Page 1

Instruction Manual

ECO 422

Changeover Unit

070-8472-02

Warning

The servicing instructions are for use by qualified

personnel only. To avoid personal injury, do not

perform any servicing unless you are qualified to

do so. Refer to all safety summaries prior to

performing service.

Page 2

Copyright E Tektronix, Inc., 1997. All rights reserved. Printed in U.S.A. Tektronix products are

covered by U.S. and foreign patents, issued and pending.

Information in this publication supersedes that in all previously published material. Specifications and price change privileges reserved. The following are registered trademarks: TEKTRONIX and TEK.

For product related information, phone: 800-TEKWIDE (800-835-9433), ext. TV.

For further information, contact: Tektronix, Inc., Corporate Offices, P.O. Box 1000, Wilsonville,

OR 97070–1000, U.S.A. Phone: (503) 627–7111; TLX: 192825; TWX: (910) 467–8708; Cable:

TEKWSGT.

Page 3

WARRANTY

Tektronix warrants that this product will be free from defects in materials and workmanship for a period of one (1) year from

the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either will repair

the defective product without charge for parts and labor, or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the warranty

period and make suitable arrangements for the performance of service. Customer shall be responsible for packaging and shipping the defective product to the service center designated by Tektronix, with shipping charges prepaid. Tektronix shall pay

for the return of the product to Customer if the shipment is to a location within the country in which the T ektronix service center

is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate maintenance

and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting from attempts

by personnel other than Tektronix representatives to install, repair or service the product; b) to repair damage resulting from

improper use or connection to incompatible equipment; c) to repair any damage or malfunction caused by the use of non-T ektronix supplies; or d) to service a product that has been modified or integrated with other products when the effect of such modification or integration increases the time or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY OTHER

WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY

PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY. TEKTRONIX AND ITS VENDORS

WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY

OF SUCH DAMAGES.

Page 4

Page 5

EC Declaration of Conformity

We

Tektronix Holland N.V.

Marktweg 73A

8444 AB Heerenveen

The Netherlands

declare under sole responsibility that the

ECO422 Changeover Unit

meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility.

Compliance was demonstrated to the following specifications as listed in the Official

Journal of the European Communities:

EN 50081-1 Emissions:

EN 55022 Class B Radiated and Conducted Emissions

EN 50082-1 Immunity:

IEC 801-2 Electrostatic Discharge Immunity

IEC 801-3 RF Electromagnetic Field Immunity

IEC 801-4 Electrical Fast Transient/Burst Immunity

High-quality shielded cables must be used to ensure compliance to the above listed

standards.

Page 6

Page 7

Table of Contents

Getting Started 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Installation 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Installation 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hints on Using the User Configuration Switches 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Check and First Time Operation 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loss of the Primary Signal 1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loss of the Backup Signal 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loss of Power to the ECO 422 1–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls and Indicators 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front-Panel Controls 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Controls 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connectors 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Video Signals (11 Channels) 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Basics 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

State Machine Discussion 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Adjust the User-Defined Threshold Levels 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Certification 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EMI Standards 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Theory of Operation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Conventions 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ECO 422 Block Level Description 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ECO 422 Detailed Circuit Description 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Input and Comparators

Control and Remote

Reference Voltage and Selector Switch Farm

Post Regulated Power Supply 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Data Report 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Procedure 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Checking Disabled 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Black Burst Checks 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

through

8

7

9

4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ECO 422

i

Page 8

Contents

Serial Digital Video Checks 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Digital Audio Checks 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment Procedure 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Adjust the User-Defined Threshold Levels 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Options 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ektronix Service 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparation 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Cleaning 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Visual Inspection 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Static-Sensitive Components 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification and Readjustments 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Corrective Maintenance 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Troubleshooting Procedures 7–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T ektronix Service Offerings 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Training 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Service Centers 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Exchange 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Factory Replacement Parts 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Etched Circuit Boards 7–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal/Replacement Instructions 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal/Replacement Instructions 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Instructions for the Connector Board 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Remove the Heat Sink 7–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging Instructions 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification T ag 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repackaging for Shipment 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Cord Options 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Electrical Parts 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrams/Circuit Board Illustrations 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replaceable Mechanical Parts 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

ECO 422

Page 9

List of Figures

Figure 1–1: Front of the ECO 422 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Rear of the ECO 422 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–3: Front Rail Mount 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Deep Rackmount 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–5: Shallow Rackmount 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–6: Assembly of Rackmounting Hardware 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–7: Installing the Instrument in the Rack Slides 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–8: Example of How the ECO 422 Can be Connected 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–9: Default Position of the User Configuration and Mode Switches 1–9. . . . . . . . . . . . . . . .

Figure 1–10: Setup for the Functional Check 1–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–1: Front-Panel Controls 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–2: Default Position of the User Configuration and Mode Switches 2–2. . . . . . . . . . . . . . . .

Figure 2–3: Rear of the ECO 422 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–4: Remote Connector Pin-Out 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–5: Wiring Required to Conform with SMPTE Fault Reporting 2–6. . . . . . . . . . . . . . . . . . . .

Figure 2–6: Setup for Adjusting R265 (the User Level for SX-7) 2–9. . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2–7: Flowchart for Adjusting R265 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents

Figure 4–1: Block Diagram of the ECO 422 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–2: Block Diagram of the Input Comparator 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–3: Block Diagram for the Control and Remote Circuit 4–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4–4: Reference Voltage and Selector Switch Farm Block Diagram 4–6. . . . . . . . . . . . . . . . . .

Figure 5–1: Setup to Check Black Burst Levels 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5–2: Setup to Check the Component Serial Digital Video Levels 5–12. . . . . . . . . . . . . . . . . . . .

Figure 5–3: Setup to Check the Serial Digital Video Composite Levels 5–14. . . . . . . . . . . . . . . . . . . .

Figure 5–4: Setup to Check the Serial Audio Levels 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–1: Remove these Screws and Post before Attempting to Remove the Connector Board 7–8

Figure 7–2: Slide the Connector Board Out this Way 7–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7–3: Remove the Heat Sinks this Way 7–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ECO 422

iii

Page 10

Contents

List of Tables

Table 1–1: Channel Configuration Switches (S1 – S11) 1–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Factory Settings of Channel Configuration Switches (S1 – S11) 2–3. . . . . . . . . . . . . . . .

Table 2–2: Truth Table for ECO 422 Switching 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–1: General Characteristics 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–2: Signal Loss Detection 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–3: Power Supply 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–4: Mechanical (Physical) Characteristics 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3–5: Environmental Characteristics 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–1: Static-Sensitive Components 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7–2: Assemblies in the ECO 422 7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

ECO 422

Page 11

Safety Summary

Terms

The general safety information in this part of the summary is for both operating

and service personnel. Find specific warnings and cautions throughout the

manual where they apply.

Terms in This Manual

Symbols

Terms on the Product

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

Symbols on the Product

ECO 422

CAUTION indicates a hazard to property including the product.

The following symbols may appear on the product:

v

Page 12

General Safety Summary

DANGER

High Voltage

Power Source

This product is intended to operate from a power source that will not apply more

than 250 volts rms between the supply conductors or between either supply and

ground. A protective ground connection by way of the grounding conductor in

the power cord is essential for safe operation.

Grounding The Product

This product is grounded through the grounding conductor of the power module

power cord. To avoid electric shock, plug the power cord into a properly wired

receptacle before connecting the product input or output terminals. A protective

ground connection by way of the grounding conductor in the power module

power cord is essential for safe operation.

Danger Arising From Loss Of Ground

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

Double

Insulated

Upon loss of the protective ground connection, all accessible conducting parts

(including controls that may appear to be insulating) can render an electric

shock.

Use The Proper Fuse

To avoid fire hazard, use only the fuse of the correct type, voltage rating, and

current rating as specified in the parts list for your product.

Refer fuse replacement to qualified service personnel.

Do Not Operate In An Explosive Atmosphere

To avoid explosion, do not operate this product in an explosive atmosphere

unless it has been specifically certified for such operation.

vi

ECO 422

Page 13

Do Not Operate Without Covers

To avoid personal injury, do not operate this product without covers or panels

installed.

Certifications and Compliances

General Safety Summary

CSA Certified Power

Cords

Safety Certification of

Plug-in or VXI Modules

Compliances

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

For modules (plug-in or VXI) that are safety certified by Underwriters Laboratories, UL Listing applies only when the module is installed in a UL Listed

product. CSA Certification applies only when the module is installed in a CSA

Certified product.

Consult the product specifications for IEC Installation Category, Pollution

Degree, and Safety Class.

ECO 422

vii

Page 14

General Safety Summary

viii

ECO 422

Page 15

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone

Disconnect Power

Use Caution When

Servicing the CRT

Use Care When Servicing

With Power On

Do not perform internal service or adjustments of this product unless another

person capable of rendering first aid and resuscitation is present.

To avoid electric shock, disconnect the main power by means of the power cord

or, if provided, the power switch.

To avoid electric shock or injury, use extreme caution when handling the CRT.

Only qualified personnel familiar with CRT servicing procedures and precautions

should remove or install the CRT.

CRTs retain hazardous voltages for long periods of time after power is turned off.

Before attempting any servicing, discharge the CRT by shorting the anode to

chassis ground. When discharging the CRT, connect the discharge path to ground

and then the anode. Rough handling may cause the CRT to implode. Do not nick

or scratch the glass or subject it to undue pressure when removing or installing it.

When handling the CRT, wear safety goggles and heavy gloves for protection.

Dangerous voltages or currents may exist in this product. Disconnect power,

remove battery (if applicable), and disconnect test leads before removing

protective panels, soldering, or replacing components.

ECO 422

X-Radiation

To avoid electric shock, do not touch exposed connections.

To avoid x-radiation exposure, do not modify or otherwise alter the high-voltage

circuitry or the CRT enclosure. X-ray emissions generated within this product

have been sufficiently shielded.

ix

Page 16

Service Safety Summary

x

ECO 422

Page 17

Getting Started

Page 18

Page 19

Getting Started

Product Description

The ECO 422 Changeover Unit (Figure 1–1 and Figure 1–2) provides automatic

selection of reference sources. Automatic changeover may occur upon fault

detection in any active source. Automatic transfer ensures uninterrupted signals

for critical applications. The ECO 422 is an in-line device without internal

buffers. Switching is by mechanical relay. The ECO 422 also provides internal

termination for unused inputs.

There are 11 identical channels. Each consists of a Primary Input, a Backup

Input, and an Output. All relays switch in unison upon fault detection in any

active channel, front-panel command, or remote command.

The ECO 422 bases error checking on signal amplitude. You can configure each

channel to check for a different type of input. There are six predefined checking

levels: no checking, PAL analog black burst, NTSC black burst, serial digital

component video, NTSC serial digital composite video, and serial digital audio.

A fault occurs when the signal is between 2 and 4 dB (or 2 and 5 dB) down from

nominal for these predefined signals. There are also two user-defined checking

thresholds available.

Separate indicators on the front-panel display faults for both the primary and

backup generator. These indicators remain on until cleared by the operator.

Figure 1–1: Front of the ECO 422

Figure 1–2: Rear of the ECO 422

ECO 422

1–1

Page 20

Getting Started

Accessories

Installation

Mechanical Installation

The ECO 422 comes with three accessories:

1. Rack slides (351-0751-01, 351-0104-03)

2. Reference card (063-1828-XX)

3. This manual (070-8472-XX)

Rackmounting. The ECO 422 is shipped with the hardware for rackmounting.

The instrument fits in a standard 19-inch rack. Spacing between the front rails of

the rack must be at least 17-¾ inches to allow clearance for the slide-out tracks.

Rack slides conveniently mount in any rack that has a front-to-rear rail spacing

between 15-½ and 28 inches. The ECO 422 requires six inches of clearance

between the instrument rear panel and any rear cabinet panel for connector space

and to provide adequate air circulation.

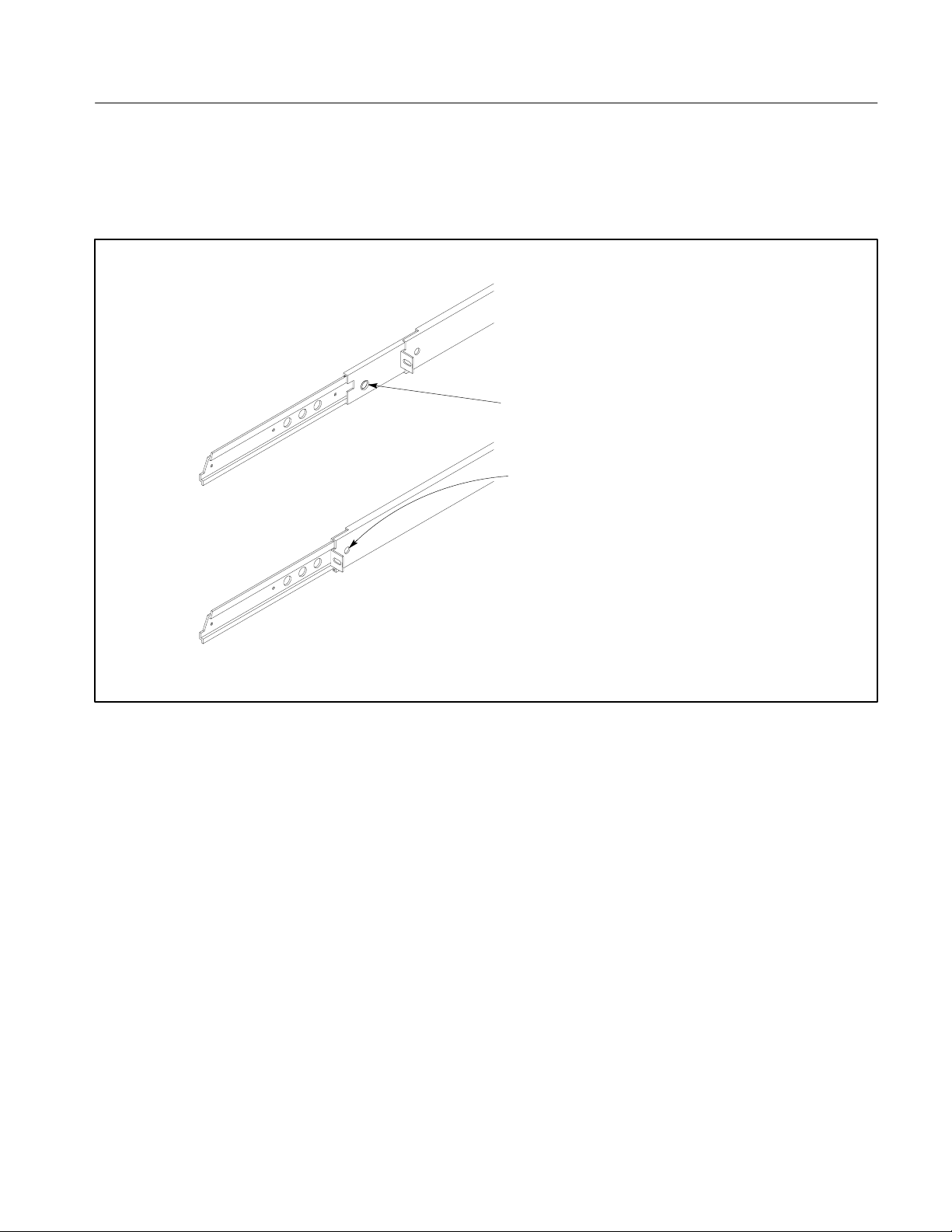

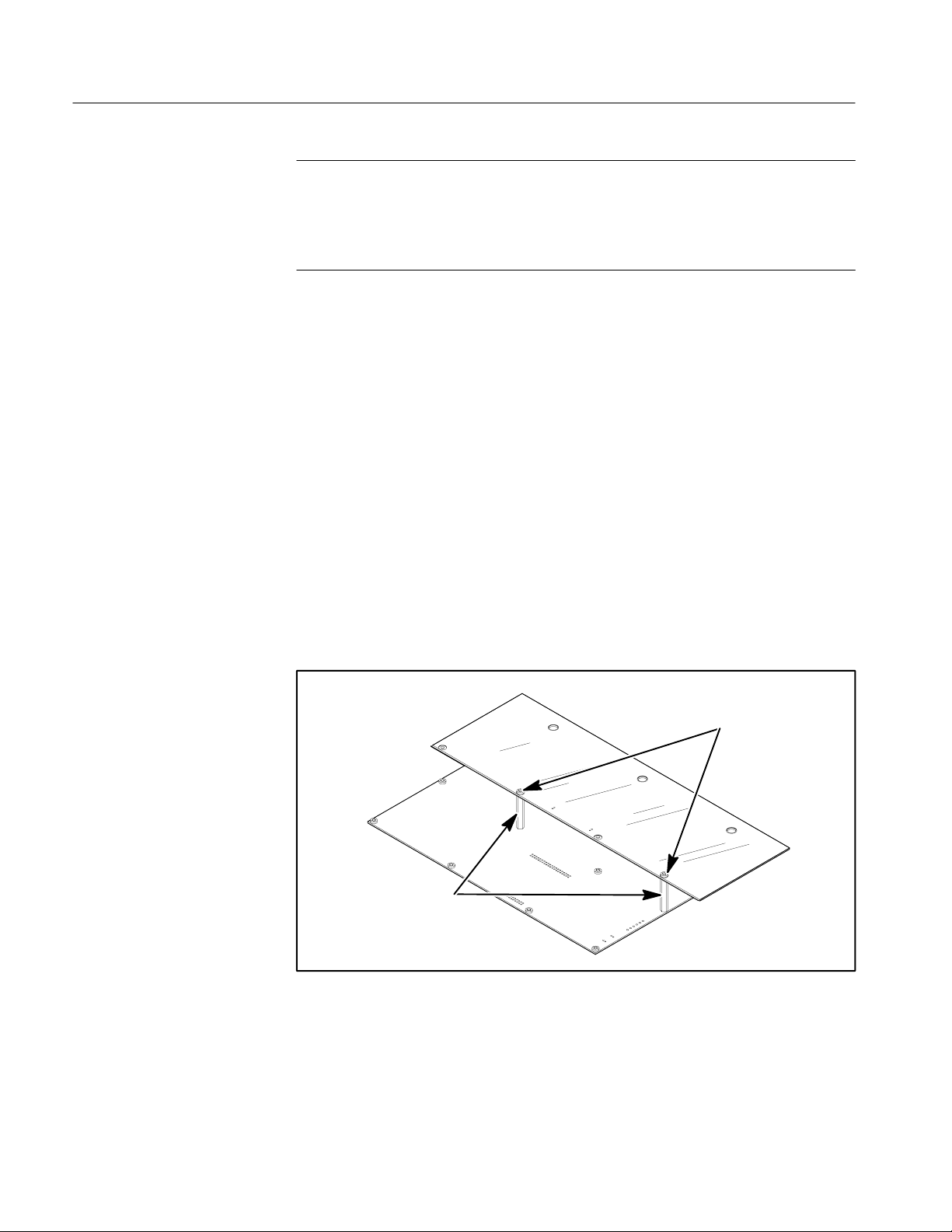

Mounting the Slide Tracks. Mount the rails using the enclosed hardware as shown

in Figure 1–6. Figures 1–4 and 1–5 shows the rail mounting details for both deep

and shallow racks. Figure 1–3 shows the front mounting deatils. Make sure that

the stationary sections are horizontally aligned, level, and parallel.

1–2

ECO 422

Page 21

BAR NUT

(Use if the front rail

is not tapped)

Getting Started

Figure 1–3: Front Rail Mount

REAR RACK RAIL

BAR NUT

PNH

SCREWS

ECO 422

Figure 1–4: Deep Rackmount

1–3

Page 22

Getting Started

BAR NUT

REAR RACK RAIL

FLUSH WITH

REAR RACK

RAIL

PNH

SCREWS

NOTE: Right hand

and left hand stationary section is

designated by the

RH and the LH

marked on the rails.

Stop latch holes

should be towards

the bottom when

slides are in place.

(The right hand rail

is shown above.)

Figure 1–5: Shallow Rackmount

CHASSIS SECTION

10–32 PHS

STOP LATCH

HOLE

INTERMEDIATE

SECTION

AUTOMATIC

LA TCHES

FLAT NUT BAR

SCREW

10–32 PHS

SCREW

FLA T

NUT

BARS

REAR

MOUNTING

ST ANTIONARY

SECTION

1–4

Figure 1–6: Assembly of Rackmounting Hardware

ECO 422

Page 23

Getting Started

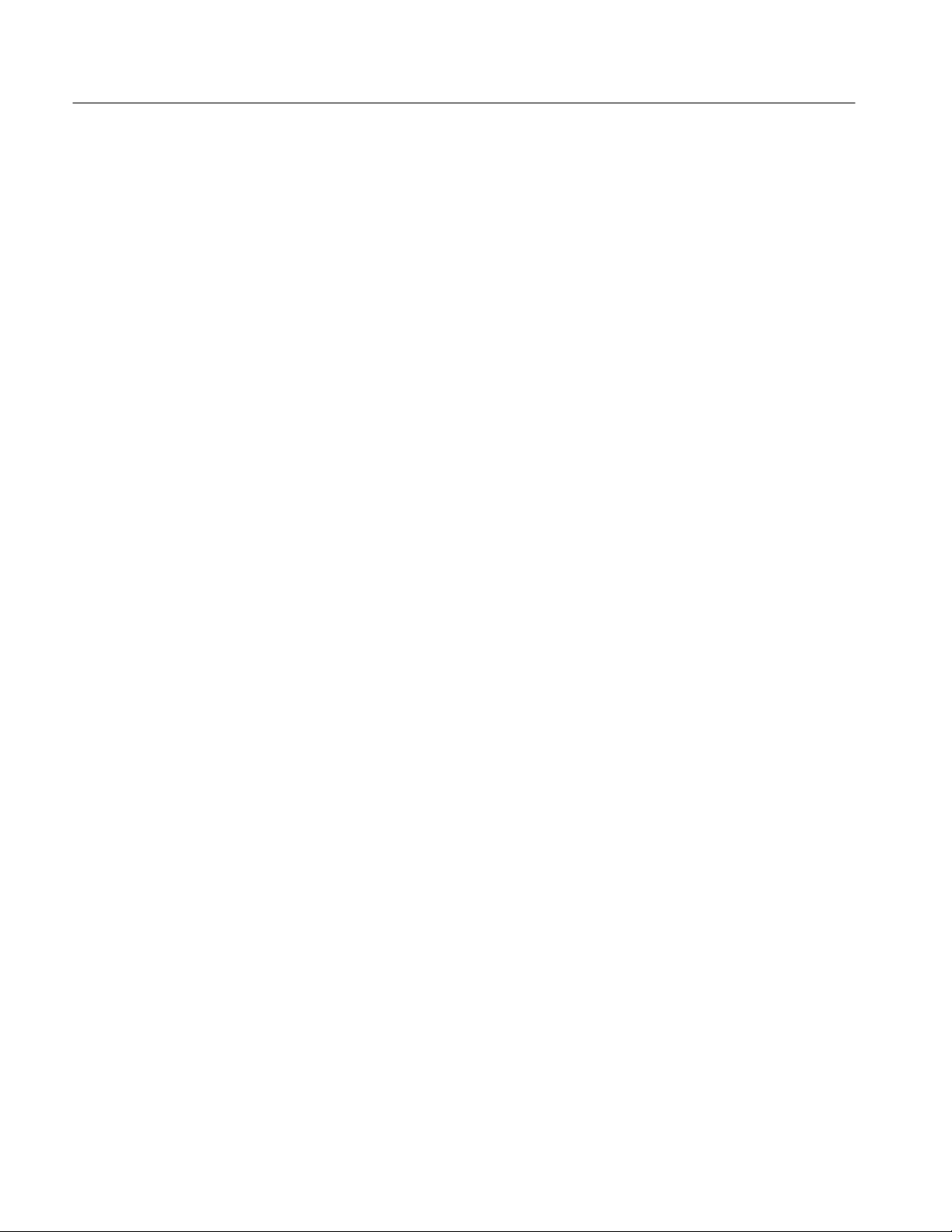

Installing the Instrument. Install the instrument in the rack, as shown in Figure

1–7.

TO INSTALL:

1. Pull the slide-out track section to the

fully extended position.

2. Insert the instrument chassis sections

into the slide-out sections.

3. Press the stop latches and push the

instrument toward the rack until the

latches snap into their holes.

4. Again press the stop latches and push

the instrument fully into the rack.

5. Tighten the front-panel retaining screws.

TO REMOVE:

1. Loosen retaining screw and pull

instrument outward until the stop latches

snap into the holes.

2. Press stop latches and remove

instrument.

Figure 1–7: Installing the Instrument in the Rack Slides

Rack Adjustments. After installation, if not properly adjusted, the slide tracks

may bind. To adjust the tracks, slide the instrument out about 10 inches, slightly

loosen the screws holding the tracks to the front rails, and allow the tracks to

seek an unbound position. Retighten the screws and check the tracks for smooth

operation by sliding the instrument in and out of the rack several times.

Once the instrument is in place within the rack, tighten the knurled retaining

screw to fasten it securely into the rack.

Rack Slide Maintenance. The slide-out tracks do not require lubrication. The dark

gray finish on the tracks is a permanent, lubricated coating.

ECO 422

Removing the Instrument. First, loosen the front-panel knurled retaining screw.

See Figure 1–7. Grasp the front handles and pull the instrument out until all

three slide sections latch. The instrument is firmly held in this position.

1–5

Page 24

Getting Started

Electrical Installation

To completely remove the instrument, first be sure to disconnect all cabling.

Then, press both release-latch buttons (visible in the stop-latch holes) and

carefully slide the instrument free from the tracks.

You can order any of the following power cord options for the ECO 422. If no

power cord option is ordered, the instrument is shipped with a North American

125 V power cord and one replacement fuse.

Option A1. Universal Europe, 220 V/16 A Power Plug (power cord and one

replacement fuse)

Option A2. United Kingdom, 240 V/15 A Power Plug (power cord and one

replacement fuse)

Option A3. Australian, 240 V/10 A Power Plug (power cord and one replacement

fuse)

Option A4 North American, 250 V/10 A Power Plug (power cord and one

replacement fuse)

Cable Installation

Unless otherwise specified, power cords for use in North America are UL listed

and CSA certified. Cords for use in areas other than North America are approved

by at least one test house acceptable in the country to which the product is

shipped. Power cord part numbers are shown in the Standard Accessories list at

the end of the Replaceable Mechanical Parts List, in Section 11.

NOTE. The BNC connectors are tightly spaced on the ECO 422 rear panel. You

may find it necessary to use a BNC Cable Tool to remove or install cables

(example: Trompeter RT–1L).

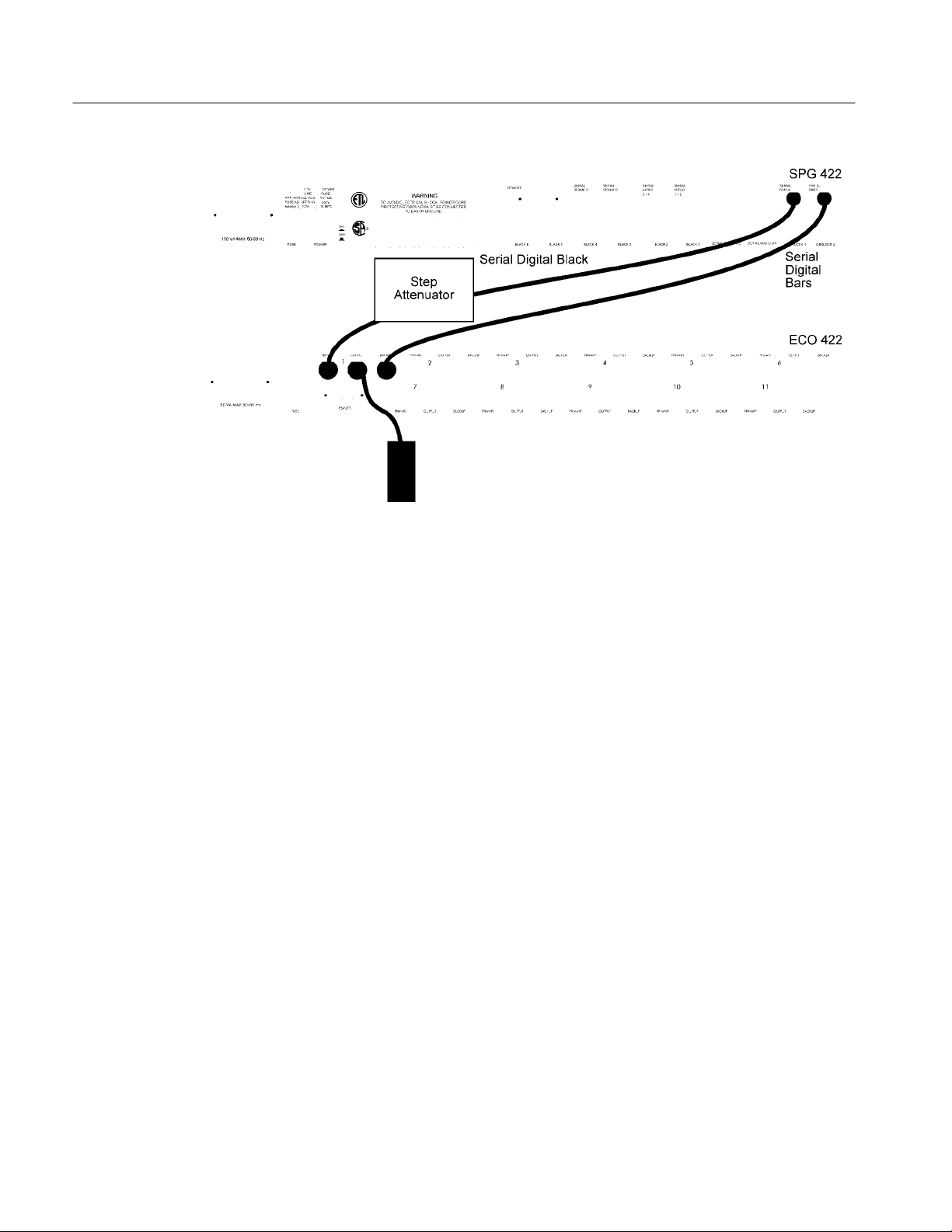

There are many different ways to configure the ECO 422. The illustration below

is only one example. One thing to keep in mind, the ECO 422 will automatically

change to the Primary signals whenever it looses power. Therefore, always

power the Backup source and the ECO 422 by the same source and the Primary

source separately. Using this scheme both power sources would have to go down

before you would lose your signals.

1–6

ECO 422

Page 25

Getting Started

Hints on Using the User

Configuration Switches

Figure 1–8: Example of How the ECO 422 Can be Connected

Use the Channel Configuration Switches Table on page 1–9 to record what type

of signals you have connected to each set of outputs on the rear panel. Then use

the DIP selection guide to make sure that the DIP switches are correctly

configured. There is also a reference card available to keep track of how the

ECO 422 is configured and aid in setting up the instrument.

There are the several different types of signal checking already available but you

may need to feed a different signal through the ECO 422. This section gives one

example, analog active video.

Active Analog Video. The ECO 422 will pass active analog video by using the no

checking mode, but there will be times when you need to check for the presence

of an active video signal. You have at least two options. First, you can set up a

custom checking level using one of the “user-defined” levels. This is great if you

are always passing color bars or some other test signal where the average picture

level remains constant and never fades to black. If the average picture level drops

below the custom set level then an error occurs, causing the ECO 422 to switch

sources. The set level could easily be well above black burst. The second option

is to use the predefined black burst level. This works very well when your goal is

to check for “present/not present” active video. It will accept long periods of

ECO 422

1–7

Page 26

Getting Started

Configuration

black without generated an error, but it will switch if the signal goes “completely” away.

Again, to summarize the three options available, if you want active video to pass

through the ECO 422:

1. No checking.

2. Set a user-defined level –– best for a constant test signal.

3. Use the predefined black setting –– best for video with a wide variation of

average picture levels or regular fades to blacks.

NOTE. Make sure that any channel not in use has checking disabled. If checking

is not disabled, errors will always be generated. No error checking also allows

the maximum voltage, current, and frequency to pass through the ECO 422.

Photocopy the list of the DIP switches below to log the configuration of your

system and use it as a quick reference. If using one of the “user-defined” levels,

write the definition on the line as a reminder.

All of these switches are available through a small access panel on top of the

ECO 422, eliminating any need to remove the top cover just to change the

function of the outputs.

There is also a Mode switch, switch S14–8. Set it for either Normal or Override

operation. If set for Normal operation, it will not allow you to manually switch

to a bad signal, unless both signals are “bad.” For example: you are set for

manual operation and the Primary signal is in error while the Backup is good.

Press the Sync Source button to change to the Backup source. No matter how

many times you press the Sync Source button again, the ECO 422 will not allow

you to return to the Primary source because it is in error. The only time that you

can switch to an “error” signal in Normal mode is when both of the signals are

bad. In that case, you can manually switch between the two signals. In Override

mode, you can always manually switch to a bad signal. The other positions of

S14 are only used for testing purposes.

1–8

ECO 422

Page 27

all open = Disabled (signal not checked)

1 = NTSC Black Burst

2 = PAL Black Burst

3 = NTSC Serial Digital Video (composite)

4 = Serial Digital Video (component)

5 = Serial Digital Audio

6 = User defined _________

7 = User defined _________

8 = Attenaution

Figure 1–9: Default Position of the User Configuration and Mode Switches

Getting Started

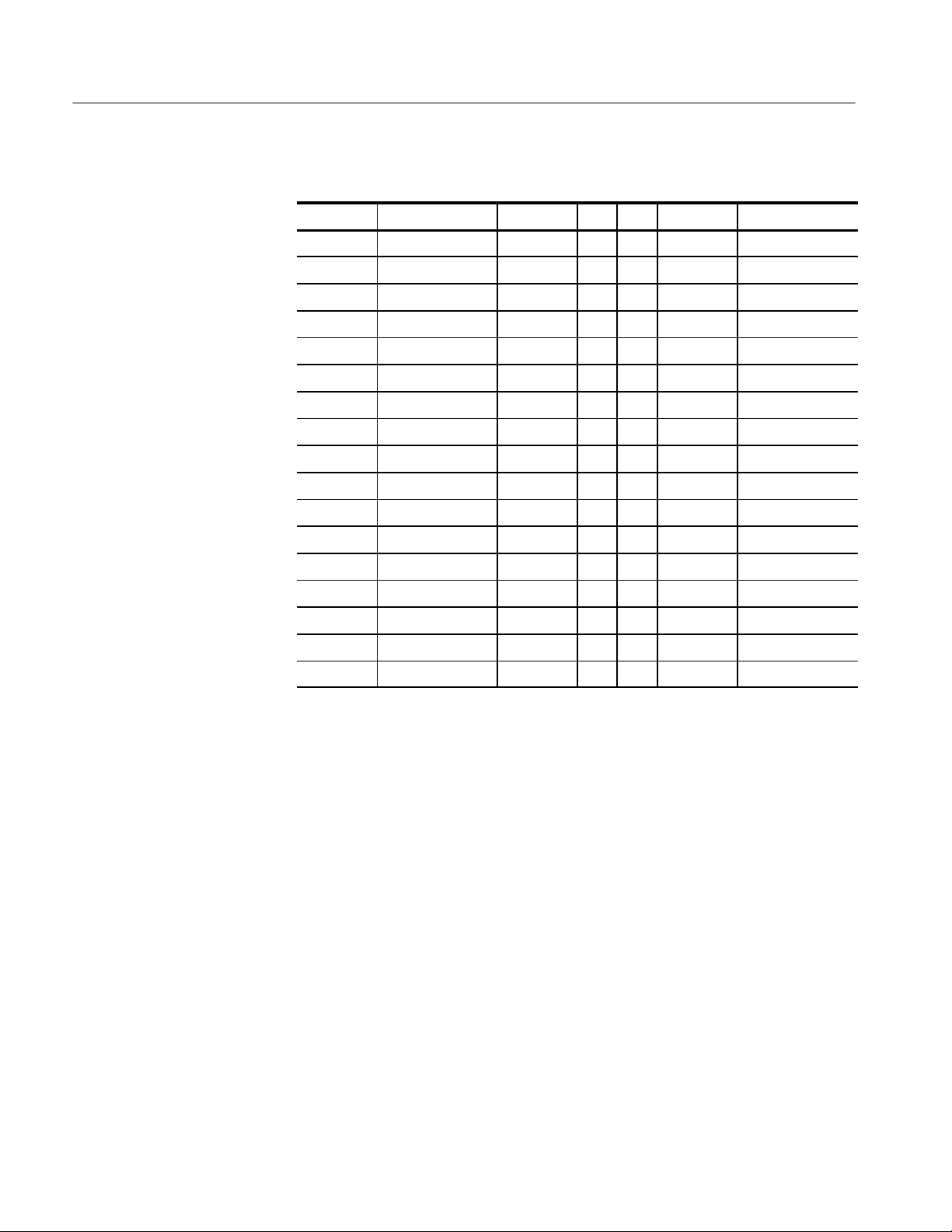

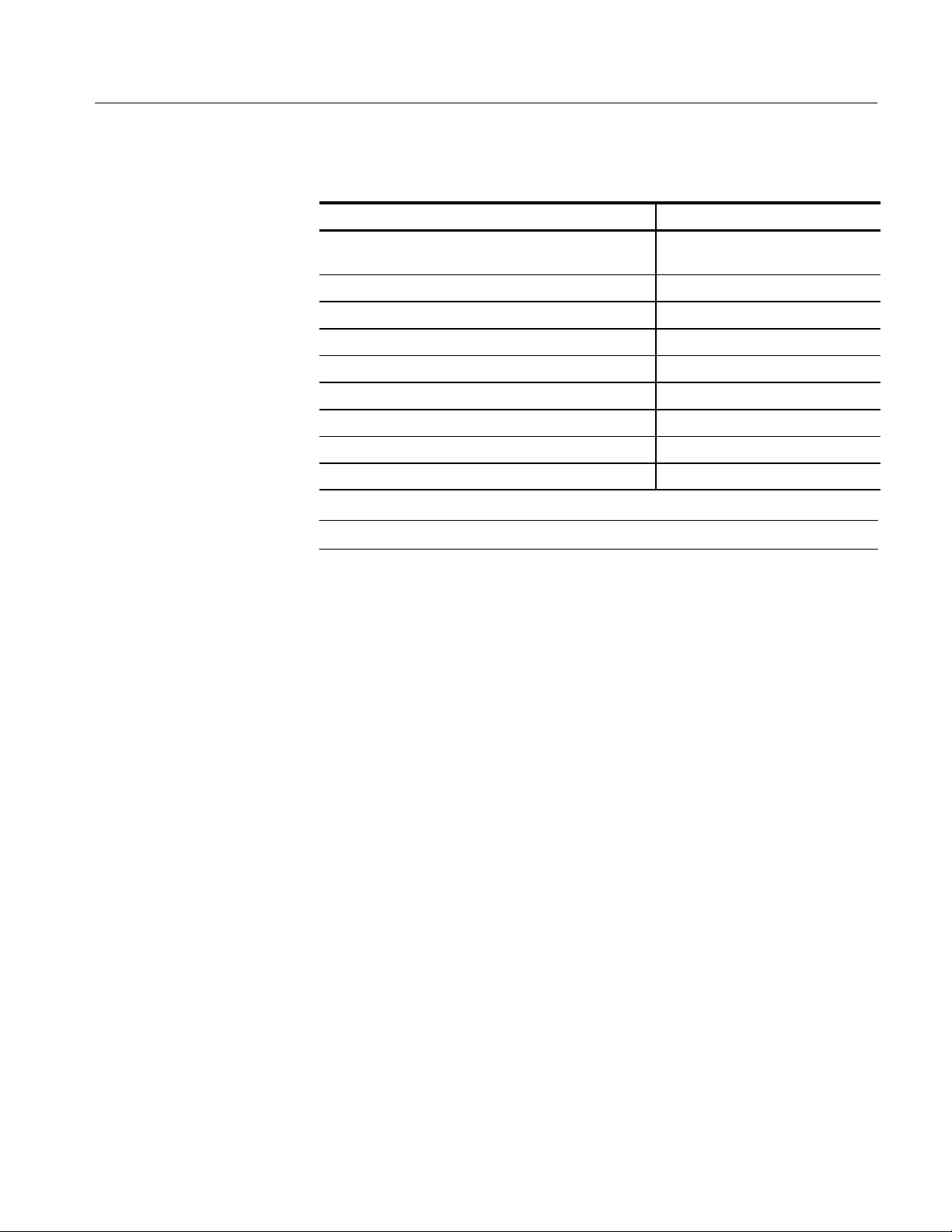

T able 1–1: Channel Configuration Switches (S1 – S11)

Attenuation

Output # /

Switch #

1 / S1

2 / S2

3 / S3

4 / S4

5 / S5

6 / S6

7 / S7

8 / S8

9 / S9

10 / S10

11 / S11

Setting

(see above)

(set with Sx–8)

On / Off

Type of Signal Attached

ECO 422

1–9

Page 28

Getting Started

Functional Check and First Time Operation

This section steps through how the ECO 422 will react under its most common

operating circumstances: two good signals, loss and then return of the Primary

signal, loss and return of the Backup signal, and loss of power. Only two input

signals are used here to avoid confusion.

For more details on the controls, what they do, and how they interact, see

Operating Basics, Section 2.

To check out the entire instrument, repeat these procedures for each of the eleven

sets of inputs and outputs.

Two Good Signals

Power down all instruments.

Connect the ECO 422 as shown in Figure 1–10.

1–10

Figure 1–10: Setup for the Functional Check

Set all of the DIP switches (S1 – S11) to open, except for S1–1, which should be

set to closed (NTSC black burst). Note that Primary input is black burst without

setup and the Backup input is black burst with setup. (This is just to illustrate

which signal is the Output.)

ECO 422

Page 29

Getting Started

Set the user switch (S14–8) to Normal (closed).

Power up all instruments.

Enable the front panel, using the Front Panel button.

Set the ECO 422 to “Switch on Fault” using front-panel buttons. (This is the

default at power on.)

If Primary is not already the source, press the Sync Source button to make

Primary the source. (This is the default at power on.)

Note that the output signal is the Primary input signal (black burst with setup)

and that none of the fault indicators light.

Press the Sync Source button to change to the Backup source.

Note that the signal changes to black burst without setup (Backup).

Check that there is no error on either signal.

Loss of the Primary Signal

Press the Sync Source button again, to switch back to the Primary input.

Disconnect the Primary signal source. (Remove the cable between the SPG 422

and the Primary 1 input of the ECO 422.)

Note the signal automatically switches to the Backup input and the Primary fault

indicator lights.

Reconnect the Primary signal source. (Replace the cable between the SPG 422

and the Primary 1 input of the ECO 422.)

Note that the Primary fault indicator remains on and the Sync Source remains the

Backup (the ECO 422 does not automatically switch back to Primary).

Press the Reset button.

Note that the Primary fault indicator turns off.

Press the Sync Source button to return to the Primary as the source.

Press the Auto Switching button to disable the “Switch on Fault” function.

Remove the Primary input signal. (Again, remove the cable between the

SPG 422 and the Primary 1 input of the ECO 422.)

ECO 422

Note that no switching occurs, but that the Primary fault indicator lights.

Press the Sync Source button to change to the Backup signal.

Press the Sync Source button again to try to change back to the Primary input. (It

should not let you change to a bad input.)

1–11

Page 30

Getting Started

Reconnect the Primary input source. (Replace the cable between the SPG 422

and the Primary 1 input of the ECO 422.)

Press the Reset button to clear the fault indicator LED.

Return the auto switching to “Switch on Fault.”

Note that the sync source is still Backup.

Loss of the Backup Signal

Loss of Power to the

ECO 422

Disconnect the Backup signal. (Remove the cable between the SPG 422 and the

Backup 1 input of the ECO 422.)

Note that the output signal has changed to the Primary input signal and the

Backup fault indicator LED lights.

Reconnect the Backup signal. (Replace the cable between the SPG 422 and the

Backup 1 input of the ECO 422.)

Clear the fault indicator by pressing the Reset button.

Press the Sync Source button to return to Backup sync source.

Remove the power source from the ECO 422.

Note that the output signal switches to the Primary input signal.

Return the power source.

1–12

ECO 422

Page 31

Operating Basics

Page 32

Page 33

Operating Basics

Controls and Indicators

Front-Panel Controls (See

Figure 2–1)

Figure 2–1: Front-Panel Controls

Sync Source – Primary/Backup. The LED indicates the current Output (whether it

is from the Primary or Backup input). It can be manually changed using the Sync

Source button. (If the ECO 422 is in Normal mode, this is only true when the

other input is good or both inputs are bad.) Only one of these LEDs can be on.

Primary is the default at power-up.

Auto Switching – Switch on Fault/Disabled. This selects whether the ECO 422 will

automatically switch to the other input source whenever it detects a fault (Switch

on Fault) or not switch (Disabled). Only one of these LEDs can be on. Switch on

Fault is the default at power-up.

Fault Indicator (Reset) – Primary/Backup. Either one or both of these LEDs could

be on. They indicate that a fault has occurred on the input. Press the Reset button

to clear the fault indicators (turn off the LEDs) after the fault has been corrected.

The fault indicator does not automatically reset after an error condition improves.

At power-up, the LEDs are reset.

Front Panel – Enabled/Locked Out. This control determines whether or not the

operator has access to the other front-panel controls. If it is Enabled, then the

user can control the instrument from the front panel. If it is Locked Out, then the

user can only toggle back to Enabled and no other front-panel controls are

available. The ECO 422 will automatically lock out after about 1 minute of

inactivity to prevent accidental switching. The front panel is automatically

locked out at power-up.

ECO 422

2–1

Page 34

Operating Basics

Internal Controls

all open = Disabled (signal not checked)

1 = NTSC Black Burst

2 = PAL Black Burst

3 = NTSC Serial Digital Video (composite)

4 = Serial Digital Video (component)

5 = Serial Digital Audio

6 = User defined _________

7 = User defined _________

8 = Attenaution

Channel Configuration Switch (11 identical clip switches S1 – S11; see Figure 2–2).

These switches select the signal type checked on a channel by setting the

amplitude comparison level. Only one switch from each DIP package should be

enabled (closed) for each channel, except for attenuation (DIP 8 on all switches),

which is allowed to be combined with either of the user–defined levels.

Figure 2–2: Default Position of the User Configuration and Mode Switches

Below is a list of the functions for each of the switches.

DIP # Input Signal

All Open Disabled (signal not checked)

1 NTSC Black Burst

2 PAL Black Burst

3 NTSC Serial Digital Video (composite)

4 Serial Digital Video (component)

5 Serial Digital Audio

6 User defined

7 User defined

8 Attenuation

Table 2–1 lists the factory setting of the switches. (NTSC or PAL black burst is

determined by the power cord option ordered with the instrument.)

2–2

ECO 422

Page 35

Operating Basics

T able 2–1: Factory Settings of Channel Configuration Switches (S1 – S11)

Attenuation

Output # /

Switch #

1 / S1 1 or 2 p Black Burst

2 / S2 1 or 2 p Black Burst

3 / S3 1 or 2 p Black Burst

4 / S4 1 or 2 p Black Burst

5 / S5 1 or 2 p Black Burst

6 / S6 1 or 2 p Black Burst

7 / S7 4 p Serial Digital Video (Component)

8 / S8 4 p Serial Digital Video (Component)

9 / S9 4 p Serial Digital Video (Component)

10 / S10 5 p Serial Digital Audio

Setting

(see above)

(set with Sx–8)

On Off

Type of Signal Attached

11 / S11 5 p Serial Digital Audio

User Configuration Switch (S14–8) –closed– –Normal–

Attenuation. Attenuation allows larger signals to have their signal level checked.

The attenuator adds about 14 dB (x5) attenuation to the signal level being

checked. This has no effect on the level of the output signal and only extends the

range of the check circuitry. Use this in conjunction with large H sync pulses to

increase the accuracy on the level check. Only use this switch in conjunction

with the User Defined Levels.

User Configuration Switch (S14 – 8). This switch determines how the ECO 422

responds to faulty signals –– either Normal or Override.

For Normal operation, the user cannot switch to a bad signal whether the

instrument is in manual or auto switch mode. For example, the ECO 422 is in

manual mode and the Primary signal is bad, while the Backup signal is good. If

the user presses the Sync Source button, the output will be the Backup signal. If

the user presses the Sync Source button again, the output continues to be the

Backup signal. It will not change to Primary until the signal is good and the fault

indicator is reset.

In the Override mode, the user can manually switch to a “bad” signal, with Auto

mode disabled.

ECO 422

Reference Level Adjustments R266 and R265. These two adjustments set the

reference level for the two user-defined signal options. Select these levels with

DIPs 6 (R266) and 7 (R265) of the Channel Configuration switches. These allow

2–3

Page 36

Operating Basics

the user to set their own signal switching level for special applications. Two

examples of signals that may require checking are an active video signal or an H

Sync signal.

The procedure used to set these levels is on page 2–8.

Connectors (See Figure 2–3)

Figure 2–3: Rear of the ECO 422

Power

Video Signals

(11 Channels)

This instrument is intended to operate from a single-phase power source with

one current-carrying conductor at or near earth-ground (the neutral conductor).

Only the line conductor is fused for over current protection. Mains frequency is

50 or 60 Hz. The operating voltage range is continuous from 90 to 250 VAC.

WARNING. Do not connect power to the ECO 422 if the top cover is not installed.

Dangerous potentials are present on the Power Supply board.

There are 33 video connectors on the rear panel. Eleven are for the Primary

input, 11 are for the Backup input, and 11 are for the Output. A general overview

of each one is below.

Primary. Input from the primary sync generator. It can be PAL black burst, NTSC

black burst, serial digital video (NTSC component or composite), or serial digital

audio if signal checking is desired. There are also two user-defined levels

available. If no signal checking is required, almost any signal can pass through

the unit (within the bandwidth and voltage/current limitations). This should be

the same signal type as its Backup signal pair.

2–4

Output. Signal output. It is either from the Primary or the Backup source. How

the ECO 422 is configured determines under what conditions the source changes.

Backup. Input from the backup sync generator. This should be the same signal

type as its Primary signal pair.

ECO 422

Page 37

Operating Basics

Remote. The rear-panel connector is a 9-pin female D-connector, with one pin

tied to ground (see Figure 2–4). The connector has the following pinout:

Figure 2–4: Remote Connector Pin-Out

The pin assignment is as follows:

Ground-Closure

Pin Signal Function

1 Auto Switching (Input)

2 Toggle Sync Source (Input)

3 Indicate Primary Sync Source Active (Output)

4 Indicate Backup Sync Source Active (Output)

5 Fault Alarm (Output)

6 Fault Reset

7 Fault Reporting +

8 Fault Reporting –

9 Ground

Auto Switching (active low)

front panel is disabled. The front panel cannot override this remote command.

Toggle Sync Source (active low)

the front panel. A low pulse will cause the ECO 422 to toggle between Primary

and Backup as the output signal.

Indicate Primary Sync Source Active (active high)

signals are the sync source.

Indicate Backup Sync Source Active (active high)

signals are the sync source.

Fault Alarm (active high)

input signals is “bad.” This alarm signal is latched and will remain high until the

error is cleared and the Reset button is pressed.

If low, the automatic switching function from the

Operates the same as the Sync Source button on

Indicates that the Primary

Indicates that the Backup

Indicates that at least one of the Primary or Backup

ECO 422

Fault Reset (active low)

the fault indicators (turns off the LEDs) after the fault has been corrected.

This operates like the front-panel Reset button. It clears

2–5

Page 38

Operating Basics

Fault Reporting – and +

will close in the cases of: loss of power to the ECO 422 or one (or more) input

signals are bad. The fault is latched and will remain until the fault is cleared.

This fault reporting system follows SMPTE 269M guidelines except the

interface is 2 pins of the Remote connector (7 & 8) instead of the standard

isolated BNC connector and there is no pulsing. When in the open state, the

leakage across the closure is less than 100 µA at any voltage from 0 to 5 VDC.

The closure is able to withstand 24 VDC in the open state without damage. In

the closed state, the maximum voltage drop across the closure should not exceed

2 V at 20 mA. The sensing device should not supply more than 20 mA of current

to the reporting device. To provide compliance with the standard, wire a BNC

connector adapter as shown in Figure 2–5.

It is normally open, indicating that everything is good. It

Reference

Operating Basics

2–6

Figure 2–5: Wiring Required to Conform with SMPTE Fault Reporting

In normal operation, the ECO 422 is basically a switch that triggers whenever an

error occurs in any channel. All 11 Channels switch at the same time.

If any channel is not being used, it is mandatory that its checking function be

disabled. Otherwise it will always trigger an error and the ECO 422 will not

operate properly.

This section covers the state machine discussions (what will happen when some

signals go bad) and how to adjust the user-defined inputs.

ECO 422

Page 39

State Machine Discussion

Table 2–2 is a truth table that gives the various states the ECO 422 outputs based

on the state of the inputs. Note that Primary is set to check a given level.

Power

Operating Basics

– the state of the power supply.

User Config

(Normal) or O (Override). In Normal mode, the ECO 422 will not switch to a

“bad signal.” In Override operation, the user is allowed to manually switch to a

“bad signal.”

Switch

the Toggle Sync Source on the remote control has been selected. Note that the

front panel and the remote control commands are ANDed together (active low)

to produce the switch results.

P – Primary input. It outputs to Output.

– Backup input. It is part of the Output set.

B

O Auto

error). It can either output Primary or Backup.

O Manual

error). It can either output Primary or Backup.

0

– bad signal.

1

– good signal.

" – switch (change the current output signal).

– the state of the user configuration switch. It can either be N

– Indicates whether or not the Sync Source button on the front panel or

– Output signal with the ECO 422 set to “Auto Switching” (switch on

– Output signal with the ECO 422 set to “Manual” (no switching on

ECO 422

# – no switch (stay with the current signal).

– Don’t care.

X

2–7

Page 40

Operating Basics

T able 2–2: Truth T able for ECO 422 Switching

Power User Config Switch P B O Auto O Manual

1 N # 0 0 # #

1 N # 0 1 B #

1 N # 1 0 P #

1 N # 1 1 # #

1 N " 0 0 " "

1 N " 0 1 B B

1 N " 1 0 P P

1 N " 1 1 " "

1 O # 0 0 # #

1 O # 0 1 B #

1 O # 1 0 P #

1 O # 1 1 # #

How to Adjust the

User-Defined Threshold

Levels

1 O " 0 0 " "

1 O " 0 1 B "

1 O " 1 0 P "

1 O " 1 1 " "

0 X X X X P P

The User-defined Threshold Levels are the two levels available from User

Configuration switches 6 and 7. They are available so that the user can trigger on

signal levels other than the seven predefined levels.

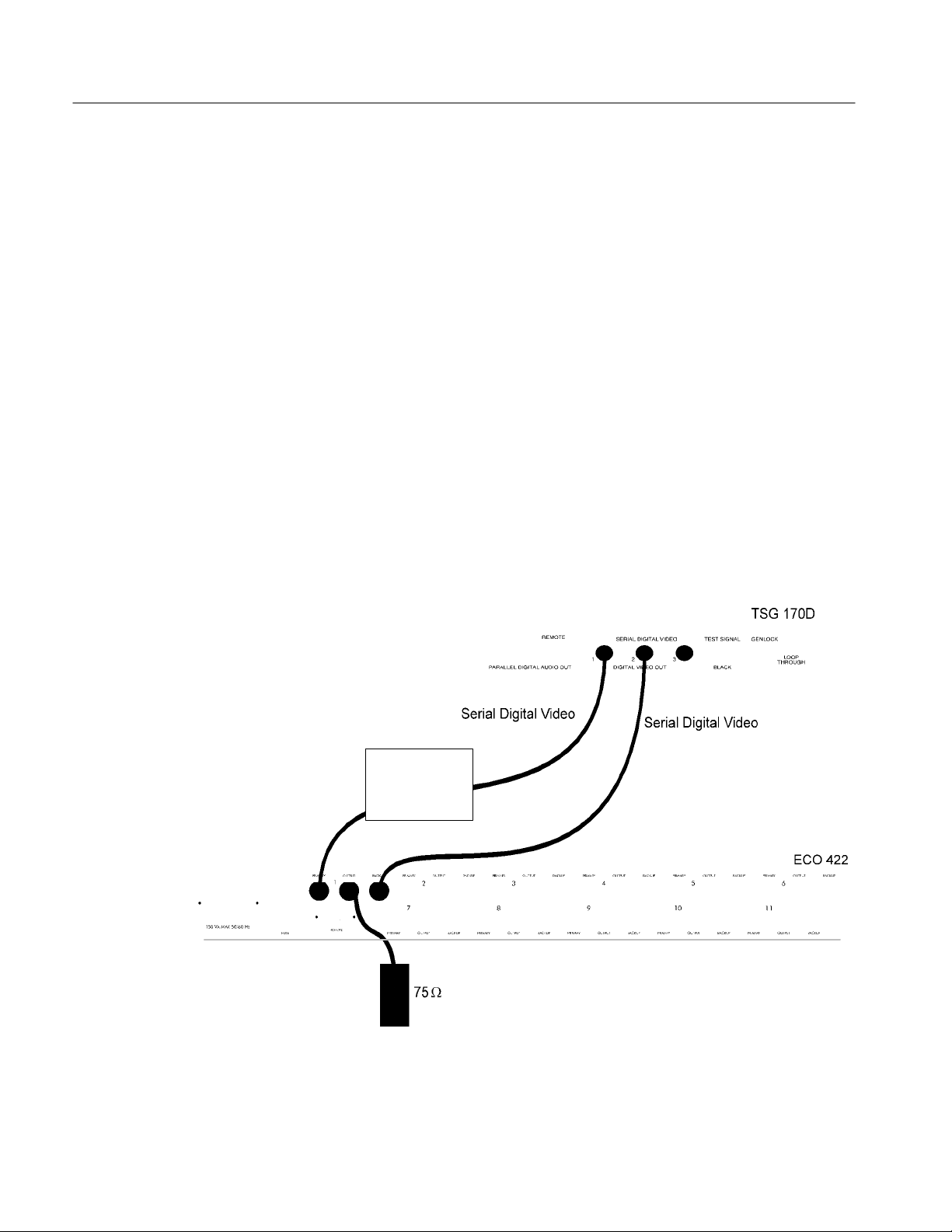

In order to set the Threshold Levels, you need:

H Two good versions of the type of signal you want to check

H A step attenuator (example: 847 Attenuator from KAY Elemetrics)

H A waveform monitor or oscilloscope (optional)

H The ECO 422

The example sets switch 7 for NTSC active video with the threshold set for a

3 dB down color bar. It uses a TSG 170D as the signal source, a 1780R

waveform monitor/vectorscope (optional) to view the signal level, and a step

attenuator.

2–8

ECO 422

Page 41

Figure 2–6: Setup for Adjusting R265 (the User Level for SX-7)

Operating Basics

ECO 422

2–9

Page 42

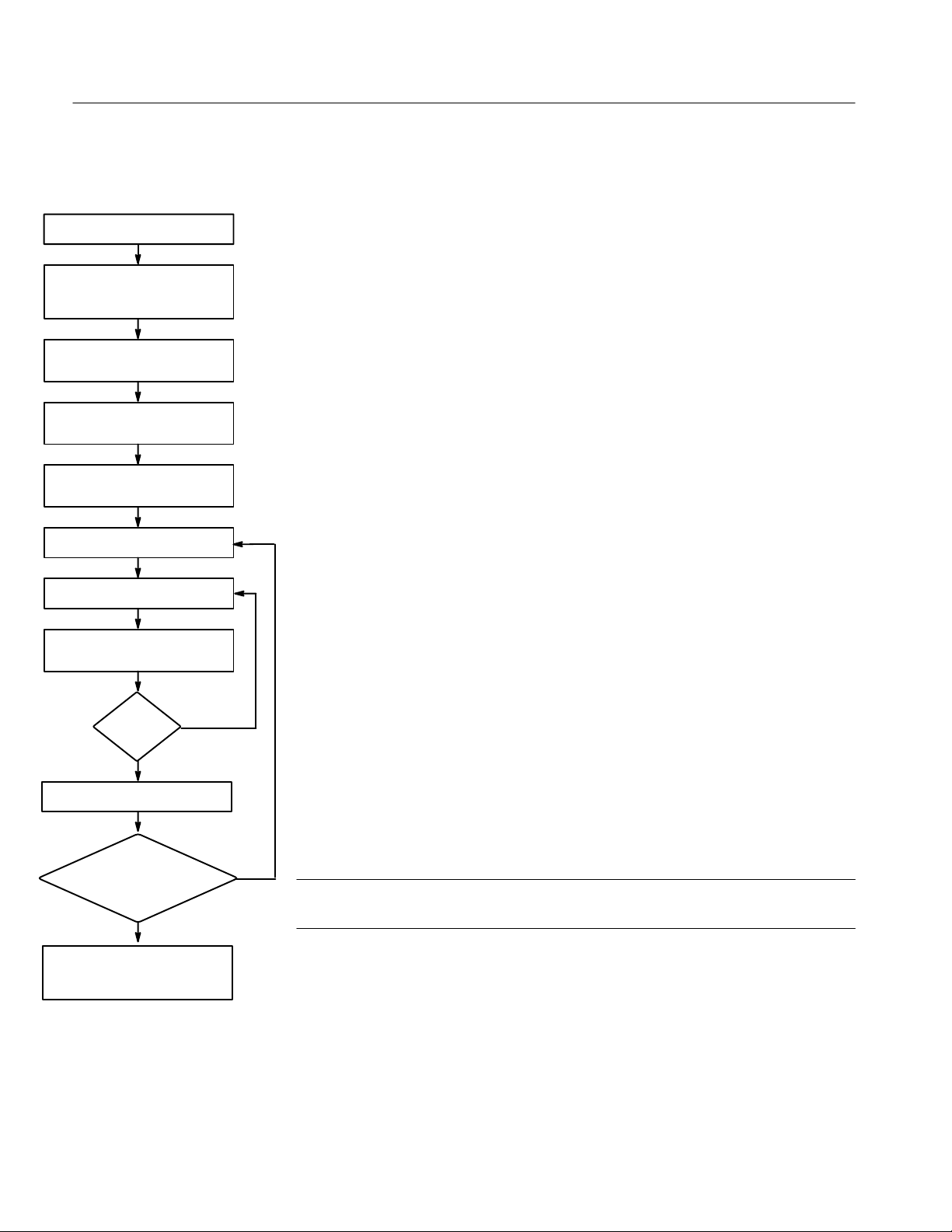

Operating Basics

Set up the equipment as shown.

Set all of the Channel

Configuration Switches to

Set all of the User Configuration

Switches to CLOSED.

Primary Sync Source.

Set the ECO 422 Auto Switching to

Set the step attenuator to 0 dB.

Press the ECO 422 Fault

Indicator Reset button.

1

2

OPEN, except S1-7.

3

4

Set the ECO 422 to

5

“Switch on Fault.”

6

7

Rotate R265 fully.

8

1. Connect the equipment as shown in Figure 2–6.

2. Set all of the User Configuration switches to “open” except for S1–7 (for

channel 1).

3. Set all S14 switches “closed.”

4. Set the ECO 422 to Primary Sync Source.

5. Set the ECO 422 Auto Switching to “Switch on Fault.”

6. Set the step attenuator to 0 dB of attenuation.

7. Rotate potentiometer R265 fully. (You are attempting to allow the minimum

signal level to pass through before the threshold is reached.)

8. Press the fault indicator Reset button. (This clears any errors.)

9. Check the fault indicator for an error indication on either the Primary or

Backup channels. If there are no faults, then proceed to the next step.

Otherwise, try rotating the potentiometer in the other direction. (You are

trying to get the minimum signal level to pass through before reaching the

switching threshold.)

10. Set the step attenuator to 3 dB of attenuation (or whatever attenuation is

required for your application).

9

Any faults

indicated?

no

Set the step attenuator to 3 dB.

Adjust R265 until the Sync Source

changes and a fault is indicated on

10

11

Did the Sync Source

change or was a fault

indicated on the

Primary?

no

12

the Primary.

yes

Figure 2–7: Flowchart for Adjusting R265

11. Check to see that the sync source has not changed to Backup and no faults

are on the Primary channel.

12. Slowly adjust R265 until the ECO 422 switches to the Backup sync source

and a fault occurs on the Primary channel. Press Reset to verify that the fault

is still preset. If the Primary fault indicator LED goes out, continue adjusting

the potentiometer. If the LED remains on, S1–7 through S11–7 are set for

your user-defined level.

yes

NOTE. If you cannot adjust R265 satisfactorily, try inserting the attenuator (close

S1–8) and repeat the adjustment steps from the beginning.

Adjust R266 in the same manner to set a user-defined level for S1–6 through

S11–6.

2–10

ECO 422

Page 43

Specifications

Page 44

Page 45

Specifications

Introduction

The items listed in the following tables describe the performance of the ECO 422

Changeover Unit. Performance Requirements are generally quantitative and can

be tested by a Performance Verification procedure contained in the service part of

this manual.

Supplemental Information is valuable data pertaining to the operation and output

capabilities of this instrument. Only a few items listed in this category may be

tested in the Performance Verification procedure.

Performance Conditions – The requirements listed in the electrical specification

apply over an ambient temperature range of 0_ C to +40_ C. The rated accuracies are valid when the instrument is calibrated at an ambient temperature range

of +20_ C to +30_ C, after a warm-up time of 20 minutes. Test equipment used

to verify Performance Requirements must be calibrated and working within the

limits specified under the Equipment Required list.

These instruments are intended to operate from an AC power source that will not

apply more than 250 V

conductor and ground. A protective ground connection by way of the grounding

conductor is essential for safe operation.

between the supply conductors or either supply

RMS

Environmental specifications are listed toward the back of the following tables.

In addition a list of appropriate safety and electromagnetic interference (EMI)

standards also can be found there.

ECO 422

3–1

Page 46

Specifications

T able 3–1: General Characteristics

Performance

Characteristics

Return Loss

All Inputs and Outputs

Insertion Loss 0.2 dB, DC to 10 MHz

Maximum Switched

Voltage

Maximum Switched

Current

Crosstalk (unselected input to

output or channel to channel)

Relay Switch Time Time that it takes for the

Requirements

Supplemental

Information

30 dB, 0 to 10 MHz

15 dB, 10 to 270 MHz

12 dB at 360 MHz (15 dB

typical)

when selected

0.5 dB, 10 to 200 MHz

1.0 dB, 200 to 360 MHz

±5 V

100 mA

–60 dB to 10 MHz

–30 dB to 200 MHz

–15 dB to 360 MHz

relays to switch and settle.

Approximately 10 msec.

3–2

ECO 422

Page 47

T able 3–2: Signal Loss Detection

Specifications

Performance

Characteristics

Input Signal Switching Level within: These are the defined

NTSC Black Burst

(sync level)

PAL Black Burst

(sync level)

Serial Digital Video

(NTSC Composite)

Serial Digital Video

(Component)

Serial Digital Audio 630 to 790 mV 710 mV 13 &

User Adjustable –100 to –700 mV

Requirements

–180 to –230 mV –200 mV 2 & 4

–190 to –240 mV –210 mV 3 & 5

450 to 630 mV 540 mV (between 2 and

450 to 630 mV 540 mV (between 2 and

Supplemental

Information

switching thresholds set

with the internal Channel

Configuration switch.

Between 2 and 4 dB down

from nominal.

5 dB down)

5 dB down)

Using the two user-defined

Channel Configuration

switches.

Per.

Ver.

10 &

11

7 & 8

14

–700 to –3500 mV

Attenuation approximately x5

Using the user-defined

Channel Configuration

switch with the attenuator

on.

ECO 422

3–3

Page 48

Specifications

T able 3–3: Power Supply

Performance

Characteristics

External Power

Voltage

Input Frequency

Range

Power Consumption

Supply Accuracy

+5 V

–5 V

Hum

+5 V

–5 V

Noise

+5 V

–5 V

Crest Factor w1.35

Fuse Required 1 ampere medium blow fuse

Requirements

90 to 250 VAC Full range, no selector

Supplemental

Information

48 Hz to 62 Hz

20 Watts, typical

+5 V ±200 mV

–5 V ±200 mV

Typical values:

10 mV

10 mV

(5 MHz measurement bandwidth)

v50 mV

v50 mV

for all applications.

T able 3–4: Mechanical (Physical) Characteristics

Characteristics Supplemental Information

Rackmount Dimensions

Height

Width

Length

Net Weight 10.8 lbs (4.9 kg)

Shipping Weight 18 lbs, 5 oz (8.3 kg)

1.734 inches (4.4 cm)

19.0 inches (48.3 cm)

22.1 inches (56.1 cm)

3–4

ECO 422

Page 49

T able 3–5: Environmental Characteristics

Characteristics Supplemental Information

Temperature

Nonoperating

Operating

Altitude

Nonoperating

Operating

Humidity 5 – 95% humidity, noncondensing

Vibration

Operating

–40_ C to +65_ C

0_ C to +50_ C IEC 1010-1 compliance to

_ C.

+40

to 40,000 feet

to 10,000 feet (4572 meters) IEC 1010-1

compliance to 2000 meters.

From 5 to 350 Hz: 0.0002 g2/Hz Acceleration

Power Spectral Density (APSD).

From 350 to 500 Hz: –3 dB/Octave Slope.

At 500 Hz: 0.00014 g2/Hz APSD.

0.31 overall GRMS.

10 minutes/axis.

Specifications

Nonoperating

Shock (nonoperating) Half Sine Wave Shock levels: 50 g’s (instru-

Transportation Qualified under NTSB Test Procedure 1A,

Vehicle Vibration (Random V ibration) Vibrate along all three aces at an overall

Second Manual Handling (Shock) Drop on all sides once from a height of

Equipment Type Measurement

Equipment Class Class I (grounded product), as defined in IEC

Installation Category Installation Category II, as defined in IEC

From 5 to 100 Hz: 0.020 g2/Hz (APSD).

From 100 to 200 Hz: –3 dB/Octave Slope.

From 200 to 350 Hz: 0.010 g2/Hz APSD.

From 350 to 500 Hz: –3 dB/Octave Slope.

At 500 Hz: 0.007 g2/Hz APSD.

2.46 overall GRMS.

10 minutes/axis.

ment), 11 msec duration, 3 shocks per

direction.

Category II (24-inch drop).

vibration level of 1.33 GRMS. One hour per

axis.

24 inches. Drop on the bottom from a height

of 48 inches.

1010-1, Annex H.

1010-1, Annex J. Rated for indoor use only.

ECO 422

Pollution Degree Pollution Degree 2, as defined in IEC 1010-1.

3–5

Page 50

Specifications

Certification

EMI Standards

The following safety standards apply to the ECO 422:

H UL3111-1 – Standard for Electrical Measuring and Test Equipment

H ANSI/ISA S82 – Safety Standard for Electrical and Electronic Test,

Measuring, Controlling, and Related Equipment

H IEC1010-1 – Safety Requirements for Electronic Equipment for Measure-

ment, Control, and Laboratory Use

H CAN/CSA C22.2 No. 1010.1-92 – Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use

The following electromagnetic interference (EMI) standard applies to the

ECO 422:

H FCC EMI Compatibility – FCC Rules Part 15 Subpart J, Class A

Refer to the compliance declaration in the front of this manual for a list of other

standards.

3–6

ECO 422

Page 51

WARNING

The following servicing instructions are for use only by qualified personnel. To

avoid injury, do not perform any servicing other than that stated in the operating

instructions unless you are qualified to do so. Refer to all Safety Summaries before

performing any service.

Page 52

Page 53

Theory of Operation

Page 54

Page 55

Theory of Operation

Introduction

This section provides information on how the ECO 422 circuitry works, in order

to troubleshoot the instrument.

Logic Conventions

Signal names are all capital letters. For example, SIGNAL.

An active low signal (normally denoted by an overscore) is a signal name

enclosed in parentheses. For example, (SIGNAL).

The aside of a signal name is always in square brackets. For example, [SIG-

NAL].

The aside of an active-low signal is the signal name in parentheses and then

enclosed in square brackets. For example, [(SIGNAL)].

ECO 422 Block Level Description (See Figure 4–1)

Figure 4–1: Block Diagram of the ECO 422

ECO 422

4–1

Page 56

Theory of Operation

The Primary and Backup signals enter through the BNCs. The signal goes

directly to the Relay where one switches through to the rear-panel Output and the

other terminates in 75 W. The rest of the circuitry determines which signal goes

to the Output.

A copy of the Primary and Backup signals go to the Primary and Backup Check

circuitry. This block consists of a peak detector that compares the peak level of

the incoming signal with a predefined level from the Reference Voltage

Generator that is selected by the Voltage Selector. The result of this check is

ANDed with the results from the ten other input sets and sent to the Decision

Logic circuit that determines the state of the relays. Additional circuitry runs the

Alarm Driver for the remote output and the fault indicators on the front panel.

ECO 422 Detailed Circuit Description

Input and Comparators

PRIMARY

INPUT

RELAY_DRIVER

BACKUP

INPUT

2

through

7

The Input and Comparator circuit takes the input signals, selects between them,

and prepares the peak signals for the Decision Logic circuit. There are five input

signal sets on the Main board and six input signal sets on the Connector board.

All of the Input and Comparator circuits are identical for each signal set,

therefore only Channel 1 (on the Connector board) is discussed.

(P_AND)

(P_TEST1)

(B_AND)

(B_TEST1)

OUTPUT

INPUT

BUFFER

INPUT

BUFFER

NEGATIVE

PEAK

DETECTOR

VREF

NEGATIVE

PEAK

DETECTOR

Figure 4–2: Block Diagram of the Input Comparator

4–2

RF Relay . The Primary input signal connects to 75 W BNC, J17. The signal

passes through a 75 W microstrip to the RF relay, K6. Meanwhile the Backup

signal enters J16 and connects to the other side of relay K6 also through a 75 W

microstrip. This relay switches the signal to either two 37.5 W resistors in series

for 75 W termination, or to the J18 output BNC. A 1.5 kW resistor (R262 for

ECO 422

Page 57

Theory of Operation

Primary and R261 for Backup) AC coupled with 47 and 0.01 F parallel

capacitors (C194 and C132 for Primary and C195 and C131 for Backup) samples

the input signals. This signal then goes to the Input Buffer.

Input Buffers. The Emitter-follower Input Buffer (Q32 for Primary and Q33 for

Backup) reduces the input capacitance that could degrade the return loss at high

frequencies. The signal may be attenuated by Q36 for the Primary circuit and

Q37 for the Backup circuit. If the ATTEN1 from the Selector Switch signal is

high, it turns on the transistor that reduces the amplitude of the signal. This

allows checking a broader range of signals without the Negative Peak Detectors

being overdriven or saturated. The output of the Input Buffers goes to the

Negative Peak Detectors.

Negative Peak Detectors. The Negative Peak Detector circuit begins with a

transistor that inverts the input signal. The Peak Detector circuit picks off the

input signal peaks, which charge the memory capacitor, C140 or C139. When no

peaks are present, the memory capacitor is discharged by R260 or R259. The DC

output of the peak detector is buffered by a low drift op-amp, U11A and B.

Control and Remote

V oltage Comparator. The Voltage Comparator takes the output of the Negative

Peak Detector and compares it to a DC reference voltage, VREF1, selected from

eight possible choices: off, five presets, or two user-defined values. When the

input negative peaks generate a voltage less than the selected reference, the

output of the comparator goes low, signaling a fault to the control circuit. The

resulting signal is (P_AND_C) for the Primary and (B_AND_C) for the Backup.

(P_TEST1) and (B_TEST1) are only for automated testing purposes. All the

Primary signals are wire-ANDed together as the (P_AND_C) signal and sent to

the Main board via J19. The same is done with all the Backup signals.

8

The Primary and Backup signals from the Voltage Comparators on the Main

board are ANDed with like signals coming from the Connector board and passed

to the Controller PLD that then generates the control signals for the switching

relays.

ECO 422

4–3

Page 58

Theory of Operation

Figure 4–3: Block Diagram for the Control and Remote Circuit

Keyboard Encoder. The front panel is connected to the Main board through J16.

The input from the front panel is scanned by the Keyboard encoder, U11. The

outputs are active high and chosen so that only one can be active at a time. The

KEY_VALID signal is ANDed with each output inside the controller to provide

switch debouncing.

Front-panel LED Driver. U12 outputs the signals to drive the LEDs on the front

panel. It drives the LEDs to +5 V.

U12 outputs the signals to driver the LEDs on the front panel. It drives the LEDs

to +5 V. The timer, U13, provides the pulsing necessary to flash the front-panel

fault LEDs and clock the front panel Time Out circuit in the Controller. When

(TIMER_DIS) is low, the timer is prevented from pulsing. When the input goes

high, the timer output goes low, turning on and allowing the Controller to flash

the LEDs.

Remote. The Remote port, J17, provides three inputs and four outputs from the

Controller. (R_AUTO) controls auto switching, (R_SOURCE) is a manual

source switch, and (R_RESET) resets the fault indicator LEDs. These signals are

buffered by U18B that is always enabled. The input has six diodes for ESD

protection.

4–4

The buffer drives the two input source light outputs through resistors to ground

because there is no remote power on the rear-panel connector. The inversion of

ECO 422

Page 59

Theory of Operation

the select lines is accomplished by cross wiring P_LED and B_LED, through the

buffer to (B_O) and (P_O), which are complimentary.

The high current (ALARM) output is provided by Q32 and a high wattage 22 W

resistor. A 10 kW pull-down is provided for test purposes.

The fault reporting output, U15 and Q33, provide a method of fault indication

that also includes remote indication of instrument failure. A 24 V, 20 mA current

limited input and ground are connected to J17–2 and J17–4. When the controller

detects an input fault or suffers a power failure, the LED in U15 shuts off. The

transistor opens up allowing Q33 to saturate to less than 1.5 V, signaling the

fault. When the LED is on, Q33 is cut off leaving less than 100 nA of leakage.

The diodes, CR48 and VR1, are provided for reverse voltage and ESD protection.

Controller. The Controller has five main functions:

H Encode the keyboard signals.

H Send the correct signals to the LED Driver.

H Generate the ALARM signal for the Remote circuit.

H Generate the Switch or Auto Switch command.

H Keep track of the Time Out circuit.

The five inputs from the Keyboard Encoder enter the Controller. KEY_VALID is

internally delayed three clock cycles to allow key data setup. The ENABLE and

the delayed KEY_VALID signal clock a toggle flip–flop high to enable the three

input gates. Once enabled, the combination of delayed KEY_VALID and each

input produces a control signal for the Controller LED Driver circuit, the

Lockout circuit, and the Fault circuit.

The fault block of the Controller uses four input signals (PFAULT), (BFAULT),

(TIMER), and RESET. These signals determine whether the (ALARM) signal

needs to be sent to the Remote, if the Primary or Backup front panel Alarm

LEDs should be on, and if the auto switch function should be activated. The

RESET command turns off the LEDs and the Remote Alarm output. The

(TIMER) signal is NANDed with the LED fault signal to make it flash.

The automatic source change with fault detection function is enabled by the

(AUTO_O) signal from the Keyboard Encoder circuitry. This signal and some

other controls generate (AUTO_ON). (AUTO_ON) can be switched off by the

(R_AUTO) control from the rear-panel Remote connector. The (AUTO_ON)

signal is also used to derive the (P_SELECT) and (B_SELECT) signals.

(AUTO_ON) and (AUTO_OFF) are sent to drive the front-panel LED circuit.

ECO 422

After the front panel is enabled, the ECO 422 will only allow the front panel

approximately 60 seconds of inactivity before it will automatically disable the

4–5

Page 60

Theory of Operation

front panel. The Controller gets a timing signal from the Timer circuit. It counts

this signal to check the inactivity of the front panel. Every time that a front-panel

key is pressed the internal counter is reset. If the counter reaches one minute, the

front panel is automatically locked out.

Reference Voltage and Selector Switch Farm

+12 V

Figure 4–4: Reference V oltage and Selector Switch Farm Block Diagram

Reference V oltages. The +2.5 V reference voltage is provided by U31. This

signal is used to produce the –2.5V_REF and the Attenuation signals.

9

VREF

for each

channel

+5 V

4–6

The +2.5 V signal from U31 is combined with ATTEN_SW and buffered by

U23B and U20B. The resulting signal is set to the Switch Farm as ATTEN_M

and ATTEN_C to control the input attenuators.

The –5 V signal is inverted and buffered by U20A, resulting in the –2.5V_REF