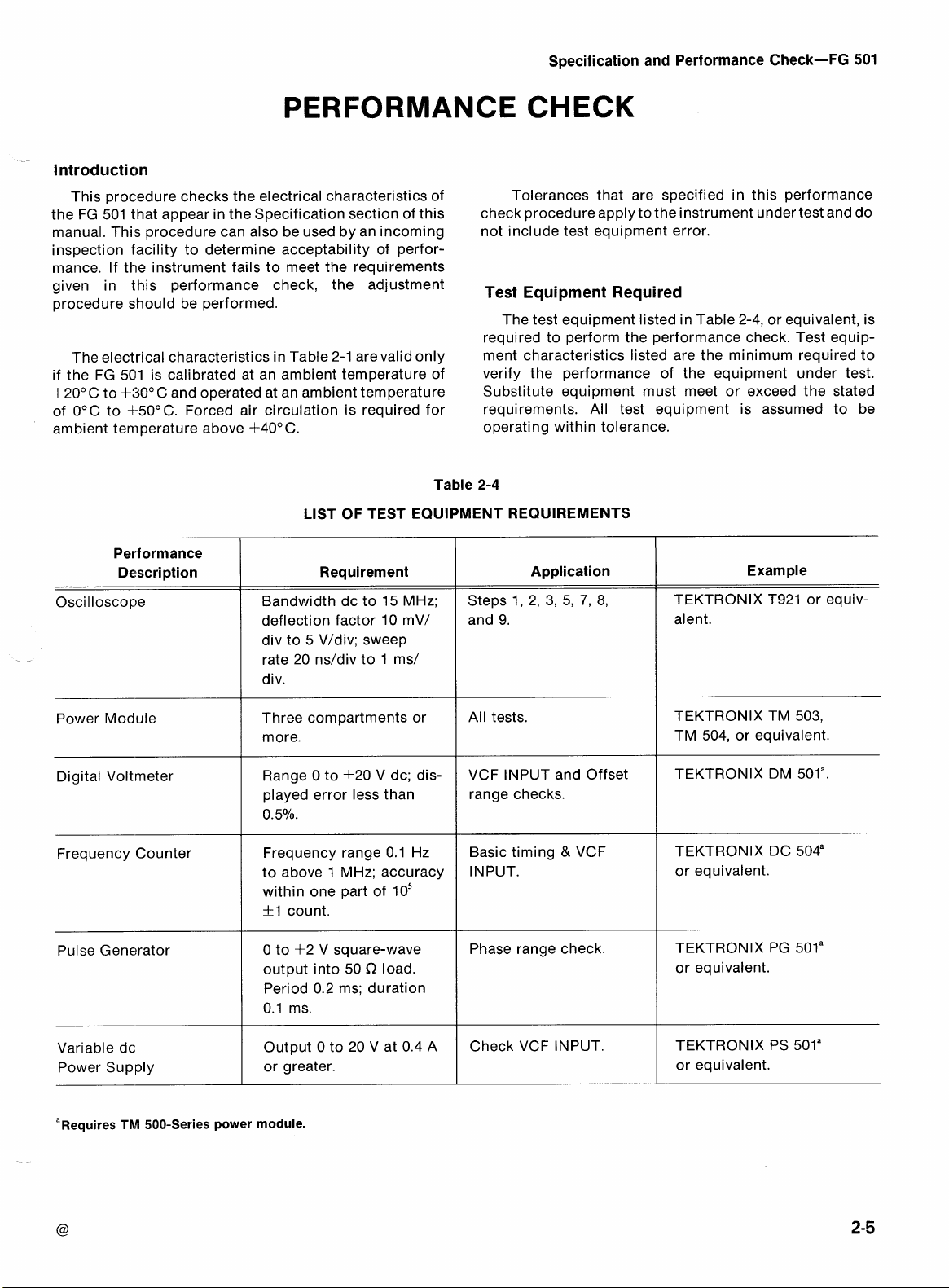

Page 19

PERFORMANCE CHECK

Introduction

This procedure checks the electrical characteristics of

the FG 501 that appear in the Specification section of this

manual. Thils procedure can also be used by an incoming

inspection facility to determine acceptability of performance. If the instrument fails to meet the requirements

given in this performance check, the adjustment

procedure should be performed.

The electrical characteristics in Table 2-1

if the FG

+20°C to +:30° C and operated at an ambient temperature

of 0°C to 4-50°C. Forced air circulation is required for

ambient temperature above +40° C.

5011 is calibrated at an ambient temperature of

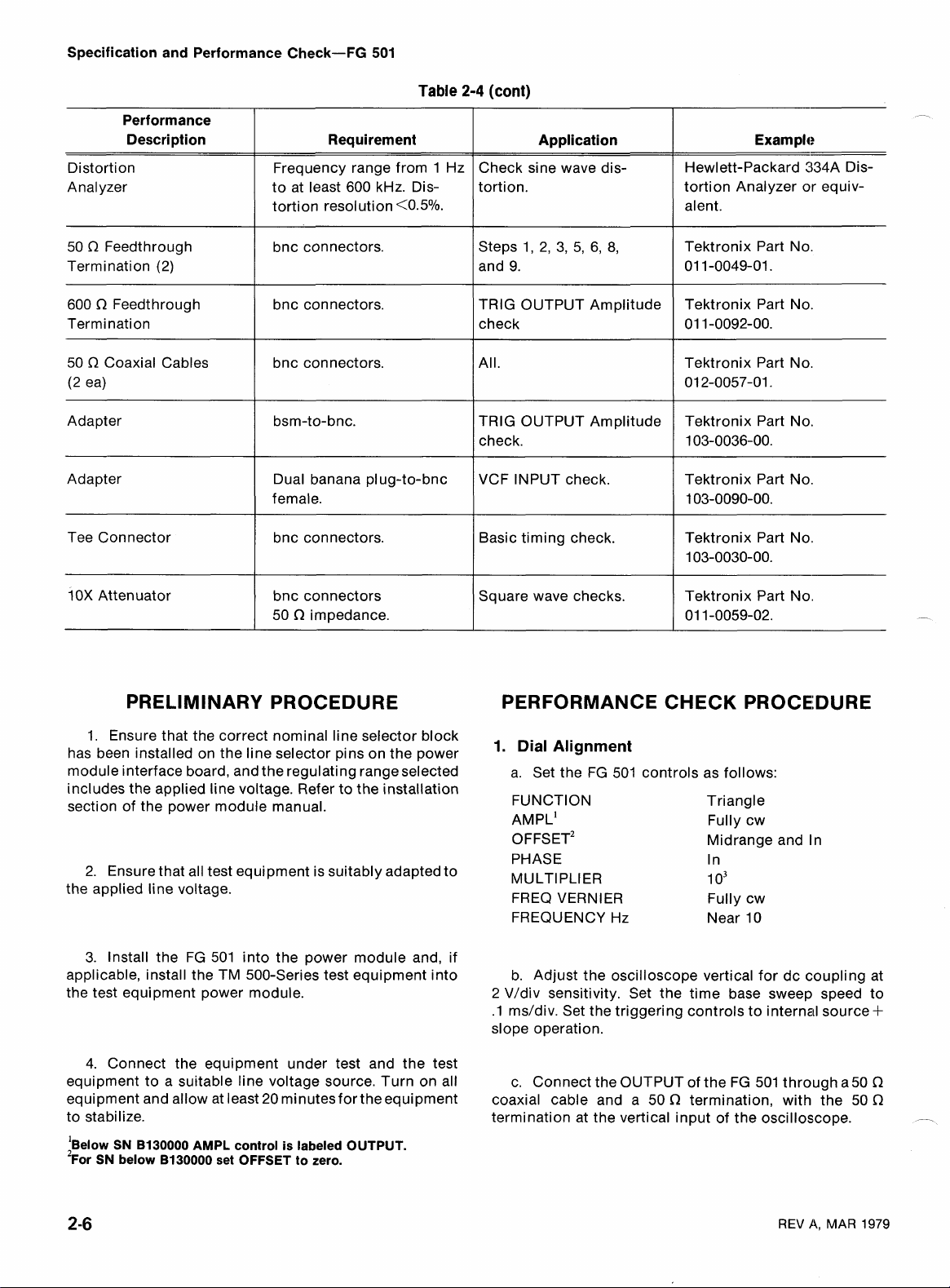

LIST

arevalid only

Table

OF

TEST EQUIPMENT REQUIREMENTS

Specification and Performance Check-FG

Tolerances that are specified in this performance

check procedure apply to the instrument under test and do

not include test equipment error.

Test Equipment Required

The test equipment listed in Table 2-4, or equivalent, is

required to perform the performance check. Test equipment characteristics listed are the minimum required to

verify the performance of the equipment under test.

Substitute equipment must meet or exceed the stated

requirements. All test equipment is assumed to be

operating within tolerance.

2-4

501

Performance

Description

Oscilloscope

Power Module

Digital Voltmeter

Frequency Counter

Pulse Generator

Requirement

Bandwidth dc to 15 MHz;

deflection factor 10 mV/

div to 5 V/div; sweep

rate 20 ns/div to 1 ms/

div.

Three compartments or

more.

Range 0 to +20 V dc; displayed error less than

0.5O/o.

Frequency range 0.1 Hz

to above 1 MHz; accuracy

within one part of

+1 count.

0 to +2 V square-wave

output into 50 load.

Period 0.2 ms; duration

0.1 ms.

lo5

Application

Steps 1, 2, 3,

and 9.

All tests.

VCF INPUT and Offset

range checks.

Basic timing

IN PUT.

Phase range check.

5,

&

7,

VCF

8,

Example

TEKTRONIX T921 or equivalent.

TEKTRONIX TM 503,

TM 504, or equivalent.

TEKTRONIX DM

TEKTRONIX DC 504"

or equivalent.

TEKTRONIX PG 501"

or equivalent.

501a

Variable dc

Power Supply

"~equires

Thll

Output 0 to 20 V at 0.4

or greater.

500-Series power module.

Check VCF INPUT

A

TEKTRONIX PS 501"

or equivalent.

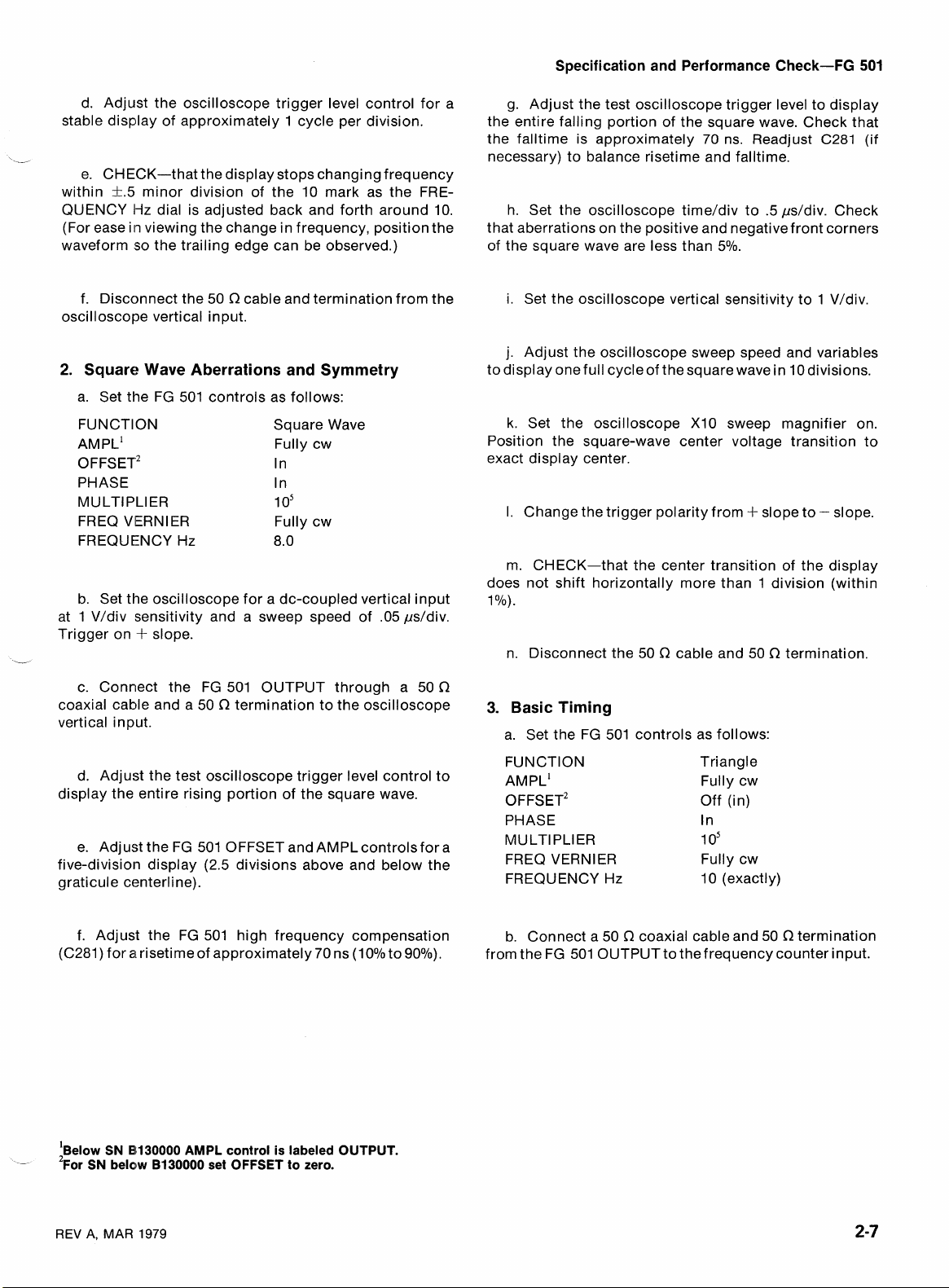

Page 20

Specification and Performance Check-FG

Performance

Distortion

Analyzer

to at least 600 kHz. Distortion resolution <0.5O/o.

501

Table

2-4

(cont)

Application

Check sine wave dis-

tortion.

Example

Hewlett-Packard 334~ Distortion Analyzer or equivalent.

50

R

Feedthrough

Termination (2)

600

R

Feedt hroug h

Termination

50

R

Coaxial Cables

(2 ea)

Adapter bsm-to-bnc.

Adapter

Tee Connector

IOX

Attenuator

bnc connectors. Steps 1, 2, 3, 5, 6,

bnc connectors.

bnc connectors.

Dual banana plug-to-bnc

female.

bnc connectors.

bnc connectors

50

R

impedance.

PRELIMINARY PROCEDURE PERFORMANCE CHECK PROCEDURE

8,

and 9.

TRIG OUTPUT Amplitude

check

All.

TRIG OUTPUT Amplitude

check.

VCF INPUT check. Tektronix Part No.

Basic timing check.

Square wave checks.

Tektronix Part No.

01 1-0049-01.

Tektronix Part No.

01 1-0092-00.

Tektronix Part No.

01 2-0057-01.

Tektronix Part No.

103-0036-00.

103-0090-00.

Tektronix Part No.

103-0030-00.

Tektronix Part No.

01 1-0059-02.

1. Ensure that the correct nominal line selector block

has been installed on the line selector pins on the power

module interface board, and the regulating range selected

includes the applied line voltage. Refer to the installation

section of the power module manual.

2. Ensure that all test equipment is suitably adapted to

the applied line voltage.

3.

Install the FG 501 into the power module and, if

applicable, install the TM 500-Series test equipment into

the test equipment power module.

4. Connect the equipment under test and the test

equipment to a suitable line voltage source. Turn on all

equipment and allow at least 20 minutes for the equipment

to stabilize.

mi el ow

SN

2~or SN below

B130000

AMPL control is labeled OUTPUT.

B130000

set OFFSET to zero.

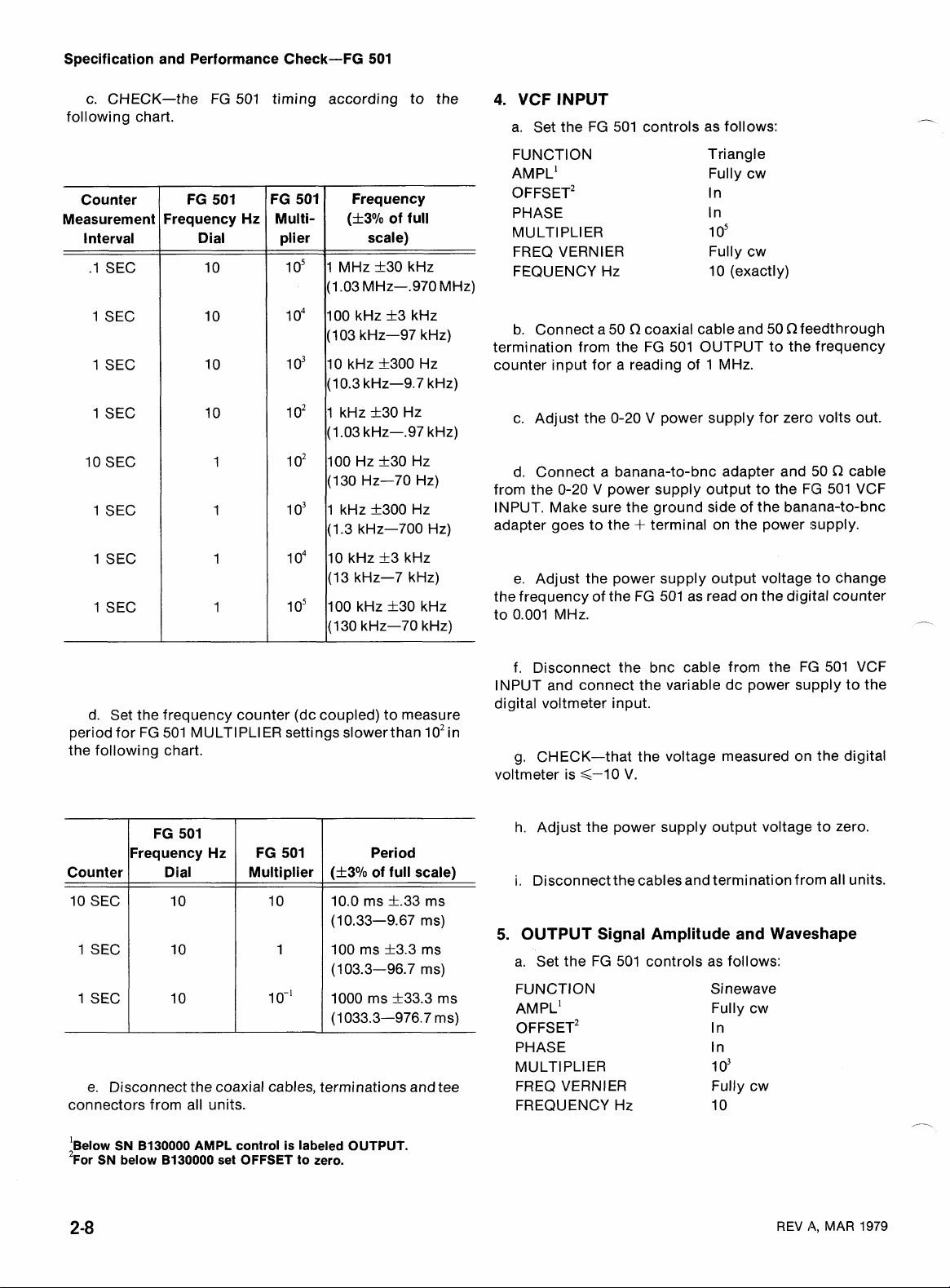

1.

Dial Alignment

a. Set the FG 501 controls as follows:

FUNCTION Triangle

AMPL'

OFFSET^

PHASE

MULTIPLIER 1

FREQ VERNIER Fully cw

FREQUENCY Hz Near 10

b. Adjust the oscilloscope vertical for dc coupling at

2 V/div sensitivity. Set the time base sweep speed to

.1 ms/div. Set the triggering controls to internad source+

slope operation.

c. Connect the OUTPUT of the FG 501 through a 50

coaxial cable and a 50 R termination, with the 50

termination at the vertical input of the oscilloscope.

FUIIY

cw

Midrange and In

In

o3

R

R

-

REV

A,

MAR

1979

Page 21

Specification and Performance Check-FG

501

\---

d. Adjust the oscilloscope trigger level control for a

stable display of approximately 1 cycle per division.

e. CHECK-that the display stops changing frequency

within k.5 minor division of the 10 mark as the FREQUENCY Hz dial is adjusted back and forth around 10.

(For ease in viewing the change in frequency, position the

waveform :so the trailing edge can be observed.)

f. Disconnect the 50

oscilloscope vertical input.

2.

Square Wave Aberrations and Symmetry

a. Set the FG 501 controls as follows:

FUNCTION

AMPL'

OFFSET'^

PHASE

MULTIPLIER

FREQ VIERNIER Fully cw

FREQUEINCY Hz 8.0

b. Set the oscilloscope for a dc-coupled vertical input

at 1 V/div sensitivity and a sweep speed of .05 pddiv.

Trigger on

+

slope.

R

cable and termination from the

Square Wave

FUIIY

cw

In

In

I

o5

g. Adjust the test oscilloscope trigger level to display

the entire falling portion of the square wave. Check that

the

falltime is approximately 70 ns. Readjust

necessary) to balance risetime and falltime.

h. Set the oscilloscope

that aberrations on the positive and negative front corners

of the square wave are less than 5%.

i. Set the oscilloscope vertical sensitivity to 1 V/div.

j. Adjust the oscilloscope sweep speed and variables

to display one full

k. Set the oscilloscope

Position the square-wave center voltage transition to

exact display center.

I. Change the trigger polarity from

m. CHECK-that the center transition of the display

does not shift horizontally more than 1 division (within

1

O/o)

.

n. Disconnect the 50 R cable and 50 R termination.

cycleof the square wave in 10 divisions.

time/div to .5 ps/div. Check

XI0 sweep magnifier on.

f

slope to - slope.

C281

(if

c. Connect the FG 501 OUTPUT through a 50

coaxial cable and a 50 R termination to the oscilloscope

vertical input.

d. Adjust the test oscilloscope trigger level control to

display the entire rising portion of the square wave.

e. Adjust the FG 501 OFFSET and AMPL controlsfor a

five-division display (2.5 divisions above and below the

graticule centerline).

f. Adjust the FG 501 high frequency compensation b. Connect a 50

ai

(C281) for

th el ow

-

2~or SN belajw B130000 set OFFSET to zero.

risetime of approximately 70 ns (10% to 90%).

SN 81130000 AMPL control

is

labeled OUTPUT.

R

3.

Basic Timing

a. Set the FG 501 controls as follows:

FUNCTION Triangle

AMPL'

OFFSET^

PHASE

MULTIPLIER 1

FREQ VERNIER Fully cw

FREQUENCY Hz 10 (exactly)

R

coaxial cable and 50 R termination

from the FG 501 OUTPUT to the frequency counter input.

FUIIY

cw

Off (i n)

In

o5

REV A, MAR

1979

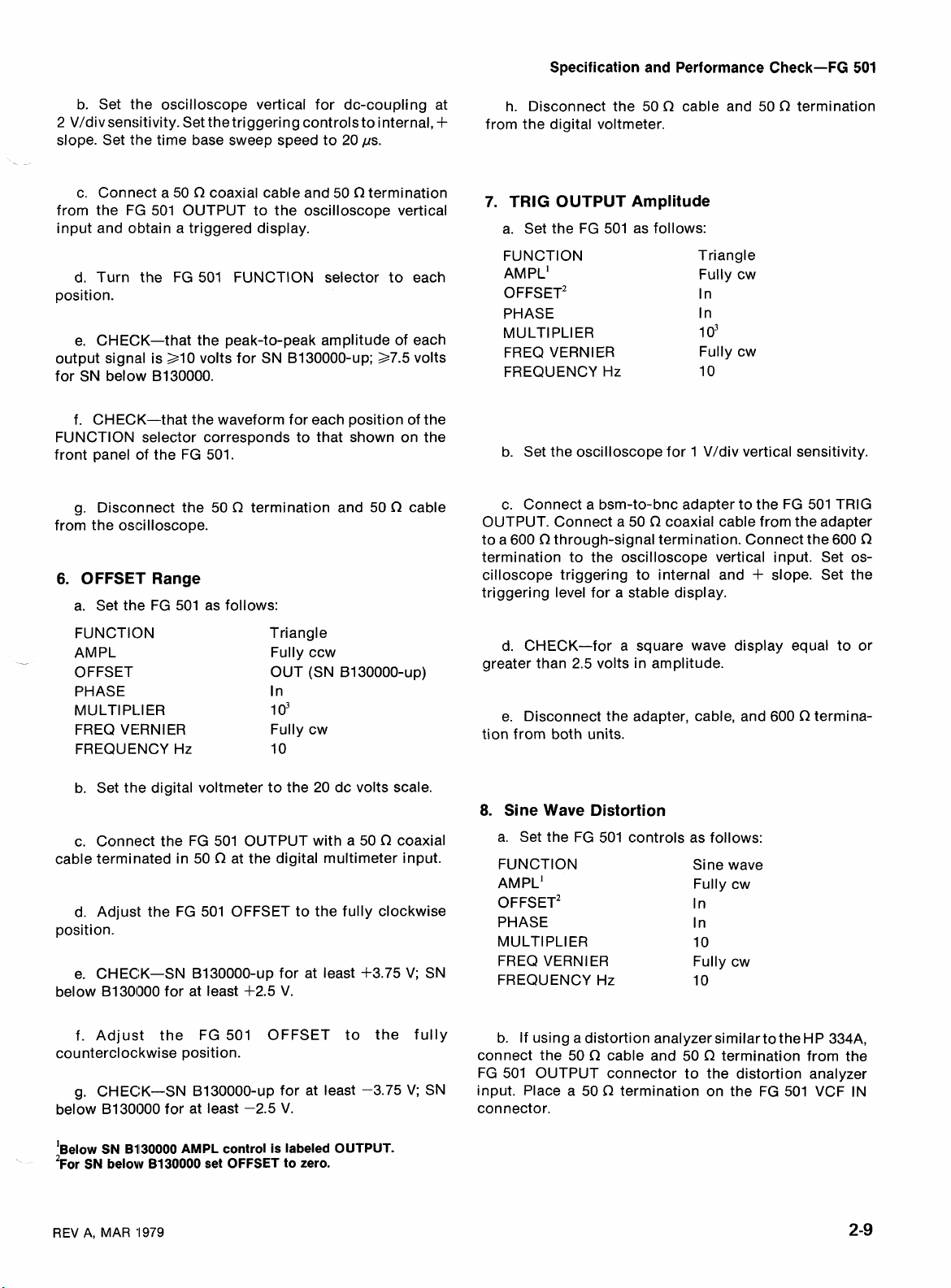

Page 22

Specification and Performance Check-FG 501

c. CHECK-the FG 501

following chart.

Counter

Measurement

Interval

.1 SEC

1 SEC

1 SEC

1 SEC

10 SEC

1 SEC

1 SEC

1 SEC

FG 501

=requency

Dial

10

timing according to the

Frequency

(f

3%

of full

scale)

1 MHz +30 kHz

(1 .O3 MHz-.970 MHz)

100 kHz f3 kHz

(103 kHz-97 kHz)

10 kHz +300 Hz

(1 0.3 kHz-9.7 kHz)

1 kHz h3O Hz

(1 .O3 kHz-.97 kHz)

100 Hz +30 Hz

(130 HZ-70 HZ)

1 kHz +300 Hz

(1.3 kHz-700 HZ)

pi!;z:7 ZZ)

100 kHz +30 kHz

(130 kHz-70 kHz)

Hz

FG 501

Multi-

plier

1

o5

1

o4

1

o3

1 02

1

o2

1

o3

1

o4

1

o5

4.

VCF

INPUT

a. Set the FG 501 controls as follows:

FUNCTION Triangle

AMPL'

OFFSET^

PHASE In

MULTIPLIER

FREQ VERNIER Fully cw

FEQUENCY Hz 1 0 (exactly)

C2

b. Connect a 50

termination from the FG 501 OUTPUT to the frequency

counter input for a reading of 1 MHz.

c. Adjust the 0-20 V power supply for zero volts out.

d. Connect a banana-to-bnc adapter and 50

from the 0-20 V power supply output to the FIG 501 VCF

INPUT. Make sure the ground side of the banana-to-bnc

adapter goes to the

e. Adjust the power supply output voltage to change

the frequency of the FG 501 as read on the digital counter

to 0.001 MHz.

coaxial cable and 50 nfeedthrough

+

terminal on the power supply.

FUIIY

In

I

o5

cw

$2

cable

d. Set the frequency counter (dc coupled) to measure

period for FG 501 MULTIPLIER settings slowerthan

the following chart.

FG 501

Hz

Frequency

Counter

10 SEC

1 SEC

1 SEC

e. Disconnect the coaxial cables, terminations and tee

connectors from all units.

Dial

FG 501

Multiplier

Period

(f

3%

of full scale)

10.0 ms k.33 ms

(1 0.33-9.67 ms)

100 ms h3.3 ms

(1

03.3-96.7 ms)

1000 ms k33.3 ms

(1 033.3-976.7 ms)

lo2

in

f. Disconnect the bnc cable from the FG 501 VCF

INPUT and connect the variable dc power supply to the

digital voltmeter input.

g. CHECK-that the voltage measured on the digital

voltmeter is <-I0 V.

h. Adjust the power supply output voltage to zero.

i.

Disconnect the cables and termination from all units.

5.

OUTPUT Signal Amplitude and Waveshape

a. Set the FG 501 controls as follows:

FUNCTION Si newave

AMPL'

OFFSET^

PHASE In

MULTIPLIER 1

FREQ VERNIER Fully cw

FREQUENCY Hz 10

FUIIY

In

o3

cw

elow ow

SN

SN

2~or

below

B130000

8130000

AMPL control is labeled OUTPUT.

set OFFSET to zero.

REV

44,

MAR

1979

Page 23

Specification and Performance Check-FG

501

b. Set the oscilloscope vertical for dc-coupling at

2

V/divsensitivity. Set the triggering controls to internal,

slope. Set the time base sweep speed to 20 ps.

R

c. Connect a 50

from the FG 501 OUTPUT to the oscilloscope vertical

input and obtain a triggered display.

d. Turn the FG 501 FUNCTION selector to each

position.

e. CHECK-that the peak-to-peak amplitude of each

output

for SN below B130000.

FUNCTION selector corresponds to that shown on the

front panel of the FG 501.

from the oscilloscope.

sign,al is 210 volts for SN B130000-up; 37.5 volts

f. CHECK-that the waveform for each position of the

Disconnect the 50

g.

6.

OFFSE'T Range

a. Set the FG 501 as follows:

coaxial cable and 50 R termination

R

termination and 50 R cable

R

+

h. Disconnect the 50

from the digital voltmeter.

7.

TRlG OUTPUT Amplitude

a. Set the FG 501 as follows:

FUNCTION Triangle

AMPL'

OFFSET^

PHASE In

MULTIPLIER 1

FREQ VERNIER Fully cw

FREQUENCY Hz 10

b. Set the oscilloscope for 1 V/div vertical sensitivity.

c. Connect a bsm-to-bnc adapter to the FG 501 TRIG

OUTPUT. Connect a 50

R

to a 600

termination to the oscilloscope vertical input. Set os-

cilloscope triggering to internal and

triggering level for a stable display.

through-signal termination. Connect the 600

cable and 50 R termination

FUIIY

cw

In

o3

R

coaxial cable from the adapter

+

R

slope. Set the

FUNCTION Triangle

-

AMPL

OFFSET OUT (SN B130000-up)

PHASE

MULTI

PL-I ER 1

FREQ VERNIER Fully cw

FREQUENCY Hz 10

b. Set the digital voltmeter to the 20 dc volts scale.

Connect the FG 501 OUTPUT with a 50

c.

cable terminated in 50

d. Adjust the FG 501 OFFSET to the fully clockwise

position.

e. CHECK-SN B130000-up for at least

below B1 30000 for at least 4-2.5 V.

f. Adjust the FG 501 OFFSET to the fully

counterclockwise position.

g. CHECK-SN B130000-up for at least -3.75 V; SN

B130000 for at least -2.5 V.

below

Fully ccw

In

o3

R

coaxial

R

at the digital multimeter input.

f3.75 V; SN

d. CHECK-for a square wave display equal to or

greater than 2.5 volts in amplitude.

R

e. Disconnect the adapter, cable, and 600

tion from both units.

8.

Sine Wave Distortion

a. Set the FG 501 controls as follows:

FUNCTION Sine wave

AMPL'

OFFSET^

PHASE In

MULTlPLl ER 10

FREQ VERNIER Fully cw

FREQUENCY Hz 10

b. If using a distortion analyzer similar to the

connect the 50

FG 501 OUTPUT connector to the distortion

input. Place

connector.

R

cable and 50 R termination

a

50 R termination on the FG 50

FUIIY

In

cw

termina-

HP 334A,

from the

analyzer

1 VCF IN

elow ow

SN B1130000

2~or SN below 8130000 set OFFSET to zero.

REV

A,

MAR

'1

979

AMPL

control

is

labeled OUTPUT.

Page 24

Specification

and

Performance Check-FG 501

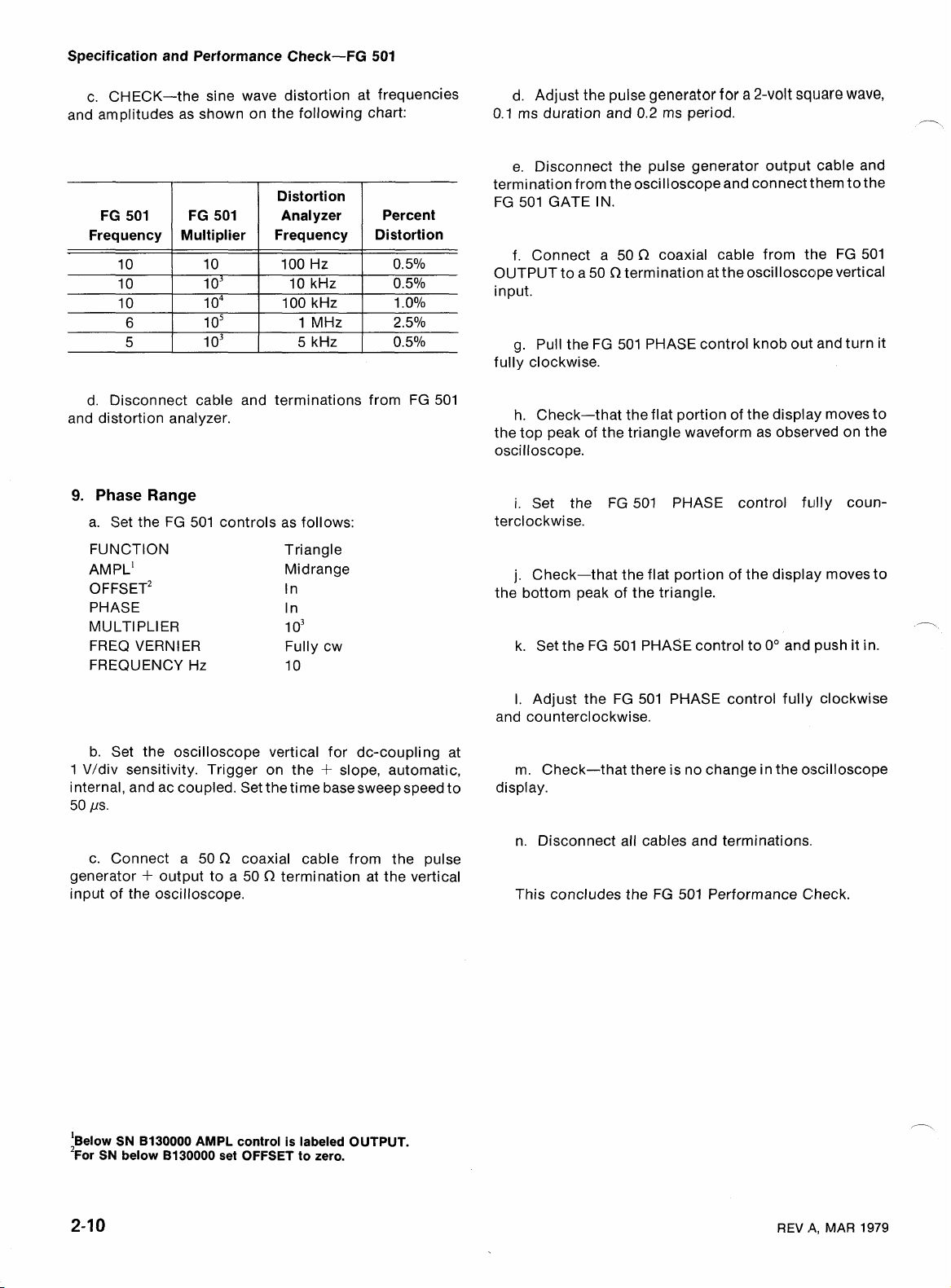

c. CHECK-the sine wave distortion at frequencies

and amplitudes as shown on the following chart:

Distortion

FG 501

Frequency

10

o5

1

o3

1

d. Disconnect cable and terminations from FG 501

and distortion analyzer.

9.

Phase Range

a. Set the FG 501 controls as follows:

FUNCTION Triangle

AMPL'

OFFSET^

PHASE In

MULTIPLIER 1

FREQ VERNIER Fully cw

FREQUENCY Hz 10

100 Hz 0.5%

10 kHz 0.5%

1 MHz 2.5%

5

HZ

Midrange

In

0.5%

o3

d. Adjust the pulse

0.1 ms duration and 0.2 ms period.

e. Disconnect the pulse generator output cable and

termination from the oscilloscopeand connect them to the

FG 501 GATE IN.

f.

Connect a 50 n coaxial cable from the FG 501

OUTPUT to a 50

input.

g. Pull the FG 501 PHASE control knob out and turn it

fully clockwise.

h. Check-that the flat portion of the display moves to

the top peak of the triangle waveform as observed on the

oscilloscope.

i. Set the FG 501 PHASE control f~~lly counterclockwise.

j. Check-that the flat portion of the display moves to

the bottom peak of the triangle.

k. Set the FG 501 PHASE control to

generator

C2

termination at t he oscilloscc~pe vertical

for

a

2-volt square wave,

0"

and push it in.

-

-

b. Set the oscilloscope vertical for dc-coupling at

+

1 V/div sensitivity. Trigger on the

internal, and ac coupled. Set the time basesweep speed to

50 /IS.

C2

c. Connect a 50

+

generator

input of the oscilloscope.

e el ow

2~or SN below B130000 set OFFSET to zero.

output to a 50 Q termination at the vertical

SN 8130000

coaxial cable from the pulse

AMPL

control

is

slope, automatic,

labeled OUTPUT.

I. Adjust the FG 501 PHASE control fully clockwise

and counterclockwise.

m. Check-that there is no change in the o:~cilloscope

display.

n. Disconnect all cables and terminations.

This concludes the FG 501 Performance Check.

REV

A,

MAR

1979

Page 25

WARNING

THE FOLLOWING SERVICING INSTRUCTIONS ARE

FOR USE BY QUALIFIED PERSONNEL ONLY. TO

AVOID PERSONAL INJURY, DO NOT PERFORM ANY

SERVICING OTHER THAN THAT CONTAINED IN

OPERATING INSTRUCTIONS UNLESS YOU ARE

QUALIFIED TO DO SO.

Page 26

Page 27

ADJUSTMENT

Section

3-FG

501

Introduction

This adjustment procedure is to be used to restore the

FG 501 to original performance specifications. Adjustment need not be performed unless the instrument failsto

meet the Performance Requirements of the Electrical

Characteristics listed in the Specification section, or the

Performance Check cannot be completed satisfactorily.

Completion of all adjustment steps in this procedure

ensures that the instrument will meet the performance

requirements listed in the Specification section. However,

to fully ensulre satisfactory performance, it is recommended that the Performance Check be performed after any

adjustment is made.

Services Available

Tektronir:, I nc. provides complete instrument repair

and adjustment at local Field Service Centers and at the

Factory

Office or representative for further information.

Servicecenter. Contact your local Tektronix Field

Table

Recali bration Interval

Recommended recali bration interval is 2000 hours of

operation or six months, whichever occurs first.

Test Equipment Required

The test equipment listed in Table 3-1, or equivalent, is

required for adjustment of the FG 501. Specifications

given for the test equipment are the minimum necessary

for accurate adjustment and measurement. All test equip-

ment is assumed to be correctly calibrated and operating

within specification.

If other test equipment is substituted, control settings

or calibration setup may need to be altered to meet the

requirements of the equipment used.

A

flexible TM 500 extender cable, Tektronix Part No.

067-0645-02, is useful for troubleshooting or adjusting the

FG 501; however, the complete Adjustment Procedure

can be performed without use of the extender.

3-1

-

Power Module

Digital Voltrneter

Frequency Counter

Pulse Generator

.-

-

--

De:scription

LIST

OF

TEST EQUIPMENT REQUIREMENTS

Performance

Requirement

Bandwidth dc to 15 MHz;

deflection factor 10 mV/

div to 5

rate 20 ns/div to 1 ms/

div.

Three compartments or

more

Range 0 to

displayed error less

than 0.5O/0.

Frequency range 0.1 Hz

to above 1 MHz; accuracy

within one part in

+1 count.

0 to

output into 50

Period 0.2 ms; duration

0.1 ms.

V/div; sweep

f

20 V dc;

+2

V square-wave

Ll

lo5

load.

Application

Steps 4 through 15

All steps

Set power supply voltages

&

Basic timing

INPUT

Set phase range

VCF

Example

TEKTRONIX T921 or

equivalent

TEKTRONIX TM 503,

TM 504, or equivalent

TEKTRONIX DM 501"

TEKTRONIX DC 504"

or equivalent

or equivalent

REV

C,

JUN

1978

Page 28

Description

Distortion Analyzer

Performance

Requirement

Frequency range from

1 Hz to at least 600

kHz. Distortion resolution <0.5O/0.

Table

3-1

(cant)

Application

Set sine wave for minimum distortion

-.

Example

Hewlett-Packard 334A

Distortion Analyzer

or equivalent

50

n

Feedthrough

Termination (2)

n

Feedthrough

600

Termination

n

Coaxial Cables

50

(2 ea)

Adapter

Tee Connector

1 OX Attenuator

1

Variable Autotransformer

TM 500 Extender Cable

"~equires

TM

500-Series Power Module.

bnc connectors

bnc connectors

bnc connectors

bsm-to-bnc

bnc connectors

bnc connectors; 50

impedance.

Output to 135 V (270 V)

at =500 W

Make connections be-

tween FG 501 and power

module.

I

C2

As required

Sine wave upper and

lower level adjustment

As required

Sine wave upper and

lower level adjustment

As required

-

As required

Setting power supplies

As required

I

Tektronix Part No..

01 1-0049-01

Tektronix Part No.

01 1-0092-00

Tektronix Part No.

01 2-0057-01

Tektronix Part

103-0036-00

Tektronix Part No..

-

103-0030-00

Tektronix Part No.

1-0059-02

01

General Radio WIOMT3W

or equivalent

Tektronix Part No.

067-0645-02 or

equivalent

No.

--

--

Adjustment Locations

See Fig. 3-1 for the locations of all adjustable components and test points mentioned in this procedure. All

adjustable components are located on the left side of the

FG 501 circuit board.

Preparation

a. Disconnect the power module from the power

source. Make sure the power module is set for the line

voltage to be applied (see power module manual for line

voltage setting). If the adjustments are to be made with the

FG 501 plugged into the power module, remove the covers

from the power module. If the adjustments are to be made

with the FG 501 on an extender cable (Tektronix Part No.

067-0645-02), be sure the extender cable is oriented with

the top of one connector toward the top of the FG 501 and

the top of the other connector toward the top of the power

module.

b. Remove the side covers of the FG 501 to gain access

to the components and test points on the circuit board.

Pull the rear end of the side coveroutwardfrorrl

the instrument (the covers snap into place).

c. Install all required TM 500-Series test equipment

into the power module(s). Install the FG 501 (in left

compartment of power module if extender cable is not

used).

d. Connect the power module that powerst he FG 501

to avariable autotransformer that is set to the middle of the

line voltage operating range selected by the

selector block in the power module. Connect the

autotransformer to a line voltage source and turn the

FG 501 on.

e. Connect all test equipment to a suitable linevoltage

source and turn it on. Allow at least 30 minutes

time before starting the adjustment procedure. All adjustments must be made at an ambient temperature

between +20°C and +30°C.

theside of

liine voltage

REV

D,

warmup

MAR

1979

-

Page 29

Fig.

3-1.

Adjustment and test point locations,

SN

8020000 & up.

REV

C,

MAR

1979

Fig. 3-2. Adjustment and test point locations, below

SN

8020000.

Page 30

Initial Control Settings

Set the following controls during warm-up time:

FG

501

FUNCTION Triangle

FUIIY

AMPL'

OFFSET^

PHASE

FREQ VERNIER Calibrated (fully cw)

MULTIPLIER 1

FREQUENCY Hz 1

DM

501

Range/Function switch 20 DC Volts

cw

In (off)

Off (pushed in, set to

o4

0")

PROCEDURE

(SN

8020000

1.

Reference Current Adjustment

a. Connect the digital voltmeter Lo input lead to

ground (at negative end of C400). Connect the Hi input

meter lead to

b. ADJUST-43400 (Reference Current) for a meter

reading of 4-13.8 V dc.

TP1 on the FG 501 (see Fig. 3-1).

and

up)

(H3.8

V dc)

5.

Adjust Square-Wave High-frequency

Compensation and Check Risetime

Control Setting Changes:

FG

501

FUNCTION Square wave

Oscilloscope

Time/div

Volts/div 2 V

Input Coupling Dc

a. Connect the FG 501 OUTPUT connector through a

M2

50

cilloscope vertical input connector. Check that the display

amplitude is at least 10 V peak-to-peak (SN 6130000-up);

7.5 V peak-to-peak for SN below

intensity, focus, and position controls for a visible,

triggered, vertically-centered five-division display.

compensation) for a square front corner and flat top with

minimum aberrations on the positive-going portion of the

square-wave display (this adjustment will affect

wave risetime).

coaxial cable to a 50 n termination at the os-

b. Set the oscilloscope variable volts/div, triggering,

c. ADJ UST-C281 (square-wave high-f requency

2 ps (Mag off)

B130000.

square-

-.

2. +20

the FG 501.

+20.0 V dc.

3.

the FG 501.

(+16.80 V to 4-17.20 V).

4.

the FG 501.

(-17.20 to -16.80 V).

FG 501.

'8elow SN 8130000 AMPL control

2~or SN below 8130000 set OFFSET to zero.

Volt Supply Adjustment

a. Move the digital voltmeter Hi input lead to TP3 on

b. ADJUST-R415

4-17

Volt Supply Check

a. Move the digital voltmeter Hi input lead to TP8 on

b. CHECK-for a meter reading of +I7 V dc, +200 mV

-17

Volt Supply Check

a. Move the digital voltmeter Hi input lead to TP9 on

b. CHECK-for a meter reading of -17 V dc, +200 mV

c. Disconnect the digital voltmeter leads from the

(+20 Volts) for a meter reading of

is

labeled OUTPUT.

d. Set the oscilloscope time base to 20 nsi (Mag on).

Set intensity, triggering, and position controls as

necessary to observe the positive-going square-wave

leading edge over approximately five horizontisl graticule

divisions.

e. Measure the

the oscilloscope instruction manual for risetime measure-

ment techniques). Adjust the position

quired. At a sweep speed of 20 ns/div, the riseti~me reading

should be no more than five horizontal divisiorls between

the

10% and 90% risetime points (100 ns or less).

f. If necessary, repeat parts c through e ifor a compromise between best leading edge and flat top

(aberrations not to exceed

than 100 ns.

6.

Dial Calibration

Control Settings:

FUNCTION

Time base

Triggering

risetime of the leading edge (refer to

controls as re-

5%) with a risetime of no more

FG

501

Triangle

Oscilloscope

10 ps

For triggered dlisplay

REV

PI,

MAR

1979

Page 31

a. Set th~e FREQUENCY Hz dial just to the point (near

10) where the frequency of the displayed waveform

becomes maximum and there is not further change. This

will be a few degrees before the waveform disappears

(there is no signal output for a part of the area above 10

and below

maxi mum frequency, use the oscilloscope horizontal

position control to move the display so that the right end of

the sweep can be viewed.

b. CHECK-that the FREQUENCY Hz dial reads 10 at

the point where the frequency of the output signal ceases

to increase.

c. If the dial does not read 10, loosen the two setscrews

on the brass collar behind the dial and panel; then position

the dial to 110 while holding the potentiometer shaft with

needle-nose pliers. Re-tighten the setscrews.

7.

X.l

Control Settings:

FUNCTION

FREQUENCY Hz Near 1

a. Set the oscilloscope to display one full triggered

square-wave cycle over 10 graticule divisions.

b. ADJUST-R45 (X.l Symmetry) so that the

going and negative-going portions of the signal are of

equal duration. Switch the oscilloscope triggering slope

repeatedly from plus to minus while making final ad-

justments to R45.

.I). For ease in determining the point of

Symmetry Adjustment

Square wave

positive-

f2

a. Connect the FG 501 output through a 50

C2

cable and 50

waveform is also to be displayed on an oscilloscope, insert

a tee connector between the 50

inputs to the counter and oscilloscope).

Time base

Triggering

b. ADJUST-R20 (XI0 Cal) for a counter reading of

10,000 (an oscilloscope display of approximately one

cycle per division).

9.

XI

Calibration

Control Settings:

FREQUENCY Hz 1

Time base 1 ms

a. Connect the FG 501 through a 50

and 50

inputs of the counter and oscilloscope to the tee connector.

1.0000 (note an oscilloscope display of about 1 cycle/division).

oscilloscope time base to

C2

b. ADJUST-R38 (XI Cal) for a counter reading of

c. Set the FG 501 FREQUENCY Hz dial to 10 and the

termination to the counter input (if the

f2

termination and the

Oscilloscope

.1 ms

Set for stable,

triggered display

Oscilloscope

(use of an oscilloscope

in this step is optional)

f2

termination to a tee connector. Connect the

.1 ms.

coaxial

coaxial cable

f2

c. Disccmnect the 50

cilloscope input connector.

Use of an oscilloscope in this step is optional.

Control Settings:

MULTI PILIER 1

FREQUEiNCY Hz 10

FUNCTION Triangle waveform

Function

Hold

Source

Trigger Level

REV

A,

MAR

1979

termination from the os-

Note

o3

Counter

1 Hz

Fully ccw

Ext

0

d. CHECK-for a counter reading of 10.000. If

neceasary, re-adjust R20 (XI0 Cal) for a 10.000 reading

(note an oscilloscope display of about 1 cycle/division).

9

e. Repeat Steps 8 and

10. 10'

Timing Adjustment

Control Settings:

MULTl PLl ER 1

FREQUENCY Hz 10

(use of an oscilloscope

in this step is optional)

Time base

Function .1 kHz

as necessary.

o5

Oscilloscope

I

YS

Counter

Page 32

a. ADJUST-CIS0 (10' XI0 Timing) for a counter

reading of 1.0000 (note an oscilloscope display of about 1

cycle/division).

11.

lo5

XI

Timing Adjustment

Control Settings:

FG 501

FREQUENCY Hz 1

Oscilloscpe

(use of an oscilloscope

in this step is optional)

Time base 10 ps

Table

3-2

FG 501

FRE-

QUENCY QUENCY TI ON

d. Set the FREQUENCY Hz dial for

MULTIPLIER switch to lo3. Place a 50

the VCF INPUT connector. Set the FUNCTION switch to

square wave.

FG

1

M&T'-

1

o4

501

1

FRE-

100 Hz 0.5%

10 kHz 0.5%

100

HZ

5 kHz 0.5%

PERCENT

I

DIISTOR-

1 .OO/O

.1

and the

S2

term~ination on

-

a. ADJUST-C79 (lo5 XI Timing) for a counter

reading of

cycle/division).

12. 1

.I000 (note an oscilloscope display of about 1

o4

XI 0

Timing Adjustment (Below SN

B060000

only)

Control Settings:

MULTIPLIER 1

FREQUENCY Hz 10

a. ADJUST-C77 (1

.I000 (note an oscilloscope display of about 1 cycle/division).

13.

Sine-wave Upper and Lower Level Adjustment

Control Settings:

FUNCTION Si ne-wave

MULTl PLl ER 10

FREQUENCY Hz 10 (100 Hz)

AMPL'

PHASE

OFFSET'

a. Connect the FG 501 to the Distortion Analyzer

S2

through a 50

b. ADJUST-Upper Level Adjustment R150 and Lower

Level adjustment R170 for minimum distortion as read by

the Distortion Analyzer.

coaxial cable and 50

o4

FG 501

o4

Timing) for a counter reading of

Clockwise

In (off)

In (off)

S2

termination.

e. Disconnect the FG 501

tion from the distortion analyzer and connect them to the

input of an oscilloscope. Set the oscilloscope to display

full triggered square-wave cycle over 10 graticule

one

divisions. Switch the oscilloscope triggering slope

repeatedly from plus to minus and check the square-wave

symmetry. If it is no longer symmetrical, repeat the X.l

Symmetry Adjustment (Step 7 of this procedure).

g.

Repeat Step 13 parts c and d as necessary

14.

Triangle

DC

Level and Phase Range

OUTPUTcable and termina-

Adjustment

Control Setting:

FUNCTION Triangle

MULTIPLIER 1

FREQUENCY Hz 10

Pulse Generator

Period

Duration

Amplitude

Oscilloscope

Time base .1 ms

a. Connect the pulse generator

C2

coaxial cable and 50

50

GATE INPUT connector.

b.

Pull the FG 501 PHASE control out (on).

o4

.2

ms

.1 ms

$2 V into 50

+

S2

termination to the FG 501

S2

output through a

c. Check the distortion at the frequencies listed in

Table 3-2.

'8elow

SN

or

8130000 AMPL control

SN below 8130000 set OFFSET to zero.

is

labeled OUTPUT.

MAR

of

1979

c. CHECK-that the display is several bursts

triangle waveforms with a horizontal bar connlecting one

burst to the next. Rotate the PHASE colntrol fully

REV

14,

,,

Page 33

clockwise and the horizontal bars should move to at least

the top of the triangle burst waveforms. Rotatethe PHASE

control fully counterclockwise and the horizontal bar

should move to at least the bottom of the triangle burst

waveforms.

d. ADJLJST-R135 (triangle DC Level) if operation is

not as described in Step 14 part c above (adjust for equal

movement of bar above and below the burst waveforms).

e.

Repe'at parts c and d above as necessary.

f. Returin the PHASE knob to

g. Disconnect the cable and termination from the

pulse generator and FG 501 GATE INPUT.

15.

Adjust Output Balance

Control :Settings:

O0

and press it in (off).

(SN

B130000 and up)

Minimum Output (ccw)

In (off)

a. Connect a 10X probe from the oscilloscope to test

point 6 (if TP6 is not present use point A, the circuit board

pad below C77 and right of

clip to chassis ground.

b. Set FREQUENCY Hz for maximum frequency as

viewed on test oscilloscope.

c. Set oscilloscope Vertical input coupling to ground

and use Position control to vertically center t he trace at the

center horizontal graticule line. Return input coupling to

dc.

d. ADJUST-R195 (f4.5 volts

positive peaks on the display extend 2.25 divisions above

the graticule center.

e. ADJUST-R205 (-4.5 volts

negative peaks on the display extend 2.25 divisions below

graticule center.

f. Repeat parts d and e as necessary.

6.

Triangle DC Level

a. Move probe tip to TP7 (emitter of Q38).

R251). Connect probe ground

%

Ampl) so the

%

Ampl) so the

Oscilloscope

Volts/div .1 V

a. Center the oscilloscope trace.

-

b. ADJUST-output balance control R274 until the

trace is centered on the screen of the oscilloscope.

c. Disconnect all test equipment.

This completes the FG 501 adjustment procedure.

PROCEDURE

(SN

BELOW

Steps 1 through 4: perform Steps

for SN B020000-up on page 3-4 except refer to Fig. 3-2.

5.

Adjust

Control Setting Changes:

MULTI PLI ER 1

Volts/Div 0.2 V

Vertical Input Coupling Dc

Triggeri rig Auto

Time Base 1 ms d. ADJUST-R99

I ntensity, Level

&

'8elow

--

2~or

-4-4.5

Volts Triangle Amplitude

Oscilloscope

Positiom For visible, triggered display vertically centered.

SN

8130000 AMPL control

SN

below 8130000 set OFFSET to zero.

FG

501

B020000)

1

through 4 as shown graticule.

o2

is

labeled OUTPUT.

b. ADJUST-R135

extends an equal distance above and below graticule

center.

7.

Gate Centering

a. Move the

b. Use vertical position control to center the display on

the graticule.

c.

Move the probe tip to TP4 (center tap of Gate

Centering R95).

d. ADJUST-R95 to re-center the display on the

e. Disconnect the probe tip and ground clip from the

FG 501 and disconnect probe from oscilloscope.

8.

Square Wave Amplitude

a. Connect a 50

connector to a 50

vertical input connector.

b. Set OFFSET and OUTPUT for a

c. Set FUNCTION to

display. If necessary, adjust OFFSET to keep display

10X probe tip to TP5 (Q85 base).

(

%

DC Level) so the display

C2

cable from the FG 501 OUTPUT

C2

termination at the oscilloscope

6

division display.

%

(square wave).

(

'L

Ampl Cal) for a 6-division

REV A, MAR

1979

Page 34

9.

Square-Wave High Frequency Compensation

Control Setting Changes:

b. ADJUST-R45 (X.l Sym) so the upper and lower

portions of the displayed square wave are of equal

duration.

--

Oscilloscope

Time Base

&

Triggering

a. ADJUST-C281

and square corner on the display.

10.

Dial Calibration

Control Setting Changes:

FUNCTION

FREQUENCY Hz Maximum displayed

Time base 1 mddivision

a. CHECK-that the FREQUENCY Hz dial reads 10; if

not, perform part b.

b. Loosen the two set screws on the brass collar

behind the FREQUENCY Hz knob. Hold R25 shaft with

pliers to maintain maximum frequency display while

rotating dial to read 10, then tighten screws.

11. XI0

a. ADJUST-R20 (XI0 Cal) for 1 triangle wave-

form/division.

12. X1

base for 10 mddivision.

Calibration

a. Set FREQUENCY Hz to 1 and oscilloscope time

Position As Required

(

Oscilloscope

Calibration

2 Ps

%

HF Comp) for best flat top

FG

501

41

(triangle waveform)

frequency

14.

lo5

XI0

Timing

Control Setting Changes:

%

FUNCTION

MULTIPLIER 1

FREQUENCY Hz 10

Oscilloscope

Time base

a. ADJUST-C19O (lo5 XI0 Timing) for one triangle

waveform/division.

15.

lo5

XI

Timing

a. Set FREQUENCY Hz to 1 and oscilloscope time

base for 10 psldivision.

b. ADJUST-C79

waveform/division. Repeat steps 14 and

for best cali bratisn.

16.

lo4

XI0

Timing

a. Set MULTIPLIER to lo4, FREQUENCY HZ to 10, and

oscilloscope time base for 10 ,&division.

b. ADJUST-C77 (lo4 XI0 Timing) for one triangle

waveform/division.

c. Disconnect the 50

cilloscope input.

(lo5 XI Timing) for one triangle

!2

(triangle)

o5

1 &division

15

as necessary

termination from the os-

b. ADJUST-R38 (XI Cal) for one triangle wave-

form/division.

c.

Set FREQUENCY Hz to 10 and oscilloscope time

base for 1 ms/division.

d.

CHECK-for one triangle waveform/division. If not,

readjust R20 and repeat parts a through d for best

calibration.

13. XI

(square-wave). Set oscilloscope time base for 10 ms/division.

Symmetry

a. Set MULTIPLIER to

lo3

and FUNCTION to

'L

17.

Upper and Lower Sine-Wave Level

Control Setting Changes:

FUNCTION

MULTIPLIER

FREQUENCY Hz 1

C2

a. Connect the 50

the distortion analyzer input.

b. ADJUST-R150

Lower Level) for a minimum distortion reading on the

analyzer.

termination on OUTPUT cable to

(

z

(sine wave)

i

o4

%

Upper Level) and R170

@

MAR

(

'L

1979

'7

Page 35

MAINTENANCE AND

Section

4-FG

501

INTERFACING

PREVENTIVE MAINTENANCE

Preventive

basis will enhance the reliability of the

checks of the semiconductors in the absence of a

malfunction are not recommended as preventive

maintenance measures. The recommended time for per-

forming preventive maintenance is just before instrument

adjustment.

Cleaning

maintenance

CAUTION

steps performed on a regular

FG

501. However,

a

Do not use acetone, MEK, MIBK, benzene, toluene,

carbon tetrachloride, trichloroethylene, methyl

alcohol, methylene chloride,

Freon com,uounds for cleaning the

clean water and a mild detergent.

sulphuric acid, or

FG

501.

Use only

INFORMATION

TROUBLESHOOTING AIDS

Circuit Descriptions

Section 5 of this manual explains circuit operation in

detail. Used conjointly with the circuit diagrams, the

section can be a powerful analytic tool.

Diagrams

A block diagram and detailed circuit diagrams are

located on foldout pages in the diagrams section. The

circuit diagrams show the component values and

assigned circuit reference numbers of each component.

The first page of the Diagrams section defines the circuit

symbols and reference designators used in the manual.

Major circuits are usually identifiable by a series of

l

component numbers.

may be shown within the diagrams,

aprons. Those portions of the circuits located on circuit

boards are enclosed with gray tint outline.

m portant waveforms and voltages

or on adjoining

-

Exterior.

or dry brush. Water and a mild detergent may be used;

however, abrasive cleaners should never be used.

Interior.

precede adjustment since the cleaning process could alter

the settings of calibration adjustments. Use low-velocity

compressed (air to blow off accumulated dust. Hardened

dirt can be removed with a soft dry brush, cotton-tipped

swab, or a coth dampened in a solution of water and mild

detergent.

Loose dust may be removed with a soft cloth

Cleaning the interior of the unit should

Adjustment

After cleaning or repairs, do the performance check as

described in Section

within specification, no adjustment is needed. If one or

more of the specifications are not met, calibrate the

instrument as directed in Section 3, Adjustment.

2

of this manual. If all functions are

Lubrication

No lubrication is required in the

FG

501.

Cam Switch Charts

Cam switches shown on the diagrams are coded on

comprehensive charts to locate the cam number of the

switch contact in the complete switch assembly, counting

from the front, or knob end, toward the rear of the switch.

The charts also indicate with a solid dot when each

contact is closed.

Circuit Board Illustrations

Line illustrations showing component locations keyed

with a grid locator and table are placed on the back of a

foldout page and sequenced as closely as possible to the

related circuit diagrams.

To identify electrical components when troubleshooting, turn to the appropriate Parts Location Grid in

the Diagrams section. Component values, descriptions,

and ordering data are given in the Replaceable Electrical

Parts list.

Component and Wiring Color Codes

Colored stripes or dots on electrical components