Page 1

xx

ECO8000 Series

ZZZ

Automatic Changeover Unit

User Manual

*P071322100*

071-3221-00

Page 2

Page 3

xx

ECO8000 Series

ZZZ

Automatic Changeover Unit

User Manual

Register now!

Click the following link to protect your product.

► www.tektronix.com/register

www.tektronix.com

071-3221-00

Page 4

Copyright © Tektronix. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries

or suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication

supersedes that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14150 SW Karl Braun Drive

P.O. B o x 5 0 0

Beaverto

USA

For product information, sales, service, and technical support:

n, OR 97077

In North America, call 1-800-833-9200.

Worl dwid e, v isit www.tektronix.com to find contacts in your area.

Page 5

Warranty

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1)

year from the date of shipment. If any such product proves defective during this warranty period, Tektronix, at its

option, either will repair the defective product without charge for parts and labor, or will provide a replacement

in exchange for the defective product. Parts, modules and replacement products used by Tektronix for warranty

work may be n

the property of Tektronix.

ew or reconditioned to like new performance. All replaced parts, modules and products become

In order to o

the warranty period and make suitable arrangements for the performance of service. Customer shall be responsible

for packaging and shipping the defective product to the service center designated by Tektronix, with shipping

charges prepaid. Tektronix shall pay for the return of the product to Customer if the shipment is to a location within

the country in which the Tektronix service center is located. Customer shall be responsible for paying all shipping

charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

result

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any damage

or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has b een modified or

integrated with other products when the effect of such modification or integration increases the time or difficulty

of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TRONIX' RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE

TEK

AND EXCLUSIVE REMEDY PR OVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

[W2 – 15AUG04]

btain service under this warranty, Customer must notify Tektronix of the defect before the expiration of

ing from attempts by personnel other than Tektronix representatives to install, repair or service the product;

Page 6

Page 7

Table of Contents

Important safety information....... .................................. ................................ ............ iv

General safety summary ..................................................................................... iv

Service safety summary ................................ ................................ ...................... vi

Terms in this manual . ................................ .................................. ..................... vii

Symbols and terms on the product......................................................................... vii

Compliance information ......................................................................................... viii

EMC compliance ......... ................................ ................................ ................... viii

Safety compliance ............................................................................................ ix

Environmental considerations............................................................................... xi

Preface ............................................................................................................. xiii

Product description ................... .................................. ................................ ..... xiii

Product documentation....... ................................ ................................ ................ xv

Conventions Used in This Manual.................................. .................................. ...... xv

Getting Started ..... . ..... . ..... ..... . ..... . ..... . .... . . .... . ..... . ..... . ..... ..... . ..... . ..... . .... . . .... . ..... . .... 1

Initial product inspection. ..... . ..... . ..... . .... . ..... . ..... . ..... . ... . . ..... . ..... . .... . . .... . ..... . ..... . .... 1

Accessories..................................................................................................... 2

Product installation ....................... ................................ .................................. ... 3

Network installation........................................................................................... 7

System considerations................ ................................ ................................ ........ 11

Signal connections .............................. .................................. ............................ 12

Operating Basics................................................................................................... 17

Operational overview... ................................ ................................ ...................... 17

Controls, connectors, and LED indicators ................................................................. 19

Initial product setup . ..... ..... . ..... . .... . . .... . ..... . ... . . ..... . ..... . .... . ..... . ..... . .... . ..... . ... . . . .... 28

How to operate an instrument with two power supplies (Option DPW only).......................... 36

How to upgrade the inst

How to use the Event Log and event history .......... .................................. .................. 48

Menus................... .................................. ................................ .......................... 53

Menu navigation .............................................................................................. 53

Main menu..................................................................................................... 54

STATUS menu ...... .................................. ................................ ........................ 56

CHANNEL menu................. ................................ ................................ ............ 62

SYSTEM CONFIG menu. . ... . . . .... . ..... . ..... ..... . ..... . ..... . .... . ..... . ..... . ... . . ..... . ..... . .... . ... 65

Remote control............................... ................................ .................................. .... 95

How to use the Web Interface ............................................................................... 95

How to use SNMP.............. ................................ ................................ .............. 98

Index

rument firmware .......... ................................ ........................ 40

ECO8000 Series Automatic Changeover Unit User Manual i

Page 8

Table of Contents

List of Figure

Figure 1: Installing or removing the instrument into or from the rack . .... . ..... . ..... . ..... . .... . . .... . .... 5

Figure 2: Location of rear panel power connectors (ECO8000 shown)...................................... 7

Figure 3: ECO8000 and SPG8000 system installation example ............................................. 13

Figure 4: ECO8020 and SPG8000 system installation example ............................................. 15

Figure 5: ECO8000 Series subsystems (ECO8020 with Option DPW shown)............................. 17

Figure 6: ECO8000 controls

Figure 7: ECO8020 controls and connectors............... ................................ .................... 19

Figure 8: Removing a Power Supply module .................. .................................. .............. 39

Figure 9: Installing the backup or replacement Power Supply module. . ..... . ..... . ..... . ..... . ..... . ...... 40

Figure 10: Sample of transfer.exe window after the upgrade is complete ........ .......................... 45

Figure 11: Main menu ............................................................................................ 54

Figure 12: STATUS menu.............. .................................. ................................ ........ 56

Figure 13: EVENT LOG (BY TYPE) submenu – part 1...................................................... 58

Figure 14: EVENT LOG (BY TYPE) submenu – part 2...................................................... 59

Figure 15: EVENT LOG (BY TYPE) submenu – part 3...................................................... 60

Figure 16: EVENT LOG (BY TIME) submenu ..................... ................................ .......... 61

Figure 17: CHANNEL submenu ................ .................................. .............................. 62

Figure 18: Custom level threshold display ....................... ................................ .............. 63

Figure 19: SYSTEM CONFIG menu – part 1.. . ..... . ..... ..... . ..... . ..... . ..... . .... . . .... . ..... . ..... . ..... 65

Figure 20: SYSTEM CONFIG menu – part 2.. . ..... . ..... ..... . ..... . ..... . ..... . .... . . .... . ..... . ..... . ..... 66

Figure 21: SYSTEM CONFIG menu – part 3.. . ..... . ..... ..... . ..... . ..... . ..... . .... . . .... . ..... . ..... . ..... 67

Figure 22: NETWORK CONFIG submenu .................................................................... 72

Figure 23: SNMP CONFIG submenu............. ................................ .............................. 74

Figure 24: EMAIL REPORTING submenu ...................... .................................. ............ 76

Figure 25: INTERNAL CLOCK submenu ................. .................................. .................. 79

Figure 26: SET LOCAL TIME submenu..................... .................................. ................ 80

Figure 27: DST SCHEDULE submenu..... .................................. ................................ .. 81

Figure 28: <type> EVENTS submenu – part 1 ................................................................ 84

Figure 29: <type> EVENTS submenu – part 2 ................................................................ 85

Figure 30: <type> EVENTS submenu – part 3 ................................................................ 86

Figure 31: OPTIONS ENABLED submenu.................................................................... 87

Figure 32: DIAGNOSTICS submenu – part 1 ... ................................ .............................. 89

Figure 33: DIAGNOSTICS submenu – part 2 ... ................................ .............................. 90

Figure 34: Example ECO8020 Web Interface window ... ................................ .................... 97

s

and connectors............... .................................. .................. 19

ii ECO8000 Series Automatic Changeover Unit User Manual

Page 9

List of Tables

Table 1: Standard and optional accessories...................................................................... 2

Table 2 : ECO

Table 3: AC line power requirements ............................................................................ 6

Table 4: Example plan for connecting signals to an ECO8000............................... ................ 12

Table 5: ECO8000 and SPG8000 system installation example connections...................... .......... 13

Table 6: ECO8020 and SPG8000 system installation example connections...................... .......... 15

Table 7: GPIO connector signal pinouts ........................................................................ 22

Table 8 : L

Table 9: LTC OUT connector signal pinouts ................................................................... 24

Table 10: Power on LED states for a Power Supply module ................................................. 25

Table 11: Power off LED states for a Power Supply module................................................. 26

Table 12: Self test error codes........................ ................................ ............................ 27

Table 13: SPG trigger cable connections and GPI configuration..................................... ........ 32

14: Signal pinouts for the SPG8000 GPI/LTC connector and the TG8000 GPS7 module LTC/GPI

Table

connector ...................................................................................................... 32

Table 15: Signal pinouts for the SPG8000 GPI connector.................................................... 33

Table 16: Signal pinouts for the TG8000 GPI port . .................................. ........................ 33

Table 17: Fault and event descriptions............ .................................. ............................ 49

Table 18: Relationship between module and channel numbers ........ ................................ ...... 50

le 19: Board voltage error codes..................................... ................................ ........ 51

Tab

Table 20: Event reporting methods and menu access points.................................................. 83

Table 21: Relationship between module and channel numbers ........ ................................ ...... 92

Table 22: Elements of the Web user interface .................................. ................................ 98

Table 23: SNMP parameters ..................................................................................... 99

8000 Series environmental requirements......... ................................ ............... 3

TC/SPG connector signal pinouts.................................................................... 23

Table of Contents

ECO8000 Series Automatic Changeover Unit User Manual iii

Page 10

Important safety information

Important saf

ety information

This manual c

for safe operation and to keep the product in a safe condition.

To saf ely p e

the end of this section. (See page vi, Servicesafetysummary.)

General safety summary

Use the product only as specified. Review the following safety precautions to

avoid injury and prevent damage to this product or any products connected to it.

Carefully read all instructions. Retain these instructions for future reference.

Comply with local and national safety codes.

For correct and safe operation of the product, it is essential that you follow

generally accepted safety procedures in addition to the safety precautions specified

in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove

the cover for repair, maintenance, or adjustment.

ontains information and warnings that must be followed by the user

rform service on this product, additional information is provided at

Before use, always check the product with a known source to be sure it is

operating correctly.

This product is not intended for detection of hazardous voltages.

personal protective equipment to prevent shock and arc b last injury where

Use

hazardous live conductors are exposed.

ile using this product, you may need to access other parts of a larger system.

Wh

Read the safety sections of the other component manuals for warnings and

cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the

responsibility of the assembler of the system.

iv ECO8000 Series Automatic Changeover Unit User Manual

Page 11

Important safety information

To avoid fire or

personal

injury

Use proper powe

certified for the country of use.

Do not use the p

Ground the product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, make sure that the product is properly grounded.

Do not disable the power cord grounding connection.

Power disconnect. The power cord disconnects the product from the power

source. S

it is difficult to operate the power cord; it must remain accessible to the user at

all times to allow for quick disconnection if needed.

Observe all terminal ratings. To avoid fire or shock hazard, observe all ratings

and markings on the product.

Do not operate without covers. Do not operate this product with covers or panels

removed, or with the case open. Hazardous voltage exposure is possible.

ee instructions for the location. Do not position the equipment so that

r cord. Use only the power cord specified for this product and

rovided power cord for other products.

Do not operate with suspected failures. If you suspect that there is damage to this

product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged

or operates incorrectly. If in doubt about safety of the product, turn it off and

connect the power cord. Clearly mark the product to prevent its further

dis

operation.

amine the exterior of the product before you use it. Look for cracks or missing

Ex

pieces.

Do not operate in wet/damp conditions. Be aware that condensation may occur if

a unit is moved from a cold to a warm environment.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry. Remove the input signals before you clean

the product.

ECO8000 Series Automatic Changeover Unit User Manual v

Page 12

Important safety information

Provide proper

details on installing the product so it has proper v entilation.

Slots and open

otherwise obstructed. Do not push objects into any of the openings.

Provide a safe working environment. Always place the product in a location

convenient for viewing the display and indicators.

Be sure your work area meets applicable ergonomic standards. Consult with an

ergonomics professional to avoid stress injuries.

Use only the Tektronix rackmount hardware specified for this product.

Servicesafetysummary

The Service safety summary section contains additional information required to

safely perform service on the product. Only qualified personnel should perform

service procedures. Read this Service safety summary and the General safety

summar

To avoid electric shock. Do not touch exposed connections.

ventilation. Refer to the installation instructions in the manual for

ings are provided for ventilation and should never be covered or

y before performing any service procedures.

Do not service alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

ent.

pres

Disconnect power. To avoid electric shock, switch off the product power and

disconnect the power cord from the mains power before removing any covers or

panels, or opening the case for servicing.

e care when servicing with power on. Dangerous voltages or currents may exist

Us

in this product. Disconnect power, remove battery (if applicable), and disconnect

test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair. Always recheck ground continuity and mains dielectric

strength after performing a repair.

vi ECO8000 Series Automatic Changeover Unit User Manual

Page 13

Terms in this manual

These terms may appear in this manual:

WAR NI NG . Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Symbols and terms on the product

Important safety information

These ter

The following symbol(s) may appear on the product:

ms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read

the mark

WARNING indicates an injury hazard not immediately accessible as you

read th

CAUTION indicates a hazard to property including the product.

ing.

emarking.

When this symbol is marked on the product, be sure to consult the manual

to find out the nature of the potential hazards and any actions which have to

be taken to avoid them. (This symbol may also be used to refer the user to

ratings in the manual.)

ECO8000 Series Automatic Changeover Unit User Manual vii

Page 14

Compliance information

Compliance in

EMC compliance

EC Declaration of

Conformity – EMC

formation

This section

environmental standards with which the instrument complies.

Meets intent of Directive 2004/108/EC for Electromagnetic Compatibility.

Compliance was demonstrated to the followin

Official Journal of the European Communities:

EN 55103:1996. Product family standard for audio, video, audio-visual and

entertainment lighting control apparatus for professional use.

Environment E2 – commercial and light industrial

Part 1 Emission

Part 2 Immunity

lists the EMC (electromagnetic compliance), safety, and

g specifications as listed in the

12

EN 55022:1987. Class B radiated and conducted emissions

EN 55103-1:1996 Annex A. Radiated magnetic field emissions

IEC 61000-4-2:2001. Electrostatic discharge immunity

IEC 61000-4-3:2006. RF electromagnetic field immunity

IEC 61000-4-4:2004. Electrical fast transient / burst immunity

IEC 61000-4-5:2005. Power line surge immunity

IEC 61000-4-6:2003. Conducted RF Immunity

IEC 61000-4-11:2004. Voltage dips and interruptions immunity

EN 55103-2:1996 Annex A Radiated magnetic field immunity

EN 61000-3-2:2006. AC power line harmonic emissions

EN 61000-3-3:1995. Voltage changes, fluctuations, and flicker

European contact.

Tektronix UK, Ltd.

Western Peninsula

Western Road

Bracknell, RG12 1RF

United Kingdom

1

For compliance with the EMC standards listed here, high quality shielded interface cables should be used.

2

Average half-cycle r.m.s. inrush current at initial switch-on, and after a 5 second power interruption, is 2 A.

viii ECO8000 Series Automatic Changeover Unit User Manual

Page 15

Compliance information

Australia / New Zealand

Declaration of

Conformity – EMC

Safety compliance

EU declaration of

conformity – low voltage

Complies with t

following standard, in accordance with ACMA:

EN 55022:1987

with EN 55103-1:1996.

Australia / New Zealand contact.

Baker & McKenzie

Level 27, AMP Centre

50 Bridge Street

Sydney NSW 2000, Australia

This section lists the safety standards with which the product complies and other

safety c

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Union:

Low Voltage Directive 2006/95/EC.

ompliance information.

he EMC provision of the Radiocommunications Act per the

. Radiated and conducted emissions, Class B , in accordance

nationally recognized

U.S.

testing laboratory lis ting

Canadian certification

Additional compliances

Equipment type

Safety class

EN 61010-1. Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

UL 61010-1. Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General Requirements.

CAN/CSA-C22.2 No. 61010-1. Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use – Part 1: General

Requirements.

IEC 61010-1. Safety Requirements for Electrical Equipment for

Measurement, Control, and Laboratory Use – Part 1: General Requirements.

Test and measuring equipment.

Class1–groundedproduct.

ECO8000 Series Automatic Changeover Unit User Manual ix

Page 16

Compliance information

Pollution degree

descriptions

Pollution degree rating

A measure of the

and within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

Pollution degree 1. No pollution or only dry, nonconductive pollution occurs.

Products in this category are generally encapsulated, hermetically sealed, or

located in clean rooms.

Pollution degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensa

Pollution degree 3. Conductive pollution, or dry, nonconductive pollution

that bec

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

Pollution degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, or snow. Typical outdoor locations.

tion degree 2 (as defined in IEC 61010-1). Rated for indoor, dry location

Pollu

use only.

contaminants that could occur in the environment around

tion occurs only when the product is out of service.

omes conductive due to condensation. These are sheltered locations

IP rating

Measurement and

overvoltage category

descriptions

Mains overvoltage

category rating

IP20 (as defined in IEC 60529).

surement terminals on this product may be rated for measuring mains voltages

Mea

from one or more of the following categories (see specific ratings marked on

the product and in the manual).

Category II. Circuits directly connected to the building wiring at utilization

points (socket outlets and similar points).

Category III. In the building wiring and distribution system.

Category IV. At the source of the electrical supply to the building.

NOTE. Only mains power supply circuits have an overvoltage c ategory rating.

Only measurement circuits have a measurement category rating. Other circuits

within the product do not have either rating.

Overvoltage category II (as defined in IEC 61010-1).

x ECO8000 Series Automatic Changeover Unit User Manual

Page 17

Environmental considerations

This section provides information about the environmental impact of the product.

Compliance information

Product end-of-life

handling

Restriction of hazardous

tances

subs

Observe the f

Equipment recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the product’s

end of life. To avoid release of such substances into the environment and to

reduce the

an appropriate system that will ensure that most of the materials are reused or

recycled appropriately.

Perchlorate materials. This product contains one or more type CR lithium

batteries. According to the state of California, CR lithium batteries are

ified as perchlorate materials and require special h andling. See

class

www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

This product is classified as an industrial monitoring and control instrument,

s not required to comply with the substance restrictions of the recast RoHS

and i

Directive 2011/65/EU until July 22, 2017.

ollowing guidelines when recycling an instrument or component:

use of n atural resources, we encourage you to recycle this product in

This symbol indicates that this product complies with the applicable European

Union re

on waste electrical and electronic equipment (WEEE) and batteries. For

information about recycling options, check the Support/Service section of the

Tekt r on

quirements according to Directives 2002/96/EC and 2006/66/EC

ixWebsite(www.tektronix.com).

ECO8000 Series Automatic Changeover Unit User Manual xi

Page 18

Compliance information

xii ECO8000 Series Automatic Changeover Unit User Manual

Page 19

Preface

Preface

Product description

This manual p

Automatic Changeover Unit. Also included is information about basic instrument

operation.

The ECO8000 Series Automatic Changeover Unit is a highly versatile automatic

sync and signal changeover unit with configurations and capabilities r equired

to address modern master sync application and other advanced sync timing

application. The ECO8000 Series offers exceptional reliability, stability, and is

designed

and/or 3G-SDI signal environments.

Each ECO

complete sync generator system, which offers extra redundancy for the critical

timing and synchronization system in the facilities.

A pair of Tektronix Master Sync / Master Clock Reference Generators

(SPG8000) for most broadcast facility timing applications.

A pair of Tektronix Test Signal Generators (TG8000) for more advanced post

production facility timing applications.

rovides safety and installation information for the ECO8000 Series

with optional high-bandwidth input changeover capabilities for HD/SD

8000 unit can be used with the following signal generators to form the

ECO8000 Series models

ECO8000 Series consist of the following models:

The

ECO8000: This model provides up to nine user-configurable BNC channels

d four LTC channels. The base configuration has three 50 MHz Electronic

an

Fast Switch (REF/ELSW) channels with options for six more 50 MHz

Electronic Fast Switch or 3 GHz Relay Switch (HREF/Relay) channels in

groups of three channels each, plus four optional LTC channels. Each channel

consisting of primary and backup inputs, and an output.

ECO8020: This model provides up to 20 user-configurable high-density

BNC channels and four LTC channels. The base configuration has five 50

MHz Electronic Fast Switch (REF/ELSW) channels with options for 15

more 50 MHz Electronic Fast Switch or 3 GHz Relay Switch (HREF/Relay)

channels in groups of five channels each, plus four optional LTC channels.

Each channel consisting of primary and backup inputs, and an output.

ECO8000 Series Automatic Changeover Unit User Manual xiii

Page 20

Preface

Key features and benefits

Innovative arc

advanced monitoring capability

Switches anal

LTC, as well as 3G-SDI, HD-SDI, and SD-SDI signals – all the timing and

synchronization signals required in modern broadcast, production, and post

production facilities

Scalable product architecture to fit various application needs

Electronic Fast Switch function for near glitch-less sync source switching,

minimizing disruption in operations if a switch is necessary to service the

primary sync source

Relay backups provide continued signal connection in the event that the

ECO loses power

Automatic and Manual changeover modes with indicator

Front panel LED indicators for the status o f each Primary and Backup channel

Front p

supply

Dual h

reference s ignals

anel LED indicators for the AC and DC status of each installed power

ot-swappable power supplies ensure continuous availability of

hitecture provides highly reliable basic ECO function and

og black burst, HD tri-level sync, AES/DARS, word clock,

Web Interface. An easy to navigate Web-based interface allows quick access to

most of the instrument settings and views. (See page 95, How to use the Web

Interface.) In most cases, it is easier to access and configure the instrument using

Web Interface. Examples of where this is especially true are:

the

Viewing instrument status

Viewing the Event Log

Viewing diagnostic results

Configuring event reporting

Configuring e-mail reporting

Configuring channel settings such as threshold levels, labels, etc.

xiv ECO8000 Series Automatic Changeover Unit User Manual

Page 21

Product documentation

Product documentation

To read about Use these documents

Product safety, installation, and

operation

Product specifications and

performan

Servicin

Clearing or sanitizing the product ECO8000 Series Declassification and Security Instructions

New features or known operational

issues

Softwa

ce verification

g the product

re licenses

ECO8000 Series User Manual

(Tektronix part number 071-3221-xx (English))

(Tektronix p

(Tektronix part number 077-0874-00 (Russian))

ECO8000 Series Video System Integration Technical Reference

(Tektronix part number 077-0877-00)

ECO8000 Series Specifications and Performance Verification Technical Reference

(Tektroni

ECO8000 S

(Tektronix part number 077-0880-00)

(Tektronix part number 077-0879-00)

ECO8000 Series Release Notes

(Tektro

tware licenses used by the ECO8000 Series are available for download from the

The sof

Tektronix Web site. T he licenses are bundled with the product firmware package.

art number 077-0873-00 (Japanese))

x part number 077-0876-00)

eries Service Manual

nix part number 077-0878-00)

Preface

Conve

ntions Used in This Manual

The following icons are used throughout this manual.

Sequence

Step

Fron

panel

power

t

Connect

power

Netw

ork

PS2 SVGA USB

ECO8000 Series Automatic Changeover Unit User Manual xv

Page 22

Preface

xvi ECO8000 Series Automatic Changeover Unit User Manual

Page 23

Getting Started

Initial produ

ct inspection

Perform the following product inspection procedure when you receive your

instrument:

1. Inspect the shipping carton for external damage, which may indicate damage

2. Remove the instrument from the shipping carton, and then check that the

NOTE. Save the shipping carton and packaging materials for instrument

repackaging in case shipment becomes necessary.

3. Verify that the shipping carton contains the basic instrument, all modules

Contact your local Tektronix Field Office or representative if there is a problem

with your instrument or if your shipment is incomplete.

to the instrument.

instrument has not been damaged in transit. Prior to shipment the instrument

is thorou

any scratches or impact marks.

you ordered, the standard accessories and any optional accessories that you

ordered listed in the table. (See Table 1.)

ghly inspected for mechanical defects. The exterior should not have

ECO8000 Series Automatic Changeover Unit User Manual 1

Page 24

Getting Started

Accessories

The following table lists the standard and optional accessories provided with

the ECO8000 Series product.

Table 1: Standard and optional accessories

Tektronix

Accessory Std. Opt.

ECO8000 Ser

Japanese and Russian language versions are available in

PDF format on the Tektronix Web site.

Power cord

(See page 2, International power cord options.)

Rackmount slides and rails kit (Option RACK only)

Adapter cable (6 feet long) from 15-pin D-sub LTC OUT

connect

LTC outputs) and 3 BNC male connectors (for General

Purpose Interface outputs) (Option XLR only)

Coaxial adapter cables from high-density m ale BNC

connec

cables, 75 Ω, 18 inches long) (ECO8020 Option CBL only)

1

To reorder the rack mounting kit, order ECO800UP or ECO802UP Option RACK.

2

To reor

3

To reorder the set of BNC adapter cables, order ECO802UP Option CBL.

ies User Manual (English)

or on the ECO8000 to 4 XLR male connectors (for

tor to standard male BNC connector (a set of 10

der the XLR adapter cable, order ECO800UP or ECO802UP Option XLR.

●

●

●

●

●

part number

071-3221-xx

Varies by

option

1

NA

2

NA

3

NA

International power cord

ns

optio

All of the available power cord options listed below include a lock mechanism

pt as otherwise noted.

exce

Opt. A0 – North America power (standard)

Opt. A1 – Universal EURO power

Opt. A2 – United Kingdom power

Opt. A3 – Australia power

Opt. A5 – Switzerland power

t. A6 – Japan power

Op

Opt. A10 – China power

Opt. A11 – India power (no locking cable)

Opt. A12 – Brazil power (no locking cable)

Opt. A99 – No power cord

2 ECO8000 Series Automatic Changeover Unit User Manual

Page 25

Product installation

Getting Started

Environmental operating

requirements

Check that the location of your installation has the proper operating environment

as listed in the following table. (See Table 2.)

CAUTION. Damage to the instrument can occur if this instrument is powered on at

temperatures outside the specified temperature range.

Table 2: ECO8000 Series environmental requirements

Parameter Description

Temperature

Relative

Humidity

de

Altitu

Operating 0 °C to +50 °C

Nonoperating

Operating 20% to 80% (No condensation); Maximum wet-bulb

Nonoperating

Operating To 3,000 m (9,842 feet)

Nonoperating

–20 °C to +60 °C

temperat

5% to 90%

temperature 40.0 °C

Maximum operating temperature decreases 1 °C for

each 30

To 15,

ure 29.0 °C

(No condensation); Maximum wet-bulb

0 m above 1.5 km.

000 m (49,212 feet)

Leave space for cooling by ensuring standard side clearance for rack mounting or

2 inches (5.1 cm) of side clearance for benchtop use. Also, ensure sufficient rear

clearance (approximately 2 inches) so that cables are not damaged by sharp bends.

For complete specifications for the instrument, refer to the ECO8000 Series

Specifications and Performance Verification Technical Reference. You can locate

this document on the Tektronix Web site (www.tektronix.com\downloads).

ECO8000 Series Automatic Changeover Unit User Manual 3

Page 26

Getting Started

Rackmount installation

(Option RACK only)

This instrumen

if Option RACK was ordered. Refer to the Rackmount Slides and Rails Kit

Instructions, Tektronix part number 071-2746-XX, that was supplied with the

instrument for instructions on how to install the rackmounting hardware.

WARNING. Personal injury or damage to the instrument can occur if the

instrument is not properly secured in the equipment rack.

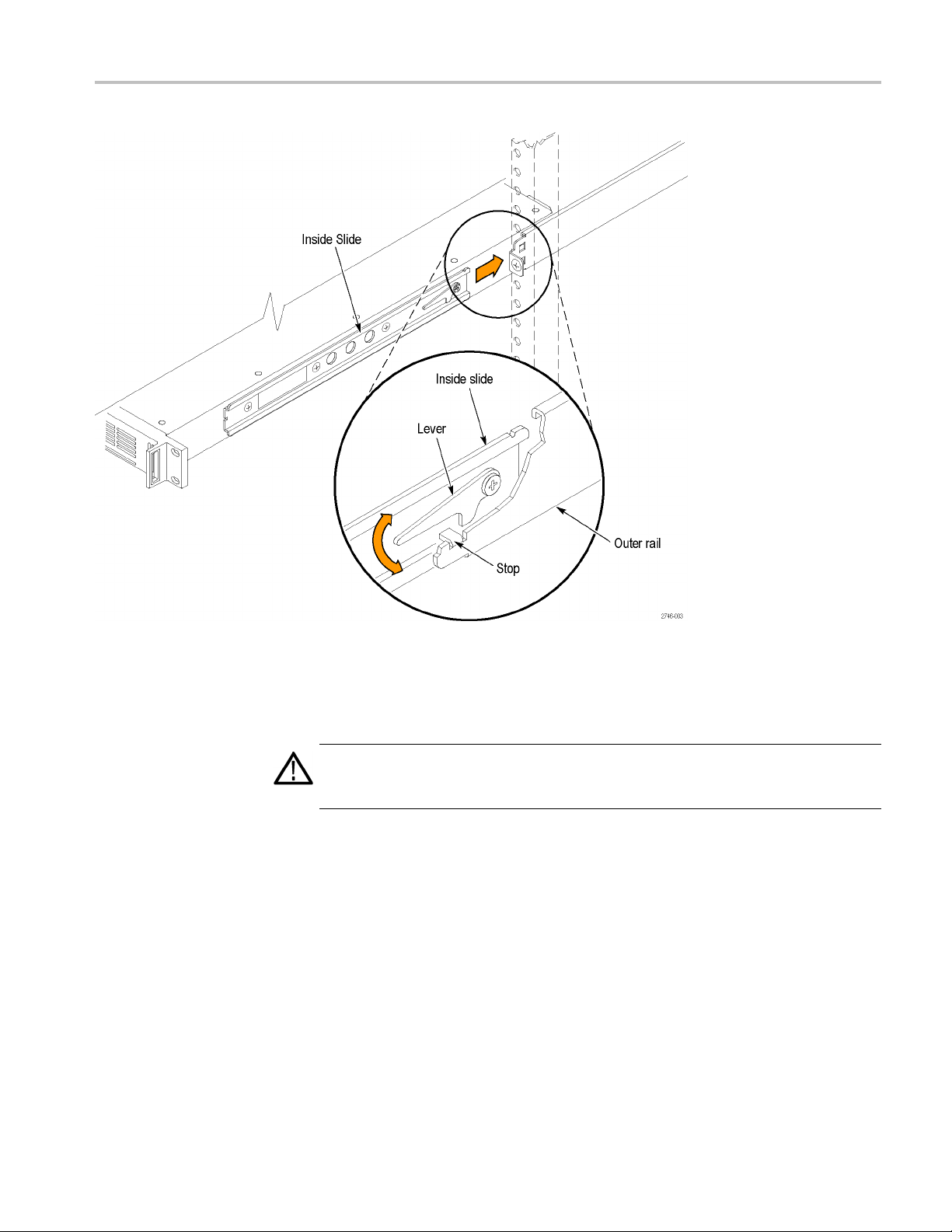

To install the instrument into an equipment rack. After you have installed the

rackmounting hardware, perform the following steps to install the instrument

into an eq

WARNING. To prevent injury during product installation, use care not to pinch

hands or fingers in the rails and slides.

1. Insert the instrument left and right slides into the ends of the rack rails while

tilting the long handle part of each lever upward. (See Figure 1.)

NOTE. Make sure to insert the instrument slides inside the inner rack rails. You

may also need to tilt the rear of the instrument up or down at a slight angle to fit

the slides into the rails.

tisconfigured at shipment for use in an equipment rack only

uipment rack:

2. Push the instrument into the rack until it stops.

CAUTION. To prevent damage to the instrument and rackmount, do not force the

instrument into the rack if it does not slide smoothly. The rails assembly may need

to be adjusted to resolve the problem.

3. Retighten any loose screws and push the instrument all the way into the rack.

If the tracks do not slide smoothly, readjust the rail assemblies.

4. When adjusting is completed, tighten all rail assembly 10-32 screws using

28 inch-lbs of torque.

5. If the instrument has knob screws on the front corners, tighten them so that

they are secured in the rack.

6. To remove the instrument from the rack, loosen the knob screws.

4 ECO8000 Series Automatic Changeover Unit User Manual

Page 27

Getting Started

Figure 1: Installing o r removing the instrument into or from the rack

To remove the instrument from an equipment rack. Perform the following steps to

remove an instrument that is installed in an equipment rack:

WAR NI NG . To prevent injury when removing the product from the rack, do not

forcefully and abruptly pull the product from the rack. Pull with the minimum

erequiredtomovetheinstrumentwith a consistent, even motion.

forc

1. Loosen the knob screws, if present, that attach the front of the instrument

he rack.

to t

2. Gently pull the instrument toward you until you can reach the levers at the

ar of the instrument.

re

3. Tilt both lever handles upward simultaneously to allow them to clear the

tops. (See Figure 1.)

s

4. Pull the instrument past the stops and out of the rack.

ECO8000 Series Automatic Changeover Unit User Manual 5

Page 28

Getting Started

Power connection

This instrumen

t operates from a single-phase power source with the neutral

conductor at or near earth ground. The line conductor is fused for over-current

protection. A protective ground connection through the grounding conductor in

the locking power cord is essential for safe operation.

CAUTION. The instrument does not have a power switch. When you connect

the power plug to one of the AC line connectors, and the Power Supply module

for that slo

t is installed, the instrument powers on. If you have only one power

supply installed, be sure to connect the power plug to the correct rear-panel

power connector.

AC power r

equirements. Check that your location provides the proper electrical

power requirements as listed in the following table. (See Table 3.)

Table 3: AC line power requirements

Parameter Description

ltage Range

Line Vo

100 - 240 VAC

WAR NI NG . To reduce the risk of fire

ck, ensure that the mains supply

and sho

voltage fluctuations do not exceed 10% of

the operating voltage range.

Line frequency 50/60 Hz

Maximum power 50 VA

6 ECO8000 Series Automatic Changeover Unit User Manual

Page 29

Getting Started

Connect the pow

Supply module installed in slot 1. If you ordered Option DPW, your instrument

was shipped with two Power Supply modules installed.

Connect the power cable(s) to the instrument first, and then connect it to the AC

power source. Connecting the power cable causes the instrument to power on.

After connecting the power, make sure that the fan in the instrument is working.

If the fan is not working, turn off the power by disconnecting the power cable

from the AC power source, and then contact your local Tektronix Field Office

or representative.

A power-on self test is run when the instrument firstbootsup. (Seepage27,

Power-on self test.)

er cable(s). Standard instruments are shipped with one Power

Network installation

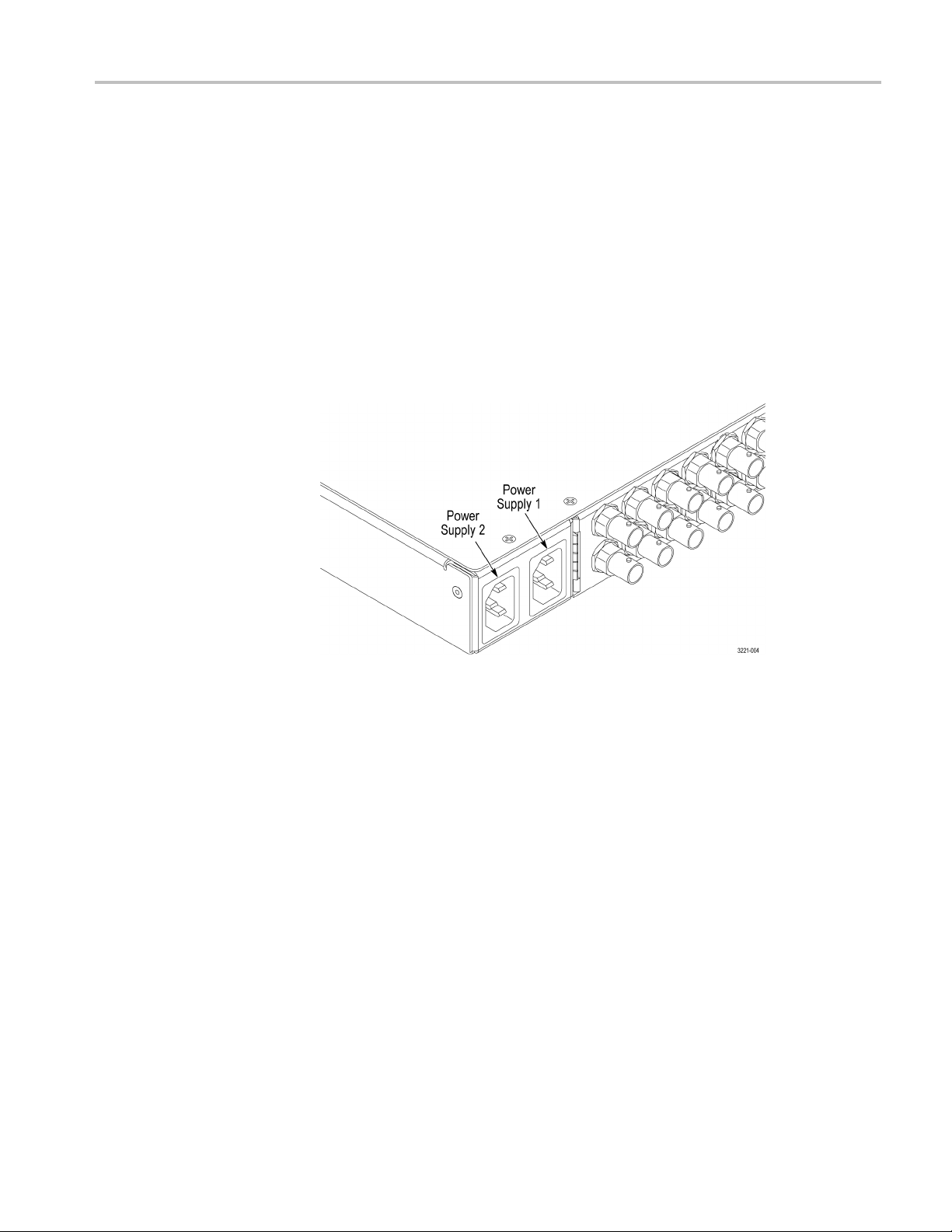

Figure 2: Location of rear panel power connectors (ECO8000 shown)

Configure the preferred supply (Option DPW only). If your instrument has two

Power Supply modules installed, configure one of the supplies to be the preferred

tive) supply. (See page 37, Configuring the p referred (active) supply (Option

(ac

DPW only).)

The ECO8000 Series has a 10/100 BASE-T Ethernet port on the rear panel that

allowsyoutouseaPCtoremotelycontroltheinstrument.

This section provides instructions for connecting the ECO8000 Series to a single

PC or to a network and for setting the network parameters on the Ethernet port.

ECO8000 Series Automatic Changeover Unit User Manual 7

Page 30

Getting Started

Connecting the instrument

to your PC(s)

To configure the network

parameters

You can use one o

PC(s):

If you are conn

cable to connect between the Ethernet port on the instrument and the Ethernet

port on th e PC.

If you are connecting the instrument to your local Ethernet network, use an

Ethernet cable to connect between the Ethernet port on the instrument and

the Ethernet hub port of your local network. By connecting to an Ethernet

network, you can access the instrument using any PC on the network.

The following two procedures describe how to configure the ECO8000 Series

network parameters. Use the first procedure if your network supports DHCP; use

the second procedure if your network does not support DHCP.

To config

a DHCP server, perform the following steps to configure the instrument to

function as a DHCP client. When the instrument is connected to the network and

DHCP service is enabled, the instrument obtains the necessary network addresses

automatically from the DHCP server.

NOTE. Under some network environments, the instrument may not be able to

get t

manually enter the appropriate network parameter values.

ure parameters for a network with a DHCP server. If your network has

he IP address automatically from a DHCP server. In this case, you need to

f the following two methods to connect the instrument to your

ecting the instrument directly to a single PC, use an Ethernet

er to your network administrator or to the user documentation supplied with

Ref

your network server operating system (OS) for detailed information about DHCP

server functions.

1. Press the front-panel BACK button as necessary to access the top-level Main

menu.

2. Press the up (▲)ordown(▼) arrow button to select SYSTEM CONFIG,

andthenpresstheENTER button to access the SYSTEM CONFIG menu.

3. Press the up (▲)ordown(▼)arrowbuttontoselectNETWORK CONFIG,

and then press the ENTER button to access the NETWORK CONFIG

submenu. The display shows whether DHCP is enabled or not.

4. If necessary, press the left (◄)orright(►) arrow button to select Enable,

and then press the ENTER button to implement the selection.

5. Press the down (▼)arrowbuttontoselectIP ADDRESS.

8 ECO8000 Series Automatic Changeover Unit User Manual

Page 31

Getting Started

6. The second line

receives an address from the DHCP server. The message “Waiting for DHCP”

will appear until the instrument receives the address.

7. After the display shows an IP address, press the BACK buttontoexitthe

NETWORK CONFIG submenu.

To configure parameters for a network without a DHCP server. If your network

does not have a DHCP server, perform the following procedure to set the network

parameter

1. Press the front-panel BACK button as necessary to access t he top-level Main

2. Press the up (▲)ordown(▼) arrow button to select SYSTEM CONFIG,

3. Press the up (▲)ordown(▼)arrowbuttontoselectNETWORK CONFIG,

4. If nec

5. If you

s:

menu.

and then

and the

submenu. The display shows whether DHCP is enabled or not.

and then press the ENTER button to implement the selection.

press the ENTER button to access the SYSTEM CONFIG menu.

npresstheENTER button to access the NETWORK CONFIG

essary, press the left (◄)orright(►)arrowbuttontoselectDisable,

connected the instrument directly to a single PC:

of the d isplay will show an IP address after the instrument

a. Press the up (▲)ordown(▼) arrow button to select IP ADDRESS,and

press the ENTER button to enter the edit mode.

then

b. Use the arrow buttons to set the IP address to be the same IP address as

PC's address except for the last number, and then press the ENTER

the

button. The last number in the address must be different than the last

number in the PC's IP address.

c. Press the up (▲) or down (▼) arrow button to select SUBNET MASK,

and then press the ENTER button to enter the edit mode.

d. Use the arrow buttons to set the subnet mask to be the same net mask

(subnet mask) used by the PC, and then press the ENTER button. Do not

enter a number if the PC does not have a net mask.

e. YoudonotneedtoenteraGATEWAY address if you are directly

connectedtoasinglePC.

f.

Press the BACK button to exit the NETWORK CONFIG submenu.

ECO8000 Series Automatic Changeover Unit User Manual 9

Page 32

Getting Started

6. If you connecte

CAUTION. To prevent communication conflicts on your Ethernet network, ask your

local network administrator for the correct numbers to enter in the NETWORK

CONFIG submenu if you connect the instrument to your local Ethernet network.

a. Press the up (▲)ordown(▼) arrow button to select IP ADDRESS,and

then press the ENTER button to enter the edit mode.

b. Use the arrow buttons to set the IP address to the address supplied by your

network administrator, and then press the ENTER button.

c. Press the up (▲)ordown(▼) arrow button to select SUBNET MASK,

and then press the ENTER button to enter the edit mode.

d. Use the arrow buttons to set the subnet mask to the address supplied by

your network administrator, and then press the ENTER button.

e. Press the up (▲)ordown(▼)arrowbuttontoselectGATEWAY

ADDRESS, and then press the ENTER button to enter the edit mode.

f. Use the arrow buttons to set the gateway address to the address supplied

by your network administrator, and then press the ENTER button.

d the instrument to your local Ethernet network:

g. Press the BACK button to exit the NETWORK CONFIG submenu.

7. Verify the Ethernet connection by using a ping command from the PC.

10 ECO8000 Series Automatic Changeover Unit User Manual

Page 33

Getting Started

System consid

Using identical sync

erations

sources

It is recommended that the primary and backup sync sources be identically

configured. If the two sync source generators have significantly different

configuratio

power.

To underst

sync sources, the sync signals will fail as the power supples on the generators turn

off. If the signal output from one of the sync generators is maintained longer,

then the ECO8000 Series may detect one input as good and the other as bad and

switch to the “good” sync source.

This might happen if the backup sync generator has only a few black outputs,

but the primary sync generator has many blacks, audio and SDI signal outputs.

The difference in the number of outputs loading the power supplies will make

the pri

detect the primary source as failed while the backup is still working, resulting in

a source switch.

The ECO8000 Series detects the loss of AC power and inhibits source switching to

mitigate this issue. However, it can still occur in extreme cases. If it is necessary

to have differently configured sync generators on the primary and backup inputs,

it is recommended that you thoroughly test the loss of power condition during the

system qualification testing.

ns, it may cause a source switch when both of the sync sources lose

and this, consider the following scenario. If power is cut to both of the

mary sync generator turn off faster. This causes the ECO8000 Series to

ng the Expansion port

Usi

to gang two ECOs

Testing the backup source

The ECO8000 Series has the ability to connect two instruments so that they

function as a single larger switch. This function is useful in situations where

more channels are needed than can be supported using only one instrument. One

nstrument operates as a master unit and the other as a slave unit.

i

A slave unit may change state if the master unit is changed from master to

isabled or if the interconnection cable is removed. It is recommended that

d

you configure the master and slave units during system setup and that you not

change the configuration while the instrument is in operation. To help enforce this

recommendation, the ECO8000 Series must b e in Manual mode before you can

change the state of the expansion port. (See page 35, Configure the Expansion

port.)

Tektronix recommends that you test the backup sync source every 6 months. The

ECO8000 Series keeps track of the last time the source was changed from primary

to backup and visa-versa. If it has been more that 6 months since a source switch,

then an event will be entered in the Event Log. You can also configure any of the

reporting methods (SNMP trap, e-mail, GPI signal, instrument beeper) to generate

an output when the backup test is due. (See page 83, EVENT submenus.)

ECO8000 Series Automatic Changeover Unit User Manual 11

Page 34

Getting Started

Signal connec

tions

Before you connect signals to the ECO8000 Series, create a table similar to the

one shown below so that you can plan which signals need to connect to which

channels on t

he ECO8000 Series.

Table 4: Example plan for connecting signals to an ECO8000

Channel Channel type Signal source Destination Signal format Notes

1

2

3

4

5

6

7

8

9

LTC1 LTC

LTC2 LTC

LTC3 LTC

LTC4 LTC

SPG trigger Loss of lock,

REF (ELSW)

REF (ELSW)

REF (ELSW)

REF (ELSW)

REF (ELSW)

REF (ELSW) Word Clock MC WC

HREF (Relay) Silence S ound room AES

HREF (Relay) SDI 1 MC SD BARS SD 525

HREF (Relay) SDI 2 MC HD BARS

Black 1

Black 2

Black 3 Basement 1080i59

Black 4

Black 5 Truck 1 1080i60

0.5 V

1V

2V

5V

hardware error

Studio 1 NTSC

Studio 2

MC Tri

MC LTC

Studio 1 LTC

Studio 2 LTC 25 FPS

Basement LTC

PAL

1080i50

5V

HD 1080i59

30 DF

30 DF 4 dB

30 DF

2.5, 2.3 dB

Channel type connection guidelines. When connecting signals to the instrument,

use the following guidelines:

Use REF (ELSW) channels to connect non-SDI signals

Use HREF (Relay) channels to connect SDI signals

You can connect non-SDI signals to HREF (Relay) channels. However, there will

be a sync interruption when p rimary/backup source switches occur.

Recommended tools. The ECO8020 uses HD BNC connectors. Due to the

tight spacing between co nnectors, it is recommended that you use a HD BNC

installation/removal tool to connect or disconnect cables on these connectors.

Listed below is one source where you can obtain this tool.

Manufacturer Part number

Amphenol®RF (www.amphenolrf.com)

227–T2000

12 ECO8000 Series Automatic Changeover Unit User Manual

Page 35

Getting Started

Example connec

tion diagrams. The following illustrations show a couple of

examples on how to connect signals from a pair of Tektronix SPG8000 generators

to the ECO8000 Series. For more detailed information about connecting signals,

see the ECO8000 Series Video System Integration Technical Reference manual.

Figure 3: ECO8000 and SPG8000 system installation example

Table 5: ECO8000 and SPG8000 system installation example connections

Connection

number (See

Figure 3.)

1

2

3

4

5

6

7

8

9

External

signal

SPG8000

primary

connector

SDI 2

SDI 1

DARS

WORD CLK

CMPST 1

SPG8000

backup

connector

SDI 2 BACKUP 9

SDI 1 BACKUP 8

DARS BACKUP 6

WORD CLK BACKUP 5

ECO8000

connector

PRIMARY 9

PRIMARY 8

PRIMARY 6

PRIMARY 5

PRIMARY 4

ECO8000 Series Automatic Changeover Unit User Manual 13

Page 36

Getting Started

Table 5: ECO8000 and SPG8000 system installation example connections (cont.)

Connection

number (See

Figure 3.)

10

11

12

13

14

15

16

17

18

19

SPG8000

External

signal

GPS signal GPS ANT GPS ANT

primary

connector

10 MHz/

BLACK 3

BLACK 2

BLACK 1

GPI/LTC

SPG8000

backup

connector

CMPST 1 BACKUP 4

10 MHz/

BLACK 3

BLACK 2 BACKUP 2

BLACK 1 BACKUP 1

GPI/LTC BACKUP

ECO8000

connector

PRIMARY 3

BACKUP 3

PRIMARY 2

PRIMARY 1

PRIMARY

LTC /S PG

LTC /S PG

NA

14 ECO8000 Series Automatic Changeover Unit User Manual

Page 37

Getting Started

Figure 4: ECO8020 and SPG8000 system installation example

Table 6: ECO8020 and SPG8000 system installation example connections

Connection

number (See

Figure 4.)

1

2

3

4

5

6

7

8

9

10

11

External

signal

SPG8000

primary

connector

SDI 2

SDI 1

DARS

WORD CLK

AES 5+6

AES 7+8

SPG8000

backup

connector

SDI 2 BACK 20

SDI 1 BACK 19

DARS BACK 9

WORD CLK BACK 14

AES 5+6 BACK 8

ECO8000

connector

PRI 20

PRI 19

PRI 9

PRI 14

PRI 8

PRI 13

ECO8000 Series Automatic Changeover Unit User Manual 15

Page 38

Getting Started

Table 6: ECO8020 and SPG8000 system installation example connections (cont.)

Connection

number (See

Figure 4.)

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

SPG8000

External

signal

GPS signal GPS ANT GPS ANT

primary

connector

AES 1+2

AES 3+4

CMPST 1

CMPST 2

BLACK 4

BLACK 5

10 MHz/

BLACK 3

BLACK 2

BLACK 1

GPI/LTC

SPG8000

backup

connector

AES7+8 BACK13

AES 1+2 BACK 7

AES3+4 BACK12

CMPST 1 BACK 6

CMPST 2 BACK 11

BLACK 4 BACK 4

BLACK 5 BACK 5

10 MHz/

BLACK 3

BLACK 2 BACK 2

BLACK 1 BACK 1

GPI/LTC BACKUP

ECO8000

connector

PRI 7

PRI 12

PRI 6

PRI 11

PRI 4

PRI 5

PRI 3

BACK 3

PRI 2

PRI 1

PRIMARY

LTC /S PG

LTC /S PG

NA

16 ECO8000 Series Automatic Changeover Unit User Manual

Page 39

Operating Basics

Operational o

Figure 5: ECO8000 Series subsystems (ECO8020 with Option DPW shown)

verview

The ECO8000 Series has three main subsystems:

Channel Control system

Configuration and Monitoring system

Redundant Power system

These thre

main ECO function, which is sensing faults on the input signals and switching to

a backup if necessary.

e subsystems are loosely coupled to assume maximum reliability of the

Channel Control system

The Channel Control system monitors the level on each input, and switches to the

other sync source if a fault occurs. This subsystem is implemented as a simple

hardware state machine to maximize reliability. This portion of the instrument is

accessed via the left keyboard, and the status is displayed on the button lights and

the per-channel LEDs on the front panel.

If the instrument is in AUTO mode, then the Channel Control system locks out

any changes from the other subsystems. This prevents most issues in the other

bsystems from impacting the basic operation of the ECO.

su

When the instrument powers on, the Channel Control system restores all basic

onfiguration settings that were in place when the instrument was powered off.

c

This restoration is independent of the processor booting to run the display and

the Configuration and Monitoring system. If the Configuration and Monitoring

system is rebooted, the Channel Control system is unaffected.

If the instrument loses power, the REF/ELSW channels will automatically switch

from electronic to relay mode to maintain the signal throughput. These channels

will automatically switch back to electronic mode when power is restored. When

the REF/ELSW channels switch from electronic mode to relay mode and back,

the sync on these channels will experience a momentary glitch.

ECO8000 Series Automatic Changeover Unit User Manual 17

Page 40

Operating Basics

Configuration and

Monitoring system

The Configurati

menus. This system is accessed via the right keyboard, the LCD, and the Web

Interface. If the instrument is in MANUAL mode, then the Configuration and

Monitoring system can program the settings in the Channel Control system.

For example, it can set the level threshold on each channel, or disable unused

channels. When the instrument is in AUTO mode, most configuration is disabled

and this sub

If the Configuration and Monitoring system processor stops running, a 20 minute

watchdog t

processor reboot. If the watchdog timer causes a reboot, the event is entered

in the Event Log.

Under certain conditions, such as after several y ears of continued use, you may

want to reboot the Configuration and Monitoring system. You can reboot this

system by pressing and holding the ENABLE and RESET buttons for about five

seconds until the instrument beeps about five times. Rebooting this system will

have no affect on the other subsystems. When this system is rebooted, a power-on

st is performed. (See page 27, Power-on self test.)

self te

Menu system. The top-level Main menu provides access to the following three

menus:

STATUS: Use this menu to view instrument faults and the Event Log. (See

page 56.)

on and Monitoring system is software based and includes the

system is used for monitoring only.

imer in the Channel Control System will automatically cause a

Redundant Power system

Channel configuration

CHANNEL: UsetheCHANNELmenutoviewandconfigure the settings for

each of the BNC or LTC (Option LTC only) channels.(See page 62.)

SYSTEM CONFIG: Usethismenutoviewandconfigure all instrument

settings except for the channel configuration.

The Redundant Power system monitors each Power Supply module (Option DPW

provides a second, backup supply) and switches to the backup if the preferred

supply has a problem. This subsystem is independent of the other two systems.

The Configuration and Monitoring system can set some parameters in the

Redundant Power system and display its status.

The channel configuration for the ECO is done in MANUAL mode. When the

system is fully configured, and all channels in use show green status LEDs and

good signal margin, switch the instrument to AUTO mode. When the instrument

is in AUTO mode, the channel configuration is disabled and the system will react

to input signal faults. In AUTO mode, monitoring can be done locally via the

LCD or remotely via the Web Interface with no risk of accidental changes that

would impact the basic ECO operation.

18 ECO8000 Series Automatic Changeover Unit User Manual

Page 41

Operating Basics

Controls, con

Figure 6: ECO8000 controls and connectors

nectors, and LED indicators

The following figures show the front-panel controls and rear-panel connectors for

the ECO8000 and ECO8020 changeover units. See the following table for a

description

of each control and connector.

Figure 7: ECO8020 controls and connectors

ECO8000 Series Automatic Changeover Unit User Manual 19

Page 42

Operating Basics

Item

(See Figure 6.)

(See Figure 7.) Description

1

Control buttons (Channel Control system):

PANEL ENABLE – Press and hold for about four seconds to enable/disable the front-panel

control butt

of the front-panel control buttons.

NOTE. The front panel must be enabled to use the following five control buttons.

ons. The instrument beeps to indicate the change in the enable/disable status

FAULT RESET

(turn yellow LEDs to green).

MODE – Press AUTO or MANUAL to select the desired changeover mode. The changeover

mode must set to AUTO to react to signal faults. The changeover mode must be set to

MANUAL bef

button is illuminated.

SOURCE – When in Manual mode, press PRIMARY or BACKUP to select which signal source

to output. This setting applies to all channels. The selected source button is illuminated.

2

Status LED’s:

SPG – When enabled, indicates the status of the SPG trigger input.

LTC – When Option LTC is installed, indicates the combined status of all LTC channels which

are enab

ECO800

ECO802

The color of the LED’s indicate their status:

Green: Indicates a no-fault condition.

Yellow: Indicates that a fault condition occurred in the past but has been corrected. Press the

FAULT RESET button to change yellow LEDs to green.

Red: Indicates an active fault condition.

– Press to clear the individual channel fault history on the front-panel LEDs

ore you can change the instrument configuration settings. The selected mode

led. If any enabled LTC channel had a fault, then this LED will be red.

0: The 1 to 9 LEDs indicate the status for each of the possible 9 installed channels.

0: The 1 to 20 LEDs indicate the status for each of the possible 20 installed channels.

Off: Indicates the channel is inactive (disabled).

3

4

5

6

LCD display showing the instrument status and the control menu.

Menu navigation (Configuration and Monitoring system) buttons:

Arrow buttons – Use to navigate through the menus or to change parameter values.

ENTER button – Use to enter submenus or to implement menu selections.

BACK button – Use to exit submenus.

Standard Power Supply module. (See page 25, Power Supply module LED states.)

Optional backup Power Supply module (Option DPW only).

See page 25, Power Supply module LED states.)

(

(See page 37, Configuring the preferred (active) supply (Option DPW only).)

20 ECO8000 Series Automatic Changeover Unit User Manual

Page 43

Item

(See Figure 6.)

(See Figure 7.) Description

7

8

9

10

11

12

13

Power connectors. When viewed from the rear of the instrument, the Power Supply 1 connector is

on the right. (

ECO8000: Opt

or 3 GHz Relay Switch channels

ECO8020: Optional channels 6–20; each row can be either 50 MHz Electronic Fast Switch

channels or

ECO8000: St

ECO8020: Standard 50 MHz Electronic Fast Switch channels 1–5.

ETHERNET – Standard Ethernet connector used for connecting the instrument to an Ethernet

network. (See page 7, Network installation.)

EXPANSION – Standard Ethernet connector used for connecting multiple ECO 8000 S eries

instrume

the Expansion port.)

GPIO – 15-pin DSUB connector used to connect G PI signals to the ECO8000 Series units. (See

page 22, GPIO connector signal pinouts.)

nt together so that they function as one larger changeover unit. (See page 35, Configure

NOTE. The SPG Trigger signal on this connector (pin 1) will operate even when Option LTC is not

installed. (See page 23, LTC/SPG connector signal pinouts.)

Operating Basics

See Figure 3 on page 13.)

ional channels 4–9; each row can be either 50 MHz Electronic Fast Switch channels

3 GHz Relay Switch channels

andard 50 MHz Electronic Fast Switch channels 1–3.

14

15

PRIMARY LTC/SPG – 15-pin DSUB connector used to connect LTC and GPI signals from Tektronix

SPG8000 or TG8000 generators to the ECO8000 Series units. (See page 31, Configure the SPG

trigger input.)

NOTE. The SPG Trigger signals on this connector (pins 1 and 2) will operate even when Option

s not installed. (See page 24, LTC OUT connector signal pinouts.)

LTC i

Option LTC only: LTC OUT – 15-pin DSUB connector for connecting LTC signals. The LTC1

signal can be be configured as an input using the CHANNEL menu. (See page 62, CHANNEL

u.)(See page 31, Configure the SPG trigger input.)

men

NOTE. The SPG Trigger signal on this connector (pin 1) will operate even when Option LTC is not

installed. (See page 23, LTC/SPG connector signal pinouts.)

BACKUP LTC/SPG – 15-pin DSUB connector used to connect LTC and GPI signals from Tektronix

SPG8000 or TG8000 generators to the ECO8000 Series units. (See page 31, Configure the SPG

trigger input.)

ECO8000 Series Automatic Changeover Unit User Manual 21

Page 44

Operating Basics

GPIO connector

signal pinouts

The following t

able lists the signals and their function for each pin on the GPIO

connector.

Table 7: GPIO connector signal pinouts

Pin

1

2

3

4

5

6

7

8 Auto mode Input – drive this pin low to assert Auto

9 Fault reset Input – drive this pin low to assert a

10

11

12 Not used

3

1

4

1

15 Not used

Signal

State – Primary Backup Output – high if Primary is selected, low

Primary f

Backup fault Output – goes low if a Backup fault is

State – Manual Auto Output – high if Manual mode is

GND Ground

Power

Manual mode Input – drive this pin low to assert

Configurable fault Output – goes low if any fault selected

GND Ground

P

B

ault

fault

rimary select

ackup select

Function

if Backup i

Output – g

present

present

selecte

Outpu

the power subsystem as indicated by

the AC or DC LEDs on the supplies

Manual mode (10 KΩ pullup resistor)

mode (10 KΩ pullup resistor)

fault reset (10 KΩ pullup resistor)

in t

also goes low during any watchdog

reboot

nput – drive this pin low to select the

I

Primary source (10 KΩ pullup resistor)

nput – drive this pin low to select the

I

Backup source (10 KΩ pullup resistor)

s selected

oes low if a Primary fault is

d, low if Auto mode is selected

t – goes low if a fault is preset in

he GPI EVENTS menu are present;

22 ECO8000 Series Automatic Changeover Unit User Manual

Page 45

Operating Basics

LTC/SPG connector

signal pinouts

The following t

able lists the signals and their function for each pin on the

LTC/SPG connector.

NOTE. The SPG Trigger signal on this connector (pins 1) will operate even when

Option LTC is not installed.

Table 8: LTC/SPG connector signal pinouts

Pin

1

2 Not used

3 Not used

4 Not used

5

6

7

8

9

10

11 No t u sed

12

13

14

15

1

The LTC 1 channel can be configured as an input or output in the CHANNEL menu. (See page 62, CHANNEL

menu.)

Signal

SPG trigger Input – Used to receive a fault-condition

LTC4– Input – LTC4– signal

GND Ground

LTC3– Input – LTC3– signal

LTC2– Input – LTC2– signal

GND Ground

LTC1– Input or output – LTC1– signal

LTC3+ Input – LTC3+ signal

LTC2+ Input – LTC2+ signal

LTC1+ Input or output – LTC1+ signal

LTC4+ Input – LTC4+ signal

Function

trigger signal from the sync generator

1

1

ECO8000 Series Automatic Changeover Unit User Manual 23

Page 46

Operating Basics

LTC OUT connector

signal pinouts

The following t

able lists the signals and their functions for each pin on the LTC

OUT c onnector.

NOTE. The SPG Trigger signals on this connector (pins 1 and 2) will operate

even when Option LTC is not installed. (See page 24, LTC OUT connector signal

pinouts.)

Table 9: LTC OUT connector signal pinouts

Pin

1

2

3 Not use

4 Not used

5

6

7

8

9

10

11 Not used

12

3

1

4

1

15

1

The LTC 1 channel can be configured as an input or output in the CHANNEL menu. (See page 62, CHANNEL

menu.)

Signal

Primary SPG trigger Output – SPG trigger signal from the

Backup S

LTC4– Output – LTC4– signal

GND Ground

LTC3– Output – LTC3– signal

LTC2– Output – LTC2– signal

GND Ground

LTC1– Output or input – LTC1– signal

LTC3+ Output – LTC3+ signal

LTC2+ Output – LTC2+ signal

LTC1+ Output or input – LTC1+ signal

LTC4+ Output – LTC4+ signal

PG trigger

Function

primary

Output –

backup input

input

SPG trigger signal from the

d

1

1

24 ECO8000 Series Automatic Changeover Unit User Manual

Page 47

Operating Basics

Power Supply module LED

states

When the instru

ment is running, the power supply LEDs indicate the status of

the supplies, including the internal fans and which of the supplies is currently

powering the instrument.

If the instrument loses power from both supplies, the LEDs continue to provide

status to help troubleshoot the root of the problem. In this mode, the LEDs flash

to conserve the power in the storage capacitor. Typically the LED flashing should

last for 10 minutes after the loss of power.

If both of the supplies are good, the system will use the supply that is configured

to be the preferred (active) supply. If one power supply has a p roblem, the system

will switch to the other supply. If either supply c an support the instrument load,

even if it

has a non-fatal problem, the system will choose the best supply and

attempt to continue to operate.

The following table shows the states of the AC and DC LEDs on a Power Supply

module when the power is on.

Table 10: Power on LED states for a Power Supply module

Power Supply state AC LED state DC LED state

Normal, Active

Normal, Backup

AC < 75 V, DC supply running

AC < 75 V, DC supply failed

AC OK, DC supply failed Green

Marginal Low or High DC, Active Orange

Marginal Low or High DC, Backup